Page 1

Surface Mount

Manual Number

1054313C

April 2011

Remote Relay Module

User Guide

UTC Fire & Security • 791 Park of Commerce Blvd. • Suite 100 • Boca Raton • FL • 33487

(561) 998-6100 • www.utcfireandecurity.com

Page 2

Surface Mount Remote Relay Module Installation Guide

COPYRIGHT INFORMATION

This publication may contain examples of data reports used in daily business operations. Examples include

fictitious names of individuals and companies for illustration only; any similarity to names and addresses of

actual business enterprises and persons is entirely coincidental.

This document is distributed on an as is basis, without warranty either expressed or implied. Successful

implementation depends solely upon the customer’s ability to integrate each product into the total inventory

of “in-house” products. While each offering has been reviewed for its compatibility and maintainability, no

assurance of successful installation can be given.

The customer accepts full maintenance responsibility. (A full scope of software and hardware maintenance

contracts are available to the customer.)

© 2011 UTC Fire & Security

All Rights Reserved

Printed in the USA

2

Page 3

Surface Mount Remote Relay Module

+24

0V

T-

T+

+24

0V

T-

T+

+24

0V

T-

T+

+24

0V

T-

T+

ACUX

Readers

Port

RRE

or

Reader

RRE

or

Reader

RRM

or

RIM

+24

0V

T-

T+

RRE

or

Reader

Figure 1: RS-485 Communication Wiring for RRM and RIM as last device

Terminate

Here

Terminate

Here

The Surface Mount Remote Relay Module (RRM) provides an interface between the ACU Controller and eight

Single Pole Double Throw (SPDT) and eight Double Pole Double Throw (DPDT) dry contact relays. The RRM

consists of an electronic circuit board with an on board screw terminal connectors. (The RRM with backplate only

is Product Number RRM16-E1L) The RRM can be installed in its own tampered enclosure. (The RRM with key

locked enclosure is Product Number RRM16-E00)

When attaching this device to a Summit system, please refer to the ACU3 Family Installation and Opera-

tion Guide for the list of input and output assignments.

Surface Mount (SMT) refers to a method of construction that allows the various module components to

be mounted directly on the surface of the board rather than using the traditional thru-hole method.

The RRM Each relay is rated 2 Amps at 30 VDC.

Two unsupervised inputs are available for power fault and cabinet tamper.

The Remote Relay Module requires 24 VDC (±15%).

The switches on the RRM are dynamic and can be changed while power is still applied to the board.

Changes will take effect immediately.

Auxiliary Power Supply for RRM

In many cases the ACU can supply the power for the RRM. The exception is when using an ACURS with a plugin transformer for its power supply. When the ACU cannot supply power, an auxiliary power supply must be used.

When using an auxiliary power supply make sure the 0V terminal on all remote modules and the ACU share a

common ground.

Do not use the relays on the ACU Controller, Remote Reader Electronics (RRE), Remote Input

Module (RIM) or Remote Relay Module (RRM) to switch any voltage above 30 volts. Failure to

heed this WARNING can cause death, personal injury or damage to unit(s).

