International comfort products PGD/S524?60 Installation Instructions Manual

INSTALLATION INSTRUCTIONS

R−410A Single Package Gas/Electric Units

PGD/S524−60

Single Phase

These instructions must be read and understood completely before attempting installation

Safety Labeling and Signal Words

DANGER, WARNING, CAUTION, and NOTE

The signal words DANGER, WARNING,

CAUTION, and NOTE are used to identify levels of

hazard seriousness. The signal word DANGER is only

used on product labels to signify an immediate hazard.

The signal words WARNING, CAUTION, and NOTE will

be used on product labels and throughout this manual

and other manual that may apply to the product.

DANGER − Immediate hazards which will result in

severe personal injury or death.

WARNING −Hazards or unsafe practices which could

result in severe personal injury or death.

CAUTION − Hazards or unsafe practices which may

result in minor personal injury or product or property

damage.

NOTE − Used to highlight suggestions which will result

in enhanced installation, reliability, or operation.

Signal Words in Manuals

The signal word WARNING is used throughout

this manual in the following manner:

!

WARNING

The signal word CAUTION is used throughout

this manual in the following manner:

!

CAUTION

Signal Words on Product Labeling

Signal words are used in combination with colors

and/or pictures or product labels.

TABLE OF CONTENTS PAGE

SAFETY CONSIDERATIONS 2..................

RECEIVING AND INSTALLATION 2..............

Step 1 − Check Equipment 2....................

Step 2 − Provide Unit Support 3..................

Step 3 − Field Fabricate Ductwork 3..............

Step 4 − Provide Clearances 7...................

Step 5 − Rig and Place Unit 7...................

Step 6 − Connect Condensate Drain 11............

Step 7 − Install Flue Hood 11.....................

Step 8 − Install Gas Piping 11....................

Step 9 − Install Duct Connections 12..............

Step 10 − Install Electrical Connections 13.........

Wiring Diagrams 15.............................

PRE−START−UP 17.............................

START−UP 17..................................

Step 1 − Check for Refrigerant Leaks 17...........

Step 2 − Start−Up Heating and Adjustments 17.....

Step 3 − Start−Up Cooling and Adjustments 20.....

Maintenance 23.................................

Troubleshooting 26..............................

Start−Up Checklist 34...........................

!

WARNING

PERSONAL INJURY, AND/OR PROPERTY

DAMAGE HAZARD

Failure to carefully read and follow this warning

could result in equipment malfunction, property

damage, personal injury and/or death.

Installation or repairs made by unqualified

persons could result in equipment malfunction,

property damage, personal injury and/or death.

The information contained in this manual is

intended for use by a qualified service technician

familiar with safety procedures and equipped

with proper tools and test instruments.

Installation must conform with local building

codes and with the national Electrical Code

NFPA70 current edition or Canadian Electrical

Code part 1 CSA C.22.1.

462 01 2103 01 07−09−13

SAFE INSTALLATION REQUIREMENTS

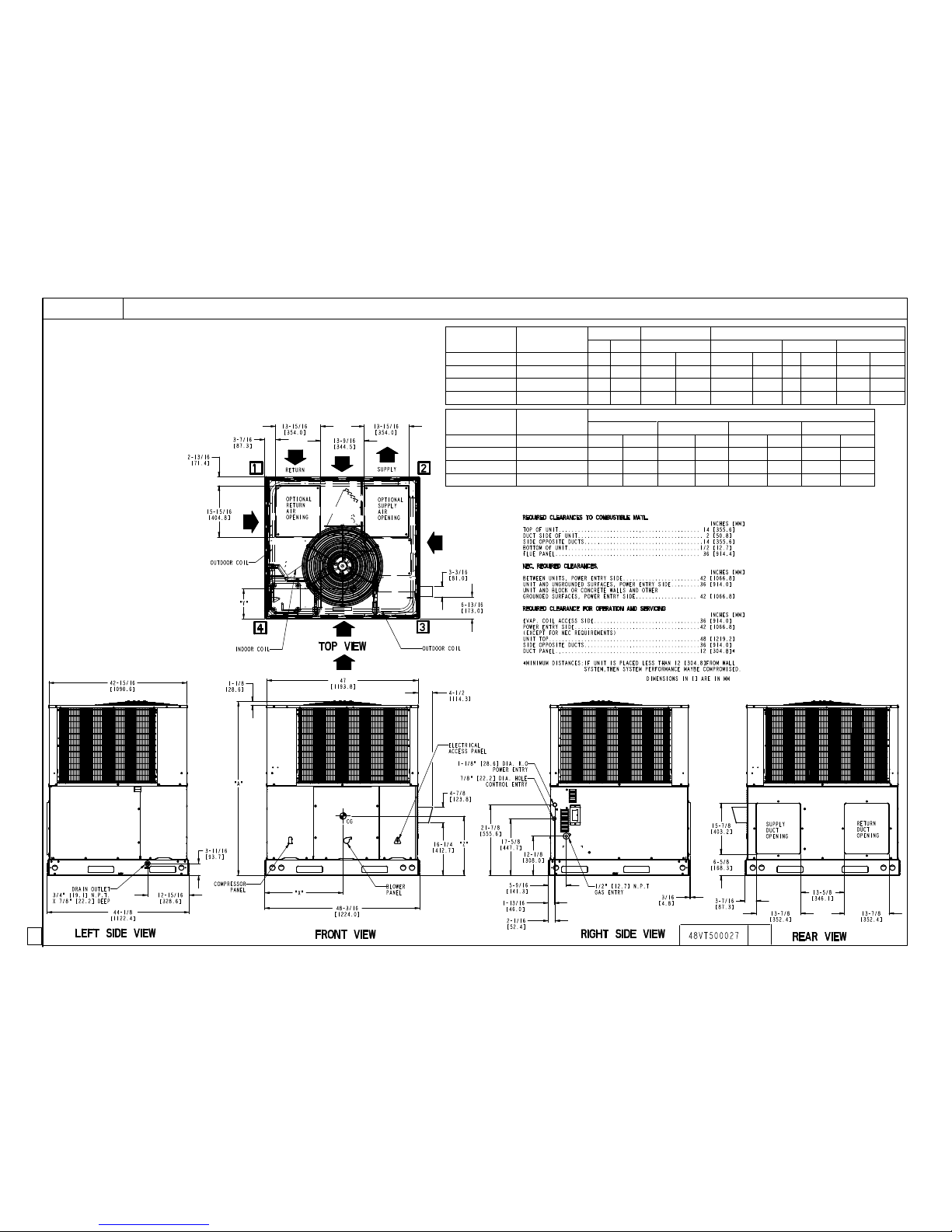

FIGURE 1

PACKAGED GAS / ELECTRIC UNIT

SAFETY CONSIDERATIONS

Improper installation adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock,

or other conditions which may cause death, personal injury, or

property damage. Consult a qualified installer, service agency, or

your distributor or branch for information or assistance. The

qualified installer or agency must use factory−authorized kits or

accessories when modifying this product Refer to the individual

instructions packaged with the kits or accessories when

installing.

