Page 1

5845-ID

g

Description

The 5845-ID (Figure 1) is an addressable glassbreak

device that interfaces with the PinPoint® system. The

system provides flexible and reliable two-way

communication between the device and the controller.

This glassbreak device is based on ShatterPro® II

technology and uses patented Pattern Recognition

Technology.

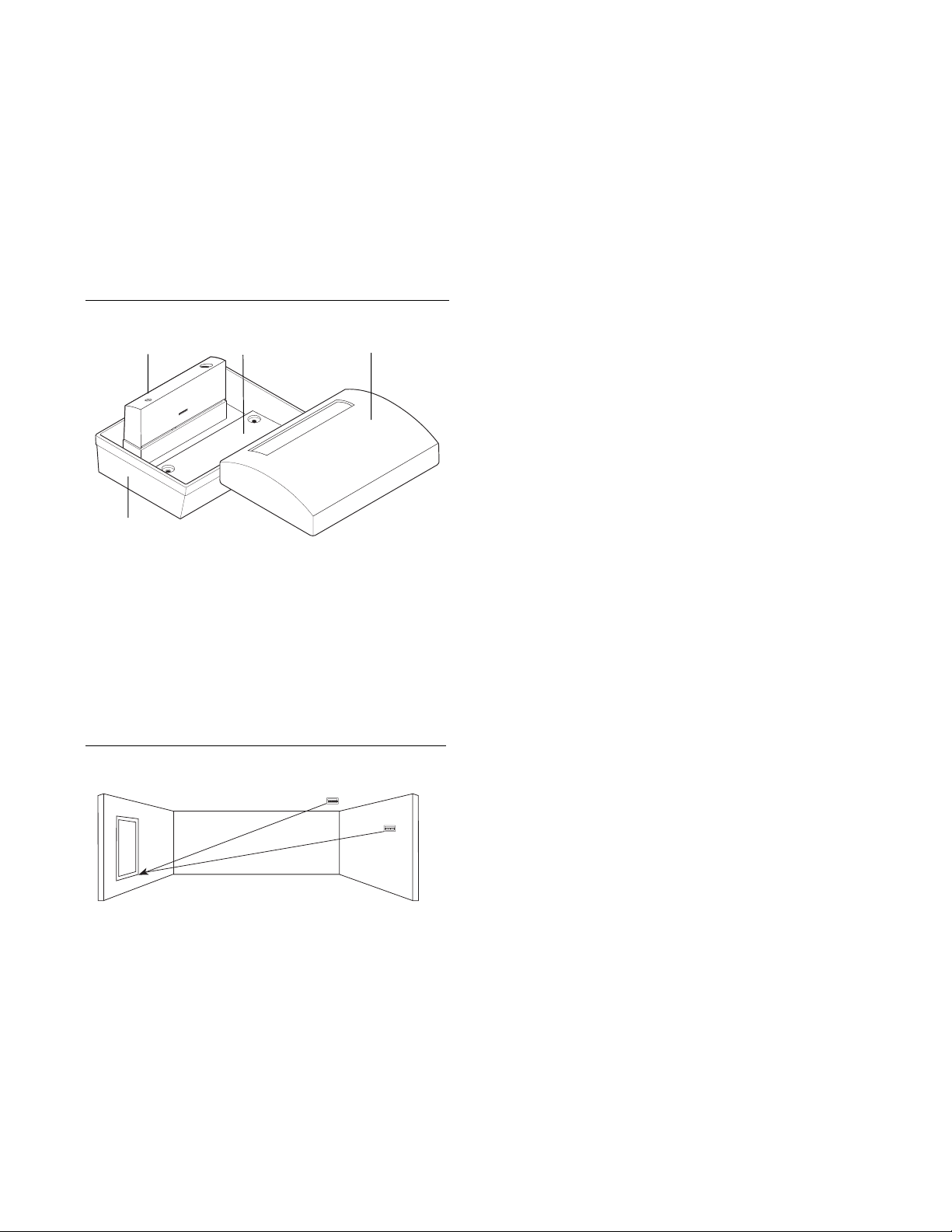

Figure 1. Exploded view

Sensor module

Base

Range

The unit is omni-directional, providing 360° coverage.

