Page 1

INSTRUCTION MANUAL

ICM33Ⅱ/ 33RⅡ CLAMP MULTIMETER

EN FR IT DE

ICM33RII

Page 2

1

ISO-TECH 33Ⅱ/33RⅡ

CLAMP MULTIMETER

INSTRUCTION MANUAL

Page 3

2

Page 4

3

INTRODUCTION

1-1 Unpacking and Inspection

Upon removing your new Digital Clamp Meter from its packing, you should have the following items:

1. Digital Clamp meter.

2. Carrying case.

3. Instruction manual.

4. Test lead set (one black , one red).

1-2 Meter Safety

Terms as Marked on Equipment .

ATTENTION — Refer to manual.

DOUBLE INSULATION — Protection Class Ⅱ

DANGER — Risk of electric shock.

Page 5

4

Symbols in this Manual

This symbol indicates where cautionary or other information is found in the manual.

Battery.

1-3 Front Panel

Refer to Figure 1 and the following numbered steps to familiarize yourself with the meter’s front panel controls and

connectors.

1. Digital Display — The digital display has a 3 1/2 digit LCD readout (maximum reading 1999) plus auto polarity,

decimal point,

=<and > .

2. Input Terminal — The black test lead is always connected to the “COM” input jack and red test lead is always

connected to the “V-Ω” input jack when measuring ACV and OHMS.

3. Function Switch — Rotate to desired function.

4. Data Hold Switch — Hold display reading for all functions and ranges.

Page 6

5

5. Trigger — Press the lever to open the transformer jaws. When the pressure on the lever is released, the jaws

will close again.

6. Transformer Jaws — Designed to pick up the AC current flowing through the conductor.

7. Hand Guard — Designed to protect user for safety.

8. Battery Cover.

9. Battery Cover Screw.

Page 7

6

7

4

2

1

8

3

5

6

9

Figure 1

Page 8

7

SPECIFICATIONS

2-1 General Specifications

Display : 3 1/2 Digital Liquid Crystal Display (LCD) with a maximum reading of 1999.

Overrange Indication : “1” indicated, show the real value for “V” function and 600A range of “A” function.

Measuring Rate : 4 times per second, nominal.

Low Battery Indication :

=is displayed when the battery voltage drops below the operating voltage.

2-2 Environmental Conditions

Indoor Use.

Maximum Altitude : 2000 meter.

Installation Category : IEC 1010-1, 600V Cat. Ⅲ

Pollution Degree : 2

Operating Ambient : 0°C to + 45°C (below 75% R.H.)

Storage Temperature : -20°C to + 60°C (below 80% R.H.) with battery removed.

Page 9

8

Temperature Coefficient : 0.2 x (specified accuracy) / °C , < 18 °C or > 28°C.

Power Requirement : Alkaline 9V.

Battery Life : Alkaline 200 hours.

Shock Proof : 4 feet drops.

Maximum Jaw Opening : 36mm

Maximum Conductor Size : 34mm diameter.

Size : 200mm (W) x 76mm (L) x 41mm (H)

Weight : 360gms (including battery)

Accessories : Test leads, battery , manual and carrying case.

This instrument complies with IEC 1010-1 and 1010-02-32.

