Page 1

TruPortal System Controller Quick Reference

(for TP-SYS-BRD, TP-SYS-2D, TP-SYS-2D-E,

TP-SYS-2D2R) en-US

The TruPortal System Controller

The TruPortal System Controller provides a solution for access control. It

consists of two boards; the I/O board and the system on module (SOM)

board. The I/O board, the larger of the two, contains the power supply and

all field wiring connections. The SOM, the smaller mounted board, contains

the main CPU and memory.

The event log buffer and the real time clock are stored in battery-backed

memory. Each reader port can accommodate a reader that utilizes Wiegand

Data1/Data0, LED control, and buzzer control.

Twelve supervised inputs (excluding tamper and power monitor) are

provided for door sense, reader tamper, or request to exit as well as four

auxiliary supervised inputs.

Interfaces

The TruPortal System Controller interfaces upstream with the browserbased TruPortal User Interface. There is no dedicated host software to install

on operators’ workstations.

The TruPortal System Controller provides two (2) Ethernet ports.

Configuration data and event/status reports are exchanged with the user

interface via the primary Ethernet ports. The secondary port is not used.

Communication via modem is not supported.

Packing List

• TruPortal System Controller PCB assembly, which consists of the I/O

board and the SOM (quantity = 1)

• Two positional terminal plug-in block (quantity = 7)

• Three positional terminal plug-in block (quantity = 10)

• Four positional terminal plug-in block (quantity = 8)

• End of line resistors 1k ohm, 1% (quantity = 24)

• Push-fit terminal tab adapters (quantity = 2)

• Battery cable (quantity =1)

• Battery bracket (quantity = 1)

• Screws for battery bracket (quantity = 2)

• Strain relief for power cable (quantity = 1)

• Terminal block cover (quantity = 1)

• Lock (quantity = 1)

• Machine screws for securing the cover (quantity =6)

• Enclosure (depending on option ordered)

• Transformer (depending on option ordered)

• Credentials (depending on option ordered)

• T-100 Proximity Readers (depending on option ordered)

• TP-SYS-2D: TruPortal 2-Door base kit. Consists of a TruPortal

System Controller, installed in UL-listed enclosure with 4 amp power

supply.

• TP-SYS-2D2R: TruPortal 2-Door base kit with readers. Consists of a

TruPortal System Controller, installed in UL-listed enclosure with 4

amp power supply. Includes T-100 Readers (quantity = 2) and

Credentials (quantity = 5).

• TP-SYS-2D-E: TruPortal 2-Door base kit for EMEA. Consists of a

TruPortal System Controller, installed in CE-compliant enclosure with

4 amp power supply.

• -E Part number suffix for panel with CE enclosure (CE 220 VAC

internal transformer). Not evaluated by UL.

Model Numbers

The panels are available in the following configurations:

• TP-SYS-BRD: TruPortal System Controller. Board only. Capable of

controlling two (2) doors. No enclosure or readers.

