Page 1

eXtremeRAID™

Installation Guide

eXtremeRAID 1100

PCI to Ultra2 SCSI

RAID Controller

P/N: 775013-01

Page 2

Page 3

eXtremeRAID™

DAC1164P™

PCI to Ultra2 SCSI

RAID Controller

Installation Guide

775013-01

© Copyright 1999 Mylex Corporation.

All Rights Reserved.

All contents of this manual are copyrighted by Mylex

Corporation. The information contained herein is the

exclusive property of Mylex Corporation and shall not be

copied, transferred, photocopied, translated on paper, film,

electronic media, or computer-readable form; or otherwise

reproduced in any way, without the express written

permission of Mylex C orporation.

Page 4

Greetings

Thank you for purc hasing the Mylex eXtremeRAID disk array controller. Requests for

technical information about this and other Mylex Corporation products should be made to

your Mylex authorized reseller or Mylex marketing representative.

Please Notice

Mylex is a registered trademark and eXtremeRAID and DAC1164P are trademarks of

Mylex Corporation.

Microsoft, MS-DOS, Windows 95, Windows 98, and Windows NT are registered

trademarks o f the Microsoft C orporation. Novell an d NetWare are a registere d trademarks

of Novell corporation. SCO and UnixWare are registered trademarks of Santa Cruz

Operations. Other names that are tra dem arks may be used herein for the purpose o f

identifying the pr oducts or services of th eir respective owners.

Unless otherwise noted, companies, names and data used in examples herein are fictitious.

Our Policy

Although reason able efforts have been made to assure the accuracy of the inf o r m ation

contained herein, this publication could include technical inaccuracies or typographical

errors. Mylex Corporation expressly disclaims liability for any error in this information,

and for damages, w hether direct, indirec t, spe cial, exemplary, consequential or otherwi se,

that may result from such error, including but not limited to loss of profits resulting from

the use or misuse of the manual or information contained therein (even if Mylex

Corporation has been advised of the possibility of such damages). Any questions or

comments regarding this document or its contents should be addressed to Mylex

Corporation at the address shown on the back c over.

The following paragraph does not apply to the United Kingdom or any country where such

provision s are inco n sistent with local l aw:

MYLEX CORPORATION PROVIDES THIS PUBLICATION “AS IS” WITHOUT

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT

NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

Some states do not allow disclaimer of express or implied warranties or the limitation or

exclusion of liability for indirect, special, exemplary, incidental or consequential damages

in certain transactions; therefore, this statement may not apply to you. Also, you may have

other rig hts which vary from jurisdiction to ju risdiction.

Information in this publication is subject to change without notice and does not represent a

commitment on the part of Mylex Corporation. Changes may be made periodically to the

information herein; th ese changes will be incorporated in new editions of the publication.

Mylex Corporatio n re serves the right t o make im provements and/or cha nges at a n y t ime in

the product(s) and/or program(s) described in this publication.

It is possible that this publication may contain reference to, or information about, Mylex

Corporation products (machines and programs), programming or services that are not

announced in your country. Such references or information must not be construed to mean

that Mylex Corporation intends to announce, provide, or make available such Mylex

products, programming, or services in your jurisdiction.

Page 5

About This Manual

This installation guide covers hardware set-up and configuration procedu r es

necessary for the installation of a Mylex DAC1164P PCI to Ultra2 SCSI

RAID controller.

Chapter 1 describes the controller, standard package contents, and usersupplied items necessary for installation.

Chapter 2 describes the steps to be performed prior to controller installation.

Chapter 3 describes the physical installation of the DAC1164P controller.

Chapter 4 describes controller start-up and the BIOS resid e nt utilities.

Appendix A describes the memory and battery backup module.

Appendix B provides hardware and environmental specifications.

Appendix C describes error messages and problem correction.

Appendix D describes the PCI Hot Plug feature.

Appendix E provides enclosure management information.

Appendix F provides regulatory agency information.

Page 6

Conventions

Throughout the manual, the following conventions are used to describe user

interaction with the product:

prompt This style of type indicates screen display messages

Enter Press the key labeled “Enter” (or “Delete”, etc.)

☛

Note

Supplementary information that can ha ve an effect on

system performance

m Caution

Notification that a proscribed action has the potential

to adversely affect equipment operation, system

performance, or data integrity

,

WARNING

Notification th at a proscribed action will

result i n equipment da ma ge , data loss, or p er s on al

injury

definitely

Page 7

Contents

Chapter 1

Introduction

Product Description ...........................................................................1-1

Controller Features ....................................................................1-2

Operating System Support .........................................................1-2

Standard Package Contents .............................................................1-3

Hardware .................................................................................... 1-3

Software ..................................................................................... 1-3

User-supplied Items ..........................................................................1-4

Chapter 2

Preinstallation Planning

SCSI Termination .......................................................................2 -2

SCSI Cabling ...................................................... ........................2-4

SCSI Drive Preparation ...................................... ........................2-5

Mixing Narrow and Wide SCSI Drives ........................................2-5

Mixing LVD with Single-ended Drives ........................................2-5

Chapter 3

Installation

Before You Begin ..............................................................................3-1

Connectors, Jumper and LEDs .........................................................3-2

External SCSI Connectors ............................................ .............3-3

Safety Considerations .......................................................................3-4

Installing the Controller ......................................................................3-5

Chapter 4

Controller Start-up

Procedural Overview .........................................................................4-1

Controller Start-up .............................................................................4-2

BIOS Options Sequence ...................................................................4-2

Setting BIOS Options ................................................................4-3

Using RAID EzAssist .........................................................................4-5

Operating System .......................................... ...... ..............................4-7

Operating System Device Drivers .....................................................4-7

Global Array Manager (GAM) ............................................................4-7

In Case of Problems ..........................................................................4-7

775013 v

Page 8

Appendix A

Memory Module and

Battery Backup Unit

Product Description ...........................................................................A-1

Features .....................................................................................A-1

DMM1100 Operation .........................................................................A-2

Battery Conditioning Prior to Use ...............................................A-2

Set-up – Enabling the Write-Back Cache ...................................A-2

Battery Backup Capacity ............................................................A-2

Maintenance ......................................................................................A-2

Removing the DMM1100 ............................................................A-3

DMM1100 Functional Description ......................................................A-3

Status Indication .........................................................................A-3

Battery and Charge Circuit .........................................................A-5

Recycling the Battery .................................................................A-5

DMM1100 Specifications ...................................................................A-6

On-board Battery ........................................................................A-6

Battery Charge Life ....................................................................A-6

Cache Memory ...........................................................................A-6

Module Dimensions ....................................................................A-6

Environmental ............................................................................A-6

Warranty .....................................................................................A-6

Appendix B

DAC1164P Specifications

General Hardware Specifications ......................................................B-1

eXtremeRAID 1164 ....................................................................B-1

Environmental Specifications .............................................................B-2

Appendix C

DAC1164P Error Messages

Error Messages ................................................................................ C-1

Start-up Error Messages ...........................................................C-1

Drive Check Error Messages ......................... ...... ...... ..... ........... C-1

Aborted Installation ...........................................................................C-2

NVRAM Error ............................................................................ C-3

System Reboot or Power Down ........................................................C-3

vi eXtremeRAID Installation Guide

Page 9

Appendix D

PCI Hot Plug

Introduction ........................................................................................D-1

Implementation ..................................................................................D-1

NetWare .....................................................................................D-1

Windows NT ...................................... ..... ...... ...... ........................D-3

Appendix E

Enclosure Management

Introduction ........................................................................................E-1

SAF-TE ............................................................................................E-1

StorageWorks .................................................................................... E-2

Appendix F

Regulatory Information

FCC Class B Compliance ...........................................................F-1

FCC Declaration of Conformity ..................................................F-2

CE Declaration of Conformity .....................................................F-3

CE Community of Europe ..........................................................F-4

Underwriters Laboratories Statement and Warning ...................F-5

Glossary

775013 vii

Page 10

viii eXtremeRAID Installation Guide

Page 11

This chapter describes:

• The eXtremeRAID™ controller

• Standard package contents

• User supplied items

Chapter 1

Introduction

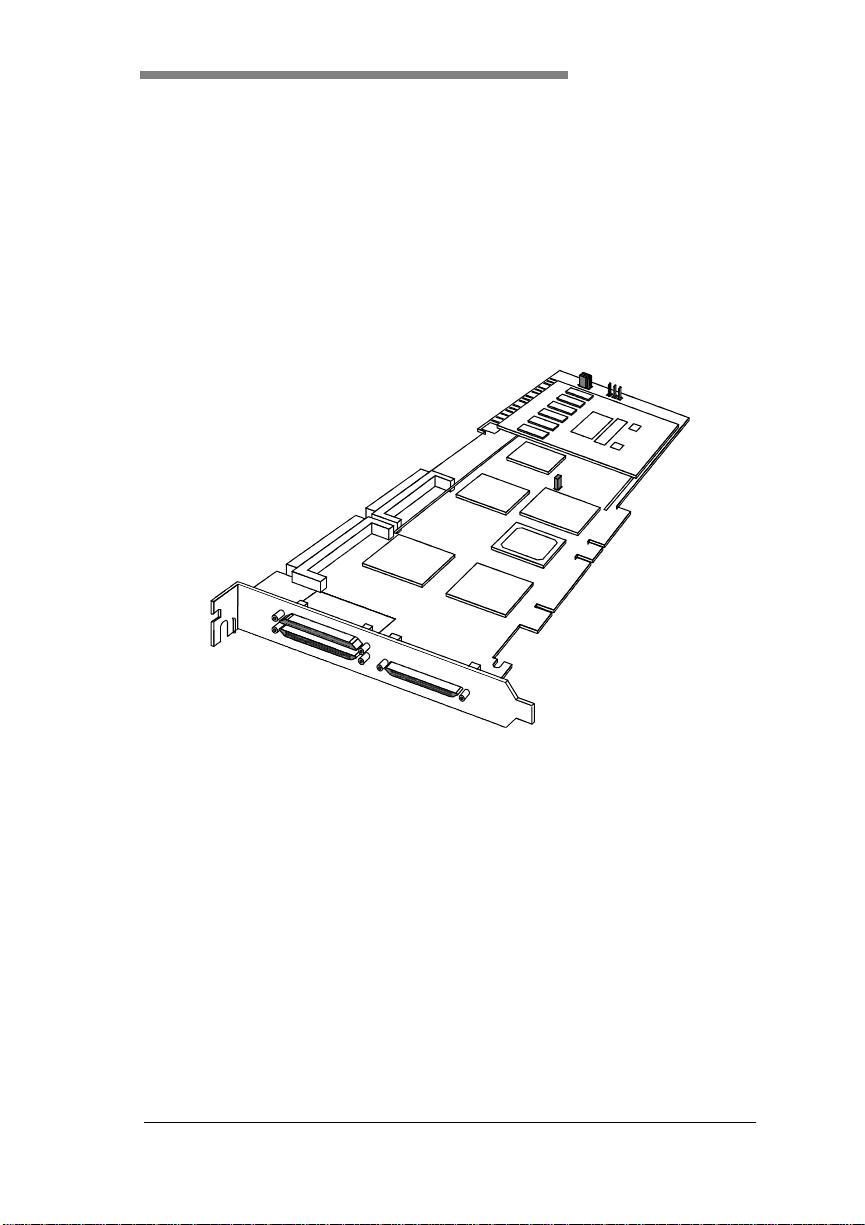

Figure 1-1. DAC1164P Disk Array Controller

Product Description

The Mylex eXtremeRAID 1100 (DAC1164P™) controller is a PCI to Ultra2

SCSI RAID controller with 64-bit PCI capability. With up to three Ultra2

SCSI channels, and a cache memory battery b acku p, this contro ller p ro vi des

the speed and functionality required by high demand server platforms.

775013 1-1

Page 12

Product Description

Controller Features

Features of the DAC 1164P controller include:

• Up to three Ultra2 SCSI channels that support RAID levels 0, 1, 3, 5,

0+1, 10, 30, and 50.

• Low-Voltage Differential (LVD) Wide Ultra2 SCSI (Fast 40).

Controller also supports SCSI 1, 2, or 3, single-ended.

• High performance RISC processor and 16MB, 32MB, or 64MB

SDRAM cache (with parity) on a full-length, 64-bit PCI version 2.1

standard card.

• Memory module (DMM1100) with memory, battery backup, and

circuitry for monitoring the battery condition.

• 1MB, 8-bit flash EEPROM for BIOS and code.

• Built-in configuration utilities (in BIOS).

• Supports controll er r edundan cy u sing a shared SC SI b us in a clu sterin g

configuratio n.

• PCI Hotplug capability allows the DAC1164P to be swapped with a

replacement without powering down the system.

m Caution

Be sure the motherboard you are using supports PCI

Hotplug before attempting to use this feature, or

serious damage to the controller and/or the

motherboard could result.

Operating System Support

MS-DOS 5.x, 6.x, and above are supported using drivers that reside in the

eXtremeRAID BIOS. Many other popular operating systems are supported

using software drivers in the Disk Array Controller Software Kit that is

included with the DAC 11 64P controller (see the Disk Array Controller

Software Kit Installation Guide and User Manual – P/N 771929)

1-2 eXtremeRAID Installation Guide

Page 13

Introduction

SCSIC

Standard Package Contents

The following items are supplied with the standard shipping package:

Hardware

• DAC 1164P Disk Array Controller with documentation on CD-ROM

• DMM1100 Memory Module with battery backup – pre-installed

Software

• RAID EzAssist disk array controller configuration utility with

documentation on CD-ROM

• Software Driver Kit with documentation on CD-ROM

• Global Array Manager (GAM) with documentation on CD-ROM

DAC1164P PCItoUltra2

Hardware Quick

Install Guide

Figure 1-2. Standard Package Contents

775013 1-3

Diskette

with

Drivers

ontroller

CD-ROM with

Additional Hardware

and Software Manuals

and GAM Client

Software

Page 14

User-supplied Items

User-supplied Items

The following user-supplied items are required to perform this installation:

• IBM-PC™ compatible host system with PCI slot (PCI 2.1 compliant)

• Network operating system software (as required)

• SCSI cables to connect the controller and disk arrays

• Static grounding strap or electrostatic discharge (ESD) safe work area

• Disk array enclosure (or equivalent) with SCSI disk drives

1-4 eXtremeRAID Installation Guide

Page 15

Chapter 2

Preinstallation Planning

This chapter describes:

• SCSI termination

• SCSI cabling

• SCSI drive preparation

• Limitations on mixing various SCSI drive types

Mylex disk array controllers are designed to work in a v ariety of SCSI RAID

application environments. Certain configuration steps need to be performed

prior to installing the controller into a RAID environment.

775013 2-1

Page 16

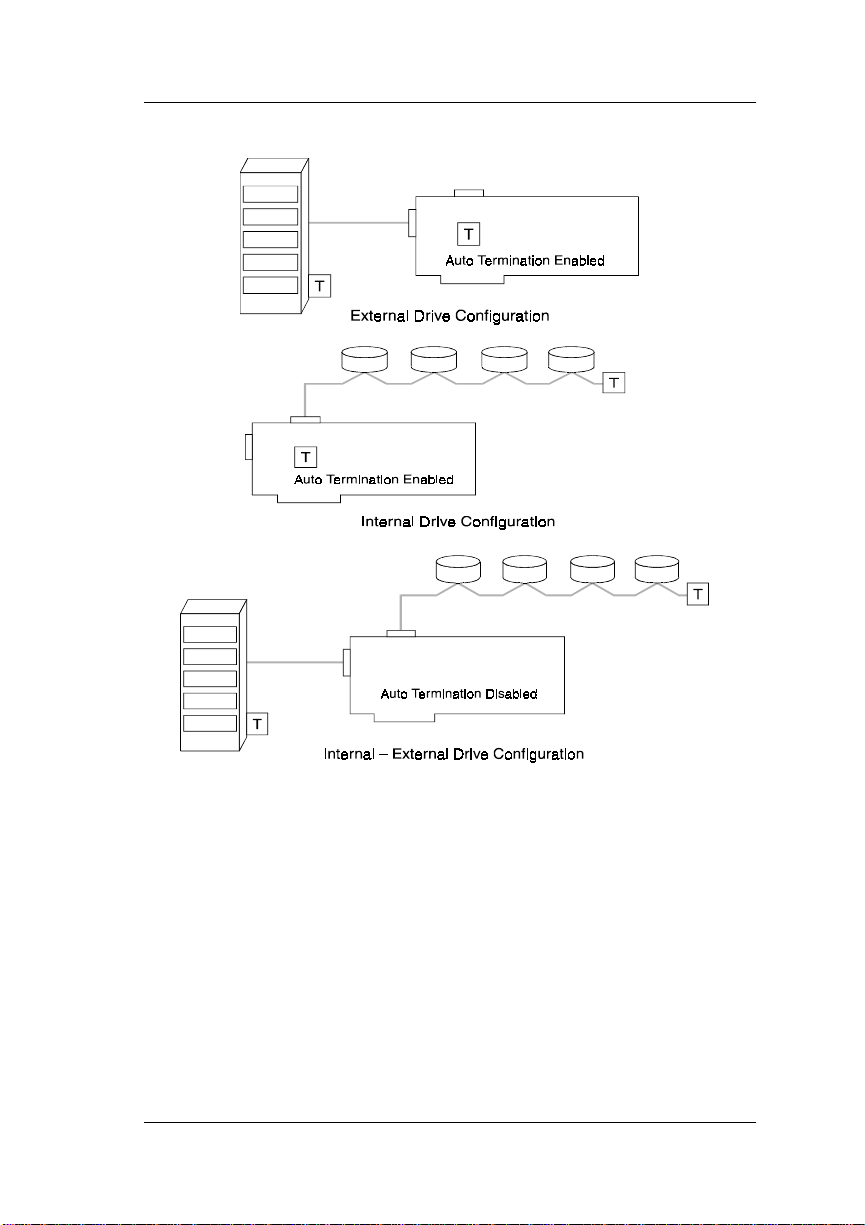

SCSI Termination

Each end of a SCSI bus must be terminated to maintain proper voltage levels

for SCSI control and data signals. The device used for this purpose is called

a terminator, and it can be built into a controller, a SCSI peripheral device, or

it can be a plug placed on the connector at the very end of a SCSI bus.

The DAC1164P controller is equipped with automatic SCS I termin ation

circuitry . If the cont roller is at the end of a SCSI b us, it automatically enables

on-board termination. The controller can also detect whether single-ended

(SE) or low-voltage differential (LVD) termination is required, and can set

the on-board termination type as needed.

If all the SCSI devices on a channel are connected either to an internal

connector of a channel, or to an external connector of a channel, the end of

the SCSI bus farthest fro m the DAC1164P controller must have a termin ato r

installed. In this case, the controller automatically enables on-board

termination. See Figure 2-1 for examples of internal or external drive

configurations.

If some SCSI devices are connected to the internal connector of a channel,

and some are connected to the external connector of the same channel, the

two ends of the SCSI bus farthest from the controller must each be

terminated. In this case, the DA C1164P contro ller automatically disables on-

board termination. See Figure 2-1 for an example of an internal – external

drive conf i gu rati on.

2-2 eXtremeRAID Installation Guide

Page 17

Preinstallation Planning

Figure 2-1. DAC1164P Termination Examples

Note

☛

When connecting SCSI devices, it is better to

terminate the ends of the SCSI bus itself than it is to

terminate the end devices on the bus. This allows hot

swap devices to be added or removed from the SCSI

bus without affecting termination.

