SHAPE SENSOR USER MANUAL

SPECIAL NOTES

S

P

E

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices which could result in personal injury or property damage.

C

I

A

L

N

O

T

E

S

As regards restraints - seat belts - it is the obligation of the DME dealer, therapists

and other health care professionals to determine if a seating restraint is required to

ensure the safe operation of this equipment by the user. SERIOUS INJURY CAN OCCUR IN THE EVENT OF A FALL FROM A SHAPE SENSOR.

It is also Invacare’s position that the SHAPE SENSOR be in a proper transport position and secured before transporting the shape sensor in a vehicle of any type.

NEVER transport the back sensor panel unless it is locked in the retracted position

or the back sensor panel removed and position standing up or on its side. DO NOT

position the back sensor panel on its front side (w/printed grid).

When transporting the shape sensor, ALWAYS loosen the clamp blocks at the front of

the frame and fold the support legs.

SPECIAL NOTES

NOTICE

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING AND UNDERSTANDING THIS MANUAL. IF YOU ARE UNABLE TO UNDERSTAND THE

WARNINGS AND INSTRUCTIONS, CONTACT AN INVACARE REPRESENTATIVE BEFORE ATTEMPTING TO USE THIS EQUIPMENT - OTHERWISE INJURY OR DAMAGE MAY RESULT.

98-110

2

SAFETY SUMMARY

SAFETY SUMMARY

WARNINGS

DO NOT use unauthorized parts, accessories, or adapters other than authorized by

Invacare.

Both gas cylinders MUST be operational and adjusted properly BEFORE using adjustable back. DO NOT operate the adjustable back if only one (1) of the gas cylinders

is operational or adjusted properly.

Extreme caution is advised when it is necessary to move an UNOCCUPIED shape

sensor. Invacare recommends using two (2) assistants and making thorough preparations. Make sure to use ONLY secure, nondetachable parts for hand-hold supports. DO NOT attempt to lift the Shape Sensor by the seat sensor, back sensor,

armrests, or legrests. Use the base frame for lifting purposes. Lifting by means of

the removable (detachable) parts of a Shape Sensor may result in injury to the

assistants or damage to the Shape Sensor.

Before attempting to transfer in or out of the Shape Sensor, every precaution should

be taken to reduce the gap distance. Turn both casters toward the object you are

transferring onto. When transferring to and from the Shape Sensor, ALWAYS ENGAGE BOTH WHEEL LOCKS. NOTE: This activity may be performed independently

provided you have adequate mobility and upper body strength.

A NOTE TO WHEELCHAIR ASSISTANTS

When assistance to the client is required, remember to use good body mechanics.

Keep your back straight and bend your knees.

S

A

F

E

T

Y

S

U

M

M

A

R

Y

ALWAYS engage both wheel locks while changing the orientation of the Shape

Sensor modules.

When adjusting the seat depth, make sure the adjustment knobs are securely locked

in place.

To maintain stability and safety, make sure the client is properly positioned in the

Shape Sensor before reclining or inclining (reverse recline).

When adjusting the back angle, DO NOT remove the back angle adjustment knobs,

as they help secure the back sensor to the frame.

When returning the client in the Shape Sensor to the full upright position, more body

strength will be required for approximately the last twenty (20) degrees of incline

(reverse recline). Make sure to use proper body mechanics (use your legs) or seek

assistance to avoid injury.

The Shape Sensor has a weight limit of 300 lbs.

3

98-110

TABLE OF CONTENTS

TABLE OF CONTENTS

T

Special Notes........................................................................................................................... 2

A

Safety Summary ...................................................................................................................... 3

B

L

Introduction to the Manual ...................................................................................................... 5

E

Quick Start ............................................................................................................................... 5

O

F

History ..................................................................................................................................... 5

C

Appropriate Applications of the T echnology .......................................................................... 7

O

N

T

E

N

T

S

Client Profiles and Disability Types......................................................................................................... 7

T erminology and Parts Description ........................................................................................ 8

Unpacking and Assembly ....................................................................................................... 9

Transporting ...........................................................................................................................11

Locking the Back Sensor Panel ........................................................................................................... 11

Transporting a disassembled Shape Sensor ........................................................................................... 12

Transporting an Assembled Shape Sensor .......................................................................................... 12

T ransfers................................................................................................................................ 13

Independent......................................................................................................................................... 13

With a Sliding Board ............................................................................................................................ 13

With a Mechanical Lift Aid .................................................................................................................... 13

Stand and Pivot ................................................................................................................................... 14

Two Person Lift ................................................................................................................................... 14

Creating a Silhouette® System .............................................................................................. 14

Commonly Asked Questions ................................................................................................ 21

T roubleshooting.................................................................................................................... 22

Technical Notes ..................................................................................................................... 22

98-110

4

INTRODUCTION

INTRODUCTION TO THE MANUAL

A user centered approach is needed to meet the

unique needs of each individual. The use of this

manual requires that the clinician have an understanding of their own needs as well as the clients

they are serving. Individuals with good clinical skills

may find the sections on “Orienting the client on the

surfaces” to be common sense and be totally baffled

by some of the more technical aspects. The

“techies” may shy away from manipulating

someone’s pelvis with their hands, but be right at

home electronically digitizing these same surfaces.

The “Quick Start” section will allow those with previous Silhouette

sary steps to successful completion of a system. It

can also be used by everyone as a checklist to make

sure steps and information are not left out of the

process.

The clinician has a responsibility when using

the Silhouette

involved, not just a product. This process allows for increased flexibility and versatility , but

if not fully understood and practiced, it can lead

to misapplication.

Please read this manual at least once, cover to

cover. Do this before the first client arrives! Hopefully, most of your questions will be answered, but if

they aren’t, call the customer service staff at

Invacare (1-800-451-3553).

Good luck using the Silhouette

®

experience to confirm the neces-

®

System as there is a process

®

system!

QUICK START

1. Lock castors at the rear of the frame.

2. Check the seat and back surfaces for flatness

and plunger position.

3. Lock the back sensor panel. Depress the handle

and pivot forward.

4. Set and lock the seat depth. (Makes sure both

pointers read the same.)

5. Set and lock the back angle.

6. Apply data forms to the data panels.

7. Insert data forms into receiving channels.

8. Take baseline for seat and back.

9. Transfer client to Shape Sensor.

10. Orient client on Shape Sensor surfaces.

QUICK START (CONTINUED)

11. Readjust surfaces to fit client.

12. Adjust footrests and armrests.

13. Stabilize client and pull back sensor lever forward.

14. Modify back shape to fit client (scapula, lateral

trunk, etc.).

15. Record seat and back shape.

16. Confirm measurements for seat depth/tilt, back

height/angle.

17. Transfer client off of Shape Sensor.

18. Remove the data panels.

19. Record serial numbers onto order form.

20. Determine necessary modifications/options and

fill in order form. (cushion density, cushion cover,

rail cuts, leg length discrepancy, solid insert, lateral supports, headrest, pelvic strap, Performance™.)

21. Determine interfacing.

22. Complete order form.

23. Fax or modem in order.

HISTORY

In the late 1980’s the National Institute on Disability

and Rehabilitation Research (NIDRR) provided grant

funds to the University of Virginia’s Rehabilitation Engineering Center to study the usefulness of custom

contoured cushions by individuals with a spinal cord

injury. This research was conducted primarily by

Drs. Steven Sprigle and Kao-Chi Chung along with

Tom Faisant RPT.

The results of this research showed that custom

contoured foam cushions provided statistically lower

pressure distributions than the clients’ usual cushions. Along with a decrease in pressure, the authors felt that improvements in posture and balance

were also realized. The researchers used an array

of 64 spring loaded plungers that were fitted with

linear potentiometers. When a client sat upon the

array of sensors, the amount of displacement at

each point was recorded by computer. The data

was later used to fabricate a cushion through the

use of a three-axis milling machine that carved a

block of HR (high-resilience) foam. This electronic

shape sensing system and computer assisted

manufacturing process was the start of the Silhou-

®

ette

System used today.

I

N

T

R

O

D

U

C

T

I

O

N

5

98-110

HISTOR Y

H

I

S

T

O

R

Y

FIGURE 1 THE ORIGINAL ELECTRONIC

SHAPE SENSOR

HISTORY (CONTINUED)

High quality polyurethane foam was chosen for custom carving because of its low cost, low

maintenance,and dynamic qualities. Pressure

against the foam is equalized due to the contouring

of the surfaces which makes fatiguing of this material less of an issue. Beta site testing was conducted

at five separate facilities to help prove the effectiveness of this technology. The centers included: The

Institute for Rehabilitation and Research, Houston

Texas; Helen Hayes Hospital, West Haverstraw, NY;

Newington Children’s Hospital, Newington, CT; National Rehabilitation Hospital, Washington, DC;

Rancho Los Amigos Medical Center, Downey, CA.

Some of the results of this Beta site testing were

presented by Anita Perr OTR/L, Andrew Lincoln, MS,

and Thomas McGovern, MS, from the Rehabilitation Engineering center of the National Rehabilitation Hospital. The conclusion of their study was that

the Silhouette

from the users ishial tuberosities, an area prone to

tissue breakdown, to the thighs, an area better suited

for weight bearing.

