Invacare®ScanBed 750

TM

User Manual (GB)

Brugermanual (DK)

Bruksanvisning (SE)

Brukerveiledning (NO)

Käyttöohje (FI)

Bedienungsanleitung (DE)

Gebruiksaanwijzing (NL)

Manuel d’utilisation (FR)

Manual del usuario (ES)

Manuale d’uso (IT)

5

GB

Table of contents

User part ...................................................6

1. General information ......................................6

2. Operation of the SB750

TM

..................................7

Technical part ..............................................10

3. Information .............................................10

4. Receiving the SB750

TM

....................................11

5. Fitting the accessories ....................................13

6. Disassembly/assembly of the SB750

TM

.......................15

7. Wiring .................................................17

8. Order numbers for accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9. Maintenance and check-ups ...............................21

10. Beds equipped with accumulator back up ....................21

11. Maintenance chart .......................................22

12. Trouble-shooting the electrical system ......................23

13. Lubrication plan .........................................23

14. Cleaning ...............................................24

15. Technical specifications ...................................24

16. Electrical data ...........................................25

17. Weight ................................................26

18. Disposal ................................................26

6

User part

Congratulations on your choice of Invacare® EC-Høng’s SB750TM nursing bed.

x The bed has been developed for patients over 12 years of age requiring care in a nursing home or

home care nursing.

x The bed combines excellent stability and ergonomic design with easy disassembly and operation.

x The unique backrest return of the bed provides the patient with excellent comfort and the carer with ideal

conditions for an ergonomically correct working position.

In order to optimise the patient’s comfort, Invacare® recommends using a 12-cm mattress.

1. General information

The SB750TM bed fulfils all requirements regarding maximum distances. However, if the bed

is used for the care of patients with small body dimensions, it must be especially noted that there

is a risk of such a patient slipping through the openings between the side rails or through the

opening between the side rail and the mattress support.

The bed must not be used by patients under 12 years of age, or by patients with body size

equivalent to an average 12 year old or smaller.

The bed, in combination with side rails, must not be used for persons under 45 kg or under 150

cm´s height, or for persons that are restless (spasms) or confused, unless

a professional risk assessment has taken place and been accepted, or

a correctly installed safety cover on the side rails are used.

When using side rails and the according safety cover, it is essential to ensure correct fitting -

otherwise there is danger of entrapment / suffocation between mattress support, side

rail and bed end!

If the bed is used by restless (spasms) or confused persons, an ACP box can be used for blocking

the hand control functions, and / or a limitation cross bar installed under the leg section of the

mattress support. This cross bar will prevent the leg section from being lowered below the level of

the mattress support, thereby reducing the opening between leg section and bed end.

Ensure the bed is adjusted to it’s lowest position before leaving the bed unattended - thereby the

effect of fall-down / entrapment accidents is reduced.

Invacare® accepts no liability for any use, change or assembly of the product

other than as stated in this User’s Manual.

When entering or exiting the bed, the height adjustment should be used. Furthermore, the backrest can be used as

support (yellow button on the hand control). However, the thigh- and leg section must be horizontal, otherwise,

there is risk of overloading of the mattress support.

The bed must be placed so that the height adjustment (up/down) is not obstructed by, for example, lifts or

furniture. Otherwise there is a risk for injury on user and/or equipment.

7

GB

2. Operation of the SB750

TM

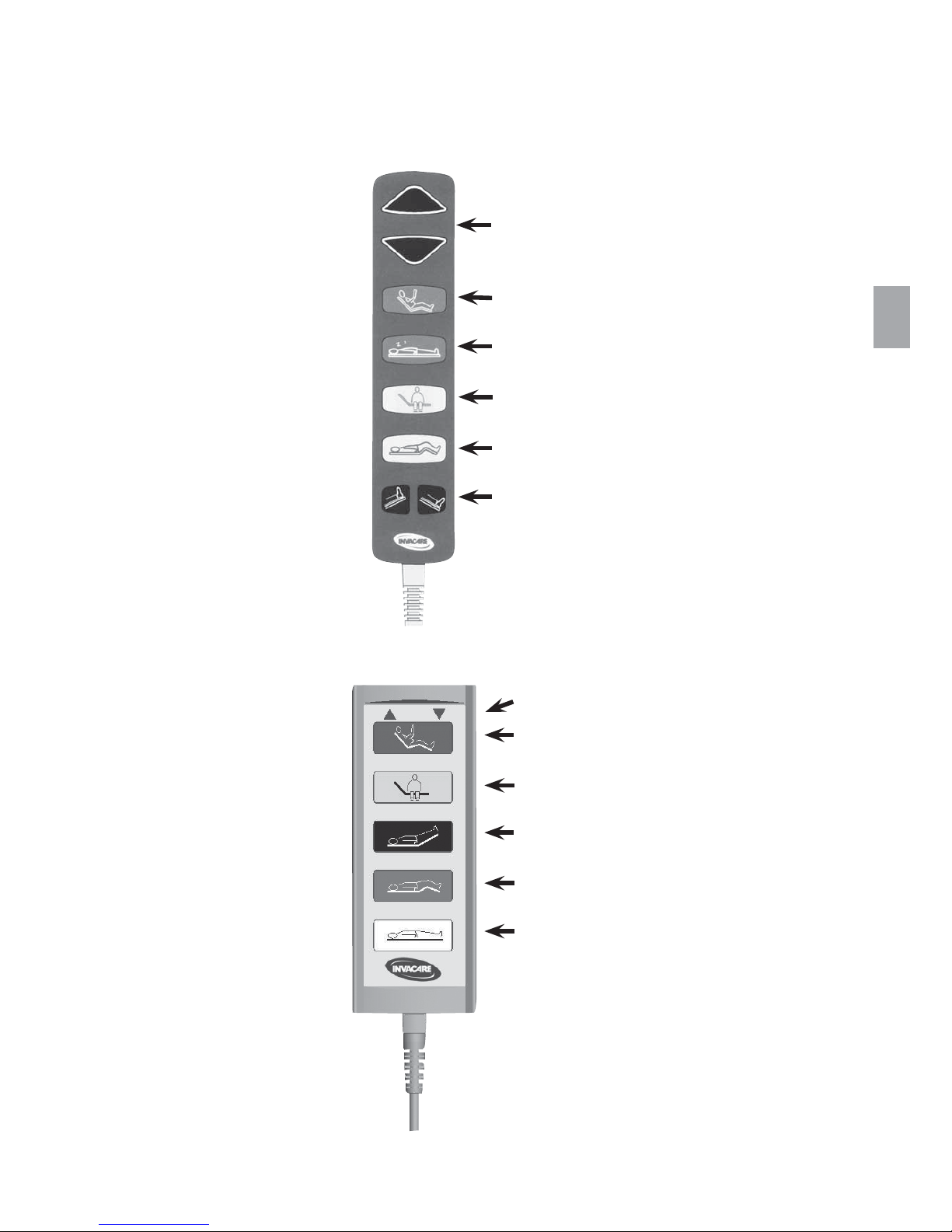

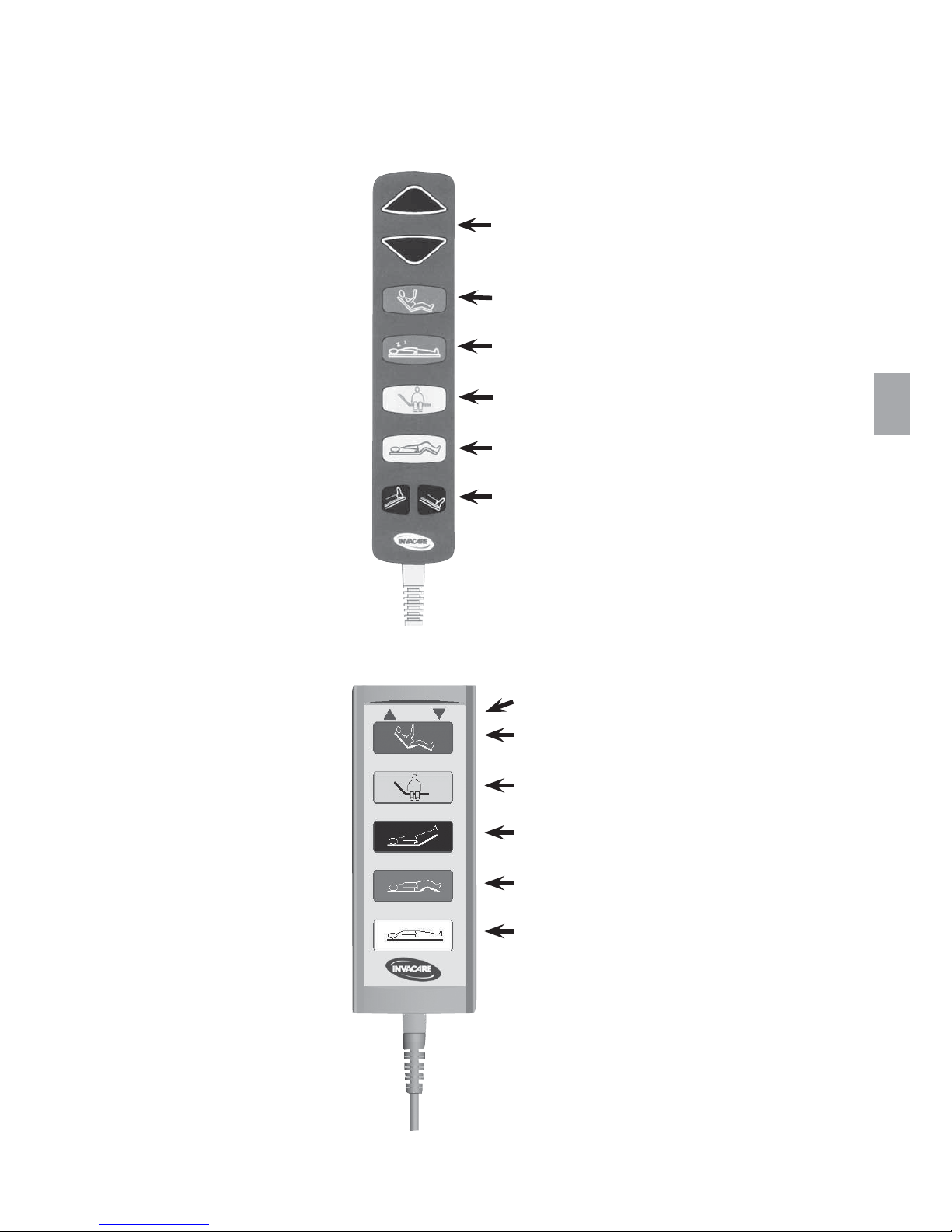

The bed can be equipped with this type of hand control (Soft Control):

Or with this type of hand control (HB 70):

Backrest

Sitting position

Leg section - electric

(not on beds with 3-sectioned mattress support

and manual adjustment of the leg section)

Thigh section

Height adjustment of the bed

UP/DOWN

Height adjustment of the bed

UP/DOWN

Sitting position, irrespective of

present position

Horizontal mattress support,

irrespective of present position

“Out of bed button”- Raises the backrest

and brings the thigh section to horizontal

Raises the thigh section and brings

the backrest to horizontal

Adjustment of leg section

UP/DOWN

(not on beds with 3-sectioned mattress

support and manual adjustment of the leg

section)

8

2)

1)

Operating the leg section on beds with gas springs

Lift the handle with one hand, while adjusting the leg section to the desired position with the other hand.

Release the handle.

Operating the leg section on SB750, 120 cm width, with Rastofix

To raise the leg section: Lift the leg section to desired height.

NB: Please ensure that both Rastofix brackets are correctly locked in place.

To lower the leg section: Lift the leg section slightly and lower to horizontal.

Always leave the bed in the lowest position. Otherwise there is a risk of squeezing due to

accidental lowering of the mattress support. A person can be seriously injured under the bed

during height adjustment.

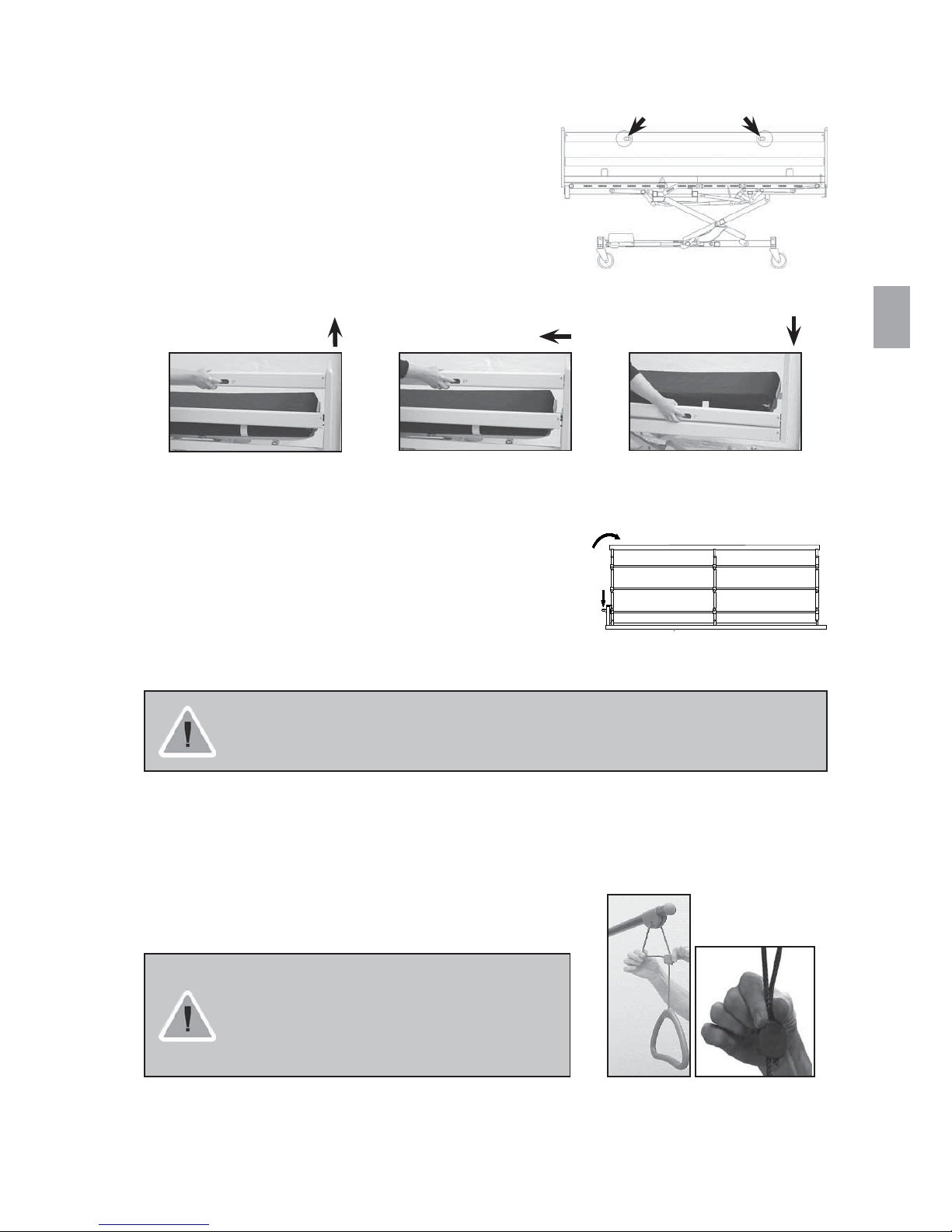

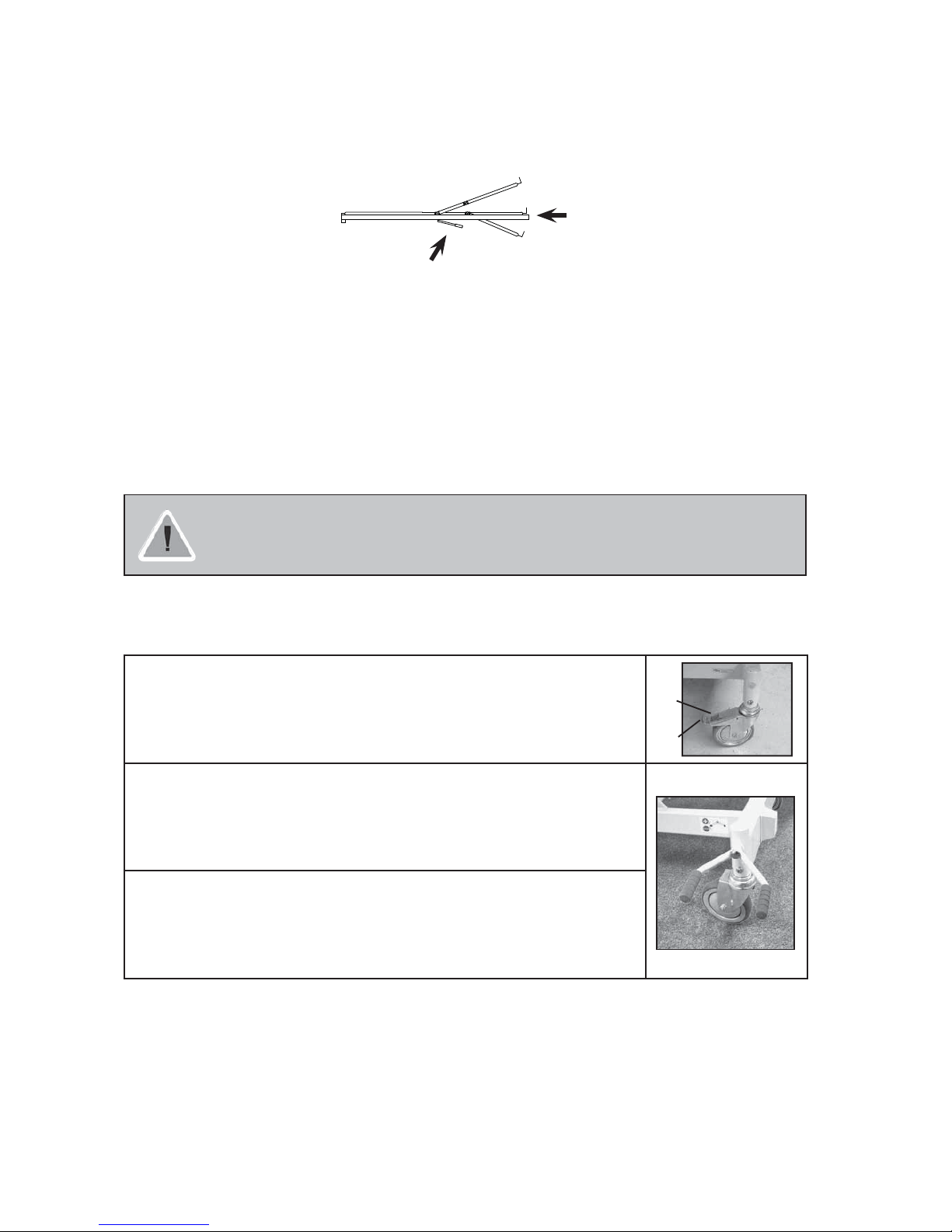

Operating the braking castors

Operating castors without central braking system

When the bed is positioned correctly, at least one castor at the head end and one

castor at the foot end must be locked.

