Page 1

REV™ Autoloader 1000

User’s Manual

D31256600 10/18/04 e

Page 2

Copyright

Copyright © 2004 Iomega Corporation. All rights reserved. Portions of this manual are © BDT Products, Inc. or its

affiliates.

Trademark Notices

Iomega, the stylized “i” logo, REV, and all Iomega brand blocks are either registered trademarks or trademarks of

Iomega Corporation in the United States and/or other countries. Microsoft and Windows are either registered

trademarks or trademarks of Microsoft Corporation in the United States and/or other countries. Certain other

product names, brand names, and company names may be trademarks or designations of their respective

owners.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 2 of 82

Page 3

1 Warnings

IMPORTANT

!

!

All safety and operating instructions should be read before this product is

operated, and should be retained for future reference. This unit has been

engineered and manufactured to assure your personal safety. Improper use can

result in potential electrical shock or fire hazards. In order not to defeat the

safeguards, observe the following basic rules for its installation, use and

servicing.

DANGER High voltage!

Risk of electric shock.

Do not remove cover (or back). No user-serviceable parts inside. Refer

servicing to qualified service personnel.

Ventilation—The product should be situated so that its location or position does not interfere with proper

ventilation.

Heat—The product should be situated away from heat sources such as radiators, heat registers, furnaces, or

other heat producing appliances.

Power sources—The product should be connected to a power source only of the type directed in the

operating instructions or as marked on the product.

Power cord protection—The AC line cord should be routed so that it is not likely to be walked on or pinched

by items placed upon or against it, paying particular attention to the cord at the wall receptacle, and the point

where the cord exits from the product.

Power Disconnection—Remove the power (electric) cable and the SCSI cable from their connections in the

back of the autoloader.

Object and liquid entry—Care should be taken to insure that objects do not fall and liquids are not spilled into

the product’s enclosure through openings.

Servicing—The user should not attempt to service the product beyond that described in the operating

instructions. All other servicing should be referred to qualified service personnel.

1.1 Precautions

Do not expose the unit to moisture. The operating temperature for this unit is between 10°C (50°F) and 40°C

(104°F).

Use the unit on a firm level surface free from vibration, and do not place anything on top of the unit.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 3 of 82

Page 4

1.2 Product Warranty Caution

The Iomega® REV™ Autoloader 1000 is warranted to be free from defects in materials, parts, and workmanship

and will conform to the current product specification upon delivery. For the specific details of your warranty, see

section 11.

The warranty for the autoloader shall not apply to failures of any unit when:

The autoloader is repaired or modified by anyone other than the manufacturer’s personnel or approved agent.

The autoloader fails because of accident, misuse, abuse, neglect, mishandling, misapplication, alteration,

faulty installation, modification, or service by anyone other than the factory service center or its approved

agent.

The manufacturer’s serial number tag is removed.

The autoloader is damaged because of improper packaging on return.

CAUTION Rough Handling at Shipping!

If you are returning the autoloader for repair, package it in its original

packaging (or in replacement packaging obtained from Iomega). Shipping

damage will void your warranty.

CAUTION Untrained or unauthorized personnel!

If problems with the autoloader occur, contact Iomega. Unauthorized

service will void your warranty.

NOTE: The most current information about this product is available at Iomega web site (www.iomega.com).

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 4 of 82

Page 5

2 Contents

1 Warnings ............................................................................................................................................. 3

1.1 Precautions................................................................................................................................ 3

1.2 Product Warranty Caution ........................................................................................................ 4

2 Contents.............................................................................................................................................. 5

3 Quick Start Guide...............................................................................................................................8

4 Features and Physical Description ...............................................................................................12

4.1 Equipment Description............................................................................................................ 12

4.2 Features................................................................................................................................... 12

4.3 Component Descriptions ........................................................................................................13

5 Installation and Setup ..................................................................................................................... 15

5.1 Installing the Optional Remote Management Unit (RMU)..................................................... 15

5.1.1 Contents of the Kit:.......................................................................................................15

5.1.2 Required Tools: ............................................................................................................15

5.1.3 Mounting Instructions: ..................................................................................................15

5.2 Installing the Optional Bar Code Reader (BCR) .................................................................... 16

5.2.1 Contents of the Kit:.......................................................................................................16

5.2.2 Required Tools: ............................................................................................................16

5.2.3 Mounting Instructions: ..................................................................................................16

5.2.4 Configuration of the Barcode Reader.......................................................................... 17

5.2.5 Barcode Labels.............................................................................................................17

5.2.6 Removing the Barcode Reader ...................................................................................18

5.3 Installing the Autoloader as a Desktop Unit........................................................................... 18

5.3.1 Checks Before Installation: .......................................................................................... 18

5.3.2 Connecting Power ........................................................................................................19

5.4 Installing the Autoloader in a Rack.........................................................................................

5.4.1 Prepare the Autoloader for Installation........................................................................ 19

5.4.2 Install the Support Rails in the Rack............................................................................19

5.4.3 Install the Rack Front Mount Brackets on the Autoloader.......................................... 21

5.4.4 Secure the Autoloader to the Rack.............................................................................. 21

19

6 Operation and Maintenance ...........................................................................................................22

6.1 Powering on the System......................................................................................................... 22

6.2 Using the Operator Control Panel and Menu Options........................................................... 24

6.3 Operational Modes.................................................................................................................. 25

6.3.1 Automatic Mode............................................................................................................ 25

6.3.2 Random Mode ..............................................................................................................25

6.3.3 Sequential Mode...........................................................................................................25

6.3.4 Loop Mode.................................................................................................................... 26

6.3.5 Autoload Mode .............................................................................................................26

6.3.6 OCP Philosophy ........................................................................................................... 26

6.4 OCP—Menu Trees..................................................................................................................27

6.4.1 User Go Offline Mode with Protection ......................................................................... 27

6.4.2 User Go Offline Mode without Protection....................................................................27

6.4.3 OCP User Interaction Mode......................................................................................... 28

6.4.4 Information ....................................................................................................................29

6.4.5 Commands ...................................................................................................................30

Configuration ...........................................................................................................................31

6.4.6 Diagnostic .....................................................................................................................34

6.5 Operation ................................................................................................................................. 37

6.5.1 Monitoring Autoloader Operation and Status.............................................................. 37

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 5 of 82

Page 6

6.6 Loading and Unloading REV disks......................................................................................... 37

6.6.1 Importing and Exporting Cartridges............................................................................. 37

6.6.2 Bulk Exchange..............................................................................................................37

6.6.3 Load and Unload a Cartridge....................................................................................... 37

6.6.4 Write Protected Media.................................................................................................. 38

6.7 Shipping................................................................................................................................... 38

7 Troubleshooting and Diagnostics................................................................................................. 39

7.1 General Guidelines .................................................................................................................39

7.2 Error LED/Error Code .............................................................................................................39

7.2.1 Viewing Error Codes via the OCP ............................................................................... 39

7.2.2 Viewing Error Codes via the RMU............................................................................... 39

7.3 Analysis Procedures ............................................................................................................... 40

7.3.1 Power/External Fan Analysis....................................................................................... 40

7.3.2 RMU Analysis ...............................................................................................................40

7.3.3 BCR Analysis ................................................................................................................ 40

7.3.4 Cartridge Won’t Eject ...................................................................................................41

7.4 Error Messages and Error Codes........................................................................................... 41

7.4.1 Error Code Description................................................................................................. 42

7.4.2 Example for an Error/Event Log: ................................................................................. 42

7.4.3 Not Ready Errors 01h–0Fh .......................................................................................... 42

7.4.4 Unit Attention 10h–1Fh ................................................................................................43

7.4.5 Recovered Errors 20h–2Fh.......................................................................................... 43

7.4.6 Hardware Errors 30h–4Fh ...........................................................................................43

7.4.7 Illegal Request Errors 50h–6Fh ................................................................................... 44

7.4.8 Aborted Command Errors 70h–73h............................................................................. 45

7.4.9 Additional Errors 7ah–7Fh ........................................................................................... 45

7.4.10Robotic Control Errors 81h–8Fh .................................................................................. 45

7.4.11Function Errors 90h–9Fh .............................................................................................46

7.4.12Low Level Axis Errors A0h–AFh .................................................................................. 47

7.4.13Electronic Hardware Errors B0h–B9h .........................................................................48

7.4.14Drive Errors BAh–BFh..................................................................................................48

7.4.15Barcode Errors C0h–CFh ............................................................................................ 49

7.4.16Network Errors D0h–D5h ............................................................................................. 49

7.4.17Subcode Descriptions ..................................................................................................49

7.5 Access Protocol.......................................................................................................................52

7.6 Error and Trace Log................................................................................................................ 52

7.6.1 Log Mode...................................................................................................................... 53

7.7 OCP User Interaction Mode Operation ..................................................................................54

7.7.1 User Interaction Mode Operational Notes...................................................................54

7.7.2 Implied Import Operation.............................................................................................. 54

8 Remote Management Unit (RMU) .................................................................................................. 55

8.1 Overview..................................................................................................................................55

8.2 Saving/Restoring Vital Product Data (VPD) on the RMU...................................................... 56

8.3 User Interface Pages .............................................................................................................. 56

8.3.1 Login .............................................................................................................................56

8.3.2 Information ....................................................................................................................58

8.3.3 Status ............................................................................................................................60

8.3.4 Configuration ................................................................................................................62

8.3.5 Maintenance .................................................................................................................69

8.3.6 Logs ..............................................................................................................................74

9 SCSI Interface Specification ..........................................................................................................76

9.1 Cable and Terminator Requirements .....................................................................................76

9.1.1 SCSI Cable Requirements........................................................................................... 76

9.1.2 SCSI Terminator Requirements................................................................................... 77

10 How to Get Help ..............................................................................................................

................. 78

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 6 of 82

Page 7

11 Limited Warranty..............................................................................................................................79

11.1 Coverage .................................................................................................................................79

11.2 Excluded Products and Problems .......................................................................................... 79

11.3 Remedies ................................................................................................................................79

11.4 Obtaining Warranty Service....................................................................................................79

11.4.1 North America...............................................................................................................79

11.4.2 Latin America................................................................................................................80

11.5 Limitations ............................................................................................................................... 80

12 Regulatory Information................................................................................................................... 81

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 7 of 82

Page 8

3 Quick Start Guide

S

t

art

U

p

M

i

s

e

en

rou

t

e

S

t

a

rt

I

n

i

c

i

o

I

n

i

c

i

a

l

i

z

a

ç

ã

o

I

n

s

t

a

l

a

c

i

ón

3

1

3

8

7

2

0

0

w

w

w.

i

o

m

e

g

a

.

c

o

m

C

o

p

y

r

i

g

h

t

©

2

0

0

4

I

o

m

e

g

a

C

o

rp

o

r

a

t

i

o

n

.

A

l

l

r

i

g

h

t

s

r

e

s

e

r

ve

d

.