Invacare saw the potential for this technology as a

natural progression of the company’s already strong

focus on customized contoured seating, and technology transfer process was initiated. The electronic

shape sensing apparatus, along with the necessary

computer interface and software made this technology difficult and expensive to apply. A group of

people, including Colin Mclaurin, Clifford Brubaker,

Dave Brienza, Stephen Springle, Peter Axelson,

Michael Heinrich, Eric-Jan Ginder and Michael

Silverman worked to develop a relatively low cost

and simple process.The idea was to change

®

cushion effectively shifted pressure

FIGURE 2 THE MECHANICAL SHAPE SENSOR

the electronic sensing unit (Figure 1) into a mechanical measuring device that could be interfaced to a

central computer using simple paper forms. The individual would still sit upon a blanket of individual

plungers, but their position would be recorded mechanically in a manner similar to a credit card imprinter. When a plunger is moved, it pushes a cable.

This cable is attached to a pointer whose position is

recorded when a pressure roller is moved across its

surface. The pointer presses against a carbonless

form making a mark that corresponds to the depth of

the plunger at that location. The imprinted form can

be then faxed to a central location where it is digitized

to produce the custom contoured cushion.

The first mechanical shape sensors (Figure 2) were

designed to record only the shapes of seat cushions. The technology quickly proved its worth and

was expanded to include a back sensing panel.

When a client is seated on a Shape Sensor, gravity

is the only force necessary to produce the seat contour. Gravity can’t be used to form the back cushion, and a mechanism was developed that gently

pushes the plungers around the individuals back.

Along with the development of the Shape Sensor,

Invacare has created software (SeatMaker), interfacing hardware, and the machinery used to produce the cushions. A good idea has become a complete system.

98-110

6

APPROPRIATE APPLICA TIONS OF THE TECHNOLOGY

FIGURE 3 ACTIVE USERS BENEFIT FROM

ENHANCED STABILITY

APPROPRIATE APPLICATIONS OF

THE TECHNOLOGY

The first step in producing a Silhouette® System is determining if the client is an appropriate candidate. The

following information on disability types and

contraindications is meant only as a general guideline. The decision whether or not to proceed with

this technology requires that the clinician have sufficient background information and a solid understanding of the clients physical needs. A mat evalu-

ation should always precede the fitting of the

client in the Shape Sensor. This assessment will

help determine the basic parameters of the support

surfaces.

Arthritis

Spina Bifida

Geriatric

Multiple Sclerosis

Muscular Dystrophy, early stages

Contraindications

Open skin ulcers (unless the client, clinician, and

caregivers have carefully designed the cushions surface to reduce pressure in this area, are able to carefully monitor the wound site, and understand that

the cushion may require additional modifications or

replacement.)

High, or fluctuating tone that would collapse

the cushions support surfaces.

Severe orthopedic complications that require

maximum support and accommodation.

Significant effort is required during the simulation to

maintain the client in the desired posture. The support to the client that is provided by the clinician should

be gentle in nature and able to be maintained during

the recording process.

The client can not shift their position independently or

be placed within the seating system consistently by

caregivers.

The client is either too large or too small to fit on the

Shape Sensor.

A

P

P

R

O

P

O

R

F

I

A

T

T

E

E

C

H

A

N

P

O

P

L

L

O

I

G

C

Y

A

T

I

O

N

S

Client Profiles and Disability Types

Seat only

The seat cushion can promote stability and balance,

(Figure 3) and provide good pressure relief for individuals with the disability of:

Paraplegia

Quadriplegia, low level

Amputee

Seat and back

A system will provide a pressure relieving seat cushion that promotes stability and balance, along with a

back cushion that supports and aligns the trunk.

This can be used by individuals who have the disability of:

Quadriplegia, low/high level

Cerebral Palsy, mild-moderate

CVA

7

98-110

TERMINOLOGY AND PARTS DESCRIPTION

M

O

O

G

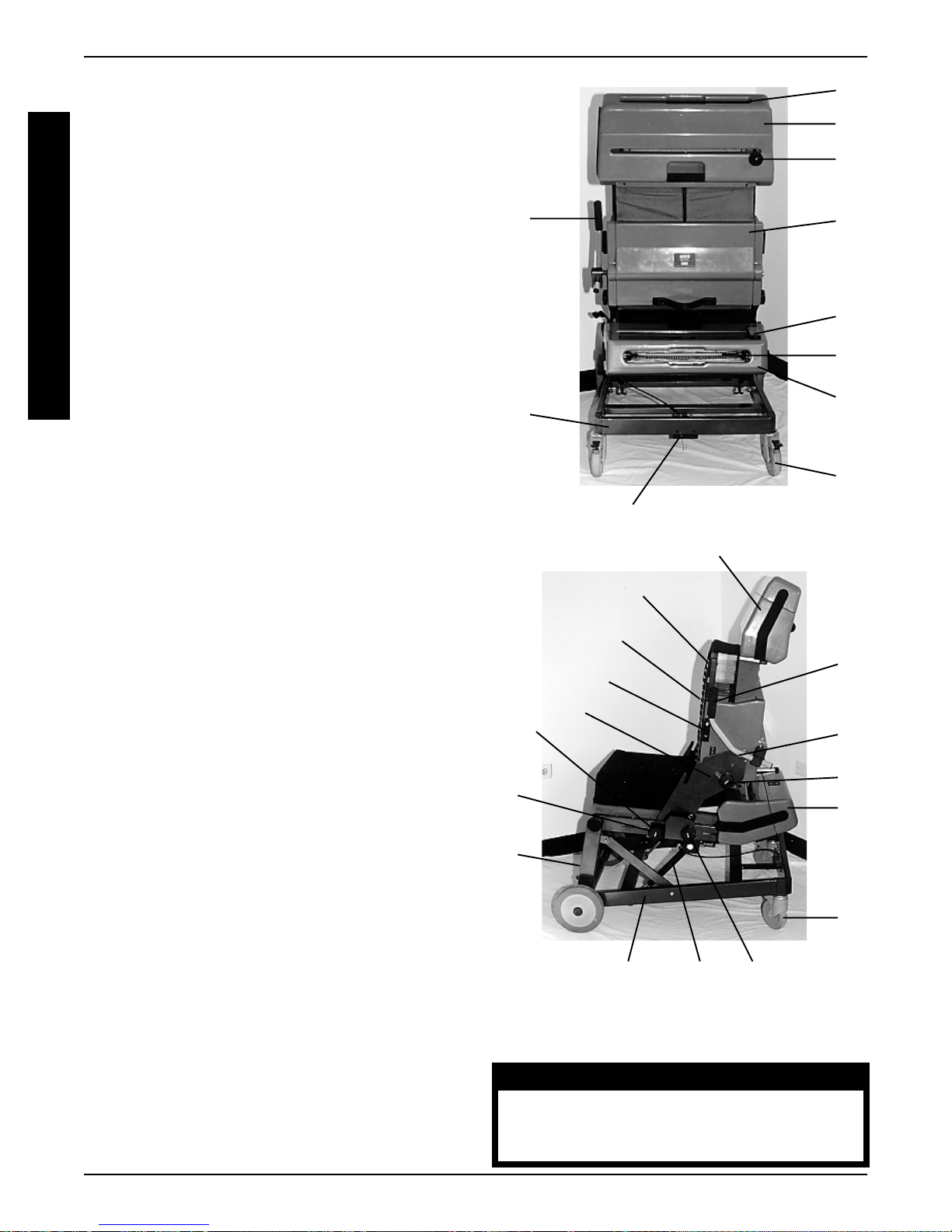

TERMINOLOGY AND PARTS DESCRIPTION (FIGURE 1)

P

A

T

E

R

I

N

L

Y

A

N

D

A. Armrest Receiving Sockets. The armrest receiv-

R

ing sockets are located on the left and right side plates.

T

These sockets act as receptacles for the armrests.

S

The height of the arm rest is adjusted by loosening

D

and tightening the knob attached to this receptacle.

E

The armrests index into the receiving sockets and can

S

provide a surface that the client can use to reposition

C

R

themselves or to help with balance and pressure re-

I

lief. The armrests are height adjustable.

P

T

B. Back Angle Adjustment Knobs. These knobs

I

are used to change the back to seat angle. The back

O

angle adjustment knobs travel in these slots providing

N

angle adjustability to the back.

S

G

K

N

D

H

Q

K

R

L

C. Back Grid. This grid is printed on the back sensor

panel to assist with determining back height and client

symmetry.

D. Back Imprint Handle. This handle is located at

the top of the back sensor panel and is used to move

the imprinter across the data panel. This handle

screws into the imprinter.

U

H

I

E. Back Location Pointers. These blue pointers are

located on the left and right side plates, just forward of

the armrest sockets and are used to help align the back

sensor panel. The pointers should read the same number on each side before locking the back sensor panel

into position. The location of these pointers is a critical

part of the requested information on the order form.

F . Back Pivot Pins. The back pivot pins are found on

both sides of the back sensor panel and are used to

suspend the back within the side plate receiving

notches.

G. Back Sensor Lever. This lever is located on the

left side of the back sensor panel and is used to push

the back plungers forward. This lever has a secondary function that locks the back sensor panel in place.

H. Back Sensor. The back sensor panel contains

100 cable driven plungers that are used to capture the

shape of an individuals back.

I. Casters. These are the rear wheels which can be

locked to prevent rotation or rolling.

J. Clamping Blocks. The clamping blocks are located at the bottom front side of the frame and are

used to hold the folding legs into a locked position.

