C

一

INVACA

RE

FACTORY

(OHIO)

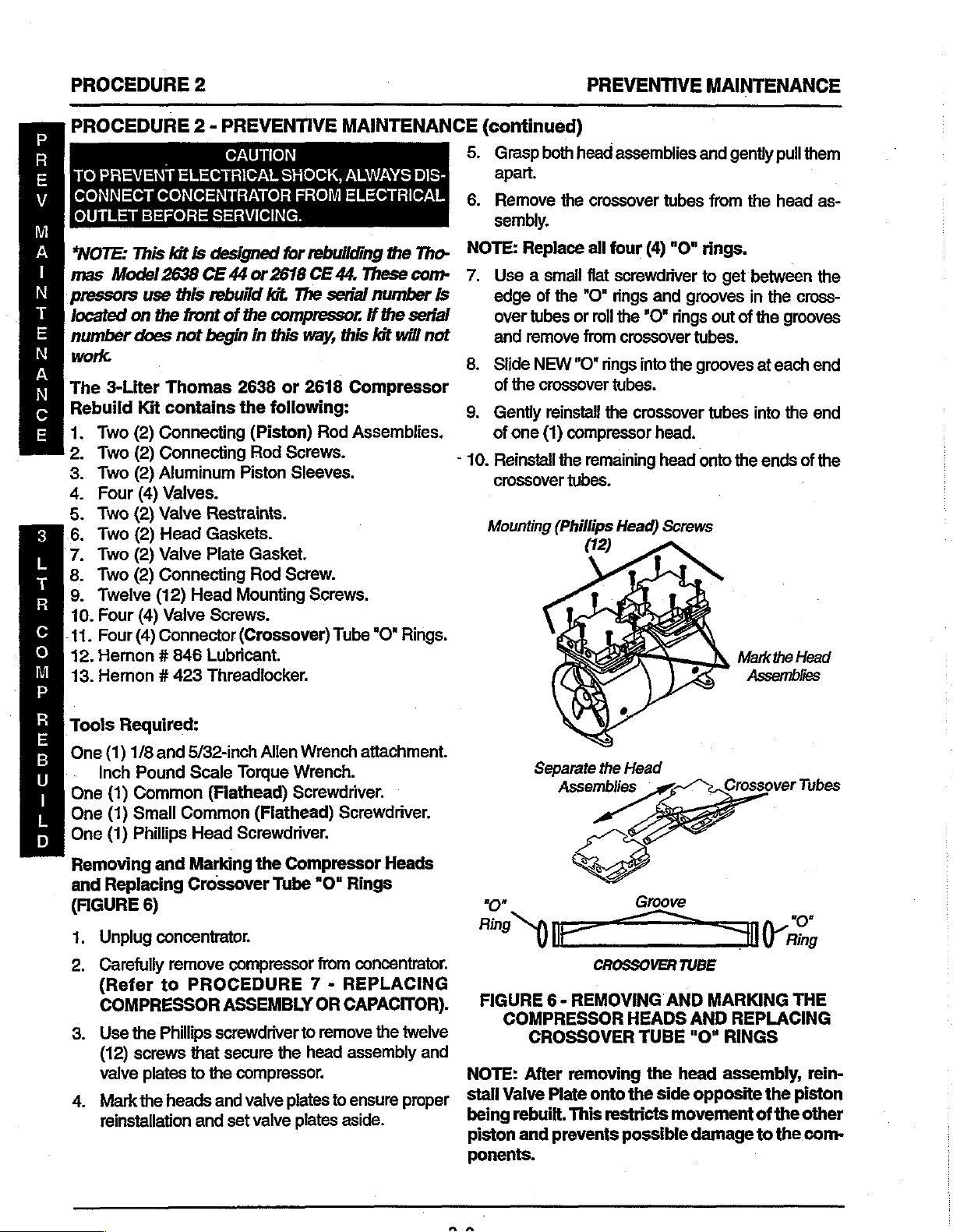

CORPORATE

899

CLEVELAND

ELYRIA,

(ELORIDA)

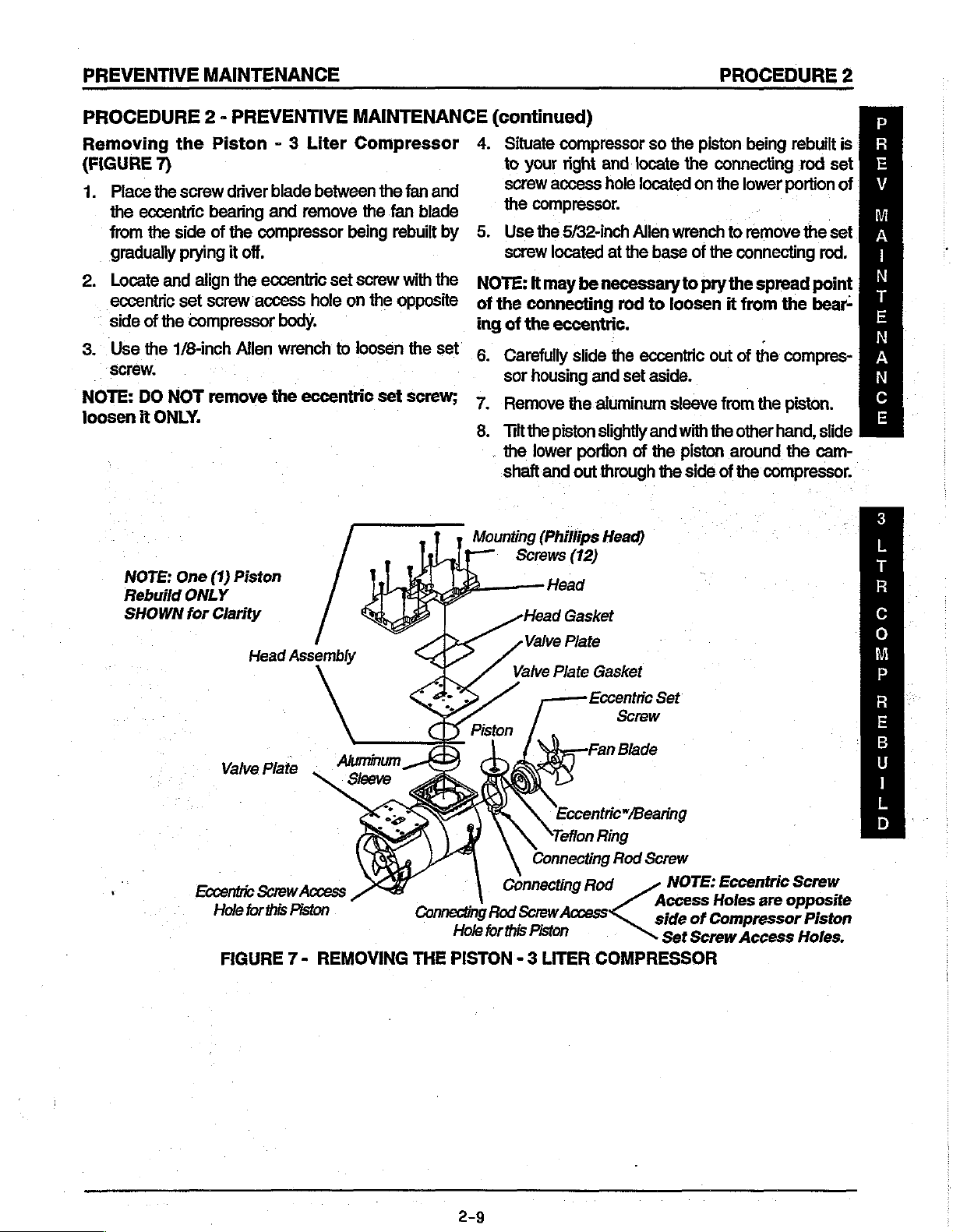

INVACARE

699

AERO

_

SANFORD,

MOBILITE

2101

E.

LAKE

SANFORD,

(TEXAS)

INVACARE

1825

WESTPARK

GRAND

PRAIRIE,

HEADQUARTERS

STREET

OHIO

44036

RESPIRATORY

LANE

FLORIDA

BY

INVACARE

MARY

FLORIDA

FORT

WORTH,

DRIVE

TX

PRODUCTS

32771

BLVD.

32773

TX

75050

REPAIR

DIST.

CENTER

CENTERS

(CALIFORNIA)

INVACARE

14030

LA

PALMA,

INVACARE

1-800-832-4707

CHOOSE

“1”

FOR:

“2”

FOR:

“3”

FOR:

“4”

FOR:

INVACARE’

—

A

CALIFORNIA

E.

183RD

CALIFORNIA

TECHNICAL

ONE

OF

ELECTRONICS

RESPIRATORY

HOMECARE

AND

ANYTHING

TECHNICAL

DIST.

STREET

90623

SERVICES

THE

FOLLOWING

PRODUCTS

BEDS,

THERAPEUTIC

ELSE

TRAINING

CENTER

“HOTLINE”

OPTIONS

RECLINERS,

SUPPORT

1-800-333-6900

LIFT-OUT

SURFACES

CHAIRS

X6697

ELYRIA,

OHIO

SHIPPING

AND

HANDLING

S

H

This

I

carefully

P

you

p

I

The

N

being

G

centrator.

/

H

If

A

cartons

N

The

‘D

L

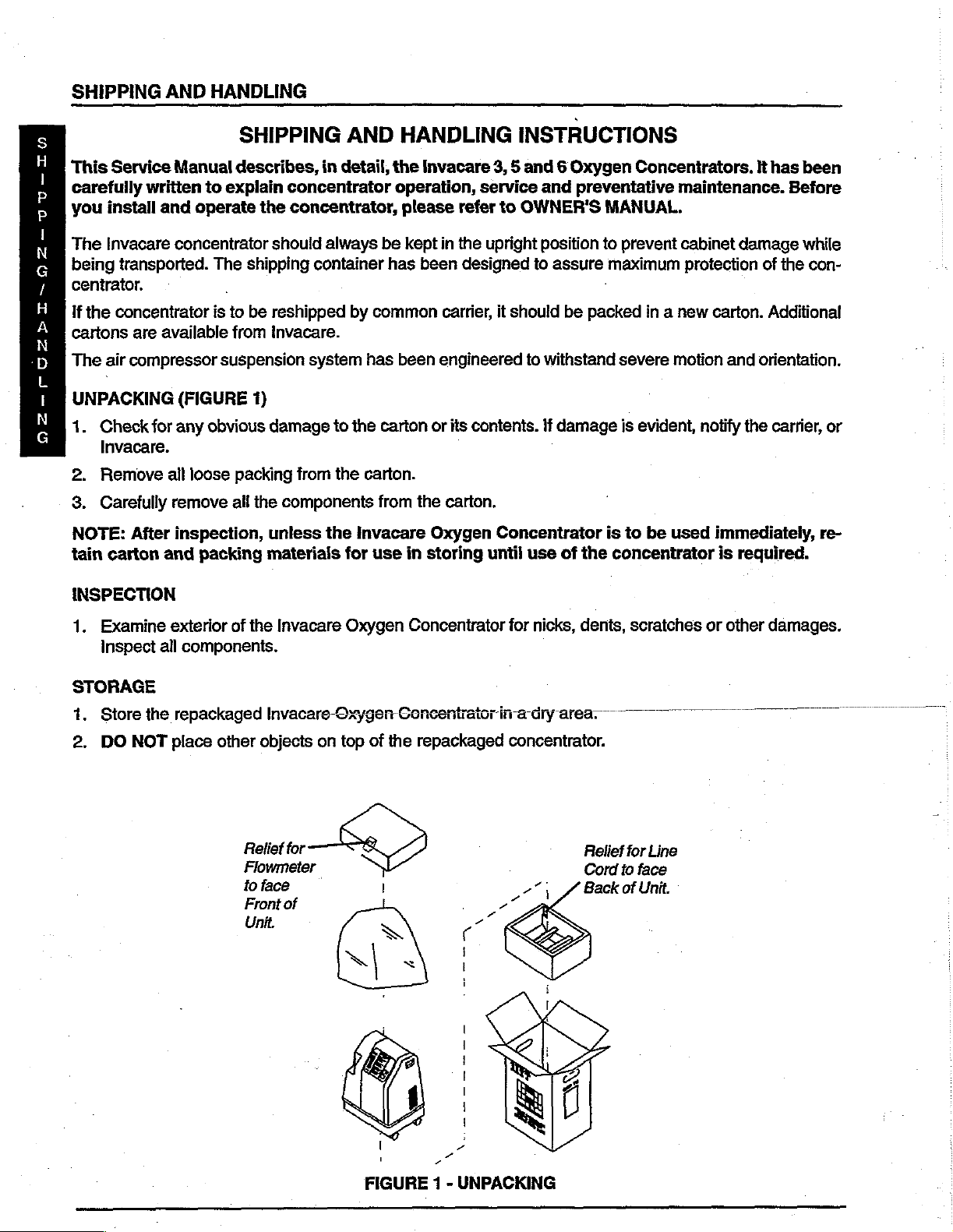

UNPACKING

р

N

1.

G

2.

3.

NOTE:

tain

Service

written

install

Invacare

transported.

the

concentrator

are

air

compressor

Check

Invacare.

Remove

Carefully

for

After

carton

SHIPPING

Manual

and

concentrator

available

(FIGURE

any

ail

remove

inspection,

and

describes,

to

explain

operate

The

is

to

from

suspension

obvious

loose

packing

all

packing

concentrator

the

concentrator,

should

shipping

be

reshipped

Invacare.

system

1)

damage

from

the

components

unless

materials

AND

in

detail,

always

container

to

the

by

common

has

the

the

carton.

Invacare

for

use

be

carton

from

HANDLING

the

Invacare

operation,

please

kept

has

been

in

refer

in

the

been

designed

carrier,

engineered

or

its

the

carton.

Oxygen

storing

INSTRUCTIONS

3, 5 and 6 Oxygen

service

upright

contents.

until

and

to

OWNER'S

position

to

assure

it

should

Concentrator

be

to

withstand

İf

damage

use

of

Concentrators.

preventative

MANUAL.

to

prevent

maximum

.

packed

the

in a new

severe

is

is

to

concentrator

motion

evident,

be

used

It

has

maintenance.

cabinet

protection

damage

of

carton.

notify

immediately,

is

Additional

and

orientation.

the

carrier,

required.

been

Before

while

the

con-

or

re-

INSPECTION

1.

Examine

inspect

STORAGE

1.

Store

the

2,

DO

NOT

exterior

all

components.

repackaged

place

other

of

the

Invacare

Invacare-Oxygen

objects

Relief

Flowmeter

to

face

Front

Unit.

on

for

of

Oxygen

top

Concentrator

Concentrator

of

the

repackaged

| .

for

nicks,

dents,

ina

dry

concentrator.

area.

Relief

Cord

Back

for

to

of

scratches

Line

face

Unit.

or

other

damages.

FIGURE 1 -

UNPACKING

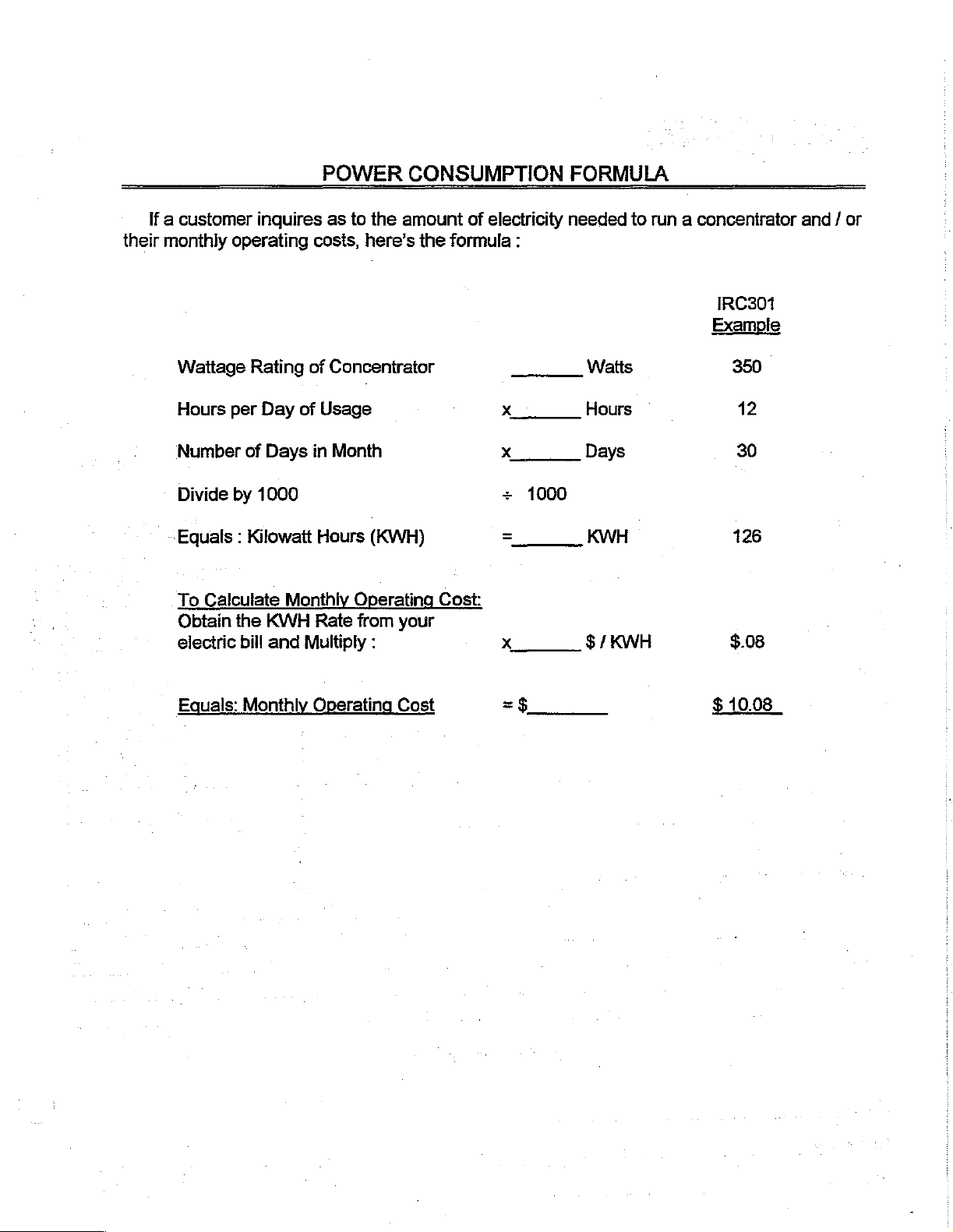

POWER

CONSUMPTION

FORMULA

If a customer

their

monthly

Wattage

Hours

Number

Divide

~Equals : Kilowatt

To

Calculate

Obtain

electric

inquires

operating

Rating

per

of

by

1000

Day

of

of

Days

Monthly

the

KWH

bill

and

Multiply

as

to

the

costs,

in

Hours

here’s

Concentrator

Usage

Month

(KWH)

Operating

Rate

from

:

amount

the

Cost:

your

of

electricity

formula

x

x

+

=

x

:

1000

needed

Watts

Hours

Days

KWH

$/

KWH

to

run a concenirator

IRC301

Example

350

©

12

30

126

$.08

and / or

Equals:

Monthly

Operating

Cost

=$

$

10.08

SEMINAR

FEEDBACK

FORM

In

an

your

1.

