InterServe 8400

System Reference

November 1997

DHAF02240

Warranties and Liabilities

The information and the software discussed in this document are subject to change without notice and should not

be considered commitments by Intergraph Corporation. Intergraph Corporation assumes no responsibility for any

errors in this document.

The software discussed in this document is furnished under a license and may be used or copied only in accordance

with the terms of the license. No responsibility is assumed by Intergraph for the use or reliability of software on

equipment that is not supplied by Intergraph or its affiliated companies.

All warranties given by Intergraph Corporation about equipment or software are set forth in your purchase

contract, and nothing stated in, or implied by, this document or its contents shall be considered or deemed a

modification or amendment of such warranties.

Copyright

1996, Intergraph Corporation including this documentation, and any software and its file formats and

audiovisual displays described herein; all rights reserved; may only be used pursuant to the applicable software

license agreement; contains confidential and proprietary information of Intergraph and/or other third parties which

is protected by copyright, trade secret and trademark law and may not be provided or otherwise made available

without prior written authorization.

Restricted Rights Legend

Use, duplication, or disclosure by the United States Government is subject to restrictions as set forth in subdivision

(c)(1)(ii) of the rights in technical data and computer software clause at DFARS 252.227-7013.

Unpublished rights reserved under the copyright laws of the United States.

Intergraph Corporation, Huntsville AL 35894-0001

Trademarks

Intergraph and the Intergraph logo are registered trademarks, and InterServe is a trademark, of Intergraph

Corporation.

Other brands and product names are trademarks of their respective owners.

FCC/DOC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy. If the equipment is not installed and used in accordance with the instruction manual, it

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at his own expense.

This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in

the Radio Interference Regulations of the Canadian Department of Communications.

Warnings

The service and upgrade instructions should be performed by qualified personnel only. Qualified personnel do not

have to be Intergraph service personnel, but those who are familiar with servicing computers, can follow

instructions in a manual to service equipment, and do so without harm to themselves or damage to the equipment.

To reduce the risk of electrical shock, do not attempt to open the equipment unless instructed. Do not use a tool for

purposes other than instructed.

There are no user serviceable parts within the power supply. In the event of failure, the power supply must be

replaced by qualified service personnel. Use Intergraph power supplies only.

Notes

Changes or modifications made to the system that are not approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

Read all safety and operating instructions before using the equipment. Keep these instructions for future reference.

Follow all warnings on the equipment or in the operating instructions.

Contents

Introduction....................................................................................................................................vii

Restrictions......................................................................................................................................vii

Conventions.....................................................................................................................................vii

Additional System Information ........................................................................................................vii

1 Before You Begin .........................................................................................................................1

Safety Precautions..............................................................................................................................1

InterServe Base Unit.............................................................................................................1

Intergraph 19-inch Rack .......................................................................................................1

Power Requirements...........................................................................................................................2

Domestic AC Distribution Box.............................................................................................2

Non-Domestic AC Distribution Box.....................................................................................3

Equipment Power Loads.......................................................................................................4

Placing the System.............................................................................................................................4

2 Installing the InterServe 8400......................................................................................................5

Uninterruptible Power Supply ............................................................................................................6

InterRAID-8e Cabinets.......................................................................................................................7

InterServe Base Unit ........................................................................................................................10

Keyboard and Mouse........................................................................................................................13

Concentrator .................................................................................................................................... 14

Installing Disk Drives ...................................................................................................................... 14

Install and Label the Disk Drives........................................................................................ 16

Additional Information.......................................................................................................19

System Cables..................................................................................................................................20

Keyboard, Mouse and Monitor............................................................................................20

InterRAID-8e.....................................................................................................................21

Intruder Alert ..................................................................................................................... 22

Expansion Board Cables.....................................................................................................25

UPS Serial Cable................................................................................................................26

System Power Cord............................................................................................................27

Cable Handlers.................................................................................................................................28

Additional Rack-mount Equipment ..................................................................................................30

Checking the Setup ..........................................................................................................................30

Starting the System ..........................................................................................................................30

v

3 Hardware Overview................................................................................................................... 31

4 System Hardware Information..................................................................................................37

System Level Functional Diagram....................................................................................................38

Processor Board (MSMT329)...........................................................................................................39

Functional Diagram............................................................................................................39

Memory Subsystem Description..........................................................................................40

Address Resources..............................................................................................................42

Board Layout...................................................................................................................... 43

I/O Expansion Board (MSMT451) ...................................................................................................44

Functional Diagram............................................................................................................45

I/O Addresses.....................................................................................................................46

vi

DMA Channels .................................................................................................................. 47

Board Layout...................................................................................................................... 47

Component Descriptions..................................................................................................... 50

I/O Connector Board (MSMT328).................................................................................................... 53

Board Layout...................................................................................................................... 53

Flash EPROM ....................................................................................................................55

LCD Board (MPCBD20)..................................................................................................................56

Power Distribution Board (MSMT385) ............................................................................................56

Side 1.................................................................................................................................57

Side 2.................................................................................................................................57

AC Input Wiring..............................................................................................................................60

Disk Drive Section (MESAN520).....................................................................................................61

Assembly Layout................................................................................................................ 61

Cable Routing and Pinouts .................................................................................................61

Channel Module.................................................................................................................63

SAF-TE Card .....................................................................................................................63

Jumper Settings..................................................................................................................63

Power Supplies (MPWS139)............................................................................................................65

Intruder Alert...................................................................................................................................68

CD-ROM Drive (CDSK178)............................................................................................................70

Combo Drive (MESAN480).............................................................................................................71

5 Accessing the System..................................................................................................................73

Servicing Restrictions ......................................................................................................................73

Opening the Base Unit .....................................................................................................................73

Avoiding Electrostatic Discharge .....................................................................................................74

Closing the Base Unit.......................................................................................................................75

6 Upgrading the System................................................................................................................77

Servicing Restrictions ......................................................................................................................77

Adding Memory...............................................................................................................................77

Adding Option Boards .....................................................................................................................80

Assigning Resources for Option Boards..............................................................................81

Adding Internal SCSI Devices..........................................................................................................84

Adding External SCSI Devices.........................................................................................................86

Understanding Cable Lengths............................................................................................. 86

Connecting the Device........................................................................................................87

Disabling Sync Negotiation................................................................................................87

7 Specifications..............................................................................................................................89

8 Low-Level Software Procedures................................................................................................91

Installing RAID Controller Flash Code ............................................................................................91

Installing Disk Section Firmware .....................................................................................................91

Setting the Default RAID Configuration...........................................................................................92

Index...............................................................................................................................................93

Introduction

This System Reference provides the information necessary to service InterServe 8400 systems.

Restrictions

This document is restricted for use by qualified personnel. In the opening, upgrading, and servicing

instructions, heed all warnings and cautions. Personal injury and damage to equipment can occur if

documented procedures are not followed.

WARNING The system produces high-leakage current. Flip the circuit breaker to the OFF position when

servicing or upgrading the base unit.

CAUTION Use an antistatic wrist strap for all servicing procedures to avoid the possibility of electrostatic

discharge.

vii

Conventions

Bold

Italic Variable values that you supply, or cross-references.

Monospace

SMALL CAPS Key names on the keyboard, such as D, ALT or F3. Names of files and

CTRL+D Press a key while simultaneously pressing another key; for example, press

Commands, words, or characters that you key in literally.

Output displayed on the screen.

directories. You can type filenames and directory names in the dialog boxes

or the command line in lowercase unless directed otherwise.

CTRL and D simultaneously.

Additional System Information

A System Setup is shipped with each system, and provides detailed information about:

u

Configuring the operating system and associated system software.

u

Using the system.

u

Using the AMIBIOS Setup program.

u

Installing system software.

A System Introduction is delivered with the system, and provides information about:

u

Intergraph Support

u

System hardware features

u

Available hardware options

viii

1 Before You Begin

Review this chapter before installing the InterServe 8400 into the Intergraph rack.

u

Set up the Intergraph rack using the Intergraph Rack Installation and Use (DHA0194x0,

supplied with the rack), and become familiar with the rack enclosure before installing the system

hardware.

u

Ensure that all Intergraph equipment has the necessary mounting hardware and other associated

items as described in each section. If any items are missing, contact the local support office

immediately to obtain the missing items.

u

Retain all packaging materials. To return equipment for repair, the customer must return it in

the original packaging to obtain warranty service (if provided by their contract agreement).

WARNING If using non-Intergraph cables with the system, ensure that they are shielded and terminated

on both ends.

Safety Precautions

1

InterServe Base Unit

u

The base unit is subject to high leakage current, and must be properly grounded. To assure

proper grounding, connect the base unit power cord only to the designated outlet on the AC

distribution box or uninterruptible power supply (UPS).

u

The base unit weighs 125 pounds (57 kg) without RAID disk drives. Two people must lift the

base unit when removing it from the pallet and installing it into the rack.

Intergraph 19-inch Rack

WARNING The Intergraph rack is intended for use only with Underwriter’s Laboratories Listed rack-

mountable accessories which meet the criteria below and are suitable for use in a 26 °C

ambient temperature.

u

Fixed devices may not weigh more than 20 pounds (9.0 kg) per vertical U (1.75 inches). The

center of gravity of fixed devices must not be deeper than 15.0 inches (38.1 cm) inside the rack.

u

Slide rail devices (between 5 U and 11 U) may not weigh more than 13.6 pounds (6.2 kg) per U.

These devices may not be extended more than 31.5 inches (78.8 cm) and their center of gravity

must not extend beyond 16.5 inches (49.1 cm).

u

Slide rail devices (less than 5 U) may not weight more than 20 pounds (9.0 kg) per U. These

devices may not be extended more than 24 inches (61 cm) and their center of gravity must not

extend beyond 13 inches (33 cm).

u

If more than one slide rail device is installed, only one device may be extended at a time. Should

you need access to a device while another is extended, push the extended device back into the

rack before extending the next device.

WARNING Extending more than one device at a time could cause the rack to fall forward, causing damage

to the equipment and injuring anyone standing in front of the rack.

2

u

Do not push on or lean against the rack. The front and side stabilizer feet must be extended at all

times.

u

Install bottom components into the rack first.

Power Requirements

This section provides information about the power requirements of the AC distribution box supplied

by Intergraph with some systems. Intergraph provides separate AC distribution boxes for domestic

and non-domestic use. This section describes the specifications and functionality of both types.

NOTE If the cutomer purchased a UPS instead of an AC distribution box, refer to the documentation

delivered with the UPS for power information.

Domestic AC Distribution Box

Specifications for the domestic AC distribution box include:

u

AC input: 110/220 VAC 60 Hz, 16 Amperes

u

Receptacles: eight NEMA 5-15R and one NEMA 6-15R

u

Power cable: 9 feet, 12 AWG, 4 conductor with NEMA L14-20P plug

u

Output rating: 1760 VA/phase @ 110 VAC, 3520 VA total

The domestic AC distribution box is rated for a maximum output rating of 3520 VA (Volt-Amperes)

at 110 VAC. The sum-total VA load that the devices pull must not exceed this maximum, else a

breaker in the AC distribution box trips when power is applied. A second AC distribution box must

be installed to provide the additional power requirement. The following figure shows the domestic

AC distribution box.

Each receptacle on the AC distribution box is rated for a specific VA. The 6-15R receptacle (J9) is

used for the power cord to the server. The remaining eight receptacles (110 V each) are for

additional devices installed in the rack. Notice that the left four (J1-J4) and right four (J5-J8) are on

different phases. Follow these guidelines when connecting equipment power cords:

u

If the NEMA 6-15R receptacle (J9) is not used, then the eight NEMA 5-15R receptacles can

support the full 3520 VA load (1760 VA per phase).

u

If the NEMA 6-15R receptacle (J9) is used, then the eight NEMA 5-15R receptacles can support

1760 VA load (880 VA per phase).

u

The power load should be balanced between the phases of the 110 VAC receptacles. For

example, do not plug four 110 VAC 2 Amp devices into phase I; instead, plug two of the devices

into the phase I and two into phase II.

WARNING The wall outlet to which the AC distribution box is connected must be a NEMA L14-20R type

outlet on a properly grounded branch circuit.

