Page 1

FLAME MONITORING SYSTEM

MODEL P522 SIGNAL PROCESSOR

APPLICATION MANUAL

Page 2

IRIS MODEL P522 APPLICATION MANUAL

Table of Contents

IRIS MODEL P522 ---------------------------------------4

WIRING AND INSTALLATION------------------------4

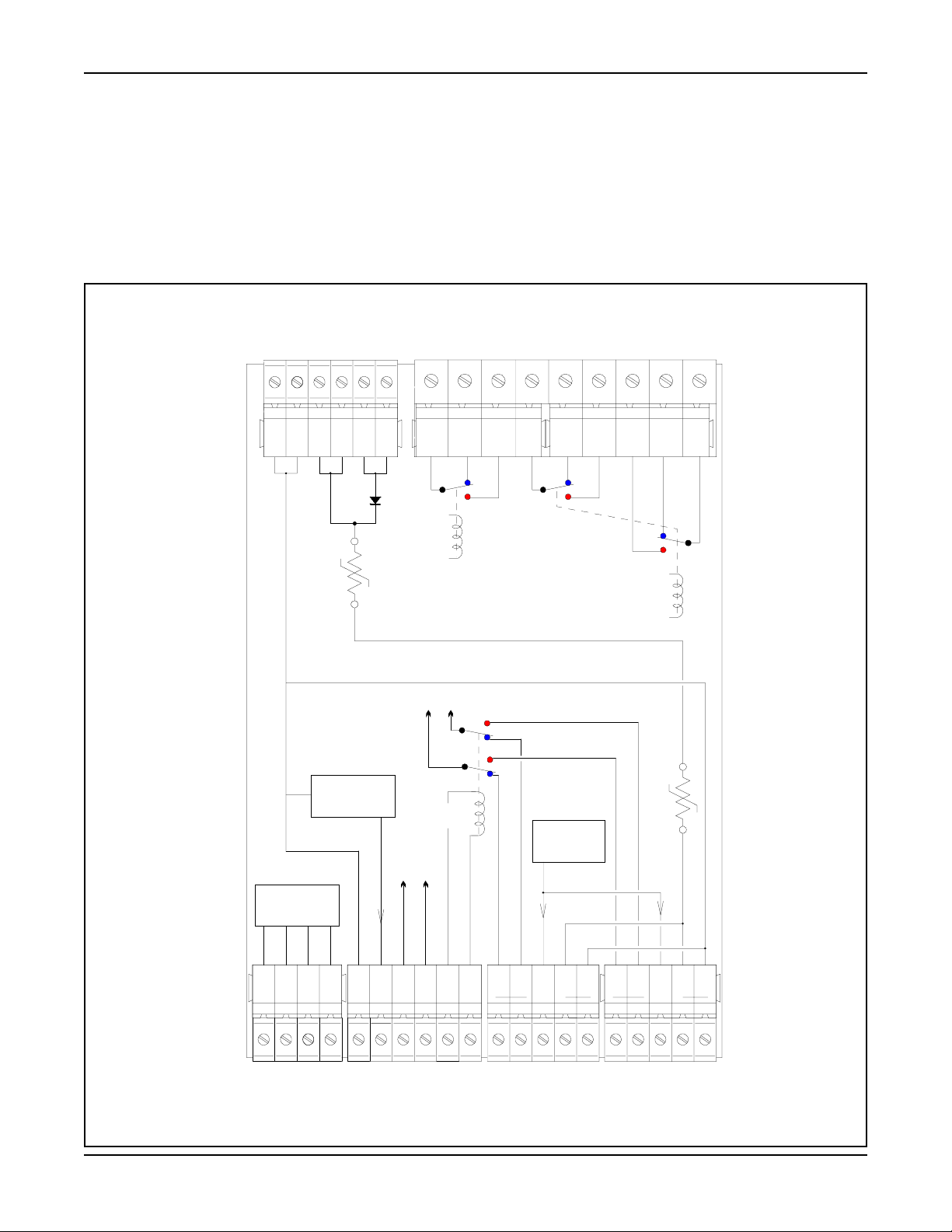

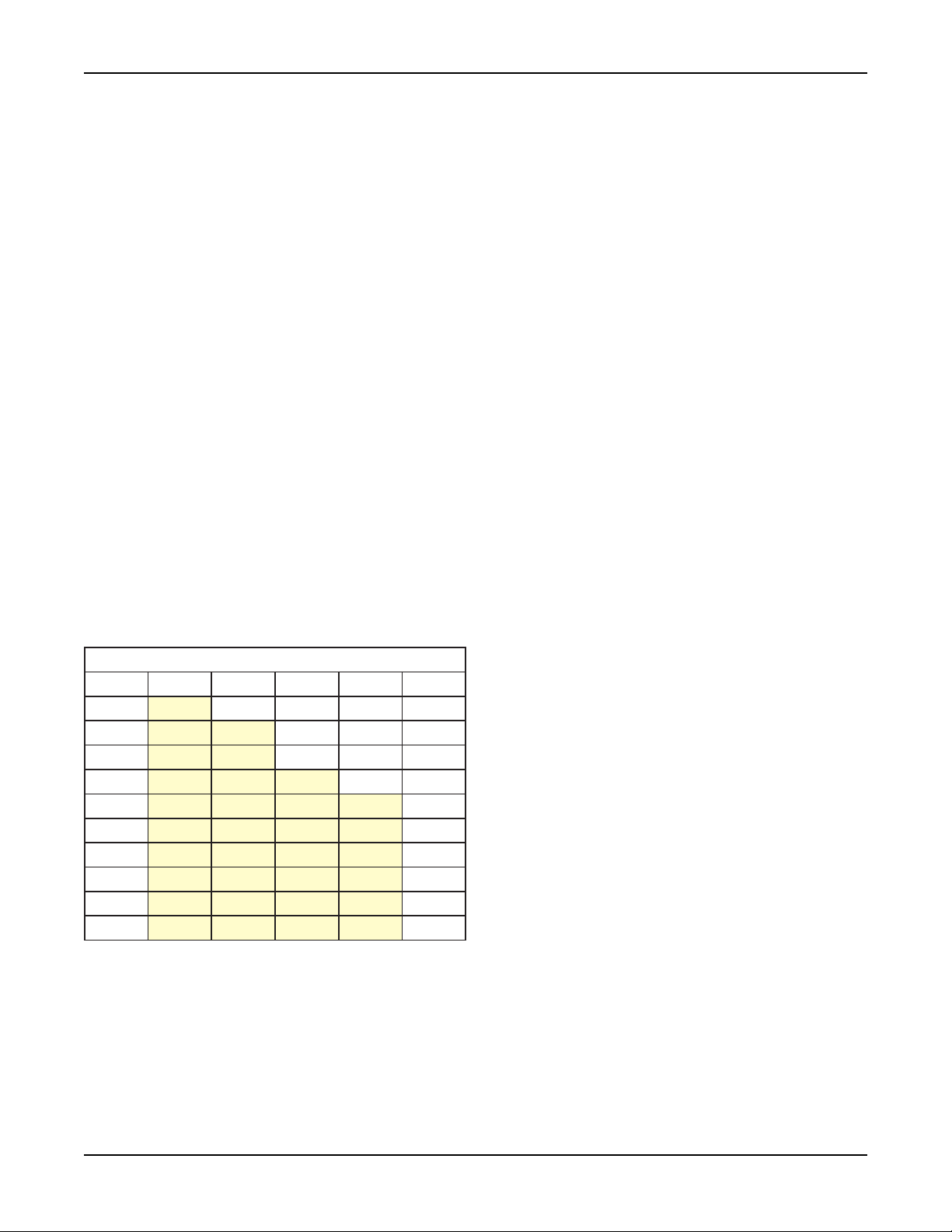

FIGURE 1 - P522 REAR MOTHERBOARD-------4

WIRING TO THE PLUG-IN TERMINALS ----------5

WIRING OF VIEWING HEAD-------------------------6

FIGURE 2 - WIRING OF VIEWING HEAD --------6

FIGURE 3 - WIRING AND ASSEMBLY -

VIEWING HEAD -------------------------------------- 7

OPTIONAL LTA ADAPTER----------------------------7

POWER SUPPLY ----------------------------------------8

FIGURE 4 - POWER SUPPLY TABLE -------------9

FACTORY STOCKED POWER SUPPLIES------- 9

REDUNDANT POWER SUPPLIES------------------ 9

SELF-CHECKING FUNCTION --------------------- 10

APPROVALS -------------------------------------------- 10

POWERING UP THE P522-------------------------- 10

SET POINTS -------------------------------------------- 11

FIGURE 5 - SET POINTS---------------------------- 11

CHANGING SET POINTS --------------------------- 11

FLAME FAILURE RESPONSE TIME (F.F.R.T.) 12

4-20mA REMOTE OUTPUT------------------------- 12

FIGURE 6 - REMOTE METER ANALOG OUTPUT 12

INSTALLATION OF VIEWING HEAD------------- 13

FIGURE 7 - VEWING HEAD CROSS-

REFERENCE TABLE--------------------------- 13

SIGHTING OF THE VIEWING HEAD------------- 13

MULTIBURNER REQUIREMENTS --------------- 14

FIGURE 8 - CUTOFF FREQUENCIES----------- 14

MULTIPLE VIEWING HEADS ---------------------- 14

DETERMINING SIGHT PIPE SIZE---------------- 15

SELECTING THE PIPE------------------------------- 15

MOUNTING HOLE------------------------------------- 15

MOUNTING OF SIGHT PIPE ----------------------- 15

INSTALLING THE VIEWING HEAD--------------- 15

PURGE AIR---------------------------------------------- 15

SETUP AND ADJUSTMENT PROCEDURES -- 16

SIGHTING ADJUSTMENT--------------------------- 16

INITIAL SETUP ----------------------------------------- 16

ADJUSTING SET POINTS -------------------------- 17

TROUBLESHOOTING GUIDE --------------------- 18

NOISE INTERFERENCE AND GROUNDING-- 18

S506 VIEWING HEAD -------------------------------- 19

S506 SELF-CHECKING VIEWING HEAD------- 20

S509 VIEWING HEAD -------------------------------- 20

S511 VIEWING HEAD -------------------------------- 21

S512 VIEWING HEAD -------------------------------- 21

ORIFICING----------------------------------------------- 23

FIGURE 9 - ORIFICING: SIGNAL-REDUCING

CHARACTERISTICS OF DISCS ---------------- 23

SIGNAL SOURCES ----------------------------------- 23

VIEWING HEAD - ANGLE OF VIEW------------- 24

FIGURE 10 - VIEWING HEAD: ANGLE OF VIEW

- DISTANCE AND DIAMETER ------------------- 25

APPLICATION OF IRIS VIEWING HEADS ----- 25

LOW NOx APPLICATIONS-------------------------- 26

APPLICATION OF P522 ----------------------------- 26

USING A PLC WITH IRIS FLAME MONITOR-- 26

FIGURE 11 - VIEWING HEAD APPLICATION

TABLES ------------------------------------------------ 27

FIGURE 11 - VIEWING HEAD APPLICATION

TABLES Cont’d--------------------------------------- 28

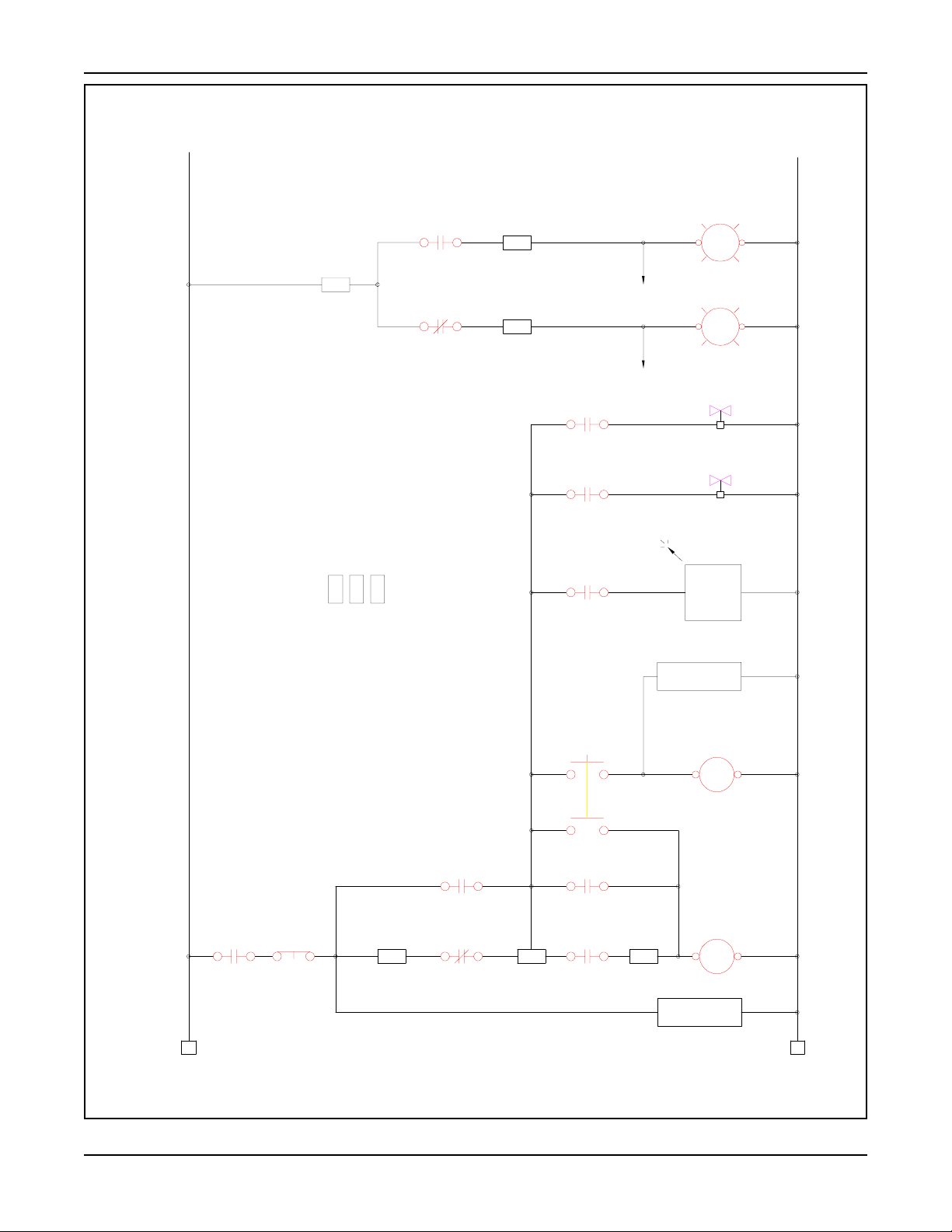

BASIC BURNER START CIRCUIT ---------------- 29

FIGURE 12 - BASIC BURNER START CIRCUIT 30

MODULE COMMUNICATIONS -------------------- 31

MODBUS COMMUNICATION ---------------------- 31

COMMUNICATING WITH MODICON PLC ----- 32

COMMUNICATION WITH HUMAN-INTERFACE

HOST COMPUTER --------------------------------- 32

RS-232 to RS-422 CONVERSION----------------- 32

SETTING ADDRESSES------------------------------ 32

TECHNICAL HELP------------------------------------- 33

FIGURE 13 - SPECIFICATIONS------------------- 34

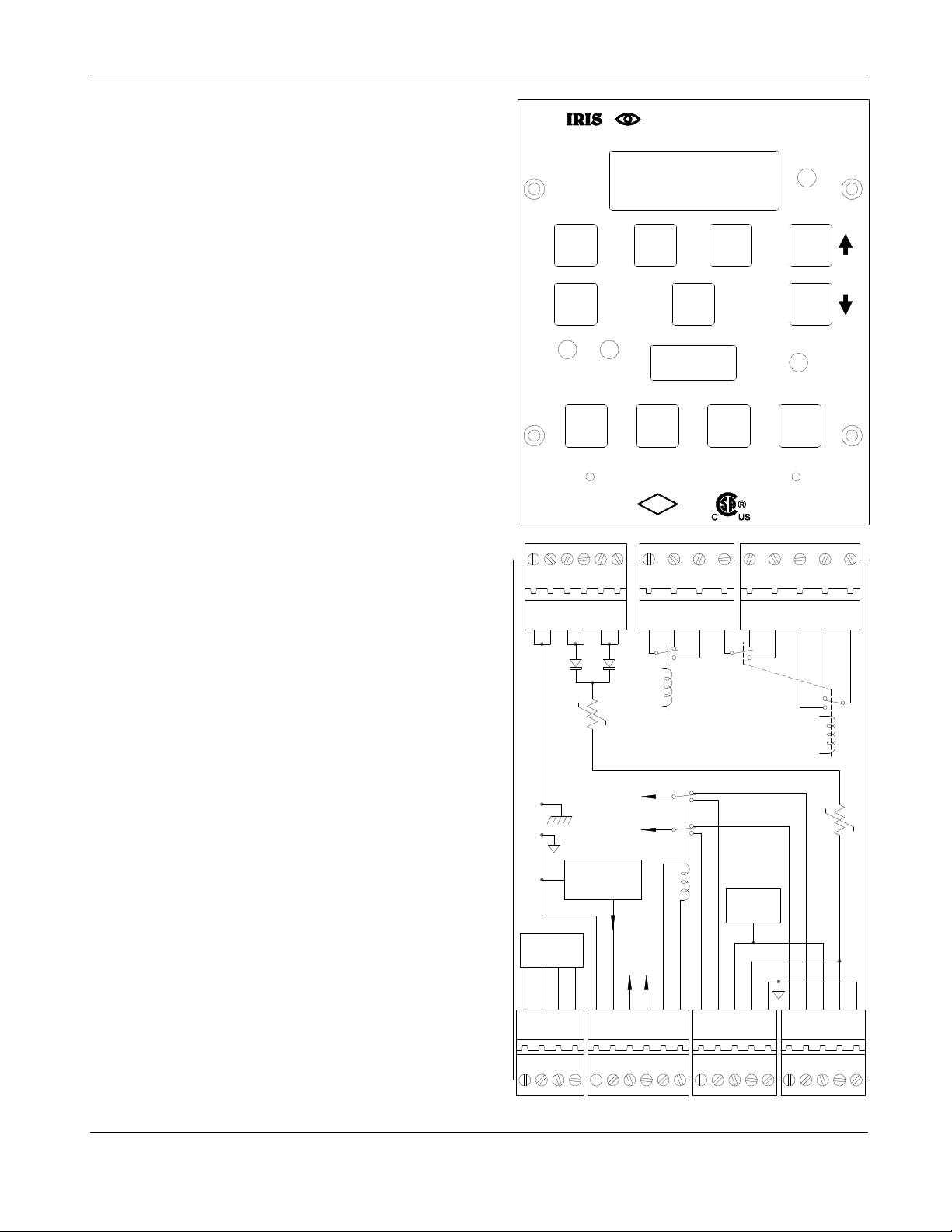

FIGURE 14 - MODEL P522 FRONT PANEL --- 35

FIGURE 15 - MODEL P522 SIDE VIEW --------- 36

FIGURE 16 - S5XX VIEWING HEAD

DIMENSIONS ------------------------------------------- 36

FIGURE 17 - IR VIEWING HEAD LOCATION-- 37

FIGURE 18 - UV VIEWING HEAD LOCATION 37

FIGURE 19 - OPPOSED FIRED VIEWING

HEAD SIGHTING -------------------------------------- 38

FIGURE 20 - VIEWING HEAD MOUNTING ---- 38

INDEX ----------------------------------------------------- 39

Page 2

Page 3

IRIS MODEL P522 APPLICATION MANUAL

Figure Index

FIGURE 1 - P522 REAR MOTHERBOARD--------------------------------------------------------------------4

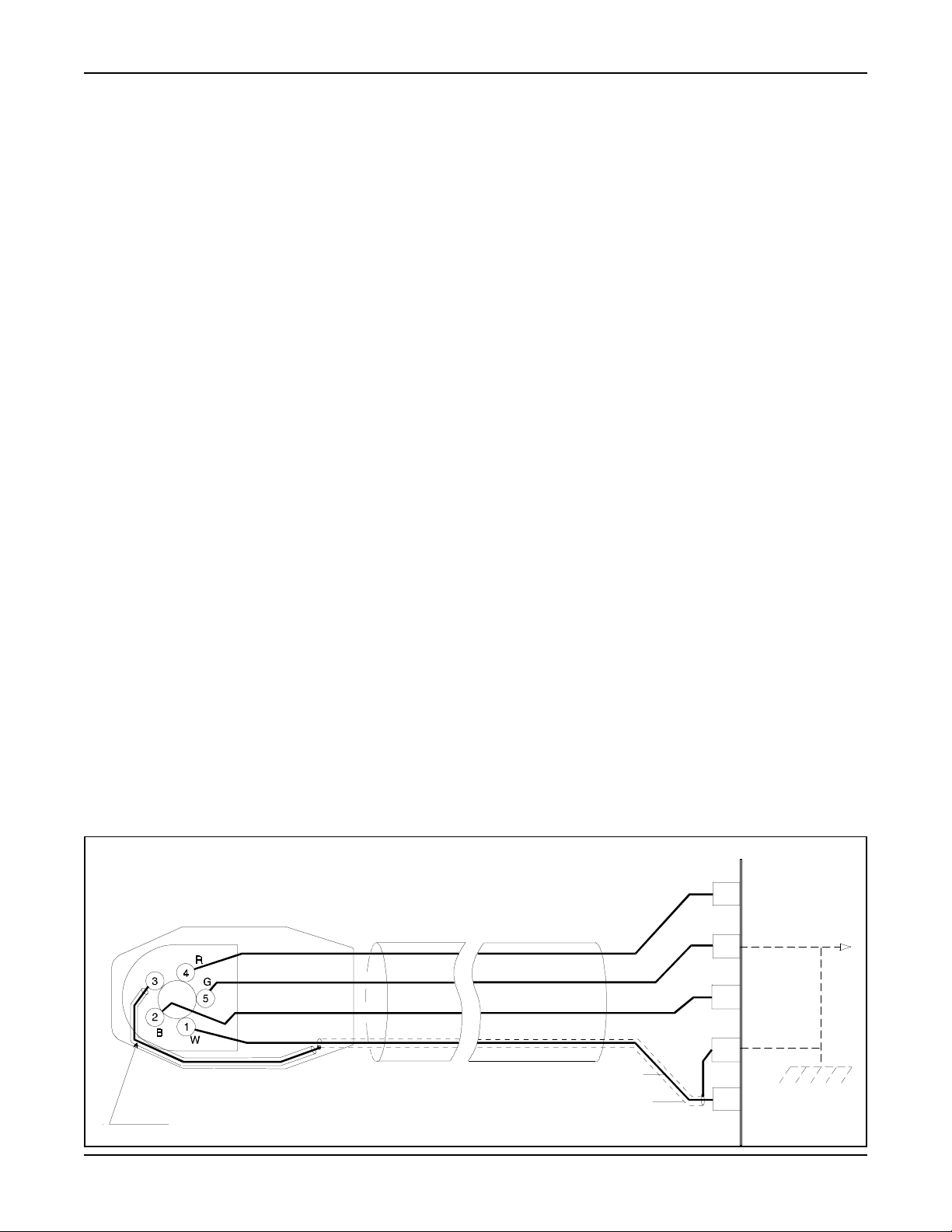

FIGURE 2 - WIRING OF VIEWING HEAD ---------------------------------------------------------------------6

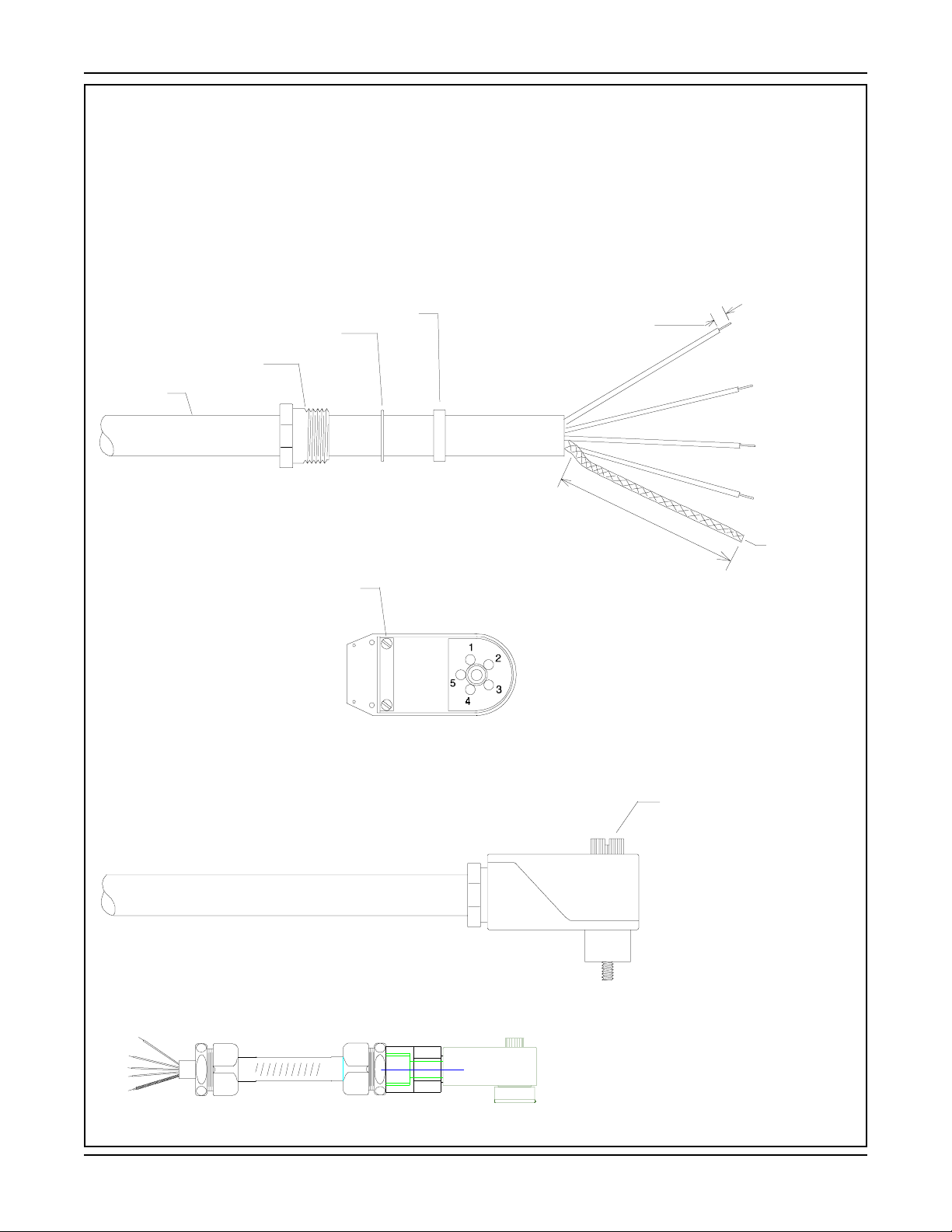

FIGURE 3 - WIRING AND ASSEMBLY - VIEWING HEAD ------------------------------------------------7

FIGURE 4 - POWER SUPPLY TABLE --------------------------------------------------------------------------9

