Page 1

F22 Online UPS

For 30KW Power Module

Uninterruptible Power Supply System

Version: 4.0

User Manual

Page 2

Table of Contents

1. Safety ............................................................................................................................... 1

1.1 Important Safety Instructions ..................................................................................... 1

1.2 EMC .......................................................................................................................... 1

1.3 Installation information .............................................................................................. 1

1.4 Maintenance ............................................................................................................. 2

1.5 Recycling the used battery ......................................................................................... 2

2. Installation ........................................................................................................................ 3

2.1 Initial Inspection ....................................................................................................... 3

2.2 Installation Environment ............................................................................................ 3

2.3 Unpacking ................................................................................................................. 4

2.4 Moving the Cabinet .................................................................................................... 6

2.5 Types of UPS Cabinet ................................................................................................. 7

2.6 Exterior ..................................................................................................................... 8

2.7 Internal Mechanisms ................................................................................................ 11

2.8 Control Panel........................................................................................................... 16

2.9 Introduction of Modules ........................................................................................... 18

2.10 Power Cable .......................................................................................................... 24

2.11 Wiring ................................................................................................................... 25

2.12 Power Module Installation ...................................................................................... 28

2.13 Battery Module Installation ..................................................................................... 30

3. Operation Mode and UPS Operation .................................................................................. 31

3.1 Block diagram of UPS .............................................................................................. 31

3.2 Operation Mode ....................................................................................................... 32

3.3 UPS Operation ......................................................................................................... 40

4. Control Panel and Display Description ................................................................................ 51

4.1 Introduction ............................................................................................................ 51

4.2 Screen Description ................................................................................................... 52

4.3 Alarm List ............................................................................................................... 76

4.4 History Record ......................................................................................................... 78

5. Interface and Communication ........................................................................................... 80

5.1 Dry Contact Port ...................................................................................................... 80

5.2 Extra Comm. Slot .................................................................................................... 82

5.3 Local Communication Ports – RS232 & USB ............................................................... 82

5.4 SNMP Slot ............................................................................................................... 82

6. Troubleshooting ............................................................................................................... 83

7. Service ............................................................................................................................ 86

7.1

Replacement Procedures Of Power Module ................................................................ 86

7.2 Replacement Procedures Of STS Module ................................................................... 86

7.3 Replacement Procedures Of Battery Module .............................................................. 86

7.4 Replacement Procedures Of Air Filter ........................................................................ 87

8. Specifications .................................................................................................................. 88

8.1 Conformity And Standards ........................................................................................ 88

8.2 Environmental Characteristics ................................................................................... 88

8.3 Mechanical Characteristics ........................................................................................ 88

8.4 Electrical Characteristics (Input Rectifier) .................................................................. 89

8.5 Electrical Characteristics (Intermediate DC Circuit) ..................................................... 89

8.6 Electrical Characteristics (Inverter Output) ................................................................. 90

Page 3

8.7 Electrical Characteristics (Bypass Mains Input) ........................................................... 90

9. UPS Installation for Parallel Rack System ........................................................................... 91

9.1 Input and Output Wiring .......................................................................................... 91

9.2 Parallel Board Setting and Power Module ................................................................... 92

9.3 Parallel Function Setting ........................................................................................... 93

9.4 Parallel Cable Connection .......................................................................................... 94

9.5 Parallel System Turn On Procedure ............................................................................ 94

Page 4

1

1. Safety

1.1 Important Safety Instructions

This UPS contains LETHAL VOLTAGES. All repairs and service must be performed by AUTHORIZED

SERVICE PERSONNEL ONLY. There are NO USER SERVICEABLE PARTS inside the UPS.

WARNING:

The UPS designed for commercial and industrial purpose, it is forbidden to apply for any life

sustainment and support.

The UPS system contains its own energy source. The output terminals may carry live voltage

even when UPS is disconnected to an AC source.

To reduce the risk of fire or electrical shock, UPS installation has to be in a controlled room

where temperature and humidity are monitored. Ambient temperature must not exceed 40°C.

The system is only for indoor use.

Ensure all power is disconnected before installation or service.

Service and maintenance should be performed by qualified personnel only.

1.2 EMC

WARNING: This is a product for commercial and industrial application in the second environment

- installation restrictions or additional measures may be needed to prevent disturbances.

1.3 Installation information

WARNING:

Installation must be performed by qualified personnel only.

The cabinets must be installed on a level floor suitable for computer or electronic equipment.

The UPS cabinet is heavy. If unloading instructions are not closely followed, cabinet may

cause serious injury.

Do not tilt the cabinets more than 10 degree.

Before applying electrical power to the UPS, make sure the Ground conductor is properly

installed.

Installation and Wiring must be performed in accordance with the local electrical laws and

regulations.

The disconnection device should be chosen based on the input current and should break line

and neutral conductors - four poles for three phases.

Before working on this circuit

- Isolate Uninterruptible Power System (UPS)

- Then check for Hazardous Voltage between

all terminals including the protective earth.

Risk of Voltage Backfeed

The isolation device must be able to carry the UPS input current.

Page 5

2

1.4 Maintenance

WARNING:

Only qualified service personnel should perform the battery installation.

The following PRECAUTIONS should be observed

(1.) Remove watches, rings, or other metal objects.

(2.) Use tools with insulated handles.

(3.) Wear rubber gloves and boots.

(4.) Do not lay tools or metal parts on top of batteries or battery cabinets.

(5.) Disconnect the charging source prior to connecting or disconnecting terminal.

(6.) Check if the battery is inadvertently grounded. If it is, remove the source of grounding.

Contacting with any part of the ground might result in electrical shock. The likelihood of

such shock can be prevented if such grounds are removed during installation and

maintenance.

UPS is designed to supply power even when disconnected from the utility power. After

disconnect the utility and DC power, authorized service personnel should attempt internal

access to the UPS.

Do not disconnect the batteries while the UPS is in Battery mode.

Disconnect the charging source prior to connecting or disconnecting terminals.

Batteries can result in a risk of electrical shock or burn from high short circuit current.

When replacing batteries, use the same number of sealed, lead-acid batteries.

Do not open or mutilate the battery. Release electrolyte is harmful to the skin and eyes, and

may be toxic.

1.5 Recycling the used battery

WARNING:

Do not dispose of the battery in a fire. Battery may explode. Proper disposal of battery is

required. Refer to your local codes for disposal requirements.

Do not open or mutilate the battery. Released electrolyte is harmful to the skin and eyes. It

may be toxic.

Do not discard the UPS or the UPS batteries in the trash. This product contains sealed,

lead-acid batteries and must be disposed properly. For more information, contact your local

recycling/reuse or hazardous waste center.

Do not discard waste electrical or electronic equipment (WEEE) in the trash. For proper

disposal, contact your local recycling/reuse or hazardous waste center.

Page 6

3

2. Installation

2.1 Initial Inspection

1. Visually examine if there is any damage inside and outside of packages in the process of the

transportation. If any damage, report it to the carrier immediately.

2. Verify the product label and confirm the consistency of the equipment.

3. If the equipment needs to be returned, carefully repack the equipment by using the originally

packing material that came with.

2.2 Installation Environment

1. The UPS is designed for indoor use only and should be located in a clean environment with

adequate ventilation to keep the environmental parameters within the required specification.

2. Make sure that transportation routes (e.g. corridor, door gate, elevator, etc.) and installation

area can accommodate and bear the weight of the UPS, the external battery cabinet and

handling equipment.

3. The UPS uses forced convection cooling by internal fans. Cooling air enters the module

through ventilation grills located at the front of the cabinet and exhausted through grills

located in the rear part of the cabinet. Please do not block the ventilation holes.

4. Ensure that the installation area is spacious for maintenance and ventilation.

5. Keep the temperature of installation area around 30°C and humidity within 90%. The highest

operating altitude is 1000 meters above sea level.

6. If necessary, install a system of room extractor fans to avoid formation of room temperature.

Air filters are necessary if the UPS is operated in a dusty environment.

7. It is recommended that you parallel the external battery cabinets to the UPS. The following

instructions of clearances are suggested:

Keep a clearance of 100cm from the top of the UPS for maintenance, wiring and

ventilation.

Keep a clearance of 100cm from the back of the UPS and the external battery cabinets for

ventilation.

Keep a clearance of 150cm from the front of the UPS and the external battery cabinets

for maintenance and ventilation.

8. For safety concerns, we suggest that you shall:

Equip with CO2 or dry powder fire extinguishers near the installation area.

Install the UPS in an area where the walls, floors and ceilings were constructed by

fireproof materials.

9. Do not allow unauthorized personnel to enter the installation area. Assign specific personnel

to keep the UPS key.

Page 7

4

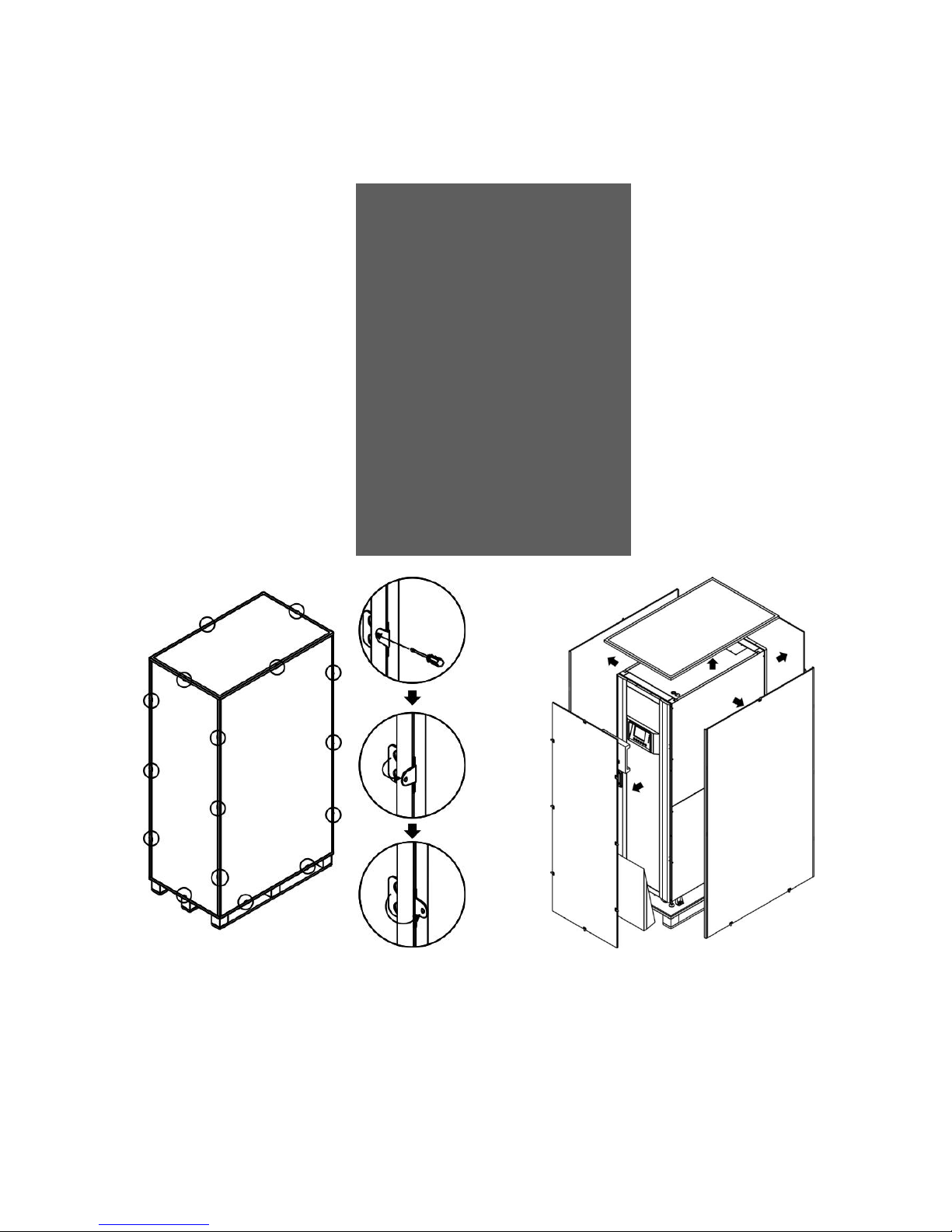

2.3 Unpacking

1. Use a forklift to move the product to installed area. Refer to Figure 2-1. Please make sure the

bearing capacity of forklift is sufficient.

2. Please follow the orders in Figure 2-2 to remove carton and foams.

Figure 2-1

Figure 2-2

Page 8

5

3. Put a ramp in the front of the cabinet and insert small wood into groove. Then, remove two

side panels. Refer to Figure 2-3.

Figure 2-3

4. Remove 4 fixing cabinet plates and loosen leveling feet by rotating them counterclockwise.

Then, move the cabinet from the pallet. Refer to Figure 2-4.

5. To fix the cabinet in position, simply rotate leveling feet clockwise. Refer to Figure 2-5.

Figure 2-4

Figure 2-5

Page 9

6

2.4 Moving the Cabinet

The UPS is fixed on the pallet with 4 fixing cabinet plates. When removing it, pay attention to

the movement of the casters to avoid accidents.

The cabinet can be pushed forward or backward only. Pushing it sideward is not allowed.

When pushing the cabinet, pay attention not to overturn it as the gravity center is high.

1. If you need to move the UPS over a long distance, please use appropriate equipment like a

forklift. Do not use the UPS casters to move over a long distance.

2. After the UPS has been removed from the pallet to ground, we suggest that at least three

people move the UPS to the installation area. One person holds a lateral side of the UPS with

hands, another holds the other lateral side of the UPS with hands, and the other person pushes

the UPS either from the front side or from the back side to the installation area and avoid

tipping the UPS.

3. The casters are designed to move on level ground. Do not move the UPS on an uneven surface.

This might cause damage to the casters. Toppling the UPS could also damage the unit.

4. Ensure that the weight of UPS is within the designated bearing capacity of any handling

equipment.

5. At the bottom of the UPS, the four casters help you to move the UPS to a designated area.

Before you move the UPS, please turn the four leveling feet counterclockwise to raise them off

the ground. This protects the leveling feet from damage when moving the UPS. Refer to Figure

2-6.