2.

3.

4.

Please

effort

to

comments

check

Subject

Contents

Instructor

Service

Format

continually

and

suggestions

the

box

Area

of

Manuals

|

Seminar

Instructor:

Location:

Date:

improve

regarding

which

(PLEASE

the

quality

this

most

Excellent

closely

[1

CHECK

of

this

course.

|Above

Home

O2

APPROPRIATE

seminar,

reflects

we would

your

Avg.|

Systems

BOX)

like

you

judgement

Average

|

to

rate

of

Below

us

and

provide

the

following

Avg. Poor

us

with

areas:

5.

Equipment

Additional

Name:

Company:

Phone:

Comments

and

Materials

and

Suggestions:

Optional

Information

TABLE

OF

CONTENTS

Section

Features

1

.....ceeerenmeecaerenasrrerentenneo

τοι

Installation

Sens

Pneumatic

02

Section

Preventive

4-Way

Compressor

7

カカ

o77gs

Section

7ou//e

Trouble

and

Illustration

Diagram

2

Maintenance

Va ル e

C7ea7n/9

Rebuilding

2679 6 わし

3

Зпоойпа

Shooting

sncataaeraramiseareo

μμ

Sequence

......c.secceeerereeeeasareneescasenecarcorenaaenenasscoracoennerensenaeno

of

ο

Operation...

ΟΡ

Record

ProOceOO

Instructions...

RC

307507

IRC

3LX/5LX/6LX...............

.......sseccsseccessercerssennensssnnersssennnenaceucess

aneaasanarzsasananz

инииинииииииитенивниииние

canta

rre

μμ

carrera

neon

1-1

1-2

1-6

1-10

μμ

rr

rannsarneraonosa

rennes

1-11

2-1

2-4

2-8

2-17

3-1

3-9

Section

Parts

4

Replacement

Section

了

oo

牛人

Mo/ex

Pilot

Venture

Co77ecfo7C カ 7

Valve

Homefill

5

Poppet

Procedures

Replacement

Literature

urnes

ezio vicricrinierii

Kit

0000050007000000

nia

ieini

Instructions

ㅁ ㄷ

000000*400088 ㅁ ㅁ ㄷ ㅁ 0 ㅁ

4-1

to

4-30

cri

nicorinieniseozinisvinionenioni

ri

vzivivene

cesser

040 ㅁ ㄷ

00000 ㅁ 00000 ㅁ 00000 ㅁ … ㅁ

042 ㅁ ㅁ

00000 ㅁ ㄴ 8 ㅠ ㅁ 0 ㅁ ㅠ 04 ㅁ 4008

5-1

5-2

5-9

INVACARE

TECHNICAL

TRAINING

1-800-333-6900

X6697

ELYRIA,

OHIO

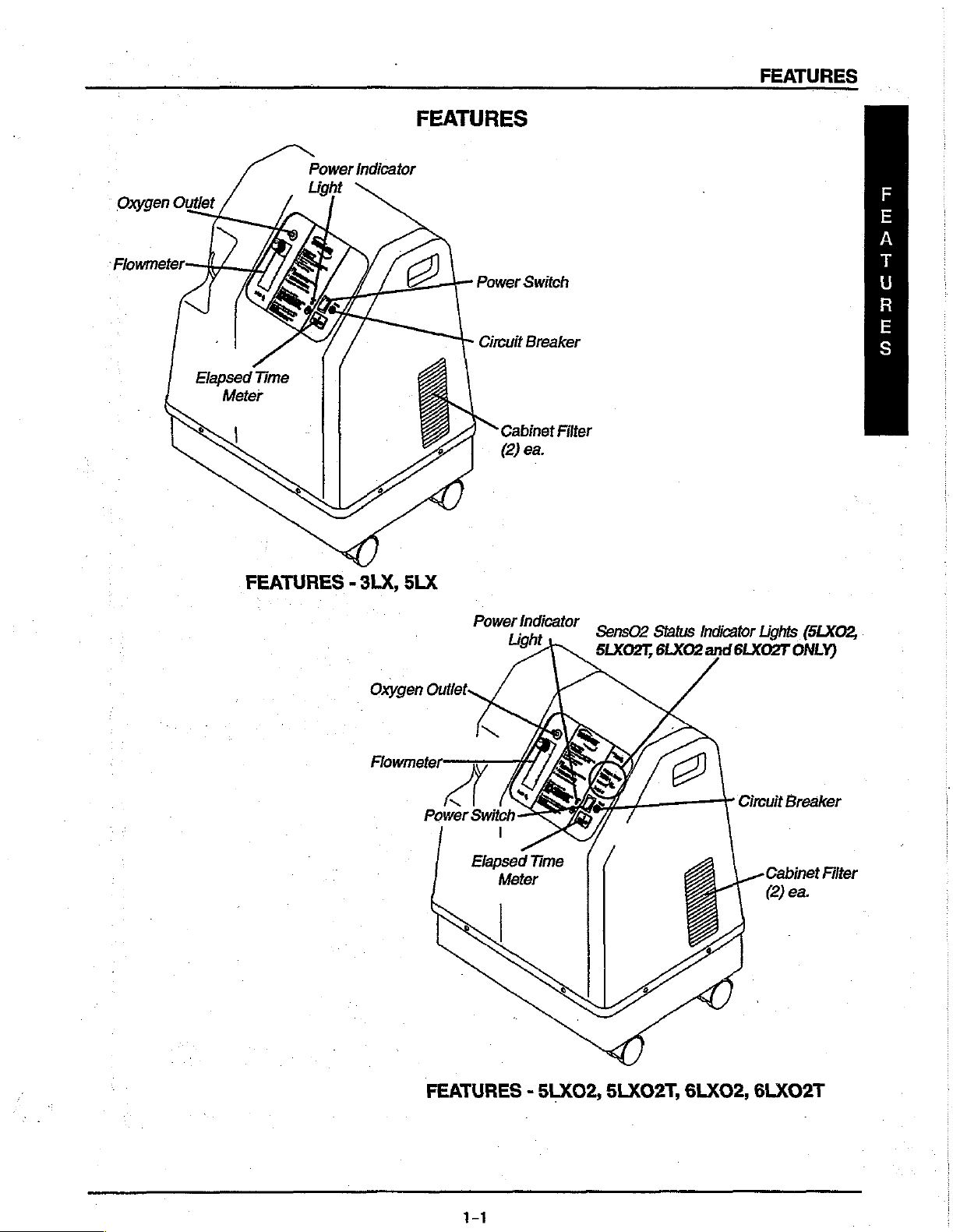

Power

FEATURES

FEATURES

indicator

Oxygen

Outlet

Elapsed

Time

Meter

FEATURES - 3LX,

SLX

Power

Circuit

Cabinet

(2)

Power

Switch

Breaker

Filter

ea.

Indicator

Sens02

5LXO2T,

Status

6LXO2

Indicator

and

Lights

6LXO2T

amacapPmnan

(5LXO2,

ONLY)

Oxygen

Outlet

Power

FEATURES - 5LXO2,

С)

Kl

<

Switch

1

Elapsed

Meter

Time

д

5LXO2T,

6LXO2,

Circuit

Breaker

Cabinet

(2)

ea.

6LXO2T

Filter

1-1

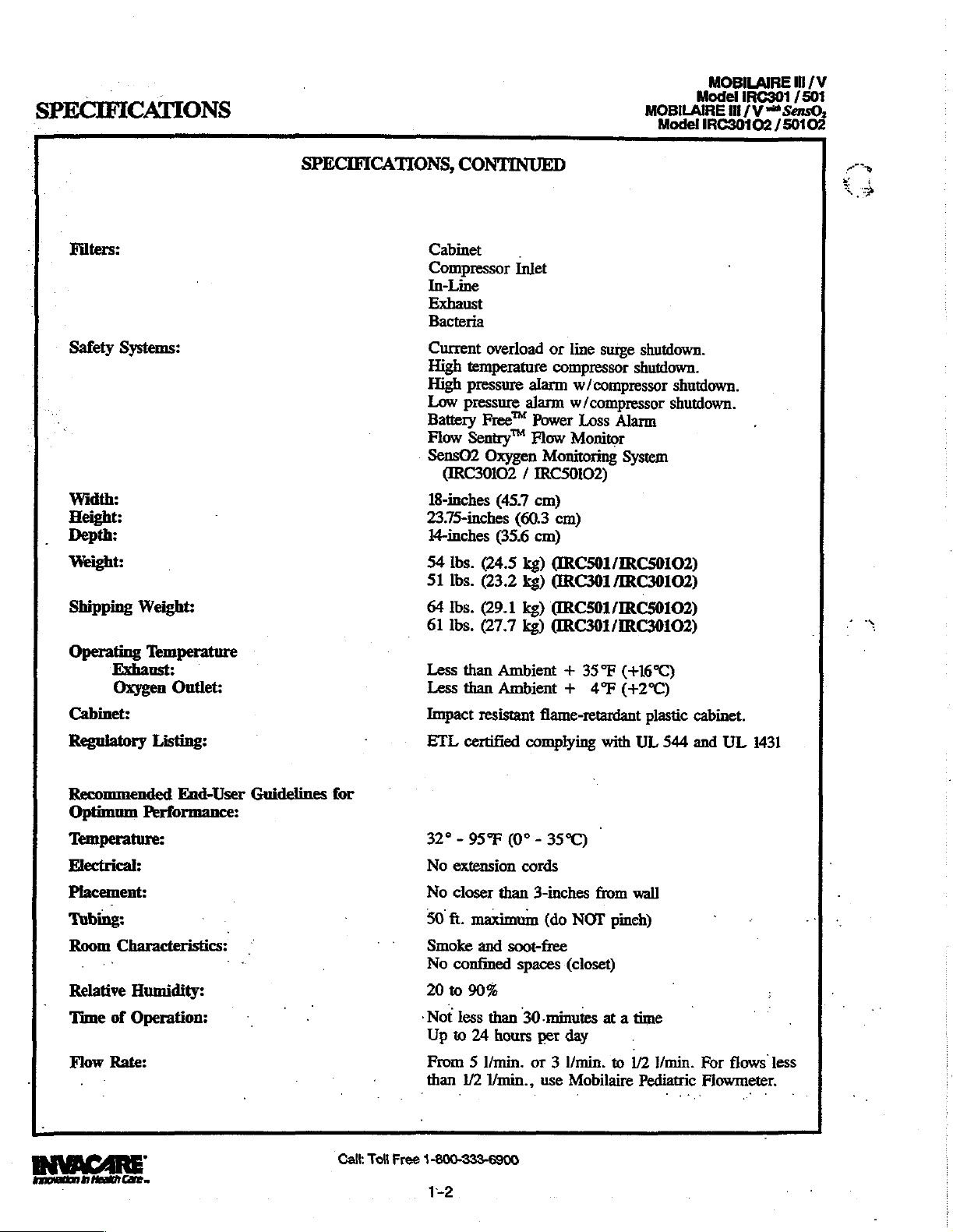

SPECIFICATIONS

MOBILAIRE

Model

MOBILAIRE

OBILAIRE

IRC301 / 501

lit / V

#5:

I

(Νορ,

Ill

/V

Filters:

Safety

Width:

Height:

Depth:

Weight:

Shipping

Operating

Exhaust:

Oxygen

Cabinet:

Systems:

Weight:

Temperature

Outlet:

SPECIFICATIONS,

CONTINUED

Cabinet

Compressor

In-Line

Exhaust

Bacteria

Current

High

temperature

High

pressure

Low

pressure

Battery

Flow

Sentry™

SensO2 Oxygen

GRC30102 / IRC50102)

18-inches

23.75-inches

14-inches

54

lbs.

51

lbs.

64

lbs.

61

Ibs.

Less

than

Less

than

Impact

.

Inlet

overload

Free™

(45.7

(35.6

(24.5

(23.2

(29.1

(27.7

Ambient + 35°F

Ambient + 4°F

resistant

or

line

compressor

alarm

alarm

w/compressor

Power

Flow

Monitor

Monitoring

cm)

(60.3

cm)

cm)

kg)

(IRC501/IRC50102)

kg)

(IRC301

kg)

(IRC501/IRC50102)

kg)

@RC301/IRC30102)

flame-retardant

w/compressor

surge

Loss

Alarm

System

/IRC30102)

(+16°C)

(+2°C)

shutdown.

shutdown.

shutdown.

shutdown.

plastic

cabinet.

Regulatory

Recommended

Optimum

Listing:

End-User

Performance:

Guidelines

‘Temperature:

Electrical:

Placement:

‘Tubing:

Room

Relative

Time

Flow

Innovation

Characteristics: — *

ーー

Humidity:

of

Operation:

Rate:

.

>

0

Henk

Care

~

ーー

for

Call:

Toll

ETL

32° - 95°F

No

extension

No

closer

50

ft.

Smoke

No

confined

20

to

-Not

less

Up

to

From 5 I/min.

than

Free

1-800-333-6900

1-2

certified

complying

(0° - 35°C)

cords

than

3-inches

maximum

and

soot-free

spaces

90%

than

30-minutes

24

hours

per

or 3 l/min.

1/2

1/min.,

(do

NOT

(closet)

day

use

Mobilaire

with

UL

-

from

wall

pinch)

at a time

to

1/2

Pediatric

544

and

Y/min.

For

Flowmeter.

UL

1431

flows

less

MOBILAIRE

Model

MOBILAIRE

MOBILAIRE

Ill

IRC301 / 501

/V

Ill

/V

“Senso.

Il / “a

senso,

SPECIFICATIONS

SPECIFICATIONS

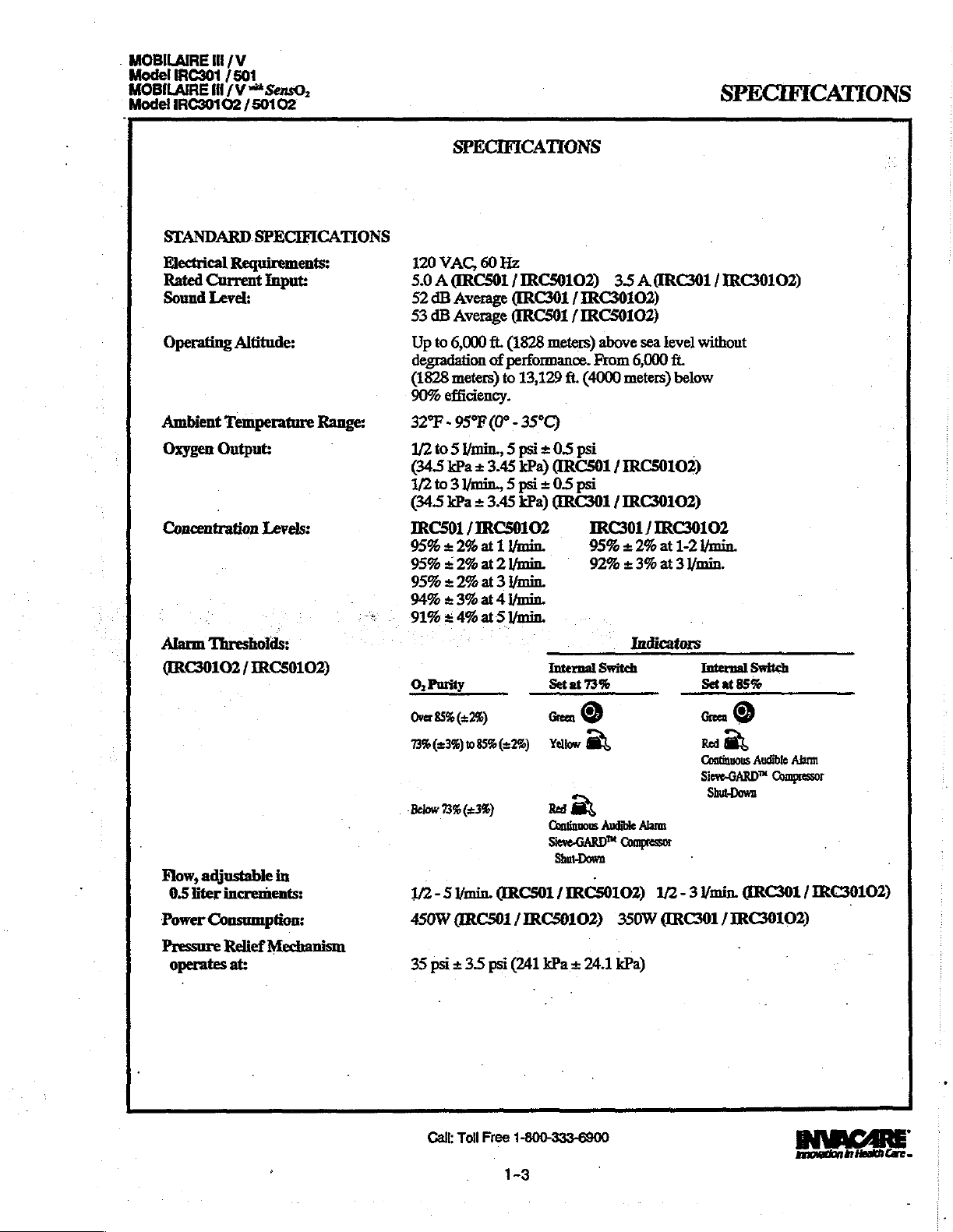

STANDARD

Electrical

Rated

Current

Sound

Operating

Ambient

Oxygen

Concentration

.

