Page 1

ShatterPoint

™

Glassbreak Sensor

Models

5600-W, 5605-W, 5620-W, 5625-W

Installation Instructions

Description

The 5600 Glassbreak Sensors are designed to detect

breaking glass caused by forced entry into a protected

window or door. The ‘Tru-Dual’ transducer design provides

excellent false-alarm immunity in noisy environments.

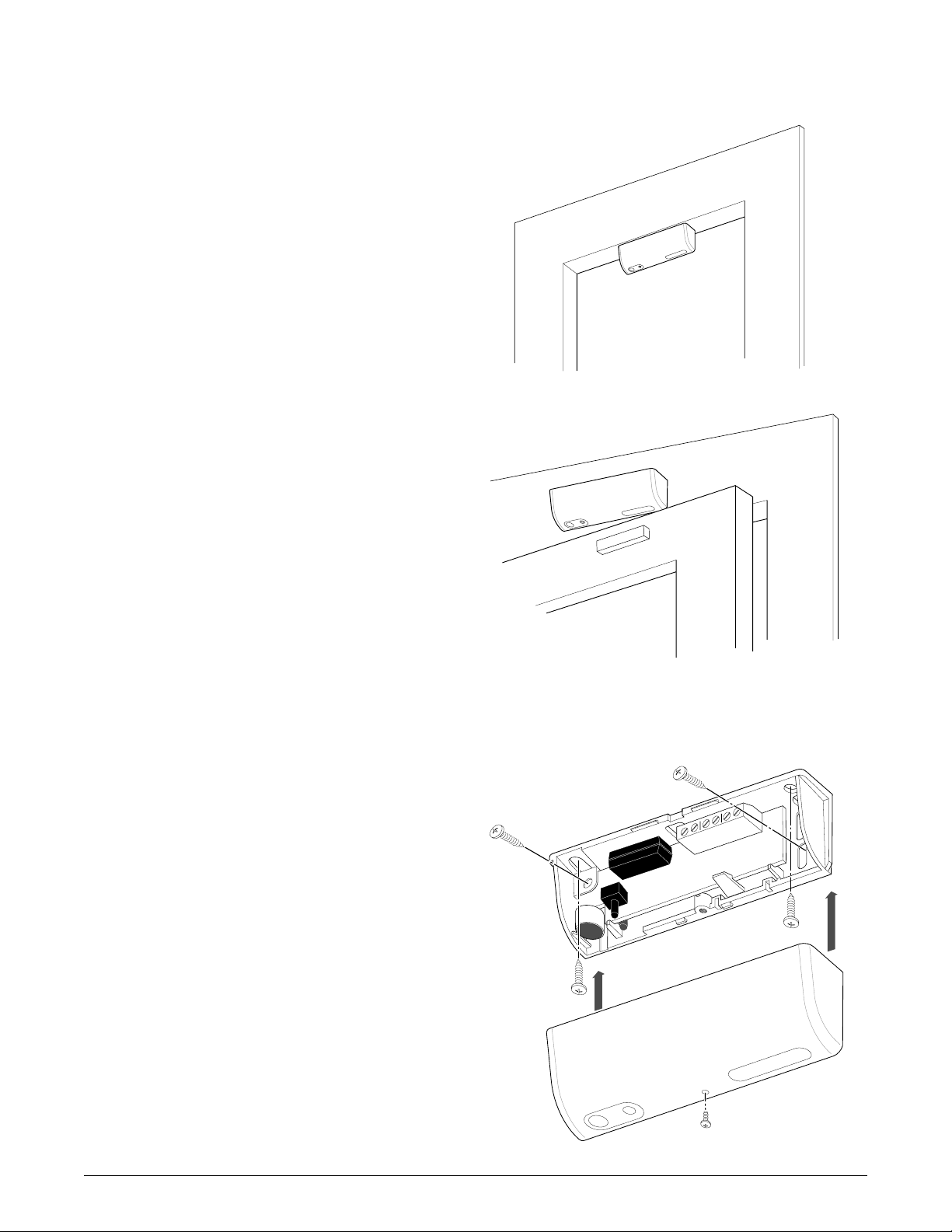

Figure 1a. Frame Mounting

The 5600 Sensors process both acoustic and vibration

information to identify breaking windows. Frame mounting

the 5600 Sensors eliminates detection concerns with drapes

and blinds. The built-in reed switch models provide

protection against forced opening of windows or doors, as

well as breaking glass.

