Page 1

DESCRIPTION

The 5600 Glassbreak Sensors are designed to detect

breaking glass caused by forced entry into a protected

window or door. The ‘Tru-Dual’ transducer design provides

excellent false-alarm immunity in noisy environments.

The 5600 Sensor processes both acoustic and vibration

information to identify breaking windows. Frame mounting

the 5600 Sensor eliminates detection concerns with drapes

and blinds. The built-in reed switch provides protection

against forced opening of windows or doors, as well as

breaking glass.

Note: This sensor may not consistently detect cracks,

bullets, or similar breaks. Glassbreak sensors should always

be backed up by interior protection such as a motion

detector.

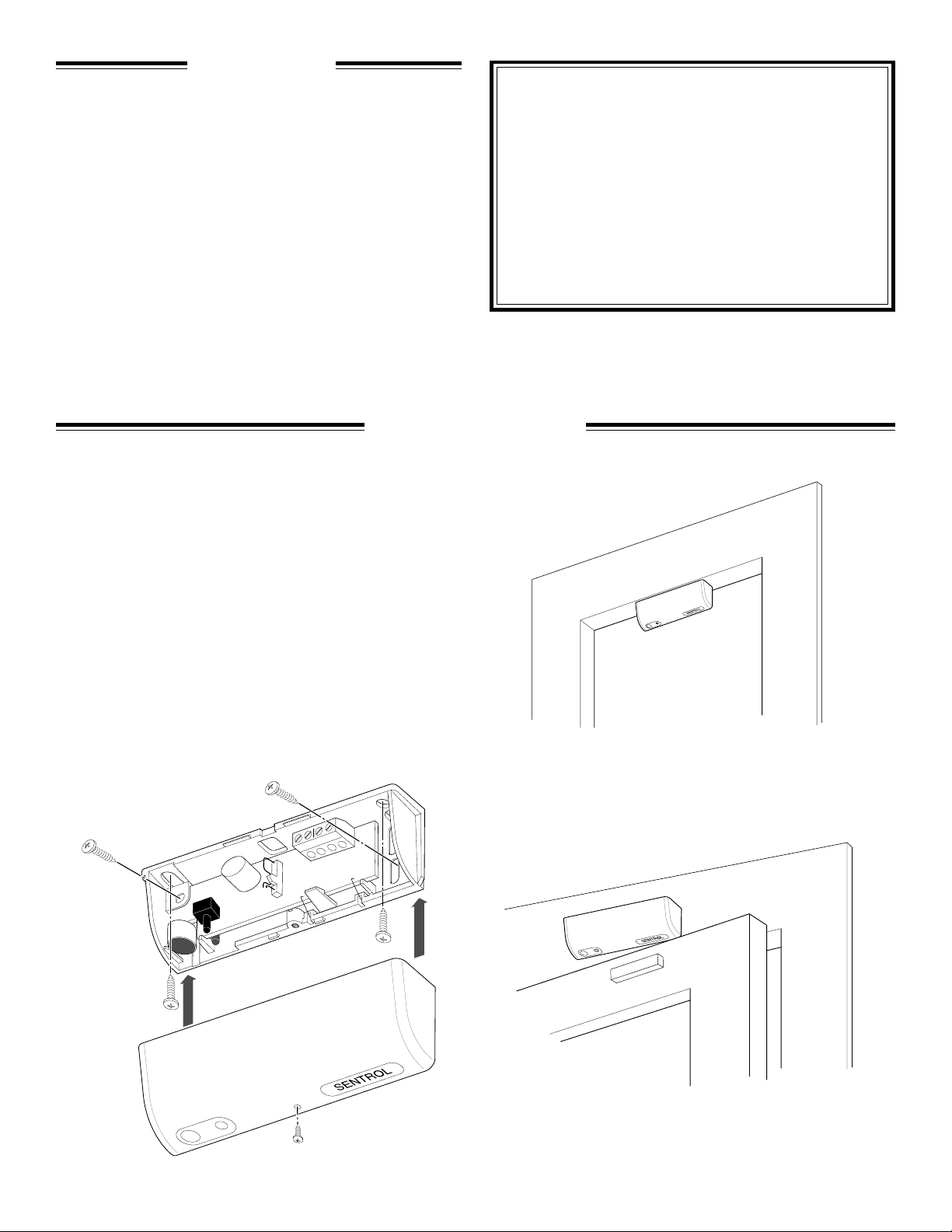

STEP 1 — MOUNTING

The 5600 sensors are designed to mount either inside the

frame (see Figure 1a) or on the facing (see Figure 1b).

