Page 1

g

ESL 560N Series

3V St andalone Smoke Alarms

4300 Series

Wireless Smoke Detector

Manual

Séries ESL 560N

Détecteurs de fumée autonome de 3 V

Manuel

CSFM

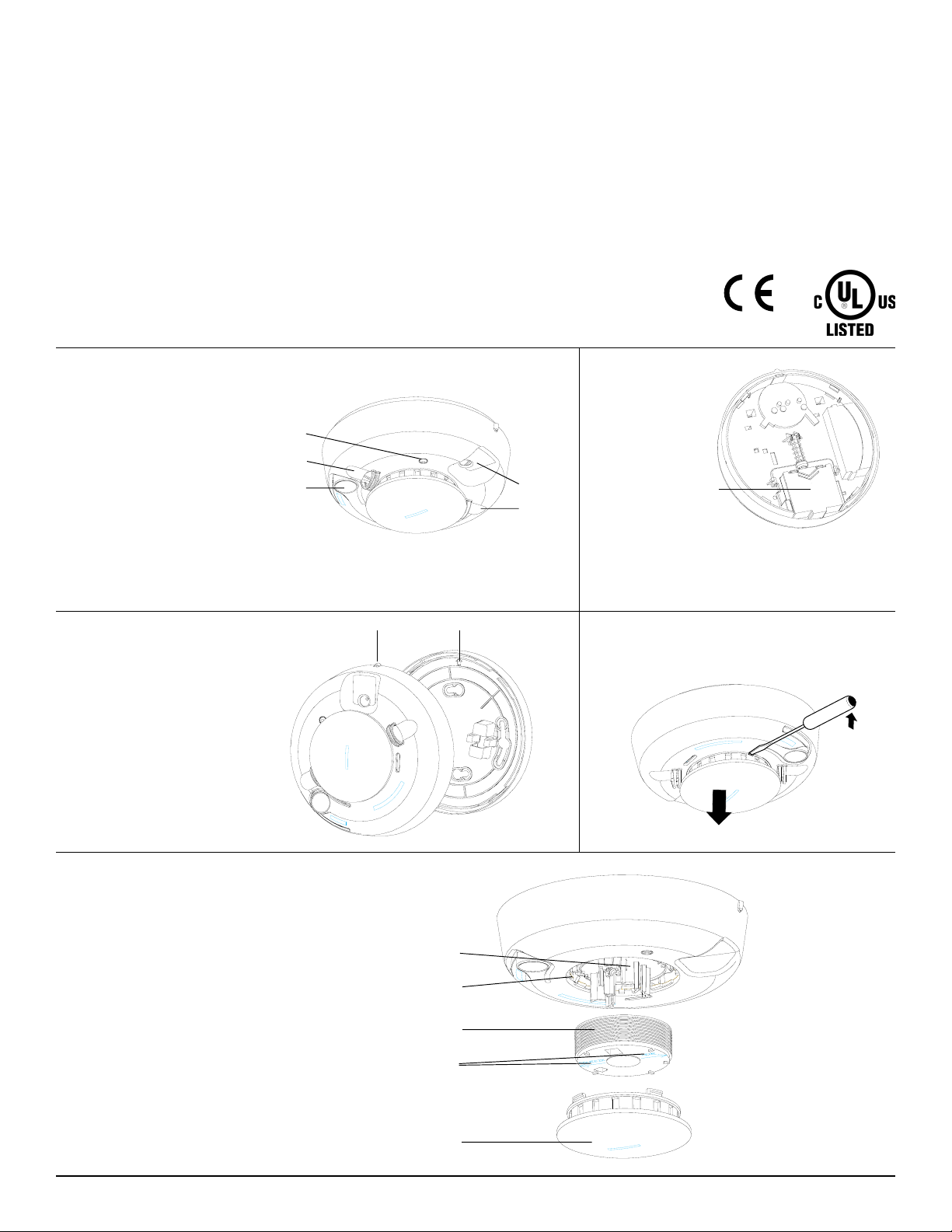

1

M LED

N Temperature sensor

O Test/Silence button

P Sounder vent

M VOYANT DEL

N Capteur de température

O Bouton de Test/Arrêt

P Évent du résonateur

3

M Alignment tab

N Alignment arrow

M T ouche d’alignement

N Flèche d’alignement

M

N

O

P

N

MN

2

M

M Battery compartment

M Compartiment de la pile

4

5

M Optical base

N Optical chamber latch

O Optical chamber

P Alignment arrows

Q Alarm cap

M Support optique

N Verrou de la chambre optique

O Chambre optique

P Flèches d’alignement

Q Couvercle de l’alarme

ESL 560N Series

M

N

O

P

Q

1

Page 2

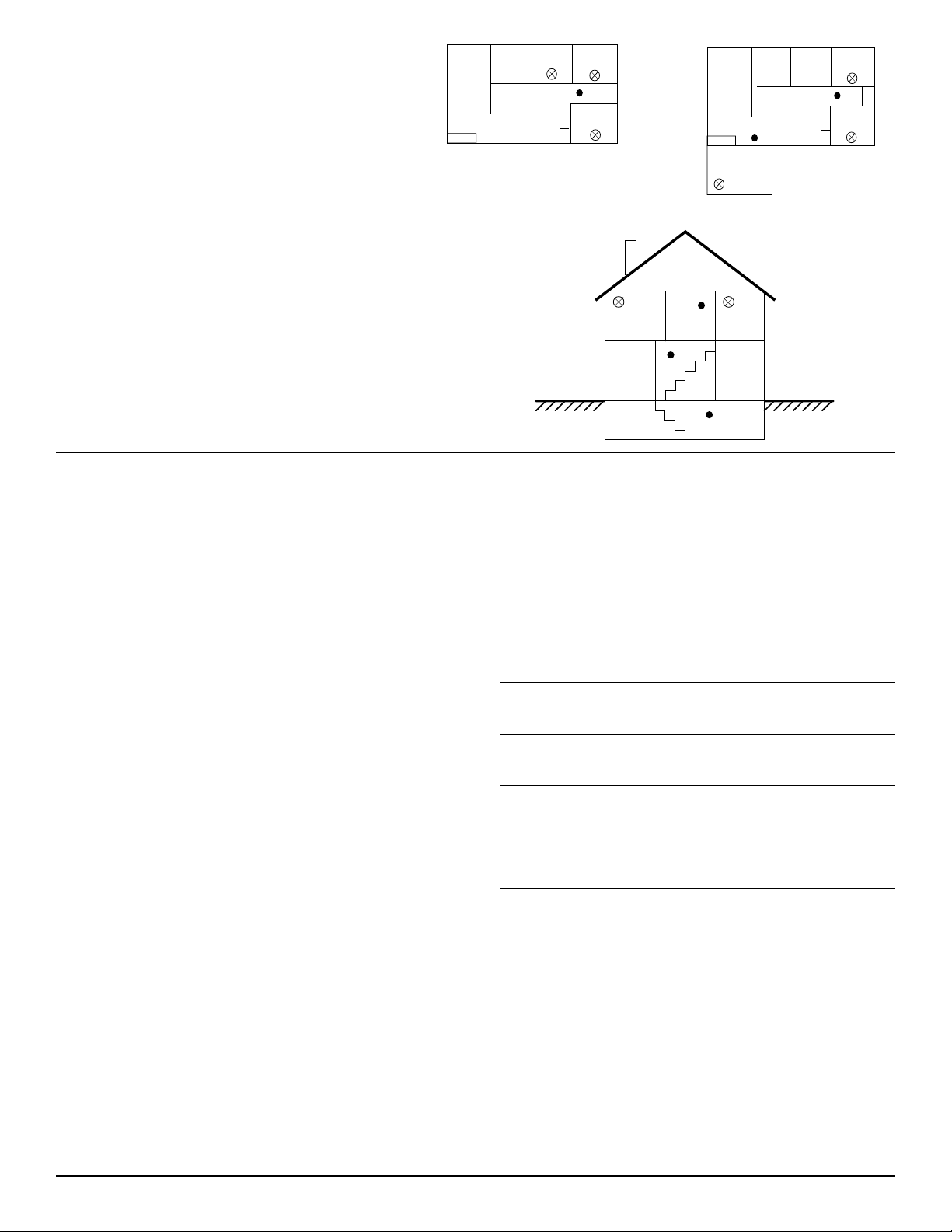

6

z Required smoke alarms

8 Additional alarms required for new construction

M Dining Room

N Kitchen

O Living Room

P Bedroom

Q TV Room

R Basement

z Détecteurs de fumée requis

8 Détecteurs supplémentaires nécessaires

dans les nouvelles pièces

M Salle à manger

N Cuisine

O Salle de séjour

P Chambre à coucher

Q Salle de télévision

R Sous-sol

A

MNOPP

P

C

B

QMNOP

P

P

PP

MO

R

Description

The ESL 560N Series smoke alarms are designed to be used as

standalone smoke alarms. The units include an optional intergrated

fixed 135°F tempeature and rate-of-rise heat detector that trips an

alarm based on temperature detected. Self-diagnostics monitors its own

sensitivity and operational status. If the unit drifts out of the UL Listed

sensitivity range or fails internal diagnostics, it extinguishes its LED.

Internal Signal Outputs

When the unit is listed with a transmitter, it provides the following

signals for interfacing:

• Alarm • Alarm restore

• Low battery • CleanMe®

• Maintenance alert

Installation

1. Slide the battery compartment cover away from the unit to unsnap

it and lift it off. See Figure 2.

2. Observing proper polarity, insert two 3V lithium batteries into the

alarm battery compartment and replace the battery cover.

3. Remove the red plastic dust cover from the unit.

4. Using the 2 screws and anchors provided, mount the base.

5. Attach the unit to the base as follows:

- Line up the raised alignment tab on the lip of the unit with the

alignment arrow on the base. See Figure 3.

- Insert the unit into the base and turn clockwise approximately 15

degrees. It should snap firmly into place.

Important: The unit cannot be attached to the base if no

batteries are installed.

6. Test the unit. See Smoke Test.

Smoke Test

The units should be tested in place annually using one of the following

methods:

A. Use Smoke! in a can® and follow the directions on the can.

