Page 1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

Part No. D0890

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

23456789012345678901

IPSO - LSG n.v.

IPSO PC30

Preprogramming, programming,

copying, operating

Nieuwstraat 146 - B-8560 Wevelgem (Belgium)

Tel. 056/41 20 54 - Fax 056/41 86 74

Page 2

Table of contents 1

1 Introduction ..................................................................................... 1

Microprocessor PC30 .............................................................................. 1

Flow charts .............................................................................................. 1

2 Classification according to modes ................................................ 3

Preprogramming mode ............................................................................ 3

Programming mode ................................................................................. 3

Copying mode .......................................................................................... 3

Operating mode ....................................................................................... 3

3 Preprogramming mode ................................................................... 7

Preprogramming ...................................................................................... 7

4 Programming mode ........................................................................ 15

Programming ........................................................................................... 15

Insert and delete a program segment ...................................................... 33

Program tables ........................................................................................ 33

5 Copying mode ................................................................................. 39

Copying mode .......................................................................................... 39

Standard programs .................................................................................. 39

6 Operating mode ............................................................................... 60

To select a program ................................................................................. 60

To start a program ................................................................................... 60

Programmed start .................................................................................... 61

Changing to another program .................................................................. 61

One time modification of the level, wash time and temperature input ...... 61

Control of the temperature ....................................................................... 61

Control of a program in progress ............................................................. 61

Rapidly going through a program ............................................................ 62

Programmed stop .................................................................................... 62

Soaking .................................................................................................... 62

Time stop ................................................................................................. 62

Interruption and stopping the program ..................................................... 63

Adding water ............................................................................................ 63

Draining water .......................................................................................... 63

Heating the bath ...................................................................................... 63

Adding soap ............................................................................................. 63

Error message ......................................................................................... 64

Total operating hours, recieved coins ...................................................... 64

Overview of the total of steps per program .............................................. 64

7 Test mode ........................................................................................ 65

8 Liquid soap connection .................................................................. 67

Version 1.27 - 2.XX ß

Code: 249/000056/04

06/02/01

contents

Page 3

Index

°C XX 17, 61, 63

°F XX 17

A

ACCL 62

Add 11, 25

ALArm 13

ALArm.XXX 25, 31

B

Bu= 13

C

CDn XX 25

CDu XX 25

CLoSE 63

Coin 7, 15

Cold 61

CoPY PrG 3, 39

D

d2 27, 29

Data.XXXX 31

dAtA.XXXX 3

dELAY XX 61

dESt .YY 39

dI 27, 29

diSt 29

dO 29

door. oPEN 60

dt XXX 29

dX LXX 63

E

E 3 2 8 3

E 4 5 5 3

E 6 1 9 3

E 7 8 8 64

E 2 2 3 64

End 31

EntEr 61

Error = 00 3

Error = 02 60

Error = 03 3

Error = 04 64

Error = 05 64

Error = 06 64

Error = 07 64

Error = 08 64

Error = 09 64

Error = 10 64

Error = 11 64

Error = 12 64

Error = 13 64

ES.tilt.XX 13

F

FC 7

FREE = XX 64

R

Ram full 15, 33, 39

S

G

GEntlE 11

Good. XXXX 3

H

HEAt 17

HEAt-Mod 11, 17

HEAt-SYS 17

HECo 11, 19, 61

HF 7

HS. XXXX 27

I

i1 9

i2 9

i3 9

i4 9

i5 9

i6 9

i8 9

i9 9

iS.tilt.XX 13

iX LXX 63

L

L XX 23, 61

LECo 7, 61

LS. XXXX 27

M

Mod 11, 17

N

no Add 25

O

oPEn door 63

P

P.XX 61

P.XX.StArt 61

PrE 3

ProG 15

ProG XX 3, 15, 60

ProGr 3

ProM. XXXX 3

PXX. End 60,64

S XX 17

SE-i 7

SoAH 25, 62

SoAh.tiME 62

SoAH.XXX 25

SoAP XX 63

SourCE.XX 39

SoX tXXX 63

SP XX 17

SP2- X 27

SPI- X 27

SPin 27

StArt 3

StoP 25, 62

StoP.tiME 62

StoP.XXX 25

T

t XX 15, 19

t °C 11

t XX 19, 61

t °F 11

t= XXXX 29

t=XX°C 61

t1. XXX 21

td XXX 27

Tu XXX 31

W

WASh 29

X

XX del 33

XX ....YY 39

XX. del 33

XX. inS 33

XX. Cool 25

XX. CYt i 15

XX. dEti 27

XX. teMP 17

XX.id XX 15

XX.ti XXX 62

XX.tistop 62

The manufacturer reserves the right to change the contents

of this instruction manual without previous notice

Page 4

Introduction 1

Microprocessor PC30

Machines equipped with the electronic freely programmable microprocessor PC30 allow you to program 30

programs ( 0 to 29) of your own choice. There are also 10 standard programs ( 30 to 39) available. The operation

of the machine, as well as the input of data necessary to obtain a wash program occur via the keyboard in the fascia

panel.

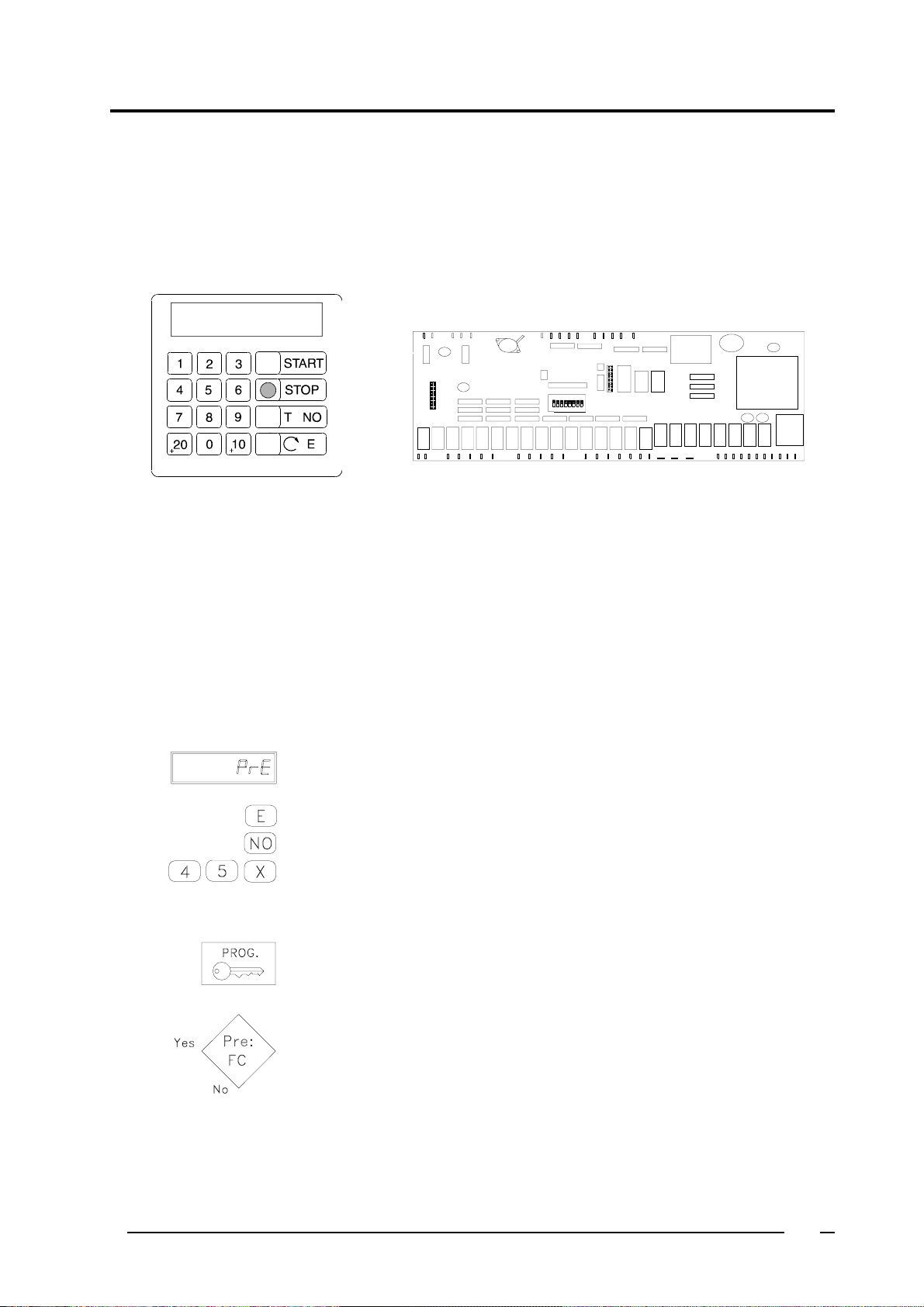

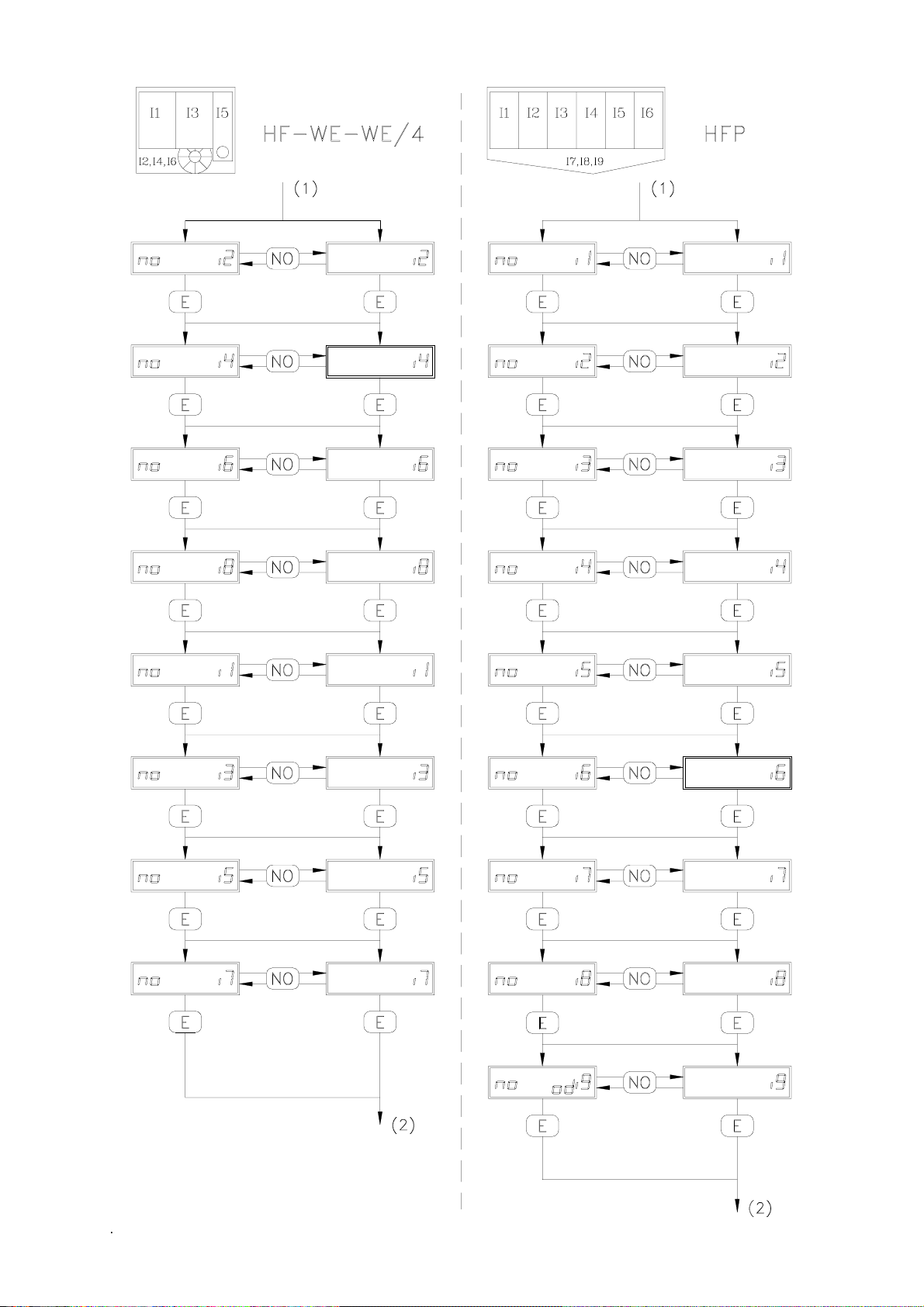

Flow charts

In this manual flow charts are frequently used. Below you can find an explication of the applied symbols.

