Installation Instructions

WTA3 & PAT3 Series

PACKAGED AIR CONDITIONER

TABLE OF CONTENTS

Page

SAFE INSTALLATION REQUIREMENTS 2........

INTRODUCTION 2.............................

RECEIVING AND INSTALLATION 2...............

Check Equipment 2...........................

Provide Unit Support 2 -- 3.....................

Install Duct Connections 3.....................

Dimensions 4................................

Connect Condensate Drain 5..................

Install Electrical Connections 5 -- 10............

PRE--START--UP 11............................

START--UP 11..................................

Check for Refrigerant Leaks 11.................

Start--Up Cooling & Make Adjustments 11 -- 12..

Check and Adjust Charge 12 -- 14............

Airflow 15..................................

Sequence of Operation 15 -- 16..............

Page

MAINTENANCE 16.............................

Air Filter 16..................................

Unit Top Removal 16..........................

Indoor Blower and Motor 17....................

Outdoor & Indoor Coil, Condensate Drain Pan 17.

Outdoor Fan 17..............................

Electrical Controls and Wiring 18...............

Refrigeration Circuit 18........................

Evaporator Airflow 18.........................

Metering Devices 18..........................

Liquid Line Strainers 18.......................

High Flow Valves 18..........................

AIRFLOW CHARTS 19 -- 20.....................

COOLING TROUBLESHOOTING GUIDE 21.......

CHECKLIST FORM 22..........................

International Comfort Products, LLC

Lewisburg, TN. 37091

Printed in U.S.A.

426 01 1302 00 11--18--08

SAFE INSTALLATION REQUIREMENTS

FIGURE 1

Installation and servicing of this equipment can be

hazardous due to mechanical and electrical components.

Only trained and qualified personnel should install, repair,

or service this equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning and replacing air filters. All other

operations must be performed by trained service

personnel. When working on this equipment, observe

precautions in the literature, on tags, andon labels attached

to or shipped with the unit and other safety precautions that

may apply.

Follow all safety codes. Installation must be in compliance

with local andnational building codes.Wear safety glasses,

protective clothing, and work gloves. Have fireextinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions included in literature and attached to

the unit.

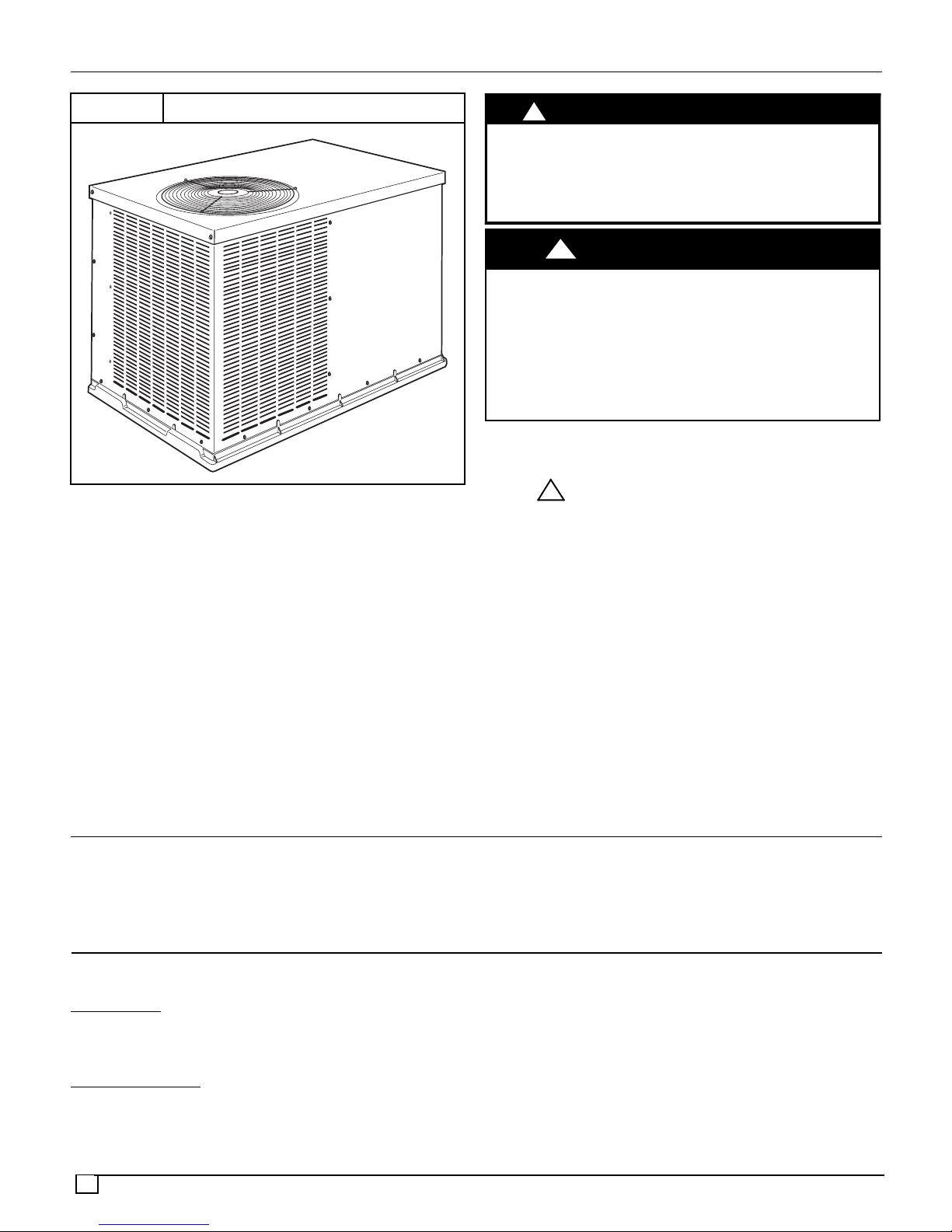

PACKAGED AIR CONDITIONER

!

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing and gloves when

handling parts.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power

switch if applicable. TAG DISCONNECT SWITCH

WITH LOCKOUT TAG.

Recognize safety information. This is the safety--alert

symbol . When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

!

CAUTION

WARNING

INTRODUCTION

The packaged unit is a fully self--contained air conditioner

designed for outdoor installation (see Figure 3 for unit

dimensions). All unit sizes have return and discharge

openings for horizontal airflow.

RECEIVING AND INSTALLATION

STEP 1 — Check Equipment

Identify

The unit model number and serial number are stamped on

the unit information plate. Check this information against

shipping papers.

Inspect

Inspect for shipping damage while unit is still on shipping

pallet. If unit appears to be damaged or is torn loose from

its anchorage, have it examined by transportation

inspectors before removal.Forward claim papers directly to

2

Unit

Shipment

Units may be installed either on a rooftop, ground level

cement slab, or directly on the ground if local codes allow.

transportation company. Manufacturer is not responsible

for any damage incurred in transit. Check all items against

shipping list. Immediately notify the nearest equipment

distribution office if any item is missing. To prevent loss or

damage, leave all parts in original packages until

installation.

STEP 2 — Provide Unit Support

For hurricane tie downs, contact distributor for details and

PE (Professional Engineering) Certificate, if required.

Slab Mount

Place the unit on a solid, level concrete pad that is a

minimum of 4” (102mm) thick with 2” (51mm) above grade.

The slab should extend approximately 2” (51mm) beyond

the casing on all 4 sides of the unit. Do not secure the unit

to the slab except when required by local codes.

A 6” (152mm) wide gravel apronshould be used around the

flat surface to prevent airflow blockage by grass or shrubs.

The unit should be level within ¼”. This is necessary for the

unit drain to function properly.

Ground

Mount

The unit may be installed either on a slab or placed

directly on the ground, if local codes permit. Place the

unit on level ground prepared with gravel for condensate

discharge.

STEP 3 — Provide Clearances

The required minimum operating and service clearances

are shown in Figure 3. Adequate ventilation and condenser

air must be provided.

NOTE: Do not restrict outdoor airflow. An air restriction at

either the outdoor--air inlet or the fan discharge may be

detrimental to compressor life.

The condenser fan pulls air through the condenser coil and

discharges it through the top grille. Be sure that the fan

discharge does not recirculate to the condenser coil. Do not

locate the unit in either a corner or under an overhead

obstruction. The minimum clearance under a partial

overhang (such as a normal house overhang) is 48”

(1219mm). above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48”

(1219mm).

Do not place the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit. Do not install

the unit on carpeting or other combustible materials.

Slab--mounted units should be at least 4” (102mm) above

the highest expected water and runoff levels. Do not use

unit if it has been under water.

Adhere to the following criteria when selecting, sizing, and

installing the duct system:

1. All units should have field--supplied filters installed in

the return--air side of the unit. Recommended sizes for

filters are shown in Table 1.

2. Avoid abrupt duct size increases and reductions.

Abrupt change in duct size adversely affects air

performance.

3. Size ductwork for cooling air quantity (CFM). The

minimum air quantity for proper electric heater

operation is listed in Table 10. Heater limit switches may

trip at air quantities below those recommended.