Non-Domestic AC Distribution Box

Specifications for the non-domestic AC distribution box include:

u

AC input: 190/264 VAC 50 Hz, 16 Amperes

u

Receptacles: eight IEC 320 10 Amperes, and one IEC 320 16 Amperes

u

Power cable: 2.5m with IEC 309 16 Amperes plug

u

Output rating: 3520 VA total @ 220 VAC

The non-domestic AC distribution box is rated for a maximum output rating of 3520 VA (Voltamperes) at 220 VAC. The sum-total VA load that the devices pull must not exceed this maximum,

else a breaker in the AC distribution box trips when power is applied. A second AC distribution box

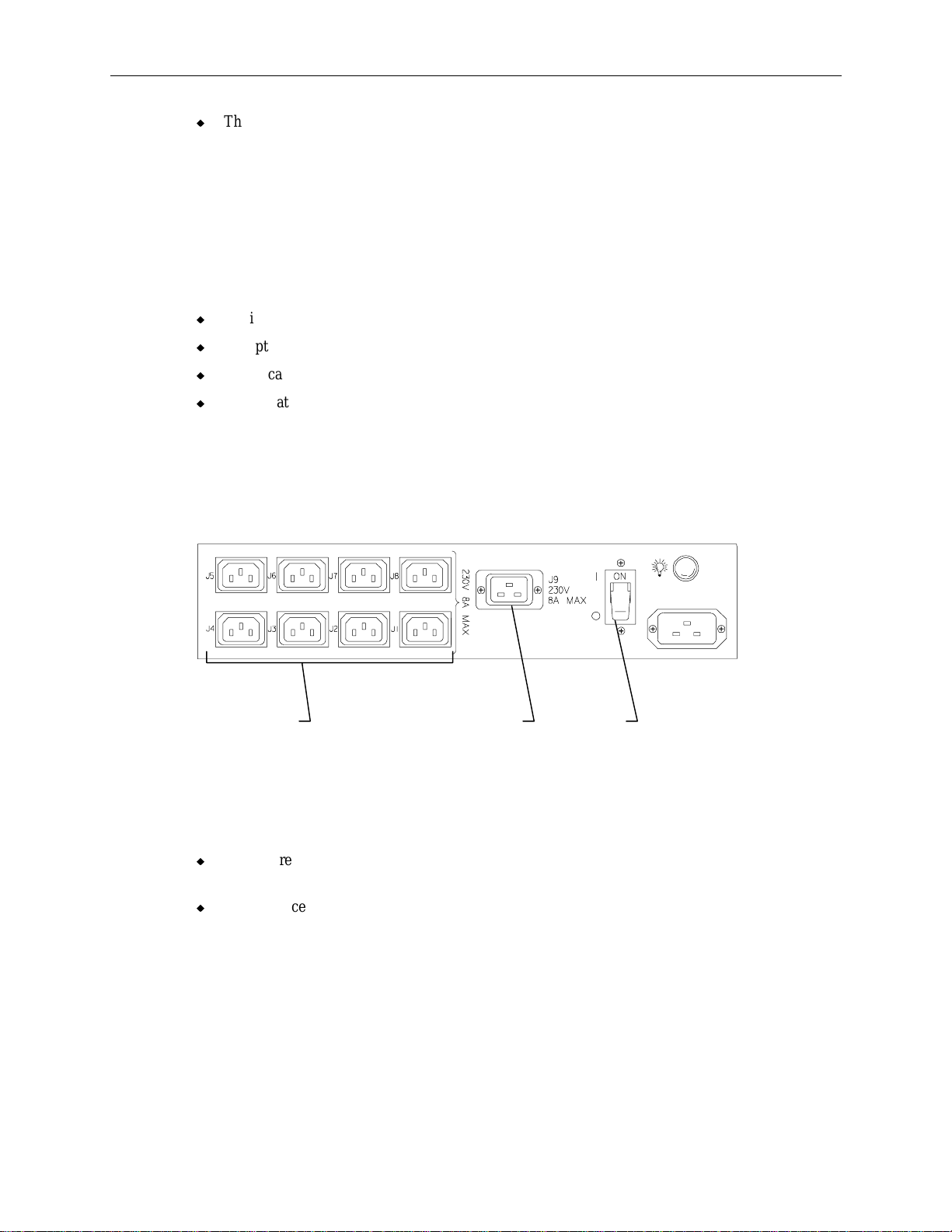

must be installed to provide the additional power requirement. The following figure shows the nondomestic AC distribution box.

3

IEC 320 IEC 320 Power

10 Amp 16 Amp switch

Each receptacle on the AC distribution box is rated for a specific VA. The IEC 320 16 Ampere

receptacle (J9) is used for the power cord from the base unit. The remaining eight IEC 320 10

Ampere receptacles are for additional devices installed in the rack. Follow these guidelines when

connecting equipment power cords:

u

If the J9 receptacle is not used, then the eight 10 Ampere receptacles (J1-J8) can support the full

3520 VA load.

u

If the J9 receptacle is used, then the eight 10 Ampere receptacles (J1-J8) can support only 1760

VA load.

WARNING The wall outlet to which the AC distribution box is connected must be an IEC 309 type outlet

on a properly grounded branch circuit.

4

Equipment Power Loads

The power load values for the base unit and disk array cabinet are provided below. Load values of

equipment must be taken into account when installing equipment to the rack.

Device

System base unit with eight drives 1200 VA

Disk drive cabinet with eight 4 GB drives 265 VA

Disk drive cabinet with eight 9 GB drives 261 VA

4-port concentrator 8 VA

8-port concentrator 10 VA

PC extender 13 VA

The VA load of Intergraph rack-mount options is printed on the back of the device. Add the VA load

for each device to determine if the AC distribution box can handle the load. If it cannot, add an

additional AC distribution box. The VA load of a device is the product of its operating Voltage (such

as 110 V or 220 V) times its current rating (2 Amperes, 3 Amperes, 6 Amperes, etc.).

Placing the System

Before you unpack the equipment and begin setting up your server, determine where you want to

place the system rack. Keep these guidelines in mind:

u

Place the rack as close as possible to the proper wall outlet. The power cord connecting the AC

distribution box or UPS to the wall outlet serves as the disconnect device.

u

Place the rack in an area where air can circulate freely around it. Ensure that the front and the

back of the rack each have 36 inches of clearance for servicing the installed hardware.

Max Load

u

Do not expose the system to high levels of dust, smoke, or moisture.

u

Place the system in an area where the temperature range stays between 10 °C and 26 °C (50 °F to

80 °F). The optimum operating temperature is 21 °C (70 °F).

u

Place the system in an area where the humidity stays between 20 and 80 % (non-condensing).

The optimum operating humidity is 50 % (non-condensing).

u

The rack is not designed to be moved when equipment is installed (other than equipment that is

pre-installed by Intergraph).

WARNING Once you install the equipment, do not move the rack. If you must move it, then remove all

equipment, move the rack to its new location, and reinstall the equipment.

2 Installing the InterServe 8400

This chapter describes how to install an InterServe 8400 and additional equipment into an Intergraph

rack. The equipment is secured in the rack along the side mounting posts, which have industry

standard 7.1 mm diameter mounting holes along the edge. The mounting posts have small round

markers to designate each vertical unit, or U. There are three mounting holes per U, and at every 4 U

there is a small square marker. The total vertical mounting height within the rack is 40 U.

The system components should be installed in the following order:

u

Uninterruptible power supply (UPS)

u

InterRAID-8e disk array cabinet

u

InterServe base unit

u

Rack-mount interface peripherals (keyboard, mouse, monitor)

u

Disk drives

u

System power and data cables

u

Rack cable handlers

5

u

Accessory components

WARNING Follow the installation instructions explicitly to avoid personal injury and damage to the server

hardware.

CAUTION To keep the rack from moving, ensure the front and side stabilizers are fully engaged and the leveling

feet are lowered firmly to the floor before installing equipment into the rack.

Note the following points before installing equipment into the rack:

u

The rack must be properly set up before placing any equipment into the rack. If installing the

equipment into an Intergraph rack, follow the instructions in Intergraph Rack Installation and Use

(DHA0194x0) supplied with the rack.

u

Do not start the system until it has been completely set up. After setup is complete, refer to the

System Setup document delivered with the system for startup and configuration instructions.

u

As equipment is installed into the rack, some components may not align properly with the holes in

the mounting posts. This occurs because some components have different tolerances in regards to

their height. If components do not align properly, loosen their screws and adjust support rails and

shelves where necessary so the components can be supported by the proper shelves or rails, rather

than by the component underneath.

u

The hole numbers stated in the instructions assume the following:

− a UPS is installed first, in the lowest 4 U space;

− an InterRAID-8e is installed next, just above the UPS; and

− the InterServe 8400 is installed next, just above the InterRAID-8e.

6

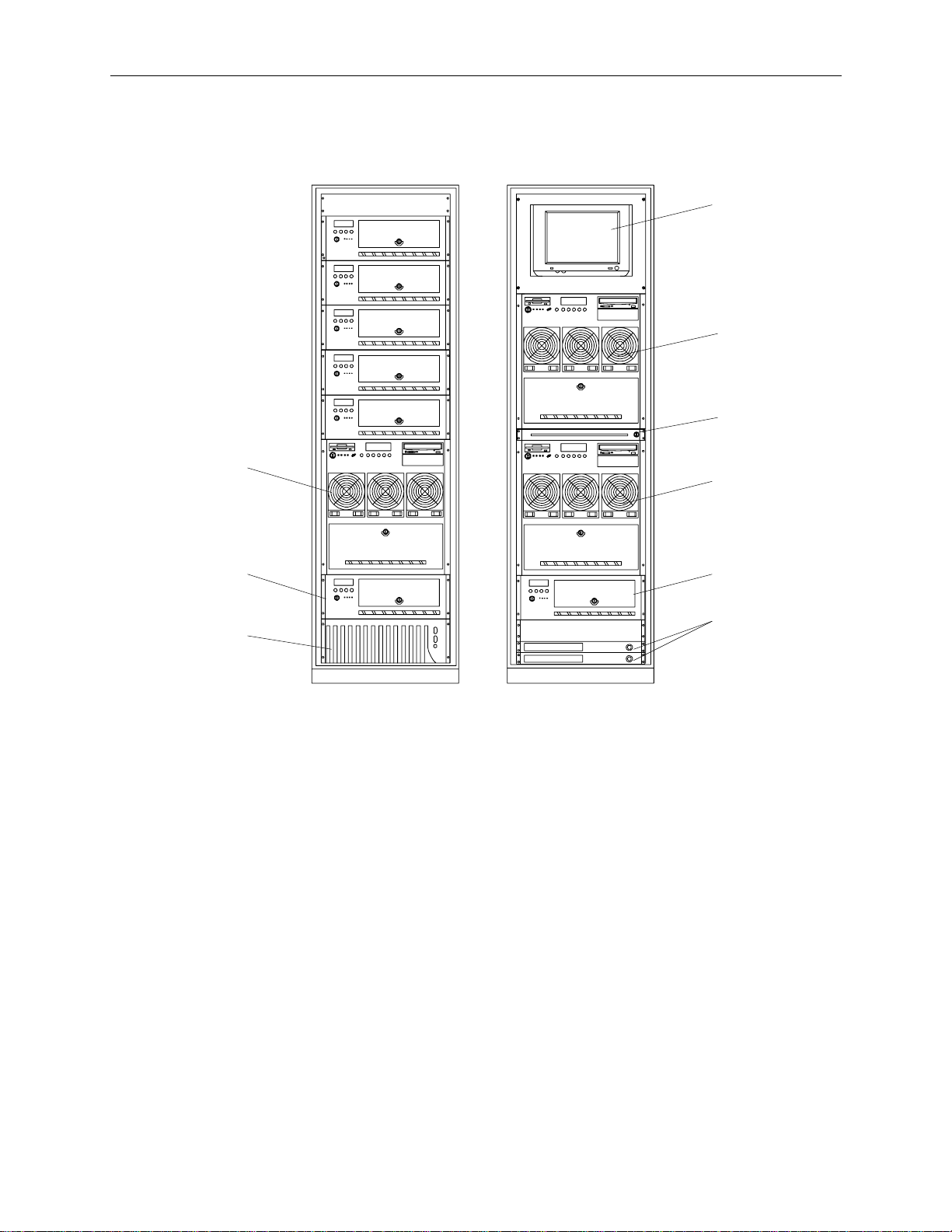

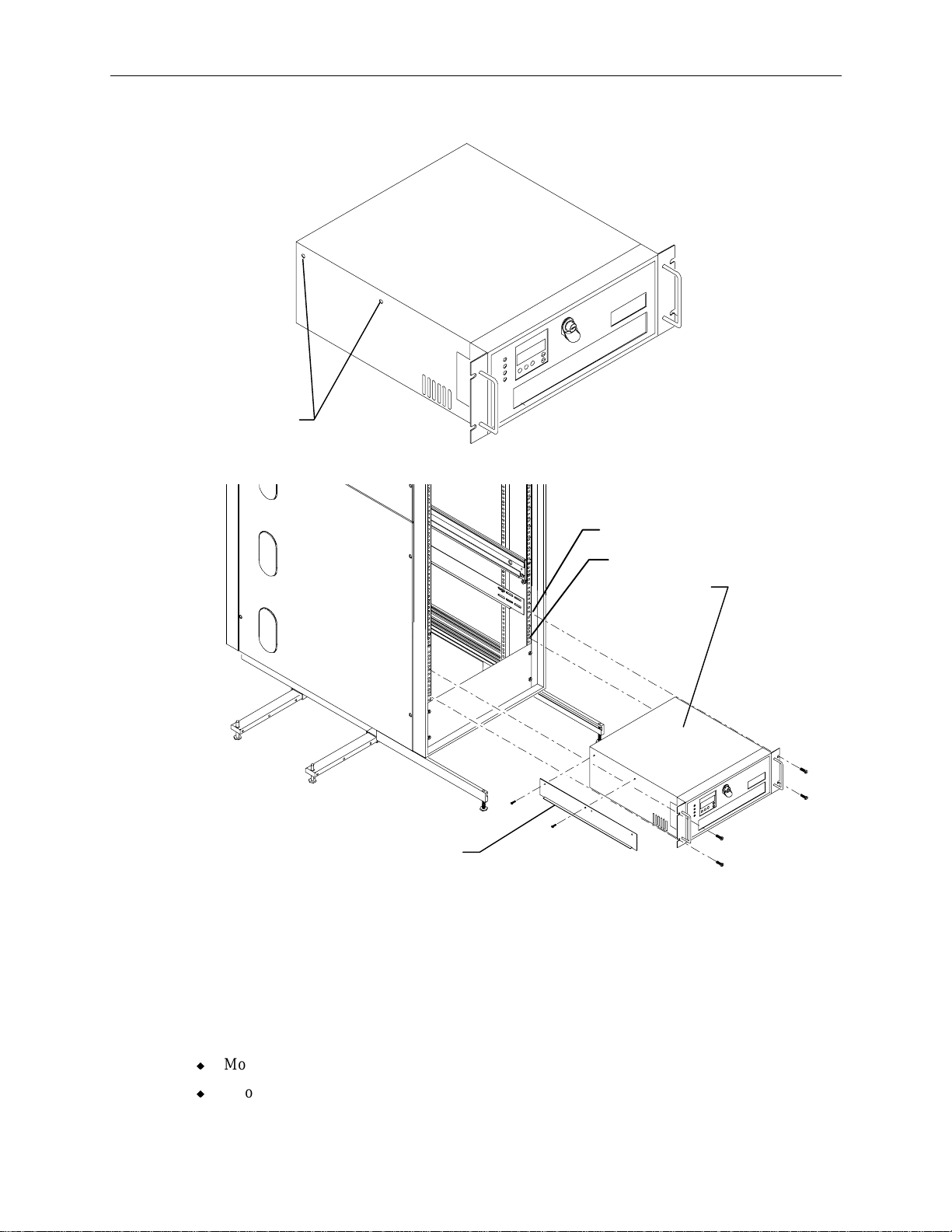

The following figure shows how two racks look when fully populated with servers, UPS or AC boxes,

InterRAID-8e disk array cabinets, monitor, and keyboard. These figures do not attempt to show every

possible variation, nor do they indicate any bundled configurations.