Figure 2-6

Page 10

7

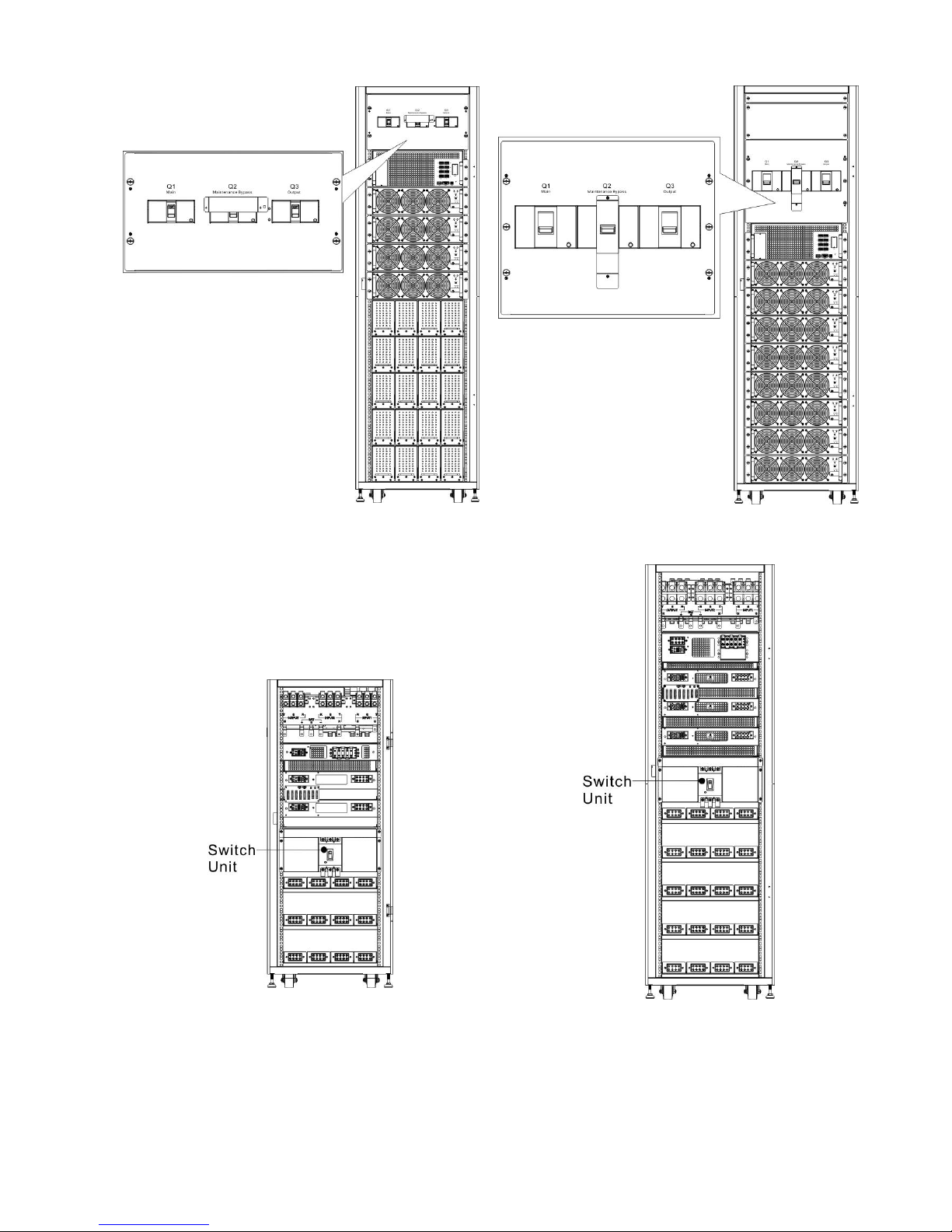

2.5 Types of UPS Cabinet

There are two series of UPS cabinets, standard and extended for different requirements.

The standard cabinets have the battery modules inside and they can work as a stand-alone UPS or

be connected to battery externally.

The extended cabinets don’t have the battery module compartments. The battery has to be

connected externally.

Please consider the external battery space and wiring gauge for installation.

Standard Series

Extended Series

Photo

Cabinet

Height

30U

42U

30U

30U

42U

42U

Switch

Unit

1 1 1 1 1

1

STS 1 1 1 1 1 1

Max.

Power

Module

3 4 4 6 8

10

Battery

Module

12

20

N/A

N/A

N/A

N/A

Page 11

8

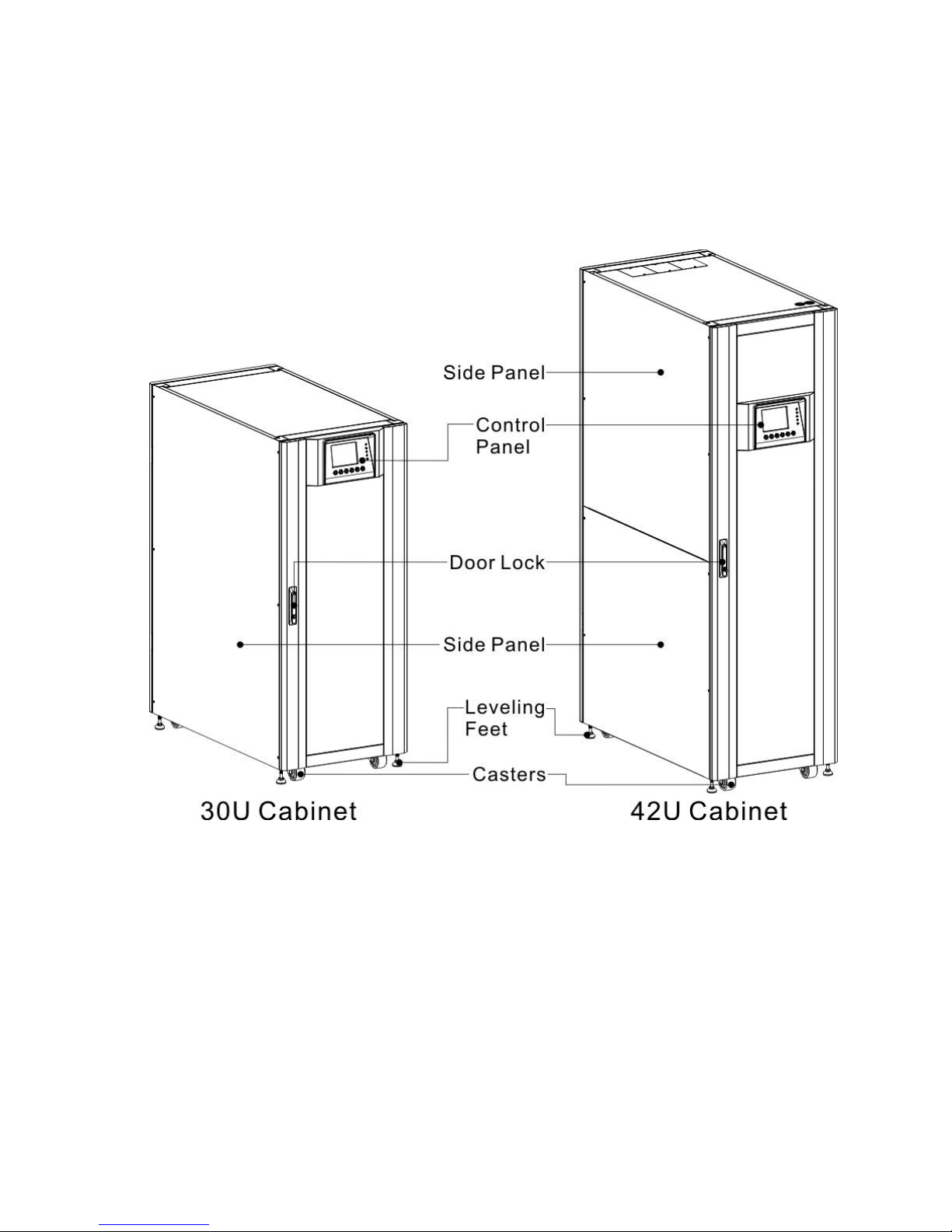

2.6 Exterior

In the front of the UPS, there are control interface (LCD Panel) and door lock.

The side panels are lockable. The casters at the bottom of the UPS cabinet can be used to move

over short distances. There are four leveling feet to fix and stabilize the UPS cabinet on the ground.

Refer to Figure 2-7.

Inside the cabinet, there are Breakers, STS Module, Power Module slots and Battery module slots

(Battery Module Slots is only for standard series). All wiring terminal blocks are located in the back

of cabinet.