4. Seal, insulate, and weatherproof all external ductwork.

Seal, insulate and cover with a vapor barrier all

ductwork passing through conditioned spaces. Follow

latest Sheet Metal and Air Conditioning Contractors

National Association (SMACNA) and Air Conditioning

Contractors Association (ACCA) minimum installation

standards for residential heating and air conditioning

systems.

5. Secure all ducts to building structure. Flash,

weatherproof, and vibration--isolate duct openings in

wall or roof according to good construction practices.

6. Flash, weatherproof, and vibration isolate all openings

in building structure in accordance with local codesand

good building practices.

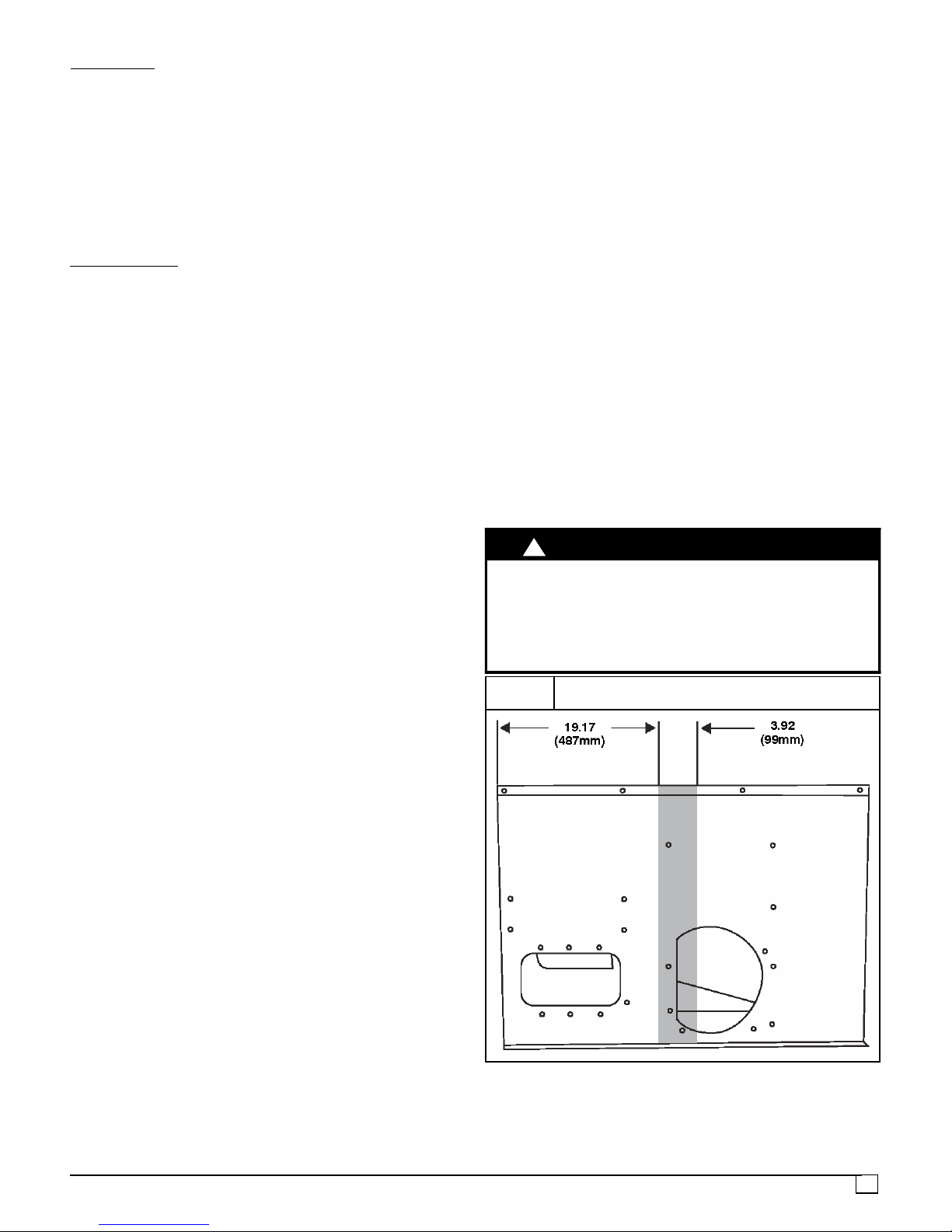

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit

components.

When connecting ductwork to unit, do not drill deeper than

¾” (19mm) in shaded area shown in Figure 2 or coil may be

damaged.

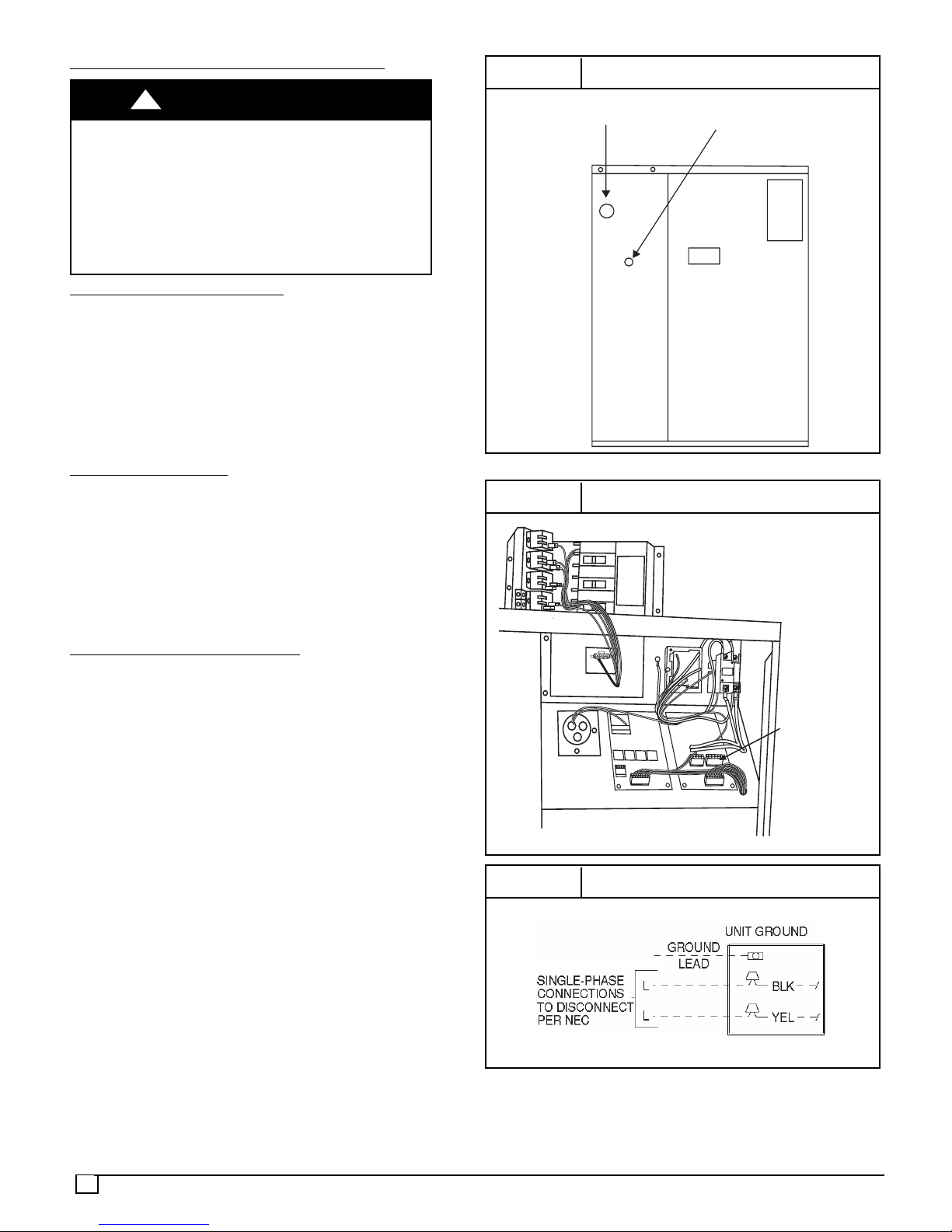

FIGURE 2

Do Not Drill Shaded Area Deeper Than ¾” (19mm)

CAUTION

STEP 4 — Install Duct Connections

The design and installation of the duct system must be in

accordance with the standards of the NFPA for

installation of non--residence type air conditioning and

ventilating systems, NFPA 90A or residence type, NFPA

90B and/or local codes and ordinances.

Select and size ductwork, supply air registers, and return

air grilles according to ASHRAE (American Society of

Heating, Refrigeration, and Air Conditioning Engineers)

recommendations.

Use the duct flanges provided on the supply and return

openings on theside of the unit. See Figure 3 for connection

sizes and locations. The 14” (356mm) round duct collars

are shipped inside the unit attached to the base pan in the

indoor blower compartment. They are for field installation

and must be removed from the indoor blower compartment

prior to start--up, even if they are not used for installation.