Wi

ndo

w

s

Mac

A

v

v

i

o

Defaults

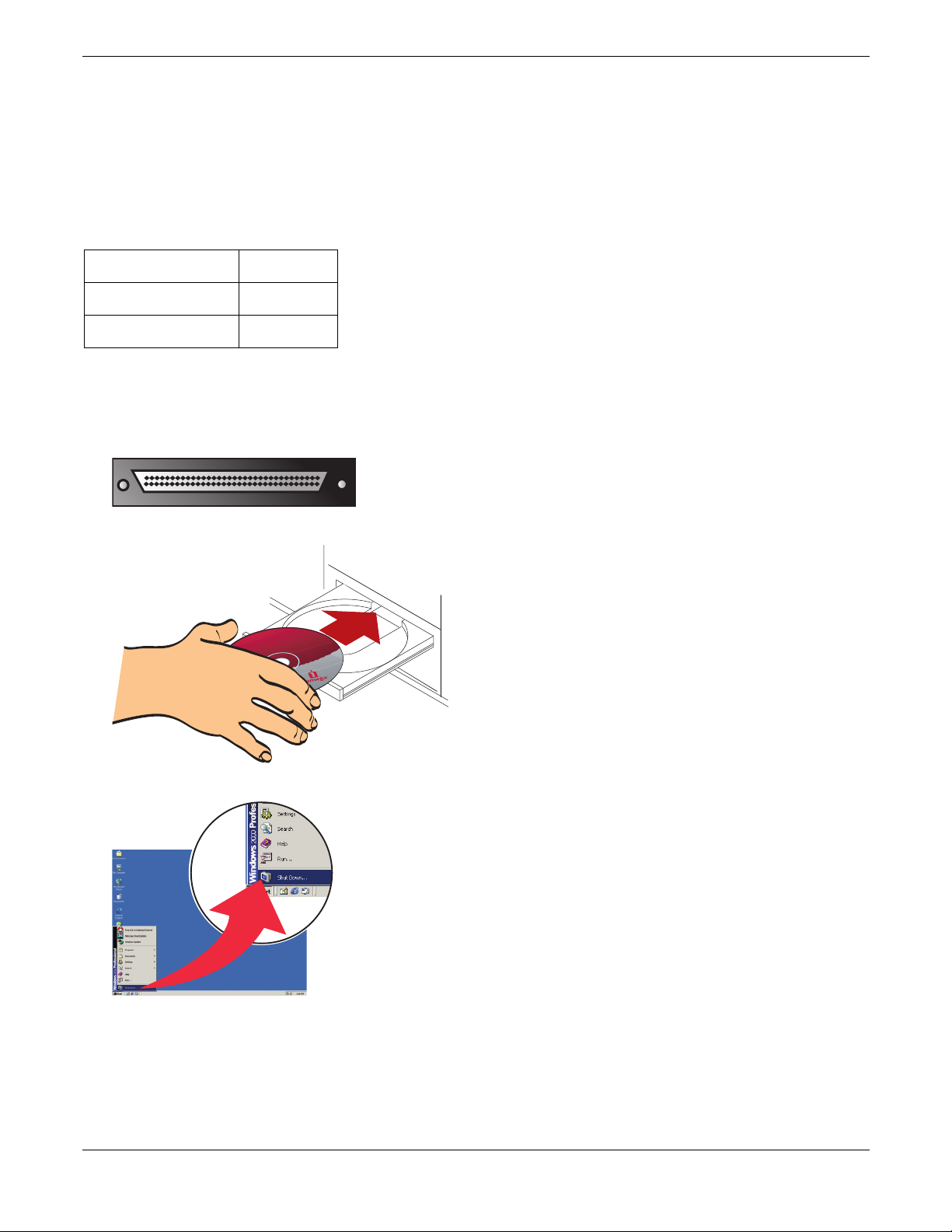

NOTE:

The following defaults have been set at the factory.

LOADR SCSI ID 6

DRIVE SCSI ID 4

Operating Mode Sequential

1. Purchase the appropriate SCSI cable.

The Iomega REV Autoloader 1000 requires a 68-pin wide connector. Consult the documentation that came

with your SCSI adaptor to find the appropriate connector type for the other end of the cable. For best result,

purchase a SCSI cable with locking screws

2. Install the REV System Software from the included CD.

3. Power off your computer.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 8 of 82

Page 9

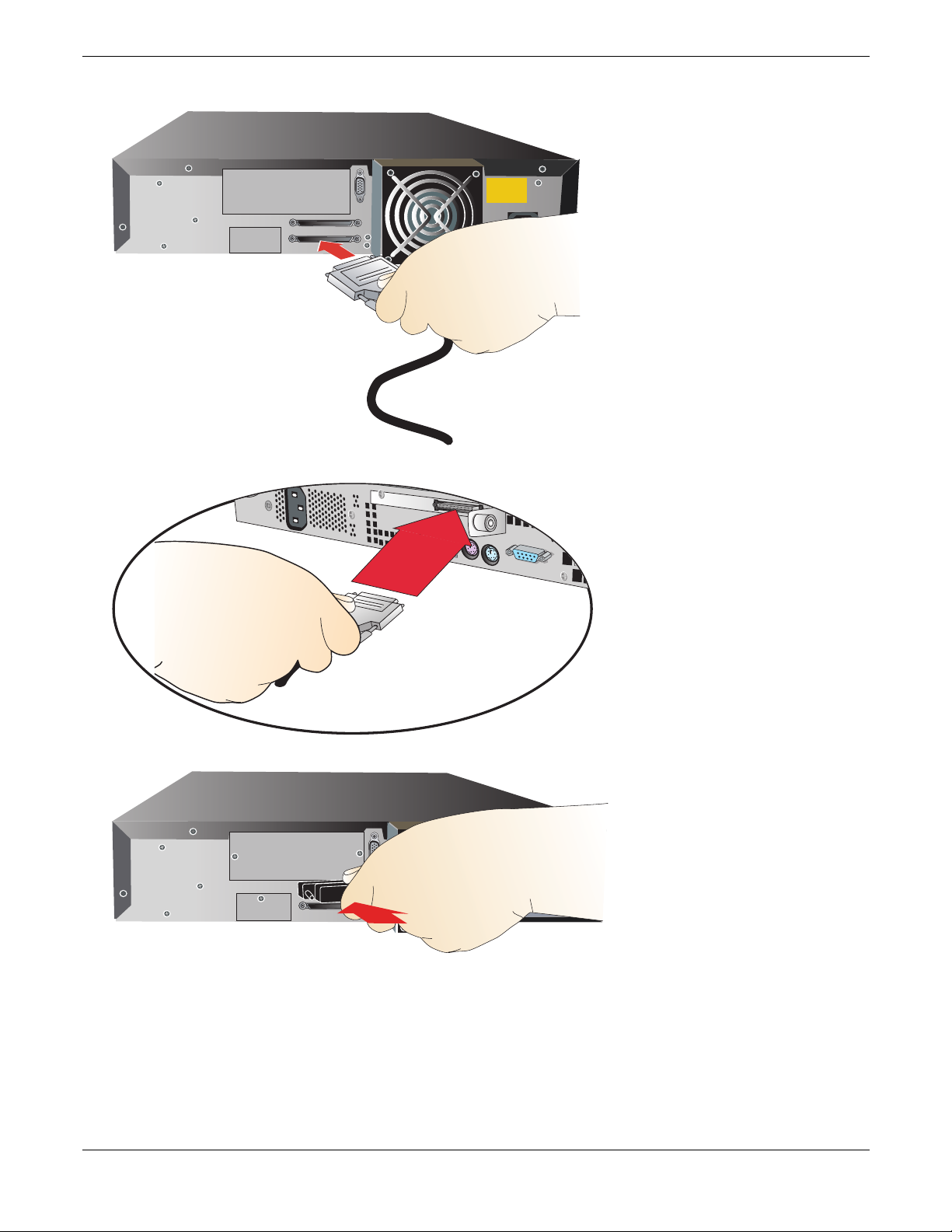

4. Connect the 68-pin wide connector on the SCSI cable to the autoloader.

5. Connect the other end of the cable to the SCSI port on your computer.

6. Connect the included SCSI terminator or another SCSI device to the autoloader’s other SCSI connector.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 9 of 82

Page 10

7. Connect the power supply to the autoloader, and then plug the power supply into an electrical outlet.

Autoloader

1000

8. Power up the autoloader. Use a long, narrow device, such as a pencil, to press the left side of the power

switch.

9. Using the Operator Control Panel (OCP), set the autoloader to an appropriate SCSI ID.

You can use any SCSI ID that is not already in use by your computer or another device. The REV autoloader

requires 2 SCSI IDs. By default the autoloader uses IDs 4 and 6. See your SCSI card’s utility or drive

properties for information on the IDs of connected devices. ID 7 is generally reserved for the SCSI adapter

card. See section 6 for more information on using the OCP.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 10 of 82

Page 11

10. Power up your computer. Insert up to 10 REV cartridges into the device to begin using your autoloader. See

3

5

G

B

/

9

0

Native/Co

mpres

sed

G

B

A

u

toloa

d

e

r

100

0

Aut

o

l

oa

d

e

r

1000

35

G

B

/

90

N

a

t

i

v

e

/

C

o

m

p

r

e

s

s

e

d

G

B

Autol

oad

e

r

1000

35

G

B

/

90

N

a

t

i

v

e

/

C

o

m

p

r

e

s

s

e

d

G

B

section 6 for more information.

A

u

toloader

1

000

R

E

ADY

/

S

E

R

VI

A

C

CT

E

I

VI

T

Y

M

E

D

DRI

I

A

VE

E

RRO

A

T

T

R

EN

T

I

O

N

CA

NC

E

L

PRE

V

I

OUS

N

EXT

ENT

E

N

E

R

TE

R

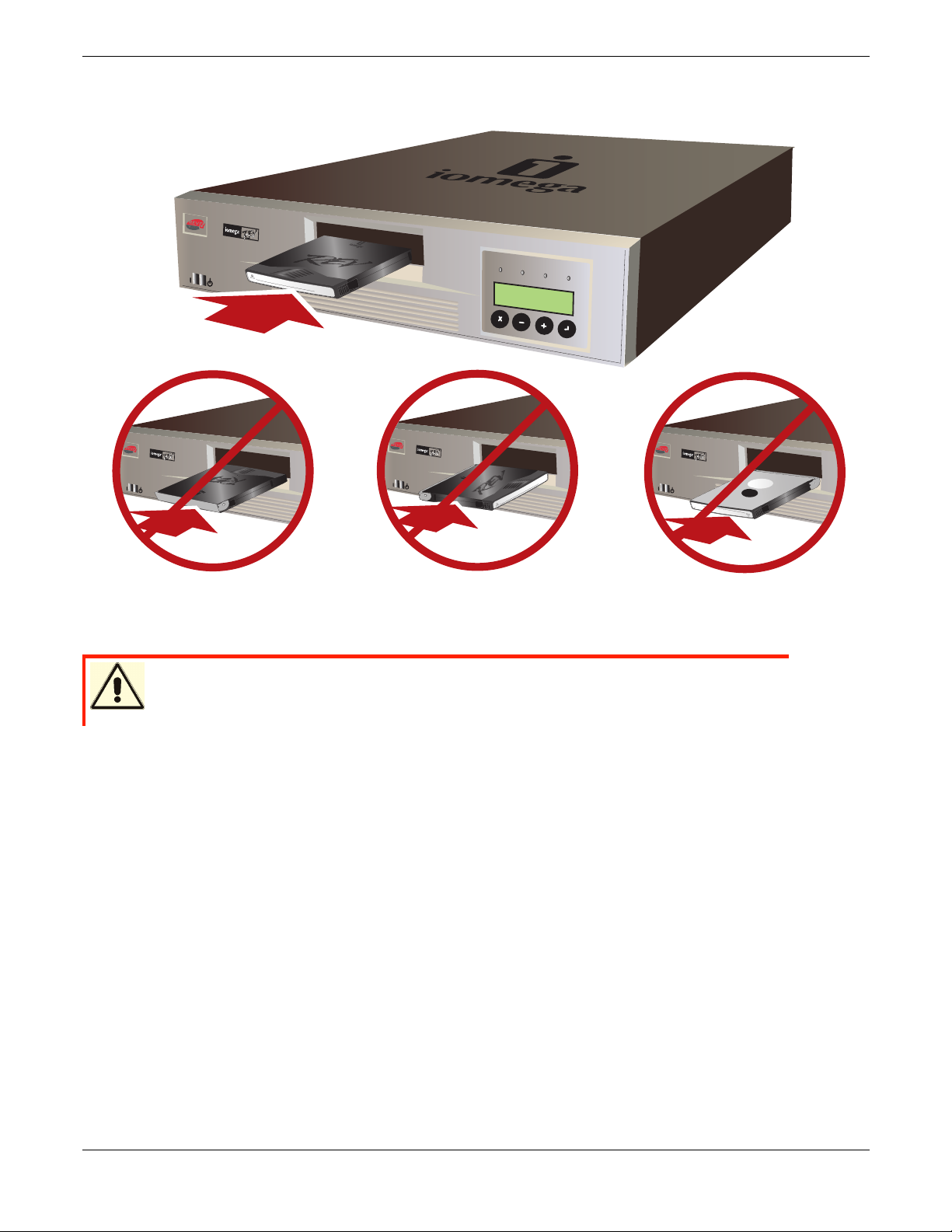

CAUTION Insert the REV cartridge as shown above. Improper insertion may

damage the cartridge, autoloader, or drive.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 11 of 82

Page 12

4 Features and Physical Description

4.1 Equipment Description

The Iomega® REV™ Autoloader 1000 provides a simple way to backup, archive, and restore your valuable data.

