Page 1

SECT ION

ENGLIS H

IRIS

*

Quickie®IRIS

*

Zippie®IRIS SE

*

Quickie®IRIS SE

* with transit option * without transit option

Supplier:

User:

Distribuidor:

Pasajero:

Cada una de las sillas se envía con un manual de instrucciones en inglés. El manual en español o

francés está disponible en formato PDF en nuestra página en Internet: www.SunriseMedical.com.

Ingrese a la página del producto específico para descargar el manual, o comuníquese con el

proveedor autorizado de Sunrise Medical.

Fournisseur:

Utilisateur / Utilisatrice:

Chaque fauteuil est livré avec un manuel d’instructions en anglais. Les versions en espagnol et en

francais sont à ançais est à votre disposition en format PDF sur le site: www.SunriseMedical.com.

Veuillez vous rendre à la page de votre produit pour télécharger le manuel dans la langue

souhaitée, ou contactez un fournisseur agréé Sunrise Medical.

Fachhändler :

Benutzer :

Zum Lieferumfang jedes Rollstuhls gehört ein Bedienungshandbuch in englischer Sprache. Diese

übersetzte Version des Handbuchs steht im PDF-Format auf unserer Website zur Verfügung:

www.SunriseMedical.com. Gehen Sie bitte zu der betreffenden Produktsite für den Download

der übersetzten Version oder wenden Sie sich an Ihren authorisierten Sunrise Medical

Fachhändler.

This manual must be given to the user of this wheelchair.

Before using this wheelchair read this entire manual and save for future

reference.

Este manual debe ser entregado al pasajero de esta silla de ruedas.

Antes de usar esta silla de ruedas, lea este manual en su totalidad y

guárdelo para futura referencia.

Ce manuel doit être remis à l’utilisateur / utilisatrice de ce fauteuil

roulant.

Avant d’utiliser ce fauteuil roulant, lisez entièrement ce manuel

et conservez le pour le consulter ultérieurement.

Dieses Handbuch muss dem Benutzer des Rollstuhls ausge-

händigt werden.

Vor dem Gebrauch des Rollstuhls lesen Sie bitte das gesamte

Handbuch, und bewahren Sie es für zukünftigen Bedarf auf.

O w n e r ’s M a n u a l

M a n u a l d e I n s t r u c c i o n e s

M o d e d ’ e m p l o i

B e n u t z e r a n w e i s u n g e n

Rivenditore :

Utente :

Ogni carrozzina è accompagnata da un manuale d’uso scritto in inglese. La versione tradotta è

reperibile nel formato PDF sul nostro sito web: www.SunriseMedical.com. Visitare la pagina del

prodotto specifico da scaricare, o contattare il fornitore Sunrise Medical autorizzato.

Il presente manuale va consegnato all'utente della carrozzina.

Prima di usare la carrozzina, leggere il presente manuale per intero e

conservarlo per riferimento futuro.

M a n u a l e d ' u s o

Page 2

ENG LIS H

SUNRISE MEDICAL LISTENS

Thank you for choosing a Quickie/Zippie IRIS tilt in space wheelchair.

We want to hear your questions or comments about this manual, the

safety and reliability of your chair, and the service you receive from

your Sunrise supplier. Please feel free to write or call us at the

address and telephone number below:

SUNRISE MEDICAL

Customer Service Department

2842 Business Park Avenue

Fresno, CA 93727

(800) 333-4000

Be sure to return your warranty card, and let us know if you change

your address. This will allow us to keep you up to date with information about safety, new products and options to increase your use and

enjoyment of the wheelchair. If you lose your warranty card, call or

write and we will gladly send you a new one

.

I. INTRODUCTION

FOR ANSWERS TO YOUR QUESTIONS

Your authorized supplier knows your wheelchair best, and can answer

most of your questions about chair safety, use and maintenance. For

future reference, fill in the following:

Supplier:

___________________________________________________________________________

Address:___________________________________________________________________________

______________________________________________________________________________________

Telephone: ________________________________________________________________________

Serial #:_____________________________ Date/Purchased: ________________________

ADDITIONAL INFORMATION YOU SHOULD KNOW

No component of this chair was made with Natural Rubber Latex.

MK-100151 Rev. A

2

Page 3

ENG LIS H

II. TABLE OF CONTENTS

I. INTRODUCTION ...........................................................................2

II. TABLE OF CONTENTS.................................................................3

III. YOUR CHAIR AND ITS PARTS ..................................................4

IV. NOTICE– READ BEFORE USE ....................................................4

V. GENERAL WARNINGS ......................

A.Weight limits................................................................................5

B. Intended Use................................................................................5

C. Attendants and Caregivers......................................................5

D. Accessories

E. Know your Chair........................................................................5

F. Reduce the risk of an Accident...............................................5

G.Safety Checklist ...........................................................................5

H.Changes and Adjustments.........................................................5

I. Environmental Conditions........................................................6

J. Terrain........................................................................................

K.Street Use ...................................................................................6

L. Motor Vehicle Safety...................................................................6

M.When you need help .................................................................6

VI. SAFETY WARNINGS: FALLS & TIP-OVERS.............................7

A.Center of Balance.......................................................................7

B. Dressing or Changing Clothes ................................................7

C.Obstacles ......................................................................................7

D. Front Caster Lift.........................................................................7

E. Reaching or Leaning ...................................................................7

F. Moving Backward.........................................................................7

G.Escalators......................................................................................8

H. Ramps, Slopes, and Sidehills .....................................................8

I. Transfer ........................................................................................

J. Curbs and Single Steps ...............................................................9

K.Climbing a Curb or Single Step...............................................9

L. Descending a Curb or Single Step .........................................9

M.Stairs............................................................................................10

N. Climbing Stairs.........................................................................10

O. Descending Stairs ....................................................................10

P. Tilt Use and Back Angle Adjustment (Mono Back)..........10

VII. WARNINGS: COMPONENTS & OPTIONS..........................11

A.Anti-tip Tubes ............................................................................11

B. Armrests.....................................................................................11

C.Push Handles .............................................................................11

D. Stroller Handle..........................................................................11

E. Cushions.....................................................................................11

F. Fasteners ....................................................................................11

G. Footrests....................................................................................11

H Pneumatic Tires.........................................................................11

I. Positioning Belts........................................................................12

J. Quick Release Axle..................................................................12

K.Rear Axles..................................................................................12

L. Rear Wheel Locks....................................................................12

M. Modified Seat Systems............................................................12

N. Tray for vent and battery.......................................................12

O. Accessory Hook ......................................................................12

VIII. USE AND MAINTENANCE ......................................................13

A. Introduction ............................................................................13

B. Critical Maintenance Tips.......................................................13

C.Maintenance Chart...................................................................13

D.Cleaning ......................................................................................13

E. Troubleshooting Chart............................................................13

F. To Mount and Remove Rear Wheels....................................14

G.Cushion Installation .................................................................14

H. Wheel Locks.............................................................................14

...........................................5

...6

I. Hub Lock....................................................................................14

J. Anti-Tip Tubes-Rear...................................................................14

K. Dual-Post Armrests .................................................................15

L. Height-Adjustable Armrests...................................................15

M.Adjustable Locking Flip-up Armrests...................................15

N.Cantilever Armrests.................................................................16

O.Swing-away Hangers/Footrests..............................................16

P. Heavy-duty, Lift-off Footrests ................................................16

Q.Articulating Legrest .................................................................16

R. Elevating Legrest.......................................................................17

S. Tilt-in-Space Mechanism .........................................................17

T. Stroller Handle Extension ......................................................18

U.Reclining Back ...........................................................................18

V. Mono Back Stroller handle ....................................................18

W.Folding the Mono back for Transport.................................18

X.Check-out ..................................................................................18

IX. DEALER SERVICE & ADJUSTMENT.........................................19

A.Dealer Service Introduction ..................................................19

B. Critical Maintenance Tips.......................................................19

C.Cleaning ......................................................................................19

D.Rear Axle....................................................................................19

E. Hub Lock Adjustment .............................................................20

F. Wheel Locks .............................................................................20

G.Single-Post Armrest Receiver ................................................20

H.Adjustable Locking Flip-up Armrests...................................21

I. Cantilever Locking Flip-back armrests ................................21

J. Swing-Away Height Adjustment............................................22

.8

K.Heavy-Duty Lift-Off Footrest ................................................22

L. Articulating Legrest..................................................................22

M.Elevating Legrest.......................................................................22

N.Contracture Footrest ............................................................23

O.Tilt-in-space Mechanism .........................................................23

P. Standard Backrest.....................................................................24

Q.Mono Back.................................................................................24

R.Dynamic Mono Back ................................................................25

S. Dynamic Mono Back Elastomer Replacement ..................26

T. Ventilator Hanger Bracket ....................................................26

U.Fixed Stroller Handle...............................................................26

V. Adjustable Stroller Handle (Mono Back)............................26

W.Caster/Fork Assembly.............................................................27

X.Frame Depth .............................................................................27

Y. Frame Width..............................................................................28

Z.Seat Pan ......................................................................................29

AA.Carriage....................................................................................29

BB.Attendant Wheel Lock Installation.....................................30

CC.Footplate Adapter Bracket..................................................30

DD.Lap Belt Instructions.............................................................31

EE.Check-Out................................................................................31

