Page 1

User Maintenance Manual

JUPITER 4852 BASIC & SITE

Telephone: +44 (0)1704 543830 Fax: +44 (0)1704 544799 Email: info@isotech.co.uk Website: www.isotech.co.uk

Isothermal Technology Limited, Pine Grove, Southport, Merseyside, PR9 9AG, England

Jupiter 4000 Series 02-04/17

Page 2

Guarantee

ⓒIsothermal Technology Limited

This instrument has been manufactured to exacting standards and is guaranteed for twelve

months against electrical break-down or mechanical failure caused through defective material or

workmanship, provided the failure is not the result of misuse.

In the event of failure covered by this guarantee, the instrument must be returned, carriage paid,

to the supplier for examination and will be replaced or repaired at our option.

FRAGILE CERAMIC AND/OR GLASS PARTS ARE NOT COVERED BY THIS GUARANTEE

INTERFERENCE WITH OR FAILURE TO PROPERLY MAINTAIN THIS INSTRUMENT MAY

INVALIDATE THIS GUARANTEE

The company is always willing to give technical advice and assistance where appropriate. Equally,

because of the programme of continual development and improvement we reserve the right to

amend or alter characteristics and design without prior notice. This publication is for information

only.

This handbook contains information that has been reproduced with the kind permission of

Eurotherm. Such data is subject to the following notice.

Isothermal Technology Limited

Pine Grove, Southport, Merseyside, PR9 9AG, England

Telephone: +44 (0)1704 543830 / Fax: +44 (0)1704 544799

Email: info@isotech.co.uk / Website: www.isotech.co.uk

2

Page 3

Contents

1 UNPACKING AND INITIAL INSPECTION ........................................................................................ 6

2 BEFORE YOU USE THE EQUIPMENT ................................................................................................. 7

3 SUMMARY OF SYMBOLS ................................................................................................................... 8

4 ELECTRICITY SUPPLY ....................................................................................................................... 9

5 THE UNIT MUST BE EARTHED ................................................................................................ 10

6 EMC INFORMATION ................................................................................................................. 11

7 CAUTIONARY NOTE ................................................................................................................. 12

8 SAFETY WARNINGS ................................................................................................................ 13

8.1 ENVIRONMENTAL CONDITIONS ........................................................................................................................ 13

8.2 DO NOT MODIFY OR DISASSEMBLE ................................................................................................................. 13

8.3 BEWARE OF ELECTRICAL CONSIDERATIONS...................................................................................................... 13

8.4 BE CAREFUL WHERE IT IS USED ..................................................................................................................... 13

8.5 BE CAREFUL WITH EXTREMES OF TEMPERATURE .............................................................................................. 13

8.6 BE CAREFUL WITH INSERTS ........................................................................................................................... 13

9 CONSIDER THE ENVIRONMENT ..................................................................................................... 14

10 INTRODUCTION ............................................................................................................................. 15

10.1 COMPARISON CALIBRATION .......................................................................................................................... 15

10.2 BASIC OPERATION ....................................................................................................................................... 15

10.3 SITE OR SELF-CONTAINED CALIBRATORS ....................................................................................................... 15

10.4 EXTERNAL STANDARDS + BASIC ................................................................................................................... 16

10.5 ADVANCED CALIBRATORS .......................................................................................................................... 16

11 MODE OF OPERATION ................................................................................................................... 17

11.1 METAL BLOCK BATH .................................................................................................................................... 17

11.2 BLACKBODY SOURCE .................................................................................................................................... 17

11.3 SURFACE SENSOR CALIBRATION .................................................................................................................... 17

11.4 FAST COOL DOWN PROBE (OPTION) ............................................................................................................. 18

12 HOW TO MEASURE THE TRUE TEMPERATURE INSIDE THE ACCESSORIES SUPPLIED WITH

THE JUPITER ........................................................................................................................................ 19

12.1 THE CONTROLLER ....................................................................................................................................... 19

12.2 THE REFERENCE THERMOMETER ................................................................................................................... 19

12.3 THE INDUSTRIAL THERMOMETER .................................................................................................................. 19

12.4 JUPITER 4852 BASIC (B)............................................................................................................................. 19

12.5 JUPITER 4852 SITE (S) ............................................................................................................................... 20

12.6 ISOTECH BASIC DRY BLOCK INTERFACE ......................................................................................................... 21

12.7 ISOTECH SITE DRY BLOCK INTERFACE ........................................................................................................... 22

13 SPECIFICATION ............................................................................................................................. 23

14 JUPITER 4852 BASIC/SITE - INITIAL TESTING ........................................................................ 24

15 JUPITER 4852 SITE - USING THE INDICATOR TO MEASURE TEMPERATURES REMOTE

FROM THE FURNACE ........................................................................................................................... 25

16 JUPITER 4852 SITE - CALIBRATION USING THE INTERNAL INDICATOR TO READ A

STANDARD AND UNKNOWN THERMOMETERS ................................................................................ 26

3

Page 4

17 JUPITER 4852 SITE - CALIBRATION USING A STANDARD THERMOMETER AND THE

INTERNAL INDICATOR ....................................................................................................................... 27

18 JUPITER 4852 BASIC/SITE - CALIBRATION USING A STANDARD THERMOMETER WITH

EXTERNAL INDICATION ..................................................................................................................... 28

19 JUPITER 4852 BASIC/SITE - CHECKING USING THE TEMPERATURE INDICATED ON THE

CONTROLLER ....................................................................................................................................... 29

20 JUPITER 4852 BASIC/SITE - MAINTENANCE ............................................................................. 30

20.1 THE BASIC WORKINGS ................................................................................................................................. 30

20.2 OPERATING PROCEDURES ............................................................................................................................. 30

20.2.1 Jupiter 4852 Uncertainty

20.2.2 Jupiter 4852 Heat Up/Cool Down

21 OPERATING THE MODEL ............................................................................................................... 32

21.1 FRONT PANEL LAYOUT ................................................................................................................................. 32

21.1.1 The Temperature Controller

21.1.2 Altering the Setpoint

21.2 CONTROLLER FEATURES ............................................................................................................................... 32

21.2.1 Setpoint Ramp Rate

21.2.2 Instrument Address

21.3 MONITORING THE CONTROLLER STATUS ....................................................................................................... 33

21.4 THE TEMPERATURE INDICATOR: SITE MODELS ONLY ...................................................................................... 34

21.5 CONNECTING TEMPERATURE SENSORS .......................................................................................................... 34

21.5.1 Platinum Resistance Thermometers, PRTs

21.5.2 Input Connections

21.5.3 Connecting Thermocouples

21.5.4 Setting the Input Type

21.6 ENABLING/DISABLING CUSTOM CALIBRATION ................................................................................................ 35