Monitor

InterServe 8400

Keyboard

InterServe

8400

InterRAID -8e

UPS

InterServe 8400

InterRAID-8e

AC Distribution

Boxes

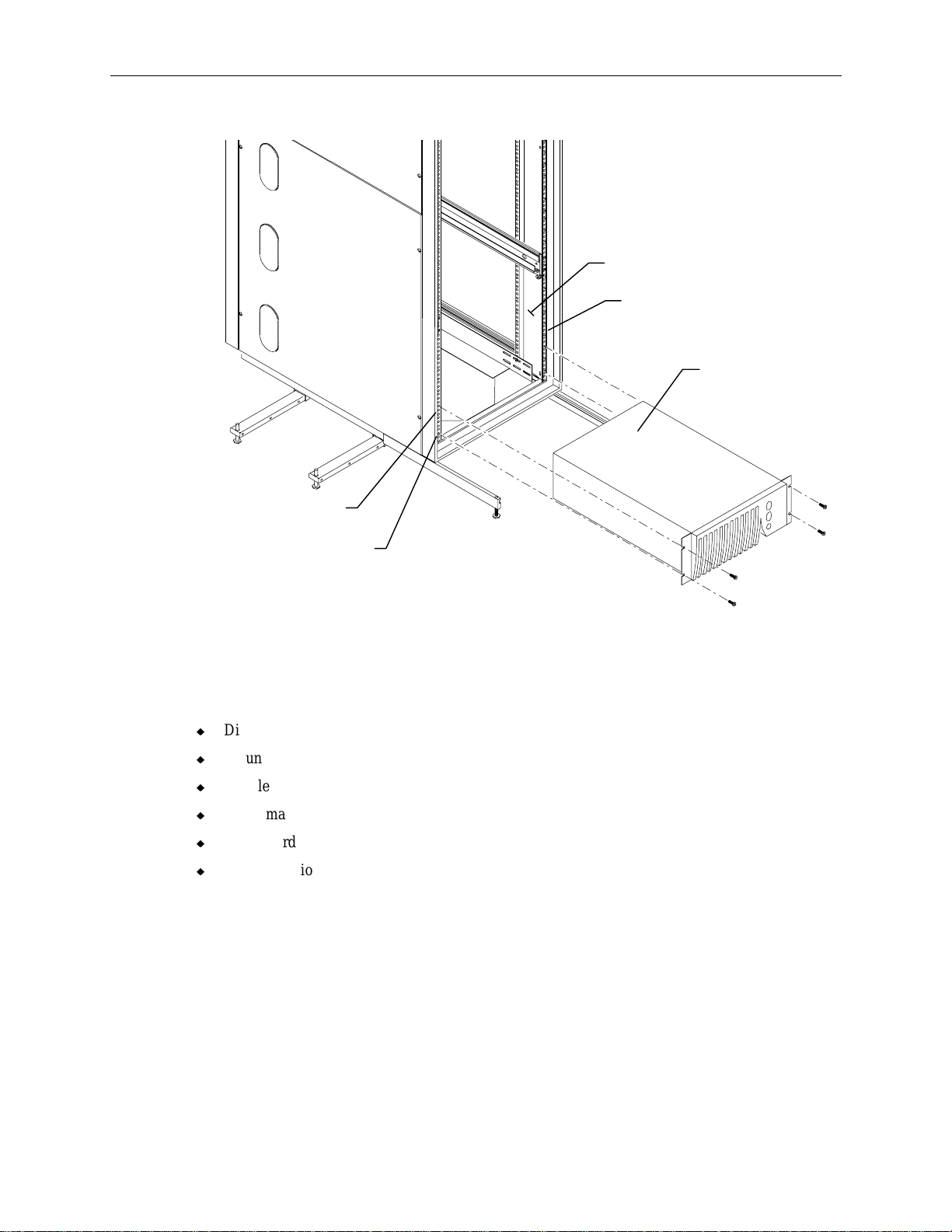

Uninterruptible Power Supply

The UPS carton contains the UPS, serial cable, and documentation. The LanSafe III software used to

monitor and configure the UPS is also included with the system.

NOTE The door hinges for the rack must be installed before installing the UPS in the bottom of the rack. For

instructions, refer to

To install the UPS into the rack:

Intergraph Rack Installation and Use

.

1. Insert tinnerman nuts at hole 3 and hole 10 in the front edge of the mounting post.

2. Slide the UPS through the front of the rack, and ensure the back of the UPS rests on the

mounting shelf inside the rack.

3. Attach the UPS to the rack using a screw at each corner.

Hole 10

7

Mounting Post

Front Edge of Post

UPS

Hole 3

InterRAID-8e Cabinets

Unpack the InterRAID-8e from the carton and verify you have the following items.

u

Disk array cabinet

u

Mounting hardware

u

Handle brackets and screws

u

Tinnerman nuts and screws

u

Power cord

u

Documentation

The mounting hardware includes two shelves to be mounted inside the rack, and two brackets to be

attached to the InterRAID-8e cabinet.

8

To install the InterRAID-8e cabinet into the rack:

1. Attach the handle brackets to both sides of the InterRAID-8e cabinet. Use the eight panhead

screws (four for each bracket) supplied with the InterRAID-8e.

Handle Bracket

NOTE The sides of the InterRAID-8e have different hole patterns to match the pattern in each handle bracket.

2. Determine the 4 U space in which to install the InterRAID-8e. The following figure shows

where the mounting shelf and tinnerman nut must be installed in a given 4 U space.

Mounting Shelf

(End View)

4 U (12 Holes)

Tinnerman

Nut

Bottom edge of

InterRAID-8e here

3. Attach the mounting shelves to the rack. Place tinnerman nuts for the shelves on the interior

face of all four mounting posts. Refer to the following figure.

Interior Face of

Mounting Post

Mounting Shelves

9

4. Place tinnerman nuts for the InterRAID-8e faceplate on the exterior face of both front mounting

posts, in holes 15 and 22. The following figure shows the tinnerman nut locations for the 4 U

space.

4 U (12 Holes)

Tinnerman Nuts

10

5. Remove and discard the flat head screws from both sides of the InterRAID-8e cabinet as shown.

Flat Head

Screws

6. Attach the mounting brackets to the InterRAID-8e and slide it into the rack as shown.

Mounting Bracket

(Note ledge is turned away

from InterRAID-8e cabinet.)

7. Secure the disk array cabinet to the rack using the screws supplied with the InterRAID-8e.

InterServe Base Unit

Hole 22

Hole 15

InterRAID-8e

Cabinet

Two boxes are included with the base unit: one for the keyboard, and one for software media and

miscellaneous parts. The software media and miscellaneous parts box contains the following items:

u

Mouse

u

Two cable handlers

u

Screws and tinnerman nuts

u

Keys for base unit and internal RAID section

u

Power cord

u

Windows NT Server kit (software and documentation)

u

Intergraph system software and online documentation (diskettes)

WARNING The server base unit is very heavy and bulky. Two people must lift the base unit when

removing it from the pallet and installing it into the rack.

To install the server into the rack:

1. Place the pallet close to the rack.

2. Four brackets secure the base unit to the pallet. Remove the two upper screws from each bracket

as shown in the following figure.

11

Brackets

Screws

3. Insert tinnerman nuts in holes 27 and 55 on both front mounting posts of the rack.

4. Extend the base unit rails from the rack until they lock. Refer to the following figure.

12

5. With a person on either side, lift the base unit and align the base unit rails in the rack with the

rail guides mounted on the side of the base unit.

Base Unit

Rails

Rail Guide

(Each Side)

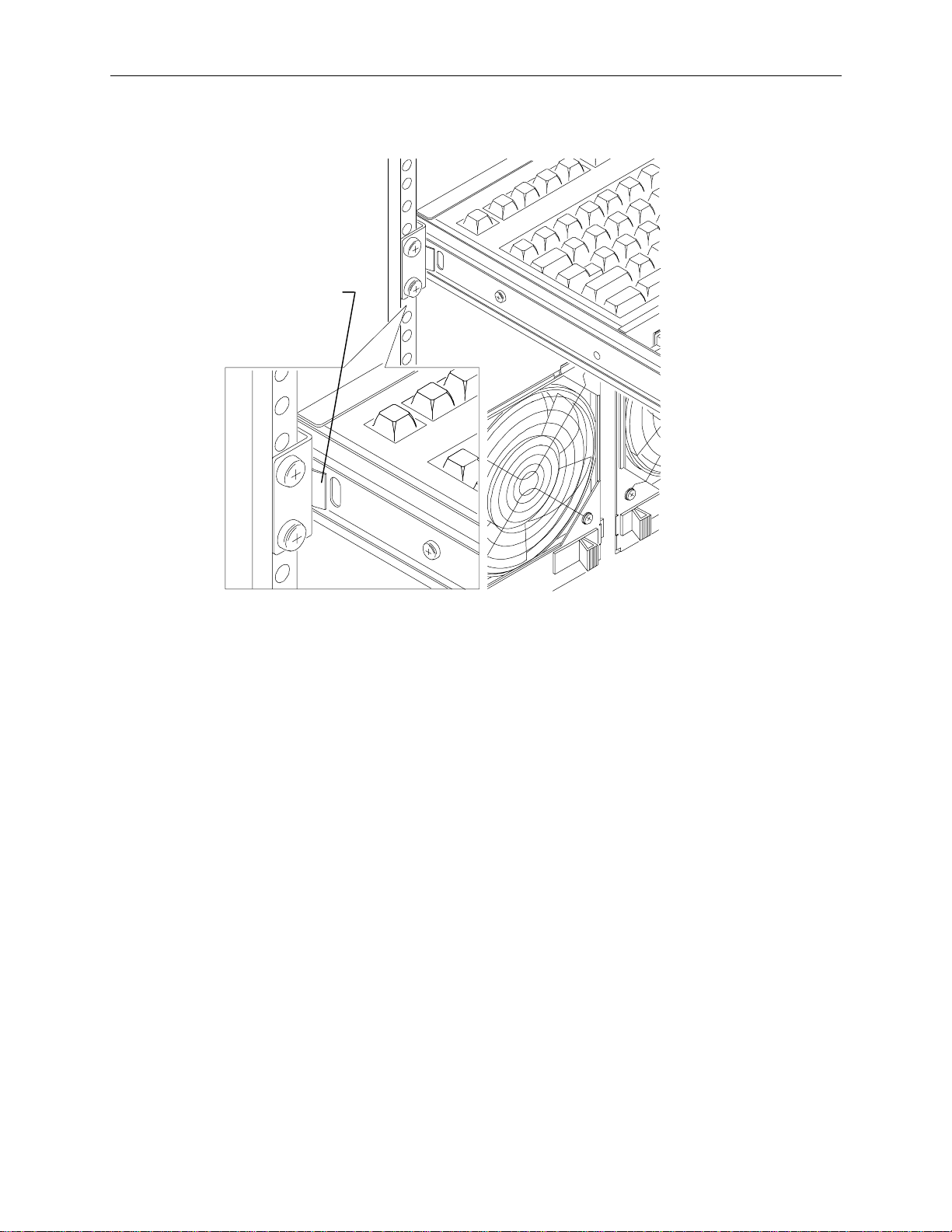

6. Slide the base unit into the rails and push the base until it stops. The metal rail button in the rail

guides hits against the base unit rail. Press the rail buttons on both sides and continue pushing

the base unit. The base unit will stop again and the metal rail button appears in the hole of the

base unit rails. Refer to the following figure.

CAUTION Ensure the board ejectors on both sides of the base unit are closed. They will interfere with the

mounting rails if not fully closed.

Base Unit

Rail

Board

Ejector

Rail

Guide

Rail

Button

7. Press the rail buttons on both sides and push the base unit into the rack.

Keyboard and Mouse

This section describes installing the keyboard and mouse into the rack. The keyboard and mouse are

installed into a sliding keyboard drawer.

13

NOTE Refer to DHAF027x0,

install the monitor.

To install the keyboard and mouse into the rack:

1. Pull out the drawer until it locks in the extended position.

2. Route the keyboard and mouse cables through the opening in the back of the tray and through the

four clamps in the cable guide.

3. Set the keyboard into the drawer.

4. Open the hand-rest tray and set the mouse into it.

Rack-Mounted Monitor Installation

Cable

Guide

, delivered with the monitor, for instructions to

Drawer

Hand Rest Tray

14

5. To retract the keyboard drawer, press the rail tabs on both sides of the drawer, then push it into

the rack.

Push in to retract

the drawer.

Concentrator

A keyboard, mouse, and monitor concentrator is included with the remote interface kit. The

concentrator comes with a 25-foot-long cable set that connects between the base unit and the

concentrator.

