Invicta BLz03-1/2, BLz05-2/2, BLz03-0.2/6, BLz03-0.3/6, BLz05-1/4 Installation And Maintenance Manual

...

BLz03 to 80

50/60 Hz

Dust Protected to EN60079-31

Installation and Maintenance

'BLz' Series Vibrators

ENGLISH

(other European languages on request)

INVICTA VIBRATORS

A Division of Grantham Engineering Limited

Harlaxton Road, Grantham,

Lincolnshire, ENGLAND NG31 7SF

Telephone: +44 (0) 1476 566301

Fax: +44 (0) 1476 590145

E-mail: sales@invictavibrators.co.uk

Web: www.invictavibrators.co.uk

OPERATIONAL CONDITIONS

The user's attention is drawn to the following notes:

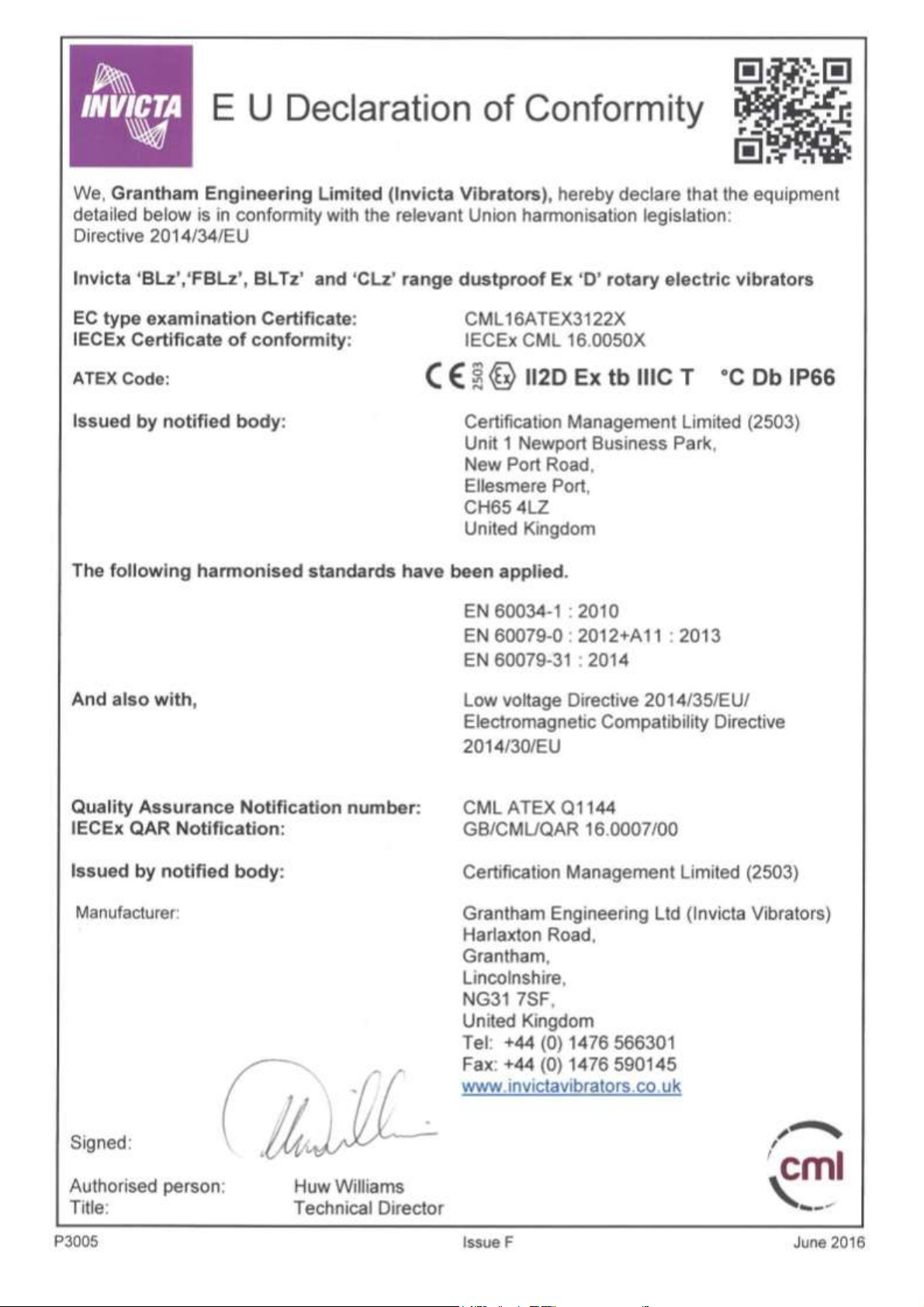

1) The vibrator is approved to the following certification:

ATEX Directive 2014/34/EU

Certificate Numbers CML16ATEX3122X and IECEx CML 16.0050X

ATEX Coding/marking II2D Ex tb IIIC T___° C Db IP66

HAZARDOUS AREA CLASSIFICATION;

Zone of Use (Dust) Zone 21 & 22

Rated Temperature Refer to tables on pages 4 & 5

Ingression Protection (BSEN60529) Main Enclosure IP66

Terminal Box IP66

The equipment is certified for use in ambient temperatures -20°C to +40°C.

The X in our certificate number signifies a special condition of use and applies to vibrators mounted in

orientations other than with a horizontal shaft and also those intended for use with variable speed drives;

i. The user is advised that this equipment is fitted with thermistors, RTDs or thermostats. Mounting the motor in any

orientation, other than with the shaft horizontal, requires the thermistors, RTDs or thermostats to be connected to a

suitable controlling and regulating device, as defined in article 1(b) of European Directive 2014/34/EU, and when

located in hazardous area , shall be covered by an appropriate EC or EU Type Examination Certificate.