Figure 2-7 Exterior

Page 12

9

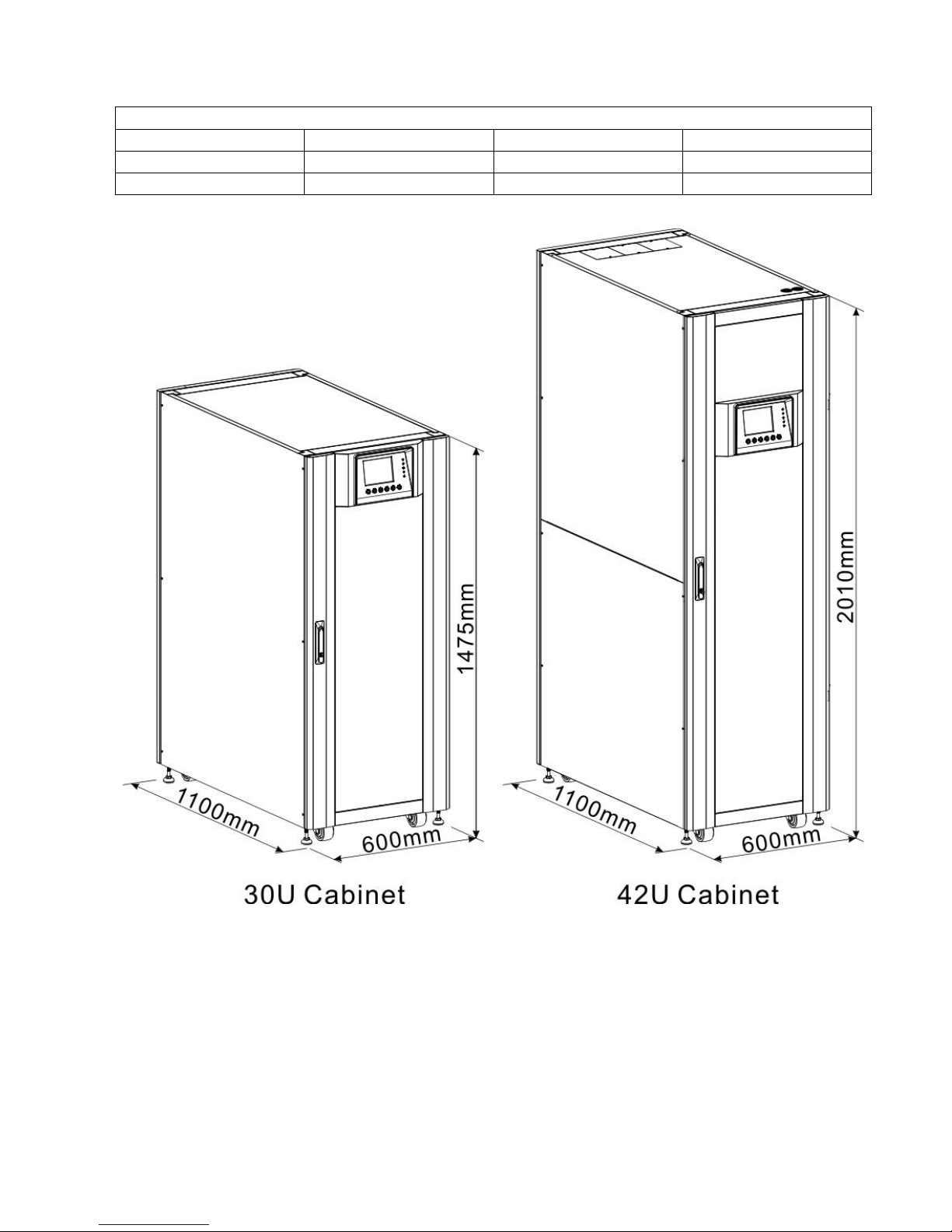

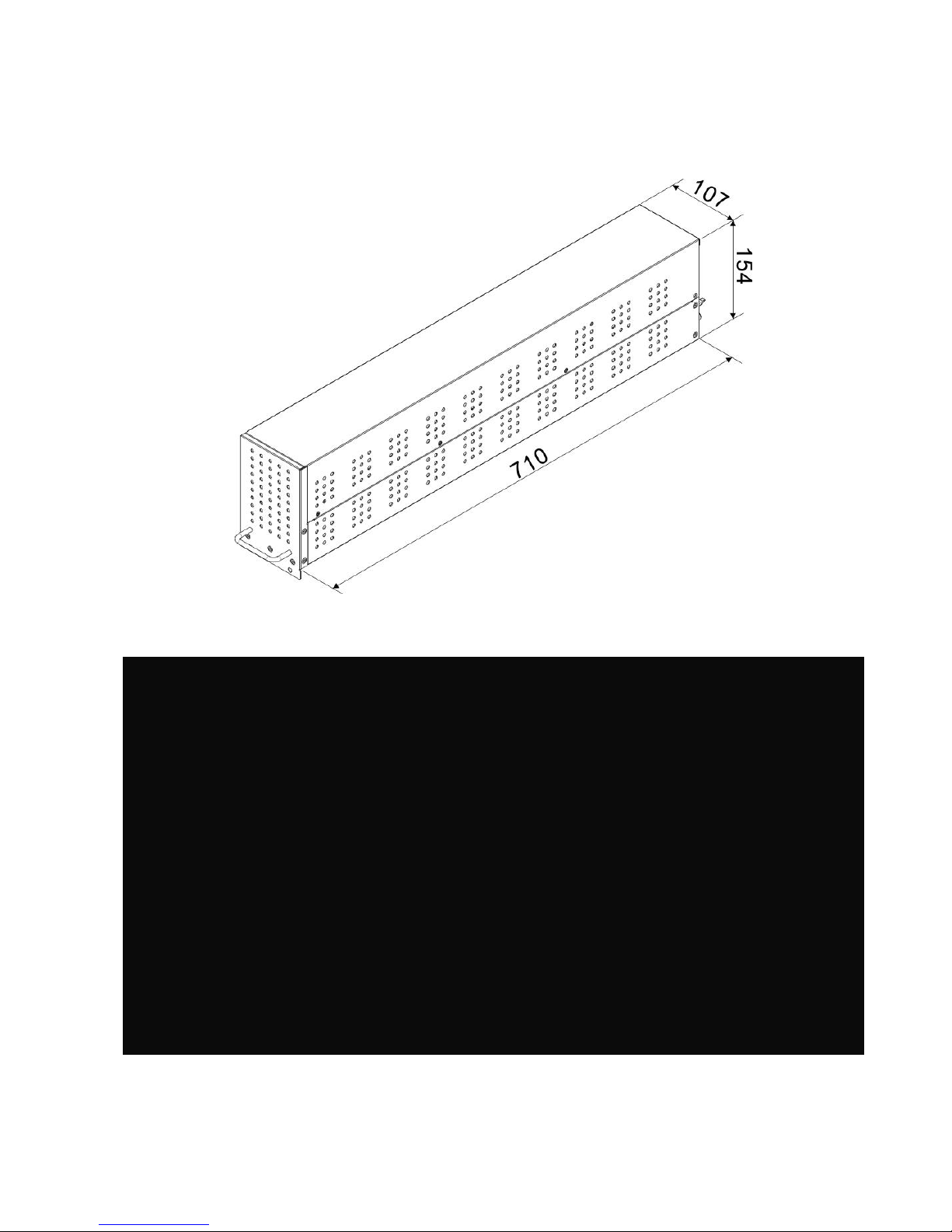

2.6.1 Mechanical Data

Dimensions

UPS cabinet

Width

Depth

Height

30U

600mm

1100m

1475mm

42U

600mm

1100m

2010mm

Figure 2-8 Dimensions

Page 13

10

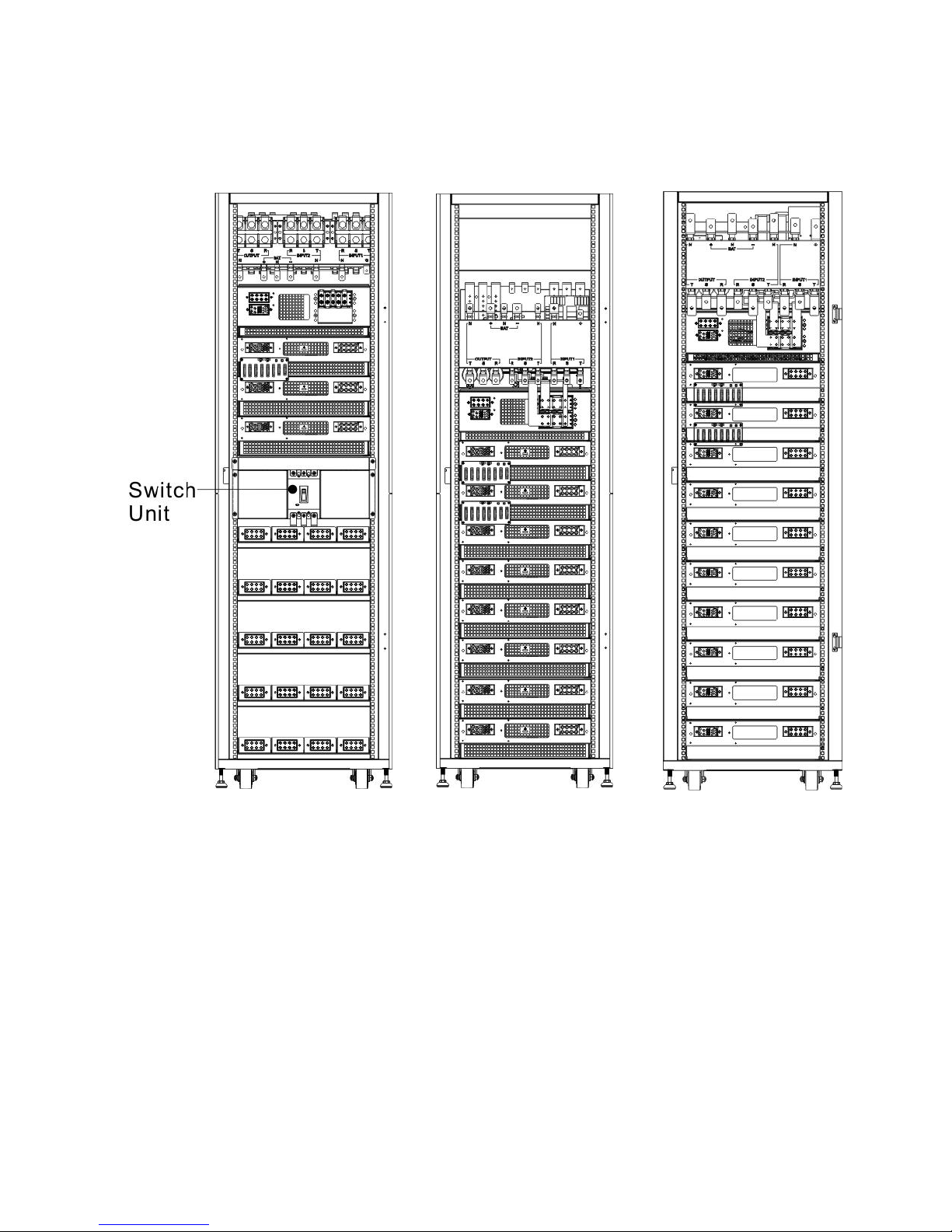

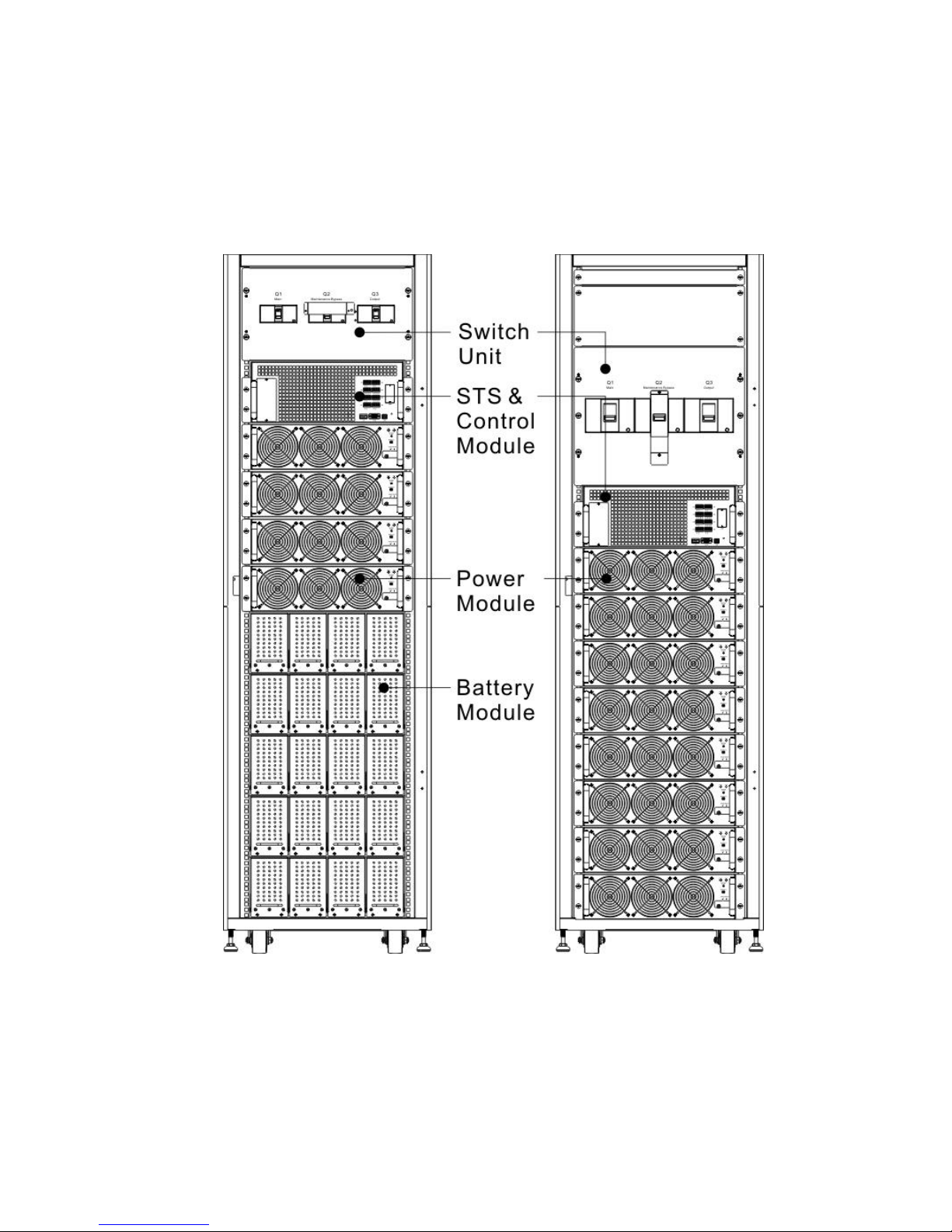

2.6.2 Front View

Unlock and open the front door and you will see the Main Breaker (Q1), Maintenance Breaker (Q2),

Output Breaker (Q3), STS Module, Power Module slots and Battery Module slots (Battery Module

Slots is only for standard series).

The cabinet of 300K Model has Maintenance Bypass Switch Only.

Standard Series Extended Series

1. Switch Unit

2. STS Module

3. Power Module

4. Battery Module

Page 14

11

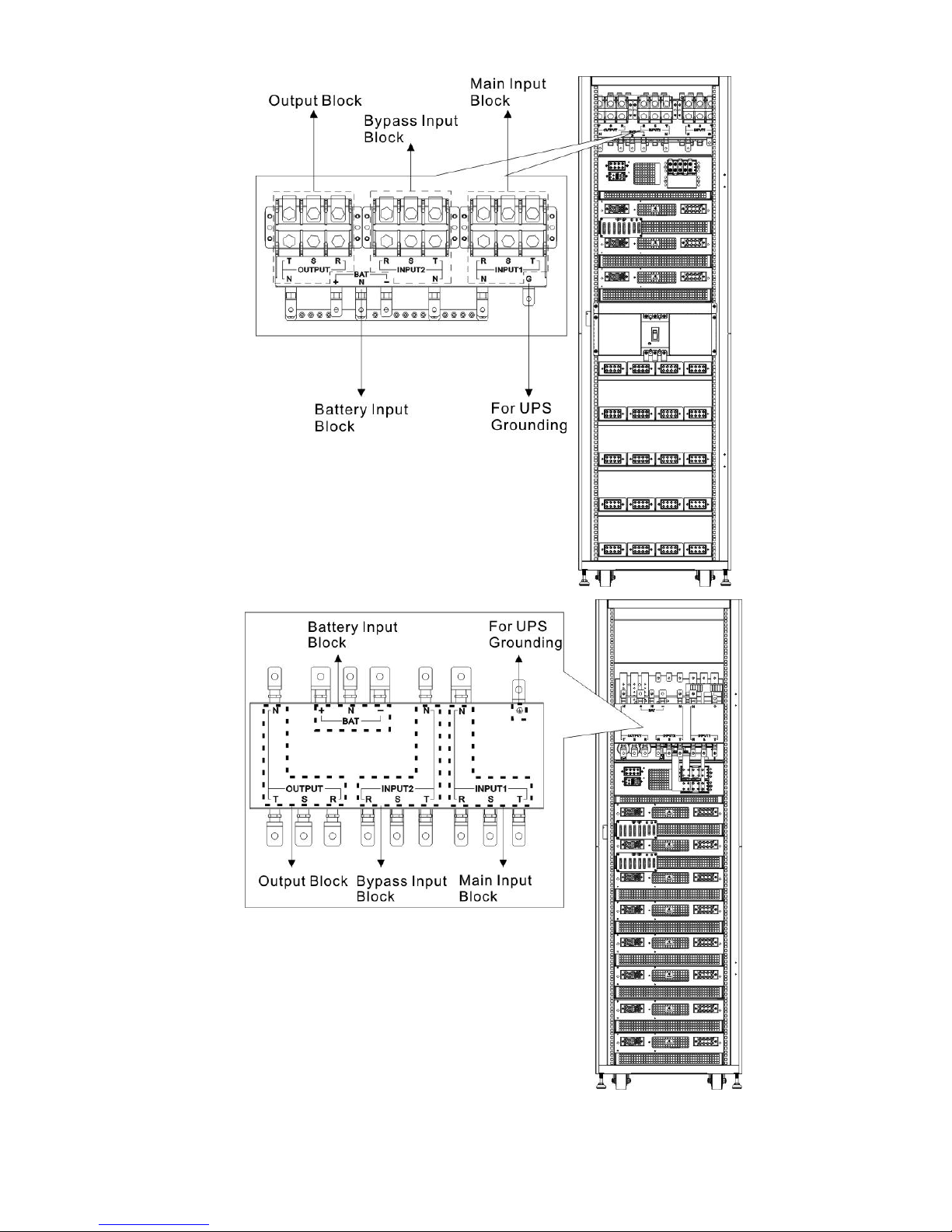

2.6.3 Rear View

Unlock and open the rear door and you will see the rear panel of UPS. There is a Battery Breaker

for internal battery modules in the standard series, but there isn’t any in the extended series.

Standard Series

Extended Series

Figure 2-10 Rear View

2.7 Internal Mechanisms

2.7.1.1 Breakers

After opening the front door, there are three breakers, Main Breaker (Q1), Maintenance Breaker

(Q2) and Output Breaker (Q3).

For the standard series, there is a battery breaker for internal battery modules. You can see it

when you open the rear door.

Page 15

12

Standard Series (42U Front)

Extended Series (42U Front)

Figure 2-11 Front Breakers

Standard Series (30U Rear)

Standard Series (42U Rear)

Figure 2-12 Rear Breaker

Page 16

13

2.7.1.2 Maintenance Bypass Switch

After opening the front door, there is one Maintenance Bypass Switch in the 300K cabinet.

Figure 2-12.1 Maintenance Bypass Switch

Page 17

14

2.7.2 Wiring Terminal Blocks

Open the UPS’s back doors and you will see the wiring terminal block. For UPS cabinet wiring,

please refer to Figure 2-13.

No.

Item

Function

Description

Output Block

Connects the critical loads

Includes R, S, T and Neutral

terminals.

Bypass Input Block

Connects bypass AC source

Includes R, S, T and Neutral

terminals.

Main Input Block

Connects main AC source

Includes R, S, T and Neutral

terminals.

For UPS Grounding

For UPS grounding

Includes one grounding terminal.

Battery Input Block

Connects an external battery

cabinet

Includes

Positive (+), Negative (-) and

Neutral (N) terminals.