Refer to Figure 2 for recommended mounting locations and

coverage range. Mounting location should provide good

mechanical coupling from glass to sensor and an

unobstructed microphone view of the glass. If structural

integrity of the frame is poor, temporarily mount sensor and

follow Step 3 for range testing. Do not exceed the tested

range of the sensor.

Figure 1a

Sentrol

ShatterPoint

Glassbreak Sensor

Installation Instructions

Models

564503 (3 Volt) 564506 (6 Volt)

™

Note: For applications with more than one framed window

or French style doors and windows, use multiple 5600s or a

ShatterPro II.

Use provided screws to securely mount the sensor to the

frame. A loosely mounted sensor will not perform correctly.

The small screw must be used to permanently attach the

cover.

Figure 1b

Page 2

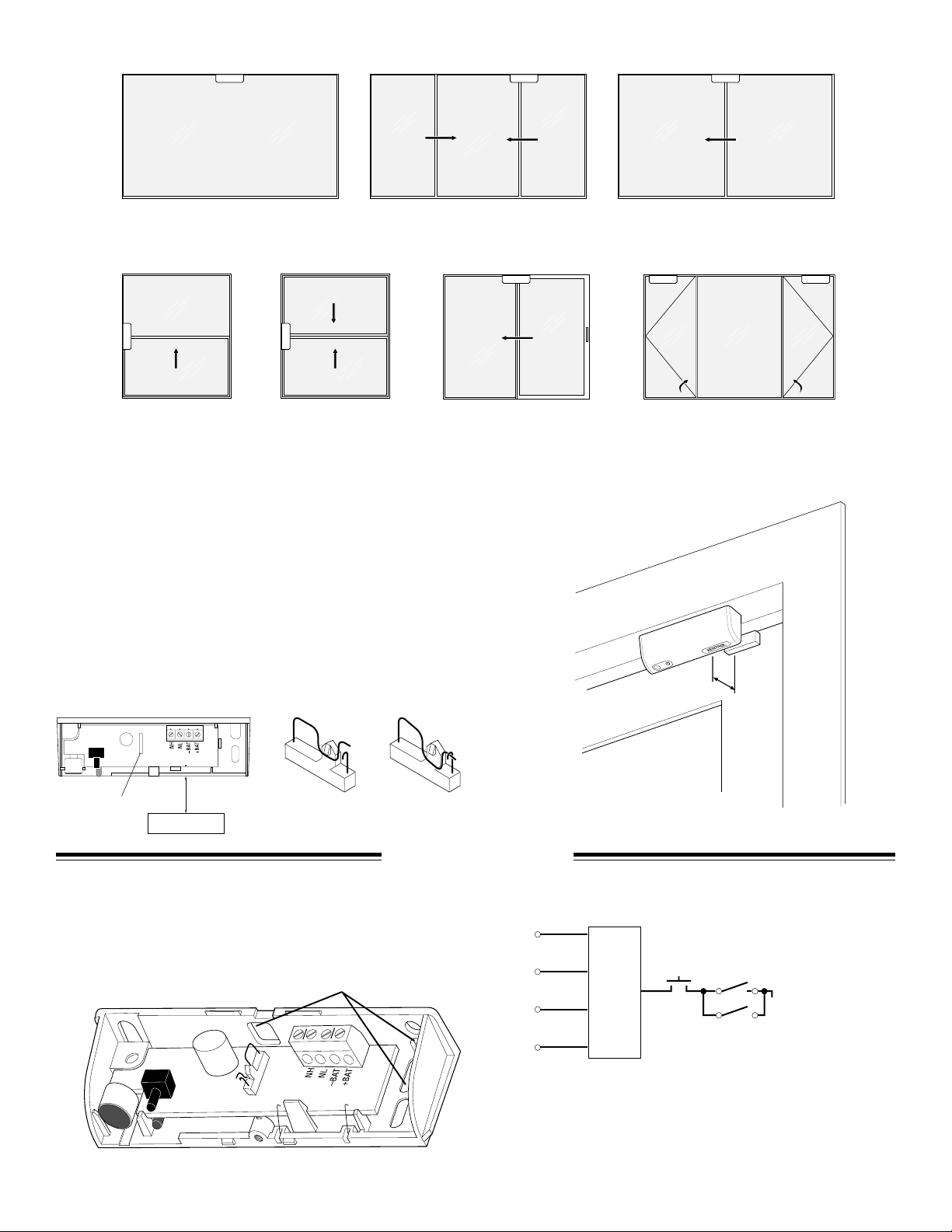

Figure 2

PICTURE WINDOW

VERTICAL SLIDE DOUBLE-HUNG HINGED CASEMENT

DOUBLE SLIDER

PATIO DOOR

Note: Not recommended for French style doors or windows, use a ShatterPro II.

