Page 1

Wireless ShatterPro Acoustic Sensor Installation

Instructions

directionally out from a broken window, a position 8 ft. (2.4 m)

Introduction

This is the Wireless ShatterPro Acoustic Sensor

Installation Instructions for models 584503-W (3 V) and

584509-W (9 V). The sensor is designed to detect breaking

glass from framed windows in the perimeter of a building.

Install the sensor on a perimeter loop armed whenever the

door and window contacts are armed. Avoid 24-hour loop

applications where the sensor is armed all day and all night.

The false-alarm technology will be pushed to its limit in a 24hour loop.

The sens or’s fals e-alarm immunity is best in rooms with only

moderate noise. Some sounds can duplicate the points on the

glassbreak pattern the sensor detects.

The sensor may not consistently detect cracks in glass, or

bullets which break through the glass. Glassbreak sensors

should always be complemented with interior protection.

Connect the sensor to a UL listed control panel, or a power

supply that provides at least four hours of standby power.

Use a 9-volt battery if longer life is needed in the 584509-W.

Mounting location

The sensor must always be in direct line of sight of all windows

to be protected. The sensor cannot consistently detect glass

breaking around corners or in other rooms. There is no

required front, back, up or down orientation.

into the room provides better detection.

Use the following guidelines to determine the best mounting

location:

• Mount the sensor at least 3.3 ft. (1 m) from the windows

being protected and at least 4 ft. (1.2 m) from noise

sources such as TVs, speakers, sinks, and doors.

• Mount the sensor in the direct line of sight of the glas s to

be protected.

• Avoid rooms smaller than 10 x 10 ft. (3m x 3m).

• Avoid locations where lined, insulating, or sound-

deadening drapes or clos ed wooden shutters are used.

• Mount the sensor in a suitable environment: temperature

between 0 and 120°F (-18 and 50°C); and humidity

between 10 and 90% noncondensing. Do not install the

sensor in humid rooms. Excess moisture on the circuit

board can eventually cause a short and a false alarm.

• Mount the sensor on a stable surface up to 25 ft. (7.6 m)

from the farthest point on the glass surface.

• Avoid locations that expose the sensor to possible false-

alarm sources such as:

• glass airlocks and vestibule areas;

• kitchens;

• corner mounting;

• residential car garages;

• small utility rooms;

• stairwells;

• bathrooms; and

• small acoustically live rooms.

Wall mount

The best wall-mount location is on the opposite wall, assuming

the glass to be protected is within the sensor’s range and line

of sight. The adjoining wall can also be used.

Ceiling mount

Mount the sensor in a location that is in direct line of sight of

the glass to be protected. However, since sound travels

P/N 11089 • REV H • OCT12 1

Coverage range

The sensor is omni-directional, providing 360° coverage.

Coverage is measured from the sensor to the point on the

glass farthest from the sensor. The sensor can be mounted as

close as 3.3 ft. (1 m) from the glass. The maximum range

depends on the type of glass being protected:

Armor-coated glass

Mount sensor no more than 12 ft. (3.6 m) from the glass.

