Page 1

Intel® Server Board SE7320VP2

User Guide

Order Number: C71354-002

Page 2

Disclaimer

Information in this document is provided in connection with Intel

otherwise, to any intellectual property rights is granted by this document. Except as provided in Intel’s Terms and Conditions

of Sale for such products, Intel assumes no liability whatsoever, and Intel disclaims any express or implied warranty, relating

to sale and/or use of Intel products including liability or warranties relating to fitness for a particular purpose, merchantability,

or infringement of any patent, copyright or other intellectual property right. Intel products are not designed, intended or

authorized for use in any medical, life saving, or life sustaining applications or for any other application in which the failure of

the Intel product could create a situation where personal injury or death may occur. Intel may make changes to

specifications and product descriptions at any time, without notice.

Intel server boards contain a number of high-density VLSI and power delivery components that need adequate airflow for

cooling. Intel’s own chassis are designed and tested to meet the intended thermal requirements of these components when

the fully integrated system is used together. It is the responsibility of the system integrator that chooses not to use Intel

developed server building blocks to consult vendor datasheets and operating parameters to determine the amount of airflow

required for their specific application and environmental conditions. Intel Corporation can not be held responsible if

components fail or the server board does not operate correctly when used outside any of their published operating or nonoperating limits.

Intel, Intel Pentium, and Intel Xeon are trademarks or registered trademarks of Intel Corporation or its subsidiaries in the

United States and other countries.

®

products. No license, express or implied, by estoppel or

* Other names and brands may be claimed as the property of others.

Copyright © 2004, Intel Corporation. All Rights Reserved

ii

Page 3

Preface

About this Manual

Thank you for purchasing and using the Intel® Server Board SE7320VP2.

This manual is written for system technicians who are responsible for troubleshooting, upgrading,

and reparing this server board. This document provides a brief overview of the features of the

board/chassis, a list of accessories or other components you may need, troubleshooting information,

and instructions on how to add and replace components on the Intel Server Board SE7320VP2. For

the latest version of this manual, refer to

http://support.intel.com/support/motherboards/server/SE7320VP2/.

Manual Organization

Chapter 1 provides a brief overview of the Server Board SE7320VP2. In this chapter, you will find

a list of the server board features, photos of the product, and product diagrams to help you identify

components and their locations.

Chapter 2 provides instructions on adding and replacing components. Use this chapter for step-bystep instructions and diagrams for installing or replacing components such as the memory,

processor, control panel board, and the battery, among other components.

Chapter 3 provides instructions on using the utilities that are shipped with the board or that may be

required to update the system. This includes how to navigate through the BIOS Setup screens, how

to perform a BIOS update, and how to reset the password or CMOS. Information about the specific

BIOS settings and screens is available in the Technical Product Specification. See “Additional

Information and Software” for a link to the Technical Product Specification.

Chapter 4 provides troubleshooting information. In this chapter, you will find BIOS error messages

and POST code messages. You will also find suggestions for performing troubleshooting activities

to identify the source of a problem.

Product Accessories

This server board is compatible with the following Intel® Server Chassis:

Intel® Server Chassis SR2400

Intel® Server Platform SR1435VP2

You may need or want to purchase one or more of the following accessory items for your server:

Processor, memory DIMMs, hard drive, floppy drive, CD-ROM or DVD-ROM drive, RAID

controller, operating system.

For information about which accessories, memory, processors, and third-party hardware have been

tested and can be used with your board, and for ordering information for Intel products, see

http://support.intel.com/support/motherboards/server/SE7320VP2/.

Intel® Server Board SE7320VP2 User Guide iii

Page 4

Preface

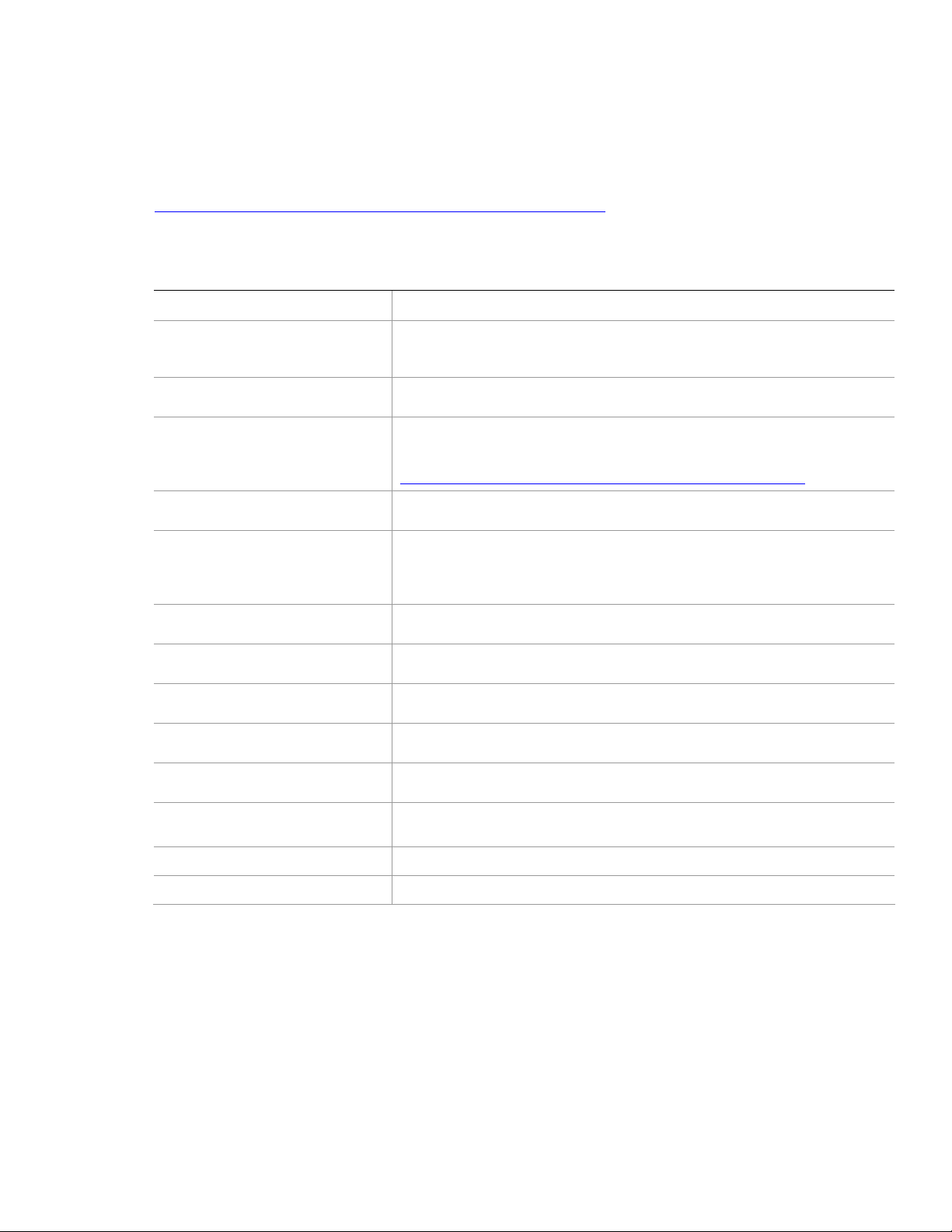

Additional Information and Software

If you need more information about this product or information about the accessories that can be

used with this server board, use the following resources. These files are available at

http://support.intel.com/support/motherboards/server/SE7320VP2

Unless otherwise indicated in the table below, once on this Web page, type the document or

software name in the search field at the left side of the screen and select the option to search “This

Product.”