1) Braking: Step on the pedal.

2) Releasing the brake: Step on the release pedal.

Operating castors with central braking system

When the bed is positioned correctly, it must be locked.

1) Braking: If the brake is in neutral, step on the red pedal.

2) Releasing the brake: Step on the green pedal, until the brake is in neutral

position.

Operating the steerable castor

The SB750

TM

with central braking system may be equipped with a steerable castor.

The steerable castor is operated by means of the central braking pedal.

1) Activating the steering: If the brake is in neutral, step on the green pedal.

2) Deactivating the steering: Step on the red pedal, until the brake is in neutral

position.

Set-off from the castors might under special conditions appear at different types of absorbing floor covering including untreated or badly treated floors. In matters of doubt, Invacare® recommends to place a suitable kind of

protection between the castors and the floor.

Release handle

Leg section - manual

9

A B

GB

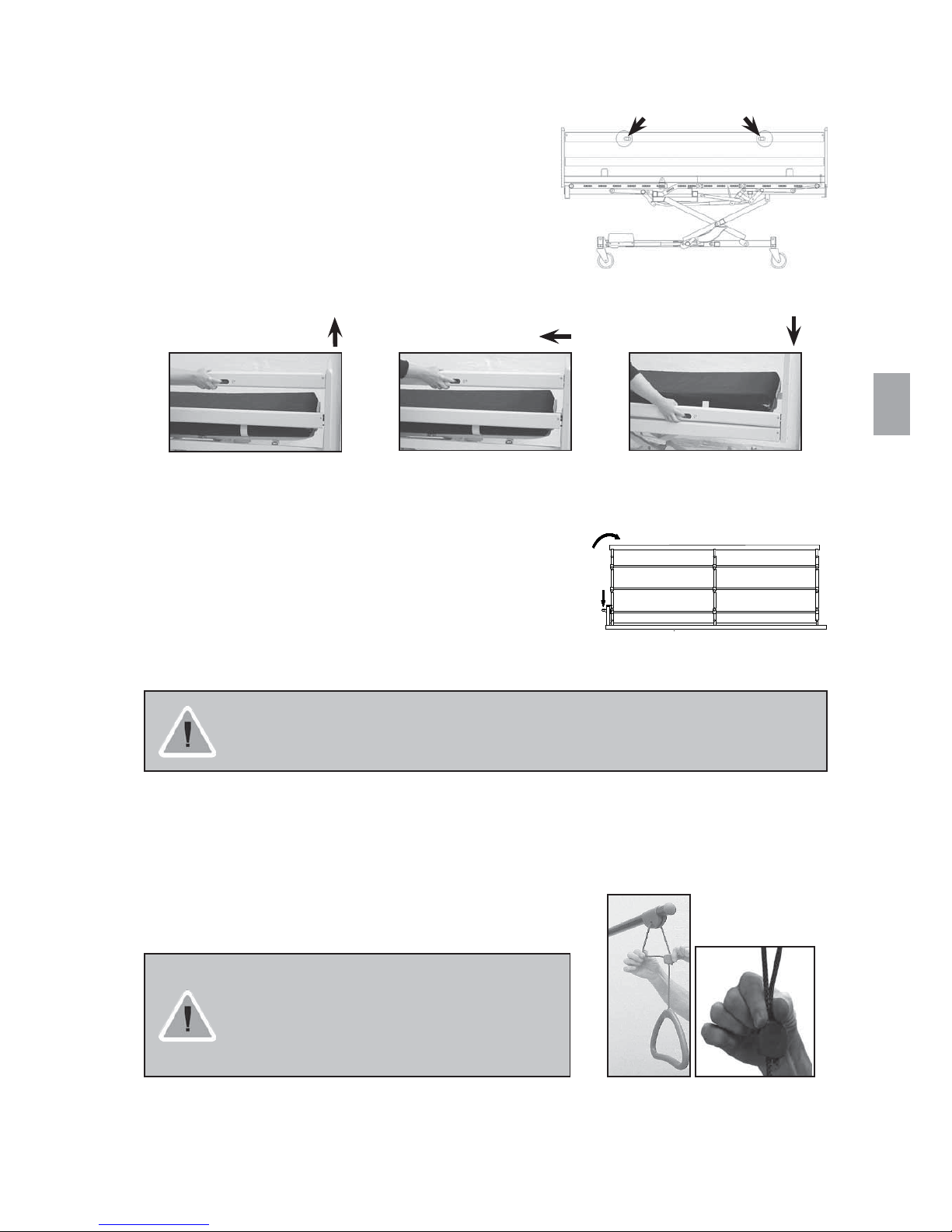

Operating the BRITT II/III/IV wooden side rail

The bed end may be equipped to lock the side rail at half height as

well as in the top position.

Normally the side rail can only be locked in top position.

Up: Pull up the top wooden side rail bar, until the locking pin locks

with an audible click.

Down: Lift the top wooden side rail bar and press the two locking

pins together. Lower the side rail.

Lift Release Lower

Operating the steel side rail

Up: Lift the top steel bar of the side rail towards the end with the

locking mechanism.

Down: Press the release button and pull the top bar of the steel

side rail away from the locking mechanism.

There is risk of entrapment of fingers on assembly and operation of the side rails.

Please ensure that the side rail locking system has engaged properly by pulling / pushing the upper bar.

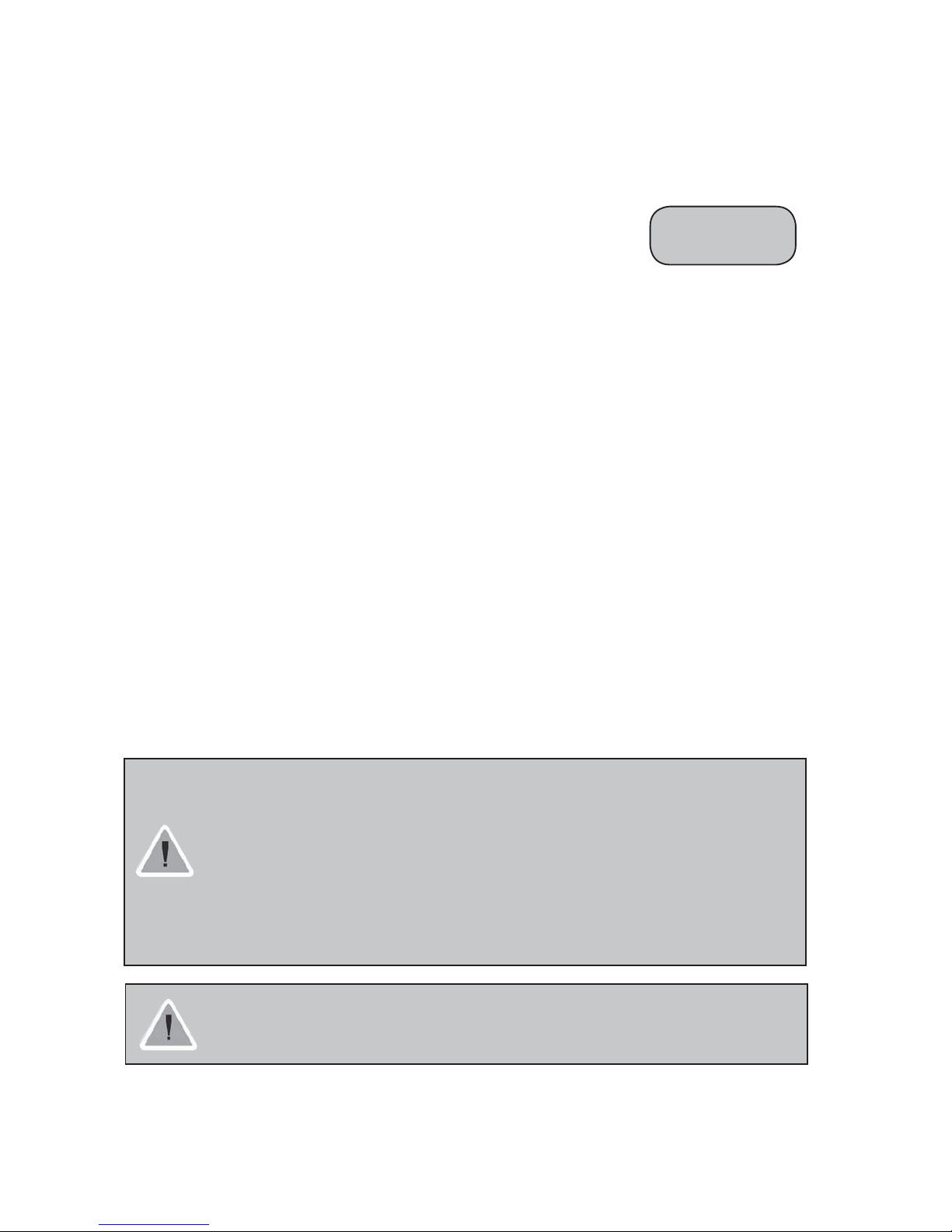

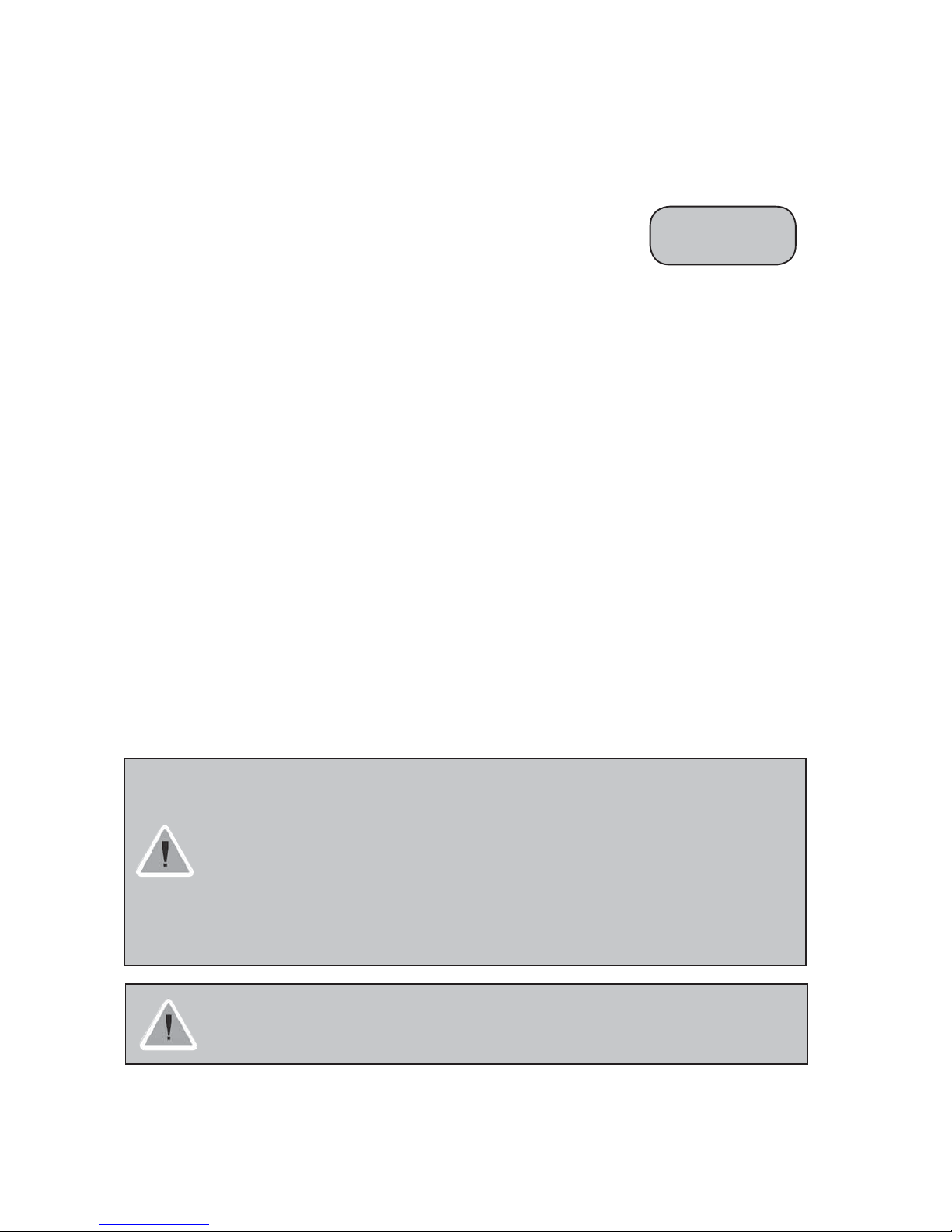

Adjusting the height of the lifting pole handle

Loosen the cord as shown in fig. A. The lifting handle can now be

adjusted to the desired height.

Press the cord together as shown in fig. B and check that the cord

is locked in the cord lock by pulling the handle.

Position the lifting pole in such a way that the

handle is above the bed. If the lifting pole is used

while the handle has been turned away from the

bed - the bed can tip when the handle is used.

Locking pins

10

QA XXX

Technical part

Invacare® is certified according to DS/EN ISO 9001 and ISO 13485 which ensures that our

customers are always supplied with Invacare® products of uniform quality.

Throughout the entire production process our materials and products are quality controlled by the operators.

Furthermore there is a final test when the product is fully assembled.

The operator carrying out the final test, which comprises of checking all

moveable parts, motors/gas springs and castors, issues a QA number on the

product thereby confirming its quality.

If the product does not correspond to the quality demands of Invacare® it will be discarded.

If, contrary to our expectations, a problem should arise in connection with the delivered product, please

contact your Invacare® supplier.

3. Information

Please read the entire technical information section carefully before using or servicing the bed.

All indications of right and left are based on a patient lying on his back in the bed.

Please note that there may be sections in this User’s Manual, which are not relevant for your bed.

x The SB750

TM

is CE-marked in accordance with directive 93/42/EEC concerning Medical Apparatus.

x The SB750

TM

is tested without remarks by HMI according to EN 1970.

x SB750

TM

is tested and approved in accordance with NF (Norme Francaise).

x SB750

TM

is EMC tested and approved in accordance with EN 60601-1-2:93 by UL Demko.

x The motors and control unit of the SB750

TM

are approved according to EN 60601:1996-03.

x

SB750

TM

has undergone a risk analysis according to EN 14971.

Max. patient weight: 185 kg.

The hand control, control unit and motors are protected according to IP 66.

A lock cam must be used on the control unit - if not, Invacare®cannot guarantee the IP protection.

Electromagnetic interference between the bed and other electrical products can occur.

To reduce or eliminate such electromagnetic interference, increase the distance between the bed

and the products or switch them off.

This medical bed can be used together with medical electrical equipment connected to the heart

(intracardially) or the blood vessels (intravascularly), provided that following points are respected:

- The medical bed should be equipped with means for potential equalization connection marked

out by a symbol shown in the back of this manual.

- Medical electrical equipment should not be fixed on the bed’s metallic accessories

such as side rails, lifting pole, drip rod, bed ends ect.

In addition, the medical electrical equipment power supply cord should be kept clear

of the accessories or any other moving part of the bed.

Invacare®accepts no liability for any use, change or assembly of the product other

than as stated in this User’s Manual.

If the functions of the bed change, please send the bed immediately for a check-up according to the maintenance

chart, chapter 11.

11

GB

4. Receiving the SB750TM

To avoid condensation, the bed should not be used until it has reached a temperature of 10-50° C.

Check whether the bed shows any signs of damage. If the bed is damaged, see terms of delivery.

If the bed has been delivered in parts, it must be assembled.

Cf. chapter 6 “Disassembly/Assembly of the SB750

TM

”.