Follow all safety codes. Wear safety glasses, protective clothing,

and work gloves. Have a fire extinguisher available. Read these

instructions thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local

building codes, the current editions of the National Fuel Gas

Code (NFGC 54/ANSI Z223.1, and the National Electrical Code

(NEC) NFPA 70.

In Canada refer to the current editions of the National Standards

of Canada CAN/CSA−B149.1 and .2 Natural Gas and Propane

Installation codes, and Canadian electrical Code CSA C22.1.

manuals, be alert to the potential for personal injury. Understand

these signal words: DANGER, WARNING, and CAUTION.

These words are used with the safety−alert symbol. DANGER

identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which may result in minor personal

injury or product and property damage. NOTE is used to

highlight suggestions which will result in enhanced installation,

reliability, or operation.

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

When removing access panels or performing maintenance

functions inside your unit, be aware of sharp sheet metal parts

and screws. Although special care is taken to reduce sharp

edges to a minimum, be extremely careful when handling

parts or reaching into the unit.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Before installing or servicing system, always turn off main

power to system. There may be more than one disconnect

switch. TAG DISCONNECT SWITCH WITH LOCKOUT TAG.

!

FIRE, EXPLOSION, ELECTRICAL SHOCK AND

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury

or unit damage.

A qualified installer or agency must use only

factory−authorized kits or accessories when modifying this

product.

CAUTION

WARNING

WARNING

Recognize safety information. This is the safety−alert symbol

When you see this symbol on the unit and in instructions or

INTRODUCTION

The PGD5 / PGS5 units (see Fig. 1) are a fully self−contained,

combination Category I gas heating/electric cooling unit

designed for outdoor installation (See Fig. 3 and 4 for unit

dimensions). All unit sizes have return and discharge openings

for both horizontal and downflow configurations, and are factory

shipped with all downflow duct openings covered. Units may be

installed either on a rooftop or on a cement slab. (See Fig. 5 for

roof curb dimensions).

2

.

Models with the number “1” in the 13th position of the model

number are dedicated Low NOx units designed for California

installations. These models meet the California maximum oxides

of nitrogen (NOx) emissions requirements of 40 nanograms/joule

or less as shipped from the factory and must be installed in

California Air Quality Management Districts or any other regions

in North America where a Low NOx rule exists.

NOTE:Low NOx requirements apply only to natural gas

installations.

In gas heating mode, this unit is designed for a minimum

continuous return−air temperature of 55°F (13°C) db and a

maximum continuous return−air temperature of 80°F (27°C) db.

Failure to follow these return−air temperature limits may affect

reliability of heat exchangers, motors, and other components.

462 01 2103 01

RECEIVING AND INSTALLATION

STEP 1 — Check Equipment

Identify Unit

The unit model number and serial number are stamped on the unit

information plate. Check this information against shipping papers.

Inspect Shipment

Inspect for shipping damage before removing packaging materials.

If unit appears to be damaged or is torn loose from its anchorage,

have it examined by transportation inspectors before removal.

Forward claim papers directly to transportation company.

Manufacturer is not responsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify the nearest

equipment distribution office if any item is missing. To prevent loss

or damage, leave all parts in original packages until installation.

STEP 2 — Provide Unit Support

IMPORTANT: The unit must be secured to the curb by installing

screws through the bottom of the curb flange and into the unit base

rails. When installing large base units onto the common curb, the

screws must be installed before allowing the full weight of the unit

to rest on the curb. A minimum of six screws are required for large

base units. Failure to secure unit properly could result in an

unstable unit. See Warning near Rigging/Lifting information and

accessory curb instructions for more details.

For hurricane tie downs, contact distributor for details and PE

(Professional Engineering) Certificate if required.

IMPORTANT: The gasketing of the unit to the roof curb is critical

for a water tight seal. Install gasketing material supplied with the

roof curb. Improperly applied gasketing also can result in air

leaks and poor unit performance.

Curb should be level to within 1/4 in. (6 mm). This is necessary

for unit drain to function properly. Refer to accessory roof curb

installation instructions for additional information as required.

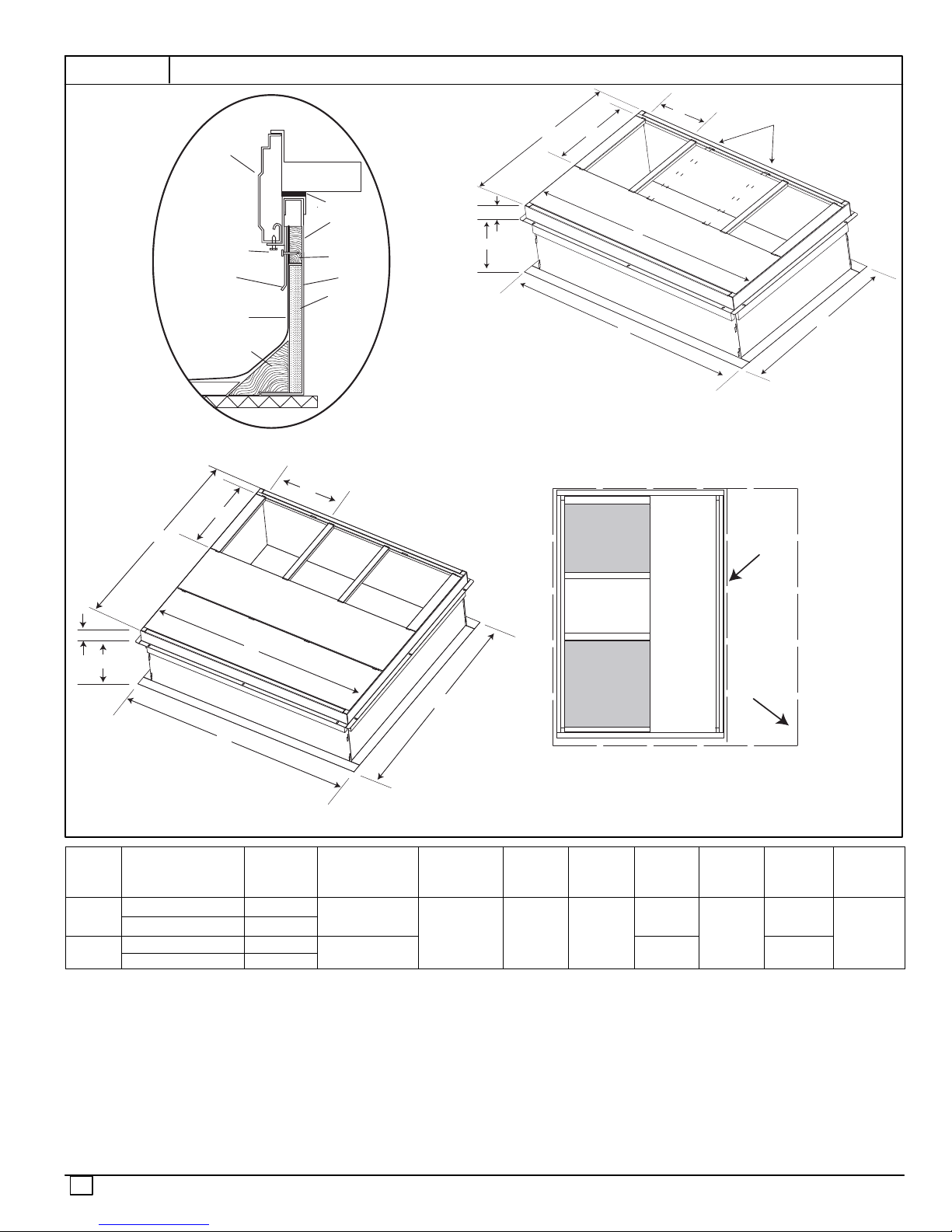

Roof Curb

Install accessory roof curb in accordance with instructions shipped

with curb. See Fig. 5. Install insulation, cant strips, roofing, and

flashing. Ductwork must be attached to curb.