This condition does not apply to the smaller vibrators in the Invicta range from BLz03 up to BLz25, fitted with ball

bearings.

ii. The user is advised that this equipment is fitted with thermistors, RTDs or thermostats, therefore, when a vibrator

mounted in any orientation is fed from a variable speed drive, it shall be connected to a suitable controlling and

regulating device, as defined in article 1(b) of European Directive 2014/34/EU, and when located in hazardous

areas, shall be covered by an appropriate EC or EU Type Examination Certificate.

iii. Where the vibrator is installed into a fixed installation where the installation is intended to minimise the risk from

electrostatic discharge the installer must ensure the vibrator is suitably earthed. The vibrator should not be operated

without a suitable earth in place. Regular checks as part of routine inspections should establish that the earth is

intact.

iv. The user shall mark the vibrator with information relevant to the chosen Variable Speed Control as detailed in BS

EN60079-0, clause 29.15.

2) The equipment has not been assessed as a safety related device (as referred to by directive 2014/34/EU Annex II,

clause 1.5).

3) Installation of this equipment shall be carried out by suitably trained personnel in accordance with the applicable

Code of Practice (EN60079-14).

4) Inspection and maintenance of this equipment shall be carried out by suitably trained personnel in accordance with

the applicable Code of Practice (EN60079-17).

Repair of this equipment shall be carried out by suitable trained personnel in accordance with the applicable Code of

Practice (EN60079-19).

The manufacturer offers a full repair service.

5) Components to be incorporated into or used as replacements in the equipment shall be fitted by suitably trained

personnel in accordance with the manufacturer's documentation.

Page 1

6) If the equipment is likely to come into contact with aggressive substances, then it is the responsibility of the user to

take suitable precautions to prevent it from being adversely affected, thus ensuring that the type of protection is not

compromised.

a) Aggressive Substances: e.g. acidic liquids or gases that may attack metals or solvents that may affect

polymeric materials (such as seals)

b) Suitable Precautions: e.g. regular checks as part of routine inspections or establishing from material

data sheet that it is resistant to specific chemicals.

7) Some Invicta vibrators are provided with either an integral cast lifting point or provision for the use of eye bolts. Users

are to ensure that shackles, eye bolts or any other required lifting equipment used are sufficiently rated to safely lift the

weight of the vibrator. The weight of each vibrator is included in the information stamped on the vibrator nameplate.

Users should also ensure that any lifting accessories or equipment is used in accordance with the manufacturer’s

instructions and the user’s codes of practice. The lifting points should be inspected for defects prior to each lifting

operation.

Note: The lifting points are designed solely to lift the vibrator only. Users should not, under any circumstance, use the

lifting point on the vibrator to lift any other plant or machinery that the vibrator may be mounted to.

WARNING: The shaft assembly inside the vibrator contains eccentric weights and is free to rotate as the

vibrator is lifted.

This potential shifting of the weight distribution should be taken into account when lifting the vibrator into

position.

Disclaimer

Invicta Vibrators are certified to comply with the European Directive 2014/34/EU (ATEX Directive) as described. It

remains the responsibility of the user to ensure that the equipment is correctly selected and rated for the environment in

which it is to be used in accordance with European Directive 99/92/EC (also known as ATEX 137 or the ATEX Workplace

Directive) and regulations 7 and 11 of the Dangerous Substances and Explosive Atmospheres Regulations 2002

(DSEAR).

Important Safety Note:

It is the responsibility of the intended user of the BLz vibrator to ensure that the installation and usage instructions

contained in this manual are fully understood before any attempt to install or use the vibrator is made. Failure to

understand and adhere to these instructions could result in fire, electric shock, explosion or serious personal injury.

This manual should be retained throughout the life of the vibrator and referred to whenever necessary.

Page 2

Page 3

Vibrator

Type

Power

Output

(Watts)

Surface Temperature

Max in +40ºC ambient

at Full Power

(°C)

Temperature Rating

Of Thermistors

(oC)

