Page 1

TruVision Analog PTZ

Camera Installation

Manual

P/N 1072692A-EN • REV 1.0 • ISS 10OCT13

Page 2

Trademarks and

Manufacturer

FCC compliance

European Union

Copyright

patents

Certification

directives

© 2013 UTC Fire & Security Americas Corporation, Inc.

Interlogix is part of UTC Climate Controls & Security, a unit of United

Technologies Corporation. All rights reserved.

TruVision name and logo are trademarks of United Technologies.

Other trade names used in this document may be trademarks or registered

trademarks of the manufacturers or vendors of the respective products.

UTC Fire & Security Americas Corporation, Inc.

2955 Red Hill Avenue, Costa Mesa, CA 92626-5923, USA

Authorized EU manufacturing representative:

UTC Fire & Security B.V.

Kelvinstraat 7, 6003 DH Weert, The Netherlands

N4131

Class B: This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

There is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

12004/108/EC (EMC directive): Hereby, UTC Fire & Security declares that this

device is in compliance with the essential requirements and other relevant

provisions of Directive 2004/108/EC.

2002/96/EC (WEEE directive): Products marked with this symbol cannot be

disposed of as unsorted municipal waste in the European Union. For proper

recycling, return this product to your local supplier upon the purchase of

equivalent new equipment, or dispose of it at designated collection points. For

more information see: www.recyclethis.info.

Contact information

For contact information, see www.interlogix.com or

www.utcfssecurityproducts.eu.

Page 3

Content

Introduction 3

Product overview 3

Before you begin 4

Installation environment 4

Camera description 5

Installing a camera 6

Pendant-mount cameras 6

Flush-mount cameras 7

Surface-mount cameras 8

DIP switch settings 11

Specifications 14

Introduction

This pocket guide provides basic information on setting up and using

the TruVision Analog PTZ Camera. Detailed information on the

cameras can be found in the configuration manual.

Product overview

This is the user manual for TruVision analog PTZ camera models

TVP-2101 (23X pendant, PAL)

TVP-4101 (23X pendant, NTSC)

TVP-2102 (23X surface, PAL)

TVP-4102 (23X surface, NTSC)

TVP-2103 (23X flush, PAL)

TVP-4103 (23X flush, NTSC)

TVP-2104 (36X pendant, PAL)

TVP-4104 (36X pendant, NTSC)

TVP-2105 (36X surface, PAL)

TVP-4105 (36X surface, NTSC)

TruVision Analog PTZ Camera 3 EN

Page 4

TVP-2106 (36X flush, PAL)

TVP-4106 (36X flush, NTSC)

Before you begin

Unpack everything. Check the items for damage, and verify that all

items are included. The camera is shipped with the following items:

Dome camera

Installation manual

CD with configuration manual

Installation environment

When installing your camera, consider these factors:

• Place the camera in a secure location.

• Ensure that the camera is in a well-ventilated area.

• Do not expose the camera to rain or moisture.

EN 4 TruVision Analog PTZ Camera

Page 5

Camera description

Figure 1: Overview of the dome camera (pendant-mount shown)

5

2

1

3

4

1. Power supply cord.

Connect 24 VAC power supply

2. RS-485 port

3. Video output.

Connect the BNC connector to a CCTV monitor.

4. Housing.

5. Bubble.

EN 5 TruVision Analog PTZ Camera

Page 6

Installing a camera

Pendant-mount cameras

1. Prepare the mounting surface and install the camera bracket.

2. Unscrew the bubble from the camera and remove the protective

tape from the PTZ module.

3. Press the two tabs on either side of the PTZ module and remove it

from the camera housing.

4. Configure the communication parameters for the PTZ camera.

Please see Section DIP Switch Settings for detailed information of

communication parameters settings.

5. Route the cables from the pendant-mount bracket, and connect it

to the PCB of the module through the cable entry hole on top of the

housing.

Note: If alarm and audio input/output relays are to be used, also

connect them to the PCB of the module.

6. Attach the camera housing to the bracket using the screws

enclosed with the bracket.

7. Insert the PTZ module into the housing:

Position the tabs on the PTZ module by aligning the arrow label on

the module with those on the housing (see below). The module

should snap firmly into position. If using an SD card, insert it into

the module before inserting the module into the housing.