FIGURE 5 - SET POINTS----------------------------------------------------------------------------------------- 11

FIGURE 6 - REMOTE METER ANALOG OUTPUT-------------------------------------------------------- 12

FIGURE 7 - VEWING HEAD CROSS-REFERENCE TABLE-------------------------------------------- 13

FIGURE 8 - CUTOFF FREQUENCIES------------------------------------------------------------------------ 14

FIGURE 9 - ORIFICING: SIGNAL-REDUCING CHARACTERISTICS OF DISCS ----------------- 23

FIGURE 10 - VIEWING HEAD: ANGLE OF VIEW - DISTANCE AND DIAMETER---------------- 25

FIGURE 11 - VIEWING HEAD APPLICATION TABLES-------------------------------------------------- 27

FIGURE 11 - VIEWING HEAD APPLICATION TABLES Cont’d ---------------------------------------- 28

FIGURE 12 - BASIC BURNER START CIRCUIT----------------------------------------------------------- 30

FIGURE 13 - SPECIFICATIONS-------------------------------------------------------------------------------- 34

FIGURE 14 - MODEL P522 FRONT PANEL ---------------------------------------------------------------- 35

FIGURE 15 - MODEL P522 SIDE VIEW ---------------------------------------------------------------------- 36

FIGURE 16 - S5XX VIEWING HEAD DIMENSIONS ------------------------------------------------------ 36

FIGURE 17 - IR VIEWING HEAD LOCATION--------------------------------------------------------------- 37

FIGURE 18 - UV VIEWING HEAD LOCATION ------------------------------------------------------------- 37

FIGURE 19 - OPPOSED FIRED VIEWING HEAD SIGHTING------------------------------------------ 38

FIGURE 20 - VIEWING HEAD MOUNTING ----------------------------------------------------------------- 38

Page 3

Page 4

IRIS MODEL P522 APPLICATION MANUAL

IRIS MODEL P522

The P520 and P522 Signal Processors are used with

the IRIS Model 500 Viewing Heads. The P522

Signal Processor is a relay panel mount version of the P520 plug-in module, and replaces the

M502 motherboard and its two plug-in daughter

boards, the A513 and the D504.

GND +26V BAT

SC C

F1

.75 A

WIRING AND INSTALLATION

Before wiring or installing the P522, we recommend

that you read the companion colour brochure describing the functions and attributes of this series of signal processors.

SC OFF

SC ON

RF C

RF OFF

SC

RELAY

RF ON

RF ON

RF

RELAY

RF C

RF OFF

RS-422

+TX

-TX

+RX

0-20mA or

4-20mA

ANALOG

CURRENT

DRIVE

-RX

GND

RMT

METER

+26V

SIG

GND SIG

VH SEL

RELAY

CHAN

SELECT

++--+

CHAN

SEL

V.H.

SEL

SIG

SHUTTER

DRIVE

+V

SC

SIG

GND

V.H.A. V.H.B.

GND

SIG

GND

F2

.25A

SIG

SC

+V

GND

Page 4

FIGURE 1 - P522 REAR MOTHERBOARD

Page 5

IRIS MODEL P522 APPLICATION MANUAL

WIRING TO THE PLUG-IN TERMINALS

Figure 1 illustrates the plug-in terminals on the rear mother

board and how they are connected internally. The flame

relay and self-checking relay contacts are situated together

in the upper right portion of the diagram.

RF C refers to the common terminal of the flame relay,

with ON being flame on, and OFF being flame off. You

will note that there are two sets of contacts used for the

flame relay.

SC C refers to the common terminal of the self-check-

ing relay. There is only one pair of contacts used

for the self-checking function. Here, the designation ON refers to the self-checking taking place in a

normal manner. OFF indicates a failure in the viewing head or processor resulting from:

- the hardware (i.e. the shutter mechanism in

the viewing head, or the output relay itself);

- electronic components anywhere, or

internal software in the P522; or

- the power to the unit is OFF – the most

likely condition.

The main power feeds in through the terminals situated on the upper left side (see GND, +26V and BAT).

Each designated terminal is a double terminal, or pair,

so that the wiring from the power supply can be “daisy

chained” from one P522 to the next without having to

twist wires together into one termination.

The pair designated BAT is for battery backup, if

used. Note the rectifier used internally to prevent

the 26 VDC main power supply from feeding into

the battery. The backup battery, if used, should be

24 volts, to ensure that the 26 VDC power feeding

the P522 will not feed back into the battery. In other

words, no current will flow from the battery as long

as voltage of the main power supply is above that of

the battery. The negative side of the battery goes to

the GND terminal on the left.

and is rated at .25 Amp. On newer units (those with

NO, CAL, and YES in red letters on the front panel)

these fuses are self-resetting types, and will recover

from an overload automatically after power is removed from the P522 for 10 seconds.

The viewing head terminals (bottom right) are iden-

