Owner's Operator And Maintenance Manual

Tilt

Recline

Tilt/Recline

Seating Systems

DEALER: THIS MANUAL MUST BE GIVEN TO THE USER

OF THE WHEELCHAIR.

USER: BEFORE USING THIS WHEELCHAIR, READ THIS

MANUAL AND SAVE FOR FUTURE REFERENCE.

WARNING/SPECIAL NOTES

WARNING

DO NOT OPERATE THIS EQUIPMENT WITHOUT FIRST READING AND

UNDERSTANDING THIS MANUAL AND THE MANUAL PROVIDED WITH THE

W

A

R

N

N

G

S

P

E

C

A

L

N

O

T

E

S

WHEELCHAIR. IF YOU ARE UNABLE TO UNDERSTAND THE WARNINGS

AND INSTRUCTIONS, CONTACT A TRAINED INVACARE DEALER OR

INVACARE TECHNICAL SUPPORT BEFORE ATTEMPTING TO USE THIS

I

EQUIPMENT - OTHERWISE INJURY OR DAMAGE MAY RESULT.

THIS SEATING SYSTEM HAS BEEN CUSTOM DESIGNED AND WILL BE

ASSEMBLED TO THE WHEELCHAIR BASE BEFORE DELIVERY TO THE USER. THE

INFORMATION CONTAINED IN THIS MANUAL IS FOR MAINTAINING AND

ADJUSTING THE SEATING SYSTEM. PROCEDURES OTHER THAN THOSE

DESCRIBED IN THIS MANUAL MUST BE PERFORMED BY A QUALIFIED

TECHNICIAN.

SPECIAL NOTES

WARNING/CAUTION notices as used in this manual apply to hazards or unsafe practices

which may result in personal injury or property damage.

NOTICE

THE INFORMATION CONTAINED IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT

NOTICE.

SEATING SYSTEM/WHEELCHAIR USER

As a manufacturer of wheelchairs and seating systems, Invacare endeavors to supply

a wide variety of wheelchairs and seating systems to meet many needs of the user.

However, final selection of the type of wheelchair and seating system to be used by an

I

individual rests solely with the user and his/her healthcare professional capable of

making such a selection.

WHEELCHAIR TIE-DOWN RESTRAINTS AND SEAT POSITIONING STRAPS

Invacare recommends that wheelchair and seating system users NOT be transported in

vehicles of any kind while in wheelchairs. As of this date, the Department of Transportation has not approved any tie-down systems for transportation of a user while in a

wheelchair, in a moving vehicle of any type.

It is Invacare’s position that users of wheelchairs and seating systems should be transferred into appropriate seating in vehicles for transportation and use be made of the

restraints made available by the auto industry. Invacare cannot and does not recommend any wheelchair transportation systems.

SAVE THESE INSTRUCTIONS.

2

TABLE OF CONTENTS

TABLE OF CONTENTS

SPECIAL NOTES ................................................................................................................................ 2

SPECIFICATIONS ............................................................................................................................... 4

PROCEDURE 1 - GENERAL GUIDELINES ...........................................................................5

REPAIR OR SERVICE INFORMATION ............................................................................................... 5

OPERATING INFORMATION .............................................................................................................. 5

SAFETY/HANDLING OF SEATING SYSTEMS/WHEELCHAIRS ......................................................... 9

PROCEDURE 2 - SAFETY INSPECTION/TROUBLESHOOTING ........................................ 11

SAFETY INSPECTION AND MAINTENANCE CHECKLIST ............................................................... 11

TROUBLESHOOTING ..................................................................................................................... 11

PROCEDURE 3 - TILT ONLY ...............................................................................................12

OPERATING TILT ONLY SYSTEMS ................................................................................................. 12

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

PROCEDURE 4 - RECLINE ONLY ....................................................................................... 14

OPERATING RECLINE SYSTEMS ONLY ......................................................................................... 14

PROCEDURE 5 - TILT/RECLINE ......................................................................................... 16

OPERATING TILT/RECLINE SYSTEMS ........................................................................................... 16

PROCEDURE 6 - VENTILATOR TRAY ................................................................................ 18

USING THE OPTIONAL VENT TRAY ................................................................................................ 18

PROCEDURE 7 - SHEAR REDUCTION ..............................................................................19

OPTIONAL VERNIER SHEAR .......................................................................................................... 19

PROCEDURE 8 - RIGGINGS ............................................................................................... 20

MECHANICAL ELEVATING/GENIUS LEGRESTS ............................................................................. 20

INSTALLING/REMOVING THE POWERED LEGS .................................................................................. 22

ADJUSTING THE POWER LEGRESTS ............................................................................................. 23

PROCEDURE 9 - ARMRESTS ............................................................................................. 27

RECLINING ARMRESTS .................................................................................................................. 27

PROCEDURE 10 - HEADREST ........................................................................................... 28

ADJUSTING HEADREST HEIGHT/DEPTH/DIRECTION ................................................................... 28

REPLACING HEADREST ................................................................................................................ 28

PROCEDURE 11 - EXTENDED ACTIVE ANTI-TIPPERS ..................................................... 29

USING THE EXTENDED ACTIVE ANTI-TIPPERS ............................................................................. 29

LIMITED WARRANTY ...................................................................................................................... 30

3

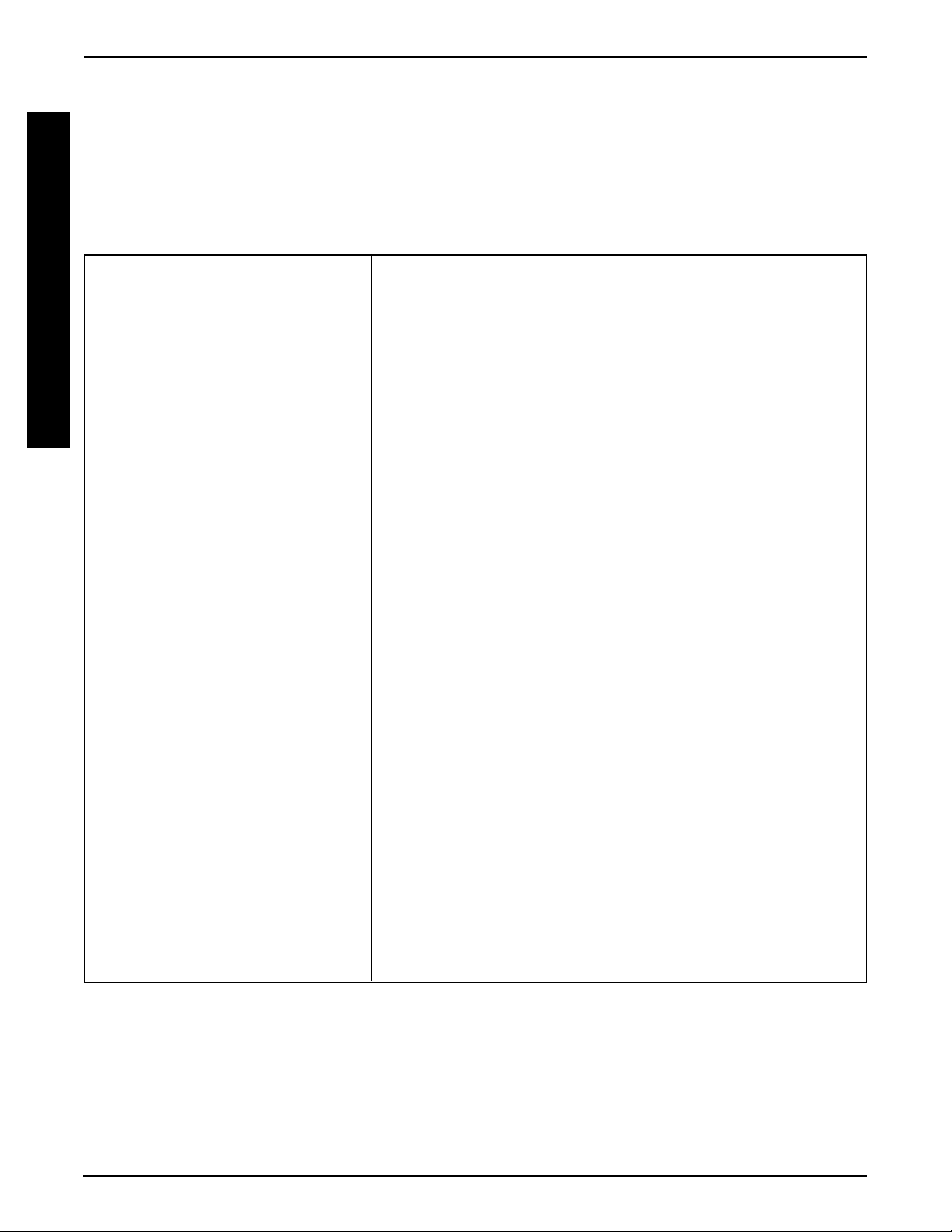

SPECIFICATIONS

SPECIFICATIONS

S

NOTE: All specifications apply to Tilt only, Recline only and Tilt/Recline systems except where specified.

P

All specifications are approximate.

E

C

NOTE: The procedures in this manual refer to RWD and FWD models except where specified.

I

NOTE: Refer to the wheelchair owner's manual for complete specifications on base and operation.