To install the concentrator:

1. Place the keyboard, mouse, and monitor in the desired location, up to 25 feet away from the base

unit.

2. Connect the keyboard, mouse, and monitor cables to the concentrator.

3. Connect the cable set to the base unit and to the concentrator. Refer to the concentrator

documentation for details.

Installing Disk Drives

The disk section in the front of the system contains eight disk drive slots. The slots are numbered

from 1 to 8, starting with the right slot. If you are installing less than eight drives into the system,

install the disk drives starting in slot 1 and fill each slot in sequence. Use the key provided in the

parts box to unlock and open the disk section door.

The disk drive boxes can hold up to six disk drives. Depending on the configuration, the system is

RAID or non-RAID system. The RAID system uses a 2-channel AMI RAID controller to provide

RAID capabilities such as disk striping, mirroring, and redundancy. The non-RAID system use a 2channel Ultra Wide SCSI controller that does not feature any RAID capabilities.

Each disk drive has a label affixed to the front. The left side of the disk drive label identifies the disk

drive size (in GB). The label has blank spaces for the numbers to indicate the adapter (ADP),

channel (CH), and SCSI ID (ID). Standard disk drives include values for the adapter, channel, and

SCSI ID filled in. Additional disk drives have a blank label which you must complete after

installation.

NOTE A labeling sheet is included in the system parts box.

15

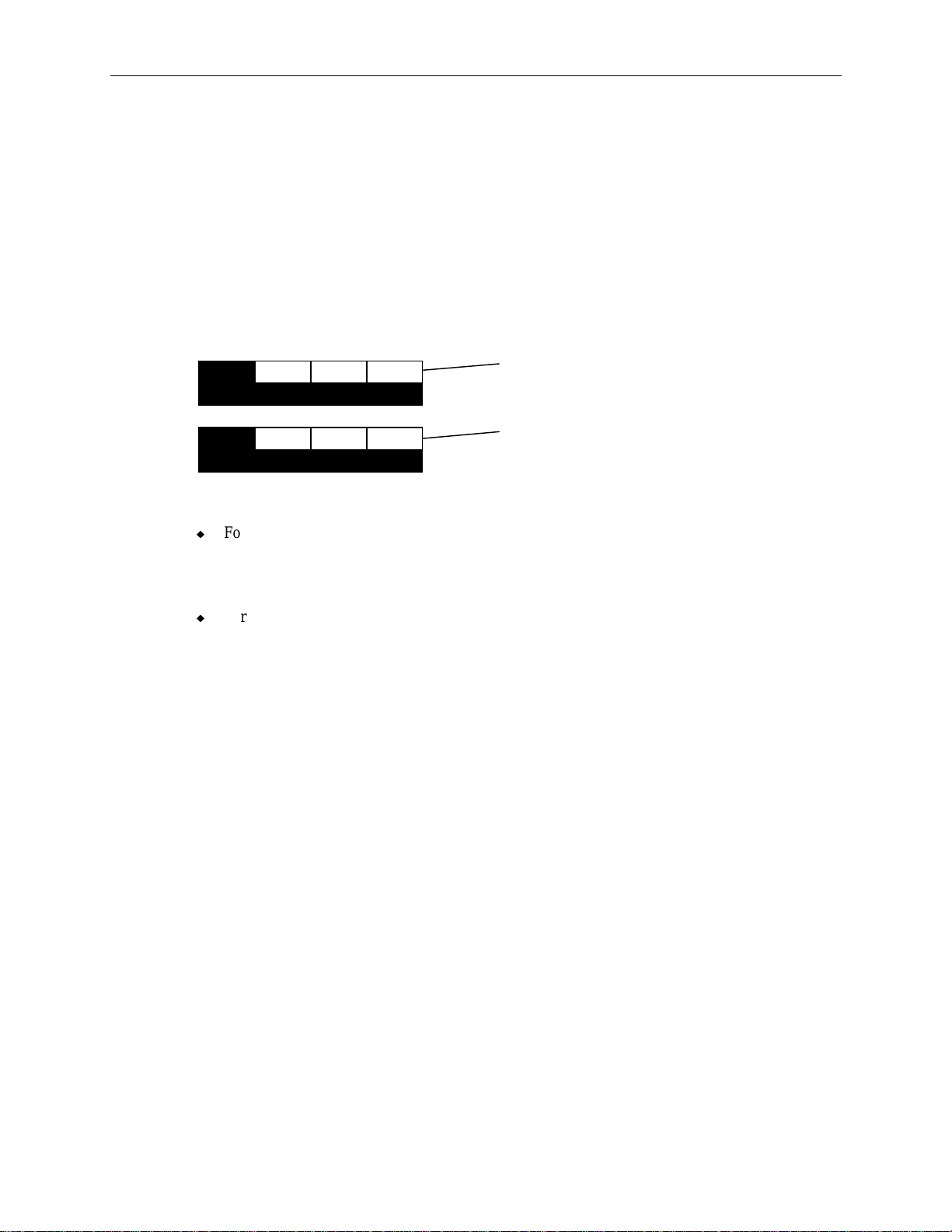

x GB

x GB

ADP

ADP

100

CH ID

CH ID

Filled-in Label

Blank Label

Note the following about RAID and non-RAID systems.

u

For a RAID system, three disk drives (with the operating system striped across all three) are

standard. These drives, called boot drives, are labeled with specific adapter, channel, and SCSI

ID. They must be installed in specific slots in the disk section. Installation details are provided

below.

u

For a non-RAID system, one disk drive (with the operating system installed) is standard. This

drive is called the boot drive. It is labeled with specific adapter, channel, and SCSI ID. The boot

drive must be installed in the lowest slot of the disk section. Installation details are provided

below.

16

Install and Label the Disk Drives

To install the disk drives:

1. Open the disk section door on the front of the base unit.

Slot 1

2. Remove the disk drives from the drive boxes.

3. Do the following when inserting drives into the slots:

−

Extend the latching clips on the drive and align the rails on the side of the drive with the slot

guides. The metal casing of the drive faces up. If you install the drive reversed, it will not

connect to the system.

−

Push the drive between the latching clips until it slides all the way into the slot and firmly

engages the connector.

−

Close the latching clips to lock the drive in the slot.

Drive Latching

Clips

4. Locate and install the boot drives (those with the completed labels).

−

Install the RAID boot drives into slots 1, 2, and 3 of the disk section, as shown in the

following figure.

17

x GB

ADP0CH

x GB

ADP0CH

x GB

ADP0CH

−

Install the non-RAID boot drive into slot 1 of the disk section, as shown in the following

0

Slot 6 Slot 5 Slot 4Slot 8 Slot 7

0

0

ID

2

ID

0

ID

1

Slot 3 Slot 2 Slot 1

figure.

x GB

0

ADP0CH

0

ID

Slot 6 Slot 5 Slot 4Slot 8 Slot 7

Slot 3 Slot 2 Slot 1

5. Install the remaining disk drives into the slots. Fill each slot upward as you install the drives.

There should be no empty slots between the drives.

18

6. Label the remaining disk drives as follows. A drive labeling sheet is included in the parts box.

Note carefully how the drives should be labeled for each slot.

−

Label RAID disk drives with ADP, CH, and ID numbers as shown in the following figure.

x GB

ADP0CH

x GB

Slot 6 Slot 5 Slot 4Sl ot 8 Slot 7

1

ADP0CH

x GB

4

ID

1

ADP0CH

x GB

ADP0CH

x GB

2

ID

1

ADP0CH

1

ID

1

0

ID

0

4

ID

NOTE Do not use the numbers 3 and 7 from the label sheet. IDs 3 and 7 are reserved for the disk section

backplane and the RAID controller.

−

Label non-RAID disk drives with ADP, CH, and ID numbers as shown in the following

figure.

19

x GB

ADP0CH

x GB

Slot 6 Slo t 5 Slot 4Slot 8 Slot 7

1

ADP0CH

x GB

Slot 3 Slo t 2

3

ID

1

ADP0CH

x GB

ADP0CH

x GB

2

ID

1

ADP0CH

x GB

1

ID

1

ADP0CH

x GB

0

ID

0

3

ID

0

ADP0CH

2

ID

0

1

ID

Additional Information

The RAID system boot drives are configured at Intergraph using the MegaRAID utilities. Additional

disk drives supplied with the system are not formatted or configured. You must configure these

drives after configuring system software to make them usable to the system. Refer to Chapter 3,

“Configuring the System,” in the System Setup document delivered with the system for more

information on configuring and using the RAID disk arrays.

If your system includes external InterRAID disk cabinets, refer to the InterRAID documentation for

instructions on how to connect them to your system and install additional RAID disk drives.

WARNING Do not turn on the system power until you are ready to configure Windows NT Server. If you

start the system, and then restart it before completely configuring the operating system, you

will have to reinstall system software as described in Chapter 7, “Installing System Software”

in the

System Setup

document delivered with the system.

20

System Cables

All cable ports on the base unit and other Intergraph equipment are keyed or molded to ensure proper

cable attachment. If a cable is not attaching easily, ensure that you are aligning the cable connector

correctly with the port.

Keyboard, Mouse and Monitor

To connect keyboard, mouse and monitor cables:

1. If using the concentrator, connect the extension cables to the keyboard, mouse, and video ports.

2. If using the rack-mount kit, connect the keyboard and mouse cables to the ports on the back of

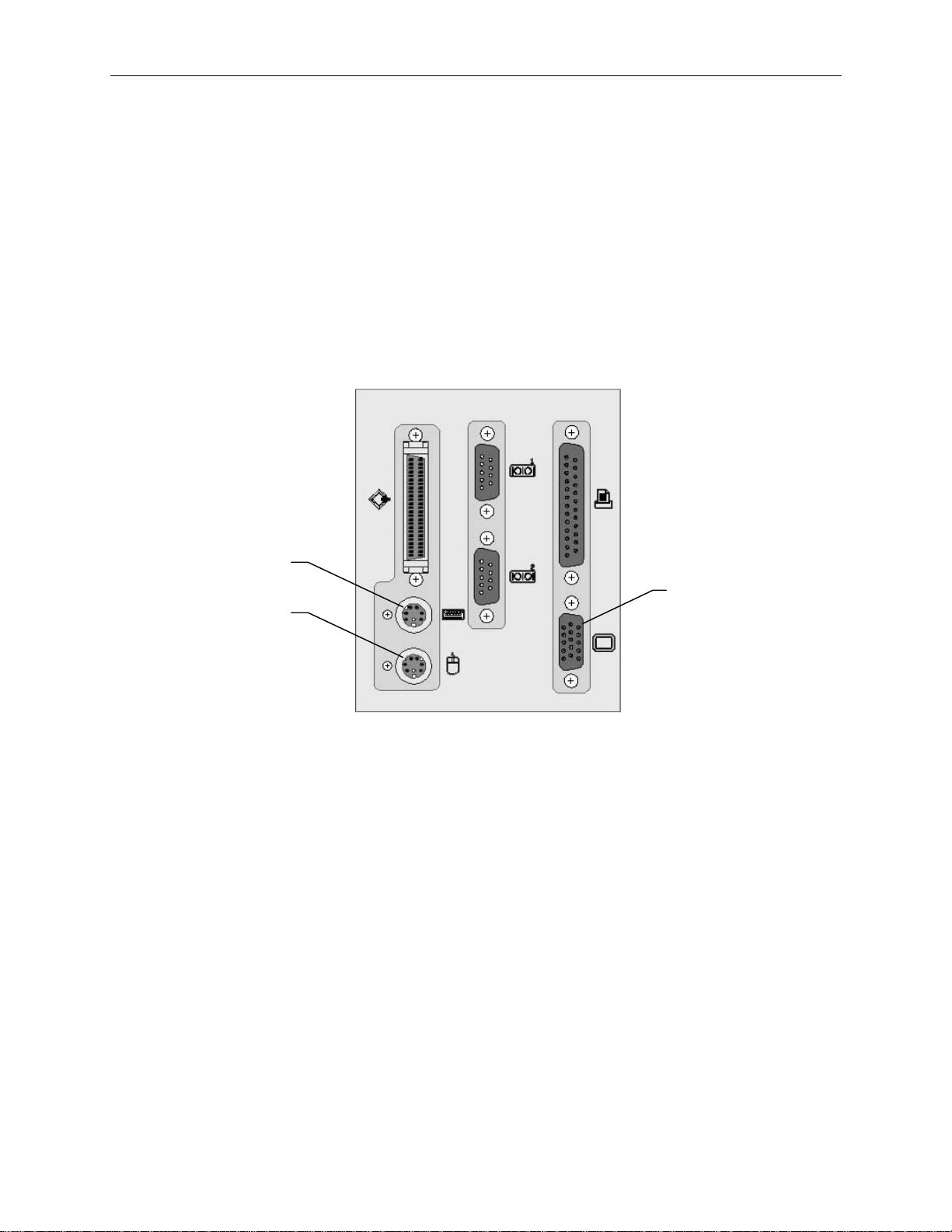

the base unit. Connect the video cable to the video port and to the monitor as shown.

Keyboard

Port

Mouse

Port

3. Connect the monitor power cord to the monitor and to the AC distribution box, UPS, or wall

outlet.

4. Connect the concentrator power cord to the AC distribution box, UPS, or wall outlet.

Video

InterRAID-8e

RAID Controll

To connect InterRAID-8e cables:

1. Connect the RAID SCSI cable to the InterRAID-8e SCSI port and to a RAID controller SCSI

port in the base unit. Refer to the following figure.

NOTE On the RAID controller, the top port is channel 0, and the bottom port is channel 1. Keep track of the

InterRAID-8e attached to each channel, for drive labeling purposes.