This gives a presentation of a text that appears on the display.

These symbols with rounded off corners stand for pressing the appropriate keys

on the keyboard.

e.g. numbers, start, stop, etc. (X stands for a number of your choice).

The symbols in rectangulars stand for mechanical interventions that need to be

executed.

e.g. turning the key switch in the front.

The representation of a rhomb refers to a software requirement.

e.g. has a frequency controlled motor been selected in the preprogram or not, has

a coin-op machine been selected or not, etc.

5

Page 5

Pre-programmeer mode Programmeer mode Kopieer mode Bediening mode

Hoofdstuk 3 Hoofdstuk 4 Hoofdstuk 5 Hoofdstuk 6

6

Page 6

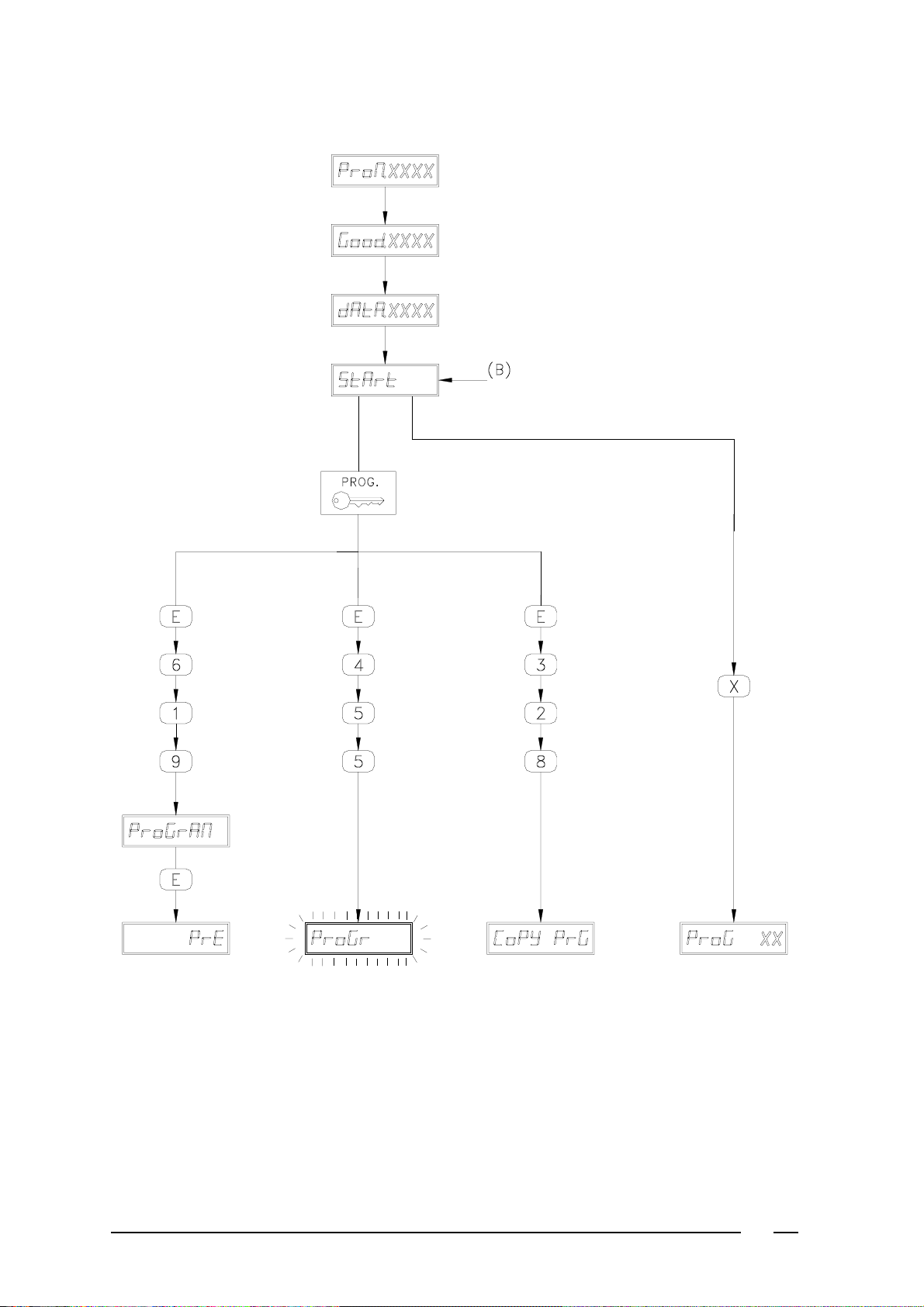

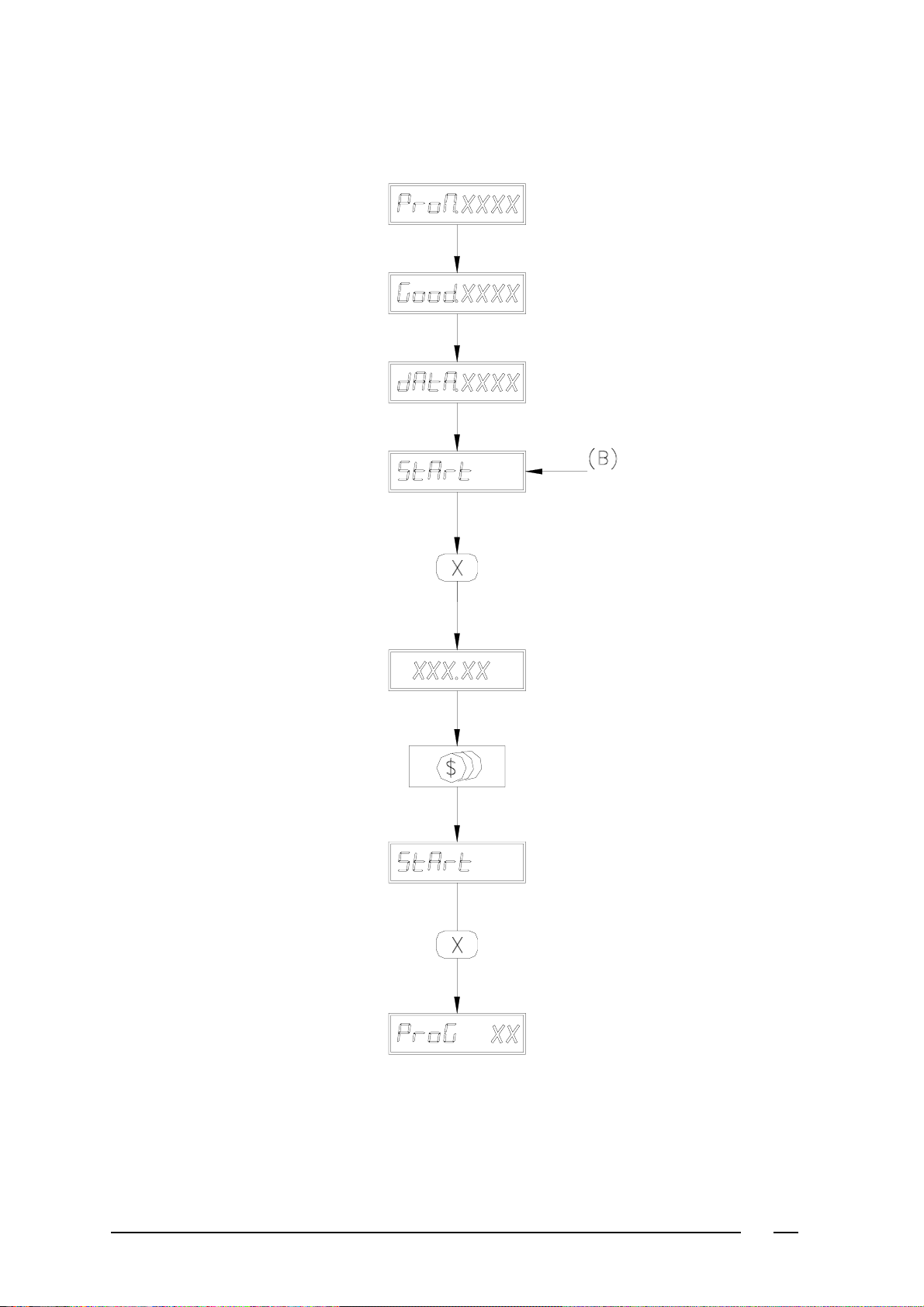

Classification according to modes 2

As soon as the electric power is connected to the machine, it will carry out a so-called " Eprom test ".

" ProM.XXXX " and " Good.XXXX " will appear temporarily on the display (XXXX stands for the number of the

Eprom version). Then " dAtA.XXXX " appears temporarily. This is the " Checksum " of the total data. This value

changes each time the program is altered.

Then " StArt " appears.

Now choose between 4 different modes.

Remark:

" Error 03 " appears on display when the electrical power is supplied to the machine for the very first time, or when

a fault is found in the Ram memory (memory wash programs). Press E .

Preprogramming mode

In this mode the machine can be initiated into its own technical specifications (e.g. coin-op or manually operated

machine, the number of water inlet valves, machine with or without heating, etc.), as well as into certain freely

programmable options (e.g. temperature in °C or °F, temperature displayed during the cycle or not, etc.).

To get into the "preprogramming mode":

- Set the key switch in the front to " PROG ".

- Put in " E 6 1 9 " (press quickly one after the other)

" ProGrAM " appears on the display. Press " E ".

" PrE " appears on the display.

To alter the "preprogram": see chapter 3.

Remark:

- The preprogram is fixed during assembly of the machine so that it usually needn't be altered anymore.

- If the key switch in the front is not set to " PROG ", " Error = 00 " (flashing) will appear for about 10 seconds after

" E 6 1 9 " is put in.

Programming mode

In this mode you can put in step by step the data necessary to obtain a complete wash cycle of your own choice.

To get into the "programming mode":

- Put the key switch in the front in the " PROG " position.

- Put in " E 4 5 5 ". (Press quickly one after the other)

" ProGr " (flashing) will appear on the display.

To program a wash program: see chapter 4.

Remark:

If the key switch in the front is not set to " PROG ", " Error = 00 " (flashing) will appear for about 10 seconds after

" E 4 5 5 " is put in.

Copying mode

In this mode existing programs can be copied to other program numbers. This can save a lot of work when almost

identical programs need to be programmed.

To get into the "copying mode":

- Put the key switch in the front in the " PROG " position.

- Put in " E 3 2 8 ". (Press quickly one after the other)

" CoPY PrG " will appear on the display.

To copy a program: see chapter 5.

Remark:

If the key switch in the front is not set to " PROG ", " Error = 00 " (flashing) will appear for about 10 seconds after

" E 3 2 8 " is put in.

Operating mode

In this mode an existing wash program can be started.

To get into the "operating mode", press the number of an existing wash program. " ProG XX " will appear on the

display ( XX stands for the selected wash program).

To start the program: see chapter 6.

7

Page 7

8

Page 8

Classification according to modes 2

Remark: coin-op machine

Press on the keyboard the number of an existing wash program.

XXX.XX = Price of the program (e.g. 120.00)

The amount due for this program.