F

Seat Width Range:

I

C

Seat Depth Range:

A

Back Height Range:

T

I

Recline Only and Tilt/Recline:

Tilt Only:

O

N

Back Angle Range

S

Tilt Only Systems:

16 to 22-inches - In 1-inch increments

16 to 22-inches - In 1-inch increments

20 to 26-inches - In 1-inch increments

20 to 25-inches - In 1-inch increments

o

to 115o - in 5o increments

90

Tilt Range

Tilt Only Systems:

Tilt/Recline Systems:

Recline Range

Recline Only and Tilt/Recline Systems:

Seat-to-Floor:

*Overall Width:

*Overall Height:

*Overall Length:

Weight of Seating System:

Armrests

Tilt Only:

**Recline Only and Tilt/Recline Systems:

Legrests:

o

Seat Angle - 0o to 45

0

5o Seat Angle - 5o to 50

0o Seat Angle - 0o to 45

5o Seat Angle - 5o to 50

0o Seat Angle - 90o to 175

5o Seat Angle - 95o to 175

o

o

o

o

o

o

0o Seat Angle - 18-1/4-inches

5o Seat Angle - 19-3/4-inches

25 to 27-inches

53-inches

48-inches - in upright position

105 lbs.

Flip Back, Adjustable Height (9 to 13-inches) - Desk or Full Length

Adjustable Height (11 to 16-inches) - Desk or Full Length

Mechanical Elevating/Genius Legrests

Power Legrests

Headrests:

Curved, Contoured, Small or Large

*NOTE: 18 x 18 Tilt/Recline System on Storm Base (short frame) with AT5544 front riggings in minimum

position, seat angle of 5o, back height of 24-inches and headrest.

4

GENERAL GUIDELINES PROCEDURE 1

This Procedure Includes the Following:

Repair or Service Information

Operating Information

Safety/Handling of Wheelchairs

REPAIR OR SERVICE INFORMATION

Setup of the Electronic Control Unit is to be performed ONLY by authorized Invacare

dealers. The final tuning adjustments of the controller may affect other activities of the

wheelchair. Damage to the equipment could occur under these circumstances. If any

individual other than an authorized Invacare dealer performs any work on these units,

the warranty is void.

OPERATING INFORMATION

WARNING

Performance adjustments should only be made by professionals of the health

care field or persons fully conversant with this process and the driver's capabilities. Incorrect settings could cause injury to the driver, bystanders, damage to

the chair and to surrounding property.

After the wheelchair has been setup, check to make sure that the wheelchair

performs to the specifications entered during the setup procedure. If the wheelchair does NOT perform to specifications, turn the wheelchair OFF immediately

and reenter setup specifications. Repeat this procedure until the wheelchair

performs to specifications.

To determine and establish your particular safety limits, practice bending, reaching

and transferring activities in several combinations in the presence of a qualified

health professional BEFORE attempting active use of the seating system/wheelchair.

DO NOT attempt to reach objects if you have to move forward in the seat.

DO NOT attempt to reach objects if you have to pick them up from the floor by

reaching down between your knees.

DO NOT lean over the top of the back upholstery to reach objects from behind

as this may cause the seating system/wheelchair to tip over.

DO NOT shift your weight or sitting position toward the direction you are reach-

ing as the seating system/wheelchair may tip over.

DO NOT operate the seating system while on an incline.

DO NOT operate the seating system while the wheelchair is moving.

TILT ONLY SYSTEMS - NEVER operate the wheelchair while in any tilted position

over 20

the wheelchair from operating in a tilt position 20

POSITION, DO NOT operate the wheelchair. Have the wheelchair serviced by a

dealer or qualified technician.

RECLINE ONLY SYSTEMS - NEVER operate the wheelchair while in any recline/

back angle combination over 20

drive lock-out does not stop the wheelchair from operating in a recline/back

angle combination 20

wheelchair. Have the wheelchair serviced by a dealer or qualified technician.

TILT/RECLINE SYSTEMS - NEVER operate the wheelchair while in any tilt/recline/

back angle combination over 20

drive lock-out does not stop the wheelchair from operating in a tilt/recline/

back angle combination 20

ate the wheelchair. Have the wheelchair serviced by a dealer or qualified technician.

o

RELATIVE TO THE VERTICAL POSITION. If the drive lock-out does not stop

o

RELATIVE TO THE VERTICAL POSITION. If the

o

RELATIVE TO THE VERTICAL POSITION, DO NOT operate the

o

RELATIVE TO THE VERTICAL POSITION. If the

o

RELATIVE TO THE VERTICAL POSITION, DO NOT oper-

o

RELATIVE TO THE VERTICAL

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

5

G

N

R

G

U

D

N

GENERAL GUIDELINESPROCEDURE 1

WARNING

Use only TSS, SAC, TRSS and TRCM actuator controls to activate the tilt/recline functions. DO

E

E

A

L

I

E

L

I

E

S

NOT USE any other actuator controls. Such devices may result in excess heating and cause

damage to the actuator and associated wiring and could cause a fire, death, physical

injury or property damage. If such devices are used, Invacare shall not be liable and the

warranty is void.

VENT TRAY - Chairs equipped with vent tray option: Reduced tilt/recline limits apply. See

MKIV TRCM operating instructions, part number 1043576.

DO NOT tip the seating system/wheelchair without assistance.

DO NOT use an escalator to move a seating system/wheelchair between floors. Serious

bodily injury may occur.

Before attempting to transfer in or out of the seating system/wheelchair, every

precaution should be taken to reduce the gap distance. Turn both casters toward the object you are transferring onto. Also be certain the power is OFF and

motor locks are engaged to prevent the wheels from moving.

DO NOT engage or disengage the motor locks until the power is in the OFF

position.

DO NOT operate on roads, streets or highways.

o

DO NOT climb, go up or down ramps or traverse slopes greater than 9

.

DO NOT attempt to move up or down an incline with a water, ice or oil film.

DO NOT attempt to drive over curbs or obstacles. Doing so may cause your

seating system/ Wheelchair to turn over and cause bodily harm or damage to

the seating system/wheelchair.

DO NOT use parts, accessories, or adapters other than those authorized by

Invacare.

DO NOT leave the power ON when entering or exiting your seating system/

wheelchair.

DO NOT attempt to lift the seating system/wheelchair by lifting on any removable (detachable) parts. Lifting by means of any removable (detachable) parts

of a seating system/wheelchair may result in injury to the user or damage to the

seating system/wheelchair.

DO NOT stand on the frame of the seating system/wheelchair.

Anti-tippers MUST BE attached at all times.

DO NOT use the footplates as a platform. When getting in or out of the seating

system/wheelchair, make sure that the footplates are in the upward position or

swing footrests towards the outside of the seating system/wheelchair.

ALWAYS wear your seat positioning strap.

Individual user weight may impact the rate of travel for each legrest assembly.

If simultaneous operation is desired, select a speed which allows for the most

uniform travel. To prevent personal injury, always verify proper positioning of legs and feet

prior to use.

WEIGHT TRAINING

Invacare DOES NOT recommend the use of its wheelchairs and seating systems as a weight

training apparatus. Invacare wheelchairs and seating systems have NOT been designed

or tested as a seat for any kind of weight training. If occupant uses said seating system/

wheelchair as a weight training apparatus, INVACARE SHALL NOT BE LIABLE FOR BODILY

INJURY AND THE WARRANTY IS VOID.

6

GENERAL GUIDELINES PROCEDURE 1

CAUTION

WEIGHT LIMITATION

S

A

F

E

T

Standard Tilt only, Recline only and Tilt/Recline systems have a weight limitation of 250 lbs.

Tilt only, Recline only and Tilt/Recline systems with the heavy duty option have a weight

limitation of 350lbs.

Never allow items to become trapped between the legrest assemblies, otherwise damage

to the power legrest may occur.

Y

S

U

M

M

A

R

Y

CAUTION: IT IS VERY IMPORTANT THAT YOU READ THIS INFORMATION REGARDING THE POSSIBLE EFFECTS OF ELECTROMAGNETIC INTERFERENCE ON YOUR POWERED WHEELCHAIR.

Electromagnetic Interference (EMI) From Radio Wave sources

Powered wheelchairs and motorized scooters (in this text, both will be referred to as pow-

ered wheelchairs) may be susceptible to electromagnetic interference (EMI), which is

interfering electromagnetic energy (EM) emitted from sources such as radio stations, TV

stations, amateur radio (HAM) transmitters, two way radios, and cellular phones. The interference (from radio wave sources) can cause the powered wheelchair to release its brakes,

move by itself, or move in unintended directions. It can also permanently damage the

powered wheelchair's control system. The intensity of the interfering EM energy can be

measured in volts per meter (V/m). Each powered wheelchair can resist EMI up

to a certain intensity. This is called its "immunity level." The higher the immunity

level, the greater the protection. At this time, current technology is capable of

achieving at least a 20 V/m immunity level, which would provide useful protec-

tion from the more common sources of radiated EMI.

W ARNING

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

There are a number of sources of relatively intense electromagnetic fields in the

everyday environment. Some of these sources are obvious and easy to avoid.

Others are not apparent and exposure is unavoidable. However, we believe

that by following the warnings listed, your risk to EMI will be minimized.

The sources of radiated EMI can be broadly classified into three types:

1) Hand-held Portable transceivers (transmitters-receivers with the antenna

mounted directly on the transmitting unit. Examples include: citizens band

(CB) radios, "walkie talkie," security, fire, And police transceivers, cellular

telephones, and other personal communication devices. **NOTE: Some cellular telephones and similar devices transmit signals while they are ON,

even when not being used;

2) Medium-range mobile transceivers, such as those used in police cars, fire

trucks, ambulances, and taxis. These usually have the antenna mounted on

the outside of the vehicle; and

3) Long-range transmitters and transceivers, such as commercial broadcast

transmitters (radio and TV broadcast antenna towers) and amateur (HAM) radios.

