Page 1

SuperBus 2000 2X16 LCD Alphanumeric

Touchpad Installation Instructions

Product summary

The SuperBus® 2000 2x16 LCD (liquid crystal display)

Alphanumeric Touchpad lets you control all programming and

operation of a compatible security system (see “Specifications”

on page 4). The 2-line, 16-character display provides

messag

The touchpad includes police, fire, and auxiliary panic buttons

that can be activated anytime.

A built in speaker provides alarm sounds, status sounds, and

button-press beeps.

es to indicate the current system status.

Installation guidelines

• Mount the touchpad in an environmentally controlled area

32 to 120°F (0 to 49°C).

• When mounting the touchpad, allow at least 4¼ inches on

the left side for the Quick Guide slide-out card.

• For Concord

be connected to the panel. For Concord systems (all

software versions) up to 16 bus devices can be connected

to the panel.

• For Concord systems with software versions 1.0–1.6, each

bus device must have a different unit number setting to

operate correctly. The touchpad unit number is factory set

to 001. For Concord panels with software version 2.0 or

later and Concord Express panels, bus unit numbers are

assigned automatically.

• Table 1 below describes the power used by the touchpad.

™

Express systems, up to 4 bus devices can

Table 2: Maximum touchpad wire lengths

Wire Gauge (Unshielded

or Shielded)

18 750 feet

22 300 feet

Maximum wire length between

touchpad and panel

Tools and equipment needed

• 4-conductor, 22- or 18-gauge wire

• Screwdriver

• Drill/bits

• #6 screws and anchors (included)

• Panhead screws for a gang box installation

• Saw or utility knife for cutting wallboard

Installing the mounting plate

The touchpad can be installed on a wall or electrical gang box,

either single- or dual-gang.

1. Separate the mounting plate from the touchpad by

pressing the tab at the bottom and sliding the mounting

plate down (see Figure 1 below).

Figure 1: Separating touchpad from mounting plate

Lift and Pull

Mounting Plate

Tab

Tab

Table 1: Touchpad power usage

Current (mA) Condition

90 Maximum alarm current

57 Typical operation

12 Standby current (no AC power)

• Do not exceed the maximum available power when using

panel power for bus devices and hardwire detectors (see

the specific panel Installation Instructions for maximum

available power).

• Table 2 below describes the maximum wire lengths

allo

wed between the touchpad and panel.