Cable Entry

Thread Size

BLz03-1/2

120

93

80

M16x1.5-6H

BLz03-0.5/4

100

106

90

M16x1.5-6H

BLz03-0.2/6

70

93

80

M16x1.5-6H

BLz03-0.3/6

70

93

80

M16x1.5-6H

BLz05-2/2

200

142

100

M20x1.5-6H

BLz05-1/4

175

106

90

M20x1.5-6H

BLz05-2/4

175

106

90

M20x1.5-6H

BLz05-0.4/6

90

119

100

M20x1.5-6H

BLz05-0.6/6

90

119

100

M20x1.5-6H

BLz05-0.9/6

90

119

100

M20x1.5-6H

BLz05-1.3/6

90

119

100

M20x1.5-6H

BLz15-3.5/2

300

131

100

M20x1.5-6H

BLz15-3/4

300

111

100

M20x1.5-6H

BLz15-1.3/6

110

121

100

M20x1.5-6H

BLz15-1.9/6

110

121

100

M20x1.5-6H

BLz20-5/2

400

130

100

M20x1.5-6H

BLz20-5/4

350

121

100

M20x1.5-6H

BLz20-2.2/6

150

112

100

M20x1.5-6H

BLz22-5/2

400

130

100

M20x1.5-6H

BLz22-5/4

350

121

100

M20x1.5-6H

BLz22-2.2/6

150

112

100

M20x1.5-6H

BLz24-8/2

500

130

120

M20x1.5-6H

BLz24-10/2

500

130

120

M20x1.5-6H

BLz24-13/2

500

130

120

M20x1.5-6H

BLz24-7.5/4

500

130

120

M20x1.5-6H

BLz24-11/4

500

130

120

M20x1.5-6H

BLz24-14/4

500

130

120

M20x1.5-6H

BLz24-4/6

510

130

120

M20x1.5-6H

BLz24-8/6

510

130

120

M20x1.5-6H

BLz24-11/6

510

130

120

M20x1.5-6H

BLz25-8/2

500

130

120

M20x1.5-6H

BLz25-10/2

500

130

120

M20x1.5-6H

BLz25-13/2

500

130

120

M20x1.5-6H

BLz25-7.5/4

500

130

120

M20x1.5-6H

BLz25-11/4

500

130

120

M20x1.5-6H

BLz25-14/4

500

130

120

M20x1.5-6H

510

130

120

M20x1.5-6H

BLz25-8/6

510

130

120

M20x1.5-6H

BLz25-11/6

510

130

120

M20x1.5-6H

BLz30-16/2

1100

130

120

M20x1.5-6H

BLz30-20/2

1100

130

120

M20x1.5-6H

BLz30-18/4

1150

130

120

M20x1.5-6H

BLz30-25/4

1150

130

120

M20x1.5-6H

BLz30-14/6

900

135

120

M20x1.5-6H

BLz30-18/6

900

135

120

M20x1.5-6H

BLz30-23/6

900

135

120

M20x1.5-6H

BLz30-7.5/8

500

129

110

M20x1.5-6H

BLz30-10/8

500

129

110

M20x1.5-6H

FULL POWER TEST DATA AND TEMPERATURE RATINGS

L SERIES VIBRATORS TO EN 60079-31

Page 4

Vibrator

Type

Power

Output

(Watts)

Surface Temperature

Max in +40ºC ambient

at Full Power

(°C)

Temperature Rating

Of Thermistors

(oC)

Cable Entry

Thread Size

BLz40-30/2

1500

133

120

M20x1.5-6H

BLz40-40/2

1500

133

120

M20x1.5-6H

BLz40-35/4

1800

114

100

M20x1.5-6H

BLz40-27/6

1800

124

110

M20x1.5-6H

BLz40-35/6

1800

124

110

M20x1.5-6H

BLz40-15/8

1100

132

120

M20x1.5-6H

BLz40-17/8

1100

132

120

M20x1.5-6H

BLz45-50/2

4000

130

120

M25x1.5-6H

BLz45-45/4

2685

130

120

M25x1.5-6H

BLz45-42/6

2310

134

120

M25x1.5-6H

BLz45-50/6

2310

134

120

M25x1.5-6H

BLz45-24/8

2000

130

120

M25x1.5-6H

BLz45-35/8

2000

130

120

M25x1.5-6H

BLz50-55/4

3350

130

120

M25x1.5-6H

BLz50-65/4

4800

130

120

M25x1.5-6H

BLz50-75/4

4800

130

120

M25x1.5-6H

BLz50-60/6

4000

122

110

M25x1.5-6H

BLz50-75/6

4000

122

110

M25x1.5-6H

BLz50-35/8

3300

100

90

M25x1.5-6H

BLz50-45/8

3300

100

90

M25x1.5-6H

BLz50-55/8

3300

100

90

M25x1.5-6H

BLz50-57/8

3300

100

90

M25x1.5-6H

BLz60-95/4

7750

130

120

M32x1.5-6H

BLz60-105/4

7750

130

120

M32x1.5-6H

BLz61-105/4

7750

130

120

M32x1.5-6H

BLz60-90/6

6200

130

120

M32x1.5-6H

BLz60-105/6

6200

130

120

M32x1.5-6H

BLz61-105/6

6200

130

120

M32x1.5-6H

BLz60-125/6

10000

130

120

M32x1.5-6H

BLz61-125/6

10000

130

120

M32x1.5-6H

BLz60-65/8

4900

117

100

M32x1.5-6H

BLz60-70/8

4900

117

100

M32x1.5-6H

BLz60-90/8

4900

117

100

M32x1.5-6H

BLz75-130/4

10250

130

120

M32x1.5-6H

BLz75-150/6

10000

130

120

M32x1.5-6H

BLz78-165/6

10000

130

120

M32x1.5-6H

BLz75-185/6

10000

130

120

M32x1.5-6H

BLz77/78-185/6

10000

130

120

M32x1.5-6H

BLz77-124/8

7750

125

110

M32x1.5-6H

BLz75-150/8

7750

125

110

M32x1.5-6H

BLz75-200/8

7750

125

110

M32x1.5-6H

BLz77-200/8

BLz80 230/6

BLz80 270/6

BLz80-205/8

7750

12500

12500

9700

125

160

160

160

110

150

150

150

M32x1.5-6H

M32x1.5-6H

M32x1.5-6H

M32x1.5-6H

Note: Cable gland temperature can exceed +70°C

FULL POWER TEST DATA AND TEMPERATURE RATINGS

L SERIES VIBRATORS TO EN 60079-31

Page 5

BEARING REPLACEMENT – IMPORTANT NOTICE

To satisfy EN13463 Part 5 Clause 6.1 & 6.2 the bearings in this equipment shall be replaced after a period not exceeding 90% of their

rated life. The user’s attention is therefore drawn to the list of bearing lives shown in the table below.