775013 2-3

Page 18

SCSI Cabling

The controller supports up to three Ultra2 SCSI channels. Each channel

supports up to 15 devices.

LVD Mode

The controller supports Ultra2 SCSI with LVD. If all drives attached to a

controller drive channel support Ultra2 SCSI with LVD, then that channel

will operate at 80 MB. This setup allows a maximum SCSI bus length of up

to 12 meters.

☛

Note

The SCSI bus length can be extended up to 25 meters

if only the controller and one driv e are on the bus in a

point-to-point configuration.

Single-ended Mode

If any device on the chann el does not have LVD electrical characteristics, the

channel will revert to single-ended operation mode. The SCSI bus lengths

will then be limited to the single-ended bus lengths shown in Table 2-1.

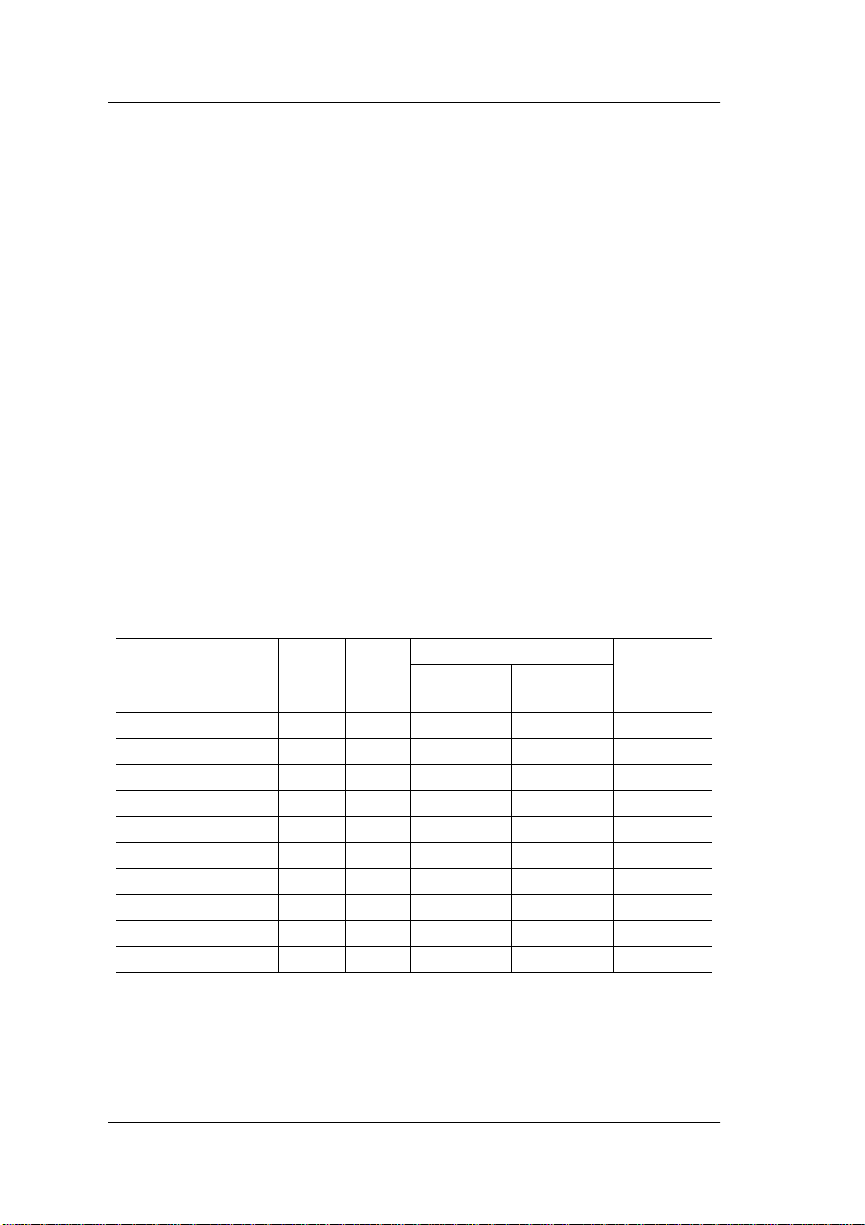

Table 2-1. Supported SCSI Formats and Bus Lengths

SCSI Trade As sociati on

(STA) Terms

SCSI-1 5 8 6 - 8

Fast SCSI 10 8 3 - 8

Fast Wide SCSI 20 16 3 - 16

Ultra SCSI 20 8 1.5 - 8

Ultra SCSI 20 8 3 - 4

Wide Ultra SCSI 40 16 - - 16*

Wide Ultra SCSI 40 16 1.5 - 8

Wide Ultra SCSI 40 16 3 - 4

Ultra2 SC SI 40 8 Not Defined 12 † 8

Wide Ultra2 SCSI 80 16 Not Defined 12† 16

Bus

Speed,

MB/Sec,

Max.

Bus

Width,

Bits

Max. Bus Length, Meters Max. Device

Single-ended Low-Voltage

Differential

Support

(Including

Controller)

* The Maximu m number of devices allowed on a Wide Ul tra SCSI bus is 8, unless bus

extender technology is used.

† This length can be extended to 25 meters if there are only 2 devices (e.g., the controller and

one drive) on the bus in a point-to-point configuration.

2-4 eXtremeRAID Installation Guide

Page 19

Preinstallation Planning

SCSI Drive Preparation

To prepare the drives for installation follow these steps:

1. Remove any terminators attached to the drive or set any drive

termination jumpers to the disabled position.

2. Set the SCSI IDs on the drives.

3. Enable term power on the drives.

Refer to the drive manual for specific information about drive configuration

settings.

To get best performance from the controller, distribute the drives equally

across the SCSI channels, and set the controller’s data transfer rate to the

optimum for the drives being used.

Mixing Narrow and Wide SCSI Drives

Do not mix narrow and wide SCSI devices on a single channel. If mixing of

narrow and wide SCSI devices is desired, dedicate at least one channel to

narrow SCSI, and at least one channel wide SCSI.

Mixing LVD with Single-ended Drives

If LVD capable drives are installed on a channel with single-ended drives, all

drives on the channel will operate as if they were single-ended drives. This

will also limit the bus length to the single-ended bus length specified in

Table 2-1.

775013 2-5

Page 20

2-6 eXtremeRAID Installation Guide

Page 21

Chapter 3

Installation

This chapter describes:

• Preparation

• Connectors and jumpers

• Safety considerations

• Controller installation procedures

Before You Begin

Installing the eXtremeRAID 1100 DAC1164P PCI to Ultra2 SCSI RAID

controller is no more difficult than installing any PCI adapter card. Follow

these steps and the installation procedures in this chapter.

, WARNING

Working with the system covers off and power

applied to the system can result in shock and

serious injury.

1. Power off the system and disconnect the power cables before starting

the installation. Refer to the instructions provided in your system

documentation. Do not disconnect cables or power cords while system

power is on.

2. Read all of the instructions in this chapter completely be fore pro ceeding. Follow the Notes, Cautions, and Warnings described in this manual

and marked on the equipment.

3. Follow electrostatic discharge (ESD) safe procedures. Use a grounded

wrist strap or ESD safe footwear, and work in an ESD safe area.

4. Perform a safety check of the installation before powering on the

system.

• Make sure that all of the cabling Pin 1 locations are correct and that

all cables are firmly seated in the connectors.

• Make sure all SCSI conventions (cable type, cable length,

termination, etc.) are correct.

775013 3-1

Page 22

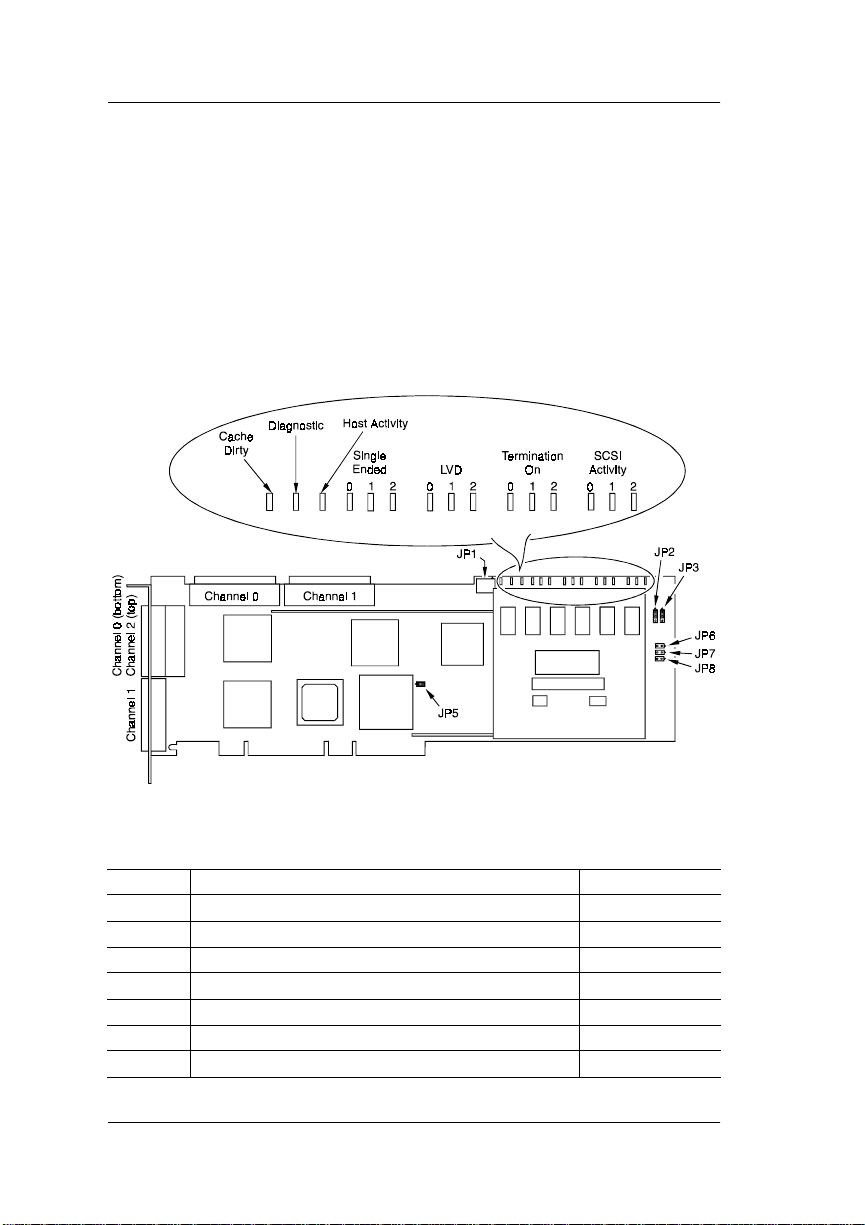

Connectors, Jumper and LEDs

Connectors, Jumper and LEDs

Up to three Ultra2 SCSI channels are supported on the controller. The SCSI

connector locations are shown in Figure 3-1 and Figure 3-2.