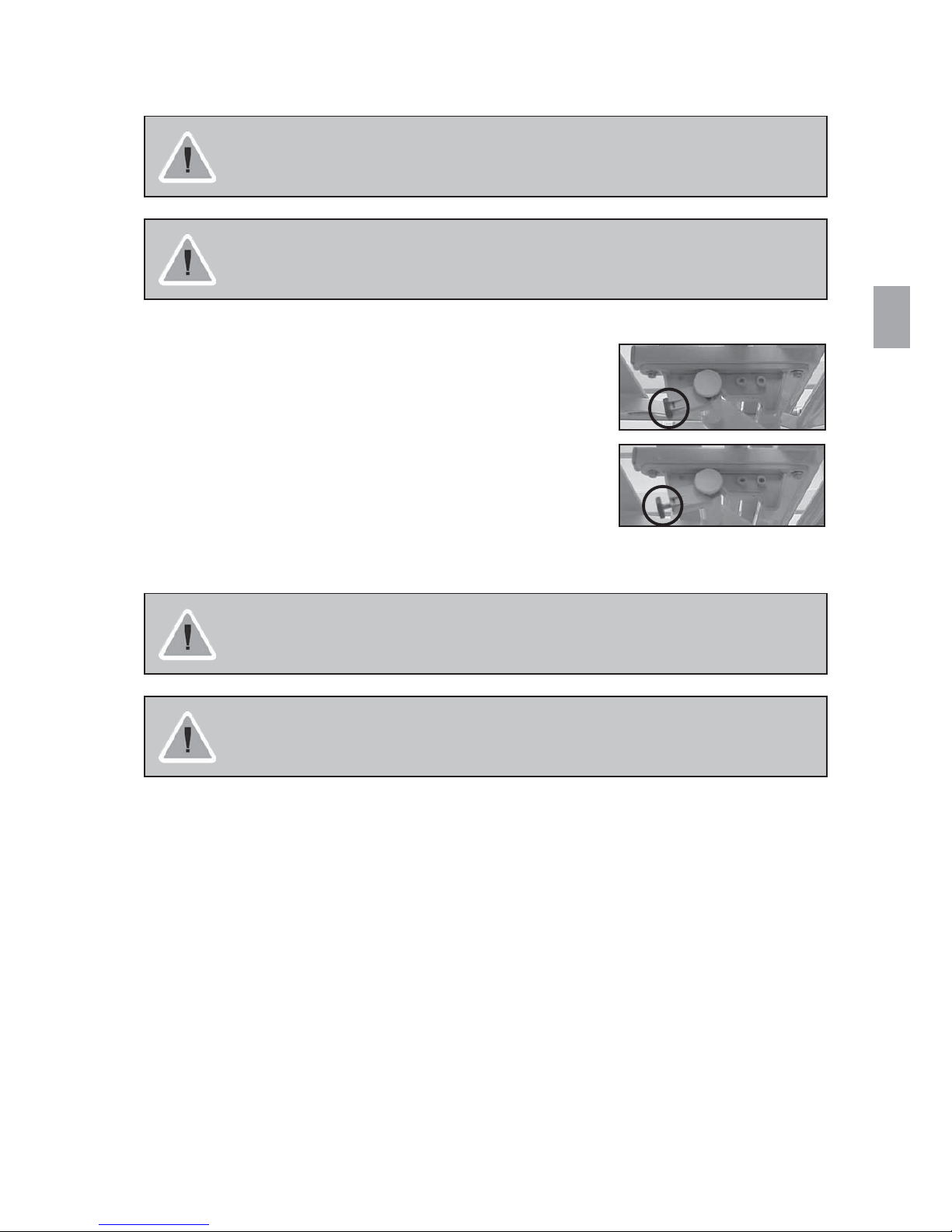

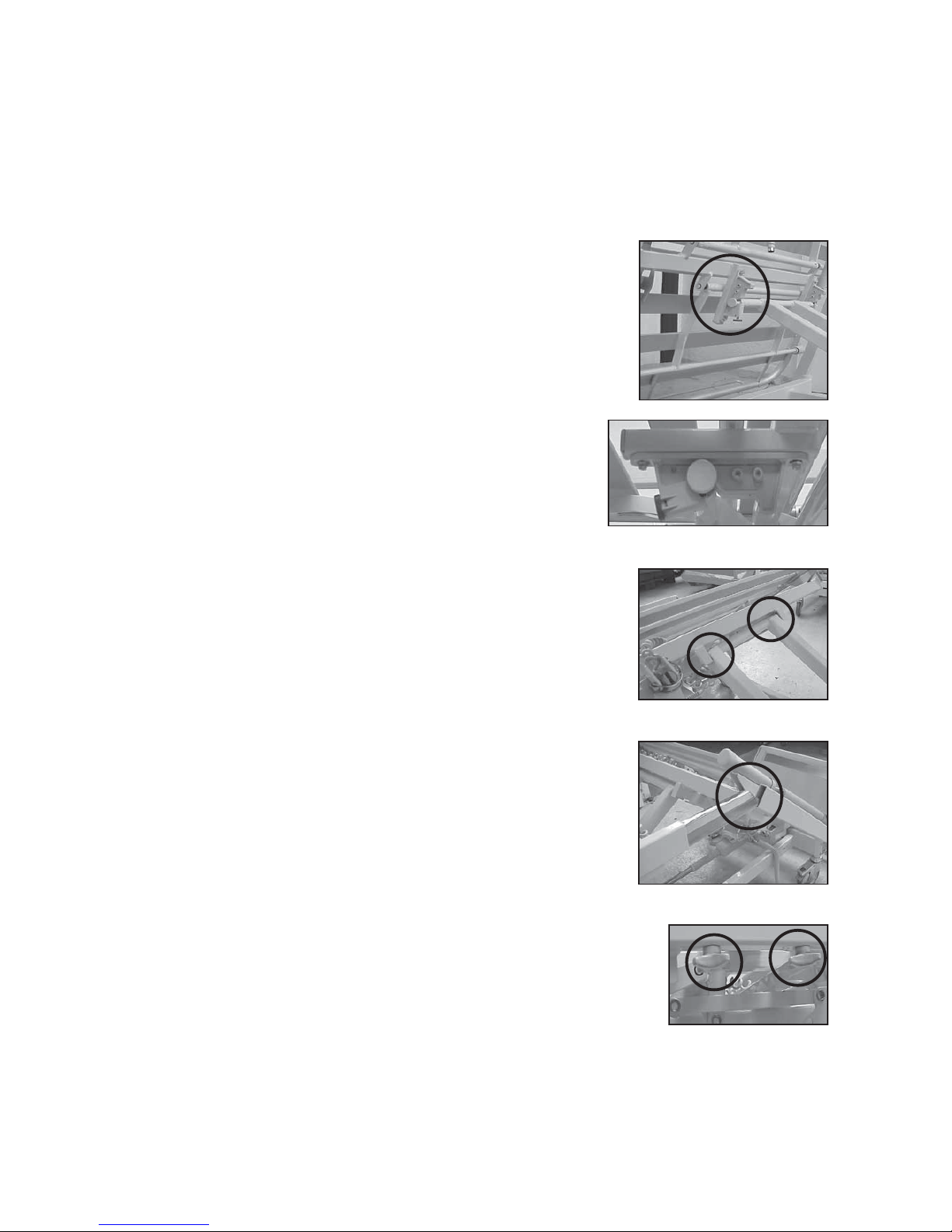

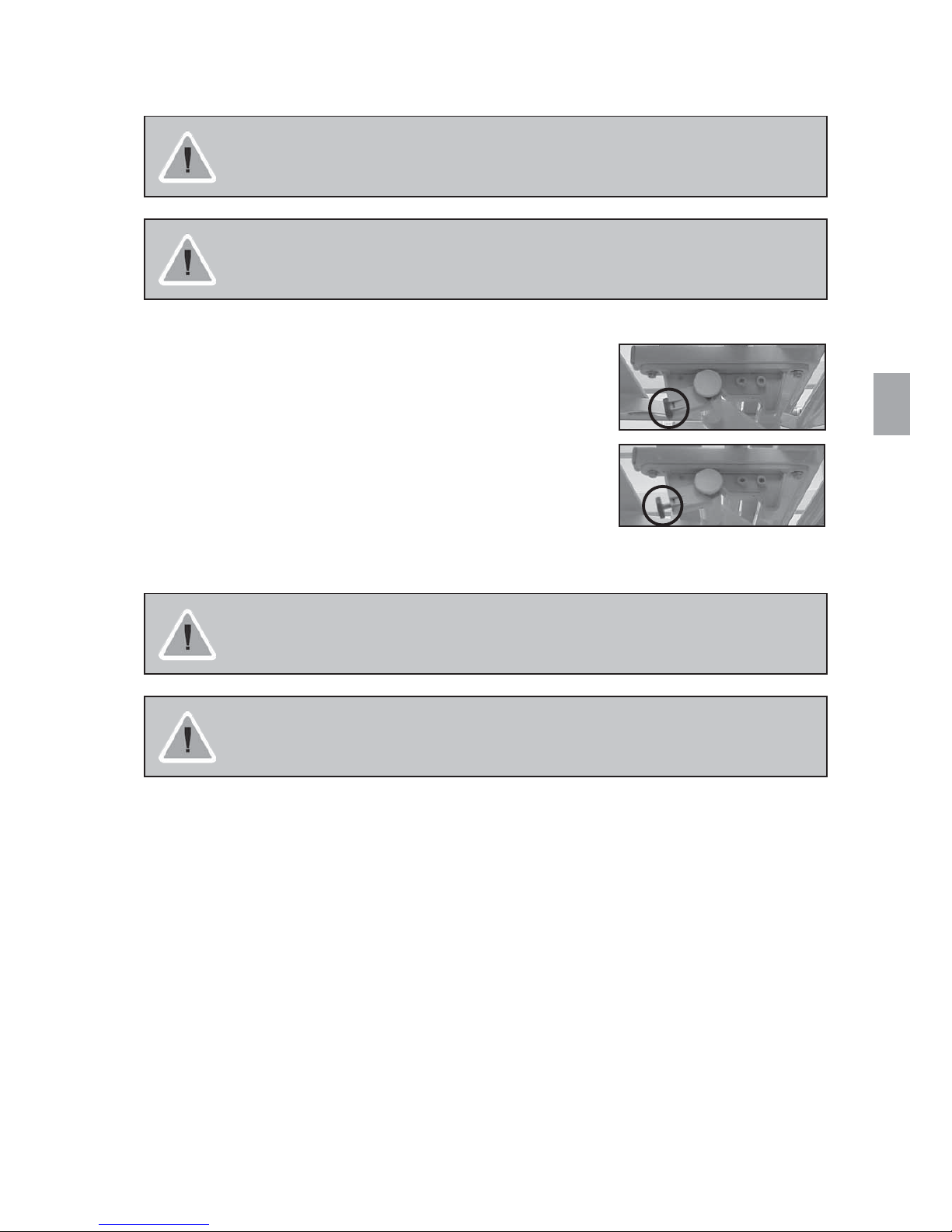

Check, that the connection between mattress support

and base frame is properly locked (cf. the picture).

Check that all plugs of the motors and hand control are

correctly connected to the control unit according to the

printed symbols.

The bed must have the brakes engaged during nursing of a patient in the bed.

Disconnect the plug from the mains before moving the bed. The cable must be kept clear off the

floor and the castors during transport.

Connect the SB750

TM

to the mains.

For ergonomic working position: Run the bed to approx. ½ height level.

Cf. chapter 2 “Operation of the SB750

TM

”.

Mount the accessories: Bed ends, side rails, lifting pole and bumper wheel.

Cf. chapter 5 “Fitting the accessories”.

Locked pin/

snap lock

Unlocked pin/

snap lock

12

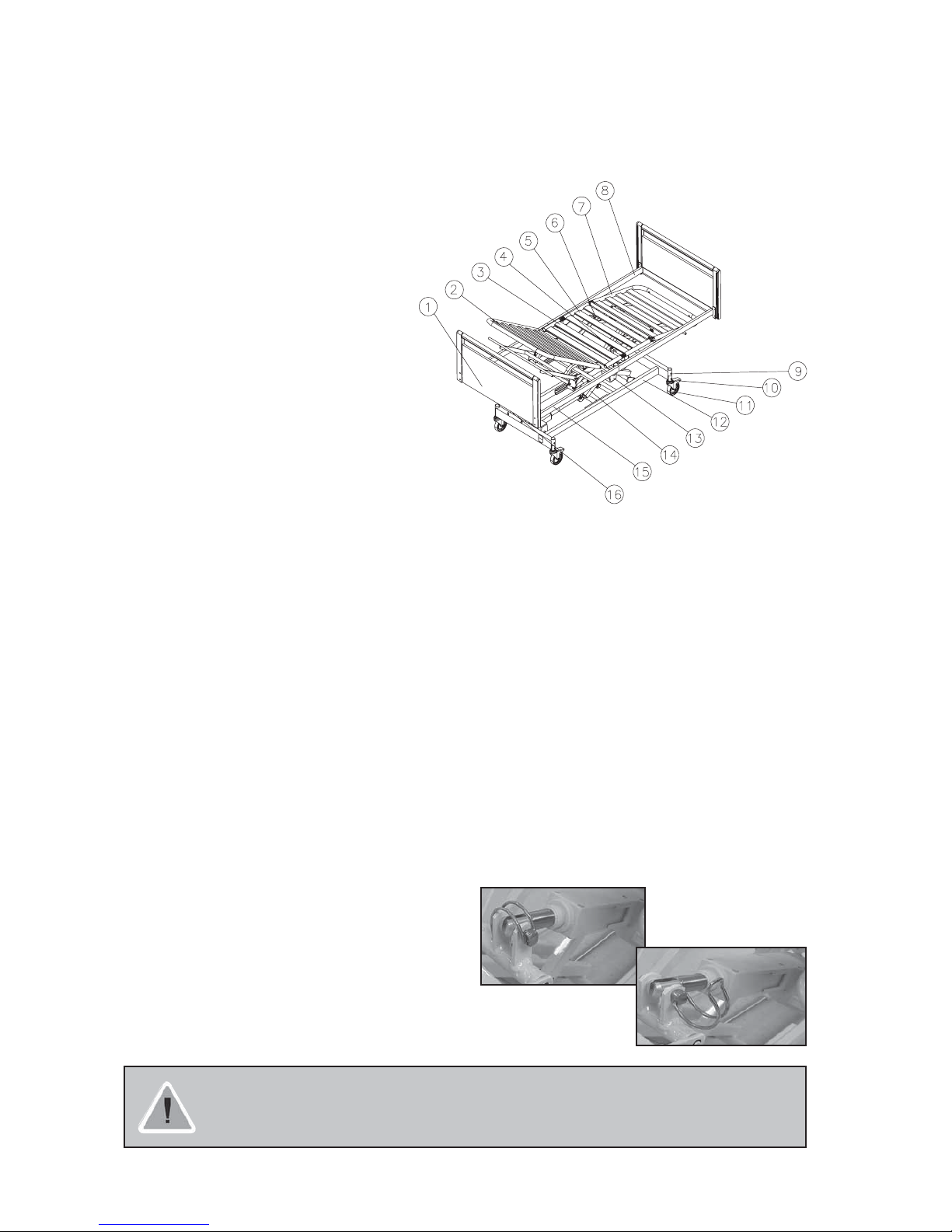

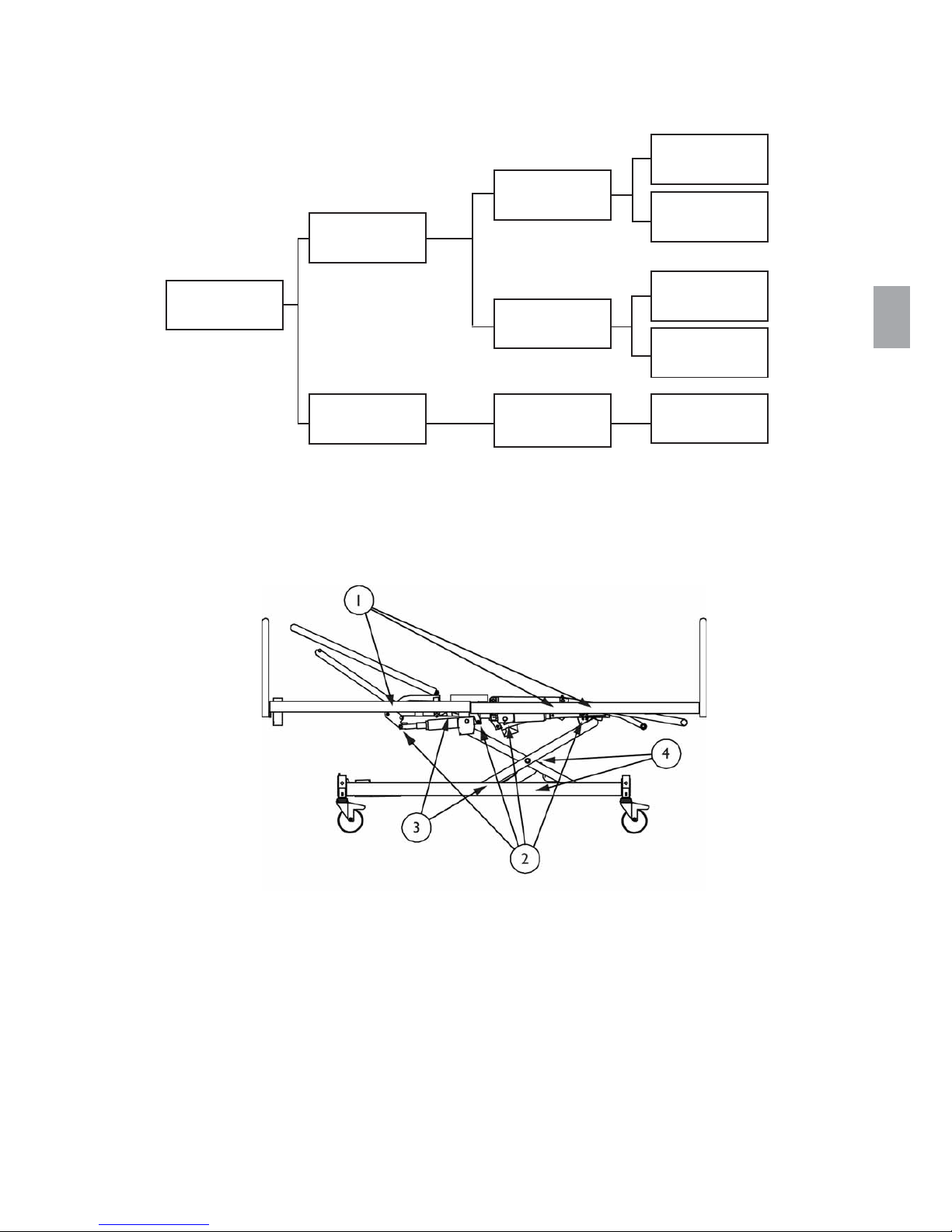

Parts of a standard bed

1. Allen key

2. Backrest

3. Seat section

4. 24 V motor, leg section or gas spring, leg section

5. Thigh section

6. 24 V motor, thigh section

7. Leg section

8. Top frame, foot end

9. Brake pedal for beds provided with central brake

10. Brake for beds provided with brake castors

11. Castor

12. Base frame

13. 24 V motor, backrest

14. Shear arms

15. Top frame, head end

16. Control unit

Accessories

x Battery box

x Fittings

x Bed end

x Wooden side rail

x Steel side rail

x Finger screw

x Lifting pole

x Bumper wheel

Emergency release of the mattress support parts

An emergency release of the mattress support is necessary

in the case of e.g. a power- or motor failure. An emergency

release of the height adjustment is NOT possible!

x Remove the plug from the mains before

emergency release of the mattress support.

x In an emergency the mattress sections are released

by pulling out the cotter pin from the motor/gas spring in question.