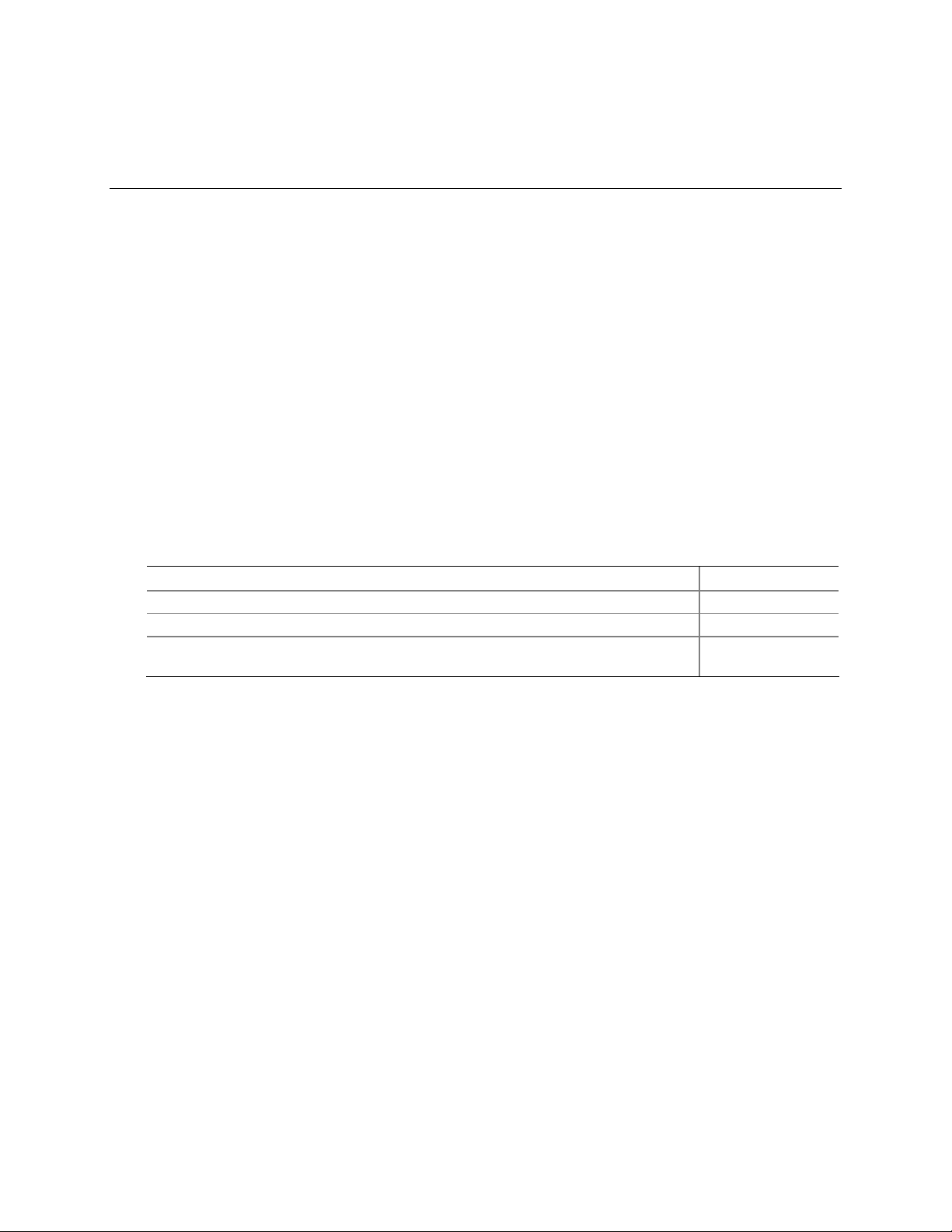

For this information or software Use this search criteria or look at this document

For in-depth technical information

about this product, including BIOS

settings and chipset information

If you just received this product and

need to install it

For virtual system tours and

interactive repair information

Accessories or other Intel server

products

Hardware (peripheral boards,

adapter cards) and operating

systems that have been tested with

this product

Chassis that have been tested with

this product

Processors that have been tested

with this product

DIMMs that have been tested with

this product

To make sure your system falls

within the allowed power budget

For software to manage your Intel®

server

For drivers Search for “Driver” (for an extensive list of drivers available)

Search for “Technical Product Specification”

See the Intel® Server Board SE7320VP2 Quick Start User’s Guide in the

product box

Use the link to the SMaRT Tool under “Other Resources” at the right side of

the screen at

http://support.intel.com/support/motherboards/server/SE7320VP2

Search for “Spares and Configuration Guide”

Search for “Tested Hardware and Operating System List”

Search for “Reference Chassis List”

Search for “Supported Processors”

Search for “Supported Memory”

Search for “Power Budget”

Search for “Intel Server Management”

Search for “Operating System Driver” (for operating system drivers)

iv

For firmware and BIOS updates Search for “Firmware Update”

For diagnostics test software Search for “Diagnostics”

Page 5

Safety Information

WARNING

Before working with your server product, whether you are using this guide or any other

resource as a reference, pay close attention to the safety instructions. You must adhere to the

assembly instructions in this guide to ensure and maintain compliance with existing product

certifications and approvals. Use only the described, regulated components specified in this

guide. Use of other products / components will void the UL listing and other regulatory

approvals of the product and will most likely result in noncompliance with product

regulations in the region(s) in which the product is sold.

Emissions Disclaimer

To ensure EMC compliance with your local regional rules and regulations, the final configuration

of your end system product may require additional EMC compliance testing. For more information

please contact your local Intel Representative.

See “

Regulatory and Integration Information” for product safety compliance and EMC regulatory

compliance information. This is an FCC Class A device. Integration of it into a Class B chassis

does not result in a Class B device.

Preface

Intended Uses

This product was evaluated as Information Technology Equipment (ITE), which may be installed in

offices, schools, computer rooms, and similar commercial type locations. The suitability of this

product for other product categories and environments (such as: medical, industrial,

telecommunications, NEBS, residential, alarm systems, test equipment, etc.), other than an ITE

application, may require further evaluation

EMC Testing

Before computer integration, make sure that the chassis, power supply, and other modules have

passed EMC testing using a server board with a microprocessor from the same family (or higher)

and operating at the same (or higher) speed as the microprocessor used on this server board.

v

Page 6

Preface

Warnings

System power on/off: The power button DOES NOT turn off the system

AC power. To remove power from system, you must unplug the AC power

cord from the wall outlet. Make sure the AC power cord is unplugged before

you open the chassis, add, or remove any components.

Hazardous conditions, devices and cables: Hazardous electrical

conditions may be present on power, telephone, and communication cables.

Turn off the server and disconnect the power cord, telecommunications

systems, networks, and modems attached to the server before opening it.

Otherwise, personal injury or equipment damage can result.

Electrostatic discharge (ESD) and ESD protection: ESD can

damage disk drives, boards, and other parts. We recommend that you

perform all procedures in this chapter only at an ESD workstation. If one is

not available, provide some ESD protection by wearing an antistatic wrist

strap attached to chassis ground any unpainted metal surface on your

server when handling parts.

ESD and handling boards: Always handle boards carefully. They can

be extremely sensitive to ESD. Hold boards only by their edges. After

removing a board from its protective wrapper or from the server, place the

board component side up on a grounded, static free surface. Use a

conductive foam pad if available but not the board wrapper. Do not slide

board over any surface.

Installing or removing jumpers: A jumper is a small plastic encased

conductor that slips over two jumper pins. Some jumpers have a small tab on

top that you can grip with your fingertips or with a pair of fine needle nosed

pliers. If your jumpers do not have such a tab, take care when using needle

nosed pliers to remove or install a jumper; grip the narrow sides of the

jumper with the pliers, never the wide sides. Gripping the wide sides can

damage the contacts inside the jumper, causing intermittent problems with

the function controlled by that jumper. Take care to grip with, but not

squeeze, the pliers or other tool you use to remove a jumper, or you may

bend or break the pins on the board.

vi

Page 7

Preface

Safety Cautions

Read all caution and safety statements in this document before performing any of the instructions.

See also Intel Server Boards and Server Chassis Safety Information on the Resource CD and/or at

http://support.intel.com/support/motherboards/server/.

SAFETY STEPS: Whenever you remove the chassis covers to access the inside of the

system, follow these steps:

1. Turn off all peripheral devices connected to the system.

2. Turn off the system by pressing the power button.

3. Unplug all AC power cords from the system or from wall outlets.

4. Label and disconnect all cables connected to I/O connectors or ports on the back of

the system.

5. Provide some electrostatic discharge (ESD) protection by wearing an antistatic wrist

strap attached to chassis ground of the system—any unpainted metal surface—

when handling components.

6. Do not operate the system with the chassis covers removed.

A microprocessor and heat sink may be hot if the system has been running. Also, there may

be sharp pins and edges on some board and chassis parts. Contact should be made with

care. Consider wearing protective gloves.

Wichtige Sicherheitshinweise

Lesen Sie zunächst sämtliche Warn- und Sicherheitshinweise in diesem Dokument, bevor Sie eine

der Anweisungen ausführen. Beachten Sie hierzu auch die Sicherheitshinweise zu IntelServerplatinen und -Servergehäusen auf der Ressourcen-CD oder unter

http://support.intel.com/support/motherboards/server/.