Note These sensors may not consistently detect

cracks, bullets, or similar breaks. Glassbreak sensors

should always be backed up by interior protection such

as a motion detector.

Mounting

The 5600 sensors are designed to mount either inside the

frame (see Figure 1a) or on the facing (see Figure 1b). Refer

to Figure 3 for recommended mounting locations and

coverage range. The mounting location should provide good

mechanical coupling from glass to sensor and an

unobstructed microphone view of the glass. If structural

integrity of the frame is poor, temporarily mount the sensor

and follow the steps in Testing for range testing. Do not

exceed the tested range of the sensor.

Figure 1b. Facing Mounting

Note For applications with more than one framed

window, use multiple 5600s or a ShatterPro II.

Use the screws provided to mount the sensor securely to the

frame. A loosely mounted sensor will not perform correctly.

The small cover screw must be used to permanently attach

the cover (see Figure 2).

ShatterPoint Glassbreak Sensor

Cover Screw

Figure 2. Mounting and Cover Screws

1

Page 2

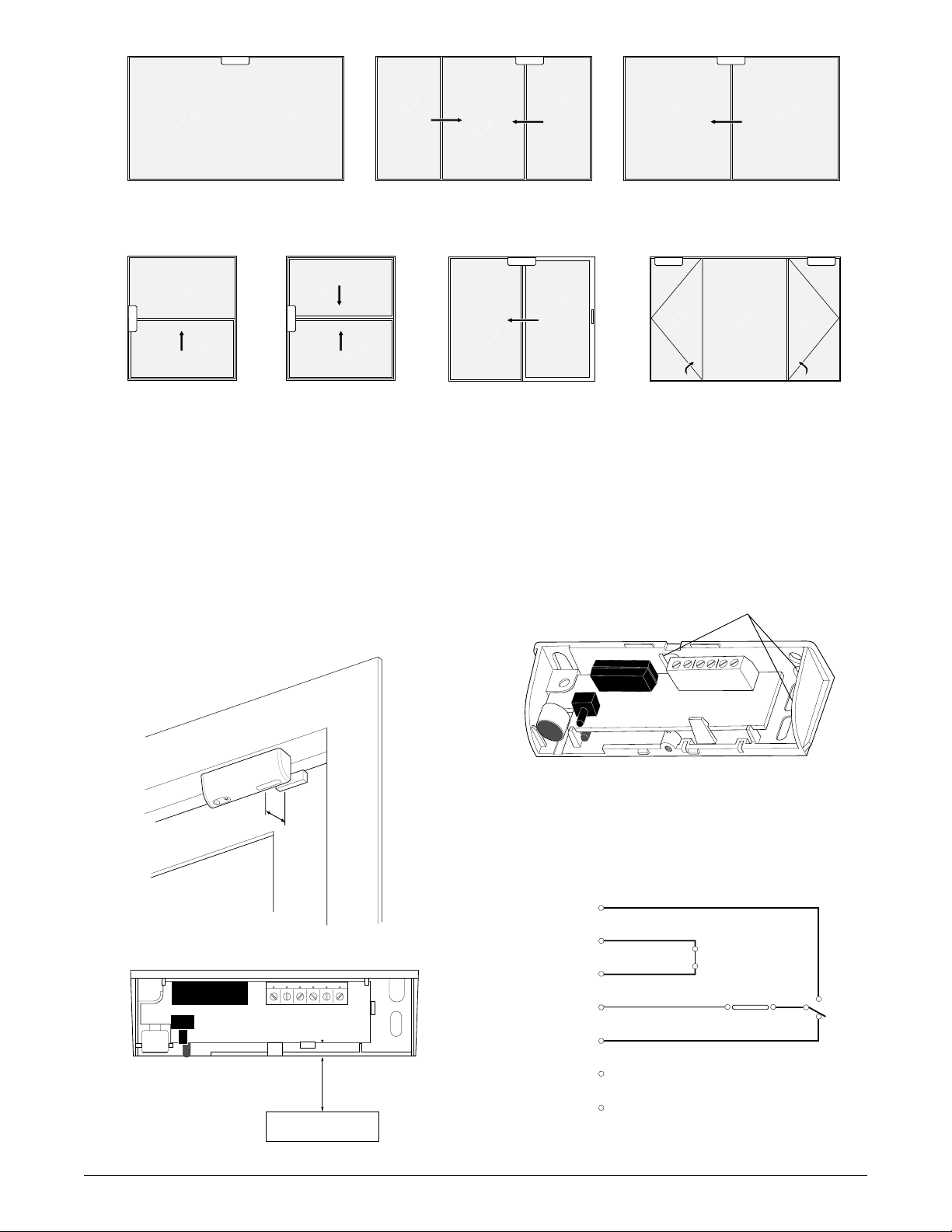

Picture Window

Double Slider

Horizontal Slider

Vertical Slide Double Hung Patio Door

Figure 3. Mounting Locations

Reed Switch Models

Models 5620 and 5625 require the magnet be mounted on

the moving portion of the window or door. Magnet

placement must be within 3/4" (19mm) of sensor, either

behind or below (see Figure 4). Center magnet as marked

on the printed circuit board (see Figure 5).

Note Mounting sensor or magnet on steel surfaces will

reduce gap.

3/4"

(19mm)

Hinged Casement

Wiring

The 5600 sensor provides multiple wiring entrances (see

Figure 6). Use rear holes or knock-out as needed. It is

recommended to tape over unused holes.

Wire Entrances

Figure 6. Wire Entrances

Figure 4. Magnet Placement

Figure 5. Centering the Magnet

2

CENTER MAGNET HERE

3/4" (19mm)

MAGNET

N.O.

TAMP

TAMP

REED (5620 Series only)

COM

N.C.

-GND

+12V

Figure 7. Output Circuit (shown powered)

ShatterPoint Glassbreak Sensor

Page 3