A minimum of 2 persons are required to release a mattress section. Both persons hold the

mattress section in locked position. One of them pulls out the cotter pin.

Both slowly lower the mattress section until it is completely down.

13

GB

5. Fitting the accessories

The tools necessary for mounting/dismounting the accessories of the SB750TM are an Allen key and an

adjustable wrench. The Allen key is kept on the inside of the cross bar at the head end of the top frame.

The Allen key is used for mounting/dismounting all fittings.

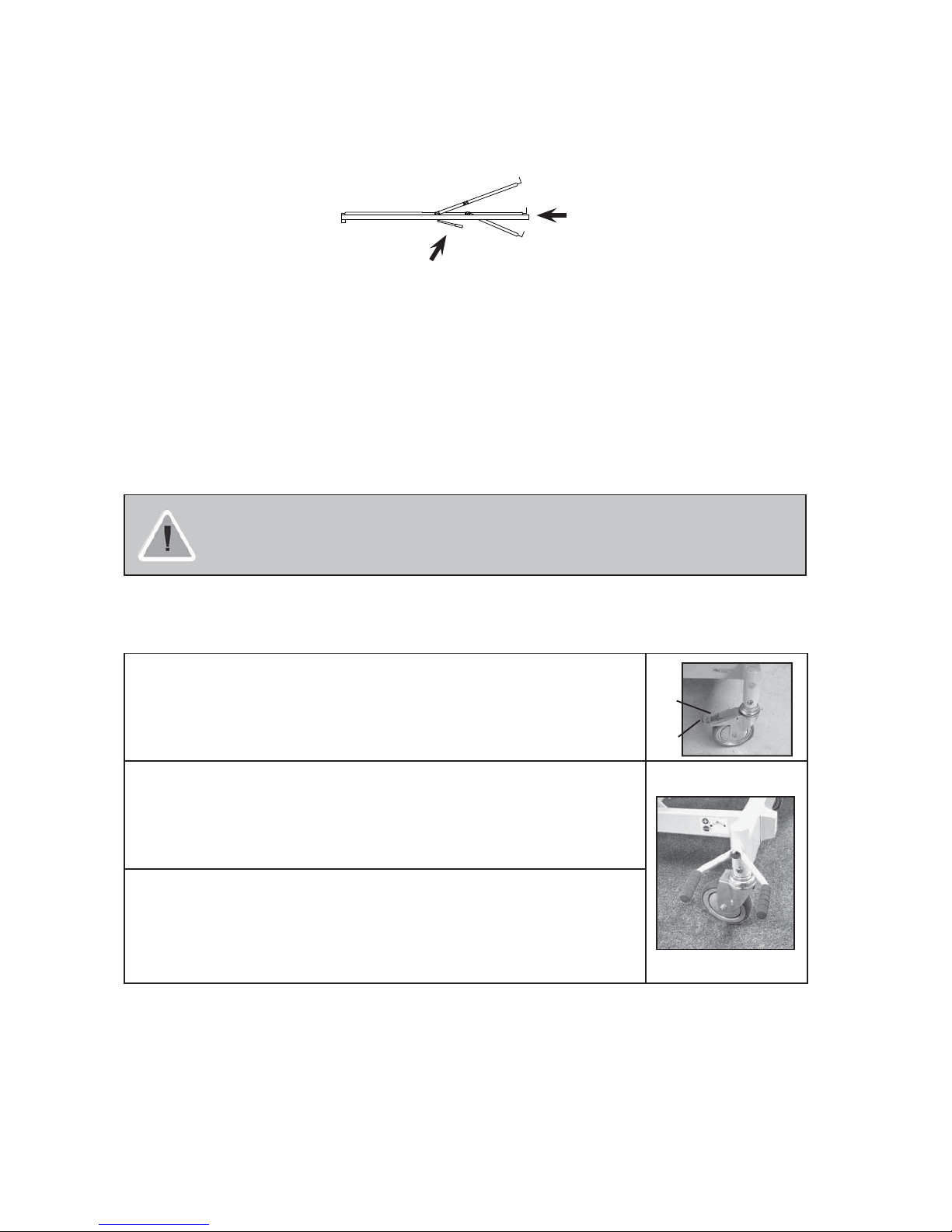

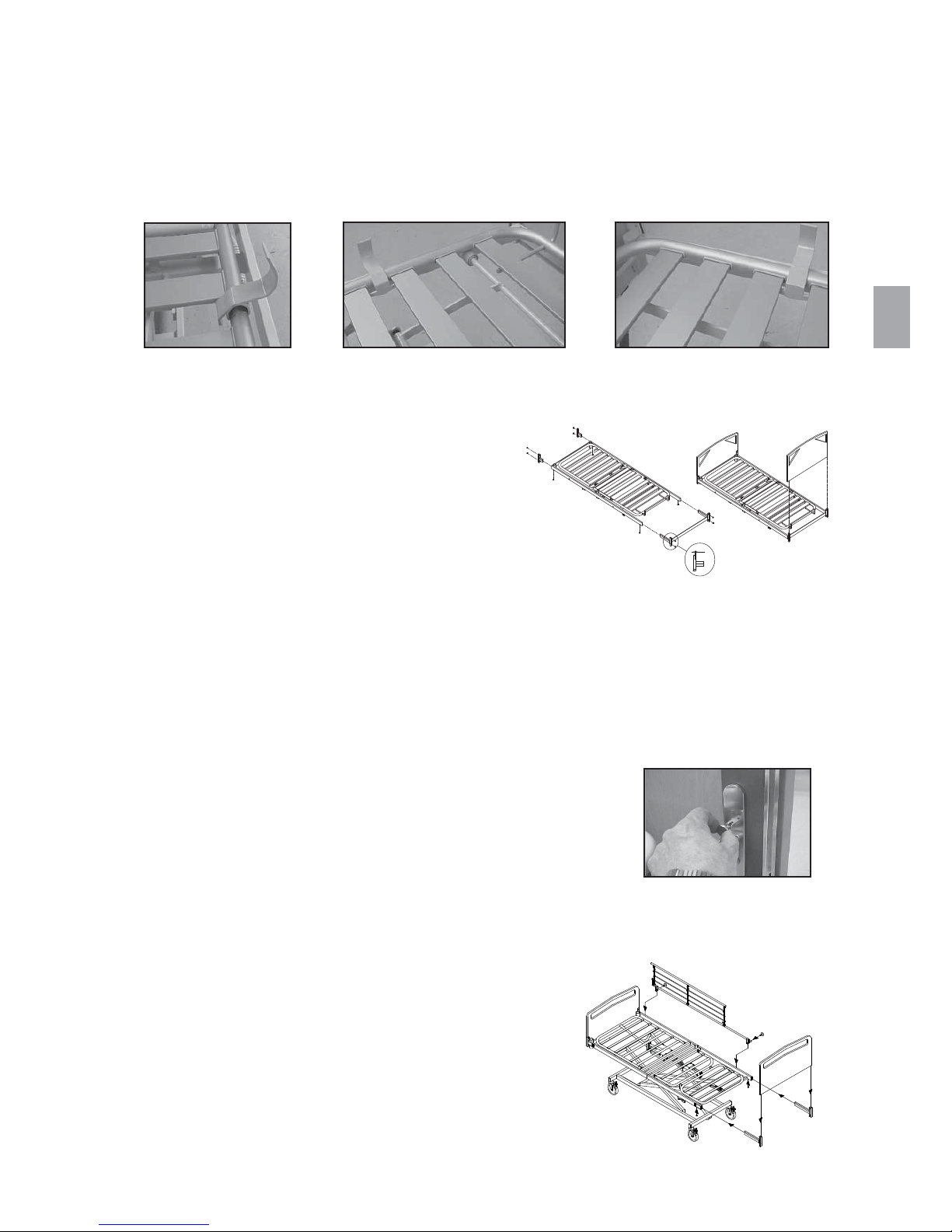

Mounting the mattress retainer

Mattress retainer is To be placed between third and To be placed between third and

squeezed down over the fourth lamella on backrest. fourth lamella on leg section.

mattress frame.

Mounting the bed end fittings

(If fittings have not been mounted in the factory)

1. Mount the 2 small fittings at the head end and tighten

them with the Allen key.

2. Mount the large fittings and the welded fitting at the

foot end and tighten them with the Allen key.

Mounting the PIGGY and ODA bed ends

Press the bed end into the U-profiles.

Mounting the FLEX III/KARIN III bed ends

Fasten the bed end to the bed end fittings with the bolts and tighten them with the Allen key.

Mounting the SANNE III bed end

Lift the bed end and place on the fittings at both sides. Push down to click into

place.

The locking pin must then be rotated and locked into postion.

Make sure that the bed end is locked.

Dismounting the SANNE III bed end

Pull the locking pin out, and turn it halfway.

Repeat at the other end. Pull the bed end up and out.

Mounting/dismounting the steel side rail

Mounting: Referring to labelling on the side rail

Tighten the side rail with 2 finger screws.

Dismounting: Loosen the finger screws, and remove the steel side rail.

14

A B C

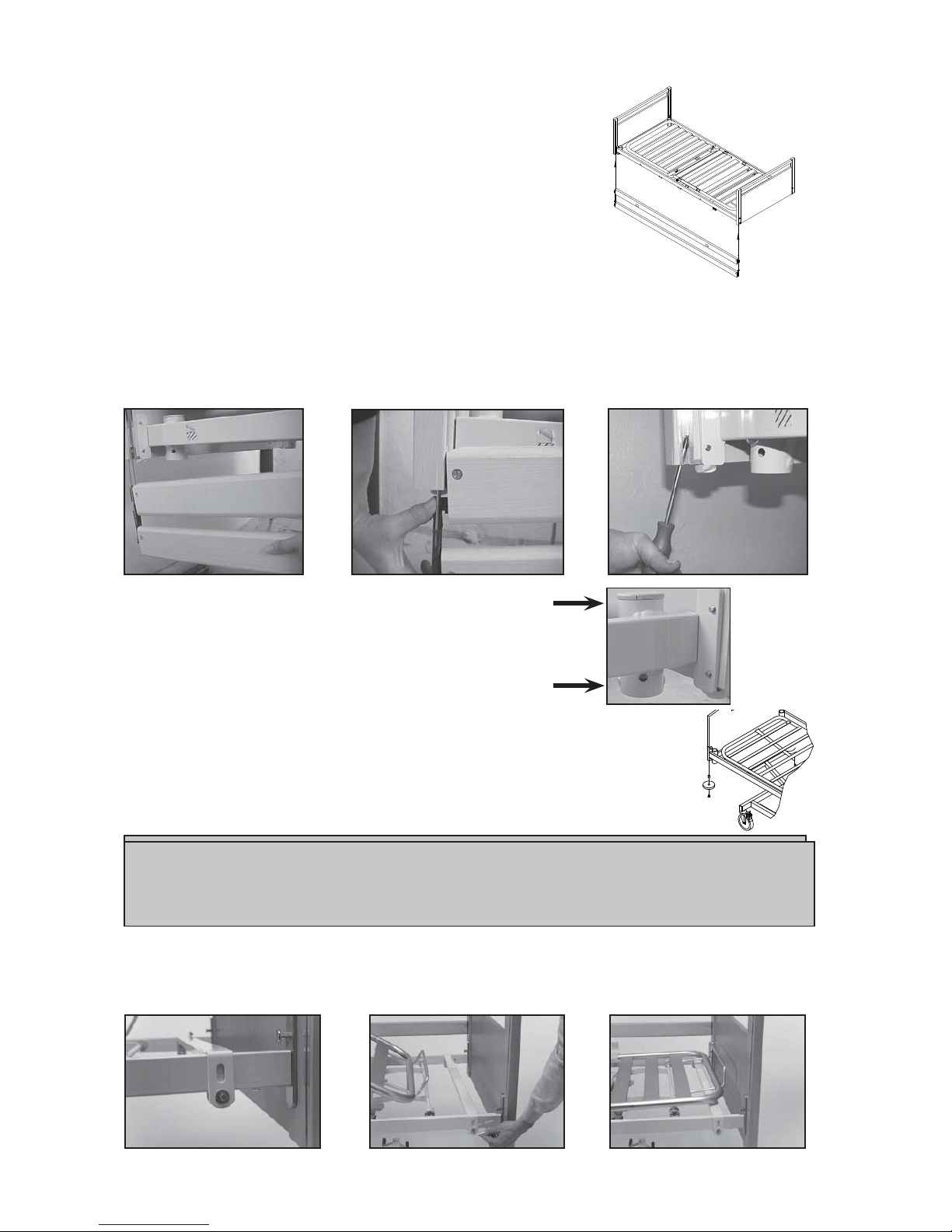

Mounting the BRITT II/III/IV side rail

1. Raise the bed about 1/3.

2. Remove the protective tape from the locking pins at the ends of the side rail.

3. Mount one end at a time. Lift the lower wooden bar and guide the metal

bow to the bed end rail (A).

4. Press the locking pin of the side rail with a finger (B).

5. Guide the side rail to the bed end until the spring support snaps into place

and prevents the side rail from falling out of the bed end.

Repeat points 3 to 5 when mounting the other end of the side rail.

Dismounting the BRITT II/III/IV side rail

1. Raise the bed about 1/3. Lower the side rail.

2. Dismount one end at a time. Lift the lower wooden bar so that the spring support is visible.

3. Press the spring support down with a wrench or a screwdriver (C).

4. Hold the lower wooden bar. Lower the side rail, until the metal bow is free of the bed end rail.

Repeat points 2 to 4 when dismounting the other end of the side rail.

Fitting the lifting pole

Remove the plastic stopper in the lifting pole tube

in which the lifting pole is to be mounted.

Mount the lifting pole - the finger screw must be used.

Fitting the bumper wheel

Mount the bushing in the bumper wheel - and tighten it with a screw under the fitting.

Bumper wheels may not be mounted on SANNE bed ends.

Lifting pole

tube with

plastic stopper

Finger screw

Correctly mounted crossbar

The screws are tightenedThe limitation crossbar is placed here

Raise the leg section of the mattress support and the lifter arm, and mount the limitation crossbar.

Tighten both screws.

Mounting the limitation crossbar under the leg section

If the bed is used by restless (spasms) or confused persons a limitation cross bar installed under the

leg section of the mattress support. This cross bar will prevent the leg section from being lowered below the level ofthe mattress support, thereby reducing the opening between leg section and bed end.

15

3.

8.

10.

9.

7.

