Page 1

Intel

®

Server Board SE7501BR2

Product Guide

A Guide for Technically Qualified Assemblers of Intel

Subassemblies/Products

Order Number: A97020-002

®

Identified

Page 2

Disclaimer

Information in this document is provided in c onnection with Intel

otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel’s Terms and Conditions

of Sale for such products, I nt el as sumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating

to sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantab ility,

or infringement of any patent, copyright or other intellect ual property right. Intel products are not designed, intended or

authorized for use in any medical , life saving, or life su staining applications or for any other application in which the failure of

the Intel product could c reate a situation where personal injury or death may occur. Intel m ay make changes to

specifications and product descriptions at any t i me, without notice.

Intel and Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the United States and other

countries.

†

Other names and brands may be c l ai med as the property of others.

Copyright © 2002, Intel Corporation. All Rights Reserved.

®

products. No license, express or i mplied, by estoppel or

Page 3

Contents

1 Description.......................................................................................................9

Server Board Features..........................................................................................................9

Server Board Connector and Component Locations...................................................11

Back Panel Connectors..............................................................................................12

Intel® Chipset.............................................................................................................12

Processor(s)............................................................................................................... 14

Memory .....................................................................................................................15

PCI I/O Subsystem.....................................................................................................15

Video Controller..........................................................................................................17

Network Interface Controllers (NICs)..........................................................................18

ACPI .....................................................................................................................20

Wakeup Events..........................................................................................................20

System Management.......................................................................................................... 21

Baseboard Management Controller............................................................................21

Field Replaceable Units and Sensor Data Records....................................................22

System Event Log......................................................................................................22

Platform Event Management......................................................................................22

Emergency Management Port....................................................................................23

Intel® Server Management .........................................................................................24

Security...............................................................................................................................25

Secure Mode..............................................................................................................26

Password Protection...................................................................................................27

Intrusion Switch Monitoring.........................................................................................28

Floppy Write Protection..............................................................................................28

Fixed Disk Boot Sector Write Protect..........................................................................28

Power Switch Mask....................................................................................................28

2 Server Board Installations and Upgrades...................................................29

Tools and Supplies Needed................................................................................................29

Before You Begin................................................................................................................29

Emissions Disclaimer..................................................................................................29

Safety Cautions..........................................................................................................29

Safety and Regulatory Compliance.....................................................................................30

Minimum Hardware Requirements......................................................................................31

Installation Notes.................................................................................................................31

Installation Procedures ........................................................................................................32

Installing the I/O Gasket and Shield............................................................................32

Installing Chassis Standoffs........................................................................................ 34

Installing the Rubber Bumper.....................................................................................35

Installing the Server Board .........................................................................................36

Making Connections to the Server Board....................................................................37

Cable Routing............................................................................................................. 38

Installing or Replacing Processor(s) ...........................................................................39

Installing Memory.......................................................................................................52

Finishing Up ...............................................................................................................53

Replacing the Back up Battery....................................................................................54

3

Page 4

3 POST and the BIOS Setup Utility.................................................................57

Power-On Self-Test (POST)................................................................................................57

Temporarily Changing the Boot Device Priority...........................................................57

BIOS Setup.........................................................................................................................58

If BIOS Setup Is Inaccessible.....................................................................................58

Starting Setup.............................................................................................................58

Setup Menus..............................................................................................................59

Menu Selection Bar....................................................................................................60

Main Menu..................................................................................................................60

Advanced Menu..........................................................................................................62

Security Menu ............................................................................................................66

Server Menu...............................................................................................................67

Boot Menu..................................................................................................................71

Exit Menu ...................................................................................................................72

Upgrading the BIOS............................................................................................................73

Preparing for the Upgrade..........................................................................................73

Performing the BIOS Upgrade....................................................................................74

Changing the BIOS Language....................................................................................75

Hot Keys.............................................................................................................................75

4 Configuration Software and Utilities ...........................................................77

System Software Update Sequence....................................................................................77

Server Configuration Wizard...............................................................................................78

Direct Platform Control (DPC) Console............................................................................... 79

DPC Console Modes of Operation..............................................................................80

Running the DPC Console..........................................................................................80

Using the System Setup Utility............................................................................................81

Creating SSU Diskettes..............................................................................................81

Running the SSU........................................................................................................82

Setting Boot Device Priority........................................................................................83

Setting Passwords and Security Options....................................................................83

Viewing the System Event Log...................................................................................85

Viewing FRU Information............................................................................................85

Viewing Sensor Data Records....................................................................................86

Updating System Firmware and BIOS........................................................................86

Managing the Server Remotely...........................................................................................87

How to Set Up Remote LAN Access...........................................................................87

How to Set Up Remote Modem or Serial Access........................................................89

How to Set Up Paging Alerts...................................................................................... 91

How Set Up LAN Alerts..............................................................................................93

Firmware Update Utility Description....................................................................................95

How to Run the Firmware Update Utility.....................................................................95

FRU/SDR Load Utility Description.......................................................................................95

How to Use the FRU/SDR Load Utility........................................................................96

Setting a System Asset Tag................................................................................................98

Creating Diskettes...............................................................................................................98

Installing a Service Partition (Optional)................................................................................ 99

Saving and Restoring the System Configuration ............................................................... 100

Using the Intel Server Management and Intel® SMaRT Tool (Optional)............................102

4 Intel Server Board SE7501BR2 Product Guide

Page 5

Installing Intel Server Management...........................................................................103

Installing Intel SMaRT Tool.......................................................................................103

5 Solving Problems........................................................................................105

Resetting the System........................................................................................................105

Initial System Startup........................................................................................................ 105

Checklist ...................................................................................................................105

Running New Application Software...................................................................................106

Checklist ...................................................................................................................106

After the System Has Been Running Correctly.................................................................. 106

Checklist ...................................................................................................................106

More Problem Solving Procedures....................................................................................107

Preparing the System for Di a gnos tic Testing............................................................107

Monitoring POST......................................................................................................107

Verifying Proper Operation of Key System Lights.....................................................107

Confirming Loading of the Operating System ...........................................................107

Specific Problems and Corrective Actions.........................................................................108

Power Light Does Not Light......................................................................................108

No Characters Appear on Screen.............................................................................108

Characters Are Distorted or Incorrect .......................................................................109

System Cooling Fans Do Not Rotate Properly..........................................................109

Diskette Drive Activity Light Does Not Light..............................................................110

Hard Disk Drive Activity Light Does Not Light...........................................................110

CD-ROM Drive Activity Light Does Not Light............................................................110

Cannot Connect to a Server.....................................................................................110

Problems with Network.............................................................................................111

PCI Installation Tips..................................................................................................111

Problems with Application Software ..................................................................................111

Bootable CD-ROM Is Not Detected...................................................................................111

Recovering the BIOS.........................................................................................................112

Clearing the Password with the Password Jumper ............................................................114

Clearing CMOS with the CMOS Jumper............................................................................115

6 Getting Help.................................................................................................117

7 Technical Reference ...................................................................................119

Configurati o n Ju mp ers......................................................................................................119

Front Panel Header ...........................................................................................................120

8 Regulatory and Integration Information....................................................121

Product Regulatory Compliance........................................................................................121

Product Safety Compliance......................................................................................121

Product EMC Compliance ........................................................................................ 121

Product Regulatory Compliance Markings................................................................122

Electromagnetic Compatibility Notices ..............................................................................123

FCC (USA)...............................................................................................................123

Industry Canada (ICES-003).....................................................................................124

Europe (CE Declaration of Conformity).....................................................................124

Taiwan Declaration of Conformity.............................................................................124

Korean RRL Compliance..........................................................................................124

Contents 5

Page 6

Australia / New Zealand............................................................................................124

Index..................................................................................................................125

Figures

Figure 1. Server Board Connector and Component Locations............................................11

Figure 2. Back Panel Connectors.......................................................................................12

Figure 3. Attaching the Gasket to the I/O Shield.................................................................32

Figure 4. Attaching the Label to the I/O Shield ...................................................................33

Figure 5. Installing the I/O Shield........................................................................................33

Figure 6. Configuring Chassis Standoffs............................................................................34

Figure 7. Installing the Rubber Bumper..............................................................................35

Figure 8. Attaching the Server Board .................................................................................36

Figure 9. Making Connections to the Server Board............................................................37

Figure 10. Routing the SCSI and Floppy Drive Cable......................................................... 38

Figure 11. Opening Socket Lever and Attaching Processor................................................40

Figure 12. Attaching Retention Mechanism........................................................................41

Figure 13. Applying Thermal Grease..................................................................................41

Figure 14. Attaching the Heat Sink and Retention Clip....................................................... 42

Figure 15. Attaching the Wind Tunnel Fan .........................................................................43

Figure 16. Attaching the Heat Sink Fan to the Top of the PWT ..........................................44

Figure 17. Attaching the Top Assembly to the Retention Mechanism.................................45

Figure 18. Processor and Wind Tunnel Installed................................................................46

Figure 19. Installing the Processor Retention Brackets......................................................47

Figure 20. Raising the Locking Bar.....................................................................................48

Figure 21. Installing Processors.........................................................................................48