P/N 466-17

12 • REV D • January 2011 1

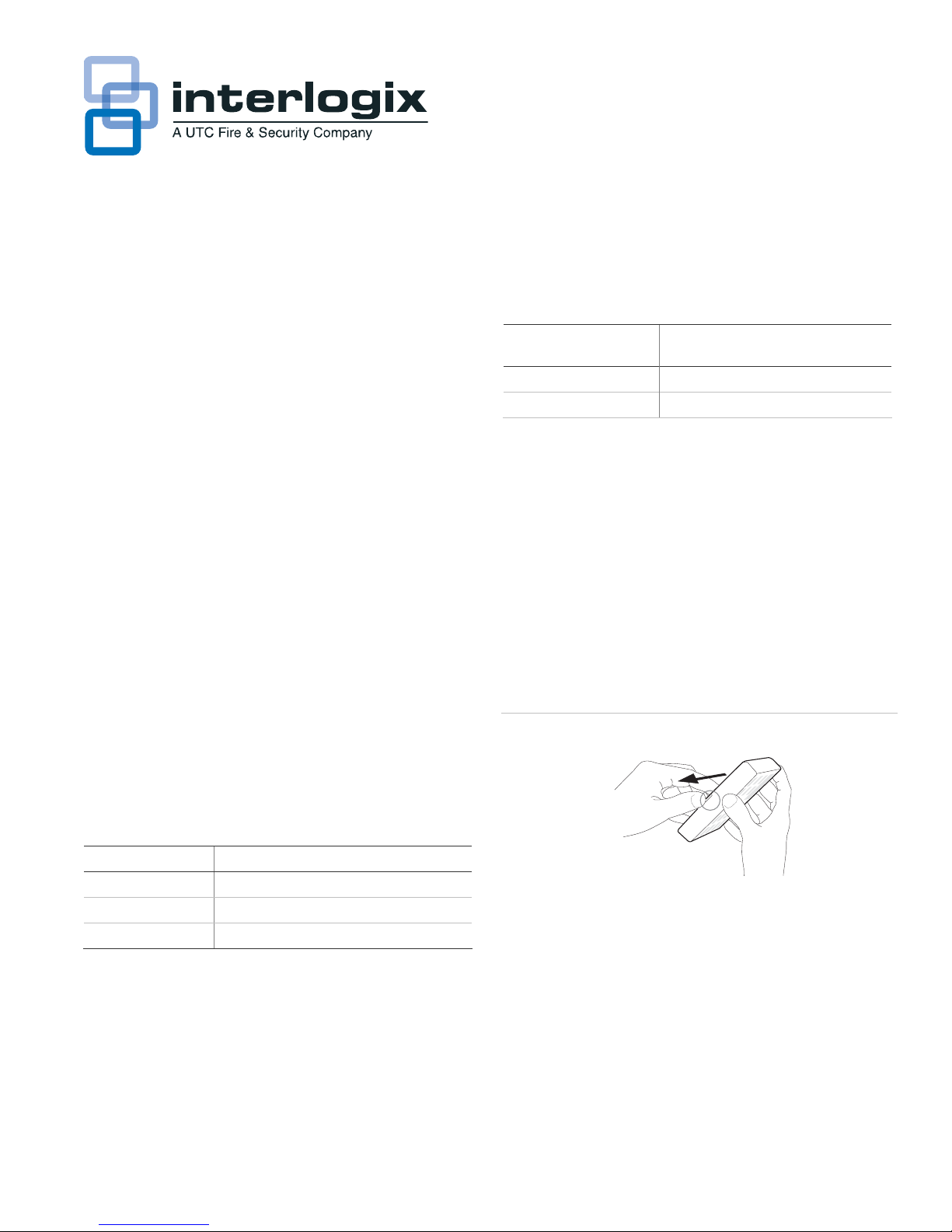

2. Place the mounting plate on the wall and mark the four

mounting holes (see Figure 2 on page 2). Be sure to leave

a 4¼-inc

Guide slide-out card.

3. Insert anchors at the marked locations where studs are

not present.

h clearance on the left side to allow for the Quick

Page 2

T

2: Mounting holes

Figure

Wire Access Area

Wall Mounting Holes (4)

Dual-Gang Mounting Holes (4)

Single-Gang Mounting Holes (4)

