Intermatic ET1705CPD82, ET1705CR, ET1715C, ET1715CPD82, ET1715CR Installation Manual

...

MODEL ET1700 Series

Snap out catch

Installation and User Instructions

WARNING

• Disconnect power at the circuit breaker(s) or disconnect switch(es) before installing or servicing.

• Installation and/or wiring must be in accordance with national and local electrical code

requirements.

• For outdoor locations or wet locations (rain-tight), conduit hubs that comply with requirements of

the UL514B (standard for fitting conduit and outlet boxes) are to be used.

• This enclosure does not provide grounding between conduit connections. When metallic conduit

is used, you must also install grounding type bushings and jumper wire.

• For plastic enclosures, bonding between conduit connections is not automatic and must be

provided as part of the installation.

• Use #18 - #10 AWG wires, rated at least 75°C - COPPER conductors ONLY.

• If the power disconnect point is out of sight, lock it in the OFF position and tag it to prevent

unexpected application power.

• Make sure there is no wire insulation under the terminal plate on the time switch connector.

Firmly tighten terminal screws.

• Do not remove insulator that is covering terminals.

• KEEP DOOR CLOSED AT ALL TIMES when not servicing.

NOTICE

• Do NOT touch circuit board components, contact can create a static discharge, which can

damage the microprocessor.

Description

The Intermatic ET1700 Series Electronic 7-Day Time Switch

automatically switches loads to a preset weekly schedule with to-theminute accuracy.

The independent 7-day programming provides complete exibility for

applications where load switching differs each day of the week.

Use the ET1700 series as an ON/OFF timer in applications requiring

7-day load control such as lighting, air conditioning systems, pumps,

etc. Each load output of the Time Switch can support up to 14 timed

ON and 14 timed OFF events per day. The program can be overridden

by pushing the ON/OFF load override button(s).

The ET1700 Series Time Switch is designed to directly switch tungsten

or ballast loads up to its rating, and inductive or resistive loads up to

30A at 120, 208, 240, or 277 VAC.

Specifications

Time Switch

• Input Voltage: 120/208/240/277 VAC, 60 Hz

• Power Consumption: 6.0 W Max.

• Contact Conguration: SPST (ET1705C), DPST (ET1725C), and

SPDT (ET1715C). See wiring diagrams on next page.

Switch Ratings—ET1705C, ET1725C (per pole)

• 30 A Inductive/Resistive, 120/240 VAC, 60 Hz

• 20 A Ballast, 120-277 VAC, 60 Hz

• 20 A Resistive, 28 VDC

• 5 A Tungsten: 120/240 VAC, 60 Hz

• 1 HP, 120 VAC, 60 Hz

• 2 HP, 240 VAC, 60 Hz

Switch Ratings—ET1715C (NO/NC) Normally Open/Normally Closed Contact

• 20 A/10 A Inductive/Resistive, 120/240 VAC, 60 Hz

• 20 A/3 A Ballast, 120-277 VAC, 60 Hz

• 5 A Tungsten: 120/240 VAC, 60 Hz

• 1 HP / ¼ HP, 120 VAC, 60 Hz

• 2 HP / ½ HP, 240 VAC, 60 Hz

Set Points (Events)—Each load output of the Time Switch can support

up to 14 timed ON and 14 timed OFF events per day.

Battery-Powered Clock Operation—3 years minimum (uses 2 AAA industrial grade alkaline batteries, supplied)

Minimum ON or OFF time—1 minute

Maximum ON or OFF time—6 days, 23 hours, 59 minutes

Shipping Weight—2.5 lb. (1.1 kg)