All the jumpers should normally be set to their (default settings ). S ee Table

3-1 for default jumper settings. Jumper locations are shown in Figure 3-1.

The controller has 15 LEDs that are active indicators while the controller is

running. The LEDs indicate termination type and status, SCSI activity, cache

status, diagnostic status, and host activity. The LED locations and meanings

are shown in Figure 3-1.-

Figure 3-1. DAC1164P Controller with Jumpers, LEDs and Connectors

Table 3-1. Jumper Descriptions

Jumper Description Default Setting

JP1 factory use only –

JP2 pins 1–2 for Arm Proc, pins 2–3 for I

JP3 pins 1–2 normal , pins 2–3 blank ROM mode 1–2

JP5 must be installed on

JP6 maintenance – do not use off

JP7 ROM emulator – do not use off

JP8 Mylex manufacturing diagnostics – do not use off

3-2 eXtremeRAID Installation Guide

2

O1–2

Page 23

Installation

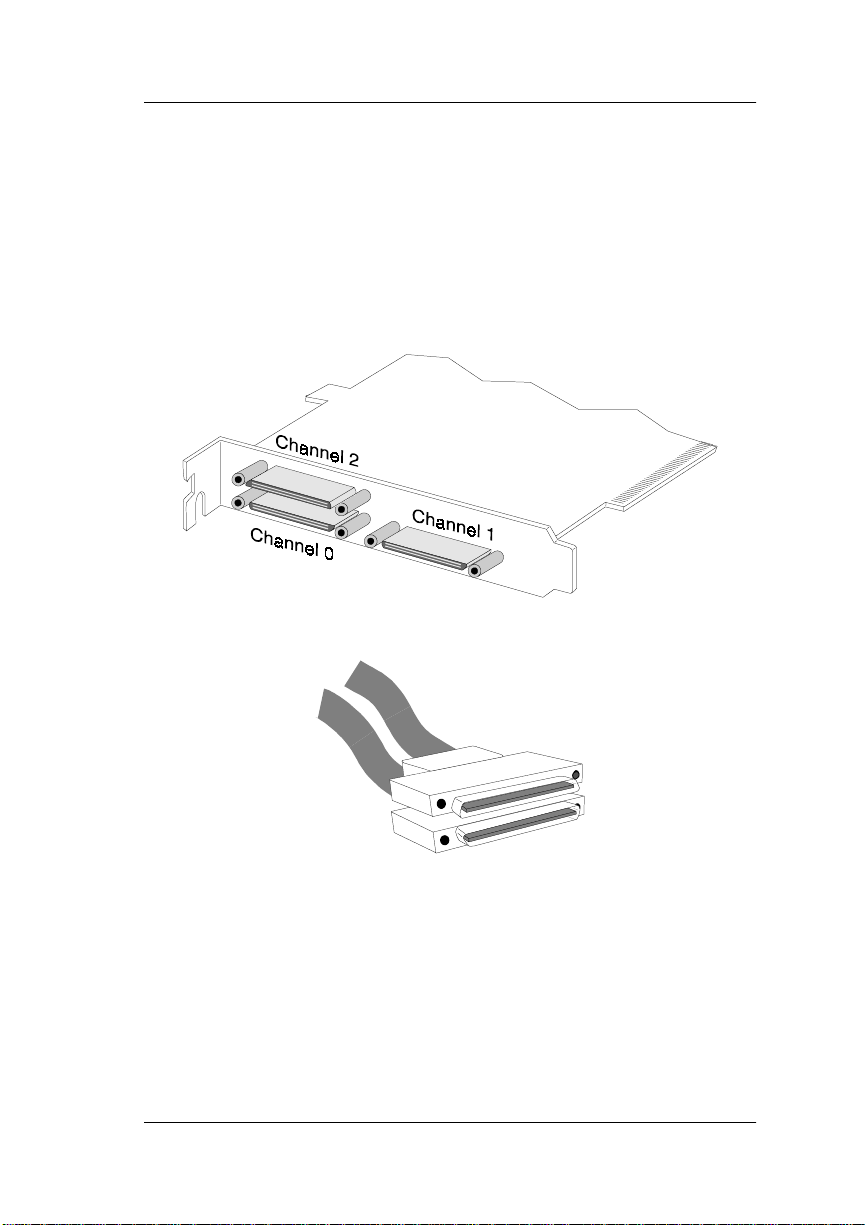

External SCSI Connectors

The external SCSI connectors on the controller are female, Ver y High

Density Cable Interconnect (VHDCI) connectors.

The cables should have the VHDCI offset connector at one end and a High

Density, 68-pin connector at the other end. Such cables with the correct

offset hood and connector assembly are required if cables are to be

connected to external channels 0 and 2 at one time.

Figure 3-2. DAC1164P Controller External Connectors

Figure 3-3. Offset Hood Cable Assembly Alignment

* Where xx is the cable length in meters.

775013 3-3

Page 24

Safety Considerations

Safety Considerations

Be sure to observe the follo wing precautions before beginning the con tr oller

installation procedure:

m Caution

Anti-static handling procedures are required. Leave

the controller in its anti-static bag until it is time to

plug the controller into the PCI slot. The use of a

grounded wrist strap and other ESD protective

measures are highly recommended.

, WARNING

Disconnect the system from the electrical wall

outlet before opening the system cabinet. Working

with the system covers off and power applied to the

system can result in shock and serious injury.

3-4 eXtremeRAID Installation Guide

Page 25

Installation

Installing the Controller

m Caution

Anti-static handling procedures are required. Leave

the controller in its anti-static bag until it is time to

plug the controller into the PCI slot. The use of a

grounded wrist strap and other ESD protective

measures are highly recommended.

Follow these steps:

1. Power off the system.

2. Power off all enclosures.

3. Disconnect system and enclosure power cords.

4. Remove the co vers or the cabin et as necessary to access the I/O slots on

the system board.

5. Choose a vacant PCI slot and remove the metal cover plate from the

slot’s access port ( usually at the back o f the cabinet). Sav e th e retaining

screw .

6. Plug the controller firmly into the PCI slot so that the controller’s

external connectors can be accessed through the access port. Use the

retaining screw to secure the controller by its mounting bracket.

☛

Note

Although the DAC1164P controller will operate very

well in a 32-bit PCI slot, a 64-bit PCI slot (if

available) is recommended fo r optimum per formance.

If the system board contains both 32-bit and 64-bit

PCI slots, the 64-bit slots are the longer ones.

7. Connect the cables from the disk array(s) to the drive channel port(s)

on the controller.

8. Look to confirm that all drive channels in use are properly terminated.

Safety check

9.

10. Reconnect the power.

11. Proceed to the next chapter.

775013 3-5

the installation.

Page 26

Installing the Controller

3-6 eXtremeRAID Installation Guide

Page 27

Chapter 4

Controller Start-up

This chapter describes:

• Start-up procedures

• BIOS options

• BIOS Configuration Utility

• Driver Installation

• What to check in case of problems

This chapter describes the DAC1164P controller start-up procedures and

messages produced by the BI OS during start -up or re-boot. This chapter also

explains three BIOS options that are available for configuring controller

operation.

Procedural Overview

The steps covered in this chapter include:

• Setting BIOS options

• RAID EzAssist (theBIOS configuration utility) – see the RAID

EzAssist Configuration Utility User Reference Guide (P/N 775029 ) for

configuration instructions and default control ler pa rameter definitions.

• Loading the operating system and operating system drivers – see the

Disk Array Controller Software Kit Installation Guide and User

Manual (P/N 771929) for installation instructions for operating system

drivers and the GAM server module.

• Installing Global Array Manager – see the Global Array Manager

Client Software Installation Guide and User Manual (P/N 771961) for

installation instructions for the GAM client.

775013 4-1

Page 28

Controller Start-up

Controller Start-up

The controller start-up procedure is the first step in confirming that the

controller is correctly install ed and w orking pr operly. The start-up procedure

should be performed prior to an y softw are conf i guratio n. There are tw o startup sequences: the BIOS Options sequence and the BIOS Configuration

Utility sequence. Either start-up sequence can be skipped by ignoring the

<ALT-M> and/or the <ALT-R> prompt when the computer is started up.

BIOS Options Sequence

After physically installing the controller and connecting the cabling, do the

following steps if you need to set or modify the BIOS options (see “Setting

BIOS Options” on page 4-3 for details:

1. Power on the computer.

2. Watch the messages on the screen for the following prompt to be

displayed:

Press <ALT-M> for BIOS options

3. Press Alt–M to get into the BIOS Options menu.

4. The BIOS Options menu provides the following items to choose from:

5. To select any of the items in the menu, highlight the selection with the

Up Arrow or Down Arrow. Press Enter to toggle any of the 3 items.