3

FIGURE 3

UNIT DIMENSIONS

Model

Size

24 208/230--1--60 268 121.6 30.13 [765] 14.0 [356] 19.0 [483] 15.0 [381]

30 208/230--1--60 299 135.6 34.13 [867] 14.0 [356] 19.0 [483] 16.0 [406]

36 208/230--1--60 352 159.7 42.13 [1070] 14.0 [356] 19.0 [483] 19.8 [503]

42 208/230--1--60 364 165.1 42.13 [1070] 14.0 [356] 19.0 [483] 21.9 [556]

48 208/230--1--60 359 162.8 42.13 [1070] 14.0 [356] 19.0 [483] 19.8 [503]

60 208/230--1--60 408 185.1 42.13 [1070] 14.0 [356] 19.0 [483] 21.9 [556]

ELECTRICAL

CHARACTERISTICS

UNIT WEIGHT

lbs kg X Y Z

UNIT

HEIGHT

in. [mm]

“A”

CENTER OF GRAVITY

inches [mm]

Table 1—Filter Data -- Throw--away Type

MODEL SIZE: 24, 30, 36 42, 48, 60

RETURN--AIR FILTER*

inches (mm)

24x24x1

(610x610x25)

30x30x1

(762x762x25)

* Required filter sizes shown are based on the larger of the

ARI (Air Conditioning and Refrigeration Institute) rated

cooling airflow or the heating airflow velocity of 300 feet per

minute for throwaway type or 450 feet per minute for

high--capacity type. Air filter pressure drop for

non--standard filters must not exceed 0.08 inches water

column.

4

STEP 5 — Connect Condensate Drain

NOTE: When installing condensate drain connection be

sure to comply with local codes and restrictions.

The packaged unit disposes of condensate water through

a w” NPT fitting which exits through the base on the

evaporator coil access side. See Figure 3 for location.

Condensate water can be drained directly onto the roof in

rooftop installations (where permitted) or onto a gravel

apron in ground level installations.Install a field--supplied 2”

(51mm) condensate trap at the end of condensate

connection to ensure proper drainage. Make sure that the

outlet of the trap is at least 1” (25mm) lower than the

drain--pan condensate connection to prevent the pan from

overflowing (see Figure 4). Prime the trap with water. When

using a gravel apron, make sure it slopes away from the

unit.

Connect a drain tube using a minimum of w” PVC or w”

copper pipe (all field--supplied) at the outlet end of the 2”

(51mm) trap. Do not undersize the tube. Pitch the draintube

downward at a slope of at least 1” (25mm). for every 10 feet

(3.0m) of horizontal run. Be sure to check the drain tube for

leaks.

FIGURE 4

Condensate Drain

!

UNIT COMPONENT DAMAGE HAZARD

Failure to follow this caution may result in damage to the

unit being installed.

1. Make all electrical connections in accordance with

NEC NFPA 70 (latest edition) and local electrical

codes governing such wiring. In Canada, all

electrical connections must be in accordance with

CSA standard C22.1 Canadian Electrical Code Part

1 and applicable local codes. Refer to unit wiring

diagram.

2. Use only copper conductor for connections between

field--supplied electrical disconnect switch and unit.

DO NOT USE ALUMINUM WIRE.

3. Be sure that high--voltage power to unit is within

operating voltage range indicated on unit rating

plate. Consult local power company for correction of

improper voltage and/or phase imbalance.

4. Insulate low--voltage wires for highest voltage

contained within conduit when low--voltage control

wires are in same conduit as high--voltage wires.

5. Do not damage internal components when drilling

through any panel to mount electrical hardware,

conduit, etc.

CAUTION

1” Min.

(25.4mm)

STEP 6 — Install Electrical Connections

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

The unit cabinet must have an uninterrupted, unbroken

electrical ground. This ground may consist of an

electrical wire connected to the unit ground screw in the

control compartment, or conduit approved for electrical

ground when installed in accordance with NEC, NFPA 70

National Fire Protection Association (latest edition) (in

Canada, Canadian Electrical Code CSA C22.1) and

local electrical codes.

WARNING

2” Min.

(51 mm)

High Voltage Connections

The unit must have a separate electrical service with a

field--supplied, waterproof disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate,NEC

and local codes for maximum fuse/circuit breaker size and

minimum circuit amps (ampacity) for wire sizing.

The field--supplied disconnect switch box may be mounted

on the unit over the high--voltage inlet hole when the

standard power and low--voltage entry points are used (see

Figure 3 and 5 for acceptable location).

When routing power leads into unit, use only copper wire

between disconnect and unit. The high voltage leads

should be in a conduit until they enter the duct panel;

conduit termination at the duct panel must be watertight.

See unit wiring label and Figures 10 -- 13 for reference when

making high voltage connections. Proceed as follows to

complete the high--voltage connections to the unit.

Single--phase units:

1. Run the high--voltage (L1, L2) and ground lead into the

control box.

2. Connect ground lead to chassis ground connection.

3. Locate the black and yellow wires connected to the line

side of the contactor.

4. Connect field L1 to black wire on connection 11 of the

compressor contactor.

5. Connect field wire L2 to yellow wire on connection 23 of

the compressor contactor.

5

Special Procedures For 208 Volt Operation

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. with disconnect switch open,

move black wire from transformer (x””) terminal marked

230 to terminal marked 208. This re--taps transformer to

primary voltage of 208 VAC.

WARNING

Control Voltage Connections

Do not use any type of power--stealing thermostat. Unit

control problems may result.

Use no. 18 American Wire Gage (AWG) color--coded,

insulated (35_C minimum) wires to make the control

voltage connections between the thermostat and the unit.

If the thermostat is located more than 100 feet from the unit

(as measured along the control voltage wires), use no. 16

AWG color--coded, insulated (35_C minimum) wires.

Standard

Connection

Form a drip--loop with the thermostat leads before routing

them into the unit. Route the thermostat leads through

grommeted hole provided in unit into unit control box (see

Figure 8). Connect thermostat leads and unit power leads

as shown in Figures 7, 8, and 9.

The unit transformer supplies 24 VAC power for the

complete system including accessory electrical heater.

Transformer is factory wired for 230 Volt operation.

Accessory Electric Heat W

iring

Refer to accessory electric heat installation instructions for

information on installingaccessory electric heat. Accessory

electric heat wiring is shown in Figure 12.