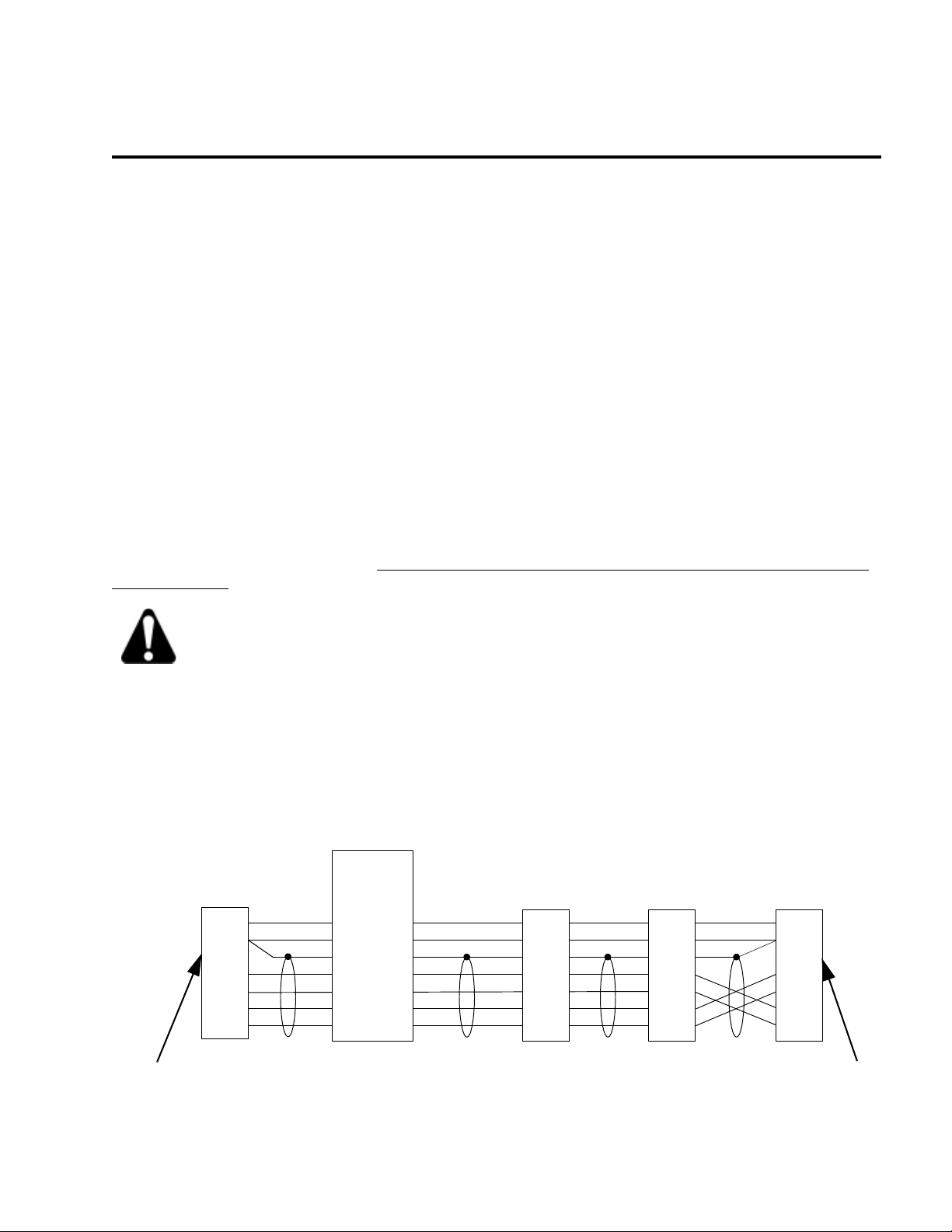

RS-485 Information

RS-485 is a differential voltage communication circuit. The Impedance is 120 ohms. End-of-line terminators are

required on both ends of the communications path (See diagram below). Multi-drop configurations are allowed

with a maximum length of 4,000 feet. Stubs can be dropped, off the RS-485 cable, but the length of any stub

cannot be longer than 10 feet. Stubs can connect to ACU Controllers or remote modules (One-Stage reader,

RRE, RIM or RRM). Stubs must not be terminated. UTC Fire & Security strongly recommends star

configurations be avoided. The all remote modules have built-in terminators that are switch selectable.