Figure 2-13 Standard Series (30U) Terminal Blocks

Page 18

15

Figure 2-14 Standard Series (42U) Terminal Blocks

Figure 2-15 Extended Series (42U) Terminal Blocks

Page 19

16

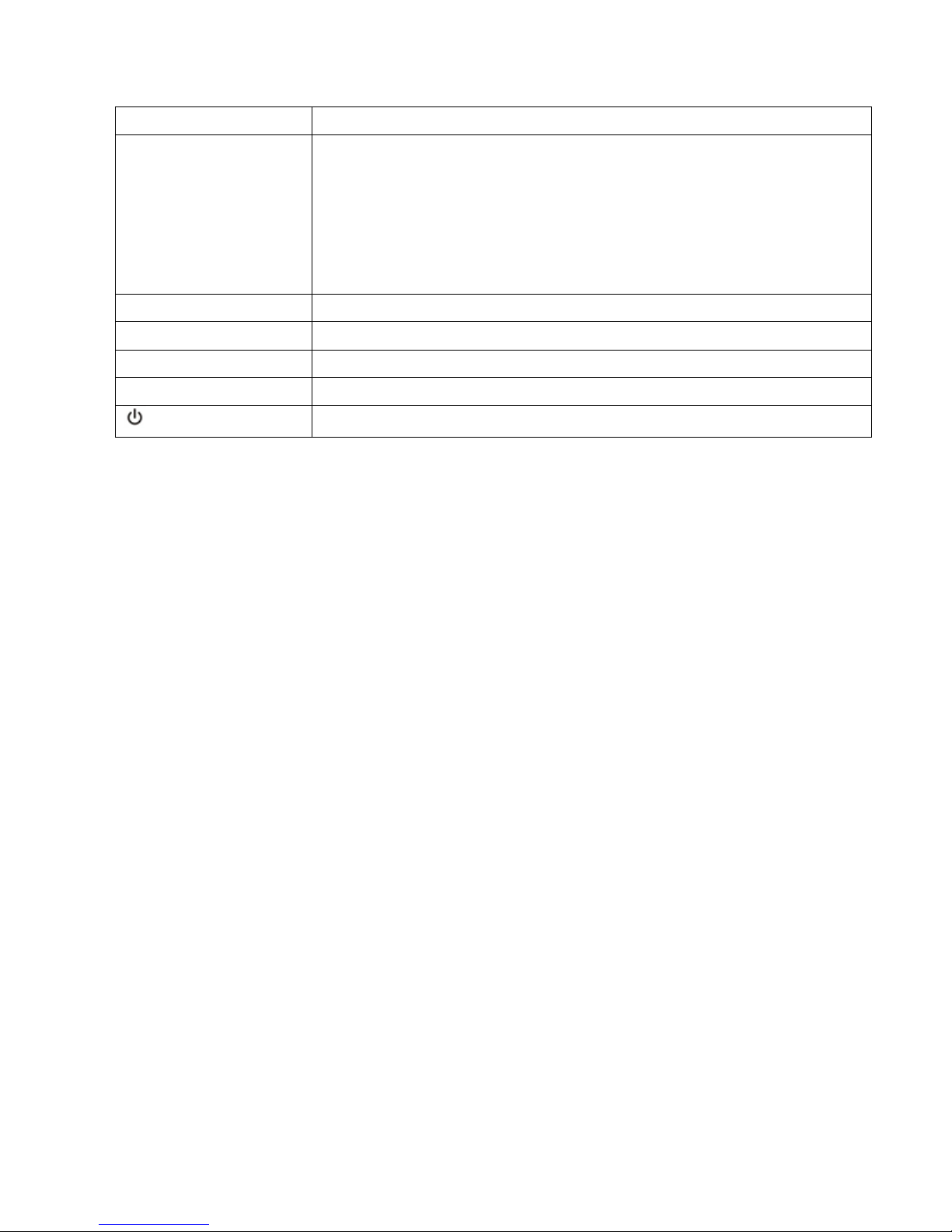

2.8 Control Panel

2.8.1 LCD Display

Through the graphic LCD display, the user can easily understand the operation mode of UPS. In

addition, the measurement, parameters, versions of firmware and warnings can be browsed in the

friendly interface. For detailed information, please refer to Chapter 4.

Figure 2-16 Control Panel

2.8.2 LED Indicators

LED

Color

Status

Definition

INPUT

Green

On

Input source is normal.

Flashing

Input source is abnormal.

Off

No input source

BYPASS

Yellow

On

Load on Bypass.

Flashing

Input source is abnormal.

Off

Bypass not operating.

INVERTER

Green

On

Load on inverters.

Off

Inverters not operating.

BATTERY

Red

On

Load on Battery.

Flashing

Low battery

Off

Battery converter is normal and battery is charging.

ALARM

Red

On

UPS fault.

Flashing

UPS alarm.

Off

Normal.

Page 20

17

2.8.3 Function Keys

Control Key

Description

Esc

When it is in Main screen, you can enter menu by pressing ESC

key.

Return to previous screen, when screen is not in Main screen.

Return to previous value in the same row, so you can change it.

For example, when changing 4-digit password, press “Esc” to

allow cursor back to previous digit.

(Up) (Left)

Key for menu page navigation or digit modification.

(Down) (Right)

Key for menu page navigation or digit modification.

Enter

Confirmation of commands, or cursor displacement.

Home

Return to Main screen.

Power On/Off

Turn on UPS or turn off UPS.

Page 21

18

2.9 Introduction of Modules

The design of STS Module, Power Module and Battery Module make maintenance and replacement

quick and easy.

The modular and hot-swappable design of Power Module makes it a highly cost-effective solution

to meet your power requirement. The number of Power Modules installed in the UPS can be based

on the initial needs. Once the power requirement increases, you can easily install more Power

Modules without interrupting the operation of the system.

Figure 2-17 Front View of Module

Page 22

19

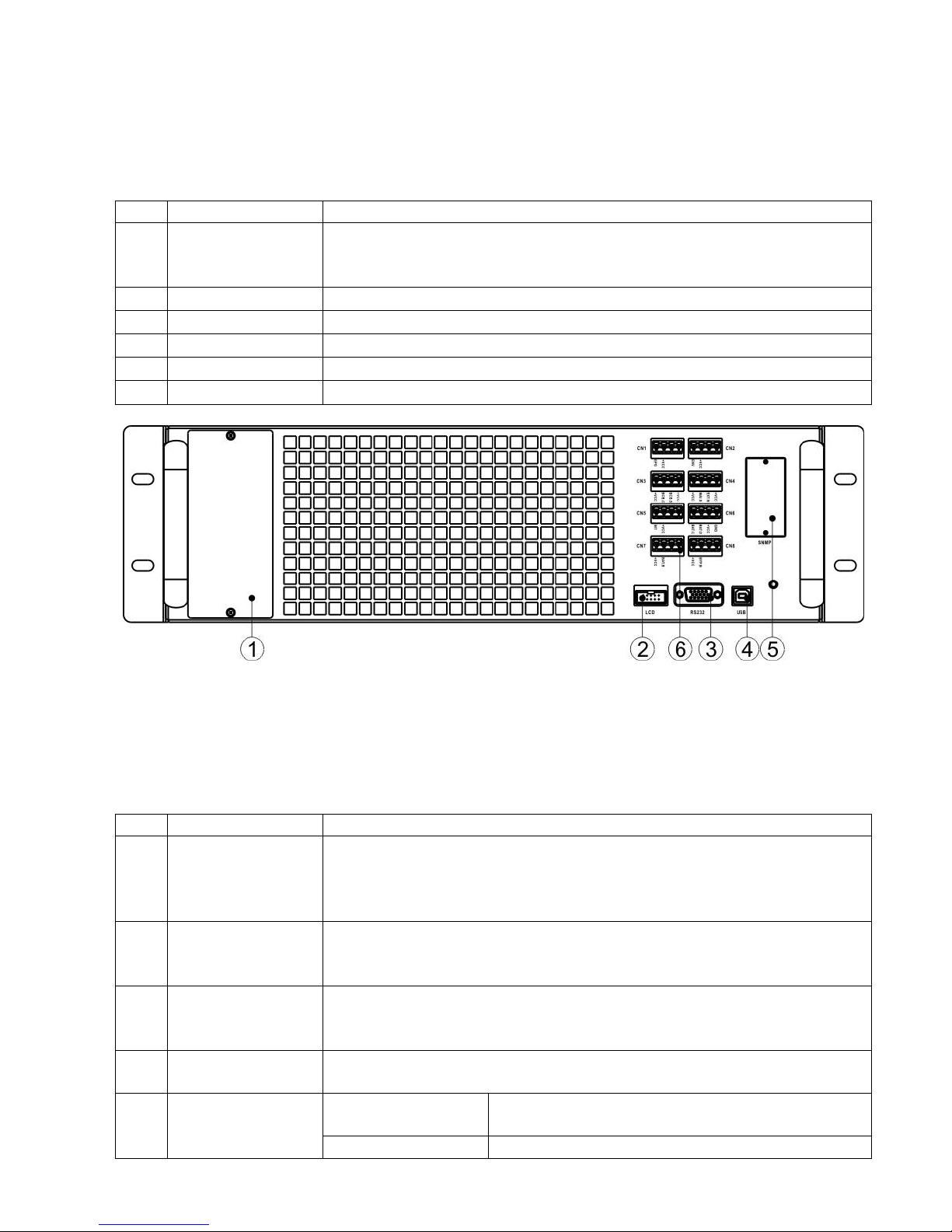

2.9.1 STS Module

The STS Module is installed before leaving factory. It provides the bypass power when UPS is in

Bypass Mode.

In addition to offering bypass power, it includes some communication interfaces. For detailed

information, please refer to Charter 5.

No.

Item

Description

Extra Comm. Slot

This slot can insert an optional card, Extra Comm. card which can

enhance the communication capability of UPS system. It can provide

another SNMP slot and some dry contact ports.

LCD Port

This port connects to Control Panel with a factory installed cable.

RS232 port

Local communication interface.

USB port

Local communication interface.

SNMP Slot

This slot can work with optional cards, SNMP, AS400 or Modbus card.

Dry contact ports

CN1 ~ CN8. For detailed information, please refer to Chapter 5.

Figure 2-18 STS Module

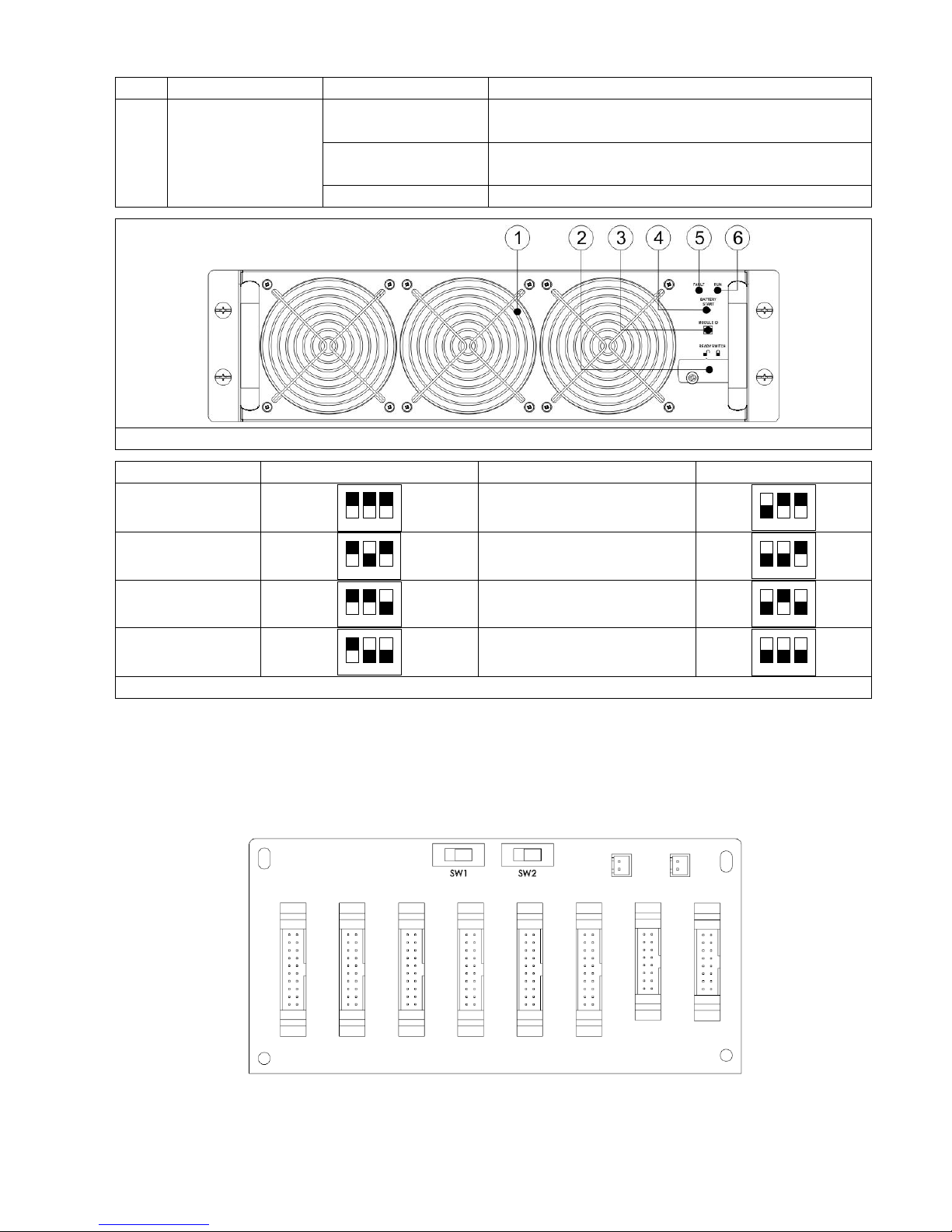

2.9.2 Power Module

Each Power Module is shipped with its own package. It has to be installed during the UPS system

installation.

The capacity of each Power Module is 30kVA/30kW. It includes a power factor correction rectifier,

a battery charger, an inverter and control circuit.

No.

Item

Description

Fan

The Power Module uses forced convection cooling by these fans.

Cooling air enters the module through ventilation grills and exhausted

through grills located in the rear of the module. Please do not block

the ventilation area.

Ready Switch

Unlock it before removing the Power Module.

Lock it when the Power Module is well installed. Then the Power

Module can start to work.

DIP Switches

There are three DIP switches for Power Module address setting. In

the same cabinet, each Power Module ID MUST be exclusive. The

setting method is shown in Table 2-1.