Page 2

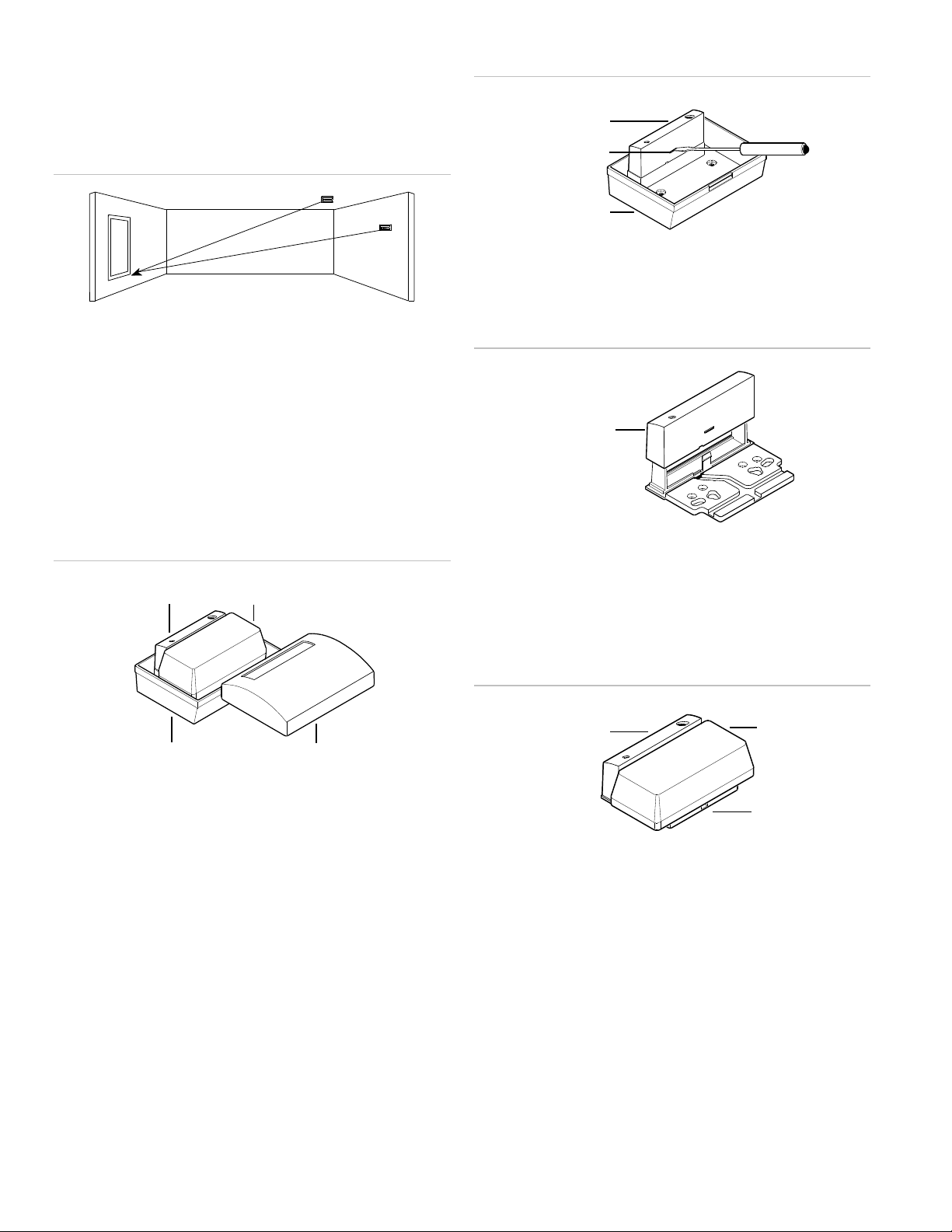

Plate, tempered, laminated, and wired glass

Sensor module

Transmitter

Base

Sensor module

Transmitter

Bracket

Sensor module

Sensor module

Catch

Base

25 ft. (7.6 m)

25 ft. (7.6 m)

Mounted on the ceiling or the opposite or adjoining wall,

(Figure 1 below) maximum range is 25 ft. (7.6 m).

Figure 1: Maximum coverage range

Installation

The sensor has two mounting options.

Sensor base housing

You can place the wireless trans mitter ins ide the sensor’s base

housing (Figure 2 below). For some large transmitters, it will

be necessary to remove the transmitter board from its housing.

Figure 2: Sensor base housing

Figure 3: Removing the sensor module

2. Snap the sensor module unto the bracket (Figure 4

below).

Figure 4: Snapping the sensor module onto the bracket

3. Run the wires to the transmitter and attach the transmitter

to the bracket (Figure 5 below). Use the punched doublestick tape provided to hold the wire in the bracket’s wire

channel, and to hold the transmitter to the bracket.

Transmitter bracket

For large transmitters that do not fit into the sensor base, or for

a smaller appearance with a standard size transmitter, use the

transmitter bracket.

To mount the sensor on the transmitter bracket, do the

following:

1. To remove the sensor module from the base, depress the

catch in the center of the sensor module (Figure 3 below)

and rock the module up off the posts.

Figure 5: Attaching the transmitter to the bracket

4. Mount the sensor/transmitter/bracket assembly. If the

transmitter’s mounting holes don’t fit the bracket’s hole

pattern, you will have to mount the bracket to the wall or

ceiling before attaching the transmitter.

Wiring

All wiring must conform to the National Electric Code (NEC)

and/or local codes having jurisdiction.

2 Wireless ShatterPro Acoustic Sensor Installation Instructions

Page 3

584503-W Wiring

UTC Fire & Security

3.5 V programmable

Transmitter

584503-W

UTC Fire & Security

3.5 V learn mode

Transmitter

584503-W

UTC Fire & Security

3.5 V System VI

Transmitter

564503-W

Black

Black

Black

Red

Green

(NL)

Red

Green

(NL)

Red

Green

Black

564509-W

Ademco

5716

transmitter

Red

Green

(NL)

Black

Red

White

Green

Figure 6 below shows the 584503-W wiring (shares transmitter

battery). The wires are:

Red - To battery +.

