Page 1

Intrusion Sensor

Application Notebook

Page 2

Copyright Copyright © 2005, GE Security Inc. All rights reserved.

This document may not be copied or otherwise reproduced, in whole or in part, except as specifically

permitted under US and international copyright law, without the prior written consent from GE.

Document number/ revision: 1055178A (December 2005).

Disclaimer THE INFORMATION IN THIS DOCUMENT IS SUBJECT TO CHANGE WITHOUT NOTICE. GE ASSUMES NO

Trademarks and patents GE and the GE monogram are registered trademarks of General Electric.

Intended use Use this product only for the purpose it was designed for; refer to the individual sensor installation

RESPONSIBILITY FOR INACCURACIES OR OMISSIONS AND SPECIFICALLY DISCLAIMS ANY LIABILITIES,

LOSSES, OR RISKS, PERSONAL OR OTHERWISE, INCURRED AS A CONSEQUENCE, DIRECTLY OR INDIRECTLY,

OF THE USE OR APPLICATION OF ANY OF THE CONTENTS OF THIS DOCUMENT. FOR THE LATEST DOCUMENTATION, CONTACT YOUR LOCAL SUPPLIER OR VISIT US ONLINE AT WWW.GESECURITY.COM.

This publication may contain examples of screen captures and reports used in daily operations. Examples may include fictitious names of individuals and companies. Any similarity to names and addresses

of actual businesses or persons is entirely coincidental.

Other trade names used in this document may be trademarks or registered trademarks of the manufacturers or vendors of the respective products.

instructions for the latest product information or visit us online at

www.gesecurity.com.

Page 3

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Chapter 1. Glassbreak/shock sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Prewire installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Inconspicuous installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Bathroom windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Skylights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Windows with curtains and blinds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Single window with wireless sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Multiple windows with wireless sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

French doors and small windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Glass doors and windows that open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Insulated glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Windows with film. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Thick glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Large rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Small rooms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Occupied areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Rooms with cleaning crews. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Storefront windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Roll-up metal shutters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Glass display and jewelry cases. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Metal enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filing cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Jewelry store safes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

ATM and night deposit boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

iii

Page 4

Intrusion Sensor

iv

Application Notebook

Chapter 2. Motion sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Pets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Wireless sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Discreet appearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Flush mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Ceiling mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Antimasking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Museums . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Office foyers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Storefront windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Hallways and lobby lighting activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Partitions or other obstacles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Request-to-exit door control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Request-to-exit roll-up door control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Room perimeters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Multilevel homes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Valuable equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Vacation homes and garages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Indoor swimming pools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Large areas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Long corridors or aisles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Schools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Outdoor areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Loading docks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Drive-through pickup areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Vegetable gardens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Outdoor swimming pools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

CCTV camera activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Outdoor lighting activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Extreme temperature conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Explosive atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Page 5

Chapter 3. Magnetic contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Nice-Duc surface wire concealment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Sliding aluminum doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Automatic garage doors with switch shunting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Wood doors with threshold contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Steel doors with threshold contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Recessed steel doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Deeply recessed doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

Overhead or curtain doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Panel or sectional overhead doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

High security doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

Explosion-proof, high-security switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Revolving doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Freezer doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

Roller-plunger contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

Doors with uneven wiring holes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

Increase gap distances with a second magnet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

Mechanical recessed switch replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

Window ventilation without false alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Window ventilation using two magnets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

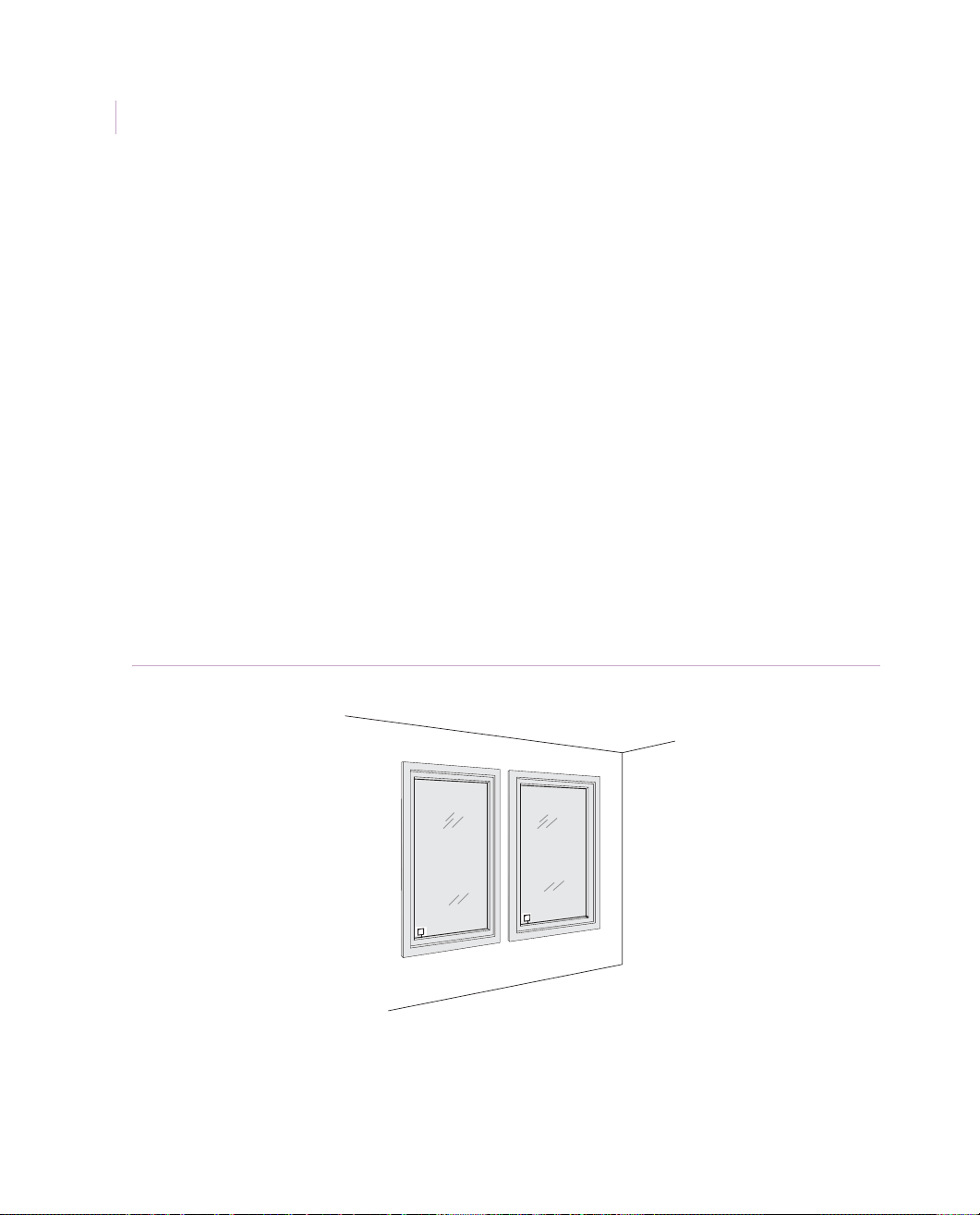

Sliding aluminum windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Windows with thin frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Windows with thin steel frames. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Double-hung windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Pella casement or awning windows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

Anderson casement windows. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

Hinged skylights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

Attic entry drop-down stairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Barrier Bars. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Roof hatches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

Metal enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .149

Cash register drawers with Bill Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Drawers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

China cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

v

Page 6

Intrusion Sensor

vi

Application Notebook

Guns and gun cabinets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Art objects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Hung art objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Computers, TVs, and stereos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Recreational equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Boat decks and cabins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .161

Boat moorings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Trucks and trailers at loading docks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Truck tailgates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Chain-link rolling gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Fence gates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Silent panic switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Chapter 4. Technical support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .169

Contacting technical support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Page 7

Preface

This is the GE Intrusion Sensor Application Notebook. This document includes a product

overview, installation guidelines, and applications for the following products:

• glassbreak/shock sensors

• motion sensors

• magnetic contacts

Although the installation and tips in this document have been developed by engin eers and

installers, GE disclaims any liability for injury or losses due to this information. This

document does not supersede codes, ordinances, or regulatory standards. Refer to each

sensor’s manual for detailed installation instructions. GE reserves the right to change

product specifications at any time.

To use this document effectively, you should have the following minimum qualifications:

• a basic knowledge of security and life safety sensors; and

• a basic knowledge of sensor installation requirements

The most current versions of this and related documentation may be found on our website.

Refer to Online publication library on page 170 for instructions on accessing our online

publication library.

1

Note: A qualified service person, complying with all applicable codes, should perform all required

hardware installation.

Page 8

Intrusion Sensor

2

Application Notebook

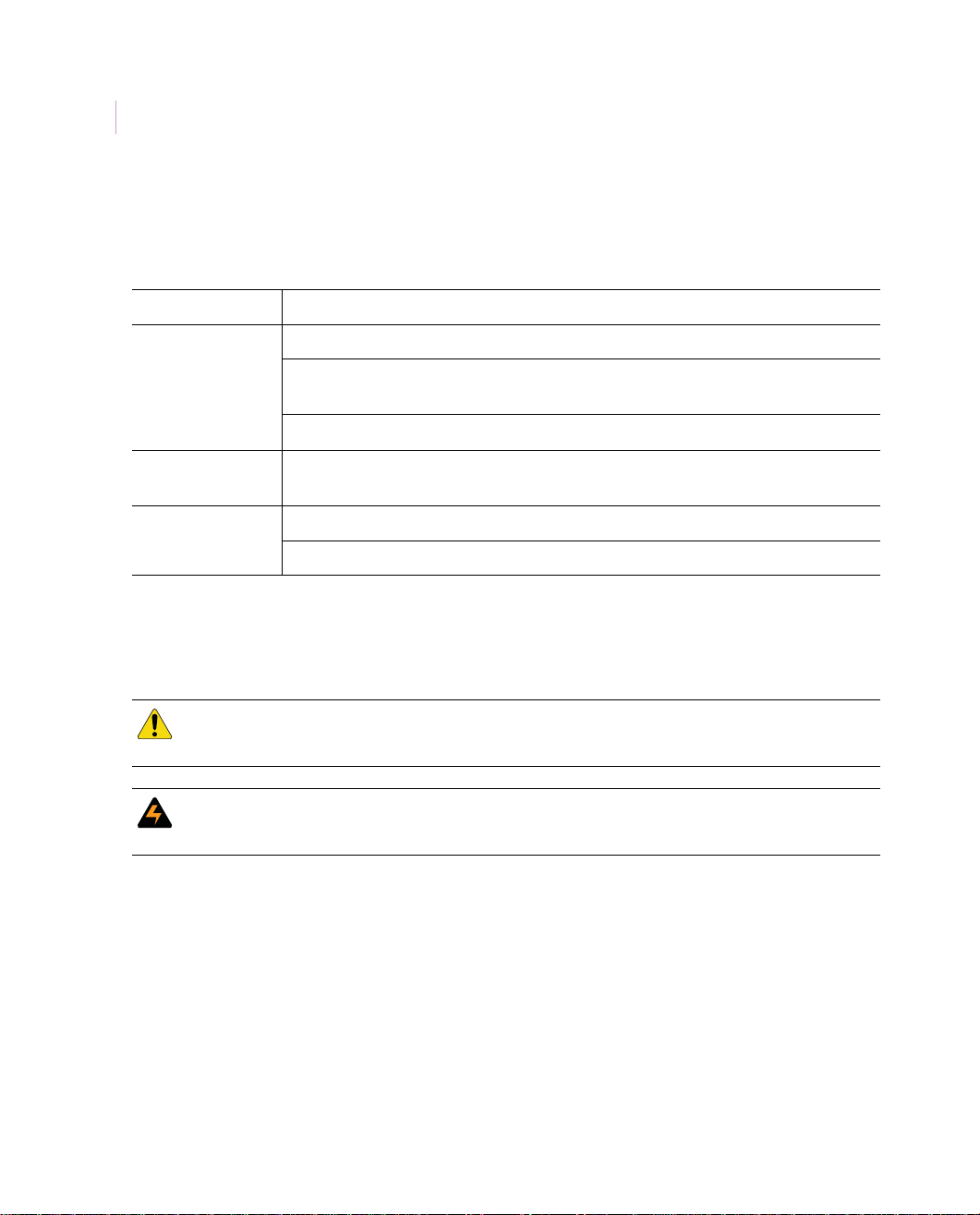

Conventions used in this document

The following conventions are used in this document:

Bold Menu items and buttons.

Italic Emphasis of an instruction or point; special terms.

File names, path names, windows, panes, tabs, fields, variables, and other GUI

elements.

Titles of books and various documents.

Blue italic (Electronic version.) Hyperlinks to cross-references, related topics, and URL

addresses.

Monospace Text that displays on the computer screen.

Programming or coding sequences.

Safety terms and symbols

These terms may appear in this manual:

CAUTION: Cautions identify conditions or practices that may result in damage to the equipment

or other property.

WARNING: Warnings identify conditions or practices that could result in equipment damage or

serious personal injury.

Page 9

Chapter 1 Glassbreak/shock sensors

This chapter provides information on glassbreak and shock

sensors including an overview of acoustic sensors, shock

sensors, and wireless-compatible sensors.

Applications in this chapter include different types of windows

and glass doors in a variety of rooms and buildings as well as

applications for metal enclosures such as filing cabinets and

safes.

Page 10

Intrusion Sensor

4

Application Notebook

Product overview

There are two basic types of glassbreak sensors: acoustic and shock. Acoustic sensors listen

for the unique sound of glass breaking, while shock sensors feel the wave generated by glass

breaking.

Acoustic sensors

Acoustic glassbreak sensors are an important part of an effective perimeter detection system.

It is very important to choose the right sensor for a particular application or environment.

GE offers you a variety of choices for virtually any glassbreak application.

ShatterPro 3, the premier technology. ShatterPro 3 acoustic glassbreak sensors give

you a potent combination of range, reliability, flexibility, and ease of use. They offer a 25 ft.

(7.6 m) radius range for extended glassbreak detection. Using patented pattern recognition

technology, the sensor is designed to eliminate common false alarms and improve detection

of framed glass breaks. It does this by listening for the unique sound of glass breaking at

numerous points across the entire frequency spectrum, not just at one or two points.

ShatterPro Plus, 24 hours a day. The ShatterPro Plus is an acoustic glassbreak sensor

combined with a passive infrared motion sensor (PIR). The sensor can detect break-ins

through glass while eliminating occupant-generated false alarms.