Figure 22. Lower Locking Bar.............................................................................................49

Figure 23. Applying Thermal Grease..................................................................................49

Figure 24. Installing the Heat Sink......................................................................................50

Figure 25. Installing the Heat Sink Clip...............................................................................51

Figure 26. Installing Memory..............................................................................................52

Figure 27. Making Back Panel Connections.......................................................................53

Figure 28. Replacing the Backup Battery ...........................................................................55

Figure 29. BIOS Recovery Jumper ...................................................................................112

Figure 30. Password Recovery Jumper............................................................................114

Figure 31. CMOS Recovery Jumper.................................................................................115

Figure 32. Configuration Jumper Location........................................................................119

Figure 33. Front Panel Header Connection Location........................................................120

6 Intel Server Board SE7501BR2 Product Guide

Page 7

Tables

Table 1. Server Board Features...................................................................................9

Table 2. 64-bit PCI Segment Configuration................................................................15

Table 3. 10/100 Megabit LEDs (NIC1).......................................................................19

Table 4. Gigabit LEDs (NIC2)....................................................................................19

Table 5. Security Operation Summary.......................................................................25

Table 6. Keyboard Commands...................................................................................59

Table 7. On-Screen Options......................................................................................60

Table 8. Menu Selection Bar......................................................................................60

Table 9. Main Menu Selections ..................................................................................60

Table 10. Primary/Secondary, Master/Slave Submenu................................................61

Table 11. Processor Settings Submenu.......................................................................62

Table 12. Advanced Menu...........................................................................................62

Table 13. PCI Configuration Submenu.........................................................................63

Table 14. PCI Configuration, Embedded Devices Submenu........................................63

Table 15. Peripheral Configuration Submenu...............................................................64

Table 16. Memory Configuration Submenu..................................................................65

Table 17. Advanced Chipset Control Submenu............................................................65

Table 18. Security Menu..............................................................................................66

Table 19. Server Menu ................................................................................................67

Table 20. System Management Submenu...................................................................68

Table 21. Console Redirection Submenu.....................................................................69

Table 22. Event Log Configuration Submenu...............................................................70

Table 23. Fault Resilient Booting Submenu.................................................................70

Table 24. Boot Menu....................................................................................................71

Table 25. Boot Device Priority Submenu......................................................................71

Table 26. Hard Drive Selection Submenu....................................................................71

Table 27. Removable Devices Submenu.....................................................................72

Table 28. ATAPI CD-ROM Devices Submenu............................................................. 72

Table 29. Exit Menu.....................................................................................................72

Table 30. Hot Keys......................................................................................................75

Table 31. Configuration Utilities...................................................................................77

Table 32. Command Line Format.................................................................................97

Table 33. Configurati o n Ju mp er (J1H1).....................................................................119

Table 34. Front Panel Header Connection Descriptions.............................................120

Table 35. Product Certification Markings....................................................................122

Contents 7

Page 8

8 Intel Server Board SE7501BR2 Product Guide

Page 9

1 Description

Server Board Features

The Intel® Server Board SE7501BR2 offers a “flat” design, with the processors and memory

subsystems residing on the board. The server board supports dual-processor operation with the

®

E7501 chipset and the Intel® Xeon™ processors with 512KB L2 Cache in the Flip-chip-

Intel

micro Pin Grid Array2 (FC-mPGA2) or in the Interposer micro Pin Grid Array (INT-mPGA)

package. The board contains embedded devices for video, network, and IDE, and it provides basic

monitoring hardware and interrupt control for dual-processors and PC/AT compatible operation.

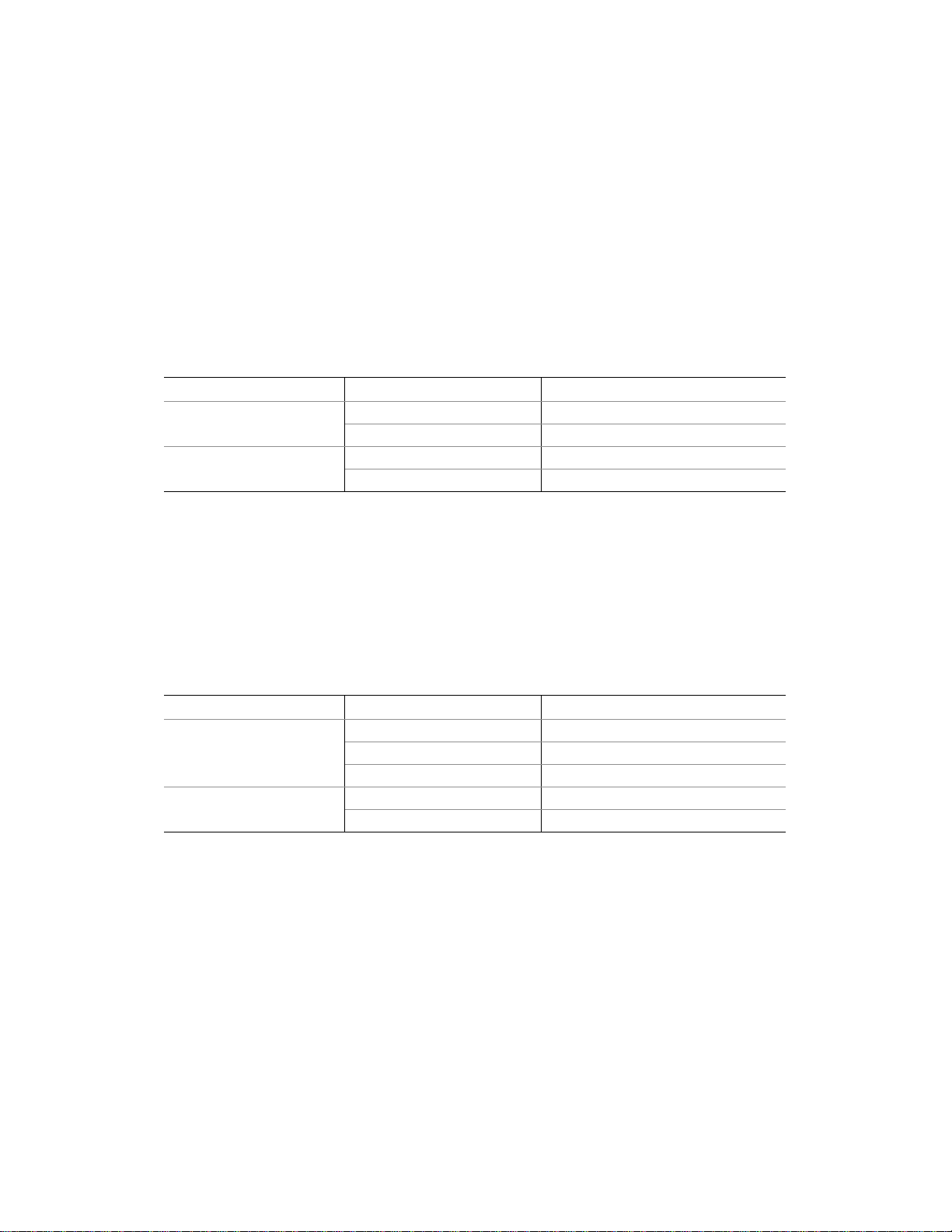

Table 1. Server Board Features

Feature Description

Processor Dual 533 or 400 FSB Intel® Xeon™ processors with 512KB L2 Cache

Chipset Intel chipset:

• Supports 533 MHz Front Side Bus (FSB), backwards compatible with 400 MHz

• Intel® E7501 Chipset Memory Controller Hub (MCH) (North Bridge)

• Intel® 82801CA I/O Controller Hub3 (ICH3) (South Bridge)

• Intel® 82870P2 PCI/PCI-X 64-bit Hub2 (P64H2) I/O hub

Memory • Registered DDR266 comp liant ECC DIMMs providing up to 8 GB of memory

• DIMM Sockets: Four 72-bit, 184-pin, gold contact

• Supported DIMM sizes: 128 MB, 256 MB, 512 MB, 1 GB, and 2 GB

Video • Integrated onboard ATI Rage† XL 64-bit SVGA video controller

• 8 MB SDRAM video memory

• SVGA video port

PCI bus Six PCI expansion slots support full or half-length boards:

• Two 64-bit, PCI-X 100 MHz expansion slots. This segment will run at 133 MHz

when only one slot is populated

• Two 64-bit, PCI-X 100 MHz expansion slots. Modular RAID on motherboard

(M-ROMB) support provided via one of these slots.

