Spec

®

Spectra Plus

User Manual

Yes, you can.

CONTENTS

Forward - Advisory Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Getting Acquainted With The Powerchair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Features - Joystick Control Knob Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Seat and Backrest Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Armrest Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tension Adjustable Backrest . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Manual Tilt-in-Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Controllers - PILOT Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Controllers - Dynamic DL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

DX-REMG80I Master Remote . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Controllers - PILOT+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-16

Controllers - Options - Chin/Dual Attendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Transfers - Getting in and out of the Chair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Footrests - Elevating Legrests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Freewheel Mode - Motor Dis-engage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Kerb Climbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Disassembly - For Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Detachable Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Drive Wheel Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Manual Brakes - Drive Wheel-Locks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Transportation - Restraint Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Tray - Fitting & Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lateral Supports - Fitting & Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Charging the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Battery Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Maintenance & Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Approved Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Product Description

The power chair supplied as standard, features rear wheel drive, Gel batteries, standard height backrest,

detachable, width and height adjustable armrests, detachable, adjustable height footrests and a joystick controller

mounted for either right or left hand control.

Without the use of tools the drive motor units are detachable and together with detachable battery box units and

disassembled frame, allow the power chair to be stowed for transportation in a suitable vehicle.

It may be used to transport a user in a moving vehicle provided the separate recommended guidelines are followed.

The product should be serviced as recommended by an authorised INVACARE dealer to ensure continual, safe

and reliable operation.

For details and additional special options for users with greater dependency, refer to your Healthcare

Professional/Prescriber or authorised INVACARE dealer.

!

FOREWORD

Important safety operating and maintenance instructions are contained in this user

manual. We urge you to read and understand it before operating your power chair and

refer to it as often as needed to help maintain safe use and all-round performance.

All procedures involved should be practiced until you are familiar with them. However, if used

improperly, it is possible for the wheelchair to become unstable. You should learn the individual

characteristics and capabilities, as well as limitations, of your own powered wheelchair.

Basic safety procedures in this user manual are to be used as a guide only. You may find it necessary to

develop your own methods for safely solving encountered problems. Never hesitate to ask for assistance.

Your powered wheelchair should receive maintenance on a regular schedule. It is recommended that the

periods between services should be 12 months. The maximum period between safety checks for the

manual wheel - lock adjustment and the electronic brake function should be 6 months.

PURPOSE OF THE POWER CHAIR

Standard power chairs are suitable for persons who require independent mobility combined with comfort,

manoeuvrability, reliability and minimal maintenance.

The intended user should possess some degree of ability with at least one hand and arm, reasonable

eyesight and a degree of spatial awareness and have received training in the use of the product,

preferably in their normal environment. Their maximum weight can be found at the rear of this manual.

It is suitable for use indoors and outdoors on dry, reasonably smooth level surfaces. It climbs slopes up to

20% (1 in 5) and kerbs up to 10cm high (an optional device may be required). It should not be used in heavy

rain or snow, loose slippery surfaces and slopes, on wet grass, etc. Passengers must NOT be carried.

Excess baggage outside of the seating area can affect stability.

ADVISORY SAFETY NOTICE

Power chairs are designed to operate in appropriate environments.

However, radio wave sources such as radio and TV broadcasting stations,

amateur radio transmitters and portable telephones can affect powered

wheelchairs.

Portable communication equipment such as citizen band radios and

portable telephones should be switched OFF whilst operating the

wheelchair.

If unintentional movement or brake release occurs, turn the wheelchair

OFF as soon as it is safe to do so.

Unauthorised modifications or the use of non-Invacare approved replacement parts may change the

structure of the wheelchair and could create a hazardous condition. Invacare will not be liable for any

unauthorised changes and modifications from the specifications of the power chair supplied.

All information and specifications in this manual are current at the time of printing, However, because of

Invacare’s policy of continual product improvement, we reserve the right to make changes at any time

without notice.

1

!

GETTING ACQUAINTED WITH YOUR NEW POWER CHAIR

Please ensure your dealer returns the WARRANTY REGISTRATION CARD. This will ensure your vehicle

is covered for the relevant warranty periods against failures due to defects in manufacturing or materials.

Please see the Owner’s Warranty Card supplied for full details.

RECOMMENDED ADJUSTMENTS TO BE CARRIED OUT BY A TRAINED AUTHORISED

INVACARE DEALER ARE IDENTIFIED WITH THIS SYMBOL.

SAFETY PRECAUTIONS

Before using your power chair, read and understand the following safety precautions:-*

• Keep your powered wheelchair in good working order. As with all electro-mechanical

vehicles, it will benefit from regular service inspections at the recommended intervals.

• We recommend that at 6 monthly intervals to check electronic brake function, manual

wheel - lock adjustment and the motor disengage operation.

• Always remember to use a safety belt when operating the wheelchair outdoors.

• Your powerchair is capable of negotiating slopes of up to 11 degrees (1 in 5 gradient), however, the

recommended safe slope for the wheelchair is advised as 6 degrees (1 in 10 gradient). Also, see page

8 - recommended driving position, and section 3 - Negotiating Slopes / Gradients..

• Take special care in bad weather. Braking and tyre grip may be affected on

wet or icy surfaces, take care on slopes and uneven surfaces.

Do not attempt to drive across slopes, which may make the vehicle

unstable, increasing the possibility of an accident and possible personal

injury.

• When climbing hills or slopes it is important to travel up in one motion.

Starting a forward movement from stationary on a slope requires extra care

to avoid tipping backwards. Start slowly and accelerate cautiously.

• When travelling down an incline, select a low speed, stop periodically if the

wheelchair moves faster than anticipated. Push the joystick forward slowly

to continue the descent. Do not lean forward.

• Avoid parking on the edge of rivers, ponds, lakes, sea, etc.

• Adjustments should only be carried out by your authorised INVACARE®

dealer to ensure correct operation and safe use.

Representative models of Invacare powered wheelchairs are tested for use in

a moving motor vehicle using recommended restraint systems. For further

information contact your authorised

INVACARE dealer. It is the responsibility of the person or authority transporting the wheelchair with an

occupant seated, to ensure the safety of the occupant and other passengers.

2

FEATURES

3

Motor speed and direction are regulated by the joystick control unit. With practice, automatic control of

acceleration, braking and change of direction will ensure a smooth, jerk-free ride. The variable speed

selector gives you total control in any environment.

The power chair cannot be driven when the batteries are being charged. Controller circuits are designed

to prevent operation during the charging process.

CHARGING • The battery gauge will indicate that your batteries are low.

BATTERIES • The batteries fitted as standard are completely sealed and therefore cannot be

Charging is straightforward, (Refer to enclosed booklet).

spilled like conventional ‘wet’ cells. Total performance and reliable operation is

dependent on the care and understanding of batteries and battery charging.

Please refer to the appropriate section and separate booklet supplied. Sealed Gel

batteries are classed as non hazardous by all air transport and travel authorities.

Mobility vehicles fitted with these batteries can be safely taken onto aeroplanes,

ships, buses, ambulances or trains without having to remove the batteries from

the equipment.

TYRES • Pneumatic drive wheels and castors are fitted as standard. Puncture proof wheels

will alleviate the need to maintain pressures and give a smooth but slightly harder

ride. These are available as options.

UPHOLSTERY * The upholstery complies with the requirements for resistance to cigarette and

match ignition ISO7176:16. Refer to section on cleaning and care of upholstery

materials. Prolonged exposure to ultra-violet light will reduce the life of the

upholstery, protect against sunlight.

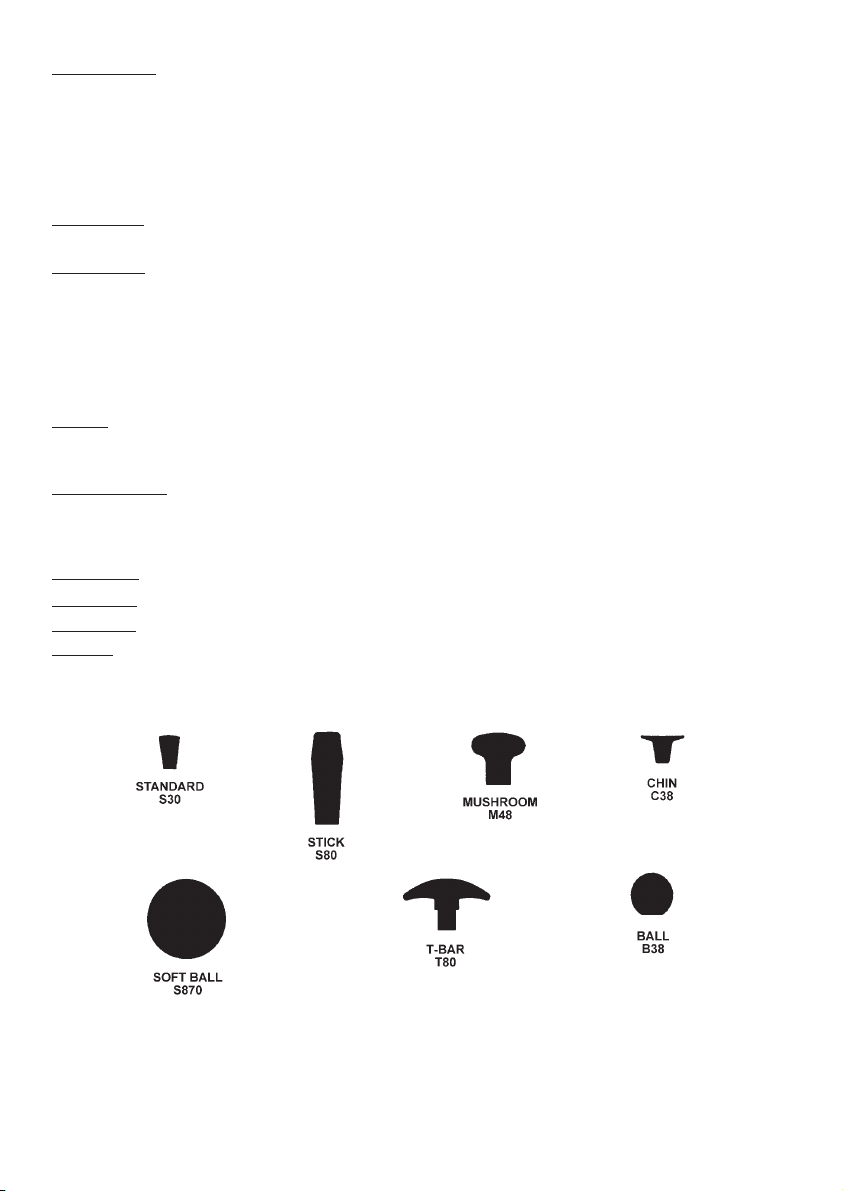

OPTIONAL * The knob fitted to your joystick is supplied as standard and is suitable for most

JOYSTICK

applications. If you find this unsuitable for your operation there is a range of

alternatives available. Please contact your wheelchair distributor for advice. Do

CONTROL not replace the joystick knob with any unauthorised device - it may cause

KNOBS

hazardous operation.