Black - To battery -.

White - Normally open (closes on alarm to battery - ).

Green - Normally closed (to battery - ).

Figure 6: 584503-W wiring

Figure 8: 584503-W connections to the UTC Fire & Security 5816

transmitter

Figure 7 below shows the 584503-W connections to the

Ademco 5816 transmitter.

Figure 7: 584503-W connections to the Ademco 5816 transmitter

Figure 8 below shows the 584503-W connections to UTC Fire

& Security transmitters.

To connect the 583403-W to the transmitter, do the following:

1. Program the learn mode transmitter into the MCA.

2. Connect the sensor to the transmitter as shown in Figure 8

above.

3. Solder the red lead to the positive battery terminal on the

underside of the circuit board.

4. Put the cover on the transmitter and put it back into the

base. Snap the sensor cover in place.

5. Test with the 5709C tes ter. (See “Testing” on page 4.)

584509-W Wiring

Figure 9 on page 4 shows the 584509-W wiring (shares

transmitter battery). The wires are:

Red - To battery +.

Black - To battery -.

White - Normally high.

Green - Normally low.

Wireless ShatterPro Acoustic Sensor Installation Instructions 3

Page 4

Figure 9: 584509-W wiring

Black

Red

White

Ademco

5716

transmitter

Green

564509-W

Black

Red

Green

(NL)

584509-W

AT&T transmitter

Black

White

(NH)

Red

Honeywell 10-6506 (T-8803) transmitter

584509-W

Black

Green (NL)

GND

Red

Figure 10 below shows the 584509-W connections to the

Ademco 5716 transmitter.

Figure 10: 584509-W connections to the Ademco 5716

Figure 12 below shows the 584509-W connections to the

AT&T transmitter.

Figure 12: 584509-W connections to the AT&T transmitter

To connect the 584509-W to the AT&T transmitter, do the

following:

1. Splice the white wire from the sensor to the green wire

from the transmitter.

2. Connect the black wire from the sensor to the battery -.

To connect the 584509-W to the Ademco 5716 transmitter, do

the following:

1. Remove the battery.

2. On SW3, set switch 6 to Off (down). On SW4, set switch 1

to ON (up). Do not use a magnet.

3. Connect loop wires (green).

4. Connect 9-V battery terminals and install the battery

observing polarity.

Figure 11 below shows the 584509-W connections to the

Honeywell 10-6506 (T-8803) transmitter.

Figure 11: 584509-W connections to the 10-6506 transmitter

3. Connect the red wire from the sensor to the battery +.

4. On the 12-position DIP switch, set switch 6 to OFF for CL.

Set switch 7 to ON for PIR or glassbreak.

If you use this transmitter inside the back box, the circuit board

must be removed from the housing. You can secure it with the

double-stick tape provided. For the most secure connections, it

is better to solder the battery connector terminals instead of

using the buddy-up clips.

Testing

The sensor is designed to detect the breaking of framed glass

mounted in an outside wall. Testing the sensor with unframed

lass, broken bottles, etc., may not trip the sensor. The sensor

typically does not trip to glass breaking in the middle of the

room.

The Pattern Recognition Technology of the sensor ignores

most false alarm sounds, including glassbreak testers. To test

the sensor, use test mode. Test mode disables glassbreak

pattern processing in upper and lower frequencies. The sensor

is then listening only for the mid-range frequencies that the

UTC Fire & Security 5709C hand-held tester reproduces. It’s

the mid-range frequencies that determines sensor range.

4 Wireless ShatterPro Acoustic Sensor Installation Instructions

Page 5

Test mode

To put the sensor in test mode, do the following:

1. Use the 5709C handheld tester to put the sensor into test

mode. Set the tester to tempered glass and hold the tester

on top of the sensor.

2. Activate the tester. The sensor will alarm, then go into test

mode for one minute. In test mode, the LED will blink

continuously. To extend test time, fire the tester at the

sensor at least once a minute.

Sensor test

The sensor must be in test mode (blinking). To test the sensor,

do the following:

1. The tester has a different setting for each type of glass.

Set the tester for tempered or laminated glass unless you

are certain that all the glass to be protected is plate glass.