B. Hold a smoldering punk or cotton wick close to the unit and

gently direct the smoke into the smoke entry openings for 20

seconds or until an alarm is indicated.

The LED should stay on, the sounder should emit a temporal 3 pattern,

and an alarm should be indicated at the control panel. Be sure to

extinguish the smoke source after testing!

Silence the Alarm

Press the Test/Silence button to silence the sounder during an alarm.

After a few minutes, the sounder and alarm resume if smoke is still

present.

Sensitivity T est

1. Press and hold the Test/Silence button for 4 seconds. Once the test

starts, the unit LED flashes 1 to 9 times.

2. Count the number of LED flashes, then use the following table to

determine if any action is necessary.

Flashes

0- 1 Indication: Unservicable hardware fault.

Action: Reset and rerun sensitivity test. If the error

persists, replace unit.

2- 3 Indication: Unit is becoming insensitive.

Action: Clean and reset the unit. Rerun sensitivity test.

If the error persists, replace the unit.

4- 7 Indication: Unit is within normal sensitivity range.

Action: N/A

8- 9 Indication: Unit is becoming too sensitive.

Action: Verify the optical chamber is snapped down

securely. Clean the unit and replace the optical

chamber.

After the LED flashes, if the sensitivity is within limits and all other

tests pass, the unit goes into alarm and resets after 7 seconds. If the

sensitivity is not within limits, or an unserviceable hardware fault has

been detected, the unit LED extinguishes until the unit is serviced.

LED Functions

Flashing = Flashes every 9 seconds to indicate normal operation.

On = Detects smoke.

Off = Trouble or maintenance is required.

When to Replace the Batteries

When the batteries are low, the unit extinguishes its LED and chirps

every 45 seconds until the batteries are replaced. The low battery trouble

chirps can be silenced for 24 hours by pressing the Test/Silence button.

Battery life is a minimum of 1 year and varies depending on how often

the unit is tested.

2

ESL 560N Series

Page 3

Replacing the Batteries

Use only 3V lithium batteries listed on the battery compartment cover.

1. To remove the unit from the mounting base, grasp the unit and turn

it counterclockwise approximately 15 degrees.

2. Slide the battery compartment cover away from the alarm to unsnap

it and lift it off. See Figure 2.

3. Remove the batteries and dispose of them properly.

4. Observing correct polarity, insert two new 3V lithium batteries into

the battery compartment and replace the cover.

5. Reattach the unit to the mounting base. See Installation, Step 5.

6. Test the system.

Cleaning

Clean the cover with a dry or damp (water) cloth as needed to keep it

free from dust and dirt.