8. Re-attach the bubble by screwing it to the housing.

EN 6 TruVision Analog PTZ Camera

Page 7

Flush-mount cameras

1. Using the drill template, drill a hole on the ceiling.

2. Unscrew the bubble from the camera and remove the protective

tape from the PTZ module.

3. Press the two tabs on either side of the PTZ module and remove

the module from the camera housing.

4. Configure the communication parameters for the PTZ camera. See

the section “DIP switch settings” on page 11 for detailed information

on the communication parameters settings.

5. Adjust the height of the two housing tabs by turning the screw on

which they are attached. The distance (h) of the tabs from the

housing ring must be greater than the thickness of the ceiling.

Housing tab

Screw

6. Make sure the housing tab is closed and then PUSH the housing

into the pass-through hole. Hold the housing and fix it by screwing

the housing tabs down to the mounting surface.

7. Insert the PTZ module into the housing:

EN 7 TruVision Analog PTZ Camera

Page 8

8. Re-attach the bubble by screwing it to the housing.

9. Install the trim ring. Align the trim ring to the housing, and insert the

fix-pins to the holes. Then rotate the ring clockwise.

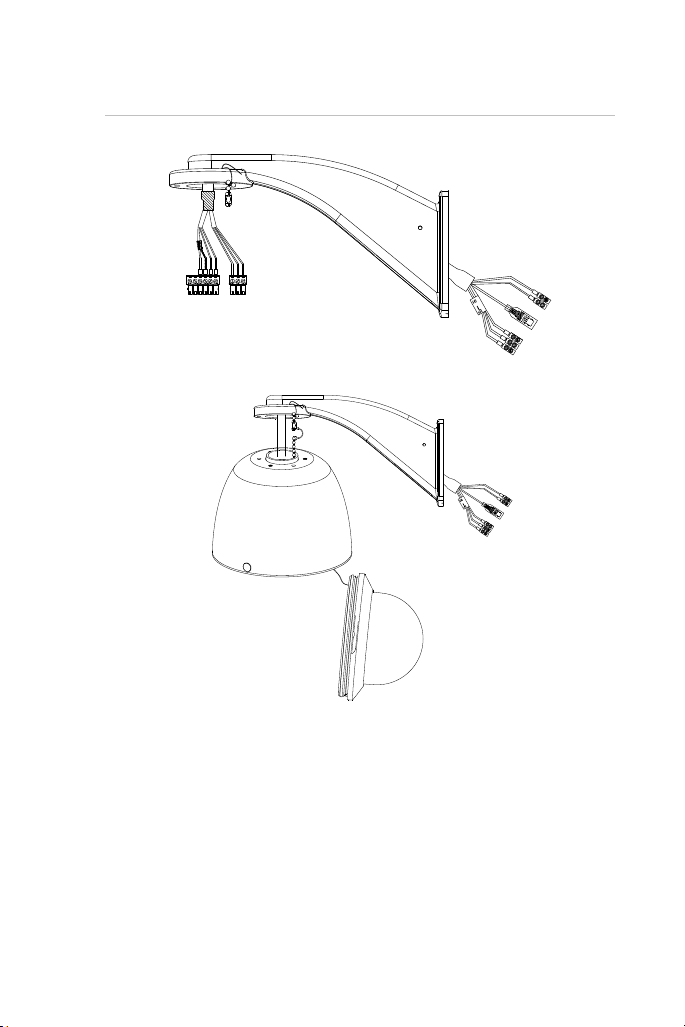

Surface-mount cameras

The PTZ camera cables can be routed either from the top or side of

the housing (see figures below). For the cables routed from the top of

the housing, you need to drill a cable hole in the ceiling.

EN 8 TruVision Analog PTZ Camera

Page 9

1. Using the mounting base as a template, mark four screw holes on

the ceiling. If you are routing cables from the top of the housing,

mark the cable hole on the ceiling and drill a hole.

B

A

2. Secure the mounting base to the ceiling with screws.

3. Unscrew the bubble from the camera and remove the protective

tape from the PTZ module.

EN 9 TruVision Analog PTZ Camera

A. Screw holes; B. Cable hole

Page 10

4. Press the two tabs on either side of the PTZ module and remove

the module from the camera housing.

5. Configure the communication parameters for the PTZ camera. See

“DIP switch settings” on page 11 for detailed information on the

communication parameters settings.