7

G

N

R

G

U

D

N

GENERAL GUIDELINESPROCEDURE 1

W ARNING

NOTE: Other types of hand-held devices, such as cordless phones, laptop computers, AM

E

E

A

L

I

E

L

I

E

S

FM radios, TV sets, CD players, cassette players, and small appliances, such as electric

shavers and hair dryers, so far as we know, are not likely to cause EMI problems to your

powered wheelchair.

Powered Wheelchair Electromagnetic Interference (EMI)

Because EM energy rapidly becomes more intense as one moves closer to the transmitting

antenna (source), the EM fields from hand-held radio wave sources (transceivers) are of

special concern. It is possible to unintentionally bring high levels of EM energy very close

to the powered wheelchair's control system while using these devices. This can affect powered wheelchair movement and braking. Therefore, the warnings listed are recommended

to prevent possible interference with the control system of the powered wheelchair.

Electromagnetic interference (EMI) from sources such as radio and TV stations, amateur

radio (HAM) transmitters, two-way radios, and cellular phones can affect powered wheelchairs and motorized scooters. Following the warnings listed below should reduce the

chance of unintended brake release or powered wheelchair movement which could result in serious injury.

1) Do not operate hand-held transceivers (transmitters receivers), such as citizens band (CB) radios, or turn ON personal communication devices, such

as cellular phones, while the powered wheelchair is turned ON;

2) Be aware of nearby transmitters, such as radio or TV stations, and try to

avoid coming close to them;

3) If unintended movement or brake release occurs, turn the powered wheelchair OFF as soon as it is safe;

4) Be aware that adding accessories or components, or modifying the powered wheelchair, may make it more susceptible to EMI (Note: There is no

easy way to evaluate their effect on the overall immunity of the powered

wheelchair); and

5) Report all incidents of unintended movement or brake release to the powered wheelchair manufacturer, and note whether there is a source of EMI

nearby.

Important Information

1) 20 volts per meter (V/m) is a generally achievable and useful immunity

level against EMI (as of May 1994) (the higher the level, the greater the

protection);

2) The immunity level of this product is not known.

Modification of any kind to the electronics of this wheelchair as manufactured

by Invacare may adversely affect the RFI immunity levels.

8

GENERAL GUIDELINESPROCEDURE 1

SAFETY/HANDLING OF SEATING

SYSTEMS/WHEELCHAIRS

Safety and Handling of the wheelchair requires the close

attention of the seating system/wheelchair user as well

as the assistant. This manual, as well as the owners

manual provided with the wheelchair, points out the most

common procedures and techniques involved in the safe

operation and maintenance of the seating system/wheelchair. It is important to practice and master these safe

techniques until you are comfortable in maneuvering

around the frequently encountered architectural barriers.

Use this information only as a basic guide. The techniques that are discussed on the following pages have

been used successfully by many.

Individual seating system/wheelchair users often develop

skills to deal with daily living activities that may differ from

those described in this manual. Invacare recognizes and

encourages each individual to try what works best for him/

her in overcoming architectural obstacles that they may

encounter, however, ALL WARNINGS and CAUTIONS

given in this manual MUST be followed. Techniques in

this manual are a starting point for new seating system/

wheelchair users and assistants with safety as the most

important consideration for all.

Also, be aware of any detachable parts. These must

NEVER be used for hand-hold or lifting supports, as they

may be inadvertently released, resulting in possible injury

to the user and/or assistant(s).

When learning a new assistance technique, have an experienced assistant help you before attempting it alone.

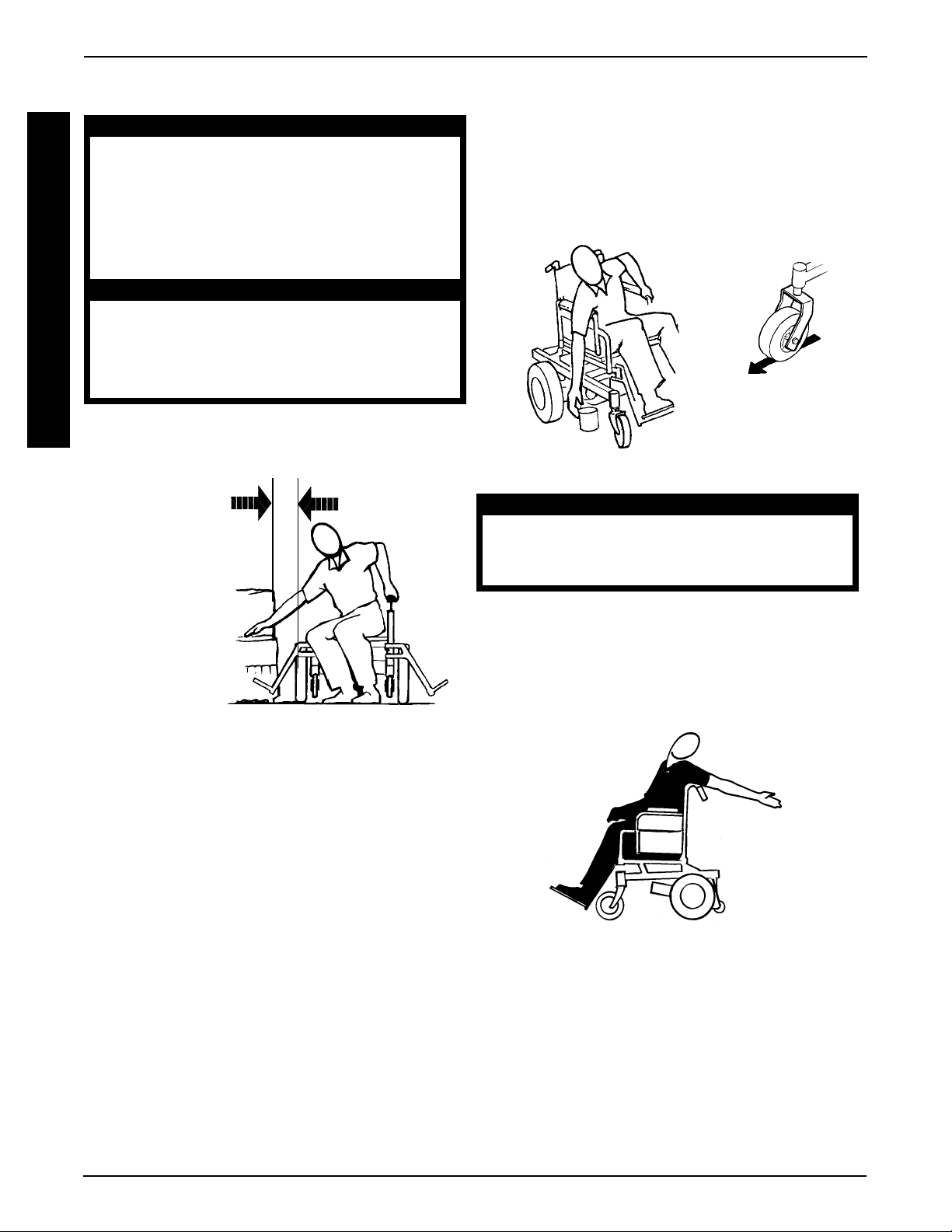

Percentage of Weight Distribution

WARNING

DO NOT attempt to reach objects if you

have to move forward in the seat or pick

them up from the floor by reaching down

between your knees.

Many activities require the wheelchair owner to reach, bend

and transfer in and out of the wheelchair. These movements will cause a change to normal balance, center of

gravity, and weight distribution of the wheelchair. To determine and establish your particular safety limits, practice

bending, reaching and transferring activities in several combinations in the presence of a qualified health professional

BEFORE attempting active use of the wheelchair.

Proper positioning is essential for your safety. When reaching, leaning, bending or bending forward, it is important to

use the front casters as a tool to maintain stability and balance.

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

Stability and Balance

WARNING

Always wear your seat positioning strap.

To assure stability and proper operation of your seating

system/wheelchair, you must at all times maintain proper

balance. Your seating system/wheelchair has been designed to remain upright and stable during normal daily

activities as long as you do not move beyond the center of

gravity.

DO NOT lean forward out of the seating system/wheelchair any further than the length of the armrests. Make

sure the casters are pointing in the forward position whenever you lean forward. This can be achieved by advancing the wheelchair and then reversing it in a straight line.

Coping With Everyday Obstacles

Coping with the irritation of everyday obstacles can be

alleviated somewhat by learning how to manage your

wheelchair. Keep in mind your center of gravity to maintain stability and balance.

A Note to Wheelchair Assistants

When assistance to the seating system/wheelchair user

is required, remember to use good body mechanics. Keep

your back straight and bend your knees.

9

GENERAL GUIDELINESPROCEDURE 1

Transferring To/From Other Seats

G

E

N

E

R

A

L

G

U

I

D

E

L

I

N

E

S

BEFORE attempting to transfer in or out of

the wheelchair, every precaution should

be taken to reduce the gap distance. Turn

both casters toward the object you are

transferring onto. Also be certain to engage motor locks to help prevent the

wheels from moving.

When transferring, position yourself as far

back as possible in the seat. This will prevent broken screws, damaged upholstery

and the possibility of the wheelchair tipping forward.

NOTE: This activity may be performed independently provided you have adequate mobility and upper body

strength.

MINIMIZE

GAP

DIST ANCE

WARNING

CAUTION

Reaching, Leaning, Bending and Bending Forward

Position the front casters so that they are extended as far

forward as possible and engage wheel locks. DO NOT

ATTEMPT TO REACH OBJECTS IF YOU HAVE TO

PICK THEM UP FROM THE FLOOR BY REACHING

DOWN BETWEEN YOUR KNEES.