X. SUNRISE LIMITED WARRANTY ..........................................

ESPAÑOL .......................................................................................34

FRANÇAIS......................................................................................70

ITALIANO....................................................................................106

DEUTSCH....................................................................................142

....32

3

MK-100151 Rev. A

Page 4

ENG LIS H

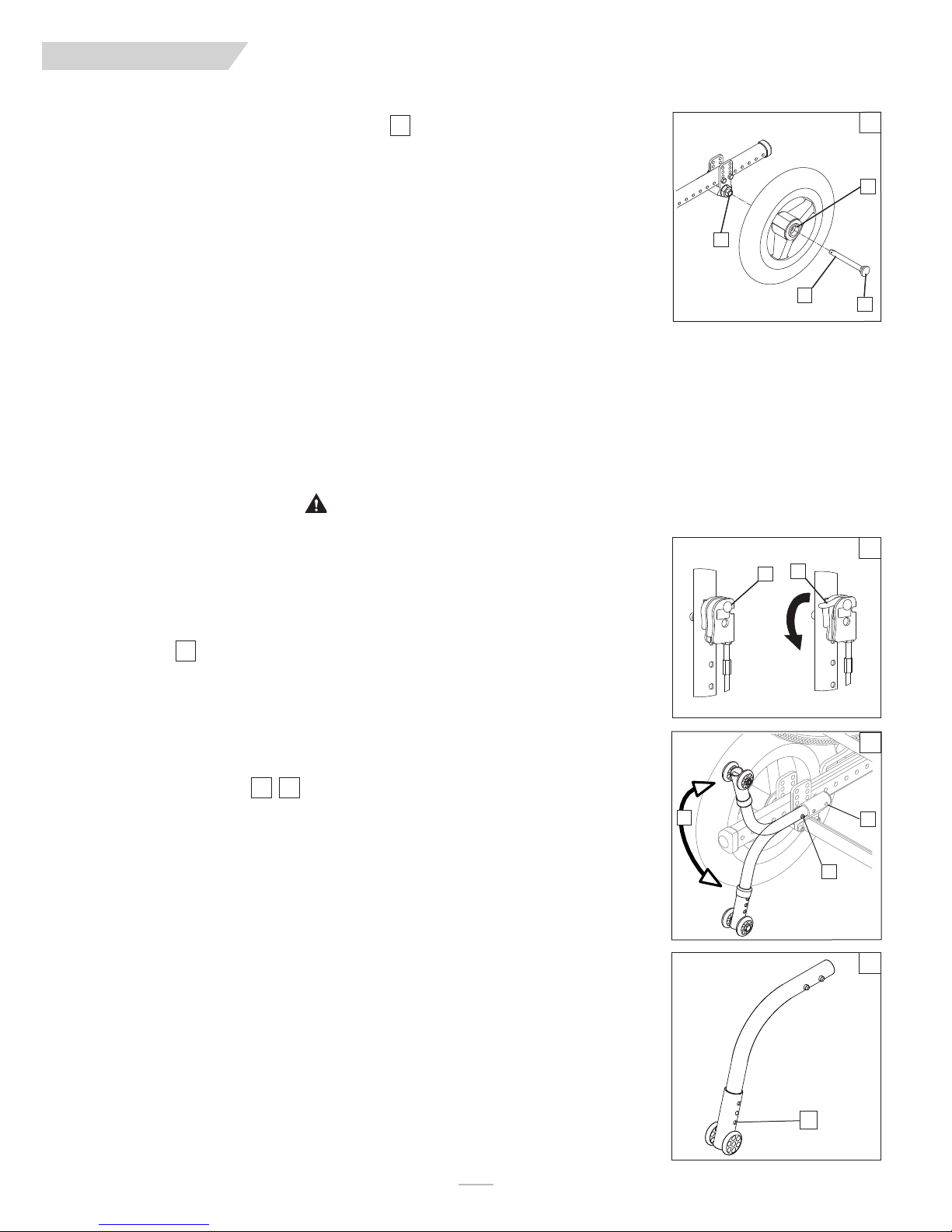

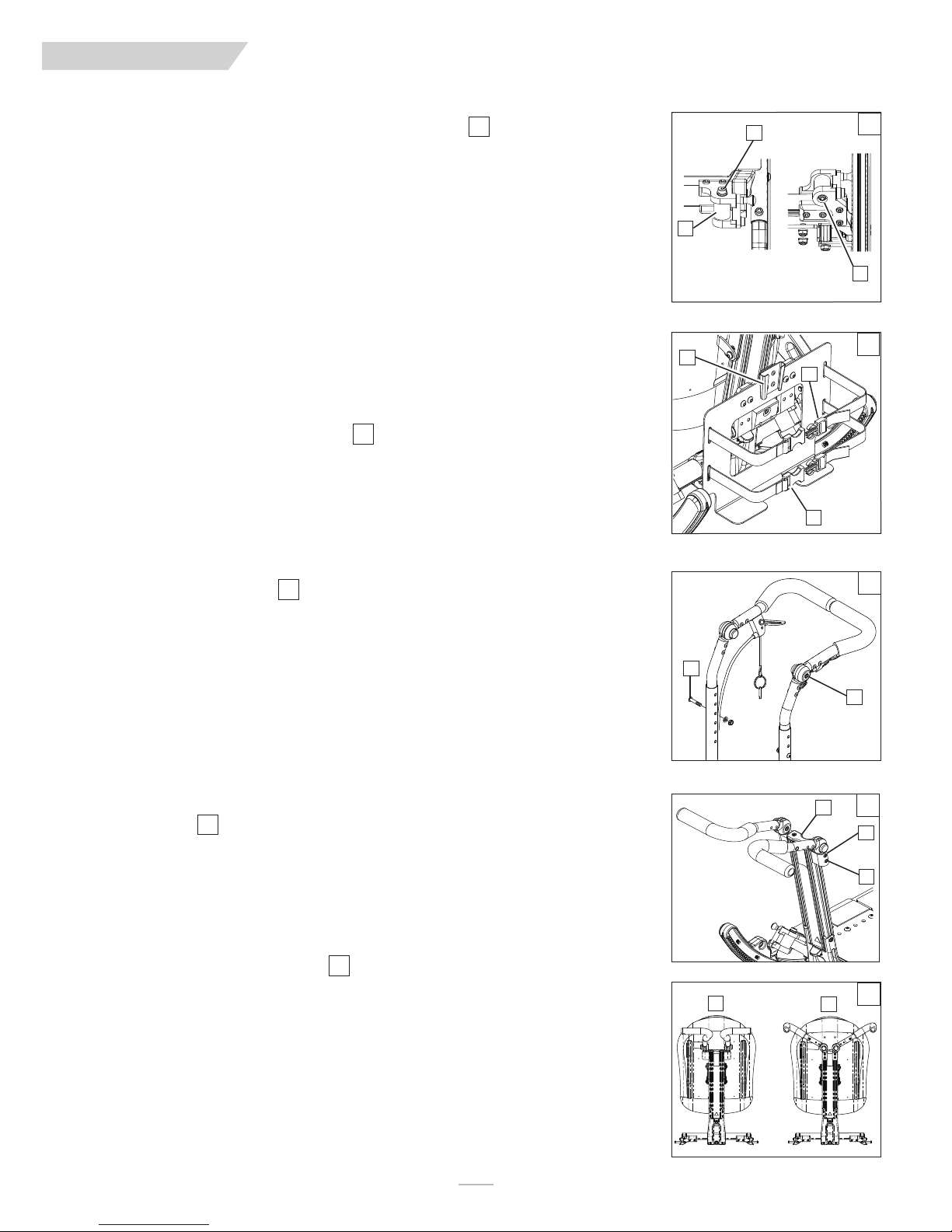

III. YOUR CHAIR AND ITS PARTS

QUICKIE IRIS

4

5

1. Headrest

1

2

2. Push Handle/Back Cane

3. Armrest

4. Footrest Hanger

5. Footplate

6. Carriage

3

7. Caster fork

8. Caster tire

9. Wheel Lock

10. 12" Rear wheel

13

11. Anti-tip

12. Adjustable seat pan

13. Tilt-in-space mechanism release lever

12

NOTE– Not all options are available on both

11

6

the Quickie and Zippie IRIS.

Please refer to the order form for

specific option availability.

7

8

A. CHOOSE THE RIGHT CHAIR & SAFETY OPTIONS

Sunrise provides a choice of many wheelchair styles to meet your needs.

This product is intended for single person use only. Final selection of the

type of wheelchair, options and adjustments rests solely with you and your

health care professional. Choosing the best chair and set-up for your safety

depends on such things as:

1. Your disability, strength, balance and coordination.

2. The types of hazards you must overcome in daily use (where you

live and work, and other places you are likely to use your chair).

3. The need for options that will improve your positioning, safety and

comfort (such as anti-tip tubes, positioning belts, or special seating

systems).

B. REVIEW THIS MANUAL OFTEN

Before using this chair you, and each person who may assist you, should

read this entire manual and make sure to follow all instructions. Review the

warnings often, until they are second nature to you.

10

9

IV. NOTICE– READ BEFORE USE

C. WARNINGS

The word

cause

are in Three main sections, as follows:

NOTE–

“WARNING”

severe injury or death

1. V– GENERAL WARNINGS

Here you will find a safety checklist and a summary of risks you

need to be aware of before you ride this chair.

2. VI– SAFETY WARNINGS: FALLS & TIP-OVERS

Here you will learnabout practices for the safe use of your chair, and

how to avoid a fall or tip-over while you perform daily activities in

your chair.

3. VII– WARNINGS– COMPONENTS & OPTIONS

Here you will learn about the components of your chair and options

you can select for safety. Consult your Premium Retailer and your

health care advisor to help you choose the best set-up and options

for safe use.

Where they apply, you will also find “Warnings” in other sections

of this manual. Heed all warnings in this section. If you fail to do

so a fall, tip-over or loss of control may occur and cause severe

injury to the rider or others.

refers to a hazard or unsafe practice that may

to you or to other persons. The “Warnings”

MK-100151 Rev. A

4

Page 5

ENG LIS H

V. GENERAL WARNINGS

A. WEIGHT LIMITS

WARNING

NEVER exceed the weight limit specified by Sunrise Medical. The weight

capacity provided by your manufacturer is for the combined weight of a rider

and items carried using on-board storage. If you do exceed the weight limit,

damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

Weight Capacities

Quickie IRIS - 250lbs/(113Kg).

Zippie IRIS - 165lbs/(75kg).

Quickie IRIS HD - 350lbs/(159kg).

B. INTENDED USE

The Quickie and Zippie IRIS Series of wheelchair's intended use is to provide mobility to persons limited to a sitting position.

WARNING

DO NOT use this device for purposes other than what is intended by the

manufacturer

1. The wheelchiar is not designed for weight training and is unsafe for

use as a seat while weight training. Weight training from the wheelchair substantially changes the stability of the chair and may cause

tipping.

2. DO NOT stand on the frame of the wheelchair.

3. NEVER allow someone to stand on your chair or use it as a step

ladder.

4. This chair is designed for a single rider only.

5. Unauthorized modifications and use of parts or accessories not supplied or approved by Sunrise Medical may change the chair structure. This will void the warranty and may cause a safety hazard. If

the warning is ignored, damage to your chair, and the potential

severe injury of the person using the chair for unintended purposes

can occur.

C. ATTENDANTS AND CAREGIVERS

WARNING

Before you assist a rider, be sure to read all warnings contained in this

manual, and follow all instructions that apply. Be aware that after consulting

a healthcare advisor, you will need to learn safe and proven body mechanics

to use and create assistive methods best suited to your abilities.

D. ACCESSORIES

WARNING

Unauthorized modifications or use of parts, or accessories not supplied or

approved by Sunrise Medical may change the chair structure. This will void

the warranty and may cause a safety hazard.

Some problems that may occur, but are not limited to:

1. Incorrect Wheels and/or tires that put the rider at risk of a fall or tipover.

2. Adding a component to the frame, changing the structural integrity of

the chair.

3. Any modification or disassembly can potentially create an unsafe situation where rider and/or attendant are put at risk.

E. KNOW YOUR CHAIR

WARNING

Every wheelchair is different. Take the time to learn the feel of this chair

before you begin riding. Start slowly, with easy, smooth strokes. If you are

used to a different chair, you may use too much force and tip over. If you

use too much force, damage to your chair, a fall, tip-over or loss of control

may occur and cause severe injury to the rider or others.

F. REDUCE THE RISK OF AN ACCIDENT

WARNING

1. BEFORE riding, you should be trained in the safe use of this chair by

your health care advisor.

2. Practice bending, reaching and transfers until you know the limit of

your ability. Have someone help you until you know what can cause

a fall or tip-over and how to avoid doing so.

3. Be aware that you must develop your own methods for safe use

best suited to your level of function and ability.

4. NEVER try a new maneuver on your own until you are sure you can

do it safely.

5. Get to know the areas where you plan to use your chair. Look for

hazards and learn how to avoid them.

6. Sunrise recommends using anti-tip tubes in evey circumstance.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

G. SAFETY CHECKLIST

WARNING

Before Each Use Of Your Chair:

1. Make sure the chair rolls easily and that all parts work smoothly.

Check for noise, vibration, or a change in ease of use. (They may

indicate low tire pressure, loose fasteners, or damage to your chair).

2. Immediately repair any problem. Your authorized supplier can help

you find and correct the problem.

3. Check to see that both quick-release rear axles are locked. When

locked, the axle button will “pop out” fully. If not locked, the wheel

may come off and cause you to fall.

4. If your chair has anti-tip tubes, lock them in place.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

H. CHANGES & ADJUSTMENTS

WARNING

1. See your healthcare advisor and have them adjust seating components any time a change or adjustment needs to be made.

2. Unauthorized modifications or use of parts not supplied or

approved by Sunrise may change the chair structure. This will void

the warranty and may cause a safety hazard.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

5

MK-100151 Rev. A

Page 6

ENG LIS H

I. ENVIRONMENTAL CONDITIONS

WARNING

1. Use extra care if you must ride your chair on a

wet or slick surface. If you are in doubt, ask for

help.

2. Contact with water or excess moisture may cause your chair to

rust or corrode. Avoid all extreme weather situations if possible.

a. Do not use your chair in a shower, pool or other body of water.

The chair tubing and parts are not water-tight and may rust or

corrode from the inside.

b. Avoid excess moisture (for example, do not leave your chair in a

damp bathroom while taking a shower).

c. Dry your chair as soon as you can if it gets wet, or if you use

water to clean it.

J. TERRAIN

V. GENERAL WARNINGS

WARNING

If your chair is

1. NEVER let anyone sit in this chair while in a moving vehicle.

2. In an accident or sudden stop the rider may be thrown from the

3. NEVER transport this chair in the front seat of a vehicle. It may shift

4. ALWAYS secure this chair so that it cannot roll or shift.

5. Do not use any chair that has been involved in a motor vehicle acci-

NOT

equipped with the Transit Option:

a. ALWAYS move the rider to an approved vehicle seat.

b. ALWAYS secure the rider with proper motor vehicle restraints.

chair. Wheelchair seat belts will not prevent this, and further injury

may result from the belts or straps.

and interfere with the driver.

dent. The frame and/or components may have been changed due to

the accident. Such items could be, but are not limited to: bent, loosened, and/or broken components that were subjected to an impact.

1

2

1. Based on ANSI/RESNA testing, Sunrise Medical recommends the use

of a caster wheel with a minimum diameter of 5”, if the wheelchair

will be overcoming obstacles up to 1/2” on a regular basis.