Insert the necessary coins in the coin meter(s).

After each insertion the amount still due will appear on the display.

Once the full amount has been inserted, " StArt " will appear again.

Press " START " to start the program.

9

Page 9

10

Page 10

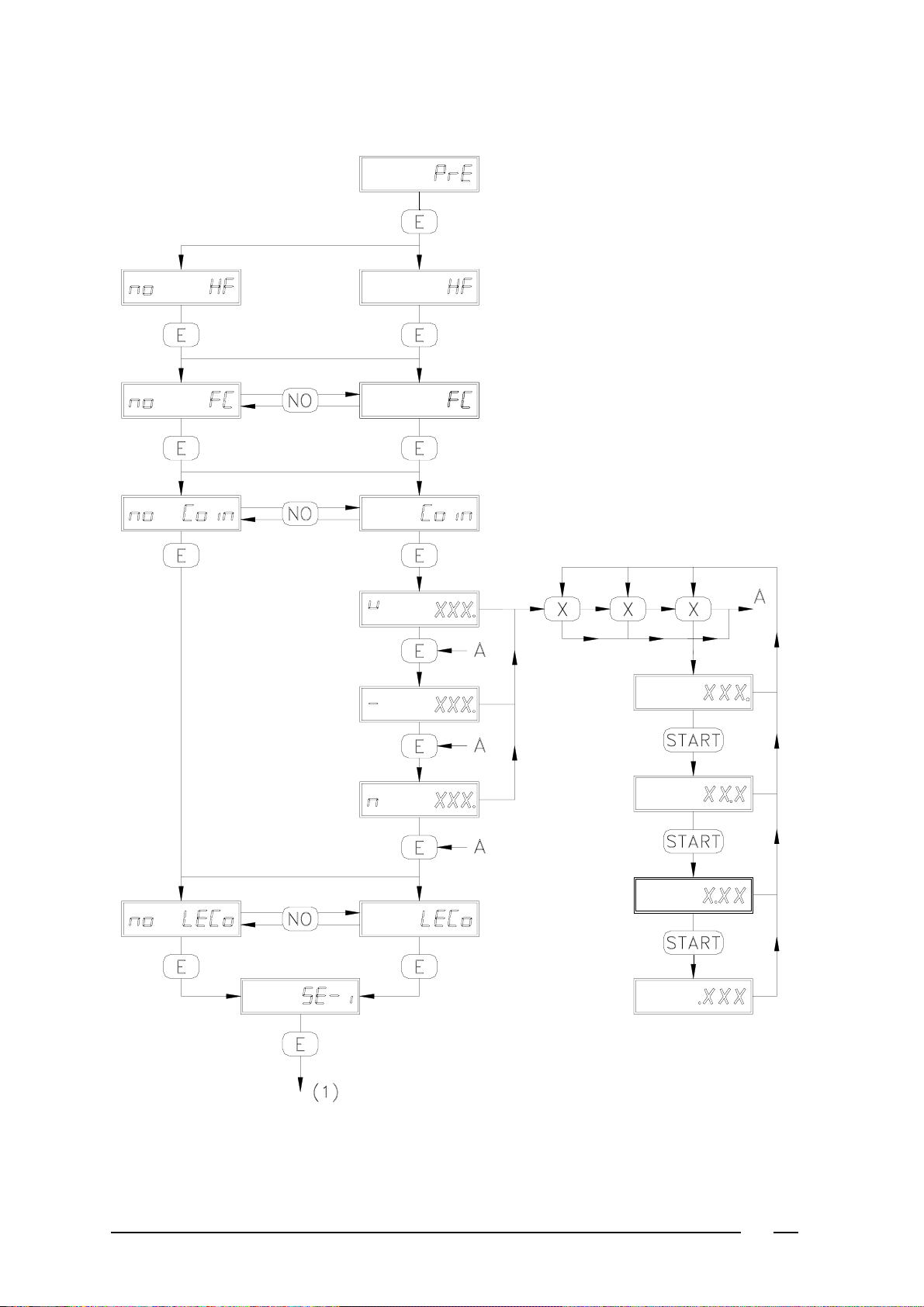

Preprogramming mode 3

Preprogramming

To get into the "preprogramming mode": see " Classification according to modes 2 ".

The selection here is generally made by altering, if necessary, the command on the display by means of

" NO " (e.g. " no FC " becomes " FC " after pressing " NO "). Confirm this selection with " E ".

While preprogramming, it is possible to return step by step by pressing the " STOP " button.

PrE = Preprogram (Altering the "Preprogram")

Press " E "

HF = Machine of type HF, WE245/304 or "high spin" WE-machine

FC = Frequency controlled (frequency controlled motor)

Coin = machine with coin mechanism

First, put in the value of the coin meter with the highest value by means of " X,X,X ".

If necessary, move the decimal point by pressing " START ".

By pressing " E " you can proceed to the other coin meters and install them in the same manner.

LECo = Level control (Control of the water level)

This means the program is temporarily stopped until the appropriate water level is reached.

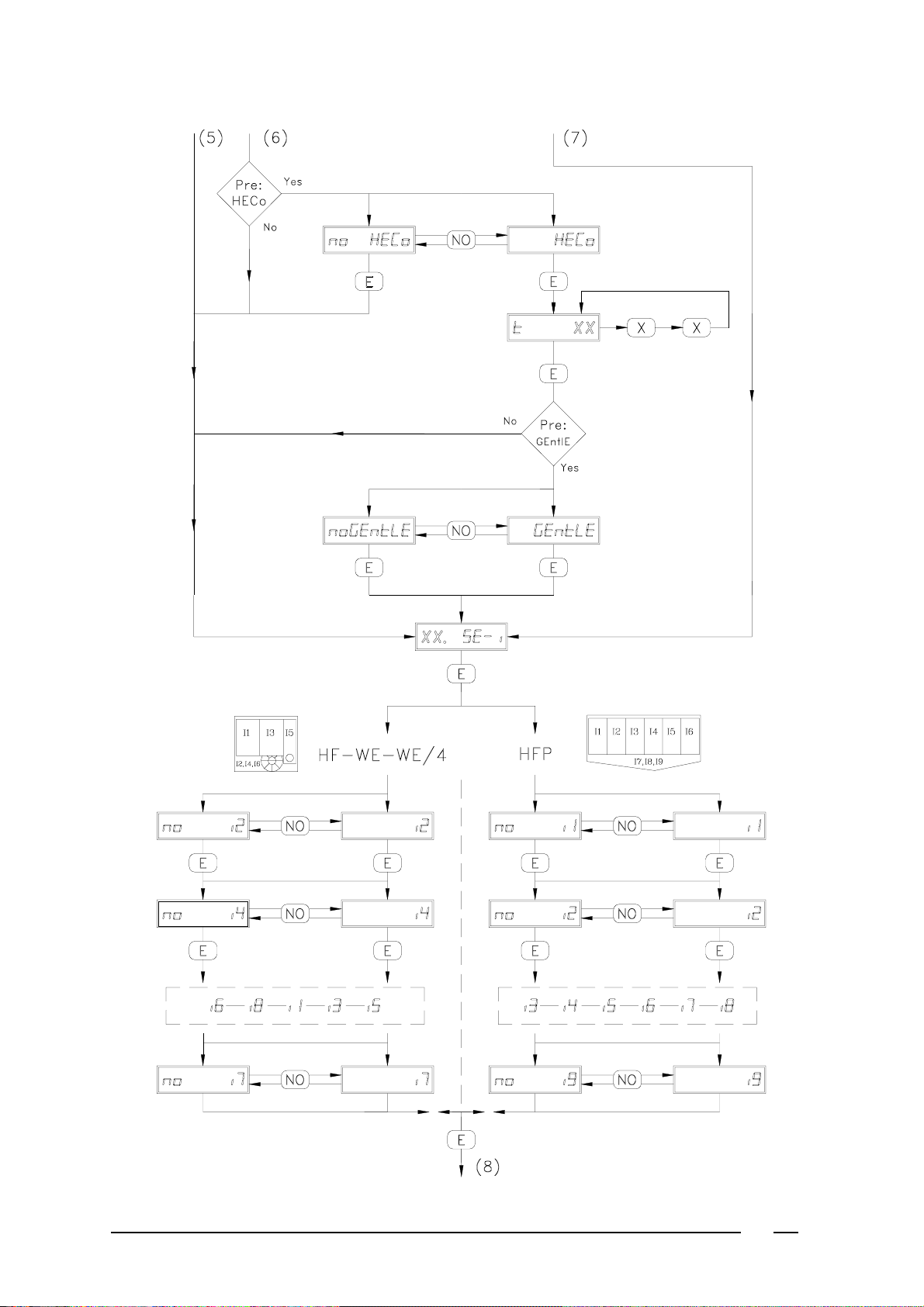

SE-i = Select inlet (Selection of water inlet valves).

11

Page 11

12

Page 12

Preprogramming mode 3

HF - WE - WE/4 HFP

Inlet valve Inlet valve

i2 Soft (tub) i1 Soft (hopper 1)

i4 Warm (tub) i2 Soft (hopper 2)

i6 Hard (tub) i3 Soft (hopper 3)

i8 ---- i4 Hard (hopper 4)

i1 Soft (prewash) i5 Hard (hopper 5)

i3 Warm (main wash) i6 Hard (hopper 6)

i5 Hard (conditioner) i7 Soft (tub)

i7 ---- i8 Warm (tub)

i9 Hard (tub)

13

Page 13

14

Page 14

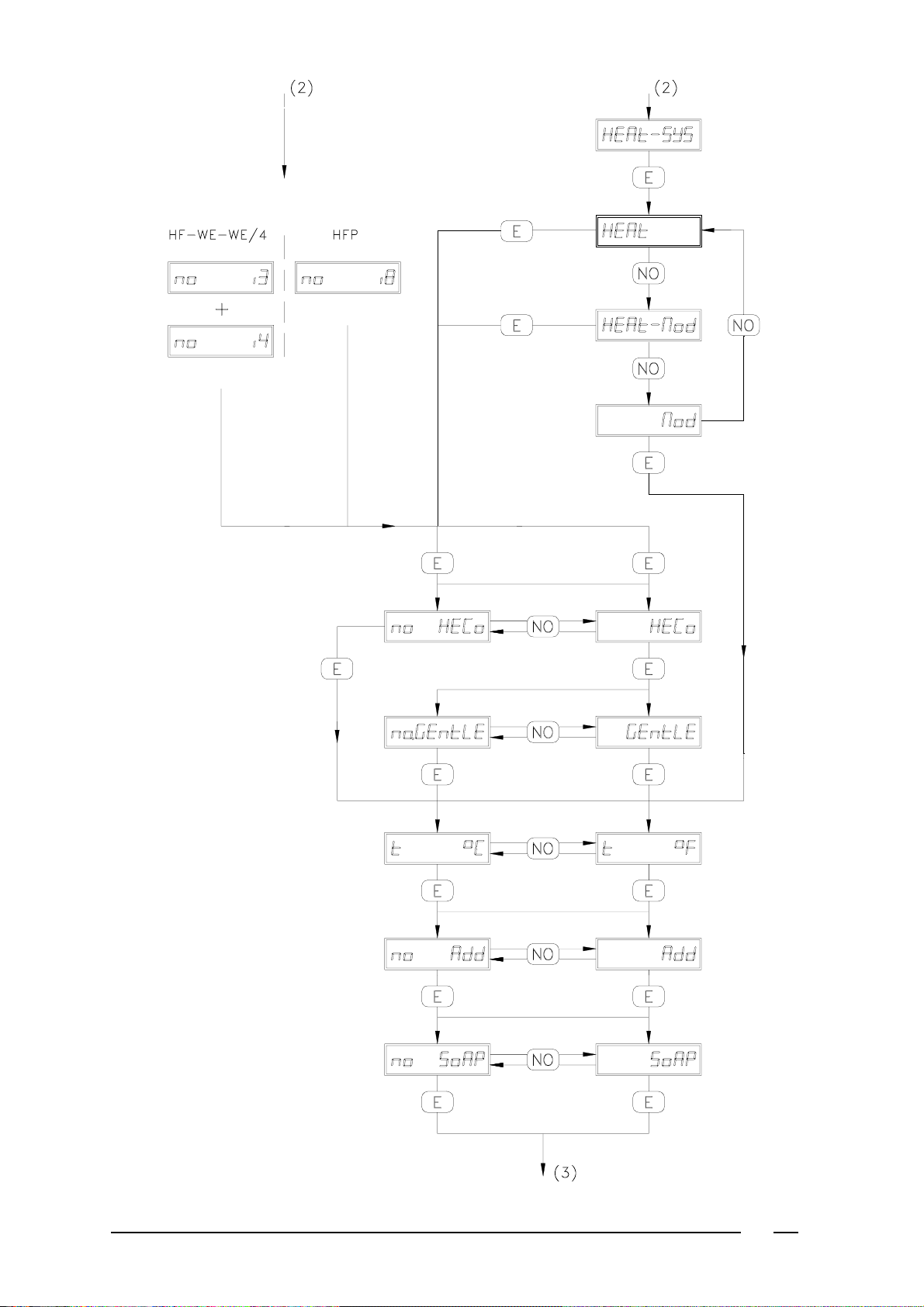

Preprogramming mode 3

HEAt-SYS = Heating System

All machines with hot water feeding can use this temperature modulation technique. This technique consists

of a controlled water feeding -and mixture process which results in most cases in obtaining the correct water

temperature in the wash bath during the filling of the tub. If this function is disabled, a traditional water mixing

procedure will be executed.