Coverage is measured from the unit to the most distant

point on the glass (Figure 2).

Minimum 3.3 feet (1 m) from the glass

Maximum 20 feet (6 m) for plate, tempered,

laminated, and wired glass; 12 feet (3.7

m) for armor-plated glass

Figure 2. Maximum range

20 ft. (6 m)

20 ft. (6 m)

installation instructions

For best detection, avoid installing in:

• Rooms with lined, insulating, or sound deadening

drapes

• Rooms with closed, inside wooden window shutters

• Corners of a room

• Glass airlocks and glass vestibule areas

For best false alarm immunity:

• Install the unit as a perimeter zone which is armed

only when the perimeter doors and windows are

armed. Avoid installing the unit as a 24-hour zone,

where the unit will be armed even when the room is in

use.

• Do not install in humid rooms such as small utility and

bathrooms. The unit is not hermetically sealed and

excess moisture on the circuit board can eventually

cause a short and a false alarm.

• Do not use where white noise, such as air compressor

noise, is present. A blast of compressed air may cause

a false alarm.

• A void rooms smaller than 10 by 10 feet (3 by 3 m) and

rooms with multiple noise sources such as noisy

kitchens, stairwells, residential garages, and other

small accoustically live rooms.

Mounting location

For best false alarm immunity the unit should be located at

least 4 feet (1.2 m) away from noise sources (televisions,

speakers, sinks, doors, etc.). The unit must always be in

direct line of sight of all windows to be protected. There is

no front or back, up or down, orientation of the sensor

required.

Wall mount

Since the sound of breaking glass travels directionally out

from the broken window , the best location for mounting

the unit is on the opposite wall, within the unit’s range

and line of sight.

Recommended glass size

Minimum 1 by 2 feet (0.3 by 0.6 m)

Glass thickness:

Plate 3/32 to 1/4 inch (2 to 6 mm)

T empered 1/8 to 1/4 inch (3 to 6 mm)

Wired 1/4 inch (6 mm)

Laminated 1/8 to 1/4 inch (3 to 6 mm)

Ceiling mount

Mount the unit on any type of ceiling in a location which

is in direct line of sight of the windows to be protected.

However, since sound travels directionally out from the

broken window , a position 6 to 10 feet (2 to 3 m) into the

room provides optimal detection.