SEAT AND BACKREST ADJUSTMENT

4

C

Warning: It should be noted that under certain conditions, and configurations of the

wheelchair, ie. for users with limited / no lateral body control, and with the backrest in the

reclined position, there is the potential to create a body trap between the armrest / side-

!

Before sitting in the chair, make sure it is NOT switched ON. If it is ON, the battery condition indicator (10

Bar display) will be illuminated.

SEA

T DEPTH ADJUSTMENT - 35mm depth adjustment

The individual fitting of the seating allows the seat depth to be adjusted by 35mm (1“). The adjustment,

which is usually only done once, is carried out as follows. You will need a large cross-headed screwdriver

and a 13mm spanner.

1. Prise off plastic cap at point A, unscrew and remove the screw and nut, repeat each side.

2. Move the backrest mounting bracket backwards to the extended position. Replace the nut and screw

into the selected hole and firmly fasten, replace plastic cap, repeat each side.

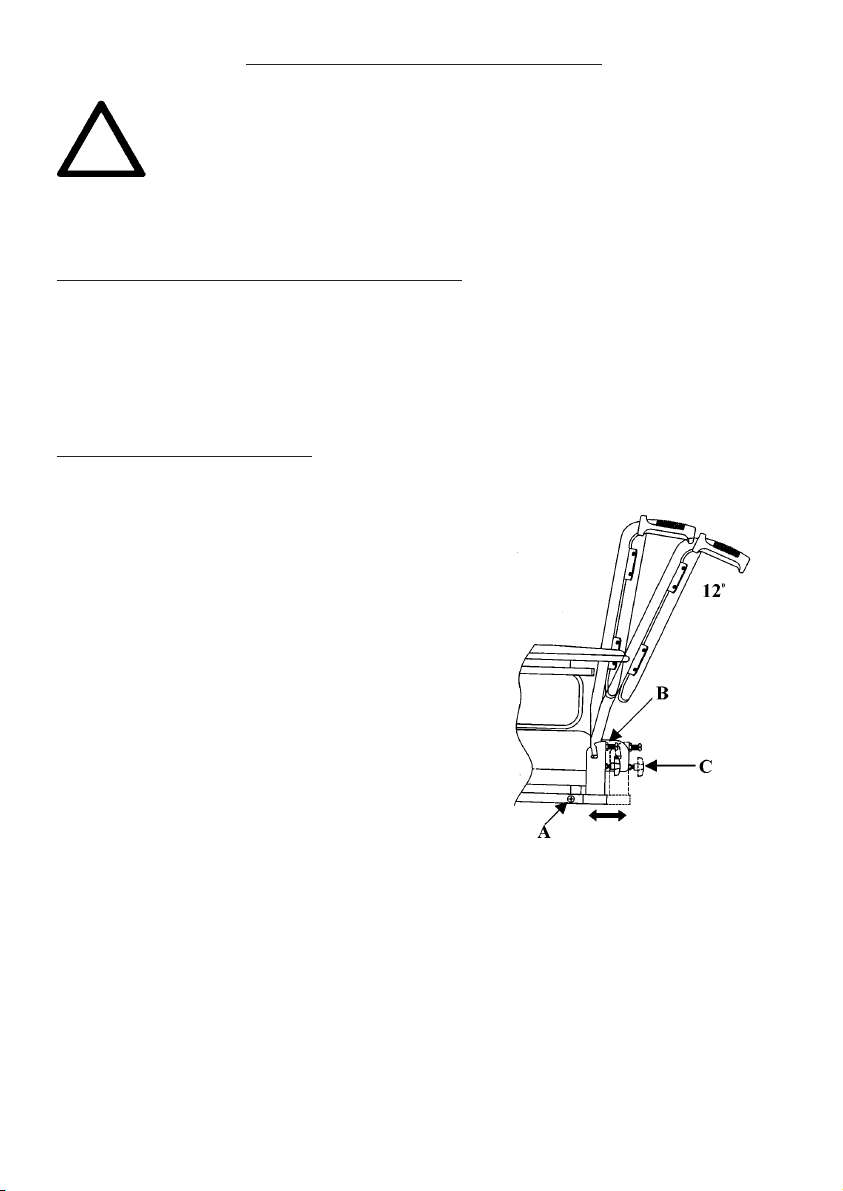

BACKREST ANGLE ADJUSTMENT

The backrest angle can be adjusted from 90˚rearwards through 12˚ The adjustment, which is normally

only required to be done once, is carried out in the

following sequence (see diagram) with the aid of the

13mm spanner and the cross-headed screwdriver. Do

the same adjustment for both sides.

1. Release the lock nut B located on the cross-headed

screw.

2. Screw the locking hand-wheel C partially out.

3. Screw the cross-headed screw in or out to give the

desired position. Adjust position of hand-wheel as

necessary.

4. Position the lock nut B up to the mounting bracket

and fully tighten.

5. Re-tighten the hand-wheel C fully; ensure backrest

assembly is secure.

panel and the backrest.

Suitable accessories are available from Invacare (lateral trunk supports_ to eliminate this risk.

Please note: Each backrest tube must be positioned in the same plane or the backrest will be twisted.

The backrest can be either folded down or detached from the chair base.

Follow these additional instructions: -

1. Unscrew the hand-wheel C approximately five full turns. Lift the backrest upwards and then fold

forwards onto the seat. Adjust armrest width to accommodate if required.

2. To detach, unscrew the hand-wheel an additional three to four turns. Do not loosen the cross-headed screw.

3. Push the backrest slightly forward and lift upwards.

4. To re-locate the backrest assembly, ensure the pins are correctly aligned into the slots of the mounting

bracket, fully re-tighten the hand-wheel on both sides.

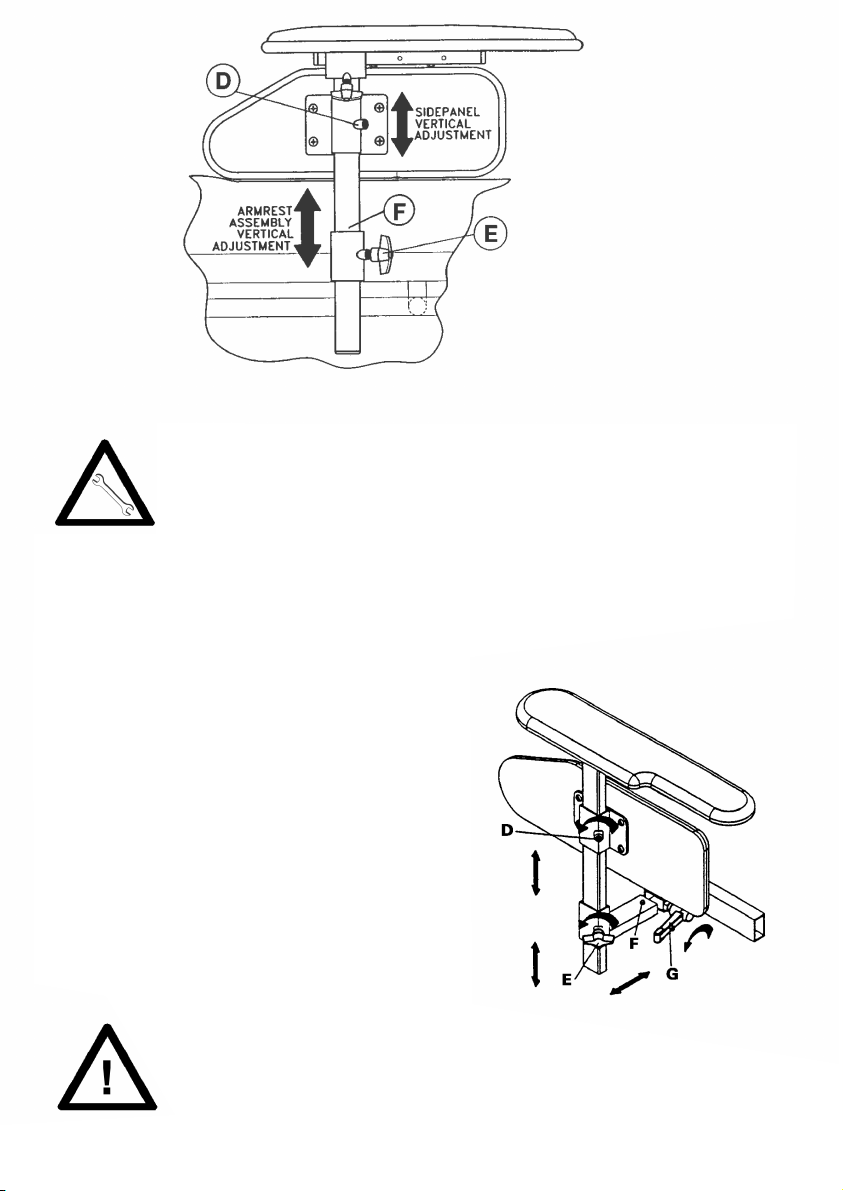

Armrest Adjustment

The armrest can be pre-set for height by positioning the self-tapping screw (F) in one of

the holes in the armrest tube. To adjust the height of each armrest, first release the locking

lever (E) which clamps the arm tube, while holding onto the armrest. Move the armrest to

the desired height position, re-tighten the locking wing screw (E). The locking lever (if

fitted) can be re-positioned without losing the clamping pressure, pull the lever slightly

outwards and turn to a more suitable locating angle.

The padded side panel can also be set to a desired height. Loosen the slotted screw (D) located in the

fixing bracket, re-tighten when desired position is achieved.

Width Adjustment

The transverse width adjustment is achieved by releasing

locking lever (G) and positioning the armrest tube to width

required and re-tightening locking lever (G). To remove the

transverse width adjustment armrest assembly complete

to allow removal of the front battery box/controller

assembly: remove seat, release locking lever (G), depress

spring button lock (F) and withdraw complete armrest unit

sideways.

NOTE: When re-assembling to chair always ensure the

spring button lock (F) is on the inside of the horizontal

mounting tube of the sideframe to prevent accidental

dismantling of armrest unit.

CAUTION: The armrests are not intended for carrying the wheelchair.