Page 11

Glassbreak/shock sensors

Chapter 1

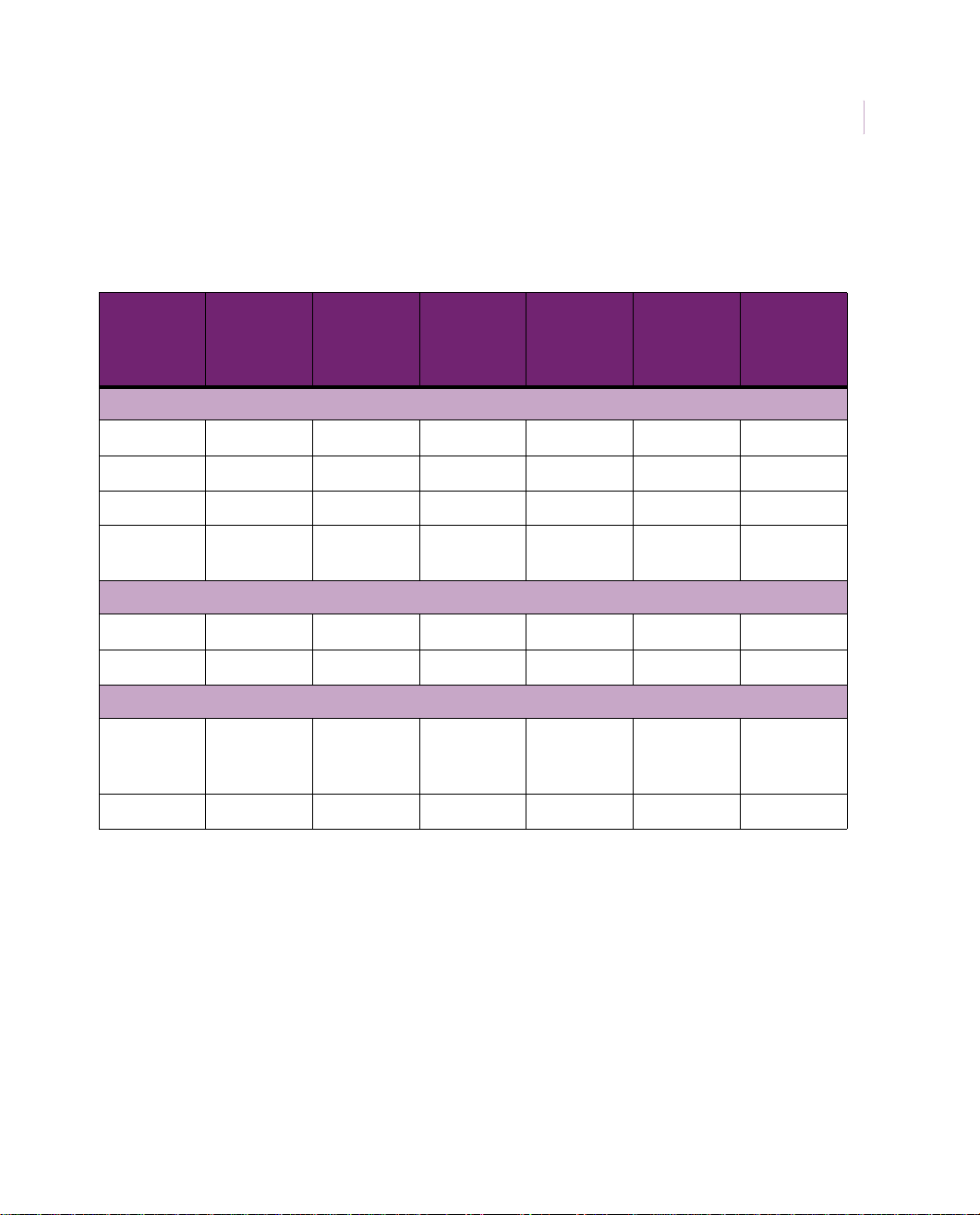

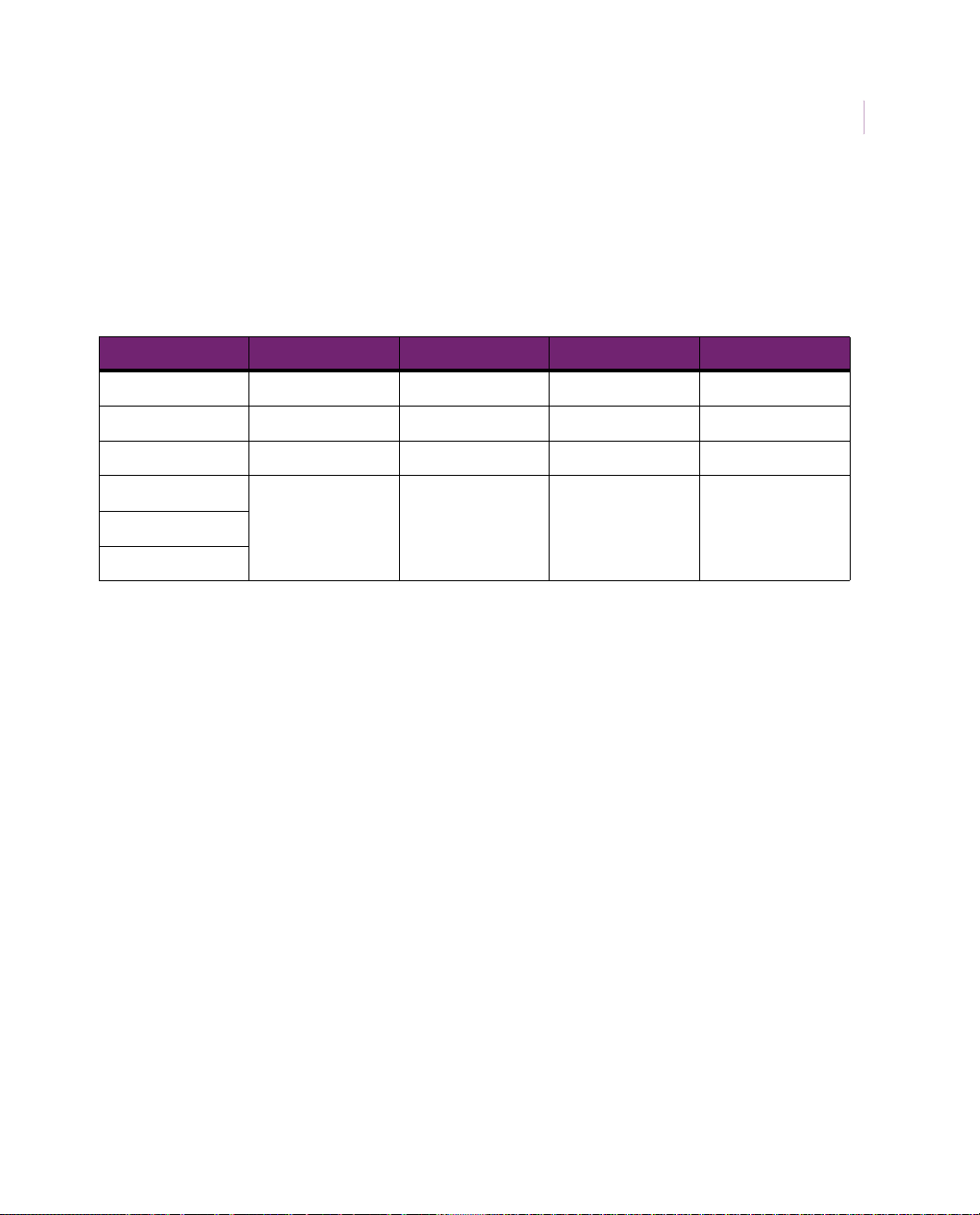

Table 1 shows product comparison information of acoustic sensors to help you choose the

right product.

Table 1. Acoustic sensors

5

Occupied

Pattern

Range to

Model

ShatterPro 3

58121NT 25 ft. (7.6 m) Yes Yes Yes Yes No

R5812NT 25 ft . (7.6 m) Yes Yes Yes Yes No

5812-RND 25 ft. (7.6 m) Yes Yes Yes Yes No

2000 25 ft. (7.6 m) Yes No No (3 x 3

ShatterPro II

5820A 25 ft. (7.6 m) Yes Yes Yes Yes No

584503*

24-hour sensors

5885

ShatterPro

Plus

5600 10 ft. (3.1 m) No No No Yes Yes

window

20 ft . (6.1 m) Yes No Yes Yes No

12 to 15 ft.

(3.7 to 4.6 m)

Automatic

test

Yes Yes Yes Yes Yes

End-user

verification

recognition

technology

technology)

area

perimeter

loop

Yes No

24-hour

application/

built-in PIR

sensor

*Also available as 5845-ID, Point ID, NX488, and 60-873-95

Page 12

Intrusion Sensor

S

6

Application Notebook

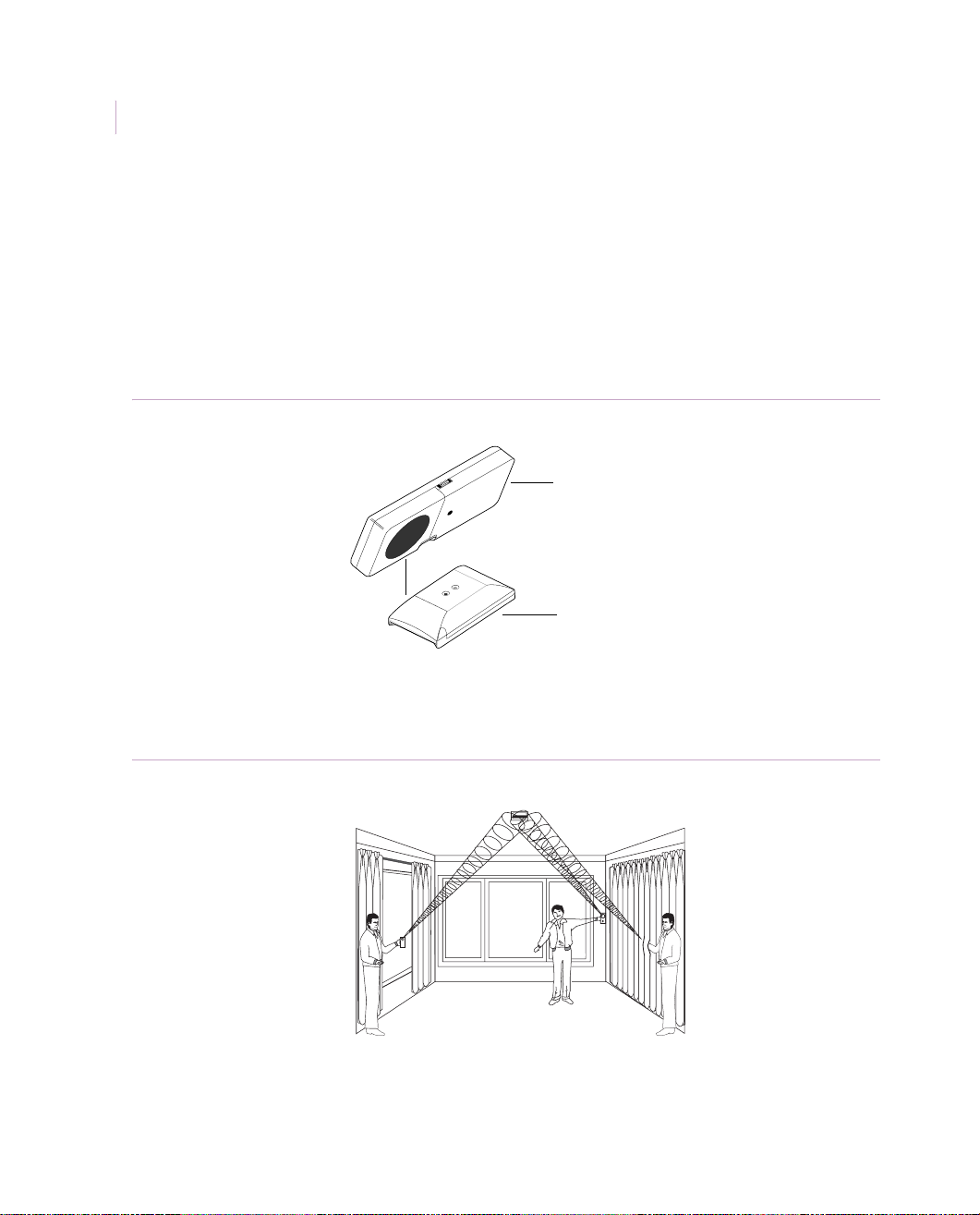

Acoustic sensor testing with the 5709C

To verify sensor range and operation for acoustic sensors (for 2000 models, see Acoustic

sensor testing with the GT-2 tester on page 7), use the 5709C tester and do the following:

1. Set the tester to the appropriate glass type. Use the tempered setting if you are

unsure about the glass type.

2. Hold the tester 1 in. (2.5 cm) from the sensor (Figure 1) and activate the sensor.

Figure 1. Hand-held tester

SENTROL

ShatterSwitch

Shatterbox II

Shatterbox

ShatterPro

5709C

Use for testing:

Plate •

Laminated •

Tempered •

Shatter Series Tester

stays on during test

Battery LED

Battery is OK if LED

• Continuous

• Single

5709C tester

1 in (2.5 cm)

Acoustic glassbreak sensor

3. Hold the tester near the surface of the glass to be protected and aim the speaker at

the sensor. Be sure the tester is at the point on the glass furthest from the sensor. If

closed drapes or curtains are present, hold the test behind them (Figure 2).

Figure 2. Testing with drapes

ensor

4. Press the test button on the tester. The sensor should indicate the glass is within

detection range of the sensor. If not, move the sensor and retest.

Page 13

Glassbreak/shock sensors

Chapter 1

Acoustic sensor testing with the GT-2 tester

To verify sensor range and operation for 2000 model acoustic sensors, use the GT-2 tester

and do the following:

1. Remove the cover from the glassbreak sensor.

2. To put the sensor in test mode, press the test button on the sensor two times. The

sensor LEDs will blink slowly. (See the sensor installation instructions for test

button location).

3. For a low frequency test, tap the wall or ceiling near the sensor. The sensor LEDs

should stay lit during the alarm event.

4. For a high frequency test, press the test button on the sensor two times. The sensor

LEDs should blink rapidly. Place the cover on the sensor. Place the GT-2 tester

behind the curtains of the window to be protected (see Figure 2 on page 6) and press

the test mode switch on the tester (Figure 3). The sensor LEDs should remain lit

during the alarm event.

5. The sensor will time out of test mode in 15 minutes.

7

Figure 3. GT-2 tester

Test mode switch

TEST

LOW

BATTERY

Page 14

Intrusion Sensor

8

Application Notebook

Shock sensors

Breaking glass produces specific shock frequencies that travel through glass and window

frames. When shock sensors feel the wave generated by breaking glass, they signal an alarm.

These sensors mount directly on the glass or the frame and give you a product virtually

immune to false alarms. Shock sensors can operate on windows with heavy drapes or

shutters and they help prevent break-in attempts by providing a visual deterrent to intruders.

Most GE shock sensors are solid-state, with no mechanical part to wear out or fail. We

incorporate a piezo transducer specifically tuned to the sh ock frequency of glass breaking,

providing both excellent detection and false alarm immunity . Use Table 2 to choose the right

shock sensor for a particular application or environment.

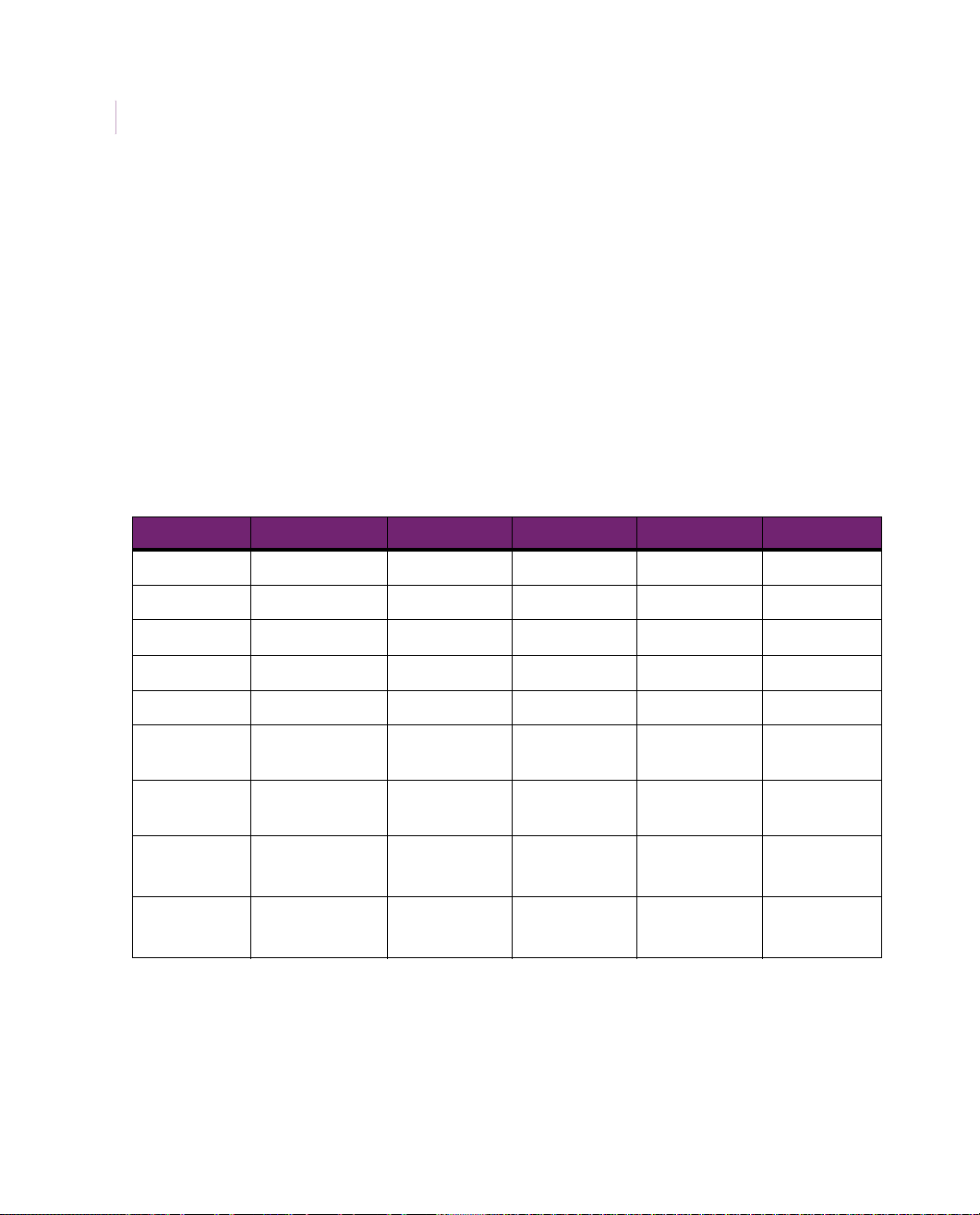

Table 2. Shock sensors

Model Coverage Mounting site Powered Indicating LED Reed switch

5150 10 ft. (3.1 m) Glass Self No No

5600 10 ft. (3.1 m) Frame Wired Yes No

5620 10 ft. (3.1 m) Frame Wired Yes Yes

5414 10 ft. (3.1 m) Glass or frame Self Yes No

5415A 10 ft. (3.1 m) Glass or frame Self Yes Yes

GS600 Varies Glass, frame,

wall, or roof

GS611 Varies Glass, frame,

wall, or roof

5402 2 x 4 x 1 ft.