Page 2

2 5845-ID

SON APEMS

Installation Instruction

Installation

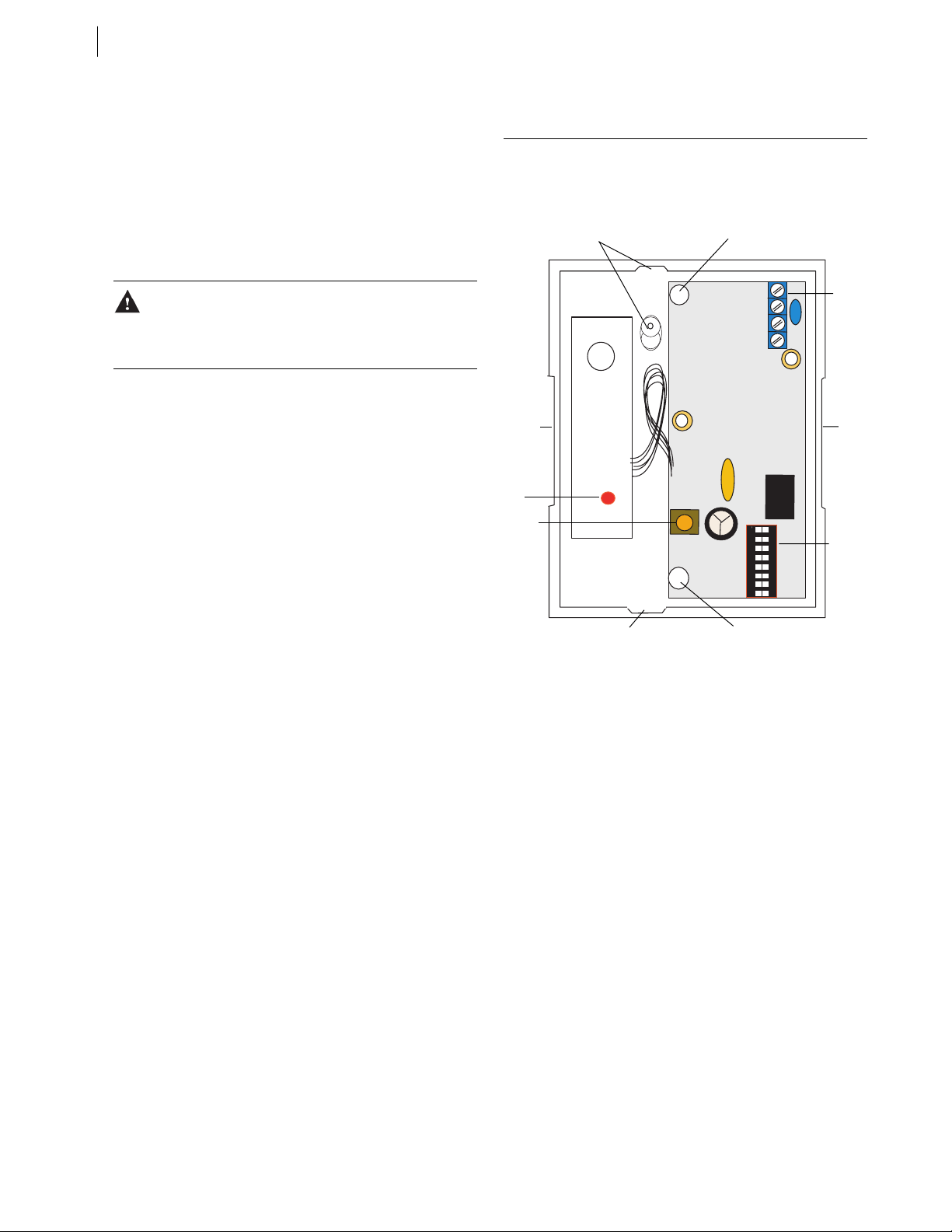

See Figure 3 and do the following steps to install the unit.

1 . Run the PinPoint system wiring to the unit location.

2. Open the unit by gently inserting a screwdriver in the

hidden opening notches that are located under the lid

in the middle of the long side of the unit.

CAUTION You must be free of all static electricity

before handling sensor circuit boards.

Touch a grounded, bare metal surface

before touching ciruit boards or wear a

grounding strap.

3 . Set the PinPoint address DIP switches. Devices are

shipped with DIP switches set to 255. This is an

invalid address. The device will not communicate with

the controller until a valid address has been set.

Refer to the controller's manual to determine the

correct address setting for each unit.

4. Remove the appropriate wiring knockouts and use the

mounting screws to remove the mounting knockouts.

5 . Pull the PinPoint wiring through the wiring knockout

holes.

6. Attach the base to the mounting surface with two

screws through the mounting knockout holes. Use

wall anchors if necessary .

7 . Strip 1/4 inch (6.4 mm) of insulation from each

PinPoint wire. Connect the wiring to the appropriate

screw terminals and tighten the screws.

8 . Replace the lid on the unit.

9. Test the unit when the PinPoint system is completely

installed and the control panel is powered.

Figure 3. Base and circuit board

PinPoint wiring

knockout

Opening

notch

LED

Tamper

switch

PinPoint wiring knockout

Mounting knockout

+ - + -

IN

OUT

ON APEM

Mounting knockout

1 2 3 4 5 6 7 8

PinPoint

terminal

block

Opening

notch

DIP

switches

Page 3

3

Testing

The Pattern Recognition Technology of the unit ignores

most false alarm sounds, including glassbreak testers. In

order to test the unit, a test mode is used. With the unit in

test mode, processing of the glassbreak pattern in the

upper and lower frequencies is disabled. The unit is then

listening only for the mid-range frequencies, which the

5709C tester reproduces. It’s the mid-range frequencies

that determine unit range.