21.7 INSTRUMENT ADDRESS ................................................................................................................................ 35

21.8 MONITORING THE INDICATOR STATUS .......................................................................................................... 36

21.9 INDICATOR OPERATION ............................................................................................................................... 36

................................................................................................................. 31

................................................................................................... 31

........................................................................................................... 32

....................................................................................................................... 32

........................................................................................................................ 32

......................................................................................................................... 33

.................................................................................... 34

........................................................................................................................... 34

............................................................................................................ 34

.................................................................................................................... 34

22 CALIBRATION DATA EXAMPLE ..................................................................................................... 37

22.1 CONNECTING A 4-20MA CURRENT TRANSMITTER .......................................................................................... 37

22.2 USING THE CURRENT LOOP INTERFACE 935-06-161 WITH THE SITE MODEL .................................................... 39

22.3 TESTING THERMAL SWITCHES ...................................................................................................................... 40

22.4 PROCEDURE FOR THE REVERSAL OF THE POLARITY FOR THE SWITCH CONTACT FEATURE ..................................... 40

22.5 SELECTING INPUT TYPE ............................................................................................................................... 40

23 USING THE PC INTERFACE ........................................................................................................... 41

23.1 CONNECTIONS ............................................................................................................................................ 41

23.2 PROTOCOL .................................................................................................................................................. 41

24 CAL NOTEPAD ................................................................................................................................. 42

24.1 DEVELOPMENT ............................................................................................................................................ 42

24.2 ISOTECH I-CAL EASY LOG .......................................................................................................................... 43

25 DIAGNOSTIC ALARMS ................................................................................................................... 44

26 APPENDIX 1: TROUBLE SHOOTING ............................................................................................. 45

26.1.1 Unit fails to operate

26.1.2 Will not control at 35°C

26.1.3 Indicator reads incorrectly

26.1.4 Unit unstable

26.1.5 Cannot establish PC Communications

......................................................................................................................... 45

.................................................................................................................. 45

.............................................................................................................. 45

.................................................................................................................................... 45

............................................................................................ 45

4

Page 5

27 APPENDIX 3: INDICATOR CONFIGURATION (REFERENCE ONLY) .......................................... 46

28 ACCESSORIES ................................................................................................................................. 48

5

Page 6

1 Unpacking And Initial Inspection

Our Packing Department uses custom designed packaging to send out your unit, but as accidents

can still happen in transit, you are advised, after unpacking the unit, to inspect it for any sign of

shipping damage and confirm that your delivery is in accordance with the packing check list. If

you find any damage or that part of the delivery is missing notify us or our agent and the carrier

immediately. If the unit is damaged you should keep the packing for possible insurance

assessment.

6

Page 7

2 Before You Use The Equipment

Please read the handbook and familiarise yourself with all warnings, hazards and safety

information. Regularly inspect the equipment, accessories and electrical leads. Do not use if there

is any sign of damage. Keep the equipment clean, only use a damp cloth. Do not use solvents or

allows liquids to enter the case.

7

Page 8

3 Summary of Symbols

ISO3864 – Caution, read the entire manual before use

IEC 417 – Caution, hot surface (risk of burn)

O

Off l On

Waste Electrical and Electronic Equipment (WEEE directive) symbol

Complies with European regulations (CE mark)

USB symbol

Ethernet RJ45 symbol

Risk of Electrical Shock

l O l O l

RS422 Serial Port

8

Page 9

4 Electricity Supply

Before connecting to the electricity supply please familiarise yourself with the parts of the manual

relevant to your model.

Your unit's supply voltage requirement is specified on a label on the instrument along with the

serial number. Only connect to a power supply matching the requirement stated on the equipment.

9

Page 10

5 The Unit Must Be Earthed

Colour

Function

Green/yellow

Earth (Ground)

Brown

Live (line)

Blue

Neutral

This equipment is a Class 1 Appliance and must be earthed (grounded). Use the supplied power

cord and plug it directly into an AC outlet with a protective earth.

If using an alternative cord ensure it is of adequate rating.

If fitting a plug to the cable we have supplied the cable is colour coded as follows:

Do not use the equipment if it is not correctly earthed. If in doubt consult Isothermal Technology

Ltd or a qualified electrician.

10

Page 11

6 EMC Information

This product meets the requirements of the European Directive on Electromagnetic Compatibility

(EMC) 89/336/EEC as amended by EC Directive 92/31/EEC and the European Low Voltage

Directive 73/25/EEC, amended by 93/68/EEC. To ensure emission compliance please ensure that

connecting leads are fully screened.

The product meets the susceptibility requirements of EN 50082-1, criterion B.

11

Page 12

7 Cautionary Note

Operators of this equipment should be adequately trained in the handling of hot and cold items.

It is important the user has been trained about the selection and use of liquids over a wide

temperature range. It is expected that personnel using this equipment will be competent with the

management of apparatus which may be powered or under extremes of temperature and are able

to appreciate the hazards which may be associated with and the precautions to be taken with,

such equipment.

12

Page 13

8 Safety Warnings

8.1 Environmental Conditions

Operating temperature: 5-40°C (41-122°F)

Relative Humidity: 5-80% - Non-condensing

8.2 Do Not Modify Or Disassemble

Do not use the apparatus for jobs other than those for which it was designed, i.e. the

calibration of thermometers

There are no user serviceable parts inside. Do not dismantle or modify the apparatus. For

repair information contact Isothermal Technology Ltd

For equipment with fans, the fan should kept free from dust build up; a soft brush or

vacuum cleaner may be used on the external grill

8.3 Beware Of Electrical Considerations

The equipment is for installation category II (transient voltages) and pollution degree

II in accordance with IEC 664 at altitudes to 2000 metres

Sensor Input Connection must never exceed 30V with reference to ground

Thermostat test inputs should be voltage free: isolate from any voltage source during test

8.4 Be Careful Where It Is Used

The equipment is not for use in hazardous areas or in an environment close to flammable

materials or gases

The equipment must be used on a flat level surface, with adequate space around it for air

flow and avoid blocking ventilation slots

Ensure free space above the unit to avoid risk of burn or fire

The equipment should only be used indoors

Site in a way that allows access to the power switch, and to allow the cable to be

disconnected

Avoid excessive heat, humidity, dust and vibration ensuring it will not be subjected to

dripping or splashing liquids

8.5 Be Careful With Extremes Of Temperature

In normal use the calibration volume, inserts and probes will become very hot and present

a burn hazard

Do not remove inserts, probes or handle the equipment when it is hot or cold.

