Page 1

Isothermal Technology Ltd

Evaluation

Fixed Points for the Thermal Calibration Laboratory

(Celebrating 10 years of Slim Cell Production)

Introduction

The advantage of fixed point calibration is the small uncertainties associated with the

method.

The very pure fixed point substance can be melted or frozen to produce an absolute

temperature for calibrating temperature sensors.

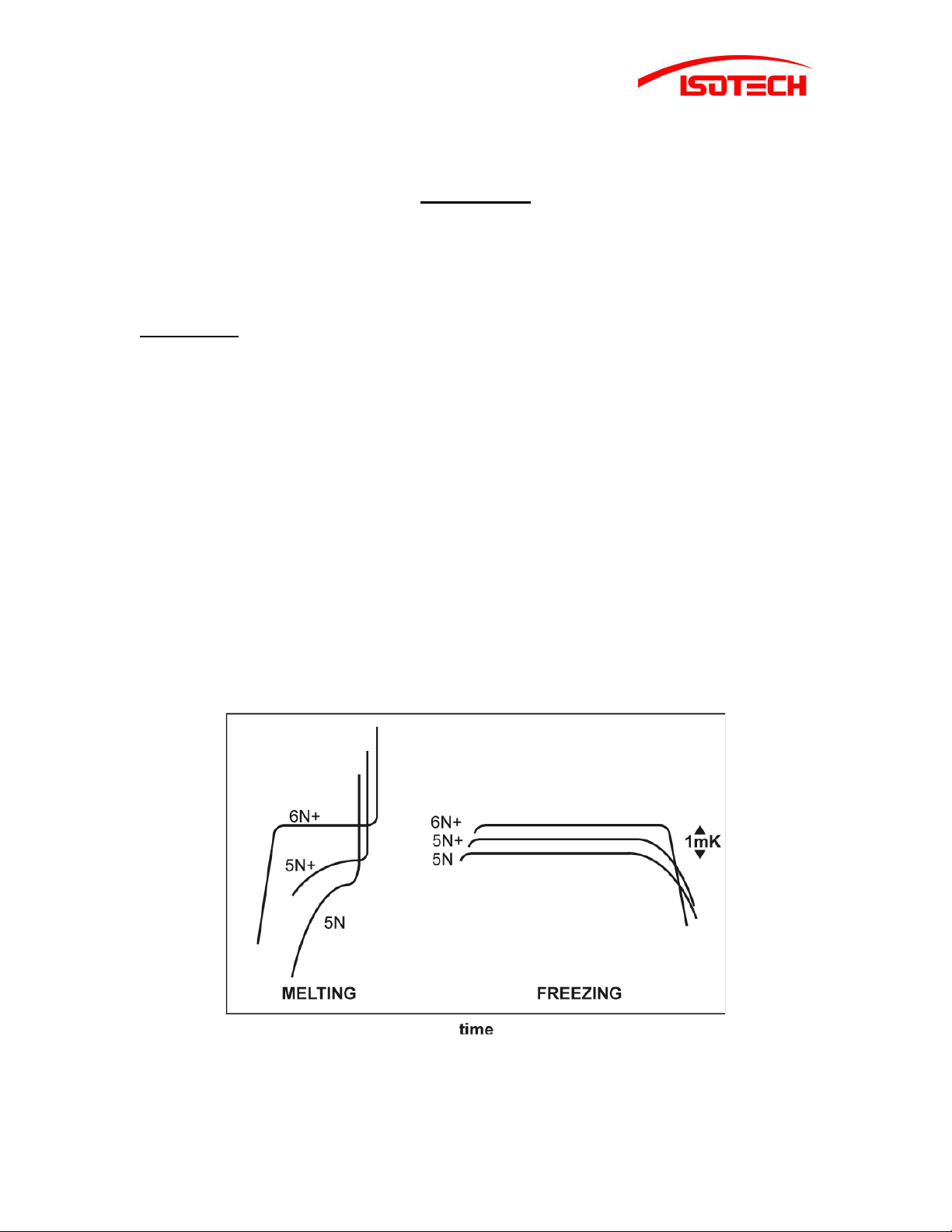

The figure below shows the changes in slope and absolute temperature that occur for

various purities.