FIGURE 5

HIGH-VOLTAGE POWER

WIRING ENTRY HOLE

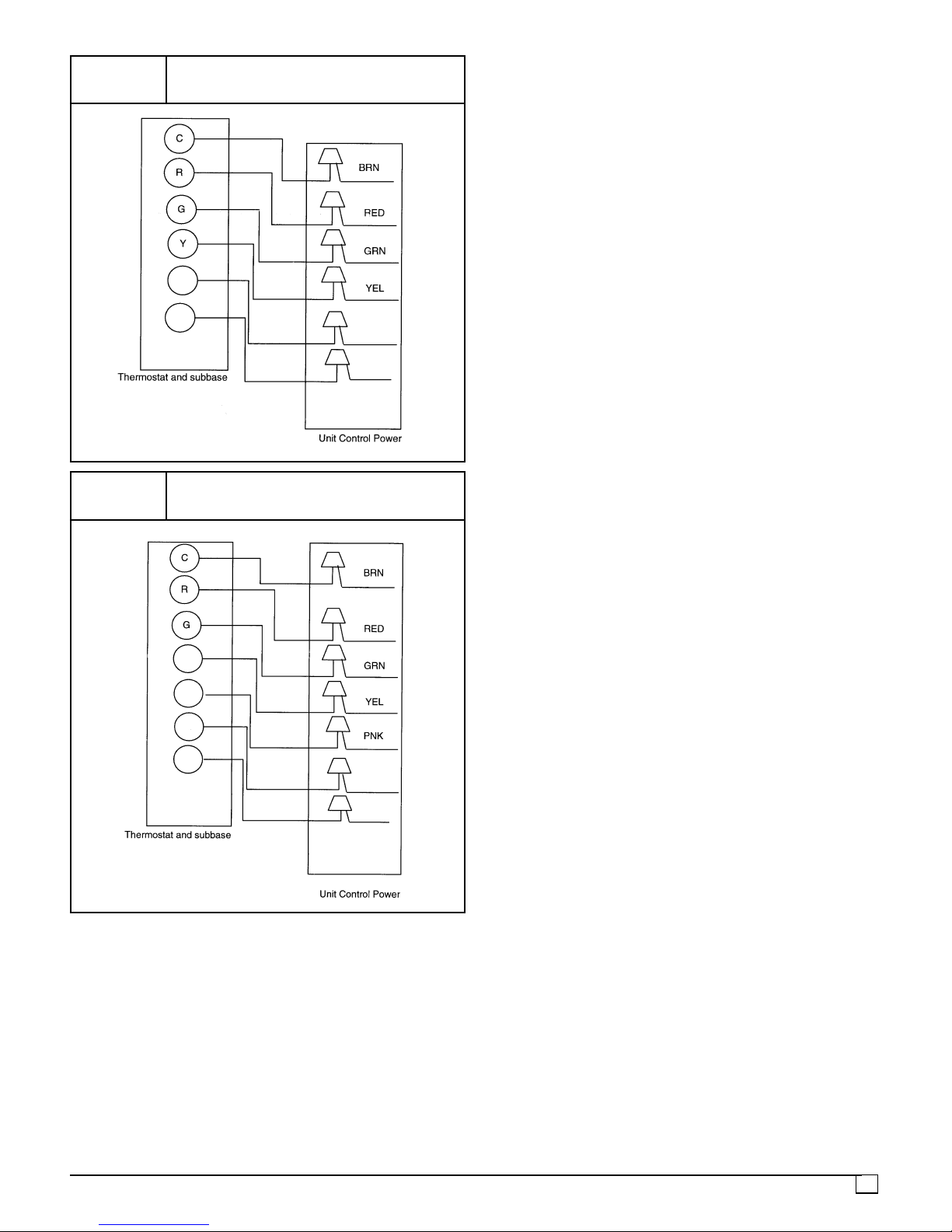

FIGURE 6

Electrical Entry Locations

LOW-VOLTAGE WIRING

ENTRY HOLE

Control Box Wiring

HEATER LOW

VOLTAGE PLUG

6

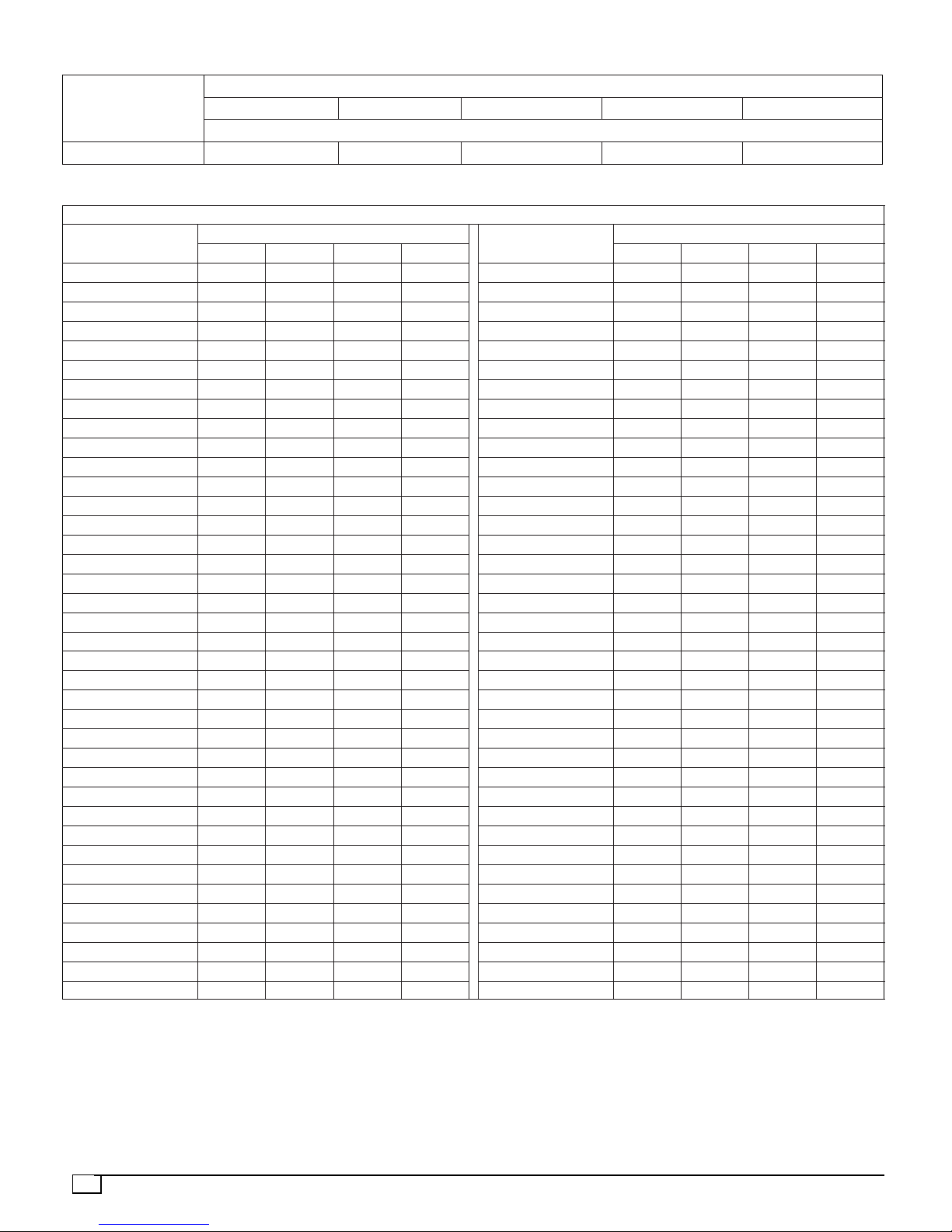

FIGURE 7

High Voltage (Line) Connections

FIGURE 8

Low Voltage (Control) Connections,

Model Sizes 24, 30, 36, 42, 48

W2

FIGURE 9

W3

WHT

VIO

Low Voltage (Control) Connections,

Model Size 60

Y1

Y2

W2

W3

WHT

VIO

7

FIGURE 10 208/230 -- 1 -- 60 WIRING DIAGRAM, MODEL SIZES 24, 30, 36, 42, 48

8

FIGURE 11 208/230 -- 1 -- 60 WIRING DIAGRAM, MODEL SIZE 60

9

FIGURE 12 ACCESSORY ELECTRIC HEATER WIRING DIAGRAM

Single--Phase

10

PRE--STARTUP

!

WARNING

ENVIRONMENTAL, FIRE, EXPLOSION,

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death and/or property damage.

1. Follow recognized safety practices and wear

protective goggles when checking or servicing

refrigerant system.

2. Relieve and recover all refrigerant from system

before touching or disturbing anything inside

terminal box if refrigerant leak is suspected around

compressor terminals.

3. Never attempt to repair soldered connection while

refrigerant system is under pressure.

4. Do not use torch to remove any component.

System contains oil and refrigerant under

pressure.

5. To remove a component, wear protective goggles

and proceed as follows:

a. Shut off electrical power to unit and install

lockout tag.

b. Relieve and reclaim all refrigerant from

system using both high-- and low--pressure

ports.

c. Cut component connecting tubing with

tubing cutter and remove component from

unit.

d. Carefully unsweat remaining tubing stubs

when necessary. Oil can ignite when

exposed to torch flame.

Use the Start--Up Checklist supplied at the end of this book

and proceed as follows to inspect and prepare the unit for

initial start--up:

1. Remove all access panels.

2. Read and follow instructions on all DANGER,

WARNING, CAUTION, and INFORMATION labels

attached to, or shipped with unit.

3. Make the following inspections:

a. Inspect for shipping and handling damage, such as

broken lines, loose parts, disconnected wires, etc.

b. Inspect for oil at all refrigerant tubing connections

and on unit base. Detecting oil generally indicates

a refrigerant leak.

c. Leak--test all refrigerant tubing connections using

electronic leak detector, or liquid--soap solution. If

a refrigerant leak is detected, see following Check

for Refrigerant Leaks section.

d. Inspect all field-- and factory--wiring connections.

Be sure that connections are completed and tight.

e. Ensure wires do not touch refrigerant tubing or

sharp sheet metal edges.

f. Inspect coil fins. If damaged during shipping and

handling, carefully straighten fins with a fin comb.

4. Verify the following conditions:

a. Ensure fan hub is positioned correctly with respect

to motor housing.

b. Make sure that air filter(s) is in place.

c. Make sure that condensate drain trap is filled with

water to ensure proper drainage.

d. Make sure that all tools and miscellaneous loose

parts have been removed.

STARTUP

STEP 1 — Check for refrigerant leaks

Proceed as follows to locate and repair a refrigerant leak

and to charge the unit:

1. Locate leak and make sure that refrigerant system

pressure has been relieved and reclaimed from both

high-- and low--pressure ports.

2. Repair leak following accepted practices.

NOTE: Install a filter drier whenever the system has been

opened for repair.

3. Add a small charge of R--22 refrigerant vapor to system

and leak--test unit.

4. Recover refrigerant from refrigerant system and

evacuate to 500 microns if no additional leaks are

found.

5. Charge unit with R--22 refrigerant, using a volumetric

charging cylinder or accurate scale. Refer to unit rating

plate for required charge. Be sure to add extra

refrigerant to compensate for internal volume of filter

drier.

STEP 2 — Start--up cooling and make adjustments

Complete the required procedures given in the

Pre--Start--Up section before starting the unit. Do not

jumper any safety devices when operating the unit. Do not

operate the compressor when the outdoor temperature is

below 40° F(4.4° C). Do not rapid--cycle the compressor.

Allow 5 minutes between on cycles to prevent compressor

damage.

!

EXPLOSION AND ENVIRONMENTAL HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

System under pressure. Relieve pressure and recover

all refrigerant before system repair or final unit disposal.

Use all service ports and open all flow--control devices,

including solenoid valves.

WARNING

Check Cooling Control Operation

Start and check the unit for proper cooling control operation

as follows:

1. Place room thermostat SYSTEM switch in OFF

position. Observe that blower motor starts when FAN

switch is placed in ON position and shuts down when

FANswitchisplacedinAUTOposition.

2. Place SYSTEM switch in COOL position and FAN

switch in AUTO position. Set cooling control below

11

room temperature. Observe that compressor,

condenser fan, and evaporator blower motors start.

Observe that cooling cycle shuts down when control

setting is satisfied. The evaporator fan will continue to

run for 30 seconds.

Checking and Adjusting Refrigerant

The refrigerant system is fully charged with R--22

refrigerant and is tested and factory sealed.