Data Forms. These are carbonless, pressure sensitive forms that attach to the data panels using self adhesive strips. There are separate forms for the seat

front and back. (Not Shown)

O

C

G

T

S

E

F

B

A

N

J

I

L

M

FIGURE 1 TERMINOLOGY AND PARTS

DESCRIPTION

P

WARNING

DO NOT use unauthorized parts, accessories, or adapters other than authorized by Invacare.

98-110

8

UNPACKING AND ASSEMBLY

K. Data Panel Receiving Slots. The data panels

are indexed into these slots to insure proper alignment

with the imprinters. The panels are clear plastic devices that hold the data forms within the imprinters.

These panels have short indexing pins that match

holes prepunched into the data forms. The panels are

fitted with a flexible handle to assist in removing them

from the receiving slots.

Footrests. The footrests attach to the front vertical

frame members and are held in place by friction. (Not

Shown)

L. Frame. The frame is the lower tubular portion of

the Shape Sensor.

M. Gas Cylinders. The gas cylinders are used to

change the tilt angle of the Shape Sensor. They are

lockable anywhere along their travel, giving an infinite

adjustment range between 0-20 degrees.

WARNING

Both gas cylinders must be operational and

adjusted properly BEFORE using adjustable

back. DO NOT operate the adjustable

back if only one (1) of the gas cylinders is

operational or adjusted properly.

N. Imprinters. These devices are located within the

back and seat sensor panels and are used to record

the position of the plungers onto the data forms. They

operate in a similar fashion as a credit card imprinter.

Plunger Caps. Each plunger is attached to a cable

using a snap fitting cap. The end of the cable is shaped

like a ball with the cap formed as the receptacle. These

caps are replaceable if necessary. (Not Shown)

S. Side Plates. The side plates are used to connect

the back sensor panel to the seat sensor panel. They

slide into the slotted seat rails and are made in a left

hand and right hand configuration.

T. Stop Blocks. The stop blocks are black plastic

components located on both sides of the back sensor

panels. These blocks are used to help store the back

in a forward folded position. The stop block on the left

side also controls the back sensor lever’s forward position.

U. Tilt Adjustment Lever. The tilt adjustment lever is

located at the bottom rear of the frame. This lever

controls the tilt angle of the Shape Sensor. The lever

is retractable, allowing it to be stored underneath the

frame.

UNPACKING AND ASSEMBLY

Note: Please refer to the “Terminology and Parts Description” portion of this manual to assist in identifying

the components referred to in this section.

Unpacking

The Shape Sensor will come shipped in three boxes.

These boxes should contain the following:

1. The lower frame

2. The back sensor panel

3. The seat sensor panel

4. Two data panels (clear plastic panels with handles)

5. One back sensor panel handle

6. Two pins for attaching the gas cylinders

7. Data forms for the seat

U

N

P

A

C

K

I

N

G

A

N

D

A

S

S

E

M

B

L

Y

O. Plungers. The plungers consist of a section of

cable and the snap fitted caps. There are 100 plungers for the seat and 100 plungers for the back. They

are located 1.75” apart and move approximately 4”.

P . Seat Depth Adjustment Knobs. Are located on the

side plates directly behind the armrest sockets. They

lock the side plates into the slotted seat rail and control

the placement of the back sensor panels position.

Q. Seat Imprint Handle. This is a flat handle located

at the rear of the seat sensor and is used to move the

imprinter across the data panel.

R. Seat Sensor. The seat sensor panel consists of

100 cable driven plungers housed within a section of

segmented foam. This component is used to capture

the shape of an individuals seat.

8. Data forms for the back

9. One pair of footrests

10. One pair of armrests

11. Two Side plates ( left and right)

12. Two back angle adjustment knobs

To remove the contents first open the boxes and lay

them on their sides. Slide the components out of the

boxes and make sure you have all of the parts listed

above before discarding the packing materials.

9

98-110

ASSEMBLY

Assembly

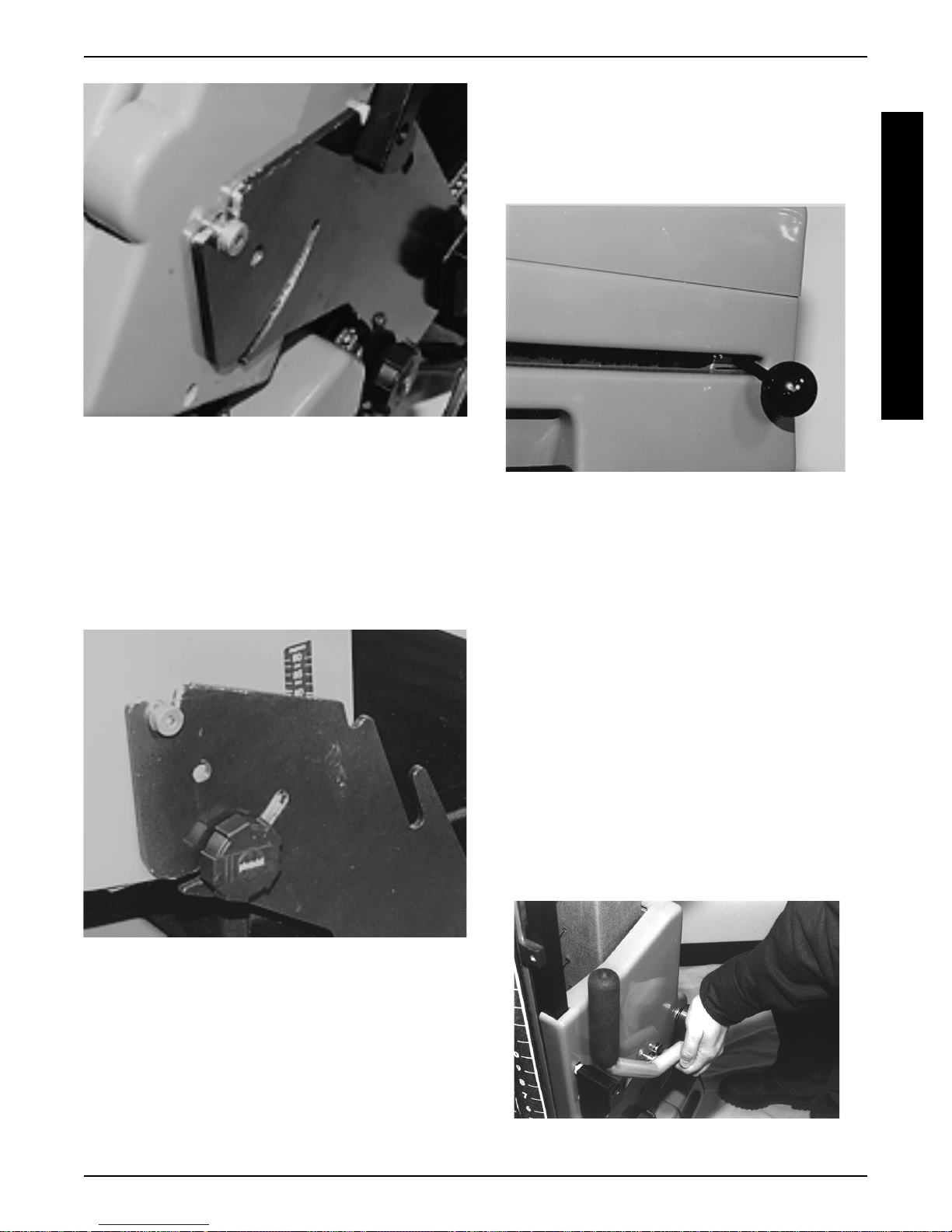

1. Install the gas cylinder clevis pins through the frame

clevis and gas cylinder receiving sockets (Figure

1).

A

S

S

E

M

B

L

Y

FIGURE 1 INSERTING THE CLEVIS AND HAIR

PINS

2. Lock the pins in place using the hairpin clips (Figure 2).

FIGURE 3 ASSEMBLED BASE FRAME

6. Lock the rear wheel castors.

7. Carefully lift the seat sensor panel (using the provided handle) and position the forward locking clips

under the front horizontal support bar. Make sure

the rear rubber bumpers are seated forward of the

rear horizontal support bar (Figure 4). The seat

sensor panel is not overly heavy (46 pounds) but

its overall size (25” x 32” x 9”) can make handling

the unit somewhat awkward until the process of

assembly has been practiced a few times. Please

be cautious and practice good body mechanics when lifting this component into place.

FIGURE 2 TIGHTENING THE CLAMP BLOCKS

3. Position the round lower frame tube underneath

the two semicircular clamp blocks and tighten

down the clamping knobs.

4. Install the left and right side plates into the slotted

seat rails with the blue pointer positioned at the

front of the frame.

5. Tighten down the adjustment knobs on these side

plates so both pointers are locked at the #18.

98-110

FIGURE 4 REAR RUBBER BUMPERS

8. Carefully lift the back sensor panel and place the

backs pivot pins into the side plate receiving

notches (Figure 5). This may require two people

as the back sensor is slightly larger and heavier

than the seat. Use the provided handles and once

again practice good body mechanics.

10

FIGURE 5 ALIGNING THE PIVOT PINS

TRANSPORTING

12. Install the Back Imprint Handle into the threaded

hole on the back imprinter (Figure 7). Be careful

not to cross thread the handle while screwing it

into place. The handle should screw easily into the

threaded receptacle.