tified as V.H. A. and V.H. B. If only one viewing

head is used, you must wire to the V.H. A. terminals. To the left of the viewing head terminals are

two terminals marked V.H. SEL (viewing head se-

lector relay). Energizing this connection with 19 to

38 VDC will cause the relay on this PC board to

switch to viewing head B. The nominal voltage of

this relay is 24V, but the 26 VDC power circuit can

be used to switch this relay, if desired.

Only the viewing head signal wire (SIG) and the sig-

nal ground wire (SIG GND) are switched with this

changeover relay; the 26 VDC and power ground

circuit is not disturbed. Make sure that the viewing

head signal wire and signal ground (braided shield

in the four-conductor cable) are both connected, because this ground connection is the only return path

for the signal and self-checking circuit. Also, the 26

VDC used to switch this relay must be connected

with the proper polarity, because the relay used is a

single-side stable type. (Relays that are polarized

magnetically offer increased contact force resulting

in higher current-carrying capability). The two terminals marked V.H. SEL go directly to the relay coil.

The pair of terminals designated CHAN SEL (to the

left of the V.H. SEL terminals) is used for selecting

channel A or channel B on the P522. Energizing

this pair of terminals causes the B channel to be selected. Polarity must be observed when wiring this

connection (the positive terminal is on the right).

This is an isolated input, so two wires are required.

Any DC voltage from 7.5 to 30 may be used. The

current required will depend upon the voltage, because this is a photocoupler interface circuit with a

3900 ohm resistor feeding the LED light source.

Figure 1 shows how these terminals are connected

inside the P522. Note the two fuses marked F1 and

F2. F1 is the main power fuse for the signal processor as well as the viewing head(s), and is rated at .75

Amp. Fuse F2 feeds only to the viewing head(s),

For example: a 26 VDC voltage will result

in a current flow of 25/3900 = .0064 Amp.

If flame is being detected and the channels are

switched, the flame relay will remain energized for

Page 5

Page 6

IRIS MODEL P522 APPLICATION MANUAL

one cycle regardless of the new set points, allowing

channel changes “on the fly,” so to speak. If the

new flame OFF set point is equal to or greater than

the current signal count, then the flame relay will

de-energize on the subsequent cycle.

The pair of terminals designated RMT METER (to

the left of the CHAN SEL terminals) is for the remote

meter connection. This output is a current-driven signal that ranges from 0 to 20 mA for remote meters,

and can be switched to a range of 4 to 20 mA for DCS

(distributed control system) applications (refer to sec-

tion 4-20mA REMOTE OUTPUT). Connect the

terminal marked “positive” to the positive meter terminal. This current signal can be used with a volt

meter by feeding the signal to a resistor connected to

the ground. The voltage developed across the resistor will follow Ohm’s law V = IR.

For example: a 3-volt meter can be used

with a resistor of 3/.02 = 150 ohms, which

will result in a full-scale reading of 3 volts

for a 20mA output.

The four terminals called +TX, -TX, +RX, and -RX

(to the left of RMT METER terminals) are used for

the serial communication link. The serial communication is achieved by using ASCII character code

transmission at 4800 or 9600 baud through the RS232 com ports on the host computer. The P522 uses

RS-422 data transmission which is over two, twisted

pairs that are differentially transmitted and received,

allowing long wire runs to be used through noisy

environments. An RS-232 to RS-422 converter must

be used to communicate with the P522, and the connections are made to the terminals marked +TX, TX, +RX and -RX. The transmitting, twisted pair

goes to the TX terminals, and the receiving, twisted

pair goes to the RX terminals.

Note: the terms “transmit” and “receive” used here

with respect to the P522 will be reversed with respect to the RS-232 connection on the host computer.

Refer to later sections in this manual for a detailed

description of the software and how it is to be used

with the P522.

WIRING OF VIEWING HEAD

Wiring of the viewing head is made to the terminals

on the lower right side of the P522. These terminals

are described as follows:

TERM DESCRIPTION

+V 24 VDC power to viewing head

GND Power Ground

SC Self-check/shutter drive signal to

viewing head

SIG Flame signal from viewing head

SIG GND Signal ground

Figure 2 shows a four-conductor cable to the viewing head. Note that the flame signal wire going to

terminal SIG is shielded, and the shield is terminated

at both ends of the cable SIG GND.