NOTE:Adjustment of the refrigerant charge is not required

unless the unit is suspected of not having the proper R--22

charge.

An accurate thermocouple or thermistor type

thermometer and a gauge manifold are required when

using the subcooling charging method for evaluating the

unit charge. Do not use mercury or small dial--type

thermometers because they are not adequate for this

type of measurement.

NOTE: Allow system to operate a minimum of 15 minutes

before checking or adjusting charge.

Model Sizes 24, 30, 36, 42, and

Model Sizes 24, 30, 36, 42, and 48 have an orifice type

expansion device. Charge must be set using the

superheat method.

1. Remove cap from low--pressure service fittings.

2. Using hose with valve core depressor, attach

low--pressure gauge hose to low--pressure service

fitting.

3. Start unit in Cooling Mode and let unit run until

system pressures stabilize.

4. Measure and record the following:

a. Outdoor ambient--air temperature (dry bulb).

b. Suction (low--side) pressure (psig).

c. Suction line temperature.

5. Locate the measured suction line pressure in the top

row of Table 2 and the measured outdoor ambient

temperature in the left column of the table. Based on

the two values, determine the required suction line

temperature.

6. If the measured suction line temperature is greater

than the tabulated temperature, add charge to the

system. If the measured suction line temperature is

lower than the tabulated temperature, remove charge

from the system.

Model Size

Model Size 60 has a TXV expansion device. Charge

must be set using the subcooling method.

A subcooling charging chart is attached to the outside of

the service access panel. The chart includes the

required liquid line temperature at given discharge line

pressures and outdoor ambient temperatures.

Proceed as follows:

1. Remove cap from high and low--pressure service

fittings.

2. Using hoses with valve core depressors, attach high

and low--pressure gauge hose to high and

low--pressure service fittings.

3. Start unit in Cooling Mode and let unit run until system

pressures stabilize.

12

60:

Charge

48:

4. Measure and record the following:

a. Outdoor ambient--air temperature (dry bulb).

b. Liquid line temperature.

c. Discharge (high--side) pressure (psig).

d. Suction (low--side) pressure (psig) -- for reference

only.

5. Using “Sub--Cooling Charging Charts,” compare

outdoor--air temperature (dry bulb) with the discharge

line pressure (psig) to determine desired system

operating liquid line temperature (see Tables 3 and 4).

6. Compare actual liquid line temperature with desired

liquid line temperature. Using a tolerance of +/-- 2° F

(+/-- 1.1° C), add refrigerant if actual temperature is

higher than proper liquid line temperature, or remove

refrigerant if actual temperature is lower than desired

liquid line temperature.

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit

damage.

When evaluating the refrigerant charge, an indicated

adjustment to the specified factory charge must

always be very minimal. If a substantial adjustment is

indicated, an abnormal condition exists somewhere in

the cooling system, such as insufficient airflow across

either coil or both coils.

NOTE: If the problem causing the inaccurate readings is a

refrigerant leak, refer to the Check for Refrigerant Leaks

section.

CAUTION

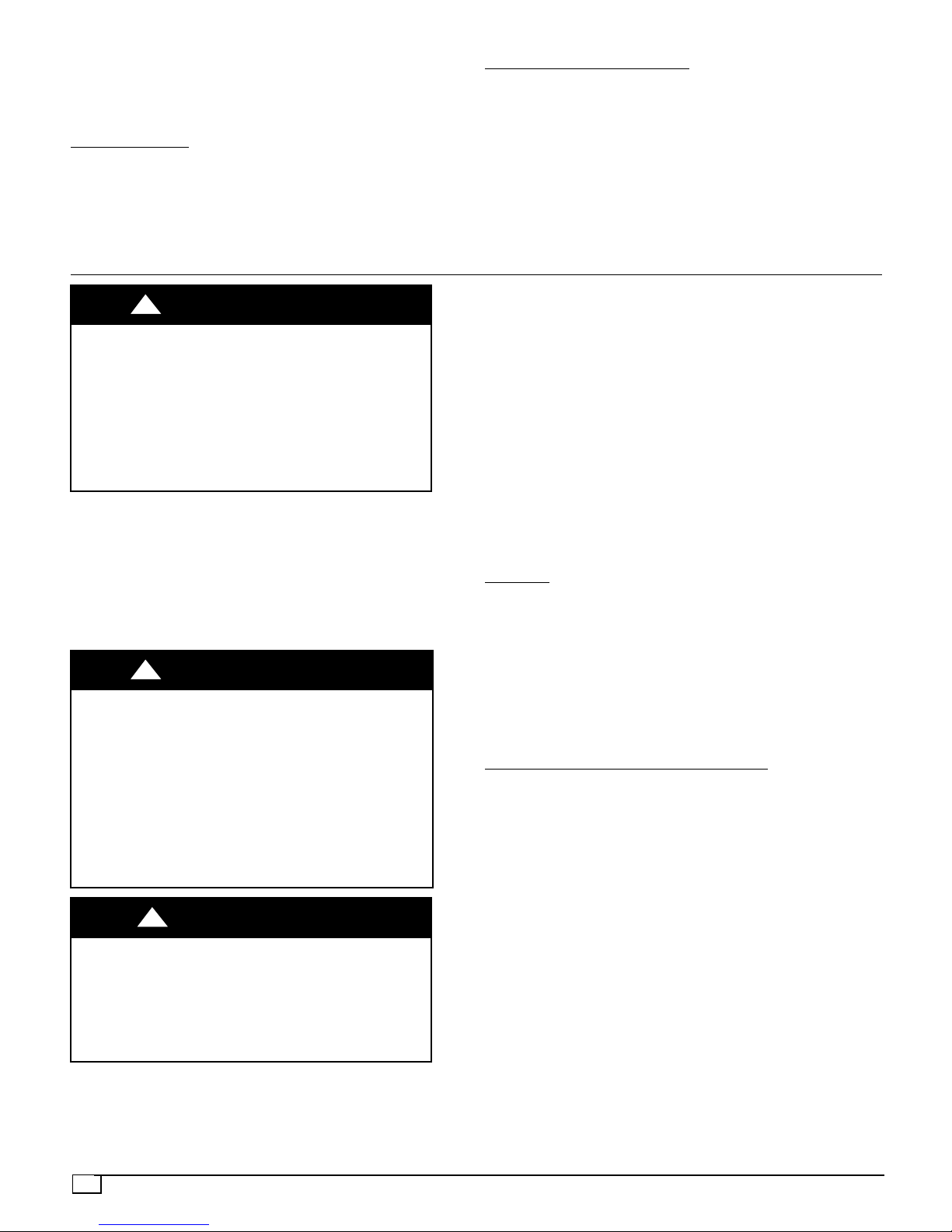

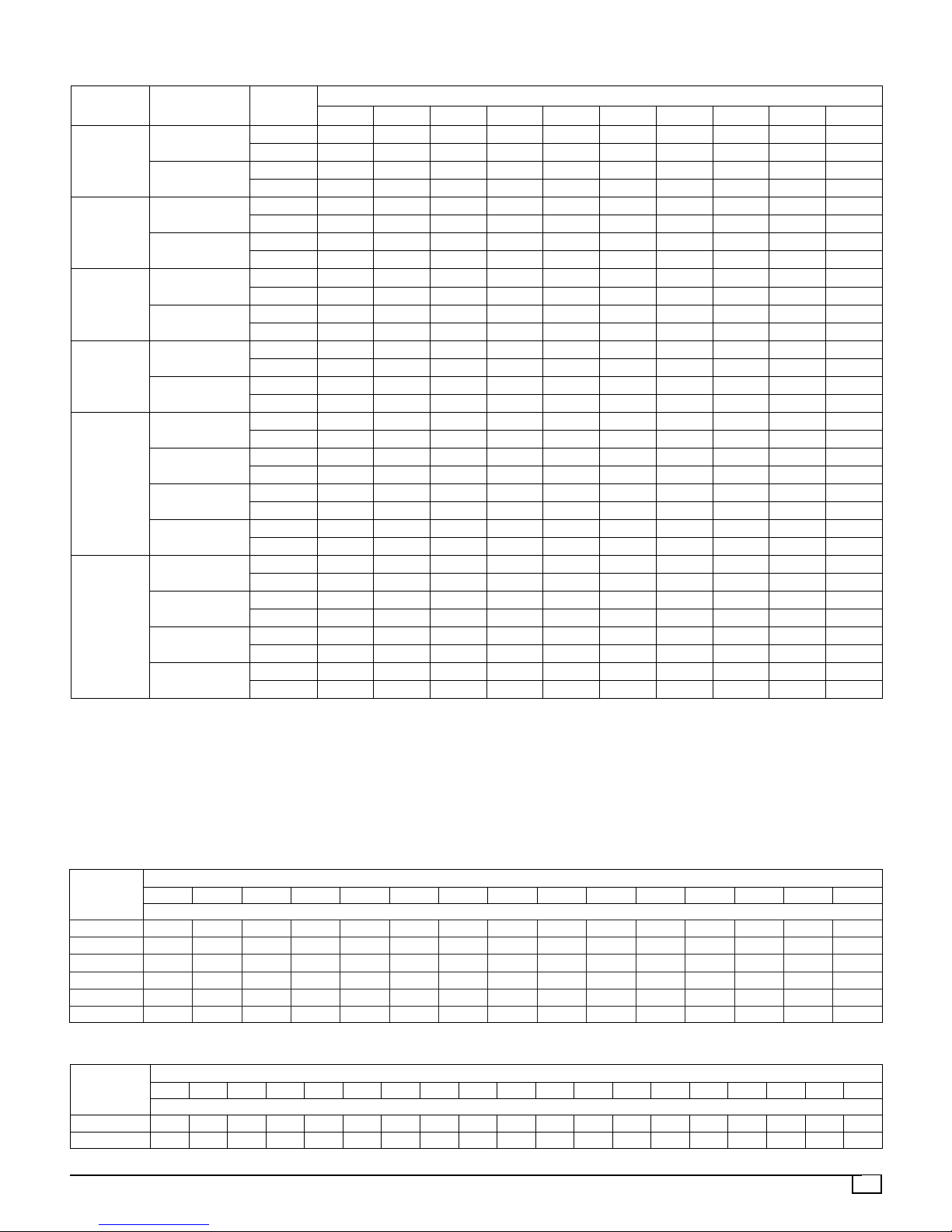

Table 2 -- Superheat Method, Sizes 24, 30 ,36, 42, and 48

Outdoor

Temperature

(°F)