Alarm

Threshoids:

(RC30102 / IRC50102)

SPECIFICATIONS

Requirements:

Input:

Level;

Altitude:

‘Temperature

Output:

.

Levels:

Range:

120

VAC,

5.0 А ERC501

52

dB

Average

53

dB

Average

Up

to

6,000

degradation

(1828

meters)

90%

efficiency.

32°F - 95°F

1/2

to 5 min., 5 psi + 0.5 psi

(34.5

kPa + 3.45

1/2

to 3 /min,, 5 psi + 0.5

(345

kPa + 3.45

IRC501 / IRC50102

95% + 2%

95% + 2%

95% + 2%

94% + 3%

s

91% = 4%

O,

Purity

Over

85% (22%)

60

Hz

/IRC50102)

([RC301 / IRC30102)

(IRCS01 / IRCS0102)

ft.

(1828

meters)

of

performance.

to

13,129

ft.

(4000

(0° - 35°C)

kPa)

(IRC501 / TRCSO102)

psi

kPa)

(RC301 / IRC30102)

at 1 Ymin.

at 2 l/min.

at 3 Ymin.

at 4 Ymin.

at 5 /min.

Internal

Set

at

Green

©

3.5

A(IRC301 / IRC30102)

above

sea

level

without

From

6,000

ft.

meters)

IRC301 / IRC30102

95% + 2%

92% + 3%

Switch

73%

below

.

at

1-2

Yenin.

at 3 /min.

.

Indicators

Internal

Set

Green

at

85%

©

Switch

Flow,

adjustable

0.5

liter

increments:

Power

Consumption:

Pressure

operates

Relief

in

Mechanism

at:

73%

(238)

085%

(22%)

Below

73%

(23%)

1/2 - 5

min.

(ERCS01 / IRC50102)

450W

(ARC501 / IRC59102)

35

psi + 3.5

Call:

Toll

psi

Free

1-3

Yellow

に

Red

m

Continuous

Sieve-GARD™

Shut-Down

-

(241

kPa + 24.1

1-800-333-6900

Audible

Alarm:

Compressor

350%

kPa)

Red

m

Continuous

Sieve-GARD™

1/2 - 3

/min.

(RC301 / IRC30102)

Audible

Alarm

Compressor

Shut-Dowa

ŒRC301 / IRC30102)

Innovation

in

Hesich

Care

—

SPECIFICATIONS

S

P

E

C

1

F

i

C

A

T

1

O

N

S

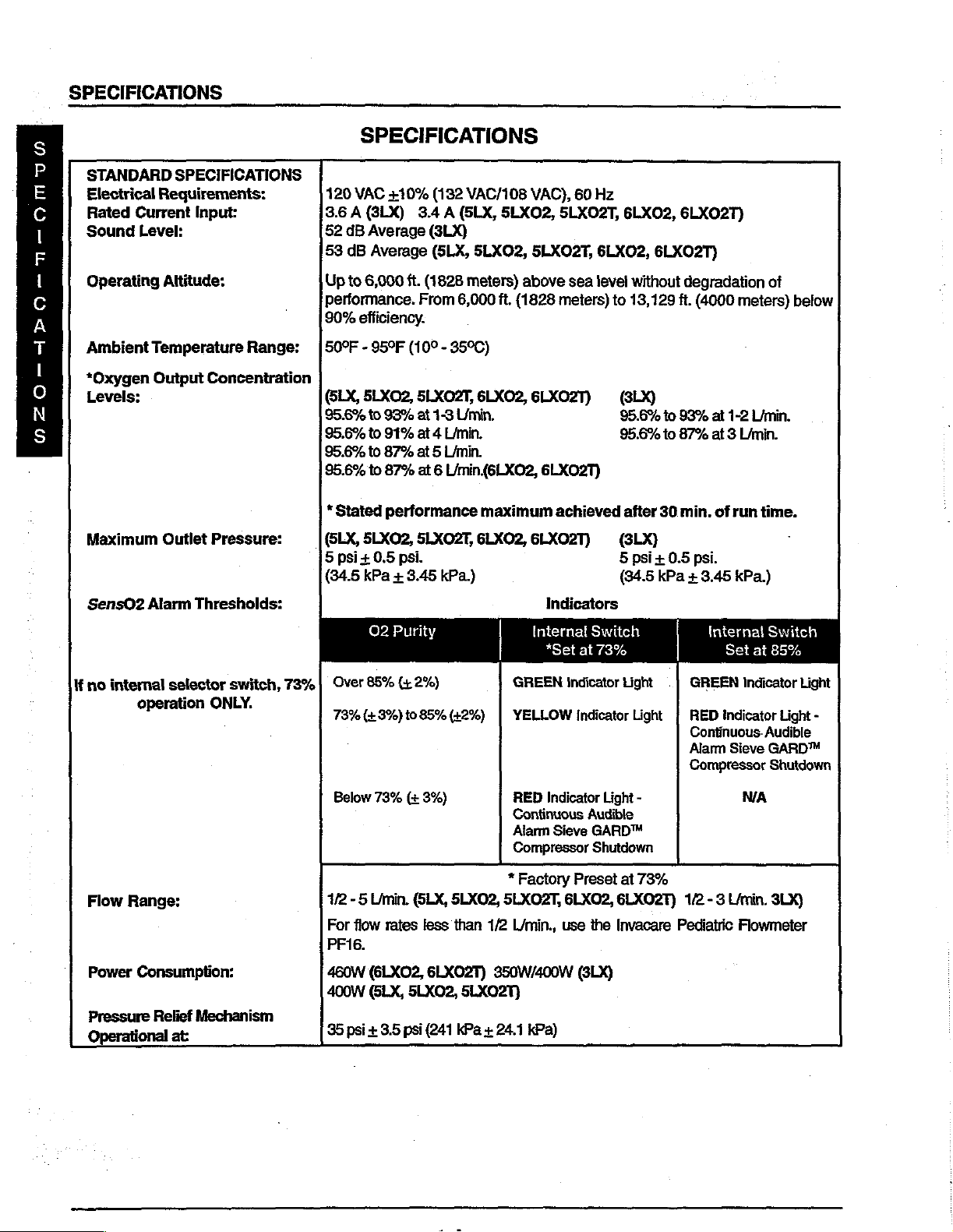

STANDARD

Electrical

Rated

Sound

Operating

Ambient

*Oxygen

Levels:

Maximum

SPECIFICATIONS

Requirements:

Current

Level:

Input:

Altitude:

Temperature

Output

Concentration

Outlet

Range:

Pressure:

SPECIFICATIONS

120

VAC

+10%

3.6 A (3LX)

52

dB

Average

53

dB

Up

to

6,000

performance.

90%

efficiency.

50°F - 95°F

@LX,

5LXO2,

95.6%

to

95.6%

to

95.6%

to

95.6%

to

*

Stated

(LX,

5LXO2,

5

psi + 0.5

(34.5

kPa + 3.45

3.4 A

Average

ft.

(1828

From

(10° - 35°C)

5LXO2T,

93%

at

91%

at 4 Limin.

87%

at 5 Limin.

87%

at 6 Umin.(6LXO2,

performance

5LXOZT,

psi.

(132

(5LX,

(3LX)

(SLX,

6,000

1-3

Umin.

kPa.)

VAC/108

5LXO2,

5LXO2,

meters)

ft.

(1828

6LXO2,

maximum

6LXO2,

VAC),

5LXO2T,

5LXO2T,

above

sea

meters)

GLXO2T)

6LX02T)

achieved

6LXO2T)

60

Hz

6LX02,

6LXO2,

level

without

to

13,129

(3LX)

95.6%

95.6%

after

(SLX)

5

psi+

(34.5

6LXO2T)

6LXO2T)

degradation

ft.

(4000

to

93%

at

to

87%

at 3 Limin.

30

min.

of

0.5

psi.

kPa + 3.45

meters)

1-2

L/min.

run

time.

kPa.)

of

below

SensO2

lf

no

Flow

Power

Pressure

Operational

Alarm

internal

selector

operation

Range:

Consumption:

Relief

Thresholds:

switch,

ONLY.

Mechanism

at:

02

Purity

Over

85%

(+

73%

73%

(+

Below

1/2 - 5

For

flow

PF16.

460W

400W

35

psi + 3.5

2%)

3%)

to

85%

73%

(+

3%)

Umin.

(LX,

rates

less

(6LXO2,

(SLX,

5LX02,

psi

(42%)

SLXO2,

than

6LXO2T)

5LX02T)

(241

kPa + 24.1

1/2

350W/400W

Indicators

Internal

*Set

GREEN

YELLOW

RED

Indicator

Continuous

Alarm

Sieve

Compressor

*

Factory

5LXOZT,

L/min.,

kPa)

Switch

at

73%

Indicator

Indicator

Light

Audible

GARD™

Shutdown

Preset

6LXO2,

use

the

(LX)

Light

Light

-

at

73%

6LXO2T)

Invacare

Internal

Set

GREEN

RED

Continuous.

Alarm

Compressor

12 - 3

Pediatric

Indicator

indicator

Sieve

N/A

L/min.

Flowmeter

Switch

at

85%

Light

Audible

GARD™

Shutdown

3LX)

Light

-

SPECIFICATIONS

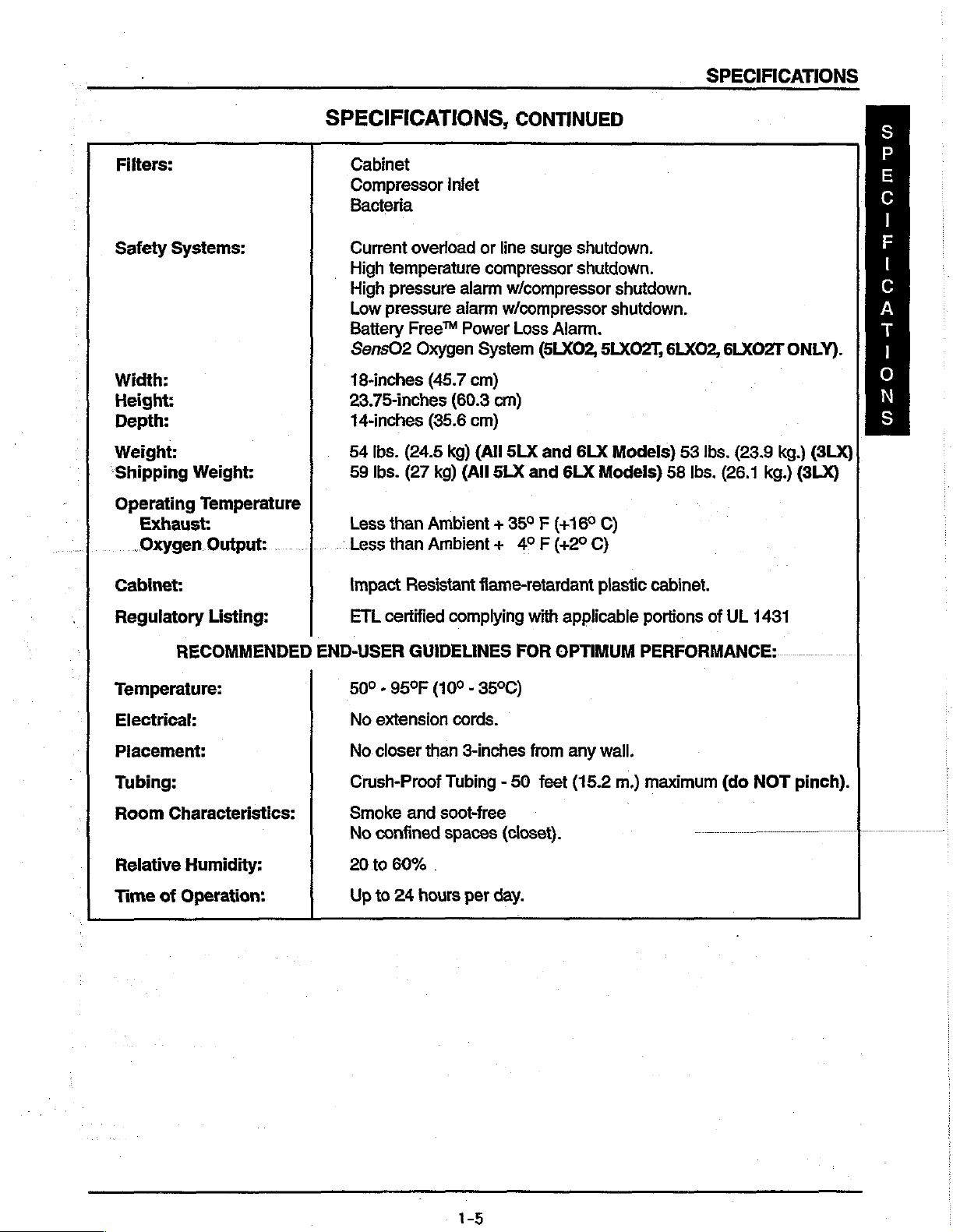

Filters:

Safety

Width:

Height:

Depth:

Weight:

‘Shipping

Operating

Exhaust:

„Oxygen

Systems:

Weight:

Temperature

Output:

SPECIFICATIONS,

Cabinet

Compressor

Bacteria

Current

High

High

Low

Battery

SensO2

18-inches

23.75-inches

14-inches

54

59

Less

|.

Less

overload

temperature

pressure

pressure

Free™

Oxygen

(45.7

(35.6

Ibs.

(24.5

Ibs.

(27

kg)

than

Ambient + 359 F (+169

than

Ambient + 49F

inlet

or

compressor

alarm

alarm

Power

System

cm)

(60.3

cm)

kg)

(All

(All

.

CONTINUED

line

surge

shutdown.

shutdown.

w/compressor

w/compressor

Loss

Alarm.

(5LX02,

cm)

SLX

and

6LX

SLX

and

6LX

(+29

shutdown.

shutdown.

5LXO2T,

Models)

Models)

C)

C)

6LX02,

53

lbs.

58

Ibs.

6LXO02T

(23.9

(26.1

kg.)

ONLY).

kg.)

(3LX)

(SLX)

5

E

A

F

|

©

A

Es

|

o

N

S

Cabinet:

Regulatory

Temperature:

Electrical:

Placement:

Tubing: Crush-Proof

Room

Relative

Time

of

Listing:

RECOMMENDED

Characteristics:

Humidity:

Operation:

Impact

ETL

END-USER

50° - 95°F

No

extension

No

closer

Smoke

No

confined

20

to

Up

to

Resistant

certified

60%

24

complying

GUIDELINES

(10° - 35°C)

cords.

than

Tubing - 50

and

soot-free

spaces

.

hours

flame-retardant

with

applicable

FOR

OPTIMUM

3-inches

per

from

feet

(closet).

day.

any

plastic

wall.

(15.2

cabinet.

portions

PERFORMANCE:.

m.)

maximum

of

一 一 一

UL

(do

1431

NOT

一

pinch).

一

1-5

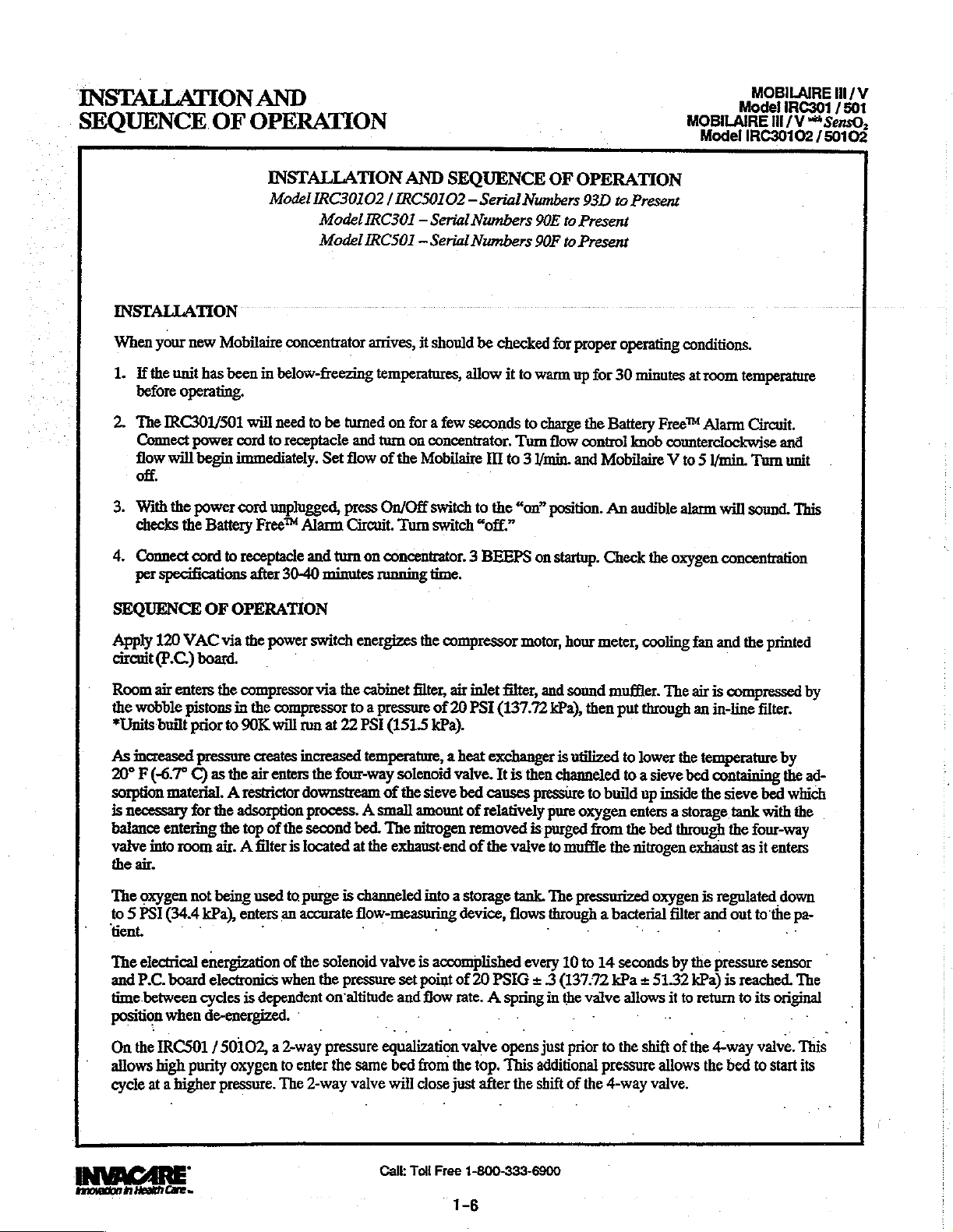

INSTALLATION

SEQUENCE

AND

OPERATION

OF

pMOBILAIRE

Е

Sa,

Y

Y

INSTALLATION

When

your

1.

ifthe

unit

before

2.