Accessory kits are available to aid in installing a new metal base

rail unit on an old roof curb.

Accessory kit number CPADCURB001A00, (small chassis) and

accessory kit number CPADCURB002A00, (large chassis)

includes roof curb adapter and gaskets for the perimeter seal

and duct openings. No additional modifications to curb are

required when using this kit.

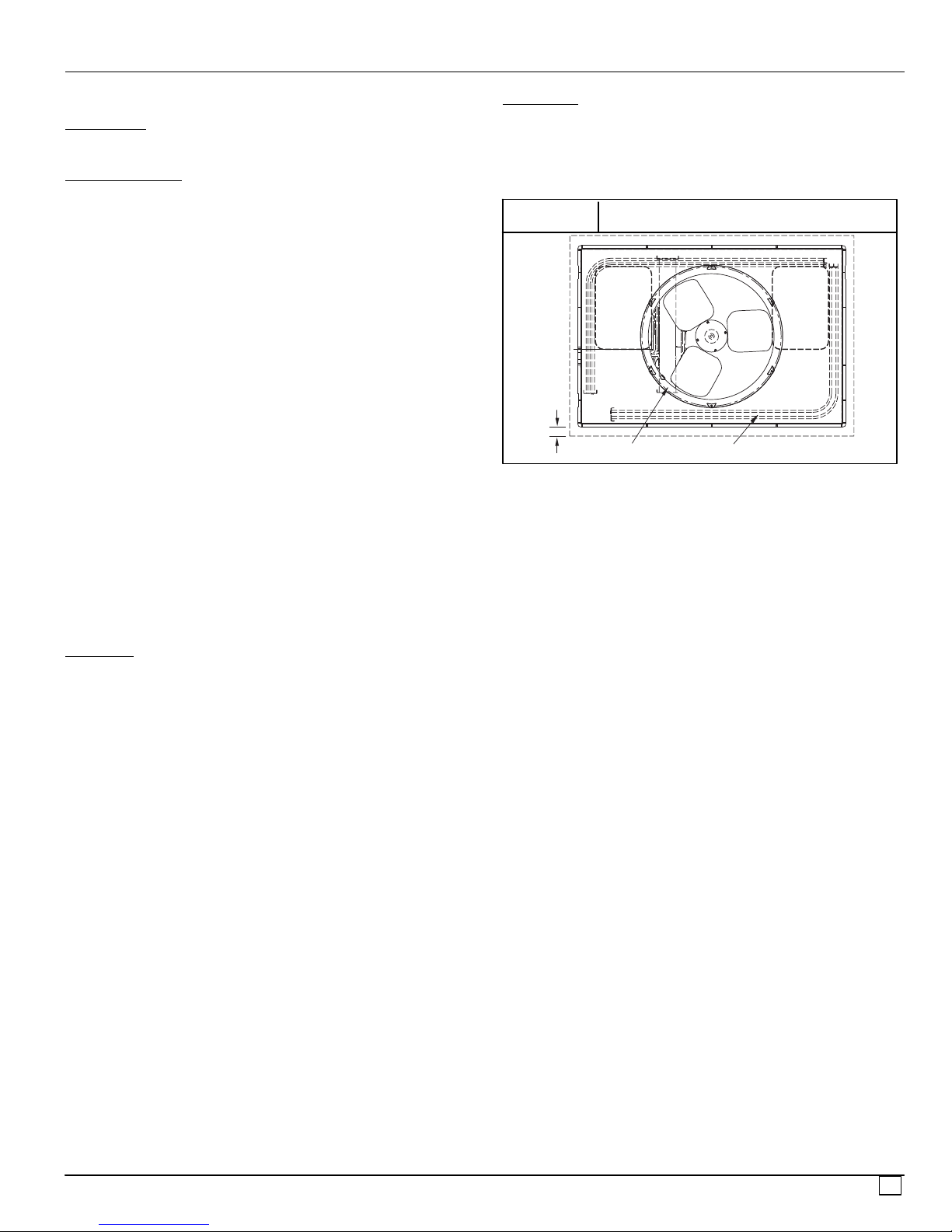

Slab Mount

Place the unit on a solid, level concrete pad that is a minimum of 4”

(102mm) thick with 2” (51mm) above grade (see Figure 2). The slab

should extend approximately 2” beyond the casing on all 4 sides of

the unit. Do not secure the unit to the slab except when required by

local codes.

FIGURE 2

2"

EVAP. COIL COND. COIL

Slab Mounting Details

OPTIONAL

RETURN

AIR

OPENING

OPTIONAL

SUPPLY

AIR

OPENING

STEP 3 — Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical

discharge units. Do not connect ductwork to unit. For horizontal

applications, unit is provided with flanges on the horizontal

openings. All ductwork should be secured to the flanges. Insulate

and weatherproof all external ductwork, joints, and roof openings

with counter flashing and mastic in accordance with applicable

codes.

Ducts passing through an unconditioned space must be insulated

and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be

ducted through the roof deck to comply with applicable fire codes.

A minimum clearance is not required around ductwork. Cabinet

return−air static shall not exceed −.25 inches water column.