Battery Start

Button

When AC input is not existing, use this button to start battery power

for UPS.

FAULT LED

ON

The Power Module is in fault condition or the

Ready Switch is unlocked.

ON/OFF 0.5 sec

The Power Module IDs conflict.

Page 23

20

ON/OFF 0.15 sec

The STS Module is not found.

RUN LED

ON

The Power Module normally works as a slave

module.

ON/OFF 0.5 sec

The Power Module normally works as a master

module.

ON/OFF 0.15 sec

The CAN Bus communication doesn’t work.

Figure 2-19 Power Module

Module Address

DIP SWITCH

Module Address

DIP SWITCH

0

1 2 3

1

1 2 3

2

1 2 3

3

1 2 3

4

1 2 3

5

1 2 3

6

1 2 3

7

1 2 3

Table 2-1 DIP switch setting and Module Address

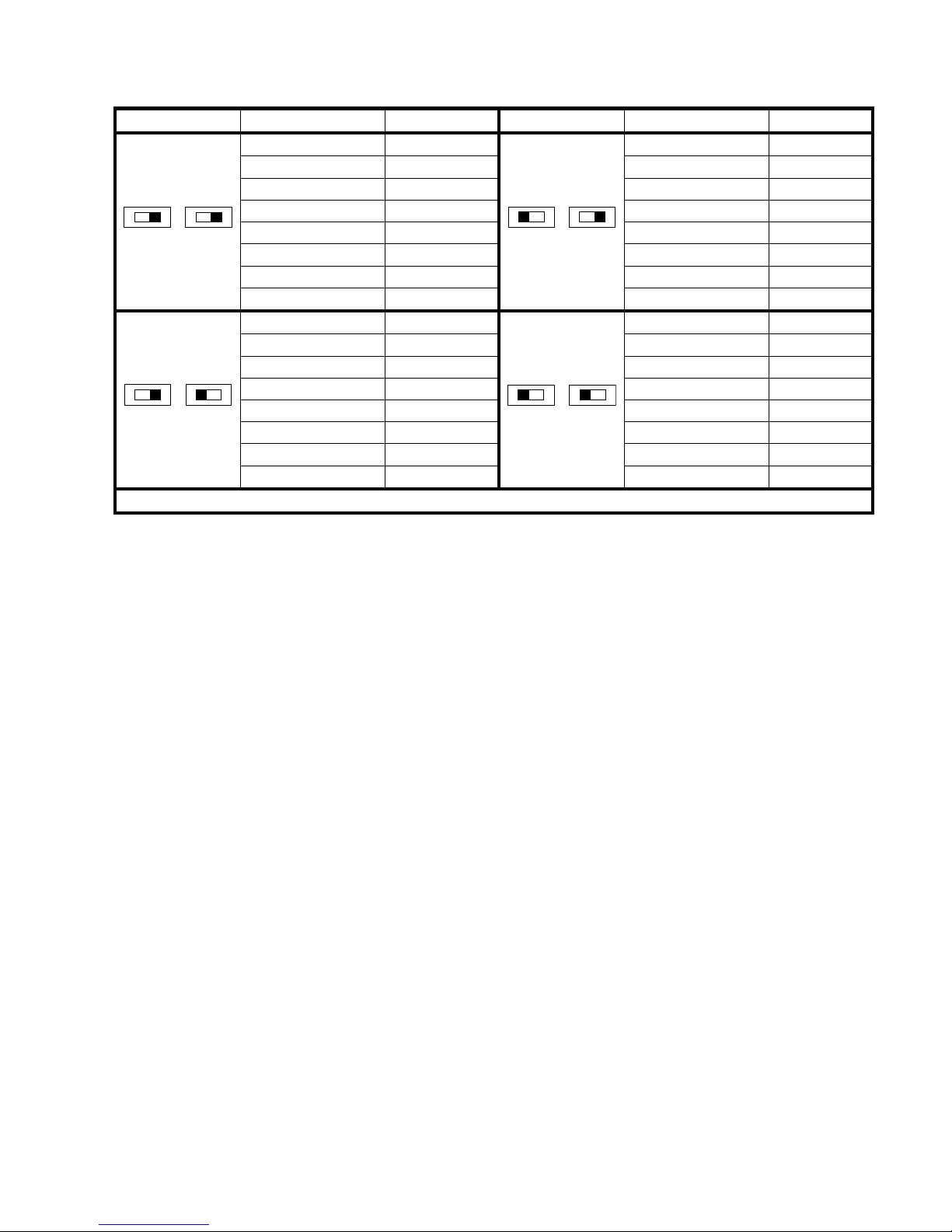

Power Module ID Assignment

According to the Module Address and the position of SW1 and SW2, the Power Module’s ID is

assigned. The Module ID is shown in Table 2-2.

These two switches, SW1 & SW2 are mounted in the Parallel board which is located at the back of

UPS cabinet. Refer to Figure 2-20.

Figure 2-20 Parallel Board

The SW1 and SW2 position have been well installed before leaving factory. It’s not necessary to

change it for single UPS system application. But for Parallel UPS system application, please follow

Page 24

21

the instructions in Chapter 9 “ UPS Installation for Parallel Rack System “ to adjust SW2.

SW1 & SW2

Module Address

Module ID

SW1 & SW2

Module Address

Module ID

SW1 SW2

0

0

SW1 SW2

0 9 1 1 1

10

2 2 2

11 3 3 3 12 4 4 4 13 5 5 5 14 6 6 6 15

7 7 7

16

SW1 SW2

0

18

SW1 SW2

0

27 1 19 1 28 2 20 2 29

3

21 3 30

4

22 4 31 5 23 5 32

6

24 6 33

7

25 7 34

Table 2-2 Module ID Assignment

Page 25

22

Page 26

23

2.9.3 Battery Module

The Battery Module is shipped with its own package. The inside batteries can be installed at

factory or installed by the end user. A Battery Module contains 10 pcs of 12V/9Ah batteries at

maximum.

Figure 2-21 Battery Module

Figure 2-22 Internal Wiring of Battery Module

Page 27

24

2.10 Power Cable

Please follow the local wiring regulations. Follow environmental conditions and

refer to IEC60950-1.

2.10.1 AC input and output maximum current and power cable configuration.

For standard model in 30U cabinet (Battery inside)

Model

30KVA

60KVA

90KVA

Current (A)

55

110

165

Power cable (mm2)

10

35

70

Fixation torque force (lb-in)

20

20

20

For standard model in 42U cabinet (Battery inside)

Model

30KVA

60KVA

90KVA

120KVA

Current (A)

55

110

165

220

Power cable (mm2)

10

35

70

95

Fixation torque force (lb-in)

20

20

20

20

For extended series in 30U & 42U cabinet

Model

30KVA

60KVA

90KVA

120KVA

150KVA

Current (A)

55

110

165

220

275

Power cable (mm2)

10

35

70

95

150

Fixation torque force (lb-in)

20

20

20

20

20

Model

180KVA

210KVA

240KVA

270KVA

300KVA

Current (A)

330

385

440

495

550

Power cable (mm2)

240

300

300

120*2

150*2

Fixation torque force (lb-in)

20

20

20

20

20

Notice: Installer has to consider the max. current and wiring gauge when considering future

extension.

2.10.2 DC input maximum current and power cable configuration.

For standard series in 30U cabinet (Battery inside)

Model

30KVA

60KVA

90KVA

Current (A)

100

200

300

Power cable (mm2)

25

95

150

Fixation torque force (lb-in)

20

20

20

Warning:

1. When Load is less than 30KVA, at least two layers of battery modules (8 modules) have to be

installed.

2. When Load is between 30KVA and 60KVA, three layers of battery modules (12 modules) have

to be installed in total.

3. When Load is larger than 60KVA, the external battery cabinet must be installed.

4. The same type of battery has to be used, if the battery is in parallel application.

Page 28

25

For standard series in 42U cabinet (Battery inside)

Model

30KVA

60KVA

90KVA

120KVA

Current (A)

100

200

300

400

Power cable (mm2)

25

95

150

240

Fixation torque force (lb-in)

20

20

20

20

Warning:

1. When Load is less than 30KVA, at least two layers of battery modules (8 modules) have to be

installed.

2. When Load is between 30KVA and 60KVA, at least three layers of battery modules (12 modules)

have to be installed.

3. When Load is between 60KVA and 90KVA, at least five layers of battery modules (20 modules)

have to be installed.

4. When Load is larger than 90KVA, the external battery cabinet must be installed.

5. The same type of battery has to be used, if the battery is in parallel application.

For extended series in 30U & 42U cabinet

Model

30KVA

60KVA

90KVA

120KVA

150KVA

Current (A)

100

200

300

400

500

Power cable (mm2)

25

95

150

240

120 x 2

Fixation torque force (lb-in)

20

20

20

20

20

Model

180KVA

210KVA

240KVA

270KVA

300KVA

Current (A)

600

700

800

900

1000

Power cable (mm2)

150 x 2

240 x 2

240*2

300*2

185*3

Fixation torque force (lb-in)

20

20

20

20

20

2.11 Wiring

WARNING:

Before connecting any wire, make sure the AC input and battery power is completely cut off.

Make sure the breakers, Main Breaker (Q1), Maintenance Breaker (Q2), Output Breaker (Q3)

and battery breaker are all in the OFF position.

Make sure the Maintenance Bypass Switch is in UPS position.

In order to have good heat dissipation, the power cables MUST come into the cabinet from top

of the cabinet. Or the cables will block the cooling ventilation and make the over temperature

failure.