SCSI Ports

(PCI Slot 4)

er

21

InterRAID-8

SCSI Port

2. Connect the power cord to the InterRAID-8e cabinet and to the AC distribution box or UPS.

22

Intru der A lert

The server base unit contains the circuitry for the intruder alert, which must be connected to the alert

switches in the top of the rack. If installing two Intergraph racks, where one contains only option

equipment (disk array cabinets, networking devices, etc.) then the expansion rack can be connected to

an adjacent rack containing the base unit. When unauthorized entry is made into the expansion rack,

the intruder alert in the base unit will activate. Chapter 3, “Using the System” of the System Setup

describes how to activate and de-activate the intruder alert.

To connect the intruder alert cable for an individual rack:

1. Connect the intruder alert cable to the intruder alert port. Intergraph installs the intruder alert

cable into the back of the rack before shipment.

Intruder Alert Cable

2. Ensure the other end of the intruder alert cable, and the white loop-back connector are attached

to the sockets in the top corner of the rack. Refer to the following figure.

Intruder Alert

Cable

23

Loopback

Connector

To connect the intruder alert cable for adjacent racks:

1. For the system rack containing the base unit, connect the intruder alert cable as for an individual

rack.

2. Remove the loopback connector from the system rack, as shown in the following diagrams.

3. Remove the top access panel in each rack.

4. Connect the link cable to the socket in the base unit rack and to the empty socket in the options

rack, as shown in the following diagrams. The link cable must run through the access panel

openings in each rack.

24

Move loopback connector

−

System Rack on the Right:

Attach cable to

open socket

Expansion Rack

−

System Rack on the Left:

Remove

thi s j u mper

Link

Cable

Front of Racks

Link

Cable

Remove

loopback

connector

Base Unit

System Rack

to open sock et

Base Unit

System Rack

Expansion Rack

Front of Racks

Expansion Board Cables

The InterServe 8400 base unit includes the following expansion boards as standard equipment:

25

Standard Board

Slot

Disk Controller (RAID MSMT489 or UW SCSI CINFD80) PCI 4

100 Base-T Fast Ethernet Network Adapter (CINF920) PCI 2

InterSite Server Monitor (FINF029) ISA 4

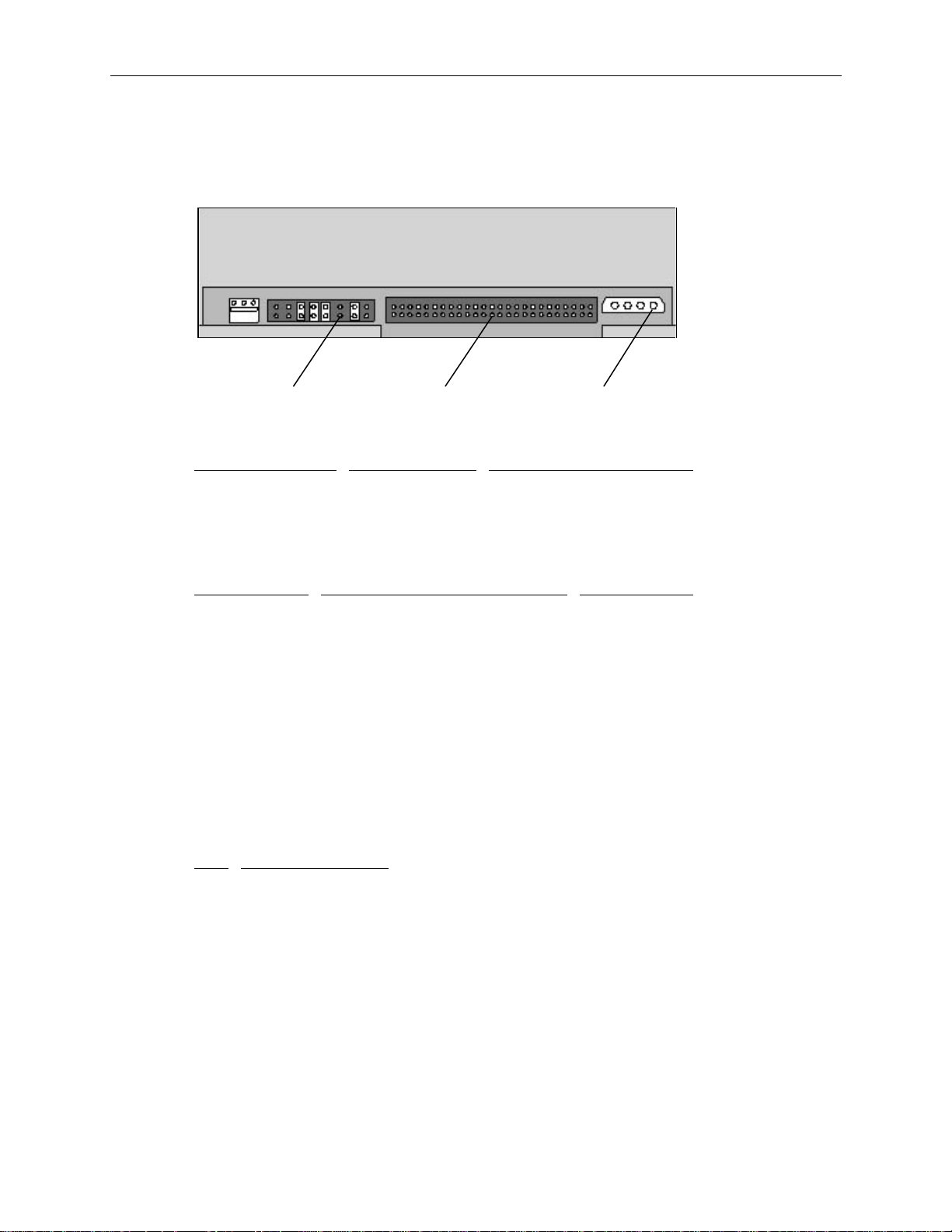

The following figure shows the slots on the back of the base unit. Connect the cables to the Ethernet

and InterSite Server Monitor card as described in the documentation for those cards.

Disk

Controller

12 11 10 9 8 7 6 5 4 3 2 1 1 2 3 4

Ethernet

Card

InterSite Server

Monitor Card

PCI Slot s

ISA Slots

If additional expansion boards are installed in the system, refer to the option board documentation for

cable hookup procedures.

26

UPS Serial Cable

Connect the serial cable to the UPS serial port and to a base unit serial port as shown in the following

figure.

Serial

Port

Serial

Ports

System Power Cord

To connect the system power cord:

1. Ensure the base unit circuit breaker switch is in the Off (down) position before attaching the

power cord to the system and wall outlet.

2. Connect the system power cord to the base unit AC receptacle and to the proper receptacle of the

AC distribution box or UPS.

27

Circuit Breaker

Switch (Off

position)

Power

Cord

3. Connect the power cord to the AC distribution box or UPS and to the wall outlet (NEMA

L14-20R or IEC 309).

NOTE The UPS starts automatically when its power cord is connected to the wall outlet. Refer to the UPS

documentation for more details.

WARNING The wall outlet must be on a properly grounded branch circuit.

28

Cable Handlers

To install cable handlers:

1. Extend the base unit to provide room in the back of the rack for installing the cable handlers.

2. On a rear mounting post, count 5 holes above the top of the base unit rail and attach a tinnerman

nut. Count an additional 4, 5, and 4 holes and attach tinnerman nuts. Repeat this for the other

rear post. Refer to the following figure.

3. Attach the cable handler to the rail using four screws. The part of the cable handler that comes

off (for inserting cables) must face the rack walls. Refer to the following figure.

Cable

Handler

Base Unit

Rail

This side faces

rack wall

NOTE Most cables that attach to the system base unit must be inserted into one of the cable handlers. The

cable handlers allow the base unit to be extended without risk of damaging cables or pulling them out

of other devices. The following figure shows how the cables are inserted.

These ends to the

base unit

29

These ends to the

devices

To route cables:

NOTE The base unit must be extended to insert cables into the cable handler.

1. Connect all the system power cords and data cables to the base unit and to the AC distribution

box or UPS.

2. Insert all cables that attach to the base unit (except for keyboard and mouse cables) into the cable

handler.

3. Additionally, there are cable ties and clamps along the rear mounting rails of the rack. Route

cables through these ties and clamps if necessary.

NOTE Cables that are attached to the base unit and connect to devices in another rack must also be inserted

into the cable handler.

4. After routing the cables into the cable handlers, fully extend the base unit to ensure there is

enough service loop in the cables.

30

Additional Rack-mount Equipment

Network hubs, routers, serial devices and other types of equipment may be installed into the rack,

provided the power requirements are within the available limits of the installed AC distribution box

or UPS.

CAUTION Refer to “Safety Precautions” and “Power Requirements” in Chapter 1, before attempting to install

additional equipment.

WARNING If using non-Intergraph cables with the system, ensure that they are shielded and terminated

on both ends.

To install additional equipment into the rack:

1. Ensure that the installed AC distribution box or UPS can support the additional equipment.

2. Install the necessary mounting shelves or rails to support the equipment into available space. Use

tinnerman nuts for the shelves or rails.

3. Install the equipment, and place tinnerman nuts where the equipment will bolt into the rack.

Secure the equipment to the rack.

4. Connect the cables to the equipment and to the appropriate ports on the back of the base unit.

All cable ports on the base unit and other Intergraph equipment are keyed or molded to ensure proper

cable attachment. If a cable is not attaching easily, ensure that you are aligning the cable connector

correctly with the port.

Checking the Setup

Before starting the system, review the following items:

u

All hardware is properly and securely installed, and all RAID disk drives are installed in the

correct locations.

u

The cables are properly attached from the base unit to the various options and peripherals

installed in the rack or in remote locations.

u

The cables attached to the server base unit are routed through the cable handler. Ensure there is

enough cable service loop to allow sliding devices to extend 31 inches.

u

The cables that run along the sides or top of the rack are installed in clips or ties to secure them

in place.

u

The power cord from the AC distribution box or UPS is attached to the correct wall outlet.

u

The base unit is retracted and secured to the rack with screws at each corner.

St arting the System

Go to Chapter 1 of the System Setup document delivered with the system, to start the system for the

first time, or for information about reinstalling the operating system or changing the RAID

configuration.

