Page 1

InterServe 9000

System Setup

October 1998

DHA031200

Page 2

Copyright

1998 Intergraph Computer Systems. All rights reserved. This document contains information protected by copyright, trade secret, and

trademark law. This document may not, in whole or in part, be reproduced in any form or by any means, or be used to make any derivative work,

without written consent from Intergraph Computer Systems.

Use, duplication, or disclosure by the United States Government is subject to restrictions as set forth in subdivision (c)(1)(ii) of the rights in

technical data and computer software clause at DFARS 252.227-7013. Unpublished rights are reserved under the copyright laws of the United

States.

Intergraph Computer Systems, Huntsville AL 35894-0001

Notice

Information in this document is subject to change without notice and should not be considered a commitment by Intergraph Computer Systems.

Intergraph Computer Systems shall not be liable for technical or editorial errors in, or omissions from, this document. Intergraph Computer

Systems shall not be liable for incidental or consequential damages resulting from the furnishing or use of this document.

All warranties given by Intergraph Computer Systems about equipment or software are set forth in your purchase contract. Nothing stated in, or

implied by, this document or its contents shall be considered or deemed a modification or amendment of such warranties.

Trademarks

Intergraph Computer Systems and the Intergraph Computer Systems logo are registered trademarks of Intergraph Computer Systems. InterServe

is a trademark of Intergraph Computer Systems.

Other brands and product names are trademarks of their respective owners.

FCC/DOC Compliance

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a residential installation.

This equipment generates, uses, and can radiate radio frequency energy. If the equipment is not installed and used in accordance with the

instructions, it may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on,

try to correct the interference as follows: reorient or relocate the affected device; increase the separation between this equipment and the

affected device; connect this equipment to an outlet on a circuit different from the circuit to which the affected device is connected; consult a

dealer or an experienced radio/television technician for help.

This Class B digital apparatus meets all requirements of the Canadian Interference-Causing Equipment Regulations. Cet appareil numérique de

la classe B respecte toutes les exigencies du Règlement sur le materiél brouilleur du Canada.

Warnings

To comply with FCC Class B limits, you must use shielded cables with this device.

Changes or modifications made to the system that are not approved by the party responsible for compliance could void the user's authority to

operate the equipment.

To reduce the risk of electrical shock, do not attempt to open the equipment unless instructed. Do not use a tool for purposes other than

instructed.

There is a danger of explosion if the battery is incorrectly replaced. Replace the battery only with the same or equivalent type as recommended

by the manufacturer. Dispose of used batteries according to the manufacturer's instructions.

Notes

Read all operating instructions before using this device. Keep these instructions for future reference. Follow all warnings on the device or in the

operating instructions.

This device is designed and manufactured to comply with approved safety standards for information processing and business equipment.

Page 3

Contents

Preface................................................................................................................................v

About This Document.......................................................................................................... v

Document Conventions........................................................................................................ v

Operating System Information ............................................................................................. v

Hardware Information......................................................................................................... vi

Ergonomic Information...................................................................................................... vii

Customer Support.............................................................................................................. vii

1 Setting Up the Hardware............................................................................................... 1

Before You Begin................................................................................................................ 2

Unpacking the Equipment.................................................................................................... 3

Placing the System............................................................................................................... 4

Setting Up a Deskside System.............................................................................................. 5

Setting Up a Rack-mount System......................................................................................... 6

Prepare the Equipment Rack................................................................................................ 7

Prepare the System............................................................................................................. 11

Installing the System into a Rack ....................................................................................... 14

Connecting the Cables ....................................................................................................... 15

Installing Non-RAID and RAID Disk Drives ..................................................................... 17

Checking the System.......................................................................................................... 21

What’s Next?..................................................................................................................... 22

iii

Hardware and Software Support Services............................................................. vii

World Wide Web................................................................................................. vii

Intergraph Bulletin Board Service ........................................................................ vii

FAXLink.............................................................................................................viii

Telephone ........................................................................................................... viii

More Support Options........................................................................................... ix

Safety Guidelines................................................................................................... 6

Tools You Need..................................................................................................... 7

Install and Label the Disk Drives ......................................................................... 18

Additional Information......................................................................................... 21

2 Setting Up the Software............................................................................................... 23

Preparing for Setup............................................................................................................ 24

Pre-Installed Software.......................................................................................... 24

Before You Start Setup......................................................................................... 24

Starting the System............................................................................................................ 26

Starting Operating System Setup........................................................................................ 26

Finishing Operating System Setup ..................................................................................... 27

Creating an Emergency Repair Disk..................................................................... 27

Creating System Software Backup Diskettes......................................................... 28

What’s Next?..................................................................................................................... 28

Page 4

iv

3 Configuring the System................................................................................................ 29

Configuring the Video Display........................................................................................... 30

Changing the Default Video Display Driver ......................................................... 30

Correcting Video Display Problems...................................................................... 30

Installing Mylex RAID Software........................................................................................ 31

Configuring Drives for a RAID Disk Array........................................................................ 32

Standard RAID Disk Drives Configuration........................................................... 32

Additional RAID Disk Drives Configuration........................................................ 35

Installing and Configuring LanSafe UPS Software............................................................. 36

Installing QFE Update Software......................................................................................... 37

Installing Intel Server Control (ISC) Software.................................................................... 37

Creating an Emergency Repair Disk .................................................................................. 37

Getting Operating System Updates..................................................................................... 37

4 Operating Notes ........................................................................................................... 39

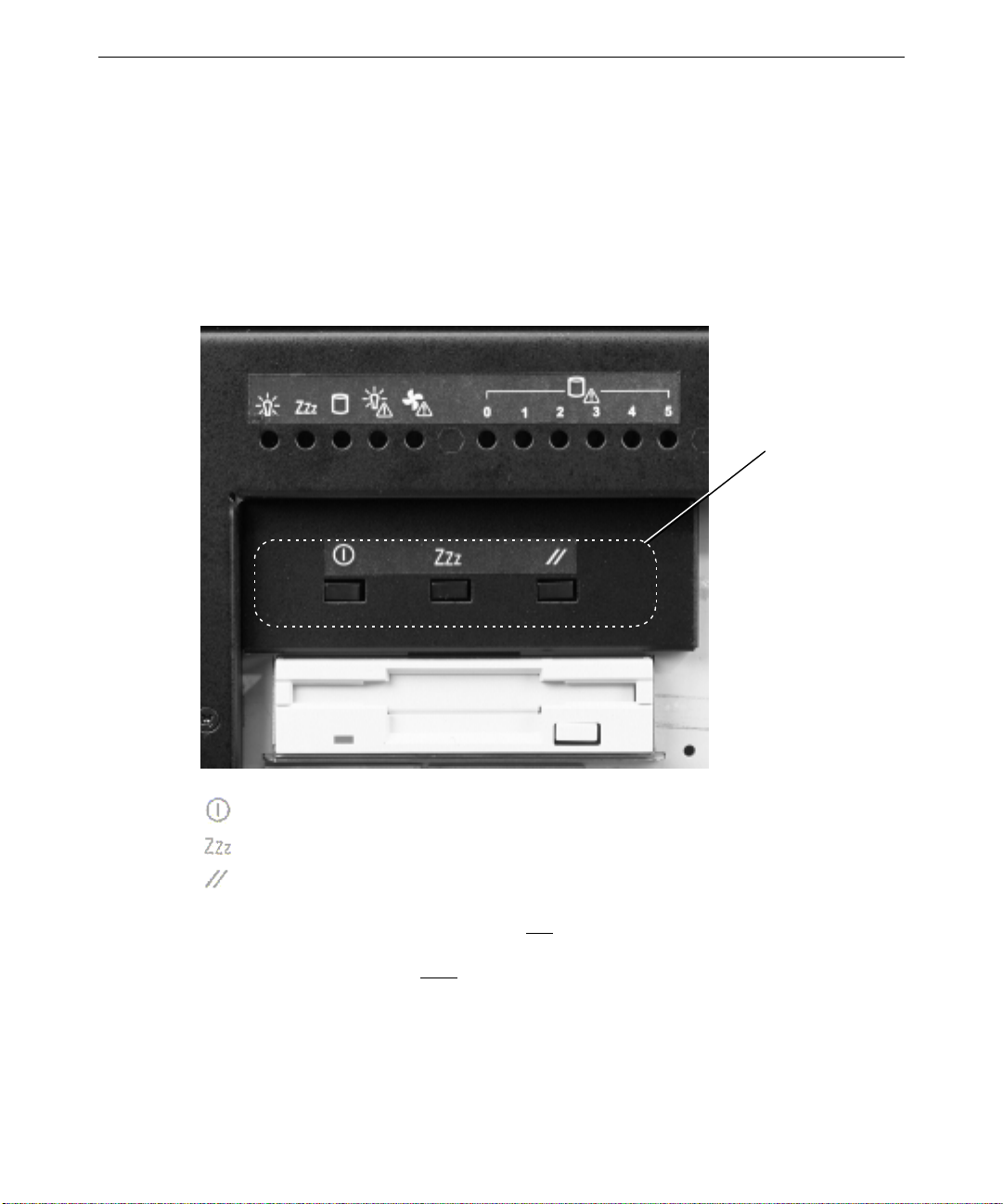

Starting and Stopping the System ...................................................................................... 40