Page 29

26

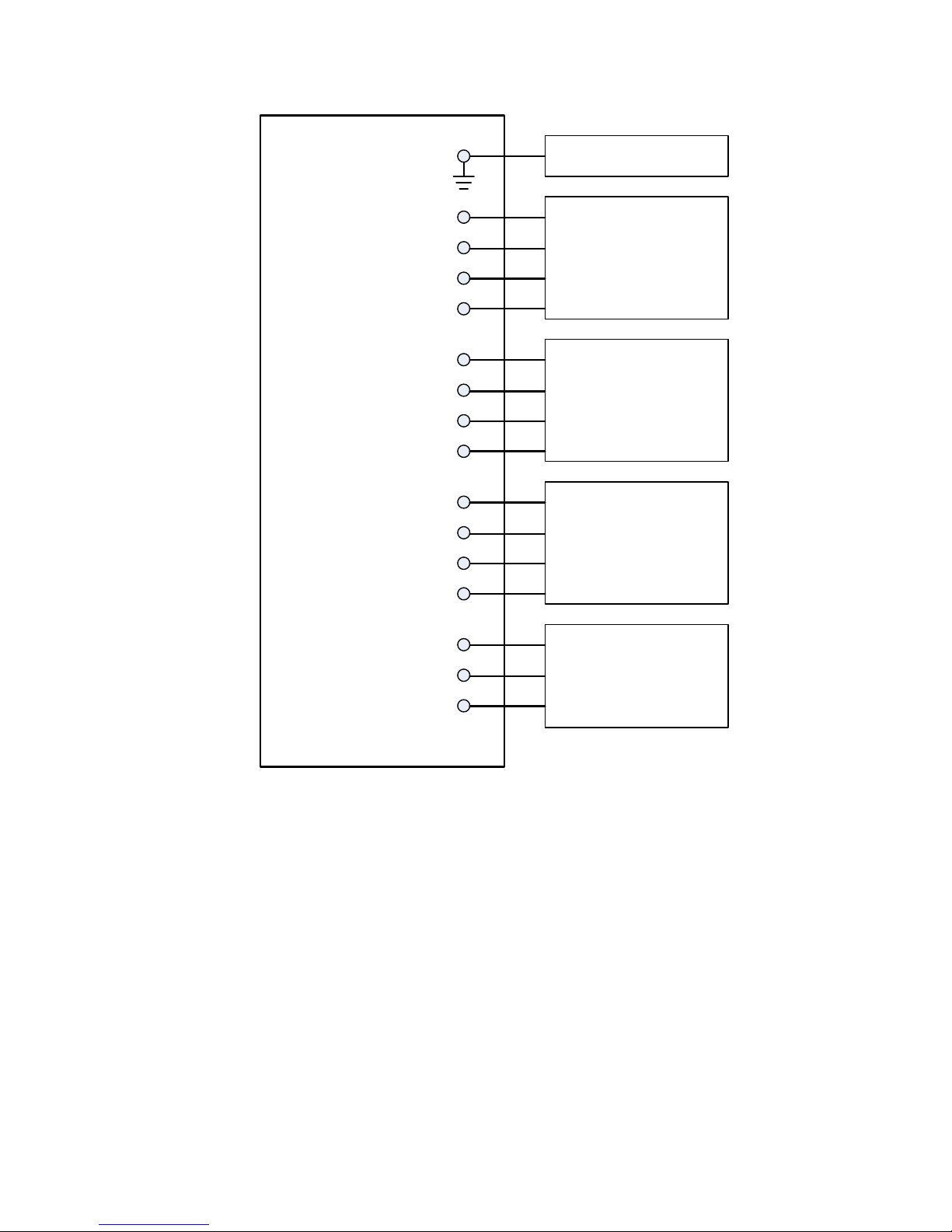

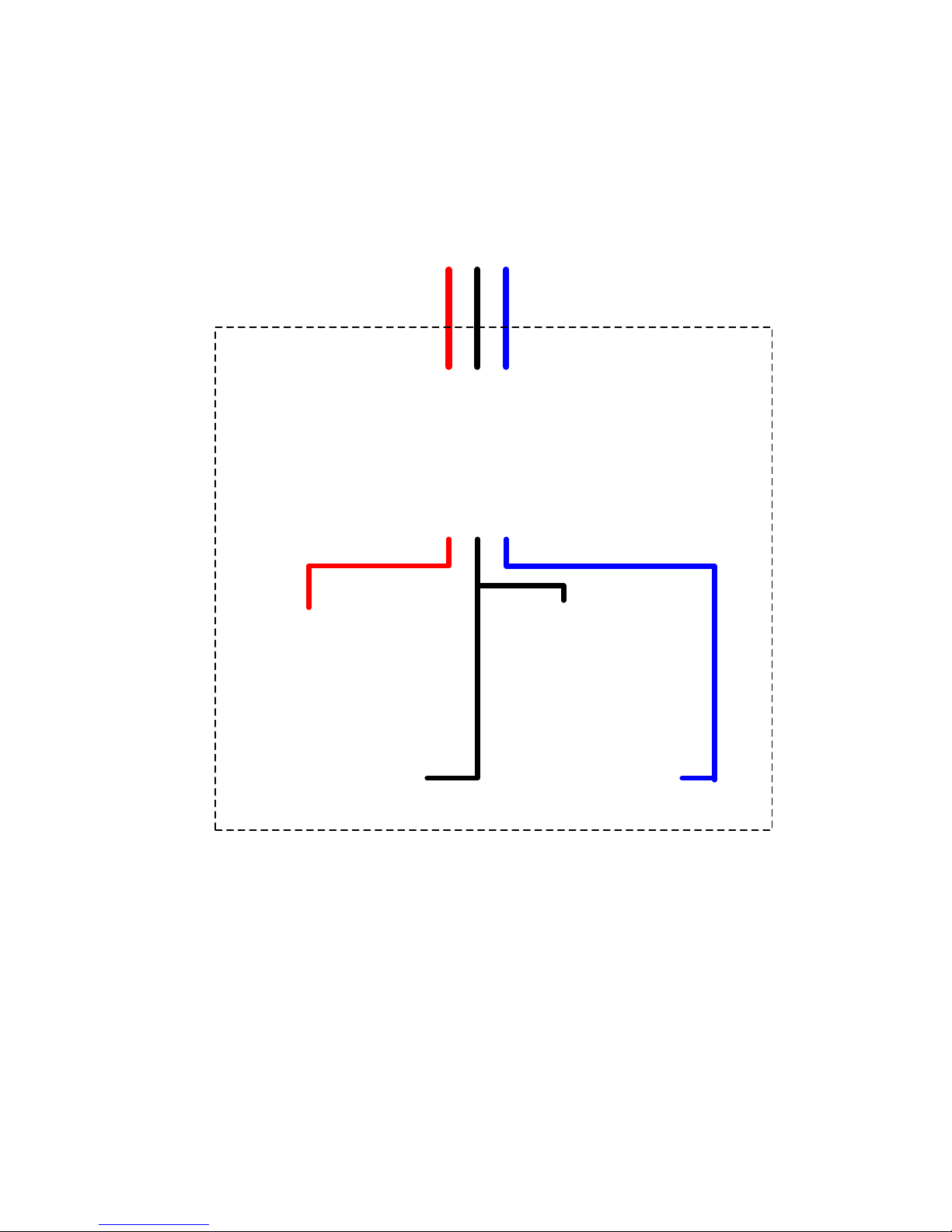

2.11.1 Installation Drawing

UPS

G To User Safety ground

Input1

R

S

T

N

To Main SUPPLY

(Power Cables)

Input2

R

S

T

N

To Bypass SUPPLY

(Power Cables)

Output

R

S

T

N

To Critical Load

(Power Cables)

BAT

+

N

-

To External BATTERY

(Power Cables)

Figure 2-23 UPS Cabinet Wiring

2.11.2 AC source connection

For Single input application, connect Input1 to the AC power source and use 3 short wires to

connect Input1 and Input2.

For Dual input application, connect input1 to the Main AC power source and connect input2 to

the Bypass power source.

The sequence of three phase, R, S and T must be connected accordingly. The wrong sequence will

alarm a warning when the UPS is powered.

The N must be connected firmly. A warning message will be indicated, if the N is not connected

well.

There is no Breaker between Input2 and STS Module, the STS module is waked up when Input2 is

powered, though the Q1 Breaker is OFF.

For the 300K cabinet, there is no input breaker nor output breaker. These breakers have to be

installed externally.

Page 30

27

2.11.3 External Battery Cabinet Connection

External Battery

Cabinet

+ Battery - Battery

Figure 2-24 External Battery Cabinet Wiring

After the battery is completely installed, be sure to set up nominal battery voltage, battery capacity

and maximum charging current in LCD setting. Otherwise, if battery setting is different from actual

installation, the UPS will keep warning. Please refer to section 4.2.6.3 and Table 4-9 for the

details.

Page 31

28

2.12 Power Module Installation

The weight of Power Module is over 30Kg so at least two persons are required for

handling.

2.12.1 Insert the Power Module

(1.) Adjust the DIP switch positions to set the different Module Address. Refer to Table 2-1.

(2.) Place the ready switch on the front panel of the module to the “ ” position (i.e., in unready

state).

(3.) Insert the Power Module into an unoccupied slot by two persons.

Page 32

29

(4.) Secure the Power Module to the cabinet by fixing the screws at the front panel of the Power

Module.

(5.) Move the ready switch to the “ ” position (i.e., in ready state).

2.12.2 Remove the Power Module

Before removing any Power Module, make sure the remaining Power Modules

can support the critical loads.

At least one Power Module MUST stay in the UPS cabinet except the UPS

system is operating in Maintenance Bypass Mode.

(1.) Turn the ready switch to the “ ” position.

(2.) The Power Module FAULT LED (RED) indicator is lit to indicate the Power Module output is off

and disconnected from UPS system.

(3.) Use a screwdriver to remove the four screws from fixing holes.

(4.) Two people pull out together and remove the Power Module from its slot.

Page 33

30

2.13 Battery Module Installation

The weight of Battery Module is heavy so at least two persons are required for

handling.

Before performing the Battery Module installation/ replacement, make sure the

Battery Breaker is in the OFF position.

2.13.1 Insert the Battery Module (Only Standard Series Cabinet)

(1.) Open the UPS’s front door and remove the panel of battery module slot.

(2.) There are 4 rails for inserting the Battery Modules in the same layer. Four Battery Modules

MUST be installed to form a set of Battery.

(3.) Regarding the maximum load of power modules, please refer to section 2.10.2 to install the

required Battery Modules.

(4.) Secure the Battery Module to the cabinet by fixing the screws of the Battery Module.

Page 34

31

3. Operation Mode and UPS Operation

3.1 Block diagram of UPS

Wiring diagram for dual inputs (90KVA~210KVA)

Wiring diagram for dual inputs (300KVA)

Figure 3-1

Page 35

32

Wiring diagram for single input (90KVA~210KVA)

Wiring diagram for single input (300KVA)

Figure 3-2

3.2 Operation Mode

This modular UPS is a three-phase, four wire on-line, double-conversion and reverse-transfer UPS

that permits operation in the following modes:

Standby Mode

Line Mode

Battery Mode

Bypass Mode

ECO Mode

Page 36

33

Shutdown Mode

Maintenance Bypass Mode (manual bypass)

3.2.1 Standby Mode

Upon connecting to utility input power, the UPS is in Standby mode before UPS is turned on (if

BYPASS enable setting is Disabled), and charger function will be active when the battery is present.

The load is not powered under this mode.

Figure 3-3 : Standby Mode Diagram

Page 37

34

3.2.2 Line Mode

In Line Mode, the rectifier derives power from the utility power and supplies DC power to the

inverter and the charger charges the battery. The inverter filters the DC power and converts it into

pure and stable AC power to the load.

Figure 3-4 : Line Mode Diagram

Page 38

35

3.2.3 Battery Mode

The UPS automatically transfers to Battery mode if the utility power fails. There is no interruption

in power to the critical load upon failure.

In battery mode, the rectifier derives power from the battery and supplies DC power to the

inverter. The inverter filters the DC power and converts it into pure and stable AC power to the

load.

Figure 3-5 : Battery Mode Diagram

Page 39

36

3.2.4 Bypass Mode

Upon connecting to utility input power, the UPS is in Bypass mode before UPS is turned on (if

BYPASS enable setting is Enabled), and charger function will be active when battery is present.

After UPS has been turned on, if the UPS encounters abnormal situations (over-temperature,

overload …, etc.), the static transfer switch will perform as a transference of the load from the

inverter to the bypass source with no interruption. If the transference is caused by a recoverable

reason, the UPS will turn back to line mode when abnormal situation is solved.

Figure 3-6 : Bypass Mode Diagram

Page 40

37

3.2.5 ECO Mode

The ECO Mode is enabled through the setting menu of LCD panel. In ECO mode, the load is

powered by bypass when the bypass voltage and frequency are within the acceptable ranges. If

the bypass is out of range, the UPS will transfer the power source of load from bypass to inverter.

In order to shorten the transfer time, the rectifier and inverter are working when the UPS is in ECO

mode.

Figure 3-7 : ECO Mode Diagram

Page 41

38

3.2.6 Shutdown Mode

When the UPS is in the off state and the utility power source is absent, the UPS will enter into

shutdown mode.

Or when the UPS has discharged the battery to the cut-off level, the UPS will enter into shutdown

mode as well.

When the UPS enters this mode, it is going to shut off the control power of UPS. The rectifier,

charger and inverter are all in off state.

Figure 3-8 : Shutdown Mode Diagram

Page 42

39

3.2.7 Maintenance bypass Mode

A manual bypass switch is available to ensure continuity of supply to the critical load when the UPS

becomes unavailable e.g. during a maintenance procedure. Before entering the maintenance

bypass mode, make sure the bypass power source is normal.

Figure 3-9 : Maintenance Bypass Mode Diagram

Page 43

40

3.3 UPS Operation

Do not start the UPS until the installation is completed.

Make sure the wiring is correct and the power cables are fixed firmly.

Make sure the Power Modules’ address have been configured. Refer to section

2.9.2 Power Module

Make sure the ready switch on the Power Module has been moved to the

“Locked” position.

Make sure all the breakers are switch OFF.

3.3.1 AC Startup

Ensure to follow this procedure when turning on the UPS from a fully powered-down condition.

The operating procedures are as follows:

Step 1: Refer to “Chapter 2 Installation” to connect the power cables and install the Power

Modules and the battery required for the UPS system.

Step 2: Switch ON the battery breaker.

Step 3: Switch ON the external power switch to power the UPS. The STS module starts running

and the LCD panel is displayed.

Page 44

41

Step 4: Switch ON the input breaker (Q1). The UPS will enter into Standby Mode, if the setting of

Bypass mode is disabled.

Or the UPS will enter into Bypass Mode, if the setting of Bypass mode is enabled.

Step 5: Make sure there is no warning or fault event happening. If yes, please refer to Chapter 6

Troubleshooting to solve it.

Page 45

42

Step 6: Press Power ON/OFF button for two seconds to enter into Line Mode as shown below.

After turning on, UPS will do self-test and start Inveter up. UPS will be transferred to Line mode

when all power modules are ready.

Step 7: Switch ON the output breaker (Q3). AC startup procedure is complete.

Page 46

43

3.3.2 Cold Start Startup

Step 1: Switch ON the battery Breaker.

Step 2: Press the “Battery Start” button on any one of Power Modules to start up the control

power of all Power modules and STS moodule as shown below.

Battery Start Button

Step 3: After pressing the “Battery Start” button, UPS will enter into Standby mode. Refer to the

diagram below for LCD display.

Step 4: Before UPS enters into shutdown mode, please press “Power On/Off” button for 2 second

immediately as shown in the diagram below.

Page 47

44

Step 5: Then, UPS will enter Battery Mode as shown in the diagram below.

Step 6: Switch ON the output breaker (Q3). Cold start startup procedure is complete.

3.3.3 Maintenance Bypass Operation

Follow the instruction to transfer to Maintenance Bypass and UPS protection as below.

3.3.3.1 Transfer to maintenance bypass

90KVA~210KVA.

300KVA

Step 1:

Remove the mechanical lock plate of

Maintenance Bypass Breaker.

Remove the mechanical lock plate of

Maintenance Bypass Switch.

Step 2

Make sure the UPS operates in Bypass

mode as shown below.

Make sure the UPS operates in Bypass

mode as shown below.

Page 48

45

Step 3

Switch ON the Maintenance Bypass

Breaker as shown below.

Switch the handle toward upside as

shown below.

Step 4

Switch OFF the Main Breaker (Q1) and

Output Breaker (Q3) as shown below.

It is possible to change the STS module,

Power Module.

Step 5

It is possible to change the STS

module, Power Module and Battery

Module.

3.3.3.2 Transfer to UPS Protection

90KVA~210KVA.

300KVA

Step 1

Make sure the maintenance is

complete. The Power Modules and STS

module have been installed well.

Make sure the maintenance is

complete. The Power Modules and STS

module have been installed well.

Page 49

46

Step 2

Switch ON the Main Breaker (Q1) and

Output Breaker (Q3) as shown below.

Please enter LCD SETUP MENU and

choose “SYSTEM” to ensure that the

“Bypass mode” is enabled. If the

“Bypass mode” is disabled, you have to

set it enabled. Then, exit the SETUP

menu and check if the UPS operates in

bypass mode.

Step 3

Please enter LCD SETUP MENU and

choose “SYSTEM” to ensure that the

“Bypass mode” is enabled. If the

“Bypass mode” is disabled, you have

to set it enabled. Then, exit the SETUP

menu and check if the UPS operates in

bypass mode.

Switch the handle toward downside as

shown below.

Page 50

47

Step 4

Turn off Maintenance Bypass Breaker

as shown below.

Lock back the mechanical lock plate as

shown below.

Step 5

Lock back the mechanical lock plate as

shown below.

3.3.4 Turn off Operation

3.3.4.1 Bypass Mode/ Standby Mode Turn Off Operation

When the UPS neither is turned on nor turned off, the UPS operates in the Standby Mode or Bypass

Mode. It depends on the “Bypass Mode” Setting.

The LCD diagrams are shown below.

Bypass Mode Setting is Disabled

Bypass Mode Setting is Enabled

Step 1: Switch OFF the Main Breaker. The LCD diagrams are shown below.

Bypass Mode Setting is Disabled

Page 51

48

UPS enters Shutdown Mode.

It is normal the Un-Connection is shown when

Power Modules have shut off their control

power.

Bypass Mode Setting is Enabled

UPS stay in Bypass mode and No AC input is indicated.

Step 2: Switch OFF the external power switch to disconnect the AC power to the UPS. Wait until

the LCD is OFF.

Step 3: Switch OFF the battery breaker, if the UPS will disconnect the AC power for a long time.

3.3.4.2 Line Mode Turn Off Operation

The LCD diagrams are shown below when the UPS operates in the Line Mode.

Page 52

49

Step 1: Press “Power On/Off” button for 2 second to turn off the UPS. Or use the

Menu-Control-System Turn Off to turn off the UPS.

After turning off, the UPS will tranfer to Standby Mode or Bypass Mode. It depends on the “Bypass

Mode” Setting.

Next, follow the Bypass Mode/ Standby Mode Turn Off Operation procedure.

3.3.4.3 Battery Mode Turn Off Operation

The LCD diagram is shown below when the UPS operates in the Battery Mode.

