Owner's Operator And Maintenance Manual

®

Terminator Junior (JR)

DEALER: THIS MANUAL MUST BE GIVEN TO THE USER OF

THE WHEELCHAIR.

USER: BEFORE USING THIS WHEELCHAIR, READ THIS

MANUAL AND SAVE FOR FUTURE REFERENCE.

WARNING/SPECIAL NOTES

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING

W

A

R

N

I

N

G

AND UNDERSTANDING THIS MANUAL. IF YOU ARE UNABLE TO

UNDERST AND THE W ARNINGS, CAUTIONS AND

INSTRUCTIONS, CONT ACT A QUALIFIED TECHNICIAN OR TOP

END CUSTOMER SUPPORT AT (800) 532-8677 BEFORE

ATTEMPTING TO USE THIS EQUIPMENT - OTHERWISE INJURY

AND/OR EQUIPMENT DAMAGE MAY RESULT .

SPECIAL NOTES

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices which

could result in personal injury or property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE.

S

P

E

C

A

L

N

O

T

E

S

As a manufacturer of wheelchairs, Invacare endeavors to supply a wide variety of wheelchairs

to meet many needs of the end user. However, final selection of the type of wheelchair to be

used by an individual rests solely with the user and his/her healthcare professional capable of

making such a selection.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

I

Invacare recommends that wheelchair users NOT be transported in vehicles of any kind while in

wheelchairs. As of this date, the Department of Transportation has not approved any tie-down

systems for transportation of a user while in a wheelchair, in a moving vehicle of any type.

It is Invacare’s position that users of wheelchairs should be transferred into appropriate seating in

vehicles for transportation and use be made of the restraints made available by the auto industry. Invacare cannot and does not recommend any wheelchair transportation systems.

AS REGARDS RESTRAINTS - SEAT POSITIONING STRAPS - IT IS THE OBLIGATION OF THE DME DEALER,

THERAPISTS AND OTHER HEALTHCARE PROFESSIONALS TO DETERMINE IF A SEATING POSITIONING

STRAP IS REQUIRED TO ENSURE THE SAFE OPERATION OF THIS EQUIPMENT BY THE USER. SERIOUS

INJURY CAN OCCUR IN THE EVENT OF A FALL FROM A WHEELCHAIR.

SAVE THESE INSTRUCTIONS

2

TABLE OF CONTENTS

T ABLE OF CONTENTS

WARNING/SPECIAL NOTES................................. 2

SPECIFICATIONS................................................. 4

PROCEDURE 1 - GENERAL GUIDELINES .............5

OPERA TING INFORMA TION .................................5

SAFETY/HANDLING OF WHEELCHAIRS ..............6

PROCEDURE 2 -SAFETY INSPECTION............... 10

SAFETY INSPECTION CHECKLIST ..................... 10

PROCEDURE 3 -

TROUBLESHOOTING/MAINTENANCE ........... 11

TROUBLESHOOTING ........................................ 11

MAINTENANCE ................................................. 11

PROCEDURE 4 - BACK ...................................... 12

FOLDING/UNFOLDING BACK ............................. 12

CHANGING THE BACK ANGLE .......................... 12

ADJUSTING THE BACK HEIGHT......................... 13

REPLACING ST ANDARD BACK UPHOLSTER Y ... 13

REPLACING CUSTOM MANUAL ADJUSTABLE

TENSION BACK UPHOLSTERY ...................... 14

REPLACING THE SPREADER BAR ....................15

REPLACING THE LOCKING MECHANISM IN

THE BACK CANE ........................................... 15

INST ALLING THE STROLLER HANDLES............. 16

PROCEDURE 5 - ARMS...................................... 17

USING CANTILEVER ARMS ............................... 17

INST ALLING/REMOVING CANTILEVER ARMS..... 17

ADJUSTING CANTILEVER ARM HEIGHT ............ 18

ADJUSTING CANTILEVER ARM ANGLE ............. 18

REPLACING/REPOSITIONING THE

CANTILEVER ARM LOCKING MECHANISM ..... 19

ARMREST P AD ADJUSTMENT/REPLACEMENT ... 19

INST ALLING T-ARM SOCKETS ........................... 20

INST ALLING/REMOVING T-ARMS ....................... 20

ADJUSTING THE T-ARMS .................................. 20

REPLACING THE T-ARM LOCKING LEVER ......... 22

PROCEDURE 6 - SEA T....................................... 23

REPLACING SEA T PAN ...................................... 23

ADJUSTING REAR SEA T HEIGHT..................... 23

ADJUSTING SEA T DEPTH.................................. 23

ADJUSTING SEA T WIDTH .................................. 25

ADJUSTING FRONT SEA T-TO-FLOOR HEIGHT .... 25

PROCEDURE 7 - WHEELS ................................. 27

REMOVING/INSTALLING REAR WHEELS ........... 27

ADJUSTING QUICK-RELEASE AXLES ................27

INSTALLING QUAD-RELEASE AXLES................. 28

ADJUSTING QUAD-RELEASE HANDLES ............ 28

HANDRIM REPLACEMENT................................. 28

REPAIRING/REPLACING REAR WHEEL,

TIRE/TUBE..................................................... 29

OPENING/CLOSING CLAMPS ............................ 29

ADJUSTING REAR WHEEL CAMBER ................. 30

DETERMINING/ADJUSTING TOE IN/TOE OUT..... 31

ADJUSTING WHEELBASE LENGTH ...................32

ADJUSTING WHEELBASE WIDTH...................... 33

REPLACING AXLE TUBE ................................... 33

REPOSITIONING THE AXLE TUBE ..................... 34

REPOSITIONING/REPLACING

FRONT CASTERS .......................................... 36

ADJUSTING FRONT CASTER HEIGHT................ 36

WHEEL LOCK ADJUSTMENT/REPLACEMENT ... 37

PROCEDURE 8 - FOOTREST/ANTI-TIPPER ........ 38

ADJUSTING/REPLACING FLIP-UP

FOOTBOARD................................................. 38

ADJUSTING/REPLACING RIGID TUBULAR

FOOTREST.................................................... 39

ANTI-TIPPER REPLACEMENT/ADJUSTMENT ..... 39

PROCEDURE 9 - SUSPENSION .......................... 40

ELASTOMERS AND SUSPENSION..................... 40

REPLACING FRONT ELASTOMERS ................... 40

LIMITED WARRANTY ......................................... 43

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

3

SPECIFICATIONS

NOTE: All specifications are

S

approximate.

P

E

Frame:

C

I

F

Seat Width:

Seat Depth

I

C

A

Seat-to-Floor

T

I

O

N

S

Back Style:

Back Height:

Back Angle:

Rear-Front Caster Distance

(measured from outside of

back of frame to center of

front caster housing)

Footrest:

Side - Wheel Clearance:

Rear Axle:

Rear Wheel Camber:

Rear Wheel Sizes:

Available Tires

Handrims:

Wheel Locks:

Front Forks:

Caster Size:

Back Upholstery:

Weight:

Shipping Weight*:

Short Frame:

Long Frame:

Front:

Rear:

Short Frame:

Long Frame:

18-inch:

20-inch:

22-inch:

24-inch:

SPECIFICATIONS

TERMINA TOR JR.

Rigid

10-16-inch - Outside to Outside of SEA T FRAME in 1-inch increments.

8 to 14-inches

10 to 16-inches

13 to 20-inches

1 1 to 18-inches

Rigid (Standard), Fold Down

10 to 16-inches - Adjustable

86o, 90o, 94o, 98o, 102o or 106

20.5-inches

22.5-inches

Flip-up Footboard (standard), Tubular 4-inch Adjustable (optional)

Adjustable 1/2 to 1-1/2-inches

Adjustable Axle Position, Telescoping

0o, 3o, 6o, 9o or 12o (Adjustable Camber System)

18, 20, 22 or 24-inch

18 x 1-3/8

20 x 1-3/8

22 x 1-3/8

24 x 1-3/8

Aluminum (standard)

Plastic Coated (optional)

High Mount Push to Lock

Non-Shock Absorbing Fork (standard), Shock Absorbing (suspension) Fork (optional)

3, 4 or 5-inch Solid, 5-inch Semi-Pneumatic (standard), 6-inch Pneumatic (optional)

Non-adjustable (standard), U240 Black - Adjustable Tension

30 lbs.

35 lbs.

o

*NOTE: 14 x 14-inch Seat Frame with complete package (22-inch wheels, folding back, push handles, solid

seat pan, and anti-tippers).

4

GENERAL GUIDELINES

PROCEDURE 1

This Procedure includes the following:

Operating Information

Safety/Handling of Wheelchairs

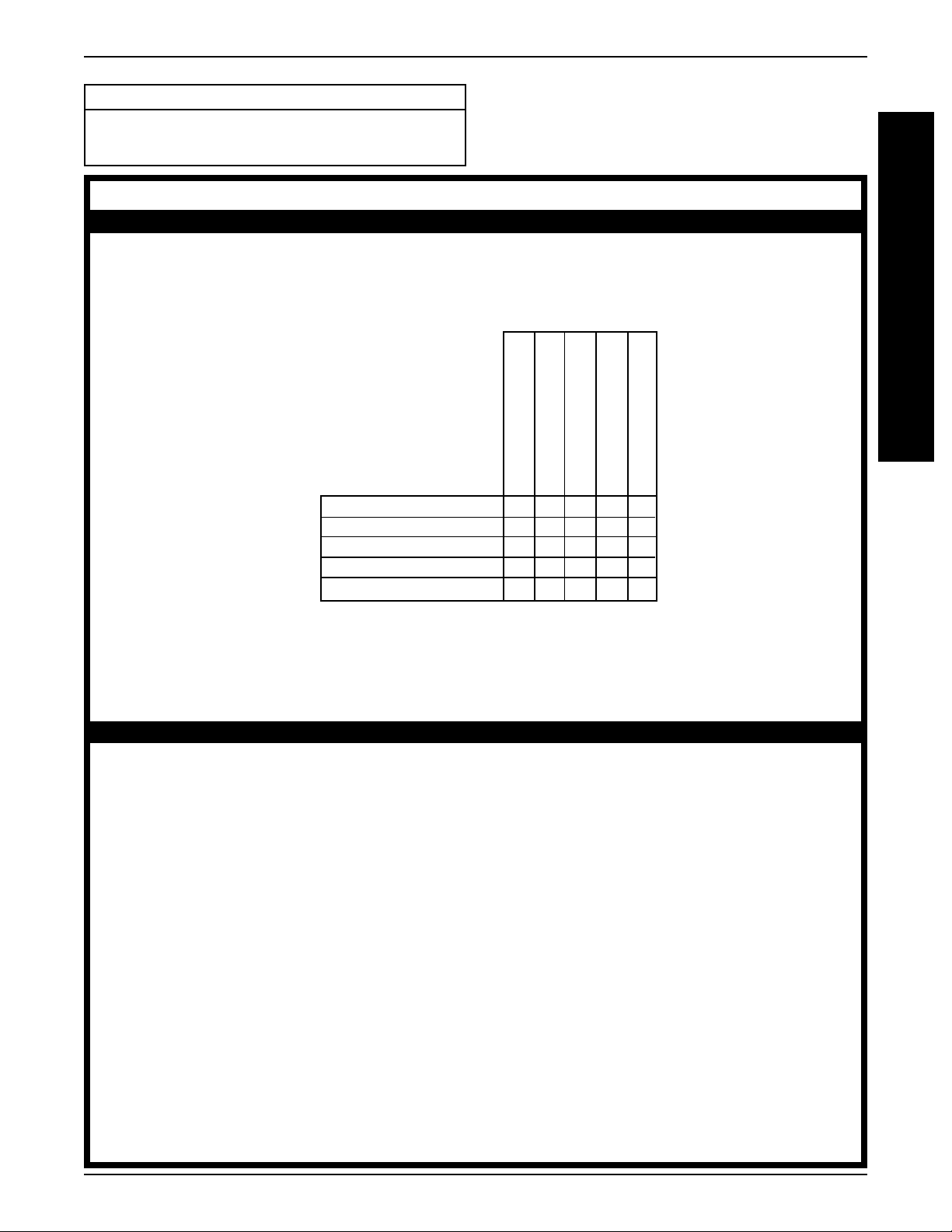

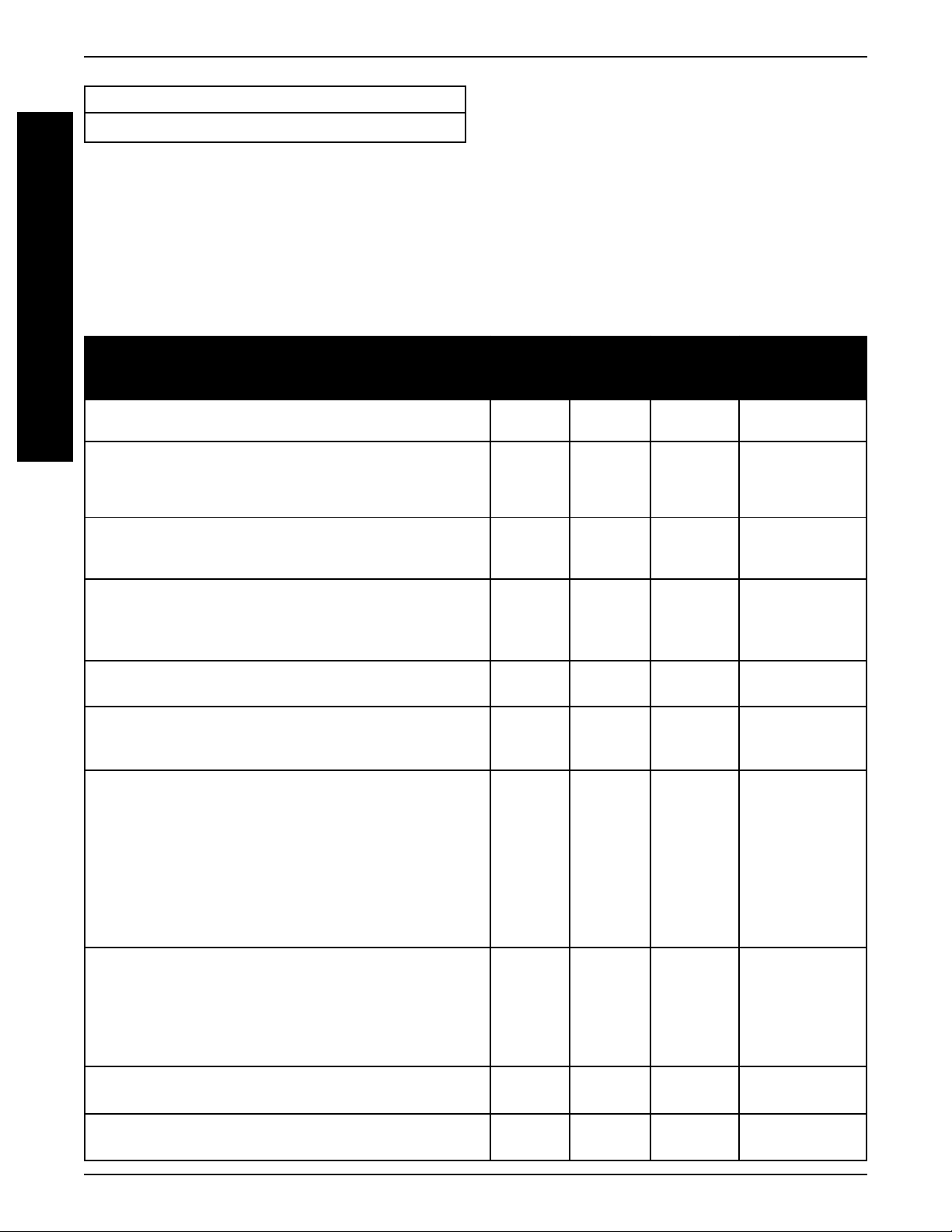

ST ABILITY

STABILITY WARNING

The position of the footrest, camber tube, back angle, the tautness of the back upholstery as well

as the user's condition are directly related to the wheelchairs stability. Any change to one (1) or

any combination of the five (5) may cause the wheelchair to decrease in stability. Use EXTREME

caution when using a new seating position.

Footrest Position

Camber Tube

Back Angle

Back Upholstery

User Condition

Footrest Position

Camber Tube

Back Angle

Back Upholstery

User Condition

●●

●

●●

✓✓

✓

✓✓

✓✓

✓

✓✓

✓✓

✓

✓✓

●●

✓✓

●

✓

●●

✓✓

●●

●

●●

✓✓

✓

✓✓

✓✓

✓✓

✓

✓

✓✓

✓✓

✓✓

✓

✓✓

✓✓

✓

✓✓

✓✓

✓✓

✓

✓

✓✓

✓✓

●●

✓✓

●

✓

●●

✓✓

✓✓

●●

✓

●

✓✓

●●

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

NOTE: When changes to the left hand column occur, follow across the chart and refer to the ✓ procedure to

maintain the proper stability, safety and handling of the racing chair.

OPERATING INFORMATION

WARNING

Unless otherwise noted, all service and adjustments should be performed while the wheelchair is

unoccupied.

T o determine and establish your particular safety limits, practice bending, reaching and transferring activities in several combinations in the presence of a qualified healthcare professional BEFORE attempting active use of the wheelchair.

DO NOT attempt to reach objects if you have to move forward in the seat.

DO NOT attempt to reach objects if you have to pick them up from the floor by reaching down

between your knees.

DO NOT lean over the top of the back upholstery to reach objects behind you as this may cause

the wheelchair to tip over.

DO NOT shift your weight or sitting position toward the direction you are reaching as the wheel-

chair may tip over.

DO NOT tilt the wheelchair without assistance.

DO NOT use an escalator to move a wheelchair between floors. Serious bodily injury may occur .

Before attempting to transfer in or out of the wheelchair, every precaution should be taken to

reduce the gap distance. Turn both casters parallel to the object you are transferring onto. Also

be certain the wheel locks are engaged to prevent the wheels from moving.

5

G

G

GENERAL GUIDELINESPROCEDURE 1

WARNING

DO NOT operate on roads, streets or highways.

o

E

N

E

R

A

L

U

I

D

E

L

I

N

E

S

DO NOT climb, go up or down ramps or traverse slopes greater than 9

DO NOT attempt to move up or down an incline with a water, ice or oil film.

DO NOT attempt to ride over curbs or obstacles. Doing so may cause your wheelchair to turn

over and cause bodily harm or damage to the wheelchair.

DO NOT use ANY parts, accessories, or adapters other than those authorized by Invacare.

DO NOT attempt to lift the wheelchair by any removable (detachable) parts. Lifting by means of

any removable (detachable) parts of a wheelchair may result in injury to the user or damage to

the wheelchair.

DO NOT stand on the frame of the wheelchair.

OPTIONAL TUBULAR FOOTREST ONLY - Check ALL Allen screws securing the tubular footrest to the

chair frame BEFORE using the wheelchair. ESPECIALLY if engaging in ANY rigorous activity.

Anti-tippers MUST BE attached at all times.

DO NOT use the footplate as a platform when getting in or out of the wheelchair.

ALW AYS wear your seat positioning strap. Inasmuch as the SEAT POSITIONING STRAP is an option on this

wheelchair (You may order with or without the seat positioning strap), Invacare strongly recommends

ordering the seat positioning strap as an additional safeguard for the wheelchair user.

.

S

A

F

E

T

Y

S

U

M

M

A

R

Y

TIRE PRESSURE

DO NOT use your wheelchair unless it has the proper tire pressure (p.s.i.). DO NOT overinflate the tires.

Failure to follow these suggestions may cause the tire to explode and cause bodily harm. The recommended tire pressure is on the sidewall of the tire.

Replacement of the tire or tube MUST be performed by a qualified technician.

WEIGHT TRAINING

Invacare DOES NOT recommend the use of its wheelchairs as a weight training apparatus. Invacare

wheelchairs have NOT been designed or tested as a seat for any kind of weight training. If occupant

uses said wheelchair as a weight training apparatus, Invacare shall NOT be liable for bodily injury and

the warranty is void.

WEIGHT LIMIT A TION

Invacare's Top End Terminator JR wheelchair has a weight limitation of 150 lbs.

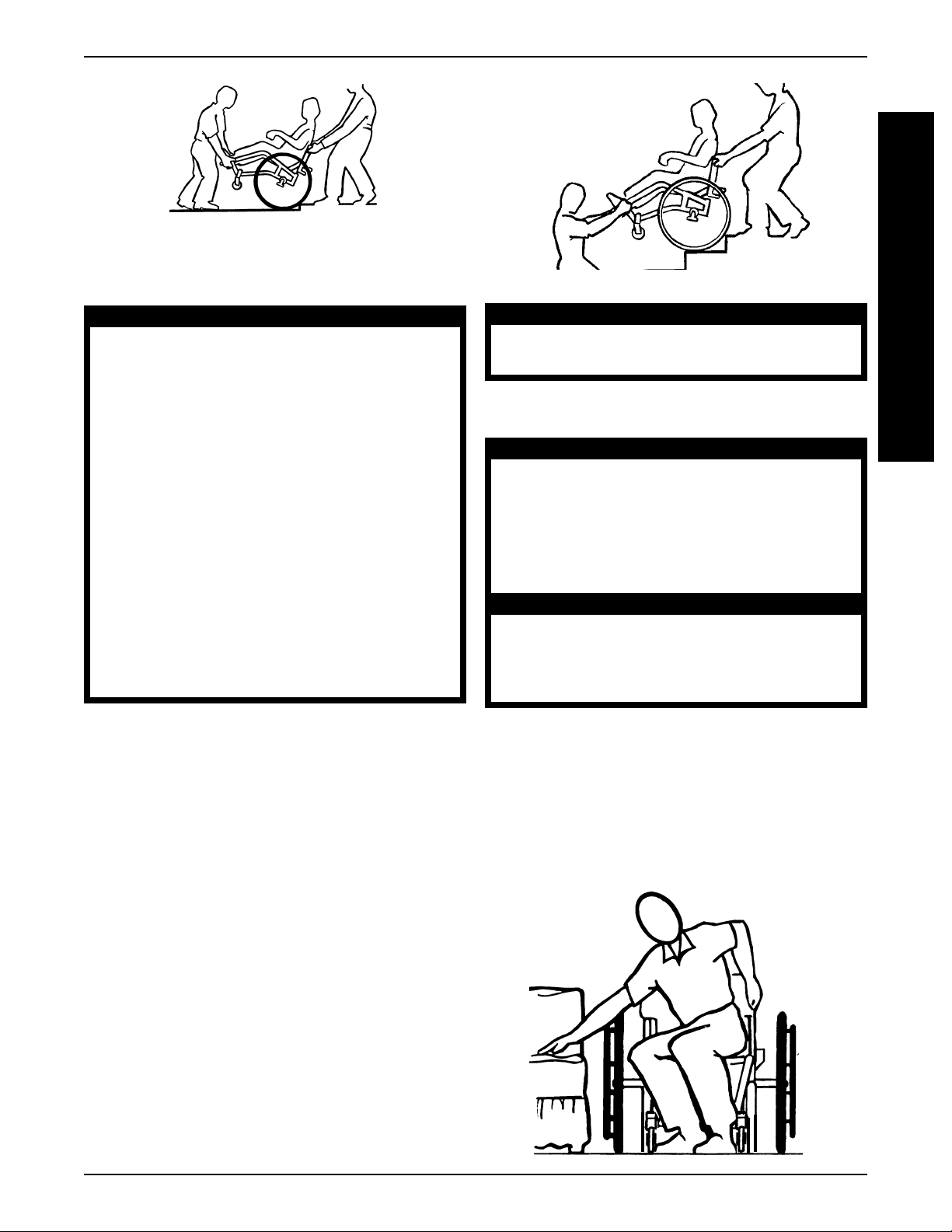

SAFETY/HANDLING OF

WHEELCHAIRS

“Safety and Handling” of the wheelchair requires the close

attention of the wheelchair user as well as the assistant.

This manual points out the most common procedures

and techniques involved in the safe operation and maintenance of the wheelchair. It is important to practice and

master these safe techniques until you are comfortable

in maneuvering around the frequently encountered architectural barriers.

Use this information only as a “basic” guide. The techniques that are discussed on the following pages have

been used successfully by many.

Individual wheelchair users often develop skills to deal with

daily living activities that may differ from those described in

this manual. Invacare recognizes and encourages each

individual to try what works best for him/her in overcoming

architectural obstacles that they may encounter, however,

ALL WARNINGS and CAUTIONS given in this manual

MUST be followed. Techniques in this manual are a starting point for the new wheelchair user and assistant with

“safety” as the most important consideration for all.

6

GENERAL GUIDELINES PROCEDURE 1

Stability and Balance

WARNING

ALWAYS wear your seat positioning strap. Inasmuch as the SEAT POSITIONING STRAP is an option on this wheelchair (You may order with or

without the seat positioning strap), Invacare

strongly recommends ordering the seat positioning strap as an additional safeguard for the

wheelchair user.

Anti-tippers MUST BE attached at all times.

To assure stability and proper operation of your wheelchair, you must at all times maintain proper balance. Y our

wheelchair has been designed to remain upright and

stable during normal daily activities as long as you do

not move beyond the center of gravity.

Virtually all activities which involve movement in the wheelchair have an effect on the center of gravity. Invacare

recommends using seat positioning straps for additional

safety while involved in activities that shift your weight.

DO NOT lean forward out of the wheelchair any further

than stability will allow. Make sure casters are pointing in

the forward position whenever you lean forward. This

can be achieved by advancing the wheelchair and then

reversing it in a straight line.

Percentage of Weight Distribution

WARNING

DO NOT attempt to reach objects if you have to

move forward in the seat or pick them up from

the floor by reaching down between your knees.