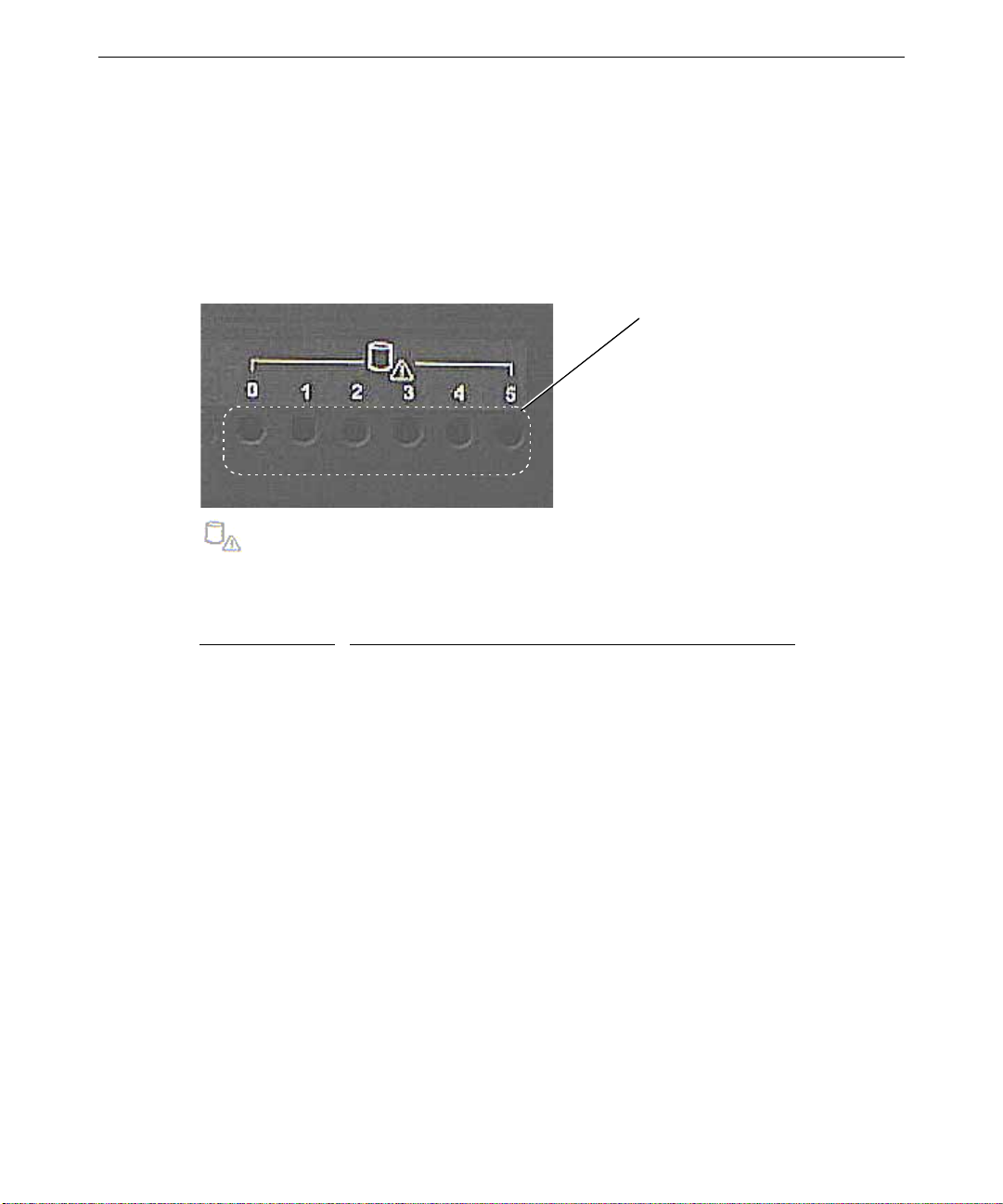

System Status LEDs........................................................................................................... 41

Disk Drive Status LEDs (RAID Systems)........................................................................... 42

System Alert...................................................................................................................... 42

Using InterSite Programs................................................................................................... 43

Additional User Information .............................................................................................. 43

What’s Next?..................................................................................................................... 44

5 Reinstalling System Software ...................................................................................... 45

Before You Begin.............................................................................................................. 46

System Software Products.................................................................................................. 46

Installing Windows NT Server 4.0 on Systems with 3 GB of Memory or Less.................... 48

Installing Windows NT Server 4.0 on Systems with More Than 3 GB of Memory.............. 49

Getting Operating System Updates..................................................................................... 52

Index................................................................................................................................. 53

Returned Goods Authorization (RGA) Form

Warranty Procedure

Repair Depot Address Labels

Page 5

Preface

InterServe 9000 System Setup describes setting up, configuring, and operating your

InterServe 9000 system.

About This Document

InterServe 9000 System Setup is organized as follows:

u

Chapter 1, “Setting Up the Hardware,” describes how to set up the system hardware.

u

Chapter 2, “Setting Up the Software,” describes how to set up the operating system and

associated system software.

u

Chapter 3, “Configuring the System,” describes how to configure the system for use.

u

Chapter 4, “Operating Notes,” describes how to use essential system features and

provides other important information.

u

Chapter 5, “Reinstalling System Software,” describes how to reinstall the operating

system and associated system software, if required.

v

Document Conventions

Bold

Italic Variable values that you supply, or cross-references.

Monospace

SMALL CAPS Key names on the keyboard, such as D, ALT or F3; names of files and

CTRL+D Press a key while simultaneously pressing another key; for example, press

Commands, words, or characters that you key in literally.

Output displayed on the screen.

directories. You can type filenames and directory names in the dialog boxes

or the command line in lowercase unless directed otherwise.

CTRL and D simultaneously.

Operating System Information

For more detailed information on the operating system, see the printed and online Microsoft

documentation delivered with the system.

See the Late-Breaking News shipped with your system for important software and

documentation information not covered in this document.

Page 6

vi

Hardware Information

An online introduction to your new system is provided in the System Introduction, which

covers subjects such as the following:

u

System features

u

System controls and connections

u

Intergraph customer support

You can display the System Introduction by using the InterSite Welcome dialog or by

opening the

Detailed reference information for your new system is provided in the System Reference,

which covers user and service technician subjects such as the following:

Part I, User’s Guide:

•

System, peripherals, and power supplies.

•

System board (slots and sockets, memory configurations, IRQ/DMA/upper memory

assignments, jumpers, external ports, hardware monitoring).

SYSINTRO.HLP file on your system.

•

Hot keys, power-on self-test (POST), BIOS Setup, and other utilities.

•

Hot-swap hard disk drives and power supplies.

Part II, Service Technician’s Guide:

•

Base unit components.

•

System board (memory, processors, and backup battery).

•

Troubleshooting checklist.

•

Hardware technical reference and system interrupt requests (IRQs).

•

Log sheet and configuration worksheets.

•

Specifications (electrical, environmental, physical).

•

Precautions against electrostatic discharges.

See the Late-Breaking News shipped with your system for important hardware and

documentation details not covered in this document.

Page 7

Ergonomic Information

Read the Ergonomics Guide delivered with your system for valuable information on ways to

minimize repetitive stress injuries when working with a computer.

Customer Support

Intergraph Computer Systems offers an assortment of customer support options.

Hardware and Software Support Services

Intergraph Computer Systems provides a variety of hardware services for Intergraph and

third-party equipment. Services include warranty upgrades, repair depot service, on-site

hardware maintenance, system administration, and network consulting. Hardware

purchased from Intergraph Computer Systems includes a factory warranty ranging from

30 days to three years. A detailed warranty description is available on the World Wide Web;

see the Support pages at http://www.intergraph.com/ics.

Intergraph Computer Systems provides complimentary software support for 30 or 90 days

following shipment of a hardware or software product. This includes World Wide Web

access, Intergraph Bulletin Board Service access, FAXLink service, and telephone (Help

Desk) support. At the end of the complimentary support period, you can purchase other

levels of software support.

vii

World Wide Web

You can visit Intergraph Computer Systems on the World Wide Web at

http://www.intergraph.com/ics. On these pages, you can get news and product

information, technical support information, software updates and fixes, and more.

Intergraph Bulletin Board Service

On the Intergraph Bulletin Board Service (IBBS), you can get technical support information,

software updates and fixes, and more.

To connect to the IBBS:

1. Set your system’s communications protocol for eight (8) data bits, no parity, one (1) stop

bit, and any baud rate up to 14,400.

Page 8

viii

FAXLink

2. Using a modem, call 1-256-730-8786. Outside the United States, call one of the mirror

sites listed on World Wide Web; see the Software Support pages at

http://www.intergraph.com.

3. At the login prompt, key in your user ID. If you have not connected before, key in new

to create a user ID.

4. Follow the menus to find what you need. The IBBS provides clear choices and online

help.

If you have trouble connecting to or using the IBBS, call the Customer Response Center at

1-800-633-7248 (product entry IBBS) or leave a message for the IBBS System Operator at

1-256-730-1413.

To use the FAXLink:

u

Call 1-800-240-4300 for information on how to get technical support information using

the FAXLink.

u

Call 1-256-730-9000 to get documents (up to five per call).

Telephone

To get customer support by telephone:

u

u

Have the following information available when you call:

u

u

u

u

In the United States, call 1-800-633-7248 between the hours of 7:00 a.m. and

7:00 p.m. Central Time, Monday through Friday (except holidays).

Outside the United States, contact your local Intergraph Computer Systems subsidiary or

distributor.

Your service number, which identifies your site to Intergraph Computer Systems. You

use your service number for warranty or maintenance calls.

Your Customer Personal Identification Number (CPIN). You get a CPIN the first time

you call the Customer Response Center; it is associated with your service number for

future call logging.

The product’s name or model number.

The product’s serial number. Software product serial numbers are included in the

product packaging. Hardware product serial numbers are on a sticker affixed to the

hardware product.

Page 9

u

Your name and telephone number.

u

A brief description of the question or problem.

More Support Options

To get information on more customer support options:

u

Visit the Support pages on the World Wide Web at http://www.intergraph.com/ics.

u

For hardware support questions in the United States, call 1-800-763-0242.

u

For software support questions in the United States, call 1-800-345-4856.

u

Outside the United States, contact your local Intergraph Computer Systems subsidiary or

distributor.

ix

Page 10

x

Page 11

1 Setting Up the Hardware

Follow the instructions in this chapter to set up an InterServe 9000 in a stand-alone deskside

configuration or to set up and install it into an Intergraph equipment rack.