• Two 32-bit, 33 MHz, PCI expansion slots

Network Dual integrated on-board Ethernet connections:

®

• Intel

• Intel

Integrated SCSI Adaptec† AIC-7901 single-channel U320 SCSI controller (Single ended mode not

supported)

PRO 10/100 Fast Ethernet Controller (Intel® 82550PM)

®

PRO Gigabit Ethernet Controller (Intel® 82540EM)

continued

9

Page 10

Table 1. Server Board Features (continued)

Feature Description

†

(WOL)

†

PC87417 Super I/O Controller (LPC bus) that provides

System I/O

National Semiconductor

the following:

• Floppy Disk Controller

• PS/2-compatible keyboard and mouse ports, 6-pin DIN connectors

• Advanced parallel port, supporting Enhanced Parallel Port (EPP) level 1.7

and 1.9, ECP, compatible 25-pin connector

• Two serial ports: One a-synch 9-pin RS-232C, one via 10-pin internal

connector

Two Ethernet controllers via RJ45 connectors: one Intel Fast Ethernet 82550PM,

one Intel Gigabit 82540EM

Five USB ports: three stacked USB connectors in I/O rear panel, two via 10-pin

internal header

Power • SSI-EEB 3.0 compliant

• Power/Sleep Switch with LED Indicator

• Wake on LAN

• Wake on Ring (WOR)

Security • BIOS password

• Keyboard password protection

• Floppy write-protect

Form Factor • SSI-EEB 3.0 compliant form factor

Server Management1

IPMI 1.5 compliant

Intel® Baseboard Management Controller (BMC)

Intel® Server Management (ISM) software Version 5.5, including support for:

• Hardware health monitoring through system sensors

• Proactive, alert notification through email, LAN and paging devices

• Remote access and diagnostics

• System Event Log manager

• Sensor Data Records manager

• Field Replaceable Unit manager

• Remote Sensor Access manager

• BIOS Console redirection

• Remote Configuration/Setup

• Serial over LAN

• Command Line Interface over LAN

• Server Configuration Wizard (SCW)

• Intel® SMaRT Tool Integration

• Online Rolling BIOS & Firmware Upgrade

• Command Line Interface over LAN

• ID LED Server Management Support

1

For additional information refer to the Intel® Server Management ver 5.5 Installation & User’s Guide

available on the ISM CD.

10 Intel Server Board SE7501BR2 Product Guide

Page 11

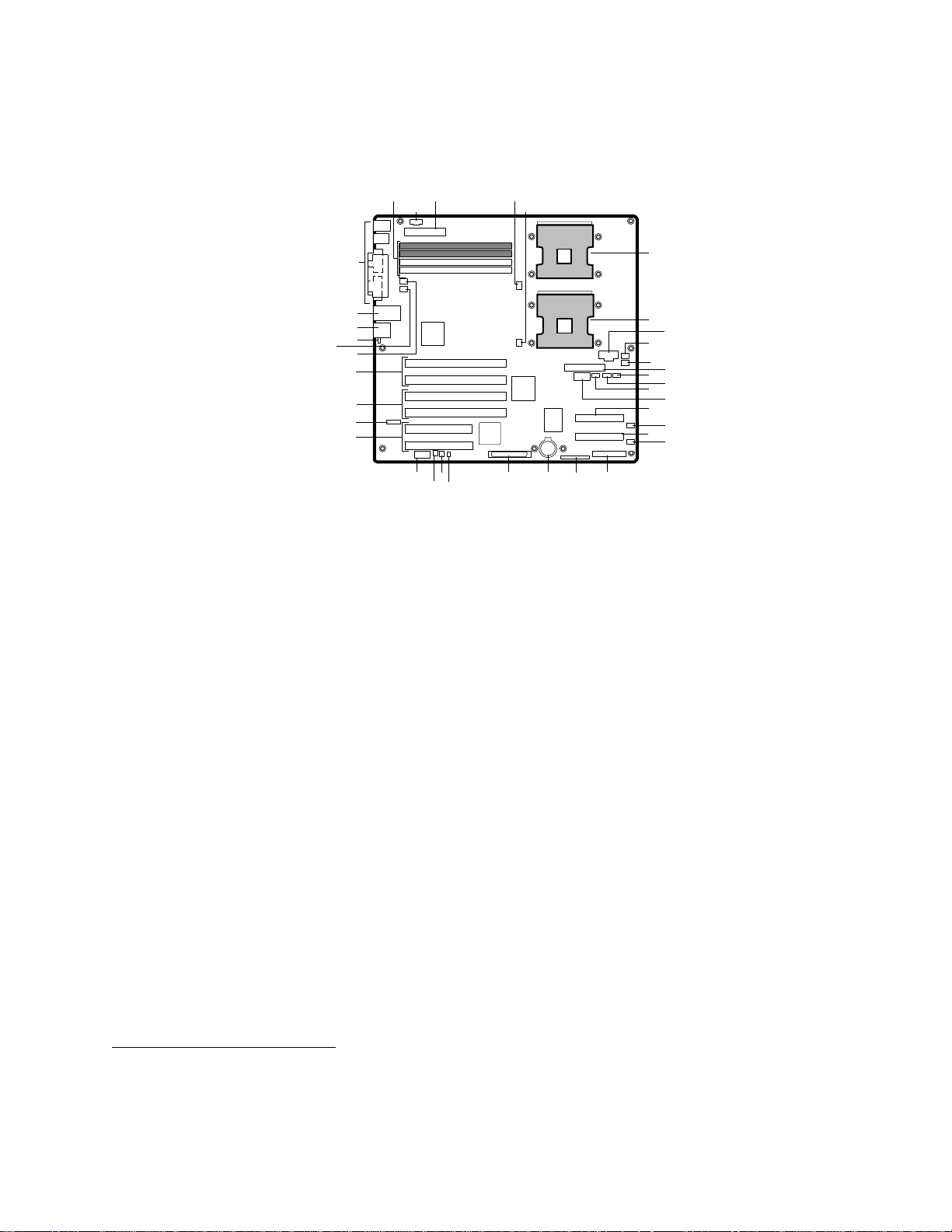

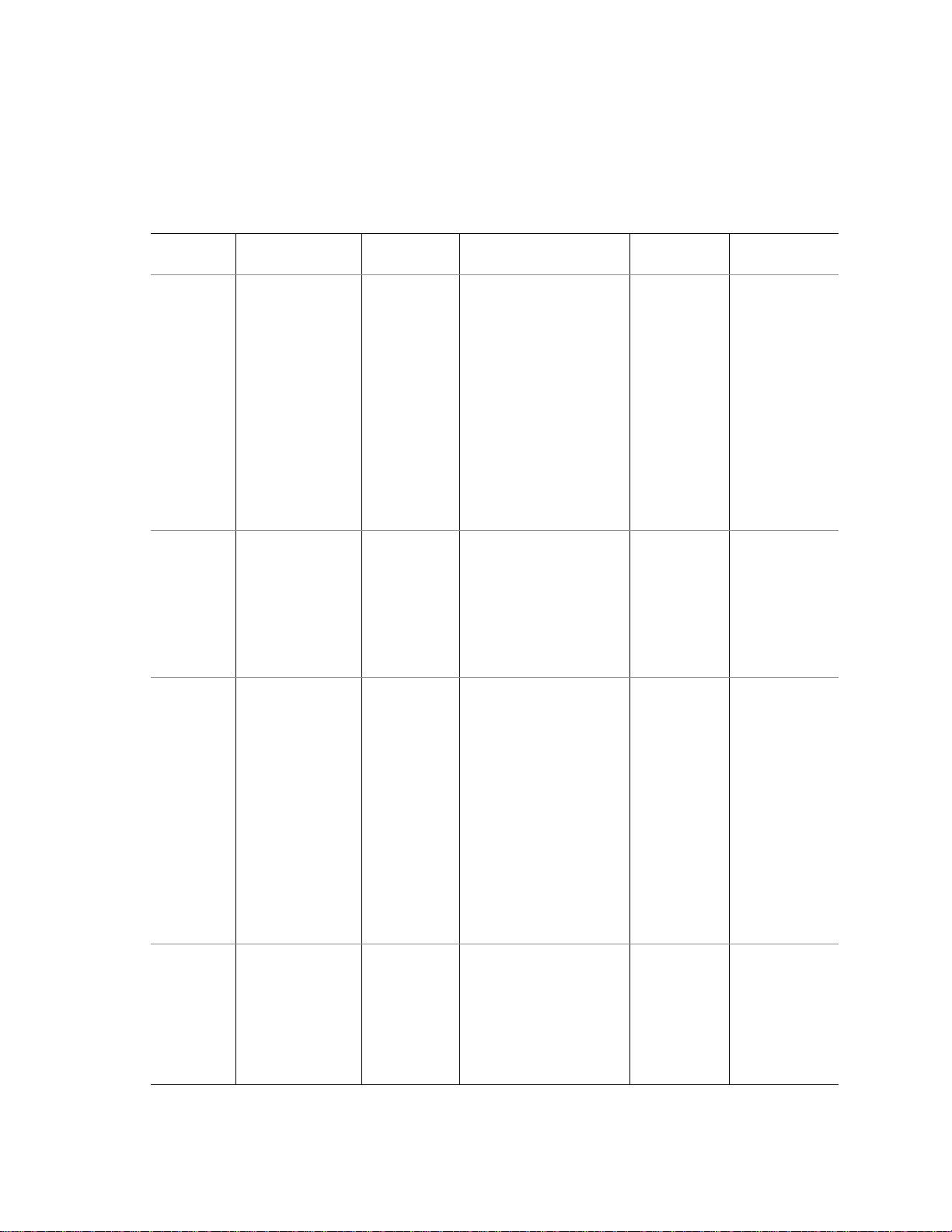

Server Board Connector and Component Locations

JJ

KK

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

OM15026

BB

FF

EE

DD

CC

AA

HH

II

V

T

U

S

GG

Z

Y

X

W

A Primary Processor (CPU1) N System Fan 3 AA System Fan 1

B Secondary Processor (CPU2) O Front Panel Connector BB System Fan 2

C CPU Po wer P Jumper Block CC ID L ED

D System Fan 6 Q Battery DD NIC 1 (10/100)