2. Your chair is designed for use on firm, even surfaces such as concrete, asphalt, indoor flooring, and carpets.

3. Do not operate your chair in sand, loose soil, or over rocky terrain.

4. If you use your chair on terrain that is rougher than described above

there is a danger that screws and bolts will loosen prematurely, and

that damage to wheels or axles could put the rider at risk of a fall,

tip-over, or loss of control.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

K. STREET USE

WARNING

1. This product is not intended for street use.

2. Avoid streets whenever possible.

3. Obey and follow all legal pedestrian pathways, and laws that apply to

pedestrians.

4. Be alert to the danger of motor vehicles in parking lots, or if you

must cross a road.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others

WARNING

L. MOTOR VEHICLE SAFETY

If possible and feasible, the rider should transfer to the Original Equipment

Manufacturer vehicle seat and use the OEM vehicle restraint.

Sunrise Medical does provide a WC-19 Wheelchair Tie-Down and

Occupant Restraint System, otherwise called a Transit Option. To Identify

whether your wheelchair has been manufactured with the Transit Option

installed, look for four points of securement. Two Front points (A), and

two rear points (B). These points are recognized by the securement point

decal which can be found on or near the securement points. If your wheelchair is equipped with the Transit Option please review the Transit

Securement supplement that was provided with the wheelchair for additional information and instructions. You can request a copy from your

authorized supplier, or Sunrise medical at 1-800-333-4000 if you don’t have

it.

1 2

A

Front Transit hook

Look for this symbol on your wheelchair. It indicates wheelchair securement points which conform to ANSI/RESNA (1998)

V.1 - Section 19 and/or ANSI/RESNA (2012) V.4 WC-19. For

more Transit related information, see the “Transit Securement

Supplement” included with your chair.

Rear Transit hook

M. WHEN YOU NEED HELP

WARNING

For The Rider:

lows all warnings and instructions that apply.

For Attendants:

1. Work with the rider’s doctor, nurse or therapist to learn safe methods best suited to your abilities and those of the rider.

2. Tell the rider what you plan to do, and explain what you expect the

rider to do. This will put the rider at ease and reduce the risk of an

accident.

3. Make sure the chair has push handles. They provide secure points for

you to hold the rear of the chair to prevent a fall or tip-over. Check

to make sure push handle grips will not rotate or slip off.

4. To prevent injury to your back, use good posture and proper body

mechanics. When you lift or support the rider or tilt the chair, bend

your knees slightly and keep your back as upright and straight as you

can.

5. Remind the rider to lean back when you tilt the chair backward.

6. When you descend a curb or single step, slowly lower the chair in

one easy movement. Do not let the chair drop the last few inches to

the ground. This may damage the chair or injure the rider.

7. To avoid tipping, or getting hung up on objects, unlock and rotate

anti-tip tubes up, and out of the way.

8. Whenever you aren’t attending the wheelchiar, ALWAYS use the

wheel-lock to secure the rear wheels, and lock anti-tip tubes in

place if you must leave the rider alone, even for a moment. This will

reduce the risk of a tip over or loss of control of the chair.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

Make sure that each person who helps you reads and fol-

B

MK-100151 Rev. A

6

Page 7

ENG LIS H

VI. SAFETY WARNINGS: FALLS & TIP-OVERS

A. CENTER OF BALANCE

WARNING

The point where this chair will tip forward, back, or to the side depends on

its center of gravity and stability. How your chair is set up, the options you

select and the changes you make may affect the risk of a fall or tip-over.

The Most Important Adjustment is:

1.

a. The position of the rear wheels. The more you move the rear

wheels forward, the more likely your chair will tip over back-

ward.

b. The position of the carriage.

The Center of Balance is also Affected by:

2.

a. A change in the set-up of your chair, including:

• The seat height and seat angle.

• Backrest angle.

b. A change in your body position, posture or weight distribution.

c. Riding your chair on a ramp or slope.

d. The use of a back pack or other options, and the location and

amount of added weight can change the balance of your chair,

To Reduce The Risk Of An Accident:

3.

a. Consult your doctor, nurse or therapist to find out what axle

and caster position is best for you.

b. Consult your authorized dealer, BEFORE you modify or adjust

this chair. Be aware that you may need to make other changes

to correct the center of balance.

c. Have someone help you until you know the balance points of

your chair and how to avoid a tip-over.

d. Use anti-tip tubes.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

B. DRESSING OR CHANGING CLOTHES

WARNING

Your weight may shift if you dress or change clothes while seated in this

chair.

To reduce the risk of a fall or tip-over:

1. Rotate the front casters until they are as far forward as possible.

This makes the chair more stable.

2. Lock anti-tip tubes in place. (If your chair does not have anti-tip

tubes, back it up against a wall and lock both rear wheels).

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

C. OBSTACLES

WARNING

Riding over curbs or obstacles can cause tipping and serious bodily harm. If

you have any doubt that you can safely cross any curb or obstacle, ALWAYS

ASK FOR HELP. Be aware of your riding skills and personal limitations.

Develop new skills only with the help of a companion.

To avoid the risk of traversing obstacles:

1. Keep a lookout for danger – scan the area well ahead of your chair

as you ride.

2. Make sure the floor areas where you live and work are level and free

of obstacles.

3. Remove or cover threshold strips between rooms.

4. Install a ramp at entry or exit doors. Make sure there is not a drop

off at the bottom of the ramp.

5. To Help Correct Your Center Of Balance:

a. Lean your upper body FORWARD slightly as you go UP over

an obstacle.

b. Press your upper body BACKWARD as you go DOWN from

a higher to a lower level.

6. If your chair has anti-tip tubes, do not go over an obstacle without

help.

7. Keep both of your hands on the handrims as you go over an obstacle.

8. Never push or pull on an object (such as furniture or a doorjamb)

to propel your chair.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

D. FRONT CASTER LIFT

WARNING

Front caster lift can occur when the front wheels, ordinarily in contact with

the ground, are either intentionally, or unintentionally caused to lift from

the ground while the rear wheels remain in contact. Pitch control (partial

or full) should

advisor and making sure that anti-tips are installed.

If you fail to heed this warning, you are at a high risk of damage to your

chair, a fall, tip-over or loss of control that may occur and cause severe

injury to the rider or others.

NEVER

be attempted without consulting your healthcare

E. REACHING OR LEANING

WARNING

If you reach or lean it will affect the center of balance of your chair. This may

cause you to fall or tip over. When in doubt, ask for help or use a device to

extend your reach.

NEVER

1.

2.

3.

4.

5.

6. If You Must Reach Or Lean:

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

reach or lean if you must shift your weight sideways or rise up

off the seat.

NEVER

reach or lean if you must move forward in your seat to do

so. Always keep your buttocks in contact with the backrest.

NEVER

reach with both hands (you may not be able to catch yourself to prevent a fall if the chair tips).

NEVER

reach or lean to the rear unless your chair has anti-tip tubes

locked in place.

DO NOT

damage one or both backrest tubes and cause you to fall.

a. Do not lock the rear wheels. This creates a tip point and makes

b. Do not put pressure on the footrests.

c. Move your chair as close as you can to the object you wish to

d. Do not try to pick up an object from the floor by reaching

e. Rotate the front casters until they are as far forward as possi-

f. Firmly grasp a rear wheel or an armrest with one hand. This will

reach or lean over the top of the seat back. This may

a fall or tip-over more likely.

reach, then back up alongside it. Backing up will rotate the casters forward.

down between your knees. You are less likely to tip if you reach

to the side of your chair.

ble. This makes the chair more stable.

help to prevent a fall if the chair tips.

F. MOVING BACKWARD

WARNING

Use extra care when you move your chair backward. Your chair is most

stable when you propel yourself forward. You may lose control or tip over

if one of the rear wheels hits an object and stops rolling.

1. Propel your chair slowly and smoothly.

2. If your chair has anti-tip tubes, make sure to lock them in place.

3. Stop often and check to be sure your path is clear.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

7

MK-100151 Rev. A

Page 8

ENG LIS H

GET READY

TRANSFER

ADJUST

VI. SAFETY WARNINGS: FALLS & TIP-OVERS

G. ESCALATORS

WARNING

NEVER

use this chair on an escalator, even with an attendant. If you do, a fall or tip-over is likely.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and

cause severe injury to the rider or others.

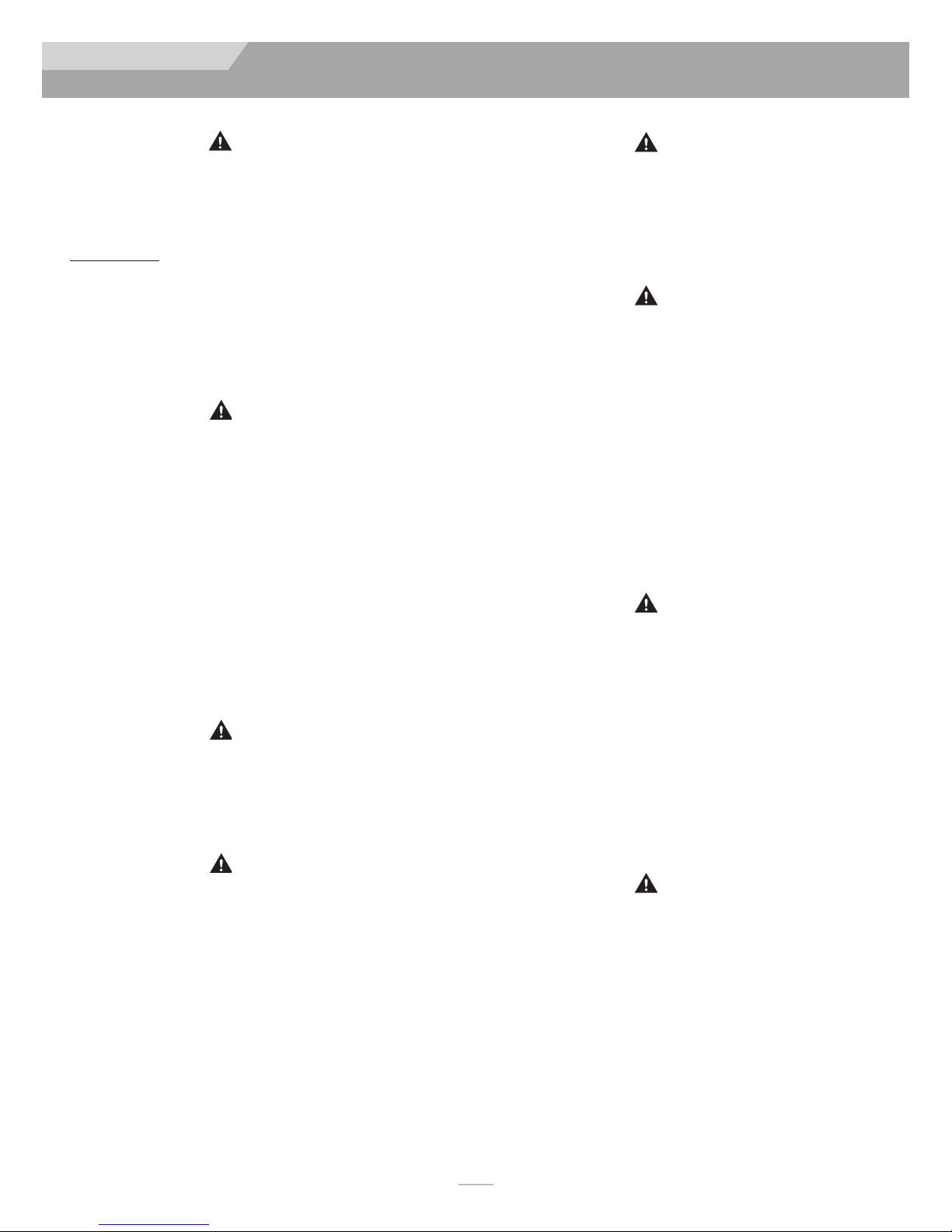

H. RAMPS, SLOPES & SIDEHILLS

3 4 5 6

WARNING

Whenever possible, avoid riding on a slope, which includes a ramp or sidehill. This will change the center of balance of your chair. Your chair is less stable and more difficult to manuever when it is at an

angle. When moving up a hill, anti-tip tubes may not prevent a fall or tip-over. Always ask for help when

riding on slopes.

Do not

1.

2. Avoid Sidehills.

3.

4.

5.

6.

7.