Before You Begin................................................................................................................ 2

Unpacking the Equipment.................................................................................................... 3

Placing the System............................................................................................................... 4

Setting Up a Deskside System.............................................................................................. 5

Setting Up a Rack-mount System......................................................................................... 6

Safety Guidelines................................................................................................... 6

Tools You Need..................................................................................................... 7

Prepare the Equipment Rack................................................................................................ 7

Prepare the System............................................................................................................. 11

Installing the System into a Rack ....................................................................................... 14

Connecting the Cables ....................................................................................................... 15

Installing Non-RAID and RAID Disk Drives ..................................................................... 17

Install and Label the Disk Drives ......................................................................... 18

Additional Information......................................................................................... 21

Checking the System.......................................................................................................... 21

What’s Next?..................................................................................................................... 22

1

Page 12

2

Before You Begin

Read this chapter before you attempt to set up an InterServe 9000. In addition:

u

Contact the local Intergraph support office if any items you ordered are missing or

damaged.

u

If you use non-Intergraph cables with the system, ensure that they are shielded and

terminated on both ends. Intergraph-supplied cables are shielded to prevent excessive

electromagnetic interference (EMI).

u

If using an external power source with your system, such as an AC distribution box or

an uninterruptible power supply (UPS), review the documentation delivered with the

power source for information about its capabilities.

u

If you need to return equipment for repair, you must ship it in Intergraph-supplied

packaging to get warranty service.

u

Follow the installation instructions carefully to avoid personal injury and damage to the

system hardware.

If you are installing the system into a rack, note the following.

u

Set up the Intergraph rack using the Intergraph Rack Installation and Use document

delivered with the rack. Become familiar with the rack enclosure before installing the

system hardware into it.

u

Do not push on or lean against the rack.

u

The rack’s front and side stabilizer feet must be extended at all times.

Page 13

Unpacking the Equipment

InterServe 9000

Corrugated

Sleeve

The InterServe 9000 base unit is between two foam pieces, and rack-mount versions include

a corrugated sleeve as part of the packing. Other items are packed in boxes.. Contents of the

boxes are as follows:

3

Parts Box

Disk

Drives

Box

u

Parts box -- contains the keyboard, mouse, and key (for the drive access door); Windows

NT Server operating system (compact disks, floppy diskettes, and documentation), if

ordered; Intergraph system software (diskettes); label sheets for disk drives; and

documentation.

u

Disk drives box -- each box contains up to three disk drives. If you ordered more than

three drives, they are delivered in an extra box.

If you ordered a monitor from Intergraph Computer Systems, it is shipped separately from

the base unit pallet. Its carton contains the monitor, the monitor AC power cord, the video

cable, and monitor documentation.

NOTE If any of the listed items were not delivered, call the Customer Response Center immediately

at 1-800-633-7248.

Save all packaging materials after setting up the system. If you return equipment for repair,

it must be in its original packaging for you to get warranty service (if provided under your

contract agreement).

Page 14

4

Placing the System

Operation of the InterServe 9000 system at conditions beyond those shown in the following

table may cause permanent damage to the system. Exposure to conditions outside the

absolute maximum ratings for extended periods may affect system reliability.

The following table provides the absolute maximum conditions.

Condition

Range

Operating temperature 0° C to +40° C

Storage temperature -55° C to +150° C

Voltage on any signal with respect to ground

-0.3V to *V

+ 0.3 V

DD

3.3V supply voltage with respect to ground -0.3 to +3.63 V

5V supply voltage with respect to ground -0.3 to +5.5 V

12V supply voltage with respect to ground -0.3 to +12.6 V

-12V supply voltage with respect to ground -13.2 to +0.3 V

means supply voltage for the device.

* V

DD

The InterServe 9000 either stands upright (pedestal mode) or installs in a rack (rack mode).

Before you set up your system, determine where you want to place it. Keep these guidelines

in mind:

u

Place the system as close as possible to the proper power outlet. The power cord

connecting the system to the facility power outlet or other power source serves as the

disconnect device.

u

Place the system in an area where air can circulate freely around it.

u

Do not expose the system to high levels of dust, smoke, or moisture.

u

Place the system in an area where the temperature range stays between 10° C and 26° C

(50° F and 80° F). The optimum operating temperature is 21° C (70° F).

u

Place the system in an area where the humidity stays between 20 percent and 80 percent

(non-condensing). The optimum operating humidity is 50 percent (non-condensing).

Install the system as described in “Setting up a Deskside System” or “Setting up a Rackmount System,” as appropriate.

Page 15

Setting Up a Deskside System

This section explains how to install a deskside (pedestal) system.

5

To set up the system:

1. Lift the base unit from the pallet and set it upright.

WARNING The base unit is heavy; two people are required to lift it out of the box. Do not let the

base unit drop onto a hard surface, or damage to internal components may result.

2. Remove the plastic bag from the base unit.

3. Connect the cables as described later in this chapter under “Connecting the Cables.”

Page 16

6

Setting Up a Rack-mount System

This section explains how to install a rack-mount InterServe 9000 system in a 19-inch

Intergraph 17 U or 40 U equipment rack. Only technically qualified personnel should install

the system. Computer equipment is secured in the rack along the mounting posts using 7.1

mm diameter mounting holes. The mounting posts have small round markers to designate

each U. There are three mounting holes per U. Further details are found in this section.

The size of racks are designated by their available vertical height and width. Knowing the

size of the rack and equipment you are installing helps determine if the rack is capable of

containing the equipment.

NOTE Physical space is not the only factor to consider when installing equipment. There are facility

and power requirements and load limitations to observe. For more information about power

requirements and load limitations, see the documentation delivered with the system and

equipment.

Safety Guidelines

Before you set up a system, please read and observe the following safety guidelines:

WARNING Avoid injury: The minimum system configuration weighs 29 kg (63 lbs), and the

maximum weighs 44 kg (97 lbs). To avoid injury, two people should lift and insert the

system into the slide assemblies in the equipment rack.

WARNING Work on only one system at a time: Extend only one system at a time from the

equipment rack. Extending more than one system can result in the rack tipping

forward on you.

WARNING Anchor the equipment rack:

support to prevent it from falling over when a system on slide assemblies is extended

in front of it. The anchors must be able to withstand a force of up to 113 kg (250 lbs).

You must also consider the weight of any other device installed in the rack.

WARNING Main AC power disconnect:

disconnect for the entire rack unit. This main disconnect must be readily accessible,

and it must be labeled as controlling power to the entire unit, not just to the system(s).

WARNING Grounding the rack installation: To avoid the potential for an electrical shock hazard,

you must include a third wire safety grounding conductor with the rack installation. If

system power cords are plugged into AC outlets that are part of the rack, then you

must provide proper grounding for the rack itself. If system power cords are plugged

into wall AC outlets, the safety grounding conductor in each power cord provides

proper grounding only for the system. You must provide additional, proper grounding

for the rack and other devices installed in it.

The equipment rack must be anchored to an unmovable

You are responsible for installing an AC power

Page 17

WARNING Overcurrent protection: The system is designed for an AC line voltage source with up

to 20 amperes of overcurrent protection. If the power system for the equipment rack

is installed on a branch circuit with more than 20 amperes of protection, you must

provide supplemental protection for the system. If more than one system is installed

in the rack, the power source for each system must be from a separate branch circuit.

The overall current rating of a system configured with three power supplies is under

12 amperes.

7

CAUTION Temperature:

must not go below 5° C (41° F) or rise above 35° C (95° F). Extreme fluctuations in

temperature can cause a variety of problems in your system.

CAUTION Ventilation:

maintain proper cooling. It must also include ventilation sufficient to exhaust a minimum of

3,150 Btu's per hour for the system. The rack selected and the ventilation provided must be

suitable to the environment in which the system will be used.

The operating temperature of the system, when installed in an equipment rack,

The equipment rack must provide sufficient airflow to the front of the system to

Tools You Need

You will need the following tools:

u

Phillips screwdrivers, #1 and #2

u

Pencil

Prepare the Equipment Rack

Before installing the system in the 19-inch equipment rack, you must attach the slide rails

and mounting brackets to the equipment rack as instructed in this section. Perform the

following steps carefully; the mounting brackets must be installed with precision to allow

room for the next system you install in a rack.

NOTE A total of four mounting brackets (two long and two short) attach to the vertical rails of the

equipment rack. The two long brackets must be installed on the front of the equipment rack.

To mark the hole spacing on the vertical rails:

1. See the following figure for a view of the vertical rail and the hole spacing details. The

vertical rails of the 17 U and 40 U racks have a hole between every 1 U, and a square

between every 4 U. All dimensions are in millimeters

2. With a pencil, mark the top and bottom hole locations for the mounting brackets on both

sides of the vertical rails.

Page 18

8

1 U Marker

To attach the mounting brackets to the front vertical rail:

1. Remove a long mounting bracket, two screws, and a bar nut from the kit. See the

following figure for a view of how to place the bar nut in relation to the mounting

bracket and vertical rail.

Bar Nut

Long Mounting

Bracket

Front Vertical Rai l

Phillips flathead screw,

#10-32 x .5

2. While facing the front of the rack, orient the mounting bracket so that the short side

with the four mounting holes is facing toward the outside edge of the vertical rail and

the bracket extends to the back of the rack.

3. Place the bracket on the mounting holes in the vertical rail.

4. Insert a screw through the marked top hole in the vertical rail and through the top hole

in the mounting bracket. Place a bar nut on the screw, and loosely tighten it. Repeat for

the marked bottom hole.

5. Install the other front mounting bracket in the same manner.

Page 19

To attach the mounting brackets to the back vertical rail:

Use the same procedure to install both mounting brackets on the back vertical rails. See

the following figure for proper orientation of the short mounting bracket.

Short Mounting

Bracket

Back Vertic a l Rail

Bar Nut

Phillips flathead screw,

#10-32 x .5

To prepare the slide assemblies:

9

1. Remove the slide assemblies from the kit. See the following figure.

4

1 Large outer bar

2 Center bar

3 Small outer bar

4 Safety latch on the small outer bar

5 Safety latch on the center bar

1 2 3

5

Page 20

10

1

2. Orient a slide assembly so that the smallest outer bar is facing down.

3. Fully extend the telescoping slide assembly until the center bar hits the safety latch on

the small outer bar (all three overlapping bars will be visible).

4. Grasp the small outer bar with your right hand so that your thumb is on the safety latch

of the small outer bar.

5. Press and hold the safety latch down, and at the same time, grasp the large outer bar

with your left hand.