When necessary, clean the interior and replace the optical chamber

(part #211) as follows:

1. To remove the unit from the mounting base, grasp the unit and turn

it counterclockwise approximately 15 degrees.

2. Remove the batteries.

3 . Slide a flat-blade screwdriver in the slot on the alarm cap and gently

push the handle down to pry the alarm cap up and off. See Figure 4.

4 . Squeeze the optical chamber where indicated and pull it up and away

from the optical base and discard. See Figure 5.

5 . Blow out or use a soft-bristled brush to remove all dust and dirt from

the optical base.

6. Line the new optical chamber up with the optical base by lining up

the the arrows on the optical chamber to the latches on the optical

base. Ensure that the LED cavity in the optical chamber is above the

LED and snap the optical chamber down into place.

7. Replace the alarm cap as follows:

-Line the alarm cap up with the unit.

-Insert the alarm cap into the unit and turn clockwise approximately

15 degrees. It should snap firmly into place.

8. Observing the proper polarity, replace the batteries and the battery

compartment cover.

9. Reattach the unit to its mounting base. See Installation, Step 5.

10. Test the unit sensitivity.

Maintenance

The units are designed for easy field service and maintenance. When

installed and used properly, they require minimal maintenance.

The units should be tested weekly.

When a unit listed with a transmitter requires maintenance, it extin-

guishes its LED and initiates the external signals described in the

following table.

Signal Action Required

CleanMe Sensitivity is out of range and the unit needs

cleaning. See Cleaning.

Maintenance Alert Unit failed to power up on self test. Perform a

sensitivity test. See Sensitivity Test. If the problem

persists, replace the unit.

Low Battery Batteries in the unit are low. Replace the batteries.

Specifications

Voltage 3VDC

Typical average standby current 35µA

Typical test current 2m A

Typical alarm current 70mA

Battery type 3V lithium, Duracell

Panasonic

Low battery threshold 2.70V causes low battery signal

Sounder 85dBa at 10' temporal pattern

Low battery beep rate 1 every 45 sec.

Sensitivity 2.2% ± 1.3% / ft.

Operating temperature 40°-100°F (4.4°-37.8°C)

Operating humidity range 0-95% non-condensing

Color Whi te

Alarm dimensions 5.6" x 2.4" (14.2cm x 6.1cm)

Base dimensions 5.4" x 0.46" (13.7cm x 1.17cm)

Drift compensation adjustment 0.5% / ft. max.

Heat detector specifications (T models):

Rate-of-rise 15°F/min>105°F (8.3°C/min>

40.6°C)

Fixed 135°F ± 5°F (57.2°C ± 2.8°C)

Listings UL217, CE, C-UL US, CSFM

®

CR123A, Sanyo®123A

®

123,

FCC Compliance

This device complies with Part 15 of the FCC rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful

interference. (2) This device must accept any interference received,

including interference that may cause undesired operation.

Means of Conformity

We declare under our sole responsibility that this product is in confor-

mity with Directive 93/68/EEC (Marking) and Directive 89/336/EEC

(EMC) based on test results using (non)-harmonized standards in

accordance with the Directives mentioned.

Product Ordering

Model Description

560NS 3V standalone smoke alarm, 85dBa sounder UL 217

562NS 3V standalone smoke alarm, two 3V lithium batteries,

562NST 3V standalone smoke alarm, two 3V lithium batteries,

Accessories

SM-200 Smoke! in a can® (canned smoke) for functional testing of

SMEXT-1 Extension tube for Smoke! in a can®

21 1 Field replaceable optical chambers (set of 10)

60-933 6 pack 3V lithium button top batteries

Certain items in the installation instructions are protected under one or

more of the following patents: 5,546,074; 5,798,701; 5,821,666;

6,756,906

(OEM customers call for transmitter compatibility)

85dBa sounder UL 217 (OEM customers call for

transmitter compatibility)

85dBa sounder, 135°F fixed/rate-of-rise heat detector, UL

217 (OEM customers call for transmitter compatibility)

smoke alarms

ESL 560N Series

3

Page 4

Selecting a Location

Selecting a suitable location is critical to the operation of smoke alarms.

This equipment should be installed in accordance with the National Fire

Protection Association’s (NFPA) Standard 72. See Figure 6.

A-11-8.3.a Where to Locate the Required Smoke Alarms in Existing

Construction.

The major threat from fire in a family living unit occurs at night when

everyone is asleep. The principal threat to persons in sleeping areas

comes from fires in the remainder of the unit. Therefore, a smoke

alarm(s) is best located between the bedroom areas and the rest of the

unit. In units with only one bedroom area on one floor, the smoke

alarm(s) should be located as shown in Figure 6 A.

In family living units with more than one bedroom area or with more

than one floor, more than one smoke alarm is required, as shown in

Figure 6 B.

In addition to smoke alarms outside of the sleeping areas, the installation of a smoke alarm on each additional story of the family living unit,

including the basement, is required. These installations are shown in

Figure 6 C. The living area smoke alarm should be installed in the living

room or near the stairway to the upper level, or in both locations. The

basement smoke alarm should be installed in close proximity to the

stairway leading to the floor above. Where installed on an open-joisted

ceiling, the alarm should be placed on the bottom of the joists. The

alarm should be positioned relative to the stairway to intercept smoke

coming from a fire in the basement before the smoke enters the

stairway.

Where to Locate the Required Smoke Alarms in New Construction.

All of the smoke alarms specified for existing construction are required

and, in addition, a smoke alarm is required in each bedroom.

Are More Smoke Alarms Desirable?

The required number of smoke alarms might not provide reliable early

warning protection for those areas separated by a door from the areas

protected by the required smoke alarms. For this reason, it is recommended that the householder consider the use of additional smoke alarms

for those areas for increased protection. The additional areas include the

basement, bedrooms, dining room, furnace room, utility room, and

hallways not protected by the required smoke alarms. The installation of

smoke alarms in kitchens, attics (finished or unfinished), or garages is

not normally recommended, as these locations occasionally experience

conditions that can result in improper operation.

Since regulations pertaining to smoke alarm/detector installation vary

from state to state, contact the authority having jurisdiction (AHJ).

Where public safety is primary, the AHJ may be a federal, state, local, or

other regional department or individual such as a fire chief, fire marshal,

chief of a fire prevention bureau, labor or health department, building

official, electrical inspector, or others having statutory authority. For

insurance purposes, an insurance inspection department, rating bureau,

or other insurance company representative may be the AHJ. In some

cases, the property owner or their designated agent assumes the role of

the AHJ. At government installations, the commanding officer or

department official may be the AHJ.