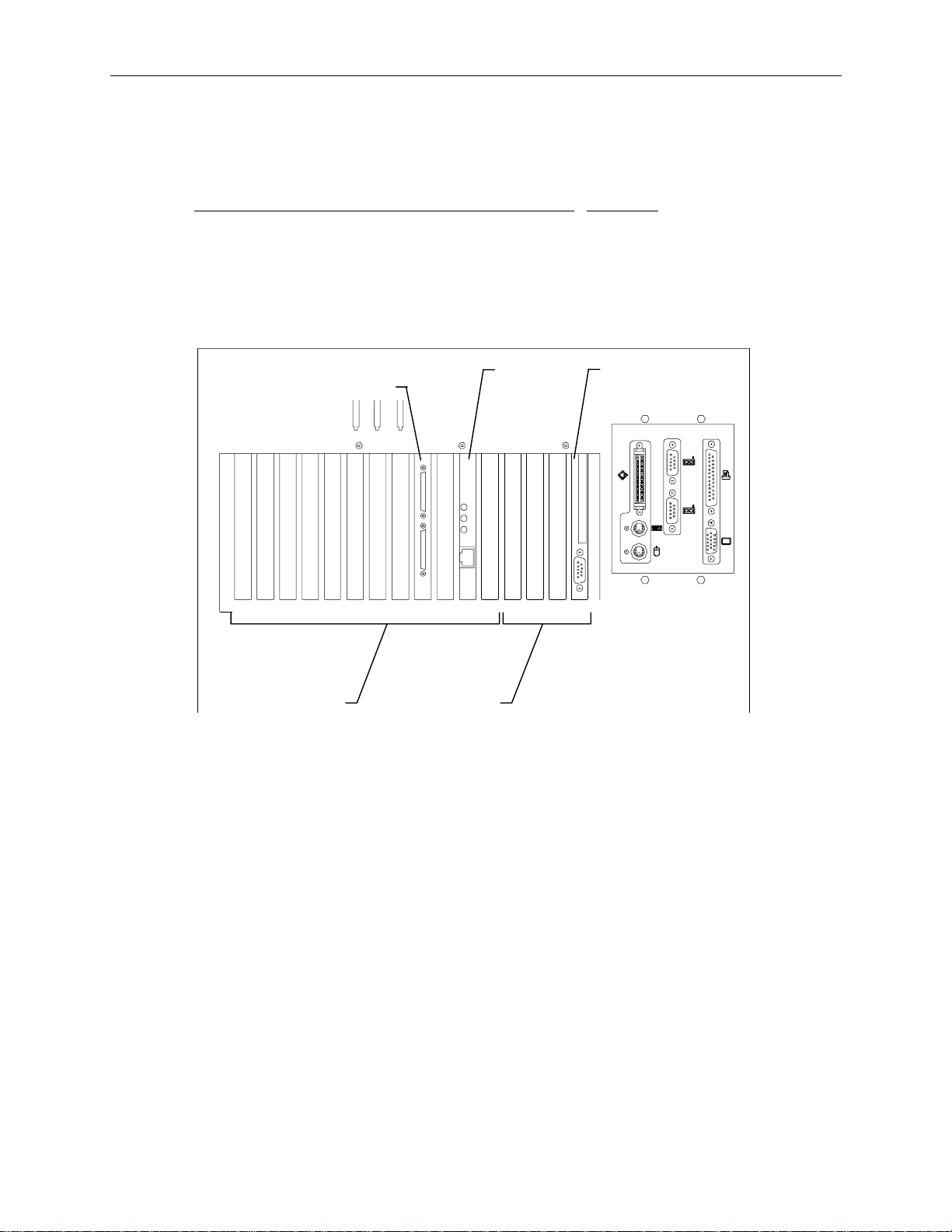

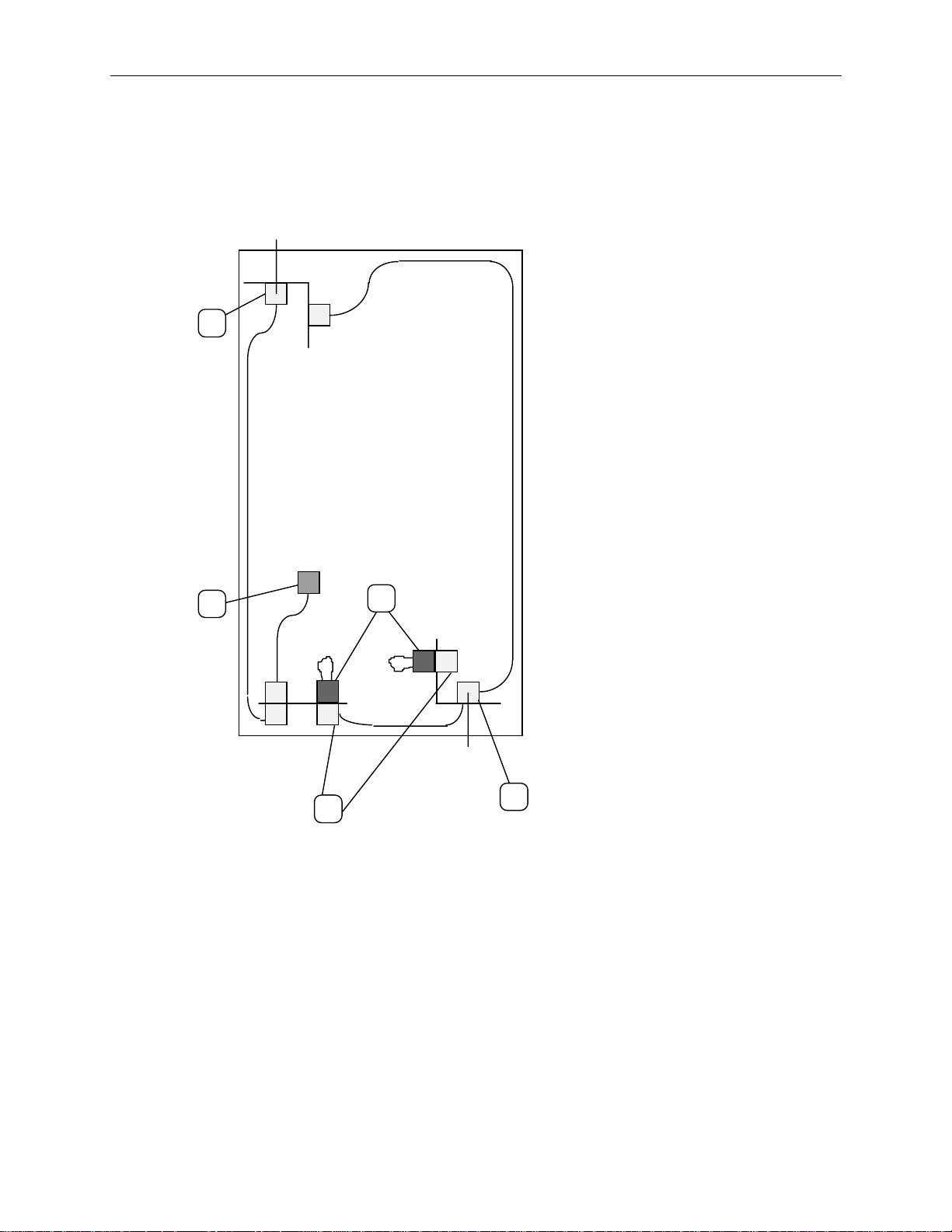

3 Hardware Overview

This chapter shows front and rear views of an InterServe 8400 base unit, including major parts and

assemblies. Under each figure is a table that states the Intergraph part number of items called out in

the figures. The Reference Page column in the table guides you to the page in this document for

specific information about the part.

31

32

A7

8

1

2

B

3

4

5

6

Find No.

Intergraph

Part No.

Description

Reference

Page

1 CFAB371F Front top cover n/a

2 MMSA4010 5.25-inch peripheral bracket n/a

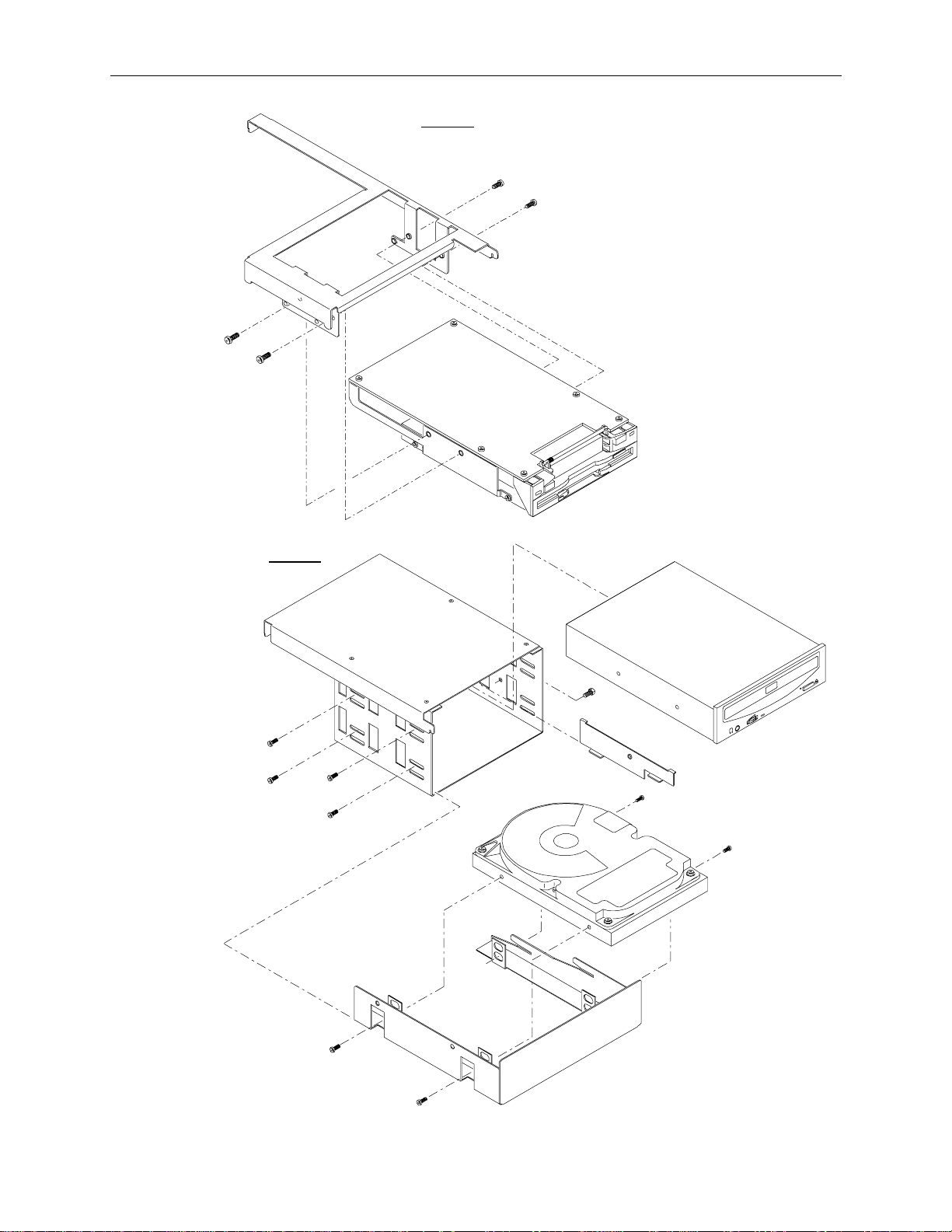

3 CDSK178 CD-ROM drive 69

4 CFAB558F Disk drive tray n/a

5 CFAB364F Airflow baffle n/a

6 MESAN160 Hot swappable system fan n/a

7 MMSA4070 3.5-inch drive bracket n/a

8 MESAN480 Combo drive 71

Detail A

33

MMSA4070

MESAN480

Detail B

MMSA401

CDSK187

CFAB253

(Optional Di sk)

CFAB558

34

2

1

3

4

6

5

Find No.

Intergraph

Part No.

Description

Reference

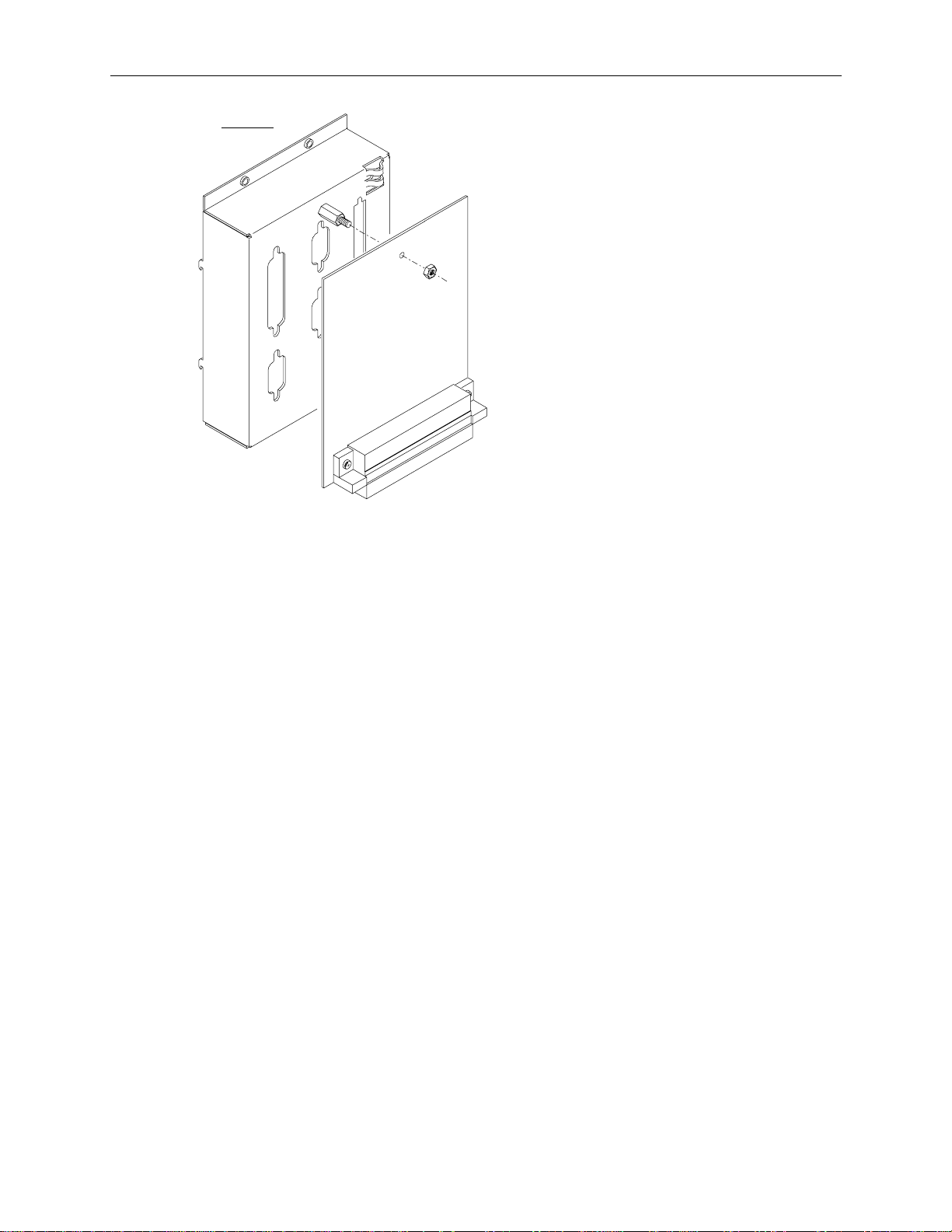

Page

1 CFAB357F Cross bar support n/a

2 MSMT329 Processor board 36

3 CFAB374F LCD back plate n/a

4 MPCBD20 LCD board 53

5 CFAB167G Disk drive section door n/a

6 MESAN520 Disk drive section 62

35

3 4

1

5

6

Find No.

Intergraph

Part No.