☛

Note

BIOS must be enabled to toggle the CD-RO M boot

and the Drive geometry parameters.

4-2 eXtremeRAID Installation Guide

Page 29

Controller Start-up

Setting BIOS Options

The available BIOS options are:

• BIOS disabled / enabled

• CD-ROM boot disabled / disabled

• 2GB / 8GB drive geometry

BIOS Disable or Enable

This option must be enabled in order to toggle the CD-ROM boot and the

drive geometry parameters shown in the BIOS Options menu. The BIOS

must also be enabled in order to boot from any device (e.g., CD-ROM) or

system drive configured on the controller, or to access any DOS partition on

any drive configured on the controller.

When BIOS Disable or Enable is selected, the following message will be

displayed. Pressing any key will restart the system.

CD-ROM Boot Disable or Enable

The default for this option is for the CD-ROM boot to be disabled (e.g., the

system will boot from a hard drive, even if there is a bootable CD installed.

If the CD-ROM boot option is enabled, and if a bootable CD is installed in

the CD-ROM drive, the system can boot from the CD.

If the CD-ROM boot option is enabled, the CD-ROM will take priority over

the disk drives. F or e x ample, u nder MS-DOS, the disk drive that is normally

Drive C will become Drive D. All subsequent drive IDs will similarly be

moved down.

775013 4-3

Page 30

BIOS Options Sequence

Enable 8GByte or 2GByte Drives

This setting affects how the BIOS reads the disk drives for the boot partition.

Drive geometries can be toggled between 8 GB and 2 GB. The default is 2

GB. When the drive geometry is changed, the drive should be formatted at

the operating system level.

m Caution

Changing this setting after da ta has been stored will

make the data unreadable. If you have already

configured your array and have stored data, you

should not change this setting.

The default BIOS geometry of the controller is set to 2 GB. Th is means that

the BIOS can only access the f irst 2 GB of any dri v e that has been conf igured

on the controller. This is adequate in most applications, since BIOS is only

used to boot the operating system. However, it does mean the operating

system must be installed in the first 2 GB of the capacity of the configured

drive. If this is not adequate, the BIOS geometry can be changed to 8 GB,

allowing the BIOS to access the first 8 GB of capacity.

As a rule of thumb, select 8 GB geometry if the following two cases apply:

1. You have a system (RAID) drive that is greater than 2.145 GB in

capacity.

2. The DOS/Windows compatible partitions could be located in an area

above the first 2.145 GB.

Otherwise the 2 GB option is fine.

4-4 eXtremeRAID Installation Guide

Page 31

Controller Start-up

☛

Note

In the event that the RAID controller needs to be

replaced, the current drive geometry will be restored

from the configuration on disk (COD).

Using RAID EzAssist

RAID EzAssist, the on-board BIOS Configuration Utility is used to build

several types of RAID configurations. Since this is a Quick Installation

Guide, only the Automatic Configuration option will be describ ed here.

The following limitations apply to Automatic C on figuration:

• Only one array will be configured using the Automatic Configuration

option.

• All drives being contro lled by the eXtremeRAID boar d can be diff erent

sizes, but will all be formatted to the size of the smallest disk controlled

by the eXtremeRAID board.

• A maximum of 7 drives can be configured into an array using

Automatic Configuration. Any additional drives will become hot

spares. The drives with the largest capacity (if mixed drive sizes are

used) will be the drives selected to become hot spares.

☛

Note

If you want to do anything other than an automatic

configuration, refer to the RAID EzAssist

Configuration Utility User Reference Guide.

To perform a RAID configuration with the Automatic Configuration option

using RAID EzAssist, do the following:

1. Power on the computer. The eXtremeRAID controller is furnished with

the BIOS enabled by default.

2. Watch the messages on the screen for the following prompt to be

displayed:

Press <ALT-M> for BIOS options

Wait approximately 5 seconds. Do not press any keys at this time.

775013 4-5

Page 32

Using RAID EzAssist

☛

Note

If the BIOS has been disabled on the controller, You

will need to press Alt–M to enable it (See your

controller’s Installation Guide for details).

3. Watch the messages on the screen for the following prompt to be

displayed:

Press <ALT-R> for RAID Configuration options

4. Press

☛

Alt–R

to get into RAID EzAssist (the configuration utility).

Note

For more detailed information on how to run RAID

EzAssist, refer to the RAID EzAssist Configuration

Utility User Reference Guide (P/N 775029), which is

included on the distribution CD-ROM.

4-6 eXtremeRAID Installation Guide

Page 33

Controller Start-up

Operating System

If an operating system is not already installed on the system, it can be

installed on a system disk on the controller. The operating system is installed

along with the operating system device drivers.

Operating System Device Drivers

Device drivers that are compatible with the controller can be found in the

Software Kit. For details on how to install and load drivers, refer to the

DAC960 Software Kit Installation Guide and User Manual (P/N 771929).

Global Array Manager (GAM)

The controller can be configured using GAM. GAM can also be used from

the server or a system client to monitor status and verify data integrity of

disks connected to the controller while the system and disks are running.

For details on how to install and run GAM, refer to the Global Array

Manager Client Softw are Installation Guide and User Manual

(P/N 771961). This manual can be downloaded at no cost from the Mylex

web site (www.mylex.com).

In Case of Problems

If problems are encountered during start-up, check the following:

• Check SCSI cabling for loose connections, pi n mismatches (make sure

pin 1 on the cable matches pin 1 on the connector), bent pins, and

damaged or crossed cables.

• Check cable length. This includes internal bus lengths in enclosures.

• Check termination.

• Check SCSI IDs on all drives.

775013 4-7

Page 34

In Case of Problems

4-8 eXtremeRAID Installation Guide

Page 35

Appendix A

Memory Module and

Battery Backup Unit

Figure A-1. DMM1100

Product Description

The Synchronous Dynamic Memory Module and Battery Backup Unit

(DMM1100) is a cache memory module that maintains data integrity in the

event of a power failure. The battery backup portion of this module monitors

the write back cache on the D AC1164P controller, and provides po wer to the

cache if it contains data not yet written to the drives when power is lost.

The controller, with the DMM1100 installed, together occupy only one PCI

slot on the host backplane.

Features

Some of the features of the DMM1100 include:

• Gas gauge circuit for battery charge monitoring

• Quick charge to replenish a drained battery

• SDRAM on the DMM1100 module

775013 A-1

Page 36

DMM1100 Operation

DMM1100 Operation

This DMM1100 consists of 16 MB, 32MB, or 64MB of SDRAM cache

memory, a rechargeable nickel-cadmium battery, a charging circuit, and

power monitoring circuitry. The controller is shipped with the DMM1100

installed, and will not function without it.

Battery Conditioning Prior to Use

Battery conditioning is automatic. There are no manu al procedures for

battery conditioning or preconditioning to be performed by the user.

Set-up – Enabling the Write-Back Cache

Maximum RAID performance is achieved when the cache is in write-back

mode. The write-back cache is enabled by toggling the write-back/writethrough mode switch. The write-back/write-through mod e switch is accessed

using RAID EzAssist (the BIOS Configuration Utility), or in GAM. Refer to

the

RAID EzAssist Configuration Utility User Reference Guide

Array Manager Client Softw are Installation Guide and User Manual

instructions on how to examine and change the mode switch.

Battery Backup Capacity

The battery backup’s capacity varies with the cache memory capacity used.

In the event of a power failure, the battery backup can be expected to

maintain cache data integrity for the periods of time shown in Table A-1.

Table A-1. Battery Backup Capacity

Memory Size Approximate Battery Charge Life

64MB 48 hours

32MB 72 hours

16MB 72 hours

or the

Global

for

Maintenance

No maintenance is required. It is recommended that the DMM1100 charge

level be periodically checked using the Gas Gauge function in GAM (see the

Global Array Manager Client Software Installation Guide and User

Manual

A-2 eXtremeRA ID Insta l la tion Gui de

).

Page 37

Memory Module and Battery Backup Unit

Removing the DMM1100

The DMM1100 only needs to be removed if the NiCd battery no longer

accepts a charge properly (NiCd battery life expectancy is approximately 5

years), or if the DMM1100 is being salvaged from a controller that has

failed.

, WARNING

Replace the battery only with the same or

equivalent type of battery recommended by the

battery manufacturer. Dispose of used batteries as

described under “Recycling the Battery” on page

A-5.

DMM1100 Functional Description

Whenever the system is running, the DMM1100’ s battery backup circuitry is

standing by, monitoring the voltage level of VCC. In the event of a power

failure, the VCC voltage level will begin to drop. When the battery backup

circuitry detects this voltage drop, it checks the status of the disk cache. If

the cache is empty, the battery backup circuitry does nothing.

If the cache contains data during a power failure, the DMM1100’s battery

backup circuitry will maintain cache data integrity until the power is

restored. When power is restored and the system finishes the bootstrap

process, the cache contents will be written to the disk array. The cache

contents will then be flushed from the cache.

Status Indication

The status of the battery can be checked with the gas gauge feature that can

be accessed in GAM (version 2.1x or greater is needed). The gas gauge

appears on the screen as two meters— a battery power meter and a charge

level meter— each calibrated from 0 to 100.

The battery power meter indicates the battery capacity in hours. It will

indicate a charge duration of up to 100 hours. The firmware will detect the

memory and assign a value based upon the ch arge le v el of the battery and the

power consumption rate of the memory.

The charge level meter displays the charge state of the battery expressed in

percent (100% indicates a fully charged battery).

775013 A-3

Page 38

DMM1100 Functional Description

When the meter on the right indicates the battery is fully charged, the meter

on the left will indicate the maximum time in hours (approximately 48 hours

for a 64MB cache or 72 hours for a 32MB or 16MB cache) that the battery

can be expected to maintain cache data integrity.