T

R

A

N

S

P

O

R

T

I

N

G

9. Install the back angle adjustment knobs through

the back angle adjustment slots into the threaded

receivers mounted on the back sensor panel (Fig-

ure 6). Tighten these knobs to position the back

at the 95 degree angle mark.

FIGURE 7 INSTALLING THE BACK

IMPRINTER

TRANSPORTING

The Shape Sensor can be transported either fully assembled, or in parts. What method is chosen is dependent upon the type of vehicle to be used and if a

portable ramp is available. The Shape Sensor should

be secured in a manner that will prevent it from shifting

around while the vehicle is moving and from becoming a projectile if an accident should occur.

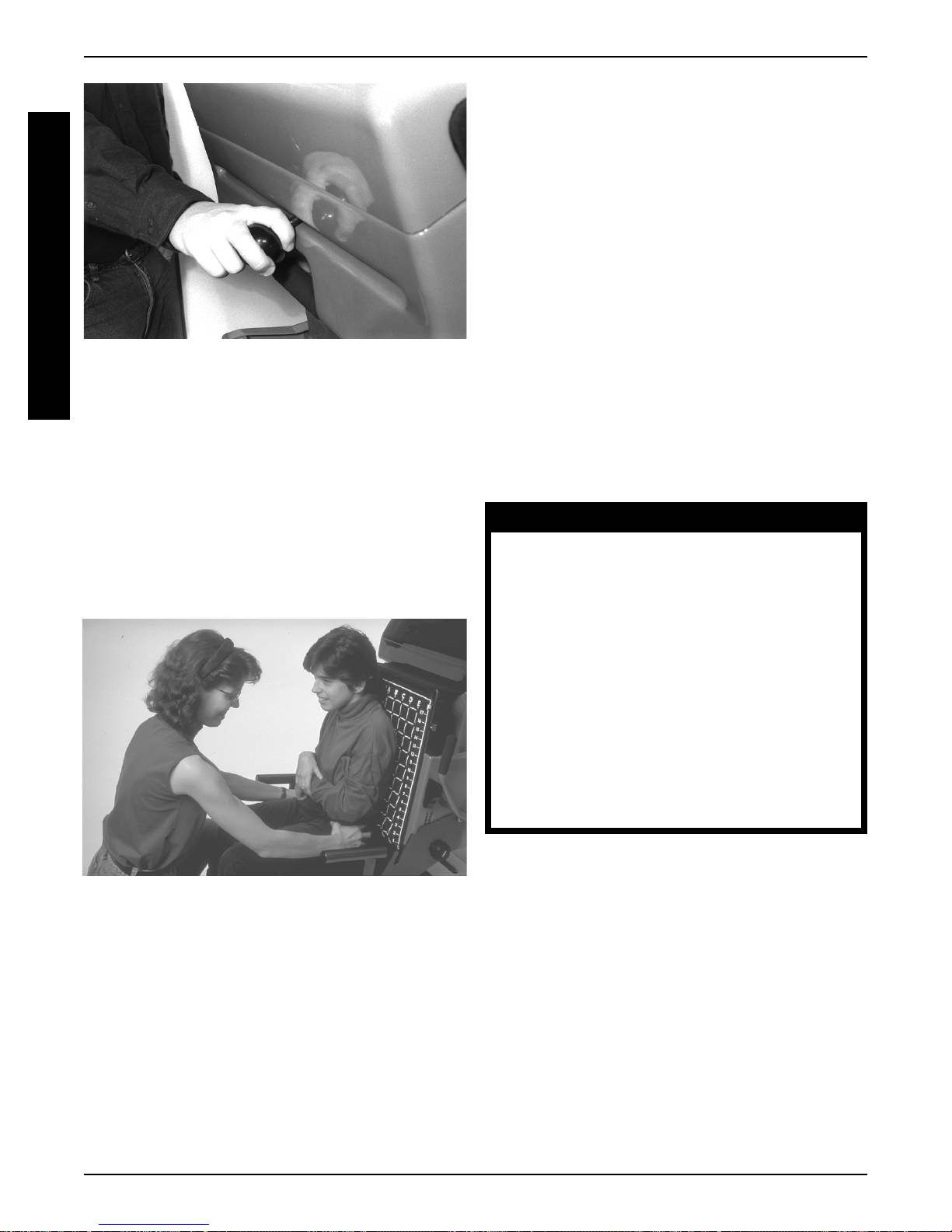

Locking the back sensor panel

Anytime a client is going to transfer onto the Shape

Sensor or whenever it is transported/disassembled,

the back sensor panel must be locked.

1. Make sure all of the plungers are flattened out and

that the back sensor lever is pushed all of the way

to the most rearward position (Figure 8).

FIGURE 6 INSERTING THE ADJUSTMENT

KNOBS

10. Install the footrests by placing them on the front,

vertical, frame tubes. The footrests hook around

these tubes and are held in place by friction.

11. Install the armrests by sliding them into the receiving sockets located on the left and right side plates.

Knobs are used to adjust the height of these armrests.

11

FIGURE 8 PUSHING IN THE SENSOR

LEVER

98-110

TRANSPORTING

2. Push the back sensor lever’s attaching block in-

wards towards the center of the back sensor panel.

T

This will release the handle from its plunger moving position into its locking position.

R

3. With the attaching block depressed, push the le-

A

N

S

P

O

R

T

I

N

G

ver forward until it rests against the stop block. The

handle should “pop” back out and lock the back

sensor into position. If the handle does not pop back

out, and the back sensor does not lock, then repeat the above steps.

Transporting a disassembled Shape Sensor

1. Lock the back sensor panel into its retracted

position (See above). Never transport or lift the

back sensor panel without it locked in the retracted

position (Figure 9)!

be stored as a complete unit or disassembled into

a more compact package. If the most compact

package is desired then proceed as follows:

6. (Optional) Loosen the clamp blocks at the front of

the frame and fold the support legs. When reassembling the frame make sure these clamps are

fully engaged.

7. (Optional) Remove the gas cylinder clevis pins and

fold the frame. Reinstall the pins into the clevis to

help prevent loss. Do not misplace these pins.

Transporting an assembled Shape Sensor

The Shape Sensor can be transported fully assembled

in a van. A ramp with a full width platform should be

used to make this process a safer procedure. The

back sensor panel can be folded forward or reclined to

improve access and handling. The method used will

be dependent upon the available head room in the van.

Folding the back sensor forward

1. Lock the back sensor panel (Page 10). Never

transport or lift the back sensor panel without it

locked in the retracted position!

FIGURE 9 ROTATING THE IMPRINT HANDLE TO

THE “LOCKED” POSITION

2. Depress the tilt adjustment lever and position the

Shape Sensor in the fully tilted position. Depressing the gas cylinders will help create the smallest

frame package.

3. Remove the back sensor and store it either standing up, or on its back side. Do not store the back

sensor on its front side (The side with the grid printed

on it.)

2. Place cardboard on the seat sensor to protect the

sensors. Loosen the back angle adjustment knobs

and rotate the back sensor panel forward (Figure

10) until the stop blocks index into the receiving

notches located on the front of each side plate.

FIGURE 10 FOLDING THE SENSOR FORWARD

3. Lift the back sensor upwards just enough to move

the stop blocks forward into the second receiving

notch (Figure 11). The stop blocks attaching bolts

will then rest into both receiving notches.

4. Remove both side plates.

5. Remove the seat sensor panel and store it either

standing up, or on its bottom side. The frame can

98-110

12

FIGURE 11 MOVING THE SENSOR TO THE

“FULL FLAT” POSITION

4. The back angle adjustment knobs can now be re-

moved and reinserted into the second threaded

receptacle to lock the back into position (Figure

12).

TRANSFERS

TRANSFERS

Care must always be taken whenever an individual

transfers onto or off of the Shape Sensor. The Shape

Sensor’s back panel and the rear castors must both

be locked before attempting a transfer. There are several methods of transfers, and what style is used should

be determined by the client and/or caregivers. The

ability to transfer can vary from total independence, to

total dependence. Never assist in a transfer unless

you are completely confident in your skills and solicit

any help needed to complete this important procedure.

When necessary, assist the client in moving across

the Shape Sensor’s seat so as not to disengage the

plunger caps. Once the transfer has been completed,

make sure that the client is stable and secure upon

the surfaces before letting them sit independently.

Independent

If the client normally performs independent transfers,

then the clinicians role is to help prepare/position the

Shape Sensor and “spot” the client during the process.

The client knows best how to prepare their own chair

and the clinician may be asked to remove or position

accessories.

T

R

A

N

S

F

E

R

S

FIGURE 12 REINSERTING THE KNOBS TO

LOCK THE SENSOR BACK

WARNING

Extreme caution is advised when it is

necessary to move an UNOCCUPIED

Shape Sensor. Invacare recommends

using two (2) assistants and making thorough preparations. Make sure to use

ONLY secure, nondetachable parts for

hand hold supports. DO NOT attempt

to lift the Shape Sensor by the seat sensor, back sensor, armrests, or legrests.

Use the base frame for lifting purposes.

Lifting by means of the removable (detachable) parts of a Shape Sensor may

result in injury to the assistants, or damage to the Shape Sensor.

1. Remove the footrests.

2. Remove whatever armrests the client requests.

Some clients may prefer that the armrest furthest

away from them be left in place as a point of stabilization and support. Other clients may require both

armrests be left in place.

3. Position yourself in a location that will allow you to

assist in the process if the client is experiencing difficulty. Keep close, but don’t inhibit the maneuver.