GB

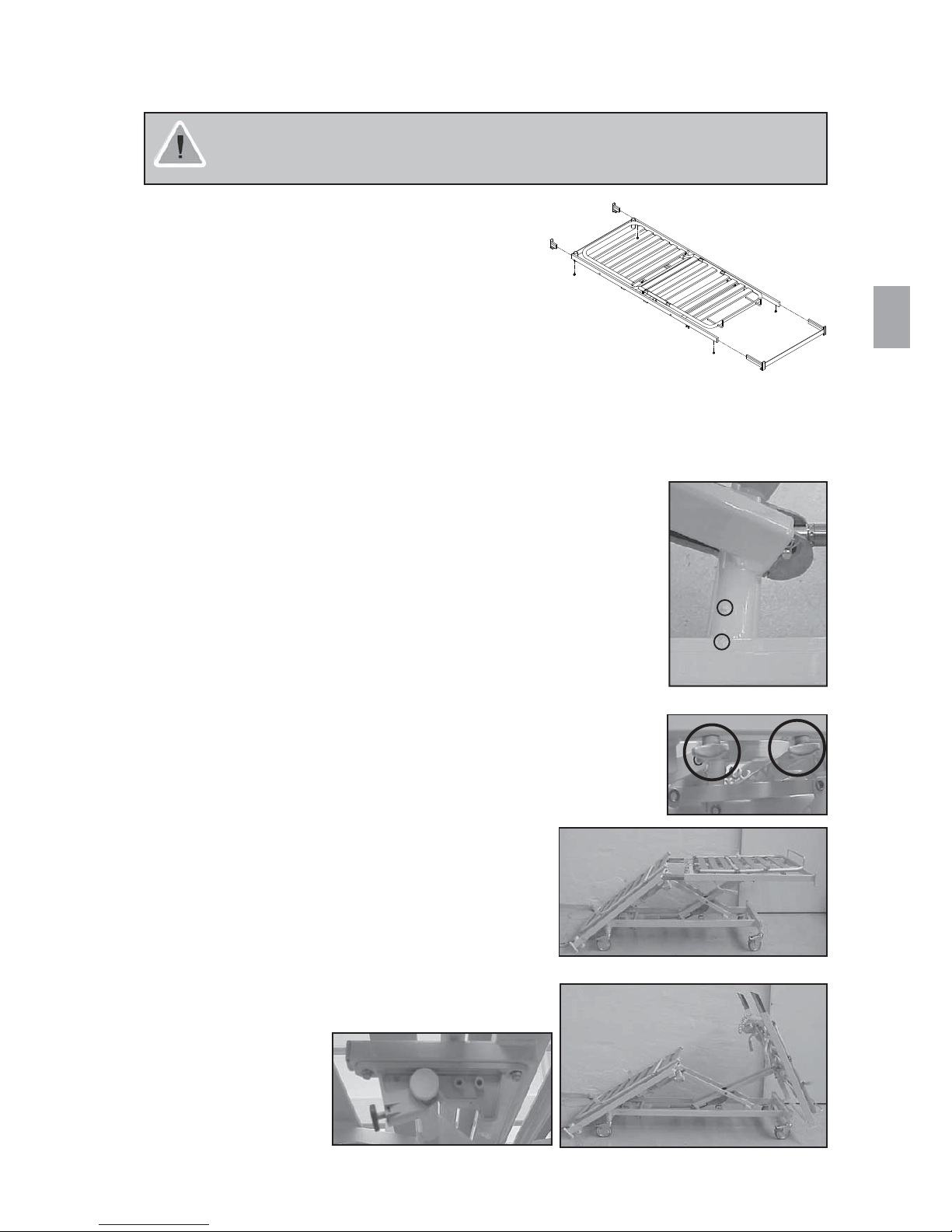

6. Disassembly/assembly of the SB750

TM

Disassembly

1. Make sure that the castors have the brakes on.

2. Dismount all accessories.

3. Run the bed to the marked height level so that the cams on the base frame’s

guide way and the shear arms are opposite each other.

4. Disconnect the power supply.

5. Remove the locking cam from the control unit.

6. Disconnect the plugs of backrest, thigh and leg motors and check that the cables

are not caught in the base frame.

7. Remove the 2x2 finger screws in the side bars.

8. Pull the head top frame out of the inserts in the side bars to

stop and lower the section onto the floor.

9. Release the 2 lock fittings/snap locks on the foot top frame by

pulling out the locking pin and turning it to the right.

10. Lower the foot-section of the top frame and lift it off the base

frame. Remove the head

section of the top frame

from the base

frame.

11. Connect the base frame to

the mains again and lower

it completely.

Operating the built-in mattress support extension

The mattress support extension is mounted using the Allen key.

The Allen key is kept on the inside of the cross bar at the head end.

1. Remove the wooden side rails (cf. chapter 5).

2. Remove the 2 screws for fastening the fitting below the side

bar

by means of the Allen key.

3. Pull out the fitting so that it extends 16 cm, insert the 2 screws

again and retighten them.

4. Loosen the 2 screws below the mattress handle on the leg section,

pull the handle completely up, and retighten the screws.

5. Insert the mattress support extension.

Warning! In order to avoid entrapment / suffocation, it is essential to avoid

extending the bed ends without extentioning the mattress support accordingly.

See page 14: Mounting the limitation crossbar under the leg section

16

7.

4.1

5.

6.

4.2

Assembly

1. Make sure that the castors have their brakes on.

2. Connect the base frame to the mains.

3. Run the bed to the marked height level so that the cams (see picture 3, page 15) on the base frame’s

guide way and the shear arms are opposite each other.

4. Lift the foot end of the top frame so that the two 2 lock

fittings/snap locks fit onto the pins on the shearing arms. (4.1)

Make sure that the locking pin has clicked into place and is

locked (4.2). Then move the foot end of the top frame into

horizontal position.

5. Place the head end of the top frame in front of the base frame and

lower it down so that the plastic gliders slide into the guide way.

6. Lift the head end of the top frame and push it into the inserts

until it stops.

7. Screw the 2x2 finger screws into the side bars.

8. Connect the plugs of the backrest, thigh and leg motors to

the control unit, see section 7 regarding wiring.

9. Mount the accessories.

17

GB

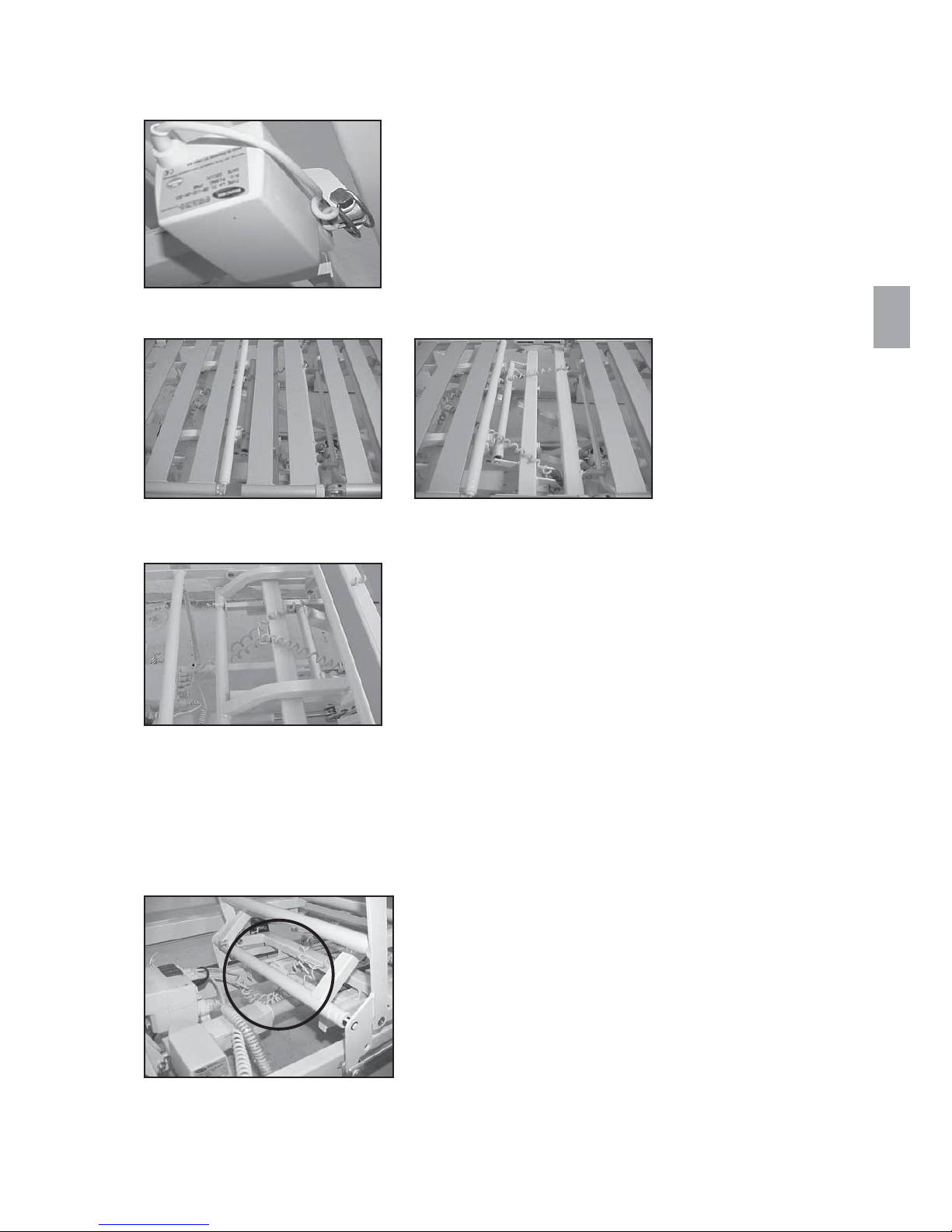

7. Wiring

The wires are mounted from the bottom and through the case of the shaft end of the motor.

Guide the wires under the lamellas.

Mount the wires through the cable bow and further to the control unit.

These photos show a bed with 2 motors for the mattress support.

Control the wiring by operating all the motors of the bed to their outer positions.

When all wires have been correctly mounted, there is no squeezing risk of the wires.

It is normal that the wires after short usage loosen a bit.

18

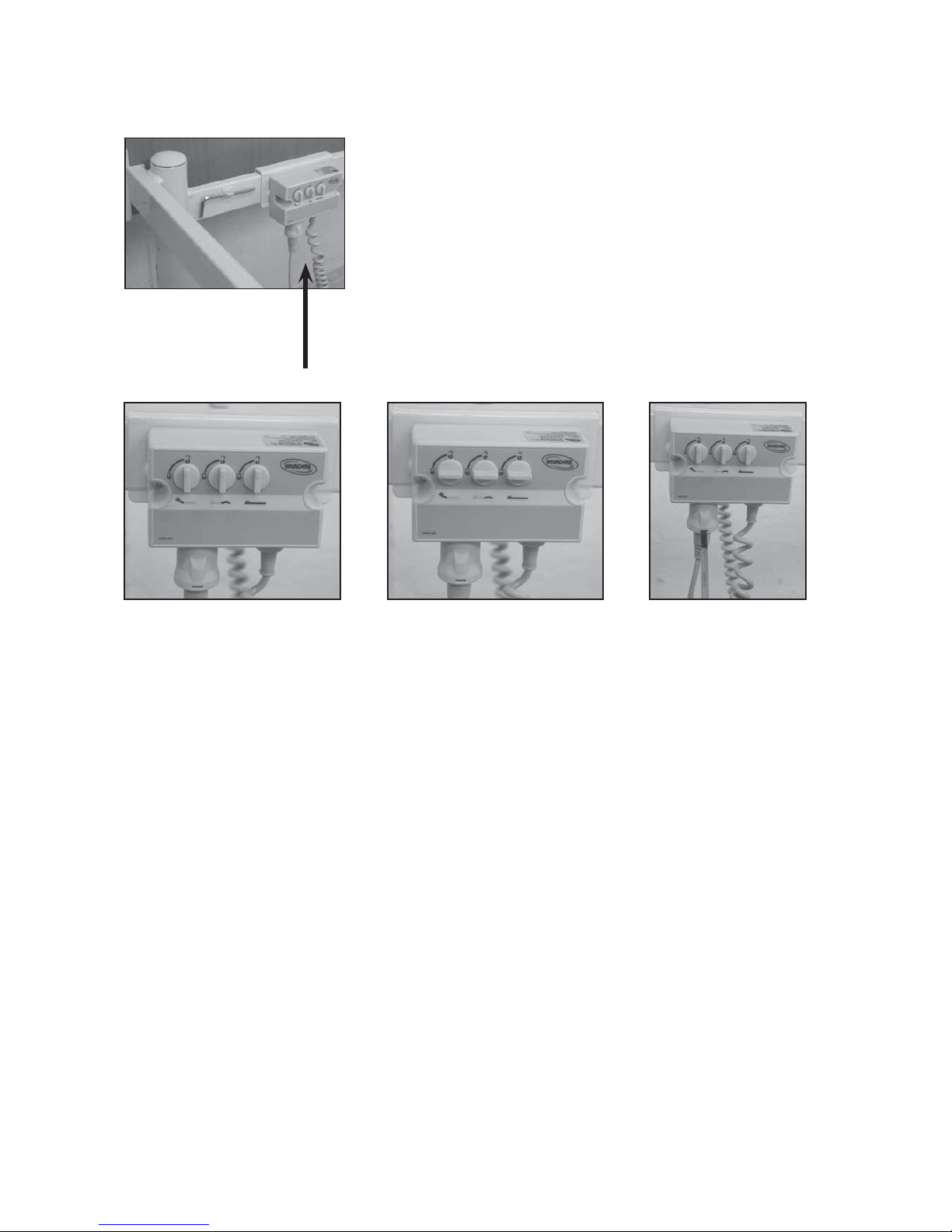

ACP Box (optional)

The hand control can be locked by activating the switch on the ACP box

located in the head end of the bed.

To check if the locking function has been activated, depress a button on the

hand control.

Open Locked Removal of

safety lock

Replacement of hand control fitted to the ACP-Box

The white locking ring on the ACP box is depressed, after which the hand control cable can be removed.

19

GB

8. Order numbers for accessories

Article Dimensions Order no.:

WOODEN BED END

SANNE III (beech) ................................85 cm ................................020429.01

SANNE III (beech) ................................90 cm ................................020740.01

SANNE III (beech) ...............................105 cm ................................021953.01

SANNE III (beech) ...............................120 cm ................................021954.01

SANNE III (cherry / beech) .........................90 cm ................................021956.07

SANNE III, increased and lowered (beech, ) *) ..........85 cm ............................ 1451258-0101

SANNE III, increased and lowered (beech, ) *) ..........90 cm ............................ 1451257-0101

SANNE III, increased and lowered (beech, ) *) .........105 cm ............................1484403-0101

SANNE III, increased and lowered (beech, ) *) .........120 cm ............................1484404-0101

*) To be used with the LILLI III wooden side rail

FLEX III (beech) ..................................85 cm ................................020417.01

FLEX III (beech) ..................................90 cm ................................020737.01

PIGGY (beech / U-profiles) .........................85 cm ................................020431.01

PIGGY (beech / U-profiles) .........................90 cm ................................018940.01

ODA (beech / U-profiles) ...........................85 cm ................................020430.01

ODA (beech / U-profiles) ...........................90 cm ................................016609.01

Bed ends are available in other versions than the above mentioned - contact Invacare®

Side rails

Scala Basic Metal side rail (foldable) ..................................................... 1432784-1015

Scala Basic Plus Metal side rail (foldable, with plastic insert) .................................. 1432787-1015

Scala Medium Metal side rail (foldable) .................................................. 1432781-1015

Scala Decubi Metal side rail (foldable) ................................................... 1432793-1015

Metal side rail Model 5539, extended (foldable, with loose finger screws) ....................50.55390.D0/L+R

BRITT IV wooden side rail (high + 2.5 cm, beech) ......................................... 1427875-0101

BRITT IV wooden side rail (high + 2.5 cm, cherry) ......................................... 1427875-0102

BRITT IV wooden side rail (high + 2.5 cm, white pigmented) ................................ 1427875-0105

BRITT III wooden side rail (beech) .........................................................020434.01

BRITT III wooden side rail, short (beech) ....................................................021342.01

BRITT III wooden side rail (cherry) .........................................................020434.02

BRITT III wooden side rail, short (white pigmented) ...........................................021342.05

BRITT III wooden side rail (white pigmented) .................................................020434.05

BRITT II wooden side rail, extended (beech) .................................................019372.01

BRITT II wooden side rail, extended (cherry)

.................................................019372.02

BRITT II wooden side rail, extended (white pigmented) .........................................019372.05

LILLI III wooden side rail (beech) ....................................................... 1433812-0101

LILLI III wooden side rail (cherry) ...................................................... 1433812-0102

LILLI III wooden side rail, extended (beech) .............................................. 1434044-0101

Covering tubes for mattress support extension ..............................................017639.D0

SUPPORT HANDLES

Support handle ................................25x30 cm ...............................021964.D0

Support handle ................................40x50 cm ...............................021963.D0

Support handle ................................25x80 cm ............................ 1417510-1015

Support handle ................................40x30 cm ............................ 1417511-1015

Support handle ................................40x95 cm ............................ 1417512-1015

LIFTING POLE

Lifting pole ..........................................................................50.57600.D0

LIMITATION CROSSBAR

Limitation crossbar (prevents the leg section from being lowered below the level of the top frame) . 1510820-1015

20

Article Dimensions Order no.:

DRIP

Drip rod ............................................................................50.60030.D0

Drip rod (for mounting in lifting pole tube) .................................................50.60910.00

BUMPER WHEELS

Bumper wheels (one) ........................................................75 mm ....50.59600.00

Bumper wheels (one) .......................................................100 mm ....50.59610.00

Bumper wheels (one) .......................................................150 mm ....50.59640.00

Bumper wheels (one, vertical) ................................................100 mm ....50.59630.D0

MATTRESSES

Dacapo Standard (38 kg/m

3

cold foam, cotton cover) ...........................85x200x10 .......1421530

Dacapo Standard (38 kg/m

3

cold foam, cotton cover) ...........................90x200x10 .......1421531

Dacapo Standard (38 kg/m

3

cold foam, cotton cover) ..........................105x200x10 .......1421532

Dacapo Standard (38 kg/m

3

cold foam, cotton cover) ..........................120x200x10 .......1421533

Dacapo Basic (38 kg/m

3

cold foam, incontinence cover) ..........................88x200x12 .......1421551

Dacapo Basic (38 kg/m

3

cold foam, incontinence cover) ..........................83x200x12 .......1421552

Dacapo Basic (38 kg/m

3

cold foam, incontinence cover) ..........................88x183x12 .......1421555

Dacapo Basic (38 kg/m

3

cold foam, incontinence cover) ..........................83x183x12 .......1421556

Dacapo Basic Heavy user (3 coated 50/50/38 kg/m

3

cold foam, incontinence cover) . . 105x200x15 .......1484429

Dacapo Basic Heavy user (3 coated 50/50/38 kg/m

3

cold foam, incontinence cover) . . 120x200x15 .......1451262

Dacapo Organic (50 kg/m

3

Organic foam, egg tray shape, incontinence cover) .......85x200x12 .......1421572

Dacapo Organic (50 kg/m

3

Organic foam, egg tray shape, incontinence cover) .......90x200x12 .......1421573

Dacapo Combi (2 coated 50/38 kg/m

3

, Visco-elastic/cold foam, incontinence cover) ....85x200x14 .......1421489

Dacapo Combi (2 coated 50/38 kg/m

3

, Visco-elastic/cold foam, incontinence cover) ....90x200x14 .......1421490

Dacapo Square (2 coated 50/38 kg/m

3

, Organic foam/cold foam, incontinence cover) . . 83x200x14 .......1421515

Dacapo Square (2 coated 50/38 kg/m

3

, Organic foam/cold foam, incontinence cover) . . 88x200x14 .......1421516

Dacapo Top (50 kg/m

3

, Visco-elastic foam, incontinence cover) ....................85x200x6 .......1421587

Dacapo Top (50 kg/m

3

, Visco-elastic foam, incontinence cover) ....................90x200x6 .......1421588

It is possible to buy custom-fit insertion mattresses for extended beds.