(0.6 x 1.2 x 0.3 m)

5422 2 x 4 x 1 ft.

(0.6 x 1.2 x 0.3 m)

Metal enclosure Self No No

Metal enclosure Wired Yes No

Wired

(analyzer)

Wired

(analyzer)

No No

No Yes

Shock sensor testing

To test shock sensors, rap the protected glass with the handle of a screwdriver in the corner

farthest from the sensor. This should trip the sensor. If the sensor does not trip, you may need

to move the sensor, or use more than one sensor in the application.

Page 15

Glassbreak/shock sensors

Chapter 1

Wireless compatible sensors

Use Table 3 to choose the right wireless compatible acoustic/shock sensor for a particular

environment or application.

Table 3. Wireless compatible acoustic/shock sensors

Model Coverage Mounting site LED Reed switch

5845 25 ft. (7.6 m) Omnidirectional Yes No

5645 10 ft. (3.1 m) Frame Yes Yes

5150 10 ft. (3.1 m) Glass No No

5812NT 5 ft. (1.5 m) Frame No No

60-873-05

NX488

Installation guidelines

9

When using glassbreak sensors, follow these guidelines:

• Glass must be in good repair (not cracked) and securely mounted in its frame.

• A bullet or BB going through the glass will probably not be detected. The

glassbreak incident must leave a fist-sized hole before a sensor is expected to detect

the incident.

• Sensors are designed to work on glass that is a minimum of 1 square foot

(0.3 x 0.3 m).

• Acoustic glassbreak sensors are designed to detect breaks in framed windows from

the outside in.

Page 16

Intrusion Sensor

10

Application Notebook

Prewire installation

Application. New construction applications offer the opportunity to prewire an acoustic

glassbreak sensor, creating an attractive, unobtrusive installation. The 5812NT and 2100

sensors, installed on a single-gang box, are especially appropriate for prewire installations.

Installation. Open the sensor and screw the back of the sensor onto the single-gang box as

shown in Figure 4.

Recommended products. 5812NT, 2100

Figure 4. Prewire 5812NT installation

Single-gang box

Sensor

Page 17

Glassbreak/shock sensors

Chapter 1

Inconspicuous installations

Application. Sometimes customers want their security system to be as inconspicuous as

possible. This is especially true in most residential, office foyers, executive offices, and

upscale retail store installations. The 5820A Recessed ShatterPro II sensor is the least

obtrusive acoustic glassbreak sensor available. When installed, the sensor is little larger than

a quarter and is rarely noticed. Another option is to hide a 5600 ShatterPoint sensor behind

curtains or blinds.

Installation. The 5820A (Figure 5) can protect an entire room. Sensor range is 25 ft.

(7.6 m) to the bottom of the glass in a 360-degree pattern. Mount the sensor on the ceiling,

the opposite wall, or an adjoining wall (Figure 6 on page 12). To install the sensor, do the

following:

1. Drill a 1 in. (2.5 cm) diameter hole through the drywall or ceiling tile in the desired

location.

2. Insert the 1 in. (2.5 cm) sleeve into the hole and insert the sensor into the sleeve. Use

the trim ring, if necessary, to cover any irregularities in the drywall hole.

11

The 5600 is a shorter range sensor that protects up to 10 ft. (3.1 m) of glass. For a hidden

appearance, mount the sensor on the window frame behind curtains or blinds (Figure 7 on

page 12). To protect windows that open, use a sensor with a built-in magnetic contact.

Recommended products. 5820A, 5600

Figure 5. 5820A installation

5820A recessed sensor

Page 18

Intrusion Sensor

12

Application Notebook

Figure 6. Wall-mounted Recessed ShatterPro II

Figure 7. ShatterPoint mounted behind the curtains

5820A recessed sensor

5600 sensor

S

ENTROL

Page 19

Glassbreak/shock sensors

Chapter 1

Bathroom windows

Application. Bathrooms are challenging environments for glassbreak sensors. Humidity

can be very high and bathrooms are acoustically live rooms. These attributes produce a

greater potential for false alarms when acoustic sensors are used. Shock sensors are a better

choice and have fewer problems than acoustic sensors in high humidity environments such

as bathrooms.

Installation. For best false alarm immunity in bathrooms, use the hermetically-sealed

GS600 shock sensor with 12 ft. (4 m) of range mounted on the glass (Figure 8). To protect

windows that open, use the frame-mounted GS611 shock sensor with built-in magnetic

contact. Both sensors work with the GS614 analyzer.

Recommended products. GS600, GS611

Figure 8. Bathroom window

13

GS600 shock sensor

Page 20

Intrusion Sensor

14

Application Notebook

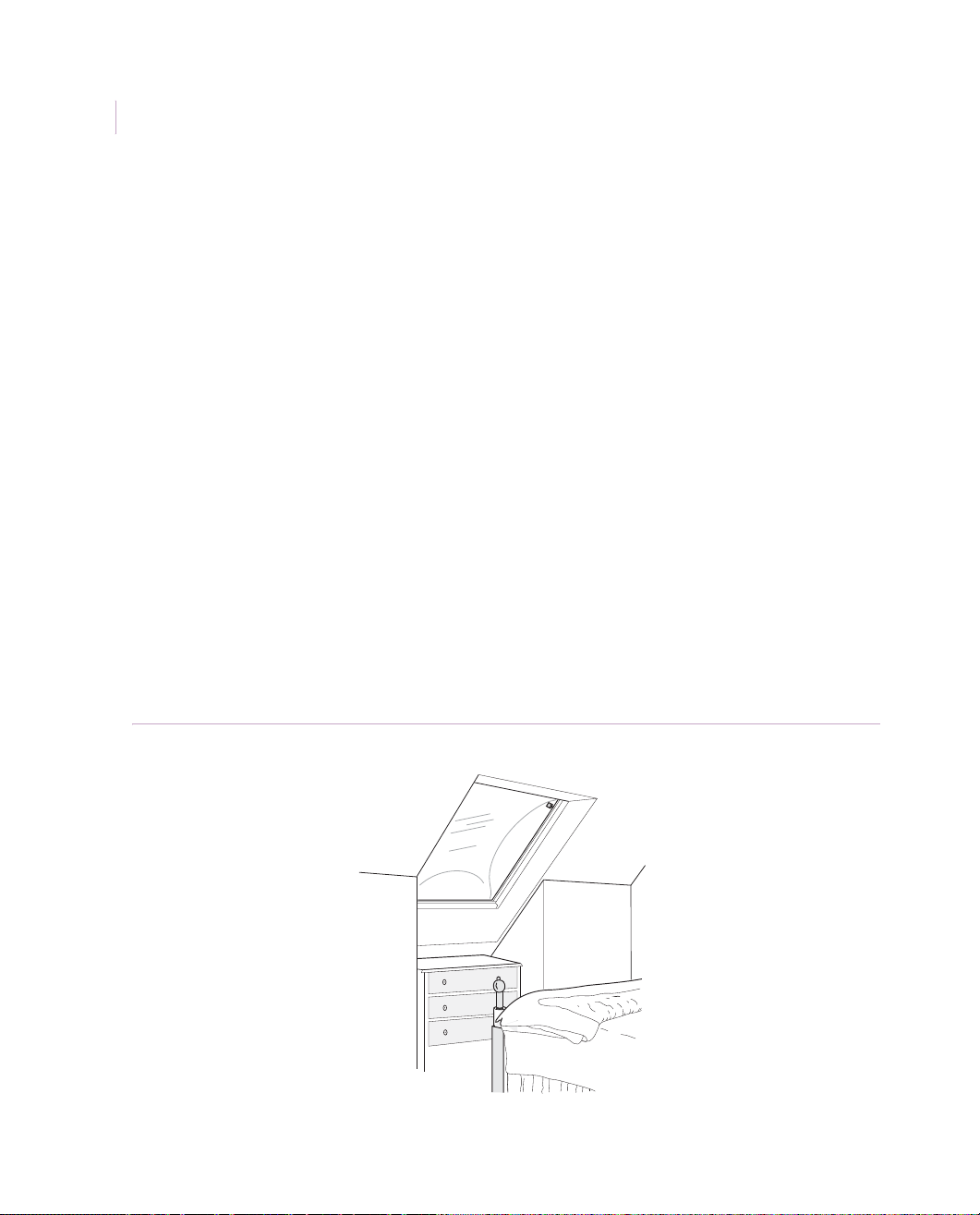

Skylights

Application. Skylights can be a vulnerable entry point to many homes and businesses. To

protect skylights made of Plexiglas or other types of plastic, use a shock sensor. To protect

glass skylights, use an acoustic glassbreak sensor.

Installation. To protect plastic skylights, mount a 5150 shock sensor in a corner of the

skylight 1 in. (2.5 cm) in from the frame (Figure 9). If more than 3.5 ft. (1.1 m) of range is

required, mount two sensors in opposite corners.

The plastic material in the skylight will absorb much of the shock energy from a break and

the range of a shock sensor on plastic is typically 50 percent less than the range on glass. For

example, a shock sensor with a 7 ft. (2.1 m) range on glass would generally have a 3.5 ft.

(1.1 m) range on a plastic skylight. See Shock sensor testing on page 8.

T o protect glass skylights, mount a 5600 sensor on the ceiling or on any wall within range of

the skylight or use a GS600 sensor mounted on the frame. To protect vented skylights, use

the GS611 with built-in magnetic contact.