462 01 2103 01

3

4

462 01 2103 01

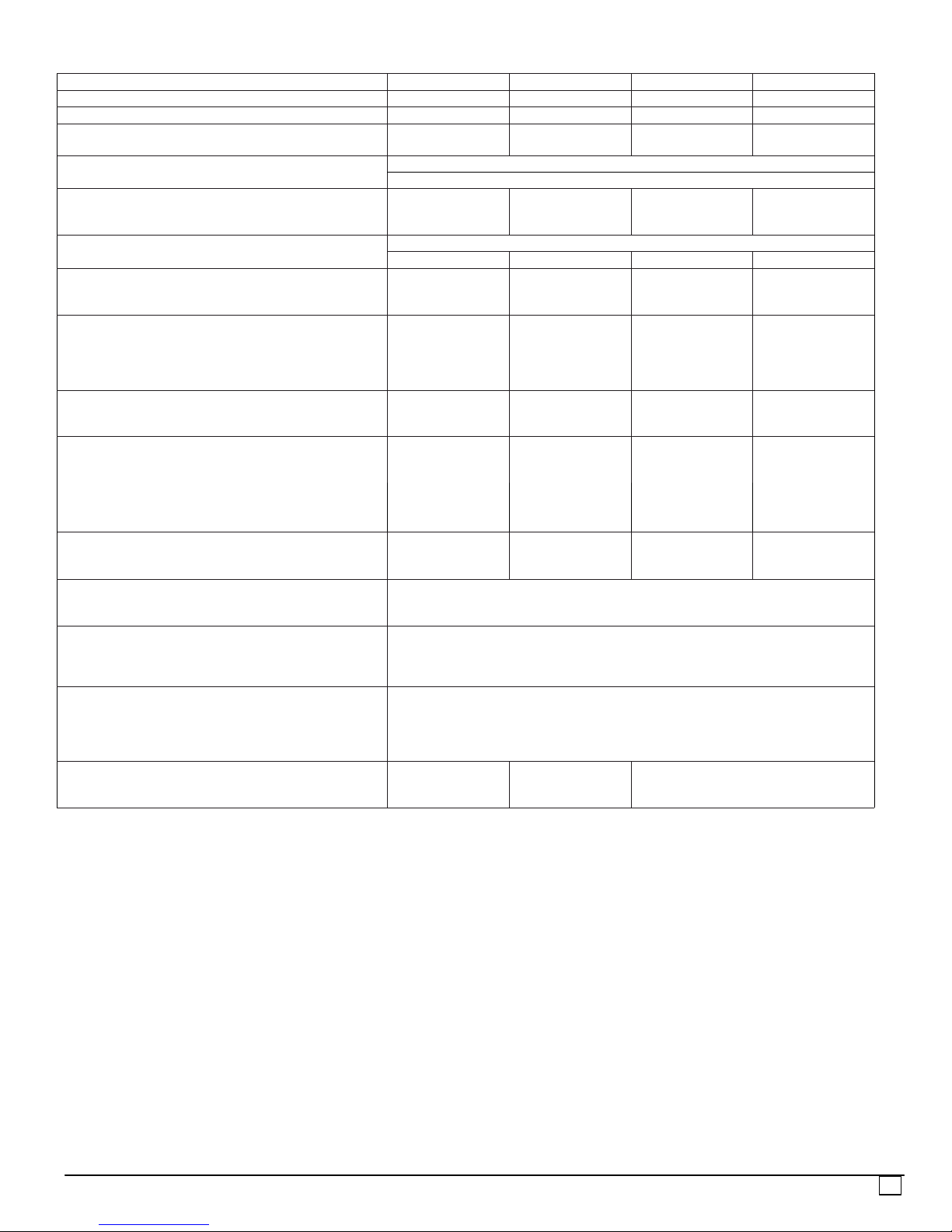

Unit

Electrical

Characteristics

Unit WT. Unit HT. Center of Gravity

LB KG A X Y Z

24040 208/230-1-60 419 189.9 44-3/4 1136.7 22-13/16 579.4 15-5/16 388.9 17-5/8 447.7

24060 208/230-1-60 426 193.1 44-3/4 1136.7 22-13/16 579.4 15-5/16 388.9 17-5/8 447.7