This chapter describes the autoloader and includes the following topics:

Autoloader features

Component descriptions

Autoloader accessories

Related products

4.2 Features

The autoloader includes the following features:

A carousel encircles the REV drive and positions the specified cartridge slot in front of the REV drive. A

robotic cartridge loader moves the cartridges between the cartridge slots and the REV drive.

Storage for up to 10 REV disks. Cartridges are stored in cartridge slots mounted on the carousel.

A cartridge access port for importing or exporting a single cartridge from the autoloader.

An LCD allows you to monitor autoloader operations, select configuration options, and control the cartridge

loader and carousel from the front panel.

The autoloader and the REV drive each include independent Small Computer System Interface (SCSI)

controllers. Each supports independent sets of SCSI messages and commands. The autoloader and the

enclosed REV drive use a wide, low-voltage differential (LVD) SCSI interface.

NOTE: The LVD SCSI interface is also compatible with single-ended (SE) SCSI.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 12 of 82

Page 13

The autoloader is designed as a standalone unit, but can be mounted in a standard 19-inch rack if desired. Rack

mount kits are available from Iomega.

4.3 Component Descriptions

The following sections describe the major components of the autoloader.

Front Panel Components

Autoloader

1000

READY

S

E

R

V

A

I

C

C

T

E

IV

I

TY

M

E

DI

D

RIV

A

E

ERR

A

T

T

O

R

E

N

T

I

ON

C

A

NC

E

L

PR

EV

I

OU

S

N

EX

T

E

N

T

E

R

( 1 ) Cartridge access port

The cartridge access port allows you to insert or remove cartridges from the autoloader.

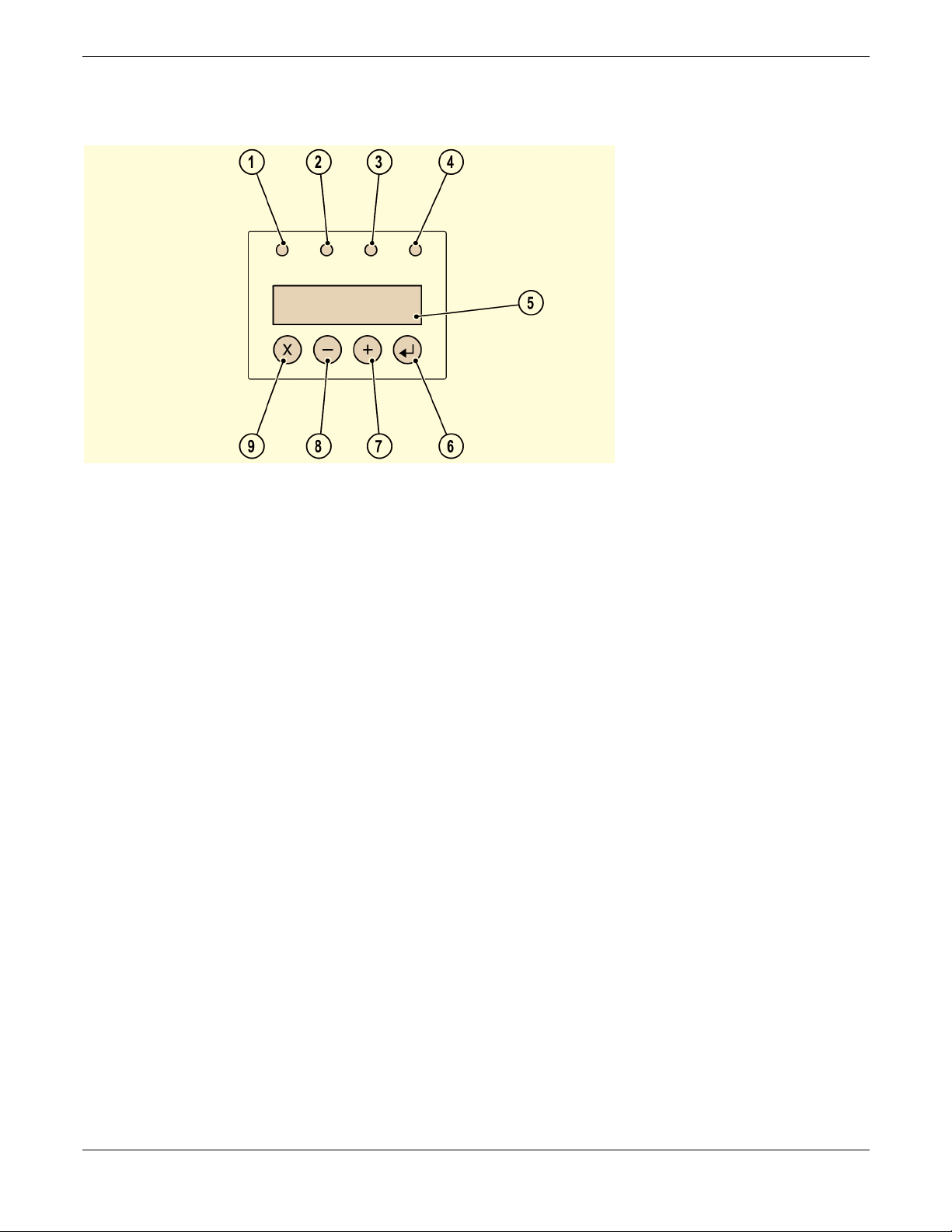

Operator Panel

( 2 ) 4 Status LEDs

( 3 ) Liquid crystal display (LCD), 16 characters per line, two lines

( 4 ) Four button keypad

For more information about the operator panel and menu operations, see page 24.

( 5 ) Power switch

The power switch allows you to turn power on and off for the autoloader and the enclosed REV drive. The

switch is recessed into the front panel to prevent the autoloader from being accidently turned off during

operation.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 13 of 82

Page 14

Back Panel Components

( 1 ) SCSI Connectors

The autoloader has two wide SCSI connectors for connecting the autoloader and REV drive to a single

SCSI bus. The connectors can accommodate either of the following:

– A shielded male, high-density wide (68-pin) SCSI cable

– A wide external terminator

The wide SCSI configuration allows up to 16 devices (including one or more initiators) to be attached to a

single SCSI bus. See SCSI Interface Specification on page 76 for more information about the SCSI

interface.

( 2 ) Fan

The system fan provides cooling for the autoloader and the REV drive.

( 3 ) Power cord connection

The power cord connection provides AC power and chassis grounding to the autoloader and the REV drive.

REV drive

The autoloader contains one REV drive. The REV drive can store up to 70 GB of compressed information on a

single data cartridge (assuming an average compression ratio of 2:1).

Cartridge Slots and Carousel

The carousel stores up to ten REV disks. The carousel consists of a drive belt, guides, and gears that move the

cartridges into position in front of the REV drive. Each cartridge is installed in a cartridge slot that ensures that the

cartridge is properly aligned to be inserted into the REV drive.

Cartridge Loader

The cartridge loader moves cartridges between the cartridge slots and the REV drive. When a cartridge slot is

positioned in front of the REV drive, the loader grips the sides of the cartridge and slides it forward or backward

between the slot and REV drive. The loader then releases the cartridge and pushes it firmly into the drive or slot.

Enclosure

The autoloader is housed in a 2 EIA units (2u) high desktop enclosure with a black, textured finish.

Autoloader Accessories and Related Products

The following accessories and products, available from Iomega, are intended for use with the autoloader:

REV disks (available in single and multi-packs)

Rack mount kit

Remote Management Unit (RMU)

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 14 of 82

Barcode Reader (BCR)

Barcode labels

Page 15

5 Installation and Setup

This chapter describes:

Installing the Optional Remote Management Unit (RMU)

Installing the Optional Bar Code Reader (BCR)

Installing the Autoloader as a Desktop Unit

Installing the Autoloader in a Rack

5.1 Installing the Optional Remote Management Unit (RMU)

5.1.1 Contents of the Kit:

RMU with built-in 10/100 Ethernet LAN Card.

5.1.2 Required Tools:

T10 Torx wrench or small flat-blade screwdriver

5.1.3 Mounting Instructions:

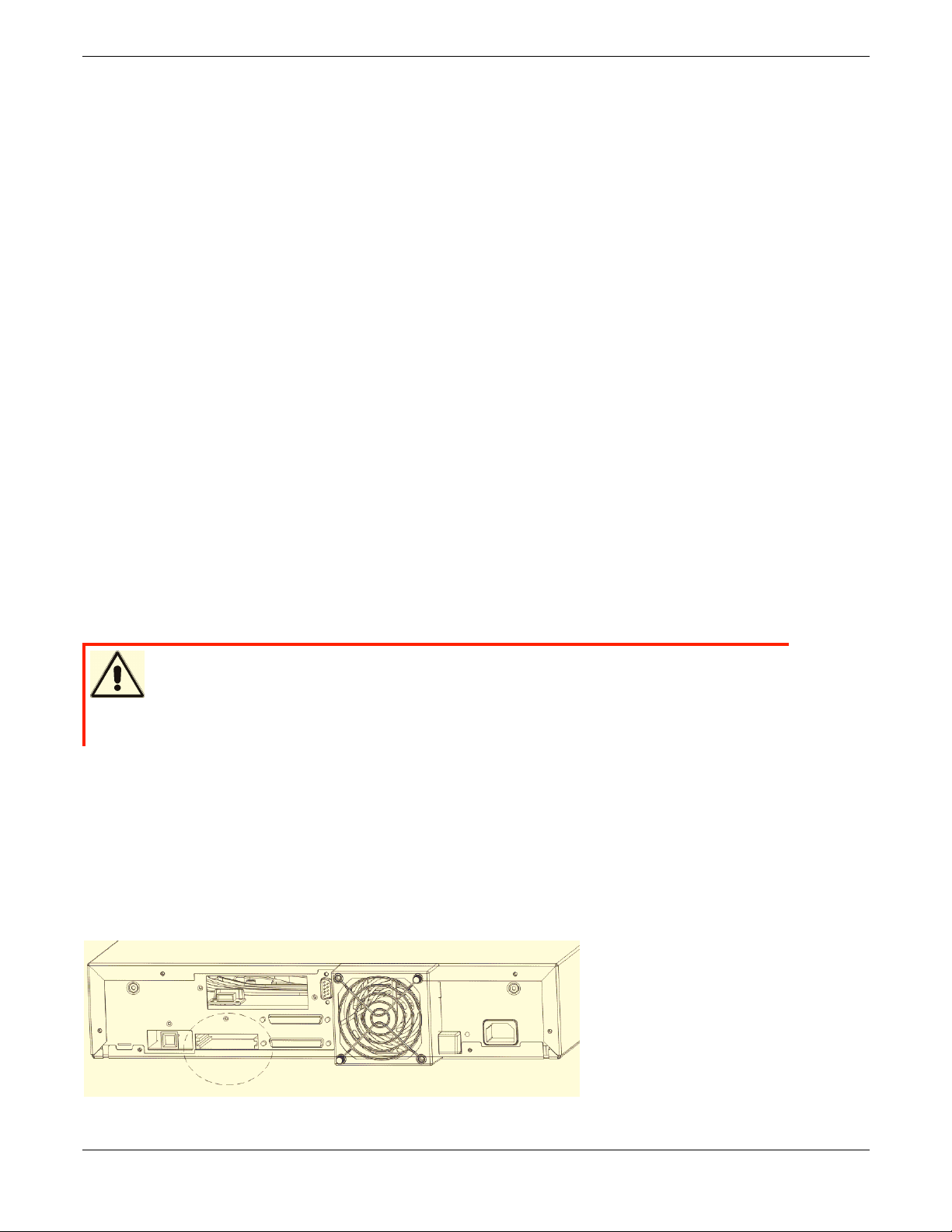

CAUTION Electrostatic discharge!