Reaching, Bending - Backwards

WARNING

DO NOT lean over the top of the back

upholstery. This will change your center

of gravity and may cause you to tip over.

Position the wheelchair as close as possible along

side the seat to which you are transferring, with the

casters aligned parallel with the object. Engage

motor locks. Shift body weight into seat with transfer.

During independent transfer, little or no seat platform

will be beneath you. Use a transfer board if at all possible.

Position wheelchair as close as possible to the desired object. Point front casters forward to create the

longest possible wheelbase. Reach back only as far

as your arm will extend without changing your sitting

position.

10

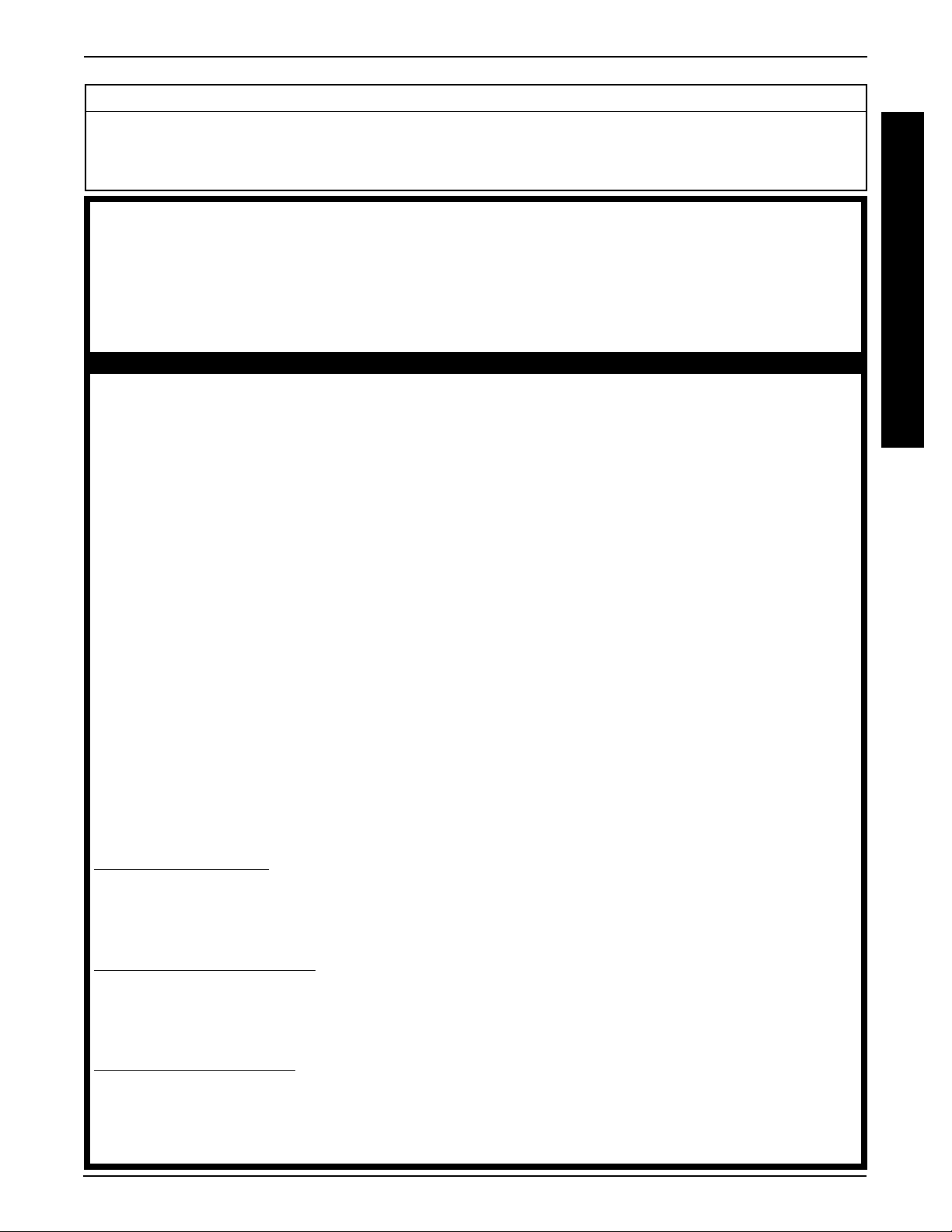

SAFETY INSPECTION/TROUBLESHOOTING

PROCEDURE 2

This Procedure Includes the Following:

Safety Inspection and Maintenance Checklist

Troubleshooting

SAFETY INSPECTION AND MAINTENANCE CHECKLIST

NOTE: Every six (6) months, take your seating system/wheelchair to a qualified dealer for a thorough inspection and servicing.

Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your seating system/wheelchair. To operate

properly and safely, your seating system/wheelchair must be cared for just like any other vehicle. Routine maintenance will extend

the life and efficiency of your seating system/wheelchair.

Initial adjustments should be made to suit your personal body structure and preference. Thereafter follow these maintenance procedures.

NOTE: Refer to the wheelchair owners manual for a complete safety inspection checklist on the base.

ITEM INITIALLY INSPECT/ INSPECT/ INSPECT/

ELECTRICAL CONNECTIONS

l Make sure all electrical connections are secure. X X

l Check limit switch position. X X

DRIVE LOCK-OUT

l Make sure Drive lock-out operates properly. X X

TILT MECHANISM

l Make sure tilt operates smoothly and properly. X X

RECLINE MECHANISM

l Make sure recline operates smoothly and properly. X X

CLOTHING GUARDS

l Ensure all fasteners are secure. X X

ARMS

l Secure but easy to release; adjustment levers engage properly. X X

l Adjustable height arms operate and lock securely. X X

ARMRESTS

l Inspect for rips in upholstery. X X

l Armrest pad sits flush against arm tube. X X

SEAT AND BACK CUSHIONS

l Inspect for rips. X X

CLEANING

l Clean cushions and armrests. X X

ADJUST ADJUST ADJUST

WEEKLY MONTHLY PERIODICALLY

TROUBLESHOOTING

NOTE: Refer to wheelchair owner's manual for complete mechanical and electrical troubleshooting guides on base.

NOTE: Refer to the individual CONTROLLER MANUAL supplied with each wheelchair for additional troubleshooting information

and explanation of error codes.

S

A

F

E

T

Y

I

N

S

P

E

C

T

I

O

N

T

R

O

U

B

L

E

S

H

O

O

T

I

N

G

SYMPTOM PROBABLE SOLUTIONS

CAUSE

Wheelchair Power ON but does not

drive.

Seating system not functioning.

System tilted beyond drive lock-out

angle.

Low Batteries.

Faulty electrical connection.

Blown Fuse.

Tilt to neutral (upright) position. Contact Dealer/

Invacare for Service.

Charge batteries.

Check all connections. Contact Dealer/Invacare for Service.

Replace fuse. Contact Dealer/Invacare for Service.

11

TILT ONLYPROCEDURE 3

This Procedure Includes the Following:

Operating Tilt Only Systems

OPERATING TILT ONLY SYSTEMS

T

(FIGURE 1)

I

L

T

O

N

L

Y

NEVER operate the wheelchair while in any

tilt/back angle combination over 20o RELATIVE TO THE VERTICAL POSITION. If the drive

lock-out does not stop the wheelchair from

operating in a tilt/back angle combination

20o RELATIVE TO THE VERTICAL POSITION, DO

NOT operate the wheelchair. Have the

wheelchair serviced by a dealer or qualified technician.

Use only TSS, SAC, TRSS and TRCM actuator

controls to activate the tilt/recline functions.

DO NOT USE any other actuator controls.

Such devices may result in excess heating

and cause damage to the actuator and associated wiring and could cause a fire,

death, physical injury or property damage.

If such devices are used, Invacare shall not

be liable and the warranty is void.

A Note About Drive Lock-Out

WARNING

2. Pull single function toggle switch back towards rear

of the wheelchair until the desired angle is achieved.

DECREASING TILT ANGLE.

1. Push the single function toggle switch forward towards

the front of the wheelchair until the desired angle is

achieved.

Optional Four-Way Toggle Switch

INCREASING/DECREASING TILT ANGLE.

1. Make sure the wheelchair is on a level surface.

2. Push four-way toggle switch forward towards the front

of the wheelchair until the desired tilt angle is achieved.

NOTE: If the wheelchair is equipped with switch options, scan to the correct ECU or Auxiliary Mode

and activate the control device in the corresponding forward direction to operate the tilt function. Refer

to the MKIV owner's manual, part number 1043576

for complete switch option operating instructions.

3. Release four-way toggle switch to neutral position.

NOTE: The four-way toggle switch will alternate

functions (increase tilt angle, decrease tilt angle)

after it has been released to the neutral position for

a minimum of one (1) second.

NOTE: Refer to the MKIV owner's manual, part number 1043576 for complete four-way toggle switch operating instructions.

Drive lock-out is a feature designed to prevent the wheelchair from being driven while in any recline/back angle combination over 20

TION. When the drive lock-out feature has been activated,

the LED on the single function toggle switch will light.

NOTE: The tilt angle range is from 0

to- floor angle and 5

o

RELATIVE TO THE VERTICAL POSI-

o

o

to 50o with a 5o seat-to-floor angle.

to 45o with a 0o seat-

Single Function Toggle Switch

INCREASING TILT ANGLE.