In addition to NFPA 72, use the following location guidelines to

optimize performance and reduce the chance of false alarms from the

alarm:

• Locate ceiling-mounted smoke alarms in the center of a room or

hallway at least 4 inches (10cm) from any walls or partitions.

• Locate wall-mounted smoke alarms so the top of the alarm is 4 to 12

inches (10 to 31cm) below the ceiling.

• Locate in a suitable environment as follows:

- Temperature between 40°F (4.4°C) and 100°F (37.8°C)

- Humidity between 0 and 95% non-condensing

• Locate away from air conditioners, heating registers, and any other

ventilation source that may interfere with smoke entering the alarm.

• Mount smoke alarms on a firm permanent surface.

• Locate away from large metallic objects when listed with a

transmitter.

Smoke alarms are not to be used with detector guards unless the

combination has been evaluated and found suitable for that

purpose.

WARNING! LIMIT A TIONS OF SMOKE

ALARMS

Wireless smoke alarms are very reliable, but may not work under all

conditions. No fire alarm provides total protection of life or property.

Smoke alarms are not a substitute for life insurance.

Smoke alarms require a source of power to work.

This smoke alarm will not operate and the alarm will not sound if

batteries are dead or not installed properly.

Smoke alarms may not be heard. A sound sleeper or someone who

has taken drugs or alcohol may not awaken if the alarm is installed

outside a bedroom. Closed or partially closed doors and distance can

block sound. This alarm is not designed for the hearing impaired.

Smoke alarms may not always activate and provide warning

early enough. Smoke alarms only activate when enough smoke reaches

the alarm. If a fire starts in a chimney, wall, roof, on the other side of

closed doors, or on a different level of the property, enough smoke may

not reach the alarm for it to alarm.

Smoke alarms are a significant help in reducing loss, injury and even

death. However, no matter how good a detection device is, nothing

works perfectly under every circumstance and we must warn you that

you cannot expect a smoke alarm to ensure that you will never suffer

any damage or injury.

4

ESL 560N Series

Page 5

Fire Prevention and Escape

The purpose of an early warning smoke alarm is to detect the presence

of fire in its early stages and sound an alarm giving the occupants time

to exit the premises safely.

Avoid Fire Hazards

No detection device can protect life in all situations. Therefore,

safeguards should be taken to avoid potentially dangerous situations as

follows:

• Do not smoke in bed.

• Do not leave children home alone.

• Never clean with flammable liquids such as gasoline.

• Properly store materials. Use general good housekeeping techniques

to keep your home neat and tidy. A cluttered basement, attic, or

other storage area is an open invitation to fire.

• Use combustible materials and electrical appliances carefully and only

for their intended uses. Do not overload electrical outlets

• Do not store explosive and/or fast burning materials in your home.

• Even after proper precautions have been taken, fires can start. Be

prepared.

In Case of Fire

In the event of a fire:

• Leave immediately. Don’t stop to pack or search for valuables.

• In heavy smoke, hold your breath and stay low, crawl if necessary.

The clearest air is usually near the floor.

• If you have to go through a closed door, carefully feel the door and

door knob to see if undue heat is present. If they seem cool, brace

your foot against the bottom of the door with your hip against the

door and one hand against the top edge. Open it slightly. If a rush of

hot air is felt, slam the door quickly and latch it. Unvented fire tends

to build up considerable pressure. Be sure all members of the

household realize and understand this danger.

• Use your neighbor ’s phone or a street fire alarm box to call the fire

department. The job of extinguishing the fire should be left to the

professionals.

Be Prepared

Practice the following steps to prepare you and your family in the event

of a fire:

• Perform fire drills regularly. Use them to assure recognition of an

alarm signal.

• Draw a floor plan and show two exits from each room. It is

important that children be instructed carefully, because they tend to

hide in times of crisis.

• Establish one meeting place outside the home. Insist that everyone

meet there during an alarm. This will eliminate the tragedy of

someone reentering the house for a missing member who is actually

safe.

• If you have children and/or physically challenged people residing in

your household, use window decals to help emergency personnel

identify the sleeping quarters of these individuals.

WARNING

Smoke alarms CANNOT provide warnings for fires

resulting from explosions, smoking in bed or other

furniture, ignition of flammable liquids, vapors and

gases, children playing with matches or lighters.

Limited Warranty

ESL is a brand of GE Security. The manufacturer warrants this smoke

alarm (except batteries) to be free from defects in material and

workmanship under conditions of normal use for a term of 3 years from

the date of manufacture.

During the warranty period, if a GE Security product or any of its

components becomes defective, it will be repaired or replaced without

charge.

Out-of-warranty units will be repaired at the discretion of the manufacturer or, if not, a card will be forwarded to the customer suggesting a

replacement unit and the cost of that unit.

This warranty does not apply to units which have been subject to abuse,

misuse, negligence or accident, or to which any modifications, alterations or repairs have been made or attempted.

This warranty is extended only to the original purchaser of the smoke

alarm and may be enforced only by such person. During the warranty

period, if the alarm or any warranted components thereof becomes

defective, it will be replaced or repaired without charge at the

manufacturer’s discretion if returned in accordance with the following

instructions:

Obtain a Return Authorization Number by calling 1-800-648-7422 or

503-692-4052, then carefully pack it in a well padded and insulated

carton and return, postal charges prepaid to:

Customer Service RMA#

GE Security

12345 SW Leveton Drive

Tualatin, OR 97062-9938

A note should be included advising the nature of the malfunction. Care

must be exercised in the proper packing of alarms returned under this

warranty as GE Security will not be responsible for warranty repairs to

equipment damaged because of improper packing.

The above warranty is in lieu of all other express warranties,

and implied warranties of merchantability and fitness for a

particular purpose are limited in duration for a period of THREE

years from the date of manufacture. Under no circumstances

shall manufacturer be liable to the purchaser or any other

person for incidental or consequential damages of any nature,

including without limitation damages for personal injury or

damages to property, and however occasioned, whether alleged

as resulting from breach of warranty by manufacturer, the

negligence of manufacturer or otherwise. Manufacturer’s

liability will in no event exceed the purchase price of the

product. Some states do not allow limitations on how long an

implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so the above limitations

and exclusions may not apply to you. Unless a longer period is

required by applicable law, any action against manufacturer in

connection with this smoke alarm must be commenced within

one year after the cause of action has occurred.