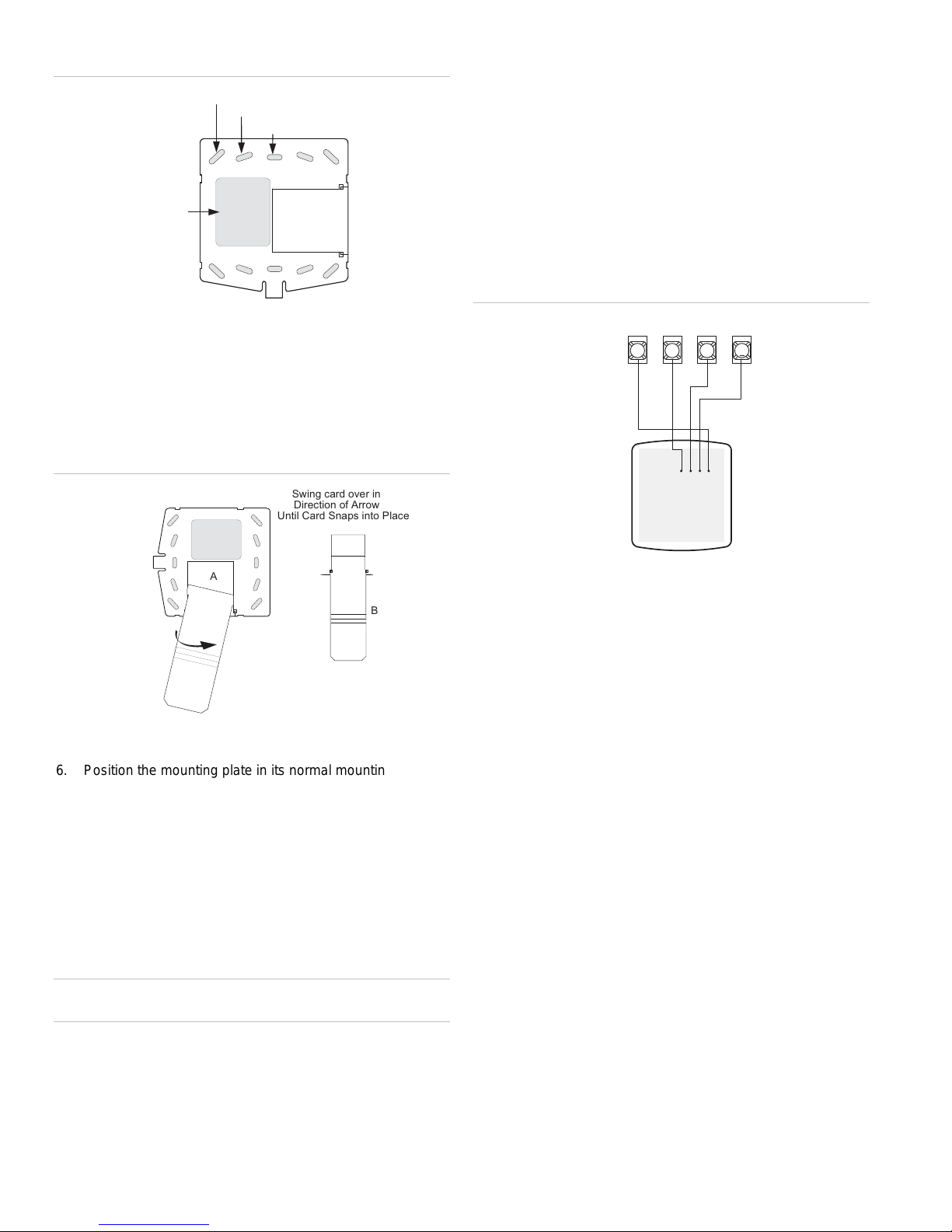

Wiring

Wiring consists of connecting the touchpad to the panel

terminals.

1. Disconnect the panel transformer and backup battery.

2. Run a 4-conductor, 18- to 22-gauge wire from the panel to

the touchpad location.

3. Splice the 4-conductor cable wires to the red, black,

green, and white wires located on the back of the

touchpad.

4. Connect the touchpad wiring to the panel terminals as

shown in Figure 4 below.

4. Looking at the back side of the mounting plate, turn it so

the tab is on the left and position the Quick Guide slideout card into the slots on back of the mounting plate (see

A in Figure 3 below). Make sure the card is unfolded and

the “Z

ones” section is facing you.

5. Slide the card in the direction of the arrow in Figure 3

below (A) until it snaps into the position shown in (B).

Figure 3: Inserting the Quick Guide Slide-Out card

Swing card over in

Direction of Arrow

Until Card Snaps into Place

A

B

6. Position the mounting plate in its normal mounting position

(tab at the bottom) and fold the card toward you at all

three scored lines. The “Zones” section should be facing

you and the folds should create a tab to slide the card in

and out.

7. Align the mounting plate wall-mount holes with the wall

anchors and secure the back-plate to the wall using the

screws provided.

OR If installing the back-plate on an electrical gang box,

line up the appropriate gang box holes on the mounting

plate with the gang box holes and secure the back-plate to

the gang box using the screws provided.

Caution: Do not over tighten screws or the back plate may

bend and prevent the touchpad from mounting properly.

8. For wall-mounted installations, cut a hole in the wall in the

wire access area of the mounting plate to pull your cable

through for wiring.

Figure 4: Wiring touchpad to panel terminals

+12V

A

BUS

B

6

NEERG/A SUB

GND/BLACK

BUS B/WHITE

BACK OF

OUCHPAD

GND

3 4 5

+12V/RED

Attaching the Touchpad to the Mounting Plate

Align the four slots on the touchpad with the four tabs on the

mounting plate and slide the keypad down until you hear the

latch on the mounting plate click into place.

Power Up

After making all wiring connections from the touchpad to the

panel, you are ready to power up the panel. Upon power up,

the panel scans the bus for connected devices and

automatically learns the unit number of each bus device.

Note: If you plan on installing systems with no alphanumeric

touchpads, it is recommended that you keep an alphanumeric

touchpad with you, specifically for programming. This touchpad

can be quickly connected and disconnected from the header

pins on the lower portion of the panel circuit board, as

described later in this document.