The position of the footrest, camber tube, back

angle, the tautness of the back upholstery as well

as the user's condition are directly related to the

wheelchairs stability. Any change to one (1) or

any combination of the five (5) may cause the

wheelchair to decrease in stability. Use EXTREME

caution when using a new seating position.

Many activities require the wheelchair owner to reach, bend

and transfer in and out of the wheelchair. These movements will cause a change to the normal balance, the

center of gravity , and the weight distribution of the wheelchair. To determine and establish your particular safety

limits, practice bending, reaching and transferring activities in several combinations in the presence of a qualified

health-care professional BEFORE attempting active use

of wheelchair.

Center of Gravity

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

Coping with Everyday Obstacles

Coping with the irritation of everyday obstacles can be

alleviated somewhat by learning how to manage your

wheelchair. Keep in mind your center of gravity to maintain stability and balance.

A Note to Wheelchair Assistants

When assistance to the wheelchair user is required, remember to use good body mechanics. Keep your back

straight and bend your knees whenever tilting the wheelchair or traversing curbs, or other impediments.

WARNING

Do not attempt to lift a wheelchair by lifting on

any removable (detachable) parts. Lifting by

means of any removable (detachable) parts of

a wheelchair may result in injury to the user or

damage to the wheelchair.

Also, be aware of any removable (detachable) parts.

These must NEVER be used for hand-hold or lifting supports, as they may be inadvertently released, resulting in

possible injury to the user and/or assistant(s).

When learning a new assistance technique, have an

experienced assistant help you before attempting it alone.

Example: 46% 54% 103 lbs. 130 lbs.

UNOCCUPIED OCCUPIED

Proper positioning is essential for your safety . When reaching, leaning, bending forward, it is important to use the

front casters as a tool to maintain stability and balance.

LENGTHENING THE WHEELBASE will increase the stability and maintain standard maneuverability of wheelchair.

SHORTENING THE WHEELBASE will increase the

maneuverability, distribute additional weight onto the rear

wheels, and decrease the stability of the wheelchair.

LENGTHENING

SHORTENING

Telescoping

Tube

7

GENERAL GUIDELINESPROCEDURE 1

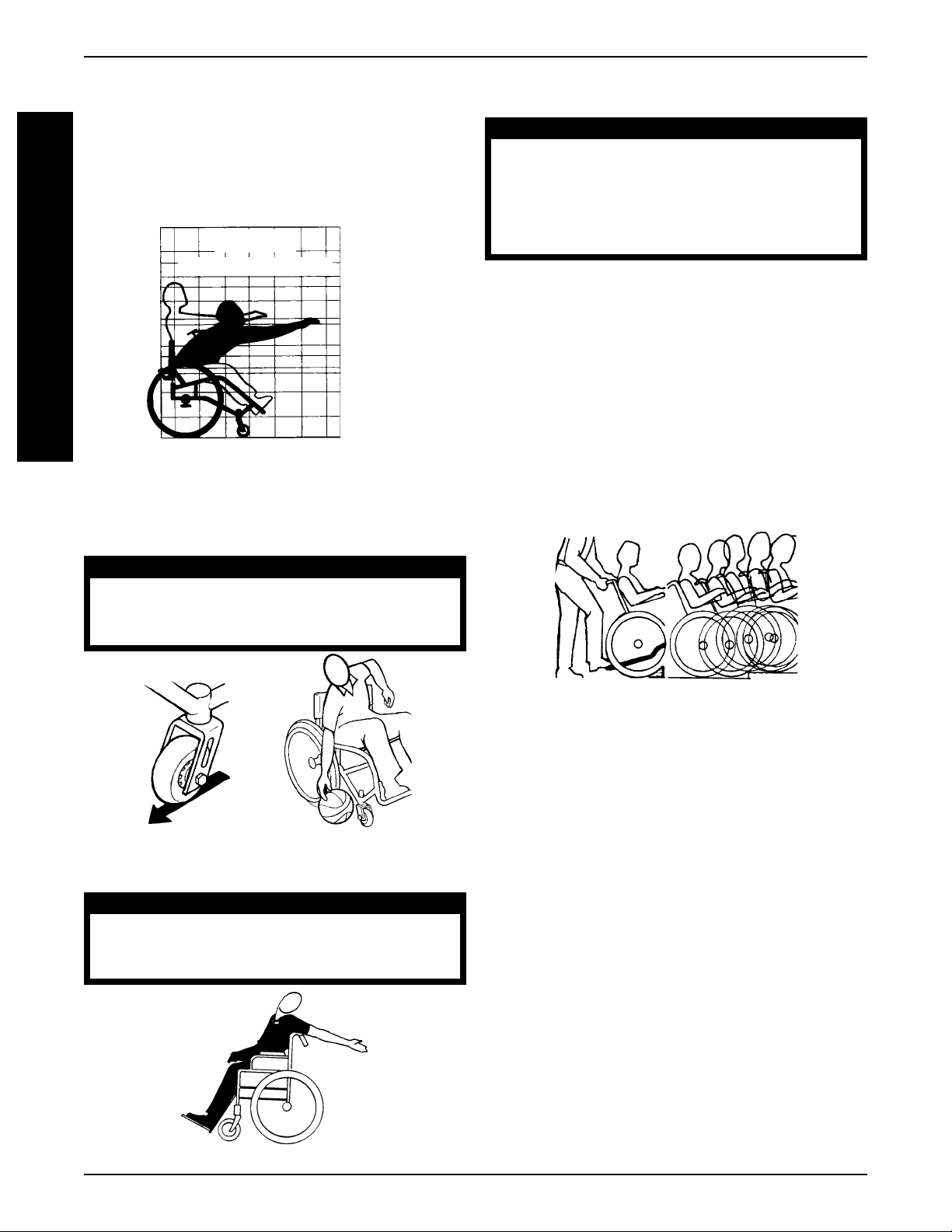

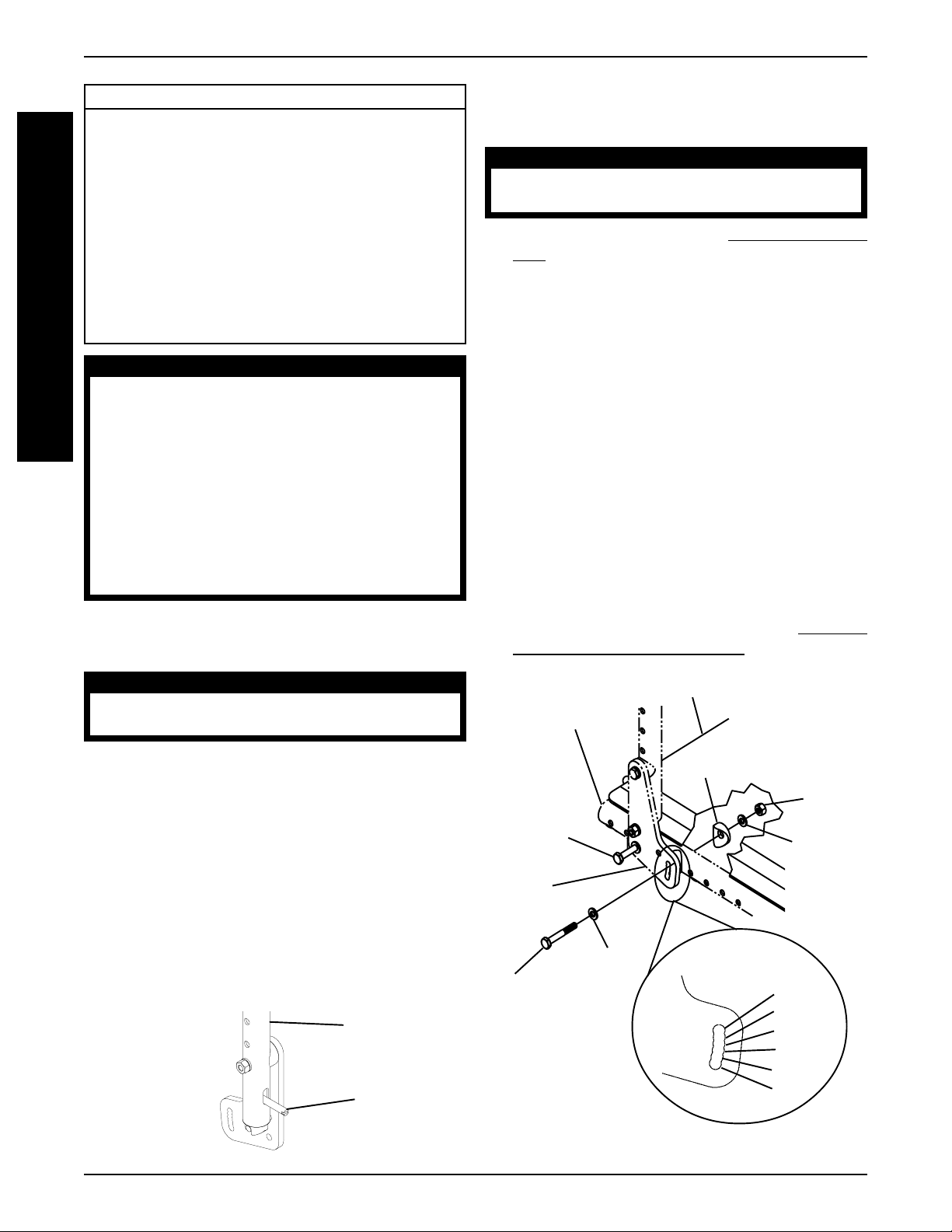

Functional Reach From a Wheelchair

The approximate reach-limit values shown in the accom-

G

panying graphs were derived on the basis of a sample of

E

91 male and 36 female wheelchair users. Note the differ-

N

ence between the maximum and the comfortable reach

E

limits, a subjective but important consideration in design.

R

G

D

A

L

FORWARD REACH

COMFORT MAXIMUM

U

I

E

L

I

N

E

S

0 8 16 24 37

INCHES

72

64

61

56

53

48

42

40

32

29

Reaching, Leaning and Bending Forward

Position the front casters so that they are extended as

far forward as possible and engage wheel locks.

INCHES

Tilting

WARNING

DO NOT tilt the wheelchair without assistance.

When lowering the front casters of the wheelchair ,

DO NOT let the wheelchair drop the last few inches

to the ground. This could result in injury to the occupant and/or damage to the wheelchair.

When tilting the wheelchair, an assistant should grasp the

back of the wheelchair on a non-removable (non-detachable) part. Inform the wheelchair occupant before tilting the

wheelchair and remind him/her to lean back. Be sure the

occupant’s feet and hands are clear of all wheels.

TILTING - CURBS:

After mastering the techniques of tilting the wheelchair,

use this procedure to tackle curbs, short stairs, etc.

METHOD 1 - Apply a continuous downward motion until

the balance point is achieved and the front casters clear

the curb. At this point, the assistant will feel a difference

in the weight distribution.

WARNING

DO NOT attempt to reach objects if you have to

move forward in the seat or pick them up from

the floor by reaching down between your knees.

REACHING, LEANING AND BENDING - FORWARD

Reaching, Leaning - Backwards

WARNING

DO NOT lean over the top of the back upholstery. This will change your center of gravity

and may cause you to tip over.

METHOD 1

Roll the wheelchair forward and slowly lower the front

casters onto the sidewalk. Do not let the wheelchair drop

the last few inches to the ground. This could result in

injury to the occupant. Push the wheelchair forward until

the rear wheels roll up and over the curb.

METHOD 2 - This method requires two (2) assistants.

The second assistant should be positioned at the front

of the wheelchair lifting upward on a non-removable (nondetachable) part of the wheelchair frame when lifting the

wheelchair and stabilizing the wheelchair when the wheelchair is being lowered to the ground.

The first assistant should stand on the sidewalk and turn

the wheelchair so that the rear wheels are against the

curb. The wheelchair should be tilted back to the balance point and, in one continuous upward movement,

the rear wheels should be pulled up and over the curb.

DO NOT return the front casters to the ground until the

wheelchair has been pulled backward far enough for

the front casters to clear the edge of the curb.