Page 53

50

Step 1: Press “Power On/Off” button for 2 second to turn off the UPS. Or use the

Menu-Control-System Turn Off to turn off the UPS.

After turning off, the UPS will tranfer to Standby Mode.

Next, follow the Bypass Mode/ Standby Mode Turn Off Operation procedure.

Page 54

51

4. Control Panel and Display Description

4.1 Introduction

This control panel and display description are located on the front door of the UPS. It is the USER

control, monitoring of all measured parameters, UPS and battery status and alarms. The control

panel and display description are divided into four functional areas: (1) LCD display, (2) LED

indications, (3) Control keys, (4) Audio Alarm, as shown in Figure 4-1.

Figure 4-1 Control panel

(1) LCD display: Graphic display and all measured parameters.

(2) LED indications. Refer to Table 4-1.

(3) Control keys. Refer to Table 4-2.

(4) Audible Alarm. Refer to table 4-3.

Table 4-1: LED indications

LED

Color

Status

Definition

INPUT

Green

On

Input source is normal.

Flashing

Input source is abnormal.

Off

No input source

BYPASS

Yellow

On

Load on Bypass.

Flashing

Input source is abnormal.

Off

Bypass not operating.

INVERTER

Green

On

Load on inverters.

Off

Inverters not operating.

BATTERY

Red

On

Load on Battery.

Flashing

Low battery

Off

Battery converter is normal and battery is charging.

ALARM

Red

On

UPS fault.

Flashing

UPS alarm.

Off

Normal.

Page 55

52

Table 4-2: Function Keys

Control Key

Description

Esc

When screen is in Main screen, it will enter into main menu by

pressing ESC key.

Return to previous screen, when screen is not in Main screen.

Return to previous value in the same row, so you can change it.

For example, when changing 4-digit password, press “Esc” to

allow cursor back to previous digit.

(Up) (Left)

Key for menu page navigation or digit modification.

(Down) (Right)

Key for menu page navigation or digit modification.

Enter

Confirmation of commands, or cursor displacement.

Home

Return to Main screen.

Power On/Off

Turn on UPS or Turn off UPS.

Table 4-3: Audible Alarm

Audio Type

Description

Power on/off

Buzzer sounds two seconds.

Battery mode

Buzzer sounds every 2 seconds.

Low battery

Buzzer sounds every half seconds.

UPS alarm

Buzzer sounds every 1 second.

UPS fault

Buzzer continuously sounds.

4.2 Screen Description

4.2.1 Start Screen

Upon starting, the UPS executes self-test. The initial screen displays and remains still in

approximately 5 seconds as shown in Figure 4-2.

Figure 4-2 Initial screen

4.2.2 Main Screen

After initialization, the main screen will display as Figure 4-3. Main screen is divided into five parts.

(1) UPS Mode: Current Operation Mode.

(2) UPS Flow Chart: Current flow chart and measurement data.

(3) Menu: Press ESC button to enter Menu screen.

(4) UPS model name with power rating. If the power rating followed with (R) means the UPS

system has redundant configuration.

Page 56

53

(5) Date and Time.

Figure 4-3 Main screen

4.2.3 MENU Screen

In the Main Screen, press ESC button to enter the MENU screen

Use UP and DOWN buttons to choose different menus, and Press ENTER to enter the sub screen,

as shown in Figure 4-4 and 4-5.

Figure 4-4 Menu tree

Figure 4-5 Menu screen

4.2.4 Control Screen

Use UP and DOWN buttons to choose CONTROL option, and press ENTER button to enter the

submenu, as shown in Figure 4-6, 4-7 and 4-8.

Page 57

54

Figure 4-6 Control menu

Figure 4-7 Control screen page 1

Figure 4-8 Control screen page 2

Page 58

55

When the control option is selected by pressing ENTER button, the confirmation screen will pop up.

Use LEFT and RIGHT buttons to choose YES or NO. Choose YES and press ENTER button to

confirm command or choose NO to cancel command, as shown in Figure 4-9.

Figure 4-9 Confirmation screen

4.2.5 Measurement Screen

Use UP and DOWN buttons to choose MEASUREMENT option, and press ENTER button to go into

the submenu, as shown in Figure 4-10, 4-11.

Figure 4-10 Measurement menu

Figure 4-11 Measurement Menu Screen

Use UP and DOWN buttons to choose System, STS, Power Module option, and press ENTER button

to go into the submenu, as shown in Figure 4-12.

Page 59

56

Figure 4-12 Measurement source selection Screen

Use UP and DOWN buttons to choose Input, Output, Bypass, Load, and Battery option, and press

ENTER button to go into submenu. The measurement can be read listed in Table 4-4.

Table 4-4: Measurement data

Menu

Item

Explanation

Input

L-N Voltage (V)

Input phase voltage (L1, L2, L3). Units 0.1V.

Frequency (Hz)

Input Frequency (L1, L2, L3). Units 0.1Hz.

Output

L-N Voltage (V)

Output phase voltage (L1, L2, L3). Units 0.1V.

L-N Current (A)

Output phase current (L1, L2, L3). Units 0.1A.

Frequency (Hz)

Output Frequency (L1, L2, L3). Units 0.1Hz.

Power Factor

Output Power Factor (L1, L2, L3).

Bypass

L-N Voltage (V)

Bypass phase voltage (L1, L2, L3). Units 0.1V.

Frequency (Hz)

Bypass Frequency (L1, L2, L3). Units 0.1Hz.

Power Factor

Bypass Power Factor (L1, L2, L3).

Load

Sout (KVA)

Apparent power. Units 0.1KVA.

Pout (KW)

Active power. Units 0.1KW.

Load Level (%)

The percentage of the UPS rating load. Units 1%.

Battery

Positive Voltage (V)

Battery Positive Voltage. Units 0.1V.

Negative Voltage (V)

Battery Negative Voltage. Units 0.1V.

Positive Current (A)

Battery Positive Current. Units 0.1A.

Negative Current (A)

Battery Negative Current. Units 0.1A.

Remain Time (Sec)

Battery run time remaining. Units 1sec.

Capacity (%)

The percentage of the capacity of the battery. Units 1%.

Test Result

Battery test result

Charging Status

Battery charging status

Temperature1(℃)

Battery cabinet temperature of STS module. Units 0.1℃.

Temperature2(℃)

Battery cabinet temperature of extra communication

card T1. Units 0.1℃.

Temperature3(℃)

Battery cabinet temperature of extra communication

card T2. Units 0.1℃.

Temperature4(℃)

Battery cabinet temperature of extra communication

card T3. Units 0.1℃.

Page 60

57

Temperature5(℃)

Battery cabinet temperature of extra communication

card T4. Units 0.1℃.

4.2.6 Setup Screen

Use UP and DOWN buttons to choose SETUP options. It’s required to enter password to access

General, SYSTEM, BATTERY, PRE-ALARM and PARALLEL sub-menus, as shown in Figure 4-13.

Figure 4-13 Setup menu

When the SETUP option is selected by pressing ENTER button, it will pop up a screen requesting to

enter password, as shown in Figure 4-14.

Figure 4-14 Enter password Screen

It’s required to enter 4-digit password to enter SETUP submenu. If incorrect password is entered,

the LCD screen will ask for re-entery.

Page 61

58

If correct password is entered, the LCD will enter the SETUP submenu, as shown in Figure 4-16.

Figure 4-16 SETUP Submenu Screen

There are two levels of password protection, user password and maintainer password.

The default password for user is “0000”. It could be change by user.

The manitainer password is owned by service personnel.

Entering different level of password can access to differnet settings. The setting can be changed in

different operation mode. The Table 4-5 lists the relevant information.

Table 4-5: All setting items in Setup Menu

UPS operation

Mode

Setting item

Standby

Mode

Bypass

Mode

Line

Mode

Battery

Mode

Battery

Test

Mode

Fault

Mode

Converter

Mode

ECO

Mode

Authorization

User

Maintainer

General

Model Name

Y Y Y Y Y Y Y Y Y Language

Y Y Y Y Y Y Y Y Y

Y

TIME

Y Y Y Y Y Y Y Y

Y

Change

Password

Y Y Y Y Y Y Y Y Y

Y

Baud Rate

Y Y Y Y Y Y Y Y Y

Y

Audible Alarm

Y Y Y Y Y Y Y Y Y

Y

Factory Reset

Y

Y

EEPROM Reset

Y Y EPO Function

Y

Y

Save Setting

Y Y Y

Y

System

Output Voltage

Y Y

Y

Bypass Voltage

Range

Y Y Y Y Y Y Y Y

Y

Bypass

Frequency

Range

Y Y

Y

Converter Mode

Y Y ECO Mode

Y Y Y Y

Y

Bypass Mode

Y Y Y Auto-Restart

Y Y Y Y Y Y Y Y

Y

Cold Start

Y Y Y Y Y Y Y Y

Y

Battery Mode

Delay Time

Y Y Y Y Y Y

Y

System

Shutdown Time

Y Y Y Y Y Y Y Y

Y

Page 62

59

System Restore

Time

Y Y Y Y Y Y Y Y

Y

Redundancy

Y Y Y Y Y Y Y Y

Y

Power Rating

Setting

Y

Y

Charger Test

Y Y Y Y Y

Y

Battery

Nominal Battery

Voltage

Y Y

Y

Battery Capacity

in Ah

Y Y Y Y Y Y

Y

Maximum

Charging

Current

Y Y

Y

Battery

Low/Shutdown

Setting

Y Y Y Y Y Y

Y

Periodic Battery

Test

Y Y Y Y Y Y Y Y

Y

Battery Test

Interval

Y Y Y Y Y Y Y Y

Y

Stop by Time

Y Y Y Y Y Y Y

Y

Stop by Battery

Voltage

Y Y Y Y Y Y Y

Y

Stop by Battery

Capacity

Y Y Y Y Y Y Y

Y

Battery Age Alert

Y Y Y Y Y Y Y Y

Y

Temperature

Compensation

Y Y Y Y Y Y Y Y

Y

Charging

Voltage

Y Y

Y

Pre-Alarm

Y Y Y Y Y Y Y Y

Y

Parallel

UPS Parallel

Y Y

Y

Independent

Battery

Y Y

Y

“Y” means that this setting item can be set in this operation mode.

4.2.6.1 Setup-General Screen

Use UP and DOWN buttons to choose between different sub-menus, and press ENTER button to go

into the GENERAL setting screen, as shown in Figure 4-17, 4-18. General setting can be set in any

operating mode and Setup-General setting list is shown in Table 4-6.

Figure 4-17 Setup-General Screen page 1

Page 63

60

Figure 4-18 Setup-General Screen page 2

Use LEFT and RIGHT buttons to choose the setting options for setting requirement, then press

ENTER. The confirmation screen will pop up, use LEFT and RIGHT buttons to choose YES or NO.

Choose YES and press ENTER button to confirm setting or choose NO to cancel the setting, as

shown in Figure 4-19.

Figure 4-19 SETUP Confirmation screen

Table 4-6: Setup-General setting list

Setting Item

Sub Item

Explanation

Model Name

Set UPS Name (xxxxxxxxxx).

The max. length is 10 characters.

Language

--

Provides 3 optional LCD languages:

English (Default)

Traditional Chinese

Simplified Chinese

Deutsch

TIME

Adjust Time

Set current date and time.

(yyyy / mm / dd hour : min : sec)

MUST be set after UPS installation

System Installed Date

Set system installed date

Page 64

61

(yyyy / mm / dd)

2015/1/1 (Default)

MUST be set after UPS installation

System Last Maintain

Date

Set system latest maintenance date

(yyyy / mm / dd)

MUST be set after UPS installation

Battery Installed Date

Set battery installed date

(yyyy / mm / dd)

MUST be set after UPS installation

Battery Last Maintain

Date

Set battery latest maintenance date

(yyyy / mm / dd)

MUST be set after UPS installation

Change

Password

--

Set New Password.

0000 (Default)

Baud Rate

--

Set COM Port0 Baud Rate

2400 (Default)

4800

9600

Set COM Port1 Baud Rate

2400 (Default)

4800

9600

Audible

Alarm

--

Set Audible Alarm

Disable

Enable (Default)

Factory

Reset

--

Restore to factory default setting

Refer to Table 4-7

EEPROM

Reset

--

Set EEPROM default

Refer to Table 4-7

EPO

Function

--

Set EPO active status

Normal Close Active

Normal Open Active (Default)

Save Setting

--

Save EEPROM

Use this feature to save the setting(s) you have

done.

Table 4-7: EEPROM Reset Category list

Setting Item

Factory Reset

EEPROM Reset

General

Model Name

Language Y Y

Adjust Time

System Installed Date

Y

System Last Maintain Date

Y

Battery Installed Date

Y

Battery Last Maintain Date

Y

Change Password

Y

Baud Rate Y

Audible Alarm

Y

Y

Factory Reset

--

--

EEPROM Reset

--

--

EPO Function

Y

Page 65

62

Save Setting

--

--

System

Output Voltage

Y

Bypass Voltage Range

Y

Y

Bypass Frequency Range

Y

Y

Converter Mode

Y

Y

ECO Mode Y Y

Bypass Mode

Y

Y

Auto-Restart

Y

Y

Cold Start Y

Battery Mode Delay Time

Y

Y

System Shutdown Time

Y

Y

System Restore Time

Y

Y

Redundancy

Y

Power Rating Setting

Y

Y

Charger Test

--

--

Battery

Nominal Battery Voltage

Y

Y

Battery Capacity in Ah

Y

Y

Maximum Charging Current

Y

Y

Battery Low/Shutdown Setting

Y

Y

Periodic Battery Test

Y

Y

Battery Test Interval

Y

Y

Stop by Time

Y

Y

Stop by Battery Voltage

Y

Y

Stop by Battery Capacity

Y

Y

Battery Age Alert

Y

Y

Temperature Compensation

Y

Y

Charging Voltage

Y

Y

Pre-Alarm

Y

4.2.6.2 Setup-System Screen

Use UP and DOWN buttons to choose between different sub-menus, and press ENTER button to go

into the SYSTEM setting screen, as shown in Figure 4-20, 4-21, 4-22.

Figure 4-20 Setup-System Screen page 1

Page 66

63

Figure 4-21 Setup-System Screen page 2

Figure 4-22 Setup-System Screen page 3

System setting can be set only when UPS is operating in certain mode. Please check available

setting item in Table 4-5 for the details. If it’s not set up in specific mode, the warning screen will

appear, as shown in Figure 4-23.

Page 67

64

Figure 4-23 Warning screen

Setup-System setting list is shown in Table 4-8.