WIRING SIDE VIEW - COVER REMOVED

CONNECT SHIELD

TO TER M 3

USE SHRINK TUBING

Page 6

WHITE

SHIELD

FIGURE 2 - WIRING OF VIEWING HEAD

RED

GREEN

BLACK

+V

GND

SC

SIG

GND

SIG

P522

+24VDC

GND

SHUTTER

DRIVE

GND

SIGNAL

Page 7

CABLE ENTRY NUT

CABLE

IRIS MODEL P522 APPLICATION MANUAL

IRIS CABLE

3 CONDUCTORS PLUS 1 COAX

3CONDUCTORS: 16 AW G 19 STRAND INSULATED WITH

CROSSED-LINKED-POLYETHYLENE .017 THK

COLORS: BLACK-RED-GREEN

1 COAX: 16 AW G 19 STRAND INSULATED WITH

CROSSED-LINKED-POLYETHYLENE .017 THK

COLOR WH ITE

36 AW G B RAIDED SHIELD 90% COVERAGE

WITH .012 THK JACKET COLOR BLACK

CABLED: POLYPROPYLENE FILLERS FOR ROUNDNESS

JACKET: CROSSE D-LINKED-POLYETHYLENE

GROMMET

FLAT WASHE R

CABLE

PREPA RATION

STRIP 3/8“ TYPICAL

(TYP)

1 3/4“

SHIELD *

CABLE CLAMP

FINAL ASSEMBLY

Optional LTA Adapter

INSULATE SHIELD WITH SHRINK

TUBING LEAVING 3/8“ STICKING OUT

CONNECTOR WITH

REAR COVER REMOVED

CONNECTOR JACKSCREW

* CABLE IS SHOWN WITH SHIELD

ALREADY REMOVED FROM W HITE WIRE

FIGURE 3 - WIRING AND ASSEMBLY - VIEWING HEAD

Page 7

Page 8

IRIS MODEL P522 APPLICATION MANUAL

A source impedance resistor is required when using

the P522 module with a S550 viewing head. This

resistor should be 330 ohm (factory installed) for

viewing head cable runs up to 500 feet, and it should

be 150 ohm for cable runs 500 feet to 1000 feet.

The resistor should be installed across the SC and SIG

GND terminals. A 1/4 watt resistor is suitable.

Originally, specifications of the IRIS Model 500 instructed that a five-conductor cable be used, with

one wire shielded. However, the standard is now a

four-conductor cable, with one wire shielded. In

this case, the shield is used as the signal ground wire

that goes to terminal SIG GND on the P522 and to

pin 3 on the viewing head plug. The shield should

be a braided type for this application –do not use a

foil type shield– so that a solid signal ground is maintained. This signal ground shield is also the selfchecking circuit return path. Refer to Figures 2 and

3 for wiring details.

Connections of the IRIS cable to the viewing head

plug should be performed as follows:

5. Slide nut (with threads toward the cable

end), the washer and the grommet onto

the cable approximately six inches.

6. Slip the cable through the bottom opening of the connector, making sure that the

cable’s outer jacket is secure under the

cable clamp, and tighten the two screws

on the cable clamp.

7. Reassemble the grommet, flat washer and

cable entry nut, and tighten.

8. Before wiring to connector, strip each

wire 3/8 inch, as shown in assembly diagram, Figure 3.

9. Proceed to wire the connector. Refer to

Figure 2 for terminal locations.

– Connect the viewing head signal wire

WHT (the shielded wire) to terminal

No. 1 by inserting it into the opening,

then tightening the retaining screw.

After removing the plug from its packaging, take the

cable entry nut out of its housing. Remove rubber

grommet and flat sealing washer. With a pair of longnosed pliers, remove the center ring only of the rubber grommet.

1. Strip two inches of the cable’s outer cover

from the cable, removing any cellophane

wrap or filler material, and strip the insulation from the shielded wire (if insulated over shield) a full two inches, to

expose shield.

2. Slide the shield back until a bulge develops close to where the wire exits the

cable’s outer covering.

3. Carefully spread a few strands of the shield

at the bulge –making sure not to break any

strands– to create an opening, and slip wire

out of shield through opening.

4. Carefully return shield to original shape

and length by pulling gently, then cover

with plastic shrink tubing to prevent shorts.

– Connect the shutter drive signal wire

BLK to terminal No. 2.

– Connect the signal ground shield from

the WHT wire to terminal No. 3 with

shrink tubing.

– Connect the 24 VDC power wire RED

to terminal No. 4.

– Connect the power ground wire GRN

to terminal No. 5.

– Assemble the back of the plug and insert

jackscrew through the plug assembly.

The cable wiring at the other end going to the signal

processor is easier. The cable should be prepared in

a similar way to the plug end – particularly the shield

from the WHT wire. Make sure the shield doesn’t

touch the other terminals.

POWER SUPPLY

Careful consideration should be given to the power

supply used for the P522. 26 VDC is used to back

bias the “steering” rectifier, as shown in Figure 1, to

Page 8

Page 9

IRIS MODEL P522 APPLICATION MANUAL

prevent the power from feeding into the 24 VDC

supply. Each P522 module draws approximately 150

mA, and each viewing head draws about 100 mA of

power (26 VDC). Actually, the S506 and S511 viewing heads use less current, but it is a good idea to

figure 100 mA for each viewing head used. Also,

the amount of current drawn by the P522 will depend upon other factors that can affect the peak current, such as whether or not there is flame being detected, the remote meter output is connected, and serial communication is occurring.

The viewing head is powered through the P522 via a

0.25 A self-resetting fuse. In other words, the 26

VDC power feeds into the P522 (through a 0.75 A

self-resetting fuse) and feeds back out through a 250

mA fuse to the viewing head, resulting in a current

drain of about 0.25 A for each P522 (with one viewing head). This small amount of current means that

one power supply could support a number of P522

modules. The self-resetting fuses change to high resistance when their current ratings are exceeded, but

recover to their normal low resistance when power

is removed.

with one viewing head each. And the 100-watt power

supply will support up to fifteen P522 modules with

one viewing head per each 100 watt. These “switching type” power supplies are efficient and very compact. To obtain the size and weight of the power

supplies, contact IRIS Systems Inc.

Each power supply can be either rail mounted or

panel mounted, and it is up to each end user to determine their installation preferences and requirements.

We recommend that not more than four P522 signal processors be supported by one 26 VDC power supply. For

instance, four P522 processors with one viewing head

each equals a total of 26 watts – a relatively small

power supply, particularly if an efficient, switching

type is used.

Other possible combinations can be used; for instance, the battery backup terminal could be used

for redundancy. However, care must be taken with

these redundant schemes to make sure that failure of

the primary power supply won’t affect the backup

power supply, as well.

REDUNDANT POWER SUPPLIES

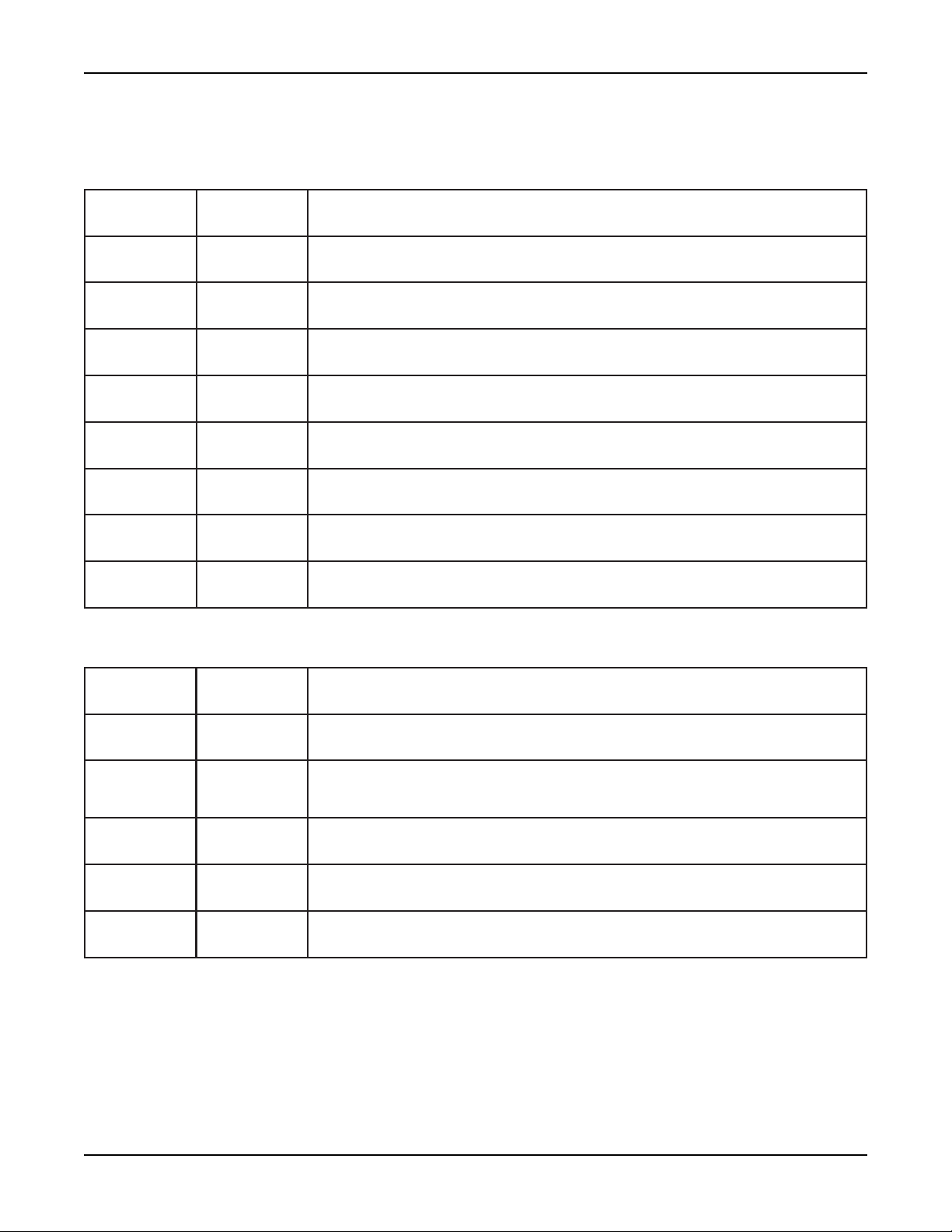

STTAWNIYTICAPACYLPPUSREWOP225PLEDOMSIRI

YTQW5.7W51W03W05W001

1

2

3

4

5

6

7

8

9

01

XXXX

XXX

XXX

XX

X

X

X

X

X

X

FIGURE 4 - POWER SUPPLY TABLE

FACTORY STOCKED POWER SUPPLIES

Power supplies are readily available from the factory for the P522 modules. The 30-watt power supply will support up to six or seven P522 modules

with one viewing head each. The 50-watt power

supply will power up to six or seven P522 modules

It may be more economical to use larger-capacity

power supplies for applications using 12 or more

P522 signal processors.

For example: the 100-watt power supply

available from the factory can handle

twelve P522 modules, each with one viewing head. Should the power supply fail, a

redundant scheme utilizing two power

supplies with “steering” rectifiers to prevent current from flowing into a failed

power supply output would prevent the 12

flame monitors from being de-energized.

The positive output from each power supply is wired

to the anodes of the MBR 1545CT. This dual,

Schottky-type rectifier, rated for 15 Amps, will present

a low forward voltage drop for this application. Both

power supplies can be adjusted for 26V output, and a

low-voltage indicator light can be used on the output

of each power supply to monitor their outputs.

Larger power supplies can be used with this redundant wiring scheme if there are more than twelve P522

Page 9

Page 10

IRIS MODEL P522 APPLICATION MANUAL

modules in a system. Care should be taken when wiring multiple P522s to ensure the selected bus wires

will carry the current. The plug-in terminals on the

P522 will accommodate a wire size up to 14AWG,

allowing for relatively high currents. Note that, if the

power wiring (26 VDC) is “daisy chained” by using

the terminal pairs provided, the pairs are “jumpered”

by copper traces on the mother board; so, if the plug

is pulled out, the jumpered connection is broken.