Risk of Fire or Electric Shock

Electronic 7-Day

Time Switch

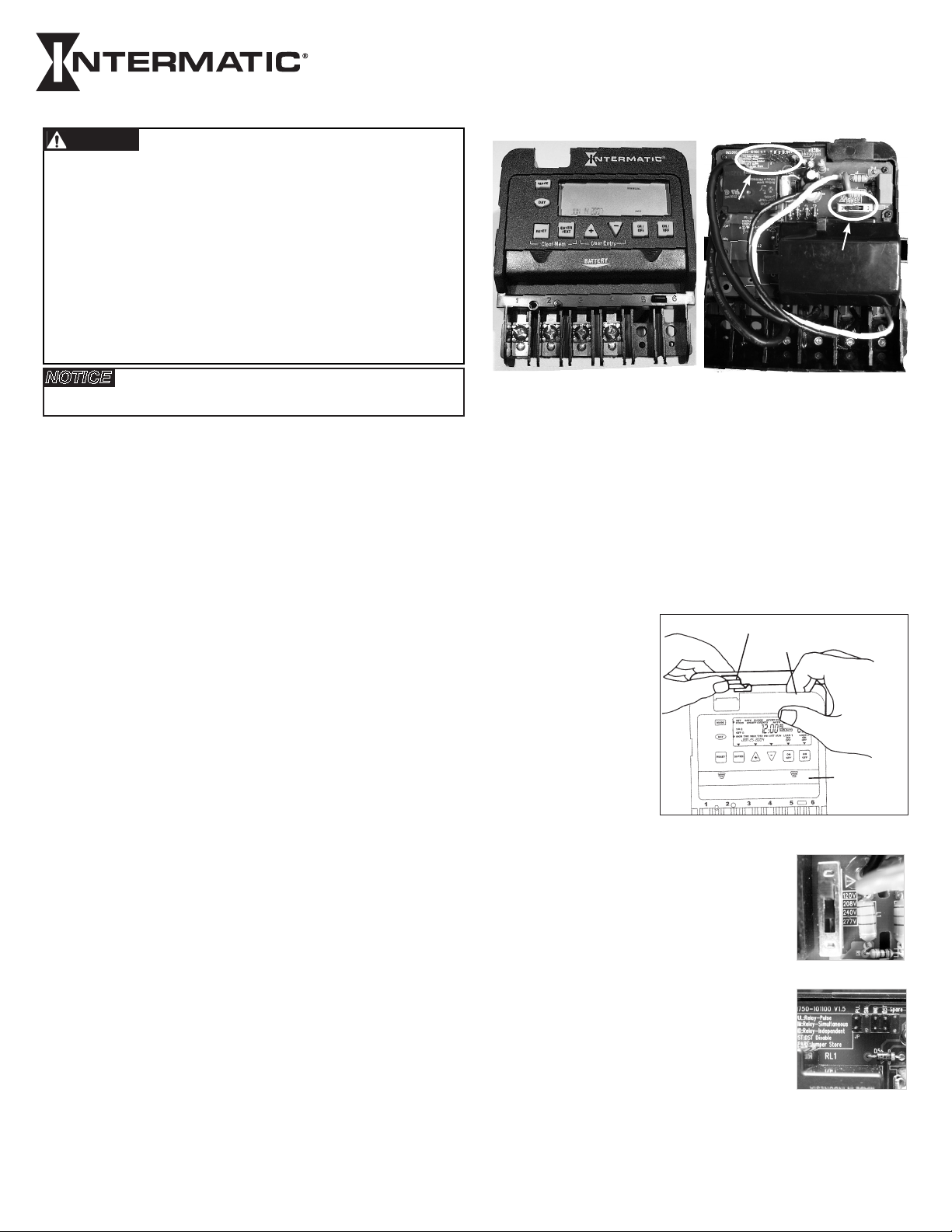

B

Front View

Enclosures—Three enclosure options are available.