☛

Note

When the charge level is 100%, the

and

hours

below the left dial) will be equal.

maximum number of hours

current numb er of

(printed out

A-4 eXtremeRA ID Insta l la tion Gui de

Page 39

Memory Module and Battery Backup Unit

Battery and Charge Circuit

On-board Battery

The on-board battery is rated at 3.6 v with a capacity of 650 mAH. The

DMM1100 has a DC-DC converter that converts 3.6 v to 3.3 v, which is the

nominal voltage required for the cache.

Battery Charger

Battery charging and conditioning are automatically han dled by the

DMM1100. No manual preconditioning needs to be performed by the user.

If the battery capacity falls below a predetermined level (which is likely to

happen after a power failure), the battery charger goes into a quick charge

mode. If the battery is fully charged, the charger goes into a trickle charge

mode.

Recycling the Battery

The on-board battery that comes with the DMM1100 has the logo of the

Rechargeable Battery Recycling Corporation (RBRC) stamped on it. The

logo means that recycling fees have been prepaid on this battery pack.

m Caution

Do not dispose of a rechargeable battery with regular

trash in a landfill. Rechargeable batteries contain

toxic chemicals and metals that are harmful to the

environment. Improperly disposing of rechargeable

batteries is also illegal.

Figure A-2. RBRC Logo

The RBRC is a non-profit corporation that promotes the recycling of

rechargeable batteries, including nickel-cadmium batteries.

Information on the RBRC program and the locations of partici pating

recycling centers can be obtained by telephoning 1–800–8–BATTERY (in

the USA), and following the recorded instructions. The information obtained

from this telephone number is updated frequently, since the RBRC program

is growing, and new recycling locations are being added regularly.

775013 A-5

Page 40

DMM1100 Specifications

DMM1100 Specifications

On-board Battery

Electrical Properties

• 3 NiCd 1.2 V, 650 mAH cells, connected in series for a total of 3.6V

at 650mAH

Physical Description

• Nominal pack size (in inches): 1.89(L) X 2.01(W) X 0.33 (H)

Battery Charge Life

Approximately 48 hours with 64MB SDRAM

Approximately 72 hours with 32MB or 16MB SDRAM

Cache Memory

16MB, 32MB, or 64MB SDRAM

Module Dimensions

Length: 3.625 inches

Width: 4.0 inches

Environmental

Temperature Operating: 0ºC to +50ºC

(+32ºF to 122ºF)

Storage: -40ºC to +60ºC

(-40ºF to +140ºF)

Humidity Operating: 45% to 85%

relative humidity (non-condensing)

Non-operating: 45% to 85%

relative humidity (non-condensing)

Warranty

3-Year, Limited

A-6 eXtremeRA ID Insta l la tion Gui de

Page 41

Appendix B

DAC1164P Specifications

General Hardware Specifications

eXtremeRAID 1164

Controller DAC1164P

CPU StrongARM™ 32-bit microprocessor, 233MHz

Memory SDRAM, 16MB, 32MB, or 64MB installed on a module

Cache Write: Selectable, Write Through or Write Back

Firmware ROM Type, Flash EEPROM, 1MB x 8

PCI 64-bit or 32-bit PCI at 33MHz, 3.3v or 5v.

SCSI Supports 3 Symbios Ultra2 LVD SYM53C895

containing a battery with backup circuitry for power fail

protection of data

Error Protection: Parity

PCI to Ultra2 SCSII I/O Processors

775013 B-1

Page 42

Environmental Specifications

Environmental Specifications

Controller DAC1164P

Temperature Operating 0°C to +55°C (+32°F to 131°F)

Storage -20°C to +70°C (-4°F to +158°F)

Humidity Operating 10% to 90% relative humidity (non-condensing)

Storage 10% to 90% relative humidity (non-condensing)

Altitude Operating Up to 3,048m (10,000 ft )

Storage Up to 15,240m (50,000 ft)

Form Factor Length: 12.280 inches

Width: 4.750 inches

Maximum.

Maximum

Power

Consumption

Component

Height:

at 5.25v

at 4.75v

0.105 inches on the solder side of the board

0.570 inches on the component side of the board

1.90A (9.98W) with 64MBytes SDRAM

1.85A (8.79W) with 64MBytes SDRAM

MTBF 244,547 hours at 55°C

B-2 eXtremeRAID Installation Guide

Page 43

Appendix C

DAC1164P Error Messages

Error Messages

Start-up Error Messages

The BIOS looks for any initialization message posted by the firmware during

the start-up sequence. If a message is found, one of the following errors

displays on screen and the installation process aborts.

DAC1164Pn fatal error--memory test failed

n

DAC1164P

DAC1164P

error

DAC1164P

Drive Check Error Messages

If the firmware finds a v alid controller configuration, b ut it doesn't match the

SCSI drives currently installed, one or more of the following messages

display:

Unidentified device found at channel x....

Device identified for chn

SCSI device at chn

If any of the above messages are displayed, the firmware will not proceed

any further in the initialization process, except to find other mismatches.

Then, the BIOS prints out the following:

DAC1164Pn Configuration Checksum error--run configuration

utility

If the firmware detects that during the last po wer c ycle the system was tu rned

off abruptly leaving some incomplete write operations, the following

message appears:

Recovery from mirror race in progress

The following messages may also appear:

Adapter cannot recover from mirror race!

fatal error--command interface test failed

n

hardware error--run diagnostics to pinpoint

n

firmware checksum error--reload firmware

x

, tgt y found at chn x', tgt y'

x

, tgt y not responding

775013 C-1

Page 44

Aborted Installation

Some system drives are inconsistent!

During the initialization, if the firmware fails to respond to the BIOS inquiry

within two minutes, the following message displays:

DAC1164Pn not responding--no drives installed.

The BIOS then inquires the firmware for its version number and other

information, and prints out the following message:

DAC1164Pn firmware version

x.xx

One or more of the following messages will be displayed if the firmware

reports the following conditions:

Warning: X system drives are offline

Warning:

Warning: The following SCSI devices are dead--chn

, tgt y...

x

No system drives found: None installed

system drives installed

X

system drives are critical

X

The BIOS repeats the same process for additional RAID controllers present

in the system. Then it proceeds to boot, if possible, from the first system

drive on the first controller.

Aborted Installation

With Firmware 5.x, the installation aborted message is displayed when the

BIOS finds that the configuration of the disk drives, as stored in the

NVRAM and configuration on disk, is different from what it senses at boot

time. When this happens, (and a brand new installation is not being

attempted) the cause is often a faulty cable or drive, or a loose connection.

Check all of the connectors, cables, drives, and try to boot. If the error

persists, it most likely indicates a genuine failure and needs to be corrected.

To correct it, boot and run the on-board BIOS Configuration Utility, RAID

EzAssist (see Chapter 4). For more information, refer to the RAID EzAssist

Configuration Utility User Reference Guide (P/N 775029).

C-2 eXtremeRAID Installation Guide

Page 45

DAC1164P Error Messages

NVRAM Error

With Firmware 5.x, if the BIOS displays a mismatch between the NVRAM

and the Configuration on Disk (COD), no drives will be installed. Normally

this error will not be displayed. If it is, boot and run RAID EzA ssist, the onboard Mylex Disk Array Configuration Utility (see Chapter 4). to recover

from the error . For more information, ref er to the RAID EzAssist Installation

Guide and User Manual.

System Reboot or Power Down

Status messages may also be av ailable from LE D indicators connected to th e

controller. Th e Cache Dirty indicator is especially imp ortant when preparin g

to power-do wn the system.

The DAC1164P controller is a caching controller with 16MB, 32MB, or

64MB of cache memory, data may still be in the cache waiting to be written

to the disk drives, when the system reports that a write command was

completed. It is very important to make sure that all data is written to the

disk before rebooting or powering down t h e sy st em, or you may lose data. It

is always a good idea t o wa it fo r 15 secon ds befo re re setting or rebooti ng th e

system.

If using the 'Cache Dirty' LED indicator, wait 3 seconds after the LED has

gone off before resetting or rebooting the system (the cache battery backup

may also be used to prevent data loss).

775013 C-3

Page 46

System Reboot or Power Down

C-4 eXtremeRAID Installation Guide

Page 47

Appendix D

PCI Hot Plug

Introduction

PCI Hot Plug is a feature that allows a PCI ca rd to be replaced while the host

system is still running. The term “Hot Plug” is somewhat misleading; the

PCI card cannot simply be pulled out of the host system while the card is

operating without risk to the card, the system, and the data on the system.

In order to replace a Hot Plug PCI card, a software command must be

invoked to power off the card slot before the card can be removed. After the

software indicates that the card is unloaded and the slot is powered off, a

physical card retainer/switch must be released to allow the card to be

removed from the PCI bus. At this point, the card can be replaced.

At this time, Mylex only supports Hot Replacement of PCI Hot Plug cards.

Future releases are planned to support Hot Upgrade or Hot Expansion

(adding a card).

Implementation

Aside from the general terms previously mentioned, PCI Hot Plug

implementation is specific to the host hardware platform and the operating

system running on it. R e fer to your host system's documenta ti on for s peci fic

details on how to implement PCI Hot Plug.

NetWare

When NetWare is installed on a system capable of PCI Hot Plug, the

following four modules are installed:

• cpqsbd.nlm - This is the Compaq system bus driver (a different driver

will be needed for a platform other than Compaq).

• ncm.nlm - This is the Novell Configuration Manager, which manages

the PCI Hot Plug system.

• ncmcon.nlm - This is the Hot Plug user interface called the Novell

Configuration Manager Console.

775013 D-1

Page 48

Implementation

• odineb.nlm - This is a module combining the Open Data-link interface

and the Novell Event Bus (NEB). The NEB controls the device drivers

through the Open Data-link.

If the NetWare installation process determines that the server supports PCI

Hot Plug and detects the appropriate driver, the installation process adds the

following two LOAD commands to the autoexec.ncf file:

• LOAD sys:\system\driver_name

This command loads the bus driver (for Compaq, this is cpqsbd.nlm).