Recommended products. 5150, 5600, GS600, GS611

Figure 9. Skylights

5150 shock sensor

Page 21

Glassbreak/shock sensors

Chapter 1

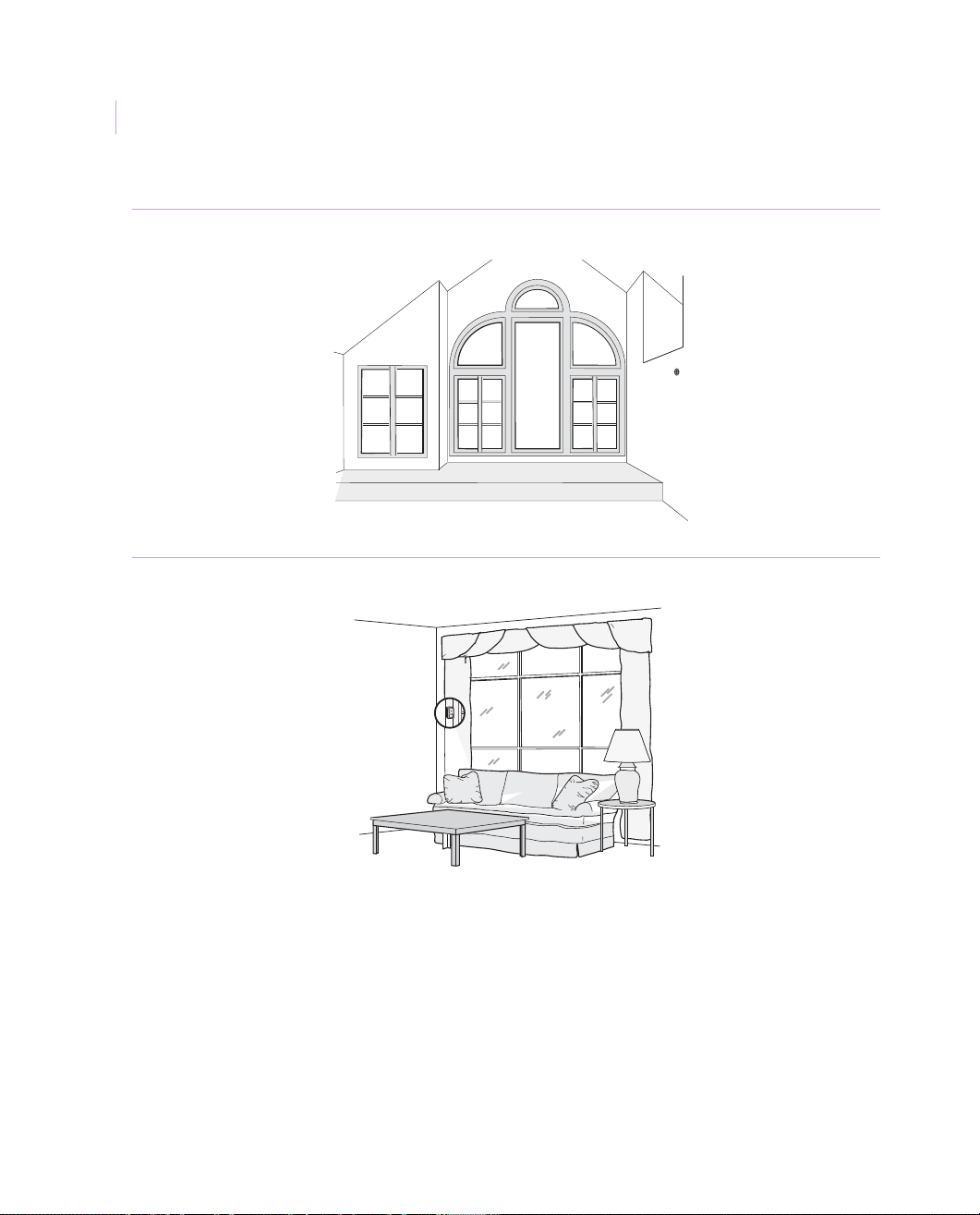

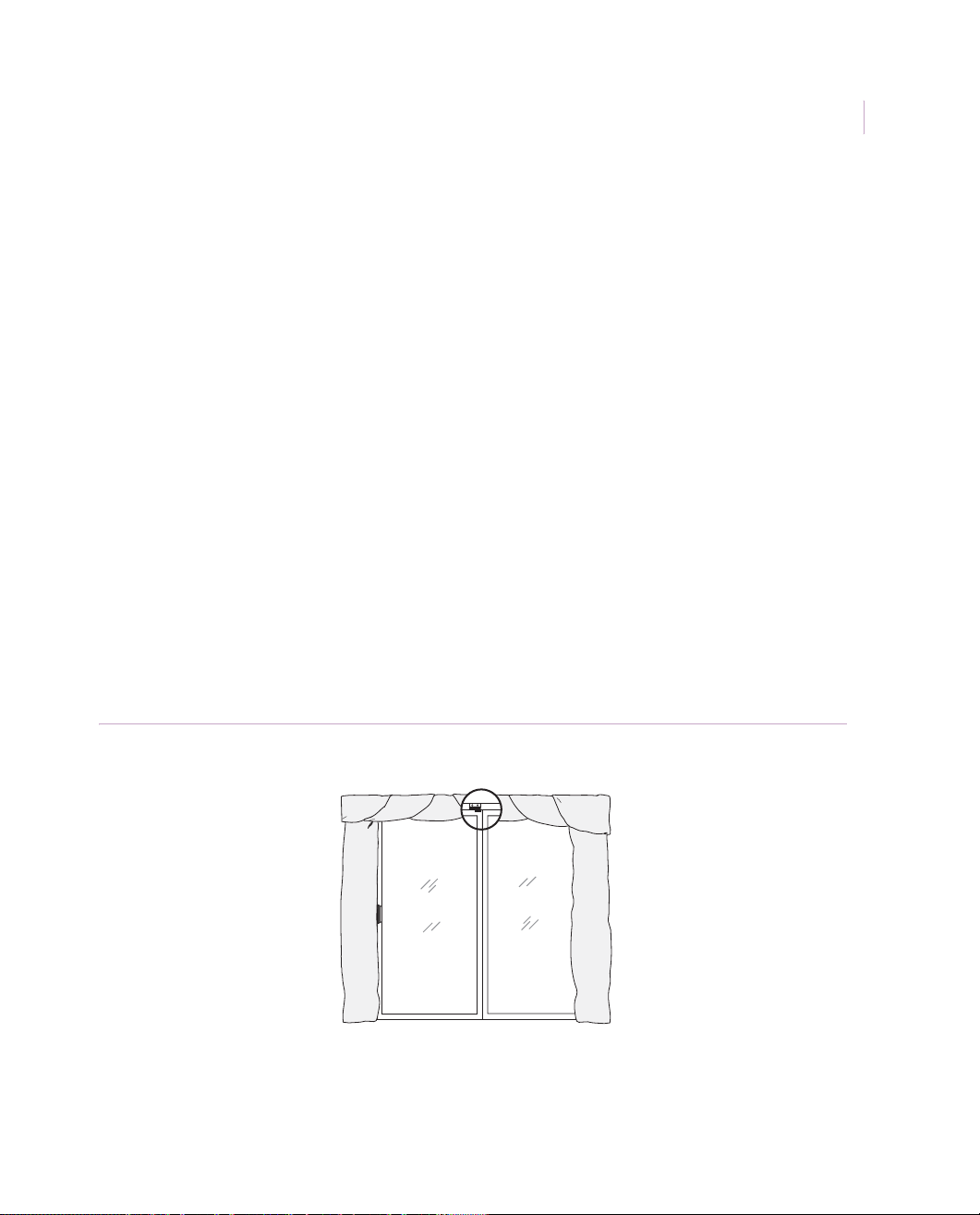

Windows with curtains and blinds

Application. Many homes and offices have windows with curtains or blinds. The 5150

shock sensor can protect windows regardless of the type of window covering present. With

proper placement, acoustic sensors can also protect windows with blinds and light drapes.

Installation. Mount shock sensors in the corner of the glass, 1 in. (2.5 cm) from the frame.

Shock sensors are not affected by curtains or blinds. See Shock sensor testing on page 8.

You can also mount a 5600 sensor on the window frame behind curtains or blinds to protect

one or more windows (Figure 10). The sensor will protect a 10 ft. (3.1 m) area, although the

range may be reduced if the window coverings are touching the glass. For windows that

open, use a sensor with a built-in magnetic contact.

For a larger range on windows with venetian or vertical blinds, mount a 5812NT

ShatterPro 3 or a 5820A Recessed ShatterPro II on the ceiling (Figure 11 on page 16),

adjoining wall, or a wall opposite the glass you want to protect. See Acoustic sensor testing

with the 5709C on page 6.

15

Recommended products. 5150, 5600, 5812NT, 5820A

Figure 10. Sensor mounted behind curtains

Sensor

Page 22

Intrusion Sensor

16

Application Notebook

Figure 11. Recessed sensor on ceiling

Sensor

Page 23

Glassbreak/shock sensors

Chapter 1

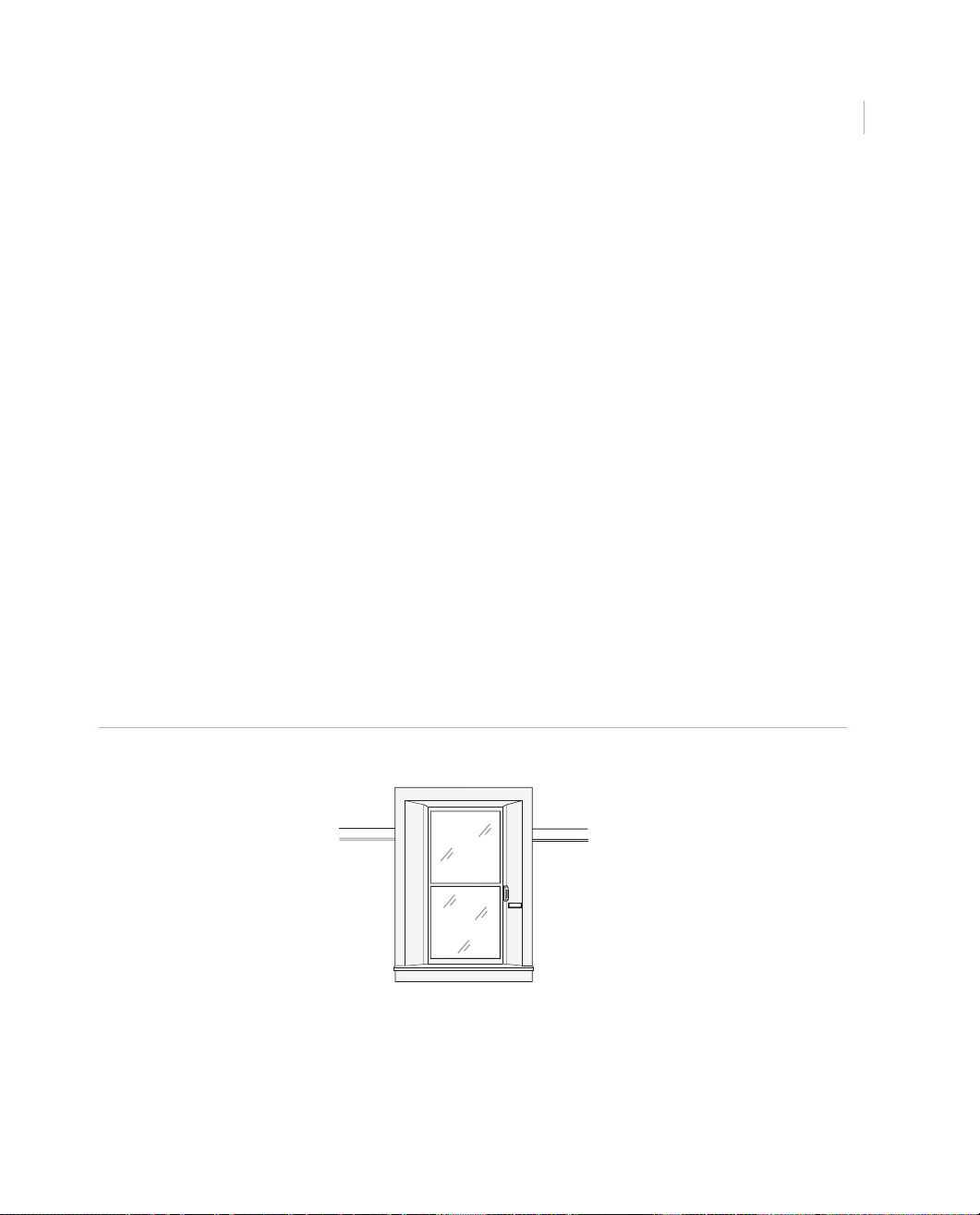

Single window with wireless sensor

Application. A wireless-compatible shock sensor can be used for economical protection of

rooms with a single window. For glass doors or windows that open, use a wireless

compatible sensor with a built-in magnetic contact.

Installation. Mount the 5150 shock sensor on the glass, 1 in. (2.5 cm) in from the corner.

Range is a 7 ft. (2.1 m) radius out from the sensor.

The 564503 frame-mounted shock sensor can protect two fixed windows in the same

window opening (Figure 12). Range for the sensor is up to 10 ft. (3.1 m). Frame mounting

affects the sensor range, so it is essential to test the sensor (see Shock sensor testing on

page 8). The sensor includes a built-in magnetic contact to protect windows that open.

These sensors must be connected to a transmitter.

Note: The 564503 Wireless ShatterPoint shares the battery of the transmitter. Its current draw of up to

15 microamps may reduce transmitter battery life by up to 50 percent. Since other devices are

likely to need battery replacement before the sensor, this is rarely a problem.