L 10 BEARING FATIGUE LIFE L SERIES DUST PROTECTED VIBRATORS TO EN60079-31

Frame Size Centrifugal Force Fatigue life (Hours) L10

Kg Newtons Bearing Types 50 Hz 90% 60 Hz 90%

Vibrators at 2880/3456 RPM

BLz 03-1/2 100 981 6301 2Z C3 49940 44950 41400 37260

BLz 05-2/2 200 1962 6304 2Z C3 28000 25200 23230 20900

BLz 15-3.5/2 350 3433 6306 2Z C3 25380 22840 21150 19035

BLz 20/22-5/2 500 4905 6308 2Z C3 29700 26730 24670 22200

BLz 24/25-8/2 800 7848 6309 2Z C3 15380 13840 12780 11500

BLz 24/25-10/2 1000 9810 NJ 2306E TVP2 C3 49050 44150 40720 36650

BLz 24/25-13/2 1300 12753 NJ 2307E TVP2 C3 41560 37400 34490 31040

BLz 30-16/2 1600 15695 NJ 2309E TVP2 C3 82540 74290 68500 61650

BLz 30-20/2 2000 19620 NJ 2309E TVP2 C3 39260 35330 32580 29320

BLz 40-30/2 3000 29430 NJ 2311E TVP2 C3 35500 31950 29460 26510

BLz 40-40/2 4000 39240 NJ 2313E TVP2 C3 28860 25970 23950 21550

BLz 45-50/2 5000 49050 NJ 2312E TVP2 C4 12343 11110 10286 9260

Vibrators at 1440/1728 RPM

BLz 03-0.5/4 50 490 6301 2Z C3 >100000 90000 85470 76920

BLz 05-1/4 100 981 6304 2Z C3 >100000 90000 >100000 90000

BLz 05-2/4 200 1962 6304 2Z C3 24640 22180 20530 18480

BLz 15-3/4 300 2943 6305 2Z C3 40560 36500 33800 30420

BLz 20/22-5/4 500 4905 6307 2Z C3 28710 25840 23930 21540

BLz 24/25-7.5/4 750 7357 6309 2Z C3 37510 33760 31130 28020

BLz 24/25-11/4 1100 10790 NJ 2306E TVP2 C3 70710 63640 58670 52800

BLz 24/25-14/4 1400 13735 NJ 2307E TVP2 C3 65650 59080 53640 48280

BLz 30-18/4 1800 17658 NJ 2309E TVP2 C3 >100000 90000 91960 82760

BLz 30-25/4 2500 24525 NJ 2309E TVP2 C3 37080 33370 30770 27690

BLz 40-35/4 3500 34335 NJ 2311E TVP2 C3 42340 38100 35130 31620

BLz 45-45/4 4500 44145 NJ 2313E TVP2 C3 38390 34550 31850 28660

BLz 50-55/4 5500 53955 NJ 2315E TVP2 C3 49060 44150 40710 36640

BLz 50-65/4 6500 63765 NJ 2317E M1A C3 42800 38520 35500 31950

BLz 50-75/4 7500 73575 NJ 2317E M1A C3 32040 28830 26580 23920

BLz 60-95/4 9500 93195 NJ2320E M1A C3 52820 47540 43820 39440

BLz60/61-105/4 10500 103000 NJ2320E M1A C3 37700 33930 31410 28270

BLz 75-130/4 13000 127530 NJ 2322E M1A C3 31320 28190 25980 23380

Vibrators at 960/1152 RPM

BLz 03-0.2/6 22 216 6301 2Z C3 > 100000 90000

BLz 03-0.3/6 32 314 6301 2Z C3 > 100000 90000

BLz 05-0.4/6 40 392 6304 2Z C3 > 100000 90000

BLz 05-0.6/6 60 589 6304 2Z C3 > 100000 90000

BLz 05-0.9/6 90 883 6304 2Z C3 > 100000 90000

BLz 05-1.3/6 130 1275 6304 2Z C3 >100000 90000

BLz 15-1.3/6 130 1275 6305 2Z C3 > 100000 90000

BLz 15-1.9/6 190 1864 6305 2Z C3 >100000 90000

BLz 20/22-2.2/6 220 2158 6307 2Z C3 > 100000 90000 >100000 90000

BLz 24/25-4/6 440 3924 6309 2Z C3 > 100000 90000 >100000 90000

BLz 24/25-8/6 800 7848 NJ 2306E TVP2 C3 > 100000 90000 >100000 90000

BLz 24/25-11/6 1100 10790 NJ 2307E TVP2 C3 > 100000 90000 >100000 90000

BLz 30-14/6 1400 13734 NJ 2309E TVP2 C3 > 100000 90000 >100000 90000

BLz 30-18/6 1800 17658 NJ 2309E TVP2 C3 > 100000 90000 >100000 90000

BLz 30-23/6 2300 22563 NJ 2309E TVP2 C3 60000 54000 50000 45000

BLz 40-27/6 2700 26487 NJ 2311E TVP2 C3 > 100000 90000 >100000 90000

BLz 40-35/6 3500 34335 NJ 2311E TVP2 C3 63300 56970 52700 47430

BLz 45-42/6 4200 41200 NJ 2313E TVP2 C3 69980 62980 58070 52260

BLz 45-50/6 5000 49050 NJ 2313E TVP2 C3 40400 36360 33670 30300

BLz 50-60/6 6000 58860 NJ 2315E TVP2 C3 55120 49610 45740 41170

BLz 50-75/6 7500 73575 NJ 2317E TVP2 C3 4 8200 43380 40000 36000

BLz 60-90/6 9000 88290 NJ 2320E TVP2 C3 94510 85060 78760 70880

BLz 60/61-105/6 10500 103000 NJ 2320E TVP2 C3 57430 51690 47300 42570

BLz 60/61-125/6 12500 122625 NJ 2320E TVP2 C3 29150 26235 24290 21860

BLz 75-150/6 15000 147500 NJ 2322E M1A C3 29260 26330 24280 21850

BLz 78-165/6 16500 161865 NJ 2322E M1A C3 21140 19025 17610 15850

BLz 75/77/78-185/6 18500 181485 NJ 2322E M1A C3 14440 13000 12030 10830

BLz 80-230/6 23000 225630 NJ2326E M1 C3 30190 27170 25160 22645

BLz 80-270/6 27000 264880 NJ2326E M1 C3 17700 15930 14750 13275

Page 6

L 10 BEARING FATIGUE LIFE L SERIES DUST PROTECTED VIBRATORS TO EN60079-31

Frame Size Centrifugal Force Fatigue life (Hours) L10

Kg Newtons Bearing Types 50 Hz 90% 60 Hz 90%

Vibrators at 720/864 RPM

BLz 30-7.5/8 750 7357 NJ 2309E TVP2 C3 >100000 90000 >100000 90000

BLz 30-10/8 1000 9810 NJ 2309E TVP2 C3 >100000 90000 >100000 90000

BLz 40-15/8 1500 14715 NJ 2311E TVP2 C3 >100000 90000 -- -BLz 40-17/8 1700 16671 NJ 2311E TVP2 C3 -- >100000 90000

BLz 45-24/8 2430 23838 NJ 2313E TVP2 C3 >100000 90000 >100000 90000

BLz 45-35/8 3500 34335 NJ 2313E TVP2 C3 -- >100000 90000

BLz 50-35/8 3500 34335 NJ 2315E TVP2 C3 >100000 90000 -- -BLz 50-45/8 4500 44145 NJ 2315E TVP2 C3 >100000 90000 >100000 90000

BLz 50-55/8 5500 53955 NJ 2317E TVP2 C3 >100000 90000 -- -BLz 50-57/8 5700 55917 NJ 2317E TVP2 C3 -- >100000 90000

BLz 60-65/8 6500 63765 NJ 2320E TVP2 C3 >100000 90000 -- -BLz 60-70/8 7000 68670 NJ 2320E TVP2 C3 -- >100000 90000

BLz 60-90/8 9000 88290 NJ 2320E TVP2 C3 >100000 90000 >100000 90000

BLz 75/77-124/8 12400 121644 NJ 2322E M1A C3 68370 61530 56970 51270

BLz 75-135/8 13500 132435 NJ 2322E M1A C3 55020 49520 -- -BLz 75-150/8 15000 147150 NJ 2322E M1A C3 38960 35060 32330 29100