• ET17x5C – TYPE 1 indoor metal enclosure

• ET17x5CR – TYPE 3R indoor/outdoor lockable metal enclosure

• ET17x5CPD82 – TYPE 3R indoor/outdoor lockable impact resistant

polycarbonate enclosure with clear cover

Knockouts—Combination 1/2-3/4 inch size, 1 on back and each side,

2 on bottom

Wire Size—AWG #18 through #10

Installation Instructions

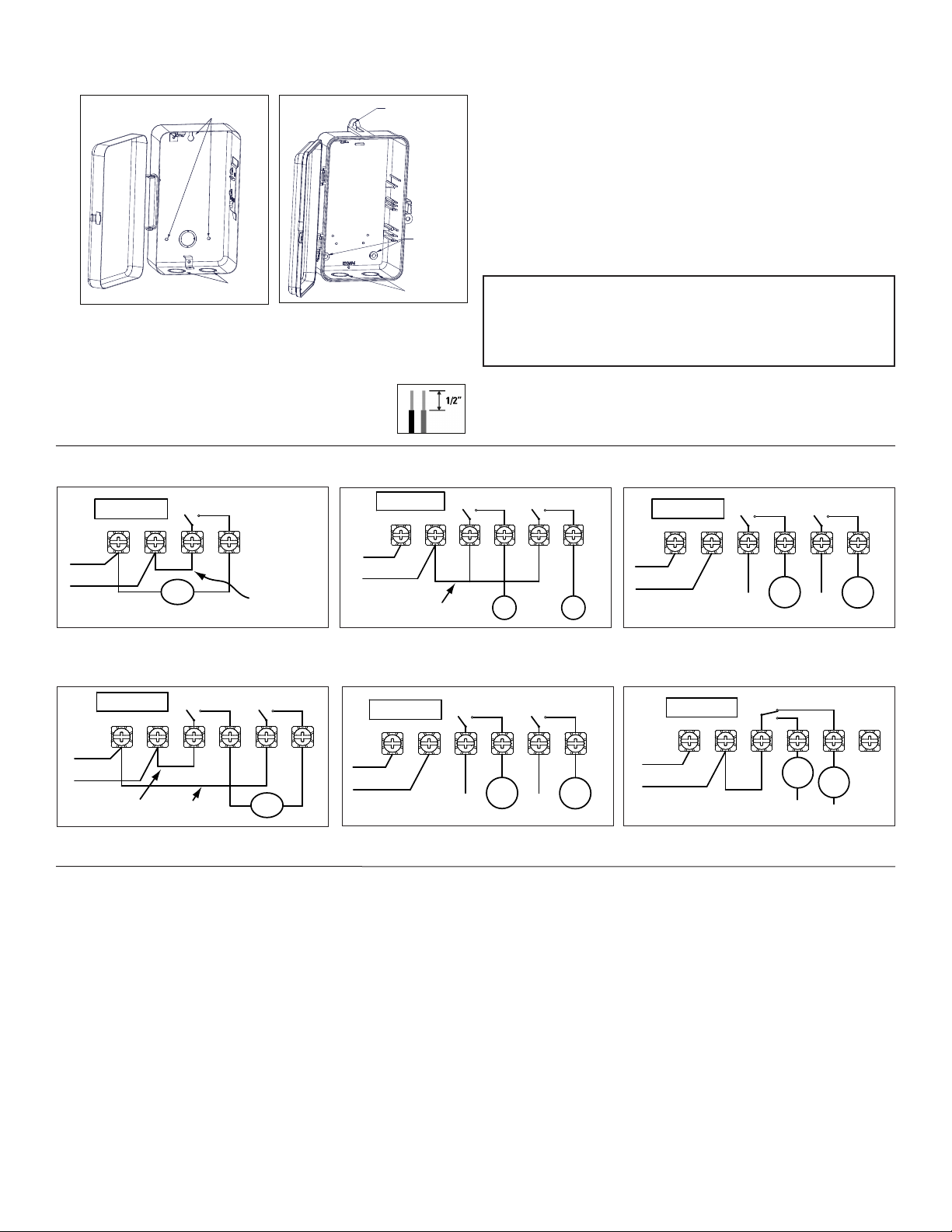

1. Remove the mechanism

from the case by

depressing the catch at

the top of the case and

pulling out, as shown.

2. Set voltage selector for desired input voltage.

The timer is shipped with voltage set for 120

VAC. To operate at 208, 240 or 277 VAC, move

the selector switch to the desired setting as

marked on the circuit board. See location A in

Rear View above and detail at the right.

3. The timer is shipped with DST (Daylight Saving

Time) enabled. To disable DST, insert a jumper

at location marked DST. See location B in Rear

View above and detail at the right.