To avoid destruction of the ESD sensitive components, please touch unit

cover or rear panel before installing the RMU.

The RMU is to be mounted on the rear of the device.

1. Power off the autoloader.

2. Remove the power cord.

3. Remove the protective covering (located on the autoloader’s rear panel). Save the screw. Save and

store the cover plate; you may use this plate later after removing the RMU.

4. Align the LAN card in the rails and insert into the unit.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 15 of 82

Page 16

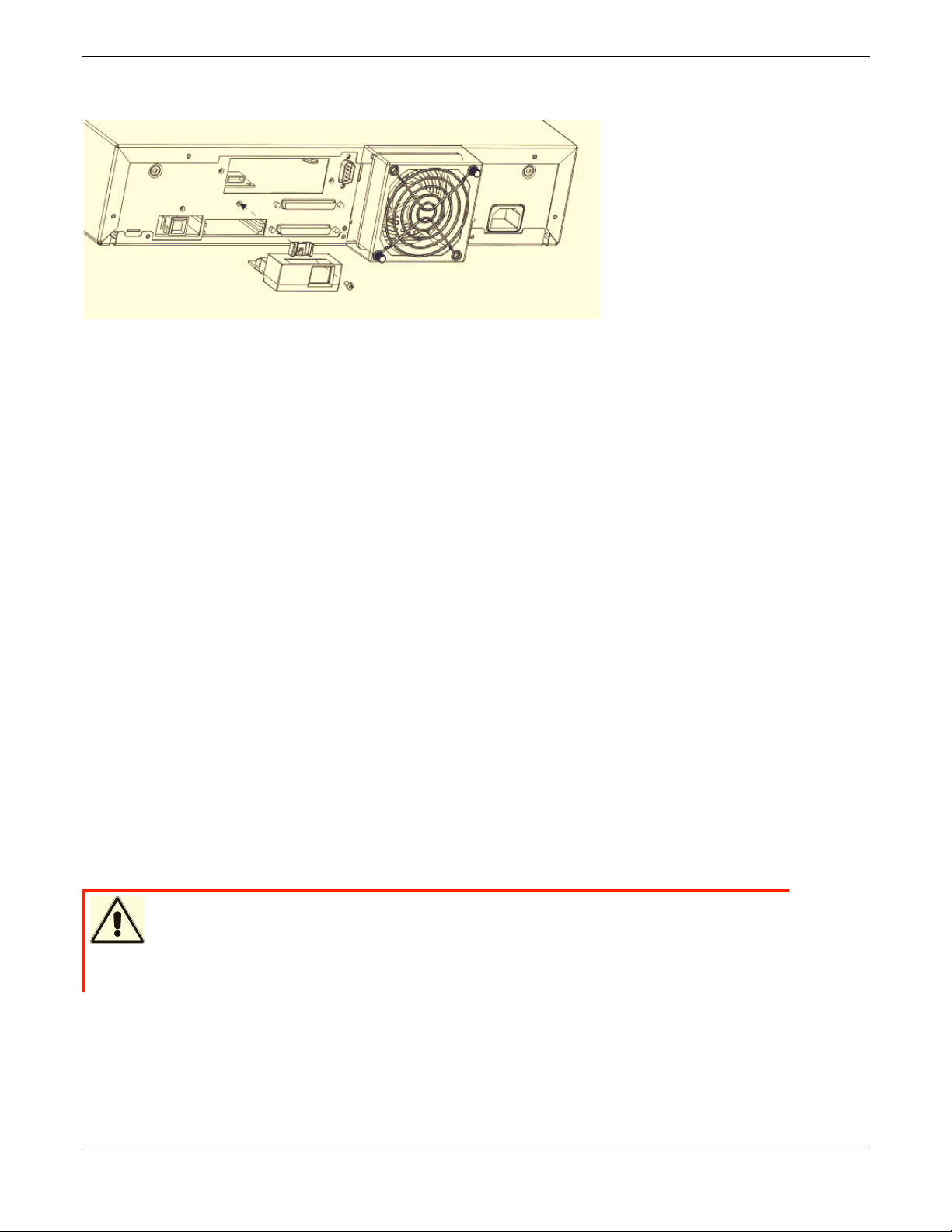

5. Attach the unit with the previously removed screw.

6. Attach an Ethernet cable to the RMU.

7. Connect the other end of the Ethernet cable to a router, switch, hub, or other computer. You may need a

crossover cable to connect the RMU directly to another computer.

8. Power ON the autoloader and wait for initialization to complete.

9. Configure the RMU via OCP, see section 6 of this manual.

You will need to set either a static IP address or enable DHCP before using the RMU.

5.2 Installing the Optional Bar Code Reader (BCR)

5.2.1 Contents of the Kit:

Barcode reader.

Barcode labels (20)

5.2.2 Required Tools:

T10 Torx wrench or small flat-blade screwdriver.

5.2.3 Mounting Instructions:

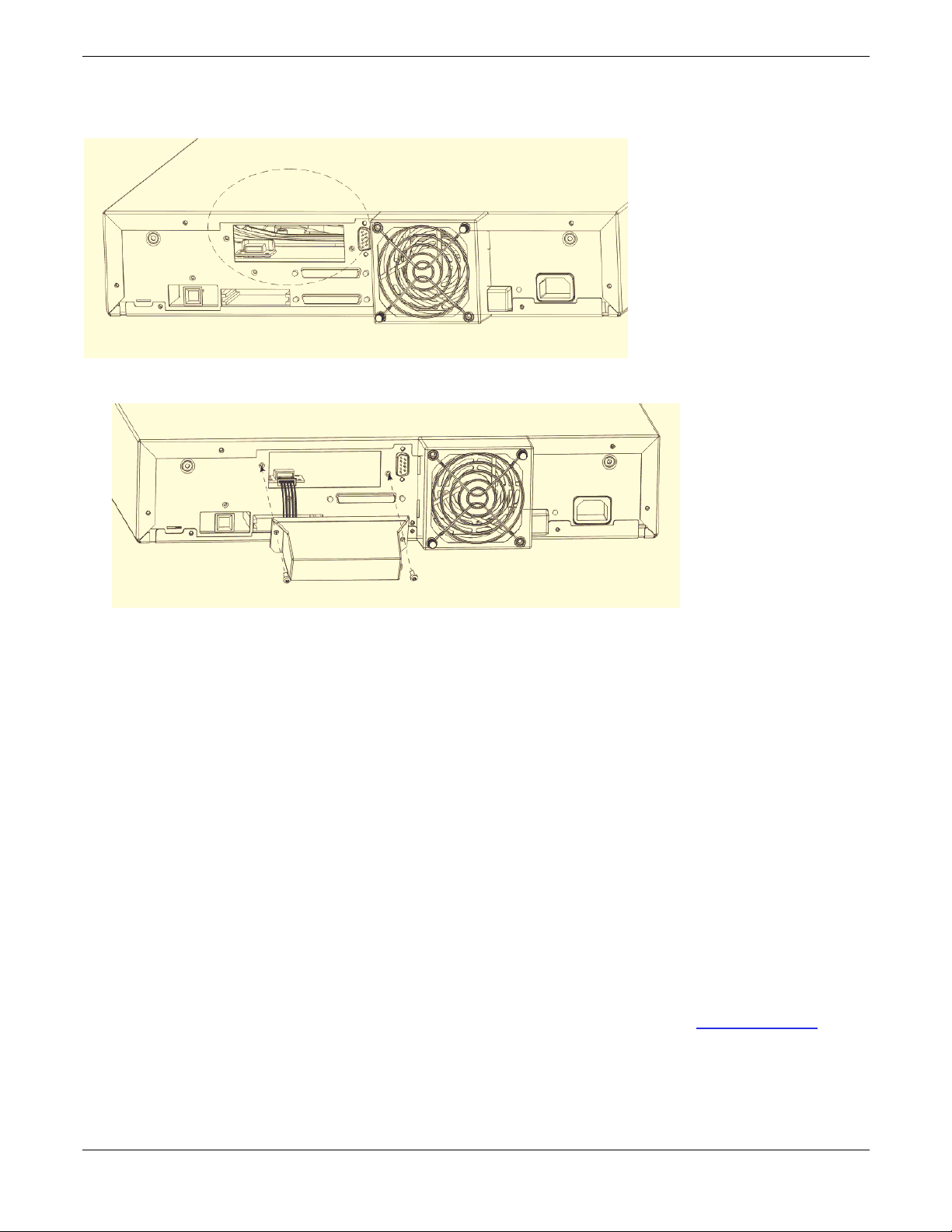

CAUTION Electrostatic discharge!

To avoid destruction of the ESD sensitive components, please touch unit

cover or rear panel before installing the BCR.

The barcode reader is to be mounted on the rear of the autoloader.

1. Power OFF the autoloader.

2. Disconnect the power cord from the outlet. Remove the SCSI cable(s) and power cord from the rear

panel of the autoloader.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 16 of 82

Page 17

3. Remove the cover plate from the rear panel. Save the screws! Save and store the cover plate; you may

use this plate later after removing the barcode reader.

4. Align the barcode reader with the slot. See the illustration for correct orientation

5. Connect the cable to the barcode controller outlet.

6. Attach the barcode reader with the previously removed screws.

7. Reconnect the SCSI cables and power cord to the autoloader.

8. Power ON the autoloader.

5.2.4 Configuration of the Barcode Reader

1. Enable Barcode Reader through the Operator Control Panel (OCP). Select menu item

CONFIGURATION/BARCODE READER and set BCR CHANGE TO “ON”.

