Page 1

DESCRIPTION

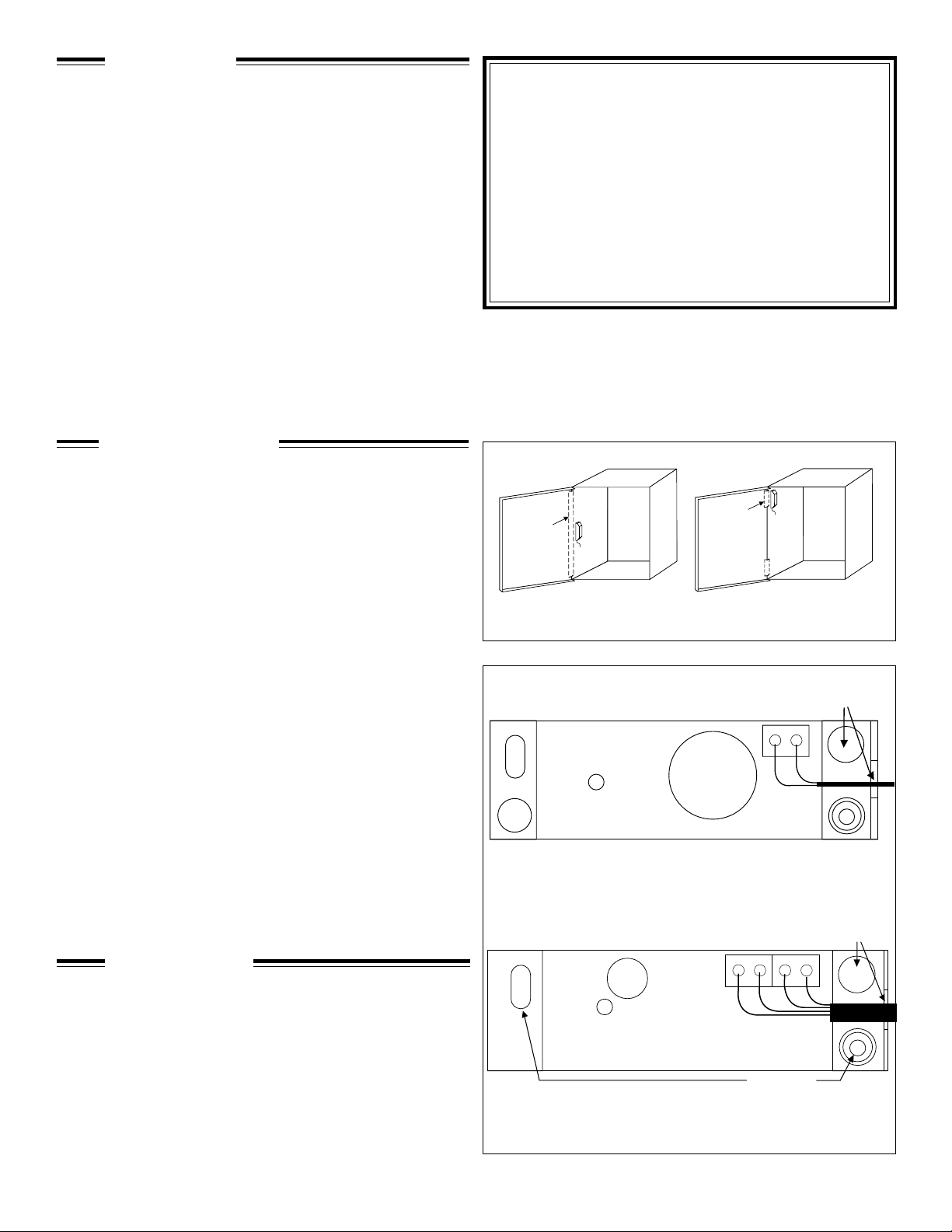

Sensor

Hinge

Sensor

Hinge

The 5402 and 5422 shock sensors respond to the shock waves

of sheet metal that is being cut, sawed, impacted, or drilled. This

quality makes it ideal for protecting sheet metal enclosures such

as control panels, alarm housings, electrical panels, and telephone

junction boxes. No sensitivity adjustments make installation quick

and easy.