Typically a 6N pure cell will melt 80% of its contents over 2mK and its contents will

freeze 50% in between 0.1 and 0.2mK. The above is the accepted method of specifying

the purity of a fixed point – see references 1 and 2 for more details.

A 5N pure cell will melt 80% of its contents over 20mK and 50% of its freeze will occur

over 1 to 2mK.

Typical Melting & Freezing Curves of Metals of Three Levels of Purity

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 2

Isothermal Technology Ltd

For all but Primary Laboratories, it is quicker, simpler and easier to use fixed point cells

during their melt. Isotech’s Slim Cells are all 6N+ pure so that the melt curve is very flat.

Small or ‘Slim’ Fixed Point Cells

These cells contain less of the metal contained in cells designed to fully realize the ITS90 Scale. By reducing the size (both diameter and length) the slim cells can be fitted into

much smaller pieces of apparatus. The negative side of such a design concept is that

thermometers being calibrated are not so deeply immersed. This may, or may not be a

problem, as we shall show later in this evaluation.

The melt plateau has the following advantages over the freeze:-

1. It can be automated. A simple timer switches on the apparatus 1 to 2 hours

before it is needed its controller set to 1°C above the melt. The cell then

automatically comes onto its melt, which will last all day. Over night the timer refreezes the cell ready for the next day. To freeze a cell means melting it first and

most of the day is lost.

2. As thermometers are calibrated (at the rate of about 1 per 20 minutes) each one

re-freezes a little of the melted cell causing the melt to lengthen i.e. the more

calibration is performed the longer the plateau.

3. Stem conduction is minimized. This is because the sensor being calibrated

passes through the apparatus, which is 1°C above the cell’s temperature before it

comes out into ambient air.

Summary Chart of the Results Obtained in this Evaluation

Slim cells in small apparatus compared to large cells in large apparatus

Slim Mercury Triple Point Cell in Europa ±0.1mK

Slim Water Triple Point Cell in Europa or Venus ±0.3mK

Slim Gallium Cell in Europa, Venus or Calisto ±0.3mk

Small Indium Cell in Calisto ±0.5mK

Slim Tin Cell in Medusa ±0.6mK

Slim Zinc Cell in Medusa ±1.4mK

Slim Aluminum Cell in Oberon ±5mK

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 3

Isothermal Technology Ltd

Experimental Results

The following results at various fixed points were all performed in the same way.

A Standard Platinum Resistance Thermometer was calibrated in a large cell in a large

apparatus. The thermometer was then transferred to the smaller cell in a large apparatus

to check out the cell’s purity.

Lastly the smaller cell was placed in the portable apparatus and the difference (if any)

gives a measure of the stem conduction error due to the portable apparatus.

For convenience I will group the cells into 3.

Group 1 comprises the Triple Point of Mercury, the Triple Point of Water and the Gallium

Cell.

1 piece of apparatus can create the conditions to melt or freeze any of group 1 cells.

Called Europa, this piece of apparatus can create temperatures around the cells from –

45°C to +140°C.

The most complex temperature to create is the Triple Point of Water, and so this will be

described first.

In 1982 a paper was presented at the 5th Conference of Temperature by Cox & Vaughn

in which was described a slush method for creating the Triple Point of Water. Briefly the

method comprised of supercooling the water cell to –7°C and then giving it a shake.

Shaking the cell initiated nucleation and sufficient (about 30%) water turned to small ice

crystals to bring the cells temperature up to +0.01°C.

This method has been adapted for use in the Europa, or Venus.

A Small Triple Point of Water Cell was placed inside the Europa apparatus the

temperature adjusted to cool the water cell to –6°C or –7°C it was then shaken to create

a slush of ice and water. After a further 30 minutes at –7°C the Europa was reset at 0°C.