BLz 75/77-200/8 20000 196200 NJ 2322E M1A C3 -- -- 12455 11210

BLz 80-205/8 20500 201105 NJ2326E M1 C3 59050 53145 49205 44285

Page 7

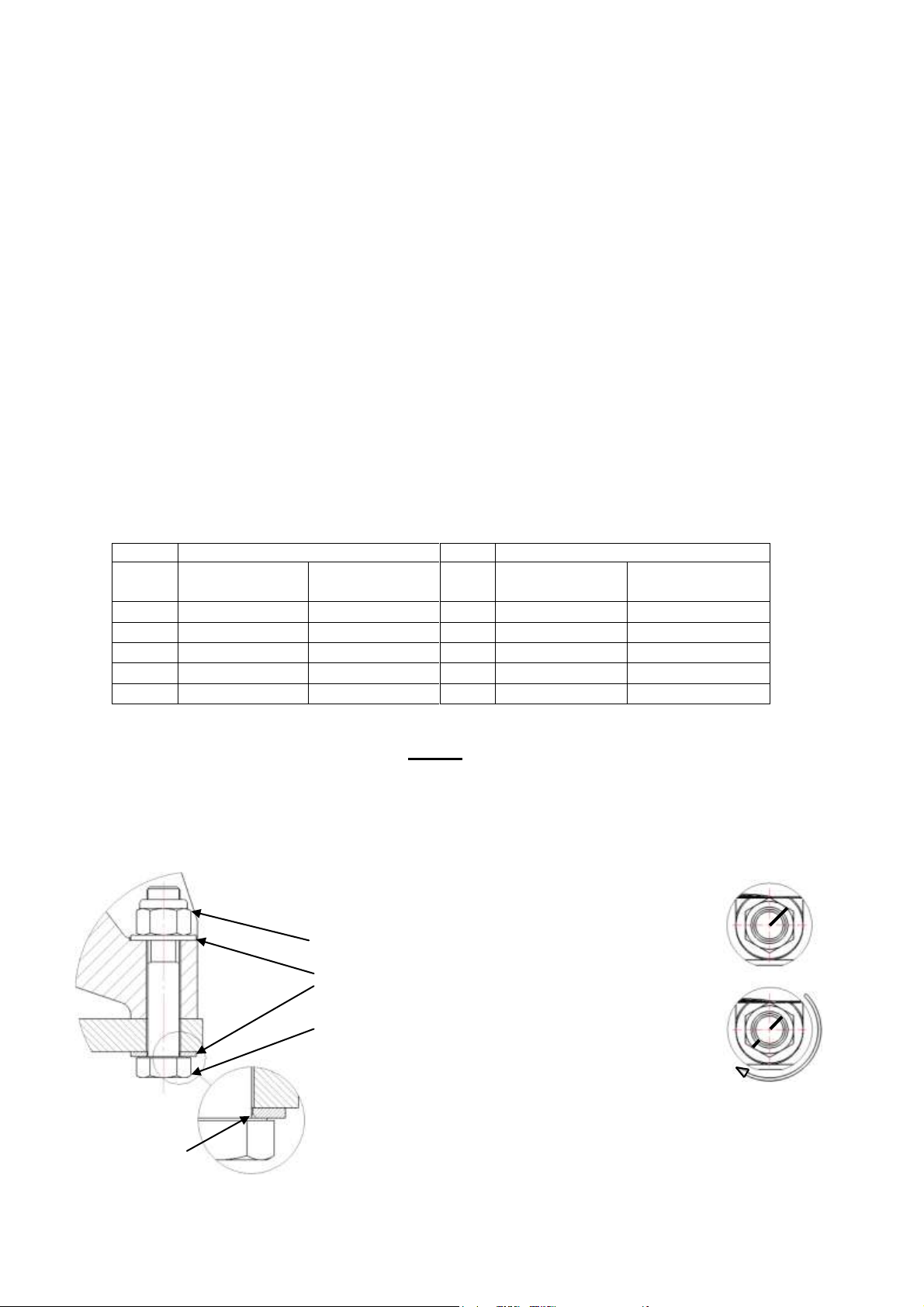

Size

Torque (N.m)

Size

Torque (N.m)

Cap-Screws

Grade 12.9

Setscrews/Bolts

Grade 8.8

Cap-Screws

Grade 12.9

Setscrews/Bolts

Grade 8.8

M 5 8 -

M 16

310

242

M 6

15

11

M 20

580

473

M 8

34

27

M 24

950

818

M 10

68

56

M 30

-

1634*

M 12

127

96

M 36

-

2854*

Use the above figures for all screws except out of balance weights. (see page 29)

FIG.2

FIG.3

FIG.1

Washer Chamfer

this side.

‘L’ SERIES VIBRATOR INSTALLATION AND MAINTENANCE

RECEIPT AND STORAGE

Each vibrator is tested and inspected on completion. Whilst every care is taken during transit they should be

inspected on receipt and any defects immediately reported to the carrier and supplier. When not for immediate

use, they can be stored for up to two years if kept in a clean, dry and temperate atmosphere, free from

vibration. After more than 2 years of storage the bearing grease should be replaced before the motor is used.

INSTALLATION GUIDANCE NOTES:

Mechanical: Inspect vibrator for any physical damage and check that rotor shaft rotates freely. Remove paint

masking stickers from motor mounting holes. ALL mounting surfaces MUST be flat and free of paint, dirt and

scale. Fixing bolts should be tightened as recommended below and tightness checked after initially running

the vibrator. Bolts and nuts should not be reused. Please ensure there is at least 50mm of clearance between

the vibrator and any surrounding static structure.

IMPORTANT - GAPS BETWEEN THE VIBRATOR FOOT AND MATING SURFACES AND INCORRECT

BOLT TIGHTNESS WILL CAUSE BOLT BREAKAGE AND DAMAGE TO THE VIBRATOR.

Fixing bolt tightening: Use Grade 8.8 bolts with Grade 8 self locking nuts, torqued to values below. Figures

below apply to un-plated dry threads.

Where capscrews are used with locking nuts, Grade 10 nuts must be fitted.

Use plain washers for BLz 03 - BLz 24 (aluminium frames) Not BLz22. If washers are used for BLz22 - BLz80

(cast iron frames) Not BLz24, hardened washers (PSN 612 to DIN 6916 or BS EN 14399-6) must be fitted.