The 5402 is a lithium battery powered, two-wire sensor. The 5422

is a 4-wire externally powered sensor operating from a

9-24 VDC supply. Both have closed loop outputs.

Sensor Operation

When the sensor is operational and detects an attack, the sensor

alarms, producing three responses:

1. The red LED on the sensor goes on for the period of time the

alarm loop is open (2-6 seconds).

2. The loop impedance of the sensor changes from <15 ohms

(closed) to >1.0 megaohms (open).

3. This is registered by the alarm panel as an alarm. After an

alarm, the sensor automatically resets itself, while the LED

extinguishes simultaneously.

STEP 1 - MOUNTING

Sheet metal enclosures to be protected shall not exceed 2 x 4 x 1 ft.

(61 x 122 x 30.5 cm), and shall have a maximum wall thickness of

0.135 inches (0.343 cm). The enclosure must be solid sheet

metal, have all sides connected (welded, bolted, etc.), and the lid

attached by hinges or screws.

Locate the sensor inside the enclosure on the side wall on or

near the hinge. If the hinge runs the length of the side, center the

sensor vertically. If the enclosure has multiple hinges, place the

sensor next to the hinge nearest the middle of the enclosure (see

Figure 1).

Sentrol Models

5402 and 5422

Metal Enclosure Assault Sensors

UL and ULC Listed

Installation Instructions

Figure 1. Solid Hinge

Multiple Hinges

Mounting the Sensor

1. Clean the area where the sensor will be mounted with a 50/50

solution of isopropyl alcohol and water on a clean cloth.

2. Dry the area.

3. Peel the backing from one side of the tape pad. Center the

tape pad on the back of the sensor. The tape pad must be

flat against the plastic case.

4. Remove the remaining backing paper from the tape pad.

Place the sensor against the metal and press firmly.

NOTE: Although the 5402 and 5422 have inherent false alarm

immunity, a few simple precautions must be observed to prevent

false detections.

1. Mount the enclosure and lid securely so that they do not

rattle. Use foam pads to eliminate lid rattle.

2. The enclosure should be clear of vibrating objects (i.e.,

bells, machinery, motors, etc.).

