International comfort products PAN324, PAN330, PAN336, PAN342, PAN348 Installation Instructions Manual

...

Installation Instructions

PAN3 Series

Single Phase

PACKAGED AIR CONDITIONERS

TABLE OF CONTENTS

Page

SAFE INSTALLATION REQUIREMENTS 2........

INTRODUCTION 2.............................

RECEIVING AND INSTALLATION 2...............

Check Equipment 2.............................

Provide Unit Support 2..........................

Provide Clearances 3...........................

Field Fabricate Ductwork 3.......................

Rig and Place Unit 3 -- 4.........................

Dimensions 5 -- 6...............................

Filter Data and Corner Weights 7.................

Connect Condensate Drain 8.....................

Install Duct Connections 8.......................

Install Electrical Connections 9 --10...............

PRE--START--UP 11............................

START--UP 11..................................

Check for Refrigerant Leaks 1 1...................

Start--Up Adjustments 11........................

Wiring Diagrams 12.............................

Checking and Adjusting Refrigerant Charge 13.....

Indoor Airflow and Airflow Adjustment 13...........

Cooling Sequence of Operation 13................

Cooling Charging Chart 14.......................

Wet Coil Air Delivery 14..........................

MAINTENANCE 15.............................

Air Filter 16....................................

Indoor Blower and Motor 16......................

Outdoor & Indoor Coil, & Condensate Drain Pan 16.

Outdoor Fan 16.................................

Electrical Controls and Wiring 17..................

Indoor Airflow 17................................

Metering Devices--Fixed Orifice 17................

TROUBLESHOOTING 18........................

START--UP CHECKLIST 19......................

Printed in U.S.A.

International Comfort Products, LLC

Lewisburg, TN. 37091

519 01 1701 01 01--28--08

SAFE INSTALLATION REQUIREMENTS

We require these instructions as a minimum for a safe

installation.

FIGURE 1

Installation and servicing of this equipment can be

hazardous due to mechanical and electrical components.

Only trained and qualified personnel should install, repair,

or service this equipment.

Untrained personnel can perform basic maintenance

functions such as cleaning and replacing air filters. All other

operations must be performed by trained service

personnel. When working on this equipment, observe

precautions in the literature, ontags, and on labels attached

to or shipped with the unit and other safety precautions that

may apply.

Follow all safety codes. Installation must be in compliance

with local and national building codes. Wear safety glasses,

protective clothing, and work gloves. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions included in literature and attached to

the unit.

Recognize safety information. This is the safety--alert

symbol . When you see this symbol in instructions or

manuals, be alert to the potential for personal injury.

Understand the signal words DANGER, WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in serious injury or death.

WARNING signifies a hazard which could result in serious

injury or death. CAUTION is used to identify unsafe

practices which may result in minor personal injury or

product and property damage. NOTE is used to highlight

suggestions which will result in enhanced installation,

reliability, or operation.

These instructions cover minimum requirements and

conform to existing national standards and safety codes. In

some instances, these instructions exceed certain local

codes and ordinances, especially those that may not have

kept up with changing residential construction practices.

!

PAN3 AIR CONDITIONING UNIT

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, turn off power

supply to the unit and install lockout tag. There may be

more than one disconnect switch. Turn off accessory

heater power switch if applicable.

INTRODUCTION

The PAN3 packaged air conditioner is fully self--contained

and designed for outdoor installation (see Fig. 1). See Fig. 3

and 4 for unit dimensions. All unit sizes have discharge

openings for both horizontal and downflow configurations

and are factory shipped with all downflow duct openings

covered. The unit may be installed e ither on a rooftop or at

ground level.

WARNING

RECEIVING AND INSTALLATION

Step 1—Check Equipment

IDENTIFY UNIT

The unit model number and serial number are stamped on

the unit information plate. Check this information against

shipping papers.

INSPECT SHIPMENT

Inspect for shipping damage while unit is still on shipping

pallet. If unit appears to be damaged or is torn loose from

its anchorage, have it examined by transportation

inspectors before removal. Forward claim papers directlyto

transportation company. Manufacturer is not responsible

for any damage incurred in transit. Check all items against

shipping list. Immediately notify the nearest equipment

distribution office if any item is missing. To prevent loss or

damage, leave all parts in original packages until

installation.