1. Make sure the wheelchair is on a level surface.

12

TILT ONLY PROCEDURE 3

Single Function

Toggle Switch

FULL UPRIGHT

POSITION

LED

Optional Four-Way

Toggle Switch (Shown

in Neutral Position)

FULL TILT POSITION

LED

T

I

L

T

O

N

L

Y

NOTE: Illustration depicts RWD models. The tilt function operates in the same manner for FWD models.

FIGURE 1 - OPERATING TILT ONLY SYSTEMS

13

RECLINE ONLYPROCEDURE 4

This Procedure Includes the Following:

Operating Recline Only Systems

R

OPERATING RECLINE ONLY

E

SYSTEMS (FIGURE 1)

C

L

I

N

E

O

N

L

Y

NEVER operate the wheelchair while in

any recline/back angle combination over

o

20

RELATIVE TO THE VERTICAL POSITION.

If the drive lock-out does not stop the

wheelchair from operating in a recline/

back angle combination 20

THE VERTICAL POSITION, DO NOT operate

the wheelchair. Have the wheelchair serviced by a dealer or qualified technician.

Reduced Recline limits apply with optional

vent tray. See MKIV TRCM operating instructions, part number 1043576.

Use only TSS, SAC, TRSS and TRCM actuator

controls to activate the tilt/recline functions.

DO NOT USE any other actuator controls.

Such devices may result in excess heating

and cause damage to the actuator and associated wiring and could cause a fire,

death, physical injury or property damage.

If such devices are used, Invacare shall not

be liable and the warranty is void.

WARNING

o

RELATIVE TO

Increasing/Decreasing Recline Angle

NOTE: The recline angle range is from 95o to 175

with a 5o seat-to-floor angle. The recline angle range

is from 90o to 175o with a 0o seat-to-floor angle.

1. Make sure the wheelchair is on a level surface.

2. Pull the four-way toggle switch back towards the rear

of the wheelchair until the desired recline angle is

achieved.

NOTE: If the wheelchair is equipped with switch options, scan to the correct ECU or Auxiliary Mode,

then activate the control device in the corresponding reverse direction to operate the recline function. Refer to the MKIV owner's manual, part number 1043576 for complete switch option operating

instructions.

3. Release the four-way toggle switch to the neutral position.

NOTE: The four-way toggle switch will alternate

functions (increase recline angle, decrease recline

angle) after it has been released to the neutral position for a minimum of one (1) second.

NOTE: Refer to the MKIV owner's manual, part number 1043576 for complete four-way toggle switch operating instructions.

o

A Note About Drive Lock-Out

Drive lock-out is a feature designed to prevent the wheelchair from being driven while in any recline/back angle

combination over 20o RELATIVE TO THE VERTICAL POSITION. When the drive lock-out feature has been activated, the LED on the four-way toggle switch will light.

14

RECLINE ONLY PROCEDURE 4

Optional Four-Way

Toggle Switch (Shown

in Neutral Position)

FULL UPRIGHT POSITION FULL RECLINE POSITION

LED

R

E

C

L

I

N

E

O

N

L

Y

NOTE: Illustration depicts RWD models. The recline function operates in the same manner for FWD

models.

FIGURE 1 - OPERATING RECLINE ONLY SYSTEMS

15

This Procedure Includes the Following:

Operating Tilt /Recline Systems

T

OPERATING TILT/RECLINE

I

SYSTEMS (FIGURE 1)

L

R

C

N

T

E

L

E

/

I

NEVER operate the wheelchair while in any

tilt/recline/back angle combination over

20o RELATIVE TO THE VERTICAL POSITION. If

the drive lock-out does not stop the wheelchair from operating in a tilt/recline/back

angle combination 20o RELATIVE TO THE

VERTICAL POSITION, DO NOT operate the

wheelchair. Have the wheelchair serviced

by a dealer or qualified technician.

Reduced Tilt and Recline limits apply with

optional vent tray. See MKIV TRCM operating instructions, part number 1043576.

Use only TSS, SAC, TRSS and TRCM actuator

controls to activate the tilt/recline functions.

DO NOT USE any other actuator controls.

Such devices may result in excess heating

and cause damage to the actuator and associated wiring and could cause a fire,

death, physical injury or property damage.

If such devices are used, Invacare shall not

be liable and the warranty is void.

WARNING

A Note About Drive Lock-Out

Drive lock-out is a feature designed to prevent the wheelchair from being driven while in any tilt/recline/back angle

combination over 20

POSITION. When the drive lock-out feature has been

activated, the LED on the four-way toggle switch will light.

o

RELATIVE TO THE VERTICAL

TILT/RECLINEPROCEDURE 5

3. Release four-way toggle switch to neutral position.

NOTE: The four-way toggle switch will alternate

functions (increase tilt angle, decrease tilt angle)

after it has been released to the neutral position for

a minimum of one (1) second.

NOTE: Refer to the MKIV owner's manual, part number 1043576 for complete four-way toggle switch operating instructions.

Increasing/Decreasing Recline Angle

NOTE: The recline angle range is from 95o to 175

with a 5o seat-to-floor angle. The recline angle range

is from 90o to 175o with a 0o seat-to-floor angle.

1. Make sure the wheelchair is on a level surface.

2. Pull four-way toggle switch back towards the rear of

the wheelchair until desired recline angle is achieved.

NOTE: If the wheelchair is equipped with switch options, scan to the correct ECU or Auxiliary Mode,

then activate the control device in the corresponding reverse direction to operate the recline function. Refer to the MKIV owner's manual, part number 1043576 for complete switch option operating

instructions.

3. Release four-way toggle switch to neutral position.

NOTE: The four-way toggle switch will alternate

functions (increase recline angle, decrease recline

angle) after it has been released to the neutral position for a minimum of one (1) second.

NOTE: Refer to the MKIV owner's manual, part number 1043576 for complete four-way toggle switch operating instructions.

o

Increasing/Decreasing Tilt Angle

NOTE: The tilt angle range is from 5o to 50o with a 5

seat-to-floor angle. The Tilt angle range is from 0

to 45 o with a 0o seat-to-floor angle.

1. Make sure the wheelchair is on a level surface.

2. Push four-way toggle switch forward towards the front

of the wheelchair until the desired tilt angle is achieved.

NOTE: If the wheelchair is equipped with switch options, scan to the correct ECU or Auxiliary Mode

and activate the control device in the corresponding forward direction to operate the tilt function. Refer

to the MKIV owner's manual, part number 1043576

for complete switch option operating instructions.

o

o

16

TILT/RECLINE PROCEDURE 5

Four-Way Toggle

Switch (Shown in

Neutral Position)

LED

FULL UPRIGHT POSITION

TILT/RECLINE COMBINATION

T

I

L

T

/

R

E

C

L

I

N

E

NOTE: Illustration depicts RWD models. The tilt/recline function operates in the same manner for FWD models.

FIGURE 1 - OPERATING TILT/RECLINE SYSTEMS

17

VENTILATOR TRAYPROCEDURE 6

This Procedure Includes the Following:

Using the Optional Ventilator Tray

V

E

NOTE: Extended Active Anti-tippers are standard when chair is equipped with vent tray. Refer to PROCEDURE 11 for

N

anti-tipper adjustment if necessary.

T

USING THE OPTIONAL VENTILATOR TRAY (FIGURE 1)

I

L

A

Maximum weight capacity for the vent tray is 40 lbs. Otherwise, injury or damage may

occur.

T

O

R

T

R

A

Y

This ventilator tray was designed to hold a ventilator that is approximately 13-inches long, 14-1/

2-inches wide, and 9-3/4-inches high. Use of ventilators larger than the above specifications

may result in damage to the ventilator.

1. Position straps to the outside of the ventilator tray and battery tray.

2. Position the ventilator (not shown) on the ventilator tray.

3. Secure strap around the the ventilator and clip together.

4. Position the ventilator battery box in the battery tray.

WARNING

CAUTION

5. Secure strap around the battery box and clip together.

6. Securely tighten the straps around the battery box and ventilator by pulling the ends of the strap through

the rear portion of each buckle. Refer to DETAIL "A".

Strap

DETAIL “A”

Strap

Rear

Portion

of Buckle

See

DETAIL "A"

Strap

Strap

Ventilator

Tray

Battery Tray

Ventilator

Battery Box

Extended Active

Anti-Tippers

FIGURE 1 - USING THE OPTIONAL VENTILATOR TRAY

18

SHEAR REDUCTION

PROCEDURE 7

This Procedure Includes the Following:

Optional Vernier Shear Reduction

OPTIONAL VERNIER SHEAR

REDUCTION

About Vernier Shear Reduction (VSR)

WARNING

The relationship between Vernier Shear Reduction (VSR) and the recline function of the seating system is dependant on the needs of the user

and MUST be set and adjusted by a trained authorized Invacare Dealer.

Have the relationship between Vernier

Shear Reduction (VSR) and the recline function

of the seating system periodically inspected to

maintain proper setting for the user. Otherwise,

injury to the user may result.

Vernier Shear Reduction (VSR) moves the back of the

seating system along with the recline function. VSR reduces shear between the user and the seating system

as the seating system reclines.

3. Push four-way toggle switch towards the left of the

wheelchair until the desired VSR is achieved.

NOTE: Left and right is determined by sitting in the wheelchair.

NOTE: The four-way toggle switch will alternate

functions (move VSR actuator UP, move VSR

actuator DOWN) after it has been released to the

neutral position for a minimum of one (1) second.

NOTE: If the wheelchair is equipped with switch options, scan to the correct ECU or Auxiliary Mode

and activate the control device in the corresponding left direction to operate the VSR function. Refer to the MKIV owner's manual, part number

1043576 for complete switch option operating instructions.