SICHERHEISMASSNAHMEN: Immer wenn Sie die Gehäuseabdeckung abnehmen um an

das Systeminnere zu gelangen, sollten Sie folgende Schritte beachten:

1. Schalten Sie alle an Ihr System angeschlossenen Peripheriegeräte aus.

2. Schalten Sie das System mit dem Hauptschalter aus.

3. Ziehen Sie den Stromanschlußstecker Ihres Systems aus der Steckdose.

4. Auf der Rückseite des Systems beschriften und ziehen Sie alle Anschlußkabel von

den I/O Anschlüssen oder Ports ab.

5. Tragen Sie ein geerdetes Antistatik Gelenkband, um elektrostatische Ladungen

(ESD) über blanke Metallstellen bei der Handhabung der Komponenten zu

vermeiden.

6. Schalten Sie das System niemals ohne ordnungsgemäß montiertes Gehäuse ein.

Der Mikroprozessor und der Kühler sind möglicherweise erhitzt, wenn das System in Betrieb

ist. Außerdem können einige Platinen und Gehäuseteile scharfe Spitzen und Kanten

aufweisen. Arbeiten an Platinen und Gehäuse sollten vorsichtig ausgeführt werden. Sie

sollten Schutzhandschuhe tragen.

vii

Page 8

Preface

重要安全指导

在执行任何指令之前,请阅读本文档中的所有注意事项及安全声明。参见 Resource

CD(资源光盘) 和/或

Server Boards and Server Chassis Safety Information

http://support.intel.com/support/motherboards/server/ 上的

(《Intel

服务器主板与服务器机箱安全信息》)。

Consignes de sécurité

Lisez attention toutes les consignes de sécurité et les mises en garde indiquées dans ce document

avant de suivre toute instruction. Consultez Intel Server Boards and Server Chassis Safety

Information sur le CD Resource CD ou bien rendez-vous sur le site

http://support.intel.com/support/motherboards/server/.

CONSIGNES DE SÉCURITÉ -Lorsque vous ouvrez le boîtier pour accéder à l’intérieur du

système, suivez les consignes suivantes:

1. Mettez hors tension tous les périphériques connectés au système.

2. Mettez le système hors tension en mettant l’interrupteur général en position OFF

(bouton-poussoir).

3. Débranchez tous les cordons d’alimentation c.a. du système et des prises murales.

4. Identifiez et débranchez tous les câbles reliés aux connecteurs d’E-S ou aux accès

derrière le système.

5. Pour prévenir les décharges électrostatiques lorsque vous touchez aux

composants, portez une bande antistatique pour poignet et reliez-la à la masse du

système (toute surface métallique non peinte du boîtier).

6. Ne faites pas fonctionner le système tandis que le boîtier est ouvert.

Le microprocesseur et le dissipateur de chaleur peuvent être chauds si le système a été

sous tension. Faites également attention aux broches aiguës des cartes et aux bords

tranchants du capot. Nous vous recommandons l'usage de gants de protection.

Intel

viii

Page 9

Instrucciones de seguridad importantes

Lea todas las declaraciones de seguridad y precaución de este documento antes de realizar

cualquiera de las instrucciones. Vea Intel Server Boards and Server Chassis Safety Information en

el CD Resource y/o en

http://support.intel.com/support/motherboards/server/.

INSTRUCCIONES DE SEGURIDAD: Cuando extraiga la tapa del chasis para acceder al

interior del sistema, siga las siguientes instrucciones:

1. Apague todos los dispositivos periféricos conectados al sistema.

2. Apague el sistema presionando el interruptor encendido/apagado.

3. Desconecte todos los cables de alimentación CA del sistema o de las tomas de

corriente alterna.

4. Identifique y desconecte todos los cables enchufados a los conectores E/S o a los

puertos situados en la parte posterior del sistema.

5. Cuando manipule los componentes, es importante protegerse contra la descarga

electrostática (ESD). Puede hacerlo si utiliza una muñequera antiestática sujetada

a la toma de tierra del chasis — o a cualquier tipo de superficie de metal sin pintar.

6. No ponga en marcha el sistema si se han extraído las tapas del chasis.

Si el sistema ha estado en funcionamiento, el microprocesador y el disipador de calor

pueden estar aún calientes. También conviene tener en cuenta que en el chasis o en el

tablero puede haber piezas cortantes o punzantes. Por ello, se recomienda precaución y el

uso de guantes protectores.

Preface

AVVERTENZA: Italiano

PASSI DI SICUREZZA: Qualora si rimuovano le coperture del telaio per accedere

all’interno del sistema, seguire i seguenti passi:

1. Spegnere tutti i dispositivi periferici collegati al sistema.

2. Spegnere il sistema, usando il pulsante spento/acceso dell’interruttore del sistema.

3. Togliere tutte le spine dei cavi del sistema dalle prese elettriche.

4. Identificare e sconnettere tutti i cavi attaccati ai collegamenti I/O od alle prese

5. Qualora si tocchino i componenti, proteggersi dallo scarico elettrostatico (SES),

6. Non far operare il sistema quando il telaio è senza le coperture.

Se il sistema è stato a lungo in funzione, il microprocessore e il dissipatore di calore

potrebbero essere surriscaldati. Fare attenzione alla presenza di piedini appuntiti e parti

taglienti sulle schede e sul telaio. È consigliabile l'uso di guanti di protezione.

installate sul retro del sistema.

portando un cinghia anti-statica da polso che è attaccata alla presa a terra del telaio

del sistema – qualsiasi superficie non dipinta – .

ix

Page 10

Preface

x

Page 11

Contents

Contents

1 Server Board Features................................................................................. 15

Connector and Header Locations .........................................................................................17

Configuration Jumpers.......................................................................................................... 18

Back Panel Connectors.........................................................................................................21

Hardware Requirements .......................................................................................................22

Processor .....................................................................................................................22

Memory .......................................................................................................................22

Optional Hardware ................................................................................................................24

Storage Devices........................................................................................................... 24

2 Hardware Installations and Upgrades........................................................ 25

Before You Begin.................................................................................................................. 25

Tools and Supplies Needed.................................................................................................. 25

Installing and Removing Memory.......................................................................................... 25

Installing DIMMs...........................................................................................................25

Removing DIMMs.........................................................................................................27

Installing or Replacing the Processor....................................................................................28

Installing the Processor................................................................................................ 28

Removing a Processor................................................................................................. 30

RJ45 Serial Port Configuration..............................................................................................31

Installing a PCI, PCI-X, or PCI-Express* Add-in Card ..........................................................32

Replacing the Backup Battery...............................................................................................32

3 Server Utilities .............................................................................................. 34

Using the BIOS Setup Utility .................................................................................................34

Starting Setup ..............................................................................................................34

If You Cannot Access Setup ........................................................................................34

Setup Menus ................................................................................................................ 34

Upgrading the BIOS..............................................................................................................36

Preparing for the Upgrade............................................................................................ 36

Upgrading the BIOS ..................................................................................................... 37

Clearing the Password.......................................................................................................... 37

Clearing the CMOS...............................................................................................................38

4 Troubleshooting........................................................................................... 39

Resetting the System............................................................................................................39

Problems following Initial System Installation .......................................................................40

First Steps Checklist.....................................................................................................40

Hardware Diagnostic Testing................................................................................................ 41

Verifying Proper Operation of Key System Lights........................................................ 41

Confirming Loading of the Operating System ..............................................................41

Specific Problems and Corrective Actions ............................................................................ 42

Power Light Does Not Light..........................................................................................42

No Characters Appear on Screen ................................................................................ 43

xi

Page 12

Contents

Characters Are Distorted or Incorrect...........................................................................43

System Cooling Fans Do Not Rotate Properly............................................................. 44

Diskette Drive Activity Light Does Not Light................................................................. 44

CD-ROM Drive or DVD-ROM Drive Activity Light Does Not Light ...............................45

Cannot Connect to a Server......................................................................................... 45

Problems with Network.................................................................................................45

System Boots when Installing PCI Card.......................................................................46

Problems with Newly Installed Application Software....................................................46

Problems with Application Software that Ran Correctly Earlier.................................... 46

Devices are not Recognized under Device Manager (Windows* Operating System)..47

Hard Drive(s) are not Recognized................................................................................ 47

Bootable CD-ROM Is Not Detected..............................................................................47

LED Information ...........................................................................................................48