TruPortal System Controller Quick Reference 1 P/N 460800001B 12JAN12 en-US

Page 2

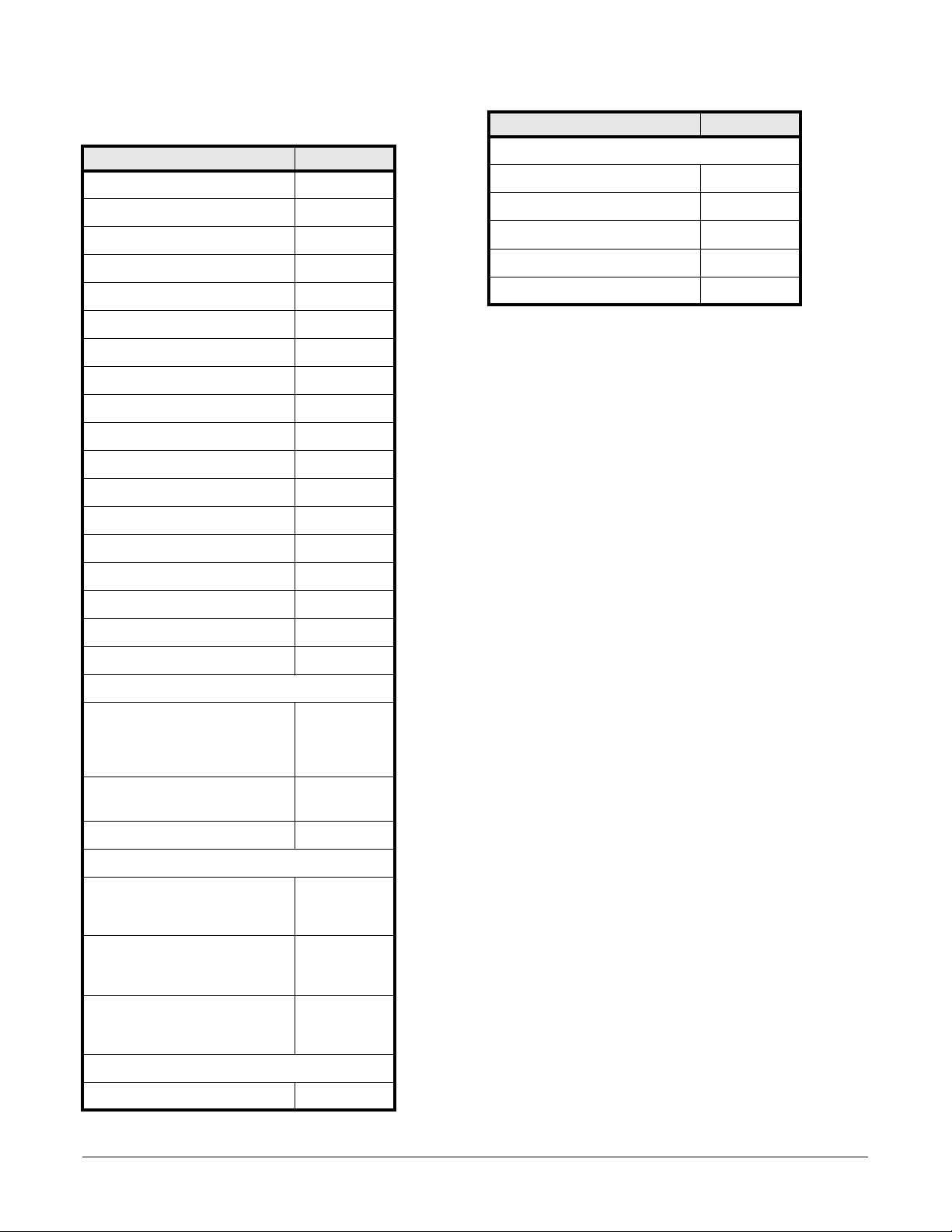

System Capacities

Attribute TP-SYS

Attribute TP-SYS

Number of persons 10,000

Number of unique credentials 10,000

Credentials per person 5

Access levels 64

Access levels per credential 8

Schedules 64

Time intervals per schedule 6

Holiday groups per schedule 8

Holiday groups 8

Holidays per holiday group 32

Holidays (total) 255

Areas 64

Reader groups 64

Operator roles 32

User-defined fields 10

Video layouts 64

Card formats 8

Number of retained events in event log 65,000

Doors/Readers

Number of doors (base board and dual

door controllers) with readers in /

Number of doors with readers in and

out

TP-ADD-2D-BRD Dual Door Control

Modules (including built in)

64 / 32

32

Cameras per DVR

TVR10 (EMEA & US) 4

TVR30 (US Only) 16

Cameras (maximum) 64

Ethernet ports (total/supported) 2/1

RS-485 SNAPP bus ports 4

Anti-attack Bushing Cap

An anti-attack bushing cap covers a rear tamper spring. It fits inside an

O-ring bushing located in the cabinet’s rear wall anti-tamper spring

knockout. Leave the O-ring bushing and cap in place if the rear tamper is

not used.

If the rear tamper is used:

1. Remove the cap and the O-ring with the edge of a flat screwdriver.

2. Discard the O-ring.

3. Align the cap for the tamper spring and knockout hole on the cabinet

back.

4. Screw the cap into the mounting surface.

5. Place the control cabinet over it, allowing the rear tamper spring to fit

inside the cap. The cap will fit into the cabinet’s tamper spring

knockout hole.