Description

Reference

Page

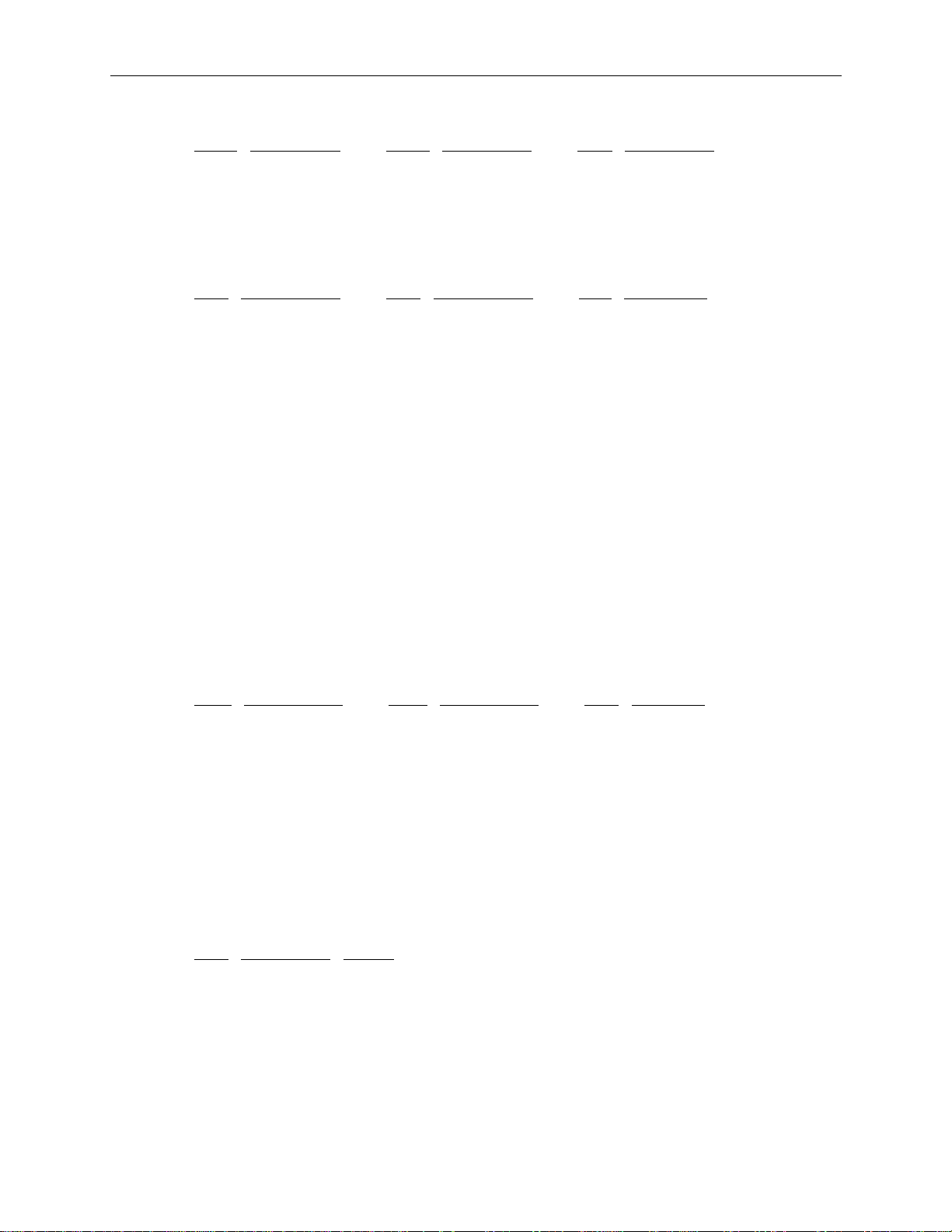

1 CFAB354F Back top cover n/a

2 MSMT328 I/O connector board 51

3 MSMT451 I/O expansion board 42

4 MSMT385 Power distribution board 56

5 n/a AC receptacle, circuit breaker switch, AC filter,

n/a

enclosure

6 MPWS139 550 W power supply, hot swappable, redundant 66

7 CFAB348 I/O panel n/a

2

7

A

NOTE The power distribution board has two board stiffeners attached. The assembly number using

MSMT385 is MESAN180.

36

Detail A

CFAB348

MSMT328

4 System Hardware Information

This chapter contains technical information about the boards, and other hardware that comes

standard with an InterServe 8400. The following hardware items are described.

u

Processor board (MSMT329)

u

I/O expansion board (MSMT451)

u

I/O connector board (MSMT328)

u

LCD board (MPCBD20)

u

Power distribution board (MSMT385)

u

Disk Drive Section (MESAN520)

u

Power Supplies (MPWS139)

u

Intruder Alert

u

CD-ROM drive (CDSK178)

u

Combo drive (MESAN480)

37

If your system includes any of the following hardware, refer to the documentation delivered with that

hardware for additional information:

u

AMI RAID controller

u

InterRAID-8e cabinet

u

Symbios Ultra Wide SCSI controller

u

100 Base-T Fast Ethernet card

u

InterSite Server Monitor

u

Concentrator

u

Uninterruptible Power Supply

38

System Level Functional Diagram

Network

Card

ISM

Card

RAID or

SCSI

Controller

Power

Data

Power and Da t a

I/O Expansion

Board

I/O Connector

Board

AC In

Speaker

Keyboard

AC Filter

and Switch

Power SupplyPower SupplyPower Supply

Power Distribution Board

Intruder

Alert

Terminal Block

Processor

Board

Cooling Fan

Cooling Fan

Cooling Fan

System

Keyswitch

LCD Board

Mouse

Monitor

AC In

Serial

Ports

Parallel

Port

SCSI

Port

CD-ROM Dri v e

Combo Drive

Disk Drive

Section

Part Page Part Page

Power distribution board (MSMT385) 56 Intruder Alert 68

I/O expansion board (MSMT451) 44 Keyboard n/a

I/O connector board (MSMT328) 53 System fans (MESAN160) n/a

Processor board (MSMT329) 39 CD-ROM drive (CDSK178) 70

LCD Board (MPCBD20) 56 Combo drive (MESAN480) 71

Processor Board (MSMT329)

This section provides a functional diagram, memory subsystem description, address resources, and

board layout for the processor board. The MSMT329 provides the following functionality:

u

Processors - two or four Pentium Pro 200 MHz, each with 1 MB L2 cache

u

Intel Orion chipset - two PCI Bridge chips, Memory Controller, four Memory Interface chips.

u

Memory - up to 4 GB using 32Mx36 SIMMs

u

Flash EEPROM - contains Basic Input/Output System (BIOS)

Functional Diagram

39

GTL Bus

Term

PCI

VRM VRM

CPU

Local Bus

OPB

82454

PCI

Local Bus

OPB

82454

CPU

P6 Processor

Externa l B us

CPU

VRM VRM

OMC-DC

82453

Memory Modules

OMC-DP

82452

MIC

CPU

GTL Bus

Term

VRM (Voltage Regulator Module)

CPU (Central Processing Unit, Pentium Pro)

OPB (Orion PCI Bridge)

OMC (Orion Memory Controller)

MIC (Memory Interface Chip)

40

Memory Subsystem Description

The processor board uses industry-standard 60 ns, fast page mode, 72 pin (parity pinout) SIMMs.

The board has 32 SIMM sockets.

u

There are four banks in the memory subsystem system, each bank containing eight sockets. Bank

0 is half-populated (four SIMMs) for base memory configurations (128 MB or 256 MB). The

first upgrade must fill the second half of Bank 0, and subsequent upgrades must completely fill

each bank sequentially from Bank 1 to 3. All SIMMs in the memory subsystem must be the same

size.

u

InterServe 8400 supports three SIMM sizes: 8Mx36 (32 MB), 16Mx36 (64 MB), and 32Mx36

(128 MB). Base systems with 128 MB (four 8Mx36 SIMMs) can be expanded with 8Mx36

SIMMs, for a maximum memory support of 1 GB. Base systems with 256 MB (four 16Mx36

SIMMs) can only be expanded with 16Mx36 SIMMs, for a maximum memory support of 2 GB.

Base systems with 512 MB (four 32Mx36 SIMMs) can only be expanded with 32Mx36 SIMMs,

for a maximum memory support of 4 GB. Only four SIMMs in Bank 0 are installed for base

memory.

Memory is organized into words, rows, and interleaves.

u

Each SIMM generates either the low word (bits 35 to 0) or the high word (bits 71 to 36) of a

72-bit doubleword (8 bits of which are ECC bits) depending on installed location. The low word

and high word sections are split on each side of the board as shown in the following figure. The

high word is called word 1 or W1, and the low word is called word 0 or W0. Due to the design,

if a row in W0 is populated, the same row in W1 (and vice versa) must also be populated for

proper operation. The same memory density SIMM must be used in the row.

u

Rows are numbered 0 through 7. Starting at the center of the board and moving out, the first 4

SIMMs on both sides are on row 0 (rows 0 and 1 if the SIMMs are double-sided). The next four

SIMMs are on row 2 (and 3 if double-sided), and so on, through the last (outermost) four SIMMs

on each side of the board, which are on row 6 (and 7 if double-sided).

u

Within each row there are four interleaves, designated i0 through i3. Base InterServe

configurations populate i0 and i1 of Row 0/1 for two-way interleave. When upgrades are

installed, all four interleaves of the adjacent rows are populated, yielding four-way interleave for

all installed memory. The correlation between banks and rows is:

Bank 0 Rows 0/1 (i0, i1, i2, i3)

Bank 1 Rows 2/3 (i0, i1, i2, i3)

Bank 2 Rows 4/5 (i0, i1, i2, i3)

Bank 3 Rows 6/7 (i0, i1, i2, i3)

41

Rows 0/1

Rows 6/7 Rows 0/1Rows 2/3Rows 4/5

i1

i2

i3

J21 J36 J37 J52

Word 1

i0

i3

i0

i1

i2

i3

i0

i1

i2

i3

Bank 0 = Rows 0/1 Bank 2 = Rows 4/5

Bank 1 = Rows 2/3 Bank 3 = Rows 6/7

i0

i1

i2

i3

i0

i1

i2

i3

Word 0

Rows 6/7Rows 4/5Rows 2/3

i0

i1

i2

i3

i0

i1

i2

i3

i0

i1

i2

The following table shows the correlation between interleaves, words, rows and the socket J numbers. The ECC

Memory Monitoring Utility, used to detect and diagnose memory problems, specifies SIMM locations by interleave

and row, but does not distinguish which word the error occurred in. Refer to the ECC Memory Monitoring Utility

Help for more information.

42

i0 i1 i2 i3

W1 W0 W1 W0 W1 W0 W1 W0

Row 0

Row 1

Row 2

Row 3

Row 4

Row 5

Row 6

Row 7

NOTE Since the ECC Memory driver does not distinguish whether an error occurred in word 0 or word 1 of a

given interleave, both words (i.e. both SIMMs) have to be changed to correct a single-bit problem. For

example, correcting single-bit errors that are occuring in interleave 0, row 0, requires replacing SIMMs

in J36 and J40.

J36 J40 J35 J39 J34 J38 J33 J37

J36 J40 J35 J39 J34 J38 J33 J37

J32 J44 J31 J43 J30 J42 J29 J41

J32 J44 J31 J43 J30 J42 J29 J41

J28 J48 J27 J47 J26 J46 J25 J45

J28 J48 J27 J47 J26 J46 J25 J45

J24 J52 J23 J51 J22 J50 J21 J49

J24 J52 J23 J51 J22 J50 J21 J49

Address Resources

Memory Address Map

The following table lists the memory address map assignments.

Memory Address Range

Description (Size)

0_00000000 - 0_0009FFFF System Board Memory (640K)

0_000A0000 - 0_000BFFFF Video Memory (128K)

0_000C0000 - 0_000C7FFF Video ROM (32K)

0_000C8000 - 0_000CFFFF SCSI ROM (32K)

0_000D0000 - 0_000DFFFF Available I/O Adapter ROM (64K)

0_000E0000 - 0_000FFFFF System BIOS ROM (128K)

0_00100000 - 0_7FFFFFFF System Board Memory (2047M)

0_80000000 - 0_AFFFFFFF Unused

0_B0000000 - 0_DFFFFFFF Typical PCI Adapter Usage

0_E0000000 - 0_FEBFFFFF Unused

0_FEC00000 - 0_FEC003FF SIO.A APIC Registers (1K)

0_FEC00400 - 0_FEC007FF I/O APIC Registers (1K)

0_FEC00800 - 0_FEDFFFFF Unused

0_FEE00000 - 0_FEE00FFF Processor APIC Registers (4K)

0_FEE01000 - 0_FFF7FFFF Unused

0_FFF80000 - 0_FFFDFFFF Reserved

0_FFFE0000 - 0_FFFFFFFF System BIOS ROM - shadow

0_FFFE0000 - F_FFFFFFFF Unused

Board Layout

S

43

ideban d Connec tor PCI Connector 1PCI Connector 0

VRM 3

VRM 1

Memory Sockets

J17 J18

OPB 0

(Primary

Compatibility)

82454

OPB 0

(Primary

Auxiliary)

82454

CPU 2CPU 0CPU 1CPU 3

J19 J20

VRM 0

VRM 2

Lithium Battery

Memory Sockets

PCI Bridge

Two PCI bridge chips (Intel OPB 0 82454) provide high-bandwidth PCI compatibility for the system.

One bridge chip supports PCI bus 0 (Primary Compatibility bus), and is the path by which processors

have access to all PC compatibility devices such as the ISA bus, BIOS PROM, and graphics

controller. PCI bus 0 supports slots 1 through 3. PCI bus 1 (Primary Auxiliary bus) is also bridged

directly off the P6 bus by the second 82454 and supports PCI slots 4 through 7. For best system

performance, high-bandwidth devices that efficiently use PCI burst protocols to transfer data as bus

masters should reside on PCI bus 1 or 2 (slots 1 though 7).

Lithium Battery

The Lithium battery on the processor board provides power to the real time clock, which the power

distribution board uses to display the current time on the LCD screen. As long as the system is

running, the batteries are not used to sustain the information. If the battery fails, the LCD screen will

not display the date and time. You can replace the failed battery following these instructions:

WARNING There is a danger of explosion if the battery is incorrectly replaced.

WARNING Replace the battery with the same or equivalent type only, as recommended by the

manufacturer. Dispose of used batteries according to the manufacturer’s instructions.

44

To replace the Lithium battery:

1. Remove the peripheral drives. It is not necessary to disconnect their attached cables.

2. Carefully remove the discharged battery by grasping it firmly and lifting upward.

3. Install the new battery in the same orientation as the discharged battery.

4. Replace the peripherals.

5. Dispose of the discharged battery according to the manufacturer’s instructions.

CPU Frequency Jumper Connectors

The following figure shows the detail for the default jumper settings for the 200 MHz processors.