5

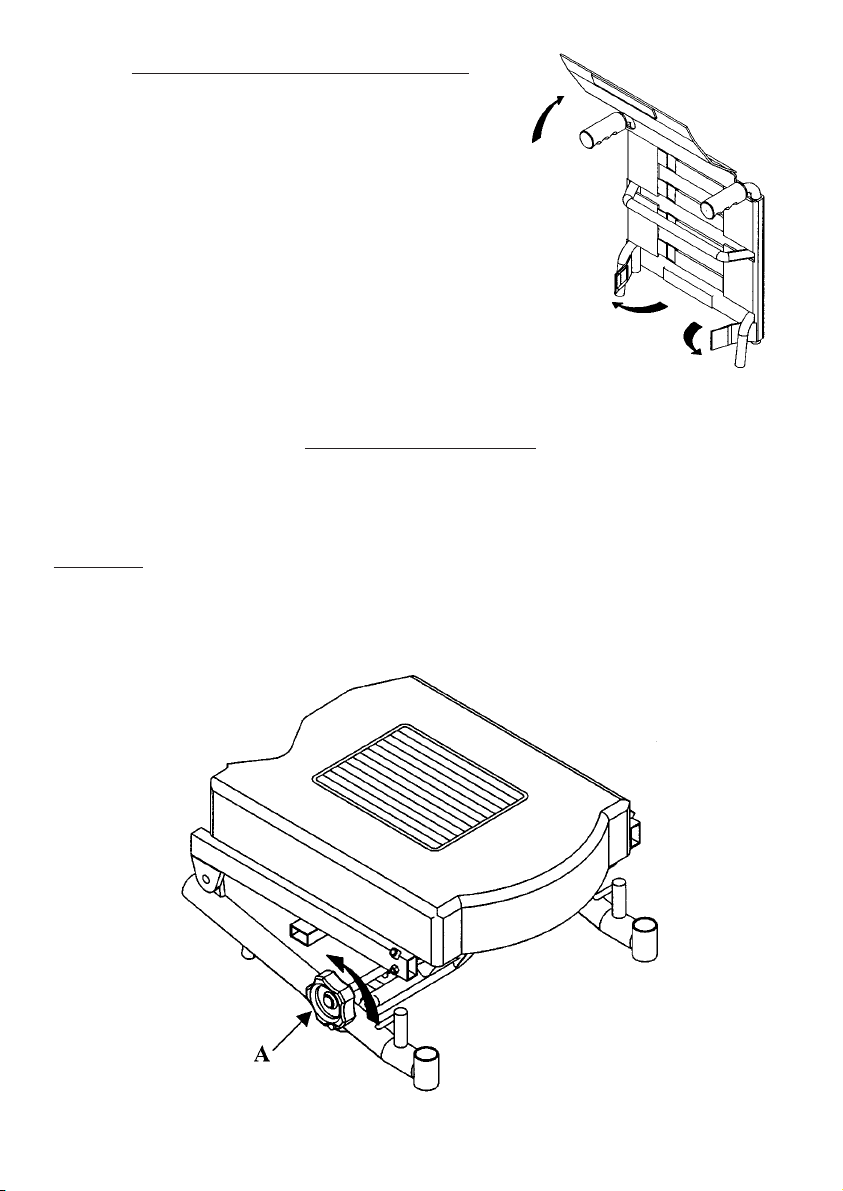

MANUAL TILT-IN-SPACE

To operate the manual tilt-in-space to allow the complete seat/backrest to tilt backwards, turn the large

hand-wheel A until the desired sitting position is achieved. Rotating the hand-wheel in the opposite

direction will lower the seat/backrest section.

T

AKE CARE: WHEN DRIVING THE POWER CHAIR WITH THE TILT-IN-SPACE OUTDOORS, THE

SEAT TILT MUST BE RETURNED TO THE NORMAL LOWERED POSITION BEFORE ATTEMPTING

KERB CLIMBING OR ASCENDING AND DESCENDING SLOPES. THIS ALSO APPLIES TO THE

OPTIONAL POWERED TILT-IN-SPACE OR POWERED RECLINING BACKREST.

TENSION ADJUSTABLE BACKREST

The backrest upholstery tension can be adjusted to achieve the

desired comfort for individual user requirements.

To achieve this, lift the backrest upholstery cover by peeling the

Velcro fastening and fold clear. Adjust the individual tension

straps to the occupant’s comfort.

Ensure the straps are correctly positioned and replace the

backrest cover, attaching securely by the Velcro fastening.

TENSION ADJUSTABLE BACKREST

The backrest upholstery tension can be adjusted to achieve the

desired comfort for individual user requirements.

To achieve this, lift the backrest upholstery cover by peeling the

Velcro fastening and fold clear. Adjust the individual tension

straps to the occupant’s comfort.

Ensure the straps are correctly positioned and replace the

backrest cover, attaching securely by the Velcro fastening.

MANUAL TILT-IN-SPACE

To operate the manual tilt-in-space to allow the complete seat/backrest to tilt backwards, turn the large

hand-wheel A until the desired sitting position is achieved. Rotating the hand-wheel in the opposite

direction will lower the seat/backrest section.

T

AKE CARE: WHEN DRIVING THE POWER CHAIR WITH THE TILT-IN-SPACE OUTDOORS, THE

SEAT TILT MUST BE RETURNED TO THE NORMAL LOWERED POSITION BEFORE ATTEMPTING

KERB CLIMBING OR ASCENDING AND DESCENDING SLOPES. THIS ALSO APPLIES TO THE

OPTIONAL POWERED TILT-IN-SPACE OR POWERED RECLINING BACKREST.

6

Fault Type

The number of flashing

bars indicate the

possible area of fault.