6. Pull the small bar out of the center bar; this takes a little force to separate them. Set the

small bar aside to attach to the chassis in a later step.

7. Orient the center bar and large outer bar assembly so that the center bar is facing up.

8. Grasp the center bar with your right hand and the large outer bar with your left hand so

that your left-hand thumb is on the safety latch of the center bar.

9. Press the safety latch, and slide the bars together. Set the center bar and large outer bar

assembly aside to attach to the equipment rack in a later step.

10. Prepare the other slide assembly by repeating steps 2–9.

To attach the center bar and large outer bar assemblies to the mounting brackets:

1. See the following figure for the center bar and large outer bar assembly.

22

5

4

4

3

2

2

2

6

7

1 Front mounting bracket

2 Screw, #8-32 x.5 Phillips trusshead

3 Kep nut

4 Large outer bar

5 Safety latch on the center bar

6 Center bar

7 Back mounting bracket

6

Page 21

2. Orient a center bar and large outer bar assembly so that the flat side is facing toward the

mounting brackets attached to the vertical rails, and the safety latch on the center bar is

near the back of the rack. Press the flat side of the outer bar into the mounting bracket.

3. Slide the assembly toward the front of the rack until the end of the outer bar is

approximately 90 millimeters from the leading edge of the bracket.

4. Gently slide the center bar toward the front of the rack, and position the oblong slot in it

over the first hole in the large outer bar. Insert an 8-32 screw through the hole in the

bar and the first slot in the front bracket. Place an 8-32 kep nut on the screw, and

loosely tighten it.

5. Position the oblong slot in the center bar over the third hole back from the front of the

large outer bar. Insert an 8-32 screw through the hole and the oblong slot in the front

bracket. Place an 8-32 kep nut on the screw and loosely tighten it.

6. The back mounting bracket has one slot in it. The end of the outer bar has four holes in

it. The holes you use depend on the depth of the equipment rack. After fitting the bar

into the mounting bracket, insert two screws through the appropriate holes in the bar

and the slot in the mounting bracket. Place an 8-32 kep nut on each screw, and loosely

tighten them.

7. Ensure that the mounting brackets and bars are positioned correctly in the rack. Then

tighten all screws firmly (6.0 inch-pounds).

11

Prepare the System

Before installing the base unit in the 19-inch equipment rack, you must attach the small bars

of the slide assemblies onto the sides of the system. You must also attach two chassis

handles to the system faceplate.

To attach the small bar of the slide assembly to the system:

1. Remove four #8-32 x .5 Phillips trusshead screws from the parts box. See the figure

below for the small bar of the slide assembly.

2. While facing the side of the system, orient the small bar so that the flat side faces the top

and the right-angle end faces the front of the system.

3. Align the first hole in the right-angle end of the bar with the first threaded hole in the

side of the chassis.

4. Insert a screw through the hole in the bar and into the chassis. Then loosely tighten the

screw.

Page 22

12

5. Align the rest of the holes in the bar with the remaining three threaded holes along the

side of the chassis.

6. Insert three more screws through the bar and into the threaded holes in the chassis wall.

Then tighten all four screws firmly (6.0 inch-pounds).

7. Install the remaining small bar on the other side of the chassis by repeating steps 1–6.

1

The faceplate

appearance may vary

from that shown.

2

1 Threaded hole in chassis

2 Safety latch

4

3 Screw, #8-32 x .5 Phillips trusshead

4 Small outer bar

3

Page 23

To attach the chassis handles:

1. Remove the handles and screws (#10-32 x .187 flathead) from the parts box.

2. Orient each handle so the two screw holes on the long edge of each handle align with

the threaded holes in the faceplate. The handles can be installed in only one way.

3. Use four screws to attach the handles (two per handle) to the faceplate.

Two handles attach to the

faceplate.

13

Page 24

14

Installing the System into a Rack

To install the system in the rack:

1. Pull the telescoping center bars out of the large outer bars until they are fully extended

and locked in place. See the following figure.

The faceplate appearance may vary from

that shown.

2

3

1

4

2

1 Small outer bar

2 Center bar

3 Large outer bar

4 Safety latch

2. With two persons, carefully lift the system and gently slide the small bars attached to

each side of the chassis into the extended center bars.

3. When the system stops, press in on the safety latches on the small bars, and gently slide

the system into the rack.

4. Connect the cables as described next in “Connecting the Cables.”

Page 25

Connecting the Cables

All cable ports on the base unit and other Intergraph equipment are keyed or molded and

clearly labeled to ensure proper cable attachment. If a cable is not attaching easily, ensure

that you are aligning the cable connector correctly with the port.

To connect the cables:

1. Connect the video cable from the monitor to the video out port on the video card located

in the I/O expansion panel. Refer to the following figure.

15

Parallel

Serial

(COM 1)

Mouse

Video Out

Serial

(COM 2)

Keyboard

Universal

Serial Bus

2. Connect the cables for the mouse and keyboard to their ports on the I/O connector panel.

3. Connect the cables for installed option boards as described in the documentation for

those boards.

4. Connect the system power cord(s) to the AC receptacle(s) on the base unit, as shown in

the following figures.

Page 26

16

AC Receptacle

AC Receptacle

5. If using an AC distribution box or UPS, connect its power cord to a grounded, three-

prong AC power outlet.

NOTE The UPS starts automatically when its power cord is connected to the power outlet. Refer to

the UPS documentation for more details.

6. Connect other cables as necessary for printers (parallel port), external SCSI devices

(SCSI port), and modems or UPS communication (serial ports).

7. Install the disk drives as described in the next section.

Page 27

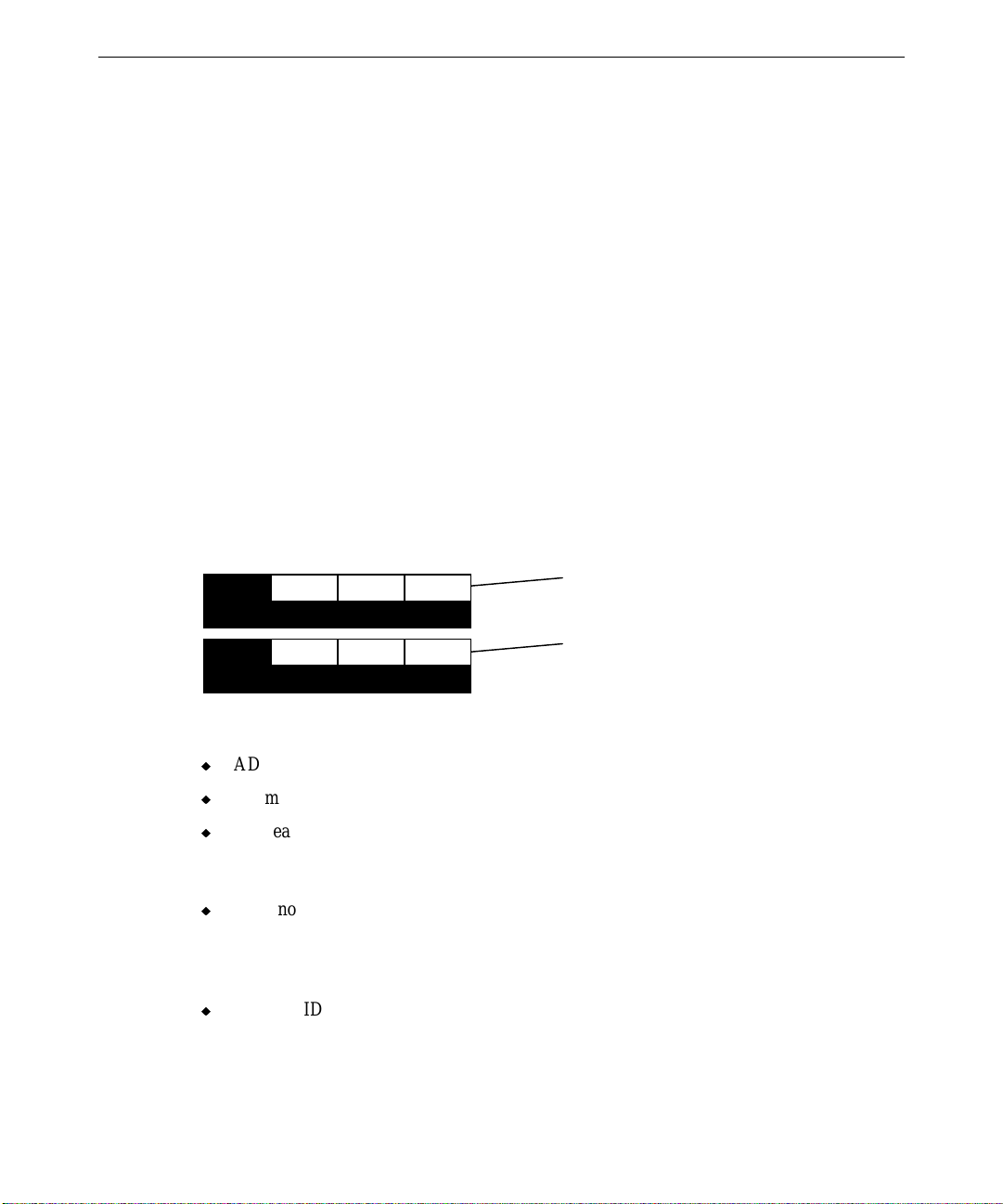

Installing Non-RAID and RAID Disk Drives

Filled-in Label

Depending on the configuration, the system is non-RAID (also called JBOD, for “just a

bunch of disks”) or RAID. A RAID (redundant array of independent disks) system uses a

1-channel Mylex RAID controller (also called a RAID adapter) to provide RAID capabilities

such as disk striping, mirroring, and redundancy. The non-RAID system use a 2-channel

Ultra Wide SCSI controller that does not feature RAID capabilities.

The disk drive section in the front of the system contains six drive slots. The slots number 1

to 6, starting with the top slot for deskside systems. For rack-mount systems, slot number 1

starts with the left-most slot). If you are installing less than six drives in the system, install

the disk drives starting in slot 1 and fill each slot in sequence.