6. Connect the cables to the PCB of the module through the cable

entry hole on the top of the housing.

7. Attach the housing to the mounting base. Align the arrow head with

the spring end of the mounting base. Push the housing up and

then sideways in the direction of arrow. When the housing is

correctly positioned, the spring automatically snaps firmly into the

lock clip. See the figures below.

Align

Push up (1) and then push

sideways (2).

8. Insert the PTZ module into the housing:

EN 10 TruVision Analog PTZ Camera

Lock clip

Page 11

9. Re-attach the bubble by screwing it into the housing.

Warning: After installation, the PTZ module will perform a PTZ

self-test and initializes with the power on. DO NOT touch and

move the camera while it is self-testing and initializing.

DIP switch settings

Two DIP switches, SW1 and SW2, are used to set the PTZ dome

address, baud rate, protocol, etc. The values are ON=1 and OFF=0.

See Figure 2 on page 12.

Each DIP switch number represents a DIP switch value, ranging from 1

to 8 from the lowest to highest.

EN 11 TruVision Analog PTZ Camera

Page 12

Figure 2: DIP switch settings

SW 1 SW 2

SW1 - ADDRESS

Rx Address = Switch Value

Switch1 Number 1 2 3 4 5 6 7 8

Switch1 Value 1 2 4 8 16 32 64 128

Rx Broadcast Address 0 off off off off off off off off

Rx Address 1 on off off off off off off off

Rx Address 255 on on on on on on on on

SW2 – Baud Rate Settings SW2 – Protocol Settings

Switch2 Number 1 2 3 Switch2 Num ber 4 5 6

2400 Baud on off off Interlogix/GE Im pac RS-

485

4800 Baud off on off PELCO-D on off off

9600 Baud on on off PELCO-P off on off

19200 Baud off off on Reserved Others

38400 Baud on off on

The rest of above is 9600 Baud

Termination Settings

Switch Number 7 Switch Number 8

Reserved Not Terminated off

Terminated on

off off off

EN 12 TruVision Analog PTZ Camera

Page 13

Address settings

DIP switch SW1 is used to set the address of the PTZ dome. See

Table 1 below to set the PTZ camera address to a specific number.

Table 1: PTZ camera addresses

Address

1 2 3 4 5 6 7 8

0 OFF OFF OFF OFF OFF OFF OFF OFF

1 ON OFF OFF OFF OFF OFF OFF OFF

255 ON ON ON ON ON ON ON ON

Baud rate settings

Use positions 1, 2, and 3 of DIP switch SW2 to set the baud rate of the

PTZ dome. The values to select are 2400 bps, 4800 bps, 9600 bps,

19200 bps and 38400 bps. The default baud rate is 2400 bps. See

Table 2 below.

Table 2: Baud rate values

Baud rate 1 2 3

2400 ON OFF OFF

4800 OFF ON OFF

9600 ON ON OFF

19200 OFF OFF ON

38400 ON OFF ON

Protocol Settings

Use positions 4, 5, and 6 of DIP switch SW2 to set the communication

protocols of the dome. See Table 3 below.

Table 3: Protocol values

Protocol 4 5 6

Interlogix-485 OFF OFF OFF

PELCO-D ON OFF OFF

PELCO OFF ON OFF

Reserved Others

EN 13 TruVision Analog PTZ Camera

Page 14

Specifications

Operating temperature Pendant-mount housing: -30 to +65 °C

Flush-mount housing: -20 to +65 °C

Surface-mount housing: -20 to +65 °C

Power supply 24 VAC +/- 3.6 VAC

Power consumption Pendant-mount housing: Max. 35 W

Flush-mount housing: Max. 15 W

Surface-mount housing: Max. 15 W

Dimensions (mm) Pendant-mount housing: Ø 220 × 266 mm

Environmental Pendant-mount housing: IP66

Weight Pendant-mount housing: 3.5 kg

Flush-mount housing: Ø 206 × 251 mm

Surface-mount housing: Ø 180 × 240 mm

Flush-mount housing: IP54

Surface-mount housing: IP44

Flush-mount housing: 3 kg

Surface-mount housing: 2.5 kg

EN 14 TruVision Analog PTZ Camera

Page 15

Page 16

Loading...

Loading...