4. ET1725C ONLY—Decide whether you want

to control multiple loads simultaneously (SIM),

independently (IND), or with a 2-second pulse

(PUL) (e.g., for use with mechanically held

contactors or bell ringing applications), and

make sure the jumper is positioned accordingly.

See location B in Rear View above and detail

at the right. (The unit is shipped with the loads

set for IND.)

With Battery

Carryover

A

Rear View

Tilt top forward

Slide down

to remove

battery case

Mounting holes

5. Mount the enclosure in the desired location using the 3 mounting

holes provided.

Mounting

Hole

Mounting

Holes

9. Insert the wire ends under the proper terminal plates (see

wiring diagrams elsewhere on this page) and tighten the

screws rmly.

10. Connect ground wire to grounding terminal at bottom of enclosure.

11. Replace the plastic insulator on the retaining post.

12. Remove the battery case by sliding it down as shown by the

arrows, then install 2 AAA alkaline batteries. Make sure the

batteries are pointing in the direction shown.

13. Verify that the display is ON to make sure the batteries are OK.

If the display shows scrambled information, press the RESET

button to clear it up.

14. Apply power to the Time Switch.

Knockouts

Knockouts

Position at eye level if possible, providing space to the left of the

enclosure for the cover to swing open fully, as shown.

6. Replace the mechanism in the enclosure.

7. Lift the left side of the plastic insulator off the retaining post and

pivot it up and away to expose the terminal strip.

8. Strip the supply and load wires to 1/2”. Use #18 -

#10 AWG wires, rated at least 75°C - COPPER

conductors ONLY.

Wiring Diagrams

Timer Power

1

2 3 4

Neutral

Hot

120VAC

Input

Load

Install jumper

only if timer input

and load voltage

are the same

ET1705 configured for SPST, 120 VAC load

Timer Power

2 3 4 5 6

1

Line 2

Line 1

240VAC Input

Install jumper only if timer input

and load voltage are the same

Line 1

Line 2

Load

ET1725 configured for 240 VAC DPST load

with jumper set to SIM

Timer Power

2 3 4 5 6

1

L2/N

Line 1

120/208/240/277

VAC Input

Install jumper only if timer input

and load voltage are the same

ET1725 configured for pulse SPST load

with jumper set to PUL

Timer Power

2 3 4 5 6

1

L2/N

Line 1

120/208/240/277

VAC Input

ET1725 configured for DPST loads

with jumper set to SIM

IMPORTANT: Press and hold the ENTER button, then press the

RESET button. The screen will ash 12:00 AM and MON, and

timer status is Manual Mode.

NOTE: You must reset the time switch using this procedure

whenever you change the jumpers.

The Time Switch is now ready for programming.

Timer Power

2 3 4 5 6

1

L2/N

ON

OFF

Line 1

120/208/240/277

VAC Input

Load

1

Load

2

ET1725 configured for 2 SPST loads

with jumper set to IND

Timer Power

2 3 4 5 6

1

Load

1

Load

2

L2/N

Line 1

120/208/240/277

VAC Input

Load

1

Load

2

ET1715 configured for SPDT load switching

Programming Overview

By pressing the MODE button, the Time Switch will cycle through the

menus necessary for programming the current time, date, and timed

events.

The basic procedure is to use the MODE button to move from one

menu to the next (e.g., DATE, TIME, etc.), the + or – buttons for the

rst part of a setting (e.g., MONTH), the ENTER button to move to the

next part of the setting (e.g., YEAR), then MODE to exit and move to

the next menu. To skip a menu, press MODE to move ahead.

If you make a mistake, press the MODE button repeatedly to

cycle back around to the error, then make the correct entry.

NOTE: DATE and TIME must be set before you can access any

other programming menus.

Setting Date

1. Press the MODE button repeatedly until the words SET and

DATE appear in the upper area of the display.

2. Press the + or – buttons to enter the current Month.

3. Press the ENTER button when the Month is correct to save the

setting. The screen advances to current Date.

4. Again press the + or – buttons to enter the current Date,

followed by the ENTER button.

5. Repeat to set the correct Year.

6. Press the MODE button to exit and advance to setting the time.

Loading...

Loading...