The next steps require this function to be either activated or disabled.

Select from:

HEAt (filling and heating system without modulation)

HEAt-Mod (filling and heating system with modulation

Mod (filling procedure consisting only of modulation; no heating system)

If no hot water inlet valves were selected (see SE-i), HEAt will automatically be selected and

HEAt-SYS will not be displayed.

HECo = Execute heating control (temperature control)

This function will temporarily stop the program while the water is being heated to the programmed temperature

GEntlE = The action and stop times of the drum will be switched while the water is being heated

If the machine is not equipped with a heating system (Mod is selected at HEAt-SYS), the function HECo and

GEntlE will not be displayed.

t °C or t °F = Choice to display temperature in °C or °F.

Add = Additional programs

These 3 options (Cool-down, time stop and soak program) can be installed later on in the programming process.

SoAP = Liquid soap injection

15

Page 15

16

Page 16

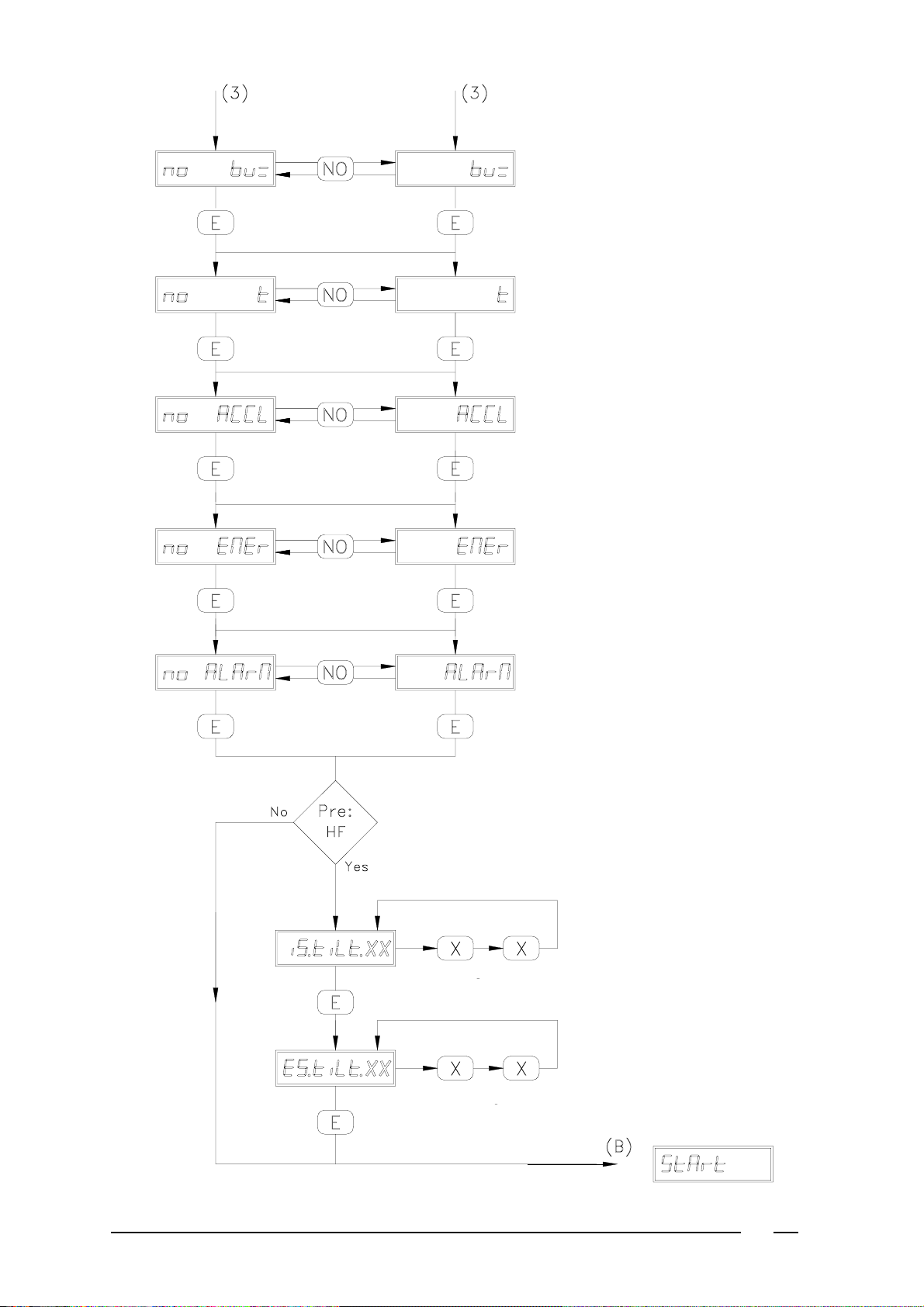

Preprogramming mode 4

Bu = Buzzer at the end of the program

t = Temperature shown on the display

ACCL = Acceleration

With this it is possible to go through a program rapidly in the "operating mode" with the bottom " E ".

EMEr = Emergency stop

The button " STOP " is used as an emergency stop in the "operating mode".

ALArm

This allows to control an external light or sound source through the exit SOAP 6 . This source can e.g. indicate

the end of a program or soak cycle. However, this reduces the number of soap exits from 6 to 5.

The following steps will not be displayed on the WE machines. On all WE machines, the preprogramming is

now finished and the display returns to StArt .

iS.tilt.XX (Intermediate Spin unbalances)

Indicate the number of unbalances allowed during intermediate spin (from 1 to 15) before the spin cycle is

skipped.

ES.tilt.XX (Final Spin unbalances)

Indicate the number of unbalances allowed during final spin (from 1 to 15) before the spin cycle is skipped.

The preprogramming phase is now finished. The display will return to StArt .

17

Page 17

18

Page 18

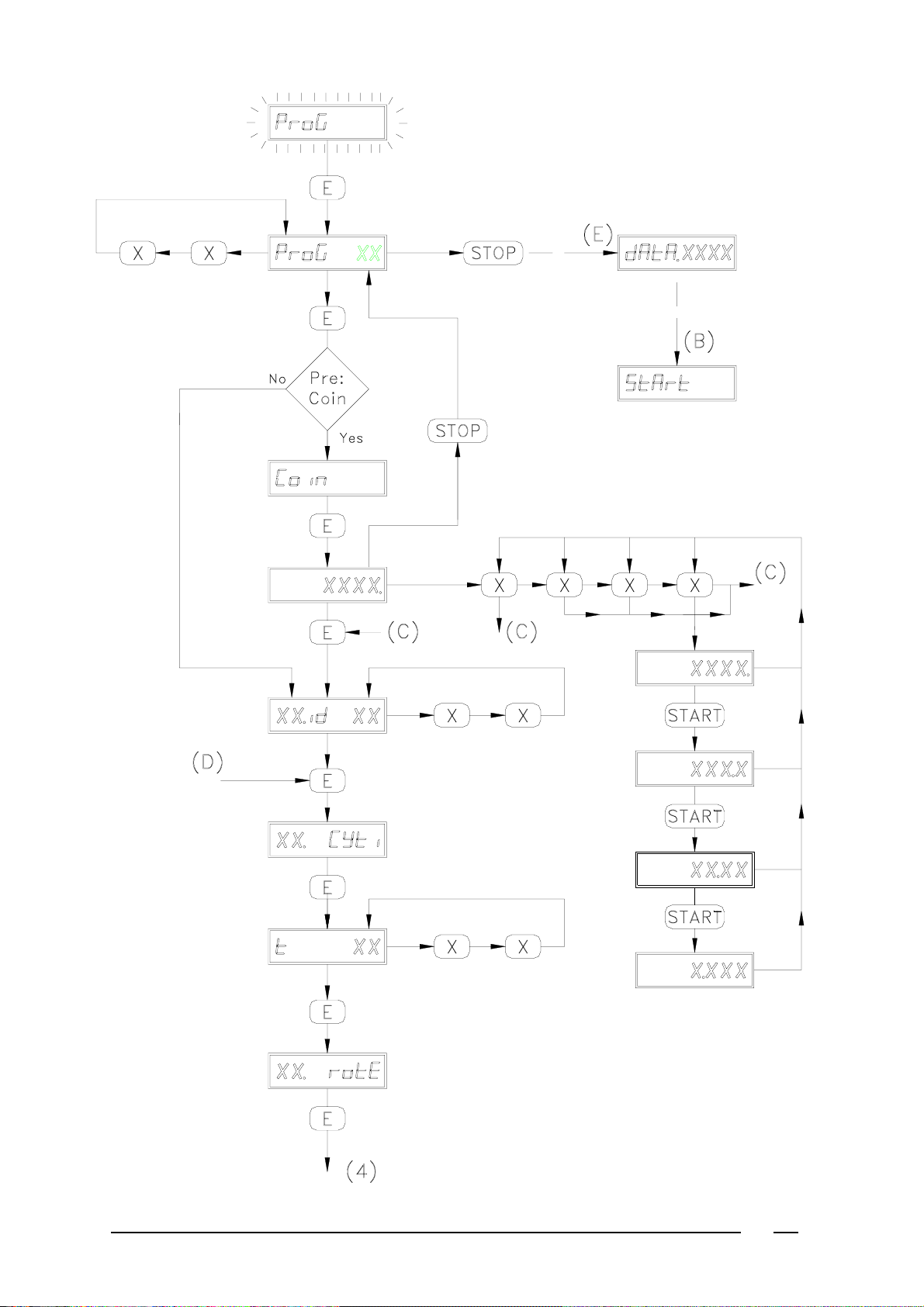

Programming mode 4

Programming

To get into the "programming mode": see Classifications according to modes 2.

The selection here is generally made by altering, if necessary, the command on the display by means of

" N O " ( e. g. " no HECo " becomes " HECo " after pressing " NO "). Confirm this selection with " E ". While

programming, it is possible to return step by step by pressing the " STOP " button.

ProG (flashing) = Programming

Press " E "

ProG XX = The program number that is to be programmed

Put in the required program number with " X,X ".

The led in the button of the selected number on the keyboard will light up. If a program number higher than 9

is selected, press the number followed by " +10 " or " +20 ". Press " E " once more.

The next step depends on the selection during "preprogramming".

- With " no Coin " (without coin meter): transition to " XX.id XX ".