8. To Reduce The Risk Of A Fall Or Tip-Over:

9. Ramps at home & work– For your safety, ramps at home and work must meet all legal require-

10. When you have to use a ramp, always stay in the CENTER of the ramp. Make sure the ramp is

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and

cause severe injury to the rider or others.

use your chair on a slope steeper than 10°.

Do not

Always

go straight up or straight down a slope.

Do not

turn or change direction on a slope.

Do not

stop on a steep slope. If you stop, you may lose control of your chair.

NEVER

use rear wheel locks to try to slow or stop your chair. This is likely to cause your chair

to veer out of control.

ALWAYS

a. Wet or slippery surfaces.

b. A change in grade on a slope (or a lip, bump or depression). These may cause a fall or tip-

c. A drop-off at the bottom of a slope or ramp. A drop-off as small as 3/4 inch can stop a

a. Lean or press your body UPHILL. This will help adjust for the change in the center of balance

b. Keep pressure on the handrims to control your speed on a down slope. If you go too fast

c. Ask for help any time you are in doubt.

ments for your area:

a. Avoid a drop off. You may need a section at the top or bottom to smooth out the transition.

b. Stay in the center of the ramp and control your speed.

wide enough so that you have no risk of going off the edge.

be aware of:

over.

front caster and cause the chair to tip forward.

caused by the slope or sidehill.

you may lose control.

use your chair on a sidehill with a slope steeper than 6°.

Do not

“cut the corner” on a slope or ramp.

Downslope less than 10°

Straight down

Control Speed

Go Slow

No Turns

Upslope less than 10°

Lean Forward

Straight up

Don’t stop

No Turns

Sidehill less than 6°

Don’t stop

No Turns

Ramps

Straight Down

Stay centered

No Drop-offs

Go Slow

3

4

5

6

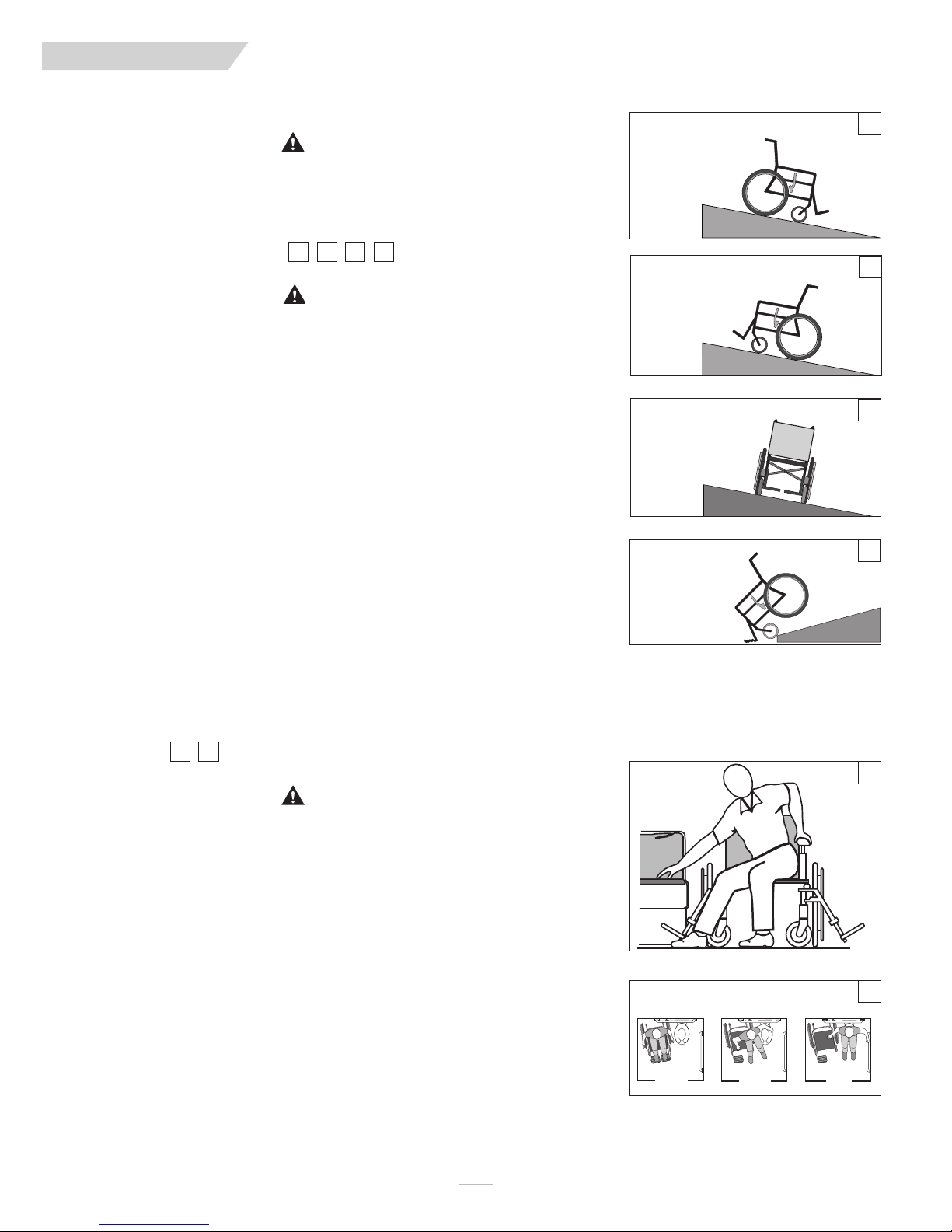

I. TRANSFER

7 8

WARNING

It is dangerous to transfer on your own. It requires good balance and agility. Be aware that there is a

point during every transfer when the wheelchair seat is not below you. To Avoid A Fall:

1. Work with your health care advisor to learn safe transfer methods

a. Learn how to position your body and how to support yourself during a transfer.

b. Have someone help you until you know how to do a safe transfer on your own.

2. Lock the rear wheels before you transfer.

3. Be aware that the chair can still slide and/or tip. The wheel lock keeps the rear wheels from

rolling while you are perforrming the transfer.

4. Make sure that the pneumatic tires are properly inflated. Low tire pressure may allow the rear

wheel locks to slip. (see table in Section G “Pneumatic Tires”

5. Move your chair as close as you can to the seat you are transferring to.

If possible, use a transfer board.

6. Rotate the front casters until they are as far forward as possible.

7. If you can, remove the footrests, or swing them out of the way.

a. Make sure your feet do not catch in the space between the footrests.

b. Avoid putting weight on the footrests as this may cause the chair to tip.

8. Make sure armrests are removed, or out of the way and do not interfere with the transfer.

9. Transfer as far back onto the seat surface as you can. This will reduce the risk that the chair will

tip or move away from you.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and

cause severe injury to the rider or others.

Optimum Transfer position

1.

2. 3.

Before transferring, remove the armrests, and footrests, and make sure the

wheel lock is set.

7

8

MK-100151 Rev. A

8

Page 9

ENG LIS H

VI. SAFETY WARNINGS: FALLS & TIP-OVERS

J. CURBS & SINGLE STEPS

9

WARNING

Before riding over curbs, or negotiating even a single step, ALWAYS ask for assistance first. Curbs and steps

can cause tipping and serious bodily harm. When in doubt as to our ability to avoid, or traverse any obstacle,

ALWAYS ask for help. Be aware of your riding skills and personal limitations, develop new skills only with the

help of a companion.

For Attendant:

1. Do not try to climb a high curb or step (more than 4 inches high) UNLESS you have help. Doing so may

cause your chair to exceed its balance point and tip over.

2. With the help of an attendant, go straight up and straight down a curb or step. If you climb or descend

at an angle, a fall or tip-over is likely.

3. Be aware that the impact of dropping down from a curb or step can damage your chair or loosen fasteners.

If you fail to heed these warnings damage to your chair, a fall, tip-over or loss of control may occur and can

possibly cause severe injury to the rider or others.

K. CLIMBING A CURB OR SINGLE STEP

Each person who assists the rider with curbs and steps should read and follow all instructions and warnings pertaining to attendants, and caregivers.

9

WARNING

For Attendant:

1. Stay behind the chair.

2. Continue backward until the rear wheels contact the face of the curb or step. Lift and roll the rear

wheels to the top of the curb.

3. Pull the chair backwards until the caster wheels have cleared the edge of the curb and return the chair

to it’s rolling position.

If you fail to heed these warnings damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

L. DESCENDING A CURB OR SINGLE STEP

follow these steps to help the rider climb a curb or single step going BACKWARD:

9

9

WARNING

For Attendant::

1. Stay at the rear of the chair.

2. Several feet before your reach the edge of the curb or step, tip the chair slightly and pull it backward.

3. When the chair is at it’s balance point, carefully step forwards until the rear wheels reach the edge of

the curb or step. Then allow the rear wheels to slowly roll down onto the lower level.

4. Push the chair forward until you are standing on the lower level.

5. When the rear wheels are safely on the lower level, tilt the chair back to its balance point.

If you fail to heed these warnings damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

Follow these steps to help a rider descend a curb or single step going FORWARD:

9

MK-100151 Rev. A

Page 10

ENG LIS H

VI. SAFETY WARNINGS: FALLS & TIP-OVERS

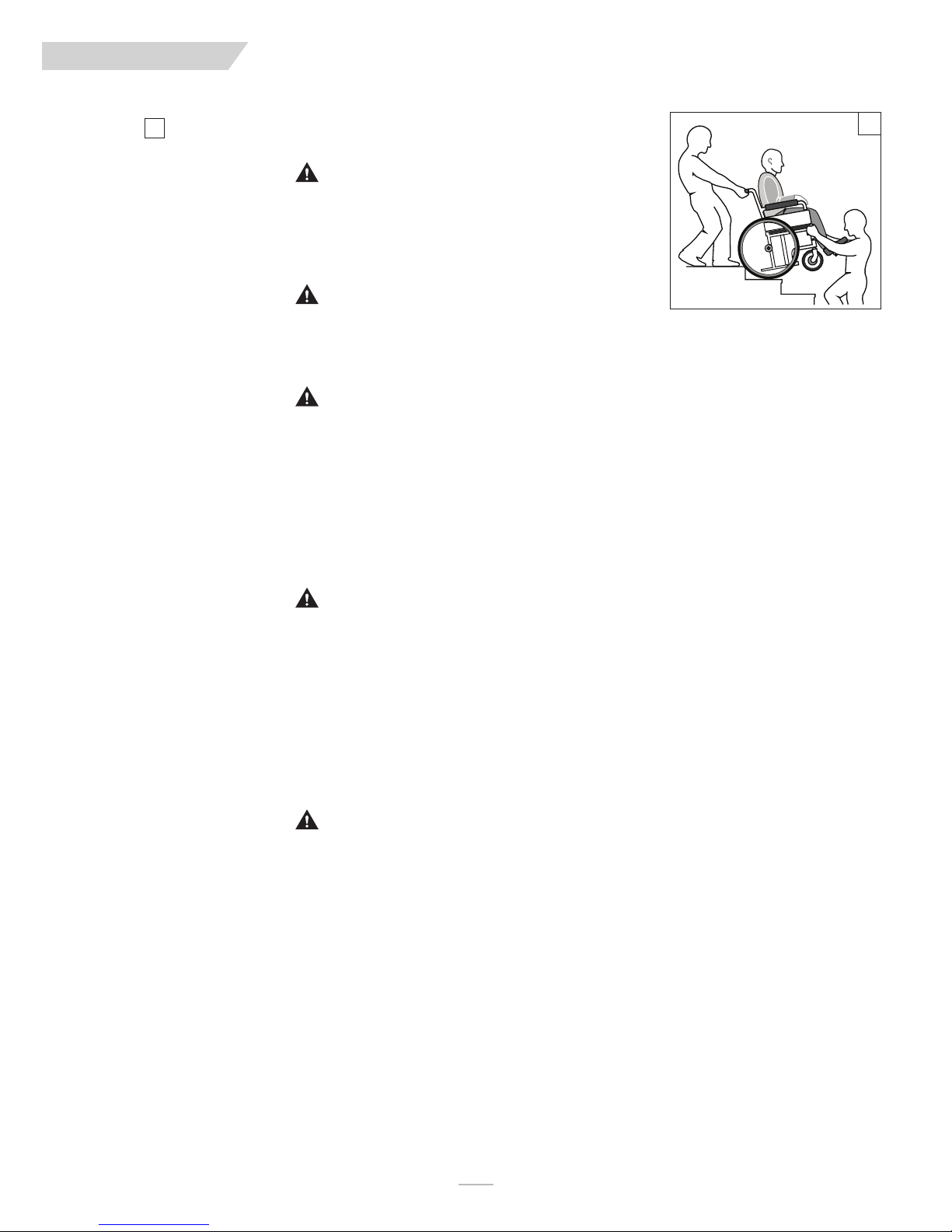

M. STAIRS

10

WARNING

1. NEVER use this chair on stairs UNLESS you have someone to help you. Doing so is likely to cause a

fall or tip-over.