REACHING, LEANING - BACKW ARDS

8

GENERAL GUIDELINES

METHOD 2

PROCEDURE 1

G

E

N

E

R

A

L

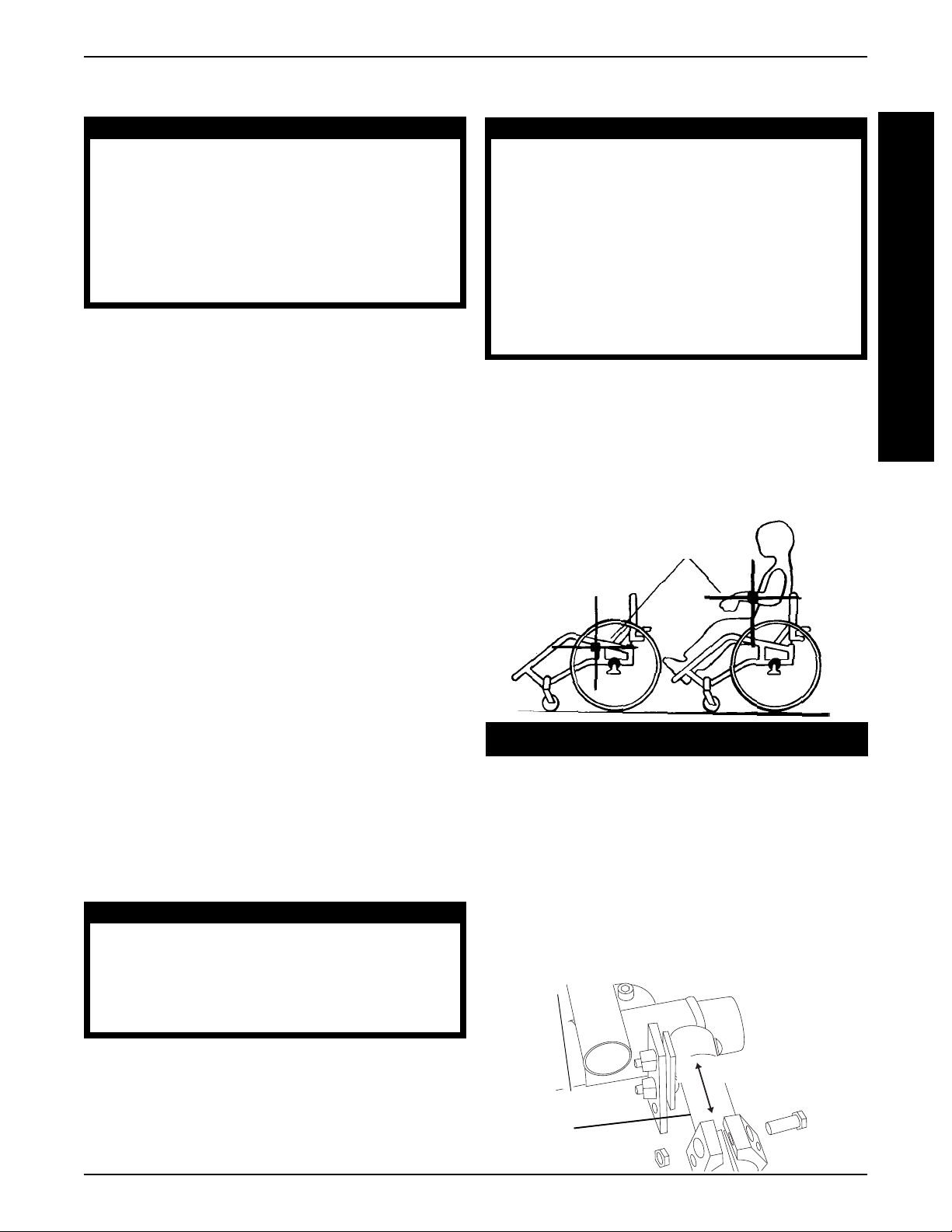

Stairways

WARNING

ALWAYS wear your seat positioning strap. Inasmuch as the SEAT POSITIONING STRAP is an option on this wheelchair (You may order with or

without the seat positioning strap), Invacare

strongly recommends ordering the seat positioning strap as an additional safeguard for the

wheelchair user.

DO NOT attempt to lift the wheelchair by any

removable (detachable) parts. Lifting by means

of any removable (detachable) parts of a wheelchair may result in injury to the user or damage

to the wheelchair.

Extreme caution is advised when it is necessary

to move an occupied wheelchair up or down a

stairway. Invacare recommends using two (2) assistants and making thorough preparations. Make

sure to use ONLY secure, non-detachable parts

for hand-hold supports.

Follow this procedure for moving the wheelchair between

floors when an elevator is NOT available:

1. Turn the anti-tippers so they are facing UP.

2. After the wheelchair has been tilted back to the balance point, one assistant (in the rear) backs the

wheelchair up against the first step, while securely

grasping a non-removable (non-detachable) part of

the wheelchair for leverage.

3. The second assistant, with a firm hold on a nondetachable part of the framework, lifts the wheelchair up and over the stair and steadies it as the first

assistant places one foot on the next stair and repeats procedure.

ESCALA TORS? SORR Y!

DO NOT use an escalator to move a wheelchair

between floors. Serious bodily injury may occur .

Transferring to and From Other Seats

WARNING

BEFORE attempting to transfer in or out of the

wheelchair , every precaution should be taken

to reduce the gap distance. Tu rn both casters

parallel to the object you are transferring onto.

Also be certain the wheel locks are engaged

to help prevent the wheels from moving.

CAUTION

When transferring, position yourself as far back as

possible in the seat. This will prevent damaged upholstery and the possibility of the wheelchair tipping forward.

NOTE: This activity may be performed independently provided you have adequate mobility and upper body strength.

Position the wheelchair as close as possible along side

the seat to which you are transferring, with the front casters pointing parallel to it. Engage wheel locks. Shift body

weight into seat with transfer.

During independent transfer, little or no seat platform will

be beneath you. Use a transfer board if at all possible.

G

U

I

D

E

L

I

N

E

S

4. The wheelchair should not be lowered until the last

stair has been negotiated and it has been rolled away

from the stairway.

5. Turn the anti-tippers so they are facing DOWN.

9

PROCEDURE 2

This Procedure includes the following:

SAFETY INSPECTION

S

Safety Inspection Checklist

A

F

SAFETY INSPECTION CHECKLIST

E

NOTE: Every six (6) months, take your wheelchair to a qualified technician for a thorough inspection and servicing.

T

Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To operate

Y

properly and safely , your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend

I

the life and efficiency of your wheelchair. Clean upholstery with mild soap and water or spray disinfectant using a

sponge. DO NOT use bleach or wash in a washing machine.

N

S

Initial adjustments should be made to suit your personal body structure, preference and abilities. Thereafter follow

P

these maintenance procedures:

E

C

T

I

O

N

ITEM INITIALLY INSPECT/ INSPECT/ INSPECT/

ADJUST ADJUST ADJUST

WEEKLY MONTHLY PERIODICALLY

GENERAL

Wheelchair rolls straight (no excessive drag or pull to one side). X X

WHEEL LOCKS

Do not interfere with tires when rolling. X X

Pivot points free of wear and looseness. X X

Wheel locks easy to engage. X X

SEAT AND BACK UPHOLSTERY

Inspect for rips or sagging. X X

Inspect fastening flaps to ensure they securely latch. X X

REAR WHEELS

Adjustable Axle Position Camber Bar is securely tightened. X X X

Quick/Quad release axles lock properly. X X

No excessive side movement or binding when lifted and spun. X X

HANDRIMS

Inspect for signs of rough edges or peeling. X X

SPOKES

Inspect for bent or broken spokes. X X

All spokes uniformly tight. X X

FRONT CASTER

Inspect wheel/fork assembly for proper tension by spinning

caster; caster should come to a gradual stop. X X

Loosen/tighten locknut if wheel wobbles noticeably or

binds to a stop. X X

Wheel bearings are clean and free of moisture. X X X

CAUTION: As with any vehicle, the wheels and

tires should be checked periodically for cracks and

wear, and should be replaced.

TIRES

Inspect for flat spots and wear. X X

If pneumatic tires check for proper inflation. X X

CAUTION: As with any vehicle, the wheels and

tires should be checked periodically for cracks and

wear, and should be replaced.

FRONT SUSPENSION FORKS (If Equipped)

Inspect elastomers for proper lubrication. X

CLEANING

Clean upholstery and armrests. X X

10

TROUBLESHOOTING/MAINTENANCE

This Procedure includes the following:

PROCEDURE 3

Troubleshooting

Maintenance

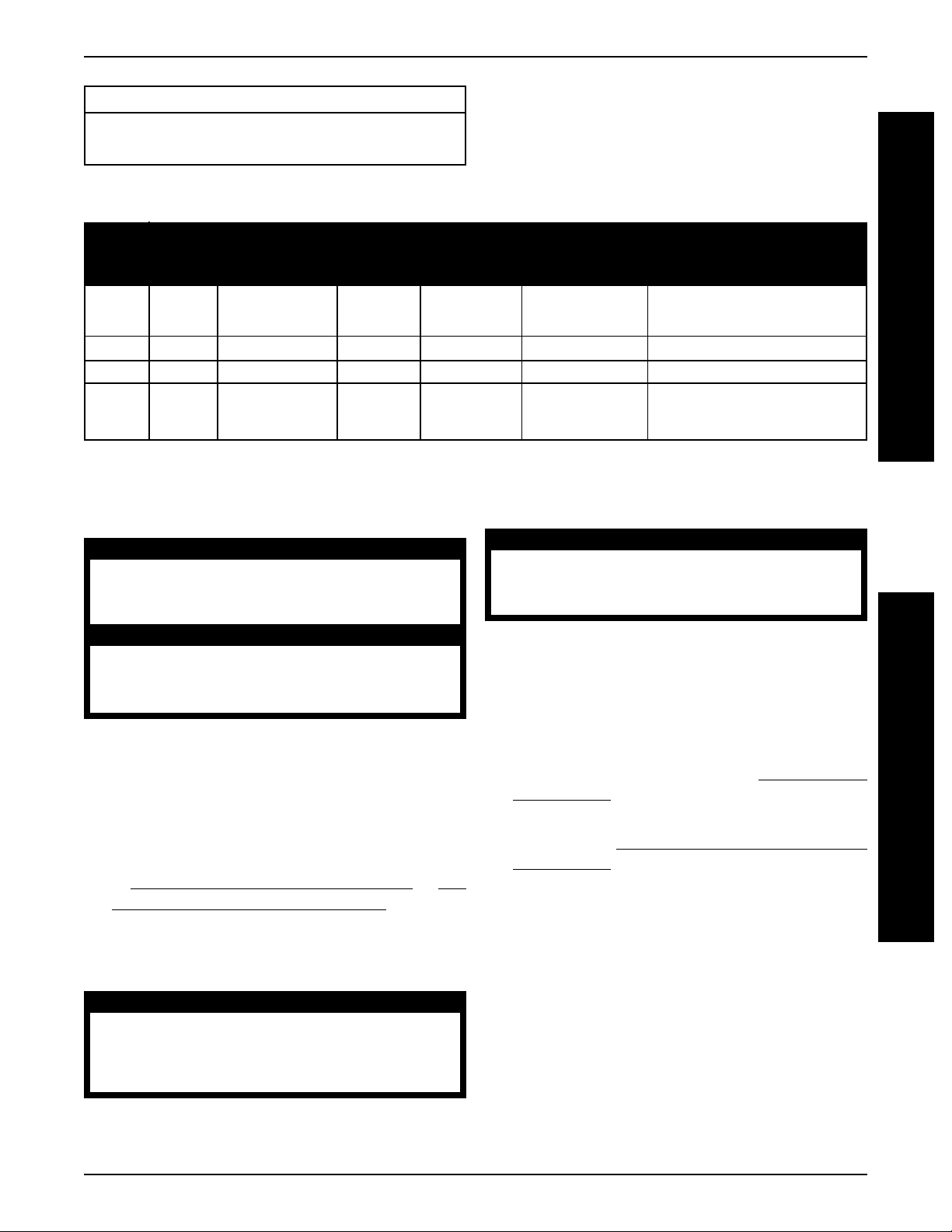

TROUBLESHOOTING

CHAIR CHAIR SLUGGISH CASTER SQUEAKS LOOSENESS SOLUTIONS

VEERS VEERS TURN OR FLUTTERS AND IN CHAIR

RIGHT LEFT PERFORMANCE RATTLES

XXXX Check tires for correct

and equal pressure.

XXX XCheck for loose stem nuts.

XXCheck spokes and nipples.

XX X Check that both casters

contact the ground at the

same time.

MAINTENANCE

Maintenance Safety Precautions

WARNING

After ANY adjustments, repair or service and BEFORE

use, make sure all attaching hardware is tightened

securely - otherwise injury or damage may result.

CAUTION

DO NOT overtighten hardware attaching to the

frame. This could cause damage to the frame

tubing.

Suggested Maintenance Procedures

1. Before using your wheelchair, make sure all nuts and

bolts are tight. Check all parts for damage or wear

and replace. Check all parts for proper adjustment.

2. Keep quick/quad-release axles free of dirt and lint to

ensure positive locking and proper operation. Refer

ADJUSTING QUICK-RELEASE AXLES or AD-

to

JUSTING QUAD-RELEASE HANDLES in PROCEDURE 7 of this manual.

3. Oil quick-release axles at least once (1) a month (3-

DO NOT use your wheelchair unless it has the

proper tire pressure (p.s.i.). DO NOT overinflate the

tires. Failure to follow these suggestions may

cause the tire to explode and cause bodily harm.

in-1 oil

®

or equivalent).

WARNING

4. Recommended tire pressure is listed on the sidewall

of the tire.

CAUTION

As with any vehicle, the wheel s and tires should

be checked periodically for cracks and wear ,

and should be replaced.

5. Check the wheels and tires periodically for cracks

and wear. If damaged, have them replaced by a qualified technician.

6. Regularly check for loose spokes in the rear wheels. If

loose, have them adjusted by a qualified technician.