- With " Coin " (with coin meter): transition to " Coin ".

Coin = Amount due for the wash program

Press " E " and then put in the amount with " X,X,X,X ".

If necessary, move the decimal point by pressing " START ".

Press " E " once more.

By pressing " STOP ", it is possible to return to " ProG XX " to change the price of another program.

By pressing " STOP " once more, one can immediately proceed to " StArt ". This enables you to modify the

amount without running through the entire program.

XX.id XX = " Program number " and " Number of program segment ".

The first XX stands for the program number which is put in with " ProG ".

The second XX stands for the number of the segment of the program.

Example:

" 02.id 03 " stands for program 2, segment 3 in this program.

A segment is a part of a program (prewash, main wash, rince, etc.) and always ends with a drain. So in order

to obtain a complete wash cycle, different segments of a program must be put in one after the other. (maximum

99 per wash cycle)

Put in the number of the segment with " X,X " and press " E ".

Should there be insufficient space in the Ram memory, the error message " Ram full " will appear.

XX. CYt i = Cycle time

This is the duration of the wash time for this segment (XX) of the program (without taking into account the

temperature and level controls).

From now on, XX stands for the number of the program segment that was put in.

Press " E ".

t XX = Time (wash time in minutes)

Put in the time with " X,X " ( from 0 to 60 minutes) and press " E ".

If " 0 " was put in, the program immediately skips to " SPin " ( or " no SPin ").

XX. rotE = Rotation (Pause and cycle times)

Press " E ".

19

Page 19

20

Page 20

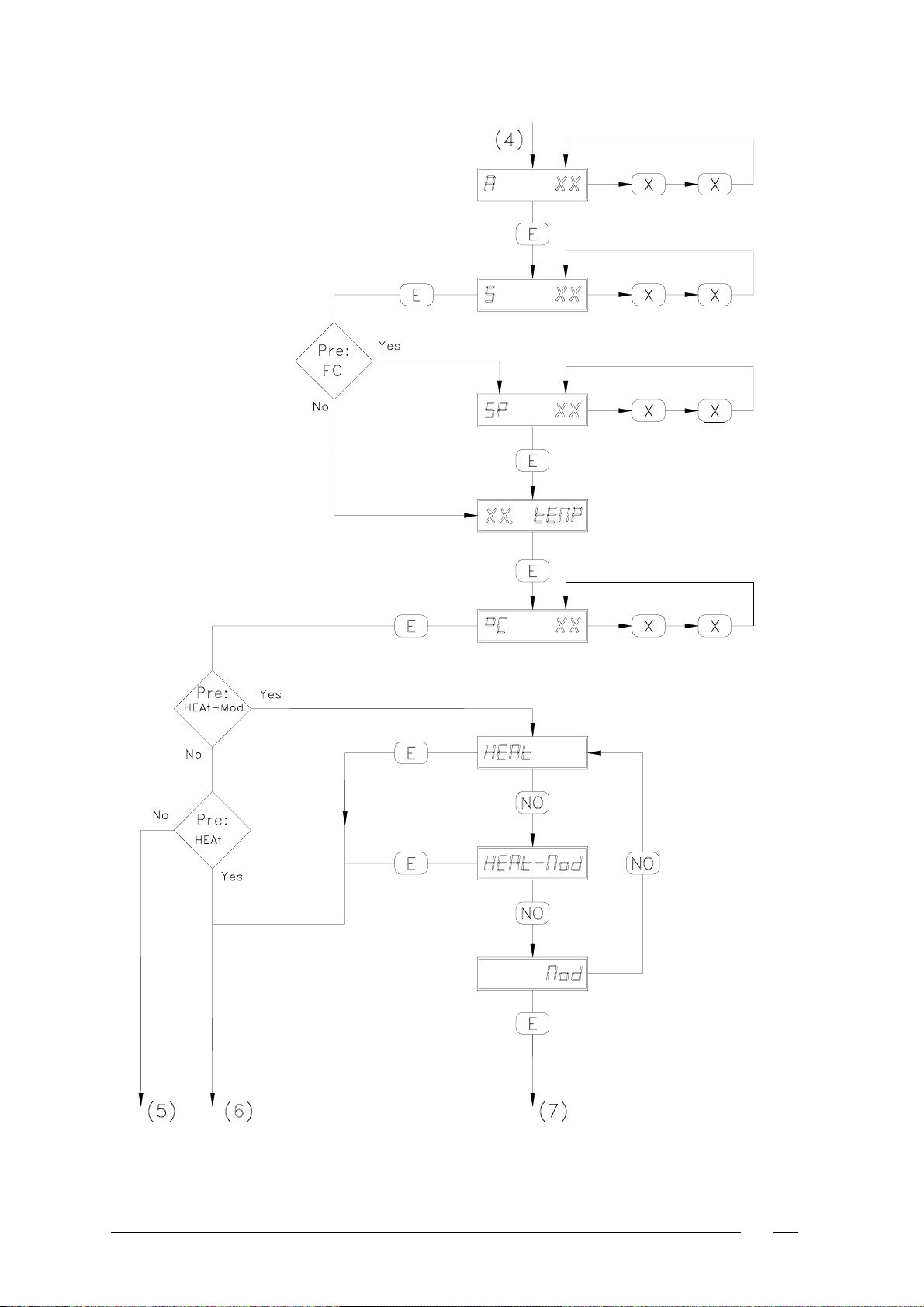

Programming mode 4

A XX = Action Time (Cycle Time)

Put in the action time (0 to 60 seconds) with " X,X ".

If the motor is frequency controlled, one decimal digit will appear which enables you to set the time accurately

to 0.1 seconds.

When " 0 " is put in (cycle without cylinder rotation), the next step (" S XX ") will be skipped.

Press " E ".

S XX = Stop time (Pause time)

Put in the pause time (1 to 60 seconds) with " X,X ".

If the motor is frequency controlled, one decimal digit will appear which enables you to set the time accurately

to 0.1 seconds. (Minimum 0.5 seconds)

Press " E ".

The next step depends on the selection during the "preprogram".

- With " no FC " (no frequency controlled motor): transition to " XX. tEMP ".

- With " FC " (frequency controlled motor): transition to " SP XX ".

SP XX = Speed

Put in the rpm speed of the wash cycle (10 to 50 rpm) with " X,X ".

Press " E ".

XX. tEMP = Temperature (temperature of the bath)

Press " E ".

°C XX = Temperature (Or °F XX °C or °F according to the setting in the Preprogramming).

Indicate the temperature (maximum 95°C) with X,X and press E .

If a cold wash bath is desired, select 0 . Now, the display will immediately show XX. SE-i .

The next step will depend on the setting selected during the preprogramming at HEAt-SYS .

If HEAt-Mod was selected, then NO will allow to choose between:

å

HEAt (heating without modulation) with transfer to HECo or XX. SE-i .

HEAt-Mod (modulation with additional heating) with transfer to HECo or XX. SE-i .

Mod (modulation without additional heating) with transfer to HECo or XX. SE-i .

Now press E .

If HEAt was selected, the display will immediately go to HECo or XX. SE-i .

å

If Mod was selected, the display will immediately go to XX. SE-i .

å

21

Page 21

22

Page 22

Programming mode 4

HECo = Heating control (Temperature control)

If no temperature control is desired, select " no HECo " and press " E ".

If temperature control is desired, select " HECo " and press " E ".

If Mod was selected, the display will immediately go to XX. SE-i .

t XX = Time (Time of the temperature control)

Put in the time when the temperature should be controlled with " X,X " (between " 0 " and the wash time that

was initiated at " Cycle time ") and press " E ".

GEntlE = switching of action and pause time (Put in at " A XX " and " S XX ") during temperature control.

XX. SE-i = Select water inlet valves

Press " E ".

i2 = Inlet 2 (Inlet valve 2) (HF-WE-WE/4) or i1 = Inlet 1 (Inlet valve 1) (HFP machine)

Choose using NO if an inlet valve should be selected or not.

Subsequently press E to continue to the next inlet valve.

In order to save space, not all inlet valves are drawn here. The action involved are identical to the first inlet.

A description of the function of each inlet valve is provided in chapter 3.

If, because of the selection of the wrong inlet valves, the water temperature should mount above the values of

°C XX , then the machine will automatically inject cold water through the inlet valve i2

(on HF-WE-WE/4) or i7 (on HFP machines) in order to protect the linen.

The next step will depend on the function selected during the preprogramming .

- With SoAP (liquid soap injection): transfer to XX. SE-L .

- Without SoAP (liquid soap injection): transfer to SoAP (or no SoAP ).

23

Page 23

24

Page 24

Programming mode 4

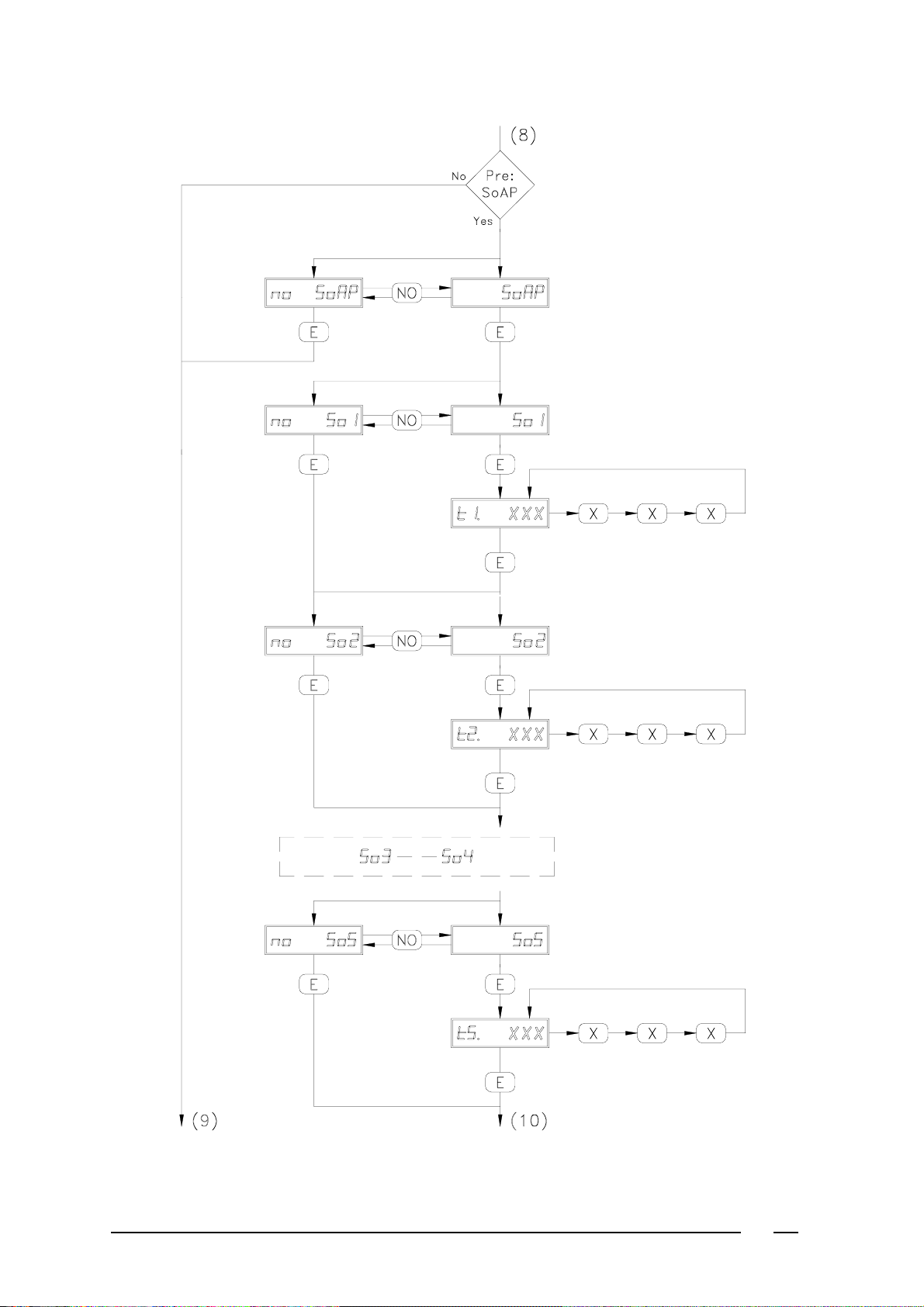

SoAP = Liquid soap injection

If soap injection is not desired, select " no SoAP " and press " E ". (Transition to " XX. SE-L ")

If soap injection is desired, select " SoAP " and press " E ".