To gauge the accuracy of this approach a 25.5ohm quartz sheathed Standard Platinum

Resistance Thermometer was calibrated in a Large Triple Point of Water Cell. Next it

was transferred to the small cell in Europa. A plateau lasting longer than 16 hours was

obtained with the thermometer reading within 0.3mK of its calibrated value (Graph 1).

Such a system, using RS232 link can be automated (with the exception of the shake) to

provide a economically priced Triple Point of Water temperature all day every day.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 4

Isothermal Technology Ltd

The Gallium Point

Either by changing cells, or by having a second Europa apparatus the melting

temperature of Gallium can also be created as described below:-

A small gallium melt point cell is placed inside the Europa, the temperature was set so

that the block was 2 to 3°C above the gallium melt point. A thermometer was placed in

the reentrant tube of the cell and the warm-up and arrival on the plateau are observed.

Once the gallium begins to melt, 5cc of warm water was introduced in the re-entrant tube

to melt a sheath around the reentrant tube, and the temperature of the Europa was

reduced to 0.5°C above the melt temperature.

The thermometer read within 0.3mK of the calibrated gallium point after 20 minutes and

remained within 0.3mK of the expected melt value for over 48 hours, (Graph. 2)

Unlike the gallium apparatus, the Europa is not self-protecting, its flexibility precludes

this. Thus after melting, it is necessary to remove the cell and freeze the gallium from the

bottom up. This is because gallium expands 3% as it freezes. Freezing is easily

accomplished by placing the cell in 30 to 50mm of cold water, or onto a bed of ice cubes.

The Europa can also be used with a Slim Mercury Triple Point Cell as follows:After placing the cell into the well of the Europa its control temperature is set to –45°C

the cell is cooled, supercooled, nucleates and quickly comes onto its freeze plateau. At

this time the set point is raised to 0.5°C below the freeze temperature and calibration

can begin. Again the more sensors are calibrated, the longer the freeze plateau.

Thus with 1 small piece of apparatus and 3 slim cells, 3 of the most fundamental points

of ITS-90 can be created and maintained for a working day or longer to an accuracy of

0.0003°C or better.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 5

Isothermal Technology Ltd

Graph 1

Graph 2

The Europa-6 and Slim Mercury Triple Point Cell give accurate realization of the ITS-90

value.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 6

Isothermal Technology Ltd

Graph 3

Graph 4

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 7

Isothermal Technology Ltd

We can go beyond the temperatures –38.8344°C, 0.01 and 29.7646°C with a second

group of cells.

The second group of slim cells comprises Indium at 156.598°C, Tin at 231.928°C and

Zinc at 419.527°C.

Small Indium Cells can be melted in a portable apparatus called Calisto.

Indium has a phase transition of 156.5985°C. For co nvenience the cells are used with

the melting point. For a short and well-defined melting point plateau the cell is place

centrally into the Calisto’s well. The temperature is set for 158.4, a metal ring is placed

over the cell re-entrant tube and insulation is added both below and above this ring. Oil

may optionally be used inside the cell for improved heat transfer to the thermometer

being calibrated. Typically one hour after switch on a 2 hour plateau will be achieved,

see chart.

Alternatively a bench top apparatus called Medusa 1 can be used with Indium, Tin and

Zinc.

Operation is very simple, Medusa 1’s controller is set to a temperature ½°C above the

melt temperature of fixed point cell. The cell will melt over a working day during which

time calibrations can be performed.

If only 1 Medusa is used only 1 fixed point can be created in a day. If 2 or 3 Medusa’s

are available it is possible by use of a timer to have Indium, Tin, Zinc melt temperatures

available all day, every day.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 8

Isothermal Technology Ltd

Because the apparatus and cells are smaller than standard cells and apparatus it is

important to discover the effects of these changes. A report of Tin and Zinc points is

presented below.

In the evaluation the Slim Zinc Sealed Cell was chosen because it is most sensitive to

stem conduction and thermal gradients, hence it has the largest errors. This is because

at lower temperature points such as Tin and Indium the gradients and stem conduction

are less because the apparatus is closer to ambient.