2. The barcode reader is controlled through the host software.

3. The autoloader and host system will sense the presence of the barcode reader.

5.2.5 Barcode Labels

The barcode reader can only operate if barcode labels are present on the REV disks. Visit www.iomega.com to

order the appropriate barcode labels.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 17 of 82

Page 18

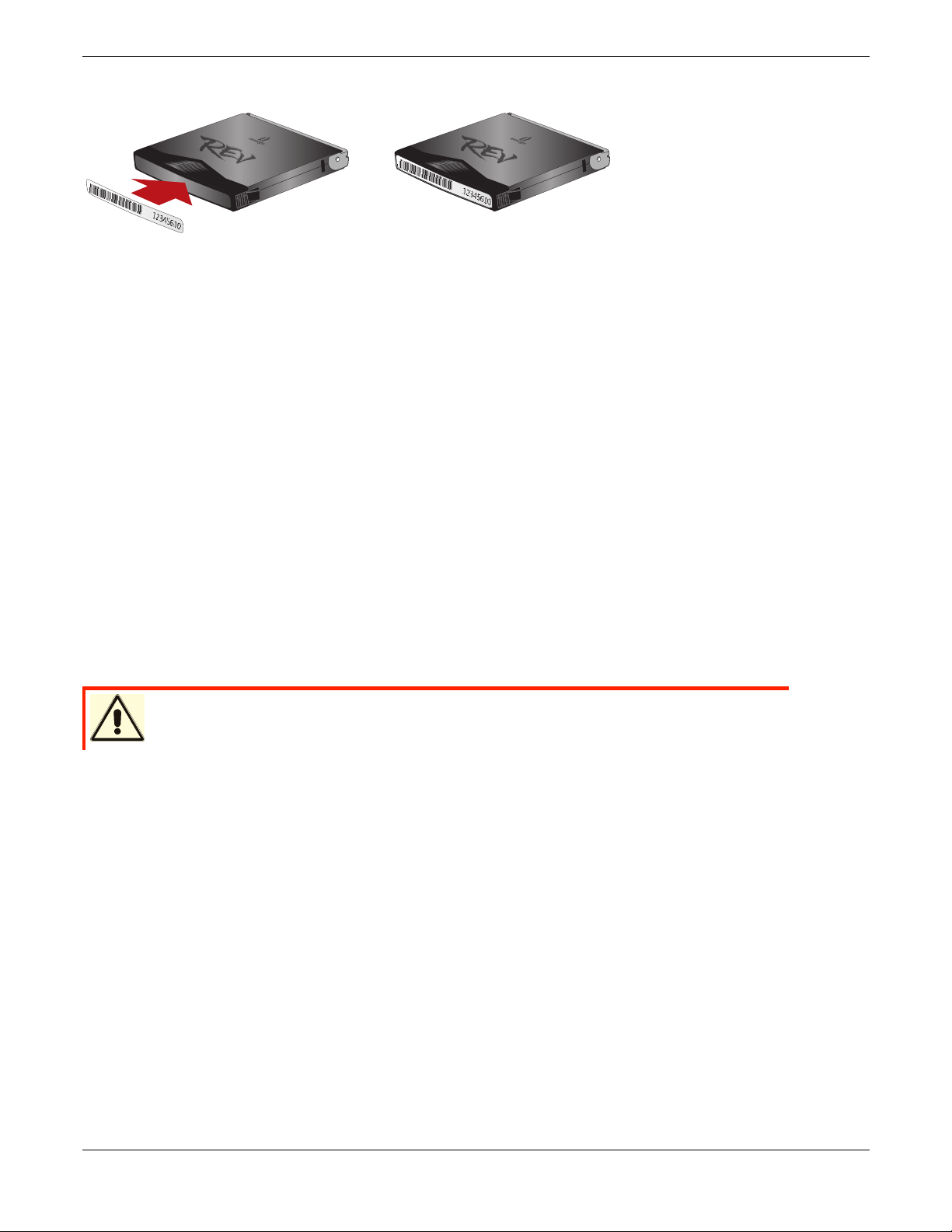

Barcode label placement:

NOTE: Replace the existing REV cartridge label only! Never place the barcode label on top of the REV

cartridge.

5.2.6 Removing the Barcode Reader

1. Disable Barcode Reader through the Operator Panel. Select menu item CONFIGURATION/BARCODE

READER and set BCR CHANGE TO “OFF”

2. Power down the autoloader.

3. Disconnect the power cable from the outlet. Remove the SCSI cable(s) and power cable from the rear

panel.

4. Remove the screws that attach the barcode reader to the rear panel.

5. Unplug the barcode reader connector from the controller outlet.

6. Replace the cover panel on the rear panel.

5.3 Installing the Autoloader as a Desktop Unit

WARNING Do not place anything on top of the autoloader!

5.3.1 Checks Before Installation:

If you install the autoloader as a desktop unit, position the autoloader in a location that is away from dust, dirt, and

debris, and is convenient to the server (host) to which it will be attached. The only restrictions are the length of the

power cord and the length of the SCSI cable.

For a desktop installation, position the autoloader in the following recommended locations:

Away from high-traffic areas, especially if the floor is carpeted.

Out of copy rooms to avoid toner and paper dust. Do not store paper supplies near any unit.

Away from moving air, such as doorways, open windows, fans, and air conditioners.

Off the floor.

In a horizontal position on a flat surface.

Where a REV disk can be easily inserted into the Cartridge Access Port.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 18 of 82

Page 19

5.3.2 Connecting Power

1. Plug the power cord into the receptacle at the rear of the autoloader

2. Plug the other end of the power cord into a grounded electrical outlet.

3. Power on the autoloader.

The autoloader will verify the drive configuration and status, build a valid cartridge inventory log, and calibrate the

robotic cartridge loader.

The OCP’s green READY/ACTIVITY LED (light-emitting diode) will blink during this initialization process.

When the autoloader completes the Power-On Self Test (POST) for the drive and the library, the green

READY/ACTIVITY LED will stop blinking.

The autoloader will be in automatic mode (the default mode) and SQ will appear in the lower right corner of the

OCP display.

For information about the autoloader’s modes of operation, see section 6.3. If a failure occurred, the red ERROR

LED will light up and an error message will be displayed on the OCP. See Troubleshooting and Diagnostics

(section 7).

5.4 Installing the Autoloader in a Rack

You can install the autoloader into a standard 19-inch rack.

Required Tools:

Phillips screwdriver, #2

Torx wrench, T10

5.4.1 Prepare the Autoloader for Installation

CAUTION Make sure there is no SCSI activity on the bus before you power OFF the

autoloader.

If the autoloader is already in operation as a standalone unit, prepare it for installation in the rack as follows:

1. Power off the autoloader using the POWER button on the front panel.

2. Remove the power cord and any cables or terminator attached to the autoloader. Note the configuration

of the cables and terminator for reconnecting them after installing the autoloader in the rack.

5.4.2 Install the Support Rails in the Rack

1. Remove the two support rails from the kit and note how they will be positioned in the rack. When the rails

are properly installed, the shelf flanges will face inward to support the autoloader.

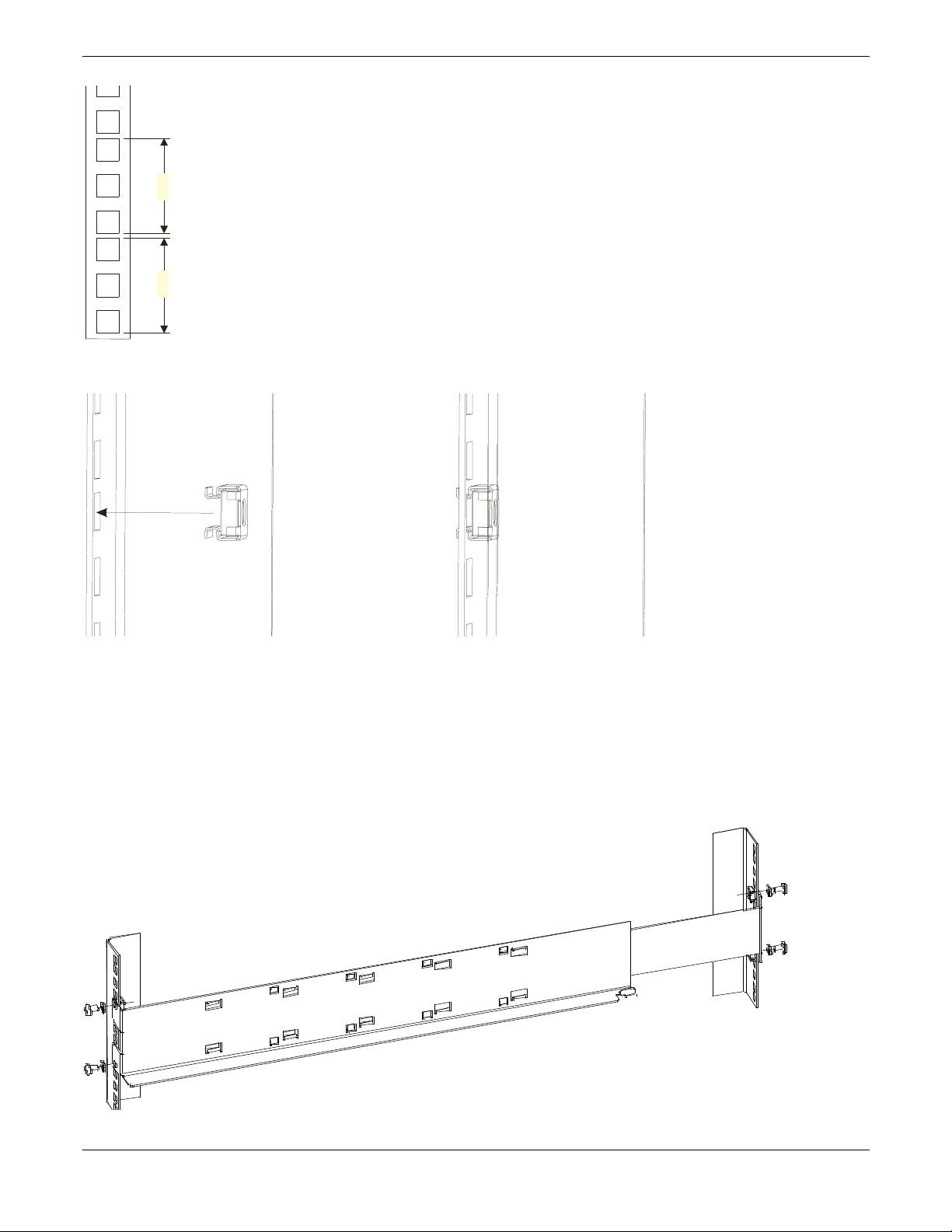

NOTE: The autoloader requires 2 EIA units of rack space for installation.

2. Identify the 2 EIA units required by the autoloader for rail placement.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 19 of 82

Page 20

4.45cm

(1.75in.)

4.45cm

(1.75in.)

3. Install the cage clip-nuts (for racks with square mounting holes) from the back side of each rail.

NOTE: To ensure proper installation of the Autoloader in your rack, it is very important to install the clip-nuts in

the correct positions on each rail.

4. Count the holes on the other three rack rails, up or down, to determine the position of the top or bottom

clip-nut.

5. From the front of the rack, position one of the rails on the appropriate side.

6. Position the front flange so that it is on the outside of the strip of mounting holes in the rack.

7. Using a #2 Phillips screwdriver, attach the rail to the rack with screws and washers from the kit.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 20 of 82

Page 21

8. Slide the rail pieces apart to match the depth of your rack.

9. Using a #2 Phillips screwdriver, attach the rail to the outside of the rack with screws and washers

supplied with the rack mount kit.