The

IRC301/501

Connect

flow

will

off.

3.

With

the

checks

4.

Connect

per

specifications

SEQUENCE

new

operating.

power

power

the

cord

Mobilaire

has

been

cord

begin

immediately.

cord

Battery

to

receptacle

OF

OPERATION

INSTALLATION

Model

IRC30102 | IRC50102 — Serial

Model

Model

concentrator

in

below-freezing

will

need

to

to

receptacle

unplugged,

Free“

Alarm

and

after

30-40

IRC301 — Serial

IRC501 — Serial

attives,

temperatures,

be

turned

and

tum

Set

flow

of

press

On/Off

Circuit.

turn

on

concentrator. 3 BEEPS

minutes

running

AND

it

should

on

for a few

on

concentrator.

the

Mobilaire

switch

Tum

switch

time.

SEQUENCE

Numbers

Numbers

be

checked

allow

seconds

HI

to

the

“off.”

OF

Numbers

90E

to

90F

to

for

it

to

warm

to

charge

Tum

flow

to 3 /min.

“on”

position.

on

startup.

OPERATION

93D

to

Present

Present

Present

proper

operating

up

for

30

the

Battery

control

and

knob

Mobilaire V to 5 l/min.

An

audible

Check

conditions.

minutes

at

Free™

counterclockwise

alarm

the

oxygen

room

temperature

Alarm

Circuit.

and

Tum

will

sound.

concentration

unit

This

Apply

120

VAC

circuit

(P.C.)

Room

air

enters

the

wobble

*Units

As

increased

20° F (-6.7°

sorption

is

necessary

balance

valve

the

air.

The

to 5 PSI

‘tient.

The

and

P.C.

time.between

position

On

the

allows

cycle

pistons

built

material. A restrictor

entering

into

room

oxygen

(34.4

i

electrical

board

when

IRC501 / 50102, a 2-way

high

at a higher

via

the

power

board.

the

compressor

in

the

prior

to

90K

will

pressure

C)

for the

not

kPa),

energization

cycles

de-energized.

purity

creates

as

the

air

adsorption

the

top

of

air. A filter

being

used

enters

electronics

is

dependent

oxygen

pressure.

switch

via

compressor

run

at

increased

enters

the

four-way

downstream

process. À small

the

second

is

located

to

purge

an

accurate

of

the

solenoid

when

the

on'altitude

*

pressure

to

enter

the

The

2-way

energizes

the

cabinet

to a pressure

22

PSI

temperature, a heat

bed.

at

the

is

channeled

flow-measuring

pressure

same

valve

the

filter,

of

(151.5

kPa).

solenoid

of

the

sieve

amount

The

nitrogen

exhaust-end

into a storage

valve

is

accomplished

set

point

and

flow

equalization

bed

from

will

close

compressor

air

inlet

filter,

20

PSI

(137.72

exchanger

valve.

It

is

bed

causes

of

relatively

removed

of the

valve

tank.

device,

of

rate. A "spring

valve

the

just

20

PSIG + 3

opens

top.

This

after

flows

the

motor,

hour

meter,

and

sound

muffler.

kPa),

then

is

utilized

then

channeled

pressure

is

every

additional

shift

to

build

pure

oxygen

purged

from

to

muffle

the

The

pressurized

through a bacterial

10

to

14

(137.72

in

the

just

valve

prior

of

the

kPa + 51.32

to

pressure

4-way

cooling

put

through

to

lower

to a sieve

up

enters a storage

the

nitrogen

seconds

allows

the

shift

The

the

bed

inside

bed

through

exhaust

oxygen

filter

by

it

to

of

the

allows

valve.

fan

air

an

temperature

the

is

and

the

kPa)

return

4-way

the

and

the

printed

is

compressed

in-line

filter.

by

containing

sieve

tank with

the

regulated

out

pressure

is

bed

the

bed

four-way

as

it

enters

down

to'the e pa

sensor

reached.

to

its

original

valve.

to

start

by

ad-

which

the

|

The

This

its

INVACARE

Innovation

in

Health

Cate

=

Cal

Toll

Free

1-800-333-6900

1-6

EN

IRC30102

Model

/50102

*

INSTALLATION

SEOUENCE

OF

AND

OPERATION

If

power

is

interrupted,

IRC301’s

trical

for

SensO,

Technical

The

tween

gen

As

of

the

Electric

to

over

oxygen

the

are

lated

concentration

and

system

your

oxygen

sensor

the

zirconia,

released

to

malfunctions.

convenience.

OXGYEN

Description

being

these

components

mounted

oxygen

zirconia

current

300°

C.

ions

are

only

from

the

oxygen

IRC501’s

enters

disk.

“reading”

INSTALLATION

the

Battery

are

equipped

The

‘Troubleshooting

SENSOR

produced

on

the

flowing

Oxygen

attracted

oxygen

the

oxygen

concentration.

TECHNOLOGY

by

is a tee

the

printed

sensor

to

the

top

molecules

to

the

ions

can pass

ions

is

calculated.

AND

SEOUENCE

Free™

alarm

with a diagnostic

the

concentrator flows

fitting

that

directs a small

circuit

board.

housing,

electrode

it

passes

electrode

on

and

The

and

top

of

on

through.

oxygen

electrons

the

the

will

sound a short

alarm

Guide

explains

CERAMIC

out

of

flow

through a screen

through

disk

bottom

Once

molecules

travel

the

pick-up

of

the

oxygen

retum

to

the

OF

OPERATION,

“beep,”

system

the

ZIRCONIA

the

product

of

oxygen

and

zirconia

extra

electrons

zirconia

ions

reach

to

the

PC

board

CONTINUED

with a long

that

signals

alarm

tank

through a precision

contacts

disk

to

disk.

the

air.

The

where

if

system’s

SENSOR

and

into

the

the

bottom

and

become

Because

bottom

number

they

are

pause,

intermittently.

the

system’s

signals

and

the

flowmeter.

orifice

electrode

of

electrode,

“counted”

mounted

electrode

oxygen

the

crystal

of

electrons

pressure

reasons

In-line

to

heats

ions.

structure

the

extra

is

directly

and

the

All

or

elec-

in

detail

be-

the

oxy-

on

the

top

the

disk

These

of

electrons

re-

oxygen

A

micro-processor

compares

PC

dible

Operating

Once

-

gin

After 5 minutes,

“If

the

for a maximum

tors,

If

the

vate,

“

When

ing

tinuously

Shut-Down

the

the

board.

Signals

indicators,

Sequence

the

power

to

produce

oxygen

such

as

oxygen

depending

oxygen

falls

below

and a yellow

red

LED / Alarm / Shut-Down

on

the

PC

signal

to

clinical

outside

and/or

switch

clinical

when

level

of

30

low

voltage,

level

upon

of

system

has

acceptable

oxygen

is

not

above

minutes

high

is

not

above

the

position

been

concentration

85% + 2%

and

LED

mode

will

activate.

board

acceptable

the

shut-down.

purity

85% + 2%

from

altitude,

85% + 2%

is

above

the

will

If

contains

clinical

turned

oxygen

start-up

of the

alarm

illuminate. If the

the

mode

software

limits

acceptable

to

ON,

the

before

exceeds

85% + 2%

after

‘the

to

reach

or

age

of

within

indicator

85% + 2%,

indicator

oxygen

purity

will

áctivate.

Call:

Tol!

that

SensO2

activating.

the

the

switch.

the

is

oxygen

Free

that

interprets

have

been

selected

limits

generate

circuit

will

No

LED’s

the

green

first 5 minutes,

85% + 2%

machine

first

30

All

sensor

in

the

73%

purity

falls

below

1-800-333-6900

1-7

LED's

before

will

affect

minutes,

units

measures

mode,

falls

85% + 2%

o

the

signal

with

the

responses

LED

are

oxygen

below

in

wait 5 minutes

will

illuminate

will

illuminate.

will

activating

the

time

the

oxygen

preset

at

purity

the

oxygen

73% + 3%

with

being

received

indicator

the

form

for

for

remain

off.

an

alarm.

required

level

the

factory

every

sensor

the

indicator

from

the

switch

mounted

of

lighted

the

at

The

Environmental

to

alarm

at

10

measures

the

red

LED’s,

concentrator

least 5 minutes.

system

reach

85% + 2%.

sequence

73% + 3%.

minutes.

purity

LED / Alarm

switch

set

innovation

sensor.

will

on

au-

fo

wait

fac-

will

It

the

be-

acti-

If a read-

con-

/

at

85%,

in

Health

-

:

Care

=

INSTALLATION/SEQUENCE

OF

OPERATION

INSTALLATION / SEQUENCE

MODEL

INSTALLATION / VERIFICATION

When

1.

2.

3.

4.

5.

SEQUENCE

Applying

printed

Room

compressed

Serial

As

ture

the

.

sieve

the

back

valve

your

new

Ifthe

unit

has

mately

The

Connect

begin

Tum

Unplug

sound.

30

concentrator

power

immediately.

unit

off.

the

This

OFF.

Connect

Check

cord

the

OF

120

circuit

air

enters

by

No.

"97K"

increased

by

20° F (6.7°

adsorption

bed

which

top

of

the

from

the

to

muffle

minutes)

power

oxygen

VAC

(P.C.)

pressure

maierial. A restrictor

second

bed

the

3LX

Invacare

been

cord

confirms

to

OPERATION

via

the

the

or

C)

is

necessary

through

sound

concentrator

in

below-freezing

before

will

need

to

outlet

Set

flow

cord

proper

outlet

concentration

the

power

board.

compressor

wobble

21

PSI

creates

before

bed

of

and

to

and tum

rate

and

and

turn

pistons

(144.79

the

for

with

the

four-way

the

MODELS

OF

BATTERY

arrives,

temperatures,

operating.

be

tumed

of

the

press

operation

switch.

via

increased

air

the

the

exhaust

on

the

Invacare 3 to 3

On/Off

on.

concentrator.

per

specifications

energizes

the

cabinet

in

the

kPa)

AFTER

enters

downstream

adsorption

balance

valve

as

5LX,5LX02,

FREE™

it

should

for 4 to 5 seconds

concentrator

L/min.,

switch

of

the

Battery

the

filter,

compressor

Serial

5LXO2T,

POWER

be

checked

allow

it

to

on.

Tum

Invacare

to

the

ON

Free™

Unit

will

sound 3 BEEPS

after

30-40

compressor

compressor

to a pressure

No.

"97K".

temperature, a heat

the.4-way

of

the

valve.

sieve

itis

process. A small

entering a storage

into

room

air. A muftler

it

exits the

concentrator.

OF

OPERATION

6LXO2,

LOSS

for

proper

to

warm

up

charge

flow contro!

position.

exchanger

then

bed

tank.

the

knob

5 to 5 L/min.

An

Power

inlet

causes

amount

Loss

minutes

motor,

filter,

of

20

is

channeled

of

The

nitrogen

is

located

6LXO2T

ALARM

operating

to

room

temperature

Battery

hour

pressure

Free!

Power

counterclockwise

and

the

Invacare

intermittent

Alarm.

audible alarm

Turn

on startup.

running

and

PSI

utilized

relatively

time.

meter,

cooling

sound

(137.72

to

lower

to a sieve

to

build

pure

removed

at

the

exhaust

muffler.

conditions.

(approxi-

Loss

Alam.

and

flow

will

6 to 6 L/min.

will

On/Off

kPa)

the

bed

up

oxygen

is

switch

fan

and

the

The

air

BEFORE

tempera-

containing

inside

the.

enters

exhausted

end

of

the

is

A

e

MA

S

E

Q

U

E

N

Cc

E

ο

F

ο)

P

'

E

R

A

T

i

о

N

The

oxygen

regulated

down

filter, a check

The

electrical

and

P.C.

board

Serial

between

On

the

the

close

No.

“97K"

cycles

the

5LX/5LX02/5LXO2T/6LX02/6LXO2T,

shift

of

the

top.

This

just

after

not

being

used

to 5 PSI

valve

and

activation

electronics

or

21 + 3 PSI

is

dependent

4-way

additional

the

valve.

pressure

shift

(34.4

out

to

of

the

when

This

of

the

to

exhaust

kPa),

enters

the

patient.

4-way

on

valve

the

pressure

(144.79 + 51.32

altitude,

allows

allows

4-way

highly

the

valve.

is

channeled

an

accurate

is

accomplished

set

flow

rate

a

P.E.

concentrated

bed

to

into

the

flow-measuring

every 8 to

point

of

20 + 3

kPa)

AFTER

and

internal

or

Pressure

oxygen

start

its

cycle

storage

tank.

device,

21

seconds

PSI

(137.72 + 51.32

Serial

environmental

No.

Equalization

to

enter

at a higher

The

pressurized

fiows

through a bacterial

by

the

"97K"

is

reached.

factors.

valve

the

just

exhausted

pressure.

pressure

kPa)

opens

The

P.E.

oxygen

sensor

BEFORE

The

time

-

just prior

bed

valve

to

from

will

is

INSTALLATION / SEQUENCE

OF

OPERATION

INSTALLATION / SEQUENCE

If

main

power

intermittently.

or

electrical

reasons

SENSO2

Technical

The

oxygen

In-line

orifice

As

SS

Electric

contact

are

zirconia,

electrons

electrons

95

are

E

Q

A

U

sensor.

E

switch

N

с

the

Ε

o

Operating

F

Once

ο

begin

P

minutes.

E

R

After 5 minutes,

Α

T

If

|

wait

ο

mental

N

reach

between

to

the

oxygen

current flowing

the

attracted

“counted”

microprocessor

It

mounted

form

the

producing

the

oxygen

for a maximum

factors

85%

is

lost,

All

units

systems

in

detail

for

OXGYEN

Description

being

these

the

oxygen

enters

electrode

to

the

only

oxygen

are

released

is

directly

and

on

compares

on

of

lighted

Sequence

power

switch

if

level

such

+2%.

clinically

the

the

LEDs,

is

the

Battery

are

equipped

malfunction.

your

convenience.

SENSOR

produced

components

sensor

the

through a metal

of

electrode

ions

from

related

oxygen

the

the

the

PC

oxygen

not

of

30

as

by

mounted

sensor,

the

disk

on

can

pass

the

to

the

concentration

P.C.

board

signal

board.

audible

has

been

acceptable

purity

above

minutes

low

voltage,

Free”

Power

with a diagnostic

The

Troubleshooting

TECHNOLOGY

the

concentrator

is a tee

it

passes

and

pick-up

the

bottom

through.

oxygen

oxygen

contains

to

clinically

Signals

indicators,

turned

exceeds

85% + 2%

from

high

fitting

on a printed

through a screen

film

resistor

When

ions

concentration.

acceptable

outside

ON,

oxygen

after

start-up

altitude,

OF

Loss

Alarm

alarm

CERAMIC

flows

that

directs a small

circuit

heats

extra

electrons

of

the

zirconia

the

and

oxygen

"reading"

software

and/or

the

before

85% + 2%

the

to

is

of

the

system

SensO,

activating.

first 5 minutes,

reach

or

age

OPERATION,

will

sound a short

system

Guide

out

of

board.

the

to

disk.

oxygen

molecules

The

calculated.

that

interprets

limits

clinically

shut-down.

circuit

the

GREEN

85% + 2%

of

the

that

explains

É

ZIRCONIA

the

product

and

contacts

disk

in

become

Because

ions

electrons

that

have

acceptable

will

wait 5 minutes

No

LEDs

machine

signals

the

flow

excess

oxygen

reach

the

retum

travel

the

signal

been

LEDs

LED

will

before

CONTINUED

"beep",

if

the

pneumatic

alarm

SENSOR

tank

of

oxygen

the

of

300°C.

of

the

bottom

to

to

selected

limits

will

will

illuminate.

remain

activating

will

affect

system

and

into

through a precision

sensing

ions.

These

crystal

electrode,

the

air.

the

PC

being

generate

for

the

illuminate

off.

the

with a long

pressure

signals

the

flowmeter.

disk.

