Page 1

Project:

Location:

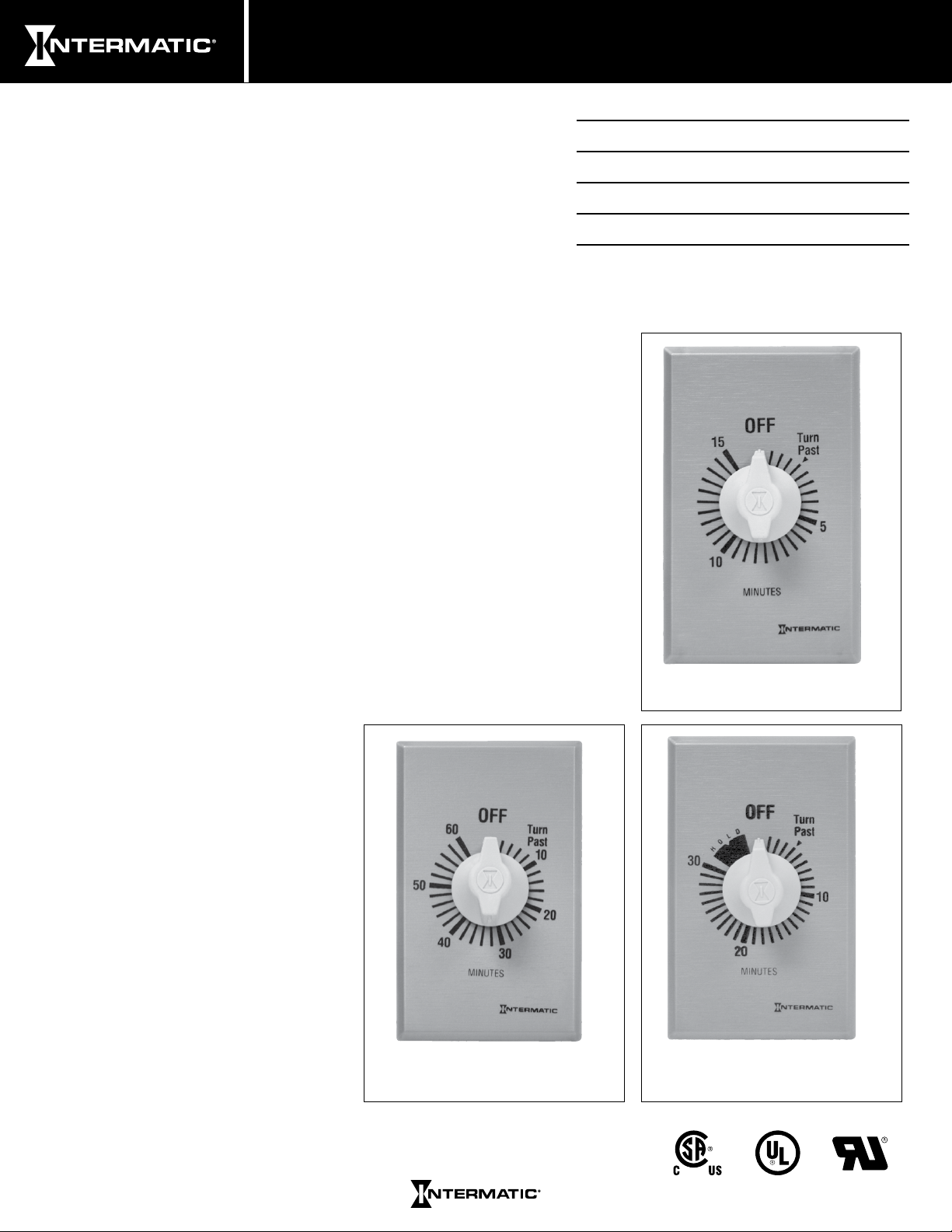

FF Series

Auto-Off Timers

FF Series

Commercial Series

The FF Series Commercial Auto-Off Timers are designed to replace

any standard wall switch - single or multi-gang. This series of

energy-efcient mechanical timers do not require electricity to

operate. In addition, they automatically limit the ON times for fans,

lighting, motors, heaters, and other energy consuming loads.

Features

• Hold feature enables the user to override the automatic

shut-off function

• Rugged time dial plate easily withstands the abuse encountered in

commercial environments

• Commercial “brushed metal” (plastic construction) look meets

NEC requirements

• Time saving up front terminal connection with teeter-type terminals

• Press-on knob design ensures quick and easy installation

• CFL compatible

Not for use with sunlamps, saunas, or loads that could cause

personal injury if timed incorrectly.