6. Secure the cabinet to the mounting surface.

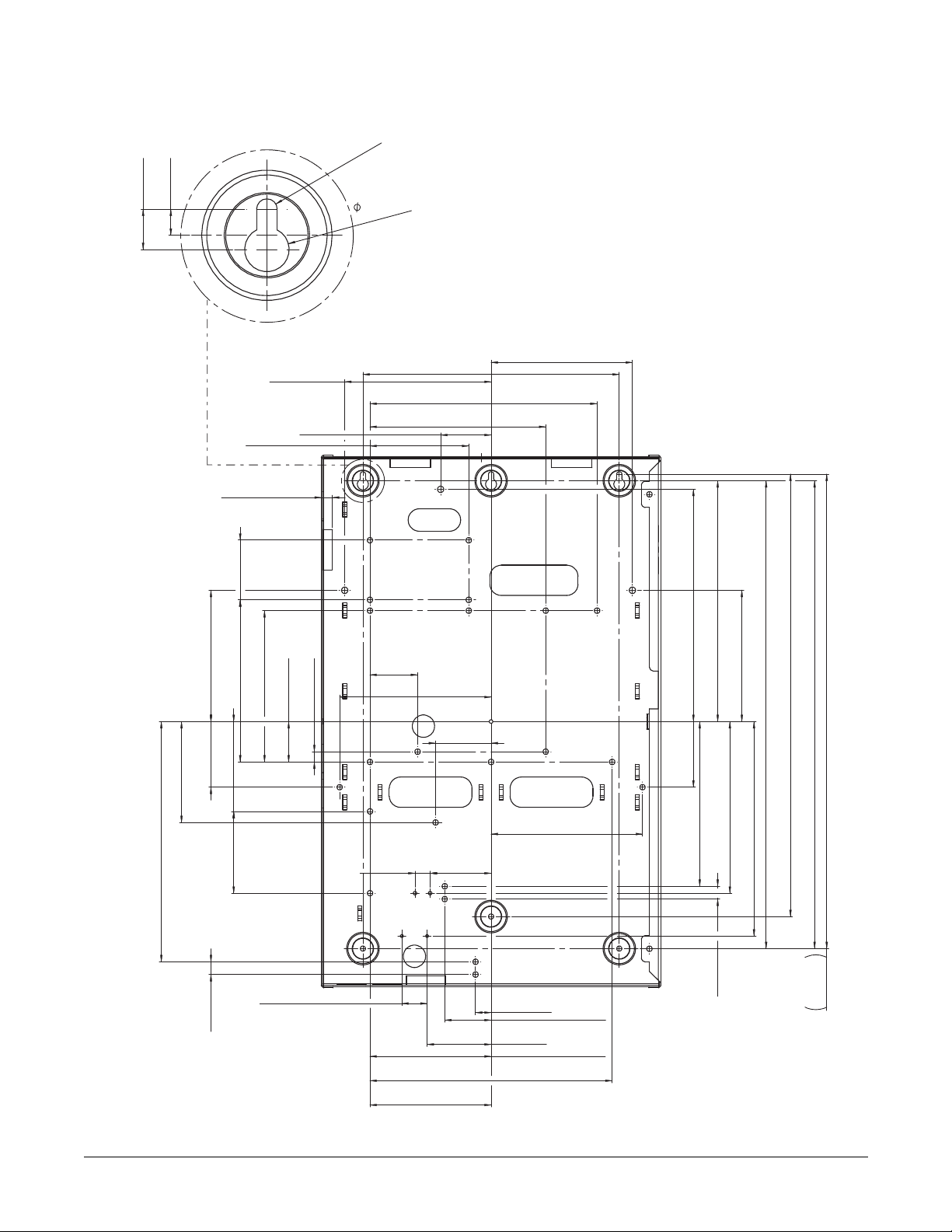

Mounting the Module

On dry wall, use 1/8 in. (3.175 mm) hollow wall, expansion anchors.

Unscrew the screws from the anchors. Mark the mounting holes. Force a

starter hole in each mark with a sharp tool. Hammer the anchors into each

hole. Align the box mounting holes over the anchor holes and screw in the

anchors until tight.

On a concrete surface, hold the control box on the mounting sur face . Mark

the mounting holes. Use a hammer drill with a 3/16 in. (4.76 mm) carballoy

drill bit and make 1in. (25.4 mm) deep holes in each marking. Insert a # 6-8

plastic anchor in each hole and hammer them in. Use # 8 X 1 in.(25.4 mm),

Phillips, wood screws to screw into the plastic anchors and mount the box.

See Figure 1 on page 9.

Readers (total) 64

Inputs/Outputs

Total number of system inputs

(including TruPortal System

Controller)

Total number of system outputs

(including TruPortal System

Controller)

Total number of TP-ADD-IO or TPADD-IO-BRD Input/Output

Expansion Add-Ons

DVR/Cameras

DVRs 4

TruPortal System Controller Quick Reference 2 P/N 460800001B 26JAN12 en-US

132

66

8

Communication Wiring

The controller communicates to the user interface via Ethernet.

The downstream communication ports are 2-wire RS-485 interfaces which

can be used to connect additional I/O panels. The interface allows multidrop communication on a single bus of up to 4000 feet (1200 m). Use

twisted pairs (minimum 22 AWG / 0.644 mm / 0.326 mm

shield for communication.

See Figure 2 on page 10.