LOW - SLUNG SET

Low-slung set with Ø75 mm braking castor .................................................021343.D0

SIDE RAIL COVERS

Scala Cover for Britt III, IV and Lilli III wooden side rail ..........................................1449412

Scala Cover for Britt III wooden side rail, short ................................................1449411

Scala Cover for Britt II and Lilli III wooden side rail, extended ....................................1493565

Scala Cover for Britt III, IV and Lilli III wooden side rail, net ......................................1449413

Scala Cover for Britt II and Lilli III wooden side rail, net, extended .................................1449415

Scala Cover for metal side rail, Basic .........................................................1449423

Scala Cover for metal side rail, increased .....................................................1449419

Scala Cover for metal side rail, extended .....................................................1449421

Safety Cover for Britt III, IV and Lilli III wooden side rail .........................................1511890

Safety Cover for Britt III wooden side rail, short ...............................................1513592

Safety Cover for Britt II and Lilli III wooden side rail, extended ....................................1511892

21

GB

9. Maintenance and check-ups

Service and maintenance of the SB750TM must only be performed by personnel who have received the

necessary instruction or training.

With normal daily use, service must be carried out according to the service schedule after 2 years use and

thereafter every second year.

When moving the bed, service must be carried out according to the service schedule.

When using Flex or Karin bed ends, which are made of a flexible type of wood, it will be necessary to tighten the

hexagon head screws at intervals other than described in the service schedule.

Note! The top frame must be supported during service inspections to prevent accidental lowering.

We recommend a safety test comprising the motors’ performance and mechanical state once a year.

Motors, hand control and control unit

These parts are serviced by exchanging the faulty part.

10. Beds equipped with accumulator back up

A bed with accumulator back up is equipped with an additional box next to

the control unit.

Preventive maintenance

The accumulators have to be exchanged after 4 years. Depending on how the

back up is used the exchange may have to take place earlier.

Frequent, sudden discharges reduce the back-up’s life.

We recommend the accumulator be tested at least once a year.

Accumulators are not damaged by continuous connection to the mains.

Exchanging the accumulators

Accumulators must be exchanged as sets and replaced with accumulators of the same type or mechanically

and electrically compatible accumulators:

The accumulators are delivered as a pair under order no.: 818323 (12V - 1,2 Ah).

Accumulators must be new and charged at least every 6 months for maintenance purposes.

Accumulators in a set must have identical production codes.

Prior to insertion make sure that the accumulator set is correctly connected cf. the drawing

(in the accumulator box), and that none of the connections are loose.

Warning

Old or faulty accumulators may generate an explosive gas mixture during charging.

The accumulator box is provided with vents to ensure adequate ventilation of the box.

The vents must not be blocked or covered, as this may result in pressure built-up and the risk of explosion.

Waste disposal

Old accumulators may be returned to Invacare

®

, alternatively they are disposed of like car batteries.

22

11. Maintenance chart

Service and maintenance of the SB750TM must only be performed by personnel who have received

the necessary instruction or training

S/N (located on mattress support): ___________________

Date: Initials:

Circlips, cotter pins and plastic fixing ring checked.

Screws tightened.

Weldings checked.

Side rail locking and moving system tested.

Castor fittings tightened.

Castor brakes checked.

Height adjustment motor checked.

Back rest motor checked.

Thigh section motor checked.

Leg section gas spring/motor checked.

Lead-in connections correctly suspended and

undamaged. Plugs undamaged.

Damaged coating repaired.

Lubrication according to the lubrication plan.

NB! The wooden side rails´ gliding system must not

be lubricated with oil - otherwise the wooden bars

will move sluggishly.

Accessories checked.

A service contract can be made in the countries, where Invacare® has its own sales company.

In certain countries Invacare® offers courses in service and maintenance of the SB750

TM

.

Spare parts lists and additional user manuals are available from Invacare®.

23

GB

12. Trouble-shooting the electrical system

Note! Make sure that the mains are connected.

13. Lubrication plan

We recommend lubricating the SB750TM according to the following instructions:

1. Lifting arm bearings - lubricate with oil

2. Motor/gas spring bearings - lubricate with oil

3. Gliders and guide ways - lubricate with grease

4. Shear arms and rollers shaft - lubricate with oil/grease

Lubricate with medically clean oil, e.g. KEW-WO 50, order no.: 813239 and grease, order no.: 1497607.

Motor plug not

connected

Sounds from the

relay

Defective motor

No motor sound

Motor does not

run

Defective control

unit

No relay sounds

Motor sounds

Piston rod does

not move

Defective motor

Defective hand

control

24

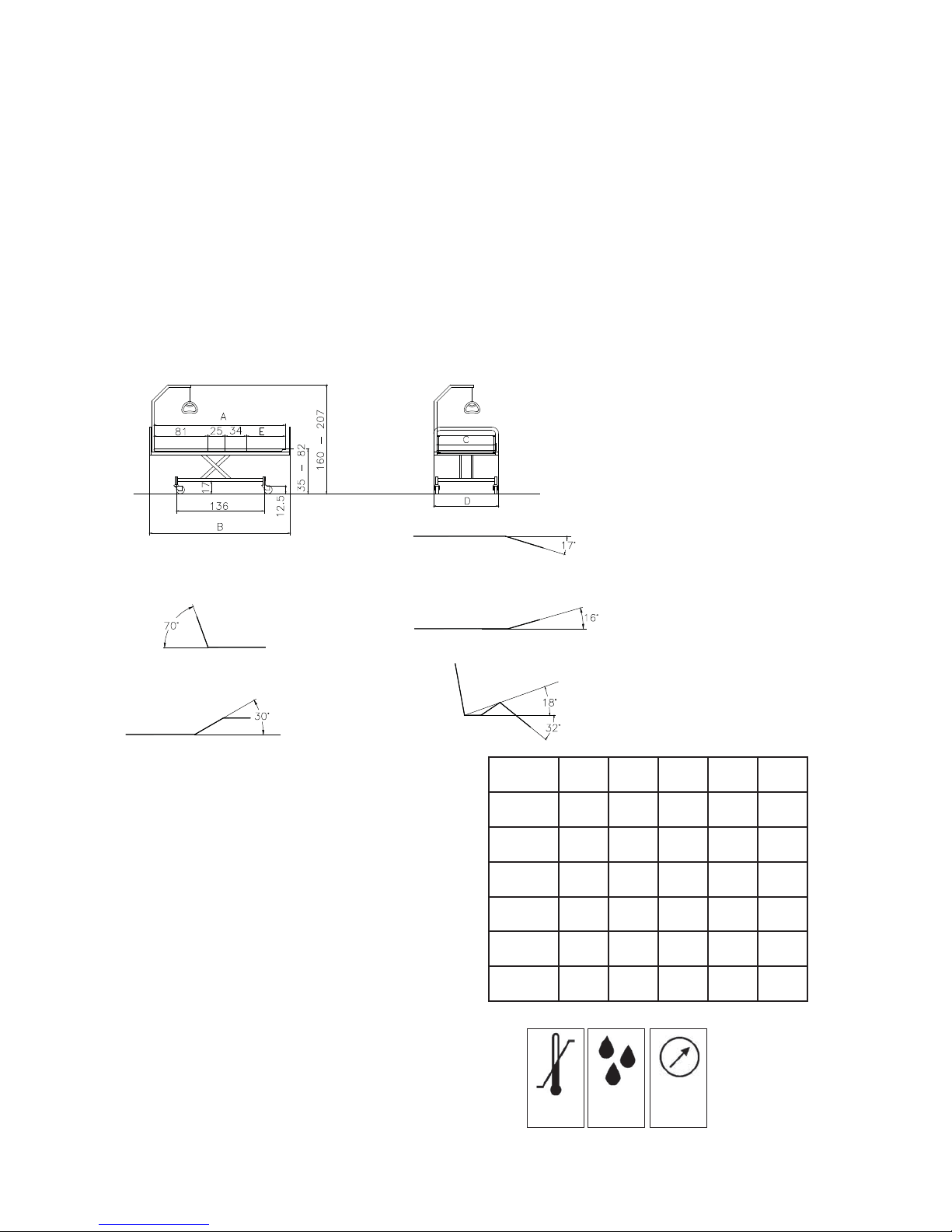

WxLABCD E

85x200 200 213 85 95 60

90x200 200 213 90 101 60

85x183 183 196 85 95 43

90x183 183 196 90 101 43

105x200 200 213 105 116 60

120x200 200 213 120 131 60

700 -

1.100 hPa

10 - 80%

-10 - 50°C

14 - 122°F

14. Cleaning

The SB750TM cannot withstand cleaning in washing machines nor flushing with a water jet. Use ordinary

disinfectioning detergents. Dry the bed after cleaning. Never use acids, alkalines or solvents. Please make sure the

power plug is removed from the socket outlet.

The back rest and the leg/thigh sections can be lowered onto the mattress support, which facilitates cleaning and

access to the control unit.

Important details for cleaning hand control, control unit and motors IP 66: Always clean with water and

brush. Water may be pressurised, but never use high-pressure cleaning or steam cleaning directly on the electrical

parts.

15. Technical specifications

All measurements are stated in cm. All angles are stated

in degrees. All measurements and angles are stated

without tolerances. Invacare® reserves the right to change

the stated measurements and angles without warning.

Transportation and storage conditions:

Temperature between -10° and 50° C

Humidity between 10 and 80 % RH

Pressure between 700 and 1.100 hPa

25

= 220 kg

GB

16. Electrical data

Voltage supply: 230 V AC/50 Hz.

Max. current input: 1,5 A.

Intermittent (periodic use of motors): 10% max. 6 min/h.

Max. accumulator capacity: 1,2 Ah.

Protection class: IP 66.

Output: 70 VA.

Sound level: 48 dB (A).

Double insulated, class II, type B.

Alternating current:

Direct current:

Max. load (SWL)

(Patient + mattress + siderail + lifting pole + other equipment).

The patient is not separated from the ground and the chassis.

Potential equalization.

The control unit has no contact breaker, disconnecting the plug is the only means of interrupting the power supply.

26

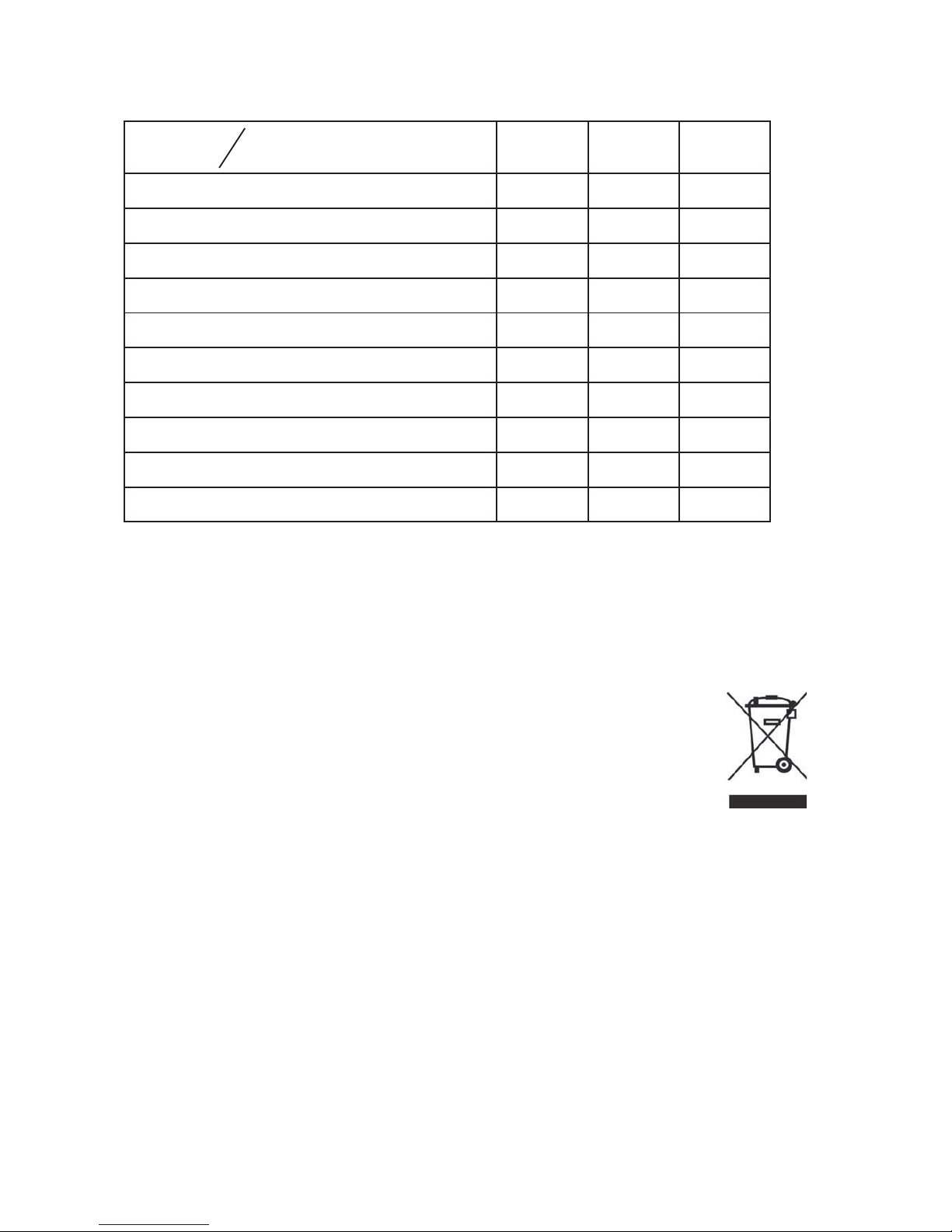

17. Weight

Measurement

Weight

85x200

90x200

105x200 120x200

Top frame, head, with mattress support 25 kg 34 kg 36 kg

Top frame, foot, with mattress support 25 kg 36 kg 39 kg

Base frame 40 kg 40 kg 42 kg

Complete bed, excluding accessories 90 kg 110 kg 117 kg

Bed end (SANNE III/FLEX III/KARIN III) 6 kg/pcs. 7 kg/pcs. 8 kg/pcs.

Wooden side rail (BRITT II/BRITT III) 7 kg/pcs. 7 kg/pcs. 7 kg/pcs.

Wooden side rail (BRITT IV) 8 kg/pcs. 8 kg/pcs. 8 kg/pcs.

Bed end (ODA/PIGGY) 6 kg/pcs. - -

Steel side rail 7 kg/pcs. 7 kg/pcs. 7 kg/pcs.

Lifting pole 6,5 kg 6,5 kg 6,5 kg

18. Disposal

This product has been supplied from an environmentally aware manufacturer that complies with the Waste

Electrical and Electronic Equipment (WEEE) Directive 2002/96/CE.

This product may contain substances that could be harmful to the environment if disposed of in

places (land fills) that are not appropriate according to legislation.

The »crossed out wheelie bin« symbol is placed on this product to encourage you to recycle

wherever possible.

Please be environmentally responsible and recycle this product through your recycling facility at

its end of life.

5

DK

Indholdsfortegnelse

Brugerdel ...................................................6

1. Generelt ................................................6

2. Betjening af SB750

TM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Teknisk del .................................................10

3. Information .............................................10

4. Ved modtagelse af SB750

TM

på opstillingsstedet ...............11

5. Montage af tilbehør ......................................13

6. Adskillelse/samling af SB750

TM

..............................15

7. Ledningsføring ..........................................17

8. Bestillingsnumre på tilbehør ...............................19

9. Vedligehold og eftersyn ...................................21

10. Specielt for senge med akkumulator back-up .................21

11. Serviceskema ...........................................22

12. Fejlsøgning i det elektriske system ..........................23

13. Smøreskitse ............................................23

14. Rengøring ..............................................24

15. Tekniske specifikationer ..................................24

16. Elektriske data ..........................................25

17. Vægt ..................................................26

18. Bortskaffelse ............................................26

6

Brugerdel

De har valgt en Invacare® EC-Høng’s SB750TM plejeseng.

x Sengen er udviklet til brugere over 12 år til pleje i hjemmet og på plejehjem.

x Sengen forener stabil konstruktion og ergonomisk design med nem adskillelse og betjening.

x Sengen sikrer ved hjælp af et unikt ryglæns-tilbageføringssystem en god liggekomfort for brugeren og

ideelle vilkår for plejeren ved nemmere forflytning.

For at optimere liggekomforten anbefaler Invacare® EC-Høng A/S, at en 12 cm madras anvendes.

1. Generelt

SB750TM opfylder alle krav til maximum afstande. Der må dog gøres opmærksom på, at hvis

sengen bliver brugt til mindre personer, er der en risiko for at glide ud igennem åbningerne for

enden af sengehestene eller igennem åbningerne imellem sengehestene og liggefladen.

