Page 1

SENTROL

ShatterPro™ II Advanced Acoustic Sensor with Pattern Recognition Technology

Protected under U.S. Patent 5,192,931 and 5,510,767

Installation Instructions for Recessed and Surface Mount Models

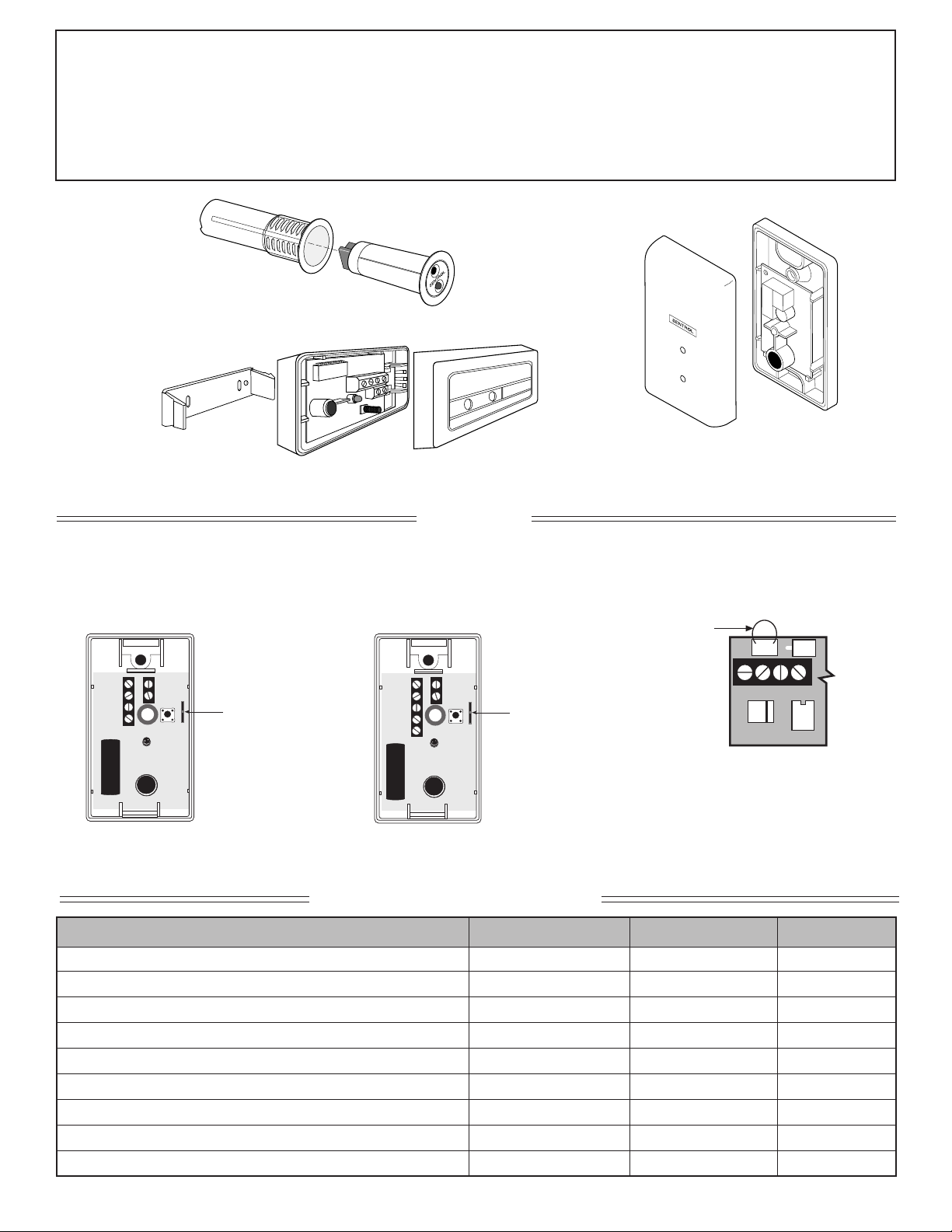

Recessed ShatterPro™ II 5820A

SENTROL

Surface Mount ShatterPro™ II

Surface Mount ShatterPro™ II 5812A

WIRING

5812EZ

™

Strip back the outer jacket on your wiring cable. This will allow wires to flex in the case. Make sure the cable is slack in the wall to

avoid stressing the wires at their connections.

Cut for latching LED

N.C.

COM

TAMP

TAMP

+

–

spring clip for

latching LED

N.C.

COM

TAMP

TAMP

NO

+

–

Loop

+

−

spring clip for

latching LED

5820A-W and 5822A-W

NOTE: When wiring the

5812EZ-W

5812A-W

5815EZ-W

5815A-W

5822A, the tamper is in series

with the alarm loop. There is

insufficient room for a separate

set of terminals for the tamper.