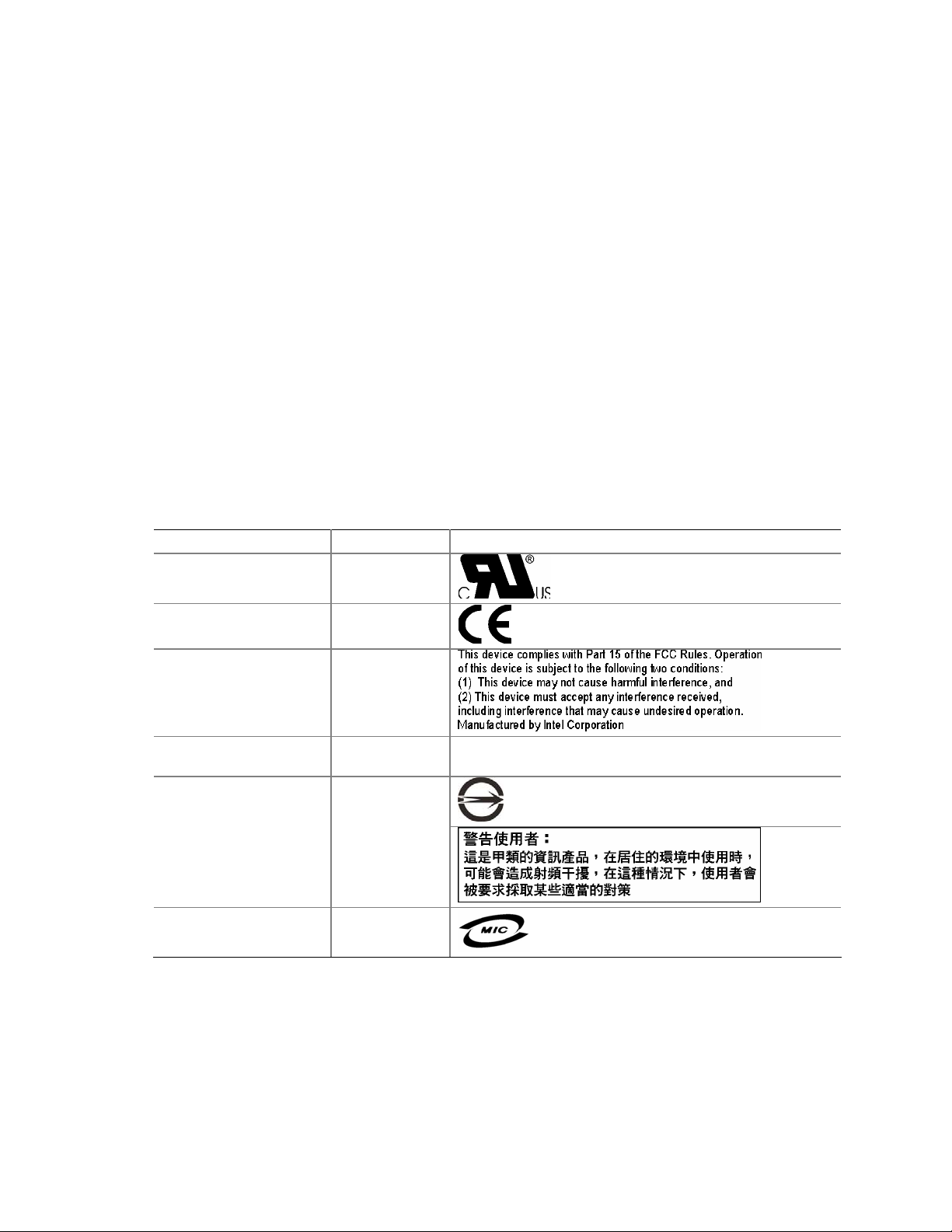

Product Regulatory Compliance ...........................................................................................49

Product Safety Compliance.......................................................................................... 49

Product EMC Compliance – Class A Compliance........................................................49

Certifications / Registrations / Declarations..................................................................50

Product Regulatory Compliance Markings................................................................... 50

Electromagnetic Compatibility Notices..................................................................................51

FCC (USA) ................................................................................................................... 51

Industry Canada (ICES-003)........................................................................................ 52

Europe (CE Declaration of Conformity)........................................................................52

Taiwan Declaration of Conformity (BSMI)....................................................................52

Korean Compliance (RRL) ........................................................................................... 52

Getting Help ....................................................................................................... 53

Intel® Server Issue Report Form....................................................................... 55

Figures

Figure 1. Intel

Figure 2. Server Board Connector and Header Locations......................................................... 17

Figure 3. Recovery Jumper Location......................................................................................... 18

Figure 4. Serial Port Configuration Jumper Location ................................................................. 19

Figure 5. BIOS Select Jumper Location..................................................................................... 20

Figure 6. Back Panel Connectors ..............................................................................................21

Figure 7. Installing Memory........................................................................................................ 26

Figure 8. Opening Socket Lever ................................................................................................28

Figure 9. Inserting Processor..................................................................................................... 29

Figure 10. Closing Socket Lever................................................................................................29

Figure 11. Installing Heat Sink...................................................................................................30

Figure 12. Changing the Serial Port Configuration .................................................................... 31

Figure 13. Replacing the Backup Battery ..................................................................................33

Figure 14. Password Recovery Jumper..................................................................................... 37

Figure 15. CMOS Recovery Jumper.......................................................................................... 38

®

Server Board SE7320VP2................................................................................ 15

xii

Page 13

Contents

Tables

Table 1. Server Board Features ..................................................................................16

Table 2. Recovery Jumper [J1H2, J1H3, J1H5] .......................................................... 18

Table 3. Serial Port Configuration Jumper [J8A3] ....................................................... 19

Table 4. BIOS Select Jumper [J1A4]........................................................................... 20

Table 5. NIC LEDs....................................................................................................... 21

Table 6. Processor Support.........................................................................................22

Table 7. Memory Capacity Support ............................................................................. 23

Table 8. Keyboard Commands.................................................................................... 35

Table 9. Keyboard Commands.................................................................................... 48

Table 10. Product Certification Markings....................................................................... 50

Table 11. Customer Support Telephone Numbers........................................................ 53