RS-485 Wiring Diagram

3

Page 4

Surface Mount Remote Relay Module Installation Guide

ON

A

B

C

TX

RX

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SW1

SW2

J2

TB1

TB2TB3

TB4TB5

TB6

K1 K2

K3 K4

K5 K6

K11 K9

K16 K14

K15 K13

K8

K12

K7

K10

ON

1

ON

1

T+ T- R+ R-

GND

GND

GND

GND

VIN

I1 I2

C NC NOK8C NC NOK8C NC NOK9C NC NO

K10

C NC NO

K11

C NC NOK5C NC NOK4C NC NOK4C NC NOK3C NC NO

K3

K7

NO NC CK7NO NC CK6NO NC CK6NO NC CK5NO NC C

K12

NO NC C

K13

NO NC C

K14

NO NC C

K15

NO NC C

K16

NO NC C

K2

NO NC CK2NO NC CK1NO NC CK1NO NC C

UTC FIRE & SECURITY

REMOTE RRELAY MODULE

U1

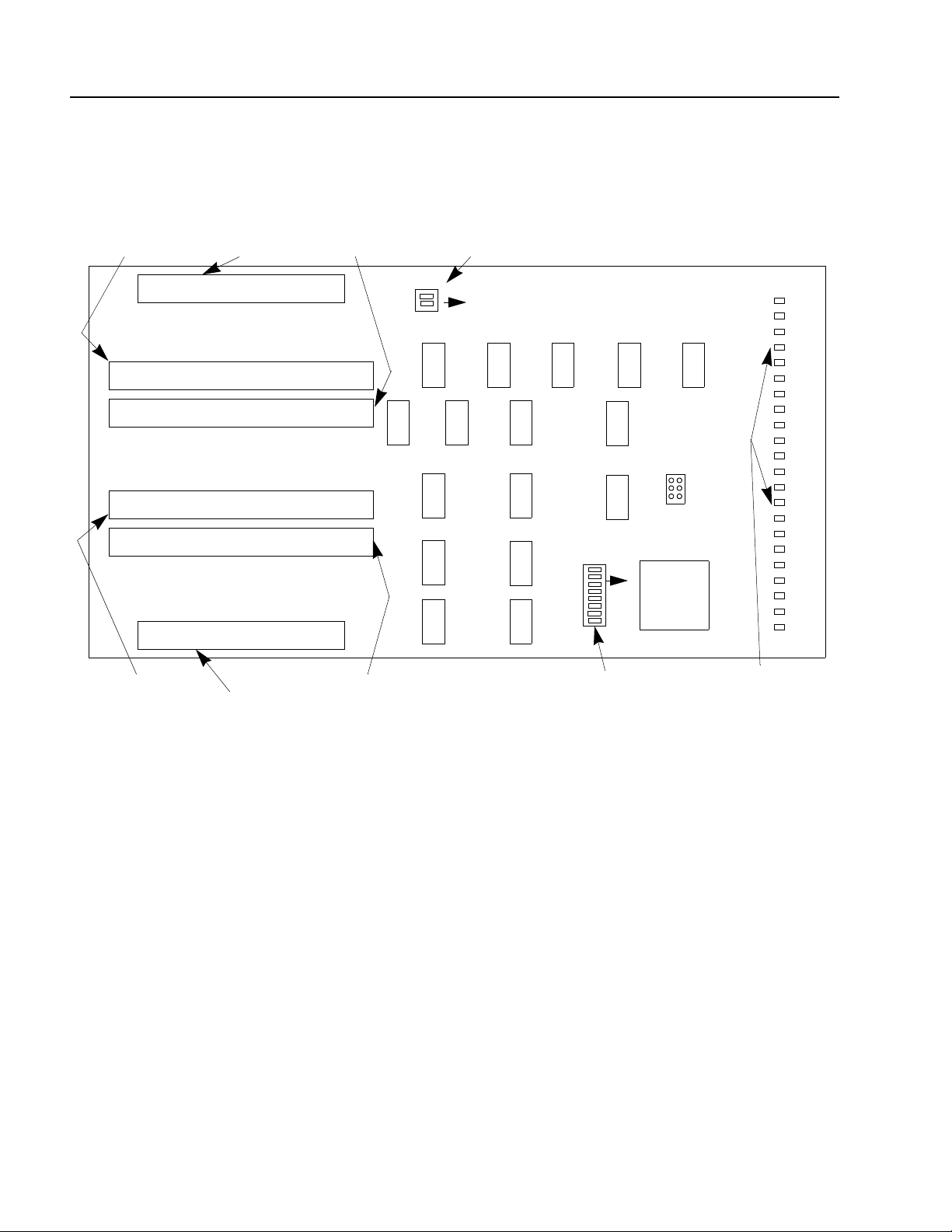

SW2 See:

Table 9

TB1 See:

Table 1

TB3 See:

Table 6

TB2 See:

Table 7

TB6 See:

Table 3

TB5 See:

Table 4

TB4 See:

Table 5

LEDs See:

Table 2

SW1 See:

Table 8

RRM SMT Circuit Board

Figure 2 shows the location of components discussed in this section for the RRM.

4

Figure 2: Locations of Components on SMT RRM

Page 5

Terminal Block Connector PIN Numbers on the RRM

Terminal Block Connector PIN Numbers on the RRM

Table 1 though Table 6 shows RRM terminal block wiring connections. Refer to the ACU Networked

Intelligent Controllers Installation Guide Chapter 3 for applicable ACU Controller connections and cable

identifications.

Connections on RRM

TB

Number

TB1 I1 Unsupervised Alarm 1

TB1 I2 Unsupervised Alarm 2

TB1 GND Alarm common ground

TB1 GND Alarm common ground

TB1 T+ To ACU Expansion Port RX+

TB1 T- To ACU Expansion Port RX-

TB1 R+ From ACU Expansion Port TX+

TB1 R- From ACU Expansion Port TX-

TB1 GND Ground

TB1 GND Ground

TB1 VIN + 24 Volts In

Table 1: RRM Wiring Connections for Expansion Port

Pin

No.