Sengen må ikke bruges af patienter under 12 år eller af patienter,

hvis kropsstørrelse svarer til eller er mindre end en gennemsnits 12-årig.

Sengen med sengehest må ikke benyttes af personer, der vejer under 45 kg,

er under 150 cm´s højde eller er urolige og konfuse, medmindre:

en faglig vurdering og accept er foretaget, eller

et korrekt monteret sikkerhedsovertræk til sengehestene bliver anvendt.

Ved brug af sengehest og tilhørende overtræk er det vigtigt, at både sengehest og overtræk

monteres som angivet - i modsat fald er der fare for klemning / kvælning mellem

liggeflade, sengehest og gavle.

Hvis sengen anvendes af urolige eller konfuse personer, kan der med fordel anvendes en

ACP-boks, til låsning af håndbetjeningen, og/eller tværprofil til placering under sengens bendel.

Denne tværprofil vil så modvirke, at bendelen kan sænkes under overrammens niveau, og dermed

mindske åbningen mellem bendel og gavl.

Efterlad altid sengen i laveste position - dermed mindskes effekten af eventuelle faldulykker fra

liggefladen.

Invacare® påtager sig intet ansvar, hvis produktet anvendes, forandres eller sættes

sammen på anden vis end som angivet i denne brugsanvisning.

Ved ind- og udstigning af sengen kan sengens højdeindstilling med fordel bruges. Endvidere kan ryglænet anvendes

som støtte (gul knap på håndbetjeningen), dog skal sengens lår- og bendel være i horisontalstilling - i modsat fald er

der fare for overbelastning af liggefladen.

Sengen skal placeres, så højdejusteringen (op/ned) ikke generes af f.eks. personløftere eller møbler. Ellers er

der risiko for kvæstelser på bruger og/eller udstyr.

7

DK

2. Betjening af SB750

TM

Sengen kan være udstyret med denne type håndbetjening (Soft Control):

Eller med denne type håndbetjening (HB 70):

Højdeindstilling af seng

OP/NED

Siddeindstilling, uanset hvilken stilling

den starter fra

Liggefladen i vandret, uanset hvilken

stilling den starter fra

“Ud af sengen knappen”- Rejser

ryglænet og bringer lårdelen i vandret

Hæver lårdelen og bringer rygdelen

i vandret

Indstilling af bendel

OP/NED (findes ikke på senge med

3-delt liggeflade og manuel indstilling af

bendel)

Siddeindstilling

Bendel - elektrisk (findes ikke på senge med

3-delt liggeflade og manuel indstilling af bendel)

Lårdel

Højdeindstilling af seng

OP/NED

Ryglæn

8

2)

1)

Betjening af bendel på senge med gas fjedre

Løft i udløserhåndtaget med den ene hånd samtidig med at bendelen hæves til den ønskede stilling med den anden

hånd. Slip udløserhåndtaget.

Betjening af bendel på SB750, 120 bred med rastofix

For at hæve bendel: Løft i sengens bendel til ønsket højde.

For at sænke bendel: Løft en smule i sengens bendel og sænk til vandret.

Efterlad altid sengen i laveste position. Derved sikres imod klemning ved utilsigtet sænkning af

liggefladen. Der kan ske alvorlig skade på person, der opholder sig under sengen, mens sengens

højde justeres.

Betjening af bremsehjul

Betjening af hjul uden centralbremse

Når sengen er anbragt det rette sted, skal mindst et hjul i hovedende og et hjul i

fodende være bremset.

1) Brems: Træd på pedalen.

2) Udløs bremsen: Træd på pedalen.

Betjening af hjul med centralbremse

Når sengen er anbragt det rette sted, skal den være bremset.

1) Brems: Fra neutral stilling trædes på den røde pedal.

2) Udløs bremsen: Træd på den grønne pedal til neutral position.

Betjening af det retningsstyrede hjul

SB750

TM

med centralbremse kan være udstyret med et retningsstyret hjul.

Det retningsstyrede hjul betjenes fra centralbremsepedalen.

1) Aktiver retningsstyret: Fra neutral stilling trædes på den grønne pedal.

2) Deaktiver retningsstyret: Træd på den røde pedal til neutral position.

Sengehjulene kan under nogle forhold sætte mærker på enkelte typer gulv - f.eks. ubehandlede eller dårlige

trægulve. Hvis der opstår tvivl, anbefaler Invacare® at der lægges en beskyttelses plade mellem hjul og gulv.

Bendel - manuel

Udløserhåndtag

9

A B

DK

Betjening af BRITT II/III/IV træsengehest

Gavltræet kan være forberedt til, at sengehesten kan låses i halv

højde og i topposition.

Normalt er der kun mulighed for at låse sengehesten i topposition.

Op: Træk op i øverste træstav til kliklyd høres fra låsepalen.

Ned: Løft op i øverste træstav, pres derefter de 2 låsepaler

mod hinanden. Sænk sengehesten.

Løft op Udløs Sænk

Betjening af metalsengehest

Op: Træk/løft i øverste rør på metalsengehesten - mod den ende,

hvor låsesystemet sidder.

Ned: Tryk udløserknappen ned, mens der trækkes i det øverste rør

på metalsengehesten - væk fra udløsersystemet.

Der er klemrisiko af fingre ved montage og betjening af metalsengehestene. Det skal sikres,

at låsesystemet er gået korrekt i indgreb, ved at trække/skubbe den øverste overligger.

Ændring af galgehåndtagets højde

Snoren løsnes som vist på billede A, hvorefter galgehåndtaget

kan justeres til den ønskede højde.

Klem snorene sammen som vist på billede B og kontroller, at

snoren er fastlåst i snorlåsen ved at trække ned i galgehåndtaget.

Galgen skal sidde, så galgehåndtaget er inde

over sengen. Hvis galgen drejes ud over sengens

side - og galgen benyttes - kan sengen vælte.

Låsepaler

10

QA XXX

Teknisk del

Invacare® er certificeret i henhold til DS/EN ISO 9001 og ISO 13485. Dette sikrer vore kunder,

at produkter produceret hos Invacare® altid leveres i en ensartet kvalitet.

Gennem hele produktionen kvalitetkontrolleres vore emner og produkter af operatørerne. Når produktet er

færdigmonteret, foretages slutafprøvning.

Operatøren, der foretager denne slutafprøvning - som bl.a. indeholder kontrol

af alle bevægelige dele, motorer/gasfjedre og hjul, kvitterer ved at sætte sit

personlige QA-nummer på produktet.

Hvis produktet ikke lever op til Invacare® EC-Høng’s fastsatte kvalitetskrav, vil produktet blive kasseret.

Skulle der mod forventning opstå problemer med det leverede produkt, bedes henvendelse rettet til Invacare®

leverandøren.

3. Information

Læs hele den tekniske del igennem, inden sengen tages i brug eller serviceres.

Al angivelse af højre og venstre forudsætter, at man ligger på ryggen i sengen.

Vær opmærksom på, at der kan forekomme afsnit i denne brugsanvisning, der ikke er relevant for Deres seng.

x SB750

TM

er CE-mærket i henhold til Direktiv 93/42/EØF om medicinsk udstyr.

x SB750

TM

er testet uden anmærkninger hos HMI i h.t. EN 1970.

x SB750

TM

er testet og godkendt i henhold til NF (Norme Francaise).

x SB750

TM

er testet og godkendt i henhold til EN 60601-1-2:93 af UL Demko.

x SB750

TM

sengens motorer og styring er godkendt jævnfør EN 60601:1996-03.

x SB750

TM

har gennemgået risikoanalysen i henhold til EN 14971.

x SB750

TM

er klassificeret 18-12-10 i h.t. ISO 9999:2007.

Max. patientvægt: 185 kg.

Styring, håndbetjening og motorer er IP 66 tætnet.

Låsekam skal anvendes på styring, da Invacare®EC-Høng ellers ikke kan garantere for tætheden.

Der kan være risiko for elektromagnetisk påvirkning mellem sengen og andre elektriske produkter. For at mindske eller undgå elektromagnetisk påvirkning skal afstanden mellem sengen og andre

produkter øges, evt. skal apparatet afbrydes. Sengen kan benyttes sammen med medicinsk elektrisk

udstyr forbundet til hjertet (intracardialt) eller blodbanerne (intravasculart), forudsat at følgende

punkter overholdes:

- Sengen skal være forsynet med potentialudligningsklemme (symbolet vist bagerst i denne manual)

- Det medicinske elektriske udstyr må ikke fastgøres på sengens metalliske udstyr såsom sengehest,

galge, transfusionsstativ, gavle o.l.

Yderligere skal det medicinske elektriske udstyrs netledning holdes fri af udstyret eller sengens

bevægelige dele.

Invacare® påtager sig intet ansvar, hvis produktet anvendes, forandres eller sættes

sammen på anden vis end som angivet i denne brugsanvisning.

Hvis sengens funktioner ændrer sig, skal den omgående sendes til eftersyn, se “Serviceskema”, afsnit 11.

11

DK

4. Ved modtagelse af SB750TM på opstillingsstedet

Af hensyn til dannelse af kondens må sengen ikke anvendes, før denne har opnået en temperatur

på 10-50° C.

Kontroller om sengen er beskadiget. Hvis sengen er beskadiget, se da leveringsbetingelserne.

Hvis sengen leveres adskilt, skal den samles.

Se afsnit 6 “Adskillelse/samling af SB750

TM

”.

Kontroller at sammenkoblingen mellem liggeflade

og understel er korrekt låst (se illustration).

Kontroller at alle stik til motorer og håndbetjening

er korrekt monteret i styringen i henhold til de

påtrykte symbolangivelser.

Sengen skal være bremset, når der arbejdes med patient i sengen.

Fjern stikproppen fra stikkontakten inden sengen flyttes.

Ledningen skal holdes fri af gulvet og sengens hjul under transport.

Tilslut SB750

TM

til netspændingen.

For bedre arbejdsstilling: Kør sengens højde ca. halvt op.

Se afsnit 2 “Betjening af SB750

TM

”.

Monter tilbehør: Gavltræ, sengeheste, galge og fenderruller - på sengen.

Se afsnit 5 “Montage af tilbehør”.

Låst pal/snaplås

Ulåst pal/snaplås

12

Standardsengens dele

1. Unbraconøgle

2. Ryglæn

3. Sædedel

4. 24 V motor, bendel eller gasfjeder, bendel

5. Lårdel

6. 24 V motor, lårdel

7. Bendel

8. Overramme-fod

9. Bremsepedal, hvis sengen har centralbremse

10. Bremse, hvis sengen har bremsehjul

11. Hjul

12. Understel

13. 24 V motor, ryglæn

14. Saksearme

15. Overramme-hoved

16. Styring

Tilbehør

x Akkumulatorboks

x Gavlbeslag

x Gavltræ

x Træsengehest

x Metalsengehest

x Fingerskrue

x Galge

x Fenderrulle

Nødsænkning af liggefladedele

Nødsænkning af liggefladedele kan være aktuel ved

f.eks. strøm- eller motorsvigt.

Sengens højdeindstillingsfunktion kan IKKE nødsænkes!

x Stikket fjernes fra netspændingen, inden

en liggefladedel nødsænkes.

x Liggefladedelene kan nødsænkes ved at fjerne

rørsplitten på den aktuelle motor/gasfjeder.

Der skal minimum være 2 personer til at nødsænke en liggefladedel. De 2 personer

fastholder liggefladedelen i den låste position. Den ene person trækker rørsplitten ud.

Begge personer sænker langsomt liggefladedelen til denne er helt nede.

13

DK

5. Montage af tilbehør

De værktøjer, der skal bruges til montage/demontage af tilbehør på SB750TM, er henholdsvis en

unbraconøgle og en skiftenøgle. Unbraconøglen sidder indvendigt på tværrøret på overramme-hoved.

Til montage/demontage af alle typer gavlbeslag anvendes unbraconøglen.

Montage af madrasstyr

Madrasstyr klemmes ned Placeres mellem 3. og 4. lamel Placeres mellem 3. og 4. lamel

over madrasramme. på ryglæn. på bendel.

Montage af gavlbeslag

(Hvis gavlbeslagene ikke er monteret ved leveringen)

1. Monter de 2 små gavlbeslag i hovedenden – skru fast

med unbracoskruer.

2. Monter de store/det sammensvejste gavlbeslag i

fodenden – skru fast med unbracoskruer.

Montage af PIGGY og ODA gavltræ

Pres gavltræet ned i U-profilerne.

Montage af FLEX III/KARIN III gavltræ

Fastgør gavltræet til gavlbeslagene med de medfølgende bolte og fastspænd med unbraconøgle.

Montage af SANNE III gavltræ

Løft sengegavlen og hægt den på beslagene i begge sider.

Tryk gavlen ind over tappene på gavlbeslaget. Herefter drejes låsepalen, således at

den går i indgreb og fastlåser gavlen. Det skal sikres, at låsepalen er helt inde.

Demontage af SANNE III gavltræ

Træk låsepalen ud og drej den en halv omgang, så den bliver ude.

Dette gøres i begge sider. Træk op og ud - og gavltræet er demonteret.

Montage/demontage af metalsengehest

Montage: Monteres iht. mærkning på sengehesten.

Sengehesten spændes fast med 2 fingerskruer.

Demontage: De to fingerskruer løsnes og metalsengehesten løftes af.

14

A B C

Montage af BRITT II/III/IV sengehest

1. Kør sengen ca. 1/3 op.

2. Afmonter beskyttelsestape ved låsepalerne i hver ende af sengehesten.

3. Monter en ende ad gangen. Løft i nederste træstiver og før metalbøjlen

op i gavlskinnen (A).

4. Låsepalen på sengehesten trykkes ind med en finger (B).

5. Sengehesten føres op i gavlen indtil fjederpalen i gavlen springer ud

og forhindrer sengehesten i at falde ud af gavlen.

Punkterne 3 - 5 gentages ved montage af den anden ende af sengehesten.

Demontage af BRITT II/III/IV sengehest

1. Kør sengen ca. 1/3 op. Sænk sengehesten.

2. Afmonter en ende ad gangen. Løft i nederste træstiver til fjederpalen i gavlen er synlig.

3. Tryk fjederpalen ind med en nøgle eller en skruetrækker (C).

4. Hold om nederste træstiver. Sænk sengehesten indtil metalbøjlen er fri af gavlskinnen.

Punkterne 2 - 4 gentages ved demontage af den anden ende af sengehesten.

Montage af galge

Fjern plastproppen i det galgerør, galgen ønskes monteret i.

Monter galgen - fingerskrue SKAL anvendes.

Montage af fenderrulle

Monter bøsning i fenderrulle - skru fast under gavlbeslag med skrue.

Fenderruller kan ikke monteres på SANNE gavltræ.

Montage af tværprofil under bendel

Hvis sengen anvendes af urolige eller konfuse personer, kan der med fordel

anvendes en tværprofil til placering under sengens bendel. Denne tværprofil vil så modvirke, at

bendelen kan sænkes under overrammens niveau, og dermed mindske åbningen mellem bendel og

gavl.

Liggefladens bendel løftes op og profilet monteres samt fastspændes som vist.

Galgerør med

plastprop

Fingerskrue

Begge skruer spændes

Korrekt monteret

bendelsbegrænser

Bendelsbegrænseren placeres her

15

3.

8.

10.

9.

7.

DK

6. Adskillelse/samling af SB750

TM

Adskillelse

1. Sørg for at hjulene er bremset.

2. Afmonter alt tilbehør.

3. Kør sengen til den afmærkede højde, således at “knasterne” på henholdsvis

understellets kulisse og saksen er placeret over for hinanden.

4. Tag stikproppen ud af stikkontakten.

5. Fjern beskyttelseskam fra styringen.

6. Afmonter stik fra ryg-, lår- og benmotor og kontroller at kablerne er fri

af understellet.

7. Afmonter de 2x2 fingerskruer i siderørene.

8. Træk overramme-hoved ud af indskuddene i siderørene til stop

og sænk det ned til gulvet.

9. Udløs de 2 låsebeslag/snaplåse på overramme-fod ved at trække

låsepalen ud og dreje den til højre.

10. Vip overramme-fod ned og løft den væk fra understellet.

Tag overramme-hoved

væk fra understellet.

11. Understellet kan nu tilsluttes netspændingen og

køres helt ned.

Betjening af indbygget liggefladeforlænger

Advarsel! For at undgå klemning / kvælning, må gavlene aldrig fastgøres i forlænget position uden at

liggefladen er forlænget tilsvarende. Se

Montage af tværprofil under bendel

For at anvende liggefladeforlængeren skal unbraconøgle bruges.

Unbraconøglen sidder indvendigt på tværrøret i hovedenden.

1. Træsengehesten afmonteres sengen (se afsnit 5).

2. Skru de 2 skruer under siderøret til fastholdelse af

gavlbeslaget af ved hjælp af unbraconøglen.

3. Træk gavlbeslaget 16 cm ud, monter og spænd de 2 skruer

igen.

4. Løs de 2 skruer, der sidder under madrasstyret på bendelen,

træk madrasstyret ud til stop og spænd de 2 skruer igen.

5. Ilæg madrasstykke.

16

7.

4.1

5.

6.

4.2

Samling

1. Sørg for at hjulene er bremset.

2. Tilslut netspænding til understellet.

3. Kør sengen til den afmærkede højde, således at “knasterne” (se illustration 3 på side 15) på henholdsvis

understellets kulisse og saksen er placeret over for hinanden.

4. Løft overramme-fod op, således at de to låsebeslag/snaplåse fanger

ind i tappene på saksen (4.1).

Det skal sikres, at låsepalen er klikket ind og låst (4.2), hvorefter

overramme-fod føres til vandret.