Allow the equipment and accessories to reach a temperature between ambient and 70°C

before switching off or storing the equipment in its case

Do not use the equipment outside its recommended temperature range

Operating the equipment at extremes of temperature for extended periods may call for

early replacement of the heating assembly

Wear appropriate protective clothing

8.6 Be Careful With Inserts

Only use inserts supplied with, or ordered specifically for, this model

Do not handle inserts while they are very hot or cold

Inserts for low temperature models may melt and cause a fire if used in high temperature

models

Only use Isotech inserts which are specially treated to avoid them from becoming stuck in

the calibration volume

Do not use powders, liquids or compounds in the insert; this may lead to the insert or

probes becoming stuck

13

Page 14

9 Consider The Environment

The equipment should be recycled or disposed of in a proper way; following the Waste

Electrical and Electronic Equipment (WEEE) directive

14

Page 15

10 Introduction

The purpose of the Jupiter models is to provide an adjustable isothermal enclosure for calibration

purposes. It has been designed to be rugged and easily maintained.

The isothermal enclosure consists of a fixed heater block into which an insert can be

placed. Temperature sensors for calibration are placed in suitably drilled holes in the insert. The

replaceable inserts enable a variety of items to be calibrated.

Additionally there are accessories to allow the calibration of surface sensors and also infrared

thermometers.

The heater block houses a heater and the control sensor used by the temperature controller to

sense the block temperature.

There are two electrically driven fans in the unit. One runs continuously and cools the electronics

in the instrument and the other is switched to cool the block when the set temperature is lower

than the block temperature.

10.1 Comparison Calibration

By definition, one compares industrial thermometers to a calibrated standard. There are three

methods commonly used.

10.2 Basic Operation

Using the controller as the “calibrated standard”. This method means

that the complete bath is calibrated by comparing the controller reading

to a calibrated standard placed in the bath.

This is a common method but is unsafe since the control sensor is

a) inaccessible

b) in the wrong place to give correct temperature of the insert

For these reasons it fails to satisfy ISO9000 and gives large uncertainties.

10.3 Site or Self-Contained Calibrators

In these an indicator and external calibrated sensor are used to measure

the temperature of the insert. This arrangement gives good results and

traceability. To recalibrate however it does mean sending the whole

calibrator back to the calibration laboratory. The calibrator is selfcontained, self-sufficient and meets ISO9000 requirements.

15

Page 16

10.4 External Standards + Basic

Here a separate indicator and calibrated sensor

are used to measure the inserts temperature.

With a suitable indicator such as the Isotech

milliK this gives the most accurate and reliable

results, depending on the indicator.

It means that the calibrator does not need

calibrating; only the indicator and its calibrated

sensor need re-calibration. One indicator may

be used with a range of blocks. This method

also meets ISO9000 requirements.

10.5 ADVANCED Calibrators

The ADVANCED model includes an indicator with channels for both

the test thermometers and an external calibrated sensor used to

measure the temperature of the insert. This allows best practice

calibration with established traceability and uncertainty. To

recalibrate however, it does mean sending the whole calibrator

back to the calibration laboratory. The calibrator is self-contained

for reference and test probes, self-sufficient and meets ISO9000

requirements.

16

Page 17

11 Mode Of Operation

11.1 Metal Block Bath

The thermometers under test are placed into suitable holes in the metal insert. For

the ADVANCED and Site models a calibrated reference probe should be placed into

the insert and the actual temperature can be read from the temperature

indicator. For the Basic models an external temperature indicator should be used.

For traceable calibration the actual value of the insert temperature should be

recorded along with the values from the sensors under test.

Wait until the temperature indicated by the controller and the output of the

thermometer are both stable (see specification for typical values) record three sets

of readings over a period of about six minutes. Check that these readings are

consistent and then calculate their average values. If the device has itself been

calibrated, correct the average values accordingly.

11.2 Blackbody Source

The Blackbody Target Kit (852-09-05) can be added for simple calibration on

infrared thermometers.

Place the target into the well with the supplied thermocouple fitted. For the

ADVANCED and Site models the actual temperature from the thermocouple

can be read from the temperature indicator. For the Basic models an external

temperature indicator should be used. The test IR thermometers should be

compared to this value.

11.3 Surface Sensor Calibration

The Jupiter can be used with an accessory to calibrate surface sensors.

The surface sensor insert (part number 852-07-15), is placed into the calibration

well.

The supplied Type N Thermocouple is placed in the pocket of the surface sensor

insert and connected to the temperature indicator of the Site models. For the

ADVANCED and Site models the actual temperature from the thermocouple can be

read from the temperature indicator. For the Basic models an external temperature

indicator should be used. The test surface thermometers should be compared to

this value.

17

Page 18

11.4 Fast Cool Down Probe (Option)

The fast cool down probe can be attached to a suitable air supply and then placed into the Jupiter

insert for rapid cooling.

Take care when placing the probe into the hot block.

Ensure the air supply is set to give an appropriate flow rate. Guard against setting so high that

the probe may be blown from the insert.

18

Page 19

12 How To Measure The True Temperature Inside The Accessories

Supplied With The Jupiter

The controller of the Jupiter controls and reads the temperature of the block surrounding the

35mm∅ by 148mm deep calibration well.

There are various accessories including the surface calibration insert and the blackbody. These

adapt the Jupiter to perform varied calibration functions.

None of these accessories actually get to the block temperature (and hence the controller’s

temperature) because each accessory has a different immersion characteristic. For this reason the

Jupiter, like all comparison baths, requires a reference thermometer to indicate the true

temperature inside the accessory.

Remember the following:-

12.1 The Controller

The controller is used to set a constant temperature and create an isothermal environment for the

comparison calibration of temperature sensors.

12.2 The Reference Thermometer

The reference thermometer is placed in the accessory or insert and measures the true temperature

inside the insert or accessory.

12.3 The Industrial Thermometer

The industrial thermometer is placed in the accessory or insert and is compared to the true

temperature as indicated by the reference thermometer. An insert will typically have a 1%

immersion error. For more details see - Depths of Immersion. Tavener J. P – available at

www.isotech.co.uk

The Jupiter 4852 series consists of two models, the Basic (B) and Site (S). Both models have

been designed to be rugged and easily maintained.

By using a proprietary plug-in controller the total electronics package can be replaced in a few

minutes. As can be seen from the parts list, remarkably few components have been used, each

of which are easily removed and replaced. All models have a temperature range of 35 to 660°C.

12.4 Jupiter 4852 Basic (B)

This model provides an isothermal enclosure (metal block) in which thermometers and

thermostats can be checked against the temperature indicated on the temperature controller.

For traceable calibration a standard (reference) probe should be placed into the metal blocks

alongside the units under test.

The probe under test should be calibrated by comparison to the standard probe.