SoI = Liquid soap injection 1

Choose with " NO " wether an inlet valve should be selected or not.

Then press " E ".

t1. XXX = Time 1 (Duration of the soap injection 1)

Put in the duration (maximum 999 seconds) with " X,X,X ".

Press " E " to continue to the next soap injection.

Only the blocks of So1, So2 , So5 and So6 are drawn to save space. The others (So3 and So4 ) are identical.

25

Page 25

26

Page 26

Programming mode 4

If during the preprogramming ALArm was selected, then So6 will not be displayed and the display will

immediately move on to XX. SE-L .

Press E .

XX. SE-L = Select level (of water)

Press " E ".

L XX = Level (of water)

Put in the level of water (by trial and error) with " X,X " and press " E ".

The next step depends on the selection made during "preprogramming".

- With " no LECo " (without level control): transition to " Add " (or " no Add ").

- With " LECo " (with level control): transition to " LECo " (or " no LECo ").

When " 0° " has been put in at " XX. tEMP ", the level can be chosen between 0 and 50.

Overflow (Very dirty linen).

å

- Put in " 0 °C " (or in °F) at " XX. tEMP ".

- Then select " no HECo ", and choose level " 00 " when " L XX " appears.

The machine will now continuously take water and drain it via the overflow during the entire wash time.

LECo = Level control

If no level control is desired, select " no LECo " and press " E ".

If level control is desired, select " LECo " and press " E ".

LS XX = Level stop

Put in the water level with " X,X " at which the processor must stop (this is automatically limited by the level

chosen in " L XX ").

The microprocessor will proceed as soon as this water level is reached, and the bath will be filled up to the level

chosen in " L XX ". Then press " E ".

27

Page 27

28

Page 28

Programming mode 4

The next step depends on the selection made during "preprogramming".

- With " no Add " (without auxiliary program): transition to " SPin " (or " no SPin ").

- With " Add " (with auxiliary program): transition to " Add " (or " no Add ").

Add = Additional program (Program extension)

If no program extension is desired, select no Add and press E to confirm (transfer to SPin ).

If a program extension is desired, select Add and press E to confirm.

Now select the desired program extensions using NO : Cool , StoP , STOP.tiME , SoAH ,

SoAH.tiME or again no Add and confirm the selection by pressing E .

XX. Cool = Cool-down

å

CDu XX = Highest cool-down temperature

Select the temperature (between 30 and 85) using X,X and press E to confirm.

CDn XX = Lowest cool-down temperature

Select the temperature (between 30 and 85 and automatically limited to the value selected under

CDu XX ) using X,X and press E to confirm.

StoP = Stop

å

Once in operating mode, the program will stop here, giving the opportunity to e.g. add additional soap or

bleach manually. The water will remain in the tub. See Operating mode: Programmed stop. The stop time

can be programmed up to 999 minutes. Once this stop time has passed, the program will resume

automatically.

StoP.XXX

Select the stop time with X,X,X (between 0 and 999 minutes) and confirm by pressing E .

If 0 was selected, the program will stop indefinitely until the START button is pressed again.

ALArm.XXX

At the beginning of this stop time, the alarm signal can be activated.

Select the duration of the alarm signal using X,X,X (between 0 and 250 seconds).

This option is only displayed if ALArm was selected during the preprogramming.

If " 999 " was selected, the signal will activated during the complete stop time.

SoAH = Soak (soak cycle)

å

Once in operating mode, the program will stop here, The water level will be increased to 25 and the

machine will execute one left-right movement once every 3 minutes. The temperature will remain constant.

See Operating mode: Soaking. The soak time can be programmed up to 999 minutes. Once this soak time

has passed, the program will resume automatically.

SoAH.XXX

Select the soak time with X,X,X (between 0 and 999 minutes) and confirm by pressing E .

If 0 was selected, the program will stop indefinitely until the START button is pressed again.

ALArm.XXX

At the beginning of this soak time, the alarm signal can be activated.

Select the duration of the alarm signal using X,X,X (between 0 and 250 seconds).

This option is only displayed if ALArm was selected during the preprogramming.

If " 999 " was selected, the signal will activated during the complete soak time.

no Add = No Additional (no program extension)

å

29

Page 29

30

Page 30

Programming mode 4

SPin = Spin

If spin is desired, select " SPin " and press " E ".

If no spin is desired, select " no SPin " and press " E ". (Transition to " d0 ", " d1 ", or " d2 ")

SPI- X = Duration of low spin

Put in the duration of the low spin (1 to 9 minutes) with " X " and press " E ".

The next step depends on the selection made during "preprogramming".

- With " no FC " (no frequency controlled motor): transition to " d1 ".

- With " FC " (frequency controlled motor): transition to " LS. XXXX ".

LS. XXXX = Low spin

Put in the speed of low spin (250 to 500 rpm) with " X,X,X,X "and press " E ".

On machines with a drum diameter larger than 850 mm, the high spin speed will be limited to 400 RPM.

d1 = Drain 1 (Drain valve 1)

Select " d1 " or " d2 " with " NO " and confirm with " E ".

d2 = Drain 2 (Drain valve 2)

SP2- X = Duration high spin

Put in the duration of high spin (maximum 15 minutes) with " X " and press " E ". (If no high spin is desired,

put in " 0 ")

The next step depends on the selection made during "preprogramming".

- With " no FC " (frequency controlled motor): transition to " XX. dEti ".

- With " FC " (frequency controlled motor): transition to " HS. XXXX ".

HS. XXXX = High spin (high spin speed)

Select the high spin speed RPM using X,X,X,X (maximally double the low spin speed) and press E to

confirm.

On machines with a drum diameter larger than 850 mm, the high spin speed will be limited to 800 RPM.

XX. dEti = Delay time

Press " E ".

td XXX = Delay time

Put in time with " X,X,X " and press " E ".

Required time: 30 to 180 seconds after spin 1

60 to 180 seconds after spin 2

31

Page 31

32

Page 32

Programming mode 4

d1 = Drain 1

Select " d0 ", " d1 " or " d2 " with " NO " and confirm with " E ".

d2 = Drain 2

d0 = Drain 0 (no drain)

Press " E " to select no drain. (Transition to the last program segment)

dt XXX = Drain time

Select the drain time using X,X,X (maximally 180 seconds) and press E to confirm. Now select between

following functions using NO the movement of the drum during draining of the water: WASh , diSt

, JoLt and DrAin . Press E to confirm.

WASh = Wash action during drain

å

diSt = Distribution (distribution speed) (not for machines type WE (no HF))

å

å

å

t= XXXX = Time

Distribution of washload during drain

Jolt = Short spin (10 seconds low spin after distribution)

Introduce for this purpose minimum 60 seconds with " Drain ".

Drain=Drain no action

Drain of water without action of drum.

Confirm selection with " E ".

This is the duration of the program segment.

Press " E ".

33

Page 33

Page 34

Programming mode 4

FrEE==XX = The maximum of segments available for programming

You can program a maximum of 160 segments.

Press " E ".

End = End of this program segment

Press " NO " to proceed automatically to the next program segment (transition to " XX.id YY ").

YY stands for the next program segment number.

Press " E " to put an end to the program.

Tu XXX = Tumble

This will be executed with a frequency of 6 sec. wash action and 9 sec. stop time. In case of frequency controlled

machines, the speed will be equivalent to the lowest programmed speed in that program.

Select the tumble time using X,X,X (from 30 to 999 sec.) and press E to confirm.

If no tumbling is required, 0 can be selected. There will then be a waiting time of 1 minute at the end of the

program.

ALArm.XXX

Here, the alarm can be activated again.

Select the duration of the alarm signal using X,X,X (between 0 and250 seconds).

This option is only displayed if ALArm was selected during the preprogramming

.

If " 999 " was selected, the signal will be activated until the door is opened.

Data.XXXX

The new " checksum" is displayed for a few seconds at the end of programming. Then it proceeds to " StArt

".

Page 35

Page 36

Programming mode 4

Insert and delete a program segment

Start the programming procedure up to " XX.id XX".

To insert a program segment

å

Press " START ".

XX. inS = Insert

Then press " E ".

The program segment " XX " moves up one place to the following number. " XX.id XX " will appear again

on the display. This program segment can now again be programmed.

Example:

Program " 01 " with 4 program segments (01, 02, 03, 04).

Suppose one segment should be inserted between 02 and 03.

Select " 01.id 03" and press " START ". " 03 ins " appears on the display. Press " E ". Now " 01.id 03 " will

appear once more. The program segment 03 must be put in again.

The previous segment 03 moves up to 04 and the previous 04 will become 05.

If there is not enough space in the Ram memory, the error message " Ram full " will appear.

To delete a program segment

å

Press " STOP ".

XX. del (flashing) = delete

Press " E ".

The program segment " XX " will now be deleted. The following program segments will move back one

place.

Example:

Program 01 with 4 segments (01, 02, 03, 04).

Segment 02 must be deleted.

Select " 01.id 02 " and press " STOP ". " 02 del " will appear on the display. Press " E ".

Now " 01.id 02 " will appear once more. This was previously program segment " 03 ". Program segment

04 was moved back to 03.

Program tables

The table on the next page shows how the programmed data are registered.

Page 37

Page 38

Copying mode 5

Copying mode

To get into the copying mode: see chapter Classification according to modes 2.

The PC 30 microprocessor is provided with 10 standard programs (30 to 39). These programs can be immediately

implemented.

On these places they cannot be modified. To modify them or to use them as structure for another program, you must

first copy them to a program number between 0 and 29. See further.

Other self-made programs can be copied the same way to other numbers (between 0 and 29) so you can use them

as a structure for a new program. This saves a lot of time when you want to program various simular programs.

CoPY PrG = Copy program

To confirm press " E ".

To cancel press any other key. (Transition to " StArt ")

SourCE.XX = Program to be copied

Put in the number of the program to be copied with " X,X " and confirm with " E ".

dESt .YY = Destination (destination of the copied program)

Put in the number of the program with " Y,Y " and confirm with " E ".

XX .... YY = Confirmation of copying

To confirm, press " E ". (Transition to " StArt ")

To cancel, press any other key. (Transition to " StArt ")

In case there isn't enough space left in the Ram memory, the error detection " Ram full " will appear.

Page 39

Operating mode 6

To get into the "operating mode": see chapter " Classification according to modes ( 2 )".

To select a program

ProG XX = Program XX (e.g. program 01)

If necessary, select another program.

The led in the button of the selected program on the keyboard lights up.

To select a program number higher than 9 you must put in the number and add " +10 " or " +20 ".

å

å

To start a program

Press " START "

The program has now started.

" XX. XX. XX " will appear on the display (e.g. " 01. 41' 15 ")

01 = program segment number

41' 15 = Total remaining program time

Example: program 15: put in " 5 " and " +10 " (2 leds light up).

To stelect one of the standard programs ( 30 to 39) you must put in " +20 " and "+10" afterwards.

Example: program 35: put in " 5 " + " +20 " + " +10 " (3 leds light up).

When the door is not properly closed, " door. oPEn " will appear.

When selecting a program number that doesn't contain a program yet, " Error = 02 " (flashing) will appear

for 10 seconds.

Program process

The remaining program time (in seconds) is displayed during the program.

After each program segment appears the next program segment number.