2. Negotiating stairs with a wheelchair always requires at least 2 attendants for safety.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

WARNING

Before you assist a rider, be sure to read the warnings “For Attendants” in Section V, Part K and follow all

instructions that apply. Be aware that you will need to learn safe methods best suited to your abilities.

N. CLIMBING STAIRS

WARNING

1. Use at least two attendants to move a chair and rider up stairs.

2. Move the chair and rider BACKWARD up the stairs.

3. The person at the rear is in control. He or she tilts the chair back to its balance point.

4. A second attendant at the front firmly grasps a non-detachable part of the front frame and lifts the chair

up and over one stair at a time.

5. The attendants move to the next stair up. Repeat for each stair, until you reach the landing.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

O. DESCENDING STAIRS

10

1. Use at least two attendants to move a chair and rider down stairs.

2. Move the chair and rider FORWARD down the stairs.

3. The person at the rear is in control. He or she tilts the chair to the balance point of the rear wheels

and rolls it to the edge of the top step.

4. A second attendant stands on the third step from the top and grasps the chair frame. He or she lowers the chair one step at a time by letting the rear wheels roll over the stair edge.

5. The attendants move to the next stair down. Repeat for each stair, until you reach the landing.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

P. TILT USE AND BACK ANGLE ADJUSTMENT (MONO BACK)

WARNING

BEFORE you operate the tilt mechanism, or back angle adjustment (MONO back):

1. Always verify that the arms of the rider are stable on the armrests or within the armrests.

2. Always verify that the legs of the rider are stable on the footrest/legrest.

3. Never place hands, feet or foreign objects into the tilt mechanism.

4. Never push or propel the chair with the seat tilted in a forward position.

5. Never add chair accessories that are not specifically designed for the IRIS.

6. Never exceed a tilted position that aligns the backrest parallel to the ground.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of control may occur and cause

severe injury to the rider or others.

WARNING

MK-100151 Rev. A

10

Page 11

ENG LIS H

VII. WARNINGS, COMPONENTS & OPTIONS

A. ANTI-TIP TUBES (OPTIONAL)

WARNING

Anti-tip tubes can help keep your chair from tipping over backward in

normal conditions.

1. Sunrise recommends the use of anti-tip tubes:

2. When locked in place (in the “down” position) anti-tip tubes should

be BETWEEN 1 1/2 to 2 inches off the ground.

a. If set

b. If set

3. If you have to climb or descend a curb, or overcome an obstacle, it

may be necessary to have an attendant make sure the anti-tip tubes

are rotated up, and out of the way, so that the chair and rider do

not get stuck and/or become unstable.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

higher

than 2 inches, they may not prevent a tip-over.

lower

than 1 1/2 inches, they may “hang up” on obstacles

and cause a fall or tip over.

B. ARMRESTS

WARNING

Armrests detach and will not bear the weight of this chair.

1. NEVER lift this chair by its armrests. They may come loose or break.

2. Lift this chair only by non-detachable parts of the main frame.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

C. PUSH HANDLES

WARNING

When you have a attendant, make sure that this chair has push handles.

1. Push handles provide secure points for an attendant to hold the rear

of this chair, to prevent a fall or tip-over. Make sure to use push handles when you have an attendant.

2. Check to make sure push handle grips will not rotate or slip off.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

D. STROLLER HANDLE

WARNING

1. Always keep hands away from the locking mechanism located at the

bottom of the back canes when folding the back down or pulling it

back up.

2. Always keep fingers away from the interior of the hinge when readjusting the adjustable stroller handle.

F. FASTENERS

WARNING

Many of the screws, bolts and nuts on this chair are special high-strength

fasteners. Use of improper fasteners may cause your chair to fail.

1. ONLY use fasteners provided by an authorized supplier (or ones of

the same type and strength, as indicated by the markings on the

heads).

2. Over- or under-tightened fasteners may fail or cause damage to

chair parts.

3. If bolts or screws become loose, tighten them as soon as you can.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

G. FOOTRESTS

WARNING

1. At the lowest point, footrests should be AT LEAST 2 inches off the

ground. If set too LOW, they may “hang up” on obstacles you can

expect to find in normal use. This may cause the chair to stop suddenly and tip forward.

2. To Avoid A Trip Or Fall When You Transfer:

a. Make sure your feet do not “hang up” or get caught in the space

between the footrests.

b. Avoid putting weight on the footrests, as the chair may tip for-

ward.

c. Footrests should be swung out of the way or removed whenever

entering or exiting the wheelchair.

3. NEVER lift this chair by the footrests. Footrests detach and will not

bear the weight of this chair. Lift this chair only by non-detachable

parts of the main frame.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

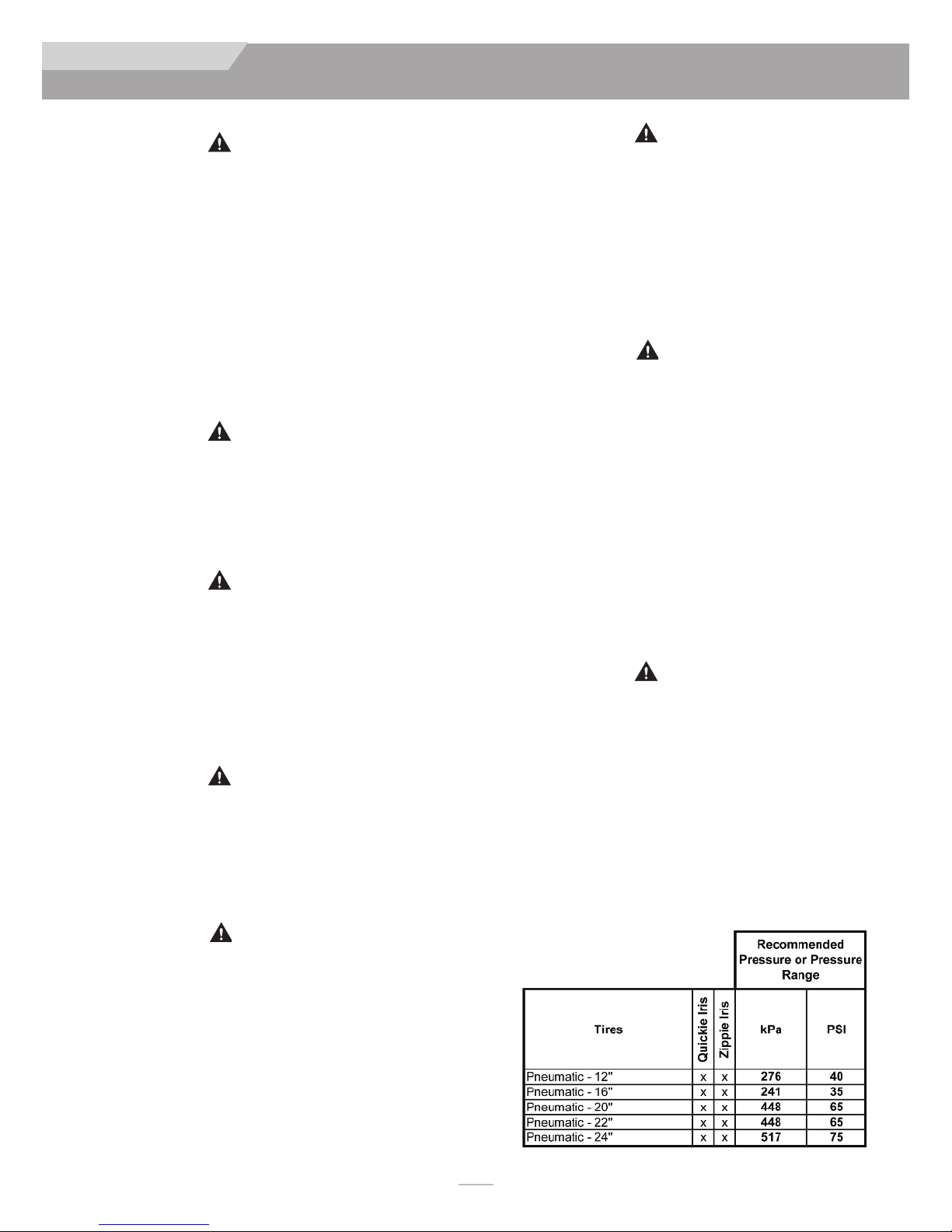

H. PNEUMATIC TIRES

WARNING

Proper inflation extends the life of your tires and makes your chair easier to

use.

1. Do not use this chair if any of the tires is under- or over-inflated. Check

weekly for proper inflation level, as listed on the tire sidewall.

2. Low pressure in a rear tire may cause the wheel lock on that side to slip

and allow the wheel to turn when you do not expect it.

3. Low pressure in any of the tires may cause the chair to veer to one side

and result in a loss of control.

4. Over-inflated tires may burst.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss of

control may occur and cause severe injury to the rider or others.

E. CUSHIONS

WARNING

1. Quickie standard foam cushions are not designed for the relief of

pressure.

2. If you suffer from pressure sores or if you are at risk that they will

occur, you may need a special seat system or a device to control your

posture. Consult your doctor, nurse or therapist to find out if you

need such a device for your well-being.

3. Seat pans are not intended to be used as a direct seating surface. A

cushion or other seating surface should be placed on the seat pan

before use.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

11

Recommended Tire Pressures

MK-100151 Rev. A

Page 12

ENG LIS H

VII. WARNINGS: COMPONENTS & OPTIONS

I. POSITIONING BELTS (OPTIONAL)

WARNING

Use positioning belts ONLY to help support the rider’s posture. Improper

use of these belts may cause severe injury to or death to the rider.

1. Make sure the rider does not slide down in the wheelchair seat. If

this occurs, the rider may suffer chest compression or suffocate due

to pressure from the belts.

2. The belts must be snug, but must not be so tight that they interfere

with breathing. You should be able to slide your open hand, flat,

between the belt and the rider.

3. A pelvic wedge or a similar device can help keep the rider from sliding down in the seat. Consult with the rider’s doctor, nurse or therapist to find out if the rider needs such a device.

4. Use positioning belts only with a rider who can cooperate. Make

sure the rider can easily remove the belts in an emergency.

5. NEVER Use Positioning Belts:

a. As a patient restraint. A restraint requires a doctor’s order.

b. On a rider who is comatose or agitated.

c. As a motor vehicle restraint. In an accident or sudden stop the

rider may be thrown from the chair. Wheelchair seat belts will

not prevent this, and further injury may result from the belts or

straps.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

J. QUICK-RELEASE AXLES

WARNING

1. Do not use this chair UNLESS you are sure that both quick-release

rear axles are locked.

2. An axle is not locked until the quick-release button pops out fully. If

the axle is not inserted fully, the wheel may come off during use,

endangering the rider.

3. Quick-release axles should be periodically cleaned and inspected for

function, and signs of wear or bending. Replace as necessary.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

K REAR AXLES

WARNING

A change in set-up of the rear wheels will affect the center of balance

of your chair.

1. The farther you move the rear axles FORWARD, the more likely it

is that your chair will tip over backward.

2. Consult your doctor, nurse or therapist to find the best rear axle

set-up for your chair. Do not change the set-up UNLESS you are

sure you are not at risk to tip over.

3. Adjust the rear wheel locks after you make any change to the rear

axles.

a. If you fail to do so, the locks may not work.

b. Make sure lock arms embed in tires at least 1/8 inch when

locked.

If you fail to heed these warnings, damage to your chair, a fall, tip-over or loss

of control may occur and cause severe injury to the rider or others.

L. REAR WHEEL LOCKS

WARNING

Rear wheel locks are NOT designed to slow or stop a moving wheelchair.

Use them only to keep the rear wheels from rolling when your chair is at a

complete stop.

1. NEVER use rear wheel locks to try to slow or stop your chair when

it is moving. Doing so may cause a fall or tip-over

2. To keep the rear wheels from rolling, always set both rear wheel

locks when you transfer to or from your chair.

3. Low pressure in a rear tire may cause the wheel lock on that side to

slip and may allow the wheel to turn when you do not expect it.