Each disk drive has a label to identify the drive. The left side of the label shows the disk

drive size (in GB). The label has spaces to further identify the adapter (ADP), channel (CH),

and SCSI ID (ID). Standard disk drives include values for the adapter, channel, and SCSI

ID filled in.

NOTE A labeling sheet is included in the system parts box.

17

x GB

x GB

ADP

ADP

CH ID

CH ID

100

Blank Label

Additional disk drives have a blank label which you must complete after installation.

u

ADP means the RAID controller number connected to the RAID section.

u

CH means the RAID SCSI bus channel of the adapter.

u

ID means the SCSI identification number of the drive slot.

Note the following about non-RAID and RAID disk drives.

u

For a non-RAID system, one disk drive (with the operating system installed) is standard.

This drive is called the boot drive. It is labeled with specific adapter, channel, and SCSI

ID. The boot drive should be installed in the lowest slot of the disk section. Installation

details are provided below.

u

For a RAID system, one RAID controller and three disk drives (with the operating

system striped across all three) are standard. These drives, called boot drives, are

labeled with specific adapter, channel, and SCSI ID. They must be installed in specific

slots in the disk section. Installation details are provided below.

Page 28

18

Install and Label the Disk Drives

The following procedures cover both non-RAID and RAID installations. To install the

drives, you must access the sides of the disk drive housing. Drives are hard mounted in the

drive carrier using four screws (two on each side) for each drive. The drive section is behind

the locked door. The key is provided in the parts box.

To install the disk drives:

1. Unlock and open the front door of the base unit.

2. Open the disk section door. The following figure shows the RAID disk section.

Slot 1

3. Remove the disk drives from the drive boxes.

4. Do the following when inserting drives into the slots:

−

Extend the latching clips on the drive and align the rails on the side of the drive

with the slot guides. The metal casing of the drive faces up. If you install the drive

reversed, it will not connect to the system.

−

With your thumb, firmly push the drive in the middle between the latching clips

until it slides all the way into the slot and firmly engages the connector.

−

Close the latching clips to lock the drive in the slot.

Slot 6

Page 29

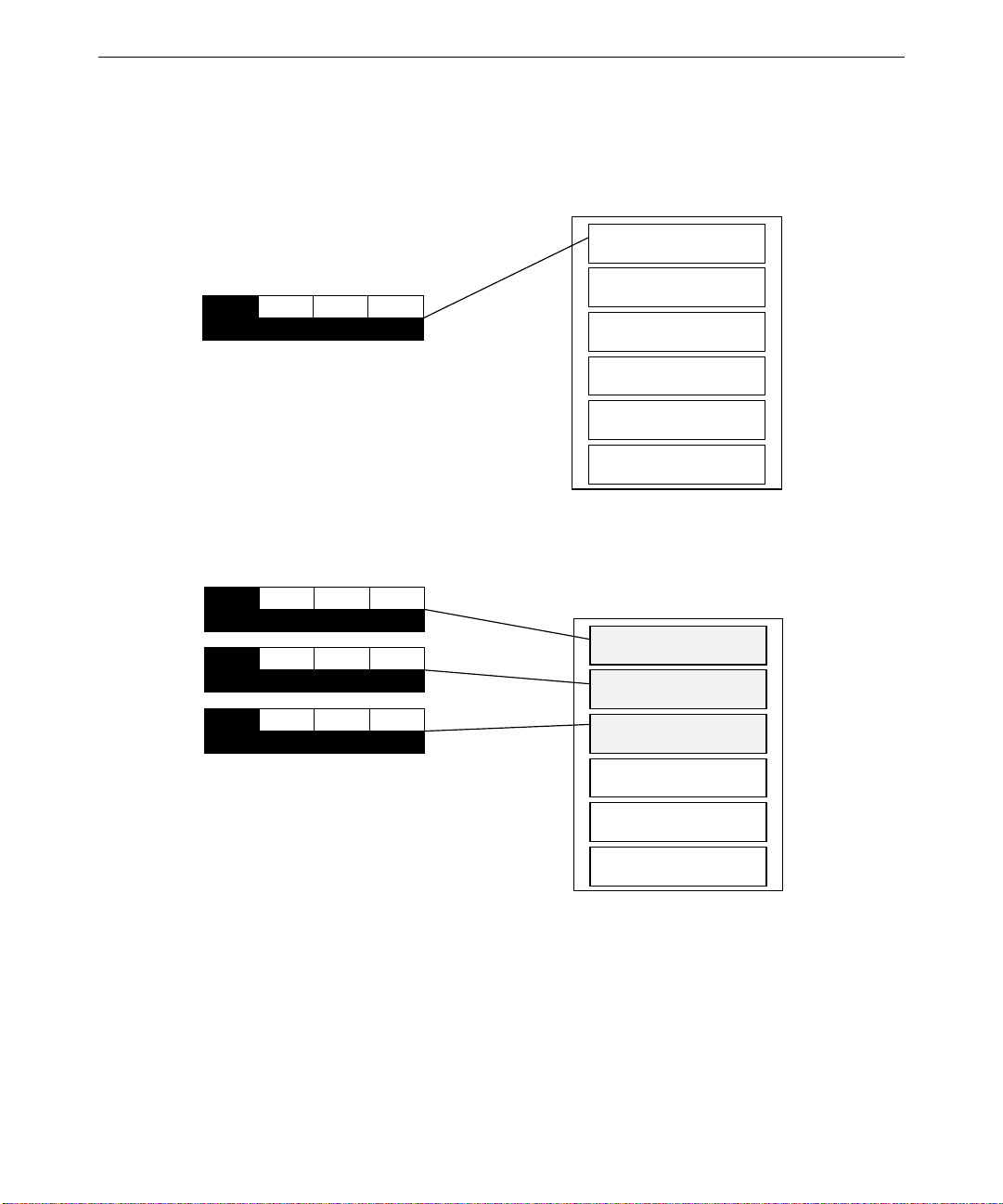

5. Locate and install the boot drives (those with the completed labels).

−

Install the non-RAID boot drive into slot 1 of the disk section, as shown in the

following figure.

Slot 1

Slot 2

x GB

−

ADP0CH0ID

Install the RAID boot drives into slots 1, 2, and 3 of the disk section, as shown in

0

Slot 3

Slot 4

Slot 5

Slot 6

the following figure.

19

x GB

ADP0CH0ID

x GB

ADP0CH0ID

x GB

ADP0CH0ID

0

1

2

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

6. Install the remaining disk drives into the slots. Fill each slot downward as you install

the drives. There should be no empty slots between the drives.

Page 30

20

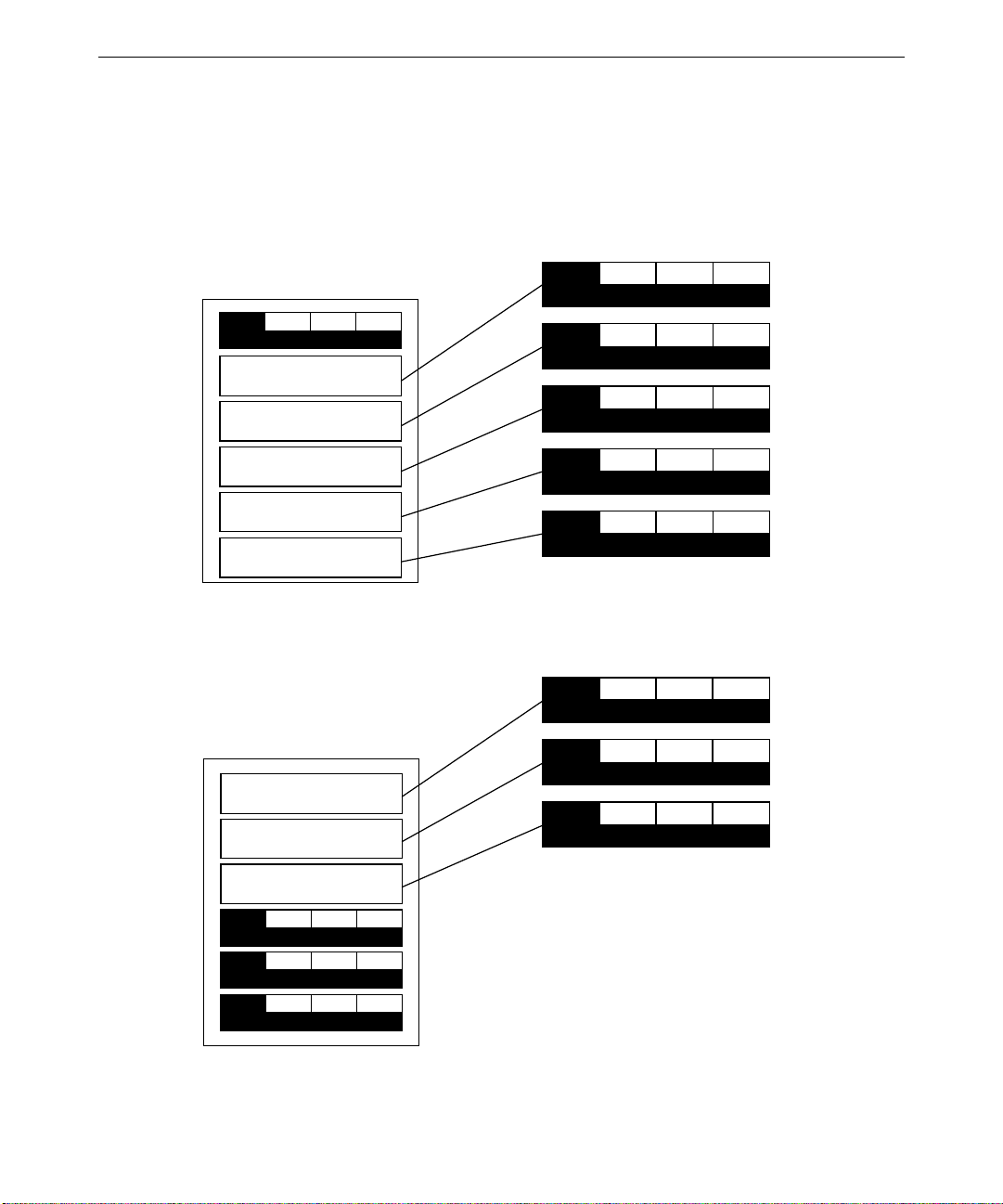

7. Label the remaining disk drives as follows. Note carefully how the drives should be

labeled for each slot.