7. Periodically check handrims to ensure they are secured to the rear wheels. Refer to

PLACEMENT in PROCEDURE 7 of this manual.

8. Periodically adjust wheel locks in correlation to tire

wear. Refer to

PLACEMENT in PROCEDURE 7 of this manual.

9. Periodically check caster wheel bearings to make

sure they are clean and free from moisture. Use a

®

Teflon

10. FRONT SUSPENSION FORKS (if equipped) - Peri-

odically lubricate the the inside of the elastomers and

the shaft of the hex bolt that secures the elastomers to

the suspension tube with a silicone based lubricant.

11. Check upholstery for sagging, rips or tears.

lubricant if necessary.

WHEEL LOCK ADJUSTMENT/RE-

HANDRIM RE-

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

M

A

I

N

T

E

N

A

N

C

E

11

PROCEDURE 4 BACK

B

A

C

K

This Procedure includes the following:

Folding/Unfolding the Back

Changing the Back Angle

Adjusting the Back Height

Replacing Standard Back Upholstery

Replacing Custom Manual Adjustable Tension

Back Upholstery

Replacing the Spreader Bar

Replacing the Locking Mechanism in the Back Cane

Installing the Stroller Handles

WARNING

ALWAYS perform this procedure in the presence of

an assistant. The position of the footrest, camber

tube, back angle, the tautness of the back upholstery as well as the user's condition are directly re lated to the wheelchairs stability. Any change to

one (1) or any combination of the five (5) may cause

the wheelchair to decrease in stability. Use EXTREME

caution when using a new seating position.

After ANY adjustments, repair or service and BEFORE

use, make sure all attaching hardware is tightened

securely - otherwise injury or damage may result.

FOLDING/UNFOLDING THE BACK

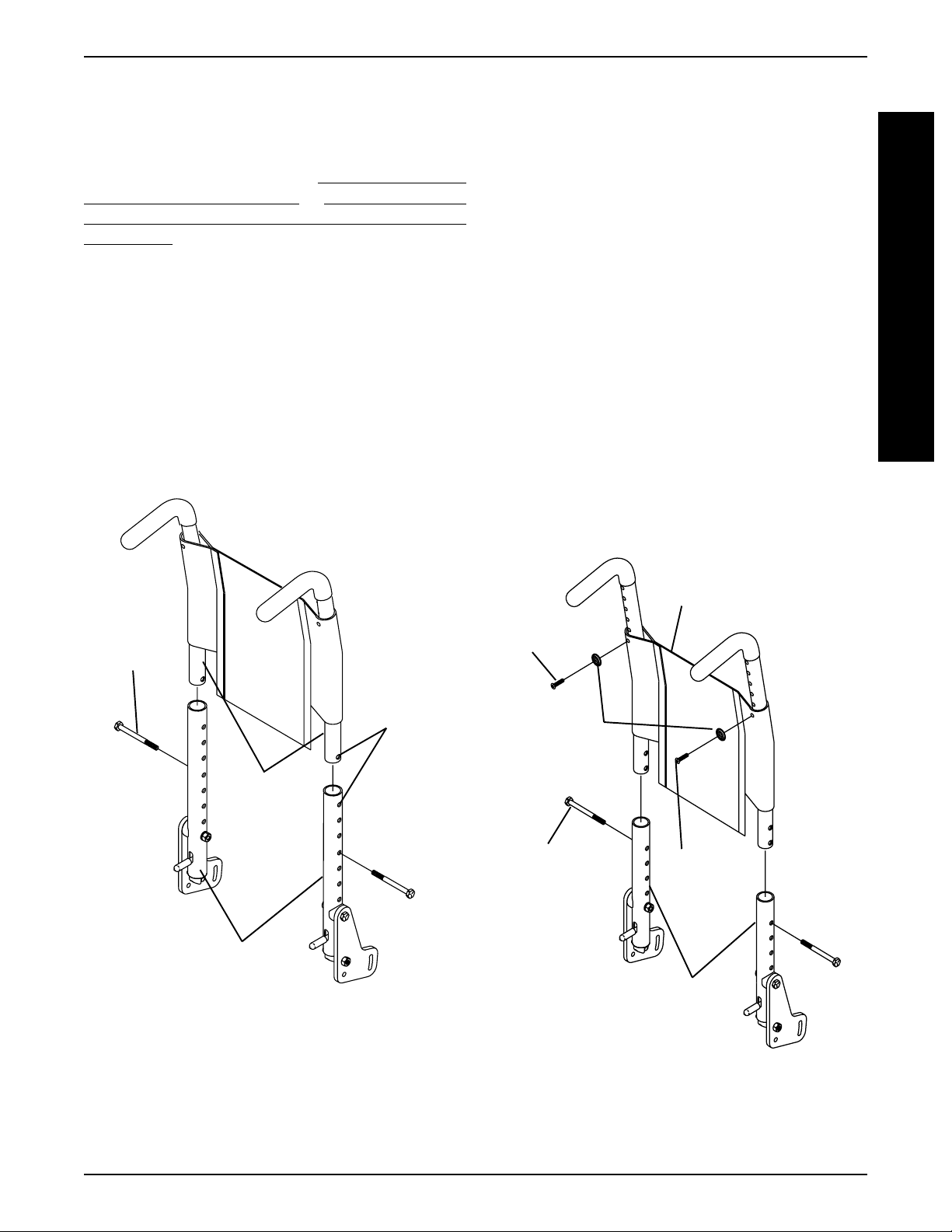

(FIGURE 1)

WARNING

Back MUST be locked securely in place and all attaching hardware tight BEFORE using the wheelchair.

CHANGING THE BACK ANGLE

(FIGURE 2)

WARNING

The following procedure MUST be perform ed

by a qualified technician.

1. Remove the seat pan. Refer to

PAN in PROCEDURE 6 of this manual.

2. Loosen, but do not remove the rear hex screw

that secures the back angle plate to the wheelchair frame.

3. Remove the front hex screw, washers, coved

washer and locknut that secure the back angle

plate to the wheelchair frame.

4. Position the back angle plate to one (1) of six (6)

back angles shown in FIGURE 2.

5. Reinstall the front hex screw, washers and coved

washer and securely tighten with locknut. Refer to

FIGURE 2 for correct hardware orientation.

6. Securely tighten the rear hex screw that secures

the back adjustment plate to the wheelchair frame.

7. If wheelchair is equipped with cantilever arms,

adjust the angle of the cantilever arm so they remain parallel to the ground/floor. Refer to

ING CANTILEVER ARM ANGLE in PROCEDURE

5 of this manual.

Wheelchair

Frame

Seat Pan

REPLACING SEA T

ADJUST-

Folding the Back

1. Pull BOTH back release levers UP.

2. While holding BOTH back release levers, push the

back canes DOWN.

Unfolding the Back

1. Pull the back canes UP towards the rear of the

wheelchair there is an audible "click".

2. Push the back canes FORWARD to ensure they

are locked in place.

3. If the back canes are not locked in place, repeat

STEPS 1-2 until the back canes lock.

Back Cane

Back

Release

Lever

FIGURE 1 - FOLDING/UNFOLDING THE BACK

Rear Hex

Screw

(Loosen,

but do not

Remove)

Back

Angle

Plate

Front

Hex

Screw

12

Coved Washer

Locknut

Washer

Washer

FIGURE 2 - CHANGING THE BACK ANGLE

BACK

ANGLES

86°

90°

94°

98°

102°

106°

PROCEDURE 4BACK

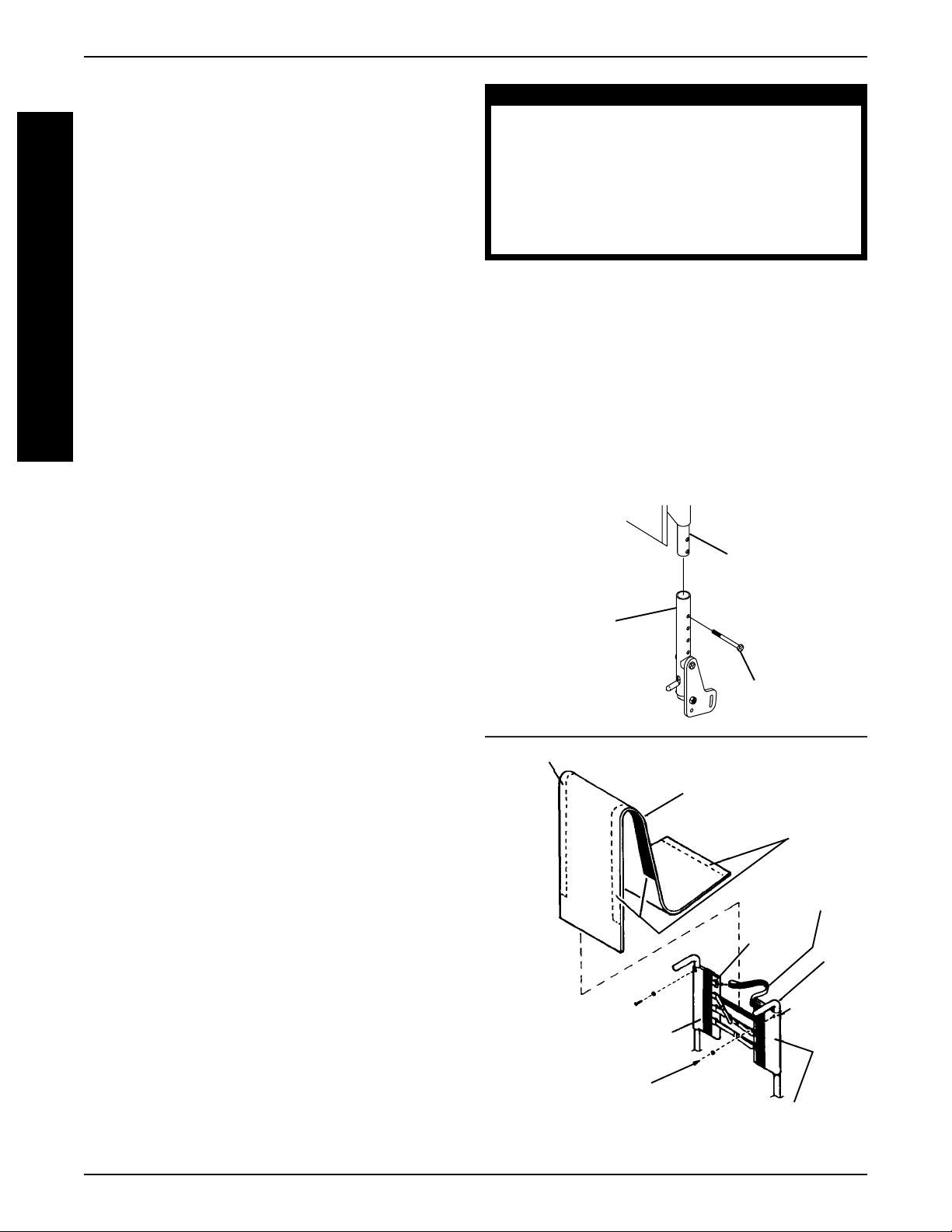

ADJUSTING THE BACK HEIGHT

(FIGURE 3)

NOTE: If necessary, remove the back upholstery to

access mounting holes. Refer to REPLACING ST ANDARD BACK UPHOLSTERY or REPLACING CUSTOM MANUAL ADJUSTABLE TENSION BACK UPHOLSTERY in this procedure of the manual.

1. Remove the back height adjustment screws that

secure the back cane to the back upright.

2. Raise/lower the back canes to the desired height.

3. Align the mounting hole in each back cane with

the desired mounting hole in each back upright.

NOTE: Both back canes should be adjusted to the

same height.

4. Install the two (2) back height adjustment screws

through the back upright mounting holes determined

in STEP 3 and the back cane mounting holes.

REPLACING STANDARD BACK

UPHOLSTERY (FIGURE 4)

1. Remove the back height adjustment screws that

secure the back cane to the back upright.

2. Slide the back assembly out of the back uprights.

3. Remove the two (2) screws and washers that secure the EXISTING back upholstery to the back

cane.

4. Slide the EXISTING back upholstery down and

off the back canes.

5. Slide the NEW back upholstery up and onto the

back canes.

6. Align the mounting hole in each back cane with

the desired mounting hole in each back upright.

NOTE: Both back canes should be adjusted to the

same height.

7. Install the two (2) back height adjustment screws

through the back upright mounting holes determined

in STEP 6 and the back cane mounting holes.

B

A

C

K

Back

Height

Adjustment

Screw

Mounting

Holes

Back

Canes

Back

Uprights

NOTE: Standard back upholstery shown for clarity.

FIGURE 3 - ADJUSTING THE BACK HEIGHT

Mounting

Screw

Washers

Back

Height

Adjustment

Screw

Back Upholstery

Mounting

Screw

Back

Uprights

13

FIGURE 4 - REPLACING ST ANDARD BACK

UPHOLSTERY

BACKPROCEDURE 4

B

A

C

K

REPLACING CUSTOM MANUAL

ADJUSTABLE TENSION BACK

UPHOLSTERY (FIGURE 5)

The Adjustable Tension Straps

The straps can be adjusted at various levels of tension to

accommodate individual end-users. The bottom two (2)

straps can be adjusted tightly to support and/or assist the

extensor muscles.