After this command is executed, NetWare autoloads ncm.nlm.

• #LOAD sys:\system\ncmcon.nlm

This command loads the Novell Configuration Manager Console,

which then loads odineb.nlm. These command s can also be ex ecuted at

the server console prompt.

☛

Note

This command is commented out. If you want the

Configuration Manager Console to be loaded every

time the system is started, remove the pound sign (#)

at the beginning of the line.

Perform the following steps:

1. Install NetWare 5 Service Patch 1.

2. Install the Mylex GAM DMI driver.

3. Restart the server. The autoexec.ncf will execute and it will load the

drivers and start ncmcon.nlm (the PCI Hot Plug user interface).

☛

Note

If any LOAD line is commented out in autoexec.ncf,

the corresponding driver can be loaded manually by

executing the LOAD command (as listed in

autoexec.ncf) at the server console prompt.

D-2 eXtremeRAID Installation Guide

Page 49

PCI Hot Plug

Windows NT

Windows NT requires additional software from the vendor who makes the

system. Since this software is not a part of NT, the software needs to be

installed after the operating system is loaded. Refer to your vendor's PCI Hot

Plug documentation.

m Caution

GAM drivers can stop PCI Hot Plug Boards from

unloading. If this problem occurs, stop GAM and

unload the GAM drivers before attempting to unload

the PCI Hot Plug controller.

Known Windows NT Issues

• Mylex Software Kit 2.1 or greater is required to support your system

vendor’s PCI Hot Plug utility.

•The macdisk.sys driver should not be loaded with a Mylex PCI Hot

Plug board; if macdisk.sys is loaded the system will hang upon

shutdown.

• When you install a Mylex card as a boot device and a Mylex Driver has

been installed prior to the installation of the Windows NT OS, NT will

not recognize the Mylex card as a PCI Hot Plug device. To fix this, the

driver must be reinstalled, and the system rebooted.

This problem occurs because PCI Hot Plug information does not get

loaded into the Windows NT registry for the Mylex controller upon

installation of Windows NT.

775013 D-3

Page 50

Implementation

D-4 eXtremeRAID Installation Guide

Page 51

Appendix E

Enclosure Management

Introduction

Mylex’s eXtremeRAID controllers support the industry standard enclosure

management protocol SCSI Accessed Fault-Tolerant Enclosures (SAF-TE).

This feature allows the host to monitor drive enclosures and detect certain

faults or operating environment conditions. The host can make a decision to

shut down the system or issue a warning based on the type of fault detected.

SAF-TE

The SAF-TE protocol follows a specification jointly worked out by nStor

Corporation and Intel Corporation. Enclosur es that are compliant with this

protocol are known as SCSI Acces sed F ault -Tolerant Enclosures (SAF-TE).

The protocol is compatible with standard SCSI buses and cabling.

The SAF-TE interface standard’s objective is to provide a non-proprietary

means of allowing third-party disks and controllers to be automatically

integrated with peripheral enclosures that support:

• Status Signals (LEDs, audible alarms, LCDs, etc.)

• Hot swapping of drives

• Monitoring of fans, power supplies, and enclosure temperature

SCSI is the underlying transport mechanism for communicating enclosure

information. All standard SCSI host adapters will work. There is n o need to

consider reserved signals or special cabling.

The SAF-TE interface can be implemented as a SCSI target that uses a SCSI

port and an 8-bit microcontroller.

All communication is initiated by the host. The SAF-TE processor acts only

in target mode. The SAF-TE processor should be periodically polled by the

host approximately every 2 to 10 seconds.

775013 E-1

Page 52

StorageWorks

StorageW orks

The eXtremeRAID 1100 supports Compaq StorageWorks™ enclosure

management. Refer to the documentation supplied with your StorageWorks

enclosure for details on how to take advantage of this feature.

E-2 eXtremeRAID Installation Guide

Page 53

Appendix F

Regulatory Information

Class B Compliance

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION

IS SUBJECT TO THE FOLLOWING TWO CONDITIONS:

4. THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE, AND

5. THIS DEVICE MUST ACCEPT ANY INTERFERENCE RECEIVED,

INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED

OPERATION.

All external connections should be made using shielded cables.

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC rules. These limits are designed to

provide reasonable protection a gainst harmful interference in re sidential installations.

This equipment generates, uses, and can radiate radio frequency energy, and if not

installed and used in accordance with the instructions , may cause harmful interferen ce

to radio communications. However, there is not guarantee that interference will not

occur in a particular installation.

If this equipme nt do e s cause interferen ce to rad i o or television equi pm e nt rec e ption,

which can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one or more of the following measures:

1. Reorient or relocate the receiving antenna

2. Move the equipment away from the receiver

3. Plug the equipment into an outlet on a circuit different from that to which the

receiver is powered.

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions.

m Caution

Only equipment certified to comply with Class B

(computer input/output devices, terminals, printers,

etc.) should be attached to this equipment.

Any changes or modif ications to the equipm ent by the

user not expressly approved by the grantee or

manufacturer could void the user’s authority to

operate such equipment.

775013 F-1

Page 54

Declaration of Conformity

Per FCC Part 2, Section 2.1077(a)

Manufacturer’s Name:Mylex Corporation

Manufacturer’s Address:34551 Ardenwood Blvd.

Fremont, CA 94555-3607

USA

Declares that the product:

Product Name:High Performance RAID Controller

Model Number(s):DAC1164P-xx

Year of Manufacture:1998

Conforms to the following Product Specification(s):

FCC:CFR 47 Part 15, Subpart B, Section 15.107(e) and Section 15.109(g)

Class B Digital Device tested per ANSI C63.4–1992 procedures

Supplementary Information:

This device complies with part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause und e sired operation.

F-2 eXtremeRAID Installation Guide

Page 55

Regulatory Information

Declaration of Conformity

Per 89\336\EEC

Responsible Party

Name: Mylex Corporation

Address: 34551 Ardenwood Boulevard

Fremont, CA 94555-3607 USA

hereby declares that the product

Trade Name: High Performance Caching RAID Controller

Model Number: DAC1164P-3E Fab. 550137-A Rev. A

conforms to the following specifications

Standards: EN 50081-1:1992, EMI

EN 55022 Class B (Radiated), Class B (Conducted)

EN 50082-1:1992, Immunity

EN 61000-4-2:1995 Electrostatic Discharge

EN 61000-4-3:1996 Radiated Susceptibility

EN 61000-4-4:1995 Electrical Fast Transients/Burst

775013 F-3

Page 56

Community of Europe

CE mark is rated for the eXtremeRAID as follows:

CISPR 22 Radiated Emission

EN55022, EN5082-1 Generic immunity standard for the following:

IEC 801-2 ESD, IEC 801-3 Radiated, and IEC 801-4 EFT/Burst

Warning!

This is a Class B product. In a residential environment this pro duc t may cause radio

interference, in which case the user may be required to take adequate measures.

Achtung!

Dieses ist ein Gerät der Funkstörgrenzwertk lasse B. In Wohnbereichen können bei

Betrieb dieses Gerät es Rundfunkstörungen aufreten, in welche n Fällen der Benutzer

für entsprechende Gegenmaßnahmen verantwortlich ist.

Avertissement!

Cet appareil est un appareil de Classe B. Dans un environnement résidentiel cet

appareil peut provoquer des brouillages radi oélectriques. Dans ce cas, il peut être

demandé à l’utilisateur de prendre des mésures appropriées.

F-4 eXtremeRAID Installation Guide

Page 57

Regulatory Information

Underwriters Laboratories Statement and Warning

, WARNING

This controller is furnished with a nonvolatile

RAM (NVRAM) chip that uses a sealed lithium

battery/crystal module. Replace the module only

with the same or equivalent type recommended by

the manufacturer. Dispose of the used battery/

crystal module according to the manufacturer's

instructions. Never incinerate a battery as it could

explode and cause serious injury.

775013 F-5

Page 58

F-6 eXtremeRAID Installation Guide

Page 59

Glossary

Cache

Controller memory used to speed up data transfer to and from a disk.

Cache Flush

Refers to an operation where all unwritten blocks in a Write-Back Cache are

written to the target disk. This operation is necessary before powering down

the system.

Cache Line Size

The Cache Line Size function is set in conjunction with stripe size and

represents the size of the data “chunk” that will be read or written at one

time. Under RAID EzAssist, the cache line size (also known as “segment

size”) should be based on the stripe size you selected. The def ault cach e line

size for Mylex eXtremeRAID controllers is 8K.

Channel

Refers to one SCSI bus on a disk array controller. Each disk array controller

provides at least one channel.

Consistency Check

Refers to a process where the integrity of redundant data is verified. For

example, a consistency check of a mirr ored dri ve will make sure th at the data

on both drives of the mirrored pair is exactly the same. For RAID Level 3 or

RAID Level 5, a consistency check makes sure that all parity data is correct.

Disk Failure Detection

The controller automatically detects SCSI disk failures. A monitoring

process running on the controller checks, among other things, elapsed time

on all commands issued to disks. A time-out causes the disk to be “reset”

and the command to be retried. If the command times out again, the disk

775013 G-1

Page 60

could be “killed” (taken “offline”) by the controller (its state changed to

“dead”). DAC1164 controllers also monitor SCSI bus parity errors and other

potential problems. Any disk with too many errors will also be ‘killed’.

Disk Media Error Management

DAC1164 controllers transparently manage SCSI disk media errors. Disks

are programmed to report errors, e v en ECC- recoverable errors. If ECC EDO

RAM is installed, the controller will correct ECC errors.

When a disk reports a media error during a read, the co ntroller reads the data

from the mirror (RAID 1 or 0+1), or computes th e data from the other blocks

(RAID 3, RAID 5), and writes the data back to the disk that encountered the

error. If the write fails (media error on write), the controller issues a

“reassign” command to the disk, and then writes the data to a new location.