19

Page 20

12.5 Jupiter 4852 Site (S)

The S is again similar to the B but this unit has the addition of a digital temperature indicator.

The indicator is independent from the controller and can be programmed to work with a

thermocouple or industrial Pt 100 resistance thermometer.

This combination of sensor and probe can be calibrated. Then the units under test can be

compared to the independent calibrated measuring systems allowing for traceable calibration.

The Jupiter 4852 Series represents the third generation of a ten year development program.

During which many customer improvement suggestions have been incorporated into the models.

Such suggestions have generally arisen from technical queries posed by equipment users,

therefore please consult with us if at all unsure with any aspect of our equipment.

The Jupiter 4852 models are part of a range of portable calibrators designed and made by

ourselves. Please contact us if you require more information about our other products.

20

Page 21

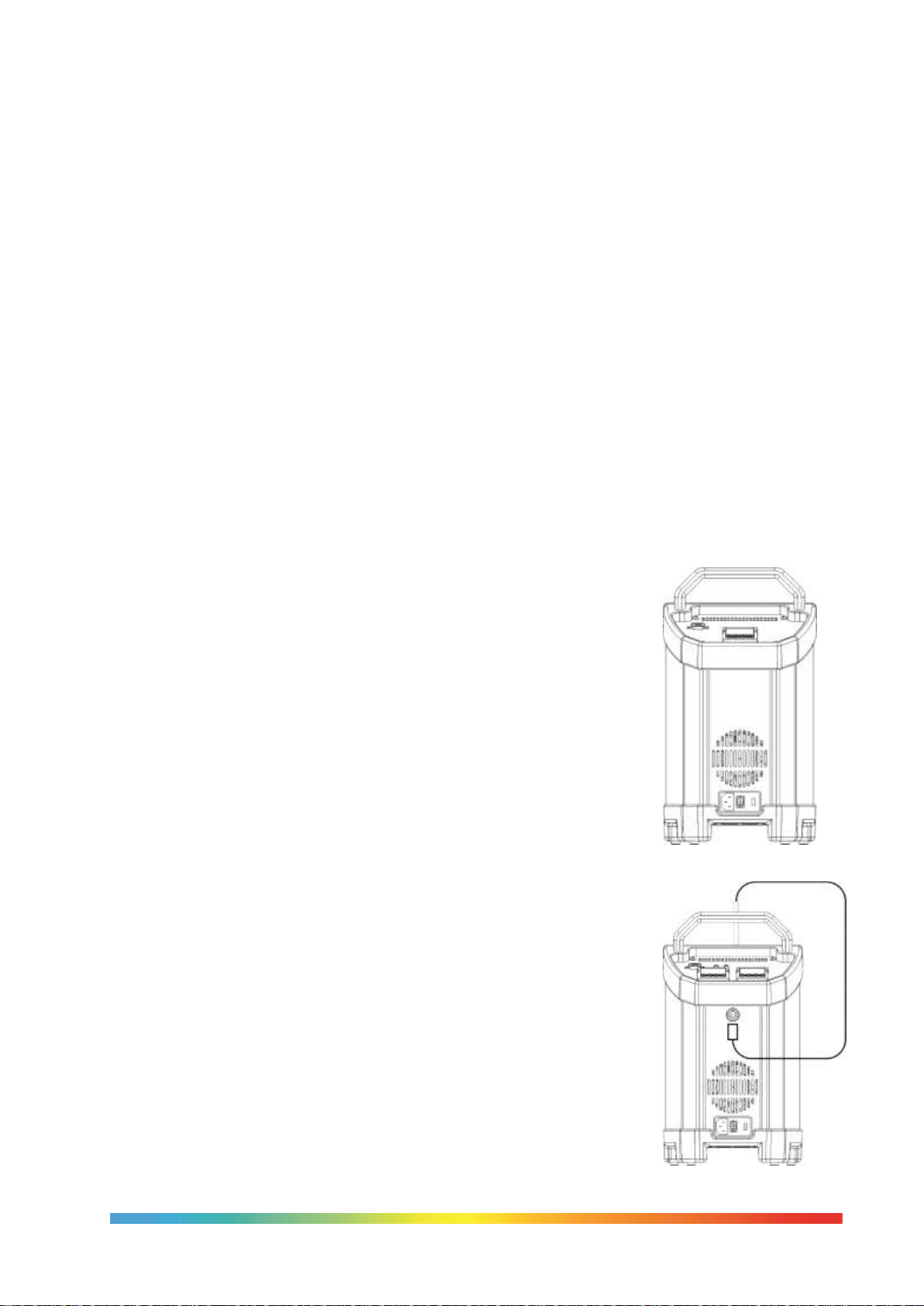

12.6 Isotech Basic Dry block interface

1. Main supply voltage connection socket

This socket allow the Mains Voltage to be

applied to power up the equipment. Use

only the supplied lead or a suitably specified

IEC alternative. Confirm the supply voltage

using the ratings label on the rear of the

equipment.

2. Power On/Off switch

Once the Power lead is connected, this

switch will power up and down the

equipment

3. Fuse carrier and window showing fuse

rating

With the mains cable disconnected, the fuse

carrier can be removed for the inspection or

replacement of the fuse. The fuse rating is

displayed through the window.

4. Temperature Controller

Refer to Section 21 for details.

5. Magnetic stirrer speed adjuster

Manual adjustment of the Magnetic stirring speed (where fitted)

6. PC Serial interface

Enables connection to a PC. Refer to Section 23 for details.

21

Page 22

12.7 Isotech Site Dry block interface

1. Main supply voltage connection socket

This socket allow the Mains Voltage to be

applied to power up the equipment. Use only

the supplied lead or a suitably specified IEC

alternative. Confirm the supply voltage using

the ratings label on the rear of the equipment.

2. Power On/Off switch

Once the Power lead is connected, this switch

will power up and down the equipment

3. Fuse carrier and window showing fuse

rating

With the mains cable disconnected, the fuse

carrier can be removed for the inspection or

replacement of the fuse. The fuse rating is

displayed through the window.

4. PRT input socket

These allow for the connection of external

Platinum resistance thermometers.

Do not connect any other form of input to

these sockets.

5. Thermocouple input socket

These allow for the connection of a range of Thermocouples to be connected.

not connect any other form of input to these sockets.

6. Temperature controller

Refer to Section 21 for details.

7. Magnetic stirrer speed adjuster

Manual adjustment of the Magnetic stirring speed (where fitted)

8. Temperature indicator

9. PC Serial interface

Enables connection to a PC. Refer to Section 23 for details.