Reed Switch

The magnet must be mounted on the moving portion of the

Figure 3

window or door. Magnet placement must be within 3/4"

(1.9cm) of sensor, either behind or below (see Figure 3).

Center magnet as marked on the printed circuit board.

Place magnet cover over center of mounting plate and slide

to either left or right until housing snaps in place.

Note: Mounting sensor or magnet on steel surfaces will

reduce gap.

HORIZONTAL SLIDER

The magnetic contact can be deactivated by closing wire

jumper switch.

CENTER MAGNET HERE

Jumper

Switch

3/4"

MAGNET

–Switch open –Switch closed

–Reed enabled –Reed disabled

STEP 2 — WIRING

The 5600 sensor provides multiple wiring entrances (see

Figure 4). Use rear holes or knock-out as needed. It is

recommended to tape over unused holes.

Figure 4

Wire Exits

2

3/4"

Output Circuit (shown powered)

N.H.

N.L.

Tamper Reed

Sensor

– Bat

+ Bat

Jumper Switch

Note: Sensor will remain in an alarm state as long as the

tamper or reed is open.

Page 3

TRANSMITTER WIRING DIAGRAMS — 3 VOLT

−

+

N.L.

−

3.5V

Alarm

(N.H.)

Alarm

(N.L.)

+ Battery

– Battery

SENTROL UNIVERSAL

TRANSMITTER

−

3.5V

+

+ Battery

– Battery

Alarm

Alarm

(N.L.)

(N.H.)

NAPCo GEM-Trans2

123

A

A

+

–

l

a

(

(

N

N

r

m

.

H

.

)

l

B

B

a

r

a

a

m

t

.

L

.

)

t

t

t

e

e

r

r

y

y

564503-W

Legend:

Alarm NL—White Wire

3V (+)—Red Wire

Grnd (-)—Black Wire

ITI 3.5V SYSTEM IV

−

3.5V

+

A

A

larm

larm

(N

(N

.L.)

.H

.)

– B

N.L.

+ B

attery

−

attery

ITI 3.5V Programmable

−

3.5V

N.L.

+

+

–

A

A

la

la

(N

(N

r

m

.L

.H

.)

.)

B

B

a

r

m

t

te

r

y

ITI 3.5V Learn mode

a

tte

r

y

3

Page 4

TRANSMITTER WIRING DIAGRAMS — 3 VOLT (continued)

+

−

N.L.

−

3.5V

A

la

rm

(N

.H

.)

A

la

rm

(N

.L

.)

+

B

a

tte

ry

–

B

a

tte

ry

Ademco model 5816

& 5816MN

DSC WSS-907U

A

A

+

–

B

la

(N

(N

r

m

.H

.)

*Remove top Battery and slide gold

terminal clip between + end of

bottom-right battery and circuit

board battery terminal. Rotate gold

clip out of the way and replace top

Battery.

B

la

a

r

a

m

tte

.L

tte

.)

ry

ry

Inovonics FA-210

3.0V

+ Battery

– Battery

Alarm

Alarm

(N.L.)

(N.H.)

*For Inovonics FA series

receivers the contact selection

header must be correspondingly

set to NC.

Linear DXT-31

3V

(6V)

TRANSMITTER WIRING DIAGRAMS — 6 VOLT

Linear T-90

(6V)

3V

43

21

OPEN

*564506-W

564506-W

Legend:

Alarm NL—White Wire

6V (+)—Red Wire

Grnd (-)—Black Wire

A

A

+

Alarm

(N.H.)

Alarm

(N.L.)

– Battery

+ Battery

(N

–

B

la

rm

.H

.)

B

la

(N

rm

a

a

tte

.L

tte

.)

ry

ry

4

Page 5

STEP 3 — TESTING

Installation Test

The sensor is ready to test once installed with cover on and

powered, no test mode setting is necessary. To test sensor,

perform Range testing to ensure adequate vibration

coupling to the sensor. After range is verified, perform

Alarm test.

1. Range testing – Indicates sensor is within detection range

by blinking the LED twice slowly. To test, rap the glass

lightly with the handle of a large screwdriver. Start close

to the sensor and proceed to furthest point of glass. If

LED does not blink over the entire glass, better coupling

between glass and sensor is needed. Try adding screws to

the window support into the frame near the sensor or use

longer screws to mount sensor, being careful not to

damage the window.