xiii

Page 14

Contents

xiv

Page 15

1 Server Board Features

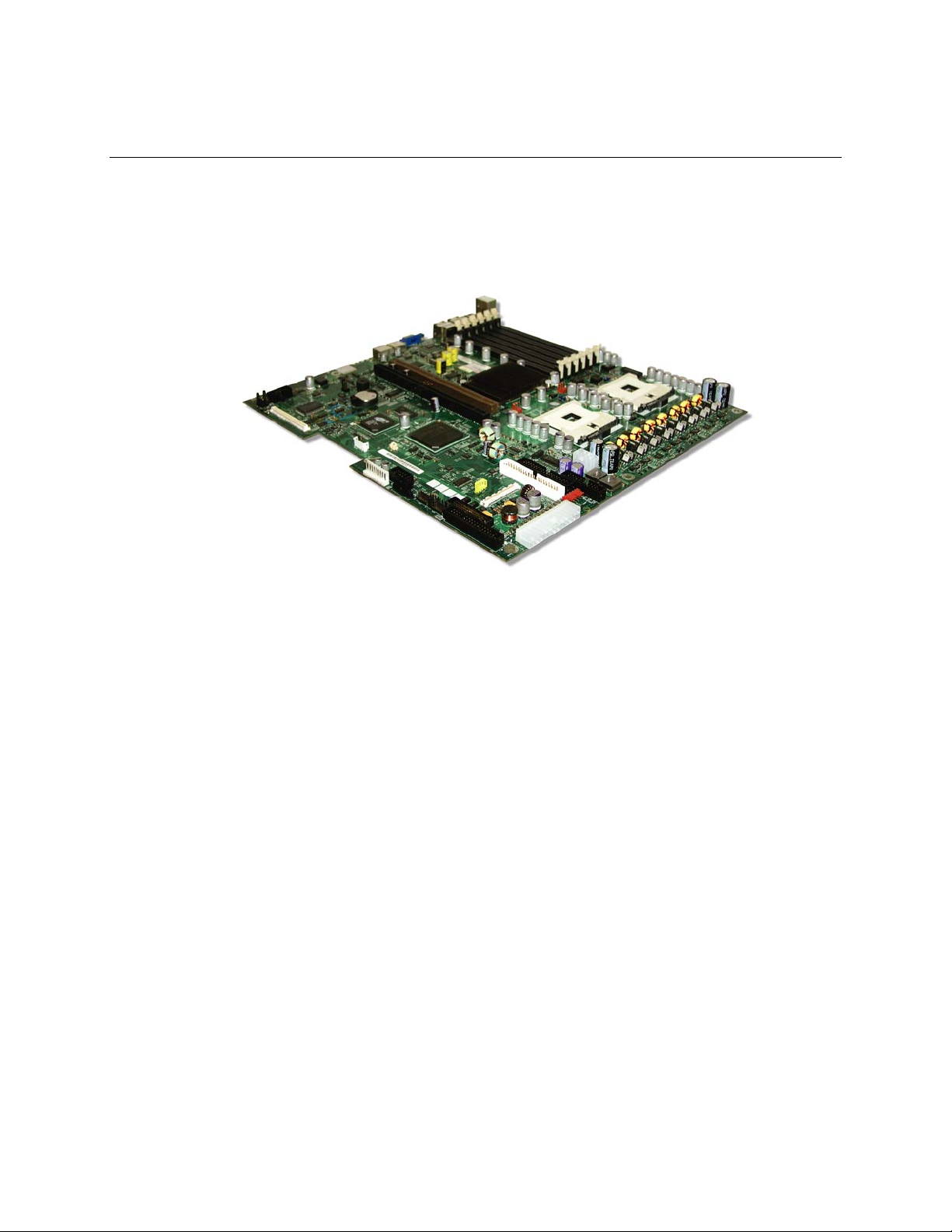

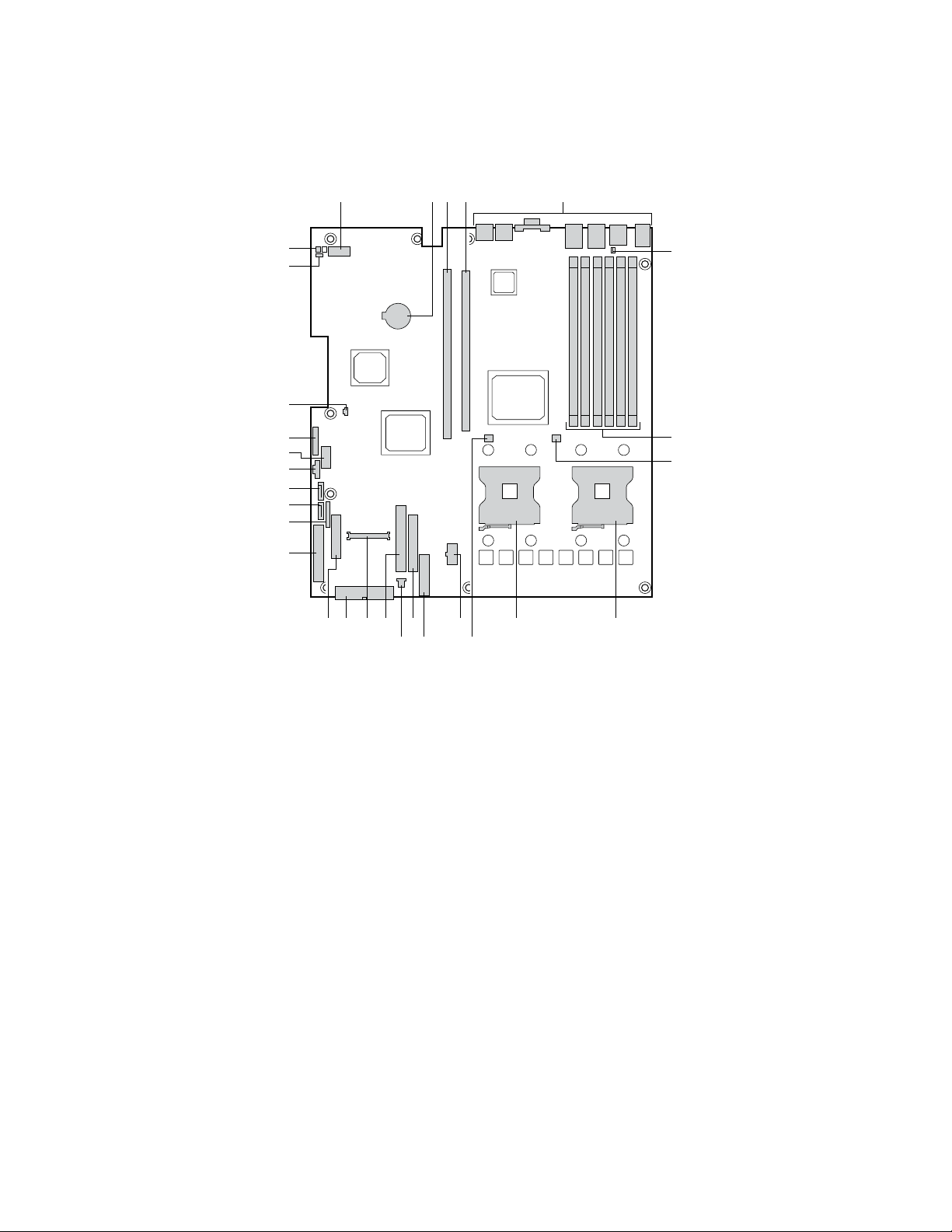

This chapter briefly describes the main features of Intel® Server Board SE7320VP2. This chapter

provides a photograph of the product, a list of the server board features, and diagrams showing the

location of important components and connections on the server board.

The Server Board SE7320VP2 is shown in the following picture.

Figure 1. Intel® Server Board SE7320VP2

Intel® Server Board SE7320VP2 User Guide 15

Page 16

Server Board Features

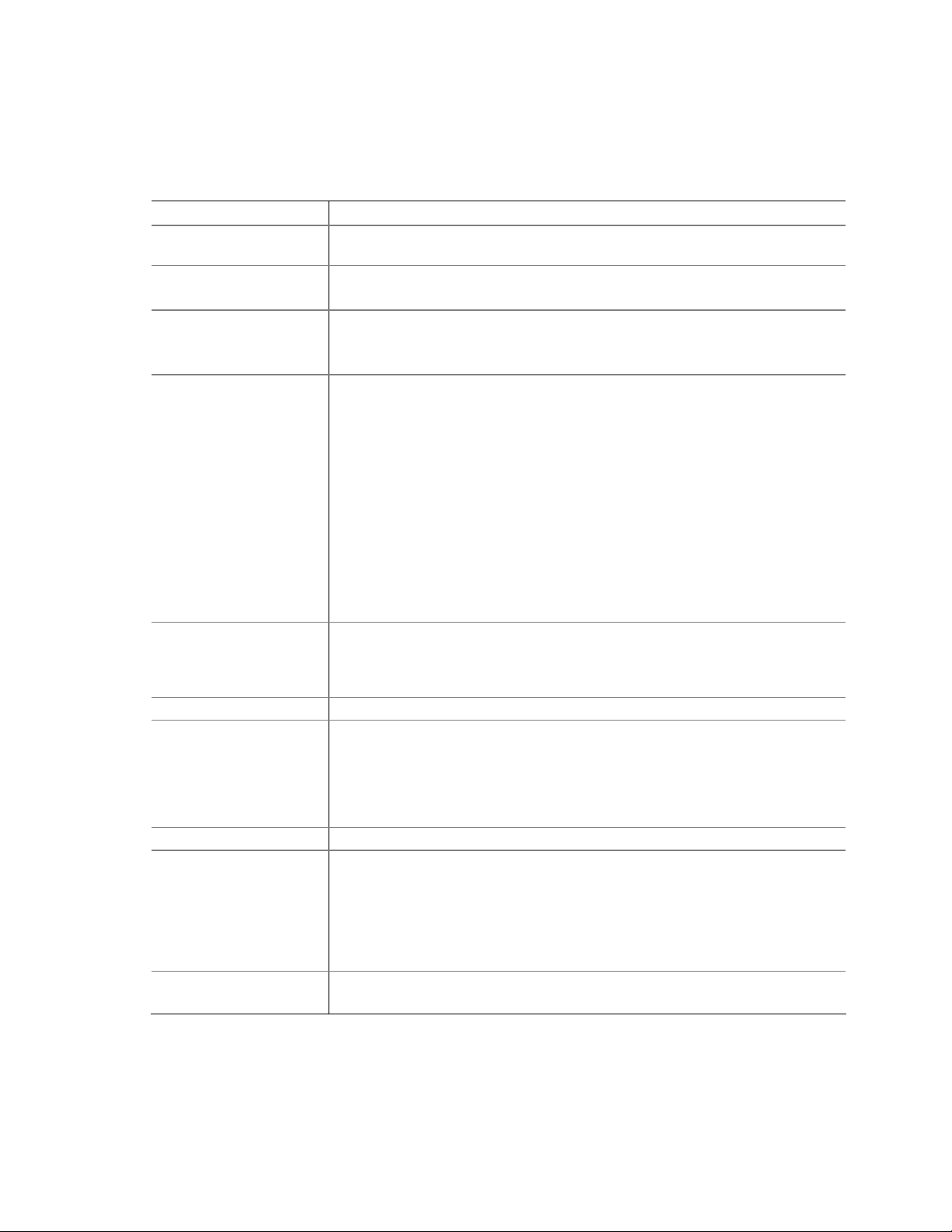

Table 1 summarizes the major features of the server board.