The Back Upholstery Cover

The back upholstery cover is designed for three (3)

reasons:

1. The first is as a modesty cover.

2. The second is to keep the cushion from sliding out of

the back of the wheelchair.

3. The third is a sacral support depending upon how far

or tight the flap is pulled under the seat cushion.

Replacing Adjustable Tension Back

Upholstery

1. Remove the back height adjustment screws that secure the back canes to the back uprights.

WARNING

After the adjustable tension back upholstery has

been positioned to the end-users individual

needs, the fastening straps MUST be securely

fastened BEFORE applying the back upholstery

cover . The adjustable back should be checked

whenever entering the wheelchair to ensure

that the fastening straps are securely fastened.

9. Secure the back upholstery cover (fastening strap)

to the back of the adjustable back upholstery (fastening strap).

10. Flip the back upholstery cover over the adjustable

back upholstery and secure the fastening straps

to the front of the adjustable back upholstery.

1 1. Lay the front portion of the back upholstery cover

on the seat pan.

12. Adjust the slack in the back upholstery cover and

then secure to the seat pan fastening straps.

Back Cane

2. Slide the back canes out of the back uprights.

3. Remove the two (2) screws and washers that secure

the EXISTING back upholstery to the back canes.

4. Slide the EXISTING back upholstery down and off

the back canes.

5. Stand behind the wheelchair and perform the following:

A. Slide anchor loop section of adjustable tension back

upholstery up onto the LEFT back cane with the upper grommet hole facing the rear of the wheelchair.

B. Slide adjuster strap section of adjustable tension back

upholstery up onto the RIGHT back cane with the

upper grommet hole facing the rear of the wheelchair.

6. Align the mounting hole in each back cane with the

desired mounting hole in each back upright.

NOTE: Both back canes should be adjusted to the same

height.

7. Install the two (2) back height adjustment screws

through the back upright mounting holes determined

in STEP 6 and the back cane mounting holes.

8. Slip adjuster straps through corresponding anchor

loops and adjust the back upholstery. Secure with

the fastening straps.

Back

Upright

Fastening Strap

Back Upholstery

Anchor Loop Section

Mounting Screw

Back Upholstery Adjuster Strap Section

Back Height

Adjustment

Screw

Back Upholstery Cover

Fastening Straps

Adjuster Strap

Anchor

Loop

Back

Cane

Upper

Grommet

Hole

14

FIGURE 5 - REPLACING CUSTOM MANUAL

ADJUST ABLE TENSION BACK UPHOLSTER Y

PROCEDURE 4BACK

REPLACING THE SPREADER BAR

(FIGURE 6)

NOTE: Make sure the spreader bar is ALWAYS attached to the wheelchair.

1. Remove the back height adjustment screws that

secure the back canes to the back uprights.

2. Remove the cantilever arms, if necessary. Refer

INSTALLING/REMOVING CANTILEVER

to

ARMS in PROCEDURE 5 of this manual.

3. Loosen, but do not remove the two (2) set screws

that secure the EXISTING spreader bar to the back

canes.

4. Slide the EXISTING spreader bar off of the two

(2) back canes.

5. Slide the NEW spreader bar onto the back canes.

6. Securely tighten the two (2) set screws that secure the NEW spreader bar to the back canes.

7. Reinstall the cantilever arms, if necessary. Refer

INSTALLING/REMOVING CANTILEVER

to

ARMS in PROCEDURE 5 of this manual.

8. Align the mounting hole in each back cane with

the desired mounting hole in each back upright.

9. Install the two (2) back height adjustment screws

through the back upright mounting holes determined in STEP 8 and the back cane mounting

holes.

Mounting

Set

Screw

Hole

Back Cane

REPLACING THE LOCKING

MECHANISM IN THE BACK CANE

(FIGURE 7)

WARNING

The locking mechanism is spring loaded. Place

your free hand over the end of the back cane

to prevent the locking mechansim from springing out of the back cane.

1. Fold the back down. Refer to

ING BACK in this procedure of the manual.

2. Unscrew the actuator from the locking mechanism.

3. Remove the locking mechanism and spring from

the back cane.

NOTE: Inspect the spring and replace if necessary.

4. Slide the NEW spring and locking mechanism into

the back cane.

5. Make sure the angled end of the locking mechanism is at the bottom of the back cane.

NOTE: The long side of the locking mechanism should

be toward the actuator opening.

6. Push and hold the locking mechanism into the back

cane.

7. Screw the actuator through the actuator opening

and into the locking mechanism mounting hole.

8. Unfold the back. Refer to

BACK in this procedure of the manual.

FOLDING/UNFOLD-

FOLDING/UNFOLDING

B

A

C

K

Back

Height

Adjustment

Screw

Back

Uprights

FIGURE 6 - REPLACING THE SPREADER BAR

Spreader

Bar

Back Cane

Actuator Opening

Actuator

Spring

Locking

Mechanism

Angled End of the Locking Mechanism

FIGURE 7 - REPLACING THE LOCKING MECHANISM

IN THE BACK CANE

15

Mounting

Hole

Long Side of

Locking Mechanism

INSTALLING THE STROLLER

HANDLES (FIGURE 8)

BACKPROCEDURE 4

B

A

C

K

NOTE: If necessary , remove the foam grip on the push

handle BEFORE performing this procedure.

1. Slide the stroller handle onto the push handle.

2. Make sure to line up the mounting holes of the

stroller handle and the push handle.

3. Press and hold the button on the quick-release

pin.

4. While holding the button, insert the quick-release

pin through the stroller handle and push handle.

5. Pull on the stroller handle to make sure it is locked

securely in place.

6. Repeat STEPS 1-5 for the opposite stroller handle.

Stroller

Handle

Button

Quick-Release Pin

Push

Handle

FIGURE 8 - INST ALLING THE STROLLER HANDLES

16

PROCEDURE 5ARMS

This Procedure includes the following:

Using Cantilever Arms

Installing/Removing Cantilever Arms

Adjusting Cantilever Arm Height

Adjusting Cantilever Arm Angle

Replacing/Repositioning the Cantilever Arm

Locking Mechanism

Arm Pad Adjustment/Replacement

Installing T-Arm Sockets

Installing/Removing T-Arms

Adjusting the T-Arms

Replacing the T-Arm Locking Lever

WARNING

Never try to lift or tip the wheelchair by the

cantilever arms or T-arms, serious injury can

occur.

After ANY adjustments, repair or service and

BEFORE use, make sure all attachment hardware is tightened securely - otherwise, injury

or damage may occur.

USING CANTILEVER ARMS

(FIGURE 1)

1. Pull the locking mechanism actuator towards the

front of the wheelchair.

2. While holding the actuator, pull UP on the cantilever arm.

NOTE: If cantilever arms rub against rear wheels when

UP, increase the wheelbase width. Refer to ADJUSTING WHEELBASE WIDTH in PROCEDURE 7 of this

manual.

NOTE: If necessary , the locking mechanism in the cantilever arm can be repositioned so the cantilever arm

will flip DOWN instead of UP. Refer to

REPOSITIONING THE CANTILEVER ARM LOCKING MECHANISM in this procedure of the manual.

3. T o lock the cantilever arm, push DOWN until there

is an audible click.

4. Pull UP on the cantilever arm to make sure it is

locked in place.

REPLACING/

Adjustment Plate

REAR

Actuator

Top Hex Screw

and Coved Washer

Bottom Hex Screw

FIGURE 1 - USING CANTILEVER ARMS - INST ALLING/

REMOVING CANTILEVER ARMS - ADJUSTING

CANTILEVER ARM HEIGHT

Coved

Washers

Spacer

Back Cane

Locknuts

Washers

FRONT

Cantilever Arm

INSTALLING/REMOVING

CANTILEVER ARMS (FIGURE 1)

Installing

1. Insert the top hex screw of the partially assembled

cantilever arm assembly through the desired back

cane mounting hole.

NOTE: The partially assembled cantilever arm assembly includes the top hex screw, coved washers and

spacer, adjustment plate and cantilever arm.

NOTE: Make sure the adjustment plate is towards the

inside of the wheelchair.

2. Insert the bottom hex screw through the bottom

hole of the adjustment plate, the coved washer

and the back cane.

3. Secure the cantilever arm to the wheelchair with

the washers and locknuts as shown in FIGURE 1.

4. If desired, adjust the angle of the cantilever arm.

Refer to

in this procedure of the manual.

Removing

NOTE: When removing the locknuts and washers from

the cantilever arm assembly, leave the hex screws,

coved washers and spacer in place.

1. Remove the locknuts and washers from the top

and bottom hex screws.

ADJUSTING CANTILEVER ARM ANGLE

A

R

M

S

2. Remove the cantilever arm assembly from the

wheelchair frame.

17

PROCEDURE 5 ARMS

A

R

M

S

ADJUSTING CANTILEVER ARM

HEIGHT (FIGURE 1)

1. Remove the washers and locknuts from the top

hex screw and the bottom hex screw.

2. Pull the cantilever arm assembly with hex screws,

spacers, and coved washers away from the back

canes.

3. Reposition the cantilever arm assembly and hardware up or down as desired.

4. Insert the two (2) hex screws with hardware and

cantilever arm assembly into the desired back cane

mounting holes.

5. Secure the cantilever arm to the back canes with

the locknuts and washers as shown in FIGURE 1.

ADJUSTING CANTILEVER ARM

ANGLE (FIGURES 2 AND 3)

NOTE: This adjustment is recommended if the back

angle has been changed.

1. Flip the cantilever arm up and out of the way.

2. Remove the locknut that secures the locking pin

to the arm adjustment plate.

3. Refer to FIGURE 3 to determine the mounting hole

in the arm adjustment plate that will be used to

correspond to the back angle.

O

86

Back Angle Bracket

Arm

Adjustment

Plate

O

94

Back Angle Bracket

Arm

Adjustment

Plate

O

102

Back Angle Bracket

Arm

Adjustment

Plate

O

90

Back Angle Bracket

Arm

Adjustment

Plate

O

98

Back Angle Bracket

Arm

Adjustment

Plate

O

106

Back Angle Bracket

Arm

Adjustment

Plate

4. Securely tighten the locking pin and washer to the

adjustment plate with a locknut.

5. Repeat STEPS 1-4 for the opposite side, if necessary .

Adjustment Plate

Locking Pin

Locknut

Washer

FIGURE 2 - ADJUSTING CANTILEVER ARM ANGLE

FIGURE 3 - CORRESPONDING ARM ADJUSTMENT

TO BACK ANGLE

18

PROCEDURE 5ARMS

REPLACING/REPOSITIONING THE

CANTILEVER ARM LOCKING

MECHANISM (FIGURE 4)

CAUTION

The locking mechanism is spring loaded. Place

your free hand over the end of the cantilever

arm to prevent the locking mechanism from

springing out of the arm.

1. Flip the cantilever arm up and out of the way.

2. Unscrew the actuator from the locking mechanism.

3. Remove the locking mechanism and spring from

the cantilever arm.

NOTE: Inspect the spring and replace if necessary.

4. Slide the NEW spring and locking mechanism into

the cantilever arm.

5. Position the angled portion of the locking mechanism in one (1) of two (2) ways:

A. ANGLED PORTION FACING UP - Arm will

flip UP.

B. ANGLED PORTION FACING DOWN - Arm

will flip DOWN.

6. Push and hold the locking mechanism into the

cantilever arm.

7. Screw the actuator into the locking mechanism

mounting hole.

8. Flip the cantilever arm up/down to lock in place.

9. Pull down/up on the cantilever arm to ensure it

has locked in place.

ARMREST PAD ADJUSTMENT/

REPLACEMENT (FIGURE 5)

Armrest Pad Adjustment

1. Remove the phillips screw from the rear of the

armrest pad.

2. Reposition the cantilever slide tube to one (1) of

five (5) positions.

3. Align the mounting hole in the cantilever slide tube

with the desired mounting hole from STEP 2.

4. Install the phillips screw UP through the desired

mounting hole in the armrest tube and the cantilever slide tube mounting hole to secure the armrest pad to the armrest tube.

5. Repeat STEPS 1-4 for opposite armrest pad if

necessary.

Armrest Pad Replacement

1. Remove the phillips screw from the rear of the

armrest pad.

2. Remove the phillips screw from the front of the

armrest pad.

3. Remove the EXISTING armrest pad from the armrest tube.

4. Position the NEW armrest pad onto the armrest

tube and cantilever slide tube.

5. Secure the NEW armrest pad to the armrest tube

and cantilever slide tube with the two (2) phillips

screws.