4. Return the back to the position noted in STEP 2 BEFORE changing the degree of recline.

Four-Way Toggle

Switch (Shown in

Neutral Position)

S

H

E

A

R

R

E

D

U

C

T

I

O

N

NOTE: VSR is electronically linked to the recline

function of the seating system and operating the recline function automatically activates VSR.

VSR function can also be used independently from the

recline function to allow for a change in seating position or

access to additional seating system options. Refer to

ING VERNIER SHEAR REDUCTION (VSR) INDEPENDENTLY OF RECLINE FUNCTION in this procedure of

the manual.

US-

Using Vernier Shear Reduction (VSR)

Independently of Recline Function

(FIGURE 1)

WARNING

The back of the seating system MUST be

returned to original position BEFORE the

degree of recline is changed (increased

or decreased). Otherwise, the relationship between Vernier Shear Reduction

(VSR) and the recline function of the seating system will change, possibly resulting in injury to

the user.

FIGURE 1 - USING OPTIONAL VERNIER

SHEAR REDUCTION INDEPENDENTLY OF

RECLINE FUNCTION

1. Make sure the wheelchair is on a level surface.

2. Note the current position of the back.

19

PROCEDURE 8 RIGGINGS

This Procedure Includes the Following:

Mechanical Elevating/Genius Legrests

Installing Power Legrests

Adjusting Power Legrests

R

Articulation Adjustment

I

G

G

N

After ANY adjustments, repair or service and BE-

I

FORE use, make sure all attaching hardware is

tightened securely - otherwise injury or damage may result.

W ARNING

G

NOTE: Tilt ONLY - For complete operating information on

S

Invacare footrests and elevating legrests, refer to the owner's

manual supplied for the base of the wheelchair.

MECHANICAL ELEVATING/

GENIUS LEGRESTS

CAUTION

DO NOT operate the recline function of

the seating system if one (1) or both of

the mechanical elevating legrest push

rods is bent. Damage to the seating system may occur.

NOTE: Mechanical elevating legrests are linked to the

recline function of the seating system. Operating the recline function automatically operates elevating legrests.

Mounting

Hole

Legrest

Release

Handle

Calfpad

Mounting Pin

NOTE: AT5544

shown. Genius

Legrest installs

the same way.

Footplate

Mechanical

Elevating

Legrest

Push Rod

Installing/Removing Mechanical

Elevating/Genius Legrests (FIGURE 1)

INSTALLING.

1. Turn elevating legrest to side (open footplate is perpendicular to wheelchair) and position the mounting

pin on the legrest mounting holes on the seat frame.

2. Insert the mounting pin into the mounting hole.

NOTE: Make sure the legrest sits flush on the seat frame.

3. Rotate the elevating legrest toward the inside of the

wheelchair until it locks in place.

NOTE: The footplate will be on the inside of the wheelchair

when locked in place.

4. Lift the elevating legrest UP and position the mechanical elevating legrest push rod around the pin on the

legrest as shown in FIGURE 1.

5. Press DOWN on mechanical elevating legrest push

rod until there is an audible "click".

6. Repeat STEPS 1-5 for the opposite elevating legrest.

7. If necessary, adjust elevating legrests. Refer to one of

the following:

ADJUSTING MECHANICAL ELEVATING LEG-

A.

RESTS in this procedure of the manual.

ADJUSTING GENIUS LEGRESTS in this proce-

B.

dure of the manual.

REMOVING.

1. Lift UP on the mechanical elevating legrest push

rod and remove from the pin on the legrest as shown

in FIGURE 1.

2. Push elevating legrest release handle toward the opposite side of the wheelchair and swing legrest to the

outside of the wheelchair.

3. Lift UP on elevating legrest and remove from wheelchair.

4. Repeat STEPS 1-3 for opposite side of wheelchair.

Adjusting Mechanical Elevating Legrests

CALFPADS (FIGURE 2).

1. Turn the calfpad towards the outside of the wheelchair.

2. Slide calfpad up or down until desired position is obtained.

3. Turn the calfpad towards the inside of the wheelchair.

Pin

FIGURE 1 - INSTALLING/REMOVING

MECHANICAL ELEVATING/GENIUS LEGRESTS

20

Adjust Calfpad

FIGURE 2 - ADJUSTING MECHANICAL

ELEVATING LEGRESTS - CALFPADS

Secure Calfpad

RIGGINGS

PROCEDURE 8

FOOTPLATE HEIGHT (FIGURE 3).

NOTE: The following procedure should be performed with

the user in the wheelchair.

1. Loosen, but do not remove the bolt and locknut that

secure the lower legrest assembly to the upper legrest

assembly.

2. Move the lower legrest assembly to the desired position for the user.

3. While holding the lower legrest in position, tighten the

bolt and locknut securely.

4. Repeat STEPS 1-4 for opposite legrest if necessary.

Upper

Legrest

Assembly

Lower Legrest

Bolt/Nut

FIGURE 3 - ADJUSTING MECHANICAL

ELEVATING LEGRESTS - FOOTPLATE HEIGHT

SPEED/HEIGHT.

NOTE: Mechanical Elevating Legrest speed and height

cannot be adjusted independently of the recline function

of the wheelchair. If the mechanical elevating legrests are

not operating as desired, have the wheelchair serviced

by an Invacare dealer or technician.

Assembly

Adjusting Genius Legrests

FOOTPLATE HEIGHT (FIGURE 4).

1. Note the angle of the footplate in relation to the legrest

as shown in FIGURE 1.

2. Loosen, but do not remove the three (3) hex bolts and

locknuts that secure the footplate to the legrest.

3. Adjust the fooplate to the desired height.

4. Line up the footplate to the angle noted in STEP 1.

5. While holding the footplate, tighten the three (3) hex

bolts and locknuts securely.

Footplate

FOOTPLATE ANGLE (FIGURE 4).

1. Note the angle of the footplate in relation to the legrest

as shown in FIGURE 1.

2. Remove the rear hex bolt and locknut that secure the

footplate to the legrest.

3. Move the footplate to the desired angle.

4. Install the hex bolt through the mounting holes that correspond to the desired footplate angle.

5. Install the locknut onto the hex bolt.

6. Line up the footplate to the angle noted in STEP 1.

7. While holding the footplate, tighten the hex bolt and locknut securely.

CALFPAD HEIGHT (FIGURE 5).

1. Turn the calfpad towards the outside of the wheelchair.

2. Slide calfpad up or down until desired position is obtained.

3. Turn the calfpad towards the inside of the wheelchair.

CALFPAD DEPTH (FIGURE 5).

1. Remove the hex bolt and locknut that secure the calfpad

and spacer to the adjustment bracket.

2. Move the legrest to one (1) of three (3) positions.

3. Reinstall the hex bolt through the spacer and calfpad.

NOTE: Make sure hex bolt sits flush adjustment bracket

channel.

4. Reinstall locknut onto the hex bolt and tighten securely.

Adjustment

Bracket

Channel

Locknut

Calfpad

Spacer

FIGURE 5 - ADJUSTING GENIUS LEGRESTS -

CALFPAD HEIGHT/DEPTH

Adjustment

Bracket

Hex Bolt

R

I

G

G

I

N

G

S

Legrest

Rear Hex Bolt

and Locknut

Hex Bolts and

Locknuts

FIGURE 4 - ADJUSTING GENIUS LEGRESTS -

FOOTPLATE HEIGHT/ANGLE

Rear Hex Bolt

and Locknut

LEGREST HEIGHT (FIGURE 6).

1. Remove the button screw that secures the adjustment link and two (2) washers to the legrest support.

2. Move adjustment link to one (1) of three (3) positions.

3. Line up the two (2) washers and adjustment link with

the mounting hole in the legrest support.

4. Install the button screw and tighten securely.

21

PROCEDURE 8 RIGGINGS

Washer

Adjustment

R

Legrest

Support

Washer

I

Button

Screw

G

G

I

FIGURE 6 - ADJUSTING GENIUS LEGRESTS -

LEGREST HEIGHT/DEPTH

N

G

INSTALLING/REMOVING THE

S

POWER LEGRESTS (FIGURE 7)

NOTE: Power legrests are linked to the recline function of the seating system. Operating the recline

function automatically operates power legs. Power

Legrests can also be operated independently of the

recline function.

W ARNING

To prevent personal injury, always verify

proper positioning of legs and feet prior to

use. Individual user weight may impact the

rate of travel for each legrest assembly. If

simultaneous operation is desired, select a

speed which allows for the most uniform

travel.

Link

NOTE: Make sure the legrest sits flush on the seat frame.

3. Rotate the power legs toward the inside of the

wheelchair until it locks in place.

NOTE: The footplate will be on the inside of the wheelchair

when locked in place.

4. Repeat STEPS 1-3 for the opposite legrest.

5. Connect power legrest connector to jumper cable

(DETAIL"B").

6. If necessary, adjust powered legs. Refer to

ING POWER LEGRESTS in this instruction sheet.

ADJUST-

Removing the Power Legrests

1. Disconnect power legrests from jumper cable.

2. Push powered legrest release handle toward the opposite side of the wheelchair and swing legrest to the

outside of the wheelchair.

3. Lift UP on powered legrest and remove from wheelchair.

4. Repeat STEPS 1-3 for opposite power legrest.

DET AIL "B"

DO NOT insert fingers between legrest

components, otherwise personal injury

may occur.

CAUTION

Never allow items to become trapped

between the legrest assemblies, otherwise damage to the power legrests may occur.

Ensure that all parts of both power legrests

are clear of any obstructions before raising and lowering, otherwise damage to

the power legrests may occur.