45 51 55 60 64 69 — — — — — — — — — —

55 — — 53 57 62 66 70 — — — — — — — —

65 — — — — 53 57 62 66 71 75 — — — — —

75 — — — — — — — 56 61 66 71 76 — — —

85 — — — — — — — — 53 58 63 67 72 — —

95 — — — — — — — — — 50 54 58 62 66 —

105 — — — — — — — — — — 50 53 57 60 64

115 — — — — — — — — — — 49 52 55 58 61

125 — — — — — — — — — — — 50 53 56 59

Outdoor

Temperature

(°C)

7 11 13 15 18 21 — — — — — — — — — —

13 — — 12 14 16 19 21 — — — — — — — —

18 — — — — 12 14 17 19 21 24 — — — — —

24 — — — — — — — 13 16 19 22 24 — — —

29 — — — — — — — — 12 14 17 20 22 — —

35 — — — — — — — — — 10 12 14 17 19 —

41 — — — — — — — — — — 10 12 14 16 18

46 — — — — — — — — — — 9 11 13 14 16

52 — — — — — — — — — — — 10 11 13 15

52 54 56 59 61 64 67 70 73 76 79 82 85 89 92

361 370 387 405 423 442 462 482 502 523 544 566 589 612 636

Measured Suction Line Pressure (PSIG)

REQUIRED SUCTION LINE TEMPERATURE (°F)

Measured Suction Line Pressure (kPa)

REQUIRED SUCTION LINE TEMPERATURE (°C)

13

Table 3 -- Subcooling Method, Size 60

Outdoor Ambient Temperature °F(°C)

Model Size

75 (24) 82 (28) 85 (29) 95 (35) 105 (41)

REQUIRED SUBCOOLING °F(°C)

60 21 (11.7) 20.5 (11.4) 20 (11.1) 19 (10.6) 16 (8.9)

Table 4 -- Required Liquid Line Temperature

REQUIRED LIQUID LINE TEMPERATURE FOR A SPECIFIC SUBCOOLING (R-- 22)

Pressure (psi)

134 71 66 61 56 924 24 22 19 16

141 74 69 64 59 972 26 23 21 18

156 80 75 70 65 1075 30 27 24 21

163 83 78 73 68 1124 31 28 26 23

170 86 81 76 71 1172 33 30 27 24

177 89 84 79 74 1220 34 31 29 26

184 91 86 81 76 1268 36 33 30 27

191 94 89 84 79 1317 37 34 31 29

198 96 91 86 81 1365 38 36 33 30

205 98 93 88 83 1413 40 37 34 31

213 101 96 91 86 1468 41 38 36 33

221 104 99 94 89 1524 43 40 37 34

229 106 101 96 91 1579 44 41 38 36

237 108 103 98 93 1634 45 42 40 37

245 111 106 101 96 1689 47 44 41 38

253 113 108 103 98 1744 48 45 42 40

262 116 111 106 101 1806 49 46 44 41

271 118 113 108 103 1868 51 48 45 42

280 121 11 6 111 106 1930 52 49 46 44

289 123 11 8 11 3 108 1992 53 51 48 45

298 125 120 115 110 2054 55 52 49 46

307 128 123 118 113 2116 56 53 50 48

317 130 125 120 115 2185 57 54 52 49

327 132 127 122 117 2254 59 56 53 50

337 135 130 125 120 2323 60 57 54 52

347 137 132 127 122 2392 61 58 56 53

357 139 134 129 124 2461 62 60 57 54

367 142 137 132 127 2530 64 61 58 55

280 121 11 6 111 106 1930 52 49 46 44

289 123 11 8 11 3 108 1992 53 51 48 45

298 125 120 115 110 2054 55 52 49 46

307 128 123 118 113 2116 56 53 50 48

317 130 125 120 115 2185 57 54 52 49

327 132 127 122 117 2254 59 56 53 50

337 135 130 125 120 2323 60 57 54 52

347 137 132 127 122 2392 61 58 56 53

357 139 134 129 124 2461 62 60 57 54

367 142 137 132 127 2530 64 61 58 55

Required Subcooling (°F)

5 10 15 20 3 6 8 11

Pressure (kPa)

Required Subcooling (°C)

14

Indoor Airflow and Airflow Adjustments

NOTE: For cooling operation, the recommended airflow

is 350 to 450 CFM for each 12,000 BTU/h of rated

cooling capacity.

Table 6 shows cooling airflows at various external static

pressures. Refer tothis table to determine theairflow for the

system being installed.

NOTE: Be sure that all supply and return--air grilles are

open, free from obstructions, and adjusted properly.

!

WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect electrical power to the unit and install

lockout tag before changing blower speed.

Airflow can be changed by changing the lead connections

at the blower motor. To change motor speeds, reposition

wire at fan motor speed terminals labeled 1--2--3--4 (refer to

Figure 13).

Remove the speed tap connector labeled 1through 5 on the

motor. While looking at the connector end that is inserted

into the motor, gently pry the locking tab outward and

remove the wire from the connector. Insert the wire into the

desired tap until it locks into place. Be sure new airflow

meets the range noted above and minimum electric heat

CFM, if equipped. Refer to table 6 and table 10.

All model sizes are factory wired for rated airflow operation.

Figure 13

1234

Motor Speed Selection

STEP 3 — Unit Controls

All units have the following factory installed or

internal--protection controls.

Compressor High Pressure Relief V

This internal valve opens when the pressure differential

between the low and high side becomes excessive.

Loss of Charge

Located on the outdoor liquid line is a low--pressure switch

which functions as a loss--of--charge switch. This switch

contains a Schrader core depressor. This switch opens at

7 psig and closes at 22 psig. No adjustment is necessary.

Compressor

This internal overload interrupts power to the compressor

when either the current or internal temperature become

excessive, and automatically resets when the internal

temperature drops to a safe level.

This overload may require up to 60 minutes (or longer) to

reset. If the internal overload is suspected of being open,

disconnect the electrical power to the unit and check the

circuit through the overload with an ohmmeter or continuity

tester.

STEP 4 — Sequence of Operation

Operation

Fan

The FAN switch on the thermostat controls indoor fan

operation. When the FAN switch is placed in the ON

position, the IFR (indoor--fan relay) is energizedthrough the

G terminal on the thermostat. The normally--open contacts

close, which then provide power to the indoor (evaporator)

fan motor (IFM). The IFM will run continuously when the

FAN switch is set to ON.

When the FAN switch is set to AUTO, the thermostat

energizes the IFR only when there is a call for cooling or, if

the unit is equipped with accessory electric heat, the

indoor--fan motor will also run while the accessory electric

heat is energized.

NOTE: Some units are equipped with a time--delay relay.

On these units, the indoor fan remains on for 30 seconds

after G or Y is de--energized.

Switch

Overload

alve

Table 5 -- Motor Speed Taps

SIZE

24 Ta p 1 Ta p 3

30 Ta p 2 Ta p 4

36 Ta p 1 Ta p 3

42 Ta p 2 Ta p 4

48 Ta p 3 Ta p 4

SIZE

60 Ta p 1 Ta p 3 Ta p 2 Ta p 4

RATED AIRFLOW HIGH AIRFLOW

RATED AIRFLOW HIGH AIRFLOW

Low

Stage

High

Stage

Low

Stage

High

Stage

Cooling Operation (model sizes 24, 30, 36, 42,

With a call for cooling (Y/Y2), the indoor fan and contactor

energize immediately, starting the compressor and the

outdoor fan motor. When the cooling demand is met, Y/Y2

de--energizes, shutting off the compressor, indoor fan, and

the outdoor fan.

Cooling Operation (model size

This unit requires a 2--stage indoor thermostat. With a first

(low) stage call for cooling (Y1), the indoor fan (low stage

speed) and contactor energize immediately, starting the

compressor (low stage) and the outdoor fan motor. If the

first (low) stage operation cannot satisfy the cooling

demand, the second (high) stage cooling (Y2) energizes.