UNIT Voltage

Corner Weight LB/KG

1 2 3 4

24040 208/230 62.8 28.5 83.8 38.0 125.6 57.0 146.6 66.5

24060 208/230 63.6 28.9 84.8 38.5 127.1 57.7 148.3 67.3

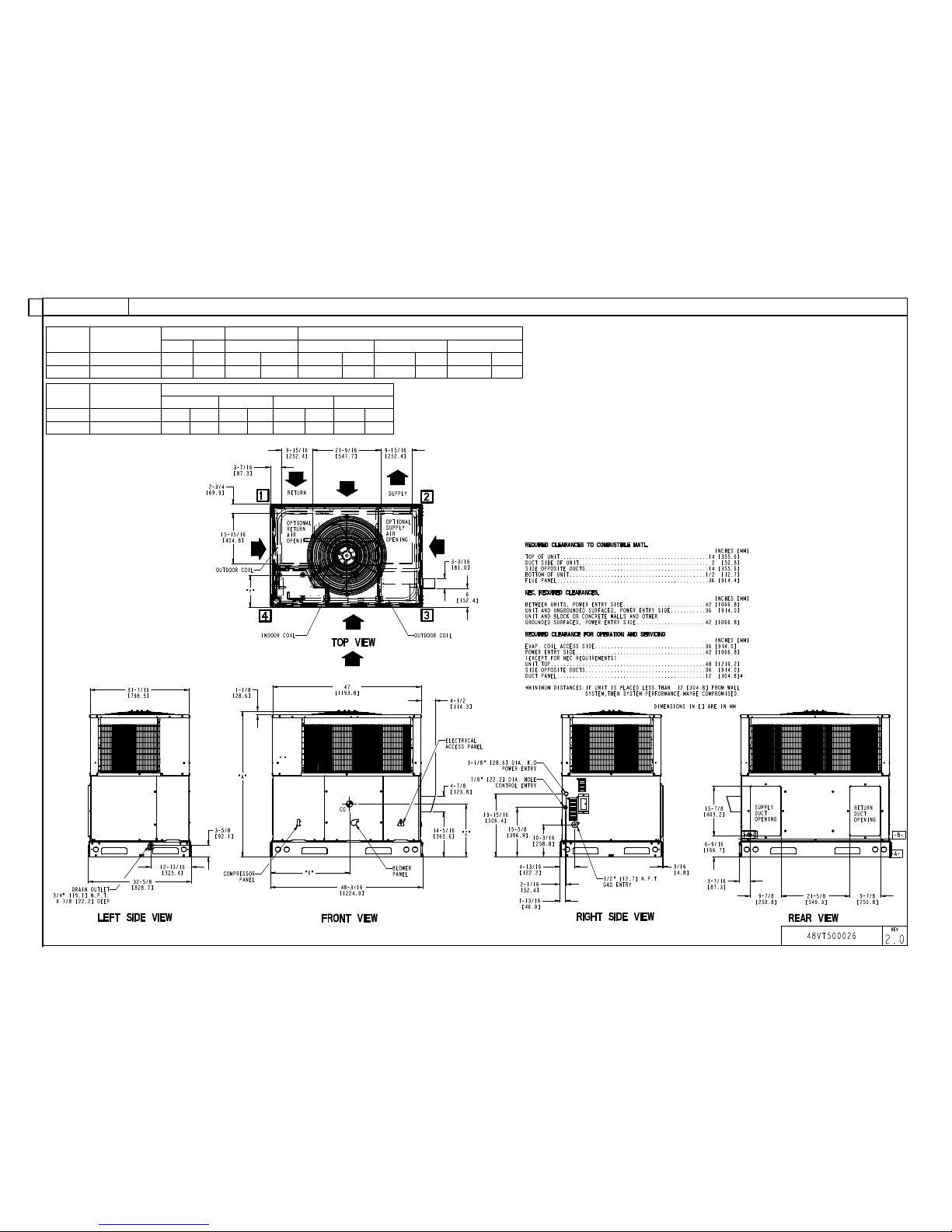

FIGURE 3

Model Size 24 Dimensions

5

462 01 2103 01

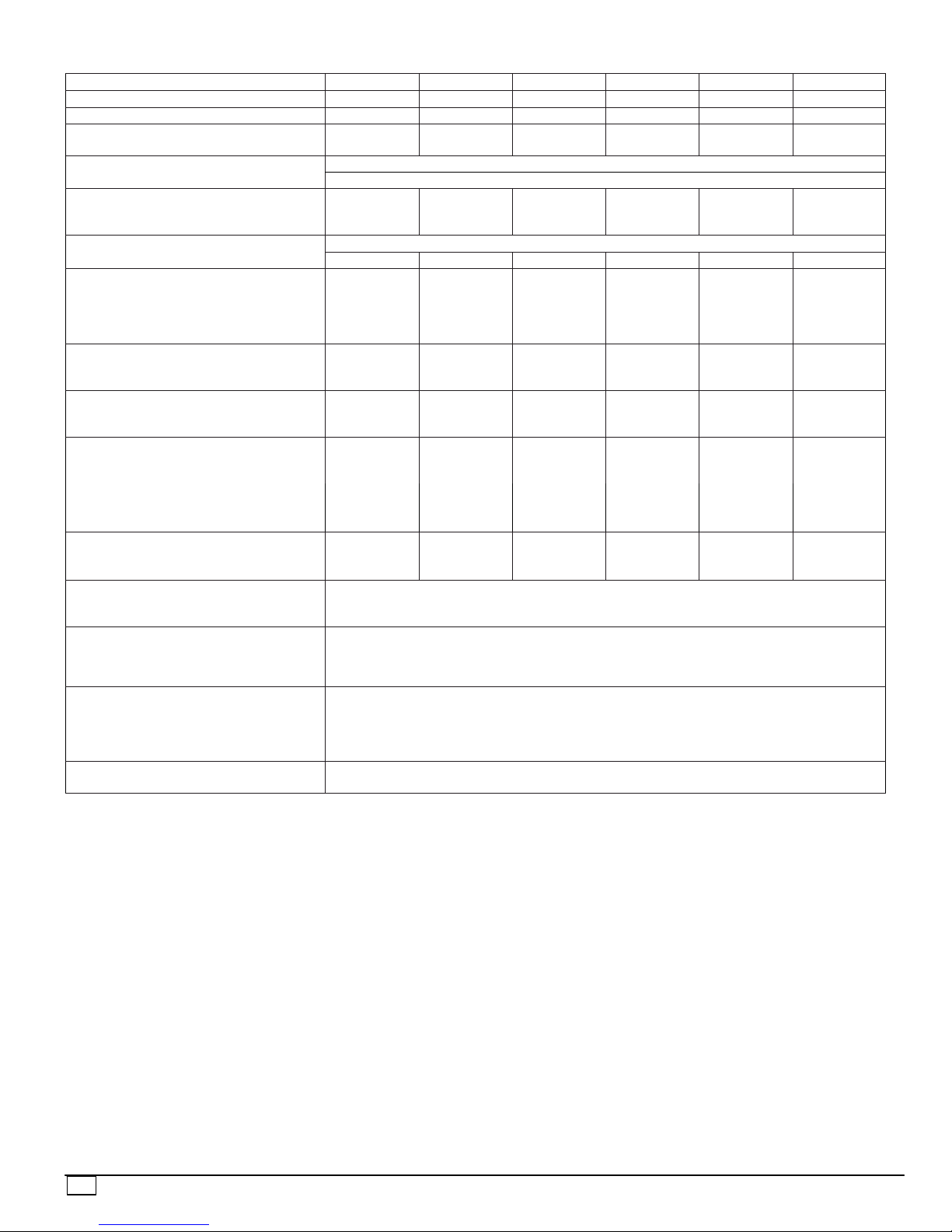

Unit

Electrical

Characteristics

Unit WT. Unit HT. Center of Gravity

LB KG A X Y Z

36060 208/230-1-60 513 232.8 48-5/8 1235.1 22-13/16 579.4 18 457.2 16-5/8 422.3

36090 208/230-1-60 521 236.4 48-5/8 1235.1 22-13/16 579.4 18 457.2 16-5/8 422.3

48090 / 115 / 130 208/230-1-60 549 249.1 50-5/8 1285.9 22-13/16 579.4 18 457.2 17-5/8 447.7

60090 / 115 / 130 208/230-1-60 600 272.3 54-5/8 1387.5 22-13/16 579.4 18 457.2 18 457.2

Unit Voltage

Corner Weight LB/KG

1 2 3 4

36060 208/230 77.0 35.0 102.6 46.6 154.0 69.9 179.6 81.6

36090 208/230 78.2 35.5 104.2 47.3 156.4 71.0 182.4 82.8

48090 / 115 / 130 208/230 82.4 37.4 109.8 49.9 164.8 74.8 192.2 87.3

60090 / 115 / 130 208/230 90.0 40.9 120.0 54.5 180.1 81.8 210.1 95.4

FIGURE 4

Model Size 36−60 Dimensions

2

FIGURE 5

Roof Curb Dimensions

G

HVAC unit

base rails

Anchor screw

field supplied

Flashing field

supplied

Roofing material

field supplied

Cant strip

field supplied

*Provided with roofcurb

HVAC unit

basepan

ROOF CURB DETAIL

B

C

Sealing

*

Gasket

Roofcurb

Wood nailer*

(field supplied)

G

C

F

A

SMALL/COMMON CURB

SUPPLY

AIR

B

H

D

Dashed lines show cross support

location for large basepan units.

E

SMALL

BASE

UNIT

A

F

D

LARGE CURB

H

UNIT

SIZE

Small

or

Large

Large

NOTES:

1. Roof curb must be set up for unit being installed.

2. Seal strip must be applied, as required, to unit being installed.

3. Roof curb is made of 16−gauge steel.

4. Attach ductwork to curb (flanges of duct rest on curb).

5. Insulated panels: 1−in. (25 mm) thick fiberglass 1 lb. density.

CATALOG

NUMBER

A

IN. (mm)

CPRFCURB010A00 11 (279)

CPRFCURB011A00 14 (356)

CPRFCURB012A00 11 (279)

CPRFCURB013A00 14 (356)

(small/common

IN. (mm)*

10 (254)

14 (356)

B

base)

E

B

(large base)

IN. (mm)*

14 (356) 16 (406)

IN. (mm)DIN. (mm)EIN. (mm)FIN. (mm)GIN. (mm)HIN. (mm)

LARGE

RETURN

AIR

BASE

UNIT

UNIT PLACEMENT ON

COMMON CURB

SMALL OR LARGE BASE UNIT

C

47.8

(1214)

32.4 (822)

43.9

(1116)

2.7 (69)

30.6 (778)

42.2

(1072)

46.1 (1170)

6

462 01 2103 01

STEP 4 — Provide Clearances

The required minimum operating and service clearances are

shown in Fig. 3 and 4. Adequate combustion, ventilation and

condenser air must be provided.

IMPORTANT: Do not restrict outdoor airflow. An air restriction at

either the outdoor−air inlet or the fan discharge may be

detrimental to compressor life.

The condenser fan pulls air through the condenser coil and

discharges it through the top grille. Be sure that the fan

discharge does not recirculate to the condenser coil. Do not

locate the unit in either a corner or under an overhead

obstruction. The minimum clearance under a partial overhang

(such as a normal house overhang) is 48−in. (1219 mm) above

the unit top. The maximum horizontal extension of a partial

overhang must not exceed 48−in. (1219 mm).