BLz 75 - 80: Half turn method.

In exceptional circumstances where tooling is not available, the half turn method may be used.

PSN 661 – High Strength nut

PSN 612 – Hardened washer under

bolt head and nut

PSN 780 - High strength bolt

Remove any paint, dirt or scale from all mating surfaces.

Fit hardened washer (PSN 612) under bolt head and nut. Pre-tighten until all mating surfaces are in contact.

Mark nuts and bolts as shown in fig. 2 and slog nut one half turn until marks are as shown in fig. 3.

Page 8

Delta

Star Y

Group 01

230v 50 Hz & 60 Hz

380 - 415v 50 Hz, 460 - 480v 60Hz

Group 03

500v 50Hz, 575v 60Hz

Group 07 380v 60Hz

Group 28

400v 50Hz

690v 50Hz

Nut size

Tightening torque

(Nm)

M4

1.1

M5

2.2

M6

3.7

Electrical

Check insulation resistance and if less than 1 megohm DO NOT USE, consult a qualified electrician. Perform

a continuity resistance check between the external earth point and end covers, terminal box lid and nameplate,

if the resistance is more than 1.0 ohms between the earth point and any of the aforementioned items, DO NOT

USE, consult a qualified electrician. Note: this continuity check should be performed after each removal and

re-fitting of the end cover and terminal box lid.

A flexible cable and suitable cable gland must be used to connect between the vibrator and supply junction

box.

The cable gland shall comply with EN60079-0 and have an IP rating equal to or better than IP66 (see table on

pages 4 & 5 for cable entry thread sizes). The supply must be suitably fuse protected. 4 core cable to be

used with flexible conductors type; 24/0.20 (BLz 03); 50/0.25 (BLz 05 – BLz 40); 56/0.30 (BLz 45 – BLz 50);

80/0.40 (BLz 60/61 – BLz 75-80): BLz 24 to BLz 80 are fitted with thermistors as standard and require a 2

core cable with flexible conductors type 30/0.25. The external earth cable must have a cross sectional area of

at least 4mm²

Flexible conductors must be terminated with insulated crimp on ring terminals, or ring terminals fitted with

insulating sleeves for L1, L2, L3 and earth. Plain soldered ends for thermistor connections T1 and T2.