Table 4-8: Setup-System setting list

Setting Item

Sub Item

Explanation

Output

Voltage

--

Set output voltage

220Vac (Default)

230Vac

240Vac

MUST be reviewed after UPS installation

BYPASS

SETTING

Bypass Voltage Range

Set bypass voltage range:

Upper limit

+10%

+15% (Default)

+20%

Lower limit

-10%

-20% (Default)

-30%

Bypass Frequency

Range

Set bypass Frequency range:

Upper/ Lower limit

+/- 1Hz

+/- 2Hz

+/- 4Hz (Default)

Converter

Mode

--

Set converter mode

Disable (Default)

Enable

ECO Mode

--

Set ECO mode

Disable (Default)

Enable

Bypass

Mode

--

Set bypass mode

Disable (Default)

Enable

MUST be reviewed after UPS installation.

If you need the Bypass power when UPS is OFF, please

enable it.

Page 68

65

Auto-Restart

--

Set auto-restart

Disable

Enable (Default)

After “Enable” is set, once UPS shutdown occurs due to

low battery and then utility restores, the UPS will return

to line mode.

Cold Start

--

Set cold start

Disable

Enable (Default)

After “Enable” is set, the UPS can be turned on without

connecting to utility by pressing Battery Start Button.

Refer to cold start operation for the details.

Battery

Mode Delay

Time

--

Set system shutdown delay time in battery mode

(0~9990sec).

0: Disable (Default)

Not 0: Enable

When this feature is enabled, UPS will shut off output

after UPS operates in Battery mode for certain seconds.

System

Shutdown

Time

--

Set system shutdown time (0.2~99min)

0.2 min (Default)

This delay time will start counting when the

CONTROL-Shutdown Restore command is executed.

System

Restore

Time

--

Set system restore time (0~9999min)

1 min (Default)

This delay time will start counting after shutdown time is

elapsed when the CONTROL-Shutdown Restore

command is executed.

Redundancy

--

Set total power and redundancy

Total Power: the QTY of Power Modules

Redundancy: the QTY of redundant power module

MUST be set after UPS installation or the QTY of

Power Module is changed

Power

Rating

Setting

Set Power Module Rating

20KVA

30KVA (Default)

The 30K cabinet can be inserted with all 20KVA power

modules. For this kind of application, the Power Rating

has to be set to 20KVA.

If setting is not corresponding to power capacity of

power module, it will show error message.

MUST be reviewed after UPS installation

Redundancy

--

Set total power and redundancy

Total Power: the QTY of Power Modules

Redundancy: the QTY of redundant power module

MUST be set after UPS installation or the QTY of

Power Module is changed

Charger Test

--

Set charger test

Disable (Default)

Enable

Page 69

66

4.2.6.3 Setup-Battery Screen

Use UP and DOWN buttons to switch different sub-menus. Press ENTER button to go into the

BATTERY setting screen, as shown in Figure 4-24, 4-25.

Figure 4-24 Setup-Battery Screen page 1

Figure 4-25 Setup-Battery Screen page 2

Battery setting can be set only when UPS is operating in standby mode. If it’s not in standby mode,

the warning screen will appear as shown in Figure 4-23. See Setup-Battery setting list in Table

4-9.

Table 4-9: Setup-Battery setting list

Setting Item

Sub Item

Explanation

Nominal

Battery Voltage

--

Set battery nominal voltage

16x12V (Default)

18x12V

20x12V

MUST be set after UPS installation

Battery

Capacity in Ah

--

Set battery capacity. (0~999)

9Ah (Default)

MUST be set after UPS installation or Battery

Page 70

67

capacity is changed.

Maximum

Charging

Current

--

Set battery maximum charging current (1~128A)

2A (Default)

MUST be set after UPS installation or Battery

capacity is changed.

Battery Low/

Shutdown

SETTING

Battery Low

Voltage

Set battery low voltage (10.5~11.5V)x(battery Number)

11V x Battery Number (Default)

Battery Low

Capacity

Set battery low capacity (20~50%)

20% (Default)

Battery Shutdown

Voltage

Set battery voltage point for system shutdown in battery

mode (10.0~11V) x (battery Number)

10V x Battery Number (Default)

BATTERY TEST

Periodic Battery

Test

Set periodic battery test disable or enable

Disable (Default)

Enable

Battery Test

Interval

Set battery test interval (7~99 Days)

30 Days (Default)

Stop by Time

Set testing time for battery test (10~1000sec)

10 sec (Default)

Stop by Battery

Voltage

Set stop battery voltage in battery test (11~12V) x

(battery Number)

11V x Battery Number (Default)

Stop by Battery

Capacity

Set battery capacity to stop battery-testing. (20~50%)

20% (Default)

Battery Age

Alert

Battery Age Alert

(Months)

Set battery age for replacement. (Disable,12~60Months)

Disable (Default)

If this feature is enabled and the battery has been

installed over this period, there is a warning “Battery Age

Alert” to indicate it.

Temperature

Compensation

--

Set battery temperature compensation. (0~-5 (mV/℃

/cl))

0(mV/℃/cl) (Default)

Charging

Voltage

--

Set battery charging voltage. (2.30~2.35V)

2.35V (Default)

Set battery float voltage. (2.23~2.35V)

2.29V (Default)

Page 71

68

4.2.6.4 Pre-Alarm Screen

Use UP and DOWN buttons to switch different sub-menus. Press ENTER button to go into the

Pre-Alarm setting screen, as shown in Figure 4-26.

Figure 4-26 Setup-Pre-Alarm screen

Pre-Alarm setting can be set in any operation mode. See Setup-Pre-Alarm setting list in Table

4-10.

Table 4-10: Setup-Pre-Alarm setting list

Setting Item

Sub Item

Explanation

Line Voltage

Range

--

Set line voltage range:

Upper limit

+5%

+10%

+15%

+20% (Default)

Lower limit

-5%

-10%

-15%

-20% (Default)

Line

Frequency

Range

--

Set line frequency range:

Upper / Lower limit

+/- 1Hz

+/- 2Hz

+/- 3Hz

+/- 4Hz (Default)

Load

--

Set UPS Overload percentage (40~100%)

100% (Default)

Set UPS load unbalance percentage (20~100%)

100% (Default)

4.2.6.5 Setup-Parallel Screen

Use UP and DOWN buttons to switch between different sub-menus. Press ENTER button to go into

the PARALLEL setting screen, as shown in Figure 4-27.

Page 72

69

Figure 4-27 Setup-Parallel screen

See Setup-Parallel setting list in Table 4-11.

The warning “Warning! Parallel Firmware Error” will appear in current event

when the parallel setting is enabled, but the firmware does not support this

feature.

The way to release this warning is to turn off the AC power source and shut

down the system. After the system shutdown completely, turn on the AC

power to restart the UPS.

Table 4-11: Setup-Parallel setting list

Setting Item

Sub Item

Explanation

UPS Parallel

--

Set UPS parallel

Disable (Default)

Enable

Independent

Battery

--

Set Independent Battery

Disable (Default)

Enable

4.2.7 Information Screen

In INFORMATION menu, you can check the serial number, firmware versions, system

configuration and settings of the UPS. There are submenus under the INFORMATION, including

Identification, System and Battery, as shown in Figure 4-28, 4-29.

Figure 4-28 Information menu

Page 73

70

Figure 4-29 INFORMATION screen

4.2.7.1 INFORMATION - Identification Screen

When Identification submenu is selected, the Model Name, Serial No. and Firmware Version will be

displayed, as shown in Figure 4-30, 4-31. Use UP and DOWN buttons to switch between different

pages.

Figure 4-30 Identification screen page 1

Page 74

71

Figure 4-31 Identification screen page 2

4.2.7.2 INFORMATION - System Screen

When System submenu is selected, the system power, nominal voltage, nominal frequency … etc.

information will be displayed, as shown in Figure 4-32, 4-33, 4-34. Use UP and DOWN buttons to

switch between different pages.

Figure 4-32 INFORMATION System screen page 1

Page 75

72

Figure 4-33 INFORMATION System screen page 2

Figure 4-34 INFORMATION System screen page 3

4.2.7.2 INFORMATION - Battery Screen

When Battery submenu is selected, the Battery nominal voltage, capacity, charging current … etc.

information will be displayed, as shown in Figure 4-35, 4-36. Use UP and DOWN buttons to switch

different pages.

Page 76

73

Figure 4-35 INFORMATION Battery screen page 1

Figure 4-36 INFORMATION Battery screen page 2

4.2.8 Events Screen

In EVENT menu, you can check the current events, history events and reset all events, as shown in

Figure 4-37, 4-38.

Figure 4-37 Events menu

Page 77

74

Figure 4-38 Events screen

When event occurs, you will see flashing warning text in the Main Screen as shown in Figure 4-39.

Figure 4-39 Alarm warning screen

4.2.8.1 Current Events

When event occurs, it will display Module ID and alarm code in Current Events screen. It can save

up to 50 events in current list. Only 4 events can be listed in one page. Therefore, if it exceeds

more than four, you have to press UP or DOWN button to read other events as shown in Figure

4-40.

Page 78

75

Figure 4-40 Current Events screen

4.2.8.2 History Events

The detailed event information is saved in history events. It can save up to 500 events in history

events. When warning occurs, it will display alarm code, alarm time and Module ID. When fault

event occurs, it will display alarm code, alarm time, Module ID and data 1~2. (Refer to Table

4-12 Alarm List) In order to record more historical information about the UPS system, the

important setting changed (refer to Table 4-13 Important setting changed), UPS operation mode

changes (refer to Table 4-14 UPS mode change) and control action executes (refer to Table

4-15 Control execution) will be saved in History Events. Refer to Figure 4-41 for display screen.

Figure 4-41 History Events screen

4.2.8.3 Reset All Events

The Maintainer password is required to enter Reset All Events screen as shown in Figure 4-42.

Then, use LEFT and RIGHT buttons to choose YES or NO. Choose YES and press ENTER button to

reset all events or choose NO to cancel this action as shown in Figure 4-43.

Page 79

76

Figure 4-42 Reset All Events screen

Figure 4-43 Reset All Events Confirmation screen

4.3 Alarm List

In Table 4-12, it provides the complete list of UPS alarm messages.

Table 4-12: Alarm List

Representation in display LCD

Explanation

Fault! Bus Over Voltage

DC bus voltage is too high

Fault! Bus Under Voltage

DC bus voltage is too low

Fault! Bus Voltage Unbalance

DC bus voltage is not balanced

Fault! Bus Short

DC bus is short

Fault! Bus Soft Start Time Out

The rectifiers can’t start due to low DC bus voltage

within specified duration

Fault! Inverter Soft Start Time Out

Inverter bus voltage cannot reach desired voltage within

specified duration

Fault! Inverter Voltage Over

Inverter Voltage is over Peak Value.

Page 80

77

Fault! Inverter Voltage High

Inverter Voltage is too high

Fault! Inverter Voltage Low

Inverter Voltage is too Low

Fault! R Inverter Voltage Short

R phase inverter Output is short-circuited.

Fault! S Inverter Voltage Short

S phase inverter Output is short-circuited.

Fault! T Inverter Voltage Short

T phase inverter Output is short-circuited.

Fault! RS Inverter Voltage Short

R-S inverter Output is short-circuited.

Fault! ST Inverter Voltage Short

S-T inverter Output is short-circuited.

Fault! TR Inverter Voltage Short

T-R inverter Output is short-circuited.

Fault! Inverter R Negative Power

R phase inverter Output Negative Power over range

Fault! Inverter S Negative Power

S phase inverter Output Negative Power over range

Fault! Inverter T Negative Power

T phase inverter Output Negative Power over range

Fault! Over Load Fault

Heavy overload causes UPS fault.

Fault! Battery Fault

Batteries reversed

Fault! Over Temperature

Make sure adequate space is allowed for air ventilation

and the fan is working

Fault! CAN Fault

CAN communication fault

Fault! TRIG0 Fault

Synchronized trigger signal fault

Fault! Relay Fault

Inverter relay fault

Fault! Line SCR Fail

Line SCR short circuit fault

Fault! EEPROM Fault

EEPROM operation error

Fault! Parallel Cable Loosen Fault

As stated.

Fault! DSP MCU Stop Communicate

As stated.

Fault! Bypass Temperature Fault

As stated

Fault! Bypass SCR Fault

As stated.

Line Fail

Utility lost or abnormal

Line Restore

Utility recovered to normal

Warning! EPO Active

Check the EPO connector

Warning! Over Load Fail

The load devices are demanding more power than the

UPS can supply. Line mode will transfer to Bypass

mode.

Warning! Communicate CAN Fail

CAN communication error

Warning! Over Load

In Line mode, the load devices are demanding more

power than the UPS can supply.

Warning! Battery Open

Battery not connected

Warning! Battery voltage High

Battery voltage is too High

Warning! Module Un-Lock

As stated.

Warning! Turn On Abnormal

As stated.

Warning! Charge Fail

As stated.

Warning! EEPROM Fail

EEPROM operation error

Warning! Fan Lock

As stated.

Page 81

78

Warning! Line Phase Error

As stated.

Warning! Bypass Phase Error

As stated.

Warning! N Loss

Neutral loss

Warning! Internal Initial Fail

As stated.

Warning! Comm Syn Signal Fail

Communicate Synchronization Signal Fail

Warning! Comm. TRIG0 Fail

Communicate Trigger signal fault

Warning! Redundancy Set Fail

As stated.

Warning! Parallel Sys Config. Wrong

Parallel System Configure error

Warning! Maintenance Bypass

Enter maintenance

Warning! Battery Age Alert

Battery Life expiration

Warning! Parallel Rack Cable Loosen

As stated.

Warning! Parallel Rack Config. Wrong

Parallel Rack Configure error

Warning! Parallel Firmware Error

Power module parallel firmware error

Warning! Battery Voltage Low

Battery voltage is too low.

Warning! ID Conflict

Power module ID conflict.

Pre-Alarm! Line Voltage Fail

Line voltage over range

Pre-Alarm! Line Voltage Normal

Line voltage recovered to normal

Pre-Alarm! Line Frequency Unstable

Line frequency over range

Pre-Alarm! Line Frequency Normal

Line frequency recovered to normal

Pre-Alarm! Over Load

Output Load over range

Pre-Alarm! Load Normal

Output Load recovered to normal

Pre-Alarm! Load Unbalance

Output Load unbalance

4.4 History Record

Table 4-13: Important setting changed

Item

No.

Description

Item

No.

Description

1