No agent, employee or representative of the Manufacturer nor any

other person is authorized to modify this warranty in any respect.

Repair or replacement as stated above is the exclusive remedy of the

purchase hereunder. This warranty gives you specific legal rights and you

also have other rights which vary from state to state.

ESL 560N Series

5

Page 6

Description

La série de détecteurs de fumée ESL 560N est conçue afin de permettre

une utilisation autonome. Chaque appareil comprend un détecteur

vélocimétrique et statique de 57 °C (135 °F) en option qui actionne une

alarme selon la température détectée. L’appareil autodiagnostic surveille

sa sensibilité et son état de fonctionnement. Si l’appareil s’éloigne de

seuil de sensibilité homologué UL ou omet un diagnostic interne, le

voyant DEL s’éteint.

Sorties signal internes

Lorsque l’appareil est doté d’un émetteur, l’interfaçage produit les

signaux suivants :

• Alarme

• Restaurer l’alarme

• Pile faible

• CleanMe®

• Alerte d’entretien

Installation

1. Retirer le couvercle du compartiment de la pile de l’appareil afin de

le dégager et de l’enlever. Voir la figure 2.

2. En respectant la bonne polarité, insérer les deux piles 3 V au lithium

dans le compartiment de pile du détecteur et replacer le couvercle.

3. Enlever le cache-poussière en plastique rouge de l’appareil.

4 . Monter la base à l’aide des deux vis et des dispositifs d’ancrage

fournis.

5 . Fixer l’appareil à la base de la façon suivante :

- Aligner la touche d’alignement sur la couronne de l’appareil avec la

flèche d’alignement de la base. Voir la figure 3.

- Insérer l’appareil sur la base et tourner d’environ 15 degrés dans le

sens des aiguilles d’une montre. Il devrait s’engager fermement en

place.

Important : L’appareil ne peut être fixé à la base si les piles

ne sont pas installées.

6. Tester l’appareil. Voir Test de fumée.

Test de fumée

Les appareils doivent être testés chaque année à l’aide d’une des

méthodes suivantes :

A. Utiliser Smoke! in a can® et suivre les directives indiquées sur le

contenant.

B. Tenir un bâtonnet de bois friable à combustion lente ou une mèche

de coton près de l’appareil et diriger doucement la fumée à

l’intérieur des ouvertures d’entrée de fumée pendant 20 secondes ou

jusqu’à ce qu’une alarme se déclenche.

Le voyant DEL doit resté allumé, le résonateur doit émettre un son de

trois pulsations, et une alarme doit être indiquée sur le panneau de

contrôle. S’assurer de bien éteindre la source de fumée une fois

le test terminé!

T est de sensibilité

1. Appuyer sur le bouton Test/Arrêt et le maintenir enfoncé pendant

4 secondes. Une fois le test démarré, le voyant DEL clignote de une à

neuf fois.

2. Compter le nombre de clignotements, puis déterminer si une action

est nécessaire à l’aide du tableau suivant :

Clignotements

0- 1 Indication : Matériel hors service.

Action : Réinitialiser et refaire le test de sensibilité. Si

l’erreur persiste, remplacer l’appareil.

2- 3 Indication : L’appareil devient insensible

Action : Nettoyer et réinitialiser l’appareil. Refaire le

test de sensibilité. Si l’erreur persiste,

remplacer l’appareil.

4- 7 Indication : L’appareil est à l’intérieur du seuil de

sensibilité normal.

Action : S.O.

8- 9 Indication : L’appareil devient trop sensible.

Action : Vérifier si la chambre optique est solidement

engagée vers le bas. Nettoyer l’appareil et

remplacer la chambre optique.

Après les clignotements du voyant DEL, si la sensibilité se situe à

l’intérieur de ses limites et que tous les tests ont été réussis, l’appareil

retourne en mode alarme et se réinitialise après 7 secondes. Si la

sensibilité se situe à l’extérieur de ses limites ou que le matériel est hors

service, le voyant DEL de l’appareil s’éteint jusqu’à la réparation de

l’appareil.

Fonctions du voyant DEL

Clignotement = Clignotement toutes les 9 secondes pour indiquer un

fonctionnement normal

On = Détecte la fumée.

Off = Problème ou entretien nécessaire.

Quand remplacer les piles

Lorsque les piles sont faibles, l’appareil éteint son voyant DEL et émet

un signal toutes les 45 secondes jusqu’au remplacement des piles. Le

signal d’avertissement de pile faible peut être éteint pendant 24 heures

en appuyant sur le bouton Test/Arrêt. La durée de vie de la pile est d’au

moins 1 an et varie selon le nombre de fois où l’appareil est testé.

Arrêter l’alarme

Appuyer sur le bouton Test/Arrêt pour arrêter le résonateur pendant une

alerte. Après quelques minutes, le résonateur et l’alarme reprennent si la

fumée est encore présente.

6

ESL 560N Series

Page 7

Remplacement des piles

Utiliser uniquement les piles au lithium de 3 V mentionnées sur le

couvercle du compartiment de la pile.

1. Pour retirer l’appareil du socle de fixation, tenir l’appareil et le

tourner d’environ 15 degrés dans le sens contraire des aiguilles d’une

montre.

2. Retirer le couvercle du compartiment de la pile de l’appareil afin de

le dégager et de l’enlever. Voir la figure 2.

3 . Enlever les piles et les éliminer comme il se doit.

4. En respectant la bonne polarité, insérer les deux piles 3 V au lithium

dans le compartiment de la pile et replacer le couvercle.

5 . Fixer de nouveau l’appareil sur le socle de fixation. Voir Installa-

tion, à l’étape 5.

6. Tester l’appareil.

Nettoyage

Nettoyer le couvercle à l’aide d’un chiffon sec ou humide (mouillé avec

de l’eau) afin d’éviter l’accumulation de poussière et de saleté.

S’il y a lieu, nettoyer l’intérieur et remplacer la chambre optique

(pièce no 211) de la façon suivante :

1. Pour retirer l’appareil du socle de fixation, tenir l’appareil et le

tourner d’environ 15 degrés dans le sens contraire des aiguilles d’une

montre.

2. Enlever les piles.

3 . Insérer un tournevis à lame plate dans la fente du couvercle de

l’alarme et pousser doucement la poignée vers le bas afin de soulever

le couvercle et de le retirer. Voir la figure 4.