Testing

The 5600 features installation tests and a hand-clap

end-user test.

End-User Test

Simply clap hands within 3 feet (1m) of the sensor and the

LED will flash quickly indicating the sensor is powered and

functioning properly.

Installation Test

The sensor is ready to test once installed with cover on and

powered, no test mode is necessary. To test sensor, perform

range testing to ensure adequate vibration coupling to

sensor. After range is verified, perform alarm test.

1. Range testing – The LED blinks slowly two times to

indicate the sensor is within detection range. To test, rap

the glass lightly with the handle of a screwdriver. Start

close to the sensor and proceed to furthest point of glass.

If LED flashes quickly, better coupling between glass and

sensor may be needed.

2. Alarm testing – Using the 5709C hand-held tester (set

for proper glass type), hold tester at furthest point of

glass and press test button while simultaneously rapping

lightly on the glass with the handle of a screwdriver.

When in alarm, the relay will open for 4 seconds and the

LED will turn on solid for 1 minute then turn off. This

verifies that the sensor triggers an alarm with the control

panel. The reed switch is in series with the alarm loop

and can be tested by opening the window or door a few

inches.

Caution Hinged style doors or windows will

significantly reduce range. Test seismic signal

thoroughly.

Alarm Memory

All 5600 Sensors include the alarm memory feature. This

helps the installer find which sensor alarmed. After an

alarm, the LED will turn on solid for 1 minute then turn off.

Any subsequent hand claps or raps to the window will result

in the LED turning on solid for 15 seconds and then turning

off (relay remains closed unless sensor alarms during this

test). To reset the sensor’s alarm memory, briefly

disconnect power.

Sensor Self-Tests

All 5600 Sensors perform a processor self-test at power up.

If the processor finds a faulty condition, the LED will stay

lit and the relay will not energize.

Normal operation will clear the LED and energize the relay.