Step 2—Provide Unit Support

For hurricane tie downs, contact distributor for details and

PE (Professional Engineering) Certificate if required.

ROOFCURB

Install accessory roof curb in accordance with instructions

shipped with curb. Install insulation,cant strips, roofing, and

flashing. Ductwork must be attached to curb.

IMPORT ANT: The gasketing of the unit to the roof curb is

critical for a water tight seal. Install gasketing material

supplied with the roof curb. Improperly applied gasketing

also can result in air leaks and poor unit performance.

Curb should be level to within 1/4 in. (6mm). This is

necessary for unit drain to function properly. Refer to

accessory roof curb installation instructions for additional

information as required.

SLAB MOUNT

Place the unit on a solid, level concrete pad that is a

minimum of 4 in. (102mm) thick with 2 in. (51mm) above

grade (See Fig. 2). The slab should extend approximately

2

2 in. beyond the casing on a ll 4 sides of the unit. Do not

secure the unit to the slab except when required by local

codes.

FIGURE 2

2"

EVAP. COIL COND. COIL

Slab Mounting Details

OPTIONAL

RETURN

AIR

OPENING

OPTIONAL

SUPPLY

AIR

OPENING

ADDITIONAL GROUND LEVEL PLATFORM

REQUIREMENTS

The unit MUST be situated to provide safe access for

servicing.

The unit must be level and supported above grade by

beams, platform, or a pad.

Platform or pad can be of open or solid construction but

should be of permanent materials such as concrete, bricks,

blocks, steel, or pressure--treated timbers approved for

ground contact. Soil conditions must be considered so that

the platform or pad does not shift or settle and leave the unit

partially supported.

Position platform separate from building foundation.

Install in well--drained area, with top surface of platform

above grade level.

Platform must be high enough to allow for proper

condensate trap installation and drainage.

Step 3—Provide Clearances

The required minimumservice clearances areshown in Fig.

3 and 4. Adequate ventilation and outdoor air must be

provided. The outdoorfan draws air through the outdoor coil

and discharges it through the top fan grille. Be sure that the

fan discharge doesnot recirculate tothe outdoor coil.Do not

locate the unit in either a corner or under an overhead

obstruction. The minimum clearance under a partial

overhang (such as a normal house overhang) is 48 in.

(1219mm) above the unit top. The maximum horizontal

extension of a partial overhang must not exceed 48

in.(1219mm).

IMPORT ANT: Do not restrict outdoor airflow. An air

restriction at either the outdoor--air inlet or the fan discharge

may be detrimental to compressor life.

Do not place the unit where water, ice, or snow from an

overhang or roof will damage or flood the unit. Do not install

the unit on carpeting or other combustible materials.

Slab--mounted units should be at least 4 in. (102mm) above

the highest expected water and runoff levels. Do not use

unit if it has been under water.

Step 4—Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on

vertical discharge units. Do not connect ductwork to unit.

For horizontal applications, unit is provided with flanges on

the horizontal openings. All ductwork should be secured to

the flanges. Insulate and weatherproof all external

ductwork, joints, and roof openings with counter flashing

and mastic in accordance with applicable codes.

Ducts passing through an unconditioned space must be

insulated and covered with a vapor barrier.

If a plenum return isused on a vertical unit,the return should

be ducted through the roof deck to comply with applicable

fire codes.

A minimum clearance is not required around ductwork.

Cabinet return--air static shall not exceed --.25 in. wc.

Step 5—Rig and Place Unit

Rigging and handling of this equipment can be hazardous

for many reasons due to the installation location (roofs,

elevated structures, etc.).

Only trained, qualified crane operators and ground support

staff should handle and install this equipment.

When working with this equipment, observe precautions in

the literature, on tags, stickers, and labels attached to the

equipment, and any other safety precautions that might

apply.

Training for operators of the lifting equipment should

include, but not be limited to, the following:

1. Application of the lifter to the load, and adjustment of

the lifts to adapt to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load as it relates to operation of the

lifting kit, such as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and

work gloves.

INSPECTION

Prior to initial use, and at monthly intervals, all rigging

brackets and straps should be visually inspected for any

damage, evidence of wear, structural deformation, or

cracks. Particular attention should be paid to excessive

wear at hoist hooking points and load support areas.