17

Recommended products. 5150, 564503

Figure 12. Wireless sensor on single window

Sensor

Page 24

Intrusion Sensor

18

Application Notebook

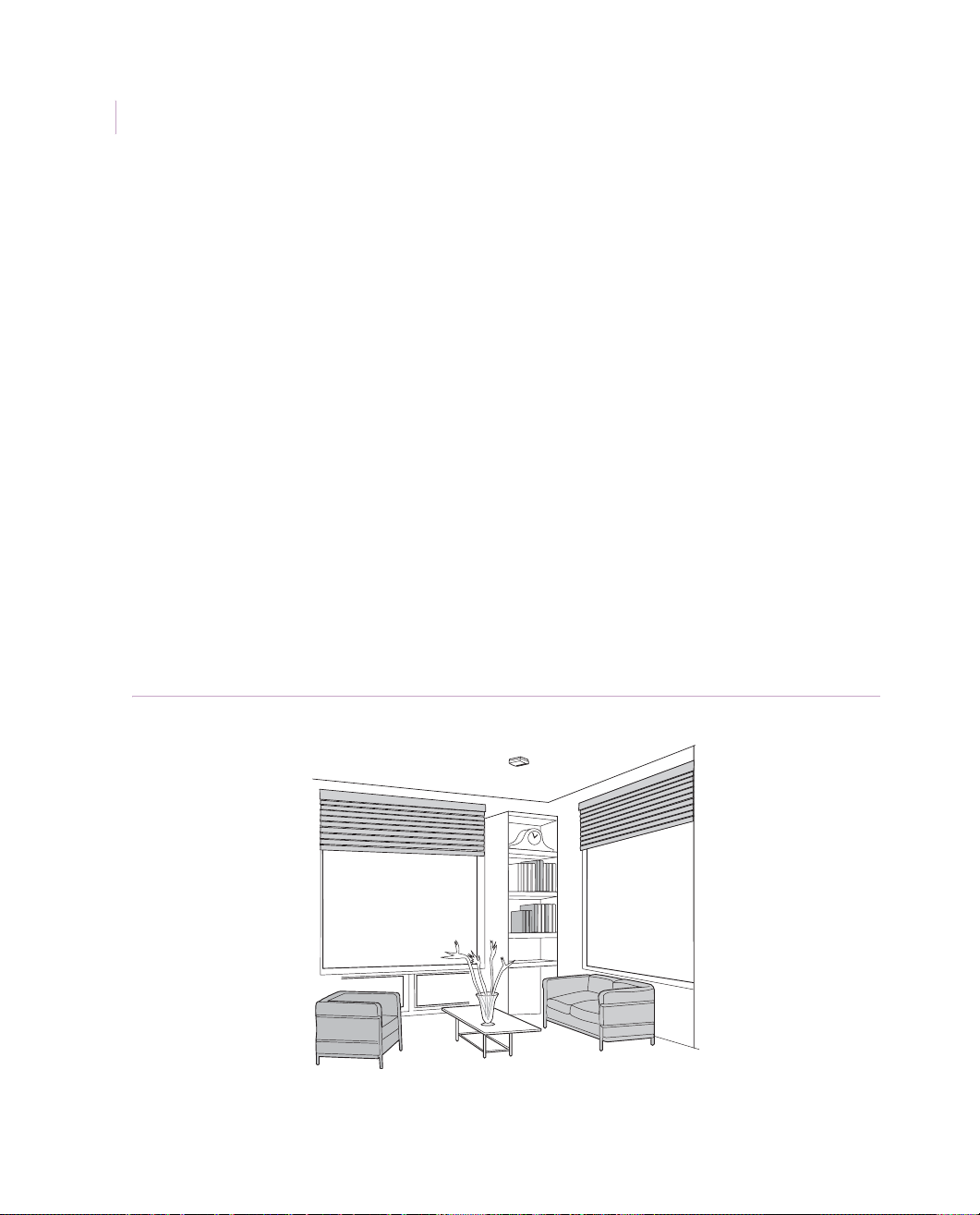

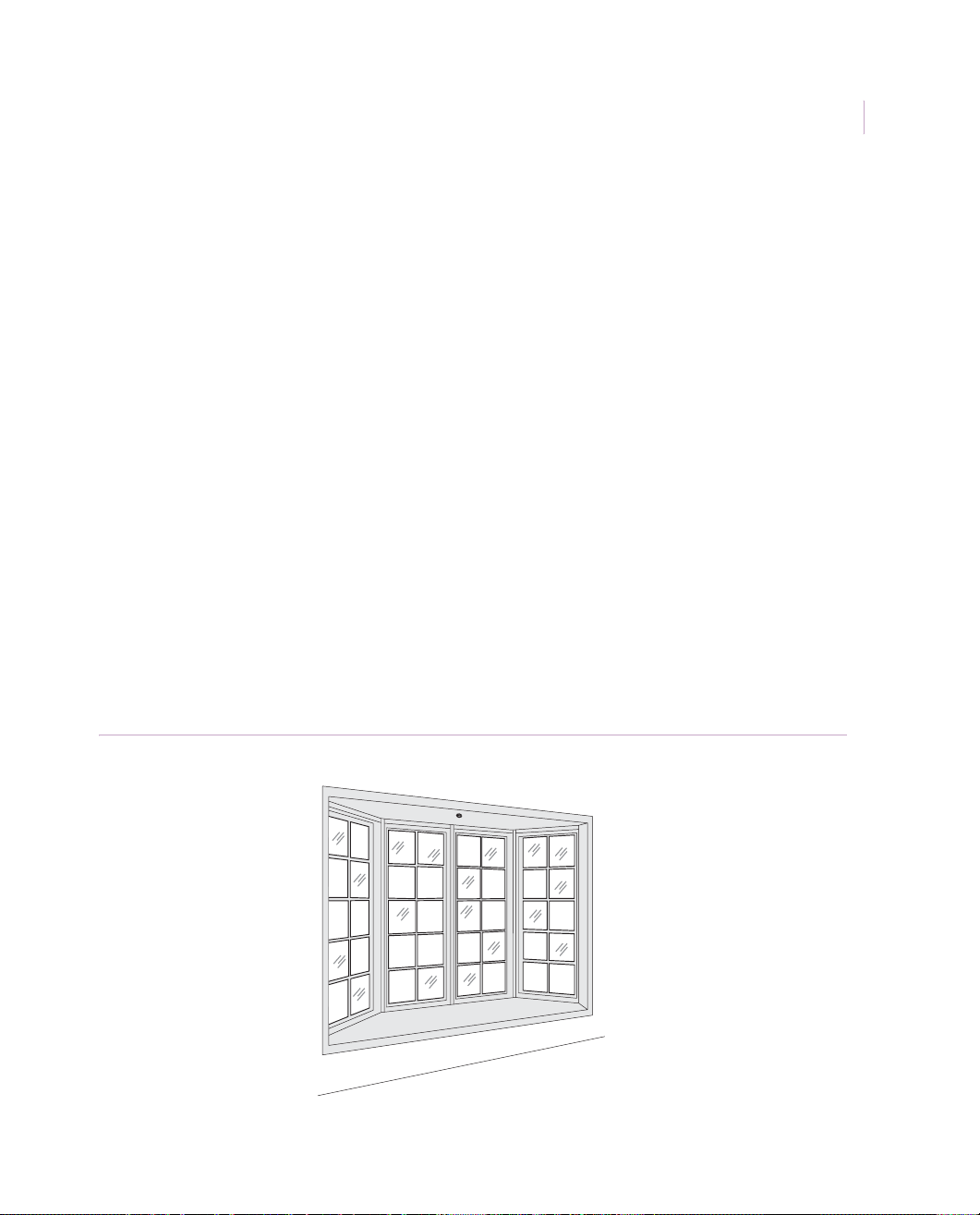

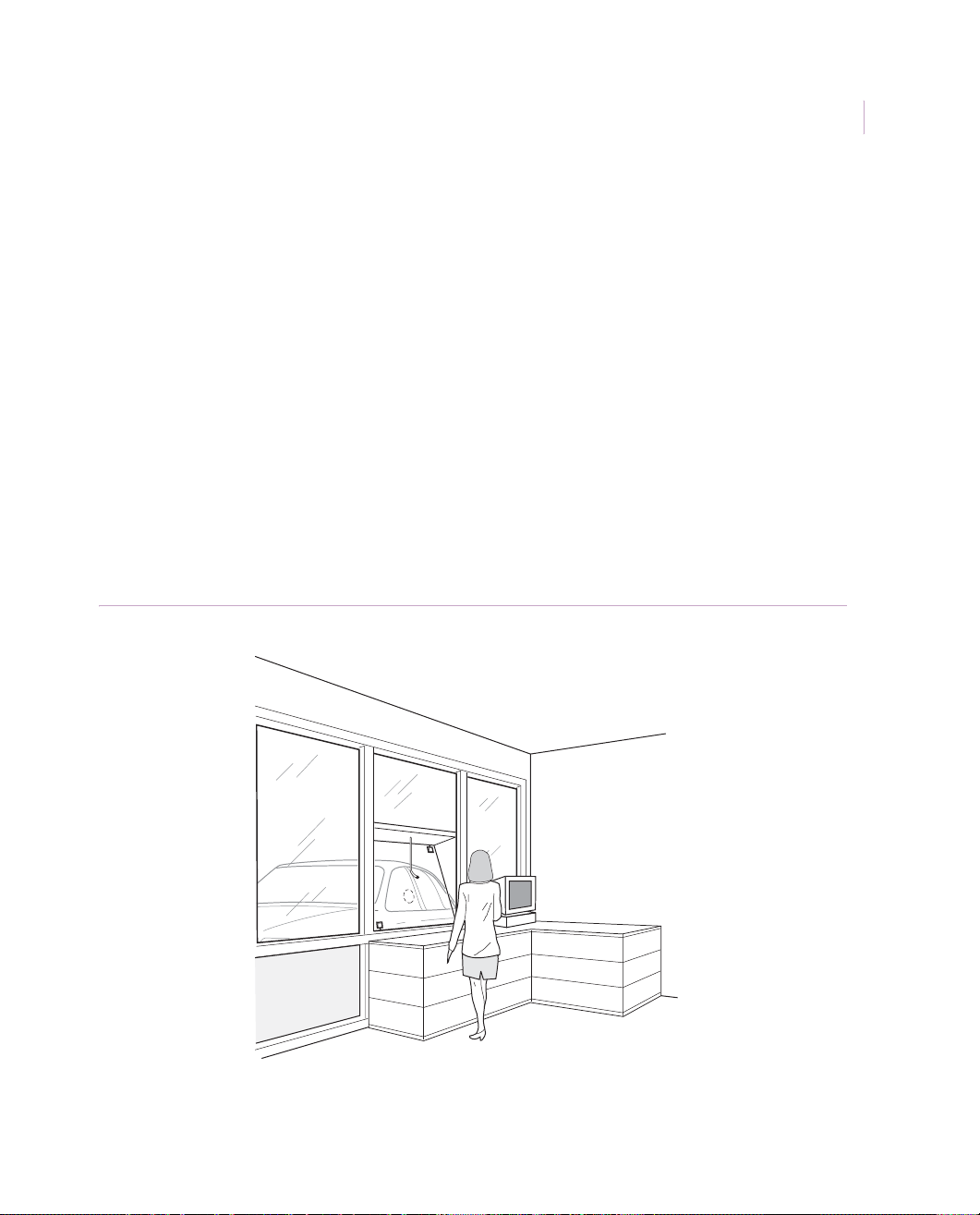

Multiple windows with wireless sensors

Application. To economically protect multiple windows use one transmitter and a 584503

Wireless ShatterPro acoustic sensor. The sensor combines excellent false ala r m immunity

and consistent detection with wireless compatibility and has a coverage radius of 20 ft. (6.1

m) if mounted on a ceiling. A single sensor can typically protect an entire room.

Installation. To hide the transmitter and provide an integrated look, mount the transmitter

inside the back box of the 584503 sensor. The transmitter can also be mounted next to the

sensor on the bracket (included with the sensor).

Note: The sensor shares the transmitter battery, which may reduce battery life by up to 50 percent.

Since other devices are likely to need battery replacement before the sensor, this is rarely a

problem.

Position the 584503 sensor a minimum of 4 ft. (1.2 m) and a maximum of 20 ft. (6.1 m) from

the glass (Figure 13). See Acoustic sensor testing with the 5709C on page 6

Recommended products. 584503, NX488, 60-873-95

Figure 13. Multiple window with wireless sensors

Sensor

Page 25

Glassbreak/shock sensors

Chapter 1

French doors and small windows

Application. Older homes often have windows with small panes and French doors. Small

windows have unique properties when they break. The sound o utput may be low since there

is not much glass to break and the glass may pop out of the window frame when hit instead

of breaking. Detection in both cases can be difficult.

Modern French doors are usually two large pan es of glass with false dividers between them.

The dividers have little effect from a detection standpoint you do not need to take any

special precautions.

19

Installation. To

mounted within 4 ft. (1.2 m) of the glass. See

protect small windows with an acoustic sensor, use a 5600 ShatterPoint

Acoustic sensor testing with the 5709C

on page 6.

For more consistent detection, use a GS600 frame-mounted shock sensor. Often several

sensors will be needed to protect a frame of multiple windows. Make sure you test the sensor

(see Shock sensor testing on page 8) and use additional sensors as needed.

Minimum glass size for glassbreak sensors is 1 square foot (0.3 x 0.3 m).

Recommended products. 5600, GS600

Figure 14. Small window protection

Sensor

Page 26

Intrusion Sensor

20

Application Notebook

Glass doors and windows that open

Application. Running wires from the glass to the frame can make glass door protection a

challenge. A shock or acoustic sensor with a built-in magnetic contact can make both

glassbreak and forced-open protection possible.

Installation. To protect glass doors and windows that open, use a 5150C or GS611 shock

sensor, or a 5620 shock/acoustic sensor. The 5150C sensor mounts on a corner of the frame

and ships with a 3 ft. (0.9 m) coil cord that reaches to a termination on the frame (Figure 15).

The 5620 and GS611 sensors have built-in magnetic contacts and mount on the frame.

Mount the sensor’s magnet on the door or movable window and mount the sensor on the

frame as close as possible to the magnet. See Shock sensor testing on page 8.

Recommended products. 5150C, 5620, GS611

Figure 15. Protection for windows and glass doors that open

Sensor

Sensor

S

E

NTR

O

L

Page 27

Glassbreak/shock sensors

Chapter 1

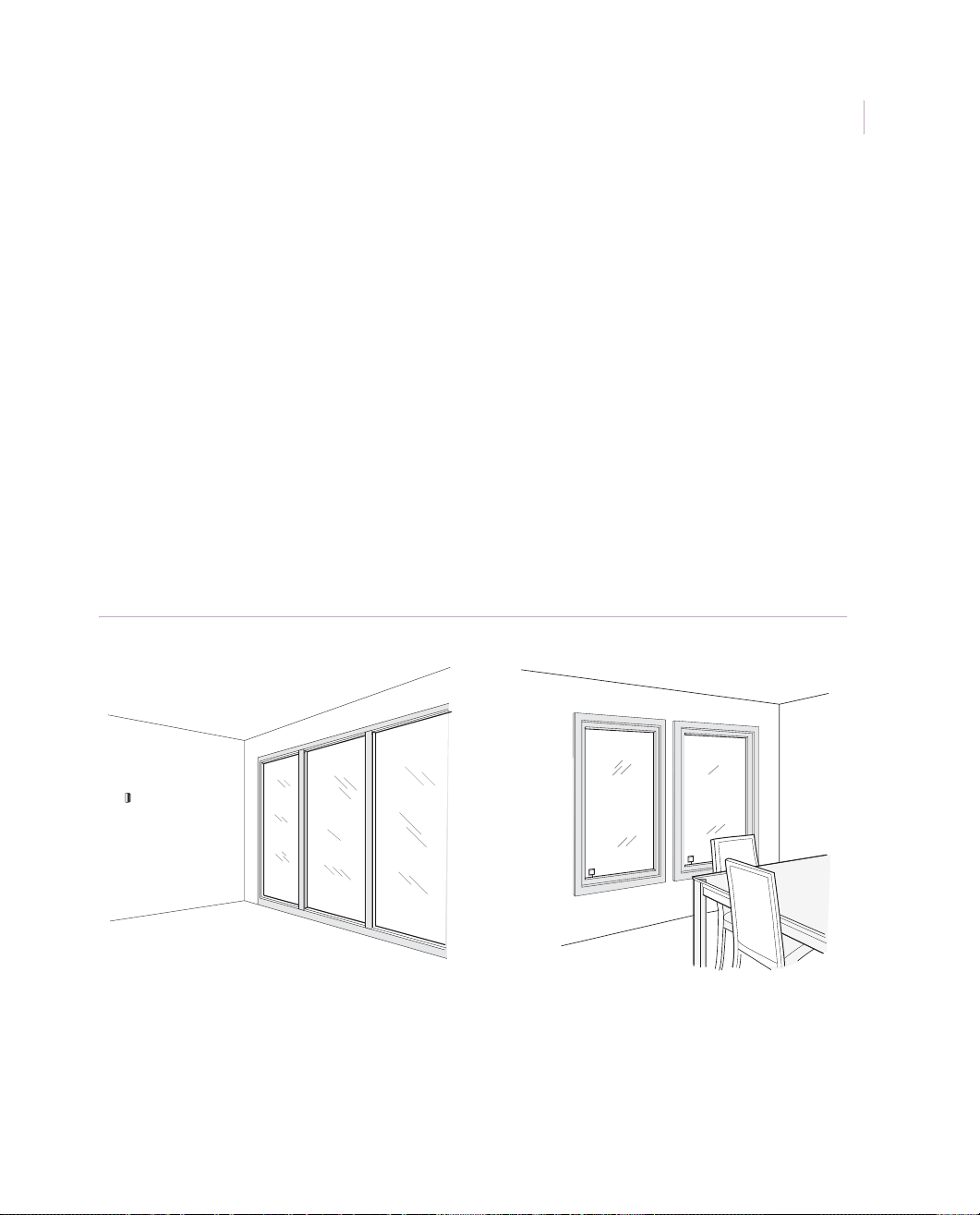

Insulated glass

Application. Many modern buildings use windows that contain two panes of glass divided

by an air space for added insulation. You can protect this insulated glass with shock and

acoustic glassbreak sensors. As long as the inside pane of the glass breaks, the sensor will

detect the break. It is possible to break the outside pane of glass without setting off an alarm.

Installation. Installation for insulated windows is the same as for other windows. Mount

5150 or GS600 shock sensors in the corner of the glass or GS611 shock sensors on the

frame. Mount 5600, 5620 or 5812NT acoustic sensors so that the protected glass is within

the sensor’s range (Figure 16).

See Acoustic sensor testing with the 5709C on page 6 and Shock sensor testing on page 8.

Recommended products. 5150, 5600, 5620, 5812NT, GS600, GS611

Figure 16. Insulated glass protection

21

Sensor

Sensors

Page 28

Intrusion Sensor

22

Application Notebook

Windows with film

Application. Film is applied to windows for a variety of reasons. In sunny climates some

commercial windows have a tinting film attached to the glass. Some commercial windows

have a plastic film attached to the glass to prevent shattering from impact or bullets. This

armor-coated glass can be found in bank drive-up windows, in retail stores, and in other

vulnerable buildings.

Installation. Tinted film does not affect shock sensors. To mount shock sensors on the

glass, cut away the film where the sensor will be placed so that the mounting tape is affixed

to the glass itself and not to the film (Figure 17).

Armor-coated glass may reduce shock sensor range. Thoroughly test shock s ensors (see

Shock sensor testing on page 8) to see if additional sensors are needed.

Recommended products. Any GE shock sensor, as long as the installation guidelines

are followed.

Figure 17. Tinted film on windows

Page 29

Glassbreak/shock sensors

Chapter 1

Thick glass

Application. Some installations may have glass thicker than the 0.25 in. (0.6 cm)

maximum thickness rating of acoustic and shock sensors. Since thick glass absorbs much of

the shock energy from a break, it is more of a challenge for glassbreak detection. Shock

sensors can be used on thick glass if they are thoroughly tested (multiple sensors may be

needed). ShatterPro sensors are not designed to protect thick glass and should not be used

for this application.

Installation. Use the 5150 or GS600 shock sensor and mount the sensor on the glass

approximately 1 in. (2.5 cm) in from the corner (Figure 18). See Shock sensor testing on

page 8 and add multiple sensors as needed.

Recommended products. 5150, GS600

Figure 18. Thick glass protection

23

Page 30

Intrusion Sensor

24

Application Notebook

Large rooms

Application. Most large rooms have several windows, often widely spaced from each

other. The most economical way to protect large rooms with multiple windows is with a

single, long-range acoustic sensor. However, be careful to match sensor range to room size.

If the sensor range extends beyond the room boundaries it is vulnerable to false alarms.

Installation. Use a 5812NT ShatterPro 3 or a 5802A Recessed ShatterPro II to protect

large glass areas and up to four walls of glass. To protect glass on more than one wall, mount

the sensor on the ceiling (Figure 19). Make sure that all protected glass is within the sensor’s

coverage pattern. The distance from the bottom of the window to the sensor must be no more

than the sensor’s maximum range.

To protect one wall of glass, mount the sensor on the opposite wall (if all protected glass is

within the sensor’s range). See Acoustic sensor testing with the 5709C on page 6.

Recommended products. 5812NT, 5820A, 2000

Figure 19. Large rooms with multiple windows

Sensor

Page 31

Glassbreak/shock sensors

Chapter 1

Small rooms

Application. False alarms are more likely in small, acoustically live rooms such as small

kitchens, glass entry airlocks, stairwells, small glass offices, and utility rooms. Shock

sensors offer the best false alarm immunity and are the most economical if there is only one

window to protect. If an acoustic sensor is preferred, you must match the range of the sensor

with the size of the protected room and glass to minimize false alarms.

Installation. In small room applications, follow these guidelines:

• To protect a single window in a small room, use a 5150 shock sensor mounted on

the glass or a 5414 or GS600 sensor mounted on the frame.

• For windows that open, use a 5415A or GS611 sensor with a built-in magnetic

contact (Figure 20). See Shock sensor testing on page 8.

• To protect multiple windows in a small room, use a 5600 ShatterPoint.

• Do not install an acoustic sensor with a large range in a small room. For example, a

sensor with 25 ft. (7.5 m) diameter range in a 10 ft. (3.1 m) room increases the risk

of false alarms. See Acoustic sensor testing with the 5709C on page 6.