During operation, the processor periodically tests itself for

conditions that could impede performance. If the processor

malfunctions, it will reset itself and perform a power-up

self-test. If memory fails, the LED will blink continuously

at 1Hz (1/2 second on, 1/2 second off) to signal the trouble.

Promptly replace a sensor which indicates a faulty

condition.

Note Test sensors at least annually for proper

operation.

Installation Tests

Test Action

Range Rap Glass Out of Range Out of Within Within Range

Test Range Range

Alarm Rap Glass & No Alarm No Alarm No Alarm Alarm

Test Key 5709C

End-User Hand Clap Sensor Hardware Hardware Fault or Alarm

Test or Too Far From Sensor or Hardware Fault Okay Fault Memory Indicated

Key 5709C

Alarm Rap Glass, No Alarm No Alarm Sensor has Alarmed Since

Memory Hand Clap, or Too Far From Sensor in Memory in Memory Last Power-Up

LED Indication

No Flash

3 Fast

Flashes

2 Slow

Flashes

Solid On

Sensor Self-Test

Test Condition LED Indication

Power-up test Normal LED Turns Off, Relay Energizes

Faulty LED Solid On, Relay Never Energizes, Alarm Condition

Memory test Normal No Indication, Sensor Functions Normally

Faulty LED Flashes at 1Hz (1/2 sec. on, 1/2 sec. off)

ShatterPoint Glassbreak Sensor

3

Page 4

Specifications Dimensions

x

Voltage ..................................................................... 9 – 16V DC

Current.............................................. 12mA typical, 20mA max.

Relay Output: Normal.........................................<15 W (closed)

Alarm ............................................................ >1 MW (open)

Open 4 seconds upon alarm

Maximum loop rating .................................. 16V DC, 50mA

Wire Terminals ........................................................ 22-18 AWG

Operating Temperature ............... 0° to +120°F (–18° to +50°C)

Humidity ........................................ 10% to 90% noncondensing

Lightning Suppression ..................... 400 Watts for 1msec pulse

RF Immunity .........................................20 V/m, 1 to 1000 MHz

Glass Types

Plate ......................................3/32'' (2.4mm) to 3/8" (9mm)

Tempered.............................1/8'' (3.2mm) to 1/4" (6.4mm)

Laminated............................1/8'' (3.2mm) to 1/4" (6.4mm)

Wired .............................................................. 1/4" (6.4mm)

Mounting Location ............................................................ Frame

Range of glass surface covered (radius from sensor)

Single-pane window ..................................... up to 10' (3m)

Multi-pane window...................................... up to 8' (2.4m)

Sliding-glass door ........................................ up to 8' (2.4m)

Armor coated glass ...................................... up to 8' (2.4m)

Minimum Glass Size.................... 12" (305mm) x 12" (305mm)

Note: Mounting sensor or magnet on steel surface will

reduce gap.

Magnet Gap Distance.............................3/4" (19mm) maximum

Housing Material ..................................... Flame Retardant ABS

Color............................................................ White or Mahogany

Sensor

Magnet

1.5"

(38mm)

3.95"

(100mm)

(10mm)

0.38"

0.25"

(6mm)

1.25"

(32mm)

0.9"

(23mm)

FCC

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2)

this device must accept any interference received, including

interference that may cause undesired operation.

Ordering Information

Description Model Number Color Choices

ShatterPoint™ 5600-W White

ShatterPoint™, with Form C relay and tamper switch 5605-W White

ShatterPoint™, with magnetic contact 5620-W White

ShatterPoint™, with Form C relay, tamper switch and magnetic contact 5625-W/M White or Mahogany

Hand-held Tester 5709C-W White

Replacement magnet 1838-N/M Cloud White or Mahogany

www.GE-Interlogix.com

© 2003 GE INTERLOGIX

12345 SW Leveton Drive

Tualatin, OR 97062

Phone: 503-692-4052

USA & Canada: 800-547-2556

Technical Service: 800-648-7424

FaxBack: 800-483-2495

GE Interlogi

14329 Rev B 05/03

Loading...

Loading...