SELF-CHECKING FUNCTION

When energized, the self checking function indicates

that both the P522 and the viewing head are functioning properly. The software in the P522 activates

the self-checking relay only if there are less than 10

pulses coming in from the viewing head during each

dark period. To energize this relay, the software must

generate pulses –at a particular rate and with a specific duty cycle– to a self-checking circuit. If this

regular pattern is not maintained, or if any of the

circuitry fails, the relay will drop out. The blinking

LED on the front panel labelled SELF-CHECK O.K.

is evidence that voltage is applied to the coil of this

self-checking relay, because both are energized by

the same voltage. The difference is that the voltage

to the coil is applied steadily, while the voltage from

the relay to the LED is gated on and off by the software in conjunction with the pulses counted during

the dark period.

Note that, with regard to the viewing head, the self

checking function still works the same way as with

the M502, A513 and D504 signal processors. For

instance, a runaway UV tube will cause a “lockout

condition” (more than 10 pulses counted during the

dark period). (Refer to section EXPLANATION

OF 1-9, > 10 PULSES COUNTED DURING THE

DARK PERIOD, in the Model 500 Signal Proces-

sor Application Manual.)

A runaway UV tube or any component failure, in-

cluding the shutter, will cause a lockout condition that

will de-energize the flame relay. The LOCKOUT light

on the P522 will indicate this condition, requiring a

reset to return to normal flame monitoring mode. A

reset can be achieved only if the lockout condition

has been corrected, and can be performed from the

front panel (by pressing the RESET button), or remotely through the serial communication.

APPROVALS

The P522 and viewing heads have Factory Mutual (FM)

Approval for Combustion Safety; Canadian Standards

Association (CSA) Certification, and National Recognized Testing Laboratories (NRTL) Listing.

POWERING UP THE P522

Once the power is connected (26 VDC) to the plug-in

connector, the P522 will be operational. There is no

ON/OFF switch on the P522; the moment it is powered on, it will reset and start up. The self-checking

light will start blinking, and one of the channel LEDs

(A or B) will light (A will be ON if the channel select

input at the plug-in connector is de-energized). Make

sure the voltage is 24 to 26 VDC. The P522 will be

reset when the power is turned on; however, the power

must be a step function (i.e., the power must be applied abruptly) for this reset to work properly.

The P522 has been designed to deal with any foreseeable power failure or anomaly.

For example: if the power goes off while

you are in the process of storing a set

point (either from the front panel or from

the remote, host computer), the internal

power monitor circuit will signal the

P522 processor to complete the store

function before shutting down in an orderly manner. This prevents bogus numbers from being stored and protects existing data in the EEPROM (Electrically

Erasable Programmable Read Only

Memory) from corruption, and is facilitated by a special internal power supply

that holds a charge (like a battery) just

long enough to allow the processor to do

its job before going dead.

This internal circuit monitors the 26 VDC power

feeding the P522, and when the voltage drops to

about 19 volts, the processor shuts down, the program stops running, and the self-checking function

ceases (the self-checking relay de-energizes). The

Page 10

Page 11

IRIS MODEL P522 APPLICATION MANUAL

blinking, SELF-CHECK O.K. light on the front panel

will go out, and the flame relay will de-energize.

Please note that the S509 and S512 viewing heads

will shut down at about 17.0 volts; these heads have

their own power-monitoring capability, and will shut

down on their own, independent of the signal processor.

When the power feeding the P522 exceeds 19 volts,

the processor starts the program again. The SELFCHECK O.K. light will start blinking, and the selfcheck relay will energize. If flame is present and a

S509 or S512 viewing head is being used, the flame

signal will not come back on until the power reaches

21.5 volts. This can cause a lockout condition if the

viewing head turns on during the dark period (defined

by the periodic self-check signal going to the viewing

head each second), requiring a manual reset of the

P522. There is a 20 per cent probability that a lockout will occur because of the duty cycle of the selfcheck function (200 mSEC on and 800 mSEC off).

The other viewing heads (the S506, S511) do not incorporate the power-monitoring shutdown function,

and will not cause a lockout condition.

To see what the current set points are, simply push the

desired button. For instance, to determine the current

FLAME ON set point, press the FLAME ON button. The

set point will be displayed on the readout for about four

seconds, then return to normal. The set points displayed

will be for the channel that is active, which is indicated by

a steady illumination of push-button A or B.

To see the other channel set points, first select the channel (A or B), then press the desired set point button.

For example: if channel A is already ON,

indicating it is functional, and B is

pressed, A will go out and B will proceed to blink slowly, indicating that further action is required. If A is already

ON and A is pressed, it will stay steady

ON and start to blink rapidly after a set

point button is pressed.

In all cases, A or B will rapidly blink after the set

point is selected. This action alerts the user that the

current display is no longer that of the flame signal,

and further action is required.

These design precautions ensure that there will never

be an unsafe situation created by abnormal line power

(115 VAC) conditions. The 26 VDC power is very

unlikely to come on gradually, but, if this did occur,

the P522 would not get a proper reset. So, there is

another function in the 87C52 processor (used in the

P522), implemented by circuitry and software, that

causes the P522 to appear dead (i.e., the front panel

will be dark) and to stay this way until the power is

recycled in an abrupt manner, initiating the reset.

SET POINTS

There are 10 set points stored in memory in the P522,

divided into two equal sets, A and B.

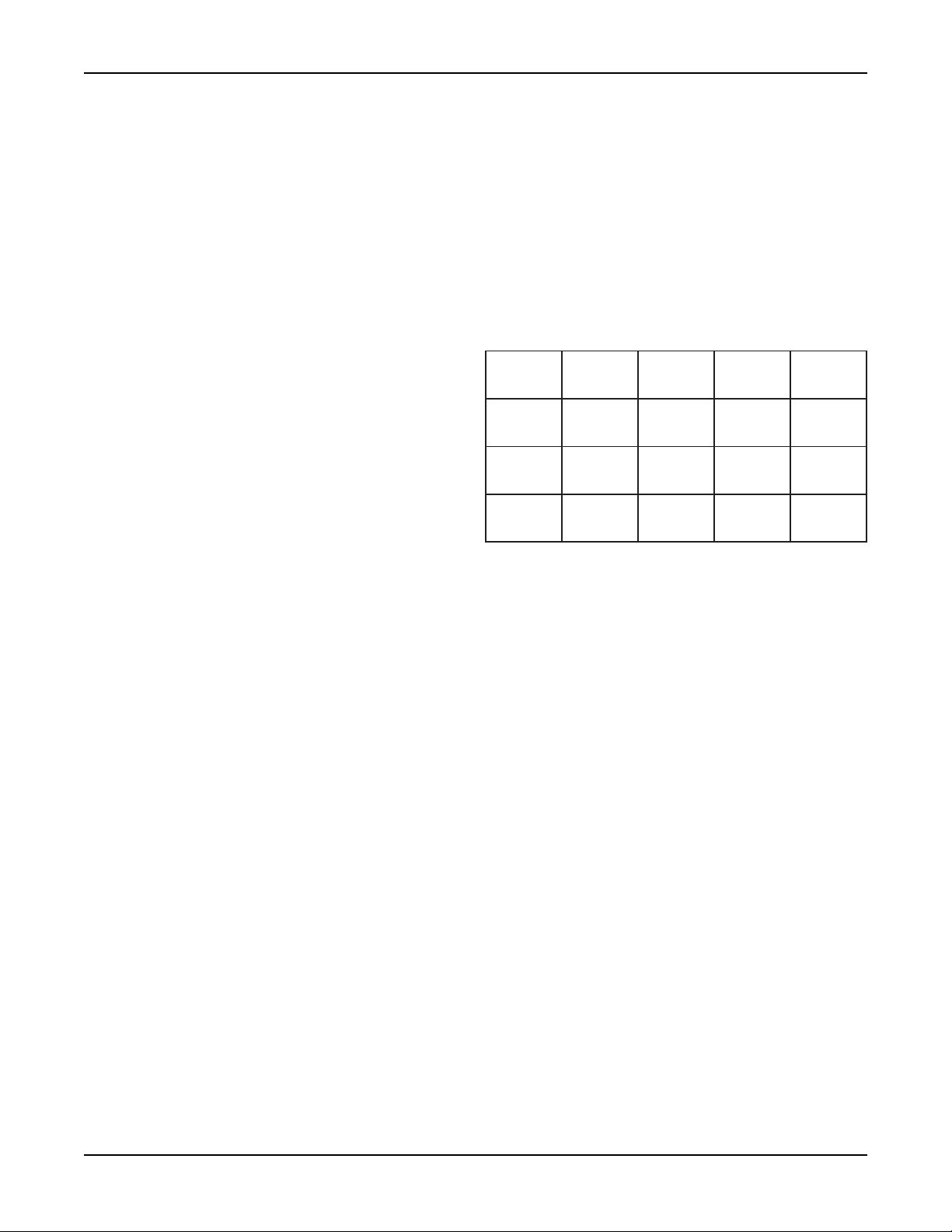

SET POINT DISPLAY NUMBER

FLAME ON 4 DIGIT NUMBER 0001-2999

FLAME OFF 4 DIGIT NUMBER 0000-2999

GAIN S ET 2 DIGIT NUMBER 00 - 99

F.F.R.T. 1 DIGIT NUMBER 1, 2 OR 3

TIME DELAY ON 1 DIGIT NUMBER 0, 1, 2 or 3

The fact that A or B is already on has nothing to do

with the process of viewing the current set points,

except that you do not have to select the channel if it

is already on. The steady illumination of A or B indicates which channel is functionally active, and is selected at the plug-in terminals marked CHAN SEL.

At any time, you can press the reset button causing

the P522 to go back to its normal operating condition. The reset button is also used for resetting the

lockout condition as explained in the section SELF-

CHECKING FUNCTION.

CHANGING SET POINTS

Changing any of the five set points is easy. Simply

bring up the desired set point and change it using the

UP or DOWN arrow buttons. When the desired number is displayed, press the STORE button. When

the set point is stored, four dashes are displayed

momentarily, indicating that the selected number was

stored into the EEPROM. Illogical settings cannot

be made; so, if four “E’s” are displayed when pushing STORE P.B., then an error was made when se-

FIGURE 5 - SET POINTS

Page 11

Page 12

IRIS MODEL P522 APPLICATION MANUAL

lecting the set points. For instance, selecting a flame

out set point that is equal to or greater than the flame

on set point will result in this error indication.

As well, the set points can be selected remotely through

the serial communication port using a host computer –

explained in greater detail later in this manual.

FLAME FAILURE RESPONSE

TIME (F.F.R.T.)

The flame failure response time, or F.F.R.T., is defined as the time it takes for the flame relay to deenergize after the flame signal (from the viewing

head) drops out. This time delay is programmable

from both the front panel of the P522 and a remote,

host computer. Only three settings are possible: one,

two and three seconds.

The maximum time delay is limited to three seconds

in compliance with the FM (Factory Mutual) limit

of the F.F.R.T. to not more than four seconds.

The P522 decision-making process occurs on a periodic basis, and the decision to start a F.F.R.T. time

delay before de-energizing the flame relay is initiated every second in step with the sampling rate of

the flame signal. This means that the actual flame

out condition (i.e., drop-out of the flame signal from

the viewing head) will, in all probability, occur during the sampling period that causes the actual

F.F.R.T. to be greater than the set time.

For example: suppose the signal from

the viewing head drops out immedi-

ately after a sampling from the P522,

and the sampling perceives flame to

be present. If the F.F.R.T. set point is

set for three seconds, there will be an

actual time delay of nearly four seconds. In other words, the actual

F.F.R.T. will be the current set-point

time, plus an additional amount of

time not exceeding one second, depending upon when the flame signal

from the viewing head drops out.

4-20mA REMOTE OUTPUT

The standard remote meter output has a 0-20mA

range and is designed to drive remote meters, as explained earlier in this manual. You can convert this

output to a 4-20mA range, as follows:

Press the front panel push-buttons (indicated

in the table below) while holding down both

the ⇑ and ⇓ buttons. Press all in each row

together (i.e., three in the first row, two in

the second row, and three in the last row).

EMALF

NO

XXX

XXX

FIGURE 6 - REMOTE METER ANALOG

Doing this toggles the function back and forth between the 0-20mA and 4-20mA ranges.

The change will be verified by four dashes “----”

and “4-20” momentarily displayed. If the module is

programmed for the 4-20mA range, “4-20” will be

displayed; toggling back to the 0-20mA range will

again cause four dashes to appear on power-up of

the unit. Tha factory default setting are 4-20.