E System Fan 5 R LVD SCSI Connector EE NIC 2 (1 gigabit)

F Floppy Disk Drive Connector S HDD LED Connector FF System I/O Connectors

G IPMB Connector T Chassis Intrusion GG DIMM Sockets

H HSBP B U EMP in Use HH Aux Power

I HSBP A V Serial B II Main Power

J USB Connector W 32/33 PCI, Slots 5 & 6 JJ CPU1 Fan Connector

K Primary IDE (ATA 100) X ICMB KK CPU2 Fan Connector

L System Fan 4 Y 64/100 PCI-X, Slots 3 & 4

2

M Secondary IDE (ATA 100) Z 64/100 PCI-X, Slots 1 & 2

Figure 1. Server Board Connector and Component Locations

2

M-ROMB support provided via Slot4

Description 11

Page 12

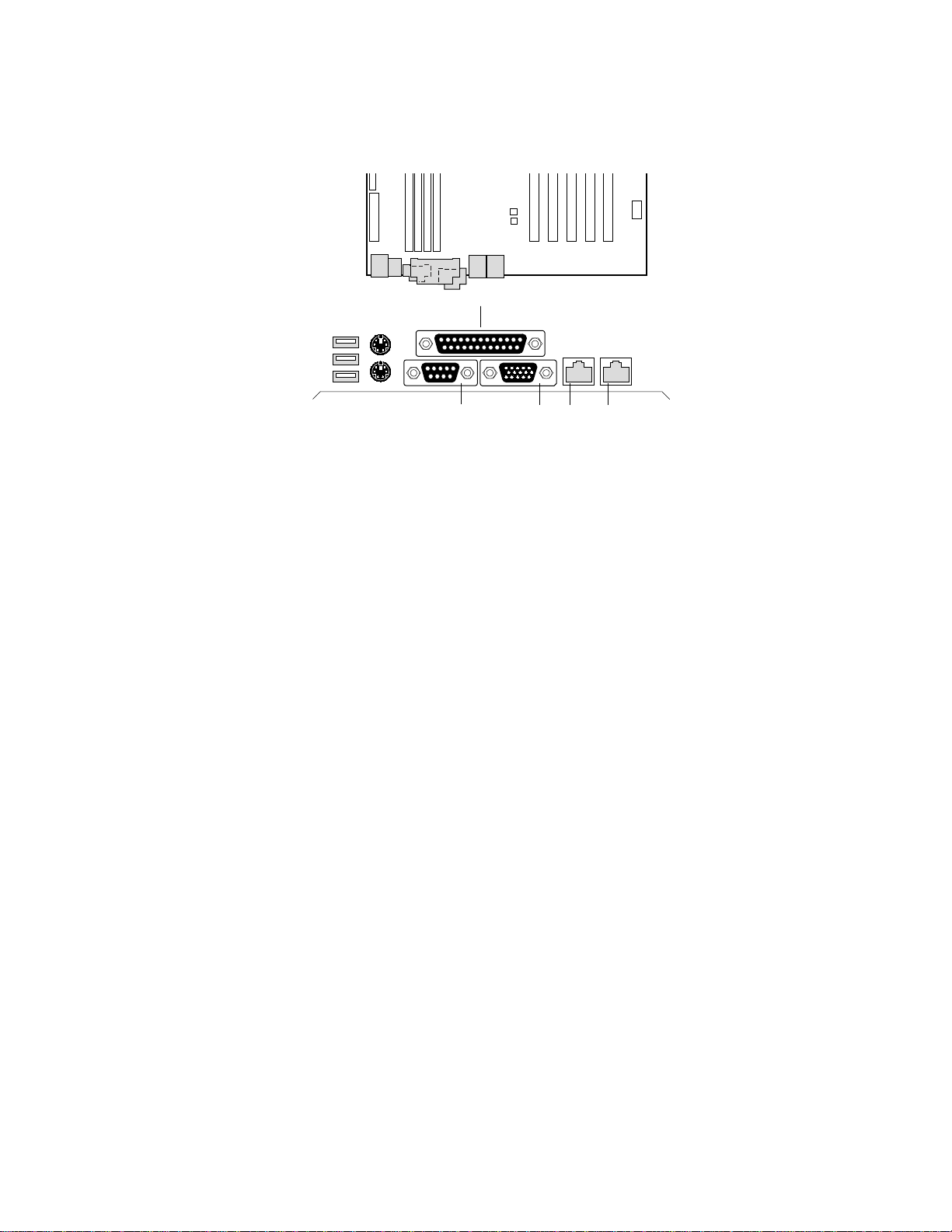

Back Panel Connectors

A

Aux. Pwr

Main Power

USB

B

DIMM Memory Connect

DIMM Memory Connect

DIMM Memory Connect

DIMM Memory Connect

C

A. USB 1, 2, 3

B. Keyboard / Mouse

C. Serial A

D. Video

E. Parallel

F. NIC2 (Gigabit)

G. NIC1 (10/100 Mb)

DEFG

OM14663

Figure 2. Back Panel Connectors

Intel® Chipset

The Intel® Server Board SE7501BR2 includes the Intel E7501 chipset (MCH, ICH3, P64H2), which

provides an integrated I/O bridge and memory controller, and a flexible I/O subsystem core (PCI).

E7501 MCH

The E7501 MCH North Bridge (MCH) integrates three main functions:

• An integrated high performance main memory subsystem

• An HI 2.0 bus interface that provides a high-performance data flow path to the P64H2

(I/O Bridge)

• An HI 1.5 bus that provides an interface to the ICH3-S (South Bridge)

Other features provided by the MCH include the following:

• Full support of registered ECC on the memory bus

• Full support of Intel® x4 Single Device Data Correction on the memory interface with x4

DIMMs

• Twelve deep in-order queue

• Full support of registered DDR266 ECC DIMMs

• Support for up to 8 GB of DDR memory

• Memory scrubbing

12 Intel Server Board SE7501BR2 Product Guide

Page 13

P64H2 I/O Hub

The primary role of the P64H2 is to provide an integrated I/O bridge to the 64-bit PCI-X segments.

This subsystem supports two independent 64-bit PCI-X segments, each with two 64-bit/100MHz

PCI-X slots. The Adaptec AIC-7901 embedded controller is enabled via one of the PCI-X

segments of the P64H2.

ICH3 I/O Controller Hub

The primary role of the ICH3 is to provide the gateway to all PC-compatible I/O devices and

features. The SE7501BR2 uses the following ICH3 features:

• 32-bit/33 MHz PCI bus interface

• Low Pin Count (LPC) bus interface

• IDE interface, with Ultra DMA 100 capability

• Universal Serial Bus (USB) interface

• PC-compatible timer/counter and DMA controllers

• APIC and 8259 interrupt controller

• Power management

• General purpose I/O

• System RTC

Super I/O

The National Semiconductor† PC87417 Super I/O Plug-and-Play Compatible with

ACPI-Compliant Controller/Extender is used on the SE7501BR2 server board. This device

provides the system with:

• Two serial ports

• One parallel port

• Floppy disk controller (FDC)

• PS/2

• Wake event control

Serial Ports

One DB9 connector is provided on the back panel for the Serial A port. The Serial A port is

compatible with 16550A and 16450 modes. This port can be set to one of four different

COM ports, each of which can be enabled separately. When enabled, each port can be programmed

to generate edge- or level-sensitive interrupts. When disabled, the serial port interrupts are

available for add-in cards.

A DH10 10-pin serial header is available on the baseboard for an optional Serial B port. The

Serial B port can be used as an Emergency Management Port.

Parallel Port

The SE7501BR2 baseboard provides a 25-pin parallel port back panel connector. The Super I/O

provides an IEEE 1284-compliant 25-pin bi-directional parallel port. BIOS programming of the

Super I/O registers enables the parallel port and determines the port address and interrupt. When

disabled, the interrupt is available to add-in cards.

†

-compatible keyboard and mouse controller

Description 13

Page 14

Floppy Disk Connector

The floppy disk connector on the server board provides the interface to the floppy disk drive from

the floppy disk controller.

Keyboard and Mouse Connectors

The separate keyboard and mouse connectors, found on the back panel of the server board, are

PS/2-compatible. The keyboard and mouse connectors are interchangeable.

Processor(s)

The Intel® Server Board SE7501BR2 accommodates one or two Intel Xeon processors with 512KB

L2 Cache via two SKT604 604-pin zero-insertion force (ZIF) sockets. The processors interface

with the system bus at 533 MHz, backwards compatible with 400 MHz. When only one processor

is installed, it should be in the socket labeled CPU1 and the other socket must be empty.