To power up the panel and verify bus communication:

1. Verify that all wiring between the panel and touchpad is

correct.

Note: If the touchpad does not display the date and time,

see “Troubleshooting” on page 4.

Connect the panel battery and plug in the panel

2.

transformer. Alphanumeric touchpads should show a date

and time display.

Connecting the touchpad for system programming only

or installations that don’t include an alphanumeric touchpad

F

as a permanent part of the system, you can connect one for

2

SuperBus 2000 2X16 LCD Alphanumeric Touchpad Installation Instructions

Page 3

system programming to the Programming Touchpad Header

on the panel.

To do this you must first connect a Programming Touchpad

Cable (60-791) to the touchpad wires (see Programming

Touchpad Cable Installation Instructions—466-1604, included

with the cable). Then, use the appropriate procedure for

connecting the touchpad.

To connect a programming touchpad to a Concord

press or Concord panel with software version 2.0 or

Ex

later:

1. With the panel powered up, connect the cable to the

Programming Touchpad Header (see Figure 5 below).

Figure 5: Connecting a programming touchpad

Programming

Touchpad

Cable (60-791)

2. Activate the service touchpad by pressing 8 + CODE + 0 +

2.

3. Enter program mode by pressing 8 + installer/dealer

CODE + 0 + 0 and program the panel using the panel

documentation.

4. When programming is completed, simply disconnect the

programming touchpad.

To connect a programming touchpad to a Concord panel

ith software versions 1.0–1.6:

w

1. Disconnect AC and backup battery power.

2. Connect the cable plug to the panel Programming

Touchpad Header pins (see Figure 5 above).

3.

Reconnect the AC and backup battery power. The

touchpad briefly displays ***********,

SCANNING BUS DEVICES, then shows a time and date

display.

Note: If the touchpad does not respond as described in step 3,

there may be a bus conflict. To correct this, change the

touchpad unit number as described in the section “Changing

the Touchpad Unit Number.”

Removing the programming touchpad from Concord

p

anels with software versions 1.0–1.6:

To prevent a trouble condition, you must delete the

programming touchpad unit number from Concord panel

memory before disconnecting it.

1. After programming is completed, return to the

ACCESSORY MODULES menu, then press É. The

display should read BUS DEVICES.

2. Press É. The display shows the lowest unit number and its

device name.

3. Press A or B until the display shows the programming

touchpad unit number.

4. Press D to delete the device and its unit number from

panel memory. The display shows:

UNIT - TYPE

14-NONE

5. Exit program mode and disconnect the programming cable

from the panel header.

Testing

Caution: Contact the Central Monitoring Station before

activating any alarms, to avoid dispatching local police and fire

departments.

Test the touchpad by arming/disarming the system, activating

the touchpad panics, bypassing sensors, and by turning chime

and lights on/off to verify correct operation. Refer to the panel

documentation for system operating instructions.

Adjusting Display

The touchpad display can be adjusted for easier viewing to

help compensate for lighting conditions in the touchpad

location. The brightness adjustment lightens or darkens the

background. The contrast adjustment lightens or darkens the

text.

To adjust display brightness:

Enter user programming mode by pressing 9 + user,

1.

partition, or system master CODE. The display shows

SYSTEM MENU, then TIME AND DATE

(Concord panels with software versions 1.0–1.6 display

USER CODES.)

2. Press B until the display shows OPTIONS, then press É.

The display shows DOWNLOADING ON/OFF (current

setting).

3. Press B until the display shows TOUCHPAD

BRIGHTNESS 2 (default setting).

4. Enter a setting from 0 (darkest background) to 3 (brightest

background), then press É.

5. The display flashes the entered selection, then stops after

pressing É and displays the new setting and brightness

level.

6. Exit user programming mode by entering:

Ç + 0 + 0 + É for Concord panels with software

versions 2.0 or later

or

Ç + 7 + É for Concord panels with software versions 1.0–

1.6.

To adjust display contrast:

Enter configuration mode by pressing the D and 6 buttons

1.

together for at least two seconds. The display shows DA

nnn.

SuperBus 2000

2X16 LCD Alphanumeric Touchpad Installation Instructions 3

Page 4

2. Press and release the 1 and 2 buttons together

repeatedly, until the desired contrast level is displayed.