25

Recommended products. 5150, 5414, 5415A, GS600, GS611, 5600

Figure 20. Small rooms

Sensor

SENTROL

SENTROL

Page 32

Intrusion Sensor

26

Application Notebook

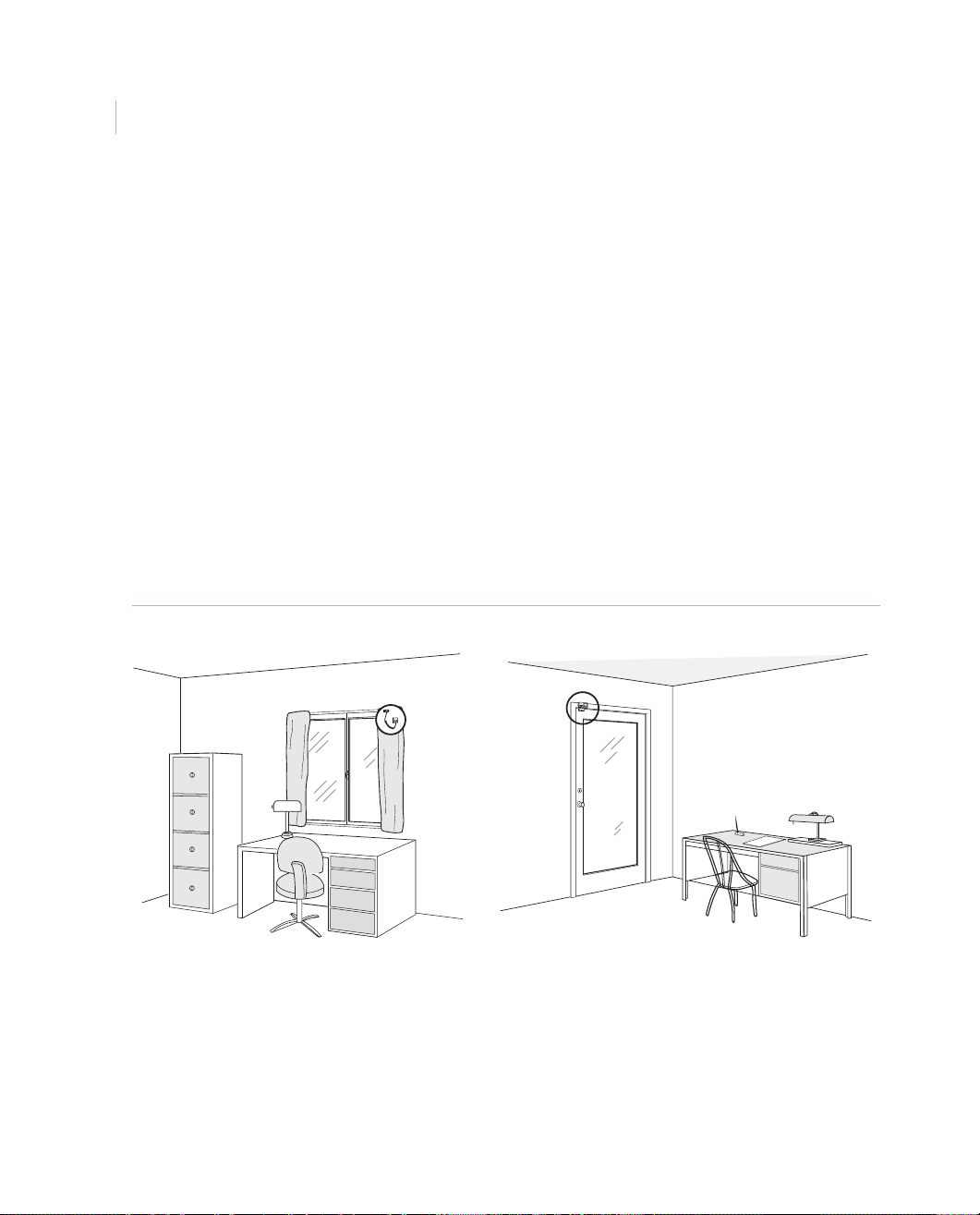

Occupied areas

Application. Occupied areas can be protected either on a perimeter loop or on a 24-hour

loop. On a perimeter loop, sensors are armed when the magnetic contacts on doors are

armed. On a 24-hour loop, sensors are armed continuo usly.

Installation. For 24-hour loop protection, mount a 5150 shock senso r on the glass 1 in.

(2.5 cm) in from the corner, or frame-mount a 5600 shock sensor with the correct sensi tivity

setting (see Shock sensor testing on page 8). The 5885 ShatterPro Plus acoustic sensor can

also be used for 24-hour loop applications.

For perimeter loop protection, use a 5600 for glass areas smaller than 10 ft. (3.1 m). For

larger glass areas, use a 5812NT, 2000, or a 5820A recessed acoustic sensor. See Acoustic

sensor testing with the 5709C on page 6.

Recommended products. For 24-hour loop protection: 5150, 5600, 5885, GS600. For

perimeter loop protection: 5812NT, 5820A, 2000.

Figure 21. Occupied areas

Sensor

Sensor

Sensor

Page 33

Glassbreak/shock sensors

Chapter 1

Rooms with cleaning crews

Application. Often the perimeter loop of the security system is armed when the cleaning

crews are in a building. If acoustic sensors are armed, they will be listening to all sounds,

including those made by night cleaning crews. Acoustic sensors are most likely to false

alarm to multiple sounds. The cleaning crews produce a combination of sounds from

vacuums, floor polishers, and clattering garbage cans, all of which combine to cause false

alarms for some sensors in some applications.

Installation. The 5150, 5600, and GS600 shock sensors provide the best false alarm

immunity for a building when it is occupied. However, multiple shock sensors can be

economically impractical for applications with large numbers of windows an d may not be an

option in applications where appearance is important.When multiple shock sensors will not

work for your application, use the 5885 ShatterPro Plus acoustic sensor that combines a

passive infrared sensor with a glassbreak sensor (Figure 22). When an occupant enters the

field of view of the PIR, the glassbreak sensor is disabled for 70 seconds. This prevents false

alarms due to loud noises such as vacuums or floor buffers. The 5885 makes 24-hour

acoustic applications possible.

27

Recommended products. 5150, 5600, GS600, 5885

Figure 22. Cleaning crew protection

Sensor

Page 34

Intrusion Sensor

28

Application Notebook

Storefront windows

Application. Merchants often want glassbreak protection on their front windows, in order

to have the alarm sound as soon as the glass breaks. While this does not prevent smash and

grab losses, it helps prevent burglars from actually entering the building.

Installation. To protect storefront windows, 5150, 5620, or GS600 shock sensors are the

best choice. The sensors mount on the glass or frame and are visible from the outside to

deter burglars before the glass is broken. Shock sensors are also less likely to be set off by

street noise or rolling metal shutters than acoustic sensors. However, multiple shock sensors

may be required to cover the same glass area that one acoustic sensor can protect

(Figure 23). See Shock sensor testing on page 8.

To successfully use acoustic sensors to protect storefront glass, store personnel must be

trained to keep the sensor’s line-of-sight clear. If the sensor’s vision is blocked by store

displays or furniture, the sensor is unlikely to detect a break-in. In stores without window

displays, mount a ShatterPro 3 or 5820A ShatterPro II on the ceiling. In stores with window

displays, Mount a 5600 ShatterPoint directly above the glass. See Acoustic sensor testing

with the 5709C on page 6.

Recommended products. 5150, GS600, 5600, 5620, 5812, 2000, 5820A

Figure 23. Storefront glass protection

New Models Are Here

Multiple

sensors

Page 35

Glassbreak/shock sensors

Chapter 1

Roll-up metal shutters

Application. Retail shops in high-risk areas will often have roll-up metal shutters to

protect glass windows at night. The clanging and banging sounds of these shutters can cause

acoustic sensors to have false alarms. False alarms can also be caused by people rattling the

shutters by or other sources of vibration.

Installation. GS600 or 5150 shock sensors provide the best false alarm immunity on

windows with roll-up shutters. The sensors mount on the glass (Figure 24) and are easily

visible from the outside to deter break-ins. See Shock sensor testing on page 8.

If acoustic sensors are preferred, use the 5812, 2000, or 5820A sensors. Mount the sensor

away from the street and roll-up shutters and within specified range limits. See Acoustic

sensor testing with the 5709C on page 6.

Recommended products. 5150, GS600, 5812, 5820A, 2000

29

Figure 24. Store windows with roll-up metal shutter protection

Multiple

sensors

Page 36

Intrusion Sensor

30

Application Notebook

Glass display and jewelry cases

Application. Museum curators and retailers with glass display and jewelry cases often

want glassbreak sensors inside their cases. Both shock and acoustic sensors can be used in

this application.

Acoustic sensors sealed within a glass display case are extremely live and are vulnerable to

false alarms if the case is accidently struck by keys or other metal objects. For this reason,

acoustic sensors are only appropriate for applications where the sensor will only be armed

when the premises are not occupied. For occupied or 24-hour protection, use shock sensors.

Installation. The 5150 and GS600 shock sensors mount directly on the glass and are the

best choice if only one piece of glass needs to be protected. For protecting multiple glass

walls in the case, use one or more frame-mounted 5600 sensors. Use a 5620 sensor with

built-in magnetic contact to detect a forced opening. T o prevent sensor tampering, you must

place the sensors inside the case (Figure 18). See Shock sensor testing on page 8 and use

multiple sensors as needed.

If using multiple shock sensors is not a viable solution, use a single acoustic sensor with a

limited range. We do not recommend the ShatterPro sensors for this application.

Recommended products. 5150, 5600, 5620, GS600

Figure 25. Glass case protection

5600 sensors

SENTROL

SENTROL

5150 sensor

Page 37

Glassbreak/shock sensors

Chapter 1

Metal enclosures

Application. The 5402 and 5422 shock sensors eliminate the need for costly lined boxes or

placement of security system controls in a vault for UL mercantile applications. To meet UL

requirements, a tamper switch is required.

Installation. To protect metal enclosures, use the self-powered 5402 or 4-wire 5422 shock

sensor. Mount the sensor on the side wall on or near the hinge. If the hinge runs the length of

the side, center the sensor vertically (Figure 26). If the enclosure has multiple hinges, mount

the sensor next to the hinge nearest the middle of the enclosure.

To mount the sensor, do the following:

1. Peel back the paper from one side of the adhesive tape pad and press it onto the back

of the sensor. The tape pad must be flat against the plastic case.

2. Use a 50/50 solution of isopropyl alcohol/water to clean the mounting area. Dry the

mounting area, then peel the backing paper from the tape pad and press the sensor

against the metal. The tape will fully adhere within 24 hours.

31

3. W ire the sensor (if applicable) to the loop according to wiring instructions.

4. To test the sensor, use the metal shaft of a medium-size screwdriver to lightly scrape

back and forth against the edge of the metal enclosure farthest from the sensor

(Figure 26). If the sensor does not respond, a second sensor may be required.

Recommended products. 5402, 5422

Figure 26. Metal enclosure

Sensor

Screwdriver

Page 38

Intrusion Sensor

32

Application Notebook

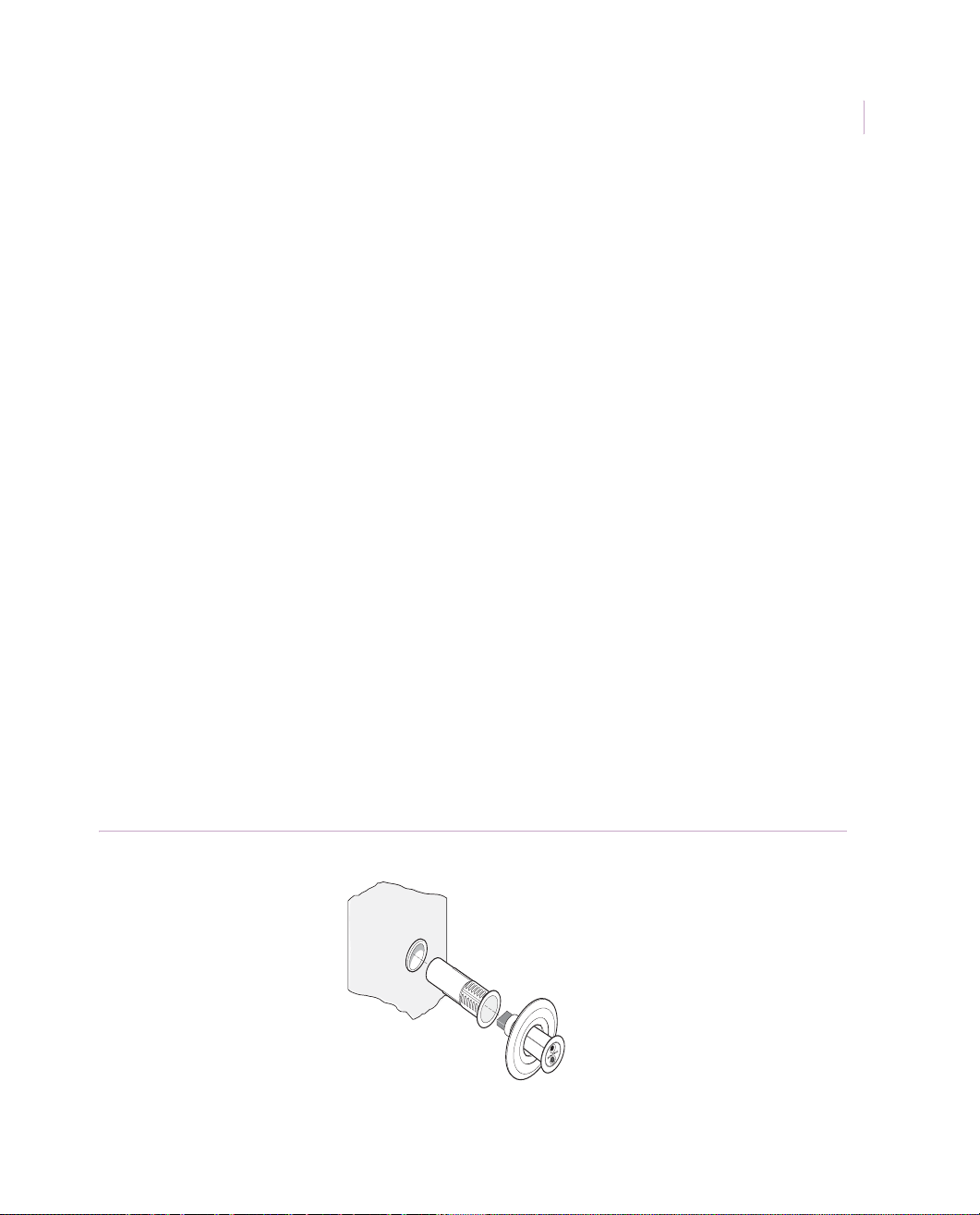

Filing cabinets

Application. Filing cabinets that contain high value documents in military , government, or

private business settings can be protected with the DV1201A sensor.

Installation. Since the lock is normally placed on one side of the upper drawer on the front

of the cabinet, mount one sensor on the side of the cabinet closest to the lock (Figure 27).

Mount the night position plate on the drawer and the day position plate on the side together

with the junction box DV1228A. Use cable kit DV1219A.

Recommended products. DV1201A (sensor), DV1219A (cable kit), DV1228A

(junction box), DV1215A (tester)

Figure 27. Filing cabinets

Sensor

Page 39

Glassbreak/shock sensors

Chapter 1

Jewelry store safes

Application. Jewelry store safes present several protection challenges. The safes hold high

value merchandise, but are generally small in size. The stores are located in public locations,

such as shopping malls and strip malls, where employee turnover can be high. The

DV1201A sensor can protect safes from internal (employee) and external threats and lower

store owner’s loss risk.

Installation. Since most attacks against safes are aimed at the door and the locking

mechanism, mount one sensor on the body of the safe and another inside the door close to

the hinges (Figure 28). Use flexible cable kit DV1219A together with the junction box

DV1228A. Also add a magnetic contact (2707A or similar) on the door. Cable outlets are

normally provided in new safes, if not, we recommend you mount the sensors on the outside

of the safe.

Recommended products. DV1201A (sensor), DV1212 (mounting plate), DV1219A

(cable kit), DV1228A (junction box), 2707A (contact), DV1215A (tester)

33

Figure 28. Jewelry safe

Sensor

Page 40

Intrusion Sensor

34

Application Notebook

ATM and night deposit boxes

Application. ATM (automatic teller machines) and night deposit boxes are located in high

activity public areas and involve cash. There is also environmental vibration from normal

operations. These factors combine to make protection a challenge.