For a complete list of supported processors, see:

http://support.intel.com/support/motherboards/server/SE7501BR2

Dual Processor Operation

The Intel Xeon processor interface is dual-processor (DP)-ready. The processor subsystem

includes a single VR (Voltage Regulator) to support both processors. Interrupt generation and

notification for the processors is done by the Advanced Programmable Interrupt Controllers

(APICs) in the ICH3 and P64H2. When two processors are installed, both processors must be of

identical revision, core voltage, and bus/core speeds.

Boxed Processor Fan Heat Sink

Complete thermal solution including a processor wind tunnel (PWT), fan, and heatsink is supplied

with each boxed Intel Xeon processor.

NOTE

✏

Do not install the Processor Wind Tunnel when using the Intel® Server Chassis

SC5200 with hot swap redundant power. To install the heat sink you must use

the Retention Mechanisms supplied with the SC5200 chassis. For this chassis,

see the installation instructions beginning on page 47.

Otherwise, install the processor wind tunnels according to the instructions

provided in this document or in the SE7501BR2 Quick Start User’s Guide. These

instructions are different than those included with the boxed processor. For

proper processor cooling, the fan inlet air temperature should be below 45 °C.

CAUTION

Clearance is required at each end of the fan heat sink to ensure unimpeded

airflow for proper cooling. Restricting the airflow through the processor heat

sink can cause overheating and subsequent failure of the processor.

14 Intel Server Board SE7501BR2 Product Guide

Page 15

Memory

The Intel® Server Board SE7501BR2 contains four 184-pin DIMM sockets and provides support

for up to 8 GB of DDR266 memory. The memory subsystem provides dual memory bus

architecture; the memory on the board is partitioned into two banks of DDR DIMMs. D I MMs must

be installed in pairs, providing a 144-bit wide data path via two separate memory buses.

The server board supports up to four ECC DDR DIMMs that are compliant with the JEDEC

DDR266 specification. A wide range of DIMM sizes are supported, including:

• 128 MB

• 256 MB

• 512 MB

• 1 GB

• 2 GB

The minimum supported memory configuration is 256 MB, using two 128 MB DIMMs. The

maximum configurable memory size is 8 GB using four 2 GB DIMMs.

NOTE

✏

DIMMs must be installed in pairs and must be populated by bank starting

with DIMM 1A and 1B (contiguous sockets). Although the SE7501BR2

server board architecture allows the user to mix various sizes of DIMMs

between banks, DIMMs must be identical within the banks. For a list of

tested memory, see:

http://support.intel.com/support/motherboards/server/SE7501BR2

PCI I/O Subsystem

The SE7501BR2 server board provides three PCI bus segments:

• Segment C with two PCI-X 64-bit / 100 MHz slots (Slot 1 and 2)

• Segment B with two PCI-X 64-bit / 100 MHz slots (Slot 3 and 4)

• Segment A with two PCI 32-bit / 33 MHz slots (Slot 5 and 6)

The following table outlines the capabilities of each 64-bit bus segment. The least capable card

installed on that bus determines the bus mode/speed. In other words, the bus will run at the speed

of the slowest installed card.

Table 2. 64-bit PCI Segment Configuration

# of slots populated per segment Segment B (mode, speed) Segment C (mode, speed)

0 PCI-X, 100 MHz PCI-X, 133 MHz

1 PCI-X, 100 MHz PCI-X, 133 MHz

2 PCI-X, 100 MHz PCI-X, 100 MHz

3

4

3

This segment will operate at 133 MHz when only one slot is populated.

4

Modular RAID on Motherboard (M-ROMB) support is provided via Slot 4.

Description 15

Page 16

Segment C: 64-bit / 100 MHz PCI-X Capable Subsystem

The 64-bit/100 MHz PCI-X segment includes:

• Two 3.3 V keyed full-length, full height PCI expansion slots that can support PCI-X add in

cards up to 133 MHz (PCI-X Slots1 and 2). These slots are backward compatible to 64-bit/100

✏

MHz, 64-bit/66 MHz, 64-bit/33 MHz, and universal keyed 32-bit/33 MHz PCI cards.

The PCI-X features include:

• Bus speed up to 133 MHz

• 3.3 V signaling environment

• Burst transfers up to a peak of 1000 Megabytes per second (MB/s)

• 8-, 16-, 32-, or 64- bit data transfers

• Plug-and-Play ready

• Parity enabled

NOTES

Speed on the PCI-X will be prog rammed by the BI O S according to loading on the

segment. When a segm ent is config ured with a sing le PCI-X 64/133 card the bus

will work at 133 MHz; with two PC I -X 64/133 cards the bus will work at 100

MHz.

If you install a slower card into one of the PCI- X 64/100 connectors, the bus speed

for both connectors will be lowered to the speed of the slowest adapter.

Segment B: 64-bit / 100 MHz PCI-X Capable Subsystem

The 64-bit/100 MHz PCI-X segment includes the following embedded device and connectors:

• Two 3.3 V keyed full-length, full height PCI expansion slots that can support PCI-X add in

cards running at 100 MHz (PCI-X Slots 3 and 4). These slots are backward compatible to 64bit/66 MHz, 64-bit/33 MHz and universal keyed 32-bit/33 MHz PCI cards.

• Integrated Adaptec AIC-7901 U320 Single Channel SCSI Controller

The PCI-X features include:

• Bus speed up to 100 MHz

• 3.3 V signaling environment

• Burst transfers up to a peak of 800 Megabytes per second (MB/s)

• 8-, 16-, 32-, or 64-bit data transfers

• Plug-and-Play ready

• Parity enabled

NOTE

If you install a slower card into one of the PCI- X 64/100 connectors, the bus speed

for both connectors will be lowered to the speed of the slowest adapter.

✏

16 Intel Server Board SE7501BR2 Product Guide

Page 17

Modular RAID on Motherboard

The SE7501BR2 server board supports M-ROMB or Zero Channel RAID (ZCR) that allows the

on-board SCSI controller to be “hidden” from the system and used by the RAID processor on the

add-in card. This support is provided via hardware and BIOS support on PCI-X Slot 4. This PCI

segment may operate as PCI 64-bit/66 MHz with some ROMB RAID controllers.

Segment A: 32-bit/33 MHz PCI Subsystem

The 32-bit / 33 MHz PCI segment includes the following embedded devices and connectors:

• Two 5 V keyed full-length, full height PCI expansion slots (PCI Slots 5 and 6)

• Integrated Intel 10/100 Fast Ethernet Controller (Intel

• Integrated Intel Gigabit Ethernet Controller (Intel 82540EM)

• Integrated ATI Rage XL video controller with 8 MB of on-board SDRAM

32-bit/33 MHz PCI features include:

• Bus speed up to 33 MHz

• 5 V signaling environment

• Burst transfers up to a peak of 132 MB/s

• 8-, 16-, or 32-bit data transfers

• Plug-and-Play ready

• Parity enabled

82550PM)

Video Controller

The Intel® Server Board SE7501BR2 includes an ATI Rage XL video controller, 8 MB video

SDRAM, and support circuitry for an embedded SVGA video subsystem.

The SVGA subsystem supports a variety of modes: up to 1600 X 1200 resolution for CRT

displays, up to 1024 x 768 resolution for TFT displays, and up to 16.7 million colors with a refresh

rate of up to 100Hz. The SE7501BR2 server board provides a standard 15-pin VGA connector, and

external video blanking logic for server management console redirection support.

Description 17

Page 18

Network Interface Controllers (NICs)

The Intel® Server Board SE7501BR2 includes one 10/100Base-TX network connection, based on

the Intel 82550PM Fast Ethernet Controller (NIC1)

connection, based on Intel 82540EM Gigabit Ethernet Controller (NIC2). Facing the rear of the

system, the gigabit controller is on the left, next to the video connector.

You can disable the embedded NICs in BIOS Setup Utility. When disabled, the controller(s) are

not visible to the operating system.

NOTE

✏

To ensure EMC (Electromagnetic Compatibility) product regulation

compliance, the system must be used with a shielded LAN cable.

5

, and one 10/100/1000Base-TX network

Supported Network Features

The SE7501BR2 supports the following features of the 82550PM and 82540EM controllers:

• Glueless 32-bit PCI Bus Master Interface (Direct Drive of Bus), compatible with PCI Bus

Specification, revision 2.1 / 2.2

• Chained memory structure, with improved dynamic transmit chaining for enhanced

performance

• Programmable transmit threshold for improved bus utilization

• Early receive interrupt for concurrent processing of receive data

• On-chip counters for network management

• Autodetect and autoswitching for 10 or 100 MB/s network speeds (82550 only)

• Support for 10 Mb/s, 100 Mb/s, and 1000 Mb/s networks, full or half duplex-capable, with

back-to-back transmit at 100 MB/s

• Integrated physical interface to TX magnetics

• The magnetics component terminates the 100Base-TX connector interface. A flash device

stores the network ID

• Support for Wake on LAN (WOL)

• Advanced Networking Service Features (Teaming, Load balancing)

5

NIC1 is the designated Intel Server Management NIC.

18 Intel Server Board SE7501BR2 Product Guide

Page 19

NIC Connector and Status LEDs

The Intel® Server Board SE7501BR2 supports two RJ45 connectors, one for the 10/100-Megabit

Fast Ethernet controller (NIC1), and the other for the Gigabit Ethernet controller (NIC2).