Description

High battery voltage

Solenoid brake fault

Possible controller fault

Possible joystick fault

Charger Connected

Right motor wiring fault

Right motor disconnected

Left motor wiring fault

Left motor disconnected

Low battery voltage

G

R

E

E

N

Y

E

L

L

O

W

R

E

D

Speed

Control

Battery Gauge

On/Off Indicator

Status Readout

Joystick

On/Off Push

Button

Motor/Battery

Connector

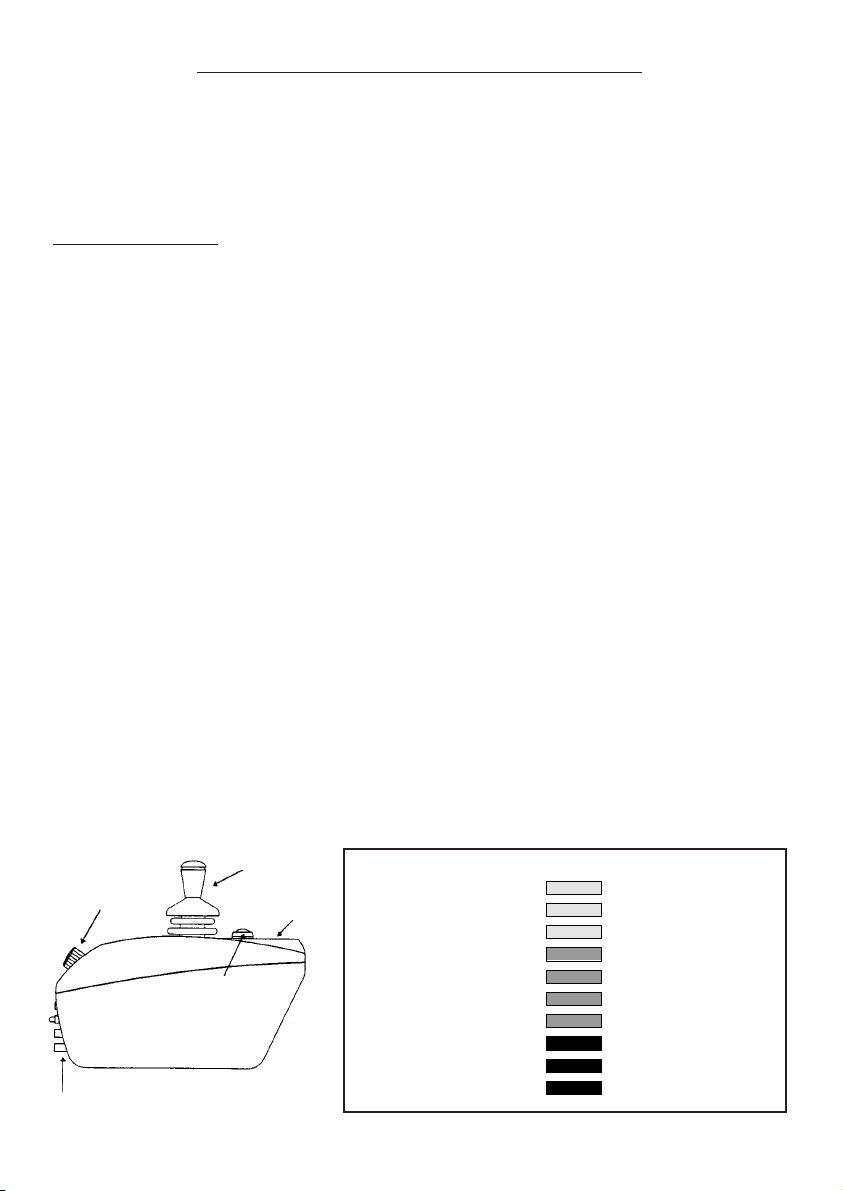

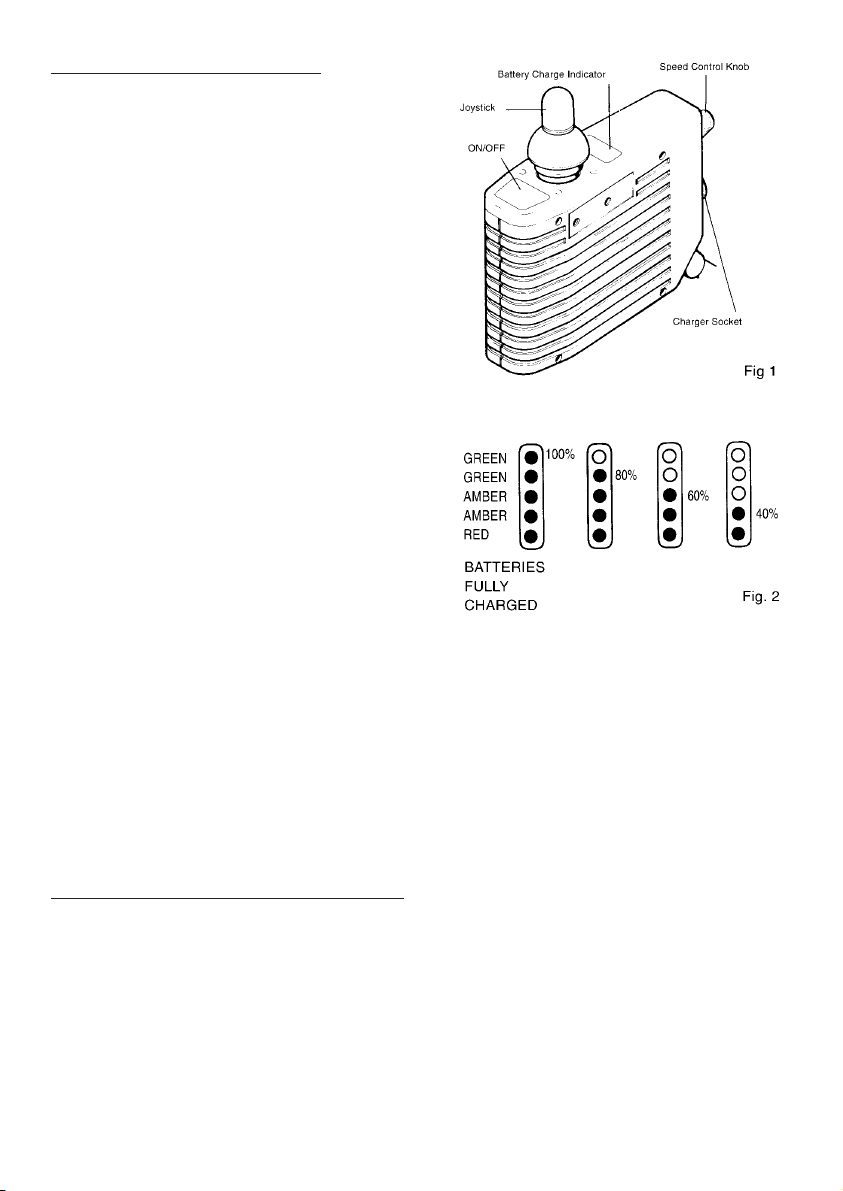

HANDLING AND OPERATION - CONTROLLERS

Your wheelchair is fitted with a programmable electronic controller that is very simple to operate. There

are a selection of options, PILOT INTEGRAL, PILOT+ and the DYNAMIC DL. Whichever is selected will

be most appropriate for your individual needs. The appearance varies, the function and driving

characteristics are basically similar. The PILOT INTEGRAL is fitted as standard.

The following instructions cover all types and available controller options.

PILOT INTEGRAL

Before you sit in the chair, make sure it is not switched ON. If it is switched ON the battery gauge indicator

will be illuminated. Once you are sitting comfortably, press the on/off switch. The joystick controls the

speed and direction of the wheelchair. The further you push the joystick from the centre position the faster

the wheelchair will move. When you release the joystick the brakes are applied automatically. DO NOT use

the on/off switch to stop the chair unless there is an emergency. If the emergency stop is applied, the

chair will slow down and stop very quickly. This is called ‘SOFT STOP’. If the controller detects a

malfunction, either in its circuits, or in the wheelchair’s electrical system, it may

halt the chair depending on the severity of the problem.

The 10 segment battery gauge display will indicate the fault type by rapidly flashing the number of bars to

indicate the possible area of the fault. See the Fault Diagnostics section relevant to the type of controller.

The speed control sets the maximum speed of the wheelchair, turn clockwise to increase, anti-clockwise

to decrease.

You may charge the batteries through the charge socket at the front of the control unit. Refer to section

on batteries and battery charging. This socket may also be used for re-programming the controller should

this be necessary (consult your dealer).

The controller units are sophisticated electronic components, and must be handled with care. Always

clean your controller by wiping with a damp cloth only if it becomes contaminated with food or drink. Make

sure the controller is securely fixed to your wheelchair.

TruCharge Battery Gauge

This is a 10 segment illuminated display which indicates if the controller is turned on and also gives the

status of the battery, the controller and the wheelchair electrical system.

Red, yellow and green bars lit: Battery charged; controller and electrical system OK.

Red and yellow bars lit: Charge battery if possible; controller and electrical system OK.

Red bars only lit or slow flash: Charge battery as soon as possible, controller and electrical system OK.

Rapid flash of bars: Indicates a fault in the controller or electrical system. See below for fault diagnostics.

Ripple up and down of bars: Joystick displaced at turn on.

7

DYNAMIC DL CONTROLLER

When the ON/OFF button is pressed, a bleep tone can

be heard from the controller and the battery charge

indicator will light up confirming that power is switched on

and the wheelchair is ready to move.

The Speed Control Knob on the rear of the Controller

enables you to reduce the maximum speed at which the

wheelchair can travel when the joystick is fully deflected

in any direction. The more you turn this knob

anticlockwise, the lower will be the maximum speed, no

matter how far you push or pull the joystick.

The Battery Charge Indicator (Fig. 2) lights up when the

ON/OFF button is pressed into ON. It gives you updated

information as to how much charge approximately is left

in the batteries, so that you can estimate how much

further you can drive before you have to recharge the

batteries. The reading will drop while the wheelchair is

being driven, and increase after the wheelchair has been

at a standstill for a few seconds. This is quite normal, and

it is best to check the indicator while the wheelchair is

stationary.

The battery charge indicator also informs you of any fault

condition when one or several of its lamps begin to flash.

Display flashing slowly: the wheelchairs moves slowly,

but with sluggish response and reduced speed indicates

the batteries are discharged below the critical level or possible controller or motor fault.

Display flashing rapidly: (twice per second) and the wheelchair not moving also indicates the batteries

are discharged below the critical level or a possible controller fault.

In both cases it is advisable to check and re-charge the batteries, if the fault indication persists, contact

the authorised INVACARE dealer.

On the rear face of the controller you find the Battery Charging Socket. Underneath is a special socket for

the connection of Programming Instruments if and when the response characteristics of the wheelchair

(acceleration, deceleration, damping etc.) are to be further adjusted to your needs (Consult your

authorised INVACARE dealer).

8

RECOMMENDED DRIVING POSITION

• INVACARE recommends that when driving your Spectra Plus during normal operating conditions the

following seat and back angles are maintained:

• Seat Angle: - approximately 4°

• Back Angle: - approximately 7°

• Failure to observe the above precautions whilst driving may lead to instability, damage to the chair, user

or those around you.

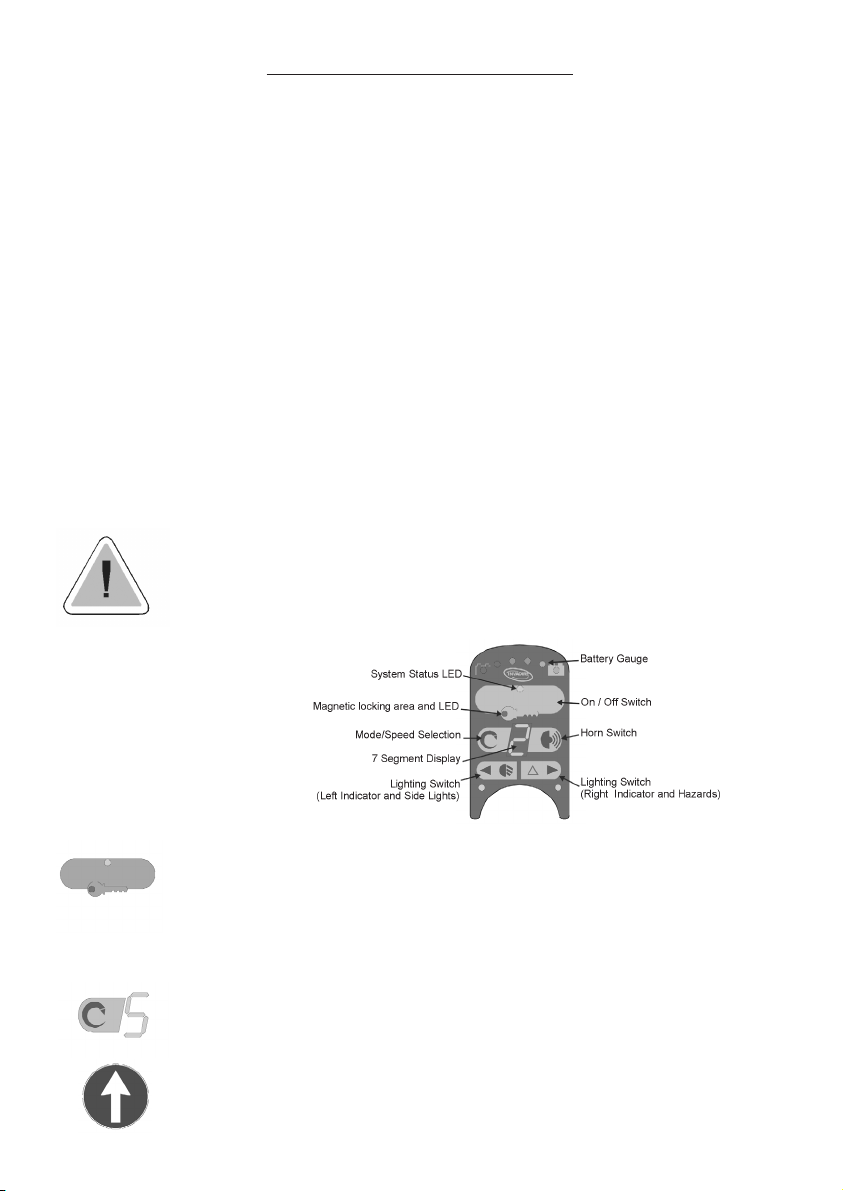

DX-REMG80I MASTER REMOTE

Please read these instructions carefully before using the DX-REMG80I, and keep this leaflet safe for future

reference.

For Information: My Local wheelchair services representative is: ......................................................................

Based at ............................................ Telephone no:................................ Department: ..................................

1) IMPORTANT INFORMATION FOR YOUR SAFETY

The information in this manual is a supplement to the user manual issued by Invacare. Do not operate this

equipment without reading, understanding and following the proper instructions and manuals, otherwise injury

or damage may result.

2) INTRODUCTION

The DX-REMG80I Remote is a primary DX Remote containing a battery gauge, magnetic key and a horn. Up

to five individual Drive Programs or profiles are available. The DX-REMG80I also features two jack sockets

allowing the connection of two external switches to duplicate the functions of the On/Off and Drive Program

select buttons.

3) HANDLING AND TRANSPORTATION

To avoid any unnecessary damage to your control system whilst driving, avoid hitting obstacles with the

controller or joystick. This also applies when transporting your chair. Avoid dropping the control system & be

wary of possible damage to cables. (i.e. Being Trapped).

DX-REMG80I Remote fitting, testing and programming must be carried out by professionals

of the health care field or persons fully conversant with this process and the driver’s

capabilities. The control system should be demonstrated to the user when the chair is

supplied. Incorrect settings could cause injury to the driver or bystanders, or damage to the

wheelchair or surrounding property.