Oxygen

board

received

with

molecules

oxygen

structure

the

The

number

where

from

the

indicator

responses

concentrator

for

at

The

system

an

alarm.

time

Environ-

required

pause,

and

ions

of

the

extra

of

they

the

in

to

least

5

will

to

If

the

oxygen

sequence

factory

When

If a reading

oxygen

below

and

at

73% + 3%.

oxygen

sensor

73% + 3%

it

is

set

85% + 2%.

level

is

will

activate,

concentration

falls

below

measures

the

at

85%,

the

not

above

depending

85% + 2%

purity

RED

RED

85% + 2%

upon

is

above

and

continuously

LED/Alarm/Shut-Down

LED/Alarm/Shut-Down

within

the

position

85% + 2%,

the

alarm

and a yellow

the

first

of

the

the

sensor

indicator

mode

mode

30

minutes,

indicator

measures

is

in

the

LED

will

activate.

will

the

switch.

oxygen

73% mode

will

illuminate.

lf

activate

oxygen

or

the

if

the

concentration

All

units

purity

every

no

switch

If

the

oxygen

selector

oxygen

are

preset

10

is

present,

switch

purity

alarm

at

minutes.

purity

falls

is

present

falls

below

the

the

SENSO,

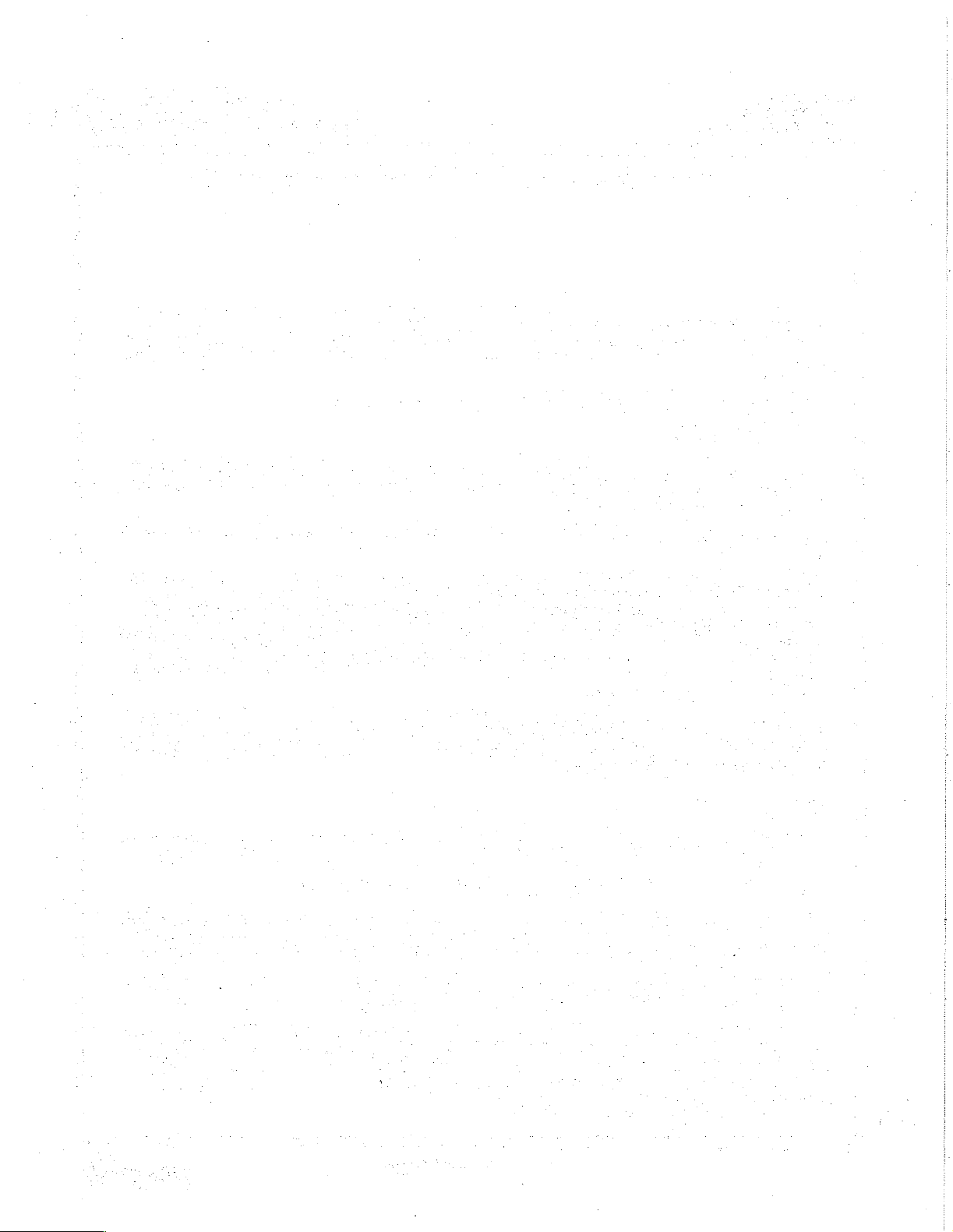

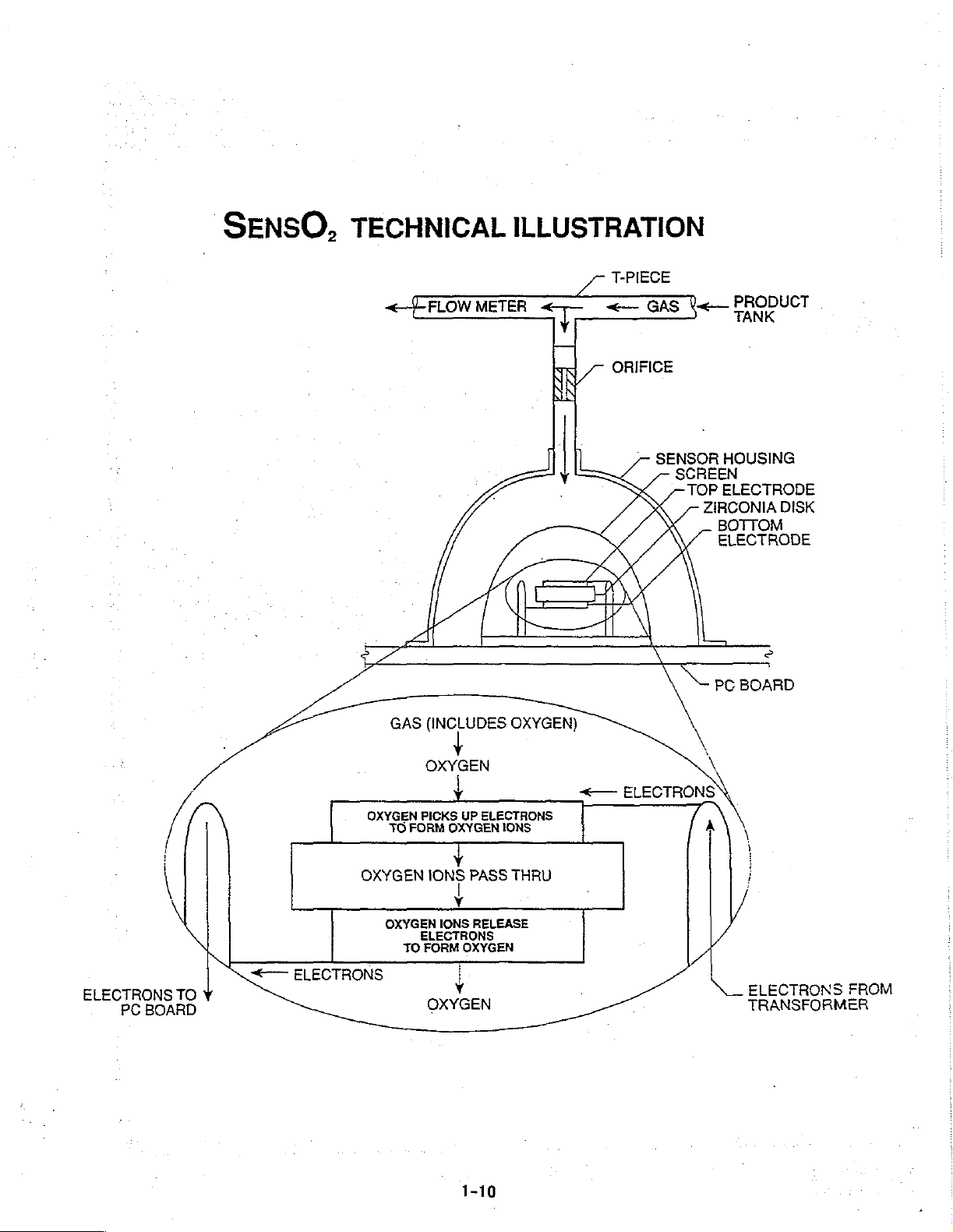

TECHNICAL

<

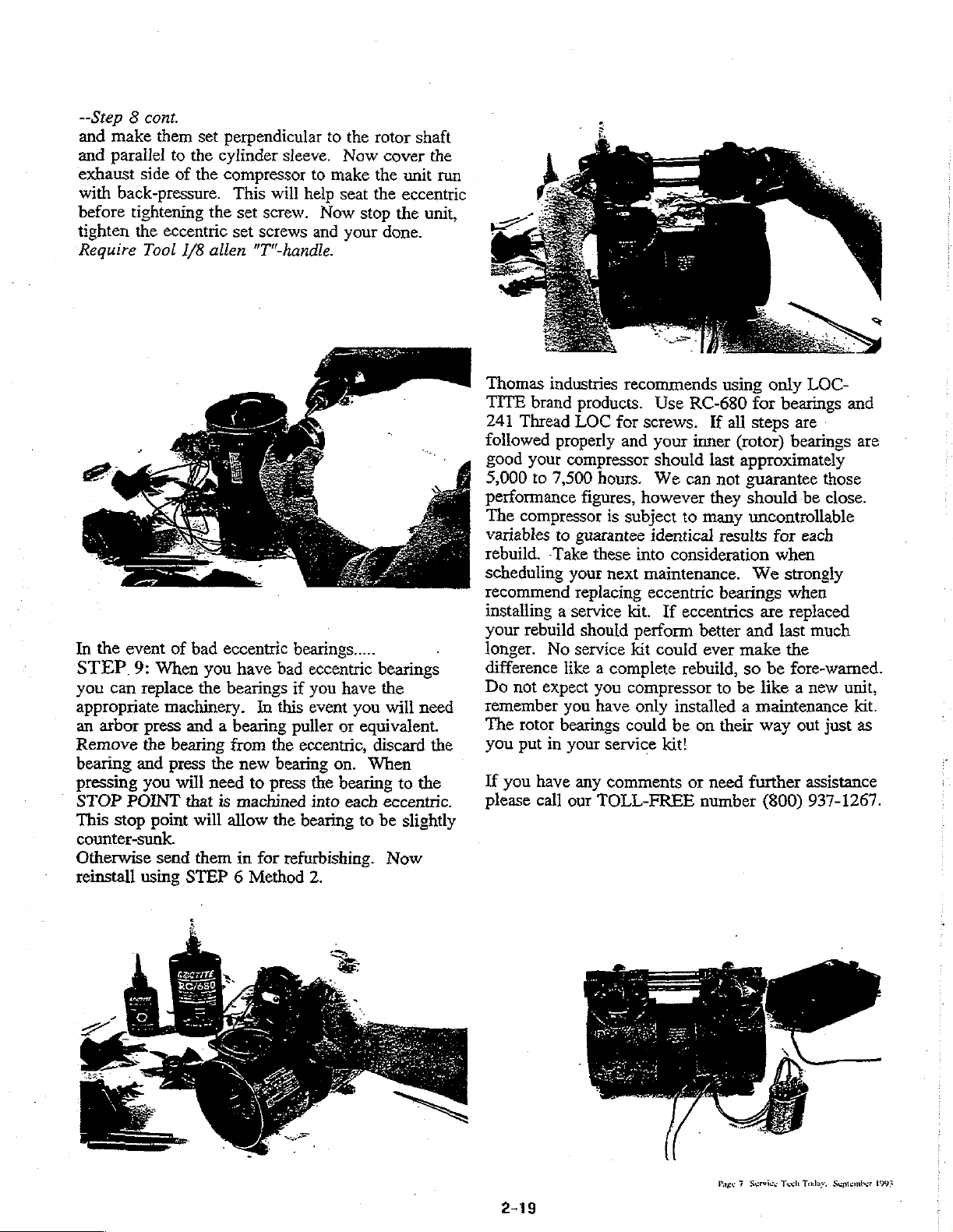

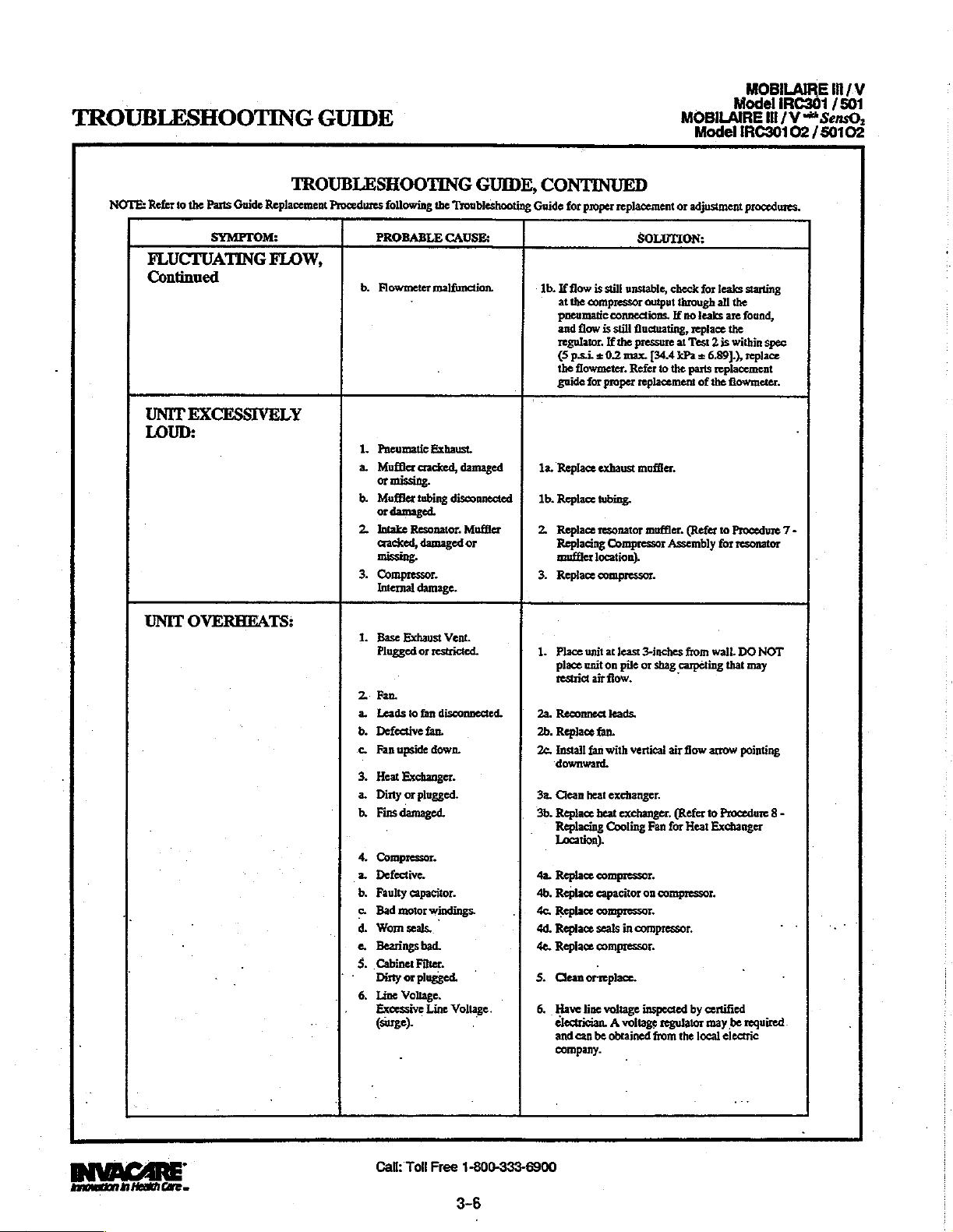

FLOW

METER

ILLUSTRATION

T-PIECE

“τρ

<—

ORIFICE

GAS

SENSOR

SCREEN

Ve

HOUSING

TOP

ELECTRODE

ZIRCONIA

BOTTOM

ELECTRODE

PRODUCT

DISK

©

一

一

一

ELECTRONS

PC

BOARD

TO

GAS

(INCLUDES

OXYGEN

OXYGEN

©

ELECTRONS

TO

OXYGEN

OXYGEN

TO

PICKS

FORM

IONS

IONS

ELECTRONS

FORM

OXYGEN

+

UP

OXYGEN

Y

OXYGEN

,

ELECTRONS

IONS

PASS

RELEASE

OXYGEN)