NIC1 drives two LEDs on its RJ45 connector. These LEDs indicate link/activity on the LAN and

the speed of operation. This connector is on the right side when looking at the I/O area at the back

of the board. The green LED to the right of the connector indicates a network connection is in

place when it is on and transmit/receive activity when it is blinking. The green LED to the left of

the connector indicates 10 Mbps operation when it is off and100 Mbps operation when it is lit and.

See the following table for an overview.

Table 3. 10/100 Megabit LEDs (NIC1)

LED Color LED State NIC1 State

Green (left)

Green (right)

Off 10-Mbps

On 100-Mbps

On On

Blinking Transmit / Receive activity

NIC2 drives two LEDs located on its RJ45 connector; this connector is on left side when looking at

the I/O area in the back of the board. The green LED to the right of the connector indicates a

network connection is in place when it is on, and transmit/receive activity when it is blinking. The

bi-color LED to the left of the connector indicates 10-Mbps when it is off, 100-Mbps operation

when it is green, and 1000-Mbps operation when it is yellow. See the following table for an

overview.

Table 4. Gigabit LEDs (NIC2)

LED Color LED State NIC2 State

Off 10-Mbps

Green/Yellow (left)

Green (right)

Green 100-Mbps

Yellow 1000-Mbps

On On

Blinking Transmit / Receive activity

Description 19

Page 20

ACPI

By using Advanced Configuration and Power Interface (ACPI), an ACPI-aware operating system

can place the system into a state in which the hard drives spin-down, the system fans stop, and all

processing is halted. In this state the power supply is still on and the processors still dissipate some

power, so the power supply fan and processor fans are still running.

NOTE

✏

ACPI requires an operating system that supports this feature.

The server board supports sleep states S0, S1, S4, and S5. When the server board is operating in

ACPI mode, the operating system retains control of the system and the OS policy determines the

entry methods and wake-up sources for each sleep state – sleep entry and wake-up event

capabilities are provided by the hardware but are enabled by the operating system.

• S0: Normal running state.

• S1: DC Power remains on. The operating system saves the context and enters a low-power

state. The system can wake from the S1 state using a PS/2 keyboard, mouse, or USB device,

by pressing the power button press, or from a wakeup event.

• S4: Hibernate or Save to Disk. The memory and machine state are saved to disk. Pressing the

power button or another wakeup event restores the system state from the disk and resumes

normal operation. This assumes that no hardware changes were made to the system while it

was off.

• S5: Soft off. Only the RTC section of the chip set is running in this state.

CAUTION

The system is off only when the AC power is disconnected.

Wakeup Events

The SE7501BR2 system supports several wakeup events.

Wake on LAN

Wake on LAN allows system power to be activated through the network. If the system is in the S1

or S4 state, it can be turned on remotely by sending a specific packet to the remote system. The

system contains a configuration option that allows the on-board NICs to be enabled to wake the

system from a S4 or S5 sleep state, even if the operating system disabled Wake on LAN when it

powered down the system. This provides an option for users who want to use standard, but

non-secure, Wake on LAN capability for operations such as after-hours maintenance. Server

management features provide a secure system power-up, plus the ability to provide BIOS boot

option.

20 Intel Server Board SE7501BR2 Product Guide

Page 21

Wake on Ring

Wake on Ring allows system power to be activated through the serial ports when this option is

enabled in Setup. If the system is in the S1 or S4 state, it can be turned on remotely by the Ring

Indicate RI signals from the serial ports.

NOTE

✏

Wake on Ring is disabled in Serial B if this port is enabled as a server

management port.

Wake on RTC Alarm

Wake on RTC alarm allows system power to be activated through a real-time clock alarm when this

option is enabled in Setup. If the system is in the S1 or S4 state, it can be turned on by an RTC

trigger event.

System Management

Intel integrates system management features into the hardware and provides additional features

through Intel

is provided below. For instructions on using the features described, refer to the Configuration

Software and Utilities chapter, beginning on page 77.

®

Server Management (ISM) software version 5.5. A brief description of the features

Baseboard Management Controller

Intel server boards incorporate a baseboard management controller (BMC), which is a dedicated

microcontroller for system management activities. The BMC performs the following functions:

• Monitors system components and sensors, including processors, memory, fans, power supplies,

temperature sensors, and chassis intrusion sensors.

• Manages nonvolatile storage for the system event log (SEL), sensor data records (SDRs), and

baseboard field-replaceable unit (FRU) inventory.

• Interfaces with the emergency management port (EMP) and LAN1 port to send alerts and

interact with remote management systems.

• Provides the main front panel control functions (power on/off, reset, and so on).

Description 21

Page 22

Field Replaceable Units and Sensor Data Records

Field replaceable units (FRUs) are major modules in the chassis that contain active electronic

circuitry. FRUs can store information-such as board serial number, part number, name, and asset

tag-that can be read using the System Setup Utility. The BMC stores FRU information for the

baseboard in a nonvolatile storage component on the board.

The BMC uses Sensor Data Records (SDRs) to identify the sensors in the system for monitoring.

SDRs provide a list of the sensors, their characteristics, location, type, and type-specific

information, such as default threshold values, factors for converting a sensor reading into the

appropriate units (mV, rpm, degrees Celsius), and information on the types of events that a sensor

can generate. The BMC stores SDR information in a nonvolatile storage component on the

baseboard.

You can use the FRU/SDR Load Utility to initialize or update the FRU and SDR information.

®

server boards are shipped from the factory with some sensors disabled because the actual

Intel

configuration of the chassis is only determined when the user completes the system configuration.

For example, chassis-specific FRU information, such as chassis part number, must be configured

when the system is configured. For these reasons, it is important to run the FRU/SDR Load Utility

as part of the system setup process. You should also run the FRU/SDR Load Utility whenever you

change the number of fans, processors, or power supplies in the server.

System Event Log

The BMC manages a system event log (SEL), where it records significant or critical system events.

These events include temperatures and voltages out of range, fan failures, and other sensor-related

events. The BIOS, software, and other devices can also log events by sending messages to the

BMC. The SEL is stored in nonvolatile storage.

You can view the current contents of the SEL by using the System Setup Utility.

Platform Event Management

Events can trigger alerts and other actions by the BMC. The server is configured with the

following set of standard events:

• Temperature sensor out of range

• Voltage sensor out of range

• Fan failure

• Chassis intrusion

• Power supply failure

• Memory error

• POST error

• Processor fault resilient booting (FRB) failure

• Fatal nonmaskable interrupt (NMI) from a source other than the front panel switch

• Watchdog timer reset, power down, or power cycle

• System restart (reboot)

22 Intel Server Board SE7501BR2 Product Guide

Page 23

Alerts can take either of these forms:

• Platform Event Pages – the BMC dials a paging service and sends a predefined paging string.

To use platform event paging (PEP), you must attach an external modem to the emergency

management port (Serial B). Use the Server Configuration Wizard to configure the pager and

emergency management port information.

• BMC LAN alerts – the BMC sends an alert to a predefined destination on the LAN.

You can configure PEP and BMC LAN alerts by using the Server Configuration Wizard or the

System Setup Utility.

Emergency Management Port

The emergency management port (EMP) refers to the use of the Serial B port, with either an

external modem or direct serial connection, for remote management. The BMC controls the port

and interfaces with remote access software, such as the Direct Platform Control or the Client

System Setup Utility applications in Intel Server Management.

You can configure the EMP by using the Server Configuration Wizard or the System Setup Utility.

EMP and Serial Over LAN

The Serial B port 10-pin header on the board can be configured in several different ways: as a

standard serial port, as an Emergency Management Port, or for serial output redirection over a

LAN. You can configure these settings using either the System Setup Utility or the Server

Configuration Wizard.

✏✏

NOTES

SC5200 Server Chassis considerations: If you have configured the Serial

B port for use as an emergency management port and set it to be “always

available”, the Serial B port will be accessible only by remote server

management software. The operating system will never be able to access the

port.

If you have configured the Serial B port for Serial Over LAN, the port’s

functionality will be impacted only when there is an active Serial Over LAN

session from a remote console. At all other times either the operating system

or the EMP will control the port, depending on your configuration.

Description 23

Page 24

Intel® Server Management

Intel Server Management (ISM) version 5.5 is a system management package that is included on

the ISM CD. ISM applications interact with the integrated hardware system management features

of the server to allow you to monitor and manage a server. Version 5.5 provides integrated in-band

(operating system up) and out-of-band (operating system down) remote management, event alerting

and logging, including e-mail notification, and proactive fault management. Some of the features

provided are:

†

• The ability to connect to the server from a Windows

over a modem, or over a direct serial connection to the server, permitting you to manage the

server from a remote location.

• Real-time monitoring and alerting for server hardware sensors.

• Emergency management when the server is off (but still connected to AC power) lets you

verify the state of the server, diagnose hardware problems, and power on/off or reset the server.

• The ability to run the Client System Setup Utility to change the configuration of the managed

server.

ISM can use an optional service partition on the managed server. The service partition is a special

disk partition on the system drive that contains a ROM-DOS

utilities, including the System Setup Utility, FRU/SDR Load Utility, and other diagnostics

packages you might choose to install. The server can be booted to the service partition, either

locally or remotely, to provide access to the utilities.