4) DRIVING THE WHEELCHAIR

The G80I Keypad

Once you are seated in your wheelchair. Switch on DX-REMG80I by gently pressing and

releasing the on/off switch located on top of the controller at the front. The system status

light will light up to show power on. (If the status light flashes rapidly it indicates that the

joystick knob was not in its central position when the controller was switched on. Simply

allow the knob to return to the central position. If this condition persists for more than 5

seconds a latched fault will occur and the 7-segment display will begin to flash. If this

happens simply turn the remote on and off to clear the fault.

Drive Programs are selected using the Drive program selection switch. The selected drive

program or profile is displayed in the 7-Segment display. Drive programs or profiles may be

setup to change speed and/or select remote joysticks actuators, or lights. Appendix A

explains the operation of lighting and actuator functions.

Move the joystick a little in the direction you wish to travel. The further you move the joystick

knob, from the central rest position, the faster the chair will move. Small gentle movements

of the joystick give fine control.

9

Releasing the joystick and allowing it to return to the center position will bring the chair to a

controlled stop. When you have finished driving, switch off by pressing and releasing the on/off

switch.

The fuel gauge on the top surface of the DX-REMG80I will have all 6 lights on, if your batteries

are fully charged. As you use up the power by driving, the green lights and then the amber lights

will go out. When only the red lights are left on, it is time to re-charge your batteries. The red

light will flash as a further reminder.

A socket is provided at the front of the G80I to allow a battery charger to be connected. Follow the instructions for

charging your batteries in the wheelchair manual. CAUTION – Only use the charger supplied by the wheelchair

manufacturer. If in doubt contact your Wheelchair Services representative.

5) MAINTENANCE

1. The DX System should be regularly checked for integrity. Loose, damaged or corroded connectors or terminals,

or damaged cabling should be replaced.

2. All switchable functions on the DX System should be regularly tested to ensure they function correctly.

3. All DX system components should be kept free of dust, dirt and liquids. If necessary wipe with a cloth dampened

with warm water or alcohol. Do not use solvents or abrasive cleaners.

4. Where any doubt exists, consult your nearest Service Center or Agent.

5. There are no user-serviceable parts in any DX System component - do not attempt to open any case.

Warning: If any DX component is damaged in anyway, or if internal damage may have occurred (for example by

being dropped), have it checked by qualified personnel before operating.

6) FAULT DIAGNOSTICS

In the event of a fault indicator flashing while driving (battery gauge and/or Status LED), the user must ensure that

the system is behaving normally. If not, the system must be turned off and a service agent contacted. If a fault is

detected the System Status LED will flash a certain number of times followed by a pause. Count the number of

flashes and refer to this table:

1) DX Module Fault - Please contact your wheelchair representative

2) DX Accessory Fault - If fitted, check seat raise is in lowered position. If fault persists

please contact your wheelchair representative

3) Left Motor - There may be a fault or a loose connection **CHECK

4) Right Motor - There may be a fault or a loose connection **CHECK

5) Left Park Brake - There may be a fault or a loose connection **CHECK

6) Right Park Brake Fault - There may be a fault or a loose connection **CHECK

7) Low Battery fault - You may need to charge your batteries

8) Over Voltage Fault - Please contact your wheelchair representative

9 or 10) Data transfer fault between modules - Please contact your wheelchair representative

11) Stall Timeout Fault - Please turn the controller off then switch it back on again

12) Module Mismatch - Please contact your wheelchair representative Contact

If you are in any doubt, please contact your Wheelchair Services representative.

7) SAFETY AND MISUSE WARNINGS

Do not operate the DX System if it behaves erratically, shows abnormal response, heating, smoke or arcing. Turn

the system off at once and consult your Service Agent.

Do not operate your DX System if the battery is nearly flat as a dangerous situation may result due to loss of power

in an inopportune place.

Ensure the controller is turned off when not in use.

No connector pins should be touched, as contamination or damage due to electrostatic discharge may result.

Radio Frequency Interference (RFI) influences most electronic equipment. Caution should be exercised with regard

to the use of portable communications equipment in the area around such equipment. While the manufacturer has

made every effort to ensure that RFI does not cause problems, very strong signals could still cause a problem. If

RFI causes erratic behavior, shut the wheelchair off immediately. Leave off while transmission is in progress.

Report any malfunctions immediately to your Service Agent.

PLEASE DO NOT MODIFY THE CONTROL SYSTEM IN ANY WAY. ANY UNAUTHORISED MODIFICATIONS

INCLUDING THE FITMENT OF UNAPPROVED SPARES OR ACCESSORIES MAY RENDER THE CONTROL

SYSTEM UNSAFE AND WILL INVALIDATE ANY SAFETY/APPROVAL MARKS AND THE WARRANTY.

WHEELCHAIR SERVICE REPRESENTATIVES MAY OBTAIN FURTHER INFORMATION ON THE DX SYSTEM FROM

DYNAMIC EUROPE LTD.

10

APPENDIX A

CONTROLLING ACTUATORS (SEAT CONTROLS) OR LIGHTS USING THE JOYSTICK

If your chair is fitted with Actuators (Seat Controls) or Lights they may be operated using the G80I’s joystick.

To control actuators or lights using the joystick:

Ensure the chair is stationary.

Press the mode/speed selection button repeatedly until one of the non-driving mode symbols, shown

below, appears on the 7 Segment Display.

Actuator & Lighting

Non-Drive Mode Symbols

Move the joystick from left to right to select the symbol for the function that you wish to control.

If you have selected an Actuator (Seat Control) Mode move the joystick forward, beyond the point of half

travel, to lift the actuator or pull back, beyond the point of half travel, to lower the actuator. Release the

joystick to stop the actuator.

If you have selected Lighting Mode , momentarily push the joystick forwards, beyond the point of half

travel, to toggle the Side Lights on or off or pull back, beyond the point half travel, to toggle the Hazard

Lights on or off. Repeat the process to turn the relevant lighting off. Hazard operation will be indicated on

the G80I by the flashing of the Left and Right Indicator Displays shown in the section below.

CONTROLLING LIGHTING FUNCTIONS USING THE KEYPAD

If lights are fitted to the wheelchair they may also be activated using the lighting controls on the G80I’s

Keypad.

Left and Right Indicators

A single short press (less than 1 second) of the Left or Right Indicator switch will toggle the Left or Right

Indicators, respectively, on or off. The associated Indicator Display will flash to show when the indicators

are activated.

Side Lights

A single long press (greater than 1 second) of the Side Light (or left indicator) Switch will toggle the Side

Lights on and off. There is no Display feedback on the keypad when the side lights are active.

Hazard Lights

A single long press (greater than 1 second) of the Hazard (or right indicator) Switch will toggle the Hazard

Lights on or off. Both Left and Right Indicator Displays will flash when the Hazard Lights are active.

Mode/Speed Selection

left Indicator and

Side Light Switch

Left Indicator

Display

Right Indicator and

Hazard Switch

Right Indicator

Display

7 Segment Display

Tilt in

Space

Back

Rest

Left Leg

Rest

Right

Leg-Rest

Seat

Height

Lights

11

PILOT+

The PILOT+ control system comprises of two or three modules - Joystick Module, Power Module and

Actuator and Lighting Module (ALM). The ALM is only required if the optional Tilt-in-space or Powered

Reclining Backrest are fitted.

On/Off Switch and Battery Gauge

The on/off switch applies power to the control system electronics, which in turn supply power to the

wheelchair’s motors. Do not use the on/off power switch to stop the wheelchair unless there is an

emergency. (If you do, you may shorten the life of the wheelchair drive components).

The battery gauge shows you that the wheelchair is switched on. It also indicates the operating status of

the wheelchair. Details are given in the PILOT INTEGRAL controller section.

Security Key

The security key can be used to lock the wheelchair to prevent unauthorised use. To lock the wheelchair

it must be switched on, the key should then be inserted into and withdrawn from the battery charging

socket, the wheelchair will now be locked.

To unlock the wheelchair, firstly switch it on. The maximum speed indicator will ripple up and down but

driving will not be possible. The key should now be inserted into and withdrawn from the battery charging

socket, the wheelchair can now be driven.

12

NEGOTIATING GRADIENTS/SLOPES

• Never attempt to climb or descend an incline where the surface is rough,

wet or slippery (gravel, loose chippings, grass, rain, black ice, snow etc.).

• If you are in a situation where by the Powerchair fails to climb a ramp and

stalls midway through the manoeuvre, DO NOT attempt to turn the

Powerchair to drive back down in a forward facing direction, always

reverse slowly in a steady, flowing action and DO NOT brake harshly, as

this will upset balance in this situation. If possible, always seek the

assistance of an attendant.

NEGOTIATING KERBS

• When approaching kerbs wherever possible mount

and dismount pavements via ramps. Always

approach the kerb head on, not at an angle.

• When approaching a kerb stop approximately 5cm

from the kerb edge, then push the joystick firmly

forward and continue to climb over the obstacle in

one movement. DO NOT pause or attempt to steer

during this movement.

• NOTE: Take care when mounting or dismounting a

kerb as it may be possible to lose drive if the

antitipping castors contact the ground.

JOYSTICK MODULE DETAILS

CONTROLS

Joystick Module without Lighting Joystick Module with Lighting

JOYSTICK

BATTERY CHARGING/

PROGRAMMING SOCKET

COMMUNICATIONS CONNECTOR

TO POWER MODULE

ON/OFF SWITCH

BATTERY GAUGE

MAXIMUM SPEED INDICATOR

MODE SWITCH

HORN SWITCH

ACTUATOR INDICATOR

LIGHTS SWITCH AND LED

LEFT TURN INDICATOR SWITCH AND LED

RIGHT TURN INDICATOR SWITCH AND LED

HAZARD WARNING SWITCH AND LED

13

Horn Switch

The horn will sound whilst this switch is depressed.

Lights Switch and LED

To turn on the wheelchair’s lights operate this switch, the associated LED will illuminate.

Left Turn Indicator Switch and LED

To turn on the wheelchair’s left turn indicator operate this switch, the associated LED will flash at the same

rate. If the LED flashes rapidly, one of the left turn indicator bulbs is defective, contact your authorised

INVACARE dealer.

Right Turn Indicator Switch and LED

To turn on the wheelchair’s right turn indicator operate this switch, the associated LED will flash at the

same rate. If the LED flashes rapidly, one of the right turn indicator bulbs is defective, contact your

authorised INVACARE dealer.

Hazard Warning Switch and LED

To turn on the wheelchair’s hazard warning lamps operate this switch, the associated LED will flash at the

same rate. The left and right turn indicator LED’s will also flash.

Getting Ready to Drive

Operate the on/off switch. The battery gauge will blink then turn on after a second.