4. Resserrer la chambre optique à l’endroit indiqué, la soulever et

l’éloigner du support optique puis la jeter. Voir la figure 5.

5 . Purger ou utiliser une brosse en soies souples afin de retirer la

poussière et la saleté du support optique.

6 . Aligner la nouvelle chambre optique sur la base en alignant les flèches

d’alignement de la chambre avec les verrous situées sur le support

optique. S’assurer que la cavité du voyant DEL dans la chambre

optique est au-dessus du voyant et appuyer sur la chambre optique

pour la mettre en place.

7. Remplacer le couvercle de l’alarme de la façon suivante :

- Aligner le couvercle de l’alarme avec l’appareil.

- Insérer le couvercle de l’alarme dans l’appareil et le tourner

d’environ 15 degrés dans le sens des aiguilles d’une montre. Il devrait

s’engager fermement en place.

8. En respectant la bonne polarité, remplacer les piles et le couvercle du

compartiment de la pile.

9. Fixer de nouveau l’appareil sur le socle de fixation. Voir Installation,

à l’étape 5.

10. Tester la sensibilité de l’appareil.

Entretien

Les appareils sont conçus afin d’en faciliter l'entretien et le changement

des pièces. Lorsqu’ils sont installés et utilisés comme il se doit, ils

requièrent peu d’entretien.

Ces appareils doivent être testés une fois par semaine.

Lorsqu’un appareil doté d’un émetteur requiert de l’entretien, le voyant

DEL s’éteint et met en marche les signaux externes décrits dans le

tableau suivant.

Signal Action nécessaire

CleanMe La sensibilité est située à l’extérieur de ses limites et

l’appareil doit être nettoyé. Voir Nettoyage.

Alerte d’entretien L’appareil ne s’est pas mis en marche en mode

autosurveillance. Effectuer un test de sensibilité

Voir Test de sensibilité. Si le problème persiste,

remplacer l’appareil.

Pile faible Les piles de l’appareil sont faibles. Remplacer les

piles.

Spécifications

Tension 3 V c.c.

Moyenne du courant d’attente type 35µA

Courant test type 2m A

Courant d’alarme type 70mA

Type de pile Lithium 3 V Duracell

Panasonic

Seuil de pile faible 2,70 V provoque un signal de pile

faible

Résonateur 85 dBA émission d’un son de 10

pulsations

Cadence du signal sonore de pile faibleUn signal toutes les 45 secondes

Sensibilité 2,2 % ±1,3 % / FT.

Température de fonctionnement 4,4 ° – 37,8 °C (40 ° – 100 °F)

Taux d’humidité de fonctionnement 0-95 % sans condensation

Couleur Blanc

Dimensions du détecteur 14,2 cm x 6,1 cm (5,6 po x 2,4 po)

Dimensions de la base 13,7 cm x 1,17 cm (5,4 po x 0,46

po)

Compensation de la dérive 0,5 % / FT max

Spécifications du détecteur vélocimétrique (modèles T) :

Vélocimétrique 8,3 °C/min>40,6 °C (15 °F/min>

105 °F)

Statique 135 °F ± 5 °F (57,2 °C ± 2,8 °C)

Homologations UL217, CE, C-UL US, CSFM

®

CR123A, Sanyo®123A

®

123,

Conformité FCC

Ce dispositif est conforme à la réglementation FCC Partie 15. Le

fonctionnement est soumis aux deux conditions suivantes : (1) Ce

dispositif ne doit pas causer un brouillage préjudiciable. (2) Ce dispositif

doit accepter tous les brouillages, y compris les brouillages pouvant

entraîner un fonctionnement indésirable.

Conformité

Nous déclarons que nous sommes les seuls responsables d’assurer la

conformité de ce produit avec la directive 93/68/EEC (marquage) et la

directive 89/336/EEC (CEM) d’après les résultats de tests effectués avec

les normes harmonisées et non harmonisées conformément aux

directives mentionnées.

Commander le produit

Modèle Description

560NS Détecteur de fumée autonome de 3 V, résonateur de

562NS Détecteur de fumée autonome de 3 V, deux piles au lithium

562NST Détecteur de fumée autonome de 3 V, deux piles au lithium

Accessoires

SM-200 Smoke! in a can® (fumée en contenant aérosol) pour

SMEXT-1 Tube de rallonge du Smoke! in a can®

21 1 Chambres optiques de rechange (ensemble de 10)

60-933 Paquet de 6 piles au lithium de 3 V avec bouton en haut

85 dBA UL 217 (L’utilisateur final doit appeler pour

connaître la compatibilité de l’émetteur)

de 3 V, résonateur 85 dBA UL 217 (L’utilisateur final doit

appeler pour connaître la compatibilité de l’émetteur)

de 3V, résonateur de 85 dBA, détecteur vélocimétrique et

statique57,22 °C (135 °F), UL 217 (L’utilisateur final doit

appeler pour connaître la compatibilité de l’émetteur)

effectuer le test de fonctionnement des détecteurs de fumée

ESL 560N Series

7

Page 8

Choisir un emplacement

Choisir un emplacement approprié est essentiel au fonctionnement des

détecteurs de fumée. Cet appareil doit être installé conformément à

la norme 72 de la National Fire Protection Association (NFPA). Voir

la figure 6.

A-11-8.3.a Où installer les détecteurs de fumée requis dans les pièces

actuelles.

La principale menace d’incendie dans une unité d’habitation familiale

se produit la nuit lorsque tout le monde est endormi. La principale

menace d’incendie pouvant affecter les personnes endormies provient

du reste de l’unité d’habitation. Ainsi, l’emplacement idéal d’un

détecteur de fumée (ou de plusieurs) est situé entre les chambres à

coucher et le reste de l’unité d’habitation. Dans les unités d’habitation

avec seulement une chambre à coucher par étage, le détecteur doit être

situé tel qu’il est illustré à la

figure 6 A.

Si l’unité d’habitation possède plus d’une chambre par étage ou si elle

comporte plus d’un étage, plusieurs détecteurs de fumée sont nécessaires

tel qu’il est illustré à la figure 6 B.