Normal Operation LED’s on the RRM

LED Description

A ON steady when board is Online

B Heart beat 1 flash per second

C Flashing when offline

Tx Flashing when transmitting data to ACU

Rx Flashing when receiving data from ACU

ON ON when Power is applied

LED’s 1 - 16

One LED per Relay

LED is ON when relay is energized

Description

Table 2: RRM Normal LED Operation

5

Page 6

Surface Mount Remote Relay Module Installation Guide

Connections for Relays K1 & K2 on RRM

TB

Number

TB6 K2 NO Relay 2 Normally Open

TB6 K2 NC Relay 2 Normally Closed

TB6 K2 C Relay 2 Common

TB6 K2 NO Relay 2 Normally Open

TB6 K2 NC Relay 2 Normally Closed

TB6 K2 C Relay 2 Common

TB6 K1 NO Relay 1 Normally Open

TB6 K1 NC Relay 1 Normally Closed

TB6 K1 C Relay 1 Common

TB6 K1 NO Relay 1 Normally Open

TB6 K1 NC Relay 1 Normally Closed

TB6 K1 C Relay 1 Common

Table 3: RRM Wiring Connections for Relays K1 & K2

Pin

No.

Connections for Relays K3 – K5 on RRM

TB5 K5 C Relay 5 Common

TB5 K5 NC Relay 5 Normally Closed

TB5 K5 NO Relay 5 Normally Open

TB5 K4 C Relay 4 Common

TB5 K4 NC Relay 4 Normally Closed

TB5 K4 NO Relay 4 Normally Open

TB5 K4 C Relay 4 Common

TB5 K4 NC Relay 4 Normally Closed

TB5 K4 NO Relay 4 Normally Open

TB5 K3 C Relay 3 Common

TB5 K3 NC Relay 3 Normally Closed

TB5 K3 NO Relay 3 Normally Open

TB5 K3 C Relay 3 Common

TB5 K3 NC Relay 3 Normally Closed

TB5 K3 NO Relay 3 Normally Open

Description

Table 4: RRM Wiring Connections for Relays K3 - K5

6

Page 7

Connections for Relays K5 - K7 on TB4

Terminal Block Connector PIN Numbers on the RRM

TB

Number

TB4 K7 NO Relay 7 Normally Open

TB4 K7 NC Relay 7 Normally Closed

TB4 K7 C Relay 7 Common

TB4 K7 NO Relay 7 Normally Open

TB4 K7 NC Relay 7 Normally Closed

TB4 K7 C Relay 7 Common

TB4 K6 NO Relay 6 Normally Open

TB4 K6 NC Relay 6 Normally Closed

TB4 K6 C Relay 6 Common

TB4 K6 NO Relay 6 Normally Open

TB4 K6 NC Relay 6 Normally Closed

TB4 K6 C Relay 6 Common

TB4 K5 NO Relay 5 Normally Open

TB4 K5 NC Relay 5 Normally Closed

TB4 K5 C Relay 5 Common

Table 5: RRM Wiring Connections for Relays K5-K7

Pin

No.

Description

7

Page 8

Surface Mount Remote Relay Module Installation Guide

Connections for Relays K8 - K11 on TB3

TB

Number

TB3 K8 C Relay 8 Common

TB3 K8 NC Relay 8 Normally Closed

TB3 K8 NO Relay 8 Normally Open

TB3 K8 C Relay 8 Common

TB3 K8 NC Relay 8 Normally Closed

TB3 K8 NO Relay 8 Normally Open

TB3 K9 C Relay 9 Common

TB3 K9 NC Relay 9 Normally Closed

TB3 K9 NO Relay 9 Normally Open

TB3 K10 C Relay 10 Common

TB3 K10 NC Relay 10 Normally Closed

TB3 K10 NO Relay 10 Normally Open

TB3 K11 C Relay 11 Common

TB3 K11 NC Relay 11 Normally Closed

TB3 K11 NO Relay 11 Normally Open

Table 6: RRM Wiring Connections for Relays K8-K11

Pin

No.