Check that the maximum speed control is set to a level which suits you.

Push the joystick to control the speed and direction of the wheelchair.

Please note that if you push the joystick before or just after you switch the control system on, the battery

gauge will ripple up and down and the wheelchair will not be allowed to move. You must release the

joystick to resume normal operation. If you do not release the joystick within five seconds the wheelchair

will not be able to move, even if you release the joystick and push it again. The battery gauge will then

flash rapidly. You can reset this condition by switching the control system off and on again.

If you do not push the joystick as you switch the wheelchair on and the battery gauge flashes rapidly, then

there may be a fault.

14

Fig. 1 Operation of Mode Switch Whilst Driving

Operating the mode switch will put the control system back into the drive mode.

If the mode switch is operated when the joystick is centred, the control system operation mode will be

changed. There are three modes - drive, speed adjustment and actuator adjustment. The diagram below

explains this action.

SPEED 1

SPEED 2SPEED 5

SPEED 3SPEED 4

DRIVE

MODE

ACTUATOR

ADJUST

SPEED

ADJUST

Maximum Speed Indicator

This is a gauge that shows the maximum speed setting of the wheelchair. There are five speed settings:

- step 1 is the lowest speed and step 5 is the highest speed

Mode Switch - Speed Settings

The mode switch is used to make the maximum speed changes and to change between wheelchair

operation modes.

If the mode switch is operated whilst you are driving the maximum speed setting will be increased by one

step. Each successive operation of the mode switch will increase the setting, when the setting is at 5 the

next mode switch operation will put the setting to 1. The diagram below explains this action.

Fig. 1 Operation of Mode Switch Whilst Driving

Operating the mode switch will put the control system back into the drive mode.

If the mode switch is operated when the joystick is centred, the control system operation mode will be

changed. There are three modes - drive, speed adjustment and actuator adjustment. The diagram below

explains this action.

Fig. 2 Operation of Mode Switch Whilst Joystick Centred

15

UP

DOWN

SELECT

SELECT

FORWARD

REVERSE

INCREASE

SETTING

DECREASE

SETTING

Speed Adjustment Mode

When the control system is in this mode the maximum speed indicator will flash. The maximum speed can

be adjusted by left or right movements of the joystick. Left will decrease the speed setting, right will

increase it. Forward or reverse movements of the joystick will take you back into drive mode.

Fig. 3 Joystick Operation in Speed Adjustment Mode

Operating the mode switch will put the control system back into drive mode or, if seat adjustment actuators

are fitted, actuator adjustment mode.

Actuator Adjustment Mode

When the control system is in this mode the actuator indicator will be illuminated. The section of the

wheelchair symbol that is illuminated shows the actuator that is selected for adjustment. To change the

selected actuator move the joystick left or right. To make an actuator adjustment move the joystick

forwards or backwards.

Fig. 4 Operation of Joystick in Actuator Adjustment Mode

16

CHIN CONTROL

ATTENDANT CONTROL

CONTROLLER OPTIONS

The optional Attendant, Chin and Centre are fitted with the PILOT+ Control System.

The display function is the same for each joystick module.

DUAL/ATTENDANT CONTROL

CAUTION: ATTENDANT, Before switching from Occupant Control to Attendant control, it is of the utmost

importance that the speed control is checked and a safe manageable speed is selected before activating

the joystick.

Failure to do so may cause the chair to move uncontrollably, causing injury to the occupant or other

people.

CIRCUIT BREAKERS - 30 AMP

The circuit breakers are located at the front of the front battery box and at the front of the rear battery

box between the two battery boxes. They are fitted to operate if a current overload should occur. If one

of the breakers operate, it will ‘pop’ out. To re-set, push the knob in after a few minutes. If the circuit

breaker continually fails, consult your authorised INVACARE dealer.

Under certain circumstances, particularly indoor use, care must be taken to ensure safe continual

operation of the motor units. If an obstacle is encountered or, with slow manoeuvring of the castor

wheels from the forward to rear position, continual full operation of the joystick control will result in motor

overload and eventual failure.

To prevent this occurrence, increase the speed to maximum, control the manoeuvre by the joystick

control, always move away from the obstacle, do not continue to drive against it.

17

18

TRANSFERS

Learning how to get in and out of a wheelchair safely and without injury is most important. Transferring to

and from your powerchair may require practice and a good sense of balance. It is recommended that

whenever possible you have assistance when transferring to and from your powerchair. It is recognised,

however, that situations may occur when assistance is not available. It is desirable to learn and practice

different techniques to accomplish a safe transfer.

Many experienced wheelchair users have developed and mastered their own method of transferring to

and from the chair, resulting in great independence and self-care. Such ability depends largely on the

strength of the individual, their capabilities and the type of chair. No single technique would be practical,

or possible, for all wheelchair users. Safety is the primary consideration in all techniques.

To carry out the transfer confidently and to eliminate the possibility of personal injury, check the following:-

• Be sure the power is turned off.

• Be sure that the brakes are on and the drive engaged.

• Tip the footplates up or remove footrest assemblies completely to reduce the risk of leg or foot injury.

• Avoid standing or putting your weight on the footplates. This may cause the chair to tip.

• Remove armrest assemblies completely for side transfers.

Attendant assistance is recommended and the following advice is relevant:-

• The attendant lifting the occupant should take special precautions to avoid tipping or injuries from

lifting, supporting, turning and lowering the patient.

• The attendant is responsible for stabilising the wheelchair and must take precautions to prevent the

wheelchair moving or sliding during the transfer, ie apply brakes and ensure chair is not in free wheel.

• Be sure that the seat which is being transferred to is stable and will not create a possible hazard by

moving or tipping when the occupant is raised or lowered.

If in doubt, ask for assistance or use a device that will ensure safe transfer, ie patient lifter or

transfer board.

LOCKING LEVER

CAUTION: It is recommended that both footrests are firmly locked in place when

seated in the chair (particularly when driving the chair). NEVER stand on the foot-

plates. If the weight of the body is placed on the foot-plates, damage may occur and

the chair may tip forward.

ADJUSTMENT

To extend the footrest laterally, release

the winged screw A, pull the footrest

forward, re-tighten when the desired

position is achieved.

It is not necessary to release the grub

screw B. This should remain

permanently in position.

To adjust the footrest length, loosen

the hex nut C on the extension tube,

use a twisting motion when sliding the

telescopic tube in and out. Be sure to

re-tighten the nuts securely when the

desired height is achieved.

THE LOWEST PART OF THE

FOOTREST MUST BE AT LEAST

6cm (2½”) FROM THE GROUND

FOR CLEARANCE.

!

FOOTRESTS

REMOVAL - Standard

Release winged screw A and slide the complete assembly from the seat frame. Ensure the winged screw

is fully tightened when the footrest assembly is replaced.

REMOV

AL - Swing - Away

Release the locking lever, swing footrest to the side, or lift up and off. Do this before sitting in the chair.

CAUTION: It is recommended that both footrests are firmly locked in place when

seated in the chair (particularly when driving the chair). NEVER stand on the foot-plates.

If the weight of the body is placed on the foot-plates, damage may occur and

the chair may tip forward.

ADJUSTMENT

To extend the footrest laterally, release

the winged screw A, pull the footrest

forward, re-tighten when the desired

position is achieved.

It is not necessary to release the grub

screw B. This should remain

permanently in position.

To adjust the footrest length, loosen

the hex nut C on the extension tube,

use a twisting motion when sliding the

telescopic tube in and out. Be sure to

re-tighten the nuts securely when the

desired height is achieved.

THE LOWEST PART OF THE

FOOTREST MUST BE AT LEAST

6cm (2•“) FROM THE GROUND

FOR CLEARANCE.

ELEV

ATING LEGRESTS

To raise or lower, release the lock by moving

the lever forward as shown.

When lowering the legrest, support the

weight of user’s leg then release the lock,

keep it from dropping too quickly. Keep in

mind that the lowest part of the footplate must

be 6cm (2”) from the ground.

19

CAUTION

When the drive is dis-engaged there are no brakes, unless the wheel-locks are applied.

Before entering or leaving the chair always re-engage the drive on both sides. On no

account dis-engage the drive when the chair is occupied, unless being pushed by an

attendant.

!

WARNING - Emergency freewheel device.

Always re-engage the emergency freewheel

device after use. Failure to do so may result

in injury.

!

PUSHING THE CHAIR - FREEWHEEL MODE

The power chair supplied is fitted with the lever dis-engage type motors. To dis-engage the drive to allow

the chair to be pushed the following instructions should be followed carefully.

To dis-engage the drive, operate the levers to the position A shown in the diagram.

LEVERS POINTING OUTWARDS.

To re-engage the drive, operate the levers to position B shown in the diagram.

LEVERS POINTING REARWARDS.

Push the chair slightly forwards to ensure that both motors are fully locked in the drive position.

CAUTION

When the drive is dis-engaged there are no brakes, unless the wheel-locks are applied.

Before entering or leaving the chair always re-engage the drive on both sides. On no

account dis-engage the drive when the chair is occupied, unless being pushed by an

attendant.

WARNING - Emergency freewheel device.

Always re-engage the emergency freewheel

device after use. Failure to do so may result

in injury. !

20

REMOVAL: (Please note that left or right hand are

identified as though being seated in the chair).

To detach the kerb climber for transportation follow

these simple instructions;

Remove the locking pin A, while holding the

assembly. Push the assembly down to release from

the locating bracket.

Pull the assembly towards you away from the right

hand retaining socket. The kerb climber is now

detached. Stow carefully.

RE-ASSEMBL

Y:

Locate the assembly into the right hand retaining bracket. Push the assembly up into the left hand bracket

and refit the locking pin A. Ensure the pin is correctly fitted firmly into place.

GOING UP

A KERB:

Adjust the speed control to the maximum position

to allow full power to the motors.

Approach the kerb head-on (90º), do not charge at

the kerb.

With the front of the kerb climber at about 2.5cm

(1”) from the edge of the kerb, push the joystick

fully forward and continue to climb in one

movement. Do not pause or attempt to steer during

this movement.

OPERATING THE CHAIR OUTDOORS - KERB CLIMBING

Always remember to use the safety belt when operating the chair outdoors.

Ensure the footrests are locked in position.

KERB CLIMBING

- Centre Mounting

It is important to follow the instructions detailed in ‘going up a kerb’ described below.

REMOV

AL: (Please note that left or right hand are

identified as though being seated in the chair).

To detach the kerb climber for transportation follow

these simple instructions;

Remove the locking pin A, while holding the

assembly. Push the assembly down to release from

the locating bracket.

Pull the assembly towards you away from the right

hand retaining socket. The kerb climber is now

detached. Stow carefully.