If thermistors are not required leave the blanking plug in the cable entry hole.

BLz Vibrators are suitable for a 3 phase 50Hz or 3 phase 60Hz electrical supply. BLz vibrators are

rated for continuous duty. The insulation class of the winding will be either ‘F’ or ‘H’ as indicated on

the nameplate. Starting can be direct on line via inverter or soft start. Each vibrator MUST BE

INDIVIDUALLY PROTECTED against overload. Each overload should be of the delayed magnetic-circuit

breaker type to prevent tripping during the high starting current requirement of vibrator starting. The overload

size should be selected based on the full load current and starting current values listed on pages 11 & 12.

NOTE When operating vibrators at speeds above pole speed the out of balance force MUST be reduced or

DAMAGE WILL OCCUR; see Page 30 for correct percentage reduction.

VOLTAGE RANGE

The voltage range data on pages 11 & 12 (230-690v 50Hz and 230-575v 60Hz) is served by four distinct

windings* thus:

* Except BLz40 8 Pole which uses group 43 windings for 460-480v 60Hz.

The winding group number and Hertz appears in the vibrator designation and on the nameplate Thus a BL25-

14/4 400v 50Hz machine will be designated BL25-14/4/01/50.

It is essential that the correct Winding (group) is used with the specified electrical supply. Noncompliance with the above instructions will result in electrical failure.

Terminal post nuts should be tightened to the values given in the table below.

Page 9

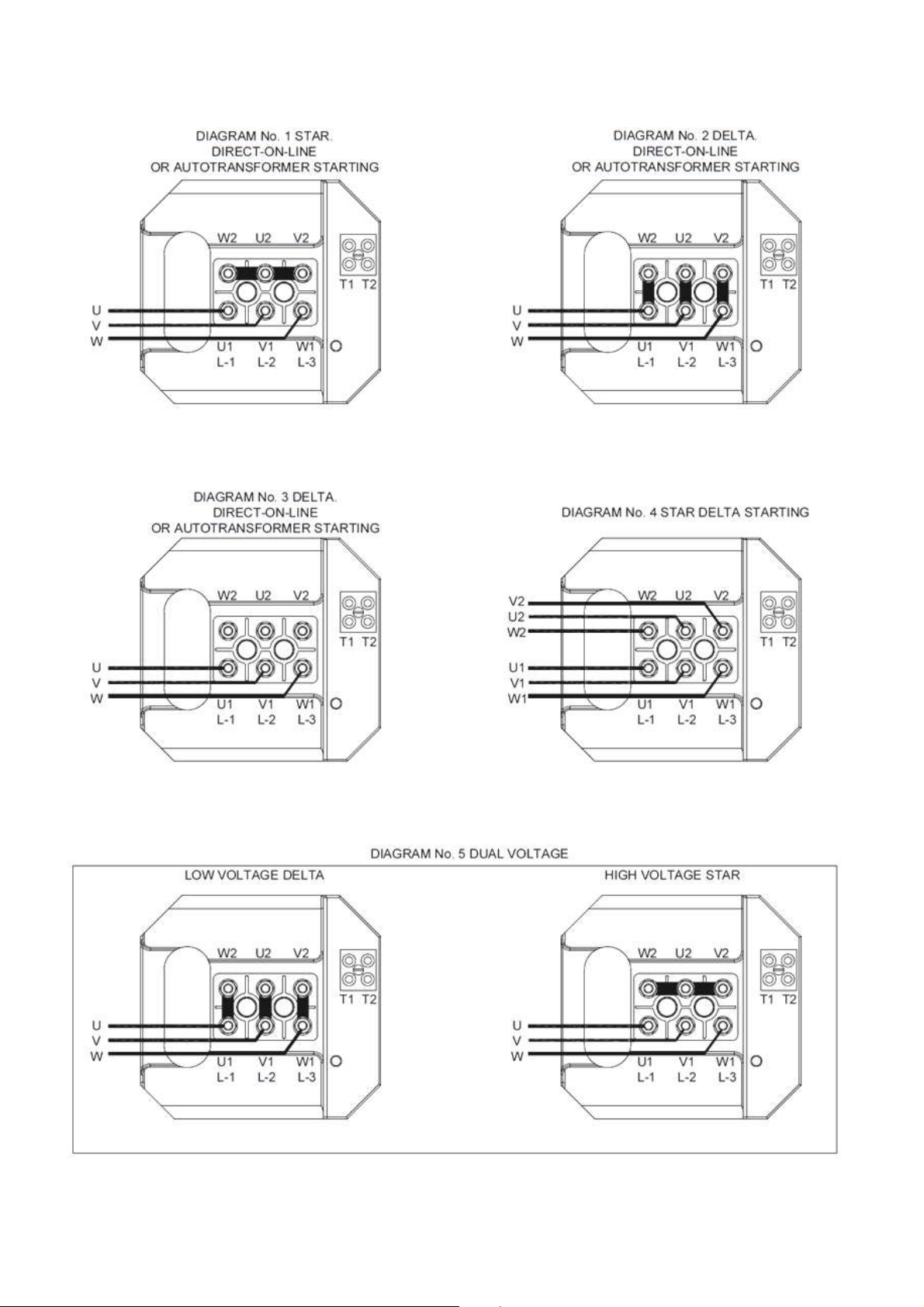

VIBRATOR TERMINAL BOX field connection 3 Phase, 50/60 Hertz

The installer is directed to the diagram number engraved on the nameplate for the appropriate field connection

diagram (below).

Refer to nameplate for required connection.

L1 - L3 are line connections. T1 & T2 are thermistor connections.