" XX. XX' XX " (e.g. " 01. 41' 15. ")

When the machine is taking water, the first decimal point will light up.

As long as there is also a level control active, this decimal point will flash.

" XX. XX' X.X " (e.g. " 01. 41' 1.5 ")

When the bath is been heated, the second decimal point will light up.

As long as there is also a temperature control active, this decimal point will flash.

" XX. XX' .XX " (e.g. " 01. 41' .15 ")

When the machine is draining water, the third decimal point will light up.

As long as there is also a distribution going on, this decimal point will flash.

" XX. XX'. XX " (e.g. " 01. 41'. 15 ")

When the machine is in high spin, the forth decimal point will light up.

In case of a low spin, the light will flash.

" PXX. End "

When the program has come to an end, " PXX. End " will appear (e.g. " P01. End

").

The buzzer sounds for 10 seconds (when de buzzer " bu= " was activated in the

preprogam).

If the alarm signal was programmed (ALArM.XXX), this will now be executed.

When the door is opened, " StArt " will appear again.

40

Page 40

Operating mode 6

In case of a programmed start (not with coin-op version)

After the program has been selected, press the " START " button for at least 5 seconds.

" dELAY .XX " will appear on the display.

The start can now be delayed per hour by entering a number between 0 and 99. Then press the " START " button

once more so that the countdown can begin (decimal point flashes). During the last hour of the countdown the

minutes are shown (flashing).

Remark:

If you want to cancel the countdown, press " STOP ".

Changing to another program

It is possible to change to another program during the first minutes after a start. Herefore you put in another

program number.

On the display " P.XX.StArt " will appear. " P.XX " stands for the new program. Then confirm by pressing

" START ".

Remark:

In case of coin-op machine, if the new program is more expensive, the additional amount required for this

program is shown in " XXX.XX ". The originally selected program will continue until the additional amount is

inserted. If this is not inserted, the original program will continue 3 minutes after the first start.

One-time modification of the level, wash time and temperature input.

Select a program number.

Before starting this program press " NO " first and then press " E " while keeping " NO " depressed. For each

program segment " L XX " followed by " t XX " and then " °C XX " will appear on the display. Adjust the data

if necessary and press " E " to continue to the wash time and temperature input of the next segment.

When all input is adapted according to your requirements, press " START " to initiate the program.

Remark:

The values of " LECo XX " and " HECo XX " are modified by the same values up to a minimum of " 00 ".

The program will be executed only once with the modifications that have been applied in this manner.

Control of the temperature of the bath

By pressing the button " T " it is possible to read the temperature and the rotation speed of the drum on the

display.These functions are only operational if the temperature reading function ("t") was selected in the "pre

program mode".

Press " T " once:

å

The temperature of the bath is displayed (" t=XX°C " followed by one horizontal bar).

Press " T " twice:

å

The programmed temperature of this segment is displayed ( " t=XX°C "followed by two horizontal bars).

Press " T " three times:

å

The highest temperature for this program is displayed ( " t=XX°C " followed by three horizontal bars).

When the displayed temperature is less than 25°C , " Cold " will appear.

Press " T " three times:

å

The rotation speed will be displayed if it is a frequency controlled machine ("FC"in th pre-progam

mode).

41

Page 41

Operating mode 6

Control of a program in progress

By pressing the " T " button for longer than 3 seconds and then letting go of this button, all steps that are put

in per program segment will be shown one after the other during 1 second. By pressing " T " once more and

keeping it depressed, the last step displayed is shown during this time span. After letting go of the " T " button

the next steps will be displayed.

At the end of a program segment " EntEr " will appear for about 3 seconds. If you want to proceed to the display

of the following segment, you must keep the " E " button depressed during this period. If not, the normal program

process will be displayed.

Rapidly going through a program

It is possible to go through the program rapidly by pressing " " (that is if acceleration " ACCL " is selected

in the "preprogram").

The seconds on the display are counted down faster. This acceleration is interrupted each time you come to an

important step (drain, cooldown, etc.). Then press the acceleration button to continue rapidly.

By means of this button it is possible to skip parts or the rest of the program.

It is not possible to advance the program during tumbling.

Programmed stop

When a time stop is programmed, the program will stop in that segment. The water remains in the tub, there is

no more drum rotation and the display shows StoP .

After pressing the START button once more, the program resumes.

Stop with predetermined stop time.

å

If a predetermined stop time was programmed, the display will alternately show StoP.tiME and the

remaining stop time counting down. After the stop time has elapsed, the program will resume automatically.

The stop time can also be interrupted by pressing the START button.

Alarm signal.

å

If the alarm signal was programmed, this will be executed at the beginning of the stop time.This can be

interrupted by pushing the " START ", or the " STOP "button.

Soaking (SoAH)

When a soak is programmed, the program will stop in that segment. The water level will be brought to 25 ,

the temperature will be kept constant and there will be one left-right drum rotation every 3 minutes.

After pressing the START button once more, the program resumes.

Soak with predetermined soak time.

å

If a predetermined soak time was programmed, the display will alternately show "SoAh.tiME"and the

remaining soak time counting down. After the soak time has elapsed, the program will resume automatically.

The soak time can also be interrupted by pressing the START button.

å

Alarm signal.

If the alarm signal was programmed, this will be executed at the beginning of the soak time. This can be

interrupted by pushing the " START ", or the " STOP "button.

42

Page 42

Operating mode 6

Time Stop (not on the coin version)

By keeping pressing the STOP button for more than 3 seconds, the program will go into time stop (only

if EMEr was selected in the preprogramming mode)

This can be used to e.g. extend a program segment in case of heavily soiled linen. The time will be stopped and

the step currently activated will be preformed indefinitely. The programmed water level and temperature will

be kept constant. During the time stop the display shows XX.tistop .

Now, the stop time can be entered if so desired. Press E to confirm.

The display now shows XX.ti XXX . Enter the desired stop time using X,X,X (between 1 and 999 minutes)

and press "E " again. The display will now alternately show StoP.tiME and the remaining stop time counting

down. After the stop time has elapsed, the program will resume automatically.

If no stop time was selected, the stop time will be indefinite until the START button is pressed again.

A " time stop " during the final spin will be automatically interrupted after 20 minutes.

Interruption and stopping the program

When the " STOP " button is briefly pressed , the text of the display flashes and after 5 seconds the machine

starts to drain the water (that is if an emergency stop " EMEr " was selected in the "preprogram").

The buzzer starts working after 30 seconds and " oPEn door " will appear and the door should be opened. Then

" CLoSE " appears.

After closing the door again you can:

- continue the program by pressing " START "

- cancel the program by pressing " STOP ".

The stop function has a delay of 60 seconds during spin 1 and a delay of 120 seconds during spin 2.

Adding water (not with coin-op version)

If you press one of the buttons from " 1 " to " 8 " during a program, the corresponding water inlet valve is opened.

While pressing this button, the number of the selected inlet valve and the level is shown in

" iX LXX ". This information is displayed for 3 seconds after the button is released.

This function does not work during the first 3 minutes of a program.

Draining water (not with coin-op version)

When you press button " 9 " during a program, drain valve " D1 " is opened.

When you press button " 0 " during a program, drain valve " D2 " is opened.

While pressing this button, the number of the selected drain valve and the level is shown in " dX LXX ". This

information is displayed for 3 seconds after the button is released.

This function does not work during the first 3 minutes of a program.

Heating the bath

By keeping the button " +10 " depressed during a program, the heating is activated. (Max. 95°C).

While pressing this button, the temperature of the bath is shown with " °C XX " (or " °F XX ").

This function does not work during the first 3 minutes of a program.

43

Page 43

Operating mode 6

Adding soap (not with coin-op version)

By pressing the button " +20 " during a program " SoX tXXX " appears.

If you then keep one of the buttons 1 to 6 depressed, soap is added through one of these valves.

While pressing the button, the selected soap valve and the time of the soap adding is displayed.

This function does not work during the first 3 minutes of a program.

Error message

When a technical error was detected during the program, " Error =XX " will appear at the end of the program

instead of " PXX.END ".

" Error = 04 " : the filling time was longer than 15 minutes

" Error = 05 " : the required temperature was not reached after 60 minutes of heating

" Error = 06 " : the door lock was released during the program

" Error = 07 " : there is still water in the tub at the end of the program

" Error = 08 " : the temperature sensor was out of order

" Error = 09 " : the thermo-magnetic protection was activated during the program

" Error = 10 " : the tilt switch was activated during the start of the program

" Error = 11 " : there was still water in the tub at the start of the program

" Error = 12 " : there was still water in the tub 3 minutes after drain, later the heating hasn't been

activated anymorre.

" Error = 13 " : during the extraction, there was no rotation speed detected (only with frequency controlled

motors).

To get back to " PXX. End " : open the door. (Attention with " Error 07 ").

Total operating hours, received coins

If you press " E 2 2 3 " before starting, the total operating hours are shown during 5 seconds.

In case of a coin-op machine " coin " will also appear after 3 seconds, followed by the number of received coins

during 5 seconds.

Overview of the total amount of steps per program.

By entering E 7 8 8 before starting a program, the display will show the first program number and the the

total amount of steps in that program.

Example: Prg 01. 08 = Program 1 containing 8 steps.

After one second, the display will automatically switch to the next program number. After the last program, the

total amount of free memory steps will be displayed with FrEE = XX .

Example: FrEE = 89

By pressing NO continuously, this overview is interrupted and the display remains fixed.

By pressing E , this overview is terminated and the display skips to the total amount of free memory steps

available.

Example: FrEE = 89

44

Page 44

45

Page 45

Test mode 7

The test mode is installed to be able to locate technical problems and is especially directed to specialized

technicians.

To get into the " test mode ":

- Turn the key switch at the front to " PROG ".

- Press " E 2 1 7 " (press quickly one after the other).

" tESt " will appear on the display.

Put in a number from " 1 " to " 7 " to select one of the following test functions:

Test 1: Control of the 8 entry contacts

With this function you can see if the entry contacts are open or closed.

Entry 1: Thermo-magnetic motor protection

Entry 2: key switch in display

Entry 3: door lock S2

Entry 4: door lock S1

Entry 5: tilt switch

Entry 6: rotation sensor

Entry 7: coin meter 2

Entry 8: coin meter 3

Example:

" t1.inP 1.o " = Entry 1 (thermo-magnetic motor protection) open

" t1.inP 1.c " = Entry 1 (thermo-magnetic motor protection) closed.

To control the next entry, press " E ".

To control the previous entry, press " NO ".

To stop this test, press the " STOP " button.

Test 2: Control of the DIP switches on the main print board.

In this test it is possible to verify whether the switches are open or closed.

In case of a machine type HF, WE245/304, or WE "high spin", these DIP

switches are used to determine how long the spin motor is activated during

acceleration to the distribution speed.

DIP switch 8: 1 second

HF 65 380V, HF 76 380V, HF 95 380V, WE 245/304, WE "high spin", all the machines with frequency

controlled motor.

DIP switch 7: 2 seconds

HF 110, HF 132, HF 165, HF 145, HF 176, HF 205, HF 234.

DIP switch 6: 3 seconds

HF 65 220V, HF 76 220V, HF 95 220V, HF 245, HF 304

Example:

" t2.diP 8.o " = DIP switch 8 is open.

" t2.diP 8.c " = DIP switch 8 is closed.

When a DIP switch is activated, " HF " will automatically be selected in the "preprogram".

To stop this test, press the " STOP " button.

46

Page 46

Test mode 7

Test 3: coin meters

In this test the operation of the coin meter is tested.

" t3.0 " will appear on the display.

Every time a coin is inserted, the sum is made of all inserted coins and the new value will appear.

By pressing the 0 button this value returns to 0.

Press the " STOP " button to leave this test.

Test 4: Control of water level sensor

In this test you can see the water level changing per 1/10 unit.

" t4.LEV 00.0 " will appear.