4. Reinstall footrests and armrests.

With a sliding board

Follow steps 1-3 above

5. Help keep the sliding board from moving away from

the support surfaces, and assist with its removal

when the transfer is complete.

With a mechanical lift aid

Only use a mechanical lift aid if you have been trained

in its operation and have all of the necessary components to safely complete the task. There should be

sufficient background information to determine if the

client remains seated on the sling at all times. Remove the footrests and armrests before starting the

transfer.

13

98-110

CREATING A SILHOUETTE® SYSTEM

Stand and Pivot

Only assist with this maneuver if you have been trained

C

R

in the process, and you have a second person avail-

E

A

able as a “spotter”.

T

I

N

Follow steps 1-4 above.

G

A

Two person lift

S

Once again, only perform this style of transfer if you

I

L

have been trained and understand the use of proper

H

O

body mechanics.

U

E

T

T

E

®

S

Y

S

T

E

M

Before attempting to transfer in or out

of the Shape Sensor, every precaution

should be taken to reduce the gap distance. Turn both casters toward the

object you are transferring onto. When

WARNING

transferring to and from the Shape Sensor, ALWAYS ENGAGE BOTH WHEEL

LOCKS. NOTE: This activity may be performed independently provided you

have adequate mobility and upper

body strength.

A NOTE TO WHEELCHAIR ASSISTANTS

When assistance to the client is required, remember to use good body

mechanics. Keep your back straight

and bend your knees.

gentle tug or push will put them back in place. With

the plungers as even as possible, accurate data

production can be assured.

FIGURE 1 CHECK FOR IRREGULARITIES

3. Lock the back sensor panel (Figure 2) by pressing in the handle and pulling it forward (Page 1 1).

CREATING A SILHOUETTE

®

SYSTEM

The process of creating a Silhouette® System is a combination of mechanical adjustments, measuring, client posturing, interfacing and paperwork. The Quick

Start guide (Page 5) is a condensed version of this

section and can be used as an easily accessible checklist once you have familiarized yourself with the following steps.

1. Lock the rear castors. The rear castors of the

Shape Sensor are equipped with a locking mechanism that stops the swiveling of the castor as well

as the wheels rotation. Depressing the lever on

top of the castor will lock it into position. The castors should be locked when a client is transferred

on or off of the Shape Sensor, the Shape Sensor

is disassembled, or surfaces or system orientation is adjusted.

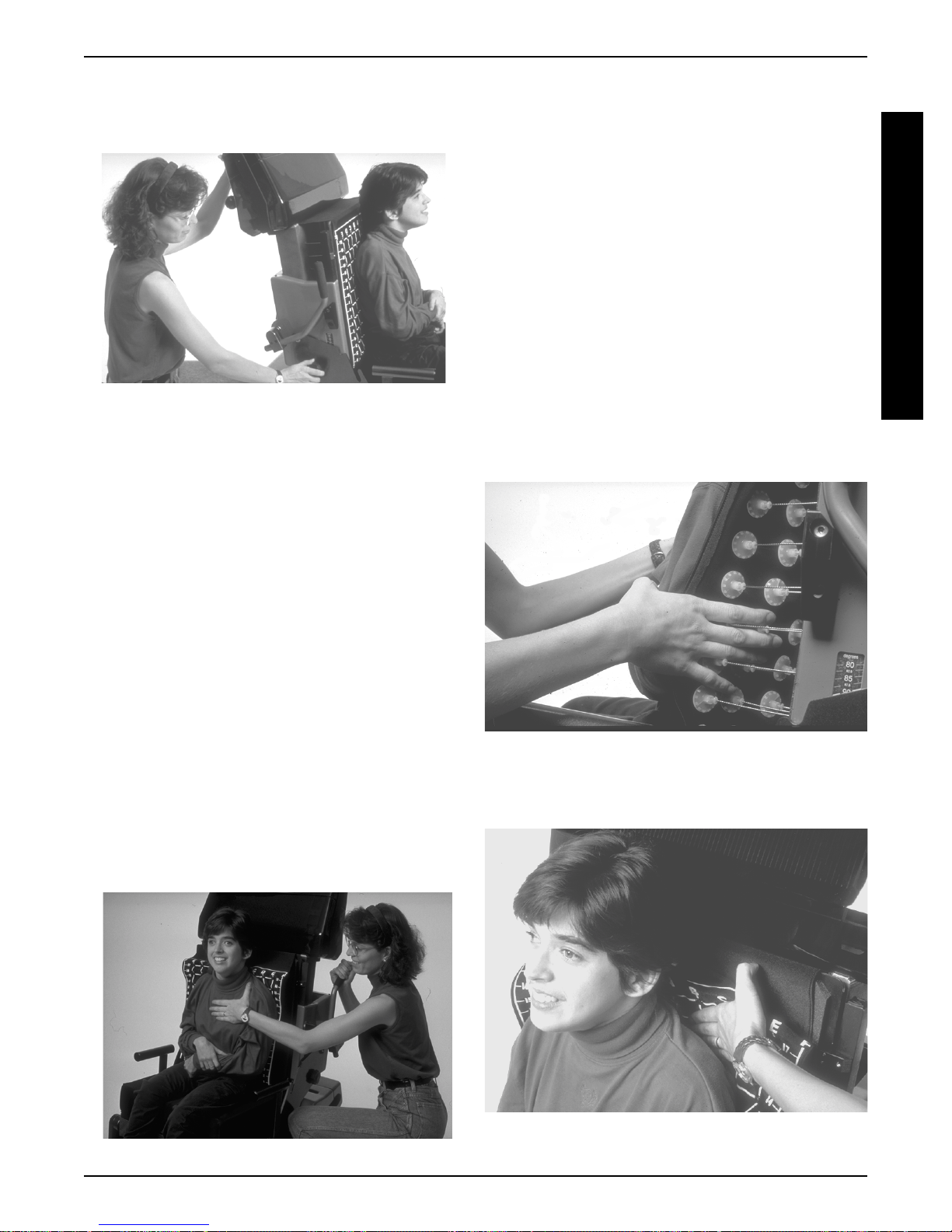

2. Check the seat and back for flatness and

plunger position. This is accomplished by running your hand across the surfaces and feeling for

irregularities (Figure 1). Only minor indentations

should be felt. The plungers can at times become

stuck in a depressed or extended position and a

FIGURE 2 MOVE THE SEAT SENSOR BACK

4. Set and lock the seat depth. The back sensor

panel should be moved to its most rearward position. This is accomplished by loosening the seat

depth adjustment knobs and sliding the side plates

along the slotted rail. Once in place, the blue pointer

found at the front of the side plates should indicate

the same number on both sides of the frame.

Tighten the knobs securely to help prevent unwanted movement of the back during transfers.

98-110

14

CREATING A SILHOUETTE® SYSTEM

5. Set and lock the back sensor angle. There are

printed graduations on the back panel to assist in

accurately recording this measurement. It is suggested that a setting of 95 degrees be used initially

and that the final angle be determined with the client in place. The back angle is adjusted by loosening/tightening the back angle adjustment knobs.

Make sure this adjustment is tight before transferring or adjusting tilt and depth. The knobs used to

adjust back angle and back sensor placement must

be tightened sufficiently to prevent any unwanted

movement during the simulation process. This is

especially important when the system tilt angle is

changed. Armrest tightness requires checking as

these components can become critical places of

stability and support during transfers.

6. Apply data forms to the data panels. There are

different forms for the back and for the seat. The

forms are clearly marked and can only be applied

to the data panels in the correct orientation. The

data panels have short metal pegs that line up with

holes prepunched in the carbonless data forms.

Orient the forms holes to match the data panel’s

pegs and apply the form using the adhesive strips.

The strips should be placed on the data panel one

at a time with care taken to make sure the form is

attached as flat as possible (Figure 3).

7. Insert the data panels into the imprinters. The

imprint handle must be all of the way to one side

for the data panel to have access into the channels. Care must be taken at this point to make

sure the data panel is properly inserted into the

channels. The clinician should have a clear view

of the panels and the channels during this operation. Do not force the data panels into place and

make sure they enter evenly. Some resistance

may be felt but the panel should advance smoothly

into position (Figure 4).

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

FIGURE 3 APPLY THE DATA FORMS

FIGURE 4 INSERT THE DATA BOARDS

8. Take a baseline for the seat and back. The

base line is the starting position for the shape sensing plungers. In order for depths to be recorded

there must be a reference point. This reference

point is produced by sliding the imprinter handles

all of the way across the data panels. This should

be performed with a smooth continuous movement and a slight resistance may be felt at the

beginning of the stroke. If the handle does not

move, check to make sure the data panel is inserted fully (Figure 5).

15

98-110

CREATING A SILHOUETTE® SYSTEM

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

9. Transfer the client onto the Shape Sensor.

10. Orient the client on the Shape Sensor ’s seat.

FIGURE 5 TAKING A BASELINE

MEASUREMENT

Please refer to the section regarding transfers

(Page 13) to assist with this important step.

This orientation process requires that the clinician

have a strong background in seating/positioning

and that a thorough mat evaluation was performed

(Figure 6). It is suggested that the following guidelines be used with the understanding that each

person is unique and there are always exceptions.

Check for pelvic obliquity . Accommodate if fixed,

andcorrect if flexible.

Check for rotation of the pelvis and trunk. Derotate if the forces are not excessive and improved

posture is realized. An apparent leg length discrepancy may actually be rotation of the pelvis.