ORDERING INFORMATION

Description Model No. Color Listing

ShatterPro™ II EZ, tamper, latch or non-latch LED 5812EZ-W White UL

ShatterPro™ II EZ, tamper, Form C, latch or non-latch LED 5815EZ-W White ULC

ShatterPro™ II, tamper, latch or non-latch LED 5812A-W White UL

ShatterPro™ II, tamper, Form C, latch or non-latch LED 5815A-W White ULC

Recessed ShatterPro™ II, latch or non-latch LED 5820A-W White

Recessed ShatterPro™ II, tamper, latch or non-latch LED 5822A-W White UL

Single Gang Box ShatterPro™ II 5825A-W White

Single Gang Box Kit for Recessed ShatterPro™ II 5829A-W White

Hand-held Tester, for testing effective range 5709C-W White

Page 2

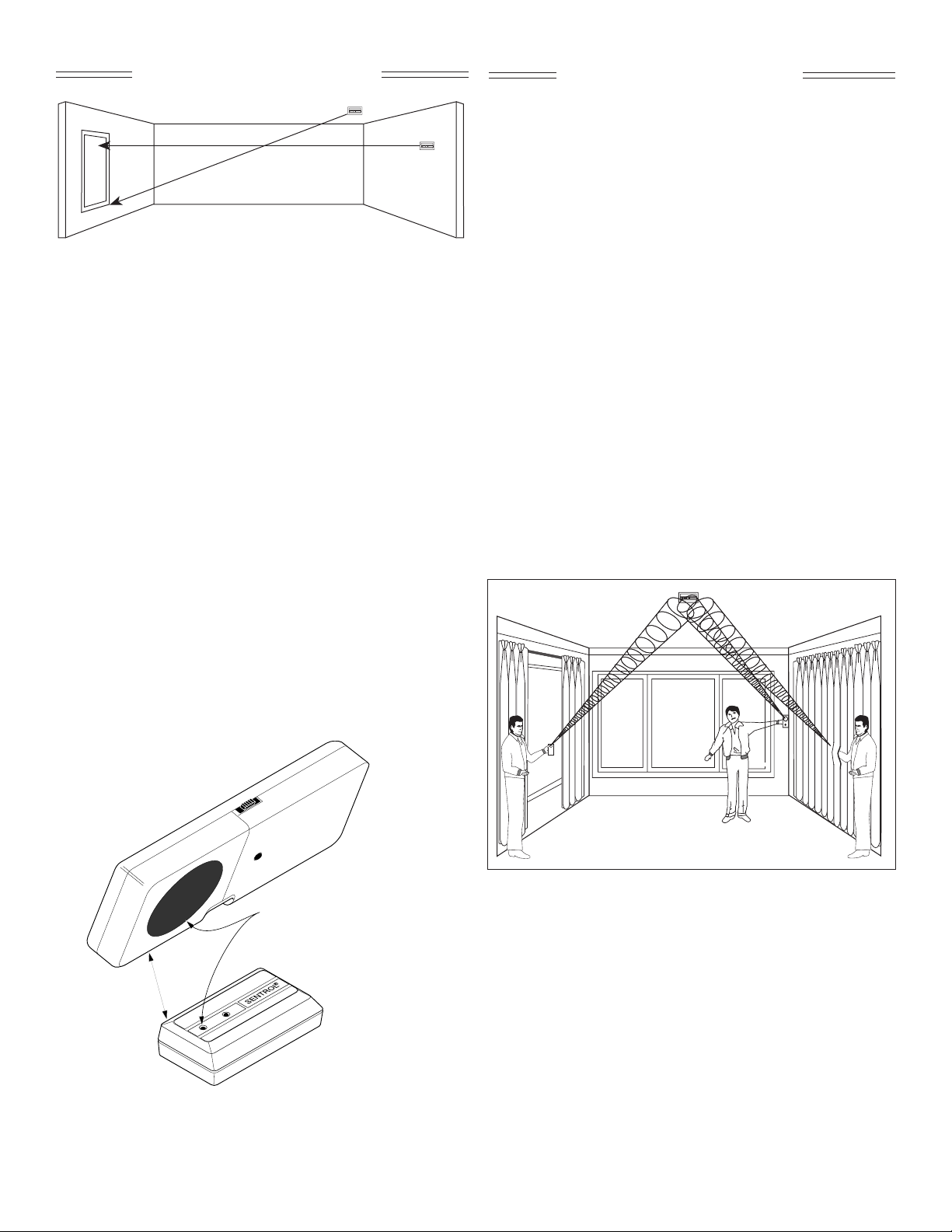

RANGE OF COVERAGE

25' (7.5 m)

25' (7.5 m)

The ShatterPro sensors are omni-directional, providing 360°

coverage. Coverage is measured from the sensor to the point on

the glass farthest from the sensor. The sensor can be mounted as

close as 3.3' (1 m) from the glass.