−

Label non-RAID disk drives with ADP, CH, and ID numbers as shown in the

following figure. For further details, refer to the guide shipped with the hard disk

drive.

x GB

ADP0CH0ID

x GB

ADP0CH

0

x GB

ADP0CH

0

0

1

ID

2

ID

Slot 2

x GB

Slot 3

Slot 4

Slot 5

x GB

x GB

Slot 6

−

Label RAID disk drives with ADP, CH, and ID numbers as shown in the following

ADP0CH

ADP0CH

ADP0CH

0

0

0

3

ID

4

ID

5

ID

figure.

0

1

2

Slot 1

Slot 2

x GB

ADP0CH0ID

x GB

ADP0CH0ID

x GB

ADP0CH0ID

x GB

ADP0CH0ID

x GB

ADP0CH0ID

x GB

ADP0CH0ID

Slot 3

4

Do not use the number 3 from the

5

label sheet for RAID systems. ID 3

is reserved for the disk section

6

backplane.

Page 31

Additional Information

The RAID system boot drives are configured at the factory using Mylex RAID configuration

utilities. Additional disk drives supplied with the system are not configured. You must

configure these drives after configuring system software to make them usable to the system.

Refer to Chapter 3, “Configuring the System,” for more information on configuring and

using the RAID disk arrays.

WARNING Do not turn on the system power until you are ready to configure Windows NT Server.

If you start the system, and then restart it before completely configuring the operating

system, you will have to reinstall system software as described in Chapter 5,

“Reinstalling System Software.”

Checking the System

Before starting the deskside system, review the following items:

u

The cables are properly attached from the base unit to the various options and

peripherals.

u

All disk drives are installed in the proper slots and labeled appropriately.

21

u

The power cord from the system’s AC receptacle is connected to the correct power

outlet.

Before starting the rack-mount system, review the following items:

u

All hardware is properly and securely installed in the rack.

u

The cables are properly attached from the base unit to the accessories installed in the

rack or in remote locations.

u

The cables attached to the server base unit are routed through the cable handler. Ensure

there is enough cable service loop to allow sliding devices to extend 31 inches.

u

The cables that run along the sides or top of the rack are installed in clips or ties to

secure them in place.

u

All disk drives are installed in the proper slots and labeled appropriately.

u

The base unit is retracted into the rack.

u

The power cord from the AC distribution box or UPS is attached to the correct power

outlet.

WARNING Once you install the equipment into the 40 U rack, do not move the rack. If you must

move it, first remove all equipment, move the rack to its new location, and then

reinstall the equipment.

Page 32

22

What’s Next?

You can do any of the following to prepare your system for use:

u

To use Intergraph’s default setup, go to Chapter 2 to start the system and go through

Windows NT Setup. If you start the system, and then turn it off before completing the

instructions in Chapter 2, you will have to reload the operating system and system

software.

u

For RAID systems, the default RAID setup is three disk drives striped to RAID level 5,

including “write through” write policy. The default setup is described in more detail in

the section, “Standard RAID Disk Drives Configuration” of Chapter 3. If you want to

reconfigure the RAID setup, refer to the Mylex documentation.

u

Intergraph Computer Systems installs the operating system through Phase 1 of the

Windows NT Setup process. Phase 2 involves establishing a domain name, determining

a security role, and setting up user accounts. If you want to reinstall the operating

system and system software, instead of completing Phase 2 of Setup, refer to Chapter 5.

Page 33

2 Setting Up the Software

This chapter provides instructions for setting up the system software for the server.

Preparing for Setup............................................................................................................ 24

Pre-Installed Software.......................................................................................... 24

Before You Start Setup......................................................................................... 24

Starting the System............................................................................................................ 26

Starting Operating System Setup........................................................................................ 26

Finishing Operating System Setup ..................................................................................... 27

Creating an Emergency Repair Disk..................................................................... 27

Creating System Software Backup Diskettes......................................................... 28

What’s Next?..................................................................................................................... 28

23

Page 34

24

Preparing for Setup

Your system’s primary system and additional disk drives were formatted and partitioned

before shipment. In Explorer or My Computer, you can right-click a disk drive and click

Properties to display the drive’s partition size and file system format. To view partition and

format information for all disk drives, you can use Disk Administrator. See the operating

system documentation and Help for more information on these tools.

Pre-Installed Software

The operating system and associated system software is pre-installed on the primary hard

disk drive. Intergraph Computer Systems installed the following system software:

u

Driver software for the installed SCSI adapter(s)

u

Driver software for the installed network adapter

u

Driver software for the installed video display adapter

u

Driver software for the installed mouse, if needed

u

InterSite software

u

Quick-Fix Engineering (QFE) update software (fixes for operating system problems or

limitations), if needed

Before Y ou St art Setup

Before starting the Setup process, have the following documentation available:

u

The Microsoft Start Here document

u

Documentation for the video display adapter delivered with the system

Get and record the following information:

u

Your name, and the name of your

company or organization:

u

For a system running Windows NT,

the CD key from the Windows NT CD

case, or the Product ID Number from

Start Here or the registration card:

Page 35

If the system is connected to a network, obtain and record the following information from

your network administrator:

u

Computer name for your system:

u

Workgroup name (if the system will be

part of a workgroup):

u

Domain name (if the system will be part

of a Windows NT domain):

u

Security role for your system in the

Windows NT domain -- primary domain

controller, backup domain controller, or

domain server:

u

If your system will be acting as a backup

domain controller or domain server,

username and password of an authorized

domain administrator account:

NOTE Determine the security role for your server before beginning system configuration. You

cannot change a server to a domain controller without reinstalling Windows NT Server. A

domain controller maintains security policy and performs user authentication for a domain.

Servers may be part of a domain, although they do not have to participate in a domain. See

the operating system documentation for a detailed explanation of the differences between

domain controllers and servers.

25

If the system is connected to a network that uses the Transmission Control Protocol/Internet

Protocol (TCP/IP), get and record the following TCP/IP information from your network

administrator:

u

Internet Protocol (IP) address for your

system:

u

IP subnet mask for your system:

u

IP domain name for your network:

u

IP address for your network’s default

gateway:

u

IP addresses for your network’s

Domain Name System (DNS) servers,

if any:

u

IP addresses for your network’s

Windows Internet Name Service

(WINS) servers, if any:

Page 36

26

The Windows NT delivery media contain software and drivers for both Reduced Instruction

Set Computing (RISC)- and Intel-based systems. When installing Windows NT distribution

files, make sure you install them from the \

delivery media. For example, if you are installing a device driver from the Windows NT

CD-ROM, key in the following when prompted for the path:

drive:\i386

where drive is the drive letter for the CD-ROM drive.

I386 directory (the Intel software directory) on the

Starting the System

The power button is behind the locked door. To start the system, unlock and open the front

door and press the power button on the front of the system. If you have an AC distribution

box connected to the system, make sure its power switch is turned on before you start the

system.

Starting Operating System Setup

When you start your system for the first time, you must configure the operating system

software for use. After you first start the system, the Microsoft End User License Agreement

(EULA) screen displays.

NOTE Before starting the system for the first time, you may want to learn more about system power,

startup, and shutdown. See Chapter 4, “Operating Notes,” for this information.

To start the computer and set up the operating system software:

1. Turn on the monitor by pressing its power switch.

2. Press the power button on the front of the system. The system starts and the EULA

screen displays on the monitor.

3. Read the terms of the EULA and then follow the instructions displayed on-screen to

complete the Setup process. A Welcome screen displays, then a prompt for user and

organization, and then a prompt for the product ID. Accept the default settings provided

by Setup, except as follows:

−

Setup asks if you want to install networking. If you choose to install networking

(default), choose “Select from list...” when prompted whether to allow Setup to

detect the network adapter. From the list, select “3Com Fast Etherlink XL Adapter

(3C905).” Allow Setup to install this driver software.

Page 37

−

Create an Emergency Repair Disk when prompted.

−

Enter a password for the Administrator account when prompted.

After you configure networking, you can join a workgroup or domain. You cannot set up a

user account until after you have completed setup and rebooted the system. See Windows

NT Help for details on setting up a user account and joining a workgroup or domain.

Finishing Operating System Setup

After operating system Setup is completed, a “Press to finish setup” icon displays on the

operating system desktop. Double-click this icon, or select Programs/InterSite/Welcome

from the operating system Start menu, to display InterSite Welcome.

InterSite Welcome helps you do the following:

u

Create a repair disk for the operating system.

u

Create backup diskettes of device driver software and other system software products.

u

Get the latest driver and other system software from the World Wide Web.

27

u

Display an online System Introduction for your system.

u

Learn about Intergraph Computer Systems customer support.

You should take advantage of the tools provided by InterSite Welcome to ensure that your

system is fully ready for use. See InterSite Welcome for more information. Also see the

following sections for information on creating an Emergency Repair Disk and creating

backup diskettes.

Creating an Emergency Repair Disk

If you did not create an Emergency Repair Disk during Setup, use the tools provided by

InterSite Welcome to do so. See the operating system documentation and Help for

information on creating an Emergency Repair Disk. You should also update an Emergency

Repair Disk after you finish configuring the system.

In the event of corrupted disk drives, the files on the repair diskettes restore the contents of

the operating system registry at the time the operating system was installed, along with the

standard operating system drivers.

Page 38

28

Creating System Software Backup Diskettes

Backup media for some device driver software and system software products may not be

delivered with the system. Use InterSite Version Manager, available through InterSite

Welcome, to create system software backup diskettes.

Version Manager lets you create backup diskettes containing device driver software and

system software products that were installed on the system before shipment, and which are

not available on the operating system CD-ROM. You may need these backup diskettes later

-- for example, if you have to reinstall a device driver or the operating system.

NOTE InterServe products are delivered with backup media of all drivers and other system software

products.