2

) with an overall

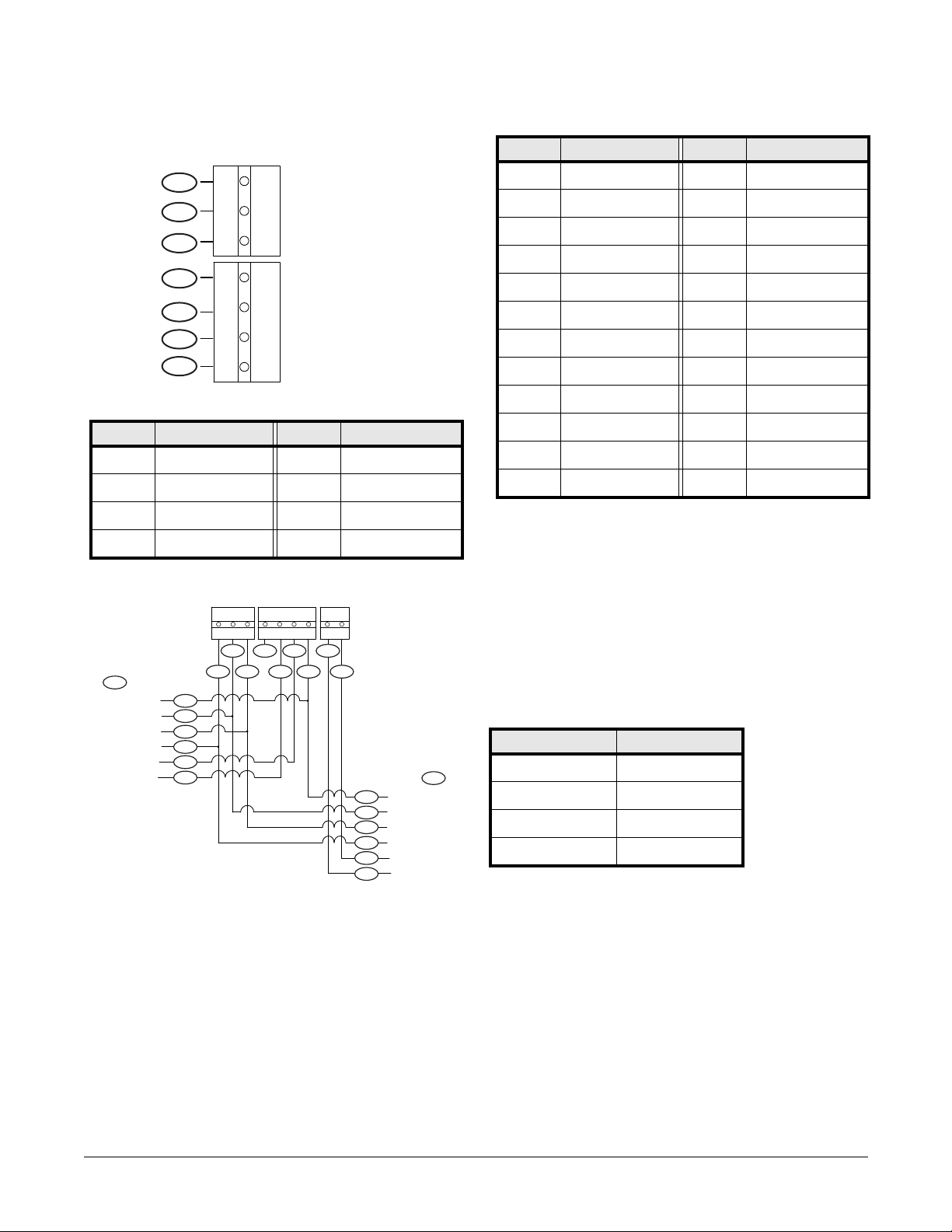

Reader Wiring

Each reader port supports Wiegand Data1/Data0. Voltage at the reader port

is passed through from the input voltage of the controller and is limited to

250 mA.

The reader supply voltage is 14 VDC. Readers that require different voltage

should be powered separately. These readers may be connected and

Page 3

powered through the dual door interface module. Refer to the reader

CN10/CN17 CN11/CN18 CN12/CN19

BZ 14 GR RD D1 D0 0 A B

123 1234 12

5

4

1 3

2

10

9

6 8

7

15

14

13

12

11

20

19

18

17

16

23

22

21

manufacturer specifications for cabling requirements.

Reader wiring

BZ + GR RD D1 D0 0

1

2

3

4

5

6

7

123 1234

CN10/CN17

CN11/CN18

Callout Description Callout Description

1 Buzzer 13 LED

2 +14 V 14 Buzzer

3 Green LED 15 Data0

4 Red LED 16 Data1

5 D1 17 Data1

6 D0 18 Data0

7 0 V 19 Buzzer

8 D1 20 LED

9 D0 21 Power

Callout Description Callout Description

1 Buzzer 5 Data1

2 +14 V 6 Data0

3 Green LED 7 Ground

4 Red LED

Wiring In and Out readers

10 Reader (Out) 22 Ground

11 Ground 23 Reader (In)

12 Power

Input Circuit Wiring

Typically, these inputs are used to monitor door position, request to exit, or

alarm contacts. Input circuits are supervised. The input circuit is able to

report a condition of “Fault” for the status of the circuit, which appears as a

“Tamper” event fo r supervised conditions.

A supervised input circuit requires a resistor be added to the circuit to

facilitate proper reporting. The standard supervised circuit requires 1K ohm,

1% resistors and should be located as close to the sensor as possible.

Relay Circuit Wiring

All relays are dry contact.

Output 30 VDC rating

Siren relay 1 A

Strobe relay 1 A

Strike r elay 5 A

Aux relay 1 A

The relays for siren and door strike have a Common pole ( C), a Normally

Closed pole (NC), and a Normally Open pole (NO). When you are

TruPortal System Controller Quick Reference 3 P/N 460800001B 12JAN12 en-US

controlling the delivery of power to the door strike, the Normally Open and

Common poles are used. When you are momentarily removing power to

unlock the door, as with a mag lock, the Normally Closed and Common

poles are used. Check with local building codes for proper egress door

installation.

Power

The TruPortal System Controller requires 18 VAC or 24 VDC for input

power at CN2, or 12 VDC at CN1 (24 VDC and 12 VDC input power were

not evaluated by UL). When powering the board from 12 VDC, the onboard battery charger will not be used and the lead-acid backup battery

Page 4

should not be connected to the TP-SYS. The power supply providing the

1

2

CN1

CN2

12 0V

2

1

2

3

1

+12V

0V

DC+

0 V

CN2

1

2

3

AC

AC

3

12 VDC must have its own backup source.

TP-SYS 110/220 VAC Power wiring diagram

wires. The earth ground connection at CN2 Pin 2 is not required if the

controller board is grounded through the mounting screws.