Ratings

Resistive: 20 Amp, 125 VAC, 50/60 Hz

10 Amp, 250 VAC, 50/60 Hz

10 Amp, 277 VAC, 50/60 Hz

Product Type:

Contact/Phone:

Model #:

Tungsten: 7 Amp, 125 VAC

Motor: 1 HP, 120 VAC, 50/60 Hz

2 HP, 240 VAC, 50/60 Hz

Dimensions: 2.79" H x 1.6" W x 1.19" D

FF60MC

FF15MC

FF30MH

Energy Controls

Page 2

FF Series

Model Number Time Cycle Switch Hold Color

FF5M 5 Minutes SPST No Brushed Metal Finish

FF5MH 5 Minutes SPST Yes Brushed Metal Finish

FF15MC 15 Minutes SPST No Brushed Metal Finish

FF15MH 15 Minutes SPST Yes Brushed Metal Finish

FF30MC 30 Minutes SPST No Brushed Metal Finish

FF30MH 30 Minutes SPST Yes Brushed Metal Finish

FF60MC 60 Minutes SPST No Brushed Metal Finish

FF60MHC 60 Minutes SPST Yes Brushed Metal Finish

FF2H 2 Hours SPST No Brushed Metal Finish

FF4H 4 Hours SPST No Brushed Metal Finish

FF6H 6 Hours SPST No Brushed Metal Finish

FF6HH 6 Hours SPST Yes Brushed Metal Finish

FF12HC 12 Hours SPST No Brushed Metal Finish

FF12HHC 12 Hours SPST Yes Brushed Metal Finish

FF315M 15 Minutes SPDT No Brushed Metal Finish

FF330M 30 Minutes SPDT No Brushed Metal Finish

FF360M 60 Minutes SPDT No Brushed Metal Finish

FF32H 2 Hours SPDT No Brushed Metal Finish

FF32HH 2 Hours SPDT Yes Brushed Metal Finish

FF34H 4 Hours SPDT No Brushed Metal Finish

FF34HH 4 Hours SPDT Yes Brushed Metal Finish

FF36H 6 Hours SPDT No Brushed Metal Finish

FF312H 12 Hours SPDT No Brushed Metal Finish

FF312HH 12 Hours SPDT Ye s Brushed Metal Finish

FF415M 15 Minutes DPST No Brushed Metal Finish

FF430M 30 Minutes DPST No Brushed Metal Finish

FF460M 60 Minutes DPST No Brushed Metal Finish

FF46H 6 Hours DPST No Brushed Metal Finish

FF412H 12 Hours DPST No Brushed Metal Finish

Specification

The timer shall be of the appropriate dimensions and design to provide for direct replacement of a standard wall switch

in a single gang 2 ½" deep junction box. The timer shall include a spiral time scale to provide easy selection of a desired

time setting. Molded white knob and brushed metal nish wall plate shall be a press-on type requiring no screw or other

hardware to secure. The polymeric time dial shall replace a standard switch plate without modications. The timer shall

have a UL listed rating of:

• 1 HP at 125 VAC, 50/60 Hz

• 2 HP at 250 VAC, 50/60 Hz

• 20 Amp, 120 VAC, 50/60 Hz

• 10 Amp, 250 VAC, 50/60 Hz

• 10 Amp, 277 VAC, 50/60 Hz

• 7 Amp, 125 VAC, Tungsten

The timer eld wiring connections shall be secured by means of a teeter-type terminal screw to provide secure

connections for appropriate wire sizes. The timer shall be ___________ (SPST)(DPST)(SPDT). The timer __________ (Shall)

(Shall Not) have a Hold feature and shall have a time cycle of ___________(See Time Cycles Listed). The timer shall be

Intermatic model _______________(See Model Numbers Listed).

Energy Controls

Page 3

Diagrams

Example for 3-way load control providing

timed override from more than one location.

Example for reverse action control. The load

is switched off when timer is operated for a

limited time then switches back on.

Example for timed selection of low or high

speed motor with optional timer to limit

operation time regardless of speed selected.

Load 1

Load 2

Line 1

Optional

Line 2

High

Low

Neutral

Hot

Load 2

Line 2

No Connections Required

For Line 1 and Load 1

Hot

Load 1

Load 2

Line 1

Line 2

Line 2

Hot

Neutral

Neutral

Load 2

Line 1

Solder Pot

Jumper From

Line 2 To Line 1

Jumper From

Line 2 To Line 1

Jumper From

Line 2 To Line 1

LOAD

FF Series

Hot

Load 1Line 1

Example for SPST motor load control.

Hot

Load 1Line 1

Load

Supply

Example for SPST large motor load control

using a 3-pole contactor or motor starter.

Jumper From

Line 2 To Line 1

Hot

Line 1

Load 2

Load 1

Line 2

55º

72º

LOAD

CR1

LOAD

CR1

Neutral

Neutral

Neutral

24

VAC

Example for control of low voltage set-back

set-up thermostats using SPDT timer.

2.79"

[7.09cm]

STRIP

GAUGE

1.60"

[4.06cm]

Load 1

Line 1

Load 2

240 VAC

Line 2

Example for breaking both sides of a 240 volt

load using DPST contacts.

Hot

Load 1

120 VAC

120 VAC

Line 1

Load 2

Line 2

Example for controlling two loads

simultaneously by using DPST contacts.

LOAD

Neutral

LOAD

Energy Controls

Page 4

FF Series

Notes

Energy Controls

Loading...

Loading...