En plus des détecteurs de fumée situés à l’extérieur des chambres,

l’installation d’un détecteur sur chacun des étages, y compris le soussol, est nécessaire. Ces installations sont illustrées à la figure 6 C. Le

détecteur de fumée de la surface habitable doit être installé dans la salle

de séjour ou près de l’escalier menant à l’étage supérieur ou aux deux

endroits. Le détecteur de fumée du sous-sol doit être installé à

proximité de l’escalier menant à l’étage supérieur. Lorsqu’il est installé

sur un plafond à claire-voie, le détecteur doit être installé à la base des

solives. Il doit être placé à proximité de l’escalier afin d’intercepter la

fumée provenant de l’incendie du sous-sol avant que la fumée

n’atteigne l’escalier.

Où installer les détecteurs de fumée requis dans les nouvelles pièces.

Tous les détecteurs de fumée des pièces actuelles sont obligatoires et, de

plus, un détecteur de fumée est requis pour chaque chambre à coucher.

Est-il préférable d’installer plusieurs détecteurs de fumée?

La quantité requise de détecteurs de fumée peut ne pas fournir une

protection suffisante aux zones séparées par une porte de celles

équipées d’un détecteur. Ainsi, il est souhaitable que l’occupant prévoit

l’installation de détecteurs de fumée supplémentaires pour ces zones

afin d’améliorer la protection. Ces zones comprennent le sous-sol, les

chambres à coucher, la salle à manger, la chaufferie d’immeuble, la

lingerie et les couloirs qui ne sont pas protégés par les détecteurs de

fumée requis. L’installation d’un détecteur de fumée dans la cuisine, le

grenier (fini ou non fini) ou le garage n’est pas recommandée dans la

plupart des cas puisque ces endroits génèrent des conditions qui

provoquent un fonctionnement inapproprié.

Puisque les réglementations relatives à l’installation de détecteurs de

fumée varient d’une province à l’autre, communiquer avec les autorités

compétentes. Lorsque la sécurité publique est primordiale, ces autorités

peuvent être un ministère fédéral, provincial, une autorité régionale,

municipale ou encore un responsable tel que le chef des pompiers, le chef

du service des incendies, le chef du bureau de prévention des incendies,

ministère de la main-d’oeuvre ou de la santé, un inspeceur en électricité

ou toute autre personne possédant un pouvoir juridique. Aux fins

d’assurance, une agence d’inspection d’assurance, un bureau de

tarification ou tout autre représentant d’une compagnie d’assurances

peuvent agir comme autorités compétentes. Dans certains cas, le

propriétaire du bien ou son mandataire désigné peuvent assumer le rôle

d’autorités compétentes. Dans les établissements gouvernementaux,

l’officier principal ou le fonctionnaire d’un ministère peut être l’autorité

compétente.

Afin d’optimiser le rendement et de diminuer le risque d’alarme

injustifiée, en plus de ceux mentionnés dans la norme 72 de la NFPA,

utiliser les règles d’emplacements suivantes :

• Situer les détecteurs de fumée suspendus au centre de la pièce et ceux

dans les corridors à une distance d’au moins à 10 cm (4 po) des murs

ou cloisons.

• Placer les détecteurs de fumée muraux de façon à ce qu’ils soient de

10 à 31 cm (4 à 12 po) au-dessous du plafond.

• Déterminer un environnement convenable de la façon suivante :

- Température entre 4,4 °C et 37,8 °C (40 °F et 100 °F)

- Humidité entre 0 et 95 % sans condensation

• Installer loin des climatiseurs, des bouches de chaleur et de toute autre

source de ventilation pouvant nuire au fonctionnement du détecteur.

• Poser les détecteurs de fumée sur une surface solide et permanente.

• Lorsque le détecteur est doté d’un émetteur, le placer loin de larges

objets métalliques.

Les grilles de protection pour détecteurs ne doivent pas être

utilisées pout les alarmes incendie, sauf si cela a été testé et

validé pout cet effet.

MISE EN GARDE! LIMITES DE

FONCTIONNEMENT DES DÉTECTEURS

DE FUMÉE

Les détecteurs de fumée sans fil sont très fiables, mais ils ne

fonctionnent pas dans certaines conditions. Aucune alerte d’incendie ne

protège la vie ou la propriété de façon complète. Les détecteurs de

fumée ne remplacent pas l’assurance-vie.

Ils nécessitent une source d’alimentation pour fonctionner.

Ce détecteur de fumée ne fonctionnera pas et l’alarme ne retentira pas si

les piles sont à plat ou si elles ne sont pas installées convenablement.

Les détecteurs de fumée peuvent ne pas être entendus. Une

personne qui a un sommeil profond ou quelqu’un qui a pris des drogues ou

de l’alcool peut ne pas être réveillé par l’alarme si le détecteur est situé à

l’extérieur de la chambre à coucher. Si le détecteur est trop loin ou si une

porte est fermée, complètement ou partiellement, le son peut ne pas

être entendu. Ce détecteur n’est pas conçu pour les personnes

malentendantes.

Les détecteurs de fumée peuvent parfois ne pas s’activer assez

rapidement pour émettre un avertissement. Ils s’activent

uniquement si suffisamment de fumée atteint l’alarme. Si un incendie

prend naissance dans une cheminée, un mur, un toit, de l’autre côté d’une

porte fermée ou sur un autre étage, il est possible que la fumée n’atteigne

pas suffisamment le détecteur pour qu’il déclenche l’alarme.

Les détecteurs sont une aide importante afin de réduire les pertes,

d’éviter les blessures et même les décès. Cependant, peu importe la

qualité de l’appareil, aucun détecteur de fumée ne fonctionne

parfaitement dans toutes les conditions, et nous devons vous avertir que

vous ne devez pas vous attendre à jamais être victime de dommage ou de

blessure.

8

ESL 560N Series

Page 9

Prévention des incendies et sortie

de secours

L’objectif d’une alerte rapide du détecteur de fumée est de signaler la

présence d’un incendie à un stade précoce et de faire retentir l’alarme

afin de donner suffisamment de temps aux occupants de quitter les lieux

de façon sécuritaire.

Éviter les risques d’incendie

Aucun dispositif de détection ne peut protéger la vie dans toutes les

situations. Ainsi, des mesures de protection doivent être mises en place

afin d’éviter les situations susceptibles de présenter un danger, telles que :

• Ne pas fumer au lit.

• Ne pas laisser les enfants seuls à la maison.

• Ne jamais effectuer des nettoyages à l’aide de liquides inflammables

tels que de l’essence.

• Entreposer convenablement les matériaux. Utiliser de bonnes

méthodes d’entretien ménager afin de garder votre résidence propre

et ordonnée. Un sous-sol désordonné, un grenier ou tout autre

endroit d’entreposage est propice aux incendies.