A

R

M

S

Angled Portion of

Locking Mechanism

Spring

Cantilever Arm

Locking

Mechanism

Actuator

FIGURE 4 - REPOSITIONING/REPLACING THE

LOCKING MECHANISM IN THE

CANTILEVER ARM

Armrest

Tube

REAR Phillips Screw

Cantilever Slide Tube

FRONT Phillips Screw

FIGURE 5 - ARMREST P AD ADJUSTMENT/

REPLACEMENT

19

PROCEDURE 5 ARMS

A

R

M

S

INSTALLING T-ARM SOCKETS

(FIGURE 6)

1. Remove rear wheels from wheelchair. Refer to REMOVING/INSTALLING REAR WHEELS in PROCEDURE 7 of this manual.

2. Position the T-arm clamp on the wheelchair frame as

shown in FIGURE 6.

NOTE: T-arm socket must be positioned on outside of

wheelchair frame.

3. Install hex bolts through T-arm clamp, wheelchair frame

and coved washers and tighten securely with locknuts.

4. Position the T-arm socket inserts in the T-arm socket

as shown in FIGURE 6.

5. Line up the mounting holes in the T-arm socket with

the threaded holes in the T-arm clamp.

6. While holding the T-arm socket and the T-arm clamp

together, install the four (4) hex screws and washers

into mounting holes and tighten loosely .

7. Adjust the T-arm socket. Refer to

T-ARMS in this procedure of the manual.

8. Repeat STEPS 2-7 for opposite side of wheelchair .

9. Install the T-arm into the T-arm sockets in this procedure of the manual.

ADJUSTING THE

2. Slide T-arm into T-arm socket until the locking lever is in

the slot in the T-arm socket and an audible "click" is heard.

3. Pull up on T-arm to make sure T-arm is locked in place.

NOTE: If the T-arm does not slide in the T-arm socket

as desired, adjust the T-arm socket. Refer to ADJUSTING THE T-ARMS in this procedure of the manual.

4. Adjust the T-arm for desired height, width and depth,

if necessary . Refer to ADJUSTING THE T-ARMS in

this procedure of the manual.

5. Repeat STEPS 1-4 for opposite side of wheelchair .

Removing T-Arms

1. Press in on the locking lever and lift the T-arm straight

up and out of the T-arm socket.

NOTE: If the T-arm does not slide up and down in the Tarm socket as desired, adjust the T-arm socket. Refer to

ADJUSTING THE T-ARMS in this procedure of the manual.

2. Repeat STEP 2 for opposite side of the wheelchair .

Wheelchair Frame

T-Arm Clamp

T-Arm Socket

Inserts

Hex Bolts

Hex Screw

T-Arm

Socket

FIGURE 6 - INST ALLING T-ARM SOCKETS

Washer

Locknut

Coved

Washer

INSTALLING/REMOVING T-ARMS

(FIGURE 7)

Installing T-Arms

1. Position the T-arm over the T-arm socket on the

wheelchair frame.

NOTE: Make sure the locking lever is towards the front

of the wheelchair.

T-Arm

Wheelchair

Frame

T-Arm

Socket

FIGURE 7 - INST ALLING/REMOVING T- ARMS

Locking Lever

(Towards the

front of the

wheelchair.)

Slot

ADJUSTING THE T-ARMS

Adjusting T-Arm Height (FIGURE 8)

1. Unlock the T-arm by flipping the T-arm release lever

towards the inside of the wheelchair.

NOTE: If necessary , pull out on the T-arm release lever and rotate 180o so it can be flipped towards the

outside of the wheelchair.

20

PROCEDURE 5ARMS

2. Slide the T-arm to one (1) of:

A. Low Height T-Arms - Nine (9) positions.

B. High Height T-Arms - Seven (7) positions.

NOTE: If the inside T-arm post does not slide up and

down in the outside T-arm post as desired, perform

one (1) of the following:

A. Tighten - Tightening the set screws on the out-

side T-arm post will make it harder to move the

inside T-arm post up and down.

B. Loosen - Loosening the set screws on the out-

side T-arm post will make it easier to move the

inside T-arm post up and down.

3. Lock the T-arm by flipping the T-arm release lever towards the front of the wheelchair.

Inside T-Arm

Post

Set

Screws

Adjusting T-Arm Depth (FIGURE 10)

1. Remove the two (2) phillips screws that secure the

arm pad to the arm tube.

2. Remove the two (2) socket screws that secure the

arm tube to the T-arm post.

3. Reposition the arm tube on the T-arm post:

A. Desk Length Arms - to one (1) of three (3) posi-

tions depending on the desired arm pad depth.

B. Full Length Arms - to one (1) of five (5) posi-

tions depending on the desired arm pad depth.

NOTE: Additional positions are obtainable by turning

the arm tube 180o.

4. Re-secure the arm tube to the T-arm post with the

two (2) socket screws. Torque to 60-70 in./lbs.

5. Reattach the arm pad to the arm tube with the two (2)

phillips screws. Tighten securely .

6. Repeat for the opposite side, if necessary .

Arm Pad

A

R

M

S

Outside

T- Arm Post

T-Arm Release Lever -

Unlocked Position

T-Arm Release Lever - Locked Position

FIGURE 8 - ADJUSTING T-ARM HEIGHT

Adjusting T-Arm Width (FIGURE 9)

1. Remove the two (2) phillips screws that secure the

arm pad to the arm tube.

2. Turn the arm pad around and reposition the arm pad

on the arm tube.

3. Re-secure the arm pad to the arm tube with the two

(2) phillips screws. Tighten securely.

4. Repeat for the opposite side, if necessary .

Arm Pad

Arm Tube

Phillips

Screw

FIGURE 9 - ADJUSTING T-ARM WIDTH

Phillips Screw

Arm Tube

Socket

Screws

Phillips

Screw

T-Arm Post

FIGURE 10 - ADJUSTING T-ARM DEPTH

NOTE: If

necessary, turn

arm tube 180

to obtain two

(2) positions.

Phillips Screw

o

Adjusting T-Arm Sockets (FIGURE 11)

NOTE: Perform this procedure if the T-arm is too loose

in the socket or does not easily slide up and down in

the socket.

1. Remove the rear wheels from the wheelchair, if necessary. Refer to REMOVING/INSTALLING REAR

WHEELS in PROCEDURE 7 of this manual.

2. Loosen, but do not remove the four (4) hex screws

and washers that secure T-arm socket to T- arm clamp.

NOTE: The T-arm socket will disassemble if the four

(4) hex screws and washers are removed.

21

PROCEDURE 5 ARMS

A

R

M

S

3. Slide the T-arm into the T-arm socket until the locking

lever is in the slot in the T-arm socket and an audible

"click" is heard.

4. Squeeze the T-arm socket the T-arm clamp together

until the socket is flush with the T-arm.

5. While holding the T-arm socket and the T-arm clamp

together, tighten the four (4) hex screws and washers.

Tighten securely.

6. Press in on the locking lever and lift the T-arm straight

up and out of the T-arm socket.

7. Repeat STEPS 3-6, if necessary until the T-arm slides

in the T-arm socket as desired.

8. If necessary, install rear wheels. Refer to

ING/INSTALLING REAR WHEELS in PROCEDURE

7 of this manual.

T-Arm

REMOV-

WARNING

The locking lever is spring loaded. Place your free

hand over the locking lever to prevent the parts

from springing off of the bottom bracket, otherwise parts may be lost or injury may occur.

3. Remove EXISTING locking lever and spring from

bottom bracket.

NOTE: Inspect the spring and replace if necessary .

4. Position spring on bottom bracket as shown in FIGURE 12.

5. Position NEW locking lever onto spring and bottom

bracket (DETAIL "A").

NOTE: Make sure the two (2) extended ends of the spring

are inside the notch in the locking lever.

6. Line up the mounting holes in the NEW locking lever,

spring and bottom bracket.

WARNING

DO NOT over tighten locknut that secures locking lever to bottom bracket. Over tightening this locknut will

prevent locking lever from operating properly, possibly

causing injury.

T-Arm Clamp

Hex Screws

and Washers

Slot

Locking Lever

FIGURE 11 - ADJUSTING T-ARM SOCKETS

Hex Screws

and Washers

T-Arm Socket

REPLACING THE T-ARM LOCKING

LEVER (FIGURE 12)

1. Remove T-arm from wheelchair. Refer to INSTALLING/REMOVING T-ARMS in this proce-

dure of the manual.

2. Remove the phillips bolt and locknut that secure

the EXISTING locking lever to the bottom bracket.

7. Install phillips bolt and tighten securely with locknut.

8. Install the T-arm onto the wheelchair. Refer to

STALLING/REMOVING T-ARMS in this procedure

of the manual.

DET AIL "A" - MOUNTING THE SPRING

Mounted

Extended Ends

Spring

Bottom

Bracket

Phillips Bolt

FIGURE 12 - REPLACING THE T-ARM LOCKING LEVER

Spring

Notch

IN-

Locknut

Locking

Lever

22

SEAT PROCEDURE 6

This Procedure includes the following:

Replacing Seat Pan

Adjusting Rear Seat Height

Adjusting Seat Depth

Adjusting Seat Width

Adjusting Front Seat-to-Floor Height

WARNING

After ANY adjustments, repair or service and BEFORE

use, make sure all attaching hardware is tightened

securely - otherwise injury or damage may result.

REPLACING SEAT PAN (FIGURE 1)

1. Remove the seat cushion from the seat pan.

2. Remove the four (4) phillips screws, locknuts and

spacers (if present) that secure the seat pan to the

frame clamps.

3. Position NEW seat pan on wheelchair frame, aligning seat pan mounting holes with frame clamps.

4. Secure the seat pan to the frame clamps with the

four (4) phillips screws, locknuts and spacers (if

present).

Phillips Screws

Seat Pan

Mounting

Holes

FRONT OF

WHEELCHAIR

Seat Pan

REAR OF

WHEELCHAIR

Spacer

Frame

Clamps

SP ACER HEIGHT DIFFERENCE

NONE 2-inch

1-inch 1-inch

2-inch NONE

1. Perform STEPS 1-2 of

2. Insert or remove spacers on top of the REAR frame clamps.

3. Perform STEPS 3-4 of

REPLACING THE SEA T PAN.

REPLACING THE SEA T PAN.

ADJUSTING SEAT DEPTH

(FIGURES 2 AND 3)

WARNING

This procedure must be perf ormed by a qualified technician ONLY .

The position of the footrest, camber tube, back

angle, the tautness of the back upholstery as well

as the user's condition are directly related to the

wheelchairs stability. Any change to one (1) or any

combination of the five (5) may cause the wheelchair to decrease in stability. Use EXTREME caution

when using a new seating position.

NOTE: Note the position of the front hex screw before

removing to ensure proper reinstallation.

1. Remove the hex screws, washers, coved spacers

and locknuts that secure the back angle brackets to

the wheelchair frame.

2. Refer to the chart in FIGURE 3 to determine mounting positions for corresponding seat depths.

3. Position the back assembly with the mounting position determined in STEP 2.

4. Secure the back assembly to the wheelchair frame with

the hex screws, washers, coved washers and locknuts.

Refer to FIGURE 2 for correct hardware orientation.

S

E

A

T

Locknuts

Wheelchair Frame

FIGURE1 - REPLACING SEA T P AN

ADJUSTING REAR SEAT HEIGHT

(FIGURE 1)

NOTE: The wheelchair frame is designed to create a

2-inch height difference between the front and the rear

of the seat pan. If desired, spacers can be added at

the rear of the seat pan to decrease this height difference. Refer to the chart below for the proper spacers.

Back

Assembly

Back

Angle

Bracket

Rear

Hex

Screw

Front Hex Screw

FIGURE 2 - ADJUSTING SEA T DEPTH

23

Small Coved

Spacers

Washers

Large

Coved

Spacers

Washers

Locknuts

Wheelchair

Frame

PROPER MOUNTING HOLES FOR BACK ANGLE BRACKET

SEAT PROCEDURE 6

S

E

A

T

Use these mounting

holes ONL Y

987654321

NEVER use this mounting hole for the

back angle bracket

Rear--------Wheelchair-------Front

SHORT FRAME

Mounting

Holes 7 and 9

Mounting

Holes 6 and 8

NEVER use these mounting holes for

the back angle bracket

LONG FRAME

BACK POSITION FOR 16-INCH SEA T DEPTHBACK POSITION FOR 14-INCH SEA T DEPTH

Mounting

Holes 7 and 9

BACK POSITION FOR 15-INCH SEA T DEPTHBACK POSITION FOR 13-INCH SEA T DEPTH

Mounting

Holes 6 and 8

BACK POSITION FOR 14-INCH SEA T DEPTHBACK POSITION FOR 12-INCH SEA T DEPTH

Mounting

Holes 5 and 7

Mounting

Holes 4 and 6

Mounting

Holes 3 and 5

Mounting

Holes 2 and 4

Mounting

Holes 1 and 3

Mounting

Holes 5 and 7

BACK POSITION FOR 13-INCH SEA T DEPTHBACK POSITION FOR 11-INCH SEA T DEPTH

Mounting

Holes 4 and 6

BACK POSITION FOR 12-INCH SEA T DEPTHBACK POSITION FOR 10-INCH SEA T DEPTH

Mounting

Holes 3 and 5

BACK POSITION FOR 11-INCH SEA T DEPTHBACK POSITION FOR 9-INCH SEA T DEPTH

Mounting

Holes 2 and 4

BACK POSITION FOR 10-INCH SEA T DEPTHBACK POSITION FOR 8-INCH SEA T DEPTH

Mounting

Holes 1 and 3

FIGURE 3 - ADJUSTING SEA T DEPTH

24

SEAT PROCEDURE 6

ADJUSTING SEAT WIDTH (FIGURE 4)

WARNING

The following procedure should only be performed by a qualified technician.