10. Repeat steps 5 through 9 to install the second rail.

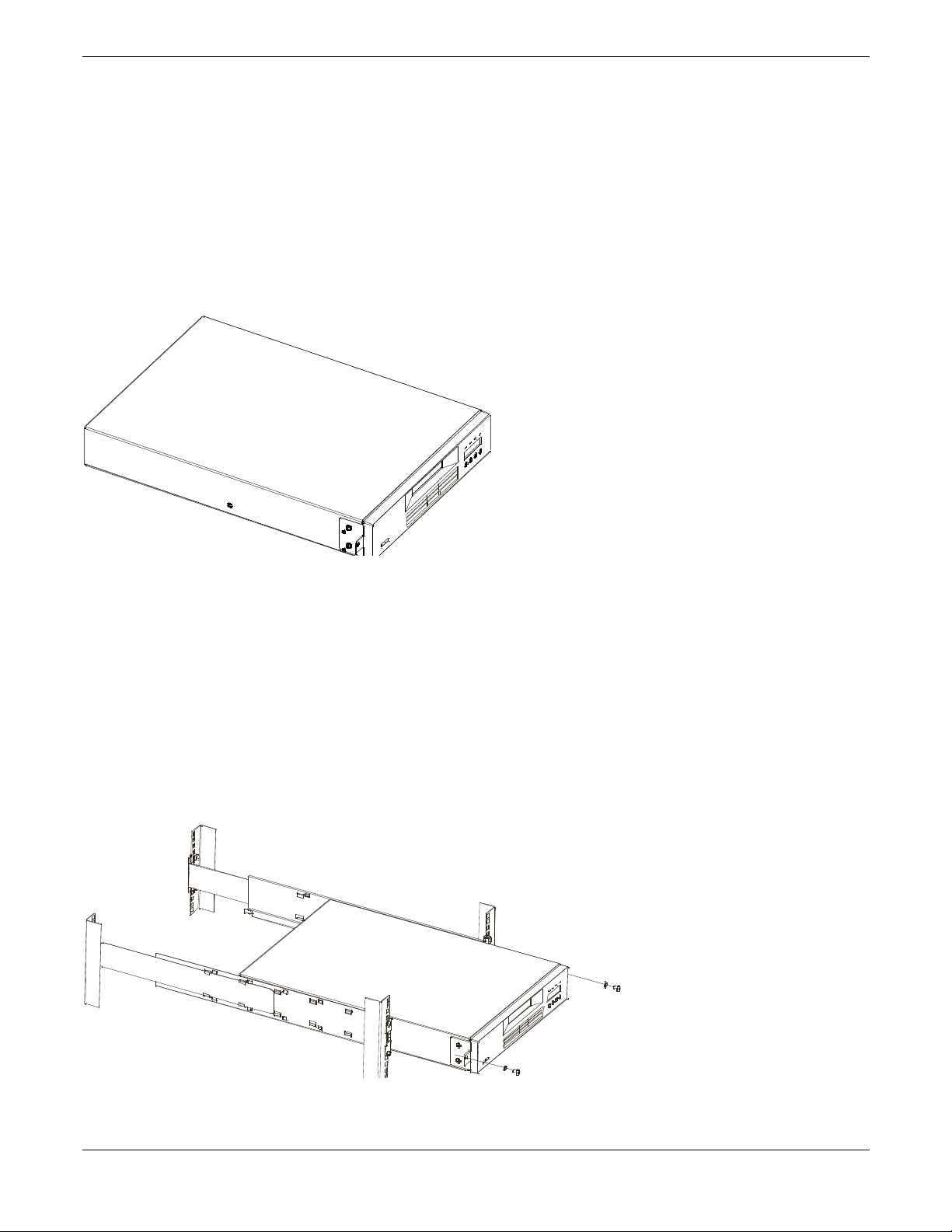

5.4.3 Install the Rack Front Mount Brackets on the Autoloader

1. Determine on which side of the autoloader the rack mount brackets will be attached. The oval hole for

attaching the bracket to the rack will be on the bottom of the arm of the bracket.

2. Using the Torx wrench, remove the two screws on each side of the autoloader cover.

3. Position the correct bracket, as determined in Step 1, on each side of the autoloader and secure by

reusing the original screws.

5.4.4 Secure the Autoloader to the Rack

1. From the front of the rack, position the autoloader on the shelf flanges between the support rails. Slide it

toward the rear of the rack until the brackets contact the rack’s mounting holes.

NOTE: Make sure that the tabs on the back of each shelf flange are fully engaged in the slots at the rear of the

autoloader.

2. Place one screw and washer from the rack mount kit into the hole in the front of each bracket. Take care

that the screws line up with the holes containing the remaining installed clip-nuts. Use a #2 Phillips

screwdriver to tighten the screws.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 21 of 82

Page 22

6 Operation and Maintenance

Autoloader

1000

This chapter describes the requirements for using the autoloader, including information about:

Powering on the System

Using the Operator Control Panel and Menu Options

Operational Modes

Configuration

Operation

Loading and Unloading REV Disks

Shipping

6.1 Powering on the System

Switch on power using the POWER button located on the front panel, after the power cord and the SCSI cable

are connected. The autoloader will power up.

If an RMU is installed, look on the rear panel of the autoloader and verify that the RMU’s green LED is on. If the

green LED is not on, check the connection to the RMU, see Installing the Optional Remote Management Unit

(RMU) in section 5.1. Otherwise call technical support.

When the autoloader powers up, or resets, it goes through several internally controlled processes that allow it to

get initialized and running. While those processes are happening, the operator panel shall have appropriate

information displayed to keep the user informed. When the autoloader finishes powering up, it will display the

Current Drive mount status in the ‘Home Screen’. It also indicates that sequential mode is ON by posting the SQ

string.

If the drive is empty, the following status will be displayed:

Drive empty

12345-7890 SQ

If the autoloader detects that a cartridge is loaded when it first powers on, the following status will be displayed on

the operator panel:

Drive loaded

12345-7890 SQ

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 22 of 82

Page 23

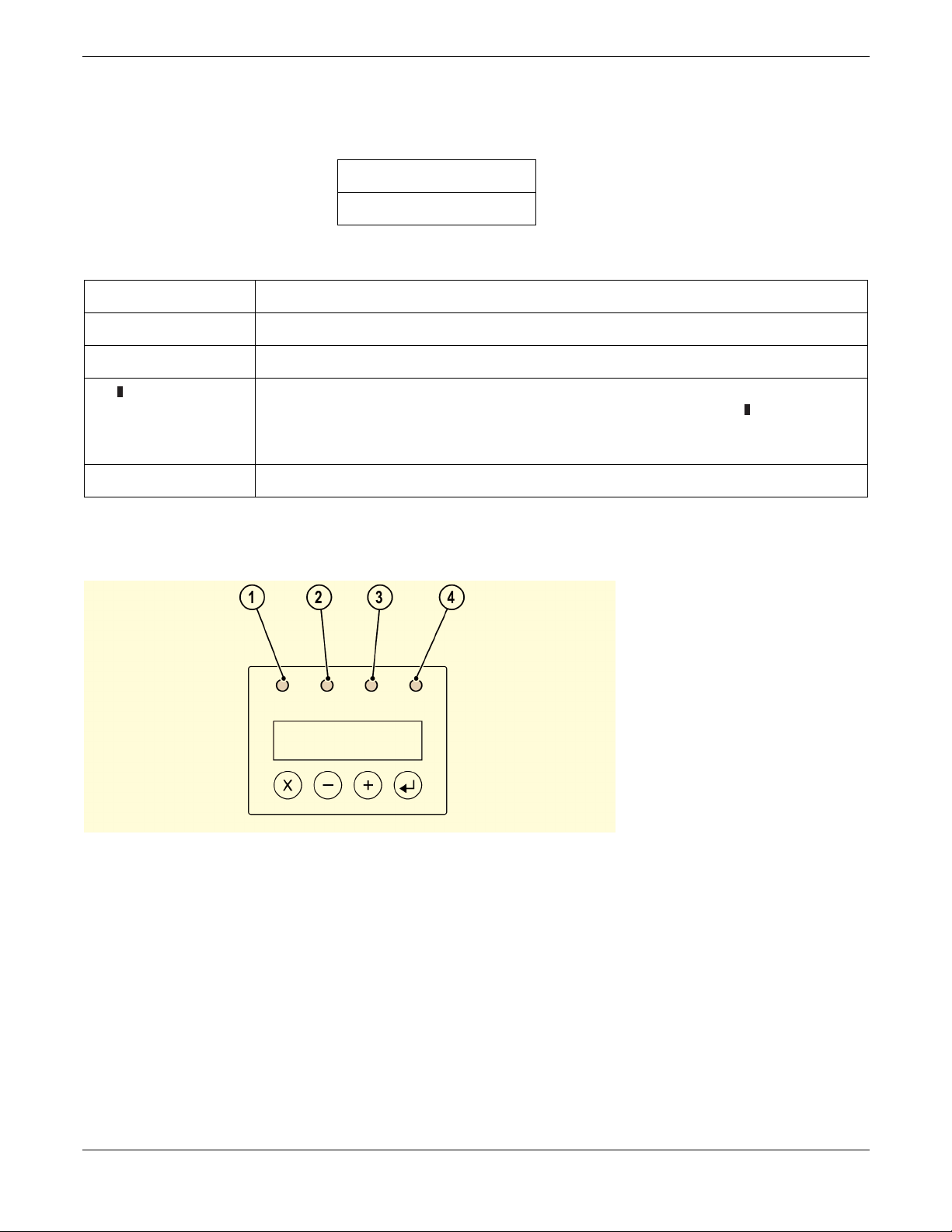

In this example, there is no cartridge in slot 6. Inventory status will be displayed as an 10-character string.

Inventory status characters

Current Drive Status/Activity

Inventory Status

The inventory status characters will be represented as follows:

Character Meaning

1 … 9, 0 Slot Full—uses the slot numbers 1 to 10 (0 represents 10).

– Slot Empty—a dash is displayed as a place holder

n /

(where n represents

the slot number)

? The cartridge is nearing the end of its life

A cartridge that is being loaded, unloaded, imported, exported, or is loaded in the

drive, will be represented by the slot number alternating with the block

invalid format, or has reached the end of its life. An invalid cartridge will be identified

the same way.

Drive loaded

12!45-7890 SQ

LEDs

character

The 4 LEDs (1-4) are updated during power up and reset sequences. Upon power up or software reset, the

autoloader will illuminate all LEDs as soon as power on self-test (POST) allows. This will help the user to verify if

all LEDs are functional.

When mechanical initialization starts, the READY/ACTIVITY LED (1) will flash at a rate of approximately 1-second

per cycle, 50% duty cycle.

When the mechanical initialization is complete, the READY/ACTIVITY LED (1) will stop flashing and be constantly

illuminated.

If an autoloader failure occurs, the READY/ACTIVITY LED (1) will be turned off and the error LED (4) will be

illuminated. The operation panel will also display an appropriate error code to help identify the failure.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 23 of 82

Page 24

6.2 Using the Operator Control Panel and Menu Options

( 1 ) READY/ACTIVITY, Green LED

It is lit any time the unit is powered on and able to function. It should blink whenever there is autoloader or

drive activity.

( 2 ) SERVICE DRIVE, Amber LED

The drive needs to be serviced. The LED will be turned off after the drive is serviced successfully.

( 3 ) MEDIA ATTENTION, Amber LED

Indicates that a REV cartridge is bad, marginal or invalid. It will be cleared when all invalid cartridges have

been exported from the autoloader.

( 4 ) ERROR, Red LED

Unrecoverable autoloader or drive failure. A message is displayed at the same time on the screen. It will be

cleared when the error state is resolved.

( 5 ) LCD display, consisting of two lines with 16 characters per line

The screen displays actions and status information, menu items or error messages equivalent to the

operation mode.

( 6 ) ENTER, button [↵]

It is used in interaction mode. Push the enter button to go to a sub menu or to force a robotic action.

( 7 ) NEXT, button [+]

It is used in interaction mode to navigate through menu items.

( 8 ) PREVIOUS, button [–]

It is used in interaction mode to navigate through menu items.

( 9 ) CANCEL, button [X]

It is used in interaction mode. Push the CANCEL button to cancel a user action and return to the last menu

item.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 24 of 82

Page 25

6.3 Operational Modes

The operational modes affect how the autoloader loads cartridges into the drive. The different modes can be

selected at the configuration menu in the OCP. They are stored in the NVRAM and are valid also after Power ON.