Do not place the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit. Do not install the

unit on carpeting or other combustible materials. Slab−mounted

units should be at least 4 in. (102 mm) above the highest

expected water and runoff levels. Do not use unit if it has been

under water.

STEP 5 — Rig and Place Unit

Rigging and handling of this equipment can be hazardous for many

reasons due to the installation location (roofs, elevated structures,

etc.).

Only trained, qualified crane operators and ground support staff

should handle and install this equipment.

When working with this equipment, observe precautions in the

literature, on tags, stickers, and labels attached to the equipment,

and any other safety precautions that might apply.

Training for operators of the lifting equipment should include, but

not be limited to, the following:

1. Application of the lifter to the load, and adjustment of the lifts to

adapt to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load as it relates to operation of the lifting kit,

such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and

work gloves.

INSPECTION

Prior to initial use, and at monthly intervals, all rigging shackles,

clevis pins, and straps should be visually inspected for any

damage, evidence of wear, structural deformation, or cracks.

Particular attention should be paid to excessive wear at hoist

hooking points and load support areas. Materials showing any kind

of wear in these areas must not be used and should be discarded.

!

WARNING

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Never stand beneath rigged units or lift over people.

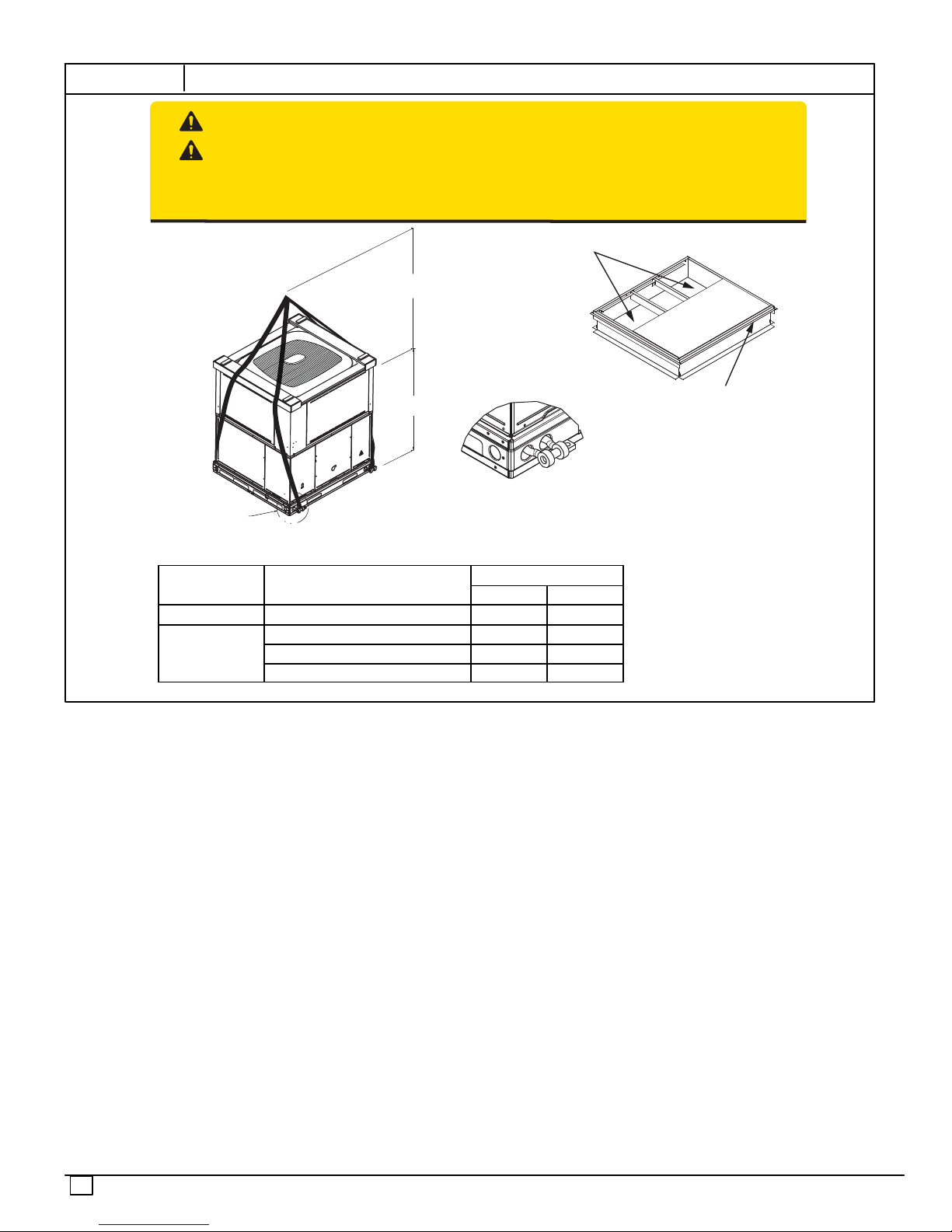

Rigging/Lifting of Unit

!

WARNING

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

When straps are taut, the clevis should be a minimum of

36 in. (914 mm) above the unit top cover.

!

WARNING

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Large base units must be secured to common curb

before allowing full weight of unit to rest on curb. Install

screws through curb into unit base rails while rigging

crane is still supporting unit.

Lifting holes are provided in base rails as shown in Fig. 3 and 4.

1. Leave top shipping skid on the unit for use as a spreader bar to

prevent the rigging straps from damaging the unit. If the skid is

not available, use a spreader bar of sufficient length to protect

the unit from damage.

2. Attach shackles, clevis pins, and straps to the base rails of the

unit. Be sure materials are rated to hold the weight of the unit

(See Fig. 6).

3. Attach a clevis of sufficient strength in the middle of the straps.

Adjust the clevis location to ensure unit is lifted level with the

ground.

After the unit is placed on the roof curb or mounting pad, remove

the top crating.

462 01 2103 01

7

FIGURE 6

Unit Corner Weight (lbs) and Rigging

CAUTION - NOTICE TO RIGGERS

PRUDENCE - AVIS AUX MANIPULATEUR

ACCESS PANELS MUST BE IN PLACE WHEN RIGGING.

PANNEAUX D'ACCES DOIT ÊTRE EN PLACE POUR MANIPULATION.

Use top skid as spreader bar. / Utiliser la palette du haut comme barre de répartition

DUCTS

MINIMUM HEIGHT: 36" (914.4 mm)

HAUTEUR MINIMUM

UNIT HEIGHT

HAUTEUR D'UNITÉ

DETAIL A

SEE DETAIL A

VOIR DÉTAIL A

VOIR DÉTAIL A

Rigging Weight

Cabinet MODEL NUMBER

lb kg

Small PG(D,S)524 431 196

PG(D,S)536 530 240

Large

PG(D,S)548 558 253

PG(D,S)560 609 276

SEAL STRIP MUST BE IN

PLACE BEFORE PLACING

UNIT ON ROOF CURB

BANDE SCELLANT DOIT ÊTRE

EN PLACE AVANT DE PLACER

L'UNITÉ SUR LA BASE DE TOIT

50CY502286 2.0

8

462 01 2103 01

Table 1 − PHYSICAL DATA PG(D,S)524−36

UNIT SIZE 24040 24060 36060 36090

NOMINAL COOLING CAPACITY (ton) 2 2 3 3

NOMINAL HEATING CAPACITY (Btu) 40,000 60,000 60,000 90,000

SHIPPING WEIGHT (lb)

(kg)

COMPRESSORS

Quantity

REFRIGERANT: R−410A

Quantity (lb)

(kg)

REFRIGERANT METERING DEVICE TXV

Size 2 Ton 2 Ton 3 Ton 3 Ton

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

(mm)

Motor Hp (Rpm)

INDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR FAN

Nominal Low Stage Cooling Airflow (Cfm)

Nominal High Stage Cooling Airflow (Cfm)

Size (in.)