Since the problem has been resolved, no error is reported to the system.

☛

Note

The soft error counter is incremented in this case. The

soft error count can be viewed using the Mylex disk

array configuration utilities.

When a disk reports a media error during a write, the controller issues a

“reassign” command to the di sk, and wri tes th e data out to a ne w locat ion on

the disk.

Drive Groups (or Drive Packs)

A group of individu al disk drives (preferably iden tical) that ar e logically tied

to each other and are addressed as a single unit. In some cases this may be

called a drive “pack ” when refer ring to just the p hysical devices. Up to eight

(8) drives can be configured together as one drive group.

All the physical devices in a drive group should have the same size,

otherwise each of the disks in the group will effectively have the capacity of

the smallest member. The total size of the drive group will be the size of the

smallest disk in the group multipli e d by the number of disks in the group.

For example, if you have 4 disks of 400MB each, and 1 disk of 200MB in a

pack, the effective capacity available for use is only 1000MB (5*200), not

1800MB.

G-2 eXtremeRA ID Insta l la tion Gui de

Page 61

Glossary

Hot Replacement of Disks (Hot Swap)

The design of the DAC1164 controllers allows for the replacement of failed

hard disk drives without interruption of system service. In the event of a

SCSI drive failure on a properly configured system (where the data

redundancy features of the controller are used), system service continues

without interruption. A message is generated by the system to alert th e

system operator.

When a replacement drive becomes available, the system operator can

remove the failed disk drive, install a new disk drive, and instruct the

controller to “rebuild” the data on the new drive, all without interrupting

system operations.

Once the rebuild is complete, the controller will be brought back into a fault

tolerant state.

Logical Drive States

The state of a logical (system) drive can be either ONLINE, CRITICAL, or

OFFLINE. Notice that the same term “online” is used for both physical and

logical drives.

Online: A Logical Drive is in an “online” state if...

All of its participating SCSI drives are “online.”

Critical: A Logical Drive is in a “critical” state if...

It has been configured at RAID le vel 1, 3, 5, or 0+1; and

One (and only one) of its SCSI drives is not “online.”

A logical drive is considered “critical” because any failure of another of its

SCSI drives may result in a loss of data.

☛

Note

I/O operation can only be performed with system

drives that are online or critical.

775013 G-3

Page 62

Offline: A Logical Drive is in an “offline” state if...

No data can be read from it or written to it.

System commands issued to offline logical drives are returned with an error

status: no operations can be performed on offline logical drives. A logical

drive can be “offline” under one of two situations described below:

• It is configured with a redundant RAID level (1, 3, 5, or 0+1), and two

or more of its SCSI drives are not “online”; or

• It is configured at RAID level 0, JBOD, or in a spanned set, and one or

more of its SCSI drives are not “online.”

Logical Drives

See “System Drives.”

Mirroring

Refers to the 100 percent duplication of data on one disk drive to another

disk drive. Each disk will be the mirror image of the other.

Pack

See “Drive Groups (or Drive Packs).”

Parity

See “Rotated XOR Redundancy.”

G-4 eXtremeRA ID Insta l la tion Gui de

Page 63

Glossary

RAID

RAID stands for Redundant Array of Independent Disks. The DAC1164

controllers implement this technology to connect up to 15 SCSI devices per

channel. Several different forms of RAID implementation have been

defined. Each form is usually referred to as a “RAID level.” All the RAID

levels supported by DAC1164 controllers are shown below.

The appropriate RAID level for a system is selected by the system manager

or integrator. This decision will be based on which of the following are to be

emphasized:

Disk Capacity

Data Availability (redundancy or fault tolerance)

Disk Performance

RAID Levels

The disk array controllers monitored by this utility support four RAID

Advisory Board-approved (RAID 0, RAID 1, RAID 3, RAID 5) and two

special RAID levels (RAID 0+1, and JBOD).

Level 0.

Block “striping” across mul tip le drives is provided, yielding higher

performance than is possible with individual drives. This level does not

provide any redundancy.

Level 1.

Drives are paired and mirrored. All data is 100 percent duplicated

on a drive of equivalent size.

Level 3.

Data is “striped” across several physical drives. Maintains parity

information which can be used for data recovery.

Level 5.

Data is “striped” across several physical drives. For data

redundancy, drives are encoded with rotated parity.

Level 0+1.

Combines RAID 0 striping and RAID 1 mirroring. This level

provides redundancy through mirroring. (Mylex RAID 6)

JBOD.

Sometimes referred to as “Just a Bunch of Drives.” Each drive is

operated independently like a normal disk controller, or drives may be

spanned and seen as a single drive. This level does not provide data

redundancy. (Mylex RAID 7)

775013 G-5

Page 64

Level 10.

multiple drive groups (super drive group). This level provides redundancy

through mirroring.

Combines RAID 0 stri ping and RAID 1 m irror in g spann ed acros s

Level 30.

Maintains parity information which can be used for data recovery.

Level 50.

For data redundancy, drives are encoded with rotated parity.

Data is “striped” across multiple drive groups ( super dri ve group ).

Data is “striped” across multiple drive groups (super drive group).

☛

Note

The host operating system drivers and software

utilities remain unchanged regardless of the level of

RAID installed. The controller makes the physical

configuration and RAID level implementation

Replacement Table

A replacement table contains information regarding which SCSI devices

have been replaced by others through standby replacement.

Rotated XOR Redundancy

This term (also known as “parity”) refers to a method of providing complete

data redundancy while requiring only a fraction of the storage capacity of

mirroring. In a system configured under RAID 3 or RAID 5 (which require

at least three SCSI dri v es ), all da ta and parit y blocks are di vi ded betw een the

drives in such a way that if any single drive is removed (or fails), the data on

it can be reconstructed using the data on the remaining drives. (XOR refers

to the Boolean “Exclusive-OR” operator.) In any RAID 3 or RAID 5 array,

the capacity allocated to redundancy is the equivalent of one drive.

SCSI Drive

A disk drive equipped with a SCSI interface (sometimes referred to as a

SCSI Disk). Each disk drive will be assigned a SCSI address (or SCSI ID),

which is a number fro m 0 to 7 (0 to 15 u nder wide or Ultra SCSI) . T he S C SI

address uniquely identifies the drive on the SCSI bus or channel.

G-6 eXtremeRA ID Insta l la tion Gui de

Page 65

Glossary

SCSI Drive States

Refers to a SCSI driv e’ s cu rrent operational statu s. At any gi ven time, a SCSI

drive can be in one of f i ve states: READY , ONLINE, STANDBY, DEAD, or

REBUILD.

The controller stores the state of the attached SCSI drives in its non-volatile

memory. This information is retained even after power-off. Hence, if a SCSI

disk is labeled DEAD in one session, it will stay in the DEAD state un til a

change is made either by using a system level utility or after a rebuild. Each

of the states is described below:

Ready: A SCSI disk drive is in a “ready” state if it...

Is powered on; and

Is available to be configured during the current session but remains

unconfigured.

Online: A SCSI disk drive is in an “online” state if it...

Is powered on; and

Has been defined as a member of a drive group; and

Is operating pr operly.

Standby: A SCSI disk drive is in a “standby” state if it...

Is powered on; and

Is able to operate properly; and

Was NOT defined as part of any drive group.

Dead: A SCSI disk drive is in a “dead” state if it...

Is not present; or

If it is present but not powered on; or

If it failed to operate properly and was ‘killed’ by the controller.

When the controller detects a failure on a disk, it “kills” that disk by

changing its state to “dead.” A SCSI drive in a dead state does not participate

in any I/O activity. No commands are issued to dead drives.

775013 G-7

Page 66

Rebuild: A SCSI disk drive is in a “rebuild” state...

While it is in the process of being rebuilt. During this process, data is

regenerated and written to the disk drive. This state is also referred to as

‘Write-Only’ (WRO).

Segment Size

See “Cache Line Size.”

Session

Refers to the period of time between any two consecutiv e system shutdowns.

System shutdown may be either a power off/on, or a hardware reset.

Standard Disk Drive

This term refers to a hard disk drive with SCSI, IDE, or other interface, that

is attached to the host system through a standard disk controller.

Standby Replacement of Disks (“Hot Spare”)

The “Standby Replacement” (or “Hot Spare”) is one of the most important

features the controller provides to achie ve automatic, n on-stop service with a

high degree of fault-tolerance. The rebuild operation will be carried out by

the controller automatically when a SCSI disk drive fails and both of the

following conditions are true:

• A “standby” SCSI disk drive of identical size is found attached to the

same controller;

• All of the system drives that are dependent on the failed disk are

redundant system drives, e.g., RAID 1, RAID 3, RAID 5, RAID 0+1.

G-8 eXtremeRA ID Insta l la tion Gui de

Page 67

Glossary

A “Standby” disk can be created in one of two ways:

3. When a user runs RAID EzAssist, all disks attached to the controller

that are NOT configured into any drive group will be automatically

labeled as “standby” drives.

3. A disk may also be added (attached at a later time) to a r unn ing system

and labeled as standby by using the “DAC1164 Software Kit” (see

appropriate chapters for DAC1164 utilities for a particular operating

system).

During the automatic rebuild process, system activity continues as normal.

System performance may degrade slightly during the rebuild process.

☛

Note

The standby rebuild will only happen on the SAME

DAC1164 controller, never across DAC1164

controllers.

To use the standby rebuild feature, you should always maintain a standby

SCSI disk in your system. When a disk fails, the standby disk will

automatically replace the failed driv e and the d ata will be rebuilt. The system

administrator can disconnect and remove the bad disk and replace it with a

new disk. The administrator can then make this new disk a standby.

Stripe Order

The order in which SCSI di sk drives appear within a drive group. Thi s or der

must be maintained, and is critical to the controller’s ability to ‘Rebuild’

failed dri ves.

Stripe Size