THRU

<—

ELECTRONS

6

ELECTRONS

TRANSFORMER

EROM

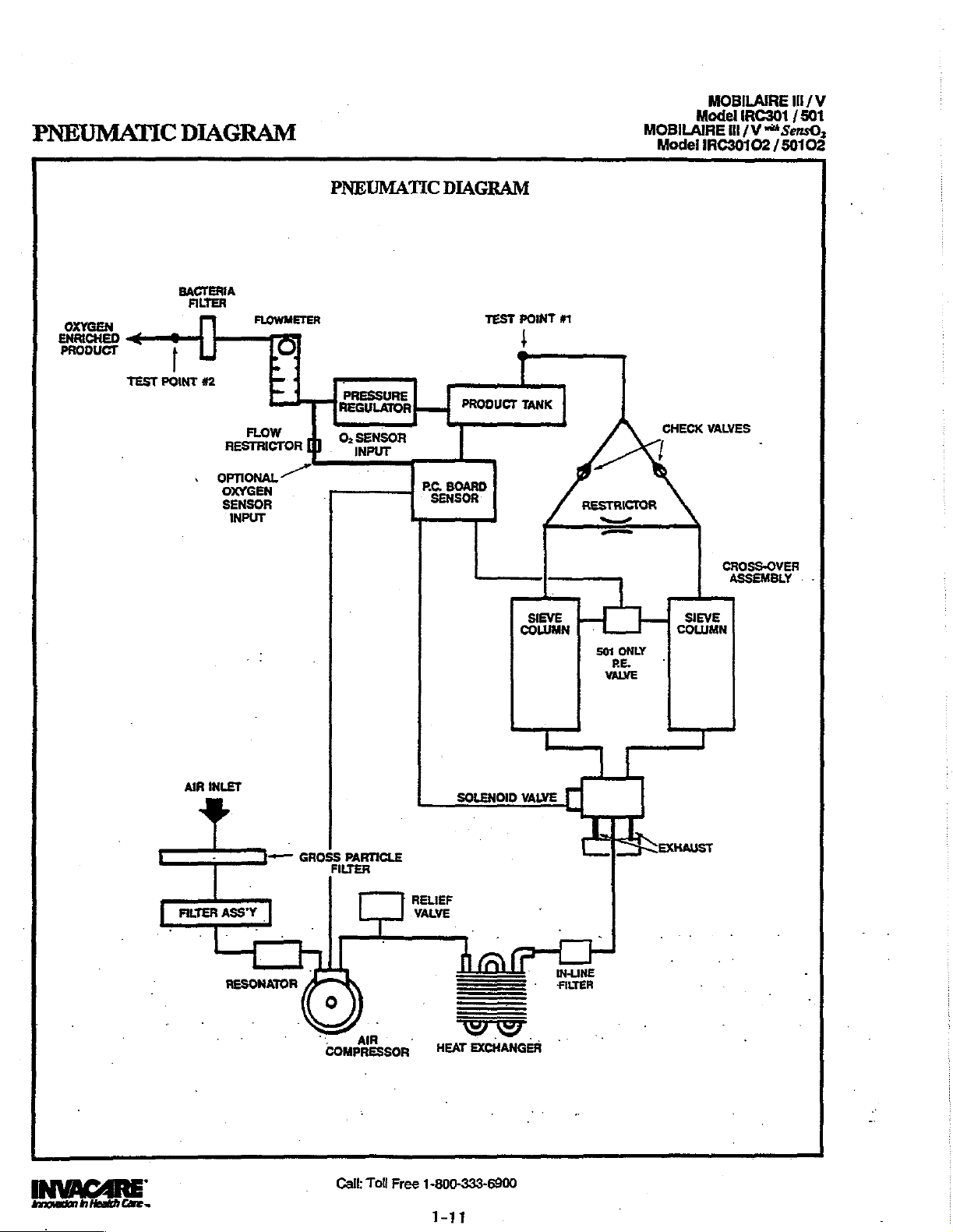

NEUMATIC

P

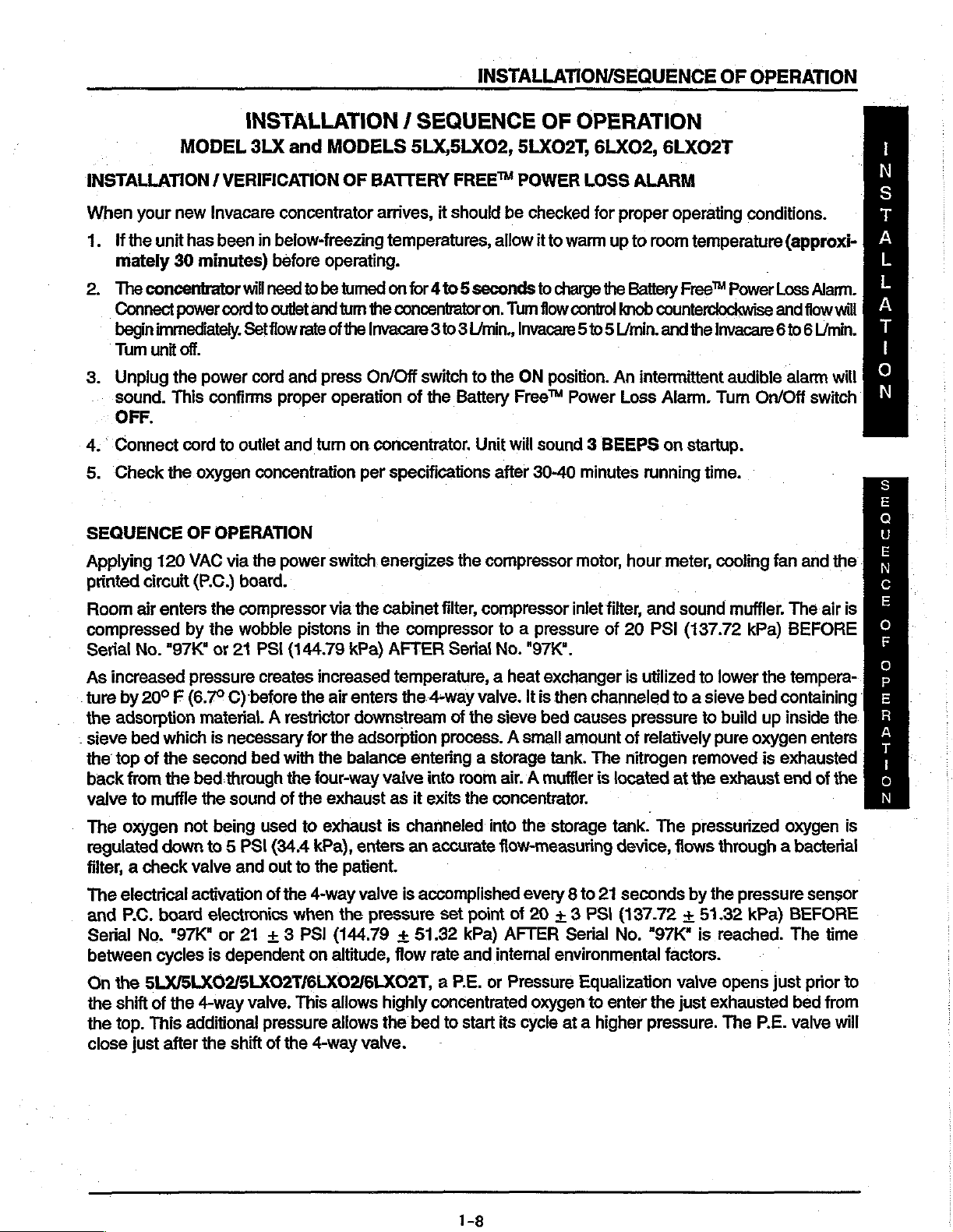

DIAGRAM

G

MOBILAIRE

Model

MOBILAIRE

Model

ill / V

IRC30102

IRC301 / 501

Ill / V

“#*

SersO,

50102

/

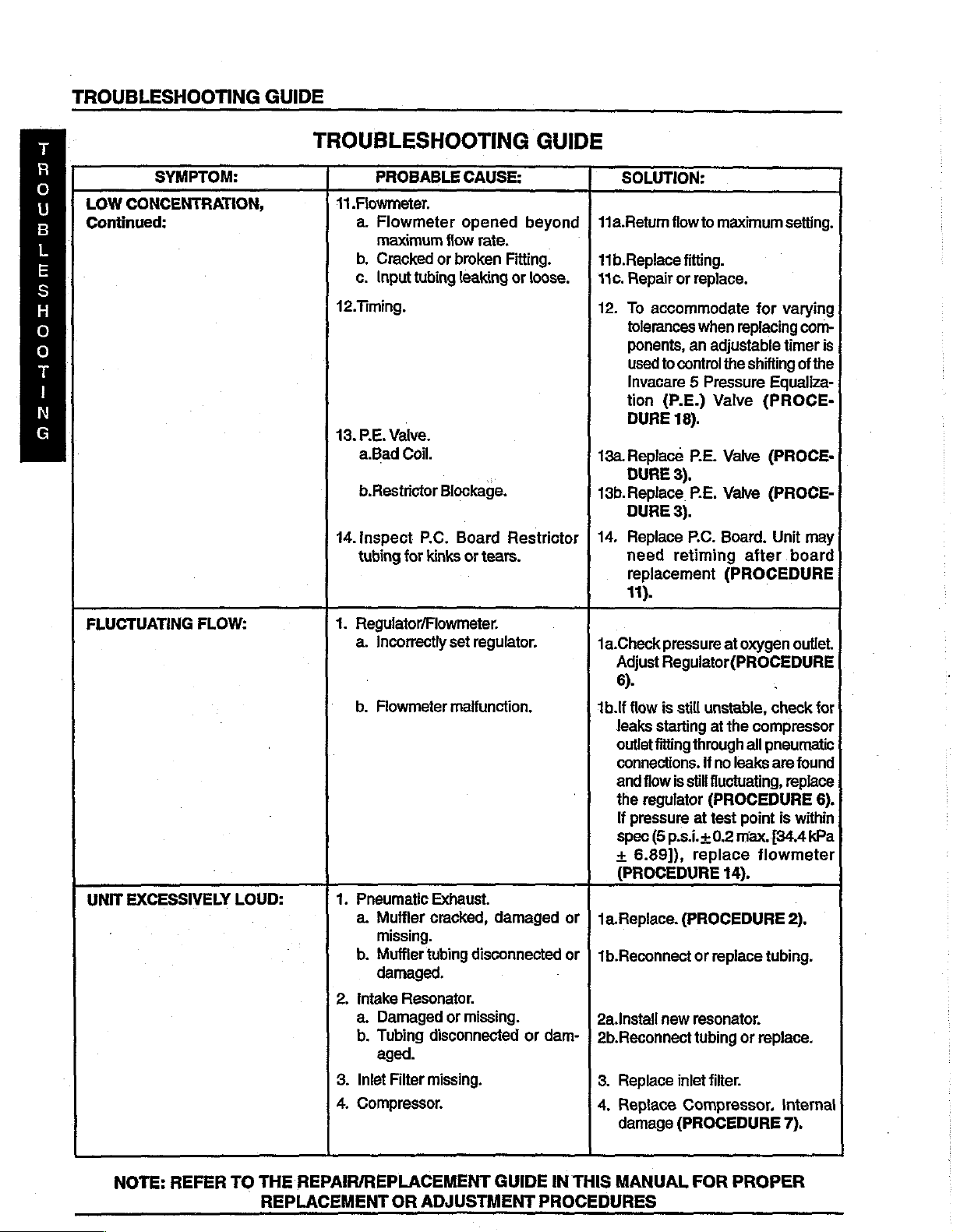

OXYGEN

ENRICHED

PRODUCT

TEST

POINT

BACTERIA

FILTER

FLOWMETER

|

#2

FLOW

RESTRICTOR

‘OPTIONAL

OXYGEN

SENSOR

INPUT

À

=

„7

PNEUMATIC

92

.

[|]

RE

SENSO!

SENSOR

'

DIAGRAM

pc.

ВО

TEST

PRODUCT

BOARD

A

COLUMN

POINT

$

TANK

SIEVE

#1

VALVES

CHECK

ge

LA

501

ONLY

RE.

VALVE

SIEVE

COLUMN

.

CROSS-OVER

ASSEMBLY - -

AIR

INLET

イイ

FILTER

ASS'Y

|

RESONATOR

PARTICLE

GROSS

FILTER

>

AIR

COMPRESSOR

RELIEF

VALVE

.

HEAT

SOLENOID

===

EXCHANGER

VALVE

・ ㆍ

-

'

FIUER

os

j

dnnovetion

hh

Heatth

Care

Call:

Toll

Free

1-800-333-6900

~

1-1

1

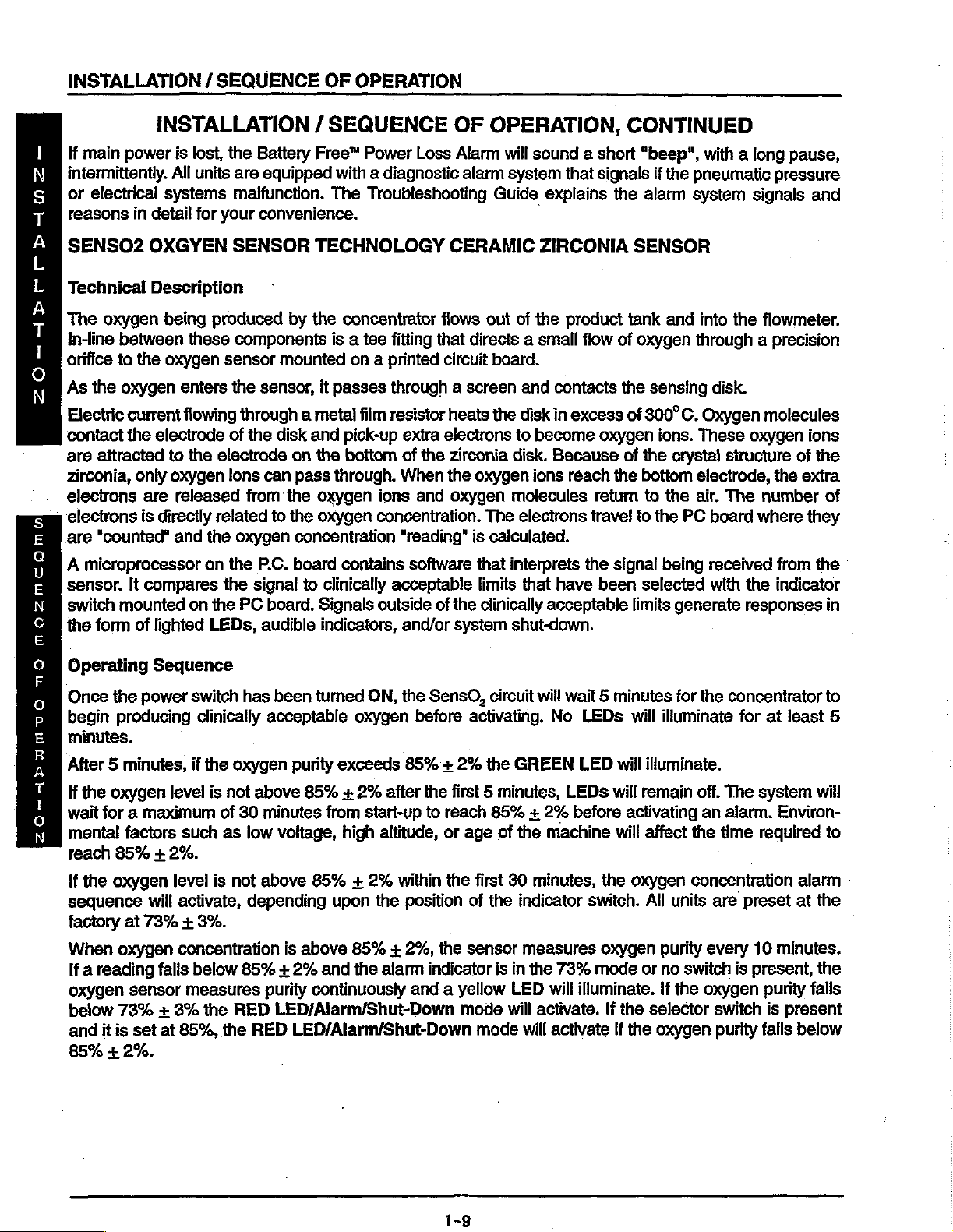

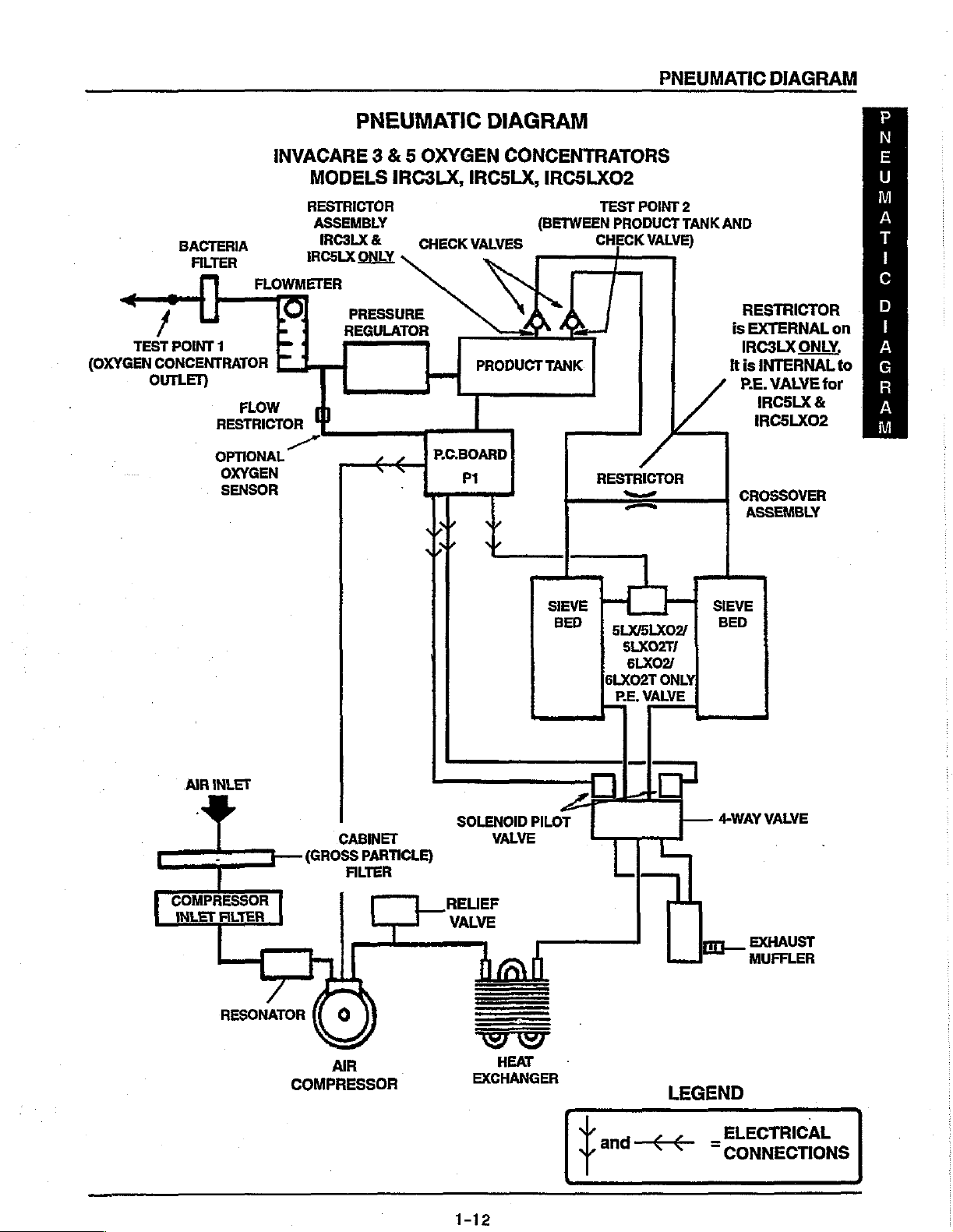

PNEUMATIC

DIAGRAM

/

TEST

(OXYGEN

CONCENTRATOR

OUTLET)

BACTERI

FILTER

POINT

OPTIONAL

.