Brackets or straps showing any kind of wear in these areas

must not be used and should be discarded.

!

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury or death.

Before installing or servicing system, always turn off

main power to system. There may be more than one

disconnect switch. Turn off accessory heater power

switch if applicable. Tag disconnect switch with a suitable

warning label.

!

UNIT FALLING HAZARD

Failure to follow this warning could result in personal

injury or death.

Never stand beneath rigged units or lift over people.

WARNING

WARNING

3

!

WARNING

!

WARNING

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Rigging brackets for one unit use only. When

removing a unit at the end of its useful life, use a new set

of brackets.

USE OF RIGGING BRACKET

NOTE: Rigging brackets are factory installed on 3--phase

units only. Single--Phase units require accessory kit

NPLIFTBK003A10.

Field Installation of Rigging Bracket (if not already installed)

1. Remove unit from shipping carton. Leave top shipping

skid on the unit for use as a spreader bar to prevent the

rigging straps from damaging the unit. If the skid is not

available, use a spreader bar of sufficient length to

protect the unit from damage.

2. Remove 4 screws in unit corner posts.

3. Attach each of the 4 metal rigging brackets under the

panel rain lip (See Fig. 5). Use the screws removed in

step 2 above to secure the brackets to the unit.

!

WARNING

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Do not strip screws when re--securing the unit. If a screw

is stripped, replace the stripped one with a larger diameter

screw (included). When straps are taut, the clevis should

be a minimum of 36 (914mm) inches above the unit top

cover .

Rigging/Lifting of Unit

1. Bend top of brackets down approximately 30 degrees

from the corner posts.

2. Attach straps of equal length to the rigging brackets at

opposite ends of the unit. Be sure straps are rated to

hold the weight of the unit (See Fig. 5).

3. Attach a clevis of sufficient strength in the middle of the

straps. Adjust the clevis location to ensure unit is lifted

level with the ground.

4. After unit is securely in place detach rigging straps.

Remove corner posts screws, and rigging brackets

then reinstall screws.

After the unit is placed on the roof curb or mounting pad,

remove the top crating.

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal

injury/death or property damage.

Rigging bracket MUST be under the rain lip to provide

adequate lifting.