Maximum lengths for wiring

I/O

Description

Connection Maximum

length of

22 AWG

Maximum line

resistance (in

Ohms)

wire (in

feet)

1

2

3

4

Callout Description Callout Description

1 Ground stud 3 Connections for AC

wiring

2 Red transformer

4 Wiring indication

wires

Power connectors

13.2 V supply

output

Supervised

inputs

5 A @ 24 VDC

relay output

(assume 15%

voltage drop)

CN3-1

CN3-3

CN10-2

CN17-2

CN21-1

CN23-1

CN24-1

CN25-1

CN26-1

CN8-1

CN8-3

CN9-1

CN9-3

CN15-1

CN15-3

CN16-1

CN16-3

CN21-2

CN21-4

CN22-1

CN22-3

CN7-1 (NO)

CN7-2 (C)

CN7-3 (NC)

CN14-1 (NO)

CN14-2 (C)

CN14-3 (NC)

300 approximately

4.8

500 approximately 8

45 approximately

0.72

1 A @ 24 VDC

relay output

(assume 15%

voltage drop)

Callout Description Callout Description

1 12 VDC input 3 18 VDC Input

CN4-1 (C)

CN4-2 (NC)

CN4-3 (NO)

CN5-1(C)

CN5-2 (NC)

CN13-1 (NO)

CN13-2 (C)

220 approximately

3.6

CN20-1 (NO)

2 24 VAC Input

The maximum input current is 2.7 A. The gauge is dependent on the length

of the wire. The TruPortal System Controller can be power ed by an internal

2

18 VAC transformer that uses 20 AWG (0.812 mm / 0.518 mm

) secondary

Note: These specified ranges have been verified by UL. Note that if

you run a longer wire, it is not verified by UL.

This equipment must be permanently connected to a mains fused spur (3 A

CN20-2 (C)

or 5 A) using 3-core cable with each core being no less than 18 AWG (1.024

mm / 0.823 mm

2

). The mains cable should be clamped securely with the

cable clamps provided within the equipment/installation kit. Knockouts are

provided on the top, bottom and sides of this equipment and these are

intended for conduit or cable glands. As a mains switch is not provided on

the equipment, a readily accessible disconnect device shall be incorporated

in the building installation wiring. Where there is doubt as to the phase of

this wiring, the device, when operated, will disconnect both poles

simultaneously.

TruPortal System Controller Quick Reference 4 P/N 460800001B 26JAN12 en-US

Page 5

Mains Supply

Item North

America

product

Internal

transformer

Input current

rating (AC)

Mains fuse T630 mA

Wa rning: For continued protection against risk of fire, replace the mains

fuse only with the same type and rating of fuse.

The Aux. DC supply output is a Class 2 Power Limited circuit.

Aux DC Supply

Item Mains

Output voltage

(DC)

Standby

battery

Maximum

recharge time

DC power

supply

rating**

Battery charge

limit

Quiescent

current

* 24 VDC and 12 VDC input were not evaluated by UL.

** This DC Power Supply Rating is for all the current requirements,

including recharging the battery.

Board protection is provided by resettable fuses which are not replaceable.

All wiring in this enclosure is required to be UL compliant. All installation

wiring within this equipment cabinet should utilize plastic cable ties to

bundle cables and attach to designated cabinet cable mounting locations to

provide strain relief for the cable harness.

Disposal of batteries should be according to the local laws and regulations

of your region. Contact your local waste management office for information

on battery recycling or disposal.

If you are not able to identify the applicable rules in your area, check the

instructions which will be available from the battery manufacturer.

Ground all enclosures in accordance with NFPA 70 and Canadian Electrical

Code, Part I.

120 V AC +10%

-15%, 60Hz

600 mA 250 mA 250 mA

250 V, UL

Listed

powered

unit

14 V ±5% 14 V ±5% 12 V ±5%

7 Ah or 18 Ah 7 Ah or 18 Ah —

24 hours 24 hours —

2.4 A 2.4 A 1.2 A

1.2 A 1.2 A —

140 mA 140 mA 200 mA

European

product

230 V AC +10%

-15%, 50Hz

T400 mA

250 V

+24 VDC

input*

Australian/

New Zealand

product

240 VAC

±10%, 50Hz

T400 mA

250 V

+12 VDC

input*

Power Setup

Power management parameters for the TruPortal System Controller are preconfigured as follows. These parameters can not be changed:

• Brownout mode: Alarm and report

• Brownout voltage (V): 10.00

• Battery size (Ah): 18

• Select Check for battery.

• Clear the Enable battery tests check box.

• Test time: 10 sec

• Low load test period: 3 min

• High load test period: 20 hr

• Low voltage (V): 11.70

• Warning voltage ( V): 11.40

• Cutoff voltage (V): 10.20

• Very low voltage (V): 9.00

• Excess charge voltage (V): 16.00

• Cutoff time: 10 sec

• No current (mA): 17

• Excess power state discharge current (A): 1.200

Configuration

Use the TruPortal Installation Wizard to discover the controller and

connected peripherals, and to change basic configuration parameter s.

1. Insert the TruPortal disc in your computer’s CD/DVD drive (W indows

only).

2. Install Microsoft .NET 4.0 Framework.

The TruPortal Utilities software will detect automatically if the .NET

software is installed and display the word “Installed” next to the link if

it is found.

3. Install Bonjour Print Services.

The TruPortal Utilities software will detect automatically if the

Bonjour software is installed and display the word “Installed” next to

the link if it is found.