1. Remove the EXISTING footplate from the wheelchair. Refer to PROCEDURE 8 of this manual.

2. Remove the EXISTING back upholstery from the

wheelchair. Refer to PROCEDURE 4 of this

manual.

3. Remove the EXISTING spreader bar from the

wheelchair. Refer to

SPREADER BAR in PROCEDURE 4 of this

manual.

4. Remove the EXISTING seat pan from the wheelchair. Refer to

cedure of the manual.

NOTE: Retain the attachment hardware for installation of the NEW seat pan.

5. Remove the axle tube from the wheelchair. Refer

to REPLACING AXLE TUBE in PROCEDURE 7

of this manual.

6. Remove the four (4) hex screws and eight (8)

coved washers that secure the two (2) EXISTING

crossmembers to the wheelchair frame.

7. Remove the four (4) frame clamps from the EXISTING two (2) crossmembers.

8. Install the four (4) frame clamps onto the NEW (2)

crossmembers.

9. Secure the two (2) NEW crossmembers to the front

and rear mounting holes in the wheelchair frame

with the hex screws and coved washers removed

in STEP 5.

10. Install the NEW axle tube. Refer to

AXLE TUBE in PROCEDURE 7 of this manual.

11. Install the NEW seat pan using the EXISTING

hardware. Refer to

procedure of the manual.

12. Install the NEW back upholstery onto the wheelchair. Refer to PROCEDURE 4 of this manual.

13. Install the NEW spreader bar onto the wheelchair .

Refer to

PROCEDURE 4 of this manual.

14. Install the NEW footplate onto the wheelchair . Refer to PROCEDURE 8 of this manual.

REPLACING SEA T P AN in this pro-

REPLACING SEA T PAN in this

REPLACING THE SPREADER BAR in

REPLACING THE

REPLACING

Hex Screws

Coved

Washers

Crossmember

Front Mounting Hole

FIGURE 4 - ADJUSTING SEA T WIDTH

Crossmember

Rear

Mounting

Hole

Wheelchair

Frame

ADJUSTING FRONT

SEAT-TO-FLOOR HEIGHT

WARNING

The position of the footrest, seat angle, back

angle, seating system/upholstery, caster size and

position, rear wheel size and position, anti-tippers,

as well as the user condition directly relate to the

stability of the wheelchair. Any change to one

(1) or any combination of the ten (10) may cause

the wheelchair to decrease in stability. EXTREME

care MUST be taken when changing the stability

of the wheelchair . Refer tothe chart in

PROCEDURE 1 o f this manual.

Determining Frame Height (FIGURE 5)

Terminator Jr. Frames come in Short and Tall.

1. To determine frame height, measure from the bottom of the caster headtube to the top of the seat rail.

2. Refer to the chart to determine the frame size.

HEIGHT (INCHES) FRAME SIZE

7-3/4 SHORT

10-1/2 T ALL

Seat Rail

HEIGHT

(INCHES)

FIGURE 5 - DETERMINING FRAME HEIGHT

ST ABILITY in

Bottom of

Caster

Headtube

S

E

A

T

25

SEAT PROCEDURE 6

S

E

A

T

Front Seat-to-floor Height Adjustment

NOTE: Refer to STABILITY in PROCEDURE 1 for

warnings concerning wheelchair stability .

Seat-to-floor height is determined by measuring from

the top of the seat rail to the ground/floor.

The different seat-to-floor heights are possible by using different combinations of rear wheel size and axle

tube position.

1. Refer to the chart below to determine available

front seat-to-floor heights for each wheelchair

frame height.

2. Determine the changes needed to the rear wheels

and axle tube by reading across the chart for the

seat-to-floor height determined in STEP 1.

3. Refer to REPOSITIONING THE AXLE TUBE in

PROCEDURE 7 of the manual to adjust the axle

tube position.

4. After adjusting the axle tube, the front casters may

need to be repositioned to ensure the caster

headtubes are perpendicular to the ground. Refer

to

ADJUSTING FRONT CASTER HEIGHT in

PROCEDURE 7.

5. Anti-tipper height (if applicable) must be adjusted

to maintain 1-1/2 to 2-inch clearance between the

bottom of the anti-tipper wheels and the floor. Refer

to

ANTI-TIPPER REPLACEMENT/ADJUST-

MENT in PROCEDURE 8 of this manual.

6. Ensure wheel locks engage properly. Refer to

WHEEL LOCK ADJUSTMENT/REPLACEMENT

in this procedure of the manual.

SHORT FRAME SEA T-TO-FLOOR HEIGHTS

FRONT SEAT-TO-FLOOR HEIGHT AXLE TUBE POSITION

REAR WHEEL SIZE (INCHES)

18 20 22 24

13-inch Upper N/A N/A N/A

14-inch Center Upper N/A N/A

15-inch Lower Center Upper N/A

16-inch N/A Lower Center Upper

17-inch N/A N/A Lower Center

18-inch N/A N/A N/A Lower

LONG FRAME SEAT-TO-FLOOR HEIGHTS

FRONT SEAT-TO-FLOOR HEIGHT REAR WHEEL SIZE (INCHES)

AXLE TUBE POSITION

20 22 24

16-inch Upper N/A N/A

17-inch Center Upper N/A

18-inch Lower Center Upper

19-inch N/A Lower Center

20-inch N/A N/A Lower

NOTE: Rear Seat-to-Floor height is two (2) inches shorter than Front Seat-to-Floor height.

NOTE: The Front Seat-to-Floor heights in the chart are determined using a 5-inch front caster.

NOTE: Refer to

Center and Lower axle tube positions.

REPOSITIONING THE AXLE TUBE in PROCEDURE 7 for an explanation of the Upper,

26

WHEELS PROCEDURE 7

This Procedure includes the following:

Removing/Installing Rear Wheels

Adjusting Quick-Release Axles

Installing Quad-Release Axles

Adjusting Quad-Release Handles

Handrim Replacement

Repairing/Replacing Rear Wheel, Tire/Tube

Opening/Closing Clamps

Adjusting Rear Wheel Camber

Determining/Adjusting Toe in/T oe out

Adjusting Wheelbase Length

Adjusting Wheelbase Width

Replacing Axle Tube

Repositioning the Axle Tube

Repositioning/Replacing Front Casters

Adjusting Front Caster Height

Wheel Lock Adjustment/Replacement

WARNING

After ANY adjustments, repair or service and BEFORE

use, make sure all attaching hardware is tightened

securely - otherwise injury or damage may result.

WARNING

During contact activities, Invacare recommends

inserting quick-release axles with the head end

to the inside of the wheelchair to prevent accidental release.

5. If there is too much movement of the rear wheel assembly in a back and forth motion, refer to

ING QUICK-RELEASE AXLES or ADJUSTING

QUAD-RELEASE HANDLES in this procedure of the

manual.

Quick-Release

Axle

Rear Wheel

Detent Pin

NOTE: Quad-Release Axle not shown. Locking pins the

same as Quick-Release Axle

FIGURE 1 - REMOVING/INST ALLING REAR WHEELS

Locking Pins

ADJUST-

Wheelchair

Frame

ADJUSTING QUICK-RELEASE

AXLES (FIGURE 2)

W

H

E

E

L

S

REMOVING/INSTALLING REAR

WHEELS (FIGURE 1)

CAUTION

Changing the size of the rear wheels can affect

the perfor mance of the wheelchair. Contact Invacare at the telephone numbers on the back

of this manual BEFORE changing rear wheel size.

1. Perform one (1) of the following:

QUICK-RELEASE - Push in the tip of the quick-release

axle and pull axle and wheel away from the wheelchair.

QUAD-RELEASE - Lift UP on the handle of the quadrelease axle and pull axle and wheel away from the

wheelchair.

2. Repeat STEP 1 for the opposite rear wheel.

3. Reinstall the rear wheel s onto the wheelchair by reversing STEPS 1-2.

WARNING

Pull on the rear wheel to make sure the detent pin

and locking pins of the quick/quad-release axle

are fully released BEFORE operating wheelchair.

Keep locking pins clean.

1. Remove rear wheel and quick-release axle from the

wheelchair. Refer to

REAR WHEELS in this procedure of the manual.

2. Depress detent pin in the quick-release axle and slide

axle through the wheel hub.

3. Release detent pin ensuring that the locking pins are

fully released.

4. Increase or decrease end play by adjusting the locknut on the end of the quick-release axle.

5. Reinstall rear wheel onto the wheelchair. Refer to

REMOVING/INSTALLING REAR WHEELS in this

procedure of the manual.

Adjustable Axle Position

Camber Bar

Locking

Pins

NOTE: End of Quick

Release axle is shown

for reference only. It is

not visible when

inserted into camber bar

FIGURE 2- ADJUSTING QUICK-RELEASE AXLES

REMOVING/INSTALLING

Locknut

Detent

Pin

Wheel

Hub

Quick

Release Axle

27

WHEELSPROCEDURE 7

W

H

E

E

L

S

INSTALLING QUAD-RELEASE

AXLES (FIGURE 3)

1. Remove rear wheel and the EXISTING quick-release

axle from the wheelchair. Refer to

STALLING REAR WHEELS in this procedure of the

manual.

2. Remove EXISTING quick-release axle from rear

wheel.

3. Insert NEW quad-release axle through rear wheel

hub.

4. Slide locking collar onto quad-release axle until it is snug

against rear wheel and tighten securely with allen screw.

5. Reinstall rear wheel and the quad-release axle onto

the wheelchair. Refer to

REAR WHEELS in this procedure of the manual.

6. Flip the handle of the quad-release axle down to release the detent pin ensuring that the locking pins

are fully released.

7. If detent pin does not fully release, proceed to

ING QUAD-RELEASE HANDLE IN AND/OR OUTin

this procedure of the manual.

8. Repeat STEPS 1-7 for the opposite rear wheel.

Quad

Release

Axle

REMOVING/INSTALLING

Allen

Screw

REMOVING/IN-

ADJUST-

Adjustable Axle

Position

Camber Bar

3. Make the following adjustments:

If the quad-release handle is not releasing the lock-

ing pins completely, rotate the quad-release handle

approximately one-quarter (1/4) turn CLOCKWISE.

If the quad-release handle hits the spokes of the rear

wheel when assembled, rotate the quad-release

handle approximately one-quarter (1/4) turn COUNTERCLOCKWISE.

4. Tighten the locking screw.

5. Reinstall the rear wheel and quad-release axle onto

the wheelchair. Refer to

REAR WHEELS in this procedure of the manual.

6. Flip the handle of the quad-release axle down to release the detent pin ensuring that the locking pins

are fully released.

7. Repeat the above procedures until the quad-release

axle locks correctly .

REMOVING/INSTALLING

Removing Play From Rear Wheels

NOTE: The adjusting locknut on the quick-release axles

originally performed this function.

1. With the rear wheel and quad-release axle still mounted

onto the wheelchair, make the following adjustment:

Tighten the length adjusting screw until there is no

in and out movement of the quad-release axle and

rear wheel.

NOTE: End of

Quad Release

axle shown for

reference only .

Rear Wheel

Hub

FIGURE 3 - INST ALLING QUAD-RELEASE AXLES

Locking

Collar

It is not visible

when inserted

into camber bar

ADJUSTING QUAD-RELEASE

HANDLES (FIGURE 4)

In and/or Out

1. Remove rear wheel and the quad-release axle from

the wheelchair. Refer to

REAR WHEELS in this procedure of the manual.

2. Loosen the locking screw.

REMOVING/INSTALLING

Quad Release

Handle

Locking

Screw

ADJUSTING QUAD-

RELEASE HANDLE IN/

AND OR OUT

REMOVING PLAY

FROM REAR

WHEELS

FIGURE 4 - ADJUSTING QUAD-RELEASE HANDLES

Adjusting

Locknut (On

Quick-Release

Axle)

Camber Bar

Locking Pins

Length

Adjustment

Screw

HANDRIM REPLACEMENT

(FIGURE 5)

1. Remove the rear wheel from the wheelchair. Refer to

REMOVING/INST ALLING REAR WHEELS in this

procedure of the manual.

28

WHEELS PROCEDURE 7

WARNING

Tire MUST be FULLY deflated BEFORE any disassembly procedures are per formed. Otherwise

injury or damage may result.

2. Remove all air from the tube by pressing down on the

pin in the center of the valve stem.

3. While carefully holding the tire, tube and rim strip to

one side, hold the allen screws and remove the locknuts that secure the handrim to the rear wheel.

4. Remove the EXISTING handrim.

5. Install NEW handrim by reversing STEPS 2-4.

WARNING