4

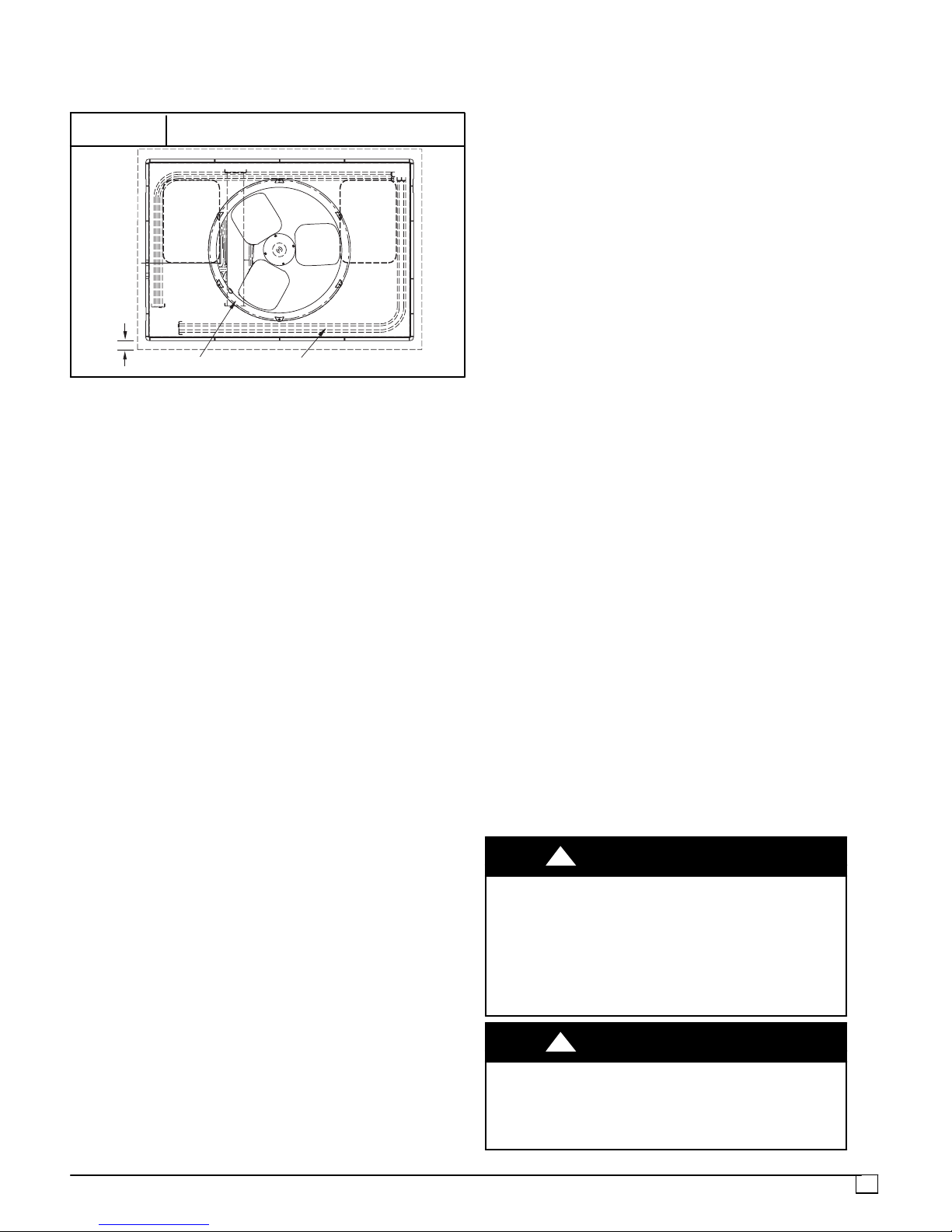

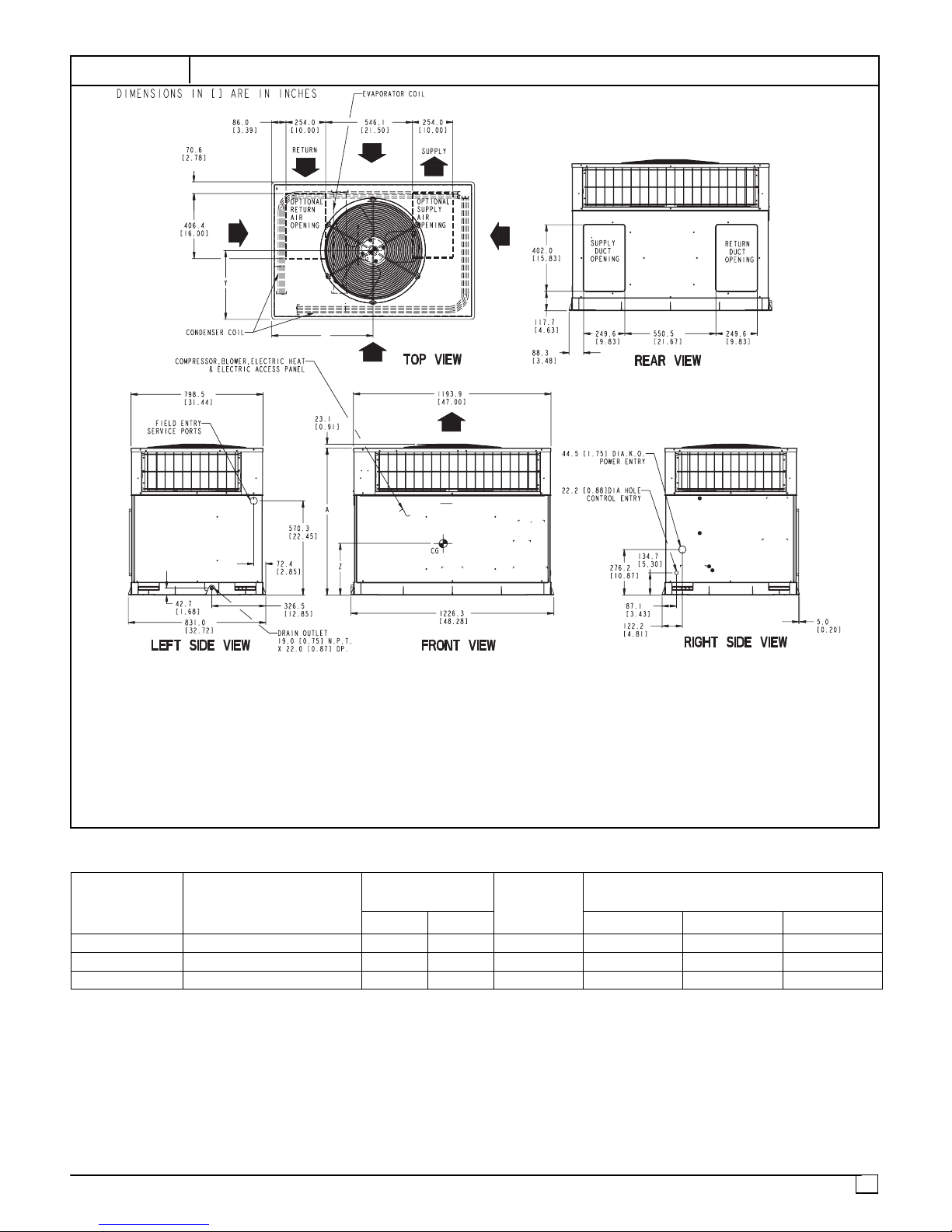

FIGURE 3

*

PAN324--36 DIMENSIONS

REQUIRED CLEARANCE TO COMBUSTIBLE MATL

(

R

efe

r t

o

M

aximu

m

O

perating

C

learance

TOP OF UNIT...................................................................................14.00 [355.6]

DUCT SIDE OF UNIT.........................................................................2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................14.00 [355.6]

BOTTOM OF UNIT.............................................................................0.50 [12.7]

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE ....................................42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE.........................42.00 [1066.8]

UNIT

ELECTRICAL

CHARACTERISTICS

.

s

)

INCHES [mm]

INCHES [mm]

UNIT WEIGHT

lb kg X Y

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAP. COIL ACCESS SIDE............................................................36.00 [914.0]

POWER ENTRY SIDE....................................................................42.00 [1066.8]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP.......................................................................................48.00 [1219.2]

SIDE OPPOSITE DUCTS ..............................................................36.00 [914.0]

DUCT PANEL .................................................................................12.00 [304.8]

*Minimum distances: if unit is placed less than 304.8 (12.00) from wall

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 304.8 [12.00] FROM

system, then systerm performance may be compromised.

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

UNIT

HEIGHT

IN. [MM]

CENTER OF GRAVITY

IN. [MM]

“A”

INCHES [mm]

Z

PAN324 208/230--1--60 318 144 37 [940] 20.0 [508] 17.0 [431] 17.6 [447]

PAN330 208/230--1--60 330 150 39 [991] 20.0 [508] 19.3 [490] 13.0 [330]

PAN336 208/230--1--60 339 152 41 [1042] 21.0 [533] 21.0 [533] 16.6 [422]