(mm)

Motor HP (RPM) 1/2 1/2 3/4 3/4

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

HIGH−PRESSURE SWITCH (psig) Cut−out

Reset (Auto)

HIGH−PRESSURE SWITCH 2 (psig)

(Compressor Solenoid)

Cut−out

Reset (Auto)

LOSS−OF−CHARGE /

LOW−PRESSURE SWITCH

(Liquid Line) (psig)

Cut−out

Reset (auto)

RETURN−AIR FILTERS Throwaway†

(in.)

(mm)

Continued next page.

426

193

10.1

4.6

2...21

13.6

2700

22

559

1/8 (825)

3...17

3.7

600

800

10x10

254x254

2...44 2...38 2...38 3...38

20x20x1

508x508x25

431

196

2−Stage Scroll

10.1

4.6

2...21

13.6

2700

22

559

1/8 (825)

3...17

3.7

600

800

10x10

254x254

20x24x1

508x610x25

522

237

1

9.5

4.3

2...21

17.5

2800

22

559

1/8 (825)

3...17

4.7

850

1200

11x10

279x254

670 ±10

470 ± 25

565 ± 15

455 ± 15

23 ± 5

55 ± 5

24x30x1

610x762x25

530

240

9.5

4.3

2...21

17.5

2800

22

559

1/8 (825)

3...17

4.7

850

1200

11x10

279x254

462 01 2103 01

9

Table 2—Physical Data PG(D,S)548−60

UNIT SIZE 48090 48115 48130 60090 60115 60130

4 4 4 5 5 5

NOMINAL HEATING CAPACITY (Btu) 90,000 115,000 130,000 90,000 115,000 130,000

SHIPPING WEIGHT (lb)

(kg)

COMPRESSORS

Quantity

REFRIGERANT: R−410A

Quantity (lb)

(kg)

REFRIGERANT METERING DEVICE TXV

Size 4 Ton 4 Ton 4 Ton 5 Ton 5 Ton 5 Ton

OUTDOOR FAN

Nominal Cfm

Diameter (in.)

(mm)

Motor Hp (Rpm)

OUTDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR COIL

Rows...Fins/in.

Face Area (sq ft)

INDOOR FAN

Nominal Low Stage Cooling Airflow (Cfm)

Nominal High Stage Cooling Airflow (Cfm)

Size (in.)

(mm)

Motor HP (RPM) 1 1 1 1 1 1

FURNACE SECTION*

Burner Orifice No. (Qty...Drill Size)

Natural Gas

HIGH−PRESSURE SWITCH (psig)

Cut−out

Reset (Auto)

HIGH−PRESSURE SWITCH 2 (psig)

(Compressor Solenoid)

Cut−out

Reset (Auto)

LOSS−OF−CHARGE /

LOW−PRESSURE SWITCH

(Liquid Line) (psig)

Cut−out

Reset (auto)

RETURN−AIR FILTERS Throwaway† (in.)

(mm)

*Based on altitude of 0 to 2000 ft (0 to 610 m).

Recommended filter sizes for field-installed air filter grilles mounted on the wall or ceiling of the conditioned structure. Required filter sizes shown are based on the larger

of the ARI (Air Conditioning and Refrigeration Institute) rated cooling airflow or the heating airflow velocity of 300 ft/minute for throwaway type or 450 ft/minute for

high-capacity type. Air filter pressure drop for non-standard filters must not exceed 0.08 IN. W.C.

558

253

558

253

558

253

609

276

609

276

2−Stage Scroll

1

15.3

6.9

3300

22

559

1/4 (1100)

2...21

19.4

3...17

5.7

1100

1600

11x10

279x254

15.3

6.9

3300

22

559

1/4 (1100)

2...21

19.4

3...17

5.7

1100

1600

11x10

279x254

15.3

6.9

3300

22

559

1/4 (1100)

2...21

19.4

3...17

5.7

1100

1600

11x10

279x254

15.8

7.2

3300

22

559

1/3 (1110)

2...21

23.3

4...17

5.7

1200

1750

11x10

279x254

15.8

7.2

3300

22

559

1/3 (1110)

2...21

23.3

4...17

5.7

1200

1750

11x10

279x254

1/3 (1110)