Installing the Power Legrests

1. Turn power legrest to side (open footplate is perpendicular to wheelchair) and position the mounting pin on the legrest with mounting holes on the

seat frame (DETAIL"A").

2. Insert the mounting pin of power legrest into the

mounting hole of the seat frame (DETAIL"A").

Jumper

Cable

Power Leg

Connector

DET AIL "A"

Calf pad

Mounting

Pin

Legrest Release

Handle

FIGURE 7 - INSTALLING/REMOVING POWER

LEGRESTS

Footplate

22

RIGGINGS

PROCEDURE 8

ADJUSTING THE POWER LEGRESTS

NOTE: The speed of the power legs MUST be adjusted to the following specifications otherwise the legs

will not work properly. For assistance in speed adjustment contact an Invacare Dealer.

A.

For TRCM Version 2.2 and earlier, TAC 1.1 and earlier: Leg up speed MUST to be set at 70% or

higher and Leg Down speed MUST be set at 50% or higher.

B. For TRCM version 2.3 or higher, TAC version 1.11 or higher: Leg up speed MUST be set at 40% or

higher and Leg Down speed MUST be seat at 35% or higher.

Adjusting the Footplate

WARNING

DO NOT remove heel loops without providing some other adequate means of support,

otherwise personal injury may occur.

ADJUSTING THE FOOTPLATE HEIGHT (FIGURE 8).

NOTE: The following procedure should be performed with the user in the wheelchair.

NOTE: T-nuts ride in the channels of the exterior/interior rails of the power legrests. Refer to FIGURE 8.

R

I

G

G

I

N

G

S

1. Loosen, but do not remove the two (2) interior button screws that secure the footplate assembly to the

T-nuts.

2. Loosen, but do not remove the two (2) exterior button screws that secure the footplate assembly to the

T-nuts.

3. Loosen, but do not remove the two (2) button screws that secure the heel loop to the T-nuts.

4. Slide footplate assembly up or down, until desired height is achieved.

5. While holding footplate assembly in position, tighten all six (6) button screws that were loosened in

STEPS 1-3.

6. Repeat STEPS 1-3 for opposite footplate if necessary.

OUTSIDE VIEW OF POWERED LEGS

Exterior Rail

Channel

T-Nuts (NOT Shown)

INSIDE VIEW OF POWERED LEGS

Exterior Rail

Channel

T-Nuts (NOT

Shown)

Exterior

Button

Screws

Button Screws

for Heel Loop

Footplate

Assembly

Interior Button Screws

Footplate

Assembly

FIGURE 8 - ADJUSTING THE FOOTPLATE HEIGHT

23

PROCEDURE 8 RIGGINGS

ADJUSTING THE FOOTPLATE DEPTH

(FIGURE 9).

1. Remove the two (2) flat head screws and the two (2)

barrel nuts that secure the footplate to the footplate clamp.

2. Reposition the footplate on the footplate clamp.

R

3. Align the depth holes on the footplate to the mounting

I

holes on the footplate clamp.

G

4. Insert the (2) barrel nuts through the bottom of the footplate

G

I

N

G

S

clamp.

5. Install the two (2) flat head screws through the footplate

and footplate clamp.

6. Securely tighten with two (2) barrel nuts.

7. Repeat STEPS 1-6 for opposite footplate if necessary.

Flush Head

Screws

Footplate

Depth

Adjustment

Holes

4. Repeat STEPS 1-3 for opposite side if necessary.

5. For additional angle adjustment, perform the following

(FIGURE 11):

A. Loosen the set screw.

B. Rotate footplate up or down to desired position.

C. Retighten set screw.

DETAIL “A”

Flush Head Screws

Footplate

Footplate

Clamp

Barrel Nuts

DETAIL “B”

Footplate

Footplate

Clamp

Barrel Nuts

Mounting Holes

FIGURE 9- ADJUSTING THE FOOTPLATE DEPTH

ADJUSTING THE FOOTPLATE ANGLE

(FIGURES 10) .

1. Loosen, but do not remove the two (2) flat head screws

and the two (2) barrel nuts that secure the footplate to the

footplate clamp. Refer to DETAIL A in FIGURE 7.

2. Rotate the footplate clamp on the pivot hinge until

the desired angle is achieved. Refer to DETAIL B FIGURE 10.

3. Securely tighten footplate to footplate clamp and hinge

pivot with the two (2) flat head screws and barrel nuts.

Footplate

Clamp

FIGURE 10 - ADJUSTING THE FOOTPLATE

ANGLE

Pivot Hinge

Direction

of Rotation

Set Screw

24

RIGGINGS

PROCEDURE 8

Adjusting the Calf Pad

ADJUSTING THE CALF PAD WIDTH (FIGURE

11).

1. Remove the two (2) button head screws from the calf

pad and calf pad bracket.

2. Reposition calf pad to calf pad bracket to desired

mounting position.

3. Align button head screws to mounting holes on calf

pad and calf pad bracket.

4. Install button head screws into calf pad bracket and

calf pad. Securely tighten.

5. Repeat STEPS 1-4 for opposite side, if necessary.

BACK VIEW

OF LEGREST

Calf Pad

Mounting

Holes

Button Head

Screws

Calf Pad

Calf Pad

Bracket

Mounting Holes

Calf Pad

Bracket

ADJUSTING THE CALF PAD DEPTH (FIGURE 12).

1. Loosen, but do not remove, depth adjustment

bracket mounting screws and slide calf pad assembly up and out of the mounting channel.

2. Remove the flat head socket screw, and locking

hex nut that secure the calf bracket to the depth

adjustment bracket.

3. Reposition the calf bracket on the depth adjustment bracket to desired position

4. Install the flat head socket screw through the calf

bracket, depth adjustment bracket and locking hex

nut.

5. Tighten locking hex nut to screw until snug. Do not

overtighten nut or calf pad will not pivot properly.

6. Align the two (2) T-nuts on depth adjustment

bracket assembly with channel on legrest. Slide

calf pad assembly to desired height. Tighten the

two (2) hex mounting screws securely.

7. Repeat STEPS 1-6 for opposite side.

Mounting

Channel

Flat

Head

Mounting

Screw

Locking

Hex Nut

Depth

Adjustment

Holes

R

I

G

G

I

N

G

S

Button Head Screws

FIGURE 11 - ADJUSTING THE CALF PAD WIDTH

Depth

Adjustment

Bracket

Calf

Bracket

Depth Adjustment

Bracket Hex Head

Screws

NOTE: Calf pad not shown for clarification purposes

only.

FIGURE 12 - ADJUSTING THE CALF PAD

DEPTH

25

PROCEDURE 8 RIGGINGS

ADJUSTING THE CALF PAD HEIGHT

(FIGURE 13)

1. Loosen, but DO NOT remove, the two (2) hex head

screws that secure depth adjustment bracket to the

T-nuts.

R

2. Slide the calf pad assembly with T-nuts up or down

I

G

G

I

N

in the channel to desired position.

3. Holding the calf pad assembly into position, tightly

secure the hex screws to the T-nuts.

4. Repeat STEPS 1-3 for opposite side, if necessary.

G

S

Depth

Adjustment

Bracket

Channel

Adjusting the Length for Power Legrest

(FIGURE 14)

1. Loosen, but do not remove, the length adjustment

button screw (screw also secures lower end of

shroud).

2. Slide footplate with outer cover up or down to desired position.

3. Securely tighten length adjustment button screw.

4. Repeat STEPS 1-3 for remaining legrest.

Outer Cover

Outer Rail

Hex Head

Screws

(T-Nuts are

not shown)

FIGURE 13 - ADJUSTING THE CALF PAD HEIGHT

Button

Screw

NOTE: Length adjustment screw is from 15-1/2inches to 20-inches.

FIGURE 14 - ADJUSTING THE LENGTH FOR

POWER LEGREST

26

PROCEDURE 9ARMRESTS

This Procedure Includes the Following:

Reclining Armrests

W ARNING

After ANY adjustments, repair or service and BEFORE use, make sure all attaching hardware is

tightened securely - otherwise injury or damage may result.

Make sure armrests are locked securely

in place BEFORE using the wheelchair.

Pinch points exist on the armrests.

NOTE: For complete operating information on Non-Reclining Armrests, refer to the owner's manual supplied for

the base of the wheelchair.

RECLINING ARMRESTS

Removing Armrests (FIGURE 1)

1. Lift the armrest release lever at the front of the wheelchair to the unlocked (horizontal) position.

2. Lift UP on the armrest and remove from the front arm

socket.

3. Press the release button at the rear of the armrest IN.

4. While holding the release button IN, remove the armrest from the seat frame.

4. Make sure the armrest release lever is in the unlocked

(horizontal) position.

5. Install the armrest into the front socket.

6. Push the armrest release lever down into the locked

(vertical) position.

Adjusting Armrest Height (FIGURE 2)

1. Make sure the seating system is in the full upright position. Refer to

TEMS in PROCEDURE 4 of this manual or OPERATING TILT/RECLINE SYSTEMS in PROCEDURE 5

of this manual.

2. Remove the socket bolt and locknut that secure the

front of the upper armrest to the lower armrest.

3. Loosen, but do not remove the two (2) socket screws

and T-nuts that secure the rear of the recliner armrest

to the back cane.

4. Refer to the chart below and adjust the armrest to the

desired height for the user.

Jÿ

HOLE #: 1 2 3 4 5 6

Armrest Height

(in inches) 11 12 13 14 15 16

Jÿ

Front armrest mounting holes are numbered from bottom to top for reference only. (There are no numbers on the

armrests.)

OPERATING RECLINE ONLY SYS-

A

R

M

R

E

S

T

S

Installing Armrests (FIGURE 1)

1. Position the armrest on the seat frame as shown in

FIGURE 1.