3. Press Ç and the display briefly shows DONE, then shows

the time and date.

Troubleshooting

Table 3 below describes what to do if the touchpad does not

operate correctly.

Table 3: Troubleshooting

Problem Action/Solution

Touchpad doesn’t

power up (no display

and no beeps when

buttons are pressed).

Touchpad display

appears blank, but

beeps sound when

buttons are pressed.

Touchpad display

shows a flashing *,

indicating a trouble

condition and system

doesn’t respond to

commands from

touchpad.

Check for correct wiring connections at

touchpad and panel terminals.

Make sure panel battery is connected

correctly and that the panel transformer is

plugged in.

Make sure panel transformer is not plugged

into an electrical outlet controlled by a

switch. Relocate transformer to an

unswitched outlet location, if necessary.

Check the touchpad display contrast setting.

It may be set to 0 (no display).

Check for correct bus wiring connections

(green and white wires) at touchpad and

panel terminals.

Make sure touchpad unit number is set to a

different number than all other bus devices.

If necessary, change the touchpad unit

number (see procedure on this page).

(Concord panels with software versions 1.0-

1.6 only.)

4. Press Ç to exit from the configuration mode.

Note: If the new touchpad unit number was previously

learned by the panel, communication between the

touchpad and the panel begins immediately. However, if

the new touchpad unit number has never been learned by

the panel, continue with step five.

5. Force the panel to scan bus devices as follows:

For systems where this is the only installed touchpad,

remove panel AC and battery power, then re-apply power.

For systems with more than one touchpad, go to another

system touchpad and enter 8 + installer/dealer CODE + 0

+ 1. The display shows SCANNING BUS DEVICES, then

a time and date display.

The touchpad and all other bus devices should operate

correctly and any bus failures should be cleared.

Note: If the panel still indicates a bus failure the panel may

have previously learned a unit number that is no longer used

by any bus device. See the specific panel Installation

Instructions for more information on deleting unused unit

numbers.

Specifications

Compatibility Concord, Concord Express, Concord Ultra

Panels

Power requirements 12 VDC nominal (see Table 1 on page 1 for

more information)

Operating temperature 32 to 120°F (0 to 49°C)

Humidity 70% relative, non-condensing

Dimensions 5.0 x 4.5 x 0.75 in. (L x W x D)

Installation Wall mount

Changing the Touchpad Unit Number (Concord

Panels with Software Version 1.0-1.6 Only)

Use the following guidelines when changing device unit

numbers to avoid communication conflicts between bus

devices and the panel:

• All bus devices with DIP switches (LED Touchpads,

ESMs, HIMs, etc.) must be set to the desired unit number

before applying power and entering program mode.

• Whenever possible, assign touchpad unit numbers before

all other panel programming.

To change the touchpad unit number:

At the touchpad, press and hold the D and 6 buttons

1.

together for at least 2 seconds. The display should show

DA n, where n is the touchpad current unit number (000 -

015).

Note: At this time, the touchpad is in configuration mode

and no longer communicating to the panel. The system

may immediately indicate a bus failure. Ignore the failure

and continue with the procedure. The bus failure will clear

after successfully changing the touchpad unit number.

2. Press É. The display shows ENTER _.

3. Enter the desired three digit unit number (000 - 015), then

press É. The display shows DA n, where n is the new

touchpad unit number.

Note: Do not use unit number 15 in Concord RF systems.

Regulatory information

Manufacturer UTC Fire & Security Americas Corporation, Inc.

1275 Red Fox Rd., Arden Hills, MN 55112-6943,

USA

UL listings UL 985 Household Fire Warning System Units

UL 1023 Household Burglar-Alarm System Units

UL1610 Central Station Burglar-Alarm Units

(Commercial Burglary)

Note: See specific panel Installation Instructions

for complete UL installation requirements for the

system you are installing

Contact information

For contact information, see www.utcfireandsecurity.com or

www.interlogix.com.

For technical support, toll-free: 888.437.3287 in the US

including Alaska, Hawaii, Puerto Rico, and Canada. Outside

the tool-free area, contact your dealer.

Copyright © 2011 Interlogix, a UTC Fire & Security Company.

All rights reserved.

4 SuperBus 2000 2X16 LCD Alphanumeric Touchpad Installation Instructions

Loading...

Loading...