1 . Lift the unit's lid off and put it back on to activate the

LED for the walk test.

2. Use the 5709C hand-held tester to set the unit into

test mode. The 5709C tester has a different setting for

each type of glass. (The tester should always be set

for tempered or laminated glass unless the installer is

certain that all the glass to be protected is plate

glass.) Hold the tester speaker directly on top of the

unit and activate the tester. The unit will alarm then

go into test mode for one minute. When in test mode,

the LED on the unit will blink continuously . Extend

the test mode time by firing the tester at the unit at

least once a minute. In normal mode the LED does

not blink unless it hears a loud sound and the unit

will not trip to the tester, unless the tester is held next

to the unit.

3. Holding the tester near the surface of the glass, aim

the tester at the unit and hold down the test button

(Figure 4). If drapes or blinds are present, test with

the tester behind the closed drapes or blinds (do not

use with heavy or lined drapes).

When the LED on the unit goes solid momentarily

while the tester is triggered, the glass is within

detection range.

4 . If the LED does not go solid, but simply continues

blinking, reposition the unit closer to the protected

windows and retest. Additional units may be required

to achieve adequate coverage. It is very rare that the

unit will not activate within its stated range of

coverage. Double check adequate battery strength in

the tester. A new tester battery may be needed to

restore range.

The unit will automatically change from test mode to

normal mode approximately one minute after it last

hears the tester. LED feedback will time out in three

minutes.

Figure 4. Testing the unit

Do not exceed the rated range of the sensor , regardless of

what the tester shows. Room acoustics can artificially

extend the range of a glassbreak sensor. The specified

range of the unit has been established for worst-case

conditions. While the unit will likely function at additional

range, it may miss a minimum output break, or room

acoustics may be changed at some future time, bringing

the unit range back into normal 20 foot (6 m) conditions.

Proper testing

The unit is designed to detect the breaking of framed

glass mounted in an outside wall. Testing the sensor with

unframed glass, broken bottles, etc., may not trip the unit.

The unit typically does not trip to glass breaking in the

middle of the room and may not consistently detect cracks

in glass, or bullets which break through the glass.

Glassbreak sensors should always be backed up by

interior protection.

Hand clap test

To verify visually that there is power to the unit and that

the microphone and circuit board are functioning, clap

your hands loudly under the unit (in normal mode). The

LED will blink twice, but the unit will not trip.

Maintenance

When installed and used properly, this unit provides

years of service with minimal maintenance. You should

test the unit annually to ensure proper operation.

Clean the cover with a damp (water) cloth as needed to

keep it free of dust and dirt. Always test the unit after

cleaning.

Page 4

4 5845-ID

Installation Instruction

Specifications

Housing material Flame retardant ABS

Operating voltage 8 to 27V, (as supplied by

the PinPoint bus)

Current draw 250µA typical average

3 mA with LED momentarily on

Microphone Omni-directional electret

Operating temperature 14 to 120°F (-10 to 50°C)

Relative humidity 10 to 90% non-condensing

Maximum line length 10,000 ft. (3 km)

Dimensions:

Width 3.13 in. (8.0 cm)

Depth 1.70 in. (4.3 cm)

Height 4.24 in. (10.8 cm)

Color White

Listing FCC, CE

FCC compliance

This device complies with Part 15 of the FCC rules. Operation is

subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired operation.

Product ordering

Product Description

5845-ID Addressable ShatterPro® II

glassbreak for use with the

PinPoint bus.

5709C Glassbreak tester

12345 SW Leveton Drive

GE Security

Tualatin, OR 97062

503-692-4052

USA & Canada: 800-547-2556

Tech Support: 800-648-7424

www.ge-security.com

1036047C / September 2004

Loading...

Loading...