The processors will not work properly if the jumper settings are changed. All four jumpers are set the

same.

Jumper Detail

(J17 - J20)

A1 B1

ON

OFF

ON

ON

J17 = CPU 3

J18 = CPU 1

J19 = CPU 0

J20 = CPU 2

I/O Expansion Board (MSMT451)

This section provides a functional diagram, the I/O address ranges, DMA channels, board layout, and

component descriptions for the I/O expansion board. The MSMT451 provides the following

functionality:

u

SCSI - integrated Adapted 7860 Ultra SCSI controller supports internal CD-ROM drive and

external 8-bit SCSI expansion

u

System I/O - integrated Standard Microsystems Corporation FDC37C932 Super I/O Controller

supports PS/2 mouse, keyboard and floppy disk drive peripherals, includes Real Time Clock and

Non-Volatile RAM, and provides serial and parallel port capabilities

u

Graphics - integrated Matrox MGA-2064W graphics accelerator, Texas Instruments TVP3026

palette DAC, and 2 MB of Window RAM (WRAM). The graphics subsystem provides single

screen support, several 2D resolutions, and video playback acceleration.

Functional Diagram

p

I/O Connector Board

Super I/O

4

Controller

FDC37C932

MSMT 328

I/O Interface

111098765

ISA Bus

82379AB

PCI - ISA Bridge

ISA Bus

ISA Slot 1

45

4

3

2

3

2

1

Cable

Buffers

Ultra SCSI

Controller

AIC-786-

VGA Video

Enable/Disable

2-

in header

PCI Local Bus

(Compatibility)

DEC 21050

PCI - PCI

PCI Local Bus

(Compatibility)

PCI Bus

(Secondary)

PCI Slot 1

PCI Slot 8

3

2

12

11

10

9

Bridge

Video

Controller

MGA-

2064W

PCMCIA

PCI Local Bus

(Auxiliary)

7

6

5

PCI Local Bus

(Compatibility)

PCI Slot 4

PCI Lo cal

Bus

(Auxiliary)

Control

Signal

Bus

ID

EEPROM

Processor Board (MSMT329)

Interface

1 = To SCSI connecto r 5 = To Parallel port 9 = To Keyboar d por t

2 = To PCMCIA connect or 6 = To Serial port 10 = To SCSI port

3 = To PCMCIA connect or 7 = To Serial port 11 = To Video port

4 = To Floppy conne cto r 8 = To Mouse port

46

I/O Addr esses

The primary system I/O devices are:

u

Adaptec AIC-7860 Ultra SCSI

u

DEC 21050 PCI-to-PCI Bridge

u

Intel 82093AA I/O Advanced Programmable Interrupt Controller (I/O APIC)

u

Intel 82454 PCIset Orion PCI Bridge (OPB)

u

Intel 82452, 82453 PCIset Orion Memory Controllers (OMC)

u

Intel 82379AB System I/O-APIC PCI-to-ISA Bridge

u

Matrox MGA-2064W G95 Graphics

u

Standard Microsystems FDC37C932 Super I/O Controller

The following table lists a small subset of the reserved I/O addresses used in the system.

Address Range

0000 - 000F DMA Controller 1 (DMA1)

Description Address Range Description

0278 - 027F Parallel Port LPT2

registers

0020 - 0021 Interrupt Controller 1

02E8 - 02EF Serial Port COM4

(INT1)

0022 - 0023 System Configuration 02F8 - 02FF Serial Port COM2

(FDC37C932)

0040 - 0043 Timer Counter 1 0370 - 0377 Secondary Floppy Disk

Controller

0060 - 0064 Keyboard (FDC37C932),

NMI Status

0070 - 0071 Real Time Clock

(FDC37C932)

0378 - 037F Parallel Port LPT1

(FDC37C932)

03B0 - 03BF Monochrome

Display/Printer Adapter

0078 - 007B BIOS Timer 03D0 - 03DF Color/Graphics Monitor

Adapter (CGA/MCGA)

0080 - 0091 DMA Page Registers 03E8 - 03EF Serial Port COM3

0092 - 0092 System Control Port 03F0 - 03F7 Floppy Controller

(FDC37C932)

0093 - 009F DMA Page Registers 03F8 - 03FF Serial Port COM1

(FDC37C932)

00A0 - 00A1 Interrupt Controller 2

0480 - 048F DMA High Page Registers

(INT2)

00B2 - 00B3 Advanced Power

Management Control/Status

04D0 - 04D1 Interrupt Controller Edge

Level Control

Ports

00C0 - 00DF DMA Controller 2 (DMA2)

Registers

00F0 - 00F1 Clear/Reset Math

0CF8 - 0CFF PCI Configuration Space

Access

B000 - DFFF Typical PCI Adapter Usage

Coprocessor

01F0 - 01F8 IDE Hard Disk Controller

(FDC37C932)

DMA Channels

The system board uses Direct Memory Address (DMA) channels to exchange data without accessing

the CPU. Some channels are assigned for specific use by the system, as defined below. Each DMA

channel appropriates full 32-bit processing. For an ISA bus, channels 0 through 3 are 8-bit and

channels 4 through 7 are 16-bit channels.

47

DMA

0 Spare 4 Cascade input for 0-3

1 Spare 5 Spare

2 Floppy I/O Controller 6 Spare

3 Parallel Port 7 Spare

Board Layout

J19 J20

Assignment DMA Assignment

1 2 3 4 5 6 7 8 9 10 11 12

PCI

ISA 4 3 2 1

SCSI J26

Floppy J29

J25

PCI Bus 0 = 1 - 3

PCI Bus 1 = 4 - 7

PCI Bus 2 = 8 - 12

PCMCIA

J27, J28

Speaker J30

Sideband Connector PCI 1 ConnectorPCI 0 Connector

Standard Board Placement

InterServe 8400

AMI RAID Controller (MSMT489)

Slot

PCI 4

or Symbios UW SCSI (CINFD80)

100 Base-T Fast Ethernet (CINF920) PCI 2

InterSite Server Monitor (CINF029) ISA 4

48

Jumper Connectors

Connector

J19 On

J20 On

J25 On

Cable Routing and Pinouts

From

J26, SCSI MCBL102A CD-ROM drive

J27, ISA Bus (PCMCIA) MCBL084A Combo drive, J6

J28, ISA Bus (PCMCIA) MCBL084A Combo drive, J3

J29, Floppy MCBL106A Combo drive, J2

J30, Speaker MCBLW660 Speaker

J26, MCBL102A, SCSI

Pin

26 CD0 33 CD7 46 MSG

27 CD1 34 CD Parity 47 SCT

28 CD2 38 TPWR 48 CMD

29 CD3 41 ATTN 49 REQ

30 CD4 43 BSY 50 I/O

31 CD5 44 ACK Remaining Ground

32 CD6 45 RST

Jumper Result

Clears Real Time Clock and CMOS data

Off

Off

Off

Signal Pin Signal Pin Signal

Default

Clears the BIOS Password

Default

Disables VGA display mode

Enables VGA display mode (default)

Cable To

J27, MCBL084A, PCMCIA ISA Bus

Pin

1 IRQ15 15 SD+(0) 28 Ground

2 IRQ14 16 SD+(1) 29 RSTDRV

3 IRQ10 17 SD+(4) 30 Ground

4 IRQ3 18 SD+(5) 31 SA+(6)

5 IRQ7 19 MEMW- 32 SA+(7)

6 IRQ9 20 MEMR- 33 SA+(10)

7 IOCS16- 21 SA+(17) 34 SA+(11)

8 Ground 22 SA+(18) 35 SA+(14)

9 IOCHRDY+ 23 SA+(21) 36 SA+(15)

10 Ground 24 SA+(22) 37 BALE

11 SD+(14) 25 SA+(1) 38 IOR-

Signal Pin Signal Pin Signal

Pin Signal Pin Signal Pin Signal

12 SD+(15) 26 Ground 39 D7BUFDIR

13 SD+(11) 27 SA+(3) 40 PWR_DWN

14 SD+(10)

J28, MCBL084A, PCMCIA ISA Bus

49

Pin

Signal Pin Signal Pin Signal

1 Spare 15 SD+(2) 28 Ground

2 IRQ11 16 SD+(3) 29 SA+(4)

3 IRQ4 17 SD+(6) 30 SA+(5)

4 IRQ5 18 SD+(7) 31 SA+(8)

5 0WS- 19 SA+(19) 32 SA+(9)

6 Ground 20 SA+(20) 33 SA+(12)

7 MEMCS16- 21 SA+(23) 34 SA+(13)

8 Ground 22 SBHE- 35 SA+(16)

9 SPKR- 23 SA+(0) 36 AEN

10 Ground 24 Ground 37 IOW11 SD+(13) 25 SA+(2) 38 Ground

12 SD+(12) 26 Ground 39 LOBUFDIR

13 SD+(9) 27 ISA BCLK 40 HIBUFDIR

14 SD+(8)

J29, MCBL106A, Floppy

Pin

Signal Pin Signal Pin Signal

2 RPM 14 DRV0- 26 TRK04 No connect 16 MTR1- 28 WRPRT6 DRATE0 18 DIR 30 RDATA8 INDEX- 20 STEP- 32 HDSEL

10 MTR0- 22 WDATA- 34 DSKCHG

12 DRV1- 24 WGATE-

NOTE All odd-numbered pins of J29 are connected to ground, except pin 29 (MID1) and pin 33 (MID0).

J30, MCBLW660, Speaker

Pin

Signal Color

1 + 5.1 V Red

2 Ground White

50

Component Descriptions

The IO Expansion Board provides PCI and ISA expansion slots. It also has the graphics, non-RAID

SCSI, mouse, keyboard, serial port, parallel port, and floppy controllers, as well as the PC

compatibility hardware (BIOS PROM, NVRAM, RTC) and interrupt logic.

Lithium

Battery

I/O Controller

Palette DAC

WRAM

BIOS

SCSI

Controller

Graphics Accelerator

PCI-to-ISA

Bridge

2

C Chip

I

(U63)

PCI-to-PCI

Bridge

Graphics Accelerator

The graphics accelerator (Matrox MGA-2064W) interfaces to the system board through the PCI bus.

This accelerator supports all of the standard VGA graphics modes in addition to native modes capable

of resolutions up to 1600 x 1200. The frame buffer interface is 64 bits wide and is clocked at 100

MHz. Color depths of 4, 8, 16, 24, and 32 bits are supported, allowing a resolution of 1280 x 1024

(24 bit color depth) in only 4 MB of frame buffer memory. Features such as bit block transfer

(BitBlt), Line Draws, and Fills provide hardware acceleration for Windows. Video playback is

accelerated through scaling and YUV to RGB color space conversion.

Palette DAC

The palette DAC operates up to 175 MHz and converts the digital RGB data in the frame buffer to

analog signals for the monitor. The device includes two fully programmable phase-locked loop clock

sources for both the memory clock and the pixel clock.

51

Window RAM

Window RAM (WRAM) is the video memory used by the MGA-2064W. The graphics frame buffer

consists of two 256K x 32 WRAM components for 2 MB of video memory. WRAM is a dual-ported

video memory specially designed to accommodate common drawing functions, offering higher

graphics performance at a lower cost than standard Video RAM.

Starting with 2 MB WRAM, a 2 MB or 6 MB WRAM mezzanine module can be added for improved

video performance. 8 MB of WRAM is the maximum amount configurable. Memory above 2 MB

increases the number of colors available at each resolution, enabling you to work in true color mode at

higher resolutions. Increased WRAM also improves color acceleration by providing extra caching

memory for storing off-screen fonts and images.

SCSI Controller

The SCSI controller is the Adaptec Ultra SCSI Adapter (AIC-7860), which provides a single-ended

bus for SCSI-1, Fast SCSI-2, and Ultra SCSI devices. The SCSI bus is dedicated to the hard disk

drives and CD-ROM drive. The SCSI bus actively terminates on the system board and at the end of

the internal SCSI cable. The AIC-7860 supports low-speed devices to allow legacy SCSI devices to

be used with the system. By default, the controller functions in Fast SCSI-2 mode rather than Ultra

mode.

Super I/O Controller

The I/O Expansion Board utilizes a Standard Microsystems Corporation (SMC) Super I/O Controller

(FDC37C932) to integrate mouse, keyboard, serial, parallel (multi-mode), floppy (2.88 MB), and

Real-Time Clock (RTC) functions into one chip.

The FDC37C932 supports four serial ports via two external port connectors (COM 1 and COM 2).

COM1 can be configured as COM1 or COM3; COM2 can be configured as COM2 or COM4. The

serial ports use the system I/O addresses shown below.

Port

Addresses Interrupts

COM1 3F8-3FF IRQ4

COM2 2F8-2FF IRQ3

COM3 3E8-3EF IRQ4

COM4 2E8-2EF IRQ3

The addresses for each serial port can be configured in AMIBIOS Setup, as described in the System

Setup document delivered with the system. Do not assign more than one device to the same COM

port number. Serial port problems occur because a serial port and another device are assigned to the

same COM number. The system and the connected serial device must be set to the same

communications parameters (baud rate, parity, number of data bits, and number of stop bits). Refer to

the serial device documentation for information about setting these parameters.

The parallel port functionality of the FDC37C932 include the following modes:

u

Normal mode (or Compatibility mode) - an industry-standard parallel interface mode. Normal

mode provides an asynchronous, byte-wide forward channel (host to peripheral), and is the base

mode common to all compliant interfaces.

52

u

SPP mode (or Byte or Bi-Dir mode) - compatible with IBM PS/2 hosts. SPP is an asynchronous,

byte-wide reverse channel (peripheral to host) mode using the eight data lines of the interface for