4. Make sure lock arms embed in tires at least 1/8 inch when locked. If

you fail to do so, the locks may not work.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

M. MODIFIED SEAT SYSTEMS

WARNING

Use of a seat system not approved by Sunrise may alter the center of balance of this chair. This may cause the chair to tip over.

1. Do not change the seat system of your chair UNLESS you consult

your authorized supplier first.

2. Use of a seating system not provided by Sunrise is prohibited for

transit use.

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

N. TRAY FOR VENT AND BATTERY

NOTE–

NOTE–

NOTE–

Vent tray only available on the Quickie IRIS.

This option is only compatible with wheelchairs having a mini-

mum floor-to-seat height of 15" (38 cm).

The battery tray components are not compatible with the

Attendant Wheel Lock option or foot release tilt.

WARNING

Never use this wheelchair as a seat in a motor vehicle unless all components are removed from the battery tray, and properly secured

separately in the vehicle.

WARNING

Always contact Technical Service before installing or removing the

battery tray components to obtain the correct assembly locations of

the strut tubes, roller carriage assembly and caster brackets.

WARNING

The combined weight of the user plus the ventilator, battery and tray

components should not exceed 165 lbs (75 kg) on the Zippie IRIS,

250 lbs (114 kg) on the Quickie IRIS, and 350 lbs (159 kg) on the

heavy duty option.

O. ACCESSORY HOOK

MK-100151 Rev. A

WARNING

The weight limit for the accessory hook is 10lbs (total) for all items

If you fail to heed these warnings damage to your chair, a fall, tip-over or

loss of control may occur and cause severe injury to the rider or others.

12

Page 13

ENG LIS H

VIII. USE AND MAINTENANCE

WARNING

The owner and/or Caregiver for the use of this product, is responsible for

making sure that it has been setup and adjusted by a trained service professional under the advice of a healthcare advisor. The chair may require

periodic maintenance or certain in-use adjustments that may be performed

by the owner or caregiver.

A. INTRODUCTION

1. Proper maintenance will improve performance and extend the useful

life of your chair.

2. Clean your chair regularly. This will help you find loose or worn

parts and make your chair easier to use. You will need a mild detergent solution and plenty of cleaning rags.

3. If discovered, repair or replace loose, worn, bent or damaged parts

before using the chair

4. To protect your investment, have all major maintenance and repair

work done by your authorized dealer.

. Insp

ect and maintain this chair strictly per the maintenance chart.

5

. If you detect a problem, make sure to order parts, or have service,

6

and repair work done at your authorized dealer before use.

. At least once per year, have a complete inspection, safety check,

7

and service of your chair made by an authorized dealer.

B. CRITICAL MAINTENANCE TIPS

1. Tire Air Pressure:

Check air pressure in pneumatic tires at least

wheel locks will not grip properly if you fail to maintain the air pressure

shown on tire sidewall.

.

ONCE PER WEEK

. The

D. CLEANING

1. Paint Finish

a. Clean the painted surfaces with mild soap or detergent at least once

a month.

b. Protect the paint with a coat of non-abrasive auto wax every three

months.

2. Axles and Moving Parts

a. Clean around axles and moving parts WEEKLY with a slightly damp

(not wet) cloth.

b. Wipe off or blow away any fluff, dust or dirt on axles or moving

parts.

3. Upholstery

a. Hand-wash (machine washing may damage fabric).

b. Drip-dry only. DO NOT machine dry as heat will damage fabric.

4. Basic Maintenance Materials available at local store

a. Tire Pump

b. Clean rags or cotten cloth.

c. Teflon-based Lubricant

d. Mild Detergent.

NOTE– You do not need to grease or oil the chair.

E. TROUBLESHOOTING CHART

2. Axles & Axle Sleeves:

When checking axles and axle sleeves every six months, make sure they

are clean and tight.

Loose sleeves will damage the axle plate and will affect performance.

C. MAINTENANCE CHART

Weekly

3 Months

6 Months

Annually

CHECK...

R Tire inflation level

R Wheel locks

R All fasteners for wear and tightness

R Armrests

R Axle and axle sleeves

R Quick-release axles

R Wheels, tires and spokes

R Casters

R Anti-tip tubes

R Frame

R Rollers

R Tilt cables and plunger

R Rocker arm

Service by authorized supplier

R

SYMPTOMS

Left turn in chair

Right turn in chair

Looseness in chair

Sluggish turning

RR R R

RRRR Make sure all nuts and bolts

RR

R

RR R R

RR R

Squeaks and rattles

Caster flutter

Chair drops fast into tilt

R

and is hard to return.

returns too fast.

Chair is hard to tilt and

SOLUTIONS

Make sure tire pressure is correct and equal in both rear tires

and front caster tires, if pneumatic.

are snug.

Make sure all spokes and nipples

are tight on radial spoke wheels.

Use Tri-Flow Lubricant

(Teflon™-based) between all

modular frame connections and

parts.

Check for proper caster plate

adjustment. See instructions for

caster plate adjustment.

Make sure both front casters

touch the ground simultaneously. If they do not, add the proper

spacers between the bottom

bearing of the caster plate and

fork stem nut until they do.

Make sure you check for this

problem on a flat surface.

Consult with an authorized supplier to adjust CG/CR forward

Consult with an authorized sup-

R

plier to adjust

13

MK-100151 Rev. A

Page 14

ENG LIS H

VIII. USE AND MAINTENANCE

F. TO MOUNT AND REMOVE REAR WHEELS

Do not use this chair UNLESS you are sure both quick-release axles are locked. An unlocked axle may come off

during use and cause a fall.

NOTE–

Axle is not locked until the quick-release button (A) pops out fully.

11

2. To Install Wheel

a. Depress quick-release button (A) fully. This will release tension on ball bearings at other end.

b. Insert axle through hub of rear wheel (B).

c. Keep pressure on button (A) as you slide axle (C) into axle sleeve (D).

d. Release button to lock axle in sleeve. Adjust axle if it does not lock.

e. Repeat steps on other side.

3. To Remove Wheel

a. Depress quick-release button (A) fully.

b. Remove wheel by sliding axle (C) out of axle sleeve (D).

c. Repeat steps on other side.

G. CUSHION INSTALLATION

a. Place cushion on seat pan with hook material side down. The beveled edge of the cushion should be in

front, press it firmly into place.

H. WHEEL LOCKS

WARNING

Wheel locks are installed at Sunrise and should be adjusted by your qualified service person. Inspect wheel locks

weekly per the maintenance chart. Do not use your chair UNLESS you are sure both wheel-locks can fully engage. A

wheel-lock that is not correctly adjusted may allow your chair to roll, or turn unexpectedly. Wheel-locks must be

adjusted after making sure the tires have the correct air pressure. When fully engaged, the arm should be imbedded

into the tire at least 1/8” to be effective. If you find the wheel locks have slipped or are not working correctly contact

your service provider for proper adjustment.

11

B

D

C

A

12

F

E

I . HUB LOCK

12

To operate Hub Lock

1. To Lock rear wheels, press button (E). Lever (F) will flip outward. Do not engage hub lock when chair is in

motion

2. To unlock wheels, press Lever (F) back down until Button (E) pops back out. Each lever operates one side of the

chair. To fully lock chair, both buttons must be pushed.

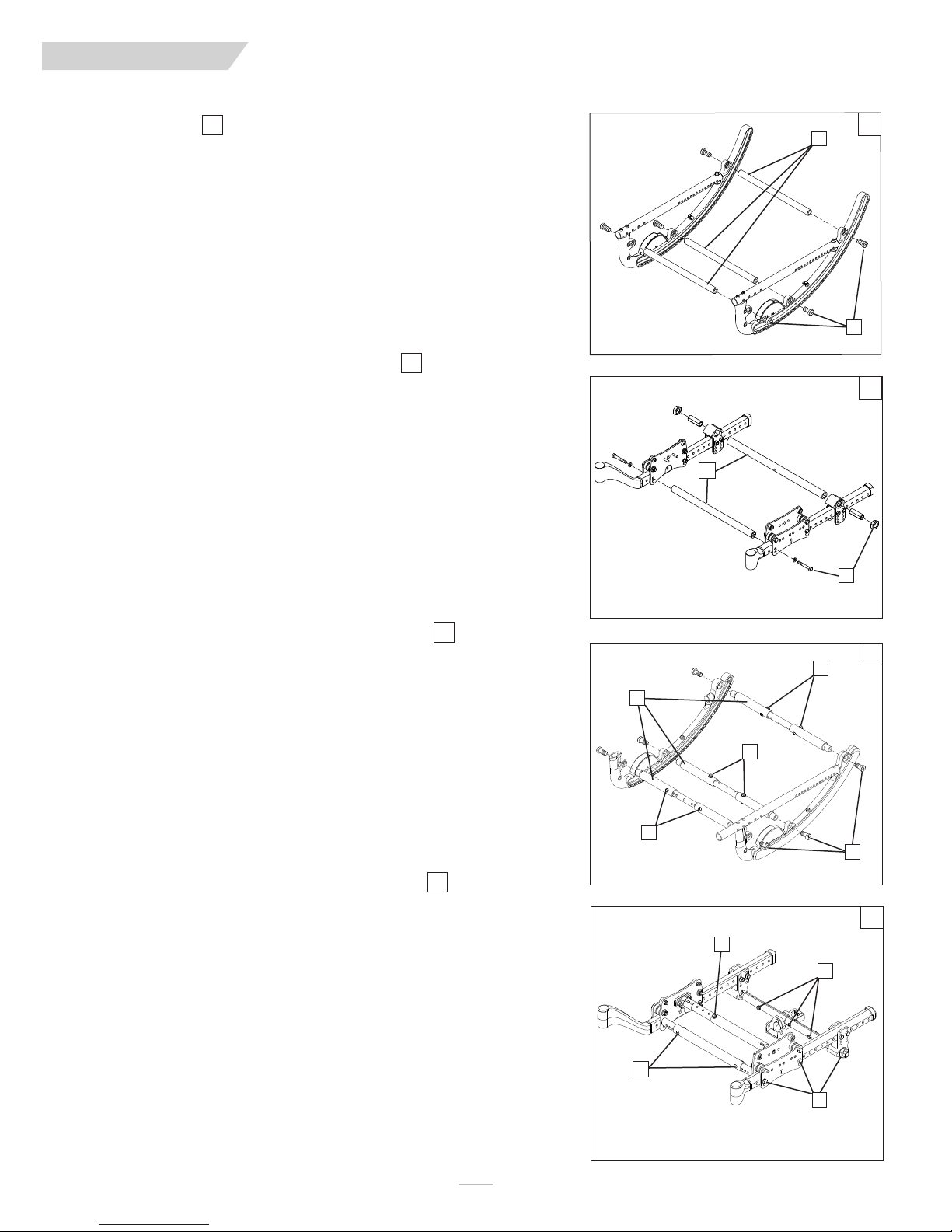

J. ANTI-TIP TUBES- REAR

Anti-tip tubes are recommended for all wheelchairs. Do not attempt to overcome Obstacles on your own.

1413

1. Inserting Anti-Tip Tubes Into Receivers

a. Press in the rear anti-tip button(G) on the anti-tip so that both buttons are drawn inside.

b. Insert the anti-tip tube into the receiver (H).

c. Turn the anti-tip tube down until front release button pops through the receiver mounting hole.

d. Insert second anti-tip tube the same way.

2. Turning Anti-Tip Tubes Up

Turn the anti-tip tubes up when being pushed by attendant, and overcoming obstacles or climbing curbs.

a. Press in the rear anti-tip tube release button (G).

b. Hold button (G) in and turn anti-tip tube up (I).

c. Release the button.

d. Repeat with second anti-tip tube.

e. Remind attendant to return anti-tips to the down position after completing the maneuver.

3. Adjusting Anti-Tip Tube Wheel

The anti-tip tube wheels may have to be raised or lowered to achieve proper ground clearance (1-1/2" to 2").

a. Press the anti-tip wheel release button (J) so that the release pin is drawn inside.

b. Raise or lower to one of the three or six pre-drilled holes.

c. Release the button (J).

d. Adjust the second anti-tip tube wheel the same way. Both wheels should be at exactly the same height.