2. Press the release button at the rear of the armrest IN.

3. While holding the release button IN, slide the armrest

onto the seat frame.

Release

Button

Armrest

Release

Lever

LOCKED (DOWN - VERTICAL)

NOTE: The armrests can be at different heights to accommodate the user.

5. Reinstall the socket bolt through the mounting hole

determined in STEP 4.

6. Reinstall the locknut and tighten securely.

7. While holding the armrest level, tighten the two (2)

socket screws and T-nuts securely.

8. Repeat STEPS 2-7 for the opposite side if necessary.

Socket

Screws/

T-Nuts

Back

Cane

Armrest

Locknut

Height

Adjustment

Holes

Socket

Bolt

UNLOCKED (UP-

HORIZONTAL)

FIGURE 1 - REMOVING/INSTALLING

ARMRESTS

FIGURE 2 - ADJUSTING ARMREST HEIGHT

27

PROCEDURE 10 HEADREST

This Procedure Includes the Following:

Removing/Installing/Adjusting Headrest

Replacing Headrest

H

E

A

D

After ANY adjustments, repair or service

and BEFORE use, make sure all attaching

hardware is tightened securely - otherwise injury or damage may result.

WARNING

R

REMOVING/INSTALLING/

E

ADJUSTING HEADREST (FIGURE 1)

S

Removing

T

1. Loosen, but do not remove, the thumb screw that secures the headrest to the headrest mounting bracket.

2. Remove the headrest from the headrest mounting

bracket.

Installing

1. Make sure thumb screw is loose.

2. Install the headrest until the headrest stop sits on the

headrest mounting bracket.

3. If necessary, adjust the height, depth or direction of the

headrest. Refer to

or

ADJUSTING HEADREST DEPTH/DIRECTION in

this procedure of the manual.

DETAIL "A"

Side to Side

Adjustment

Left to Right

Adjustment

ADJUSTING HEADREST HEIGHT

Up and Down

Adjustment

Offset Fixture

Adjustment

Depth

Adjusting Headrest Height

1. Loosen the set screw on the headrest stop.

2. Loosen, but do not remove, the thumb screw that secures the headrest to the headrest mounting bracket.

3. Position the headrest to the desired height.

4. Tighten the thumb screw that secures the headrest

to the headrest mounting bracket.

5. Tighten the set screw on the headrest stop.

6. If necessary, adjust the depth or direction of the headrest . Refer to

RECTION in this procedure of the manual.

ADJUSTING HEADREST DEPTH/DI-

Adjusting Headrest Depth/Direction

1. Loosen, but do not remove, the three (3) socket screws

that secure the offset fixture to the slide tube.

2. If necessary, reposition the headrest to the desired

depth by sliding the headrest towards the front of the

wheelchair or towards the rear of the wheelchair.

3. If necessary, reposition the headrest to the desired

position (headrest will move in any direction). Refer to

DETAIL "A".

4. While holding the headrest in the desired position, securely tighten the three (3) socket screws.

5. If necessary, adjust the height of the headrest . Refer

ADJUSTING HEADREST HEIGHT in this proce-

to

dure of the manual.

REPLACING HEADREST (FIGURE 2)

1. Remove the three (3) socket screws that secure the

headrest to the headrest mounting bracket.

2. Position the new headrest on the headrest mounting

bracket and secure with the existing three (3) socket

screws.

3. If necessary, adjust the height, depth or direction of the

headrest. Refer to

or

ADJUSTING HEADREST DEPTH/DIRECTION in

this procedure of the manual.

ADJUSTING HEADREST HEIGHT

Slide Tube

Socket Screws

Height Adjustment

Thumb Screw

Headrest Stop

Headrest Mounting Bracket

FIGURE 1 - REMOVING/INSTALLING/

ADJUSTING HEADREST

Headrest Mounting Bracket

Set Screw

Socket

Screws

Headrest

NOTE: One (1) style of headrest shown for clarity.

Both styles of headrest attach the same way.

FIGURE 2 - REPLACING HEADREST

28

PROCEDURE 11ANTI-TIPPERS

This Procedure Includes the Following:

Using the Extended Active Anti-Tippers

ADJUSTING THE EXTENDED

ACTIVE ANTI-TIPPERS (FIGURE 1)

NOTE: Extended Active Anti-tippers are standard when

chair is equipped with vent tray.

WARNING

Power chairs equipped with ventilator tray MUST have extended active

anti-tippers installed, otherwise, injury

or damage may occur.

Power chairs that are NOT equipped

with optional ventilator tray MUST

have either the standard anti-tippers

or the the optional extended active

anti-tippers installed, otherwise, injury

or damage may occur. See DETAIL "A" in

FIGURE 1.

NOTE: The recommended height requirement for

the anti-tippers, which is factory preset, is 1/4-inch

off of the ground.

1. Loosen locknut C, B, and A.

2. Lift anti-tipper place 1/4-inch block underneath

wheel.

Standard

Anti-tippers

Extended

Active

Anti-tippers

DETAIL "A"

Dust Cover

is placed here

A

N

T

I

-

T

I

P

P

E

R

S

Extended Anti-tip

Assembly

3. Tighten locknut A upward against bearing.

4. Tighten locknut B upward against locknut A.

5. Tighten locknut C downward against bearing inside anti-tip assembly.

6. Remove 1/4-inch block.

7. Repeat procedure for remaining anti-tip assembly.

8. Install dust cover on each anti-tip assembly.

Locknut C

Bearings

Locknut A

Locknut B

1/4-inch Block

FIGURE 1 - ADJUSTING THE EXTENDED

ACTIVE ANTI-TIPPERS

Ground/Floor

29

WARRANTY

W

A

R

R

A

N

T

Y

LIMITED WARRANTY

PLEASE NOTE: THE WARRANTY BELOW HAS BEEN DRAFTED TO COMPLY WITH FEDERAL LAW

APPLICABLE TO PRODUCTS MANUFACTURED AFTER JULY 4, 1975.

This warranty is extended only to the original purchaser/user of our products.

This warranty gives you specific legal rights and you may also have other legal rights

which vary from state to state.

Invacare warrants this product to be free from defects in materials and workmanship

for a period of one (1) year from date of purchase. If within such warranty period any

such product shall be proven to be defective, such product shall be repaired or replaced, at Invacare's option. This warranty does not include any labor or shipping

charges incurred in replacement part installation or repair of any such product. Invacare's

sole obligation and your exclusive remedy under this warranty shall be limited to such

repair and/or replacement.

For warranty service, please contact the dealer from whom you purchased your Invacare

product. In the event you do not receive satisfactory warranty service, please write directly

to Invacare at the address at the bottom of the page. Provide dealer’s name, address, date

of purchase, indicate nature of the defect and, if the product is serialized, indicate the serial

number. Do not return products to our factory without our prior consent.

LIMITATIONS AND EXCLUSIONS: THE FOREGOING WARRANTY SHALL NOT APPLY TO SERIAL

NUMBERED PRODUCTS IF THE SERIAL NUMBER HAS BEEN REMOVED OR DEFACED, PRODUCTS SUBJECTED TO NEGLIGENCE, ACCIDENT, IMPROPER OPERATION, MAINTENANCE OR

STORAGE, COMMERCIAL OR INSTITUTIONAL USE, PRODUCTS MODIFIED WITHOUT

INVACARE'S EXPRESS WRITTEN CONSENT INCLUDING, BUT NOT LIMITED TO, MODIFICATION THROUGH THE USE OF UNAUTHORIZED PARTS OR ATTACHMENTS; PRODUCTS DAMAGED BY REASON OF REPAIRS MADE TO ANY COMPONENT WITHOUT THE SPECIFIC CONSENT OF INVACARE, OR TO A PRODUCT DAMAGED BY CIRCUMSTANCES BEYOND

INVACARE'S CONTROL, AND SUCH EVALUATION WILL BE SOLELY DETERMINED BY INVACARE. THE WARRANTY SHALL NOT APPLY TO PROBLEMS ARISING FROM NORMAL WEAR OR

FAILURE TO ADHERE TO THESE INSTRUCTIONS.

THE FOREGOING EXPRESS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY OTHER WARRANTIES

WHATSOEVER, WHETHER EXPRESS OR IMPLIED, INCLUDING THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PAR TICULAR PURPOSE, AND THE SOLE REMEDY FOR VIOLATIONS OF ANY WARRANTY WHATSOEVER, SHALL BE LIMITED TO REPAIR OR REPLACEMENT OF

THE DEFECTIVE PRODUCT PURSUANT TO THE TERMS CONTAINED HEREIN. THE APPLICATION OF

ANY IMPLIED WARRANTY WHATSOEVER SHALL NOT EXTEND BEYOND THE DURATION OF THE

EXPRESS WARRANTY PROVIDED HEREIN. INVACARE SHALL NOT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES WHATSOEVER.

THIS WARRANTY SHALL BE EXTENDED TO COMPLY WITH STATE/PROVINCIAL LAWS AND REQUIREMENTS.

30

NOTES

NOTES

N

O

T

E

S

31

Invacare Corporation www.invacare.com

USA Canada

One Invacare Way 570 Matheson Blvd E. Invacare is a registered trademark of Invacare Corporation

Elyria, Ohio USA Unit 8 Mississauga, Ontario Yes,you can is a trademark of Invacare Corporation.

44036-2125 L4Z 4G4, Canada ©

2003 Invacare Corporation

800-333-6900 800-668-5324 Part No. 1090207 Rev 1 - 04/03

Loading...

Loading...