One thing to consider when feeding the 4-20mA signal to a remote computer or DCS, is that there is no

isolation between the P522 ground and the remote

system ground. If there is a ground potential difference between the two systems, then there could be

serious noise and performance problems. You will

not encounter this problem when using a remote

meter by itself, because it will not be tied into another electrical system (will not be sharing grounds).

The bargraph reading on the front panel will not be

affected by this change to 4-20mA output. It will remain the same as before (i.e., go to zero on no signal

EMALF

FFO

OUTPUT

TESNIAGTRFF

XX

NO

LEDEMIT

Page 12

Page 13

IRIS MODEL P522 APPLICATION MANUAL

detected). The 4-20mA output will still perform the

same way on the high end (i.e., on a strong signal, it

will saturate at the same level, slightly above 22mA).

Specifications for the analog current output signal

are provided in SPECIFICATIONS Figure 13.

INSTALLATION OF VIEWING HEAD

Before beginning the actual installation, determine

the best location for mounting the viewing head based

upon the following factors:

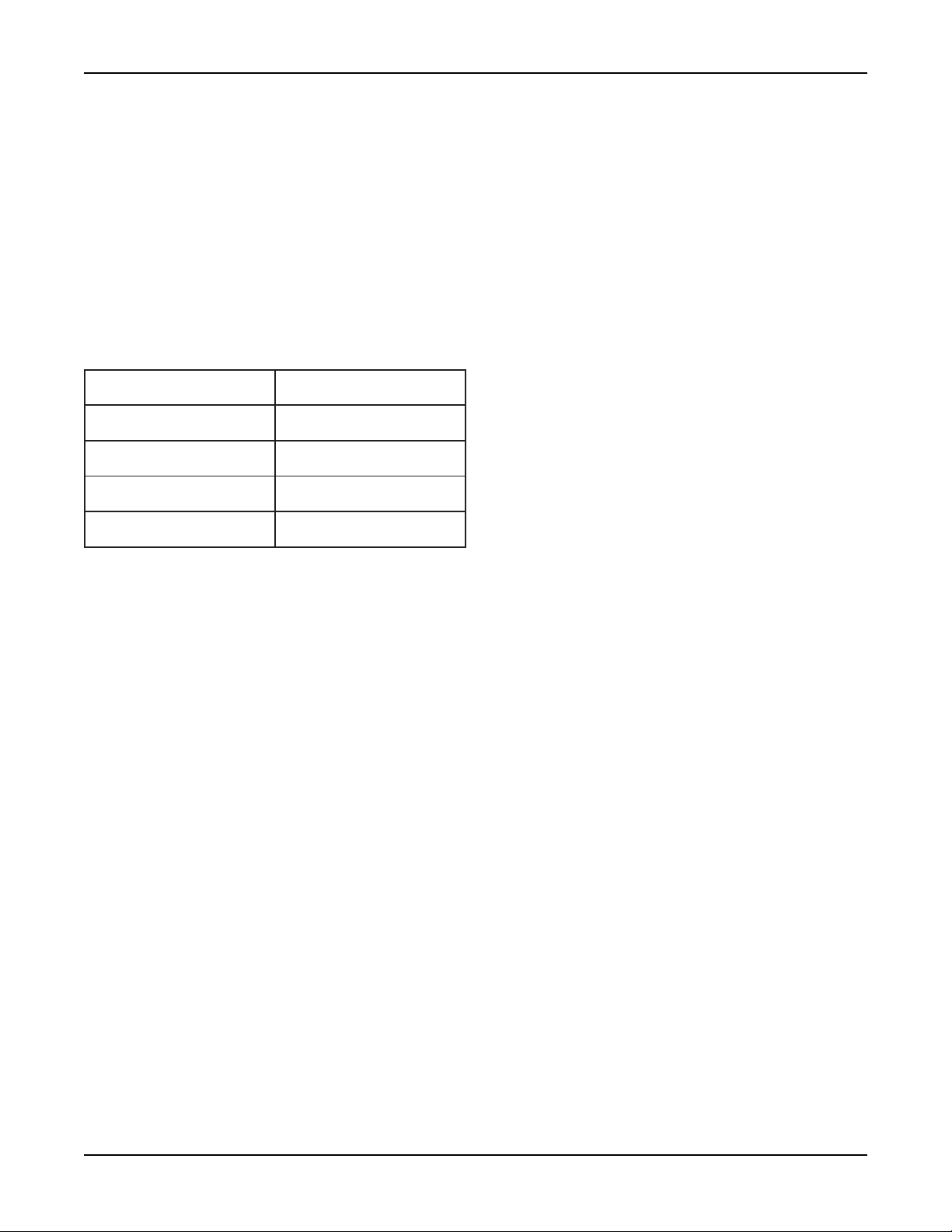

VIEWING HEAD CROSS-REFERENCE

REBMUNDLOREBMUNWEN

605S605S

S2XRI905S

SGRI115S

SRI215S

The model S5xx series of viewing heads have in

place a sensor for sensing the internal temperature

of the head. To access the reading of the viewing

head temperature, press the “Reset” and the “Down”

arrow key at the same time. The temperature reading will be displayed in the four-digit readout. The

reading (indicated in °C) will disappear and the normal reading will continue after several seconds.

VIBRATION

Do not install the viewing head where it could be

subject to vibration. A vibrating viewing head

(flicker type) can simulate flame when viewing a

glowing background. Provide an antivibration mount

if excessive vibrations are present.

CLEARANCE

Make sure there will be sufficient room to remove

the housing for servicing (see Figure 16).

SIGHTING OF THE VIEWING HEAD

FIGURE 7 - VEWING HEAD CROSS-

REFERENCE TABLE

PRESSURE

The viewing head lens will withstand 5 psi. If the

lens assembly is exposed to greater than 5 psi through

sight pipe, then an isolation unit must be used. An

IRIS isolation unit with purge air entrance is available as an accessory.

TEMPERATURE

The viewing head will withstand an ambient temperature to 80°C (176°F). However, the case tem-

perature of the housing must not exceed 60°C

(140°F). Purge air will help reduce conducted heat

through sight pipe to flange (a plastic nipple will also

help), but direct radiation can cause housing case

temperature to exceed limits. If the ambient heat

(direct radiation) is excessive, then a fiber optic extension should be used (please refer to the IRIS

Model 500 Fiber Optic System manual). This system is composed of a viewing head, a fiber optic

assembly, and an amplifier module.

In general, the sighting of the viewing head should

be parallel to the center line of the burner in the direction of the burner flame. This applies to both the

UV type as well as the flicker type. Flicker type

detectors respond to the high frequency flicker of

the flame; so, in order to achieve maximum discrimination between burners, the near portion of the

primary combustion zone should be favoured –

meaning the sight pipe should be mounted as close

as possible to the burner center line. The sight pipe

should be aimed at the root of the flame, which radiates the most intense, high-frequency flicker energy.

Sighting along the flame rather than across it permits the detector to view a greater depth of the flame

root, obtaining better response (see Figure 17).

When sighting for a UV viewing head, you must aim

for the UV zone, which is usually at the very first

part of the flame root. UV radiation from most flames

is restricted to a narrow region: it starts very close

to the burner nozzle and does not extend out very far

from the burner nozzle. You may have to angle the

sighting inward toward the flame root, as shown in

Figure 18.

Page 13

Page 14

IRIS MODEL P522 APPLICATION MANUAL

The effectiveness of the sighting will depend upon

both the type of viewing head as well as the fuel.

UV flame detection works fine on natural gas, but

will cause problems with fuels that either block or

absorb the UV signal.

For example: in a pulverized coal burner,

there can be unburned fuel at the burner

nozzle, creating a “skirt” that blocks the

UV radiation coming from the flame.

Heavy oil burners can also cause problems with UV-type flame detection, particularly if the fuel has a high sulfur content, which will absorb the UV radiation.

MULTIBURNER REQUIREMENTS

Multiburner installations require discrimination.

This means that, in spite of the brightness of other

flames in the furnace, the flame relay must respond

only to the presence or absence of the flame produced by the burner that it is monitoring. Not every

viewing head can be positioned so that its line of

sight does not intercept flames from other burners –

a situation that occurs in multi-level, opposed fired

furnaces where the burners face each other.

In such cases, the sighting angle is setup as described

above, with the viewing head sighting along the

flame directly into the flame root. If an opposing or

adjacent burner flame falls within the line of sight of

the viewing head, it may be effectively tuned out by

setting the FLAME OFF set point high enough to

ignore this background. If discrimination cannot be

achieved by doing this, it is recommended that the

filter switch in the viewing head (except the S506

&115S215S&055S255s

LLzH631zH61

UV, which doesn’t have one) be switched to a higher

position. This reduces the low-frequency flicker

reaching the detector so that the set points can be

adjusted to affect flame discrimination. The four

cutoff frequencies are outlined in Figure 8.

A higher filter position creates a narrower bandwidth,

causing an overall reduction in the flame signal; however, the ratio of flame ON to flame OFF may be improved by properly setting this four-position filter.

Note the readings on the four-digit display when making these adjustments. The four-digit number is an

absolute indication of signal strength, and is not affected by changing the gain of the analog output.

MUL TIPLE VIEWING HEADS

This system can accommodate the parallel operation

of two viewing heads with one signal processor. The

flame signals will be additive, possibly requiring a

lower sensitivity setting. A word of caution about

this type of operation: the unwanted background with

the burner flame out will also be additive, possibly

causing a discrimination problem in multiburner

applications.

Note: The S5xx-series viewing heads

cannot be wired in parallel.

Another variation is to switch the flame signal ON and

OFF from each viewing head.

For example: one viewing head can be used

for the igniter, and the other for the main

burner. While proving flame from the igniter, the main burner signal circuit can be

opened, leaving only the igniter viewing

head signal to be read. And, when proving

flame from the main burner, the igniter signal circuit can be broken.

LzH172zH42

MzH5013zH33

HzH6814zH25

5zH57

6zH001

7zH551

8zH512

FIGURE 8 - CUTOFF FREQUENCIES

Page 14

We recommend that only the flame signal from each

viewing head be switched, leaving the other connections to the viewing head intact (the one exception

would be the S506 UV head). Both the flame signal

and shutter drive circuits should be switched so that

when the head is not being used, the shutter is not

switched on and off. This was done in the design of

the rear mother board (see section WIRING AND

INSTALLATION).

Page 15

IRIS MODEL P522 APPLICATION MANUAL

Note that both the SIG and SIG GND circuits are

switched. However, this can cause a lockout condition if the transfer of the viewing heads is done during the dark period. This problem can be avoided

by changing channels when switching heads (i.e.,

by wiring the two terminal blocks V.H. SEL and

CHAN SEL together in parallel). This will inform

the P522 that the viewing heads are being transferred,

and the pulses counted during the dark period will

be ignored.

DETERMINING SIGHT PIPE SIZE

In order to determine the proper sight pipe, it is important to understand how the viewing head “views”

the flame. The viewing head employs a plano-convex lens in front of the photodetector that focuses

the flame radiation on the surface of the detector.

The active photodetector element is quite small, and

its diameter and the focal length of the lens determines the angle of view. For the S509 viewing head,

this angle of view is about 2.8 degrees. For the S512,

the angle is slightly less.

To understand what this means, imagine a circular

target of flame radiation, one inch in diameter, 24

inches away from the lens: this is the maximum field

of view the detector sees. In other words, a one-inch

diameter sight pipe two feet long will allow maximum signal to be detected. A two-inch diameter

sight pipe four feet long presents the same target.

Actually, a one-inch target three feet away causes

an immeasurable signal attenuation, so you can use

a two-inch diameter pipe up to six feet long, with no

signal attenuation.

In this way, the flame signal can be optimized by

adjusting the viewing head to the target at the end of

the pipe.

SELECTING THE PIPE

We recommend a black iron pipe to provide reliable

flame sensing. The viewing head is tapped for a oneinch national pipe thread (NPT) threaded pipe. Any

diameter sighting-pipe larger than one inch will require

a reducer coupling or swivel mount (see Figure 20).