Page 10

9

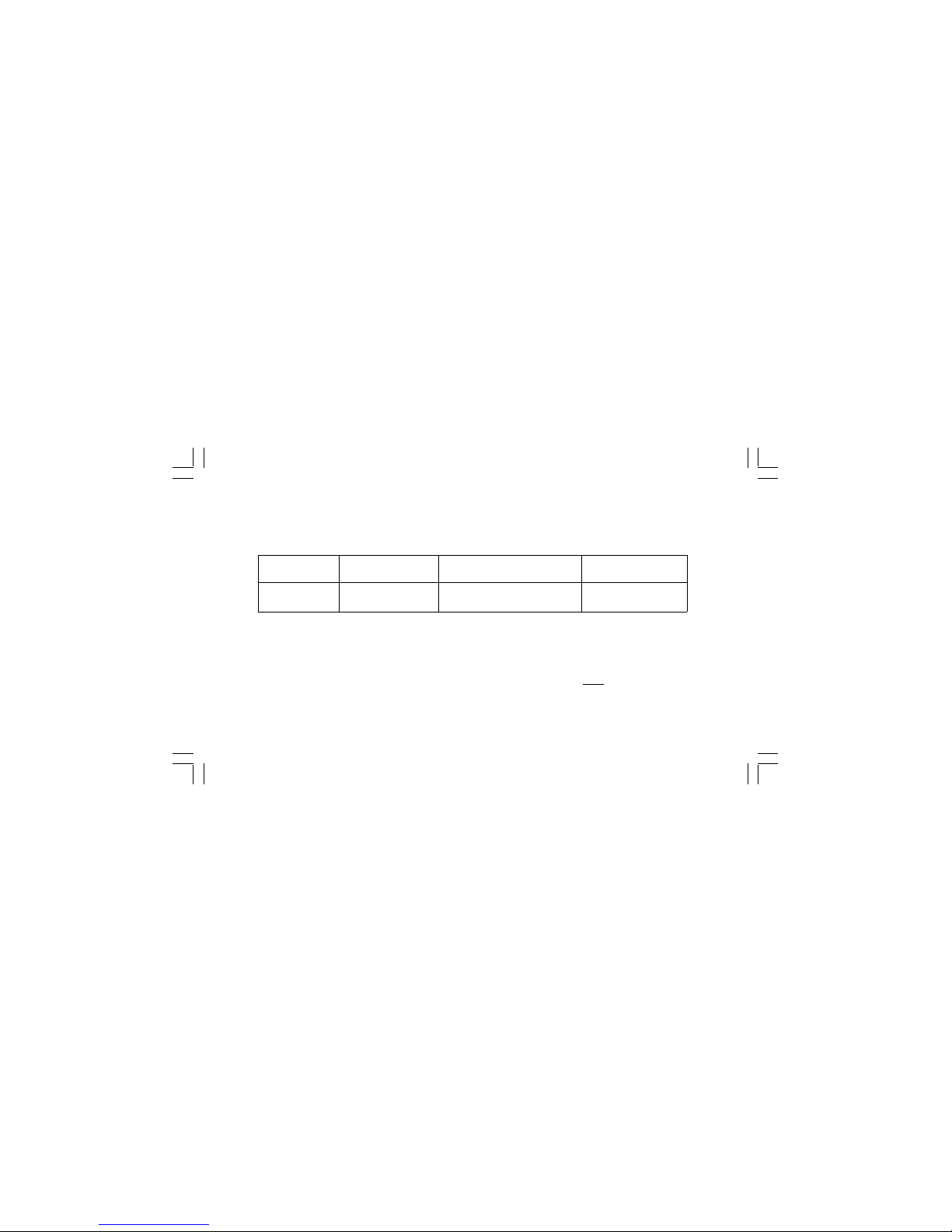

2-3 Electrical Specifications

Accuracy is ±(%reading + number of digits) at 23 °C ± 5 °C at less than 75% R.H.

(1) AC Voltage : Auto-ranging

Range Resolution Accura cy

Overload

protection

±(1.2% reading + 3digits)

40Hz ~ 500Hz

600V r.m.s. 600V 1V

* AC Conversion Type : Average Sensing rms indication. (33Ⅱ)

AC Conversions are ac-coupled, true rms responding , calibrated to the rms value

since wave input , the basic accuracy is for sine wave at full scale, for non-sine wave

accuracy refer to ** (33RⅡ)

Crest Factor : 2 to 3, add 1.4% to Accuracy. where C.F. = Peak

3 to 4, add 3% to Accuracy. RMS

Input impedance : 2M Ω // 2nF approx.

Page 11

10

(2) AC Current : Auto-ranging

Range Resolution Accuracy

Overload

protection

200A 0.1A ±(1.9% reading + 5 digits) 50/60Hz

600A 1A

±(1.5% reading + 5 digits) 50/60Hz (for 0 ~ 400A)

±(2.5% reading + 5 digits) 50/60Hz (for 400 ~ 600A)

800A

* AC Conversion Type : Average Sensing rms indication. (33Ⅱ)

AC Conversions are ac-coupled, true rms responding , calibrated to the rms value

since wave input , the basic accuracy is for sine wave at full scale, for non-sine wave

accuracy reference to ** (33RⅡ)

Crest Factor : 2 to 3, add 1.4% to Accuracy. where C.F. = Peak

3 to 4, add 3% to Accuracy. RMS

Page 12

11

(3) Resistance : Auto - ranging

Range Resolution Accura cy

Over voltage

protection

600V r.m.s.

2000Ω 1Ω

±(1.5% reading + 2 digits)

Max. Open

Circuit Voltage

3V

(4) Instant Continuity Description : Internal sounder will operate when resistance is less than 50 Ω .

(5) Data Hold : Hold display reading for all functions and ranges.

(6) Auto Power Off : Once the Clamp-On meter is powered on, a timer is activated which will turn the unit off after

approximately 30 minutes. If you wish to continue making measurements after the unit

automatically powers off, you must switch the function selector to “OFF” and then back to

the desired function.