1. Mounted on opposite wall or adjoining walls, range is 25 ft.

(7.5m) for plate, tempered, laminated and wired glass.

2. Mounted on the ceiling, maximum range is 25 ft. (7.5m) for

plate, tempered, laminated and wired glass.

3. For armor-coated glass, mount sensor no more than 12 ft.

(3.65m) from glass.

Recommended Glass Size:

Minimum 1' x 2' (0.3 m x 0.6 m) or larger

Glass thickness:

Plate: 3/32" to 1/4" (2.4 mm to 6.4 mm)

Tempered: 1/8" to 1/4" (3.2 mm to 6.4 mm)

Wired: 1/4" (6.4 mm)

Laminated: 1/8" to 1/4" (3.2 mm to 6.4 mm)

TESTING THE SENSOR

Put Sensor in Test Mode

1. Connect 9-volt battery to sensor for pre-testing.

2. Use double-stick tape provided to temporarily mount sensor

in desired location.

3. Use Sentrol 5709C Hand-Held Tester to put sensor into test

mode. Set tester to tempered glass and hold on top of

sensor. Activate tester this will trip sensor into test mode

for one minute. In test mode, LED will blink continuously.

To extend test time, activate tester at least once a minute.

Test the Sensor (sensor must be in test mode, blinking)

1. The 5709C tester has settings for different types of glass.

Use tempered setting if unsure of glass type.

2. Hold tester near surface of glass to be protected and aim at

sensor. Press test button.

If drapes or blinds are present, hold the tester behind the

closed drapes or blinds.

3. If LED stays on for four seconds, glass is within detection

range of sensor.

4. If LED does not stay on, reposition the sensor and retest.

(Verify adequate battery strength in tester.)

5. For latching LED: open the spring clip and provide a power

reset by removing power and resetting the LED.

For Best Detection, Avoid Installing In:

Rooms with lined, insulating, or sound deadening drapes.

Rooms with closed wooden window shutters inside.

SENTROL

ShatterSwitch

Shatterbox II

Shatterbox

ShatterPro

5709C

Use for testing:

Laminated •

Shatter Series Tester

stays on during test

Battery LED

Battery is OK if LED

Hold tester so that the speaker is

within 1 inch of sensor microphone

In test mode the sensor LED will light

solid for about 4 seconds,

then blink for about a minute

<1 inch

• Single

• Continuous

Plate •

Tempered •

How Test Mode Works:

Test Mode is activated by the hand-held tester when the tester is

held directly over the microphone and set off. The sensors LED

will blink continuously for 1 minute. During this time, the

installer can test the unit using the instructions above. When the

system is armed and the ShatterPro II trips to an alarm condition,

the LED will latch solid for 4 seconds and then revert back to a

1 minute test mode. At the end of one minute, the LED will

extinguish if in set up LED mode, or the LED will latch if set

for Latching LED. Open spring clip for Latching LED.

Page 3

MOUNTING

D

DD

is distance from glass.

The optimum performance zone

is distance D in either direction

on the glass.

ShatterPro

D' ≤ 25'

Locate sensor at least 4' from noise sources (TVs, speakers, sinks,

doors, etc.), and at least 3.3' away from nearest point of glass to

be protected.

Sensor location should be in direct line of sight of glass to be

protected.

Surface Mount

Wall Mounting

The best location for mounting the sensor is on the opposite wall

assuming the glass to be protected is within the sensors range

and line of sight (see figure). The ceiling and adjoining (side)

walls are also good sensor locations.

Ceiling Mounting

Mount the sensor in any type of ceiling in a location which is in

direct line of sight of the windows to be protected. However,

since sound travels directionally out from the broken window, a

position 8' (2.4 m) into the room provides better detection (see

figure).

AVOIDING FALSE ALARMS

Areas to Avoid:

Glass airlocks and glass vestibule areas

Kitchens

Corner mounting

Residential car garages

Small utility rooms

Stairwells

Bathrooms

Other small acoustically live rooms

For glassbreak protection in such applications, use Sentrol

shock or ShatterPoint (model 5600, 5620) sensors on the

windows or window frames.

Do Not Install In Humid Rooms

No glassbreak sensor is hermetically sealed. Excess moisture

on the circuit board can eventually cause a short and a false

alarm.