RE-ASSEMBL

Y:

Locate the assembly into the right hand retaining bracket. Push the assembly up into the left hand bracket

and refit the locking pin A. Ensure the pin is correctly fitted firmly into place.

GOING UP A KERB:

Adjust the speed control to the maximum position

to allow full power to the motors.

Approach the kerb head-on (90º), do not charge at

the kerb.

With the front of the kerb climber at about 2.5cm

(1“) from the edge of the kerb, push the joystick

fully forward and continue to climb in one

movement. Do not pause or attempt to steer during

this movement.

If the kerb climb is un-achievable do not continue the manoeuvre, move away from the obstacle and if

possible find an alternative location.

GOING DOWN A KERB:

Approach the edge of the kerb square on. Drive forward down the kerb at a moderate speed. Kerbs of

7.5cm (3“) or more may tip the chair onto the foot plates. It is advisable to go down the kerb backwards

to overcome this problem.

The kerb climbing device will return to the climbing position after each manoeuvre.

NOTE: Climbing kerbs in excess of 10cm (4“) will be restricted if the foot plates are in the fully extended

position. Refer to page 16 for correct foot plate adjustment.

21

DIS-ASSEMBLY

To enable the chair to be carried in the boot of most cars, follow these instructions:

Step 1: Disconnect the Motor/Battery connector from the control box and remove the armrests. Release

the locking lever.

Step 2: Remove the calf strap from the footrests. This is simply attached by Velcro fastening. Remove

the footrests completely by releasing the cam latch situated on the inside of the footrest frame hanger.

CAUTION: Do not drive the chair with the footrests in the unlatched position.

Step 3: Remove the kerb climber assembly (if fitted) as described.

Step 4: Detach the seat and backrest assembly as previously shown. When replacing the seat

assembly, ensure the brackets are located correctly on the seat frame tube.

Step 5: Disconnect the motor leads and the connecting cables from the battery boxes. Carefully lift the

battery boxes clear of the frame by the straps provided. Remove the battery tray. When refitting the battery

tray it is important that it is correctly located on the support pins.

Step 6: Remove the detachable motors as described.

The disassembled chair is now ready to be loaded safely in a suitable vehicle. Reversing the procedure

will allow the chair to be reassembled at your destination.

SPECIAL NOTE: Care must be taken when stowing the detached parts for transportation to ensure that

no damage occurs, particularly to the motor assemblies and controller units.

Due to the weight of the battery boxes, consideration must be given to their secure positioning in the event

of emergency braking.

EXTREME CARE MUST BE TAKEN WHEN LIFTING THE HEAVIEST COMPONENTS I.E. BATTERY

BOXES, FRAME AND MOTOR UNITS. ASSUME THE CORRECT LIFTING POSITION. SEEK

ASSISTANCE IF IN DOUBT.

22

DETACHABLE MOTORS

For practical purposes and ease of operation, it is advisable to detach the motors as the last component

of the chair to be dismantled and to re-attach first.

PLEASE NOTE: Assistance may be required while this operation is carried out.

Step 1: Unscrew the knurled locking knob A. This can be unscrewed completely and still be retained in

position.

Step 2: Release the side retaining pin B by turning it 180˚.

Step 3: Unbolt clamp C on the vertical frame member.

Step 4: Support the weight of the chair on the side the motor is being detached. Pull the motor assembly

towards the back of the chair, take care to hold the motor assembly when it becomes detached. Repeat

operation for both sides.

SPECIAL NOTE: Care must be taken when stowing the detached parts for transportation to ensure that

no damage occurs, particularly to the brake housing and gearbox unit.

To re-attach the motor assemblies, align the bottom tube rail with the tube of the motor assembly and push

firmly home. Re-tighten fully the knurled locking knob A. Do the same for both sides.

For ease of operation, it is advisable to re-attach the motor assemblies as the first operation in the

reassembly of the wheelchair after transportation.

NOTE: The disassembly and reassembly of the motor assemblies can be handled and attached easier if

the chair is carefully tipped onto the front, taking into account that the leg rests are not attached.

The chair can be transported disassembled safely in a suitable vehicle. Reversing the above procedures

will make your chair ready at your destination.

23

DRIVE WHEEL REMOVAL

To remove the rear drive wheels for puncture repairs carefully follow these instructions.

Release the four bolts shown as A in the diagram. Check the tyres for wear, if excessive, replacement is

recommended.

The wheel is a split rim. It is important that the bolts securing the rims together are NOT released if the

tyre is pneumatic and INFLATED.

Upon reassembly tighten the fixing bolts securely. The wheel is alloy, do not over-tighten as this may

damage the wheel rim.

If the tyre is being inflated with the wheel on the chair, ensure the wheel is off the ground during inflation.

Inflate the tyre slowly to recommended pressure, ensuring an even fit around the rim.

DRIVE WHEEL-LOCKS -

(MANUAL BRAKES)

24

When transferring to and from the chair ensure the

wheel locks are firmly ON and the motor drive is in the

engaged position.

When transporting the complete chair in a vehicle, it is

important that motor drive is engaged and the wheel

locks are firmly ON. This will aid the use of the chair

restraints and protect the motor/gearbox from possible

damage.

The Power chair was tested to

ISO 7176-19 using Unwins

Webbing Restraints with

Tongue and Buckle Straps. The

system comprises of front

adjustable straps complete with

quick release buckles and rear

adjustable straps complete with

karabiners and braided straps.

The straps are secured at the

specified points shown in Fig.

No.2. Both positions are

labelled “TIE DOWN POINT”.

The diagram (Fig. No.2) shows

the headrest arrangement,

which must be fitted, and the

occupant’s inertia seat belt

which also must be used.

Fig. No.2

FRONT

ADJUSTABLE

STRAPS

COMPLETE WITH

QUICK RELEASE

BUCKLES

REAR ADJUSTABLE

STRAPS

COMPLETE WITH

KARABINERS AND

BRAIDED STRAPS

THREE POINT

DOUBLE INERTIA

REEL HARNESS

HEADREST MUST

BE FITTED

BATTERY STRAP

ASSY

Fig. No.1

The restraint strap

must be tight and the

Velcro firmly

fastened.

FRONT

TRANSPORTATION OF WHEELCHAIRS IN VEHICLES

RECOMMENDED RESTRAINT METHODS

For additional information, consult your authorised Supplier.

For transportation purposes other than disassembly, the Spectra Plus may be used in vehicles which

have been modified specifically for the purpose. The power chair must be secure using these

recommended restraint methods.

• The power chairs are not designed or manufactured to be replacements for purpose built vehicle

seating.

• The occupant must be secured to the vehicle separately in addition to any wheelchair restraints.

See Fig. No. 2.

• Manually operated drive wheel locks must be used whilst the power chair is being

transported.

• Fig. No. 1. shows the route of the battery restraint strap and the position of the Velcro fastening.

The Power chair was tested to

ISO 7176-19 using Unwins

Webbing Restraints with

Tongue and Buckle Straps. The

system comprises of front

adjustable straps complete with

quick release buckles and rear

adjustable straps complete with

karabiners and braided straps.

The straps are secured at the

specified points shown in Fig.

No.2. Both positions are

labelled „TIE DOWN POINT“.

The diagram (Fig. No.2) shows

the headrest arrangement,

which must be fitted, and the

occupant’s inertia seat belt

which also must be used.

Recommended alternative headrests may be used without affecting the CE marketing of the

power chair, provided a full risk assessment has been carried out by those who have

recommended the headrest to be safe for use with the power chair.

25

See Fig No.4

TRANSPORTA

TION

CAUTION

INVACARE always advises that a Powerchair secured in a vehicle will not provide the

equivalent safety level and security as bespoke seating systems and recommends transfer

to the vehicle seating, but also recognises that it is not always practical for the user to be

transferred.

In cases where transfer is not possible then the Powerchair should only be secured as follows:

NOTE

Your safety during transportation, largely depends upon the diligence of the person securing the Tie-downs

and passenger restraints, it is your responsibility to ensure that your Powerchair has been secured safely.

1. The Spectra Plus

TM

has been crash tested and has met all pass requirements of ISO7176 Part 19 and

is suitable for transportation with an occupant in a vehicle.

2. Seek confirmation from the transporter that the vehicle is suitably designed, insured and equipped to

transport a passenger seated in a Powerchair.

3. The Powerchair should always be transported in a forward facing direction. Rearward facing is only

acceptable if your head and back can be supported by a suitable bulkhead.

4. Ensure the hook and eye battery restraint straps securely hold down the front and rear battery boxes

and cradles. In addition to the hook and eye straps, a buckle strap (Part No. 6003226) must be fitted

for transportation in vehicles, see fig 1.

5. Invacare recommend the 4 point tie down system with karabinas should be used to secure your chair

within the vehicle (see Fig 2,3 and 4).

6. When attaching the tie-downs to the Powerchair, it is imperative they are fixed onto the Tie-down

points only of the Powerchair (see fig 3 and 4) and not onto any attachments or accessories (wheels,

castors, footrests, armrests, anti-tipping levers etc.)

7. If your Powerchair has a headrest it should always be used during transportation. Your Spectra Plus™

Powerchair MUST be fitted with a headrest, metal buckle lap belt and transport strap to be used during

transportation. For advice or to purchase these items contact Invacare or your local dealer.

8. During transportation it is essential that you are secured by three point lap and diagonal occupant

restraint system, which is anchored to the vehicle wall and floor rails. Powerchair lapbelts can be used

in addition to the three point restraint system but must not be considered as an alternative to the

occupant restraint system.

9. Invacare recommend the Gemini System with 4-Point Heavy Duty Webbing Tie-Down System with

Karabina should be used to secure your chair within the vehicle, these restraints are available from

Unwin Safety Systems (based in UK TA12 6EY, Tel:+44(0) 1935 827740,

http://www

.unwin-safety.com).

The following system is recommended for use:

4 Point Gemini Wheel Chair Restraint with Karabiners: SWR / 09

3 Point Double Inertia System: QIR / 3H / ATF / FA / WH

Heavy Duty ‘D’ Rings: QB 20 / 2 / 1589

26

Fig. No.3

Fig. No.4

From tie-down point

Rear tie-down point

!

OPERATION - REMOVAL (Switch OFF the Controller)

TRAY ASSEMBLY

FITTING - OPERATION INSTRUCTIONS

IMPORTANT: ENSURE THAT THE JOYSTICK CONTROL UNIT IS SWITCHED OFF BEFORE

FITTING, REMOVING OR ADJUSTING THE TRAY ASSEMBLY.

The tray assembly comes ready assembled and is designed to fit to either the left or right hand side of

the wheelchair.