Set the footrest height so each thigh is level and

at the same height. The footrest height can also

control the depth of the leg channels and influences

clearance under tables.

Position the lower extremities in the desired

amount of ab/adduction taking into account the limitations of the wheelchair frame and the therapeutic benefits of the posture. Increased abduction

can mean a more stable posture, but may exceed

the overall width of the clients chair.

Adjust the armrests to help support the upper

extremities and trunk. Be careful to not elevate or

depress the shoulder girdle.

11. Orient the client to the Shape Sensor back.

WARNINGS

ALWAYS engage both wheel locks while

changing the orientation of the Shape

Sensor modules.

When adjusting the seat depth, make

sure the adjustment knobs are securely

locked in place.

FIGURE 6 POSITIONING THE CLIENT ON THE

SEAT

Center the client on the Shape Sensor so that

an equal amount of cushion shows on both sides.

Asymmetries of the client may not allow for equal

space on both sides.

Check pelvic tilt and position the client with a neutral to slightly anterior orientation. Use your thumbs

and forefingers of each hand to gently hold the clients pelvis. The need for excessive force to position the pelvis may require that smaller adjustments

be made. A neutral to anteriorly tilted pelvis can

assist with spinal extension and reduced

kyphotic posturing.

To maintain stability and safety, make

sure the client is properly positioned in

the Shape Sensor before reclining or inclining (reverse recline).

When adjusting the back angle, DO NOT

remove back angle adjustment knobs

as they help secure the back sensor to

the frame.

Adjust the seat depth with the clients pelvis oriented to the desired tilt and the thighs fully supported. Do not cause posterior pelvic tilt by overextending the seat depth. If there is a significant

amount of thigh that remains unsupported, even

with the seat depth set to the maximum amount,

then the remaining surfaces can be produced at

the factory by extrapolating the cushions shape

forward. This will be covered more fully in the “measurements” section.

Adjust the back angle for the desired comfort

level and to accommodate any limitations of movement. The head should be balanced over the

98-110

16

CREATING A SILHOUETTE® SYSTEM

shoulders and hips. The client should have a natural

forward gaze and not be pushed forward in the

system (Figure 7).

FIGURE 7 ADJUSTING THE BACK ANGLE

Adjust the tilt angle to help balance the client and

to allow gravity to assist in the fitting process. The

clinician should be aware of the limitations that the

clients wheelchair may have upon the ability to tilt.

Functional issues such as forward reach and swallowing must also be taken into consideration.

Center the clients trunk on the back surface

using the printed grid as a guide.

14. Take the back shape. Gently place one hand on

the individuals sternum while pulling the back sensor lever all of the way forward. Tell the client they

may feel a slight pressure against their sacrum

(buttocks) during this phase (Figure 8).

15. Quickly, visually check to make sure that all of

the extended plungers are touching the client in

the areas desired. The clinician can manually extend or depress the plungers to fine tune the shape

(Figure 9). The area behind the scapula should

be flattened to reduce interference with upper extremity movement (unless protraction of

the shoulders is a desired feature) (Figure 10). If

for any reason the client’s posture or the back’s

shape does not seem right, then retract the lever

and start over. Make sure the shapes are right

before recording them.

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

Check the clients trunk for rotation and the

shoulders for a level orientation. It is impor-

tant at this time to critically evaluate the amount of

force and support an individual will need to maintain the desired posture. Only gentle assistance

should be necessary to support the client during

the fitting phase. If significant force is necessary

then other intervention strategies should be considered.

12. Release the back sensor lever from its locked

position by pressing it in and moving it rearwards

into the plunger activation position.

13. Confirm the clients posture from the feet up to

the head.

FIGURE 9 EXTENDING THE PLUNGERS

FIGURE 8 TAKING THE BACK SHAPE

FIGURE 10 FLATTENING THE AREA BEHIND

THE SCAPULA

17

98-110

CREATING A SILHOUETTE® SYSTEM

16. Record the back and seat shape by pulling the

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

imprinting handles across the data panels. Pull

each imprinting handle only once. A baseline and

a contour line should now be printed on each data

form. If the base line was not recorded, it can be

taken once the client transfers out of the Shape

Sensor.

17. Confirm measurements with the client still seated

in the Shape Sensor.

Cushion length. Retract the back sensor lever

to create a flat panel and measure from this surface to the place on the clients thighs that the cushion is to end. What you are measuring is the actual cushion length not the clients seat depth. Take

into account the wheelchairs available depth. Silhouette

®

seat cushions are produced with a

rounded rear section that allows them to be fully

inserted into the wheelchair with minimum interference from the back push handles. Issues such

as the clients activity level and propulsion method

should be taken into account when determining

the cushions length. If the client has their knees

pulled into a tucked position for improved maneuverability then the cushion may be quite short. If

the client propels using their lower extremities then

clearance should be provided for the calf to allow

sufficient movement rearwards. Lengths can be

produced from 8”-22”.

Back height. The individuals back height is dependent upon activity level and the need for postural support. There is no magic rule for determining back height. In order to promote upper extremity function the scapula area should be free from

interference. This can be accomplished by stopping the back height below the scapula or flattening the area behind it. The number printed on the

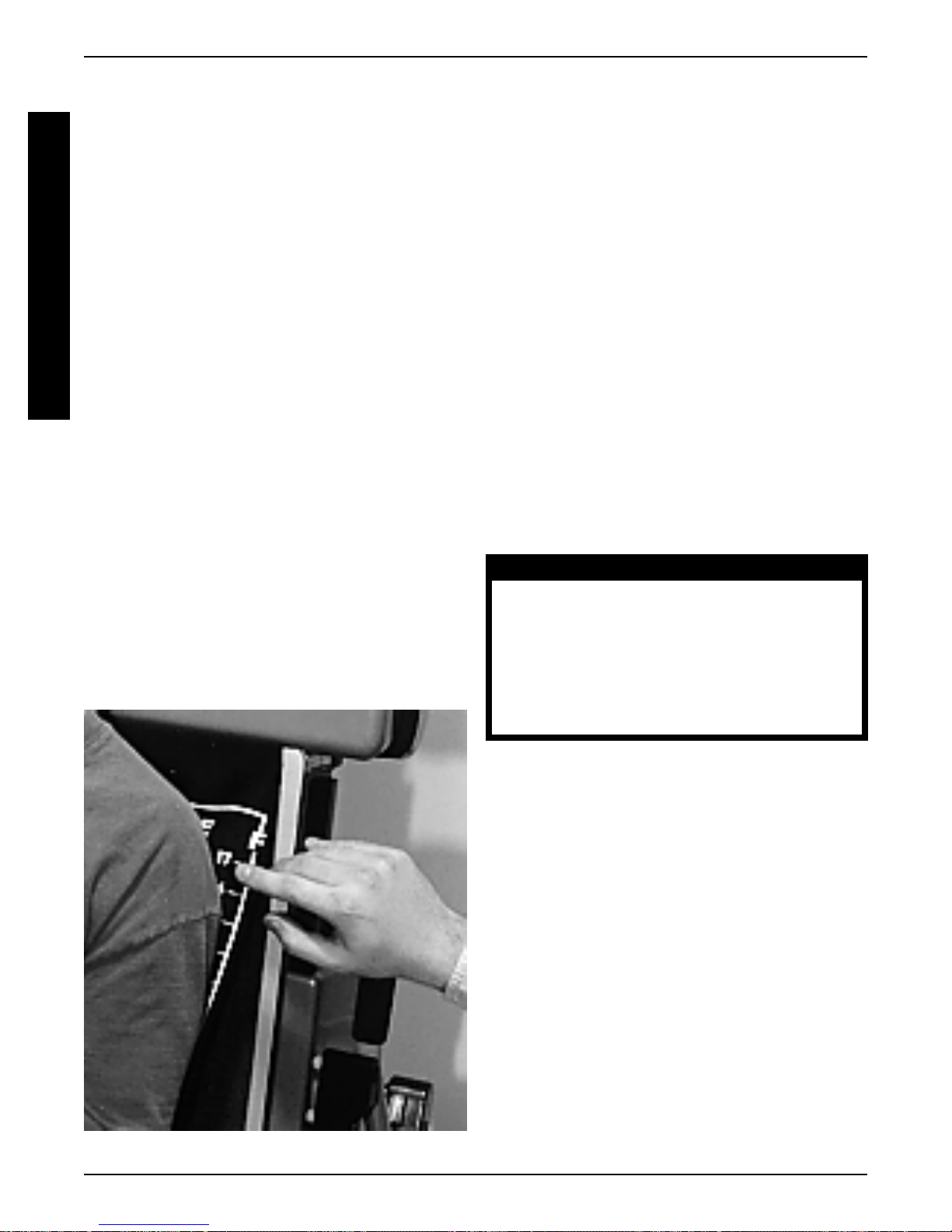

back grid is used to determine back height (Fig-

ure 11). Do not measure the back height with a

tape measure, but write down the number printed

on the front of the back sensor grid.

Leg length. This measurement is taken to help

determine footrest height and desired floor to seat

height. This is especially important for individuals

who propel using their feet or who transfer using

the stand and pivot technique.

Back Angle. The back angle measurements are

printed on the side of the back sensor panel.

Tilt Angle. The tilt angle can be taken using an

inclinometer or bubble level. This angle will assist

with setting up the clients finished system.