5

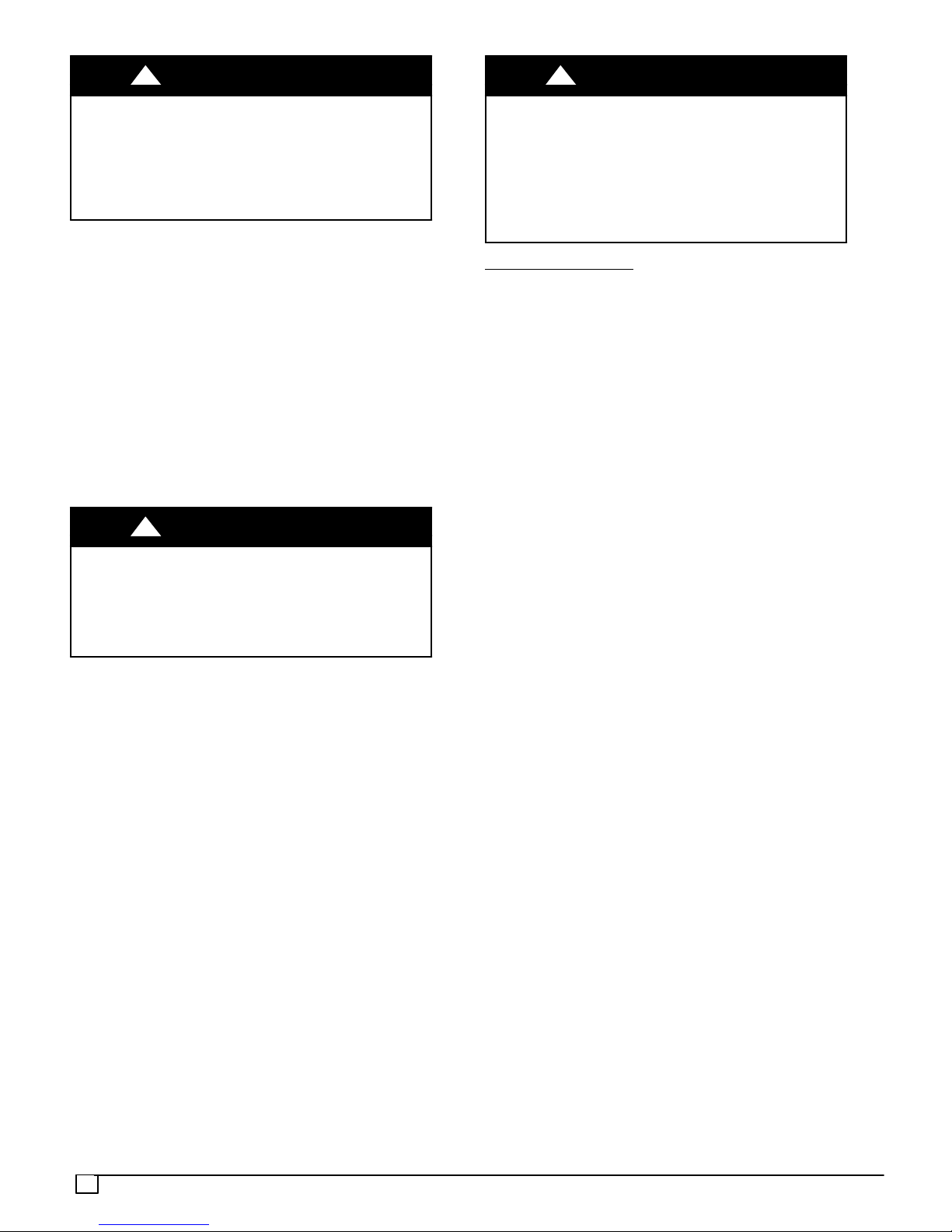

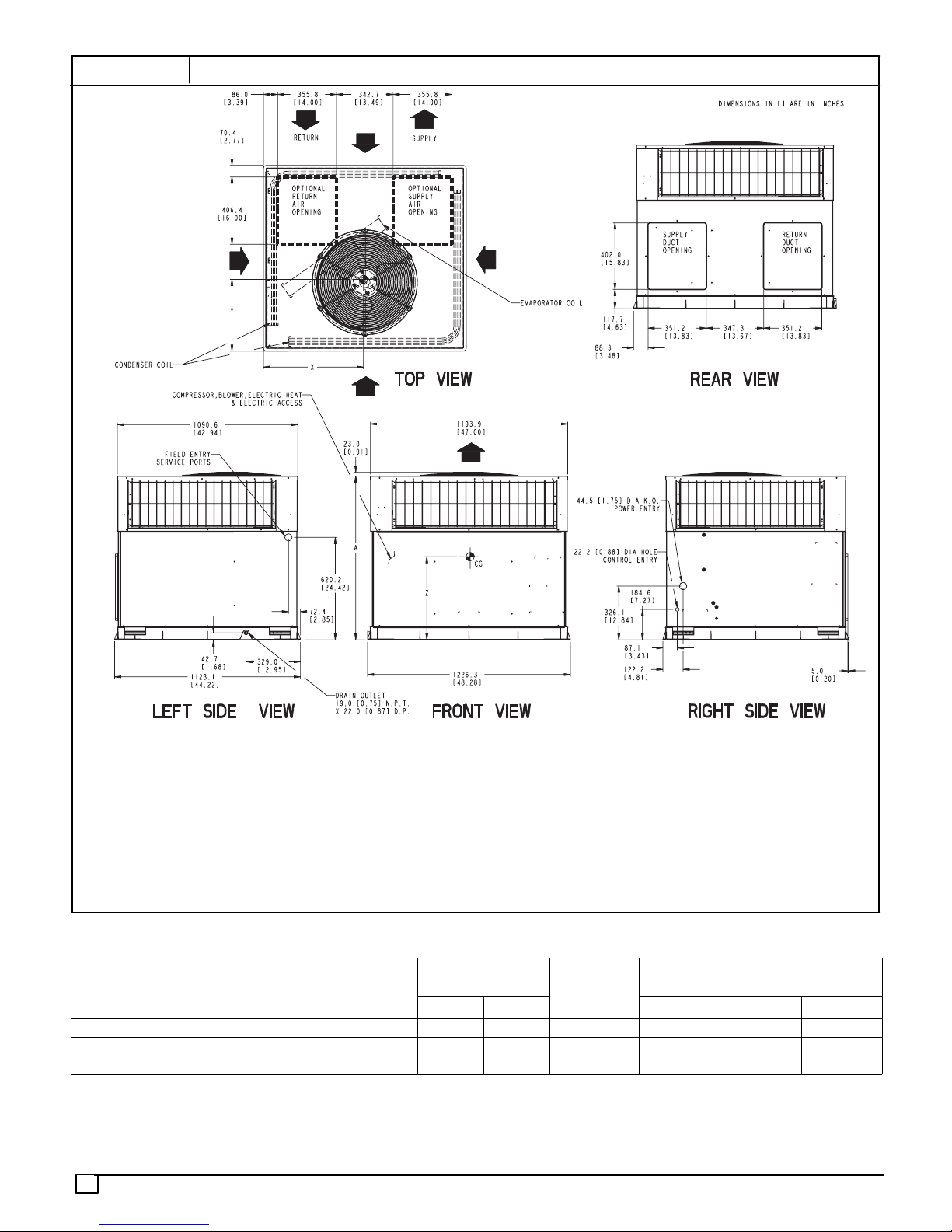

FIGURE 4

*

[

]

PAN342--60 DIMENSIONS

REQUIRED CLEARANCE TO COMBUSTIBLE MATL

(

R

efe

r t

o

M

aximu

m

O

perating

C

learance

TOP OF UNIT...................................................................................14.00 [355.6]

DUCT SIDE OF UNIT.........................................................................2.00 [50.8]

SIDE OPPOSITE DUCTS ................................................................14.00 [355.6]

BOTTOM OF UNIT.............................................................................0.50 [12.7]

NEC. REQUIRED CLEARANCES.

BETWEEN UNITS, POWER ENTRY SIDE ....................................42.00 [1066.8]

UNIT AND UNGROUNDED SURFACES, POWER ENTRY SIDE .36.00 [914.0]

UNIT AND BLOCK OR CONCRETE WALLS AND OTHER

GROUNDED SURFACES, POWER ENTRY SIDE.........................42.00

UNIT

ELECTRICAL

CHARACTERISTICS

.

s

)

INCHES [mm]

INCHES [mm]

1066.8

REQUIRED CLEARANCE FOR OPERATION AND SERVICING