Table 1. Server Board Features

Feature Description

Processors Support for up to two Intel® Xeon™ processors with an 800 MT/s MHz front side

bus and frequencies starting at 2.8 GHz.

Memory Six DIMM slots supporting DDR266MHz or DDR333MHz memory

Memory mirroring and memory sparing options

Chipset Intel® E7320 chipset, including:

Intel E7320 MCH

Intel 6300ESB ICH

I/O Control External connections:

Stacked PS/2 ports for keyboard and mouse

RJ45 Serial B port

Two RJ45 NIC connectors for 10/100/1000 Mb connections

Two USB 2.0 ports

One USB port header, which supports two USB ports

One DH10 Serial A header

Two SATA-100 connectors with integrated RAID 0/1 support

One ATA100 connector

SSI-compliant and custom front panel headers

SSI-compliant 24-pin main power connector, supporting the ATX-12V

standard on the first 20 pins.

Add-in PCI, PCI-X, PCIExpress* Cards (riser(s)

required)

Video On-board ATI* RAGE XL video controller with 8MB SDRAM

Hard Drive Ultra ATA/100 support:

LAN Two 10/100/1000 NICs

Fans Four SSI-compliant 3-pin fan connectors

Server Management

One low-profile riser connector that supports a riser card with a PCI or PCI-X

slot that is capable of speeds up to 66 MHz.

One full-height riser connector, utilizing Intel® Adaptive Slot technology. This

connector supports a riser card with PCI, PCI-X, and/or PCI-Express* slots.