2. Hold the tester near the surface of the glass to be

protected and aim the speaker at the sensor. Be sure the

tester is at the point on the glass farthest from the

detector. If closed drapes or curtains are present, hold the

tester behind them (Figure 13 below).

Room acoustics can artificially extend the range of a

glassbreak sensor. The specified range of the sensor has been

established for worst-case conditions. While the sensor will

likely function at additional range, it may miss a minimum

output break, or room acoustics may change at some future

time, bringing the sensor range back into normal 20 ft. (6 m)

conditions. Do not exceed the rated range of the sensor,

regardless of what the tester shows.

Hand clap test

You can check the sensor while in normal mode, simply by

clapping your hands loudly under the sensor. The LED will

blink twice, but the sensor will not trip. This verifies visually that

there is power to the sensor, and that the microphone and

circuit board are functioning.

The hand clap activation is only momentary, so there is no

appreciable effect on battery life.

To disable this custom test function, remove the circuit board

from the housing and clip one of the wires on the LED. The

LED will no longer be operational, but the sensor can still be

tested using the transmitter and the control panel.

Maintenance

Figure 13: Testing behind curtains

3. Press the test button on the tester. The LED on the sensor

should stay on for 4 seconds to indicate the glass is within

detection range of the sensor. If the LED does not stay on

for 4 seconds, move the sensor and retest.

If the sensor will not activate within its stated range of

coverage, check for battery strength in the tester. A new tester

battery will likely restore range. You may need to use

additional sensors to achieve adequate coverage.

The sensor will automatically change from test mode to normal

mode approximately one minute after it last hears the tester. In

normal mode the LED does not blink unless it hears a loud

sound. In normal mode, the sensor will not trip to the tester,

unless the tester is held next to the sensor. Each time the

sensor alarms, it also goes into test mode for one minute.

When installed and used properly, the sensor provides years of

service with minimal maintenance. You should test the sensor

annually to ensure proper operation.

Clean the cover with a damp (water) cloth as needed to keep it

free of dust and dirt. Always test the sensor after cleaning it.

Wireless ShatterPro Acoustic Sensor Installation Instructions 5

Page 6

Specifications

Operational voltage

584503-W

584509-W

2.8 to 4.5 VDC

6 to 16 VDC

Current draw

584503-W

584509-W

17uA typical average

23 uA typical average, 5 mA w ith LED

momentarily on

Alarm duration

Four seconds

Output

584503-W

584509-W

Normally closed output and normally open

output with open drain MOSFETs; 700 Ohm

max. closed resistance; 10 Mohm min. open

resistance. Output voltage must be less than

or equal to supplied battery voltage

Normally low output with NPN transistor and

10M pull-up resistor and normally high output

with PNP transistor to power + 16 VDC max.

output voltage

RF immunity

20 V/m, 1 MHz to 1000M Hz

Microphone

Omnidirectional electret

Recommended glass

thickness

Plate

Tempered

Wired

Laminated

3/32 to 1/4 in. (2.4 to 6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

1/4 in. (6.4 mm)

1/8 to 1/4 in. (3.2 to 6.4 mm)

Operating temperature

14 to 120°F (-10 to 50°C)

Dimensions

4.25 x 3.13 x 1.70 in (108 x 80 x 43 mm)

Housing material

Flame-retardant ABS

Color

White

Wiring

22 AWG UL stye 1061, CSA T2, color-coded

wire, passes VW-1 flame test

Note: The 584503-W typically w orks down to 2.1 VDC and the

584509-W typically w orks down to 3.0 VDC, w hich allows most

transmitters to send low battery trouble alarms.

Product

Description

584503-W

Wireless ShatterPro, 3-V model with optional bracket

584509-W

Wireless ShatterPro, 9-V model with optional bracket

Accessories

5709C-W

Glassbreak hand-held tester, white

FCC compliance

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the instructions may cause harmful

interference to radio communications. There is no guarantee

that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment on and off, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different

from the one where the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

Under FCC rules, Part 15 for Class B digital devices, operation

is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received,

including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party

responsible for compliance could void the us er’s authority to

operate the equipment.

Product ordering

Contact information

www.utcfireandsecurity.com or www.interlogix.com

6 Wireless ShatterPro Acoustic Sensor Installation Instructions

For customer support, see www.interlogix.com/customer-

support

© 2012 UTC Fire & Security Americas Corporation, Inc.

Interlogix is part of UTC Climate Controls & Security, a unit of

United Technologies Corporation. All rights reserved.

Loading...

Loading...