10. Switch Contact (thermostat)

Warning:

Warning: Do

22

Page 23

13 Specification

Model

Parameter

Jupiter 4852 Basic/Site

Temperature Range

35°C to 660°C

Stability

±0.02°C at 100°C ±0.03°C at 650°C

Display Resolution

0.01°C from 30.00 to 99.99°C then 0.1°C over PC

Interface

Blackbody Source

±0.3°C

Surface Sensor Calibrator

±0.5°C

Cools from 650°C to 150°C

in 60 minutes

Heats from 30°C to 650°C

in 20 minutes

Best Performance

See Graph (refer to Section 20.2.1 and 20.2.2)

Calibration volume

35mm diameter by 148mm deep

Standard Insert

6 pockets, 2 x 4.5mm, 2 x 6.4mm, 1 x 8.0mm, 1 x

9.5mm diameter, all 140mm deep

Indicator units

°C, °F, K

Power

115Vac or 230Vac 50/60Hz 1000 Watts

Dimensions

384H (including handle) x 212W x 312Dmm

Weight

8.5kg

23

Page 24

14 Jupiter 4852 Basic/Site - Initial Testing

This unit was fully tested before despatch to you but please check its operation as outlined

below.

After connecting the Jupiter 4852 to the electricity supply, the temperature controller display will

show the temperature of the block and the last set-point value. The S controller and indicator

both go through a self-test sequence first. The fan on the front panel should be heard running.

Change the set-point to 100°C and observe that the block temperature rises and settles to this

value. For the S; place a thermometer in an insert in the block and connect it to the suitably

configured indicator. Confirm that the indicator agrees within ±2°C of the controller.

Change the set-point to 70°C; this should cause the second cooling fan to operate until the

temperature falls to below 75°C when it will turn off.

Your unit should have performed as described above and can now be used for calibration.

If any problems or faults arise during these tests please contact us or our agents for help and

advice.

IMPORTANT NOTICE

The controller's function settings are preset and will not require adjustment.

24

Page 25

15 Jupiter 4852 Site - Using The Indicator To Measure

Temperatures Remote From The Furnace

1. Remove the Jupiter 4852 from its case and visually inspect it for any damage it may have

sustained since it was last used. Insert the required metal insert into the furnace block.

2. Connect the Jupiter 4852 to a suitable power supply and set the controller to either 0°C if the

furnace is not to be used or to the required temperature if it is going to be used to calibrate

thermometers.

3. If the standard thermometer is going to be used to measure a temperature other than the

metal block, reconfigure and set the offset of the indicator accordingly. Connect the standard

thermometer to the indicator which will now display its temperature.

4. If the indicator is going to be used to measure the temperature of a remote thermometer,

reconfigure and set the user calibration of the indicator to correspond to that type of

thermometer, connect the thermometer to the indicator and the corresponding temperature

will be displayed.

5. If the Jupiter 4852 has itself been calibrated, correct the average values accordingly. If there

is no calibration use an uncertainty figure of ±1% for the temperature indicated by the

standard thermometer and indicator.

6. Reset the controller and/or repeat the calibration for another thermometer.

7. When the calibration is complete, reset the controller to 0°C and wait until the unit has cooled

to below 400°C before moving the Jupiter 4852 to a new location. The Jupiter 4852 must be

cooled to below 100°C before it can be put back into its carrying case.

25

Page 26

16 Jupiter 4852 Site - Calibration Using The Internal Indicator To

Read A Standard And Unknown Thermometers

1. Remove the Jupiter 4852 from its case and visually inspect it for any damage it may have

sustained since it was last used. Insert the required metal insert into the furnace block using

the tool supplied to avoid damage to the heater assembly.

2. Connect the Jupiter 4852 to a suitable power supply and set the controller to the required

temperature.

3. Place the thermometer(s) for calibration and the standard thermometer into suitable holes in

the metal insert; wait for the temperature to stabilise.

4. When the temperature indicated by the controller and the standard are stable (see

specification for typical values) record the reading of the standard. Connect the thermometer

under test, in place of the standard, to the indicator and re-reconfigure the indicator for the

new sensor type as necessary if user calibration is enable for the standard it will need to be

turned off or modified for the unit under test. Record the temperature of the thermometer

under test. For security reconnect the standard thermometer, reconfigure the indicator and

make sure the temperature has not changed from the first reading.

5. If the Jupiter 4852 has itself been calibrated, correct the average values accordingly. If there

is no calibration, use an uncertainty figure of ±1% for the temperature indicated by the

standard thermometer and indicator.

6. Reset the controller and/or repeat the calibration for another thermometer.

7. When the calibration is complete, reset the controller to 0°C and wait until the unit has cooled

to below 400°C before moving the Jupiter 4852 to a new location. The Jupiter 4852 must be

cooled to below 100°C before it can be put back into its carrying case.

26

Page 27

17 Jupiter 4852 Site - Calibration Using A Standard Thermometer

And The Internal Indicator

1. Remove the Jupiter 4852 from its case and visually inspect it for any damage it may have

sustained since it was last used. Insert the required metal insert into the furnace block using

the tool supplied to avoid damage to the heater assembly.

2. Connect the Jupiter 4852 to a suitable power supply and set the controller to the required

temperature.

3. Place the thermometer(s) for calibration into a suitable insert(s) in the metal block and wait

for the temperature to stabilise, connect the standard thermometer to the indicator.

Ensure the indicator is configured for the correct sensor and where applicable the calibration

data has been entered and user calibration enable.

4. When the temperature indicated by the controller and that of the other thermometers are

stable (see specification for typical values) record three sets of readings over a period of

about six minutes. Check that these readings are consistent and use their average values for

the final calibration figures.

5. If the Jupiter 4852 has been calibrated, correct the figures accordingly.

6. Reset the controller and/or repeat the calibration for another thermometer.

7. When the calibration is complete, reset the controller to 0°C and wait until the unit has cooled

to below 400°C before moving the Jupiter 4852 to a new location. The Jupiter 4852 must be

cooled to below 100°C before it can be put back into its carrying case.

27

Page 28

18 Jupiter 4852 Basic/Site - Calibration Using A Standard

Thermometer With External Indication

1. Remove the Jupiter 4852 from its case and visually inspect it for any damage it may have

sustained since it was last used. Insert the required metal insert into the furnace block using

the tool supplied to avoid damage to the heater assembly.

2. Connect the Jupiter 4852 to a suitable power supply and set the controller to the required

temperature.

3. Place the thermometer(s) for calibration and the standard thermometer into suitable holes in

the metal insert; wait for the temperature to stabilise.

4. When the temperature indicated by the controller and that of the other thermometers are

stable (see specification for typical values) record three sets of readings over a period of

about six minutes. Check that these readings are consistent and use their average values for

the final calibration figures.