There are 2 basic modes that the OCP operates in. First is the User Interaction mode. This mode is employed

when a user is pushing buttons on the OCP (Operator Control Panel). The second mode is the System Driven

mode. This is the normal mode of operation. In this mode, the OCP displays status associated with the actions

that were caused from commands issued via the Drive’s serial interface. When an OCP button is pressed and

released, the OCP automatically transitions to User Interaction mode. User Interaction mode will continue until 1.5

minutes after a user stops pushing buttons, or the requested robotic action stops; whichever is longer. At this time

the OCP will return to System Driven mode.

If necessary, the OCP will automatically transition to the System Driven mode. When this occurs, the autoloader

must remember what the User was doing before the display mode changed. Therefore the next button pressed

will only transition the OCP to the User Interaction mode from the System Driven mode.

6.3.1 Automatic Mode

Automatic Mode is the default setting and allows the autoloader to switch between Random and Sequential Mode

depending on the SCSI command received. In this mode Sequential Mode is activated after Power On.

Every MOVE MEDIUM, READ ELEMENT STATUS or INITIALIZE ELEMENT STATUS command disables

Sequential Mode and activates Random Mode. The unit will switch back to Sequential Mode with every OCP

initiated Load Command.

6.3.2 Random Mode

In Random Mode the Media Exchanger SCSI target is visible on the SCSI bus, i.e. the autoloader allows the host

application software to select any cartridge in any order. Cartridges can be moved by MOVE MEDIUM commands

in random order. Unload commands to the drive should not be executed.

6.3.3 Sequential Mode

In Sequential Mode the Media Exchanger is no longer visible on the SCSI bus. Cartridge replacements are

initiated by an ‘Unload’ command sent to the drive.

Sequential Mode presumes that the first cartridge was previously loaded to the drive, i.e. the operator determines

the first cartridge to load by loading the desired cartridge into the drive using the ‘Load Cartridge’ menu item on

the OCP. When the first disk is unloaded with a drive ‘Unload’ command, the autoloader removes the cartridge

from the drive and puts it in its original slot. After that, the next cartridge in order will be moved into the drive. This

queue stops if the last cartridge has been ejected and unloaded from the slot.

In Sequential Mode the display shows the following screen where the string ‘SQ’ indicates that Sequential Mode

is activated:

Drive empty

12345-7890 SQ

To further determine how you want cartridges loaded into the drive while in Sequential Mode, you can set Loop

Mode and Autoload Mode from the OCP.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 25 of 82

Page 26

6.3.4 Loop Mode

Loop Mode is a special type of Sequential Mode. The cartridge exchange queue will not terminate with the last

cartridge but restart with the first cartridge. This mode allows endless backup operation without user interaction.

6.3.5 Autoload Mode

This is also an option of Sequential Mode and could be combined with Loop Mode. The first cartridge will be

loaded automatically if the unit powers up with an empty drive. In this case user interaction via OCP is not

required.

6.3.6 OCP Philosophy

During the following discussion of the OCP operation, several functional nuances may be clarified by defining

several rules the OCP must abide by. These rules of operation constitute a ‘philosophy’.

Any operational conflict between commands received over serial interface and those entered via the front panel

will be avoided with a reservation mechanism on a ‘first-come, first-served’ basis. Any reservation by OCP is

canceled by an OCP logout or the timeout, which cancels the User Interaction Mode.

Robotic firmware will not allow a user to select an impossible request. Those situations will include, but are not

limited to:

Importing to a full slot

Exporting from an empty slot

Mounting (Loading) from an empty slot

Dismounting (Unloading) an empty drive

Any error detected by the library or drive controller and not recoverable through predetermined software

algorithms, will be considered as fatal. An error code will be displayed on the LCD and the error LED will become

illuminated. The error code will remain on the OCP until a button is pressed, the OCP will return to the Home

Screen.

Numeric error codes are only used for unrecoverable, fatal errors, otherwise text status messages are provided.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 26 of 82

Page 27

6.4 OCP—Menu Trees

6.4.1 User Go Offline Mode with Protection

6.4.2 User Go Offline Mode without Protection

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 27 of 82

Page 28

6.4.3 OCP User Interaction Mode

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 28 of 82

Page 29

6.4.4 Information

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 29 of 82

Page 30

6.4.5 Commands

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 30 of 82

Page 31

Configuration

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 31 of 82

Page 32

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 32 of 82

Page 33

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 33 of 82

Page 34

6.4.6 Diagnostic

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 34 of 82

Page 35

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 35 of 82

Page 36

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 36 of 82

Page 37

6.5 Operation

After you install and configure the autoloader and install your application software on the host computer, the

autoloader performs most operations automatically. Operator intervention includes the following activities:

Monitoring autoloader operation and status

Performing autoloader and REV drive operations

6.5.1 Monitoring Autoloader Operation and Status

During normal operation, the ‘Status screen’ is displayed on the LCD. You can use this screen to monitor

autoloader activities. By default, the ‘Status’ screen displays the current operating status of the autoloader and

REV drive.

To set the operator panel to user interaction mode, press a key. This mode allows you to use the [Enter] or

[Cancel] and [+] or [–] buttons to display options for issuing commands to the autoloader, viewing information

screens, and configuring the autoloader.

6.6 Loading and Unloading REV disks

The ‘Commands’ screen provides options for importing and exporting cartridges, loading and unloading a

cartridge from the REV drive, and updating the cartridge inventory.

6.6.1 Importing and Exporting Cartridges

The Import command under the Library Commands menu allows you to place a cartridge into a specific cartridge

slot through the cartridge access port.

When you issue an Import command, the cartridge carousel moves the specified cartridge slot into position in

front of the cartridge access port and slides the door open. You can then push the cartridge into the slot through

the door. The cartridge loader then grasps the cartridge, pulls it into the autoloader, and closes the door.

The ‘Export’ command allows you to remove a cartridge from a specific cartridge slot through the cartridge access

port. When you issue an ‘Export’ command, the cartridge carousel moves the specified cartridge slot into position

in front of the cartridge access port and slides the door open. The cartridge loader then pushes the cartridge far

enough out through the door to allow you to remove it.

6.6.2 Bulk Exchange

The menu item Bulk Exchange was designed to make the autoloader more user friendly. This item enables a user

to import or export a specific amount of cartridges e.g. this item makes sense if a user wants to exchange a

complete set of cartridges. Bulk Exchange operation starts with slot 1. If a cartridge is available this cartridge will

be exported. It’s up to the user to import a new cartridge or to move to the next slot 2. The same procedure then

takes place for slot 2 to slot 10.

6.6.3 Load and Unload a Cartridge

The load cartridge command under the ‘Commands’ menu allows you to load the cartridge in the specified slot

into the REV drive. When you issue a ‘Load cartridge’ command, the cartridge carousel moves the specified

cartridge slot into position in front of the REV drive. The cartridge loader then extracts the cartridge from the

cartridge slot and inserts it into the REV drive.

The ‘Unload cartridge’ command causes the REV drive to unload the disk from the disk path and eject the

cartridge. After the cartridge is ejected, the cartridge carousel moves the slot from which the cartridge originated

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 37 of 82

Page 38

into position in front of the REV drive. The cartridge loader then extracts the cartridge from the REV drive and

returns it to the cartridge slot.

6.6.4 Write Protected Media

If the drive detects write-protected media, an internal bit is set and the autoloader posts the “WP” string on the

display indicating write-protected media is loaded in the drive.

The display shows the following status:

Drive loaded

12345-7890 WP

As soon as the write protected media is ejected, the drive resets the internal bit and the “WP” string on the display

is removed. See the REV System Software help for information on write-protecting media.

6.7 Shipping

If you need to ship the autoloader, use the original shipping carton and packing materials to prevent damage. The

shipping carton and packing materials are not intended to be used for shipping items other than or in addition to

the autoloader.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 38 of 82

Page 39

7 Troubleshooting and Diagnostics

7.1 General Guidelines

The autoloader includes features to support troubleshooting and diagnostic operations.

If the red error LED is on, an error message and error code Will appear on the OCP.

To check if the autoloader is operational the system offers a system test. It is accessible via the item “Diagnostic”

in the system menu. To perform a system test, the REV drive must be empty and at least one slot must contain a

cartridge.

7.2 Error LED/Error Code

1. If the red error LED is on and an error message and error code are displayed on the Status Screen note

the code or information.

2. Press Enter to attempt recovery and initialization. Cycling power may also be necessary.

NOTE: If the Media Attention LED turns red, this is an indication that a drive error occurred pointing to the

media as the possible problem. To determine the drive error code after the cartridge is unloaded and

returned to the I/O Door for removal, perform one of the following procedures to determine the latest

drive error code.

7.2.1 Viewing Error Codes via the OCP

1. Take the autoloader offline.

2. From the OCP, press Enter to access the Information Menu.

3. Press Next to access LOADER INFO.

4. Press Next or Previous until ERROR LOG appears.

5. Press Enter to display the most recent error code.

6. Line one will indicate ERROR CODE 0; line two will show a single hex digit drive error code (see Error!

Reference source not found. in section 7.4).

7. Press Previous to view previous error codes (up to ten error codes are stored).

7.2.2 Viewing Error Codes via the RMU

1. Login as Administrator.

2. Click on Logs and then Drive.

The drive error log table described for serial communication is displayed.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 39 of 82

Page 40

7.3 Analysis Procedures

7.3.1 Power/External Fan Analysis

If the autoloader does not power on:

1. Ensure power cord is plugged in at the autoloader and at the electrical outlet.

2. Try another electrical outlet or plug another device into outlet to test.

3. Try another power cord.

4. If none of the above are successful in restoring power to the unit, contact technical support.

If air does not flow from the external fan on the rear panel of the autoloader:

1. Ensure power is switched off and the power cord removed.

2. Ensure the external fan is making a firm connection by removing and replacing the fan.

3. Plug the power cord into the autoloader and switch on the POWER button.

4. If the fan remains off, replace the rear fan.

7.3.2 RMU Analysis

NOTE: Both the OCP and the serial port must be offline (logged out) before the RMU can complete its

Administrator or Service login.

If the RMU is not functioning at all or if it is intermittently functioning, review the following steps to ensure that it is

properly configured, or, to help determine which part needs to be replaced. The complete RMU electronics

resides both on the main board in the base unit and on the RMU attachment plugged into the rear of the base

unit.

1. Check that the RMU attachment is securely connected to the RMU connector in the rear of the

autoloader.

2. Check that the correct IP, Gateway, and subnet mask addresses are keyed into the network parameters

and that the NETWORK is in the ON state. From the OCP, navigate to NET PARAMETER in the

Configuration Menu.

3. Check that the correct IP address is being used on the web browser.

4. If the Ethernet connection is a direct connection between the PC and the autoloader, check that a special

_crossover_ Ethernet cable is being used. Otherwise, if the autoloader connection is made to a network

hub or switch, ensure that a normal “straight-through” Ethernet cable is being used.

5. Check the Ethernet cable carefully (or try another cable) and, if the RMU is connected to a network hub or

switch, try a different port.

6. If the RMU is still malfunctioning, contact technical support.

7.3.3 BCR Analysis

If the server (host) has reported inventory problems relating to inability to read bar code labels, or, if some or all of

the cartridge labels are not being displayed on the RMU (Status _ Media), use the following procedure to

determine if the BCR needs to be replaced.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 40 of 82

Page 41

1. Check that a supported bar code label (or labels) are being used. Also, check for damaged labels.

2. Check that the bar code function configuration has been enabled properly:

From the OCP, navigate to BARCODE READER in the Configuration Menu.

BCR must be configured to ON. If it is OFF, change to ON.