13

I

H

G

14

J

MK-100151 Rev. A

14

Page 15

ENG LIS H

VIII. USE AND MAINTENANCE

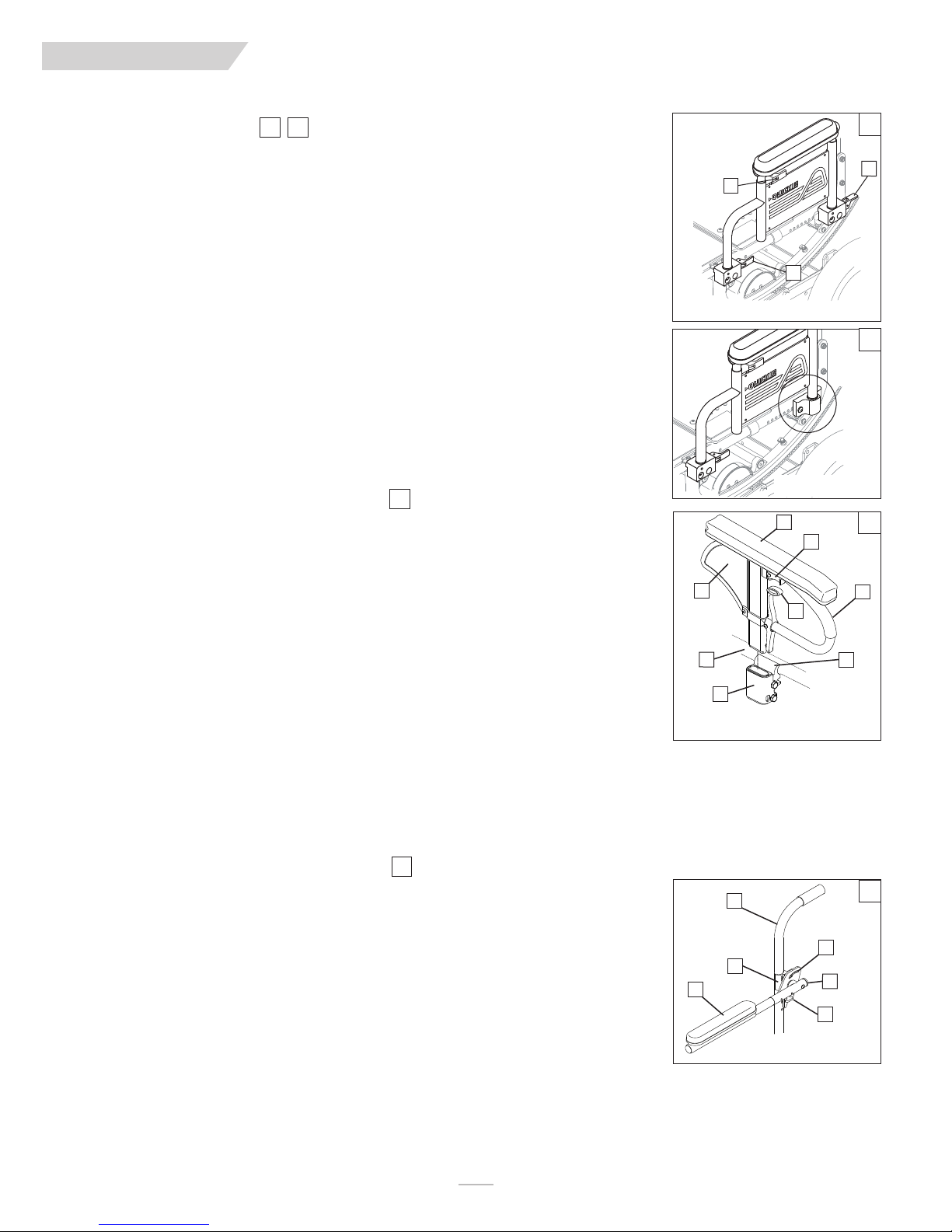

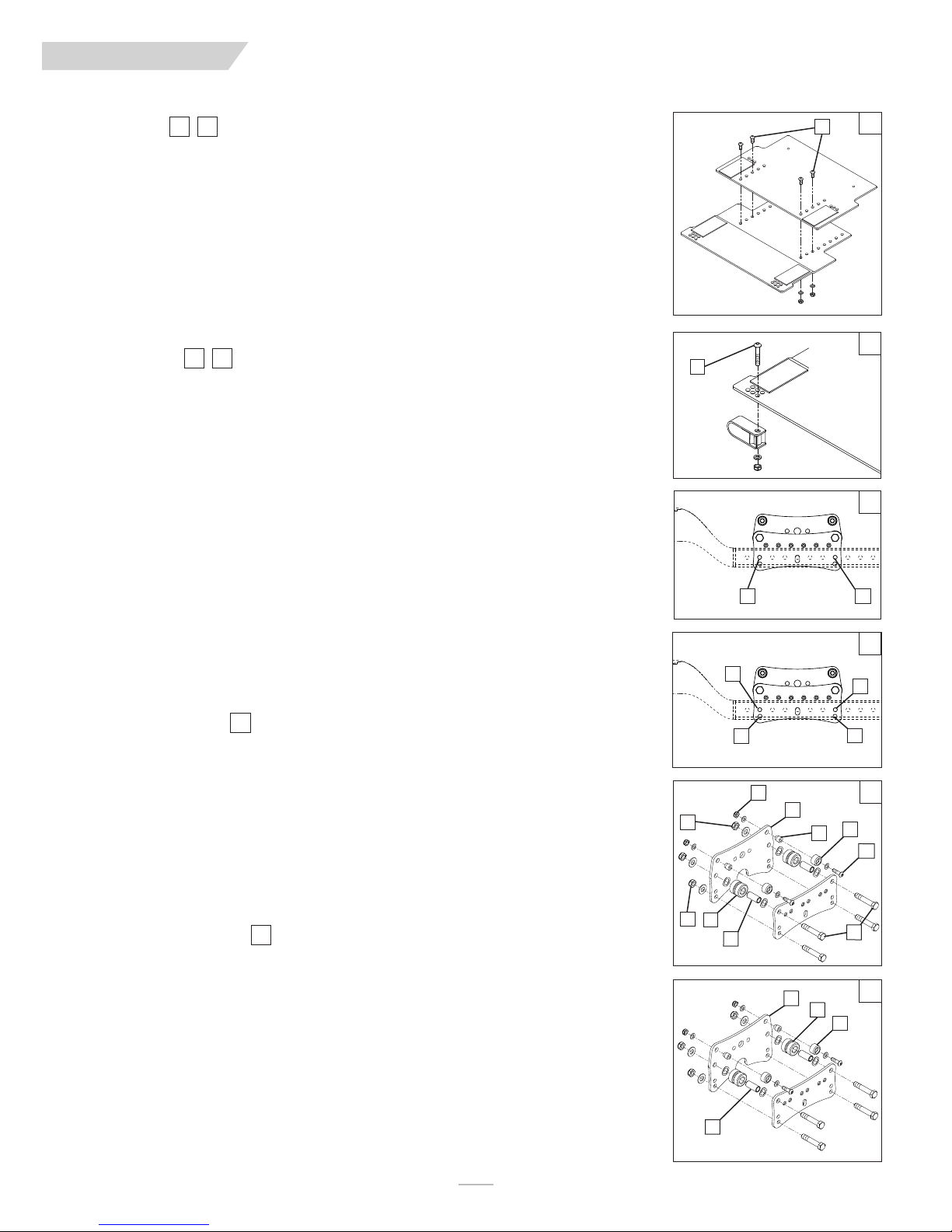

K. DUAL-POST ARMRESTS

1615

1. Installation or Removal

a. The assembly is held securely in place when the securing lever (A) is facing outside.

b. Pull front securing lever (A) forward to release.

c. Insert or remove armrest.

d. Return securing lever to locked position.

2. Height-Adjustment (optional)

a. Release the upper securing lever (C).

b. Set armrest at desired height.

c. Return securing lever to locked position.

d. Move armrest up or down to allow armrest to snap into place.

3. Flip Back (optional)

a. Release the front securing lever only (A).

b. Flip the armrest back, it remains attached to the rear receiver.

c. To detach armrest completely pull rear securing lever (B) up.

d. Move armrest down into place.

e. Return securing lever to locked position.

L. HEIGHT-ADJUSTABLE ARMRESTS (optional)

17

1. Installation

a. Slide the outer armpost (1) into the receiver(7) mounted to the wheelchair frame.

b. The armrest will automatically lock into place.

2. Height Adjustment

a. Rotate release lever (2) to second stop.

b. Slide armrest pad (4) up or down to desired height.

c. Return lever (2) to locked position against armpost.

d. Push arm pad down until upper armpost locks firmly into place.

3. Removing Armrest

a. Grip release lever (3) and pull up to remove the armrest.

C

Flip-Back receivers

6

1

7

A

Fixed receivers

4

2

3

8

15

B

16

17

5

M. ADJUSTABLE LOCKING FLIP-UP ARMRESTS

1. Flip up and down

a. Release the upper securing lever (2).

b. Flip the armrest back (1), it remains attached to the back post.

c. Move armrest down into place.

d. The lever (2) locks itself in position automatically.

Height adjustable single post

1. Outer armpost

2. Release Lever Height

3. Release lever

4. Armrest pad

5. Transfer bar

6. Side panel

7. Receiver

18

8. Clamp

6

5

1

Adjustable Locking Flip-Up

1. Armrest Pad

2. Upper Securing Lever

3. Flip-back tube

4. Angle Adjust Bracket

5. Clamp

6. Back cane

18

4

3

2

15

MK-100151 Rev. A

Page 16

ENG LIS H

VIII. USE AND MAINTENANCE

N. CANTILEVER ARMRESTS

19

1. Flip Back the armrest for access and transfers.

a. Release the armrest (A) by pulling up on the securing lever (this will unlock the armrest).

b. Rotate the armrest back.

2. Return the armrest to the riding position

a. Rotate the armrest back to riding position.

b. Be sure to lock the armrest by returning the securing lever to It’s locked position.

NOTE–

Figure shows Lever(A) in locked position.

O. SWING-AWAY HANGERS/FOOTRESTS

20

Swing-in-Swing-out Hangers and Footrests (60°, 70º, 80°)

1. Installation

a. Place swing-in/swing-out pivot saddle into the receiver (A) on front frame tube with the footrest

facing inward or outward from the frame.

b. Rotate the footrest inward until it locks into place on locking plate.

2. Removal

a. To remove footrest, release latch (B) by pulling lever upward or pushing lever downward.

b. Rotate footrest inward or outward and lift.

19

A

20

B

A

P. HEAVY-DUTY, LIFT-OFF FOOTRESTS (optional)

21

1. Installation

Slide pivot saddle (C) into receiver (D) on front frame tube until it locks into place.

2. Removal

To remove footrest, push release latch (E) while lifting up footrest from receiver.

Q. ARTICULATING LEGREST (optional)

22

1. Installation or Removal

To install or remove Articulating Legrest (ALR) see instructions for Swing-away Footrest installation.

2. Elevation Adjustment

a. To raise legrest, lift to desired position. Legrest will automatically lock in place.

b. To lower legrest, while seated in chair, press release lever (F) down and lower Legrest to desired position.

Legrest will automatically lock in place.

3. Height Adjustment of the Calf Pad

a. Rotate the tube clamp (G) towards the outside.

b. Slide calf pad assembly up or down.

c. Rotate calf pad assembly (H) back in the desired indented position.

21

D

C

F

G

E

22

H

MK-100151 Rev. A

16

Page 17

ENG LIS H

VIII. USE AND MAINTENANCE

R. ELEVATING LEGREST (optional)

23

1. Installation or Removal

To install or remove Elevating Legrest (ELR) see instructions for Swing-away Footrest

installation.

2. Elevation Adjustment

a. To raise legrest, lift to desired position. Legrest will automatically lock in place.

b. To lower legrest, while seated in chair, press release lever (I) down and lower legrest to desired position.

Legrest will automatically lock in place.