NOTE You may not have to create backup diskettes for all system software. If Version Manager

does not list drivers or other system software products, then they are available on the

operating system software CD, or on backup media delivered with the system.

If the system requires Quick-Fix Engineering (QFE) update software, it is included in the

system software available for backup diskette creation. QFE update software contains fixes

for operating system problems or limitations, and is only shipped with the system if it is

needed. If QFE update software is shipped with the system, you should create a QFE backup

diskette for use if you have to reinstall the operating system. See the

QFE diskette for information on the applicability and installation of QFE update software on

your system.

README.TXT file on the

See Version Manager Help for information on creating system software backup diskettes.

Visit the Intergraph Computer Systems site on the World Wide Web and vendor bulletin

boards for new and updated drivers.

What’s Next?

See the online System Introduction for information on system features and controls.

See Chapter 3, “Configuring the System,” to configure the system for use.

See Chapter 4, “Operating Notes,” for related details.

Page 39

3 Configuring the System

Follow the instructions in this chapter to configure the InterServe 9000 for use.

Configuring the Video Display........................................................................................... 30

Changing the Default Video Display Driver ......................................................... 30

Correcting Video Display Problems...................................................................... 30

Installing Mylex RAID Software........................................................................................ 31

Configuring Drives for a RAID Disk Array........................................................................ 32

Standard RAID Disk Drives Configuration........................................................... 32

Additional RAID Disk Drives Configuration........................................................ 35

Installing and Configuring LanSafe UPS Software............................................................. 36

Installing QFE Update Software......................................................................................... 37

Installing Intel Server Control (ISC) Software.................................................................... 37

Creating an Emergency Repair Disk .................................................................................. 37

Getting Operating System Updates..................................................................................... 37

29

Page 40

30

Configuring the Video Display

The first time you start the system, it uses the installed video display adapter running at

1024 x 768 to run the video display. For the system to use the installed video adapter at

other display resolutions, you must configure the video display driver. Refer to the

documentation delivered with the video display adapter for information about available

settings. For information on using the Display Properties dialog, refer to the operating

system documentation and Help.

Changing the Default Video Display Driver

After configuring the video display and restarting the system, you should configure the

system to use the Intergraph video display driver by default.

To change the default video display driver:

1. Open System in the Windows NT Control Panel. The System dialog displays.

2. Under Operating System, select the Startup list; then select the appropriate non-VGA

Windows NT Server option from the displayed list.

3. Select OK.

Correcting Video Display Problems

If the system’s video display is black, not synchronized, or distorted after you restart the

system, you may have a video configuration problem.

Do not press

correct the problem by using the Last Known Good option to return the system to the last

known good configuration recorded by Windows NT.

To use the Last Known Good option:

1. Power down and restart the system.

2. Press the space bar at the following prompt:

Press space bar NOW to invoke the Last Known Good Menu

If using the Last Known Good option fails to correct the video display problems, you can

obtain a functional video resolution by restarting the system in VGA mode.

CTRL+ALT+DEL to log on to the Windows NT operating system. Instead, try to

Page 41

To restart the system in VGA mode:

1. Power down and restart the system.

2. At the boot screen, select the VGA mode option.

After logging on to Windows NT in VGA mode, check for the following common

configuration problems and solutions:

u

A multi-sync monitor is selected, but a graphics display device with different video

timings (such as an Intergraph InterVue monitor) is connected to the system. Select the

appropriate monitor type as described previously.

u

The monitor selection is inappropriate for the monitor connected to the system. Select a

new monitor.

u

There is not enough video display memory to support the selected graphics resolution

and color depth. Install and reconfigure the video display to use a lower resolution and

color depth.

Restart the system and, when the boot screen displays, select the appropriate non-VGA

Windows NT Server to use the reconfigured video display driver. If problems persist,

contact the Intergraph Customer Response Center at 1-800-633-7248 for help.

31

Installing Mylex RAID Software

Mylex RAID software is installed at the factory on RAID systems. If you have to reinstall

the operating system and associated system software, you must reinstall the Mylex RAID

software after configuring the operating system. Install the software from the backup

diskette supplied with the system, or from the backup diskette you created using Version

Manager. Refer to Version Manager Help for more information about using Version

Manager.

NOTE The MYLEXPCIDRV product contains some administrative utilities for use with the Mylex

software. See the

of these utilities.

To install Mylex software:

1. Log on to Windows NT using an administrative account.

2. Insert the diskette containing the Mylex RAID software in the system’s floppy disk

drive.

3. Run

SETUP.EXE on the diskette.

4. Respond yes or no appropriately to the questions about Windows NT. At the Welcome

dialog, select Next. The Mylex Install Destination Path dialog displays.

README.TXT in the product directory for instructions on installation and use

Page 42

32

5. If you agree with the destination directory, select Next. Otherwise, select Browse and

enter a new directory path. The files will be copied and a Mylex program group created.

Setup also displays a message that the driver is present on the system.

For information on configuring and using the RAID disk drives, and for information on

using the Mylex RAID controller, refer to the Mylex documentation delivered with the

system.

Configuring Drives for a RAID Disk Array

NOTE This section only applies to systems that use RAID disk drives. For technical information

about the disk drive section, refer to the

This section explains the standard RAID disk configuration and provides guidelines to

configure additional RAID drives. The standard RAID hardware is pre-configured by

Intergraph Computer Systems before shipment. The following information is provided to

help you understand how RAID is implemented, which should be valuable if you need to

configure additional RAID hardware.

Standard RAID Disk Drives Configuration

System Reference

.

The InterServe 9000 systems contain three main RAID hardware components:

u

An internal disk section

u

Three or more RAID disk drives

u

One or more RAID controllers (adapters)

The RAID disk drives are installed in slots 1, 2, and 3 of the disk section. These three drives

are grouped (packed) into one array. This array appears as a single drive in Windows NT

Disk Administrator, at double the size of one of the drives. For example, three 4 GB disk

drives appear as an 8 GB logical drive if the RAID level is set to RAID 3 or RAID 5 (12 GB

if the RAID Level is set to RAID 0). RAID 5 is the default.

The Mylex RAID controller BIOS and the Mylex RAID configuration utility let you view

and change the way in which the RAID controller treats the RAID drives. For example, you

can change the configuration so that each drive is a separate array, instead of all three being

in one array.