Compare the units under test to the standard thermometer.

5. Reset the controller and/or repeat the calibration for another thermometer.

6. When the calibration is complete, reset the controller to 0°C and wait until the unit has cooled

to below 400°C before moving the Jupiter 4852 to a new location. The Jupiter 4852 must be

cooled below 100°C before it can be put back into its carrying case.

28

Page 29

19 Jupiter 4852 Basic/Site - Checking Using The Temperature

Indicated On The Controller

1. Remove the Jupiter 4852 from its case and visually inspect it for any damage it may have

sustained since it was last used. Insert the required metal insert into the furnace block using

the tool supplied to avoid damage to the heater assembly.

2. Connect the Jupiter 4852 to a suitable power supply and set the controller to the required

temperature.

3. Place the thermometer for calibration into a suitable hole in the metal insert and wait for the

temperature to stabilise.

4. When the temperature indicated by the controller and the output of the thermometer are

both stable (see specification for typical values) record three sets of readings over a period

of about six minutes. Check that these readings are consistent and then calculate their

average values.

5. If the Jupiter 4852 has itself been calibrated, correct the average values accordingly.

7. Reset the controller and/or repeat the calibration for another thermometer.

8. When the calibration is complete, reset the controller to 0°C and wait until the unit has cooled

to below 400°C before moving the Jupiter 4852 to a new location. The Jupiter 4852 must be

cooled below 100°C before it can be put back into its carrying case.

29

Page 30

20 Jupiter 4852 Basic/Site - Maintenance

Turn the electricity supply off before attempting any cleaning operation.

The only moving parts are the fans. They have sealed-for-life bearings. Depending on the

environment in which it is used, periodic cleaning is recommended. Cleaning may be

accomplished by the use of a small dry paint brush.

The instrument should be periodically checked to ensure it is in good order both mechanically

and electrically.

20.1 The Basic Workings

The purpose of the Jupiter 4852 models is to provide an adjustable isothermal enclosure for

calibration purposes.

The isothermal enclosure consists of a fixed heater block into which an insert can be placed.

Items for calibration are placed in suitably drilled holes in the insert. The replaceable inserts

enable a variety of items to be calibrated.

The heater block houses a heater and the control sensor used by the temperature controller to

sense the block temperature. To obtain and maintain a required temperature the controller

varies the power to the heaters via a solid state relay.

There are two electrically driven fans in the unit. One runs continuously and cools the

electronics in the instrument and the other fan cools the heater block when called upon to do so

by the temperature controller. This second fan is operated by the controller to cool the heater

block when the set point is 5°C or more lower than the block temperature, when this second fan

is on cooling to temperature appears on the controller to signify this.

20.2 Operating Procedures

The following operating procedures have been written for one of the two models as indicated by

the Procedures heading. However the procedure may be common to the other models and in

such cases the relevant models are indicated in brackets.

Please note: No oils, greases or powders should be introduced into the Jupiter 4852 or its

inserts.

Only use Isotech supplied inserts.

The inserts are specially plated for use in the block. Using non-Isotech inserts may lead to

failure of the block and cause the insert to seize in the block.

30

Page 31

20.2.1 Jupiter 4852 Uncertainty

20.2.2 Jupiter 4852 Heat Up/Cool Down

A full evaluation of the Jupiter 4852 is available, please contact the factory for availability

31

Page 32

21 Operating The Model

21.1 Front Panel Layout

21.1.1 The Temperature Controller

The controller has a dual display, the upper display indicates the nominal block temperature, and

the lower display indicates the desired temperature or setpoint.

21.1.2 Altering the Setpoint

To change the setpoint of the controller simply use the UP and DOWN keys to raise and lower the

setpoint to the required value. The lower display changes to indicate the new setpoint.

21.2 Controller Features

21.2.1 Setpoint Ramp Rate

By default the Dry Blocks are configured to heat and cool as quickly as possible. There may be

some calibration applications where it is advantageous to limit the heating or cooling rate.

An example might be when testing bimetallic thermostats; by forcing the Dry Block to heat at a

controlled rate it is easier to determine the temperature at which the thermostat changes state.

The Dry Block can have its heating rate limited with the Setpoint Ramp Rate feature. This feature

is accessed from the Scroll key. Depress the key until the display shows,

SP.RAT

The upper display will show the current value, and is adjustable from OFF to 999.9. The units are

°C/min and are adjustable via the UP/DOWN keys.

When the SP.RAT is active the lower setpoint display will now automatically update with the

current value, known as the working setpoint. The setpoint can be seen by pressing either the UP

and DOWN key.

The Setpoint ramp rate operates when the bath is heating and cooling.

32

Page 33

21.2.2 Instrument Address

The controller has a configurable "address" which is used for PC communications. Each instrument

has an address; this allows several instruments to be connected in parallel on the same

communications bus. The default value is 1. This address would only need to be changed if more

than one Dry Block is connected to the same PC port.

To check the Address value press the scroll key until the lower display indicates,

ADDR

The upper display will show the current value that can be modified with the UP and DOWN keys.

21.3 Monitoring The Controller Status

A row of beacons indicate the controllers status as follows,

OP1 Heat Output

OP2 Cool Output (only for models which operate below 0°C)

REM This beacon indicates activity on the PC interface

For models fitted with cool down fans, such as the Calisto and Jupiter, the lower display will

alternate between the setpoint and the message, cooling to temperature. This message is not an

error but is showing that the cooling fan is operating. It will automatically switch off when the

temperature is within 5°C of the setpoint.

Units

Momentary pressing of the Scroll key will show the controller units °C or °F.

33

Page 34

21.4 The Temperature Indicator: Site Models Only

The Site models include an electronic temperature indicator. The indicator can be configured for

the desired sensor type, and for custom calibration data. The customer calibration data can be

set ON or OFF.

21.5 Connecting Temperature Sensors

21.5.1 Platinum Resistance Thermometers, PRTs

Set the input type to suit from either the front panel of the Isotech Config Software utility.

PRTs can be connected to Inputs P1 and P2. When connecting a PRT ensure the corresponding

thermocouple input is not used, that is if connecting a PRT to Input P1 then Input T1 must not be

used, is if connecting a PRT to Input P2 then Input T2 must not be used.

21.5.2 Input Connections

The five pin cable plug to suit PRTs is part number 935-16-107. These are readily available,

suppliers include RS Components (Part Number 129-8573) and Farnell (Part Number 112-2585).

With three wire PRT connections ensure identical lead resistance in all three legs of the connection

by using the same length and gauge of cables.

21.5.3 Connecting Thermocouples

Set the input type to suit from either the front panel of the Isotech Config Software utility.