3. Power off the autoloader and remove the BCR.

4. Check pins and connector for damage.

5. Reinstall the BCR.

6. Power on the autoloader.

7. Perform a re-inventory via the OCP or view the inventory via the RMU to determine if the labels are now

being read.

8. If the BCR is still not functioning properly, contact technical support.

7.3.4 Cartridge Won’t Eject

If a cartridge will not respond to the UNLOAD command in the Commands Menu, this means that a cartridge will

not unload from the autoloader’s drive.

1. Navigate to UNLOAD in the Commands Menu and press Enter on the OCP.

2. If the cartridge will not eject from the drive, navigate to BULK EXCHANGE in the Commands Menu and

remove all other cartridges from the autoloader.

3. Try ejecting the cartridge by right clicking on the drive icon on the host computer and selecting Eject.

4. Power cycle the autoloader.

5. Contact technical support.

7.4 Error Messages and Error Codes

This chapter describes error codes and associated subcodes of the autoloader. The codes should be used for

analyzing failure situations and to analyze the error log stored in the autoloader.

Different sub code classes are joined to the main errors. In the following tables, the specific sub code class is

defined in the error description. To get the correct subcode, look in the associated sub code class table.

The error codes are divided in two parts:

Errors which will be visible on SCSI interface.

Errors which will be visible on user interfaces like OCP, serial monitor and RMU.

Depending on the error type the errors are only reported on the specific interface, but always stored in the error

log.

The tables with error codes visible on user interfaces (OCP, serial monitor and RMU) contain a column with

recommended actions for the user.

The last section describes all drive error codes. The entries in the drive error log are similar to the error message

code on the autoloader LCD

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 41 of 82

Page 42

7.4.1 Error Code Description

Autoloader error entries have 4 information values which describe the error in detail.

AA BB CC DD

Indicator for hard

error or recovered

error

80—hard error

40—recovered error

The <AA> indicator for the type of error code is only available in the error log. Recovered errors will not be

displayed on the OCP.

The <DD> subcode specific information is not described in this document, since it is used only for detailed failure

analysis in service and repair.

Main error code Error subcode Subcode specific

information

7.4.2 Example for an Error/Event Log:

EVENT -6

80 93 0b 20

Sequence number -6 indicates the position in the sequence list, 0 being the most recent. In this example, the log

shows a load error:

Type 80 = Unrecovered error

Code 93 = Load error

Internal error 0B = Door Stop

Cmd 20 = Load

After pressing Enter, the associated time stamp will be displayed in the following format:

ddd:hh:mm:ss:HH

ddd: days

hh: hours

mm: minutes

ss: seconds

HH: 1/100 second

The time stamp is set at zero at system start up. The complete Error Log can be printed out also through the

Serial Monitor or the optional RMU.

7.4.3 Not Ready Errors 01h–0Fh

Error Code Description

01h Unit scanning library, Please wait

02h Manual intervention required

03h Cause not reportable

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 42 of 82

Page 43

04h Firmware upgrade in process

05h Front door is open

06h Working on other SCSI cmd

08h Loader is in sequential mode

09h Loader is offline

0A–0Fh Reserved

7.4.4 Unit Attention 10h–1Fh

7.4.5 Recovered Errors 20h–2Fh

Error Code Description

20h Error log overflow

21h SCSI parity error

22h-2Fh Reserved

7.4.6 Hardware Errors 30h–4Fh

Error Code Description

30h Media not present

31h POST soft failure

32h Loader communications timeout

33h Loader communications UART error or buffer overflow

34h Bad status returned from loader

35h Unexpected status from test

36h Cartridge has no home

37h REV drive handle problem

38h No cartridge in drive during unload

39h Loader mechanism problem after retries

3Ah Timeout moving cartridge

3Bh Reserved

3Ch Couldn’t unlock door after retries

3Dh Error during scanning

3Eh Couldn’t lock door after retries

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 43 of 82

Page 44

3Fh Unexpected door open

40h Didn’t find all expected slots during belt movement

41h Cartridge already in drive during cartridge loading

42h Slot empty during cartridge loading

45h-4Fh Reserved

7.4.7 Illegal Request Errors 50h–6Fh

Error Code Description

50h No slot free for transfer

51h All slots empty

52h Parameter length error

53h SCSI invalid opcode

54h Invalid element address

55h Invalid field in CDB (Command Description Block)

56h Invalid mode on write buffer

57h Invalid drive specified

58h Invalid test number at diagnostic

59h Invalid offset on write buffer

5Ah Invalid size on write buffer

5Bh Bad controller image checksum

5Ch Invalid LUN

5Dh Parameter list error: invalid field

5Eh Parameter list error: parameter not supported

5Fh Parameter value invalid

60h Saving parameters not supported

63h SCSI invalid ID message

64h Media Load/Eject failure

65h Destination element full

66h Source slot or drive empty

67h Unrecognized loader command

68h Wrong header length

69h Bad sequence number

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 44 of 82

Page 45

6Ah Wrong checksum

6Bh Command unspecified

6Ch Configuration problem: no bar code reader installed

6Dh Flash image does not fit boot code

6Eh Medium removal prevented by drive

6Fh Firmware image contains wrong personality

7.4.8 Aborted Command Errors 70h–73h

Error Code Description

70h SCSI message error

71h SCSI parity error

72h SCSI invalid message

73h SCSI overlapped command attempt

74h-79h Reserved

7.4.9 Additional Errors 7ah–7Fh

Error Code Description

7Ah-7Dh Reserved

7Eh Reservation conflict status

7Fh Reserved

7.4.10 Robotic Control Errors 81h–8Fh

Error Code Description Recommended Action

81h Invalid internal command error.

This error indicates that the robotic

received an undefined internal command

or an invalid parameter to a command.

82h Device status not suitable to execute this

command.

If the robotic is busy, some commands

can’t be executed at the same time. This

error will indicate a probable conflict. This

is not an error condition, but does result in

reporting busy condition to the host for the

requested SCSI command.

Retry operation, after several

occurrences contact technical

support

Retry operation, after several

occurrences contact technical

support

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 45 of 82

Page 46

83h Inventory not valid.

The cartridge inventory is not valid,

because of manual changes or previous

fatal errors.

Perform an inventory rescan

(menu item COMMANDS/REINVENTORY)

84h Source element not ready.

Transport source element unexpected

state.

85h Destination element not ready.

Transport destination element unexpected

state.

86h Assigned to a rejected user attempt to

access door while media removal is

prevented.

87h Is used for several robotic command

timeout conditions.

89h Timeout detected by loader on system

testing

8Fh No error after loader recovery. Only informational message, no

Perform an inventory rescan

(menu item COMMANDS/REINVENTORY)

Perform an inventory rescan

(menu item COMMANDS/REINVENTORY)

Finish IMPORT/EXPORT,

afterwards retry operation

Reset the unit (menu item

CONFIGURATION/RESET)

Reset the unit (menu item

CONFIGURATION/RESET),

restart System Test

action required

7.4.11 Function Errors 90h–9Fh

Error Code Description Recommended Action

90h Mechanical initialization failure.

The robotic wasn’t able to get into its safe

mechanical init position. Manual

intervention will be necessary.

91h Scan failure.

Fatal error during cartridge scan, building

up inventory.

92h Preposition failed.

Belt positioning error.

93h Cartridge mount error.

Movement of cartridge into drive failed.

Reset the unit (menu item

CONFIGURATION/RESET), after

further occurrences contact

technical support

Perform an inventory rescan

(menu item COMMANDS/REINVENTORY)

Run Library Verify Test (menu item

DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Run Library Verify Test (menu item

DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 46 of 82

Page 47

94h Cartridge dismount error.

Failure during cartridge removal and

transport back to the slot.

Run Library Verify Test (menu item

DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

95h Import error.

Device wasn’t able to finish import of new

cartridge without error.

96h Export error.

Fatal error during cartridge export.

97h-9Fh Reserved

Run Library Verify Test (menu item

DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Run Library Verify Test (menu item

DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

7.4.12 Low Level Axis Errors A0h–AFh

Error Code Description Recommended Action

A0h Belt axis error.

Error during cartridge carrier movement

(position not found).

A1h Slider axis error.

Transport slider unable to reach estimated

position.

Run Library Verify Test (menu

item DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Run Library Verify Test (menu

item DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

A2h Gripper position error.

Gripper unable to reach position.

A3h Cartridge pick error.

Missing cartridge during pick operation of

gripper.

A4h Door function error.

Slider door in front bezel not in requested

position during device operation.

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 47 of 82

Run Library Verify Test (menu

item DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Run Library Verify Test (menu

item DIAGNOSTICS/LOADER

DIAG./LIBRARY VERIFY), after

further occurrences contact

technical support

Reset the unit (menu item

CONFIGURATION/RESET), after

further occurrences contact

technical support

Page 48

A5h Fan error.

Loader has detected a Fan error.

Subcode :

F1 Fan at rear connector plate was the

originator

A6h-AFh Reserved

Subcode F1: replace fan at rear

connector plate

7.4.13 Electronic Hardware Errors B0h–B9h

Error Code Description Recommended Action

B0h ROM error.

A defective ROM was detected.

B1h RAM error.

A defective RAM was detected.

B2h NVRAM error.

A defective NVRAM was detected.

B5h Display error.

A defective display was detected.

B6h Memory error.

A defective memory was detected.

B7h Fatal system error. Contact technical support

B8h Barcode error Perform an inventory rescan (menu

Retry operation, after several

occurrences contact technical

support

Contact technical support

Retry operation, after several

occurrences contact technical

support

Contact technical support

Contact technical support

item COMMANDS/REINVENTORY), after several

occurrences contact technical

support.

B9h Database error Contact technical support

7.4.14 Drive Errors BAh–BFh

Error Code Description Recommended Action

BAh Disk load timeout. Retry operation, if not successful

contact technical support

BBh Disk unload timeout. Power-cycle unit, retry operation, if

not successful, contact technical

support

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 48 of 82

Page 49

BCh Overtemperature problem.

Subcode : The original drive error code is

reported

BDh No connection to drive. Contact technical support

BFh Drive broken, needs repair. Contact technical support

Check ambient temperature

(should not exceed 35°C), after

further occurrences contact

technical support

7.4.15 Barcode Errors C0h–CFh

Error Code Description Recommended Action

C0h Library verify test. Autoloader has

multiple readings for a single barcode

label.

C1h-CFh Reserved

Check barcode labels, perform a

rescan inventory

7.4.16 Network Errors D0h–D5h

Error Code Description Recommended Action

D0h Error at network initialization Check cable connection, check

Network configuration, retry operation,

if not successful contact technical

support

D1h Telnet server error Check cable connection, power-cycle

unit, after several occurrences contact

technical support

D2h Web server error Check cable connection, power-cycle

unit, after several occurrences contact

technical support

D3h RMU EEPROM Access Error Check RMU connectivity, power-cycle

unit, after several occurrences contact

technical support

D4h No RMU found Check RMU connectivity, power-cycle

unit, after several occurrences contact

technical support

D5h Error in write data to RMU EEPROM Check RMU connectivity, power-cycle

unit, after several occurrences contact

technical support

7.4.17 Subcode Descriptions

Error Subcode Description

00h No error

01h Communication timeout

Iomega® REV™ Autoloader 1000—User’s Manual

Copyright © 2004. Iomega Corporation. All rights reserved. Page 49 of 82

Page 50

02h Length expired before expected character

03h Any other kind of driver error

10h Start pattern missing

11h Sequence enumeration error

12h Packet length error

13h Checksum mismatch

14h End pattern missing

15h Drive busy—command rejected

16h General drive error

17h Byte stuffing error

18h Command negative acknowledged

21h Carrier state error

22h Repetitions error. Number of repetitions reached.

23h Move to slot position repetitions error. Number of repetitions at move to slot

reached.