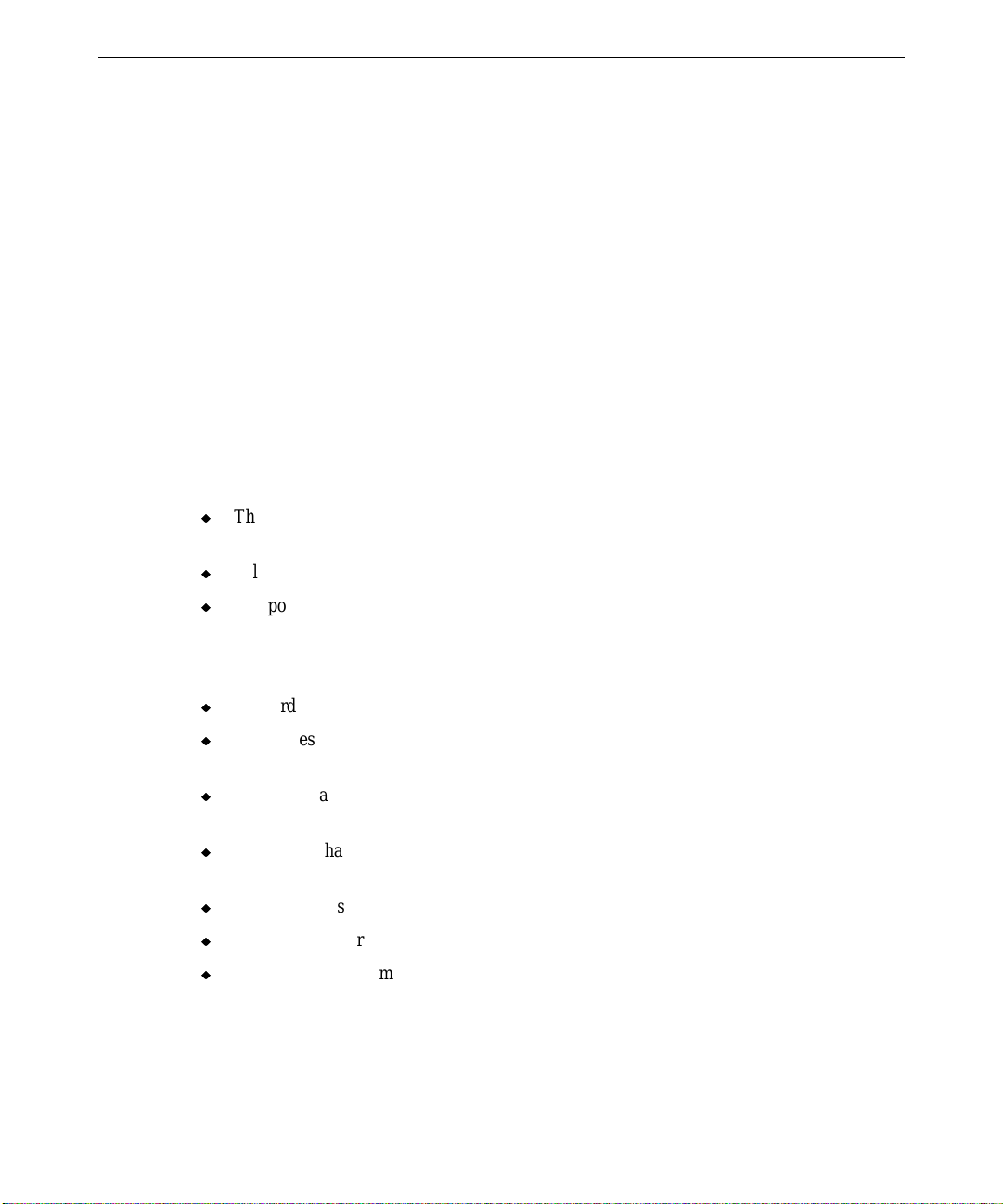

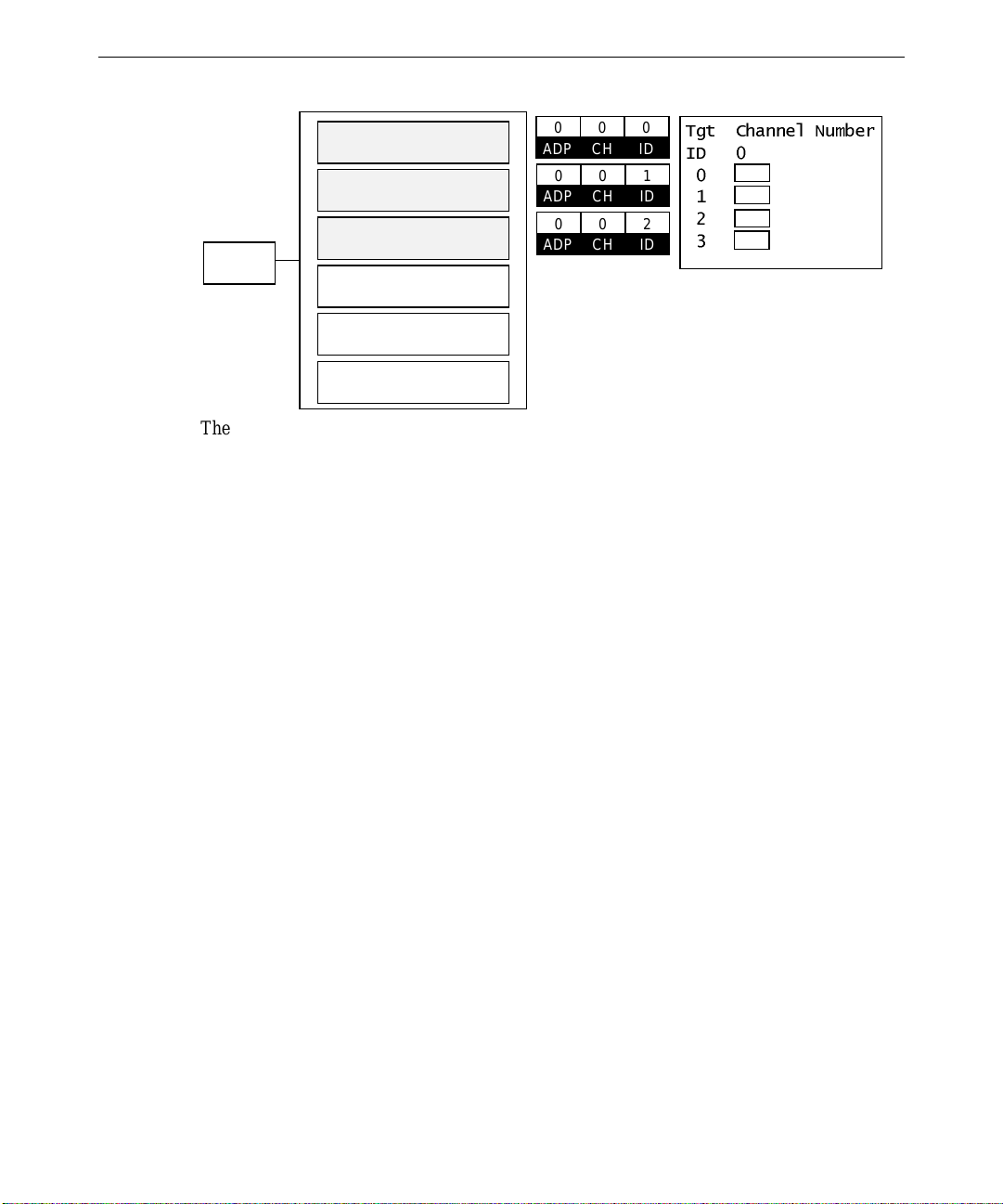

The following figure shows the correlation between the disk drives (labeled), their slot

location (shaded areas), and how they are identified in Mylex BIOS and the Mylex utility.

Page 43

33

ADP

ADP

ADP

ADP 0

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

SCSI ID 0

SCSI ID 1

SCSI ID 2

SCSI ID 4

SCSI ID 5

SCSI ID 6

0CH0ID0

0CH0ID1

0CH0ID2

7JW&KDQQHO1XPEHU

,'

Mylex IDDisk L ab el

The non-volatile memory and flash EEPROM on the RAID controller board stores the

configuration data. When you restart the system, the RAID controller uses this information

to define the RAID configuration to the operating system.

Throughout the Mylex RAID configuration utility, a banner at the top of the display shows

the title, version number, date, controller name, slot number, and firmware version. The

bottom of the display indicates the actions you can take for each menu option. Additionally,

information boxes describe possible actions not allowed. Warning boxes display when the

next action could destroy data on the drives, erase configurations, or has other serious system

consequences.

The following table defines the terms you will see while running the Mylex RAID

configuration utility to configure the drives.

RDY Disk drive ready for configuration

CDR CD-ROM drive

TAP Tape drive

UNF Unformatted drive

PAK Configured packs

DRVS Number of drives in a pack

SIZE Size of the packs (in megabytes)

ONL Drive online (part of pack)

DED Failed drive

RBD Rebuilding

WRO Rebuilding (write only)

FMT Formatting

SBY Standby drive

Page 44

34

The default RAID configuration for the three standard RAID drives is as follows:

u

RAID level - 5

u

Write policy - write through

u

Device Spinup - two drives every 12 seconds

u

Ultra SCSI - enabled

If you modify the RAID configuration, and want to return to the default settings, use the

following procedure.

To reset the default RAID configuration:

1. Reboot the system.

2. When prompted, press

ALT+R to enter the Mylex RAID configuration utility. The Main

Menu displays.

MYLEX Disk Array Controller-Configuration Utility Version X.XX X/XX/XX

2 Channel - 7 Target DAC960P #1 Firmware version x.xx

Main Menu

01. Automatic Configura tion

02. New Confi guration

03. View/Upda te Configu ratio n

04. Rebuild

05. Initializ e System D rive

06. Consisten cy Check

07. Tools

08. Select DA C960

09. Advanced Functions

10. Diagnosti cs

If more than 3 Physical Driv es ar e pre sent , choose t his

option to cre ate one RA ID 5 Syste m Dri ve a utomatical ly.

Use cursor keys for selection, hit <ENTER> to select, <ESC> to Quit

The Help window (box below the Main Menu) briefly describes the operations you can

perform with the highlighted option. Use the cursor keys to select the options in the

Main Menu and press

ENTER to select the highlighted option.

3. Move the cursor down and select New Configuration to set up one 8 GB array to RAID

level 5, and “write through” write policy.

4. Restart the system.

Page 45

Additional RAID Disk Drives Configuration

The Mylex RAID controller BIOS manages up to eight disk drives. If a system has more

than eight drives configured across multiple RAID controllers, you must ensure that the

RAID disk drive containing the operating system (boot drive) is recognized during the BIOS

scan sequence. The BIOS scan sequence starts with the internal devices and then moves to

the PCI slots in the following order: A1, A2, A3, B1, B2, B3, B4. The operating system

boot device must be attached to the RAID controller that is seen first during the scan of the

PCI slots. See the System Reference for more information.

If your system was shipped with more than three RAID drives, then the extra drives are not

configured. Before you can use them, the additional RAID drives must be configured into

one or more arrays using the Mylex RAID controller BIOS or the Mylex RAID configuration

utility. The following steps provide the general guidelines; see the Mylex documentation for

detailed instructions.

To configure additional drives:

1. Reboot the system.

35

2. When prompted, press

ALT+R to enter the Mylex RAID configuration utility. The Main

Menu displays.

3. Select the RAID controller to which the unconfigured RAID drives are connected.

4. From the Main Menu, select View/Update Configuration, then use this option to make

additions to the configuration. This allows you to retain the existing configuration and

create new drive groups. See the Mylex documentation for details.

5. Select the unconfigured RAID drives (shown as RDY) and configure them into one or

more arrays as desired.

CAUTION Do not place different size drives into the same array. If you do, the size of the larger drives

will be truncated to that of the smaller drives, and the remainder will be unusable.

6. When the configuration has been applied, set the drive options to your desired settings.

7. Once all of the RAID drives are defined, press

ESC twice, and then select YES to save

the configuration.

8. From the Main Menu, select Initialize System Drive. Follow the instructions in the

Mylex documentation to mark a system drive and then intialize the drive.

Preparation of the array is complete at this point. You can exit the Mylex RAID

configuration utility and reboot the system. The new RAID pack appears as unpartitioned

disk space under the Disk Administrator utility. You must partition and format the disk

drive space.

Page 46

36

Installing and Configuring LanSafe UPS Software

Systems equipped with a uninterruptible power supply (UPS) are shipped with LanSafe III

software to configure and monitor operation of the UPS. The software must be installed

before you can configure and monitor UPS operation. The following instructions assume

that you are installing LanSafe III UPS software on your system for the first time.

To install LanSafe III UPS software:

1. Insert the LanSafe III CD-ROM into the CD-ROM drive.

2. Run

3. When the Welcome dialog displays, select Install.

4. Select Full Installation to install the software onto the server. If you are installing the

NOTE If you select Install remote services only, Setup asks for a location to install the files. Select

the default location, or enter an alternate pathname; then select Continue. After the software

is installed, click OK and restart the system.

5. When asked if the computer is part of a UPS group, select No; then select Continue.

6. Select Power Rite Pro II; then click Continue.

7. Select the COM port to be used; then select Continue.

8. Enter an access code to safeguard the UPS operation; then select Continue.

9. Select Shutdown Timing Operations; then select Continue.

10. Select Yes for the Automatic Load Option; then select Continue.

11. A dialog asks for a location to install the files. Accept the default location, or enter an

12. Select LanSafe III Power Monitor Service and click Startup. The Service dialog

SETUP.EXE in the NTWIN directory on the CD-ROM drive.

remote services on a non-UPS system, select Install remote services only; then select

Continue.

alternate pathname; then select Continue. When the software is installed, open the

Control Panel and double-click Services. The Services dialog displays.