The DV1221A sensor ignores environmental vibrations while ensuring actual attacks are

detected. The sensor sounds an alarm before the intruder gains access to the contents of the

machine.

Installation. For ATMs, the best locations for sensors are the door and as close to the

dispenser opening as possible. These locations are the most likely points of attack.

To protect night deposit boxes, use the same sensors. Attenuate the chute and the landing

place with rubber insulating material to reduce the noise created by the falling cash boxes

when deposited (Figure 29).

Recommended products. DV1221A (sensor), DV1219A (cable kit), DV1228A

(junction box), DV1215A (tester)

Figure 29. ATM and night deposit boxes

Sensors

Rubber pad

Page 41

Chapter 2 Motion sensors

This chapter provides information on motion sensors.

Applications include both indoor and outdoor sensors for

residential, commercial, and industrial installations.

Page 42

Intrusion Sensor

36

Application Notebook

Product overview

Passive infrared (PIR) motion sensor technology provides one of the most reliable and cost

effective methods for protecting spaces in homes, offices, or industrial facilities. PIR motion

sensors sense temperature contrasts between a relatively stable background and hotter or

colder objects moving across their fields of view. The sensors emit no energy of their own,

they merely see infrared images.

RCR sensors

The PrecisionLine dual technology sensors combine range-controlled radar (RCR)

technology with a passive infrared (PIR) system. This combination increases false alarm

immunity by allowing them to sense human-sized objects within a specified range. Both the

RCR and the PIR system must be triggered to set off an alarm, unless in stealth mode (radar

only). An internal jumper allows you to disable the PIR and use the radar-only stealth mode

to detect intruders faster. The stealth mode can also be used for covert installations (mounted

behind walls or drop-tile ceilings).

Page 43

Chapter 2

Motion sensors

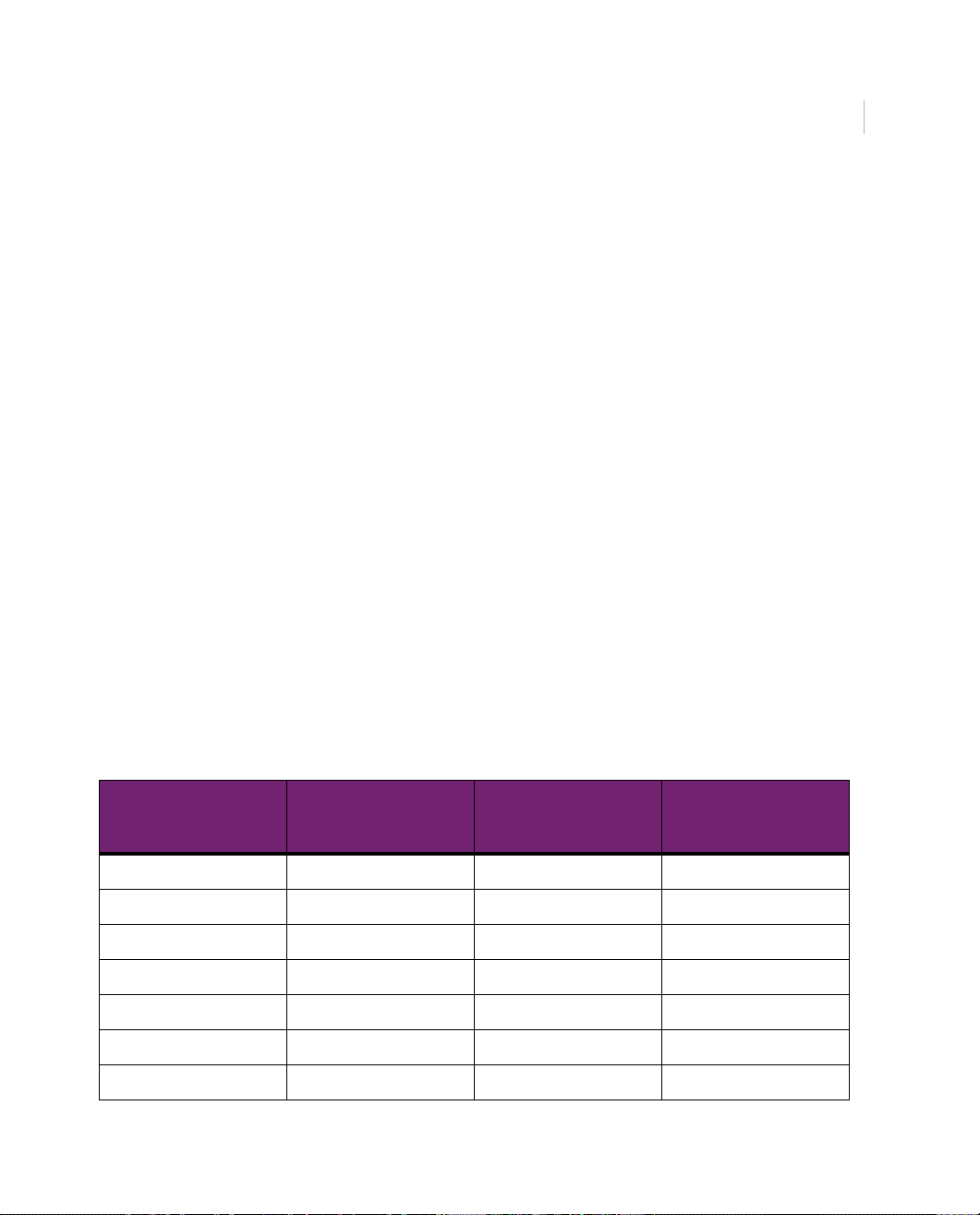

Choosing the right motion sensor

GE Security offers a complete line of motion sensors suitable for every application. The

sensors fit compactly and unobtrusively into any environment. Use Table 4 to help you

match the appropriate PIR sensor with your installation needs.

Table 4. PIR sensors and descriptions

Motion sensor Description

6255 SureShot Residential/commercial - 30 x 30 ft. room, wall, corner, or ceiling

mount, pet alley, curtain, 40 ft. single spot lens, stairwell coverage

6255FM SureShot Flush Mount Residential/commercial - Prewired wall or ceiling retro flush mount

6351 Sharpshooter DesignLine Residential/commercial - 35 x 35 ft. room, wall or corner mount, 90

degree wide angle, pet alley, vertical barrier lens, mounts 1/8 in. from

ceiling

6155 Sharpshooter Residential/commercial - 45 x 45 ft. room, wall or corner mount, pet

alley, curtain, 90 ft. long range, extra-wide lens

37

6187CTX Industrial

Sharpshooter

6197 Intrinsically Safe PIR Commercial - Hazardous areas with ignitable atmospheres,

6198 Non incendive PIR Industrial - Hazardous areas, for use in Class I Division 2, Groups A, B, C,

AP100PI Residential/commercial - Form A, mirror optic wall mount, 33 x 40 ft.

AP450

AP450A

AP475 Commercial/Industrial - Form C, long range wall mount, 75 ft. single

Commercial/industrial - Outdoors, warehouses, locker rooms, food

processing plants, underground parking lots, dusty, cold, or wet

environments

government sites, pharmaceutical labs, oil refineries, grain elevators

Industrial - Hazardous areas, for use in Class I, II, and III; Division 1 and

2; Groups A, B, C, D, E, F, and G

and D (only)

room, corner or wall mount, 5 curtains at 33 ft. each, mounting height 6

to 10 ft.

Residential/commercial - Form A/Form C, 50 ft., wall mount, low profile,

9 curtains, mounting height 6 to 10 ft .

curtain barrier, mounting height up to 16 ft.

Page 44

Intrusion Sensor

38

Application Notebook

Table 4. PIR sensors and descriptions (continued)

Motion sensor Description

AP669 Commercial/industrial - Form C, 60 ft. diameter 360° coverage, ceiling

AP633A Commercial/industrial - 200 ft. long range, 80 ft. wide angle, wall

AP750 Residential/commercial - Form A/Form C, mirror optic wall mount, 50 x

mount, 18 curtains at 30 ft. each, mounting height 7 to 15 ft., coverage

patterns: full 360°, 90° curtain, L-turn pattern, corridor intersection

mount, 12 selectable coverage patterns, mounting height 6 to 10 ft .

65 ft. coverage, corner or wall mount, 7 curtains at 50 ft. each, mirror

mask allows coverage patterns, mounting height 6 to 10 ft.

AP-750W

NX482

Wireless residential/commercial - Form A/Form C, mirror optic wall

mount, 50 x 65 ft. coverage, corner or wall mount, 7 curtains at 50 ft.

each, mirror mask allows coverage patterns, mounting height 6 to 10 ft .

AP950PI Residential/commercial/industrial - Form A, 35 ft. range with up to 80

pound pet immunity, 50 ft . range with no pet immunity, corner or wall

mount, 9 curtains, 2 units in 1 housing, mounting height 7 to 10 ft.

AP950AM Commercial/industrial - Antimasking high security, 50 ft. range, corner

or wall mount, 9 curtains

RCR-50 Dual technology commercial - Range control: 20, 30, 40, and 50 ft .,

tamper, Form C, retail, warehouse, office space, public sector projects,

high security

RCR-PET Dual technology residential/commercial - Range control: 9, 18, 27, and

35 ft., Form A, pet immune up to 80 pounds

RCR-A (Form A)

RCR-C (Form C)

Dual technology residential/commercial/industrial - Range control: 9,

18, 27, and 35 ft., no pets, tamper (RCR-C only), retail, office space, public

sector projects, high security

RCR-90 Dual technology commercial/industrial - Range control: 60, 70, 80, 90

ft., tamper, Form C, retail, warehouse, office space, public sector

projects, high security

RCR-REX Dual technology commercial/industrial - Request-to-exit, Range: 3 to

15 ft. depth, 7.9 ft. width, mounting height 7 to 15 ft., tamper, Form C

60-511-319.0 Wireless residential/commercial - DS924 PIR, 35 x 40 ft. coverage,

tamper, sensitivity options, 3.6 VDC lithium battery

Page 45

Chapter 2

Motion sensors

Table 4. PIR sensors and descriptions (continued)

Motion sensor Description

60-511-02-95 Wireless residential/commercial - DS924 PIR, 35 x 40 ft. coverage,

tamper, sensitivity options, 1.5 VDC lithium battery

60-639-95R Wireless residential/commercial - SAW PIR, 35 x 40 ft. coverage,

tamper, sensitivity options

60-639-95R-OD Wireless residential/commercial - Outdoor SAW PIR, 35 x 40 ft.

coverage, tamper, sensitivity option

60-639-02-95R Wireless residential/commercial - SAW PIR, pet immune to 40 pounds,

1.5 VDC lithium battery, 35 x 40 ft. coverage, tamper, sensitivity options

60-703-95 Wireless residential/commercial - Crystal PIR, 35 x 40 ft. coverage,

tamper, sensitivity options

60-807-95R Wireless residential/commercial - SAW PIR, pet immune up to 40

pounds, 35 x 40 ft. coverage, tamper, sensitivity options

60-807-01-95R Wireless residential/commercial - SAW PIR, pet immune to 40 pounds,

35 x 40 ft. coverage, tamper, 3.6 VDC lithium battery

39

60-807-02-95R Wireless residential/commercial - SAW PIR, pet immune to 40 pounds,

35 x 40 ft. coverage, tamper, 1.5 VDC lithium battery

60-880-95 Wireless residential/commercial - 315 MHz AP750W with learn mode

4D signal processing with gliding focus mirror optics

Page 46

Intrusion Sensor

40

Application Notebook

Installation guidelines

Use the following installation guidelines for motion sensors:

• Position the sensor so that any intruder must cross the sensor’s field of view. To

trigger an alarm, an intruder must cross both the positive and negative elements of

one zone.

• Test the sensor in the direction of likely intruder motion and walk test monthly. See

Walk test on page 42.

• Locate the sensor so that valuables are well within its coverage pattern.

• Terminate each protection zone on a solid object such as a wall or floor.

• Use an industrial sensor in locations where a standard sensor may be affected by

water, steam, or oil.

• Do not aim sensors at sources of rapid heating or cooling. These sources include

forced air ducts, space heaters, fireplaces, direct sunlight, strong white lights, and

mirrors that can reflect strong light.

• Do not obstruct the sensor’s field of view.

• Seal optics when possible.

Page 47

Chapter 2

Motion sensors

Outdoor installation guidelines

T est your appl ication over a 24-hour perio d and use the follo wing guidelines when installing

outdoor motion sensors:

Sunlight. Avoid direct sunlight on the plastic lens (even with UV stable plastics).

Temperature. Make sure the temperature range is within sensor specifications. For

example, the 6187CTX sensor is rated to work from -40 to 120°F (-40 to 50°C). Be

aware of temperatures in excess of the sensor ’s specifications.

Humidity/rain/fog. If conduit is used, run conduit out the side or bottom of the sensor

to keep conduit condensation from draining into the sensor housing. Make sure the

conduit openings and the mounting holes on the sensor are well sealed.

Birds and animals. Depending on the size, speed, and proximity to the sensor, warmblooded animals can trigger an alarm. The larger the animal, the farther away it can be

detected. Avoid directing the sensor towards bushes or branches where birds can perch.

You can mount two sensors in parallel to require alarm verification.

Trees and bushes. Tree branches or bushes can cause an alarm when the wind moves

them, and can block detection. Keep branches and bushes at least 30 ft. (9.15 m) from

the sensor.

41

Page 48

Intrusion Sensor

42

Application Notebook

Walk test

To ensure proper operation, always walk test the sensor location. To walk test, do the

following:

1. Mount the sensor in the desired location.

1. Walk throughout the intended coverage pattern.

2. Verify the sensor alarms (see the specific sensor installation instructions).

Most sensors walk test more accurately if you wait 10 seconds between tripping the sensor

and walking again. This allows the sensor to stabilize between trips.

Prewiring

Prewiring allows you to work with the builder in the planning stage to determine optimum

locations for sensors. It will also allow you to avoid many of the hazards inherent in postconstruction installations such as drilling through the electrical cables, plumbing, and ductwork hidden in existing walls.

When wiring after construction, compromises are usually the norm. Existing walls, lighting

fixtures, air conditioning ducts, and other obstacles often determine sensor and control panel

locations. Compromises such as these can leave blind spots in security installations.

Motion sensors are available that will fit into standard outlet boxes just like a light switch.

The flush-mount SureShot (6255FM) sensor fits into a standard single-gang box, remodel

box, or rough-in plate in two easy steps.You simply connect the wires to the proper terminals

on the back of the unit, then screw the unit into an outlet box like you would a switch.

Page 49

Chapter 2

Motion sensors

False alarm reduction

Many GE motion sensors allow you to select one or two zone detection (Figure 30). Each

zone is made up of two fields of view, one positive and one negative. With one zone

selected, an alarm will be indicated when an intruder moves across one positive and one

negative field. With two zones selected, an intruder must cross the positive and negative

fields of two zones before an alarm is indicated. We recommend two-zone detection (except

when using long-range and curtain lenses) to reduce the chance of false alarms. See the

sensor’s installation instructions for details on setting the zone detection.

Figure 30. Zone selection

One-zone detection

2 beams

Two-zone detection

2 beams

2 beams

43

+

-

+

-

+

-

Masking areas on motion sensors

Most motion sensors include masks to modify the coverage pattern to fit specific

applications. Coverage curtains should be masked to avoid sources of false alarms such as

heaters, air conditioners, and windows. Available masks include:

• Plastic masks to cover large areas (Figure 31 on page 44)

• Adhesive labels used on mirror curtains (Figure 32 on page 44)

• Undercrawl window masks to improve false alarm immunity in the presence of

objects within 5 ft. (1.5 m) and directly under the sensor (Figure 33 on page 44)

Page 50

Intrusion Sensor

44

Application Notebook

Figure 31. Plastic masks

Figure 32. Adhesive labels for the mirror

Figure 33. Undercrawl mask

1

1

A

B

A

B

2

2

7.9 ft.