Thermocouples can be connected to Inputs T1, T2 and T3. When connecting a thermocouple

ensure the corresponding PRT input is not used, that is if connecting a thermocouple to Input T1

then Input P1 must not be used, is if connecting a thermocouple to Input T2 then Input P2 must

not be used.

Input connectors are the industry standard “miniature thermocouple plugs”.

21.5.4 Setting the Input Type

A 100 Ohm resistance thermometer can be connected to the PRT Connector or a thermocouple

may be connected to the miniature TC Connector.

Ensure that only a PRT or a TC is connected at any one time. If a PRT and TC are

connected simultaneously the indicator will read in error.

Check that any sensor placed into the equipment is suitable for the temperature range. Sensors

can be damaged if taken outside their normal operating limits.

34

Page 35

The desired sensor type is easily set, press the Scroll key until the lower display indicates,

In.Typ

The upper display will show the current set sensor type,

J.tc J thermocouple

K.tc K thermocouple

L.tc L thermocouple

r.tc R thermocouple (Pt/Pt13%Rh)

b.tc B thermocouple (Pt30%Rh/Pt6%Rh)

n.tc N thermocouple

t.tc T thermocouple

S.tc S thermocouple (Pt/Pt10%Rh)

PL.2 PL 2 thermocouple

rtd 100 Ohm platinum resistance thermometer.

T012 E thermocouple

Again the value can be modified with the UP and DOWN keys.

21.6 Enabling/Disabling Custom Calibration

Custom calibration allows the indicator to be programmed to suit a particular temperature sensor.

This allows the indicator to automatically show the true temperature, without having to manually

apply a correction.

When the Custom or User Calibration is active the indicator will show the REM beacon lit

continuously. The use of User calibration can make a significant difference to the accuracy of the

instrument, and this REM beacon provides a clear and continuous indication of the calibration

status. Isotech will configure and set user calibration when the Dry Block is ordered with a

temperature sensor.

To alter the calibration status press the Scroll key until the lower display shows,

UCAL

The upper display will indicate either,

ON for user calibration

Or

OFF for factory calibration of the indicator

Use the UP and DOWN keys to toggle between the two values.

When calibrating an unknown sensor against a calibrated probe it may be necessary to switch

the calibration off for the unknown, and on for the calibrated probe.

21.7 Instrument Address

Like the controller, the indicator has a configurable "address" which is used for PC

communications. Each instrument has an address; this allows several instruments to be connected

in parallel on the same communications bus. The default value is 2 (The controller defaults to 1).

35

Page 36

This address would only need to be changed if more than one Dry Block is connected to the same

PC port.

To check the Address value press the scroll key until the lower display indicates,

ADDR

The upper display will show the current value that can be modified with the UP and DOWN keys.

21.8 Monitoring The Indicator Status

For the indicator the REM beacon is lit continuously when the user calibration is active, the REM

beacon flashes when the PC communications port is active.

Units

Momentary pressing of the Scroll key will show the controller units °C or °F.

21.9 Indicator Operation

The indicator can be configured with up to five custom calibration points; the points contain "data

pairs". First the temperature (point) and secondly the Error (offset) at this temperature point.

Isotech Dry Block calibration certificates will show the values to suit a particular sensor.

These values can be inspected, and modified with the following procedure,

Hold the PAGE key down until the display indicates,

CONF

GOTO

then

0

CODE

Set the Code to 2 with the UP key

The display reads,

CONF

Press the Page Key until the controller shows

CAL

Now use the Scroll key to examine the data pairs. The values Pnt 1- Pnt 5 and Ofs 1 to Ofs 5

can be modified with the UP and DOWN keys.

To exit this mode hold the Page key until the top display shows,

CONF

GOTO

And then set the upper display to Lev 1. While in this mode take care not to modify other

parameters.

36

Page 37

22 Calibration Data Example

A maximum of five points may be entered, shown as Pnt 1 to Pnt 5 for the temperature point

and Ofs 1 to Ofs 5 for the offset values.

The Pnt values must be entered in ascending order.

Set a Pnt to a value lower than the previous point to disable it.

The indicator would be programmed with the following data:

Pnt 1 100 Ofs 1 0.8

Pnt 2 300 Ofs 2 1.1

Pnt 3 500 Ofs 3 2.1

Pnt 4 -999 Ofs 4 0

Pnt 5 -999 Ofs 5 0

22.1 Connecting A 4-20mA Current Transmitter

The transmitter should be powered externally, a 2.49 Ohm current sense resistor is fitted

internally to the equipment and this allows the indicator to read mA input.

To scale the linear to display temperature:

1 The scaling can be configured in the CAL sub-menu within CONF menu.

2 Access the Input sub-menu by pressing the Page button.

3 Set the input type to mV.

4 Press again to enter the mv.hi value (see table below)

5 Press again to enter the mv.lo value (see table below)

6 Press again to enter the rng.hi value (see table below)

7 Press again to enter the rng.lo value (see table below)

8 To exit press Page and Scroll buttons together and select level 1 using the up/down

buttons.

37

Page 38

38

Page 39

22.2 Using the Current Loop Interface 935-06-161 with the Site model

Connect the Transmitter to the equipment as shown in the above image.

Note: do not connect 935-06-161 via the PRT socket. The Current Loop interface has built in

resistance and does not require the internal resistance of the equipment. Connect via the

Thermocouple socket only.

39

Page 40

22.3 Testing Thermal Switches

The Site Model Jupiter’s include a switch test facility which is used in conjunction with the

supplied Cal Notepad Software. See Cal Note Pad manual or instructions on how to use this.

22.4 Procedure for the reversal of the polarity for the Switch Contact

feature

1. Enter Configuration level on the temperature Indicator as described in INDICATOR

OPERATION

2. Press the PAGE button to enter IO-1

3. Press the Scroll button to enter I.SENSE

4. Use the up/down button to toggle between nor or inv

5. Exit this level by pressing PAGE and SCROLL together and selecting either LEVEL 1 or

LEVEL 2 and the polarity will have changed.

22.5 Selecting Input Type

40

Page 41

23 Using The PC Interface

The 4000 series models include an RS422 PC interface and a special converter cable that allows

use with a standard RS232 port. When using the bath with an RS232 port it is essential that this

converter cable is used. Replacement cables are available from Isotech, part number ISO-232-

432. A further lead is available as an option, Part Number ISO-422-422 lead which permits up

to 5 instruments to be daisy chained together.

The benefit of this approach is that a number of calibration baths may be connected together in

a "daisy chain" configuration - and then linked to a single RS232, see diagram.