The compressor is switched into high stage cooling

(internal solenoid valve inside the compressor) and the

indoor fan switches to high stage speed. When second

stage cooling is satisfied, Y2 de--energizes switching the

60)

48)

15

compressor and indoor fan back to low stage

cooling/speed. When the low stage cooling demand is met,

Y1 de--energizes, shutting off the compressor, indoor fan,

and outdoor fan.

Continuous Fan

With the continuous Indoor fan option selected on the

thermostat, G is continuously energized. For model sizes

24, 30, 36, 42 and 48 the selected airflow setting is

provided. For model size 60, the systemruns low stage (Y1)

airflow for continuous fan operation.

MAINTENANCE

!

PERSONAL INJURY AND UNIT DAMAGE HAZARD

Failure to follow this warning could result in personal

injury or death and unit component damage.

The ability to properly perform maintenance on this

equipment requires certain expertise, mechanical skills,

tools and equipment. If you do not possess these, do not

attempt to perform any maintenance on this equipment,

other than those procedures recommended in the

Owner’s Manual.

To ensure continuing high performance and to minimize the

possibility of premature equipment failure, periodic

maintenance must be performed on this equipment. This

unit should be inspected at least once each year by a

qualified service person. To troubleshoot unit, refer to Table

11 -- Troubleshooting Guide.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

!

ELECTRICAL SHOCK HAZARD

Failure to follow these warnings could result in personal

injury or death:

1. Turn off electrical power to the unit beforeperforming

any maintenance or service on this unit. Install lockout tag.

2. Use extreme caution when removing panels and

parts.

3. Never place anything combustible either on or in

contact with the unit.

UNIT OPERATION HAZARD

Failure to follow this caution may result in improper

operation.

Errors made when reconnecting wires may cause

improper and dangerous operation. Label all wires prior

to disconnecting when servicing.

WARNING

WARNING

!

CAUTION

Electric Resistance Heating

Electric heaters are available as accessories and must be

field installed. On a call for “Emergency Heat” the

thermostat energizes W which energizes the heater relay

and in turn energizes the electric heaters. The IFR is

energized which starts the indoor--fan motor. If the heaters

are staged, W2 is energized when the second stage of

heating is required. When the need for heating is satisfied,

the heater and IFM are de--energized.

The minimum maintenance requirements for this

equipment are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain

each cooling season for cleanliness. Clean when

necessary.

3. Inspect blower motor and wheel for cleanliness at the

beginning of each cooling season. Clean when

necessary.

4. Check electrical connections for tightness and controls

for proper operation each cooling season. Service

when necessary.

5. Ensure electric wires are not in contact with refrigerant

tubing or sharp metal edges.

Air

Filter

NOTE: Never operate the unit without a suitable air filter in

the return--air duct system. Always replace the filter with the

same dimensional size and type as originally installed. See

Table 1 for recommended filter sizes.

Inspect air filter(s) at least once each month and replace

(throwaway--type) or clean (cleanable--type) at least twice

during each cooling season or whenever the filter becomes

clogged with dust and lint.

Unit Top Removal (Outdoor--Coil

NOTE: When performing maintenance or service

procedures that require removal of the unit top, be sure to

perform all of the routine maintenance procedures that

require top removal, including coil inspection and cleaning,

and condensate drain pan inspection and cleaning.

Only qualified service personnel should perform

maintenance and service procedures that require unit top

removal.

Refer to the following top removal procedures:

1. Remove screws on unit top cover surface. (Save all

screws.)

2. Remove screws on unit top cover flange. (Save all

screws.)

3. Lift top from unit carefully. Set top on edge and make

sure that top is supported by unit side that is opposite

duct (or plenum) side.

4. Carefully replace and secure unit top to unit, using

screws removed in Steps 1 and 2, when maintenance

and/or service procedures are completed.

Side)

16

Indoor Motor and Blower

NOTE: All motors are pre--lubricated. Do not attempt to

lubricate these motors.

For longer life, operating economy, and continuing

efficiency, clean accumulated dirt and grease from the

blower wheel and motor annually.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Disconnect and tag electrical power to the unit before

cleaning and lubricating the blower motor and wheel.

To clean the blower motor and wheel:

1. Remove the blower housing:

a. Remove the screws on the external side of the duct

panel that fasten the housing to the duct panel

assembly.

b. Remove the side access panel and unscrew the

mounting bracket that fastens the blower housing

to the internal partition panel fo the control box

assembly.

c. Make sure that the blower housing is supported by

hand before completely removing the mounting

bracket.

d. Slide the blower housing from the rails of the duct

panel and place it outside the unit.

2. Remove the blower wheel from the housing:

a. Loosen the set screw which secures the wheel to

the motor shaft.

b. Loosen the three mounting legs of the motor by

removing the bolts that fasten themounting legs to

the housing.

c. Slide out the motor assembly (motor, belly band

and the 3 mounting legs) from the hub of the wheel.

d. Remove the filler panel at the discharge end of the

blower housing by removing the two screws that

fasten it to the housing.

e. Remove the wheel form the housing.

3. Remove the cakedon dirt from the wheel and themotor

usingabrush.

4. Remove lint and dirt accumulations from the wheel and

housing with a vacuum cleaner, using a soft brush

attachment.

5. Remove grease and oil with a mild solvent.

6. Reassemble

a. Slip the wheel back in the housing with the hub set

screw parented in the correct direction.

b. Install the filler panel.

c. Reinsert the motor assembly in the wheel hub and

align the mounting legs with the housing mounting

hold locations.

d. Tighten the mounting bolts to fasten the motor

assembly with the housing.

e. Center the wheel in the housing by sliding it, align

the flat end of the shaft with the set screw and

tighten the set screw.

WARNING

f. Slide back the blower housing into the mounting

rails in the duct panel and install the mounting

bracket back in its position.

g. Install the screws on the external side of the duct

panel to fasten duct panel with the housing.

h. Replace the side access panel.

Outdoor Coil, Indoor Coil, and Condensate Drain

Inspect the condenser coil, evaporator coil, and

condensate drain pan at least once each year.

The coils are easily cleaned when dry; therefore, inspect

and clean the coils either before or after each cooling

season. Remove all obstructions, including weeds and

shrubs, that interfere with theairflow through the condenser

coil.

Straighten bent fins with a fin comb. Ifcoated with dirt or lint,

clean the coils with a vacuum cleaner, using the soft brush

attachment. Be careful not to bend the fins. If coated with oil

or grease, clean the coils with a mild detergent and water

solution. Rinse coils with clear water, using a garden hose.

Be careful not to splash water on motors, insulation, wiring,

or air filter(s). For best results, spray condenser coil fins

from inside to outside the unit. On units with an outer and

inner condenser coil, be sure toclean between the coils. Be

sure to flush all dirt and debris from the unit base.

Inspect the drain pan and condensate drain line when

inspecting the coils. Clean the drain pan and condensate

drain by removing all foreign matter from the pan. Flush the

pan and drain trough with clear water. Do not splash water

on the insulation, motor, wiring, or air filter(s). If the drain

trough is restricted, clear it with a “plumbers snake” or

similar probe device.

Outdoor

1. Remove 6 screws holding discharge grille and motor to

2. Turn motor/grille assembly upside down on top cover to

3. Inspect the fan blades for cracks or bends.

4. If fan needs to be removed, loosen setscrew and slide

5. When replacing fan blade, position blade so that the

6. Ensure that setscrew engages the flat area on the

7. Replace grille.

Fan

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to

unit components.

Keep the condenser fan free from all obstructions to

ensure proper cooling operation. Never place articles

on top of the unit.

top cover.

expose fan blade.

fan off motor shaft.

hub is 8” (3.2mm) away from the motorend (8” (3.2mm)

of motor shaft will be visible).

motor shaft when tightening.

Pan

17

Electrical Controls and Wiring

Inspect and check the electrical controls and wiring

annually. Be sure to turn off the electrical power to the unit.

Remove access panel to locate all the electrical controls

and wiring. Check all electrical connections for tightness.

Tighten all screw connections. If any smoky or burned

connections are noticed, disassemble the connection,

clean all theparts, re--strip the wire end and reassemblethe

connection properly and securely.

After inspecting the electrical controls and wiring, replace all

the panels. Start the unit, and observe at least one complete

cooling cycle to ensure proper operation. If discrepancies

are observed in operating cycle, or if a suspected

malfunction has occurred, check each electrical component

with the proper electrical instrumentation. Refer to the unit

wiring label when making these checks.

NOTE: Refer to the Cooling Sequence of Operation in this

document to understand proper control operation.

Refrigeration

Annually inspect all refrigerant tubing connections and

the unit base for oil accumulations. Detecting oil generally

indicates a refrigerant leak.

If oil is detected or if low cooling performance is

suspected, leak--test all refrigerant tubing using an

electronic leak--detector, halide torch, or liquid--soap

solution. If a refrigerant leak is detected, refer to the

Check for Refrigerant Leaks section.

If no refrigerant leaks are found and low cooling

performance is suspected, refer to the Checking and

Adjusting Refrigerant Charge section.