MOUNTING HOLE

Cut a hole for the sight pipe in the burner front

windbox at the selected location. The hole should

be large enough in diameter to allow adjustment of

the sighting angle. If register vanes interfere with

the desired line of sight, trim the interfering vanes to

ensure an unobstructed view of the flame.

MOUNTING OF SIGHT PIPE

After cutting the pipe to the desired length, thread

one end of the pipe to fit the viewing head flange or

required coupling (see Figure 20). Insert the other

end of the pipe into the mounting hole, align the pipe

to the desired sighting angle, and tack weld it in place

to allow further sighting adjustments. Make sure

the tack weld will support the weight of the detector

when it is installed. Once the final position has been

determined, weld the sight pipe in place.

INST ALLING THE VIEWING HEAD

The viewing-head flange screws directly onto a oneinch NPT threaded pipe (see Figure 20). Use a crescent wrench to tighten the flange onto the sight pipe.

The angle of view for the S511 viewing head is 1.1

degrees. This translates into a one-inch, circular target 52 inches away from the lens. In other words, a

one-inch diameter sight pipe four feet long (or, a twoinch diameter sight pipe eight feet long) will allow

maximum signal to be detected.

For a detailed explanation of how the angle of view

is derived, refer to section ANGLE OF VIEW OF

VIEWING HEAD.

If a long sight pipe is required, then we recommend

that a swivel mount be used to overcome any optical

misalignment that might be present (see Figure 20).

PURGE AIR

Use a flexible air supply line, allowing repositioning of the sight pipe until the permanent detector

position has been verified. A continuous flow of air

must be maintained in order to keep the head cool

and the sight pipe clean. We recommend that at least

three CFM at approximately eight inches of water

column above windbox pressure be provided for each

viewing head. The air supply must be clean, free

from oil and water, and preferably cool.

Page 15

Page 16

IRIS MODEL P522 APPLICATION MANUAL

SETUP AND ADJUSTMENT

PROCEDURES

Multiburner applications require the most care in

adjustments to ensure proper flame out operation

under worst-case conditions (refer to previous section MULTIBURNER REQUIREMENTS).

These same procedures can be followed for singleburner applications, even though the adjustment refinements described here may not be necessary.

There are two, basic worst-case conditions in a

multiburner installation:

One is the initial light off of other burners

after the first burner has been established

(particularly if the established burner, or

burners, has a flame envelope that overlaps the trial burner sighting). If there is a

flame out or ignition failure of this burner

(or its igniter) during this startup sequence,

the flame monitor must detect this condition – meaning that it must discriminate

between the lack of flame and the background flame of the established burner.

This would represent “flame discrimination under low fire conditions.”

Second would be when the fired unit is in

a high fire condition (i.e., all burners are

firing at maximum rate, when suddenly

one burner flames out – possibly because

of a clogged oil gun or some other type of

fuel disruption). This is also a dangerous

condition, particularly for two- to fourburner installations. The flame monitor

must detect this flamed out burner so the

fuel valve (safety shutoff valve) supplying this burner will close. This means that

the flame OFF threshold for this flame

monitor must be set above the signal level

produced by the other burners that are in a

high-fire condition.

pipe and the diameter of the sight pipe is large enough

to allow a range of angles to be viewed (see section

ANGLE OF VIEW OF VIEWING HEAD).

As a general rule, the sighting of the S506 viewing

head is more likely to be “line-of-sight” than the S512

infrared flicker viewing head, which will read flame

signals bouncing off the side of the sight pipe and

other “reflectors.” Sometimes, the reading with the

IR detectors can be greater with a reflective signal

than the direct line of sight. The UV viewing head,

on the other hand, will have to be aimed at the part

of flame having the highest concentration of UV

which is usually at the root of the flame (at the throat

of the burner) and in a very narrow range.

The angle of view of the S506 is somewhat wider

than the S512 or S509, but this does not offset the

fact that the UV radiation present is very narrow.

This is not true, however, for low NOx gas burners;

the UV is usually much less in intensity with this

type of burner, and spreads out in front of the burner,

getting readings from all over the furnace when many

burners are on. This is particularly true when fuel

gas recirculation is used.

Another factor to consider when aiming the viewing

heads is the load condition of the boiler. The flames

from a burner can be radically varied at different

loads – one of the reasons for trying to select a sighting that will minimize the changing flame at different loads. If the flame front moves farther away at

higher loads, then a sighting parallel to the burner

axis will be best. A large-diameter sight pipe with a

swivel mount is recommended for all installations

on large, multiburner boilers. (Refer to Figure 20.)

INITIAL SETUP

A. The initial settings for the P522 signal

processor should be as follows:

1. F.F.R.T. (Time Delay Off) to 3 SEC.

2. GAIN SET to 25.

SIGHTING ADJUSTMENT

Before making definitive settings (i.e., establishing

the set points) for flame ON/OFF, you must optimize the sighting of the viewing head. This can be

done if a swivel joint is used at the end of the sight

Page 16

3. TIME DELAY ON to 0.

4. FLAME ON to 200.

5. FLAME OFF to 100.

Page 17

IRIS MODEL P522 APPLICATION MANUAL

The above settings will be satisfactory for

most applications, but are used only as a

starting point. So many variables can

affect the readings that it is impossible

to catalogue all the settings, and each

viewing head has its own characteristics

for the different types of fuels and burners. We recommend that you become

knowledgeable about the characteristics

of the different viewing head models

available before applying them to a particular application. Detailed descriptions

of the viewing heads are provided in this

manual, and the VIEWING HEAD AP-

PLICATION TABLES (Figure 11) are

a useful summary of the viewing heads

and their response to different fuels.

B. The initial settings for the flicker type

viewing heads (S509, S511, S512) should

be as follows:

1. Set filter switch to LL position.

2. Gain potentiometers (POTS) full

clockwise (these are 25-turn potentiometers – a slight clicking sound will

be heard when the POT is maximum

clockwise). There are two POTS on

the S509: one for the Si channel, and

one for the PbS channel. If the fuel is

natural gas, turn the Si channel off

(POT full counter clockwise). Refer

to section S509 VIEW HEAD.

C. There are no initial settings for the S506

UV viewing head. It is important that

this viewing head be properly aimed to

pick up the maximum signal, as described

in the previous section.

ADJUSTING SET POINTS

Before adjusting the set points, take readings with

the P522 on the two worst-case conditions described

(see section SETUP AND ADJUSTMENT PRO-

CEDURES). Write down the readings for the burner

ON and OFF (with other burners on) under low load

conditions, and then the readings for the burner ON

and OFF under high load conditions.

There must be a definitive ratio between the readings for burner ON and burner OFF. This ratio can

be defined by using the lowest reading for burner

ON from both of the load conditions, and the high-

est reading for burner OFF from both of the load

conditions. If the readings are 2:1 or more (BNR

ON to BNR OFF) then there should be no problem

discriminating between burners.

A good balance for the set points would be:

ON

OFF

SET POINT

SET POINT

= .75A + .25B

= .25A + .75B

where A is the lowest burner ON reading, and B is

the highest burner OFF reading.

Actually, a smaller ratio will work, as long as the

lowest BNR ON reading and the highest BNR OFF

reading never deteriorates to the point the former is

equal to or less than the latter. In other words, A

must always be greater than B. Using a safety factor

of 2:1 will allow for flame signal changes that probably will occur over a period of time.

A. FOR FLICKER TYPE VIEWING

HEADS: If unable to achieve discrimi-

nation from background signals (for models S509, S511 and S512 viewing heads),

remove the viewing head housing from

the flange and place the filter switch to

the next highest position L. Reinstall the

viewing head and take another set of readings. Note: the filter switch should be

moved only one position at a time for

each set of readings. Refer to section

MULTIBURNER REQUIREMENTS.

B. FOR THE S509 VIEWING HEAD: If

you are still unable to achieve satisfactory flame OFF operation, remove the

viewing head and turn the Si channel off

by turning the Si POT at least 30 turns

counter clockwise. The signal level will

now be lower because only the PbS detector is being used, so the set points must

be re-evaluated. If you are using an S511

viewing head and not achieving success-

Page 17

Page 18

IRIS MODEL P522 APPLICATION MANUAL

ful discrimination, it is likely due to the

automatic gain control (AGC) action (see

sections on the viewing heads for a detailed explanation of this problem).

When using the PbS only or the S506

(same for the S512), make sure the sig-

nal is not saturating, particularly at

high load conditions. (Refer to section

ORIFICING.)

C. For the S550, the S552 and the S556, see

corresponding manual(s).

TROUBLESHOOTING GUIDE

A. NO FLAME SIGNAL and NO DISPLAY

1. Check wiring (refer to section WIRING AND INSTALLATION).

2. Check the voltage at PWR IN terminals with a volt meter. It should measure approximately 26 VDC. If not,

check the power supply and wiring,

or replace the power supply.

3. Check the voltage at pins 4 (26 VDC)

and 5 (PWR GND) of the viewing

head connector. If the voltage is zero,

check the wiring of the connector for

shorts and/or replace the viewing head

cable. If 26 VDC is measured, then

the viewing head may be defective,

and should be replaced.

C. FLAME SIGNAL SHOWS ON DIS-

PLAY; FLAME ON RELAY AND

LIGHT ARE OFF.

1. The viewing head is incorrectly wired,

or defective (see B, above).

2. The set point values for flame ON

are incorrect.

D. FLAME SIGNAL SHOWS ON ANA-

LOG BARGRAPH DISPLAY; FLAME

ON LIGHT IS OFF; LOCKOUT

LIGHT IS ON.

1. The viewing head may be defective.

3. If 26 VDC is measured, remove the

power for 10 seconds. If the self-resetting fuse has tripped, removing then

reapplying power will reset the fuse.

B. DIGITAL DISPLAY IS SHOWING

0000 AND NO FLAME SIGNAL

1. Using a volt meter, check at viewing

head A terminals, on the bottom of the

mother board, for 26 VDC across +V

and GND. If the voltage is low, check

the power supply. If the supply is okay,

removing and reapplying the power after 10 seconds will reset the 0.25A selfresetting fuse if it has tripped.

2. If the voltage measures 26 VDC at

P522 terminals, remove the connector

from the viewing head, and open the

red connector (refer to viewing head

wiring diagram of this plug, Figure 2).

2. There may be a noise or ground-

ing problem (see NOISE INTER-

FERENCE AND GROUNDING,

following section).

3. Press RESET button on front panel.

E. 1-9 LED STAYS ON

1. There may be a noise or grounding

problem (see D2, above).

2. The viewing head may be defective.

F. FRONT PANEL BUTTONS DO NOT

RESPOND.

1. The P522 front panel may be locked out.

NOISE INTERFERENCE

AND GROUNDING

On the plug-in terminals going to the viewing heads

at the bottom of the P522, the terminals marked GND

go to pin 5 on the viewing head plug (see section

WIRING OF VIEWING HEAD). Pin 5 of the view-

Page 18

Page 19

IRIS MODEL P522 APPLICATION MANUAL

ing head male receptacle has an internal tab that

grounds this connection to the viewing head housing.

The terminal marked GND connects to the chassis

ground of the P522. This ground is made through the

etch on the rear side of the PC board to the metal base.

It is important that the AC power be a grounded

source (i.e., GND going to plant ground – refer to

section POWER SUPPLY). Interference problems

can occur if the power supply chassis and the P522

chassis are at a different ground potential than the

viewing head housing, which will be at a ground

potential associated with the burner front. In these

situations, the IRIS flame monitor effectively supplies a plant ground between the burner front and

the panel enclosure. If there is a large potential difference between these points, considerable current

can flow through the viewing head cable, which can,

in turn, damage the P522 signal processor or the associated power supply.

If there is a voltage difference between the viewing

head and the sight pipe, then you should use a nonconductive, one-inch plastic nipple between the sight

pipe and the viewing head mounting flange. This

voltage difference can be easily measured by disconnecting the viewing head from the mounting

flange so that there is no continuity between the viewing head and the boiler front.

Note: Use a battery operated multimeter

on a high voltage AC range for making

this measurement.

This measurement should be made under various

conditions (i.e., during the sequencing of the igniter

and burner).

In addition to using the isolated nipple for the viewing head flange, you must use a nonconductive rubber or plastic hose for the purge air (there is a 1/2inch NPT pipe thread on the flange). This will prevent the current from flowing through the IRIS cable

(power ground) back to the P522.