• Utiliser avec soin les matières combustibles et les appareils électriques

et uniquement selon leurs utilisations spécifiques. Ne pas surcharger

les prises de courant.

• Ne pas entreposer d’explosifs ou des matières à combustion rapide

dans votre résidence.

• Même après la mise en place de précautions, un incendie peut éclater.

Soyez prêt.

En cas d’incendie

En cas d’incendie

• Quittez les lieux immédiatement. Ne prenez pas le temps d’emballer

ou de chercher les biens de valeur.

• En présence de fumée épaisse, retenez votre respiration et restez près

du sol, rampez si besoin est. L’air pur se trouve normalement près du

plancher.

• Si vous devez franchir des portes fermées, vérifiez soigneusement si

la porte ou la poignée présente une chaleur excessive. Si elles

semblent fraîches, appuyez votre pied sur le bas de la porte avec

votre hanche sur la porte et une main sur l’arête supérieure. Ouvrezla un peu. Si une poussée d’air chaud est ressentie, claquez la porte

rapidement et verrouillez-la. Un incendie qui est contenu dans un

espace clos a tendance à accumuler beaucoup de pression. Assurezvous que les membres de la maison familiale comprennent ce danger.

• Servez-vous du téléphone de votre voisin ou de l’avertisseur

d’incendie public pour communiquer avec le service d’incendie.

Éteindre un incendie doit être effectué uniquement par des

professionnels.

Soyez prêt

Répétez les étapes suivantes afin de vous préparer à un incendie :

• Effectuez régulièrement des exercices d’évacuation en cas d’incendie.

Utilisez-les pour aider à reconnaître le signal d’alarme.

• Si vous devez franchir des portes fermées, vérifiez soigneusement si

la Dessinez un plan d’étage et indiquez deux sorties pour chaque

pièce. Il est important que les enfants soient bien renseignés parce

qu’ils ont tendance à se cacher lors de crise.

• Déterminez un lieu de rencontre à l’extérieur de la maison. Insistez

pour que tous se réunissent à cet endroit durant une alerte. Ceci évite

de retourner à la maison aller chercher un membre de famille

manquant qui est effectivement en sécurité.

• Si un de vos enfants ou des membres de votre famille sont aux prises

avec des difficultés physiques, placez des autocollants dans les

fenêtres pour aider le personnel affecté aux urgences à identifier les

chambres à coucher de ceux-ci.

Garantie limitée

ESL est une marque de GE Security. Le fabricant garantit que ce

détecteur de fumée (à l’exception des piles) est exempt de défaut de

matériel et de fabrication dans des conditions normales d’utilisation

pour une durée de trois (3) ans suivant la date de fabrication.

Durant cette période de garantie, si un produit GE Security ou un de

ses composants est défectueux, GE effectuera la réparation ou le

remplacera sans frais.

Les appareils dont la garantie n’est plus en vigueur seront réparés à

la discrétion du fabricant ou, dans le cas contraire, une carte est

envoyée au client, lui suggérant un appareil de rechange et

mentionnant le coût de cet appareil.

Cette garantie ne s’applique pas aux appareils qui ont subi des usages

à mauvais escient, de la négligence ou un accident ou auxquels des

modifications, des altérations ou des réparations ont été effectuées.

Cette garantie est accordée uniquement à l’acheteur initial du

détecteur de fumée et ne peut être exercée que par cet acheteur.

Pendant la période de garantie, si l’alarme ou ses composants

garantis sont défectueux, ils seront remplacés ou réparés sans frais à

la discrétion du fabricant s’ils ont été retournés selon les instructions suivantes :

Obtenir un numéro d’autorisation de retour en communiquant au

1 800 648-7422 ou au (503) 692-4052. Ensuite, emballer

l’appareil dans une boîte matelassée à isolation thermique et préaffranchie. Envoyer le

colis à :

Service à la clientèle RMA no

GE Security

12345 SW Leveton Drive

Tualatin, OR 97062-9938

États-Unis

Une note doit être incluse afin de décrire la nature de la

défectuosité. Lorsqu’une alarme sous garantie doit être retournée,

une attention particulière doit être apportée lors de son emballage,

car GE Security n’effectue aucune réparation pour les appareils qui

ont subi des dommages à cause d’un emballage inadéquat.

La garantie ci-dessus remplace toutes les garanties

expresses ou implicites de qualité marchande et d’aptitude

à un usage particulier et elle est d’une durée limitée de

TROIS ans suivant la date de fabrication. En aucun cas le

fabricant ne saurait être tenu responsable des dommagesintérêts indirects ou consécutifs de toute nature, y compris

mais non exclusivement, les dommages-intérêts découlant

de préjudices corporels ou de dommages matériels, et

quelle qu’en soit la cause, censément consécutifs à une

violation de la garantie par le fabricant, la négligence du

fabricant ou autre. La responsabilité du fabricant ne saurait

en aucun cas excéder le prix d’achat de ce produit.

Certaines provinces ne permettent pas une limite de durée

de la garantie implicite ou l’exclusion ou la limite des

dommages-intérêts indirects ou consécutifs. Ainsi, les

limites énoncées ci-dessus peuvent ne pas s’appliquer à

vous. Sauf si une durée plus longue est exigée par une loi

applicable, les recours contre le fabricant relativement à ce

détecteur de fumée doivent être intentés en moins d’un an

après l’événement donnant lieu au litige.

Aucun mandataire, employé ou représentant du fabricant ni

personne d’autre n’est autorisé à modifier la présente garantie de

quelque façon que ce soit. La réparation et le remplacement comme

indiqué ci-dessus sont les recours exclusifs de l’acheteur en vertu de

la présente garantie. La présente garantie vous procure des

garanties juridiques spécifiques, ainsi que d’autres garanties qui

varient d’une province à l’autre.

MISE EN GARDE

Les détecteurs de fumée NE PEUVENT PAS émettre

d’avertissements pour les incendies causés par une explosion, la

fumée de cigarette dans un lit ou autres meubles, l’allumage de

liquides inflammables, de vapeurs et d’essence, des enfants qui

jouent avec des allumettes ou des briquets.

ESL 560N Series

9

Page 10

12345 SW Leveton Drive

GE Security

Tualatin, OR 97062

503-692-4052

USA & Canada: 800-547-2556

Tech Support: 800-648-7424

www.gesecurity.com

1039047B / September 2004

Loading...

Loading...