Page 10

01**

Y 01*

Y 01*

Y 03*

28**

Y 28*

Type

Output

230 Volts

50 Hz

380 Volts

50 Hz

400 Volts

50 Hz

500 Volts

50 Hz

400 Volts

50 Hz

690 Volts

50 Hz

Watts

FLC

SC

FLC

SC

FLC

SC

FLC

SC

FLC

SC

FLC

SC

2 POLE - 2880 RPM

BLz 03

120

0.33

2.7

0.18

1.6

0.19

1.6

0.16

1.2

0.2

1.7

0.12

1.0

BLz 05

200

0.60

5.2

0.34

3.1

0.35

3.0

0.27

2.4

0.58

5.0

0.33

2.8

BLz 15

300

0.98

5.2

0.58

3.1

0.56

3.0

0.46

2.4

0.58

5.0

0.33

2.8

BLz 20/22

400

1.35

9.8

0.79

5.9

0.78

5.6

0.64

4.5

0.81

5.8

0.47

3.4

BLz 24/25

500

2.03

17.8

1.19

10.8

1.17

10.2

0.98

8.2

1.22

10.6

0.70

7.4

BLz 30

1100

3.6

27

2.2

16

2.1

16

1.7

13

BLz 40

1500

5.0

48

3.0

29

2.9

28

2.3

22

2.9

35

1.7

21

BLz 45

4000

12.7

89

7.6

53

7.3

51

5.8

41

4 POLE - 1440 RPM

BLz 03

100

0.34

1.4

0.19

0.9

0.20

0.8

0.17

0.7

BLz 05

175

0.71

2.9

0.41

1.7

0.41

1.7

0.35

1.3

BLz 15

300

1.24

4.0

0.71

2.4

0.71

2.3

0.60

1.9

0.75

2.4

0.44

1.4

BLz 20/22

350

1.68

6.3

0.95

3.8

0.97

3.6

0.81

2.9

1.03

3.8

0.60

2.2

BLz 24/25

500

2.28

15.1

1.34

9.2

1.32

8.7

1.14

7.0

1.43

9.4

0.83

5.5

BLz 30

1150

4.3

42

2.5

25

2.5

24

2.1

19

2.62

25

1.51

14.5

BLz 40

1800

6.4

56

3.8

34

3.7

32

3.1

26

3.86

33

2.23

19.3

BLz 45

2685

9.2

83

5.4

49

5.3

48

4.5

41

5.5

59

3.2

34.3

BLz 50-55

3350

11

109

6.5

65

6.4

64

5.3

53

6.6

66

3.8

38

BLz 50-65, 75

4800

14.9

137

8.8

81

8.6

79

7.1

65

8.8

90

5.1

52

BLz60/61

7750

22.3

241

13.4

145

12.9

140

10.4

113

13.1

193

7.6

112

BLz 75

10250

28.9

200

17.4

120

16.7

115

13.5

93 6 POLE - 960 RPM

BLz 03

70

0.8

0.87

0.47

0.48

0.46

0.5

0.38

0.43

BLz 05

90

0.94

1.56

0.53

0.87

0.54

0.9

0.46

0.55

BLz 15

110

1.03

1.55

0.59

0.85

0.6

0.9

0.5

0.78

BLz 20/22

150

1.55

2.78

0.87

1.53

0.9

1.60

0.76

2.0

BLz 24/25

510

2.79

12.2

1.58

7.4

1.61

7.0

1.33

5.6

1.7

7.4

0.99

4.3

BLz 30

900

5.2

26

2.9

16

3.0

15

2.5

12

3.2

16

1.85

9.3

BLz 40

1800

8.7

43

4.9

26

5.0

25

4.3

20

5.4

27

3.1

15.6

BLz 45

2310

11.0

76

6.2

46

6.3

44

5.5

35

6.9

49

4.0

28

BLz 50

4000

15.2

106

8.7

64

8.8

61

7.4

49

9.3

64

5.3

37

BLz 60/61-90,105

6200

19.4

188

11.4

114

11.2

108

9.5

86

11.6

112

6.7

64

BLz 60/61-125

10000

31.2

222

18.4

131

18.0

128

14.8

105

18.3

233

10.5

135

BLz 75/77/78

10000

31.2

222

18.4

131

18.0

128

14.8

105

18.3

233

10.5

135

BLz80

12500

44

266

26.6

161

25.3

153

20.2

122 8 POLE - 720 RPM

BLz 30

500

4.0

18

2.2

11

2.3

10.4

2.0 8 BLz 40

1100

6.2

23

3.5

14

3.6

13.5

3.1

11

BLz 45

2000

10.6

40

5.9

24

6.1

23

5.3

18

BLz 50

3300

15.0

96

8.4

58

8.6

55

7.6

44

BLz 60

4900

23.0

170

12.9

103

13.3

97

11.8

78

14.4

106

8.3

62

BLz 75 /77

7750

34.8

216

19.9

130

20.1

124

17.4

99

20.6

126

11.9

71

BLz80

9700

40.7

237

23.8

138

23.6

137

See Voltage Range note & also connection diagrams on pages 9 & 10.

See Voltage Range note & also connection diagrams on pages 9 & 10.

See Voltage Range note & also connection diagrams on pages 9 & 10.

See Voltage Range note & also connection diagrams on pages 9 & 10.

FULL LOAD AND STARTING CURRENTS IN AMPS FOR BLz SERIES VIBRATORS (Winding groups 01, 03 & 28)

Maximum Figures for +40oC Ambient

*STAR = Y **Delta =

Page 11

Loading...

Loading...