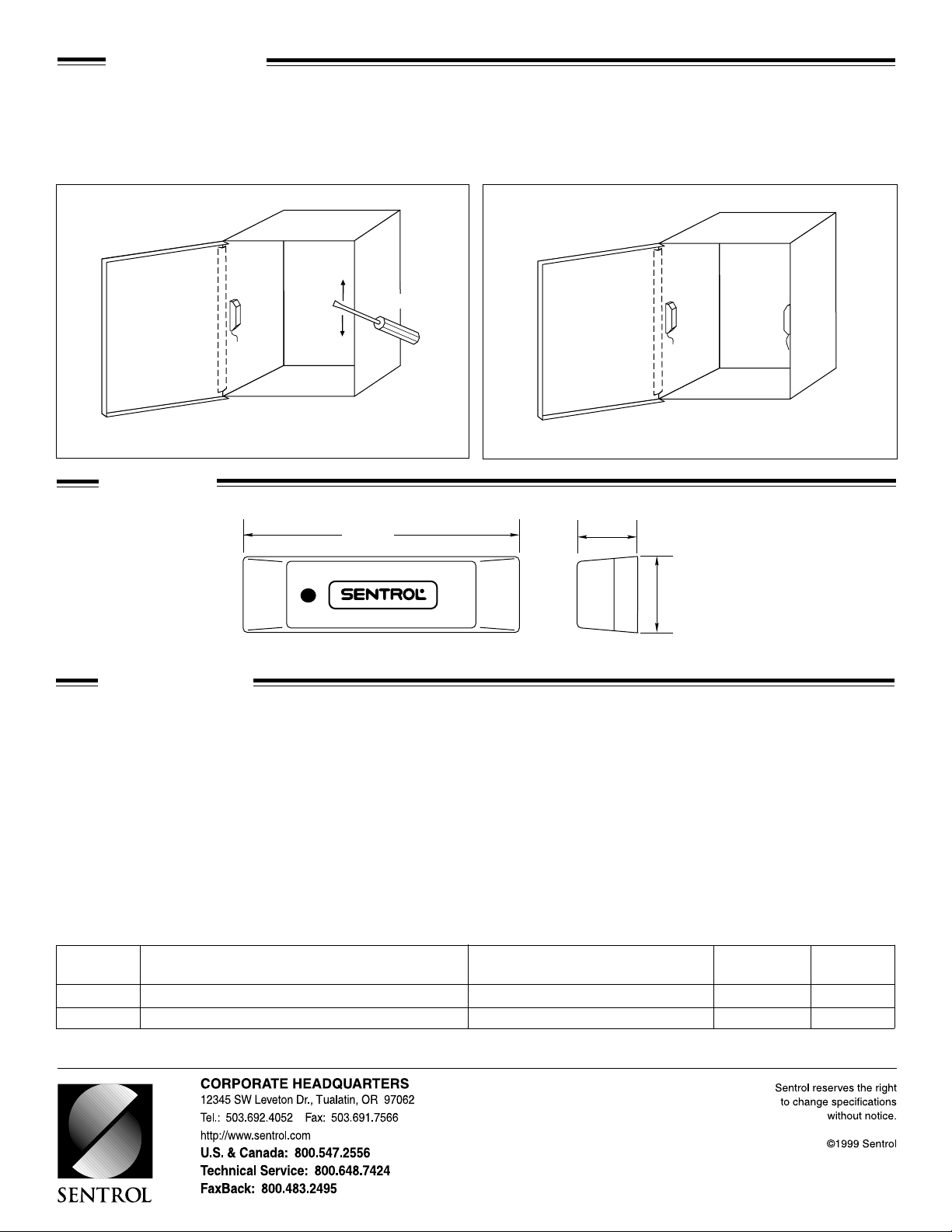

STEP 2 - WIRING

Remove the cover by depressing the snap in the slot at the end of

the sensor and lifting the cover. Connect wires to the terminal

block as labeled on the circuit board (see Figure 2).

Run the wires out the terminal block end of the plastic base. Notch

out center wire exit in the cover and snap in place.

Figure 2.

LED

5402 Wiring Guide

LED

Battery

Power

Input

+

Alarm

Loop

Out

Out

Alarm

Loop

Ð

Out

Screw Holes

Wire Exits

Wire Exits

Out

5422 Wiring Guide

Page 2

STEP 3 - TESTING

To verify sensor operation, lightly scrape the metal shaft of a

screwdriver (8" or larger) back and forth against the metal edge of

the enclosure (see Figure 3). The LED should light. Do not use the

side with sensor to test as it will be most sensitive. If the sensor

range is not sufficient, add another sensor (see Figure 4).

Sensor

Screwdriver

Figure 3. Vibration test

DIMENSIONS

3.46"

8.8 cm

NOTE: Be sure to test the sensor at least annually to ensure

proper operation.

Sensor

Sensor

Figure 4. Two sensor placement

0.84"

2.1 cm

R

1.10"

2.8 cm

SPECIFICATIONS

ALL MODELS

Resistance: Normal ............................................................................................................................... <15 ohms (closed)

Alarm.......................................................................................................................... >1.0 megaohms (open)

Time Open on Alarm ........................................................................................................................................... 2-6 seconds

Operational Voltage (5422) ...................................................................................................................................... 9-24 VDC

Current Draw (5422) .....................................................................................................................................15 mA maximum

Number of Leads...................................................................................................................................... 2 (5402) or 4 (5422)

Maximium Loop Rating...................................................................................................................................24 VDC, 50 mA

Wire Lead Size.................................................................................................................................................... 16-22 gauge

Mounting ..................................................................................................................................................................Tape pad

Dimensions ................................................................................................................................... 3.46" L x 1.1" W x 0.84" H

(8.8 cm x 2.8 cm x 2.1 cm)

ORDERING INFORMATION

Model Description Loop Color Listing

Number Configuration

5402-W Lithium battery, 2-wire Closed loop, NC Grey UL/ULC

5422-W External power, 4-wire Closed loop, NC Grey UL/ULC

G-3763-0499

1030900 Rev A

Loading...

Loading...