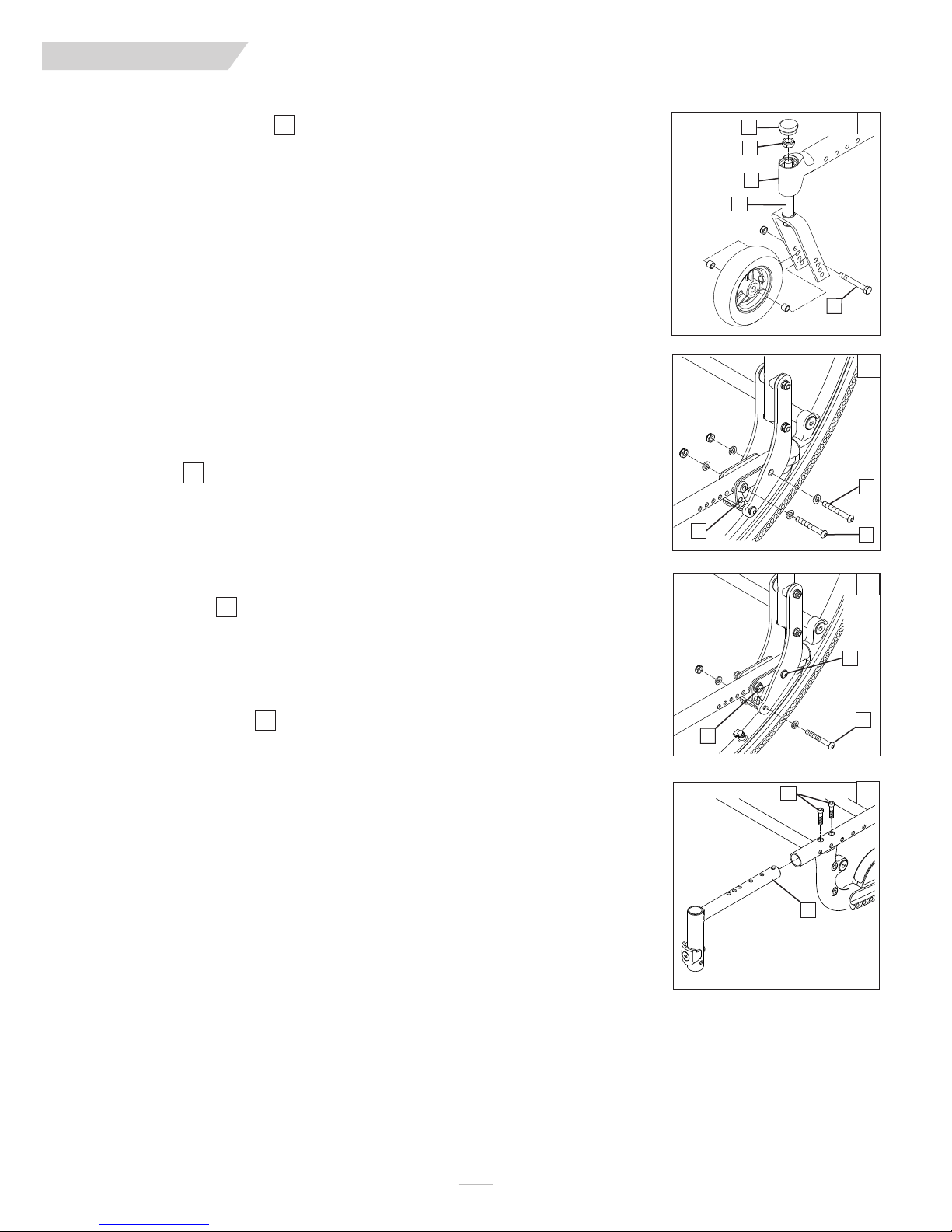

S. TILT-IN-SPACE MECHANISM

The tilt-in-space mechanism is installed by Sunrise. Two cable/trigger mechanisms positively lock the chair in

place from -5º to 60º depending on the set-up. The Quickie/Zippie IRIS has the capability to provide from 0º to

5º of forward tilt. DO NOT ATTEMPT TO MAKE THIS ADJUSTMENT. This adjustment must be done by an

authorized supplier.

24

1. Trigger Tilt Operation

a. Depressing both triggers (A) at the same time disengages the locking mechanism and allows the seat and

back to rotate in space. Releasing the triggers positively locks the rockers in place.

b. The approximate degree of tilt the seat is at can be seen on the tilt indicator (C).

c. To lock out the tilting function, insert the locking pin (B) into the trigger holder.

I

23

24

A

B

C

2. Foot Release

a. Depressing foot pedal (D) disengages the locking mechanism and allows the seat and back to rotate in

space. Releasing the foot pedal positively locks the rockers in place.

b. The approximate degree of tilt the seat is at can be seen on the tilt indicator (C).

25

17

25

D

MK-100151 Rev. A

Page 18

ENG LIS H

VIII. USE AND MAINTENANCE

T. STROLLER HANDLE EXTENSION (option)

26 27

Installation

a. Press button (E) on the stroller handle so that release pins are drawn inside the tube.

b. Insert the tube into the back tube receiver (F) until the release pin protrudes through the receiver

mounting hole.

U. RECLINING BACK

The dual trigger reclining mechanism is installed by Sunrise.

To Recline or Raise Backrest

a. Depress both triggers (G) at the same time. Releasing the triggers positively locks the backrest in place

within its 60° range.

b. To lock out the adjustment system, insert the locking pin (H) into the trigger holder.

NOTE– ALWAYS

V. MONO BACK STROLLER HANDLE

Height/Angle Adjustment

a. Press button (A) on the stroller handle so that it releases the push handle.

b. Adjust the push handles to a comfortable position.

NOTE– ALWAYS

the locked position.

lock the dual trigger reclining mechanism securely in place after positioning the backrest.

28

lock Push handles by moving them slightly being sure to hear the mechanism click into

F

E

26

27

G

H

28

A

W. FOLDING THE MONO BACK FOR TRANSPORT

29

Height/Angle Adjustment

a. Push down on the release lever(B) and fold the backrest forward for easier transport of the chair.

b. To return the back to the riding position just pull up on the back until it locks into place at the original

position.

NOTE–

AFTER FOLDING OR UNFOLDING THE MONO BACK,

locked position by moving it slightly and listening for the mechanism to click into the locked position.

ALWAYS

check to make sure it is in the

X. CHECK-OUT

Once the wheelchair is assembled and adjusted, it should roll smoothly and easily. All accessories should also

perform smoothly. If you have any problems, follow these procedures:

1. Review assembly and adjustment sections to make sure the chair was properly prepared.

2. Review the troubleshooting guide.

3. If your problem persists, contact your authorized supplier. If you still have a problem after contacting

your authorized supplier, contact Sunrise customer service. See the introduction page located in the

front of this User’s Manual for details on how to contact your authorized supplier, or Sunrise customer

service.

29

B

MK-100151 Rev. A

18

Page 19

ENG LIS H

IX. DEALER SERVICE & ADJUSTMENT.

WARNING

The owner of this chair is responsible for makiing sure that it has been setup and adjusted by a trained service

professional under the advice of a healthcare advisor. Service or adjustments should only be done with the

advice of a healthcare professional. Always use parts and accessories that have been recommended and

approved by Sunrise Medical when servicing this chair.

A. DEALER SERVICE INTRODUCTION

1. At least once per year, this chair should have a complete inspection, safety check, and regular service

made by an authorized dealer.

2. If you have discovered a worn, bent, or damaged part, repair or replace them with recommended parts

before returning this chair to service.

3. All major maintenance and repair work should be done by the authorized dealer.

B. CRITICAL MAINTENANCE TIPS

1. Torque settings:

A torque setting is the optimum tightening which should be made on a particular fastener. It is important to use

proper torque settings where specified. When not specified, torque settings should be 60 in-lbs

2. Dealer Service and Adjustment Reference materials:

Go to www.sunrisemedical.com for parts manuals, instruction sheets, and instructional videos that will aid in the

repair of the Quickie/Zippie Family of wheelchairs.

.

TOOLS YOU WILL NEED

1. Imperial Hex key set

2. Metric Hex key set

3. Imperial Open-end Wrench set

4. Metric Open-end Wrench set

5. Torque wrench

6. Imperial Hex bit Socket set

7. Metric Hex bit Socket set

8. Phillips and Flat screwdrivers

C. CLEANING

1. Paint Finish

a. Clean the painted surfaces with mild soap or detergent.

b. Protect the paint with a coat of non-abrasive auto wax.

2. Axles and Moving Parts

a. Clean around axles and moving parts with a slightly damp (not wet) cloth.

b. Wipe off or blow away any fluff, dust or dirt on axles or moving parts.

c. DO NOT USE 3 in 1 oil, or WD-40 ® for lubrication. Only use Teflon based Lubricant when working on

this wheelchair.

D. REAR AXLE

1. Rear Wheel Axle Adjustment

Tight axle sleeves should be maintained for proper performance of the wheelchair.

a. To adjust the axle (A) you will need a 3/4" wrench (B) to turn the outside axle nuts (C).

b. You will also need a 1/2" wrench to hold the the opposite end of the axle (D), and prevent the axle from

turning, while you are adjusting the nut.

c. Turn the outside axle nut clockwise to tighten.

d. There should only be zero to ten thousandths of an inch (.010") of play.

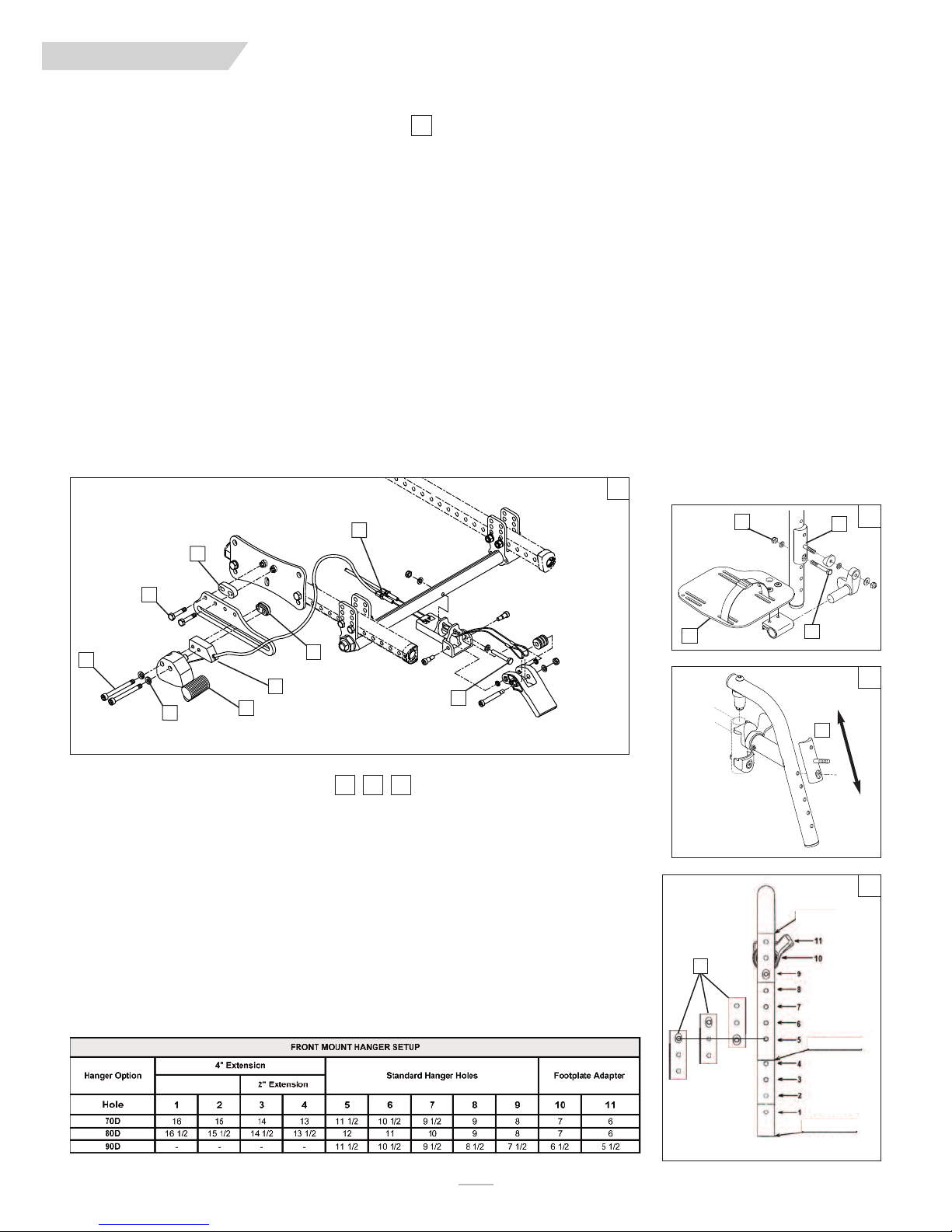

2. Moving the Rear Axle for Weight Distribution

Weight distribution between the front and rear wheels is primarily adjusted by moving the rear axles forward or