2. Alarm testing – Using the Sentrol 5709C hand-held

tester (set for proper glass type), hold tester close to

sensor and press test button while simultaneously

rapping lightly on the glass with the handle of a

screwdriver. Proper sequence is important to alarm

sensor. When alarmed, the outputs will change state for 4

seconds and the LED will turn on solid for 4 seconds

then turn off. This verifies that the sensor has triggered

an alarm. The panel should report an alarm condition

from the attached transmitter. The reed switch can be

tested by opening the window or door a few inches.

Caution: Hinged style door or window will significantly

reduce range. Test seismic signal thoroughly.

Sensor Self-Tests

All the 5600s perform a processor self-test at power up. If

the processor finds a faulty condition, the LED will stay lit

and the output will stay in an alarm state.

Normal operation will clear the LED and cause normal

output states.

During operation, the processor periodically tests itself for

conditions that could impede performance. If the processor

malfunctions, it will reset itself and perform a power-up

self-test. If memory fails, the LED will blink continuously at

1Hz (1/2 second on, 1/2 second off) to signal the trouble.

Promptly replace a sensor which indicates a faulty

condition.

Note: Test sensor at least annually for proper

operation.

Note: The 5645’s do not have alarm memory.

Installation Tests

Test Action LED Indication

No Flash

Range Rap Glass Out of Range Within Within

Test Range Range

Alarm Rap Glass & No Alarm No Alarm Alarm

Test Key 5709C

End-User Rap Glass Too Far From Sensor or Hardware Fault Sensor Alarm

Test Okay

2 Slow

Flashes

Sensor Self-Test

Test Condition Indication

Power-up test Normal LED Turns Off, Normal Output States

Faulty LED Solid On, Alarm Condition

Memory test Normal LED is off

Faulty LED Flashes at 1Hz (1/2 sec. on, 1/2 sec. off) continuously

Solid On

5

Page 6

SPECIFICATIONS DIMENSIONS

Electrical

Voltage (564503) .............................................................2–5V DC

Voltage (564506) .............................................................4–9V DC

Current (564503) ..................................................... <10µA typical

Current (564506) ..................................................... <20µA typical

Wire Terminals ............................................................ 22-18 AWG

Environment

Operating Temperature .................. 0° to +120°F (–18° to +50°C)

Humidity ............................................ 10% to 90% noncondensing

RF Immunity ............................................. 20 V/m, 1 to 1000 MHz

Features

Glass Types

Plate ........................................ 3/32'' (2.4 mm) to 3/8" (9 mm)

Tempered .............................. 1/8'' (3.2 mm) to 1/4" (6.4 mm)

Laminated .............................. 1/8'' (3.2 mm) to 1/4" (6.4 mm)

Wired ................................................................ 1/4" (6.4 mm)

Mounting Location ............................................................... Frame

Range of Glass Surface Covered (Radius from sensor)

Single-pane window ........................................ up to 10' (3 m)

Multi-pane window .......................................... up to 8' (2.4 m)

Sliding-glass door ........................................... up to 8' (2.4 m)

Minimum Glass Size ............................. 18" (45 cm) x 18" (45 cm)

Magnet Gap Distance ............................... 3/4" (1.9 cm) maximum

Note: Mounting sensor or magnet on steel will reduce gap.

Housing Material ......................................... Flame Retardant ABS

Color ..................................................................................... White

Sensor

Magnet

0.375''

0.953 cm

0.395''

1.00 cm

3.95''

10.0 cm

2.26''

5.74 cm

1.25''

3.18 cm

0.9''

2.3 cm

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Re-orient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

Protected under U.S. and foreign patents including: 3,863,250; 4,745,398; 4,837,558; 5,192,931 and other patents pending.

Ordering Information

Description Model Number Color

Wireless ShatterPoint™, 3 Volt with magnetic contact 564503-W/M white/mahogany

Wireless ShatterPoint™, 6 Volt with magnetic contact 564506-W/M white/mahogany

Hand-held Tester 5709C-W white

Replacement magnet 1838-N/M white/mahogany

SENTROL, inc

CORPORATE HEADQUARTERS

12345 SW Leveton Dr., Tualatin, OR 97062

Tel.: 503.692.4052 Fax: 503.691.7566

http://www.sentrol.com

U.S. & Canada: 800.547.2556

Technical Service: 800.648.7424

FaxBack: 1.800.483.2495

Sentrol reserves the right

to change specifications

without notice.

©1998 Sentrol, Inc.

G-3190-0198

14258 Rev. B

Loading...

Loading...