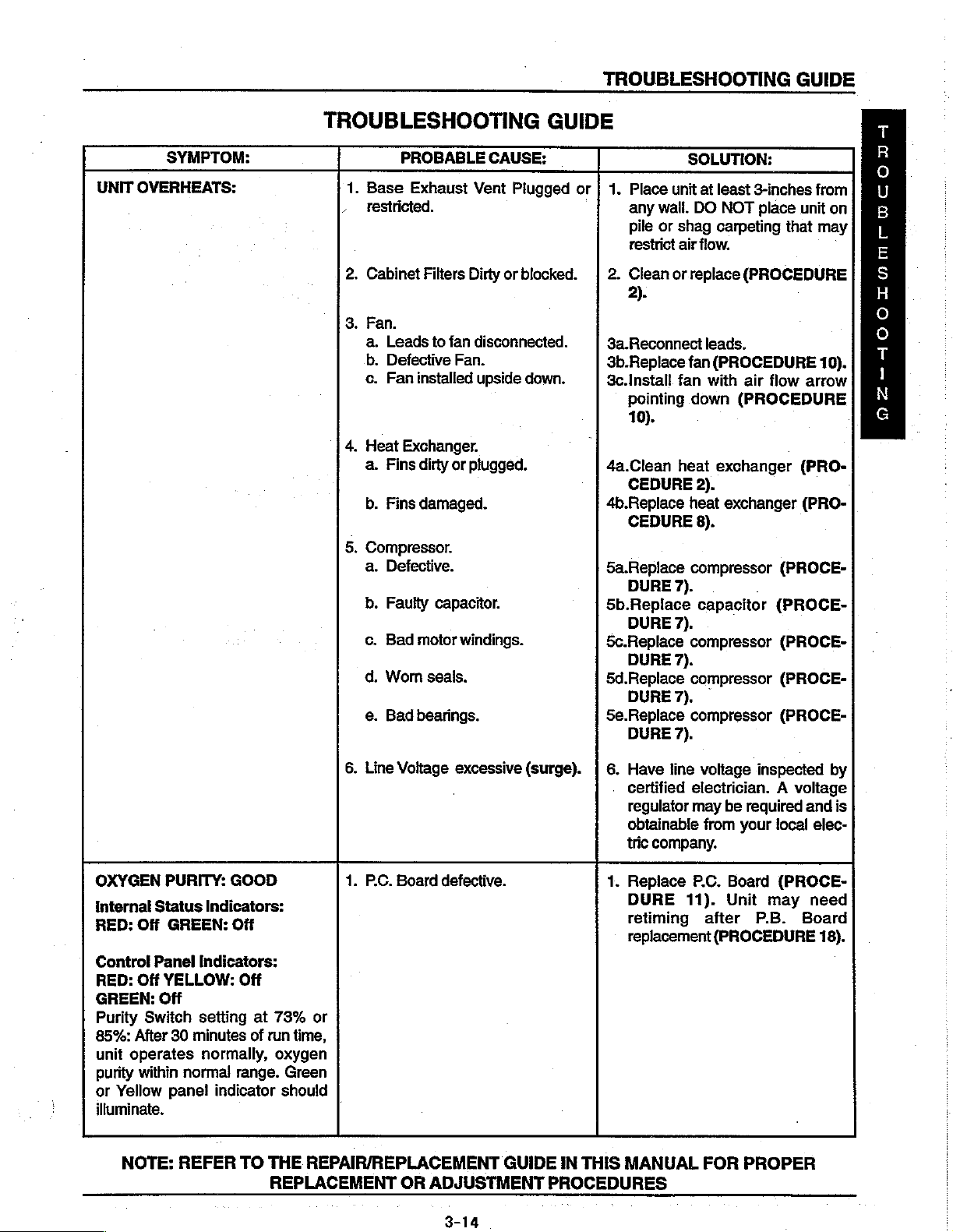

INVACARE 3 & 5 OXYGEN

A

FLOWMETER

1

|

FLOW

RESTRICTOR

OXYGEN

SENSOR

PNEUMATIC

MODELS

RESTRICTOR

ASSEMBLY

IRC3LX

IRC5LX

Τη

&

ONLY

PRESSURE

REGULATOR

|

IRC3LX,

CHECK

个

P.C.BOARD

ANS

-

DIAGRAM

CONCENTRATORS

IRC5LX。

(BETWEEN

VALVES

PRODUCT

PI

IRC5LXO2

TEST

POINT

2

TANK

PRODUCT

CHECK

TANK

VALVE)

上

一

SIEVE

BED

RESTRICTOR

=

デー

sxsLxo | BED

SLXO2T/

6LXO2/

6LXO2T

РЕ.

МАМЕ

ONLY!

AND

RESTRICTOR

is

EXTERNAL

IRC3LX

It

is

INTERNAL

P.E.

IRCSLX

IRCSLXO2

CROSSOVER

ASSEMBLY

SIEVE

ONLY,

VALVE

for

&

on

to

P

N

E

Y

M

A

T

I

o

D

I

A

G

R

A

M

|

SOLENOID

|

RELIEF

VALVE

a

VALVE

di

HEAT

EXCHANGER

I

~

2

CH

VALVE

4-WAY

i

|—

πι

EXHAUST

MUFFLER

PILOT

L

IP

LEGEND

_

ELECTRICAL

Fora

<<

=conNECTIONS

AIR

INLET

y

-

CABINET

(Goss

CET]

—

RESONATOR

COMPRESSOR

PARTICLE)

FILTER

AR

INVACARE

RESPIRATORY

©

OXYGEN

Invacare

Some

-IRC

-IRC

-IRC3LX

-IRC5LX

-IRC5LXO, 5 Liter

In

the

componenis.

Item

Item

produces

of

them

301

501

3

5

3

5

following

#1

The

The

(i.e.

#2

Intake

This

primarily

are:

Liter

Liter

Liter

Liter

block

Gross

gross

lint,

filter

many

Machine

Machine

Machine

Machine

Machine

Filter

CONCENTRATOR

models

diagram

Particle

particle

animal

(Filter

removes

as a compressor

of

Oxygen

with

Sensor

we

show a typical

Filter

filter

(20

fur,

etc.)

from

Assembly)

particles

filter.

Concentrators.

for

O,

output

oxygen

p.p.i.)

is

entering

down

to 1 micron

used

the

OPERATION

concentrator

to

stop

large

concentrator.

in

size.

particles

It

and

is

used

its

of

dirt

Item # 3

item

#4

Item

#4A

Resonators

This

device

of

the

compressor.

Air

Compressor

The

function

average

This

require

Thomas

concentrator

maximum

compressed

air

under pressure

brand

Capacitor

The

capacitor

compressor

does

nothing

of

the

working

air

oil-less

we

manufacture.

is

an

motor.

more

(Muffler)

compressor

pressure

is

routed

to

produce

piston

electrical

compressors

storage

than

is

to

the

reduce

to

compress

of

approximately

molecular

oxygen.

device

noise

filtered

sieve

Invacare

in

most

used

from

beds

of

the

to

help

the

air

20

uses

intake

to

an

p.s.i.

which

start

the

INVACARE

TECHNICAL

TRAINING

4-800-333-6900

1-13

X6697

ELYRIA,

OHIO

Нет

#5

Item

#6

Item

#7

Item

#8

Item

#9 P.E.

Heat

Exchanger

The

heat

and

transfers

Inline

The

the

Filter

inline

Numatics

Solenoid

A

four-way

air

to

the

Sieve

Spring

material

Beds

loaded

through

Valve

This

item

the

sieve

exchanger

it

to

(IRC

filter

is a .3

Solenoid

Valve

valve

sieve

manufactured

bed

cannisters

strips

the

nitrogen

canisters.

is

only

used

bed

with

removes

the

airstream

301/

507

micron

Valve.

and

from

on 5 liter

oxygen

the

supplied

Only)

filtering

by

directs

filled

the

with

room

machines.

before

heat

produced

by

device

Numatics

exhaust

molecular

air

but

allows

the

pressurizing

by

the

fan.

that

is

Inc..

air

out

Sieve

oxygen

Its

function

the

compression

used

to

protect

that

directs

of

the

sieve

material. This

to

pass

`

is

to

pressurize

cycle

starts.

compressed

beds.

Item

item

item

item

Item

#10

#11

#12

#13

#14

Restrictor

An

orifice

the

Sieve

flow

Check

Check

oxygen

tank.

P.C.

This

with a hole

Cannister

through

Valves

Valves

generated

Board

device

information

valves

Product

A

for

valve

and

Tank

cannister

delivery

out

of

Regulator

The

adjustable

5

p.s.i.

outlet

diameter

and

thus

the

Sieve

are

Beds.

one-way

by

the

Sensor

measures

and

if

there

of

approximately

uses

are

pressure

it

in

problems

to a patient.

the

flowmeter.

pressure

pressure.

of

.042”.

determines

flow

devices.

Sieve

the

circuit

Beds

in

the

related

1-1/2

The

larger

regulator

reduces

This

the

They

goes

product

to

help

to

liters

volume

the

volume

component

rate

at

which

are

used

to

and

stays

tank , and

decide

when

pressure,

which

the

more

input

pressure

back-pressures

room

air

to

insure

in

the

product

takes

to

shift

this

etc.

stores

oxygen

stable

the

to a constant

can

that

the

flow

E

TECHNICAL

TRAINING

1-800-333-6900

X6697

ELYRIA,

OHIO

Item

ltem

#15

#16

Flowmeter

The

flowmeter

oxygen

Bacteria

This

the

dispensed

Filter

patient

is a gas

Filter

consist

oxygen

measuring

to a patient.

of

a .3

micron

stream.

device

element.

which

It

is

the

controls

final

the

filter

amount

used

in

of

INVACARE

TECHNICAL

TRAINING

1-800-333-6900

1-15

X6697

ELYRIA,

OHIO

PREVENTIVE

MAINTENANCE

]

PROCEDURE

2

[IA

QHOO

HOIVdLN

ヨ

H

ヨ

ヨ

ONVN

ONOS

ヨ

1NIVI

NbDAXO

"ON

TVIH

ヨ

S

Ou!

"ON

TACON

AA

A

AOS]

E<

-ZH-UZAZOU

ヨ

AILN

ヨ

HVOVANI

ヨ

人 ハ

ヨ

Hd

ЗНАМОЙ

SRIDOVANI

na

PURA

6-1

SM

АНЗАЯ

—

10

9960

pesde|3

eses

ploo9y

(she

16191

ljeulqeo

4(>

94001

ueelo

eled

UONSJHUSoUOO

Mold

(ZOSNZS

"UILUA

LNOHLIM

PEqUOSEIS

ueBAXO

SLINN)

хэецо

49949

SIN

ヨ

LVd

N

ヨ

ヨル

14616

1

B

ヨ

OAmVnNNY

6907

76004 12042

Jell

elueloeg

ATIVONNY

@98IdeH

(Блежы

лебиецохз

зещаео

зеен

гов4еы

ивею

uohelueouoo

(ST3dOW

ロ

ヨ

HIO

ue6Axo

<OSM

ヨ

H

49849,

ヨ

SV

S)

39411

SHTOH

JosseJduio

39IUI

10SSe』dUJ0O

000'02

jo

doz

998Id9H

人 H

piinqey

ヨ A ヨ

"Z0x19

"X19

‘x1£

ISTOXA

JIJnA

*

101

SheUx

STEGONM

OUJ-UJ

ヨ

ODPJdOL

89BIdeH

119)

«uoocao

(120x719

‘ZOX19

120X19

2-1

CABINET

|

PROCEDURE

1

INVACARE

PROCEDURE

TO

PREVENT

ELECTRICAL

1.

Unpiug

2.

Remove

8.

Lift

NOTE:

4.

To

unit.

the

cabinet

When

re-install

3LX,

1 - REMOVING

ELECTRICAL

OUTLET

the

eight

(8)

straight

required,

cabinet,

REPAIR / REPLACEMENT

INVACARE - 5LX/SLXO2/SLXO2T

BEFORE

mounting

up.

vacuum

reverse

CABINET

SHOCK,

SERVICING.

screws

inside

STEPS

that

of

the

2-3.

(FIGURE

CAUTION

ALWAYS

secure

cabinet

1)

DISCONNECT

cabinet

and

GUIDE

AND

INVACARE - 6LXO2/6LXO2T

CONCENTRATOR

assembly

exposed

Cabinet

to

the

foam

Assembly

base

assembly.

insulation.

FROM

AMZ-Wro

Base

Mounting

FIGURE 1 -

Screws

REMOVING

2-2

(8

each)