279x254

3...38 3...33 3...31 3...38 3...33 3...31

670 ± 10

470 ± 25

565 ± 15

455 ± 15

23 ± 5

55

± 5

24x36x1

610x914x25

609

276

15.8

7.2

3300

22

559

2...21

23.3

4...17

5.7

1200

1750

11x10

10

462 01 2103 01

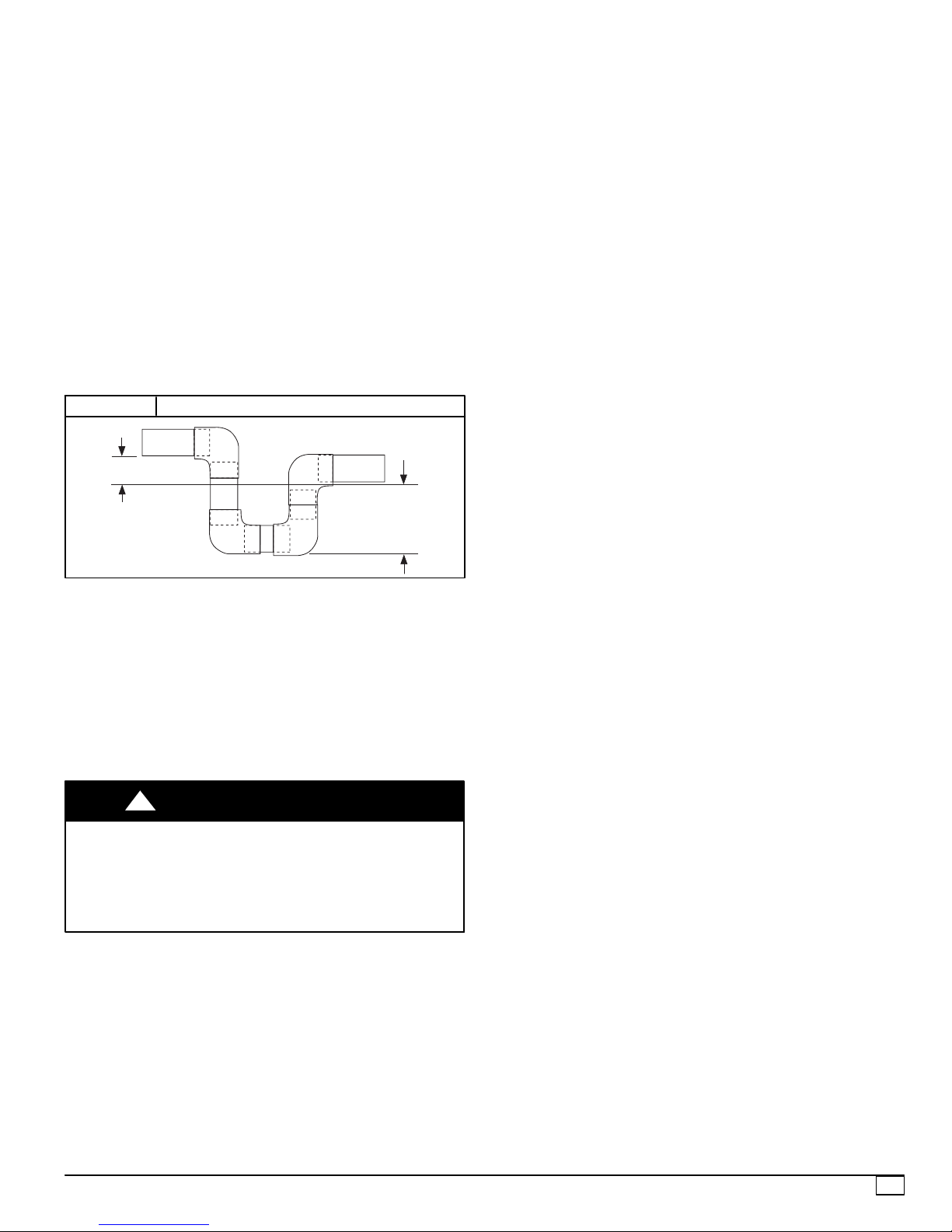

STEP 6 — Connect Condensate Drain

NOTE: When installing condensate drain connection be sure to

comply with local codes and restrictions.

Unit disposes of condensate water through a 3/4 in. NPT fitting

which exits through the base on the evaporator coil access side.

See Fig. 3 & 4 for location.

Condensate water can be drained directly onto the roof in rooftop

installations (where permitted) or onto a gravel apron in ground

level installations. Install a field−supplied 2−in. (51 mm)

condensate trap at the end of condensate connection to ensure

proper drainage. Make sure that the outlet of the trap is at least 1

in. (25 mm) lower than the drain−pan condensate connection to

prevent the pan from overflowing (See Fig. 7). Prime the trap

with water. When using a gravel apron, make sure it slopes away

from the unit.

Connect a drain tube using a minimum of 3/4−in. PVC or 3/4−in.

copper pipe (all field−supplied) at the outlet end of the 2−in. (51

mm) trap. Do not undersize the tube. Pitch the drain tube

downward at a slope of at least 1−in. (25 mm) for every 10 ft (3.1

m) of horizontal run. Be sure to check the drain tube for leaks.

FIGURE 7

1-in. (25 mm) min.

Condensate Trap

TRAP

OUTLET

2-in. (51 mm) min.

STEP 7 — Install Flue Hood

The flue assembly is secured and shipped in the return air duct.

Remove duct cover to locate the assembly (See Fig. 9).

NOTE:Dedicated low NOx models MUST be installed in

California Air Quality Management Districts where a Low NOx

rule exists.

These models meet the California maximum oxides of nitrogen

(NOx) emissions requirements of 40 nanograms/joule or less as

shipped from the factory.

NOTE:Low NOx requirements apply only to natural gas

installations.

!

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

The venting system is designed to ensure proper venting. The

flue hood assembly must be installed as indicted in this section

of the unit installation instructions.

Install the flue hood as follows:

1. This installation must conform with local building codes

and with NFPA 54/ANSI Z223.1 National Fuel Gas Code

(NFGC), (in Canada, CAN/CGA B149.1, and B149.2)

latest revision. Refer to Provincial and local plumbing or

wastewater codes and other applicable local codes.

2. Remove flue hood from shipping location (inside the return

section of the blower compartment−see Fig. 9). Remove

the return duct cover to locate the flue hood. Place flue

hood assembly over flue panel. Orient screw holes in flue

hood with holes in the flue panel.

3. Secure flue hood to flue panel by inserting a single screw

on the top flange and the bottom flange of the hood.

Step 8 — Install Gas Piping

The gas supply pipe enters the unit through the access hole

provided. The gas connection to the unit is made to the 1/2−in.

(12.7 mm) FPT gas inlet on the gas valve.

Install a gas supply line that runs to the heating section. Refer to

the NFGC for gas pipe sizing. Do not use cast−iron pipe. It is

recommended that a black iron pipe is used. Check the local

utility for recommendations concerning existing lines. Size gas

supply piping for 0.5 in. wc maximum pressure drop. Never use

pipe smaller than the 1/2−in. (12.7 mm) FPT gas inlet on the unit

gas valve.

For natural gas applications, the gas pressure at unit gas

connection must not be less than 4.0 in. wc or greater than 13 in.

wc while the unit is operating. For propane applications, the gas

pressure must not be less than 11.0 in. wc or greater than 13 in.

wc at the unit connection.

A 1/8−in. (3.2 mm) NPT plugged tapping, accessible for test

gauge connection, must be installed immediately upstream of the

gas supply connection to the gas valve.

When installing the gas supply line, observe local codes

pertaining to gas pipe installations. Refer to the NFPA 54/ANSI

Z223.1 latest edition (in Canada, CAN/CGA B149.1).

NOTE:In the state of Massachusetts:

1. Gas supply connections MUST be performed by a

licensed plumber or gas fitter.

2. When flexible connectors are used, the maximum length

shall not exceed 36 inches (915 mm).

3. When lever handle type manual equipment shutoff valves

are used, they shall be T−handle valves.

4. The use of copper tubing for gas piping is NOT approved

by the state of Massachusetts.

In the absence of local building codes, adhere to the following

pertinent recommendations:

1. Avoid low spots in long runs of pipe. Grade all pipe 1/4 in.

(6.35 mm) for every 15 ft (4.6 m) of length to prevent

traps. Grade all horizontal runs downward to risers. Use

risers to connect to heating section and to meter.

2. Protect all segments of piping system against physical and

thermal damage. Support all piping with appropriate

straps, hangers, etc. Use a minimum of one hanger every

6 ft (1.8 m). For pipe sizes larger than 1/2 in., follow

recommendations of national codes.

3. Apply joint compound (pipe dope) sparingly and only to

male threads of joint when making pipe connections. Use

only pipe dope that is resistant to action of liquefied

petroleum gases as specified by local and/or national

codes. Never use Teflon tape.

4. Install sediment trap in riser leading to heating section

(See Fig. 8). This drip leg functions as a trap for dirt and

condensate.

5. Install an accessible, external, manual main shutoff valve

in gas supply pipe within 6 ft (1.8 m) of heating section.

6. Install ground−joint union close to heating section between

unit manual shutoff and external manual main shut−off

valve.

7. Pressure test all gas piping in accordance with local and

national plumbing and gas codes before connecting piping

to unit.

8. Check for gas leaks at the field−installed and

factory−installed gas lines after all piping connections

have been completed. Use a commercially available soap

solution (or method specified by local codes and/or

regulations).

462 01 2103 01

11

Loading...

Loading...