Circuit

Evaporator Airflow

The heating and/or cooling airflow does not require

checking unless improper performance is suspected. If a

problem exists, be sure that all supply-- and return--air

grilles are open and free from obstructions, and that the

air filter is clean. When necessary, refer to the Indoor

Airflow and Airflow Adjustments section to check the

system airflow.

Metering

Model sizes 24, 30, 36, and 42 use an orifice type

metering device.

Model sizes 48 and 60 use a hard shutoff, balance port

TXV. The TXV maintains a constant superheat at the

evaporator exit.

Liquid Line

The liquid line strainers (to protect metering devices) are

made of wire mesh and are located in the liquid lines on the

inlet side of the metering devices.

High Flow V

High flow valvesare located onthe compressor hot gas and

suction tubes. Large black plastic caps distinguish these

valves from the smaller service valves. These valves can

not be accessed for service in the field. Ensure the plastic

caps are in place and tight or the possibility of refrigerant

leakage could occur.

Devices

Strainers

alves

!

EXPLOSION, SAFETY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

System under pressure. Relieve pressure and recover all

refrigerant before system repair or final unit disposal. Use

all service ports and open all flow--control devices,

including solenoid valves.

WARNING

TROUBLESHOOTING

Use the Troubleshooting Guide (see Table 11) if problems occur with these units.

STARTUP CHECKLIST

Use Start--Up checklist to ensure proper start--up procedures are followed.

18

Table 6 -- Dry Coil Air Delivery*

Model

Size

24

30

36

42

48

60

Motor

Speed Tap

1

2

2

3

1

2

3

4

1

2

3

4

1

2

3

4

External Static Pressure (Inches Water Column)

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Watts — 99 100 118 130 142 — — — —

CFM — 848 793 757 698 632 — — — —

Watts — — — — — 222 233 244 257 260

CFM — — — — — 970 918 861 795 729

Watts — 155 146 157 170 — — — — —

CFM — 1108 995 951 884 — — — — —

Watts — — — — — 261 275 286 291 315

CFM — — — — — 1117 1053 1014 980 877

Watts 180 166 179 191 204 216 — — — —

CFM 1344 1215 1172 1136 1095 1051 — — — —

Watts — — — 261 276 290 301 316 329 342

CFM — — — 1343 1304 1272 1234 1190 1148 1100

Watts 269 283 305 321 336 349 360 — — —

CFM 1440 1404 1369 1333 1301 1273 1239 — — —

Watts — — 418 432 450 465 480 490 503 518

CFM — — 1572 1543 1504 1475 1441 1418 1380 1332

Watts — 204 209 216 229 236 249 — — —

CFM — 1129 1087 1027 994 932 881 — — —

Watts — — 233 245 254 266 276 289 — —

CFM — — 1164 1122 1066 1025 954 906 — —

Watts 386 398 409 418 425 435 438 441 451 —

CFM 1680 1652 1625 1583 1555 1515 1477 1444 1403 —

Watts — 440 448 457 462 469 477 480 485 486

CFM — 1745 1717 1684 1651 1612 1573 1537 1508 1470

Watts 224 235 251 266 277 291 298 — — —

CFM 1334 1288 1259 1224 1181 1157 1117 — — —

Watts — — 286 301 311 325 333 344 370 —

CFM — — 1333 1296 1261 1232 1199 1170 1062 —

Watts 608 626 643 660 668 685 697 — — —

CFM 1931 1900 1878 1844 1817 1789 1755 — — —

Watts 737 755 770 787 799 817 826 812 782 —

CFM 2093 2061 2028 2001 1971 1934 1899 1850 1757 —

* Air delivery values are without air filter and are for dry coil (See Wet Coil Pressure Drop table). Deduct

field--supplied air filter pressure drop and wet coil pressure drop to obtain external static pressure available for

ducting.

Notes:

1. Do not operate the unit at a cooling airflow that is less than 350 cfm for each 12,000 Btuh of rated cooling capacity.

Evaporator coil frosting may occur at airflows below this point.

2. Dashes indicate portions of table that are beyond the blower motor capacity or are not recommended.

Table 7 -- Wet Coil Pressure Drop

STANDARD CFM (S.C.F.M.)

MODEL

SIZE

24 .027 .034 040 .047 .053 -- -- -- -- -- -- -- -- -- -30 -- .036 .042 .050 .055 .063 .072 .081 -- -- -- -- -- -- -36 -- -- -- .050 .055 .063 .072 .081 .090 .097 -- -- -- -- -42 -- -- -- -- .042 .049 .052 .059 .065 .071 .078 .085 .091 -- -48 -- -- -- -- -- -- .072 .081 .090 .097 .108 .120 .129 .139 -60 -- -- -- -- -- -- -- -- -- .071 .078 .085 .091 .098 .114

600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000

Pressure Drop (inches water column)

Table 8 -- Filter Pressure Drop Table

CFM

500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

FILTER SIZE

24x24x1 0.06 0.07 0.08 0.08 0.09 0.09 0.09 0.10 0.11 0.12 0.14 0.15 — — — — — — —

30x30x1 — — — — — — — — 0.08 0.09 0.10 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18

Pressure Drop (inches water column)

19

Table 9 -- Accessory Electric Heater Pressure Drop Table

CFM

HEATER kW

600 800 1000 1200 1400 1600 1800 2000 2200

Pressure Drop (inches water column)

5--20 0.06 0.08 0.10 0.13 0.15 0.18 0.20 0.23 0.25

Table 10 -- Minimum Airflow for Safe Electric Heater Operation

Unit Size

5kW 7.5 kW 10 kW 15 kW 20 kW

Minimum Airflow (CFM)

24 400 550 650 -- -- -- -- -- --

30 450 600 800 850 -- -- --

36 450 600 800 850 900

42 450 600 800 850 900

48 450 600 800 850 900

60 450 600 800 850 900

20

SYMPTOM CAUSE REMEDY

Compressor and condenser

fan will not start.

Compressor will not start

but condenser fan runs

Compressor cycles (other

than normally satisfying

thermostat)

Compressor operates

continuously

Excessive head pressure

Head pressure too low

Excessive suction pressure

Suction pressure too low

Table 11 -- Troubleshooting Guide

Power failure Call power company

Fuse blown or circuit breaker tripped Replace fuse or reset circuit breaker

Defective contactor, transformer, or high--pres-

sure, loss--of--charge or low--pressure switch

Insufficient line voltage Determine cause and correct

Incorrect or faulty wiring Check wiring diagram and rewire correctly

Thermostat setting too high

Faulty wiring or loose connections in compressor circuit

Compressor motor burned out, seized, or Determine cause

internal overload open Replace compressor

Defective run/start capacitor, overload, start

relay

Low input voltage Determine cause and correct

Refrigerant overcharge or undercharge

Defective compressor Replace and determine cause

Insufficient line voltage Determine cause and correct

Blocked outdoor coil Determine cause and correct

Defective run/start capacitor Determine cause and replace

Faulty outdoor fan motor or capacitor Replace

Restriction in refrigerant system Locate restriction and remove

Dirty air filter Replace filter

Unit undersized for load Decrease load or increase unit size

Thermostat temperature set too low Reset Thermostat

Low refrigerant charge Locate leak, repair, and recharge

Air in system

Outdoor coil dirty or restricted Clean coil or remove restriction

Dirty air filter Replace filter

Dirty condenser coil Clean coil

Refrigerant overcharged Recover excess refrigerant

Air in system

Condenser air restricted or air short--cycling Determine cause and correct

Low refrigerant charge Check for leaks, repair, and recharge.

Restriction in liquid tube Remove restriction

High heat load Check for source and eliminate

Compressor valves leaking Replace compressor

Refrigerant overcharged Recover excess refrigerant

Dirty air filter Replace filter

Low refrigerant charge Check for leaks, repair and recharge

Metering device or low side restricted Remove source of restriction

Insufficient evaporator airflow

Temperature too low in conditioned area Reset Thermostat

Outdoor ambient below 55°F (12.7°C) Install low--ambient kit

Filter drier restricted Replace filter

Replace component

Lower Thermostat temperature setting below

room temperature

Check wiring and repair or replace

Determine cause and replace

Recover refrigerant, evacuate system, and

recharge to capacities shown on rating plate

Recover refrigerant, evacuate system, and

recharge

Recover refrigerant, evacuate system, and

recharge

Increase air quantity

Check filter–replace if necessary

21

START--UP CHECKLIST

(Remove and Store in Job File)

1. Preliminary Information

Model Number:

Serial Number:

Date:

Technician:

2. Pre--Start--Up

____ Verify that all packing materials have been removed from unit

____ Check all electrical connections and terminals for tightness

____ Check that the indoor (evaporator) air filter is clean and in place

____ Verify that the unit installation is level

____ Check blower (indoor) and propeller (outdoor) for location in housing/orifice (no rubs) and set screw tightness

3. Start--Up

Electrical

Supply Voltage (measured):

Compressor Amps (measured):

Indoor (evaporator) motor amps:

Temperatures

Outdoor (condenser) air temperature (dry bulb):

Indoor return air temperature: (dry bulb) (wet bulb):

Indoor supply air -- cooling: (dry bulb) (wet bulb):

Pressures

Refrigerant suction pressure during cooling (psi):

Refrigerant discharge pressure during cooling (psi):

____ Verify proper refrigerant charge using charging chart

22

Loading...

Loading...