Description

8

Page 9

Connections for Relays K12 - K16 on TB2

Setting the DIP Switches on the SMT RRM

TB

Number

TB2 K12 NO Relay 12 Normally Open

TB2 K12 NC Relay 12 Normally Closed

TB2 K12 C Relay 12 Common

TB2 K13 NO Relay 13 Normally Open

TB2 K13 NC Relay 13 Normally Closed

TB2 K13 C Relay 13 Common

TB2 K14 NO Relay 14 Normally Open

TB2 K14 NC Relay 14 Normally Closed

TB2 K14 C Relay 14 Common

TB2 K15 NO Relay 15 Normally Open

TB2 K15 NC Relay 15 Normally Closed

TB2 K15 C Relay 15 Common

TB2 K16 NO Relay 16 Normally Open

TB2 K16 NC Relay 16 Normally Closed

TB2 K16 C Relay 16 Common

Table 7: RRM Wiring Connections for Relays K12-K16

Pin

No.

Description

Setting the DIP Switches on the SMT RRM

SW1 Settings on RRM

1 = OFF 2 = OFF Address 4

Switches 1,2 - Communication

Address:

Switch 3 Spare

Switch 4 Spare

Switch 5 Spare

Switch 6 Spare

Switch 7 Spare

Switch 8 Spare

Table 8: RRM DIP Switch SW1 Settings

1 = ON 2 = OFF Address 5

1 = OFF 2 = ON Address 6

1 = ON 2 = ON Address 7

9

Page 10

Surface Mount Remote Relay Module Installation Guide

SW2 Settings on SMT RRM

The 2-position DIP switch - SW2, located on the RRM (Figure 2), is used to terminate the RS-485 communications.

Switch

Number

SW2-1 ON Termination of Receive Pair

SW2-2 ON Termination of Transmit Pair

Table 9: RRM DIP Switch SW2 Settings

Alarm Numbers on the SMT RRM

Zone

Input

IN1 97 101 105 109 113 117 121 125

IN2 98 102 106 110 114 118 122 126

Offline 99 103 107 111 115 119 123 127

Expansion Port 1 Address: Expansion Port 2 Address:

45674567

Table 10: RRM Alarm Numbers for the Host PC

Function

10

Page 11

Relay Numbers on the SMT RRM

Relay Numbers on the SMT RRM

Relay

Number

K1 112 128 144 160 48 64 80 96

K2 113 129 145 161 49 65 81 97

K3 114 130 146 162 50 66 82 98

K4 115 131 147 163 51 67 83 99

K5 116 132 148 164 52 68 84 100

K6 117 133 149 165 53 69 85 101

K7 118 134 150 166 54 70 86 102

K8 119 135 151 167 55 71 87 103

K9 120 136 152 168 56 72 88 104

K10 121 137 153 169 57 73 89 105

K11 122 138 154 170 58 74 90 106

K12 123 139 155 171 59 75 91 107

K13 124 140 156 172 60 76 92 108

K14 125 141 157 173 61 77 93 109

K15 126 142 158 174 62 78 94 110

K16 127 143 159 175 63 79 95 111

Expansion Port 1 Address: Expansion Port 2 Address:

45674567

Table 11: RRM Relay Numbers for the Host PC

11

Page 12

Surface Mount Remote Relay Module Installation Guide

RRM Field Wiring Test

After making all connections, the following tests should be made. Connections should already be completed at the ACU and the auxiliary power supply if used.

Test points and expected voltages

From To Voltage Tolerance

GND VIN + 24 VDC 3.5 VDC

T+ T- + 4.0 VDC* 0.5 VDC

R+ R- + 2.5 VDC * 0.5 VDC

+24V Bldg. Gnd. 24 VDC 3.5 VDC

GND Bldg. Gnd. 0 VDC 0.5 VDC

T+ Bldg. Gnd. Less than 6.0 VDC N/A

T- Bldg. Gnd. Less than 6.0 VDC N/A

R+ Bldg. Gnd. Less than 6.0 VDC N/A

R- Bldg. Gnd. Less than 6.0 VDC N/A

Table 12: RRM Test points and Voltages

* After the first reader is connected these voltages will modulate due to data on the line. Most Digital

Volt Meters should indicate about 2.0 VDC.

Power-Up Self-Test on the RRM

The Remote Relay Module should always be tested after installation. The indicators for the RRM are the

red LED’s located on the component board. The test should be completed in less than 10 seconds. The

LED’s will light as follows:

LED Description

A ON at power-up

B ON when successful RAM test is finished

C ON when successful PROM test and initialization completed

ON ON when Power is applied

Table 13: Power-up LED Indicators on the RRM

After all three LED’s have lit, LED B will flash at a 1 Hz rate.

12

Loading...

Loading...