An Isotech Model 909/25.5ohm SPRT was used for all measurements since it has a long

sensing length and would show large stem conduction errors if these exist.

Method

The 25.5ohm SPRT was calibrated in a large sealed cell in furnace 17701. Values being

obtained for a freeze plateau.

Subsequently the same apparatus and thermometer were used in conjunction with a

Slim Sealed Zinc Cell to evaluate any difference in plateau values.

Next the same Slim Sealed Zinc Cell was placed in a Medusa I and the melt

characteristics were monitored.

A similar procedure was adopted to test the Slim Tin Cell.

Discussion of Results

The melt curves attached are actual results taken regularly on our UKAS accredited Slim

Cell Fixed Point System. The Slim Cells themselves are metal clad for rugged use, and

the Cells are now 5 years old, and in use most days of the year.

The Zinc Cell, Serial No. Zn 160 began its melt just 1.4mK below the ITS-90 value and

ended just 1.4mK above the ITS-90 value. This is within the uncertainty of calibration of

the SPRT used.

The Tin Cell Serial No. Sn 101 began its melt just 0.6mK below the ITS-90 value and

ended 0.2mK above the ITS-90 value, again within the uncertainty of calibration of the

SPRT used.

The set points were 1.5 to 2°C above the melt tempe rature so that the melts would be

complete within a working day.

By adjusting the set point closer to the melt temperature longer plateaus can be

obtained.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 9

Isothermal Technology Ltd

N.B. Plateau length is proportional to the difference of melt and set point temperatures

i.e. if a 2°C difference gives a 5 hour melt a 1°C difference will give a 10 hour

melt.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 10

Isothermal Technology Ltd

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 11

Isothermal Technology Ltd

Group 3 comprises Aluminum and Silver Slim Cells.

In order to get a long, uniform plateau from these cells it is necessary to house them in

an expensive piece of apparatus containing a sodium heat pipe called Oberon, the

cell/apparatus combination gives a melt plateau of 2 or more hours with a flatness of 3 to

5mK – see graph.

For details of Isotech’s range of slim cells and apparatus ask

for a free copy of Databook 2.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 12

Isothermal Technology Ltd

In 2002, a German DKD accredited laboratory applied to widen its accreditation to

include a set of slim cells, mercury, water triple point, gallium, indium, tin, zinc and

aluminium. The slim cells and apparatus were sent to PTB for intercomparison to the

National Standards of Germany.

The results are tabulated below: -

Slim Cell

∆T (mK)

Hg 137 0 1

Ga 123 -0.173 0.25

In 125 -1.4 2

Sn 132 +1.4 2

Zn 64 +0.3 2

Al 160 +1 3

u/c (mK)

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Page 13

Isothermal Technology Ltd

References

1. Optimal Realization of the Defining Fixed Points of the ITS-90 that are used for

Contact Thermometry.

CCT Working Group – B.W. Mangum (retired from NIST), Chairman; P.

Bloembergen (retired from VSL); M. V. Chattle (retired from NPL); B, Fellmuth

(PTB); P. Marcarino (IMGC); and A. I. Pokhodun (VNIIM).

2. The Freezing Points for High Purity Metals as Precision Temperature Standards.

Precision Measurements with Standard Resistance Thermometers; E. H.

McLaren.

3. Completely Automated Fixed Points from ITS-90 for Industry – Points On The

Temperature Scale (POTTS).

John P. Tavener, Isothermal Technology Limited (Isotech), Pine Grove,

Southport, England.

4. Sealed Cells, Open Cells, Slim Cells.

Isotech Journal of Thermometry – Vol. 2, No. 1, Second Quarter 1991.

Isothermal Technology | Pine Grove | Southport | Merseyside | PR9 9AG | United Kingdom

Tel: +44 (0)1704 543830 / 544611 | Fax: +44 (0)1704 544799 | info@isotech.co.uk | www.isotech.co.uk

Loading...

Loading...