(2.4 m)

5.0 ft.

(1.5 m)

The examples show the AP750 sensor. For masking options for a specific motion sensor , see

the installation instructions for that sensor model.

Page 51

Chapter 2

Motion sensors

Loop supervision

If a resistor is placed at the end of a protection zone (at the last unit in the line), that zone

becomes a supervised loop. A small amount of current can always be applied to that loop,

allowing it to watch the wiring at all times. You can then program the system to give a

warning light or audible alarm if it is tampered with during daytime hours. Supervising the

loop is a security technique used to prevent internal tampering.

Terminal blocks with shared terminals

The SureShot and some older Sharpshooter sensors have SPDT (single-po le double-throw)

contacts in which the normally open (NO) and one of the tamper (TAMP) terminals are

shared. When wiring a tamper switch in series with the alarm output in the normally closed

configuration, be sure to wire the terminals as shown in the correct diagram in Figure 34. If

the jumper wire is placed from the normally closed (NC) terminal to the NO terminal, as

shown in the incorrect diagram, no alarm will sound. When wiring a tamper switch in series

with the normally closed alarm loop, place the jumper or EOL device between the COM and

T/NO terminals.

45

Figure 34. Wiring terminal blocks with shared terminals

Incorrect

NC COM T/NO TAMP + –

Correct

NC COM T/NO TAMP + –

Page 52

Intrusion Sensor

46

Application Notebook

Peripheral control

Motion sensors can be used to control peripheral devices in applications such as:

• CCTV cameras (see CCTV camera activation on page 76)

• Lights (see Hallways and lobby lighting activation on page 58 and on page 80)

• Recorded messages (see Museums on page 55)

Swivel brackets

The 6083-N swivel bracket can be used with the 6187CTX outdoor PIR sensor, the 6198

nonincendive PIR sensor, and the 6197 intrinsically safe PIR sensor in areas where

mounting is difficult.

You can mount the bracket on a flat wall or in a corner (Figure 35). The maximum adjusting

angle for a flat-wall mount is 22.5 degrees. Mount the bracket with the small self-tapping

screws that ship with it.

Figure 35. Swivel bracket

Flat wall, tip view Corner view

22.5°

Page 53

Chapter 2

Motion sensors

Pets

Application. Because PIR sensors are sensitive to moving, heat-radiating sources, they can

be triggered by animals as well as humans. To avoid this false alarm hazard, do one of the

following:

• Use a sensor with pet immunity

• Use a sensor with a pet alley lens

• Mount a sensor upside down to create a pet alley

Installation using a sensor with pet immunity. The introduction of the

PrecisionLine RCR-PET with its dual technology RCR (range-controlled radar) and PIR,

has virtually eliminated the need to create a pet alley associated with nominal motion

sensors. The RCR-PET provides excellent pet immunity for animals up to 80 pounds, and

detects only objects within a very precise range of user settings. Table 5 gives examples of

pet immunity limits for RCR-PET sensors. The table is not accurate for other sensors.

The AP100PI, PI6000, and AP950PI sensors also have pet immunity. See specific sensor

installation instructions for details.

47

Recommended products. RCR-PET, AP100PI, AP950PI, PI6000

Table 5. RCR-PET hair chart

Long hair

2 in. (5.1 cm) long

up to 80 lbs.

Chinook Collie Basenji Doberman

Husky English setter Border terrier Great Dane

Poodle Pointer Cocker spaniel Greyhound

Retriever Pug French bulldog Mastiff

Sheepdog Toy poodle Mini bull terrier Pit bull

German shepherd Weimaraner Welsh corgi St. Bernard

Medium hair

1.5 in. (3.8 cm) long

up to 50 lbs.

Short hair

1 in. (2.5 cm) long

up to 30 lbs.

Cats

Not recommended,

use a pet alley

application

Page 54

Intrusion Sensor

48

Application Notebook

Installation with a pet alley lens. To install the sensor, do the following:

1. Mount the sensor, with the pet alley lens installed, against the wall at the desired

height.

2. Mask the sensor to avoid tables, chairs, cat climbing posts, and other objects a pet

could jump on. Remember that the size of the pet should also be considered while

aiming and adjusting the sensor.

3. Remind the homeowner that furniture moved into the sensor coverage pattern can

give a pet a place to climb or jump and can result in false alarms.

4. Test the sensor (see Walk test on page 42).

Recommended products. 6155 with 6074 pet alley lens, 6255 with pet alley shield

Figure 36. 6155 sensor with pet alley lens coverage

Top view

35 ft.

(10.7 m)

0 ft.

35 ft.

(10.7 m)

3.3 ft.

(1 m)

0 ft.

Side view

35 ft.

(10.7 m)

Page 55

Chapter 2

Motion sensors

Installation creating a pet alley. To create a detection-free area close to the floor,

mount an AP450, AP750, or AP950 sensor 3.5 ft. (1.1 m) above the floor, upside down

(sensor window towards the ceiling). Make sure the under-crawl mask is in place to reduce

exposure to the ceiling. As shown in Figure 37, pets are free to roam below the mounting

height of the sensor without causing an alarm.

Recommended products. AP450, AP750, AP950

Figure 37. Pet alley

49

Sensor

3.5 ft. (1.1 m)

Page 56

Intrusion Sensor

50

Application Notebook

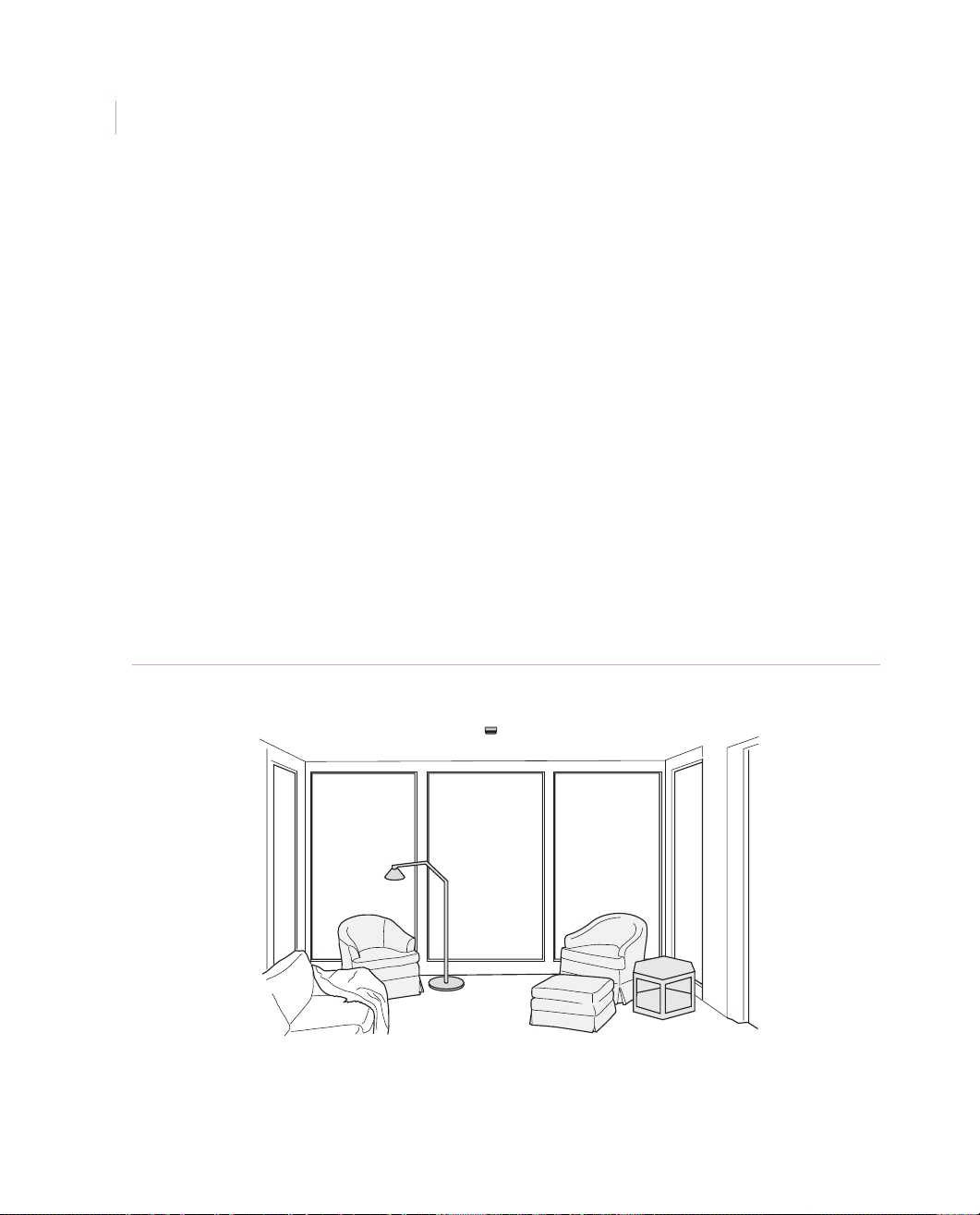

Wireless sensors

Application. Wireless motion sensors can be used in residential and commercial

applications. Wireless sensors are especially useful for installations where it is difficult or

impossible to run wires. See Choosing the right motion sensor on page 37 for descriptions of

wireless sensor models.

Installation. Wherever possible, use a single sensor to cover more than one room

(Figure 38). To install the sensor, do the following:

1. Mount the back box.

2. Attach the sensor to the swivel bracket that is incorporated into the front cover of

the back box.

3. Walk test the sensor (see Walk test on page 42).

Recommended products. NX-482, AP750W, 60-880-95, 60-639-95R, 60-703-95,

60-511-02-95

Figure 38. Wireless sensor installation

Sensor

Page 57

Chapter 2

Motion sensors

Discreet appearance

Application. When adding a security system to an existing residence, the appearance of the

system is often very important to the homeowner. The homeowner is concerned with sensor

placement, wiring and control panel location, and holes drilled through existing walls.

The 6351 DesignLine sensor combines an attractive, unobtrusive design with an easy-tomount snap-on bracket. It can be mounted in a corner within 1/8 in. (0.3 cm) of the ceiling.

This sensor can save you installation time and cost, and has a standard 90-degree lens that

provides entire room coverage with one sensor.

Installation. To install the sensor, do the following:

1. Choose a mounting location close to the ceiling in the corner adjacent to the room’s

entrance (Figure 39) to get the best sensor line of sight. Pull wiring through the

ceiling where possible for a faster, easier installation.

2. Using the foam spacer, mount the bracket to the wall. Connect the wires to the

sensor terminal block and snap the cover in place.

51

3. Most rooms need only one-zone sensitivity, but if the room is subject to temperature

fluctuations or other instability, adjust the sensor for two-zone sensitivity.

4. Test the sensor (see Walk test on page 42).

Recommended products. 6351

Figure 39. DL6351 mounting

exploded view

6351

6351

corner mount

Page 58

Intrusion Sensor

52

Application Notebook

Flush mount

Application. Flush-mount motion sensors make protection no more intrusive in a room

than an electrical outlet or switch. Flush-mount PIR sensors are most often used in prewired

security installations, but can also be used in retrofit installations.

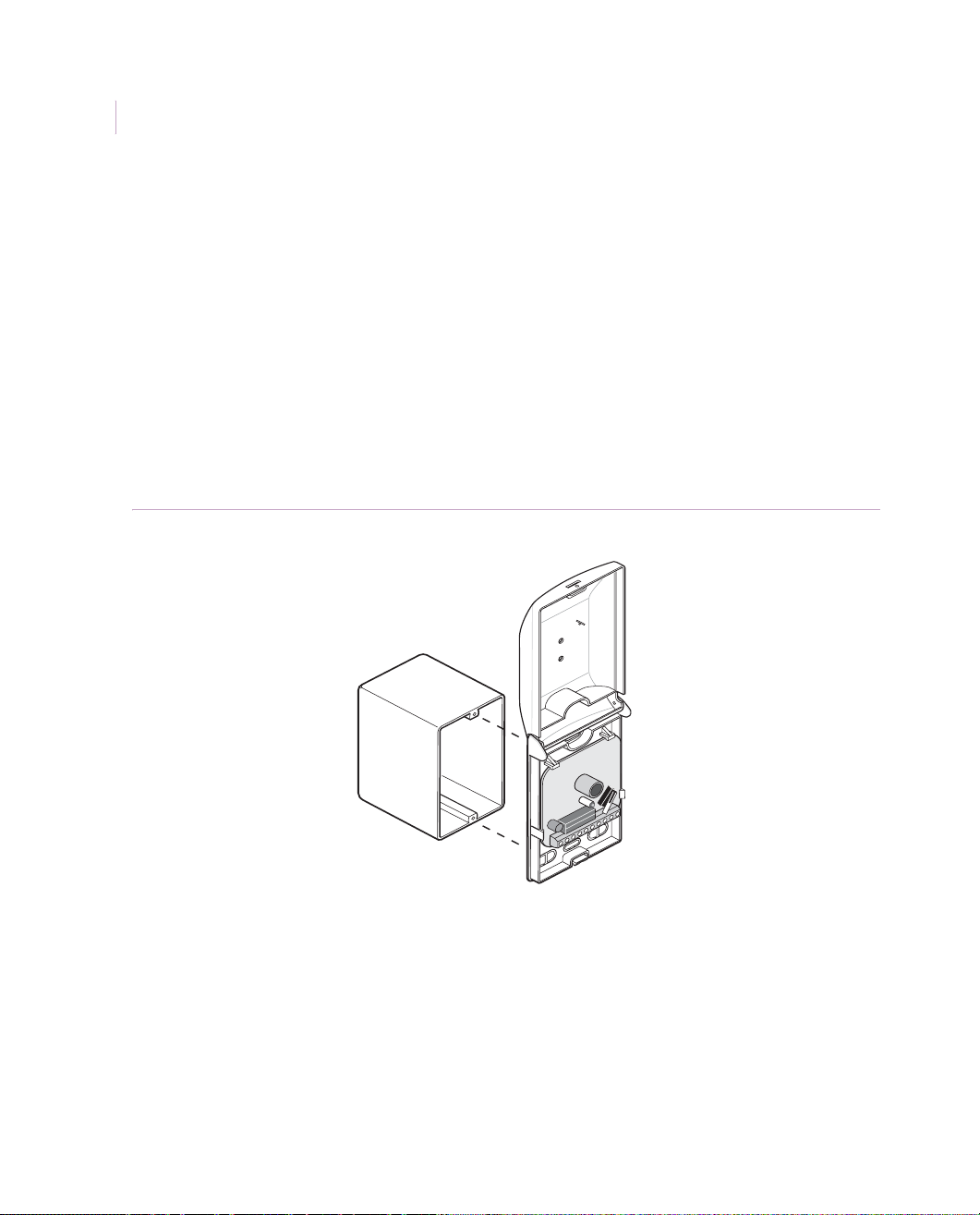

Installation. The 6255FM flush mount SureShot (Figure 40) fits into a standard, plastic

single-gang box. If the security system is to be prewired, mount a single-gang box for each

sensor as planned with the builder. Sensor wires can be easily run through walls and routed

to the control panel. Due to noise problems, do not run PIR sensor wires beside AC wires.

To install the sensor, do the following:

1. Mount the box in the ceiling. For retrofit installations, take care to cut a hole in the

wall just large enough to fit the single-gang remodel box.

2. Run wires through the box to the sensor terminal block.

3. Screw the sensor into the single-gang box as you would an electrical outlet and walk

test the sensor to ensure correct operation. See Walk test on page 42.

Recommended products. 6255FM

Figure 40. 6255FM flush mount SureShot

6255 flush mount sensor Single-gang box

PET

ALLEY

®

Page 59

Chapter 2

Motion sensors

Ceiling mount

Application. Mounting a sensor in the ceiling is a good way to hide wiring in single-level

homes. Running wires in an attic allows you to easily avoid water pipes, duct work, and high

voltage wiring. It also provides complete coverage of rooms with obstructions such as halfwalls and shelving that can block wall mounted sensor coverage.

Installation. For flush mount installation, install a standard plastic single-g ang outlet box