4. Click Discovery and Installation Wizard.

5. Select a Language and click [Next].

The wizard will search the network for all TP controllers.

6. Select the controller to configure from the list and click [Next].

7. Type the Administrator’s current Password.

The default administrator User Name is

The default administrator Password is demo

8. Choose a new password for the administrator.

The Administrator account has access to all aspects of the TP

controller configuration. Leaving default user names and passwords in

place is dangerous. Anyone familiar with the product will know the

defaults.

9. Type the passwor d in the New Password and Confirm Password

fields and click [Next].

10. Change the settings on the Network Configuration tab as directed by

the site’s network administrator.

admin

TruPortal System Controller Quick Reference 5 P/N 460800001B 12JAN12 en-US

Page 6

11. Click [Next].

The wizard will discover controllers and I/O expansion modules

connected to the TP controller.

12. Click [Sync with PC] to set the correct time on the controller.

13. Select the appropriate Global Input EOL Terminations to indicate

how the tamper circuits and sensors on the doors and readers are

wired.

14. For each general purpose auxiliary input that is connected:

a. Select a Mode.

b. Observe the inputs to determine they are working and

communicating with the controller.

15. For each general purpose auxiliary output that is connected:

a. Click the icon next to the State to change state.

b. Observe the outputs to determine they are working and being

activated by the controller.

16. For each door controller, select the Number of Doors controlled.

17. For each door:

a. Select the appropriate Mode for contact, request to exit and

tamper circuits.

b. Select commands from the Door Control list to test each door

for proper installation and electrical wiring.

18. When you have tested all devices, click [Finish].

Jumpers

Jumper Description

CN37 External LED indication for power (to be wired to the

outside of the enclosure)

CN38 Controls SNAPP 1 termination. 120-ohm termination

is added across the bus when the shunt jumper is

installed on the pin header.

CN39 Controls SNAPP 2 termination. 120-ohm termination

is added across the bus when the shunt jumper is

installed on the pin header.

Status LEDs

The following chart describes the purpose of each LED on the I/O board.

I/O board

LED

LEDs 1 and 2 During normal operation, the heartbeat is indicated

LED 3 Orange L ED indicates co mmunication occurring on

LED 4 Orange L ED indicates co mmunication occurring on

LED 5 Orange L ED indicates co mmunication occurring on

LED 6 Orange L ED indicates co mmunication occurring on

LED 7 Green LED indicates link and activity on primary

LED 8 Y ellow LED indicates speed on primary Ethernet port

LED 9 Green LED indicates link and activity on secondary

LED 10 Yellow LED indicates speed on secondary Ethernet

LED 11 Not applicable

Description

by a one second blink rate on LED 2.

During firmware upgrade:

• When LED 1 and LED 2 are both ON, the

board is in monitor program mode (bootloader

mode).

• When LED 1 is ON and LED 2 is off,

programming (flash) firmware is in progress.

SNAPP port 1.

SNAPP port 2.

SNAPP port 4.

SNAPP port 3.

Ethernet port (Eth0).

(Eth0).

Ethernet port (Eth1).

port (Eth1).

CN40 Controls SNAPP 3 termination. 120-ohm termination

is added across the bus when the shunt jumper is

installed on the pin header.

CN41 Controls SNAPP 4 termination. 120-ohm termination

is added across the bus when the shunt jumper is

installed on the pin header.

CN35 If the panel needs to be started on battery only, without

ever having AC or DC power, this connector should be

momentarily shorted.

TruPortal System Controller Quick Reference 6 P/N 460800001B 26JAN12 en-US

LED 12 Green LED indicates the presence of power to the

board at connector CN2.

LEDs 1 through 10 will be switched off when the enclosure is closed.

The following chart describes the purpose of each LED on the SOM board.

SOM board

LED

Power LED Green LED indicates SOM power.

Status 1 Yellow LED, along with the green power LED,

Status 2 Red LED is off. Currently not defined.

Description

indicates initialization.

Page 7

TruPortal Reader Output LEDs

Warning

The following chart describes the behavior of TruPortal reader output based

on different actions of the door.

Reader Mode LED

LED Mode

RLED ID

ON Color

1 Disabled N/A

OFF Color

ON Time

OFF Time

Repeat Count

Beep Count

RdiLine1

RdiLine2

2 Unlocked

GREENGREEN30000

3 Locked RED GREEN 5 0 0 0

4 Facility RED RED 30 0 0 0

N/A N/A

5Card Only REDRED30000

6 Pin Only RED RED 30 0 0 0

7Card & Pin REDRED30000

8 Card or Pin RED R ED 30 0 0 0

Replace Battery

The event log buffer and the real time clock are backed up by a 3 V battery.

Without power being applied to the controller, the battery will retain events

and transactions for up to one year.

This battery should be replaced annually to insure that proper backup

functionally is maintained. Remove the insulator from the battery holder

after installation. Replacement battery: Panasonic CR2354 Lithium coin cell

battery.

When changing the lithium battery,

replacement must be a Panasonic

CR2354 only.