5. Stil overramme-hoved foran understellet og sænk overramme-hoved

ned, således at plastgliderne fanger ind i kulissen.

6. Løft overramme-hoved og skub det ind over indskuddene til stop.

7. Skru de 2x2 fingerskruer i siderørene.

8. Monter stik fra ryg-, lår- og benmotor i styringen,

se afsnit 7 vedr. ledningsføring.

9. Monter diverse tilbehør.

17

DK

7. Ledningsføring

Ledningerne monteres nedefra og op igennem spor i akselende på motoren.

Ledningerne føres op under lamellerne.

Ledningerne monteres igennem kabelbøjle og videre herfra ned i styringen.

Disse fotos viser en seng med 2 motorer til liggefladen.

Efter montering kontrolleres ledningsmonteringen ved at køre sengens motorer ud i alle yderpositioner.

Når alle ledninger er korrekt monteret, er der ikke nogen risiko for klemning af ledninger.

Det er almindeligt, at ledningerne efter kort tids brug slappes en smule.

18

ACP Boks (tilbehør)

Håndbetjeningen kan låses ved at aktivere omskifteren på ACP boksen

placeret i hovedenden at sengen.

Det bør kontrolleres om låsefunktionen er aktiveret korrekt ved at betjene

håndbetjeningens knapper.

Åben Låst Afmontering af

låsering

Udskiftning af håndbetjening

Den hvide låsering på ACP boksen trykkes ind hvorefter håndbetjeningens kabel kan trækkes ud.

19

DK

8. Bestillingsnumre på tilbehør

Varebetegnelse Dimensioner Bestillingsnr.:

GAVLTRÆ

SANNE III (bøg) ..................................85 cm ................................020429.01

SANNE III (bøg) ..................................90 cm ................................020740.01

SANNE III (bøg) .................................105 cm ................................021953.01

SANNE III (bøg) .................................120 cm ................................021954.01

SANNE III (kirsebær / bøg) .........................90 cm ................................021956.07

SANNE III, forhøjet og sænket (bøg) *) ................85 cm ............................ 1451258-0101

SANNE III, forhøjet og sænket (bøg) *) ................90 cm ............................ 1451257-0101

SANNE III, forhøjet og sænket (bøg) *) ...............105 cm ............................ 1484403-0101

SANNE III, forhøjet og sænket (bøg) *) ...............120 cm ............................ 1484404-0101

*) Benyttes med LILLI III træsengehest

FLEX III (bøg) ....................................85 cm ................................020417.01

FLEX III (bøg) ....................................90 cm ................................020737.01

PIGGY (bøg / U-profiler) ...........................85 cm ................................020431.01

PIGGY (bøg / U-profiler) ...........................90 cm ................................018940.01

ODA (bøg / U-profiler) ............................85 cm ................................020430.01

ODA (bøg / U-profiler) ............................90 cm ................................016609.01

Gavltræ findes i andre udførelser end ovennævnte - kontakt Invacare®

SENGEHESTE

Scala Basic Metalsengehest (fældbar) .................................................... 1432784-1015

Scala Basic Plus Metalsengehest (fældbar med plastindlæg) ................................... 1432787-1015

Scala Medium Metalsengehest (fældbar) .................................................. 1432781-1015

Scala Decubi Metalsengehest (fældbar) .................................................. 1432793-1015

Metalsengehest 5539, forlænget (fældbar med løse fingerskruer) ............................50.55390.D0/L+R

BRITT IV træsengehest (højde + 2.5 cm, bøg) ............................................1427875-0101

BRITT IV træsengehest (højde + 2.5 cm, kirsebær) ........................................ 1427875-0102

BRITT IV træsengehest (højde + 2.5 cm, hvidpigmenteret) .................................. 1427875-0105

BRITT III træsengehest (bøg) ..............................................................020434.01

BRITT III træsengehest, kort (bøg) .........................................................021342.01

BRITT III træsengehest (kirsebær) ..........................................................020434.02

BRITT III træsengehest, kort (hvidpigmenteret) ...............................................021342.05

BRITT III træsengehest (hvidpigmenteret) ....................................................020434.05

BRITT II træsengehest, forlænget (bøg) ......................................................019372.01

BRITT II træsengehest, forlænget (kirsebær) ..................................................

019372.02

BRITT II træsengehest, forlænget (hvidpigmenteret) ............................................019372.05

LILLI III træsengehest (bøg) ........................................................... 1433812-0101

LILLI III træsengehest (kirsebær) ....................................................... 1433812-0102

LILLI III træsengehest, forlænget (bøg) ................................................... 1434044-0101

Dækrør ved brug af liggefladeforlænger .....................................................017639.D0

STØTTEGREB

Støttegreb ....................................25x30 cm ...............................021964.D0

Støttegreb ....................................40x50 cm ...............................021963.D0

Støttegreb ....................................25x80 cm ............................ 1417510-1015

Støttegreb ....................................40x30 cm ............................ 1417511-1015

Støttegreb ....................................40x95 cm ............................ 1417512-1015

GALGE

Galge ...............................................................................50.57600.D0

BENDELSBEGRÆNSER

Bendelsbegrænser (hindrer, at bendel kan sænkes under overrammens niveau) .................. 1510820-1015

20

Varebetegnelse Dimensioner Best. nr.:

TRANSFUSIONSSTATIV

Drop stativ ..........................................................................50.60030.D0

Holder til drop stativ (til montering i galgerør) ..............................................50.60910.00

FENDERRULLER

Fenderruller (1 stk.) .........................................................75 mm ....50.59600.00

Fenderruller (1 stk.) ........................................................100 mm .... 50.59610.00

Fenderruller (1 stk.) ........................................................150 mm .... 50.59640.00

Fenderruller (1 stk., opret stående) ............................................ 100 mm ....50.59630.D0

MADRASSER

Dacapo Basic (38 kg/m

3

koldskum, inkontinensbetræk) ..........................88x200x12 .......1421551

Dacapo Basic (38 kg/m

3

koldskum, inkontinensbetræk) ..........................83x200x12 .......1421552

Dacapo Basic (38 kg/m

3

koldskum, inkontinensbetræk) ..........................88x183x12 .......1421555

Dacapo Basic (38 kg/m

3

koldskum, inkontinensbetræk) ..........................83x183x12 .......1421556

Dacapo Basic Heavy user (3 lags 50/50/38 kg/m

3

koldskum, inkontinensbetræk) .....105x200x15 .......1484429

Dacapo Basic Heavy user (3 lags 50/50/38 kg/m

3

koldskum, inkontinensbetræk) .....120x200x15 .......1451262

Dacapo Combi (2 lags 50/38 kg/m

3

, Viskoelastisk/koldskum, inkontinensbetræk) ......85x200x14 .......1421489

Dacapo Combi (2 lags 50/38 kg/m

3

, Viskoelastisk/koldskum, inkontinensbetræk) ......90x200x14 .......1421490

Dacapo Square (2 lags 50/38 kg/m

3,

Organic skum/koldskum, inkontinensbetræk) .....83x200x14 .......1421515

Dacapo Square (2 lags 50/38 kg/m

3,

Organic skum/koldskum, inkontinensbetræk) .....88x200x14 .......1421516

Dacapo Top (50 kg/m

3

, Viskoelastisk skum, inkontinensbetræk) ....................85x200x6 .......1421587

Dacapo Top (50 kg/m

3

, Viskoelastisk skum, inkontinensbetræk) ....................90x200x6 .......1421588

Til forlængede senge findes mulighed for tilkøb af indskudsmadrasser i tilpassede mål.

LAVBYGNINGSSÆT

Lavbygningsæt med Ø75 mm bremsehjul ..................................................021343.D0

SENGEHEST BETRÆK

Scala Cover til Britt III, IV og Lilli III træsengehest ..............................................1449412

Scala Cover til Britt III træsengehest, kort ....................................................1449411

Scala Cover til Britt II og Lilli III træsengehest, forlænget .........................................1493565

Scala Cover til Britt III, IV og Lilli III træsengehest, net ...........................................1449413

Scala Cover til Britt II og Lilli III træsengehest, net, forlænget .....................................1449415

Scala Cover til metal side rail, Basic ..........................................................1449423

Scala Cover til metal side rail, forhøjet .......................................................1449419

Scala Cover til metal side rail, forlænget ......................................................1449421

Safety Cover til Britt III, IV og Lilli III træsengehest ..............................................1511890

Safety Cover til Britt III træsengehest, kort ....................................................1513592

Safety Cover til Britt II og Lilli III træsengehest, forlænget ........................................1511892

21

DK

9. Vedligehold og eftersyn

Service og vedligehold af SB750TM sengen må kun udføres af trænet/uddannet personale.

Ved normal daglig drift skal service ifølge serviceskema ske efter 2 års anvendelse, derefter hvert andet år.

Ved genanbringelse af sengen bør serviceskema følges.

Ved anvendelse af Flex og Karin gavle som er af blødt materiale, er det nødvendigt at efterspænde 6-kants

skruerne ved anden tidsintaval end angivet i serviceskema.

Bemærk! Overrammen skal understøttes, mens der foretages serviceeftersyn for at hindre

utilsigtet sænkning.

Det anbefales at der foretages en kontrol af motorernes arbejdsevne og mekaniske tilstand, 1 gang årligt.

Motorer, håndbetjening og styring

Al service i forbindelse med ovenstående sker ved ombytning/udskiftning af den/de defekte dele.

10. Specielt for senge med akkumulator back-up

Hvis denne seng er udstyret med akkumulator back-up, vil der sidde en ekstra kasse ved

siden af styringen.

Forebyggende vedligehold

Akkumulatorerne skal udskiftes senest efter 4 års brug. Eventuelt tidligere afhængigt af

brugsmønsteret.

Hyppig og kraftig afladning mindsker levetiden.

Det anbefales at afprøve akkumulatorfunktionen mindst én gang årligt.

Akkumulatorerne tager ikke skade ved kontinuerlig tilslutning til netspændingen.

Udskiftning af akkumulatorer

Akkumulatorerne må kun udskiftes sætvis med originale akkumulatorer eller mekanisk og elektrisk kompatible

typer.

Akkumulatorsæt leveres under varenr.: 818323 (12V - 1,2 Ah)

Akkumulatorerne skal være nye eller vedligeholdelsesladede minimum hver 6. måned. Akkumulatorerne,

som udgør et sæt, skal være forsynet med identiske produktionskoder.

Inden isætning sikres, at akkumulatorsættet er koblet korrekt sammen - jævnfør tegning

(i akkumulatorrummet på styringen) - og at ingen af konnektorerne er løse.

Advarsel

Udtjente eller defekte akkumulatorer kan danne knaldgas ved forsøg på opladning.

Akkumulatorrummet er forsynet med en udluftning, som sikrer en korrekt og nødvendig udluftning af

akkumulatorrummet. Denne udluftning må ikke blokeres eller afdækkes, idet der kan opstå overtryk med

eksplosionsfare til følge.

Bortskaffelse

Kasserede akkumulatorer kan returneres til Invacare

®

eller bortskaffes ligesom bilakkumulatorer.

22

11. Serviceskema

Service og vedligehold af SB750TM må kun udføres af trænet/uddannet personale

S/N (placeret på liggefladen): ___________________

Dato: Init.:

Låseringe, rørsplitter og plast-fixeringsring er

kontrolleret.

Skruesamlinger er spændt efter.

Svejsninger er efterset.

Sengehestens låse- og bevægesystem er afprøvet.

Hjulbefæstigelsen er efterspændt.

Brems på hjul er kontrolleret.

Højdereguleringens motor er kontrolleret.

Ryglænets motor er kontrolleret.

Lårdelens motor er kontrolleret.

Bendelens gasfjeder/motor er kontrolleret.

Ledningsføringer er korrekt ophængt og

ubeskadigede. Stik er ubeskadigede.

Lakskader er repareret.

Smøring udført efter smøreskitse.

NB! Træ sengehestens glidersystem må ikke smøres

med olie, da træstavene vil ellers gå trægt.

Tilbehør er efterset.

I lande, hvor Invacare® har eget salgsselskab, er der mulighed for at tegne servicekontrakt.

Endvidere kan Invacare® tilbyde kurser i eftersyn og vedligeholdelse af SB750

TM

.

Reservedelsliste og ekstra brugsanvisninger kan rekvireres hos Invacare® EC-Høng.

23

DK

12. Fejlsøgning i det elektriske system

NB! Kontroller først, at netspænding er tilsluttet.

13. Smøreskitse

Det anbefales at smøre SB750TM i henhold til nedenstående plan:

1. Lejer for løftearme - smøres med olie

2. Lejer for motorer/gasfjeder - smøres med olie

3. Glidere og kulisser - smøres med fedt

4. Aksel og ruller for saks - smøres med olie/fedt

Til smøring anvendes medicinsk ren olie, f.eks. KEW-WO 50, bestillingsnr.: 813239 og fedt, bestillingsnr.: 1497607.

Motorstik ikke

forbundet

Relæ-lyd

Defekt motor

Ingen motorlyd

Motor kører ikke

Defekt styring

Ingen relæ-lyd

Motorlyd

Stempelstang

bevæger sig ikke

Defekt

håndbetjening

Defekt motor

24

WxLABCD E

85x200 200 213 85 95 60

90x200 200 213 90 101 60

85x183 183 196 85 95 43

90x183 183 196 90 101 43

105x200 200 213 105 116 60

120x200 200 213 120 131 60

700 -

1.100 hPa

10 - 80%

-10 - 50°C

14 - 122°F

14. Rengøring

SB750TM tåler ikke rengøring i vaskeanlæg eller vandstrålebaseret rengøring. Ved rengøring af sengen

anvendes almindelige desificerende rengøringsmidler. Efter vask aftørres sengen. Brug aldrig syrer, baser eller

opløsningsmidler. Sørg for at sengens stikprop er trukket ud af stikkontakten.

Sengens ryglæn og ben-/lårdel kan lægges helt frem over liggefladen, hvilket letter rengøring og adgang til styring.

Specielt vedr. rengøring af håndbetjening, styring og motorer IP 66: Vaskes med børste og vand.

Vandet må godt være under tryk, men der må ikke spules direkte på eldelene med en højtryksrenser eller

damprenser

15. Tekniske specifikationer

Alle mål er opgivet i cm. Alle vinkler er opgivet i grader.

Alle mål og vinkler er opgivet uden tolerancer.

Invacare® forbeholder sig retten til at ændre på ovenstående mål og vinkler uden forudgående varsel.

Transport og opbevarings forhold:

Temperatur mellem -10° og 50° C

Luftfugtighed mellem 10 og 80 % RH

Lufttryk mellem 700 og 1.100 hPa

25

= 220 kg

DK

16. Elektriske data

Tilslutningsspænding: 230 V AC/50 Hz.

Max. strømforbrug: 1,5 A.

Intermittent (periodisk brug af motorerne): 10% max. 6 minutter/time.

Max. akkumulatorkapacitet: 1,2 Ah.

Tæthedsklasse: IP 66.

Effekt: 70 VA.

Lydtryk: 48 dB (A).

Dobbeltisoleret, klasse II, type B.

Vekselstrøm:

Jævnstrøm:

Max. last (SWL)

(Patient + madras + sengehest + galge + evt. andet tilbehør).

Patienten er ikke adskilt fra jord og chassis.

Potentialeudligning.

Styringen har ingen afbryder, hvorfor stikproppen er eneste adskillelse fra netspændingen.

26

17. Vægt

Mål

Vægt

85x200

90x200

105x200 120x200

Overramme-hoved, med liggeflade 25 kg 34 kg 36 kg

Overramme-fod, med liggeflade 25 kg 36 kg 39 kg

Understel 40 kg 40 kg 42 kg

Samlet seng excl. tilbehør 90 kg 110 kg 117 kg

Gavltræ (SANNE III/FLEX III/KARIN III) 6 kg/stk. 7 kg/stk. 8 kg/stk.

Træsengehest (BRITT II/BRITT III) 7 kg/stk. 7 kg/stk. 7 kg/stk.

Træsengehest (BRITT IV) 8 kg/stk. 8 kg/stk. 8 kg/stk.

Gavltræ (ODA/PIGGY) 6 kg/stk. - -

Metalsengehest 7 kg/stk. 7 kg/stk. 7 kg/stk.

Galge 6,5 kg 6,5 kg 6,5 kg

18. Bortskaffelse

Dette product er fremstillet af en miljøbevidst producent, som opfylder normerne i Waste Electrical og Electronic

Equipment (WEEE) direktiv 2002/96/CE.

Dette produkt kan indeholde stoffer, der kan være skadelige for miljøet, hvis de ikke bortskaffes

i henhold til gældende lovgivning.

Symbolet, den »overkrydsede skraldespand«, er placeret på dette produkt for at opfordre til

genbrug, hvor det er muligt.

Tag venligst miljøansvar og genbrug dette produkt gennem din lokale genbrugsstation, når dets

levetid er omme.

5

SE

Innehållsförteckning

Brukardel ...................................................6

1. Allmänt .................................................6

2. Användning av SB750

TM

....................................7

Teknisk del .................................................10

3. Information .............................................10

4. När SB750

TM

tas emot på uppställningsplatsen ................11

5. Montering av tillbehör ....................................13

6. Demontering/montering av SB750

TM

........................15

7. Kabelföring .............................................17

8. Artikelnummer för tillbehör ...............................19

9. Underhåll och kontroll ....................................21

10. Speciellt för sängar med batteri-back-up .....................21

11. Serviceschema ..........................................22

12. Felsökning i det elektriska systemet ........................23

13. Smörjschema ...........................................23

14. Rengöring ..............................................24

15. Tekniska specifikationer ..................................24

16. Elektriska data ..........................................25

17. Viktuppgifter ...........................................26

18. Avfallshantering .........................................26

6

Brukardel