EVAP. COIL ACCESS SIDE............................................................36.00 [914.0]

POWER ENTRY SIDE....................................................................42.00 [1066.8]

(EXCEPT FOR NEC REQUIREMENTS)

UNIT TOP.......................................................................................48.00 [1219.2]

SIDE OPPOSITE DUCTS ..............................................................36.00 [914.0]

DUCT PANEL .................................................................................12.00 [304.8]

*Minimum distances: if unit is placed less than 304.8 (12.00) from wall

*MINIMUM DISTANCES: IF UNIT IS PLACED LESS THAN 304.8 [12.00] FROM

system, then systerm performance may be compromised.

WALL SYSTEM, THEN SYSTEM PERFORMANCE MAYBE COMPROMISE.

UNIT WEIGHT

lb kg X Y

UNIT

HEIGHT

IN. [MM]

“A”

CENTER OF GRAVITY

IN. [MM]

INCHES [mm]

PAN342 208/230--1--60 412 187 40.98 [1041] 21.0 [533] 21.0 [533] 17.1 [434]

PAN348 208/230--1--60 442 201 46.98 [1193] 21.0 [533] 20.0 [508] 17.4 [442]

PAN360 208/230--1--60 446 202 46.98 [1193] 21.0 [533] 20.0 [508] 17.6 [447]

6

Z

Loading...

Loading...