By pressing " START " now the drain valve will be closed and water is taken through I2.

The respective level is shown on the display.

If you press " STOP " the water inlet is temporarily interrupted until you press "START " once more.

To stop this test, press the " STOP " button.

Test 5: Control of temperature sensor

" t5. XX.X " will appear on the display. " XX.X " stands for the respective temperature in the tub.

To stop this test, press the " STOP " button.

Test 6: Control of the 24 exits

With this test you can activate each exit contact one after the other.

Exit 1: soap inlet 1

Exit 2: soap inlet 2

Exit 3: soap inlet 3

Exit 4: soap inlet 4

Exit 5: soap inlet 5

Exit 6: drain valve 1

Exit 7: drain valve 2

Exit 8: door lock

Example:

" t6.out 22.o " = Exit 22 (water inlet I2) is open.

You can close this exit contact by pressing 1 and water is taken via this valve.

On the di.splay appears:

" t6.out 22.c " = Exit 22 (water inlet I2) is closed.

To open this entry contact again, press 0.

To control the next exit, press " E ".

To control the previous exit, press " NO ".

To stop this test, press the " STOP " button.

Exit 9: high spin

Exit 10: low spin

Exit 11: distribution speed

Exit 12: wash action right

Exit 13: wash action left

Exit 14: heating

Exit 15: water inlet cool-down

Exit 16: water inlet I8

Test 7: Keyboard

" t8. -- " appears on the display.

For each key you press on the keyboard, the respective function is shown.

To stop this test, press the " STOP " button twice.

Exit 17: water inlet I7

Exit 18: water inlet I6

Exit 19: water inlet I5

Exit 20: water inlet I4

Exit 21: water inlet I3

Exit 22: water inlet I2

Exit 23: water inlet I1

Exit 24: soap inlet 6

Ram reset

With this function the entire data in the Ram memory is erased.

Press 0 when " tESt " appears.

On the display " Code " is shown.

Put in " 7 5 3 " (press quickly one afer the other).

By doing a Ram reset all the manually programmed program segments are erased.

47

Page 47

Liquid soap connection 8

Connection of the liquid

soap hoses

Electrical connection of

the liquid soap pumps

A rubber connection has been placed over the air break opening at

the back of the machine. There are 5 holes in this rubber connection,

through each of which a liquid soap hose can be driven (S1...S5).

Press the hoses until they appear well inside the soap dispenser.

The central gap in the rubber connection remains and serves as air

breaker.

On machines equipped with a liquid soap connection, connect the

wires directly on the print board next to the ground wire connection

(option). Connect as indicated on the wiring diagram.

The two connectors on the right give a tension of 220V ~ (max. 4A)

which can be applied to drive 220V ~ soap pumps. If more than 4A

is required, an external tension will have to be used.

6 connections have been provided, of which one (S6) can be used to

drive a waterproofing pump (e.g. for rain coats, etc.).

The 220V can be transformed to other values to drive other type soap

pumps.

Example: pumps 24V ~.

Also, pumps with different operating tension can be combined.

Example: 5 pumps 220V ~ and 1 pump 24V ~.

With an external tension 24V DC

48

Page 48

Standard programs 9

You can see on the naxt page the composition of the standard programs.

Program 30: Hot wash 1 40° - 90°

Program 31: Wamr Wash 40° - 60°

Program 32 : Synthetisch 1 35° - 40°

Program 33 : Synthetisch 2 40°

Program 34 : Fijne was 30° - 30°

Program 35 : Wol 20°

Program 36 : Dekbed 30° - 40°

Program 37 : Gordijnen 30° - 40°

Program 38 : Stijven

Program 39 : Kookwas 2 40° - 90° (Warme tussenspoeling)

49

Page 49

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

Total time :

41'30"30

Name:

01 02 03 04 05 06 07 08

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

50

Page 50

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

Total Time: Name:

01 02 03 04 05 06 07 08

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

51

Page 51

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

Total time :

Name:

01 02 03 04 05 06 07 08

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

52

Page 52

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

Total Time: Name:

01 02 03 04 05 06 07 08

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

53

Page 53

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

01 41'30" Hot wash

Total time :

Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

4141414141

4090000

/////

XX///

/////

37///

/////

X/X/ /

XX///

///XX

X////

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

13 10 20 20 16

10 10 13 13 13

1 / 111

500 / 500 500 500

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////1000

30 / 303060

8.30 14.30 3.30 3.30 11

30

54

Page 54

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

01 41'30" Hot wash

Total Time: Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

28 28 28 28 28

4090000

/////

XX///

/////

37///

/////

X////

/X///

/////

/////

/////

////X

X/X/ /

XX///

///XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

20 20 25 25 20

20 20 25 25 20

1 / 111

400 / 400 400 400

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////800

30 / 303060

8.30 14.30 3.30 3.30 11

30

55

Page 55

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

30 41'30" Hot wash 1

Total time :

Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

4141414141

4090000

/////

XX///

/////

37///

/////

X/X/ /

XX///

///XX

X////

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

13 10 20 20 16

10 10 13 13 13

1 / 111

500 / 500 500 500

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////1000

30 / 303060

8.30 14.30 3.30 3.30 11

30

56

Page 56

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

30 41'30" Hot wash 1

Total Time: Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

28 28 28 28 28

4090000

/////

XX///

/////

37///

/////

X////

/X///

/////

/////

/////

////X

X/X/ /

XX///

///XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

20 20 25 25 20

20 20 25 25 20

1 / 111

400 / 400 400 400

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////800

30 / 303060

8.30 14.30 3.30 3.30 11

30

57

Page 57

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

31 41'30" Warm wash

Total time :

Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

4141414141

4060000

/////

XX///

/////

37///

/////

X/X/ /

XX///

///XX

XX///

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

13 10 20 20 16

10 10 13 13 13

1 / 111

500 / 500 500 500

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////1000

30 / 303060

8.30 14.30 3.30 3.30 11

30

58

Page 58

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

31 41'30" Warm wash

Total Time: Name:

01 02 03 04 05 06 07 08

714222

12 12 15 15 15

33333

28 28 28 28 28

4060000

/////

XX///

/////

37///

/////

XX///

/X///

/////

/////

/////

////X

X/X/ /

XX///

///XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

20 20 25 25 20

20 20 25 25 20

1 / 111

400 / 400 400 400

X30XXX

/////

/////

/X///

/////

/////

/////

////7

////800

30 / 303060

8.30 14.30 3.30 3.30 11

30

59

Page 59

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

32 27'30" Synthetics 1

Total time :

Name:

01 02 03 04 05 06 07 08

410222

10 10 12 12 12

44444

4141414141

35 40 0 0 0

/////

XXXXX

/////

24///

/////

XXX / /

XX///

///XX

X////

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

13 13 20 20 16

10 10 13 13 13

////2

////400

30 30 30 30 X

/////

/////

XXXX /

/////

/////

/////

////2

////800

////60

4.30 10.30 2.30 2.30 7

30

60

Page 60

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

32 27'30" Synthetics 1

Total Time: Name:

01 02 03 04 05 06 07 08

410222

10 10 12 12 12

44444

28 28 28 28 28

35 40 0 0 0

/////

XX///

/////

24///

/////

X////

/X///

/////

/////

/////

////X

XXX / /

XX///

///XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

20 20 25 25 20

20 20 25 25 20

////2

////350

30 30 30 30 X

/////

/////

XXXX /

/////

/////

/////

////2

////700

////60

4.30 10.30 2.30 2.30 7

30

61

Page 61

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

33 19'30" Synthetics 2

Total time :

Name:

01 02 03 04 05 06 07 08

8222

10 10 10 10

5555

35 35 35 35

35000

////

X///

////

3///

////

XX / /

X///

//XX

X///

////

///X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

13 20 20 16

10 13 13 13

///3

///500

30 30 30 X

////

////

XXX /

////

////

////

////

////

///30

8.30 2.30 2.30 5.30

30

62

Page 62

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

33 19'30" Synthetics 2

Total Time: Name:

01 02 03 04 05 06 07 08

8222

10 10 10 10

5555

25 25 25 25

35000

////

X///

////

3///

////

X///

////

////

////

////

///X

XX / /

X///

//XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

20 25 25 20

20 25 25 20

///3

///400

30 30 30 X

////

////

XXX /

////

////

////

////

////

///30

8.30 2.30 2.30 5.30

30

63

Page 63

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

34 22' Gentle wash

Total time :

Name:

01 02 03 04 05 06 07 08

47222

33555

10 10 10 10 10

30 30 30 30 30

30 30 0 0 0

/////

XX///

/////

23///

/////

XXX / /

/////

///XX

X////

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

20 20 20 20 16

13 13 13 13 13

////2

////500

30 30 30 30 X

/////

/////

XXXX /

/////

/////

/////

/////

/////

////30

4.30 7.30 2.30 2.30 4.30

30

64

Page 64

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

34 22' Gentle wash

Total Time: Name:

01 02 03 04 05 06 07 08

47222

33555

10 10 10 10 10

25 25 25 25 25

30 30 0 0 0

/////

XX///

/////

23///

/////

X////

/X///

/////

/////

/////

////X

XXX / /

/////

///XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

25 25 25 25 20

25 25 25 25 20

////2

////400

30 30 30 30 X

/////

/////

XXXX /

/////

/////

/////

/////

/////

////30

4.30 7.30 2.30 2.30 4.30

30

65

Page 65

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

35 18'30' Cold wash

Total time :

Name:

01 02 03 04 05 06 07 08

9222

3336

12 12 12 12

25 25 25 25

20000

////

X///

////

3///

////

XX / /

////

//XX

X///

////

///X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

18 18 18 16

13 13 13 13

///1

///400

30 30 30 X

////

////

XXX /

////

////

////

////

////

///30

9.30 2.30 2.30 3.30

30

66

Page 66

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

35 18'30" Cold wash

Total Time: Name:

01 02 03 04 05 06 07 08

9222

3336

12 12 12 12

22 22 22 22

20000

////

X///

////

3///

////

X///

////

////

////

////

///X

XX / /

////

//XX

PEIL

PEILSTURING

PROG. UITBREID.

LAAGZWIEREN

AFVOER

HOOGZWIEREN

VRIJLOOP

TIJD

ONTWARREN

ALARM

25 25 25 20

25 25 25 20

///1

///350

30 30 30 X

////

////

XXX /

////

////

////

////

////

///30

9.30 2.30 2.30 3.30

30

67

Page 67

Program :

SEGMENT

WASH TIME

TEMPERATURE

HEAT. SYS

HEATING.CONTROL

WASH ACTION

SOFT (TUB)

WARM (TUB)

HARD (TUB)

SOFT (VOORWAS)

WARM (PREWASH)

HARD (CONDITIONER)

SOAP INJECTION

36 22' Duvet

Total time :

Name:

01 02 03 04 05 06 07 08

66222

55555

10 10 10 10 10

30 30 30 30 30

35 40 0 0 0

/////

XX///

/////

22///

/////

XXX / /

X////

///XX

X////

/X///

////X

LEVEL

LEVEL CONTROL

ADD PROGRAM.

LOW SPIN

DRAIN

HIGH SPIN

DELAY

TOTAL TIME

TRUMBLE

ALARM

20 20 20 20 20

10 10 15 15 15

////1

////500

30 30 30 30 X

/////

/////

XXXX /

/////

/////

/////

/////

/////

////30

6.30 6.30 2.30 2.30 3.30

30

68

Page 68

Program :

ONDERDEEL

WAS TIJD

TEMPERATUUR

VERWARM. SYS

TEMP. STURING

WASBEWEGING

ZACHT (BAK 1)

ZACHT (BAK 2)

ZACHT (BAK 3)

HARD (BAK 4)

HARD (BAK 5)

HARD (BAK 6)

ZACHT (KUIP)

WARM (KUIP)

HARD (KUIP)

ZEEPINJECTIE

36 22' Duvet

Total Time: Name:

01 02 03 04 05 06 07 08