CABINET

Assembly

INVACARE

innovation

in

Health

°

Care

ra

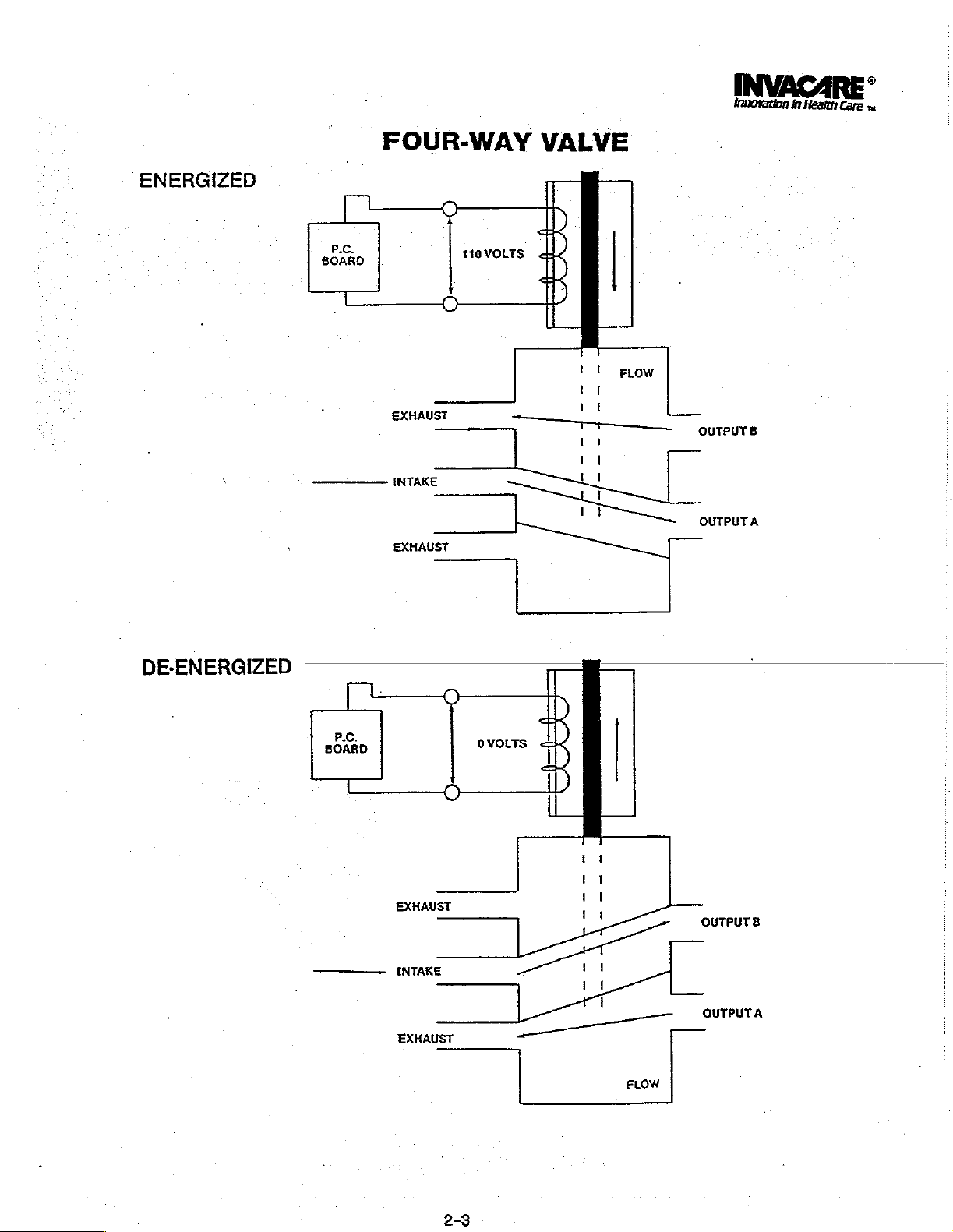

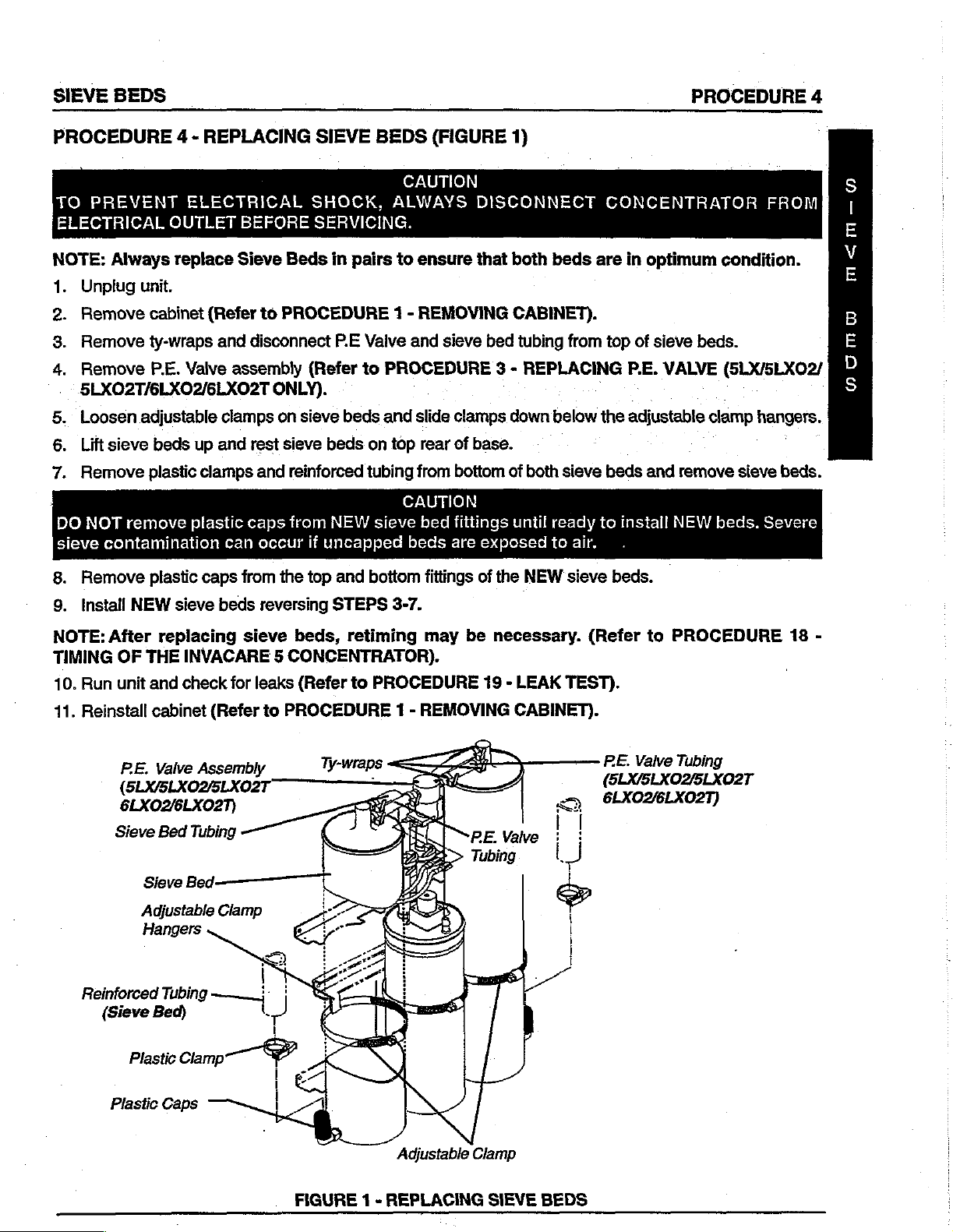

ENERGIZED

[

Р.С.

BOARD

FOUR-WAY

EXHAUST

q

Tel

INTAKE

EXHAUST

0

一

110

一

一

0

VOLTS

VALVE

$

4

<

OA

—

iii

A

Tr

1

LI

Ut

AAA

FLOW

|]

OUTPUT

OUTPUTA

B

DE-ENERGIZED

PC.

BOARD

Lo

EXHAUST

INTAKE

一

EXHAUST

ονοιτς

一

一

στ

|

中

<

-

AT

4

ia

pa

Va

rt

11

a

1

i

OUTPUTA

FLOW

INVACARE’

Innovation

in

Health

Care

sa

SOLENOID/SPRING

KIT

NO.

2001177

-

UPGRADE

2

3

À

5

&

NOTE:

The

Mobilaire V (IRCS01

REMOVING

CAPSULE

“Tum

Oxygen

Remove

Monet

2.

to

3.

KIT

one

()

Se

Coi

(9

One

one

Done

wo

Ciamps

a

Sleeve

O-Rings

Six

(6)

following

instructions

e

THE

OFF

power

Concentrator.

asen

Remove

the

the

support

Remove

the

INCLUDES

Hose

11-inches

onde

Cap.

JF

Solenoid

i

(8)

O-Rings

are

apply

and

IRC501

SPOOL/SLEEVE

and

UNPLUG

5/8-inch

o ho

four (4)

screws

frame.

clear

tubing

THE

pring

needed - two

WARNING

truss

bass

that

KIT

Solenoid/Spring

of

FOLLOWING:

τς

ος

used

to

Case

{2}

to

Mobilaire

rade.

9

upg

AND

the

cord

from the

・

head

screws

assembly

that

secure

is

connected

the

i

in

are

lll

(RC301)

SOLENOID

‘nat

the

control

to

Solenoid

μα.

conjunction

-

spares.

and

Mobilaire

-

secure

panel

the

bottom

‘

Kit

and

Installation

Assembly

Servicing

Instructions

and

Capsule.

3

Remove

plate

4.

Remove

5.

6

Gently

7.

Inspect

are

The

set.

that

special

interchanging

8.

Push

you

NOTE: A soft

9.

body.

MOT

the

two

to

the

valve

the

spool/sleeve

Remove

two

endplate

remove

spoot

present,

assembly.

spool

Spools

only

can

than

ed

tap

Now

twist

replace

and

are

one

(1)

precautions

the

sleeve

firmly

dowel

the

outside

with

hammer

the

sleeve

the

m

(2)

screws

body

and remove

(2)

screws

assembly

spool

for

steeve

not

of

grip

using a 3mm

spring.

and

out

of

nicks,

scratches

entire

WARNING

assembly

interchangeable.

assembly

be

taken

spools.

out

of

either

the

sleeve.

(nylon,

diameter

(nylon,

partially

sleeve

as

you

|

o

unos

(25

mm

Allen)

the

from

the

endplate

Allen

valve

body.

or

wear.

assembly

valve

is a precision

be

wood,

out

on

It

cleaned

to

prevent

end

of

etc.)

of

the

wood

or

of

the

are

removing

Me

alano

the

that

secure

plate.

of

wrench.

If

any

spool/sleeve

or

is

at a time

slightly

sleeve

matched

recommended

the

accidental

valve

body

smaller

can

rubber)

valve

it

to

body.

from

|

rien

the

of

these

or

that

be

gently

the

the

until

us-

valve

ton

4.

Move

the

control

NOTE:

This

will

capsule

5.

Unscrew

spool/sleeve

SPOOL/SLEEVE

(FIGURE

N ° Sloan

1.

Remove

secure

cap)

2.

Remove

1)

to

End

the

the

n

the two

the

the

the

Plate

panel

to the

make

access

easier.

inlet

filter

and

GENERAL

solenoid

spool/sleeve.

solenoid

before

solenoid

rr

(2)

6/32 x Finch

capsule

capsule

|

Spring

|

一

CC

.

right-side

to

the

spoolsieeve

disassembling

capsule.

CLEANING

..

assembly.

fiat

(which

include

and

gasket

Spoot

p

|

-

一

FIGURE 1 —

of

the

concentrator

and

solenoid

the

INSTRUCTIONS

not

head

screws

coil

Sleeve

|

ELEK

0

ings

Needed

that

and

ry

end

Valve

CLEANING

10

to

a.

b.

©.

to

You

ings/cautions

valve/spool

Numatics® - is a Registered

Body

.

THE

Piate

SPOOL/SLEEVE

en

Apply

Numatics®

spool

by

rubbing

Allow a few

white)

and

Apply

the

RUB.

Let

dry

MUST

adhere

assembly.

o

ee

yes?

Valve

Cleaner

the

lands

minutes

then

Numatics Valve

”

for

wipe

off

then wipe

tothe

listed

off

seston;

when

5

Solenoid

olenoid

the

7

(Coil)

ASSEMBLY

iy

(P/N

briskly

with a soft

cleaner

the

residue.

Cleaner

again.

all

residue

manufacturer's

cleaning

Trademark

Ca

Capsule

р

x

{End Cap)

0137-135)

to

dry

(will

DO

from

the

the

of

Numatics,

to

the

clean

cloth.

tum

NOT

spool.

war

T

solenoid

-

3-Inch

Flat

Screws

Inc.

Head

2-4

d.

After

time,

e

After

and

possibly

11.

To

clean

DO

NOT

the

sleeve

a.

Remove

plastic

from

DO

NOT

assembly

Pletely

b.

After

assembly,

the

‘agitate

all

You

MUST

ings/cautions.

valve/spool

©.

After

and

possibly

DO

NOT

clean

d.

the

Replace

the

valve

let

the

let

the

use a hard/sharp

knittng

the

use

as

removed

the

sleeve

the

contaminates.

cleaner

the

spool

spool

has

dry,

blow

in

the

sleeve

O-rings

needle

grooves

out any

left

assembly.

the

O-ring

Numatics

residue

from

O-rings

soak

the

has

soaked

sleeve

in

soak

spool

assembly:

WARNING

Valve

from

the

have

sleeve

WARNING

adhere

to

the

listed

assembly.

the

sleeve

let

use

dry,

inside

blow

left

any

the

has

out

in

the

sleeve.

WARNING

cleaning

of

the

O-rings

has

in acetone.

been

removed

contaminates

with

WARNING

instrument

from

the

(or

equivalent)

on

the

Cleaner

the

inner

been

assembly

in

acetone

the

acetone

acetone

when

been

removed

any

contaminates

tools

sleeve.

on

the

been

wiped

off

from

the

compressed

sleeve

sleeve

cleaner

diameter

removed

manufacturer's

cleaning

(brushes,

sieeve

or

that

may

assembly

to

remove

assembly.

to

clean

cannot

of

from

in

acetone.

for a few

to

completely

the

from

the

or

pads,

assembly

the

second

acetone

moisture

air

damage

using

the

the

sleeve

be

com-

the

sleeve.

the

sleeve

minutes,

remove

ls

warn-

solenoid

acetone

moisture

etc.)

by

.

a

O-rings

After

.

to

REINSTALLING

SOLENOID

1.

2.

3

4

REPLACING

OF

CHANGER

NOTE:

NOTE:

1.

Do

the

2

3.

4.

5

THE

CAPSULE

Reinstall

ing

“plate

Piug

the

Instali

tubber

assembly.

Reinstall

THE

Remove

the

aluminum

Route

heat

valve

Reinstall

Reinstall

Attach

the

sure

the

solenoid

The

but

When

either a screwdriver

middle

not

heat

exchanger

endplate

that

the

and

in

the

white

assembiy

the

new

coll

gasket

is

the

inlet

THE

4-WAY

VALVE

(FIGURE

8-inch

oniy

change

removing

the

hose

connector

overtighten

and

if

the

new

assembly

the

clear

control

cabinet

assembly

SPOOL/SLEEVE

(FIGURE

on

spring

center:

connector

positioned

HOSE

2)

stainless

that

the

is

positioned

of

the

into

to

the

and new end

filter.

properly

FROM

ASSEMBLY

steel

the

hose

the

clamps

or a 1/4-inch

runs

from

of

the

4-way

the

spool/sleeve

THE

WARNING

the

clamps

.

The

heat

PVC

middie

with

to

to

the

exchanger

hose

connector

the

overtightened,

tt-inch

to

the

and

secure

tubing

panel.

AND

properly

before

making

on the

MIDDLE

THE

must

residue

the

socket

heat

exchanger

assembly.

secure

is

tubing

spring

on

of

the

assembly.

NEW

assembly

assembiy.

solenoid

HEAT

the hoses

made

will

the

clamps.

1)

spool/sleeve

spool.

solenoid

cap

TO

spring

if

from

the

valve

that

the

with

adjustable

bottom

base

in

the

assembling

sure

that

CONNECTOR

EX-

be

replaced

is

apparent.

hoses,

use

wrench.

to

-

of

soft

collapse.

from

the

4-way

flowmeter.

mak-

end-

”

the

to

assembly

NOTE:

ff a kit

O-rings

spares.

12.

To

replace the

sleeve

DO

NOT

damage

13

Gently

14.

To

replace

the

valve

15.

The

sleeve

16.

Insertion

rectly locate

Form

grooves.

is

used,

but

only

spool,

assembly.

tilt

the

may

result.

turning

spool,

the

sleeve,

body.

should

of

the

the

No.

91-170

there

six

carefully

WARNING

spool

or

insert

gently

be

roughly

end

plates

assembly

899

Cleveland

(P/N

will

be a total

(6)

are

needed.

align

the

force

it

it

into

sleeve.

push/twist

centered

and

bumper/spacers

in

the

valve

St.

«

2001187)

spool.

into

the

in

body.

PO.

of

eight

Two

the

(8)

(2)

are

with

the

sleeve

as

sleeve

into

the

valve

body.

will

cor-

INVACARE’

Innovation

Box

4028

Rev.

©

in

Elyria,

Ohio

9/92

Health

44036-2125

FIGURE 2 —

MIDDLE

ASSEMBLY

Carew

U.S.A.

REPLACING

CONNECTOR

TO

«

Phone

THE

THE

HOSE

OF

THE

HEAT

EXCHANGER

14800)

333-5900

FROM

4-WAY

THE

VALVE

2-5

PROCEDURE

2

PREVENTIVE

MAINTENANCE

PROCEDURE

TO

<mav

MOZrP2MAZ—~prps

PREVENT

DISCONNECT

TRICAL

NOTE:

cally

maintenance

places

nance

The

of

additional

factory-trained

preventive

Power

preventive

trator.

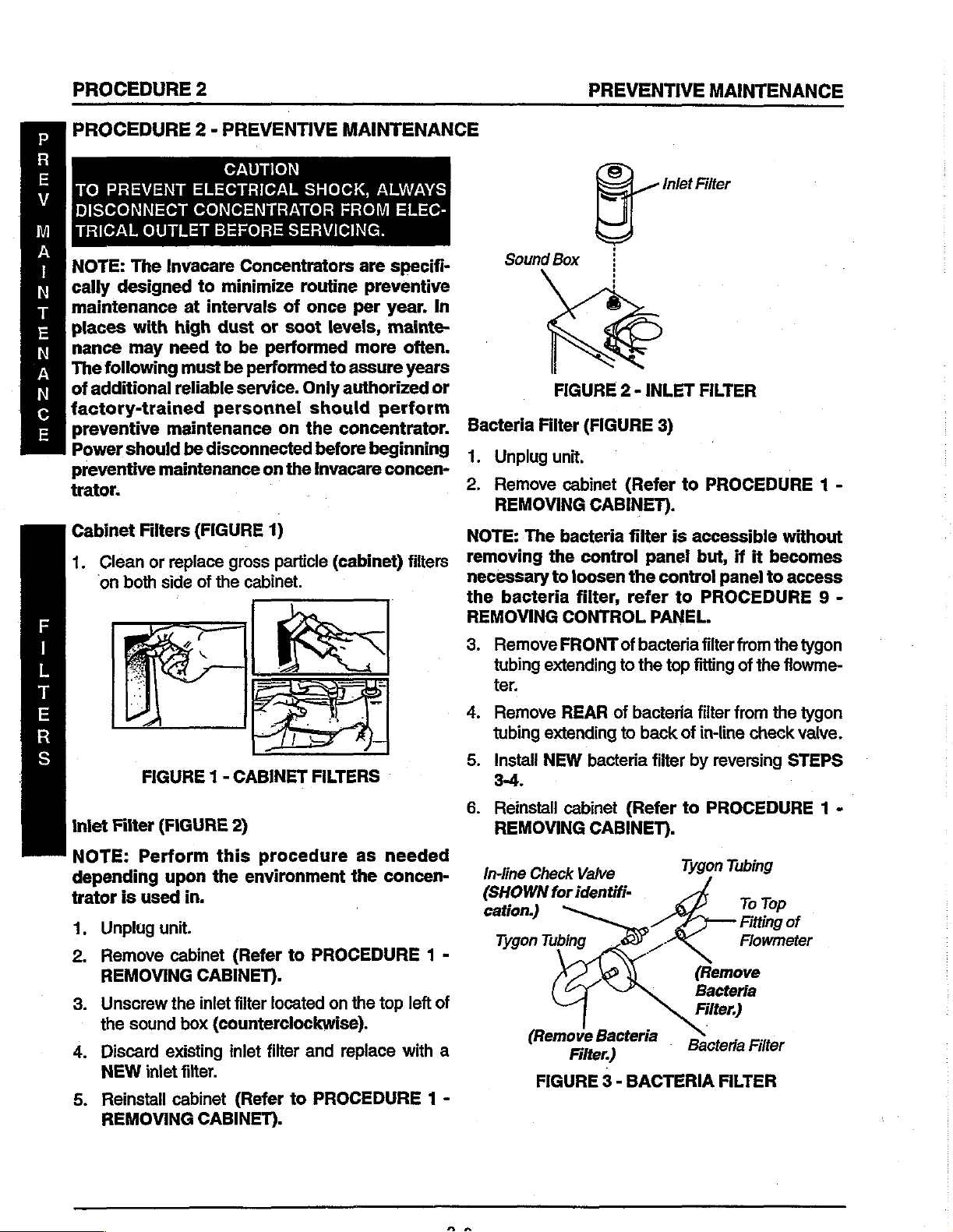

Cabinet

1.

OUTLET

The

designed

with

may

following

should

maintenance

Filters

Clean

‘on

or

both

2 - PREVENTIVE

CAUTION

ELECTRICAL

CONCENTRATOR

BEFORE

Invacare

at

high

need

must

reliable

maintenance

be

Concentrators

to

minimize

intervals

dust

to

be

be

performed

service.

personnel

disconnected

(FIGURE

replace

side

of

gross

the

cabinet.

SHOCK,

SERVICING.

routine

of

once