WARNING

When returning the client in the Shape

Sensor to the full upright position, more

body strength will be required for approximately the last twenty (20) degrees

of incline (reverse recline). Make sure

to use proper body mechanics (use your

legs) or seek assistance to avoid injury.

FIGURE 11 INDICATING BACK HEIGHT

98-110

18. Transfer the client off of the Shape Sensor and

position them in their own wheelchair. Make sure

the back sensor panel is locked before the transfer, and that the client is supported properly and all

belting/strapping is secured in their chair.

19. Remove the data panels from the imprinters.

The data panels have a flexible strap to assist with

their removal. Make sure the imprinters are all of

the way to one side to allow the panels to be pulled

out of their channels.

20. Remove the data forms from the panels and fill

in the requested information on each section (date,

dealer name and number, client name, contact

person, and phone number)

21. Copy the Shape Sensor ’s serial number onto

the order form. There is a separate serial number

for the back and seat. This is a very important

step! Each Shape Sensor has its own “personal-

ity” that assists in fabrication and this is recorded

by Invacare in their computer system. The cushions can not be produced without this number.

18

CREATING A SILHOUETTE® SYSTEM

22. Determine the necessary cushion modifications and options and write this information on the

order form. Additional changes in the cushion are

available to the clinician if they are using SeatMaker

software and can modify the cushion on screen

before sending the data to Invacare.

Cushion density . There are two choices for cushion density, soft or firm. Soft foam is generally chosen for instances were maximum pressure relief

is desired. Firm foam will provide increased stability and support.

Cushion thickness. Cushions are available in

4”,5”, and 7” thickness. The thickness of the cush-

ion is determined by the overall depth of the contour and the functional characteristics desired. A

7” cushion can only be provided if the clinician uses

SeatMaker software to design the cushion.

Cushion width. The cushions width is determined

by the clients width and the dimensions of the

wheelchair. Widths can be produced from 10”-

22”.

Cushion fabric. Cushion covers are available in

four different styles, but only in one color (black).

The variety chosen is dependent upon the clients

function and the environment where the individual

resides. Consideration should be given for the purchase of a second cover as they are custom made.

If an additional cover is desired at a later date then

the dimensions of the cushion would have to be

sent back to the factory to serve as a pattern.

®

Lycra

. The smooth texture of this fabric can make

transfers easier. It should not be used if the client

is incontinent.

®

Waterproof L ycra

. This cover has a layer of thin,

stretchable material bonded to the lycra making it

waterproof. The top surface of the cover can still

absorb moisture but fluids can’t pass into the cushion. If the cover does become wet it can be dried

easily. This cover would be appropriate for individuals that experience incontinence on a periodic

basis.

®

Stretch Vinyl

. The waterproof coating is on the

outside of this cover making cleanup a much easier

task. This is the suggested option for persons who

are incontinent.

®

Polartec

. This fabric is a polyester fleece mate-

rial commonly used for jackets and sporting apparel. It is very durable and comfortable to sit upon.

It is not waterproof.

Rail Cuts. Rail cuts can be specified if a cushion

needs to drop between the seat rails of a wheelchair in order to create a specific floor to seat height.

Rail cuts on the back will allow the cushion to extend between the push handles helping to increase

seat depth with maximum surface contact maintained to the back. Rail cuts will require that the

clinician provide the necessary mounting materials.

Leg Length Discrepancy. If a client has a leg

length discrepancy then the cushion will need to

be cut back for the shorter leg. The overall length

of the cushion should be measured with the longer

leg. This will be the cushion length recorded on

the order form. The length of the discrepancy for

the shorter leg should then be indicated on the options portion of the order form.

Solid Insert. A solid insert consists of a 1/4” thick

panel of rigid plywood, cut to be 2” less than the

width of the cushion. This panel is meant to be

used with a seat cushion that is placed directly

upon the sling upholstery of the wheelchair. This

can be a low cost alternative to a drop seat or

modular shell. An insert should only be used by

individuals that can independently regulate the

placement of the cushion within the chair.

Lateral supports. When a cushions lateral trunk

supports require additional depth or strength, then

auxiliary supports should be considered. The optional trunk supports are made with a quick release

feature and can be purchased with varying degrees

of offset. The offsets are available in 1/2”,1”, 1-1/

out and 1/2”, 1”, 1-1/2” in, and straight configu-

2”

rations. It is best to have all of these brackets available to assist in the fitting process. The hardware

used to attach the supports to the cushion is

mounted inside the modular shell. The support

can be moved along an extruded rail within the shell

to adjust the desired height. The metal support

bracket can be bent to create a curved surface.

The bracket can only be bent with significant force

applied and requires that the padding be removed.

The padding will slide off of the bracket once the

locking dot has been pressed out of position (Fig-

ure 12).

Headrest. There are many clinical reasons for

using a headrest. This can vary from helping to

reduce neck hyperextension to providing a surface

upon which to rest the head when the individual is

tilted back. There are three styles of headrest pads

available; small, large, and two step. The mounting hardware is removable and adjustable

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

19

98-110

CREATING A SILHOUETTE® SYSTEM

C

R

E

A

T

I

N

G

A

S

I

L

H

O

U

E

T

T

E

®

S

Y

S

T

E

M

FIGURE 12 REMOVING LATERAL INSERTS

ions on sling, modular shells, KwikFit, and custom.

®

Cushions on sling. The Silhouette

cushions can

work quite effectively, in some instances, when

placed directly on a sling. The most common application is when a seat cushion is used by active

user in an ultra-light base. It is beneficial if the sling

is tight and matching Velcro® is available on the

slings fabric. Additional firmness of support can

be achieved by using the optional solid insert.

There are many wheelchair styles that have an

integral seatboard as part of the chair. This is usually a metal pan with Velcro® attached to the surface.

Modular Shells. The modular shells are made

to the dimensions of the cushion in 14”,16”, or 18”

widths and between 10”-21” in length. These shells

consist of two extruded aluminum channels, and

two plastic endcaps (Figure 13). The channels

are used for attaching the mounting hardware and

auxiliary supports such as lateral trunk supports.

The end caps connect the channels, and create a

smooth and attractive surface. The cushions are

covered with the fabric of choice and are held into

the shells using Velcro

®

. The modular shells come

complete with all hardware for mounting into the

wheelchair.

in all directions. If it is unknown whether or not an

individual requires a headrest then the modular

shell for mounting the back cushion should be

specified as “headrest ready”. The mounting holes

for the headrest will be prepared and then filled

with attractive caps.

Pelvic strap. Every seating system should use a

pelvic positioning strap. This is a necessary safety

option and will help stabilize the pelvis. The variety

offered for the Silhouette

®

System attaches to the

wheelchair seat rails. This will allow for precise

positioning and optimum angle of pull.

Performance Shaping. When a client is very active and is using an ultra-light chair then Performance™ Shaping should be considered. This option will maintain the leg troughs produced during

the simulation and add an undercut behind the calf

to allow for increased flexion of the knees. The leg

troughs will help to stabilize the lower extremities

and the undercut allows for an increased “tucked”

posture that can improve stability and maneuverability.

23. Determine the interfacing of the cushions to the

wheelbase. There are four basic choices; cush

98-110

FIGURE 13 SILHOUETTE® MODULAR SHELL

20

COMMONLY ASKED QUESTIONS

KwikFit. The back KwikFit system consists of

two aluminum channels connected together with

a solid ABS panel. This system has all of the benefits of the modular shell design, but is a broader

range of sizes. The back comes complete with

attaching hardware that is adjustable in depth and

angulation. The seat KwikFit system is a flat ABS

panel with hardware that snaps easily onto the

wheelchair’s seat tubes. Both the back and seat

KwikFit systems are covered by the fabric of

choice.

®

Custom. Silhouette

seat and back cushions can

be interfaced into a chair using standard hooks

and hangers. The seat cushion can be placed

directly upon a drop seat. The back cushion can

be glued to a board that has been prepared with

the necessary T-nuts. The attaching hardware can

then be bolted through the cover. Custom mounting is an easy process for those that have the necessary equipment for fabrication.

24. Fill in order form and fax to Invacare at 1-800-

870-4928.

COMMONLY ASKED QUESTIONS

The following should address some of the common

questions that clinicians and clients may have regarding the Silhouette® System. Unfortunately, not all situations or applications can be predicted and some questions may still remain. If this is the case, then please

feel free to contact Customer Service (1-800-451-

3553).

Cushion Life. The life of a Silhouette® cushion de-

pends upon the type of environment, and the use it is

exposed to. There is a 60-day unconditional guarantee and a two year replacement warrantee.

®

Growth. How much growth a Silhouette

accommodate is dependent on what kind of growth is

experienced. If the growth is linear, then the back can

be shifted in the wheelchair. One method of extending

the life of a seat system is to purchase the interfacing

(modular shells or custom) oversized with the additional foam extending underneath the back. When a

new cushion is made then the interfacing can still be

used. This method of accommodating growth is limited by the type of wheelchair being used. When growth

is actually weight gain, then the amount that can be

accommodated is proportional to the individuals size.

The cushions are soft in their construction and some

accommodation is possible. The cushions can also

be carved by hand to adjust for weight gain,and then

re-coated.

cushion can

Large Clients. How large of an individual can use Silhouette

®

The Shape Sensor is 18” wide, and any part

of the client that extends over these surfaces will be

extrapolated by the computer following the clients recorded curve (up to 21”). The measuring limits of the

Shape Sensor for cushion length is similar, but the extrapolation of leg length is a much more accurate procedure. The Shape Sensor is rated for up to 300 lbs.