For Best False Alarm Immunity:

Avoid 24-hour loop applications (perimeter loop OK).

Dont use where white noise, such as air compressor noise,

is present. (A blast of compressed air may cause a false

alarm.)

Avoid rooms smaller than 10' x 10' (3 m x 3 m) and rooms

with multiple noise sources such as kitchens, glass booths,

noisy areas, garages, bathrooms, etc.

In rooms less than 10' x 10', use a reduced-range ShatterPro

II, (models 5820A-W2, 5812A-W2), or ShatterPoint (model

5600, 5620).

Proper Testing

The ShatterPro II is designed to detect the breaking of framed

glass mounted in an outside wall. Testing the sensor with

unframed glass, broken bottles, etc., may not trip the sensor.

The ShatterPro II typically does not trip to glass breaking in

the middle of the room. No burglar breaks glass in the middle

of a room, so such breaks are false alarms.

Recessed

Wall or Ceiling Mount

Drill 1" (2.5 cm) hole. (Spade bit makes cleaner hole than

twist bit.) (Drill 1-1/16" (2.7 cm) hole for hard woods.)

Run wires through hole.

Connect wires to terminal as shown in wiring diagrams.

Do not install in rooms with ultrasonic sensors.

Pre-Wire Installation for the 5812EZ

Single Gang Box

1. Place the 5811EZ trim plate accessory over the single gang box.

2. Route wire through wire entry hole.

3. Mount the sensor to the single gang box using the screw holes

that align to the gang box.

4. Attach wires to terminal strip and snap front cover in place.

Optimum

Detection

Zone

Mounting location can affect the ShatterPro’s detection ability.

To ensure optimum performance, the ShatterPro’s coverage

zone width should be no greater than two times the distance

from the sensor to the closest point of glass. For instance, if

the ShatterPro is mounted 10 feet from the glass, its optimum

performance zone will be 10 feet in either direction of the “midpoint” (see illustration above). ShatterPro can be mounted

from 3.3' to 25' from the farthest point on the glass.

Avoid 24-Hour Loop Applications

The ShatterPro II is recommended for perimeter loops and is designed

to function in occupied areas. In 24-hour loop applications, where the

sensor is armed all day and all night, the false alarm technology will be

pushed to its limit. Some sounds can duplicate the points on the

glassbreak pattern the ShatterPro II detects.

Install the ShatterPro II on a perimeter loop which is armed

whenever the door and window contacts are armed.

Protecting Occupied Areas

The ShatterPro IIs false alarm immunity is best in rooms with only

moderate noise. For 24-hour occupied area protection, use Sentrol

shock sensors or the ShatterPro Plus 5885 or ShatterPoint (5600,

5620).

NOTE: ShatterPro II may not consistently detect cracks in glass,

or bullets which break through the glass. Glassbreak sensors

should always be complemented with interior protection.

Connection to Panel

The ShatterPro II should be connected to a UL Listed control

panel, or a power supply that provides at least four hours of

standby power.

Page 4

SPECIFICATIONS

2.75"

(6.99 cm)

4.5"

(11.43 cm)

Electrical

Voltage ...................................................................... 9 to 16 VDC

Current ............................................... 12 mA typical, 25 mA max.

Relay output............ Normally closed, open 4 seconds upon alarm

On resistance ................................................ 10 Ohm 5 +10

Off resistance....................................................... > 1 MOhms

Maximum loop rating (relay or tamper loop) .........................

...................................................................... 16 VDC, 50 mA

Wiring terminals ......................................................... 22-18 AWG

Environmental

Lightning suppression ..........................400 watts for 1 msec pulse

RF Immunity ..............................20V/m min from 1MHz to 1GHz

Microphone ............................................ Omni-directional electret

Operating Temperature ............. 0° F to 120° F (-18° C to +50° C)

Humidity ............................................10% to 90% noncondensing

ACCESSORIES

5825A Single Gang Box

ShatterPro™ II

NOTE: This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. There is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment on and off, the user is encouraged to

try to correct the interference by one or more of the following measures:

Re-orient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Under FCC Rules, Part 15 for Class B digital devices, operation is subject to the

following two conditions:

1) This device may not cause harmful interference.

2) This device must accept any interference received, including interference

that may cause undesired operation.

(Back box

not included)

2.53" diameter (6.43 cm)

1" diameter hole (2.54 cm)

5829A Single Gang Box Plate

for 5820A.

(Back box

not included)

5812EZ Pre-Wire Installation with 5811EZ and Single Gang Box

SENTRO L

CORPORATE HEADQUARTERS

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

FaxBack: 800.483.2495

G-3513-798

15651 Rev. A

Loading...

Loading...