• Memory and Clock Backup: Panasonic 3 V CR2354 Lithium coin cell

• Wiring

SOM. Maximum available output current is 1 A. [Example:

250 mA for (Reader power) + 400 mA for (SNAPP Ports) =

650 mA total current used.] Drawing more will cause the output

voltage to drop as the system regulator starts to current limit.

- The power applied from the mains to the transformer in the

enclosure is 120 VAC for North America (230 VAC for Europe,

and 240 VAC for Australia).

battery

- Ground: 14 A WG (1.628 mm / 2. 08 mm

from the fused terminal block to the ground lug

- Module Bus (RS-485) Cabling (device communication and

power): Recommended: 22 AWG (0.644 mm / 0.326 mm

Caution: Battery may explode if mistreated. Do not

recharge, disassemble or dispose of in

fire. Follow local code for proper disposal

of used lithium battery.

Note: For longer cable distances, or where one cable connects many

4 conductors, shielded twisted pair, 120 impedance, low

capacitance, 41 pF/meter or 12.5 pF/foot (such as Belden 9842).

- Maximum Length: Up to 2000 feet (610 m) of cable on a Module

bus port.

expansion modules (daisy chained, star wiring configurations are

not acceptable), a 120-ohm terminating resistor will need to be

Specifications

The TruPortal System Controller is for use with UL Listed access control

power limited power supplies. These specifications are subject to change

without notice.

• Primary Power:

- AC power: 18 VAC ± 10%

- DC power: 24/12 VDC ± 10% (Not evaluated by UL.)

- Maximum input power: 2.7 A

- Total current that can be sourced from panel: 1 A.

installed across A and B communication terminals of the last

module on the bus cable.

- Separate Power (or door strike) Wiring: Recommended:18 AWG

(1.024 mm / 0.823 mm

color-coded is preferable)

- Inputs/Sensor Cabling: 22 AWG (0.644 mm / 0.326 mm

2 wires (For electrically noisy environments, use twisted pair,

and/or shielded cable.)

- Outputs/Signaling: 22 AWG (0.644 mm / 0.326 mm

2 conductors

Note: It is up to the installer to ensure that the sum of the loads on all

the supply outputs from the TruPortal System Controller plus th e

current consumed by the controller is equal to or less than 1.2 A

(see power table). The 1.2 A output current from the regulator

also includes at least 200 mA to power the I/O board and the

• Reader Cabling: 22 AWG (0.644 mm / 0.326 mm

Listed installations: 22 AWG / 0.644 mm / 0.326 mm

Maximum for reader data lines: 500 feet (150 m). Maximum fo r power

wiring: 300 feet (91.44 m).

N/A N/A

2

2

),, provided in the panel

2

),

), stranded and insulated (2 conductors;

2

),

2

),

2

),(For Canadian UL

2

), shielded.

TruPortal System Controller Quick Reference 7 P/N 460800001B 12JAN12 en-US

Page 8

- Basic reader (no LEDs, buzzer control, or tamper): 4 conductors

- Reader with LEDs: 6 conductors

- Reader with LEDs, plus buzzer and tamper: 9 conductors

• Relays outputs:

- Siren relay, 1 A @ 30 VDC

- Strobe relay, 1 A @ 30 VDC

- Strike relay, 5 A @ 30 VDC

- Aux relay, 1 A @ 30 VDC

• Environmental:

Temperature:

– Operating: 32° to 120° F (0° to +49° C)

– Storage: -40° to 185° F (-40° to 85° C)

Humidity: 10 to 85% ± 5% RHNC

BTU Output: 73.7 BTU/hour

• Mechanical:

Dimensions: H 6.30 x W 9.84 x D 1.65 inches (H 16 0 x W 250 x

D 42 mm)

We ight of I/O board and SOM board: 1.04 lbs. (0.47 kg)

Weight of accompanying parts:

– Enclosure: 13.2 lbs. (6 kg)

– Transformer: 2.2 lbs (1 kg)

– Battery retention bracket:0.2 lb. (0.09 kg)

– 18 Ahr battery: 12.8 lbs. (5.8 kg)

• UL294 Listed

• FCC Part 15

•CE marking

• RoHS compliant

•WEEE

• FCC part 15

•ULC Listed

• AES128 certified (Certificate #1496)

TruPortal System Controller Quick Reference 8 P/N 460800001B 26JAN12 en-US

Page 9

GG

D

DD

D

E

DDD

DD

D

EE

FF

N

N

N

KK

K

H

J

K

N

D

D

N

D

N

N

N

N

H

N

G

150mm ±0.5 0

[5.91in ±0.02]

150mm ±0.50

[5.91in ±0.02]

47.12mm

[1.86in]

174.12mm

[6.86in]

130mm ±0.5

[5.12in ±0.02]

10.92mm (5 POS)

[0.430in]

50mm ±0.5

[1.97in ±0.02]

230mm ±0.5

[9.06in ±0.02]

254.00mm

[10.000in]

140.00mm

[5.51in]

145mm ±0.5

[5.71in ±0.02]

224.92mm

[8.86in]

97.79mm

[3.85in]

59.08mm

[2.33in]

232.46mm

[9.15in]

J

N

J

6.48mm

[0.255in]

10.00mm

[0.394in]

R2.55mm

[0.1004in]

11. 00mm

[0.433in]

160.51mm

[6.32in]

149.84mm

[5.90in]