Page 13

12

OPERATION

This instrument has been designed and tested in accordance with IEC Publication 1010, Safet y Require-

ments for Electronic Measuring Apparatus and has been supplied in a safe condition. This inst ruction

manual contains some information and warnings which have to be followed by the user to ensure safe

operation and to retain the instrument in safe condition.

3-1 Precautions and Preparations for measurement

1. Make sure that the battery is properly connected.

2. The instrument should only be operated between 0°C ~ 45°C and at less than 75% R.H.

3. Do not use or store this instrument in a high temperature or high humidity environment and do not store the unit

in direct sunlight.

4. Do not replace battery with power on condition.

5. If the unit is not to be used for a long period of time, remove the battery.

6. Do not forget to turn off after use.

Page 14

13

7. If the meter is used near equipment that generates electro magnetic noise, the display may be unstable or

indicate incorrect measurement values.

8.

Maximum rated voltage to earth for voltage measurements terminals is 600V CAT. III.

9. When using the instrument as a Voltmeter or ohmmeter never clamp the jaws around or onto a conductor.

TEST EQUIPMENT RISK ASSESSMENT

Users of this equipment and or their employers are reminded that Health and Safety Legislation require them to

carry out valid risk assessments of all electrical work so as to identify potential sources of electrical danger and

risk of electrical injury such as from inadvertent short circuits. Where the assessments show that the risk is

significant then the use of fused test leads constructed in accordance with HSE guidance note GS38 “ Electrical

Test Equipment for use by Electricians” should be used.

THIS INSTRUMENT MUST NOT BE USED ON UNINSULATED CONDUCTORS AT A VOLTAGE

GREATER THAN 600V ac/dc.

Page 15

14

3-2 AC Current Measurement

1. Set the function switch to the desired current position.

2. Open the Spring-loaded clamp by pressing the trigger on the right side of the meter.

3. Position the clamp around the wire or the conductor and release the clamp trigger, make sure that the clamp is

entirely closed. The clamp must be positioned around only one conductor of a circuit . If the clamp is placed

around two or more current carrying conductors, the meter reading will be FALSE.

3-3 AC Voltage Measurement

1. Set the function switch to the " V ~ " position.

2. Connect the black test lead to the "COM" terminal and the red test lead to the " V- Ω " terminal.

You can now connect the test probes to the circuit to be measured.

3-4 Resistance Measurement

1. Set the function switch at "

<Ω " position.

2. Connect the black test lead to the "COM" terminal and red test lead to the " V- Ω " terminal.

3. Verify that the power to the circuit under test is off. Connect test leads to the circuit to make the measurement.

4. The internal sounder will operate if the resistance of the circuit under test is less than 50 Ω .

Page 16

15

MAINTENANCE

WARNING : TO AVOID ELECTRICAL SHOCK REMOVE TEST LEADS BEFORE OPENING THE COVER.

4-1 General Maintenance

1. Repairs or servicing not covered in this manual should only be performed by qualified personal.

2. Periodically wipe the case with a dry cloth and detergent do not use abrasives or solvents

.

4-2 Battery Replacement

The meter is powered by a single 9V battery. Refer to Figure 2 and use the following procedure to replace

the battery.

1. Disconnect the test leads from the circuit being measured and turn the meter off. Remove the test leads from

the front terminals of the meter.

2. Position the meter face down.

3. Remove the battery cover from the instrument by removing the screw and then lifting off the cover.

4. Lift the battery from the case top and carefully disconnect the battery connector leads.

5. Snap the battery connector leads to the terminals of a new battery and reinsert the battery into the case top.

Make sure that the battery leads do not become pinched between the case bottom and case top.

6. Replace the case bottom and reinstall the screws.

Page 17

16

Screw

Battery Cover

9V Battery

Top Case

Bottom Case

Figure 2

Page 18

Asia

Iso-Tech

460 Alexandra Road, #15-01A

PSA Building

Singapore 119963

Europe

Iso-Tech

PO Box 99

Corby

Northamptonshire

NN17 9RS

United Kingdom

Japan

West Tower (12th Floor)

Yokohama Business Park

134 Godocho, Hodogaya

Yokohama, Kanagawa 240-0005 Japan

USA

7410 Pebble Drive

Fort Worth

Texas 76118-6961

Canada

1701 Woodward Drive

Ste 108 Ottawa

Ontario K2C 0R4, Canada

South America

Av. Pdte. Eduardo Frei M. 6001-71

Centro Empresas El Cortijo

Conchali, Santiago, Chile

Loading...

Loading...