Two IDE channels that support either one or two drives

SATA support

Two SATA ports

RAID level 0/1 support

Two processor fan connectors

Two PCI fan connectors

One 20-pin fan connector to provide power and management of system fans in

the Intel® Server Chassis SR2400 and in the Intel® Server Platform

SR1435VP2

On-board Essentials server management

Support for Intel® Server Management 8

16

Page 17

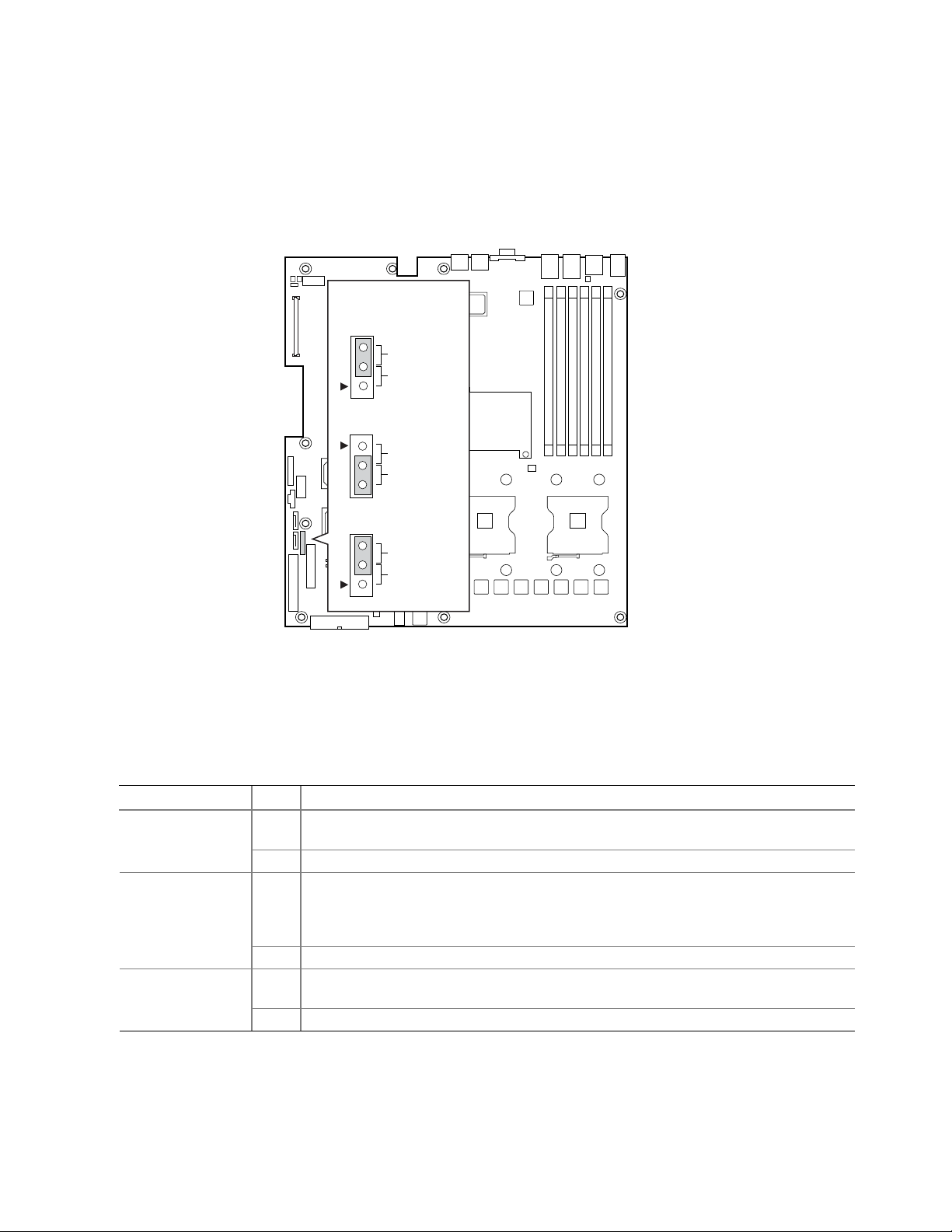

Connector and Header Locations

Server Board Features

A

CC

B

C

D

E

F

BB

AA

Z

Y

X

G

H

W

V

U

T

RS

P

N

Q

O

A Serial Port A header K Processor 2 fan header U Configuration jumpers

B Battery

C Full-height PCI slot M Fan board connector W SATA 0 connector

D Low-profile PCI slot N Floppy connector Z Power supply connector

E Back panel I/O ports O PCI fan connecors (two) Y OEM RMC connector

F Serial port selection jumper P IDE connector Z Front panel USB header

G DIMM sockets

H Processor 1 fan header R Main power connector BB BIOS Select jumper

I Processor 1 socket S 50-pin front panel connector CC Chassis intrusion header

J Processor 2 socket T 34-pin front panel connector

L +12V processor power

connector

Q 100-pin Floppy / Front Panel /

ATA connector

L

M

J

K

I

TP00941

V SATA 1 connector

AA IDE power connector

Figure 2. Server Board Connector and Header Locations

17

Page 18

Server Board Features

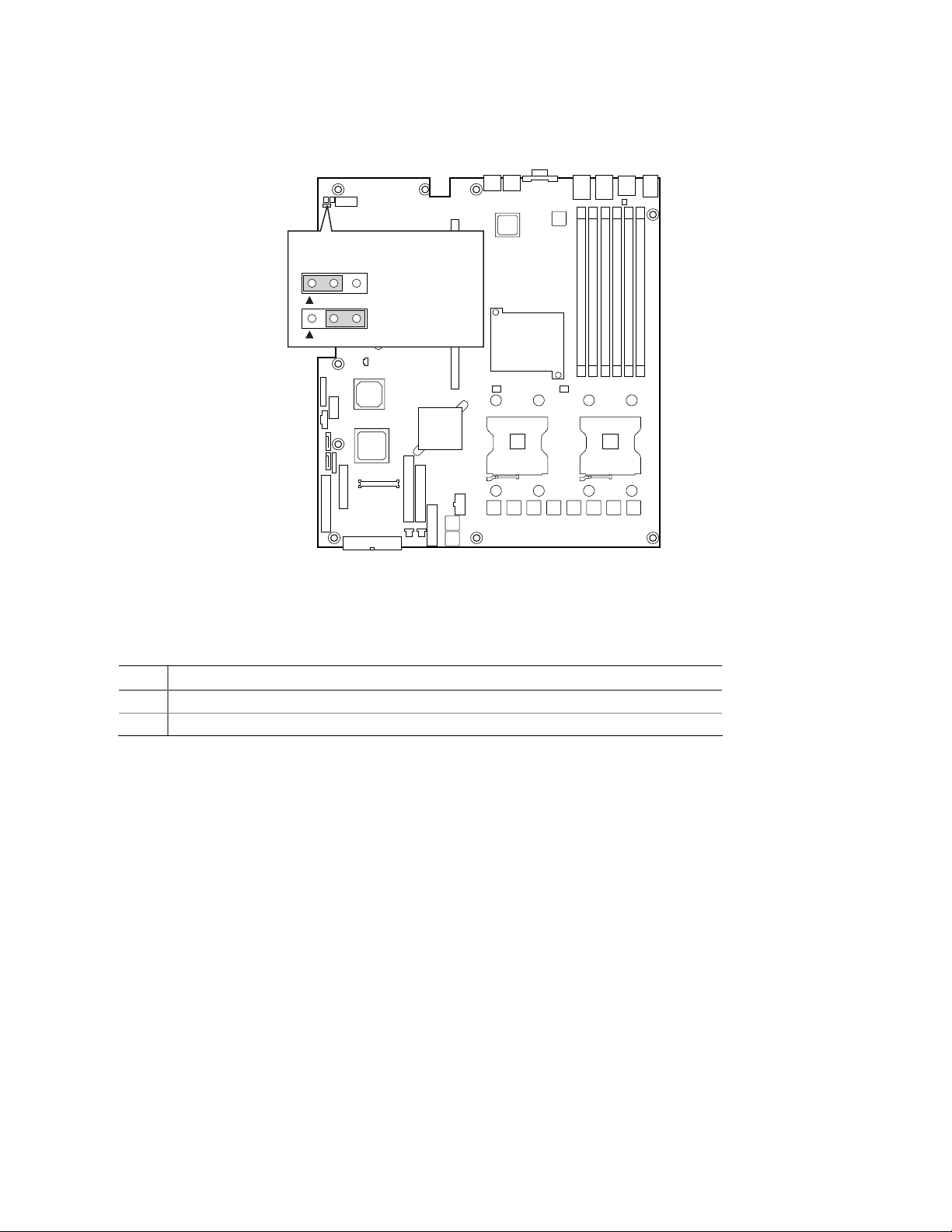

Configuration Jumpers

Recovery Jumpers

J1H2, J1H3, J1H5

J1H2 Pass Clr

3

2

2

3

Protect

Erase

J1H3 Rcvr Boot

Recovery Boot

Normal Boot

J1H5 CMOS Clr

3

2

BMC Control

Force Erase

Figure 3. Recovery Jumper Location

Table 2. Recovery Jumper [J1H2, J1H3, J1H5]

Jumper Name Pins What happens at system reset…

J1H2: Password

Clear

J1H3: Recovery

Boot

J1H5: CMOS

Clear

1-2 If these pins are jumpered, administrator and user passwords will be cleared on the

next reset. These pins should not be jumpered for normal operation.

2-3 These pins should be jumpered for normal system operation.

1-2 If these pins are jumpered, the system will attempt to recover the BIOS by loading the

BIOS code into the flash device from a floppy disk. his jumper is typically used when

the BIOS has become corrupted. These pins should not be jumpered for normal

operation.

2-3 These pins should be jumpered for normal system operation.

1-2 If these pins are jumpered, the CMOS settings will be cleared on the next reset.

These pins should not be jumpered for normal operation.

2-3 These pins should be jumpered for normal system operation.

TP00942

18

Page 19

Serial Port Configuration Jumper

Server Board Features

J8A3

34

1-3: DCD to DTR (Default)

2-4: DSR to DTR

2

Figure 4. Serial Port Configuration Jumper Location

Table 3. Serial Port Configuration Jumper [J8A3]

Pins What happens at system reset…

1-3 Serial port is configured for DCD to DTR (default)

2-4 Serial port is configured for DSR to DTR.

TP00944

19

Page 20

Server Board Features

BIOS Select Jumper

J1A4

BIOS Select

1-2: Normal

Operation (Default)

3

2-3: Force to

Lower Bank

3

Figure 5. BIOS Select Jumper Location

Table 4. BIOS Select Jumper [J1A4]

Pins What happens at system reset…

1-2 System is configured for normal operation

2-3 Force BIOS to lower bank

TP00949

20

Page 21

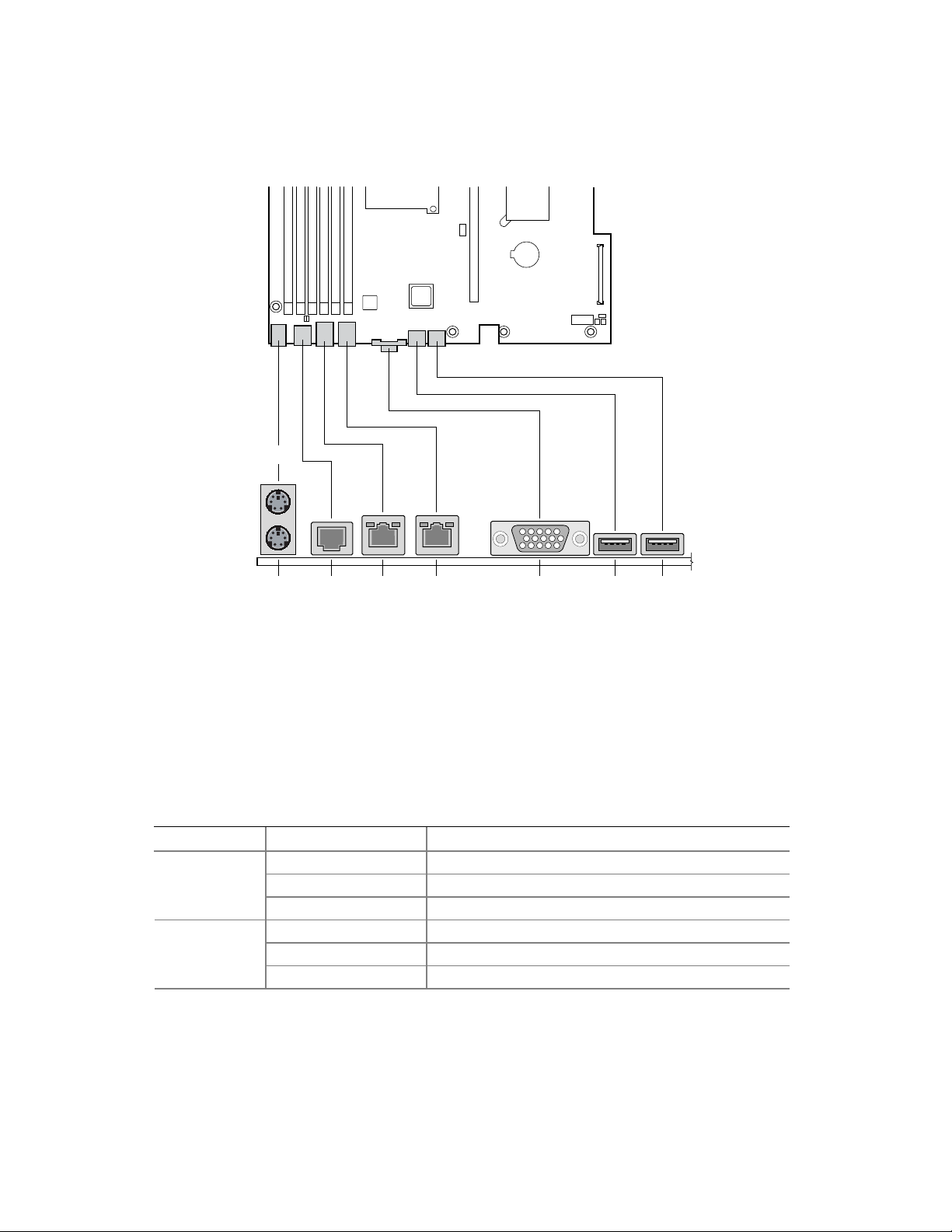

Back Panel Connectors

A

Server Board Features

FC D E G HB

TP00943

A Mouse E NIC2 (1 Gb)

B Keyboard F Video

C Serial Port B G USB1

D NIC1 (1 Gb) H USB2

Figure 6. Back Panel Connectors

The NIC LEDs at the right and left of each NIC provide the following information.