40.00mm

[1.57in]

10.14mm

[0.40in]

238.53mm

[9.391in]

130.00mm

[5.12in]

463.43mm

[18.245in]

438.15mm

[17.25in]

463.43mm

[18.25in]

65mm ±0.50

[2.56in ±0.02]

163.12mm

[6.42in]

170mm ±0.5

[6.69in ±0.02]

212mm ±0.5

[8.37in ±0.02]

55mm ±0.5 0

[2.17in ±0.02]

15.00mm

[0.59in]

60.36mm

[2.38in]

100mm ±0.5

[3.94in ±0.02]

65mm ±0.50

[2.5591in ±0.0197]

89.0mm ±1.0

[3.504in ±0.039]

81.00mm

[3.19in]

12.70mm

[0.50in]

469.9mm

[18.5in]

12.70mm

[0.50in]

25.00mm

[0.98in]

119.9mm ±1.0

[4.721in ±0.039]

15.37mm

[0.61in]

45.87mm

[1.81in]

63.40mm

[2.50in]

119.92mm

[4.72in]

239.84mm

[9.44in]

Figure 1: TruPortal System Controller enclosure

TruPortal System Controller Quick Reference 9 P/N 460800001B 12JAN12 en-US

Page 10

Figure 2: TruPortal controller

1K

Input 2

Input 1

Input 1

Input 2

0V

Input 3

0V

Input 3

Input 4

1K

1K

1K

1K 1K

1K

1K

Input 4

+12V

Aux 1 +V output

Aux 2 +V output

0V

C

Siren Relay

Strobe Relay

External Tamper

0V

NC

Aux

Power

C

N0

0V

SW

V0V0V

B

-

A +

+V

Ethernet

Port 1

+

-

To 12V battery

(Power limited to

200mA per port)

Ethernet

Port 2

3V

Coin

Cell

IP Setting

Term 4

Term 3

Term 2

Term 1

12VDC Input

18VAC/

24VDC Input

0V

NO

Network Interface

(Access Control System Host Communications)

CN1

CN2

CN3

CN4

CN5

CN6CN43

CN7

CN8

CN9

CN10 CN11

CN12

CN13

CN14

CN15

CN16

CN17

CN18 CN19

CN20

CN21 CN22

CN23

CN24

CN25

CN26

CN27

1

2

1

2

3

1

2

3

1

2

1

212

1

2

3

4

12

312

3

1 2

3

12

3

1 2

3

4

1 2

12

1 2

3

12

3

1 2

3

1 2

3

1 2

3

4

12 12

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

3

2

1

4

3

2

1

+V

Relay option

if fitted

RS485

Bus 1

RS485

Bus 2

RS485

Bus 3

RS485

Bus 4

VBUS

Panasonic p/n

CR2354

To secure battery use

bracket p/n 28005B

and

2 of the 8-32 screws

from the supplied

accessories kit.

14V

SND

18VAC/24VDC

Power Indication LED

Config

Factory set : do not adjust

OSDP1 Comms LED

OSDP2

Comms

LED

Microcontroller

Status LEDs

Speed LEDs

(10Mbits/100Mbits)

Link (Activity) LED

Link (Activity) LED

Te st

Add shunt to

Term 1~4 if

120Ω

termination

is required

SNAPP 4 LED

SNAPP 2 LED

SNAPP 3 LED

SNAPP 1 LED

SNAPP LEDs

indicate bus

comms

USB 2

Dual Port

CN37

CN32

+

RED

BLACK

WW Modem

Socket

SOM Status LEDs

The 1K EOL resistors and NO contacts on the

supervised inputs are shown as a typical

configuration only and do not restrict the actual use

of these inputs in the field.

0V

B

-

A +

+V

0V

B

-

A +

+V

0V

B

-

A +

+V

Buzzer

Access

Reader 1

0V

+V

Green LED

Red LED

D

1

D

0

D

1

D

0

N0

C

Egress

Reader

Aux

Relay

Strike

Relay

Door Controller 1

1K

Input

Input

Aux

RTE

0V

DR

TR

0V

Input

Input

N0

C

NC

1K

1K

1K

1K 1K

1K

1K

Buzzer

Access

Reader 2

0V

+V

Green LED

Red LED

D

1

D

0

D

1

D

0

N0

C

Egress

Reader

Aux

Relay

Strike

Relay

Door Controller 2

1K

Input

Input

Aux

RTE

0V

DR

TR

0V

Input

Input

N0

C

NC

1K

1K

1K

1K 1K

1K

1K

Non Power Limited

Power Limited

Power Limited

Power Limited

Power Limited

Power Limited

Power Limited

Power Limited

Battery leads to be routed

directly under board

Maintain 0.25in spacing between power

and Non Power Limited circuits

POWER +

POWER -

The 1K EOL resistors and NO contacts on the supervised inputs are shown as a typical configuration only and do not restrict the actual use of these inputs in

the field.

The battery leads at CN32 must be routed away from power limited circuits. Maintain 0.25 inches (6 mm) spacing between non-power limited (that is, battery

leads and AC Mains) and power limited wiring.

TruPortal System Controller Quick Reference 10 P/N 460800001B 26JAN12 en-US

Loading...

Loading...