-based client workstation over a LAN

†

operating system and DOS-based

The service partition must be installed before the operating system is installed. Instructions for

creating a service partition are available on the Quick Start Users guide.

For more information on Intel Server Management and the individual ISM applications, see the

Intel Server Management Installation and User’s Guide on the ISM CD.

24 Intel Server Board SE7501BR2 Product Guide

Page 25

Security

The SE7501BR2 BIOS provides a number of security features. This section describes the security

features and their operation.

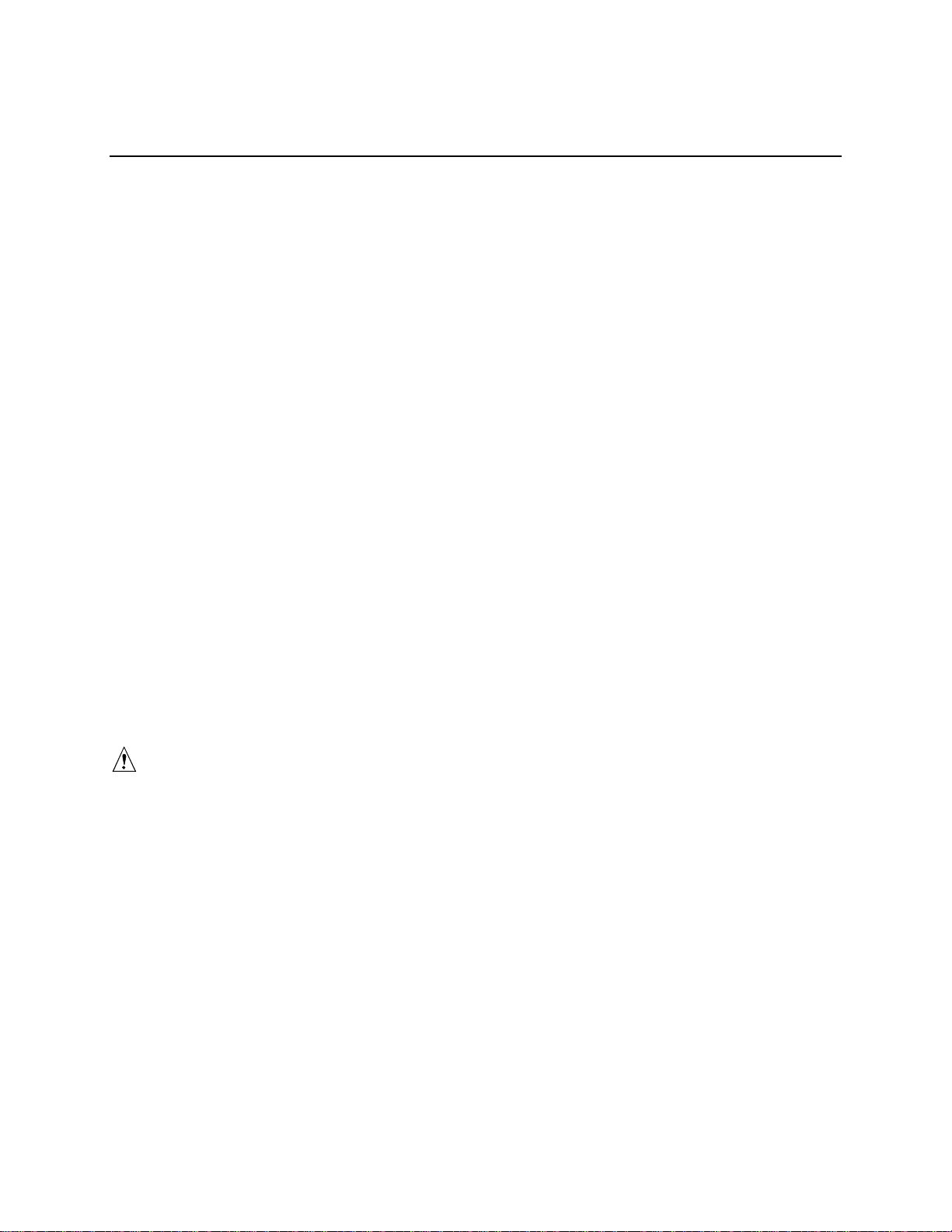

Table 5. Security Operation Summary

Mode

Secure

Mode

Secure

Boot

Password

on boot

Fixed disk

boot

sector

Entry Method/

Event

Keyboard

inactivity timer or

runtime

activation of hot

key

Power On/Reset User

Power On/Reset User

Power On/Reset Set feature

Entry

Criteria

User

password

enabled in

Setup

password

and Secure

Boot

enabled in

Setup

password

set and

password on

boot enabled

to Write

Protect in

Setup

Behavior

On-board video goes

blank if selected in

Setup.

Floppy writes are

disabled if selected in

Setup.

Except for the

password, no mouse or

keyboard input is

accepted.

Keyboard LEDs flash

Front panel buttons are

disabled, except for

NMI.

User is prompted for

password if booting from

drive A.

System enters Secure

Mode just before

scanning option ROMs.

See above for other

Secure Mode behavior.

System halts for User

Password before

scanning option ROMs.

The system is not in

secure mode.

Except for the

password, no mouse or

keyboard input is

accepted.

Write protects the

master record of the IDE

hard drives if the system

boots from a floppy. The

BIOS will also

write-protect the boot

sector of the C: drive if it

is an IDE drive.

Exit Criteria After Exit

User or

administrator

password

followed by

[Enter]

User or

administrator

password

followed by

[Enter]

User or

administrator

password

followed by

[Enter]

Set feature

to Normal in

Setup

Video is

restored.

Floppy writes

are enabled.

Keyboard and

mouse inputs

are accepted.

Front panel

buttons are

enabled.

See above for

Secure Mode

behavior.

Power and

Reset

switches are

enabled.

PS/2 keyboard

and mouse

inputs are

accepted.

The system

boots

normally.

Boot

sequence is

determined by

setup options.

Hard drive will

behave

normally.

Description 25

Page 26

Secure Mode

Secure mode refers to a system state where many of the external inputs and outputs are disabled to

prevent tampering. These include PS/2 ports, floppy and on-board video. When secure mode is in

effect, you must enter a password before the system will accept any keyboard or mouse input,

except for the password entry. When secure mode is in effect, you cannot turn off the system

power or reset the server from the front panel switches.

Secure mode has no effect on functions enabled via remote server management or power control

via the watchdog timer.

Taking the system out of secure mode does not change the state of system power. In other words, if

you press and release the power button while secure mode is in effect, the system will not be

powered down when secure mode is later removed. However, if the front panel power button

remains depressed while secure mode is removed, the server will be powered off.

Secure mode is configured through the BIOS setup options or through the System Setup Utility.

Hot Key Activation

A hot key combination allows the user to activate secure mode immediately instead of waiting for

the configured inactivity time-out to expire. The hot key combination is configured through Setup.

Either Ctrl-Alt-L or Ctrl-Alt-Z can be configured as valid hot keys.

NOTE

✏

Hot keys work only with PS/2 keyboards.

Secure Boot Mode (Unattended Start)

The Secure Boot mode allows the system to boot and run the operating system without requiring

the user password, even if the user password is set. However, until the user password is entered,

mouse and keyboard input is not accepted (except for password entry). If Secure Boot is enabled,

secure mode is enabled shortly before boot. To prevent unauthorized tampering with any option

ROM based setup utilities, enable the “Option ROM Menu Mask” setting in the security menu.

Using Secure Boot

When secure mode is in effect:

• You can boot the server and the operating system will run, but you must enter the user

password to use the keyboard or mouse.

• You cannot turn off system power or reset the server from the front panel switches.

Secure mode has no effect on functions enabled via the Server Manager Module or power control

via the real time clock.

26 Intel Server Board SE7501BR2 Product Guide

Page 27

Password Protection

The BIOS uses passwords to prevent unauthorized tampering with the system.

Entering the user password permits the modification of the time, date, language, user password, and

password on boot setup fields. When a user password is configured, the server can be booted into

secure mode. See the Secure Boot Mode (Unattended Start) section above. Other setup fields can

be modified only if the administrator password is entered.

If a wrong password is entered three times in a row, the BIOS stops validating passwords and the

BIOS security engine returns a failure for any further password validation attempt. If the user

enters three wrong passwords in a row during the boot sequence (i.e., when entering Setup), the

system is placed into a halt state. This feature makes is difficult to break the password by the “trial

and error” method. When entering a password, the backspace key is accepted as a character of the

password. Pressing the backspace key to replace a mistyped character will result in a wrong

password.

If the user or administrator password is lost or forgotten, the password clear jumper can be used to

clear both passwords. See Chapter 5 under “Clearing the Passwords with the Password Clear

Jumper.”

If only the administrator password is set, you:

• Must enter the administrator password to enter BIOS Setup.

• Must enter the administrator password to boot the server if Password on Boot is enabled in the

BIOS Setup.

• Must enter the administrator password to exit secure mode.

If both passwords are set, you:

• May enter the user password to enter BIOS Setup. However, you will not be able to change

many of the options.