Low Floor to Seat Heights. When a low floor to

seat height is desired, the proper chair should first be

chosen. Custom interfacing using a drop seat may

be necessary for extreme conditions, or when the optimum chair can’t be provided. Care should also be

taken when specifying the thickness of the cushion.

Restriction of Movement. Clients and clinicians alike

may have concerns that a custom contoured seat

cushion will restrict an individuals capacity to freely

move about. Comments such as “I don’t like to sit in

just one spot,” and “I like to move around a lot” are

frequently heard. The Silhouette

®

cushion is made

from soft polyurethane foam and shifts in position are

readily achievable. Invacare has found through interviewing previously skeptical clients, that the reason they

had moved around so much in the past, was that they

were often uncomfortable. The Silhouette® cushion

increased their comfort making constant shifting less

of a necessity.

Shear. Shear is a difficult phenomena to measure

and quantify. The less a surface has to deform, the

less shear it will exert on the client’s tissue. The Silhouette

®

surface is contoured to the client’s shape and

should theoretically, cause less shear.

Shorter Seat Depths. When only a seat cushion is

being produced, then a dense material of known thickness can be added to the front of the back sensor’s

surface. This thickness will have to be related back to

the factory to assist in the fabrication process. If the

client requires both back and seat, then the attachment hardware holding the seat sensor panel will have

to be modified. This modification process can be performed at the factory or written directions can be given.

The modification will require the purchase of two retaining clips and two bumpers. It will also require the

drilling and tapping of four holes.

Small Clients. Cushions can be made as small as

10” x 10”, and Invacare rates the low end capacity of

the Silhouette

®

at 50 lbs. Very small clients do not have

sufficient weight to press into the Shape Sensor’s seat.

Some clinicians have had good success in applying

additional force onto the client to produce the desired

C

O

M

M

O

N

L

Y

A

S

K

E

D

Q

U

E

S

T

I

O

N

S

21

98-110

TROUBLESHOOTING

contour. This can be a tricky procedure, and caution

should be taken so that asymmetries are not introduced

Transfers. The ability to transfer must be considered

T

when screening a candidate for a Silhouette

R

ease of transfer will be dependent upon the type of

O

U

cover used and depth of contour. The depth can be

B

adjusted for individuals whose abilities may be com-

L

promised by a deeper cushion.

S

H

TROUBLESHOOTING

O

The process of producing a Silhouette® seating sys-

O

tem using the mechanical Shape Sensor, quickly be-

T

comes an easy and rewarding method of intervention.

I

N

The tools are durable and simple in design, but as with

G

all things, problems may arise. Refer to this trouble

shooting guide for answers to some of those problems.

Bent Cable. If a cable becomes bent, attempt to

straighten it. If the bend can’t be sufficiently repaired to

allow operation then it will have to be replaced. If the

bent cable is located in a nonessential area then note

this on the order form and cushions can be produced.

A bent cable is easy to find on the computer and its

position can be adjusted.

Data Form put into Wrong Imprinter. This really

isn’t a problem. Make sure to indicate on the form

which sensor made the impressions.

®

seat. The

Seat Depth Won’t Lock. If the seat depth can’t be

locked, and the knob keeps spinning, then remove the

back sensor panel and slide out the side plate. Inspect the carriage bolt that attaches the knob to the

side plate. Chances are, the edges of the bolt have

worn, and a new one should be installed.

TECHNICAL NOTES

Periodic maintenance of the Shape Sensor and Silhouette® seating systems is recommended. Information regarding the care of the cushions and interfacing

should be passed on to the client.

Shape Sensor

Keep the slotted seat rail free from debris.

®

If the Shape Sensor is used to make ContourU

ions, then plaster should be prevented from getting into

any moving parts and surfaces kept clean.

Replace the gas cylinders when they no longer lock in

position.

Check before each fitting that the clamping blocks,

used to fold the frame, are securely tightened.

Do not store objects on top of the Shape Sensors seat.

Cushions and Interfacing

Wash the covers in cold water and tumble dry on low

heat.

cush-

Footrest Length. There can be times when the footrests can’t accommodate the clients leg length. Use

any surface available such as books or boards to support the feet. The feet need to be supported for the

legs to be positioned properly.

Jammed Data Panel. This condition can be averted

by always confirming the panel is seated properly in

the receiving channels before pushing it into the imprinter. When a jam does occur, firmly grasp the stuck

end of the panel with a pair of pliers and pull it out. If

you pull too hard on the cord style handle it could break

away from the panel. If this technique does not work,

then the sensor should be returned to the factory.

Plunger Disconnected. When a plunger becomes

disconnected simply snap it back over the ball end of

the cable. If the cable is pressed down into the foam,

then depress the foam cell around it, and pull it back

up. If the ball end of the cable is broken or missing

then it will have to be replaced. If the damaged cell is

located in a nonessential area then notify this on the

order form and cushions can be produced. A stuck or

broken sensor is easy to find on the screen of the computer and its position can be adjusted.

Do not immerse the cushions into water as they are

made from open cell foam and will soak up water like

a sponge. The urethane coating does not make the

foam waterproof only water resistant. If the cushion

must be immersed, then squeeze out the excess water and dry thoroughly before returning to service.

Periodically check the fasteners that hold the interfacing hardware, and tighten if they have become loose.

Data Forms

The data forms are used to record the contour of the

client and are clearly marked for installation onto the

data panels. There is a form for the seat, and a form

for the back. There is a front and back to the back

form, and a top and bottom to the seat form. Inspection of the data form will show 50 rows along the

Topshape and 50 rows along the Bottomshape, Each

one of these rows corresponds to one of the plungers.

A finished data form should have imprinted upon it one

base line and one contour line. Always bring duplicate

forms to a fitting in case one is incorrectly printed.

Tear off the side stubs along the perforations and discard the portion of the foam with the adhesive.

98-110

22

TECHNICAL NOTES

Separate the Topshape section from the Bottomshape

section by tearing along the two perforations.

Fill in the requested information including; Dealer name,

dealer number, dealer phone number, contact person,

date, client name and any remarks.

Make sure the data form’s serial number is recorded

on the order form.

Fax the data forms along with the order form to Invacare

at 1-800-870-4928. This fax line can accommodate

the longer forms.

Order Form

Information regarding the order form and available options is presented in the section titled “Creating a Silhouette

order form be filled out. Within the order form, the type

of simulator back is requested. If the model being used

is complete with a Sensor panel then mark

Earlier models of the Shape Sensor were made for

producing seats only. These models used a strap style

back.

Guarantee

Invacare

cushions for 60 days from the date of shipment. The

cushions are also covered for a full two years for defects in materials or workmanship.

Serial Numbers

Each Shape Sensor has a separate serial number for

the back and seat sensor. These numbers must be

recorded on the order form as they give Invacare important information regarding the “personality” of the

machine. The serial numbers are located on the back

of the Shape Sensor.

SeatMaker

SeatMaker is a computer program created by Invacare

to input and manipulate the data produced on the

Shape Sensor. This software can be used by the clinician to further refine the cushions and as a method

to review the data before sending it off for production.

The inputting of data into the computer is accomplished

by touching each of the imprinted data points using a

stylus and digitizing tablet. The cushions shape can

be modified and fine tuned to exactly meet the clients

needs. Once the changes are made, then the data

can be sent by modem to the factory.

®

System”. It is important that all parts of the

Sensor.

unconditionally

guarantees Silhouette

General Shape Sensor specifications

Measuring grid:

10 x 10 data grid spaced 1.75” apart

Maximum depth of contour measuring capacity:

4.5” (seat and back)

Cushion construction:

HR 32 polyurethane foam with segmented top

section

Seat sensor depth:

17.5” front to back, adjustable to 11”

Seat sensor width:

20” (17.5” measuring area)

Back sensor height:

19.5” from top of seat (17.5” measuring area)

Back sensor width:

20” total (17.5” measuring area)

Seat-to-back angle adjustment:

80-110 degrees

Tilt-in-space angle adjustment:

0-20 degrees

Wheelchair transfer height:

23.5” from floor

Weight Limitation:

®

Shape Sensor dimensions

Fully assembled: 30.5”W x 43”L x 57”H

With back sensor folded flat: 30.5”W x 48”L x 35”H

Base frame: 30.5”W x 37”L x 11”H

Seat sensor module: 25”W x 32”L x 9”H

Back sensor module: 26”W x 32”L x 12”H

Shape Sensor weight:

Frame 50 lb.

Back sensor module 68 lb.

Seat sensor module 46 lb.

Features

Direct measurement and recording of total posture

Tilt-in-space adjustment for more accurate simulation

Seat depth adjustable.

Sturdy 8” wheels and 5” casters with brakes and rota-

tional lock.

Removable arm rests and foot rests

300 lbs.

(folded flat for transport)

T

E

C

H

N

I

C

A

L

N

O

T

E

S

23

98-110

INVACARE CORPORATION l

INVACARE CANADA l

5970 Chedworth Way l

Phone (905) 890-8300, 1-800-668-5324, Fax (905) 890-5244

Form No. 98-110 Part No. 0900117 Rev. B (5/99) Printed in USA

1200 TAYLOR STREET l

Phone 1-(800)-333-6900

Mississauga, Ontario Canada L5R 3T9 l

Elyria, Ohio 44036-2125 l

Loading...

Loading...