Another source of interference is from high-voltage

spark igniters. A high voltage of 6 KV or more is

usually supplied by a step-up autotransformer and,

not being isolated from the power line, it can cause

interference, particularly if there are grounding problems. The usual problem occurs when the transformer is energized, resulting in a bogus flame signal. The problem is not caused by the spark across

the gap, but by radiation from the high-voltage wiring feeding the spark gap. It is the secondary wiring

of the transformer (high-voltage AC) that causes this

interference – both the insulated wire to the spark

gap, as well as the ground return. This circuit loop

acts like a giant antenna. Also, this type of transformer can cause a ground problem because it is an

autotransformer, and because it is not isolated from

the power line. The high-voltage current to the igniter must return to the transformer through the plant

ground, which is the conductive metal of the plant.

The solution to these problems is to locate the ignition transformer as close as possible to the igniter,

and away from the P522 and power supply. The

shorter the secondary wire run, the better. Also, the

ground return path should be examined. Is the igniter properly grounded, and is this a good plant

ground? Plus, you should examine the grounding of

the transformer case: we recommend that there be a

good plant ground on the transformer case, and that

the transformer be enclosed in a metal enclosure that

is also grounded.

Usually, there are no straightforward solutions to

electrical interference problems; each will have its

own unique causes. However, there are certain precautions or guidelines that you should be aware of.

The first thing to check is the grounding of the installation. Make sure the AC power feeding the system is grounded, and that the ground is a bona fide

plant ground. And, make sure the proper cable is

being used for the viewing head.

Note: Do not use cables that employ foil

type shields (aluminum-polyester). We

recommend you use the standard IRIS

cable that has a braided shield.

S506 VIEWING HEAD

The S506 viewing head employs a UV tube that has

a spectral response of 185-260nm. It is an inherent

pulsing device (i.e., the power supply has been designed so that the tube emits pulses when UV radia-

Page 19

Page 20

IRIS MODEL P522 APPLICATION MANUAL

tion is present). Its output is randomly-spaced pulses,

with an average pulse rate proportional to the UV

radiation present. The digital count when reading

natural gas will be about the same as the S512, and

probably will be less when reading a heavy oil flame.

The very narrow spectral response of the UV tube

makes this type of detector ideal for discriminating

between flame, glowing refractory, and other burners. However, because of its response to only the

very short wavelengths, problems can occur because

this radiation is easily absorbed and masked by unburned fuel or other impurities in the coal (i.e., with

pulverized coal). Sour gas (H2S) will readily absorb

these short 200 nm wavelengths, as well as other

waste fuels resulting in a dropout of the flame signal. Even standard glass will absorb this wavelength;

therefore it is necessary to use a quartz lens with this

viewing head.

In general, the S506 viewing head will work well on

natural gas flames. It will respond to oil flames, but

with a lower signal level. The sighting should be

parallel to the axis of the burner and aimed at the

foot of the flame. Photographs of gas and oil flames

using visual- and UV-sensitive film clearly show that

the UV zone is much smaller than the visible zone,

and the highest UV intensity occurs near the flame

root. In addition, the zone of higher UV intensity

does not overlap the same zones of adjacent or opposing burners; so, with proper sighting, discrimination is predictable.

S506 SELF-CHECKING

VIEWING HEAD

The self-checking characteristics of the S506 are

implemented by using a shutter that blocks the flame

light path every second for 200 milliseconds. The

reason for doing this, presumably, is to detect a runaway UV tube. The McGraw Edison-type tube traditionally used for UV flame detection is known to

have an avalanche mode (runaway condition) that

creates pulses when there is no flame present.

The UV tube used in the S506 is a different type of

tube, having an anode and cathode instead of the

dual-anode type used by others. This tube also uses

a relatively low voltage for operation, and we have

experienced a runaway condition with this tube only

once, with a tube that had been subjected to such a

significant shock that the electrodes inside were

clearly bent.

Why use self-checking if the tube does

not runaway? Because any runaway

failure, for any reason, is unacceptable,

and self checking monitors all electronic

components, from the UV tube to the

flame relay.

Each time the shutter closes, the flame signal is blocked,

resulting in a cessation of pulses. This is interpreted by

the P522 as a normal condition (no pulses during the

dark period) and the flame relay is kept energized. If

this does not occur, the P522 will go into a lockout

state, causing the flame relay to de-energize (see section SELF CHECKING FUNCTION).

S509 VIEWING HEAD

As explained in the S509 product brochure, this viewing head employs a two-colour photodetector using

a “see-through” silicon (Si) front element and a lead

sulfide (PbS) back element. It is important to understand how this viewing head operates with respect

to different fuels and flame conditions.

The electromagnetic spectrum, or spectral range, for

the Si element is 350 nm to 1100 nm; for the PbS

element it is 1100 nm to 3000 nm. The Si element will

detect all incandescent type flames such as oil, pulverized coal, and most waste fuels. It will not see natural

gas or propane fuels at all. The PbS element will detect

all flames, including natural gas and propane.

For this reason, the S509 viewing head will exhibit

stronger signals for oil and pulverized coal than for

natural gas, providing both the Si and PbS 25-turn

POTS are full clockwise (full on). Typical “bright”

signals for oil can read as high as 2900 on the digital

display, while natural gas may read as high as 2100.

For instance, a propane torch two inches away from

the viewing head will read 1900. (The above, typical readings are made with the filter switch in the

LL position.)

An important characteristic that must be explained

is the nonlinearity of the Si channel on “bright” sig-

Page 20

Page 21

IRIS MODEL P522 APPLICATION MANUAL

nals. The Si element is a photodiode that is operated in the photovoltaic mode (the diode generates

current when exposed to light or radiation). The sensitivity range of this device in this mode is quite large,

from nanoamperes to milliamperes – so some means

to prevent saturation in the first stage of amplification is required. (The PbS element, on the other hand,

has a rather limited dynamic range exhibiting not

more than a 15:1 ratio from dark to a bright signal.)

In order to prevent saturation, an AGC type circuit

is used, so that the DC component or “brightness”

signal doesn’t saturate, causing a loss of the AC component or flicker signal. On a “bright” signal, this

Si channel is limited, or compressed, so that there is

a maximum signal reached that will not be exceeded,

no matter how much brighter the signal is.

Another non-linear characteristic can be attributed

to both the Si and PbS channels on “bright” signals

exhibiting a large AC/DC component, such as an incandescent light source. In this case, the amplifiers downstream of the first stage are in a clipping

mode (i.e., approaching 120Hz squarewave) which,

even though the signal is AC, has a limiting characteristic. This is indicated on the digital display with

a count or signal strength of about 2900. (This is

with the filter switch in the LL position; the display

will read about 2100 with the filter switch in the H

position.) Fortunately, flame signals do not exhibit

this large AC/DC component, so the amplifiers

downstream play a lesser role with this type of nonlinearity (see section SIGNAL SOURCES).

However, if it is determined that there is a limiting

action taking place (readings on the digital display of

2700 – 3000), and if this is interfering with the ON/

OFF ratio, causing a discrimination problem, it can

be easily resolved by turning both the Si and PbS 25turn POTs down. No effect will be noticed until about

10 turns counter clockwise, and we recommend 15

counter clockwise turns on the first try. The digital

display must be used for this adjustment to detect when

the signal pulls out of a limiting or compressing mode

(i.e., when the signal goes below 2700).

S511 VIEWING HEAD

This viewing head uses a germanium photodiode that

has a narrower spectral range (750 nm to 1900 nm)

than the lead sulfide cell used in the S509 and S512

viewing heads. It will detect all types of flames,

including natural gas and propane.

Being a photodiode, it is operated in the photovoltaic mode – the same as the Si element in the S509.

The same type AGC circuit is used, which is inherently nonlinear. If it appears that a limiting action

needs correction, the same remedy can be used here

as on the S509.

S512 VIEWING HEAD

The S512 viewing head employs a PbS-only photodetector, and performs in a similar manner as the S509

two-colour model with the Si channel turned off (i.e.,

Si channel potentiometer turned full counter clockwise).

It has been our experience that, for many applications using the S509, the Si channel is not used;

usually, it is turned off. There are two reasons for

this, the primary reason being the inherent

nonlinearity caused by the AGC in the Si channel.

The wide dynamic range of the Si photodetector requires control of the gain of the first amplifier stage.

If this were not done, amplifier saturation of the signal would occur on bright flame signals, resulting in

the loss of the flicker signal.

The problem occurs because the AGC responds to

the brightness of the flame.

For example: when a burner is on, the

flame monitor is picking up a strong,

bright signal from the root of the flame;

when the burner goes out, the flame

monitor is reading background flame

from other burners. This background

flame is less bright, causing the AGC circuit to increase the gain of the amplifier

with a consequential reduction in the discrimination ratio (the ratio between the

count displayed with flame ON and the

count displayed with flame OFF). The

AGC nonlinearity is self-defeating, so to

speak, and is the principle reason this Si

element is usually turned off.

The other reason is that the Si photodetector will not

see propane or natural gas. If this is the main fuel, then

Page 21

Page 22

IRIS MODEL P522 APPLICATION MANUAL

you should definitely turn off the Si channel, which

cannot contribute to the flame signal from the burner

(when it is gas) but can only read background glow –

which will certainly cause a discrimination problem.

An important aspect of using the S512 instead of the

S509 has to do with linearity. The non-linearity of

the Si channel due to the AGC circuit has already

been explained. This AGC is used upstream of the

25-turn potentiometer, so you have no control over

this action except for the viewing head sighting, or

for using orificing to change the amount of signal

reaching the photodetector. On the other hand, the

PbS channel upstream from its potentiometer is linear for low to medium brightness flames (i.e., no

distortion of the flame signal occurs with regard to

amplifier saturation (signal clipping) or nonlinear

amplification (AGC) as with the Si channel).

However, saturation will occur with the PbS channel

on high brightness flames. You can detect this by

observing the digital display reading for boiler load

conditions as they vary from low to high. If there is

not much of a signal increase between low load and

high load, then the PbS detector is saturating.

For example: if the burner flame signal

on oil reads 1950 under low load conditions, and reads 2000 on high load conditions, you can be sure that the PbS detector is saturating.

To resolve this condition, reduce the signal brightness by orificing (see next section ORIFICING).

The orifice disc (installed in the flange) is located

immediately in front of the lens and will reduce the

amount of signal radiation the same way a camera

aperture reduces the amount of light.

As mentioned in the previous section on the S509,

saturation can occur downstream from the gain adjustment potentiometers because of the signal amplification process. This type of saturation can be detected on the digital display by observing the signal

count. The S509 will be completely saturated at a

count of 2800 – 3000. Saturation begins (waveform

just starts to clip) at a count of 2100. This threshold is

somewhat dependent upon the flicker frequencies and

their distribution, but for the lower frequencies (up to

200 Hz) the count of 2100 can be taken as the threshold. This amplifier type saturation usually will not

occur with the S512 viewing head when reading actual flames. It can occur when reading artificial signal sources, such as incandescent and fluorescent

lamps, because of the large AC/DC component. It

should be noted that amplifier type saturation is not

harmful per se, but saturation of the photodetector

caused by high brightness flames can be.

You cannot control the nonlinearity caused by the

AGC action of the Si channel on the S509, but with

the Si channel turned off you can control the linearity of the PbS channel by observing the count on the

digital display, and reducing the gain when necessary by orificing. Saturation of the PbS detector can

only be corrected by orificing; turning down the gain

adjustment potentiometer will not help, because it is

the PbS cell upstream that is the cause.

Another nonlinearity of the PbS detector that should

be noted has to do with the signal sensitivity and

temperature. The PbS-type detector becomes less

sensitive with increasing temperature.

For example: the sensitivity or signal will

drop to one half with an increase in temperature from 25°C to 50°C. A further

increase in sensitivity will occur above

50°C. This is the reason for the 60°C

operating temperature limitation on the

viewing head. This characteristic is inherent in all PbS detectors, but should not

cause a problem with respect to flame

monitoring and discrimination. The signal level will be stable once a temperature equilibrium has been reached.

This sensitivity-versus-temperature characteristic is

another reason why the PbS cell should not be exposed to high brightness flames. The radiation of the