Note: The RS 422 standard specifies a maximum lead length of 1200M (4000ft). A true RS422

port will be required to realise such lead lengths. The Isotech conversion leads are suitable for

maximum combined lead lengths of 10M that is adequate for most applications.

23.1 Connections

For RS232 use simply connect the Isotech cable.

RS422 Connections

Pin Connection

4 Tx+ A

5 Tx- B

8 Rx+ A

9 Rx- B

1 Common

23.2 Protocol

The instruments use the "Modbus Protocol"

If required, e.g. for writing custom software the technical details are available from our

Document Library at www.isotech.co.uk

41

Page 42

24 Cal Notepad

Cal Notepad can be used can be used to log and display values from the Dry Blocks and an

optional temperature indicator such as the milliK or TTI-10. The software requires Windows 9X,

XP, a minimum of 5Mb of free hard drive space and free serial ports for the instruments to be

connected.

24.1 Development

Cal Notepad was developed by Isothermal Technology using LabVIEW from National

Instruments. The license details are shown on the download page and in the Cal Notepad

manual.

42

Page 43

24.2 Isotech I-Cal EASY LOG

This application allows logging of data from the 4000 series model. Additionally if a license is

purchased it allows for fully automatic calibration including certificate printing and the calculation

of coefficients.

Refer to the Isotech I-Cal EASY handbook and help system for more details

More information can be downloaded from the Isotech website

http://www.isotech.co.uk/downloads

43

Page 44

25 Diagnostic Alarms

Display

shows

What it means

What to do about it

E.Conf

A change made to a parameter takes

a finite time to be entered. If the

power to the controller is turned off

before the change has been entered

then this alarm will occur.

Do not turn the power off to the

controller while ConF is flashing

Enter configuration mode then return

to the required operating mode. It

may be necessary to re-enter the

parameter change since it will not

have been entered in the previous

configuration.

E.CaL

Calibration error

Re-instate Factory calibration, refer

to Isotech

E2.Er

EEPROM error

Return to Isotech for repair

EE.Er

Non-vol memory error

Note the error and contact Isotech.

E.Lin

Invalid input type. This refers to

custom linearisation which may not

have been applied correctly or may

have been corrupted.

Go to the INPUT list in configuration

level and set a valid thermocouple or

input type

Emod

IO1, OP2, or OP3 has been changed

If this has been field changed by the

installation of a new board, enter

config level, then exit back to

operator level.

If the message occurs at any other

time return to factory for repair.

Diagnostic alarms indicate a possible fault within the controller or connected devices.

Additional Information;

1. If the input is too high HHHHH will be displayed.

2. If the input is too low LLLLL will be displayed.

44

Page 45

26 Appendix 1: Trouble Shooting

26.1.1 Unit fails to operate

Check fuse (refer to page 21, item 3). If fuse blows repeatedly consult Isotech or local agent.

26.1.2 Will not control at 35°C

Check room temperature. Minimum operating temperature of 35°C is for a room temperature of

20°C.

26.1.3 Indicator reads incorrectly

Two sensors connected simultaneously.

Indicator incorrectly configured.

26.1.4 Unit unstable

Control parameters have been interfered with - consult your local agent.

26.1.5 Cannot establish PC Communications

For RS232 you must use the Isotech adaptor cable.

Ensure the addresses of the controller and indicator match those set in Cal Notepad.

Ensure each controller and indicator is set to a unique address.

Refer to ‘Using the PC Interface’ section and the Cal Notepad manual for further details.

45

Page 46

27 Appendix 3: Indicator Configuration (Reference Only)

Name

Description

Value

unit

Instrument Units

`C (0)

dEcP

Decimal Places in Display

NN.NN

CtrL

Control Type

PID (0)

Act

Control Action

REV (0)

COOL

Cooling Type

LIN (0)

PwrF

Power Feedback Enable

OFF (0)

Pdtr

Manual/Auto Transfer PD

Control

NO (0)

FoP

Forced Output Enable

NO (0)

Sbrt

Sensor Break Type

SB.OP (0)

rnGH

Process Value High Limit

670

rnGL

Process Value Low Limit

0.00

Name

Description

Value

inPt

Linearisation Type

RTD

CJC

CJC Type

(EXT)

imP

Sensor break impedance

AUTO (1)

Name

Description

Value

UCAL

User Calibration Enable

YES (1)

Pnt1

User Cal Point 1

0

Pnt5

User Cal Point 5

-99.00

OFS1

User Cal Offset 1

0.00

Pnt2

User Cal Point 2

-99

OFS2

User Cal Offset 2

0.00

Pnt3

User Cal Point 3

-99

OFS3

User Cal Offset 3

0.00

Pnt4

User Cal Point 4

-99.00

OFS4

User Cal Offset 4

0.00

OFS5

User Cal Offset 5

-99.00

Config.INST

Config.IP

Config.CAL

Note: User Cal values are unique to each instrument. If available set values to those from

calibration certificate

46

Page 47

Config.AL

Name

Description

Value

AL_1

Alarm 1 Type

OFF (0)

Ltch1

Alarm 1 Latching

NO (0)

AL_2

Alarm 2 Type

OFF (0)

Ltch2

Alarm 2 Latching

NO (0)

AL_3

Alarm 3 Type

OFF (0)

Ltch3

Alarm 3 Latching

NO (0)

AL_4

Alarm 4 Type

OFF (0)

Ltch4

Alarm 4 Latching

NO (0)

Name

Description

Value

id

Module Identity

CMS (7)

Func

Module Function

CMS (65)

bAud

Baud Rate

9600 (0)

Prty

Comms Parity

NONE (0)

rES

Comms Resolution

FUL (0)

Name

Description

Value

id

Module Identity

LOG (3)

Func

Module function

NONE (0)

SEnS

Sense of Output

NOR (0)

Name

Description

Value

id

Module Identity

LOG (3)

Func

Module function

NONE (0)

SEnS

Sense of Output

NOR (0)

Config.HA

Config.1A

Config.2A

47

Page 48

28 Accessories

Dry Block Use

Standard Dry Block Insert

2 x 4.5mm; 2 x 6.4mm; 1 x 8mm and 1 x 9.5mm

852-07-11

Dry Block Insert: Type B

1 x 3.5mm; 1 x 5mm; 1 x8mm; 1x 10mm and 1 x 13mm

852-09-03

Dry Block Insert: Type C

6 x 6.5mm and 1 x 8mm

852-09-04

Blank Dry Block Insert

852-07-07

Blackbody Use

Blackbody Target Kit

852-09-05

Surface Sensor Use

Surface Sensor Calibrator Kit

852-07-15

Probes

Standard Probe for On-Site Model

935-14-72/DB

Current Loop Interface

935-06-161

Carrying Case

931-22-111

48

Loading...

Loading...