The cut-out section is to accommodate the Joystick Control unit and determines which side the tray is

fitted i.e. Joystick Control fitted to the right hand side, therefore the tray fixings will be fitted to the left

hand side, and vice-versa.

Follow these simple instructions to fit:-

1. Remove the two screws A holding the arm pad to armrest support tube B.

2. Fit the slide mounting tube C beneath the armrest support tube using the existing screws, (see

diagram). Tighten the screws securely, (do not over tighten as this will damage the T-nut inserts

within the arm pad).

3. Loosen the wing screw D and slide the tray support tube extension into the slide mounting tube C.

4. With the occupant seated in the chair, adjust the tray to a comfortable working position, tighten

wing screw D.

5. Side to side lateral adjustment can be achieved by loosening the 4 screws E and sliding the tray

surface to the required position.

6. Ensure the tray is firmly positioned, level and central to the occupant’s requirements.

OPERA

TION - REMOVAL (Switch OFF the Controller)

The Tray can be placed to the side or removed completely to allow the occupant to get in and out of the

chair safely.

To do this, loosen the wing screw D, lift the tray and place to the side of the chair or remove completely

by pulling the tray assembly forward.

Do not attempt to drive the chair with the tray placed to the side as this may be hazardous to the

occupant and other people.

27

Fig 2.

Line up the

support rail with

the holes in the

backrest as

shown in Fig 2

Fig 1.

With the longer screws provided attach the

support rail to the backrest through the flanges

into the screw inserts. Do not screw into the

backboard. Tighten securely, but do not

overtighten as this may damage the screw-

threaded inserts.

With the support rails secured, slide the lateral

support into the support rail from the bottom.

Adjust to the occupant’s requirements and firmly

tighten the hand wheel (B).

LATERAL SUPPORT

FITTING INSTRUCTIONS

THE LATERAL SUPPORTS CAN ONLY BE FITTED TO THE FIRM UPHOLSTERED BACKREST

ASSEMBLY (VISCOUNT SEATING).

To attach the lateral supports to the back of the backrest assembly follow these instructions.

Remove the existing pan-head screws from the top of each flange shown in Fig 1. Marked (A). The

lower screws of each flange remain in place.

With the longer screws provided attach the

support rail to the backrest through the flanges

into the screw inserts. Do not screw into the

backboard. Tighten securely, but do not

overtighten as this may damage the screw

threaded inserts.

With the support rails secured, slide the lateral

support into the support rail from the bottom.

Adjust to the occupant’s requirements and firmly

tighten the hand wheel (B).

28

MAINS

SOCKET

CHARGER

CONTROLLER

FRONT

CHARGING BATTERIES

The battery charger supplied with the wheel chair was developed to charge the batteries fitted to these

products. Using alternatives will damage the batteries which are fitted as standard and invalidate the

warranty on these components.

The charger and electronic controller are designed to prevent the wheelchair operating during the charging

process.

Refer to the operating instructions supplied with the battery charger for a detailed description of the battery

charging.

If the mains lead needs to be extended, make sure an approved adaptor is used. DO NOT extend the

charger lead to the chair.

Ensure that both battery charger leads are safely routed so that they cannot be tripped over. When

charging is completed, safely stow the leads away to avoid danger when driving away.

BATTERIES

The batteries fitted as standard to the wheelchair are sealed ‘Gel’ batteries and therefore cannot be spilled

like conventional ‘wet’ batteries. Keeping the chair working to its maximum potential means that the

batteries must be cared for and correctly charged. Nightly re-charging is necessary if the chair has been

used during the day to ensure that the chair is ready for use the following day. A separate booklet is

supplied as a guide to the care and performance of the batteries and charger.

Powered wheelchair batteries do not maintain a constant full battery charge level as an automobile

battery; therefore, a shorter battery life can be expected. For maximum battery life maintain batteries as

described.

Plug the charger plug into the charger socket at the front of the controller for the PILOT INTEGRAL and

the PILOT+ controller and into the rear of the DYNAMIC DL controller as shown in the relevant diagrams.

29

BATTERY CONNECTIONS

The chair is fitted with two maintenance free „Gel“ batteries. For battery replacement we recommend to

contact your authorised INVACARE dealer in order to ensure that replacement batteries are of the correct

type and specifications, and that they are correctly installed and connected.

A diagram showing the correct wiring connection is available on the inside of the front and rear battery box

lid. It is of the utmost importance that the battery connections are wired as shown in these diagrams. Pay

attention to ensuring all connections are tightened correctly.

Pollution fr

om improper disposal

Have your batteries installed by a properly trained powerchair technician. Used batteries must NOT be

disposed of by means of a Domestic Refuse Disposal Unit (Dustbin) etc. All used batteries should be

recycled through an approved source. Please contact your authorised INVACARE dealer for correct

advice.

30

KEEPING YOUR CHAIR IN GOOD CONDITION

Your powerchair will benefit from periodic inspection, adjustment and replacement of worn parts. Regular

maintenance will enhance:-

• Reliable performance.

• Safety.

• Extended battery life.

• Confidence in operation.

• Low operating costs.

You can help keep your chair in good condition by following a simple guide to home maintenance.

CHROME/P

AINTWORK

This should be dried after contact with moisture. Clean once a month with a good quality auto-wax. Do not

use abrasive cleaners such as chrome cleaner or scouring cleaners as these will scratch the finish.

Do not store your chair in damp conditions.

UPHOLSTER

Y

The upholstery on the powerchair is vinyl or „Plush“ cloth material. Occasionally wipe with a damp cloth

moistened with soapy water. DO NOT use abrasive or chemical cleaners as this may damage the fabric

or vinyl coating.

Vinyl upholstery will become hard and prone to cracking if the special coating, which is applied to maintain

flexibility is removed by the abrasive, chemical cleaners or solvents.

Ultra-violet light can also reduce the life of the upholstery coating. This is a normal ageing process,

necessary precautions should be taken to guard against periods of long-term exposure to sunlight.

The result of these conditions cannot be covered by the specified warranty period.

BA

TTERIES

Keep your batteries well charged (see ‘advice on batteries and battery charging’ booklet). Keep batteries

in a dry, frost-proof place. Be sure battery terminals remain tight and not corroded.

FOOTRESTS

Footrests are easily adjusted for height, clamp nuts must be securely tightened. Do not stand on the

footplates.

CABLES AND CONNECTIONS

On a weekly basis, inspect all plug connections to be sure they are securely attached. A visual inspection

is usually adequate.

Ensure locking safety catch operates correctly and secures motor plugs.

Inspect all wires for worn insulation. If any are found they should be replaced immediately. Make sure

cables and wires are secured, and that they are routed away from any moving parts.

TYRES

Check the tread on your tyres regularly. Tyre pressure - inflate to recommended pressure as indicated in

the technical information section. Do not exceed the maximum air pressure indicated on the tyre.

Moulded tyres do not require pneumatic pressure, check periodically for wear.

31

DO NOT OVER

continuously for

DRIVE WHEEL

The dis-engage

Recommended

Remember that

unnecessarily re

CONTROLLER AND CHARGER

Servicing of the controller and charger should only be carried out by your local approved

dealer.

Do not attempt to open the units. Broken seals will invalidate the warranty.

BRAKES

WE STRONGLY RECOMMEND EVERY 6 MONTHS TO CHECK THE FUNCTION OF THE

ELECTRONIC BRAKES AND WHEEL - LOCKS ADJUSTMENT. ( THIS SERVICE MAY

NOT BE FREE OF CHARGE ).

MOTORS

The motors are fitted with long life brushes. These should be inspected for wear at twelve

months or more frequently if you use the chair daily for long periods. The brushes should

be replaced when they have worn down to 8mm in length.

DO NOT OVERLOAD THE MOTORS IN PROLONGED STALL CONDITIONS. If the chair is used

continuously for long periods, pause periodically to allow the motors to ‘cool down’.

DRIVE WHEELS

• Check that the control box is switched ‘on’, the display will be illuminated and remain

stationary.

• Check that both motors are engaged.

• Check that the main controller cable is firmly pushed ‘home’.

• Do not move the joystick until the display is illuminated.

IF THE WHEELCHAIR PULLS TO ONE SIDE

• Check that the motors are fully engaged.

• Check that pneumatic tyres are inflated to correct pressure.

• Check that the castors move freely, and there is no free play at castor stem.

• Check joystick drive function is in line with the left and right response. One motor may be

unplugged.

If your chair still has a problem after making these checks, please contact your authorised

INVACARE dealer.

32

The dis-engage facility is simple to operate following the recommended instructions.

Recommended correct use will maintain safety and ease of operation.

FAULT FINDING

Remember that most power drive problems are battery related. Sometimes expensive components are

unnecessarily replaced when in fact the problem was batteries.

If an electrical problem exists, always check the batteries first, also check cable

connections for good contact. The electronics involved in the controller and lift and recline

modules are quite sophisticated:- electronic repairs should be carried out by trained

personnel.

IF YOUR CHAIR WILL NOT ST

ART

29

DAILY WEEKLY MONTHLY 6 MONTHLY YEARLY

BATTERY CAPACITY

★★★

BATTERY TERMINALS

★★★

JOYSTICK OPERATION

★★

JOYSTICK LOCATION

★

SEAT BELT CONDITION

★ ★★★★

TYRES AND PRESSURE

★★

FOOTREST LOCATION

★★★

ARMREST LOCATION

★★

FRONT CASTORS

★

PLUGS AND SOCKETS

★★★

UPHOLSTERY CONDITION

★

BRAKE FUNCTION

★★

MOTOR BRUSHES

★★

MOTOR DISENGAGE

★★★

FRAME CONDITION

★★

MAINTENANCE SCHEDULE

Recommended 6 monthly service checks to be carried out by an

authorised INVACARE dealer.

SPECTRA PLUS

TECHNICAL INFORMA

TION

DIMENSIONS:

Seat Width: 38cm - 46cm

Overall Width: 55cm

Overall Length: 100cm

Height: 89cm

Total Weight: 70kg

Battery Weight: 30AH - 11.7kg 40 AH - 14.8kg

Maximum Carrying Capacity: 18stone (114.3kg)

Tyre Size - Front 312mm x 50mm - (12%” x 2%”)

Tyre Size - Rear 200mm x 50mm - (8“ x 2“)

Maximum Permissible Incline: 12 - 20% - 1 in 5

Speed: Variable up to 4mph (6kph)

Tyre Pressure - (REAR) Min 35psi (238kpa) Max 40psi (272kpa)

Recommended maximum tyre pressure is indicated on the side wall of the tyre.

BATTERY OPTIONS: 2 x 30ah Sonnenschein A512/30 Gel or equivalent

2 x 40ah Sonnenschein A512/40 Gel or equivalent