• Must enter the administrator password if you want to enter BIOS Setup and have access to all

of the options.

• May enter either password to boot the server if Password on Boot is enabled in the BIOS Setup.

• May enter either password to exit secure mode.

Setting Passwords

Each password can be independently set or cleared in the BIOS setup utility or in the System Setup

Utility. The passwords can be up to seven characters long and can contain only alphanumeric

characters (a-z, 0-9). Numbers from the NumLock pad are recognized as different characters than

the numbers in the top row of a standard PS/2 keyboard. The passwords are not case-sensitive.

When set, a password can be cleared by changing it to a null string.

Description 27

Page 28

Intrusion Switc h Monit or ing

To help prevent unauthorized entry or use of the server, the Intel Server Management software

monitors the chassis intrusion switch if one is installed in the chassis. Opening an access cover will

transmit an alarm signal to the server board, where BMC firmware and server management

software process the signal. The system can be configured through ISM to respond to an intrusion

a number of ways, including powering down or locking the keyboard.

Floppy Write Protection

When selected in Setup, the option for floppy write protection prevents writes to the floppy disk

while the system is in secure mode. Floppy write protection is in effect only while the system is in

secure mode. When not in secure mode, write protection is disabled and the floppy diskette drive

operates normally.

Fixed Disk Boot Sector Write Protect

The fixed disk write-protect switch is set to “Write Protect” to prevent writes to the fixed IDE disk

boot sector. This feature works only with IDE drives and only the boot sector is write protected.

Power Switch Mask

The power switch mask enables and disables the power button feature. If it set to masked, the

system power cannot be turned off with the power button after booting the operating system.

Termination is also disabled. Termination is a feature that terminates system power when the

power switch is held down for more than four seconds.

28 Intel Server Board SE7501BR2 Product Guide

Page 29

2 Server Board Inst allations and Upgrades

Tools and Supplies Needed

• Phillips† (cross head) screwdriver (#1 bit and #2 bit)

• Needle nosed pliers

• A ruler

• Pen or pencil

• Antistatic wrist strap and conductive foam pad (recommended)

Before You Begin

Emissions Disclaimer

To ensure EMC compliance with your local regional rules and regulations, the final configuration

of your end system product may require additional EMC compliance testing. For more information

please contact your local Intel Representative.

See “Regulatory and Integration Information” on page 121 for product Safety and EMC regulatory

compliance information. This is an FCC Class A device. Integration of it into a Class B chassis

does not result in a Class B device.

Safety Cautions

These warnings and cautions apply throughout this chapter. Only a technically qualified person

should configure the server board.

CAUTIONS

System power on/off: The power button DOES NOT turn off the system

AC power. To remove power from system, you must unplug the AC power

cord from the wall outlet. Make sure the AC power cord is unplugged before

you open the chassis, add, or remove any components.

Hazardous conditions, devices & cables: Hazardous electrical

conditions may be present on power, telephone, and communication cables.

Turn off the server and disconnect the power cord, telecommunications

systems, networks, and modems attached to the server before opening it.

Otherwise, personal injury or equipment damage can result.

Risk of burn: If the server has been running, any installed processor and

heat sink on the processor will be hot. To avoid the possibility of a burn, be

careful when removing or installing server board components that are located

near processors.

29

Page 30

Electrostatic discharge (ESD) & ESD protection: ESD can damage

disk drives, boards, and other parts. We recommend that you perform all

procedures in this chapter only at an ESD workstation. If one is not

available, provide some ESD protection by wearing an antistatic wrist strap

attached to chassis groundany unpainted metal surfaceon your server

when handling parts.

ESD and handling boards: Always handle boards carefully. They can

be extremely sensitive to ESD. Hold boards only by their edges. After

removing a board from its protective wrapper or from the server, place the

board component side up on a grounded, static free surface. Use a

conductive foam pad if available but not the board wrapper. Do not slide

board over any surface.

Installing or removing jumpers: A jumper is a small plastic encased

conductor that slips over two jumper pins. Some jumpers have a small tab on

top that you can grip with your fingertips or with a pair of fine needle nosed

pliers. If your jumpers do not have such a tab, take care when using needle

nosed pliers to remove or install a jumper; grip the narrow sides of the

jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with

the function controlled by that jumper. Take care to grip with, but not

squeeze, the pliers or other tool you use to remove a jumper, or you may

bend or break the stake pins on the board.

Safety and Regulatory Compliance

See “Regulatory and Integration Information” on page 121 for product Safety and EMC regulatory

compliance information.

Intended uses: This product was evaluated for use in servers that will be installed in offices,

computer rooms, and similar locations. Other uses require further evaluation.

EMC testing: Before computer integration, make sure that the chassis, power supply, and other

modules have passed EMC testing using a server board with a microprocessor from the same

family (or higher) and operating at the same (or higher) speed as the microprocessor used on this

server board.

Server board diagram label provided: Place the label inside the chassis in an easy-to-see location,

preferably oriented similarly to the server board.

30 Intel Server Board SE7501BR2 Product Guide

Page 31

Minimum Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet the following

minimum requirements. For a list of qualified memory and chassis components see:

http://support.intel.com/support/motherboards/server/SE7501BR2

Processor

Minimum of one Intel Xeon processor with 512K cache support. For a complete list of supported

processors, see:

http://support.intel.com/support/motherboards/server/SE7501BR2

Memory

Minimum of two 128 MB ECC, DDR266 compliant registered DIMMs on 184-pin gold DIMMs.

Power Supply

Minimum of 450 W. Your supply must provide a minimum of 1.2 A of 5 V standby current or the

board will not boot.

Installation Notes

Installation Process Quick Reference

Step Where the information is located

Remove the access cover Your chassis manual

Install the I/O shield Page 32

Install the standoffs Page 34

Install the rubber bumper Page 35

Install the server board Page 36

Connect cables to the server board Page 37. Refer also to your chassis

manual

Install the processor and processor wind tunnel in the Intel® Server

Chassis SC5200 base chassis or in a reference chassis

Install the processor in the Intel® Server Chassis SC5200 with Hot

Swap Redundant Power

Install memory Page 52

Page 40

Page 47

Server Board Installation and Upgrades 31

Page 32

Installation Procedures

Installing the I/O Gasket and Shield

NOTE

✏

An ATX 2.03-compliant I/O shield is provided with the server board. The

shield is required by Electromagnetic Interference (EMI) regulations to

minimize EMI. If the shield does not fit the chassis, obtain a properly sized

shield from the chassis supplier.

Attaching the Gasket to the I/O Shield

1. Remove the backing strip from the gasket.

2. Press the gasket onto the inside face of the I/O shield as shown.

OM14074

Figure 3. Attaching the Gasket to the I/O Shield

32 Intel Server Board SE7501BR2 Product Guide

Page 33

Attaching the Label to the I/O Shield

1. Remove the backing from the label included with your server board.

2. Press the label onto the outside face of the I/O shield.

U

S

B

1

2

3

M

O

U

S

E

K

Y

B

D

P

A

R

A

L

L

E

L

N

E

10/10

T

0 M

Outside face

B

of I/O shield

OM14360

Figure 4. Attaching the Label to the I/O Shield

Installing the I/O Shield

The shield fits the rectangular opening in the back of a chassis. The shield has cutouts that match

the I/O ports on the server board. Install the shield from inside the chassis before installing the

server board.

1. Position one edge so that the dotted groove is outside the chassis wall, and the lip of the shield

rests on the inner chassis wall.

2. Hold the shield in place, and push it into the opening until it is seated. Make sure the I/O shield

snaps into place all the way around.

Insert top edge

as shown.

Shield installs

from inside

of chassis.

Chassis back

Rotate into chassis opening

until shield clicks into place.

Chassis back

OM14625

Figure 5. Installing the I/O Shield

Server Board Installation and Upgrades 33

Page 34

Installing Chassis Standoffs

If your chassis does not have standoffs placed as shown below, you must rearrange them so they

match the holes in the server board. Failure to properly rearrange the metal standoffs may cause the

server board to malfunction and may permanently damage it.

NOTE

✏

The Intel SC5200 chassis comes with positions 1, 4, 5, 6, 18, 20, 23, and 26

preinstalled. Install standoffs in the remaining positions (16, 19, and the

eight marked P). Install standoffs in the eight positions marked P, regardless

of whether one or two processors will be installed. Standoffs are included

with your chassis. Your chassis may be different from the illustration.

1

4

5

6

16

P

P

P

P

P

P

P

P

18

19

OM14626

Figure 6. Configuring Chassis Standoffs

20

23

26

34 Intel Server Board SE7501BR2 Product Guide

Page 35

Installing the Rubber Bumper

1. Measure and mark the bumper placement location in your chassis by placing your ruler against

the standoffs as shown below.

2. Remove the backing from the bumper and press it firmly into position in the chassis.

1

4

6

7

P

P

P

P

18

19

P

P

P

P

7

08

3"

(7.6 cm)

20

23

26

OM14835

Figure 7. Installing the Rubber Bumper

Server Board Installation and Upgrades 35

Page 36

Installing the Server Board

Placing the Server Board into the Chassis