Table 5. NIC LEDs

LED Color LED State Description

Off No network connection

Left LED

Right LED

Solid Amber Network connection in place

Blinking Amber Transmit/receive activity

Off 10 Mbps connection (if left LED is on or blinking)

Solid Amber 100 Mbps connection

Solid Green 1000 Mbps connection

21

Page 22

Server Board Features

Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet the

requirements outlined below. For a list of qualified components, see the links under “Additional

Information and Software.”

Processor

One or two Intel® Xeon™ processors with an 800MHz front side bus and a minimum of 2.8 GHz

frequency must be installed. The following table outlines the supported processors. For a complete

list of supported processors, see the links under “Additional Information and Software.”

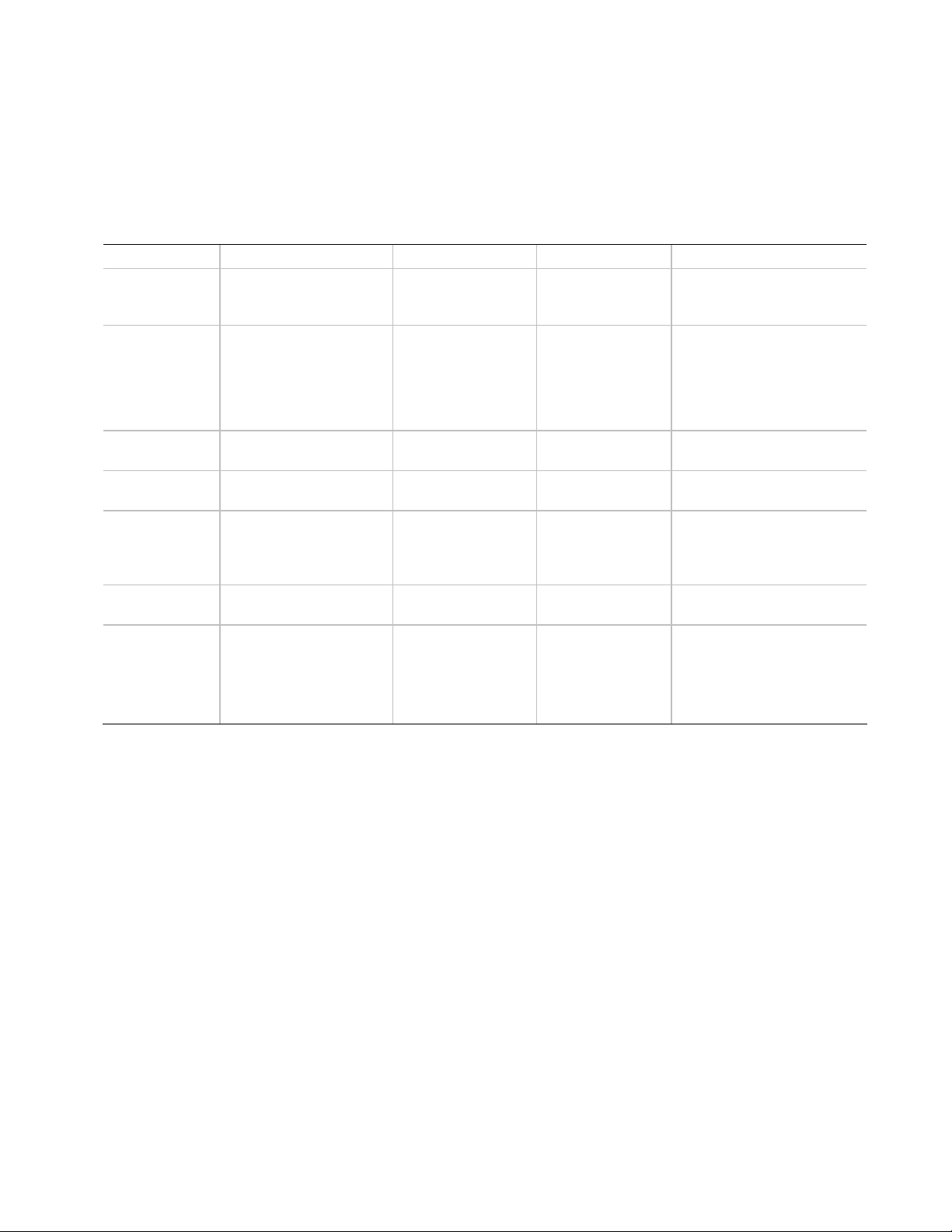

Table 6. Processor Support

Processor Family FSB Frequency Frequency

Intel® Xeon™ 800 MHz 2.8 GHz

Intel® Xeon™ 800 MHz 3.0 GHz

Intel® Xeon™ 800 MHz 3.2 GHz

Intel® Xeon™ 800 MHz 3.4 GHz

Intel® Xeon™ 800 MHz 3.6 GHz

Memory

The Server Board SE7320VP2 provides six DIMM sockets across two channels, Channel A and

Channel B. Channel A consists of DIMM sockets 1A, 2A, and 3A. Channel B consists of DIMM

sockets 1B, 2B, and 3B.

If six DIMMs are installed, the following maximum capacitites are possible:

For DDR266 DIMMS: Maxixmum capacity of 24GB

For DDR333 DIMMS: Maximum capacity of 16 GB

A minimum of one 256MB DIMM is required in DIMM socket 1A. This uses single-channel

interleave. However, for dual-channel interleave, providing optimum performance, a minimum

of two DIMMs should be installed in DIMM sockets 1A and 1B. Except for the option of

installing a single DIMM in socket 1A, DIMMs must be installed in pairs and populated as

follows:

DIMM1A and DIMM 1B: Populate these two sockets together first

DIMM 2A and DIMM 2B: Populate these sockets in addition to DIMM 1A and DIMM 2A if

four DIMMs are to be used.

DIMM 3A and DIMM 3B: Populate these sockets after DIMM 1A, DIMM 1B, DIMM 2A, and

DIMM 2B have been populated.

22

Page 23

Server Board Features

DIMMs must meet the following requirements:

Use only DDR266 or DDR33, registered DDR DIMM modules

Use only DIMMs that comply with the DDR specifications.

DDR266 and DDR333 memory can be mixed on the server board, but when mixing DIMM

types, DDR333 memory will be treated as DDR266.

Use only DIMMs with DIMM organization of x72 ECC

Use only 184-pin DIMMs

Use only DIMMs with the capacities outlined in the following table

Table 7. Memory Capacity Support

DIMM Type 256MB 512MB 1GB

X8, single row 256MB 512MB 1GB

X8, double row 512MB 1GB 2GB

X4, single row 512MB 1GB 2GB

X4, stacked, double row 1GB 2GB 4GB

In determining your memory requirements, the need for memory sparing or memory mirroring must

be considered. For a complete list of supported memory DIMMs, see the links under “Additional

Information and Software.”

Memory Sparing and Mirroring

The Intel® E7320 chipset supports memory mirroring and memory on-line sparing. Both memory

mirroring and memory on-line sparing provide a way to prevent data loss in case a DIMM fails.

With memory mirroring the system maintains two copies of all data in the memory subsystem. If a

DIMM fails, the data is not lost because the second copy of the data is available from the mirrored

DIMM in the opposite channel. The system will not fail due to memory error unless both the

primary and the mirrored copy of the data become corrupt at the same time.

In a mirrored system, the maximum usable memory space is one-half of the installed memory, with

a minimum of four DIMMs installed.

One method for memory mirroring is available, with four identical DIMMs are used in DIMM

sockets 1A, 1B, 2A, and 2B.

If the DIMM in socket 1A fails, the DIMM in socket 2B takes over.

If the DIMM in socket 1B fails, the DIMM in socket 2A takes over.

23

Page 24

Server Board Features

For memory on-line sparing, one DIMM per channel is used as the memory spare. The spare

DIMM is not available for use, but is kept in reserve. If a DIMM begins to fail, the content of the

failing DIMM is copied to the spare DIMM in that channel. When all of the data is copied to the

spare DIMM, the primary DIMM is removed from service and the spare DIMM takes its place.

When memory on-line sparing is used, the spare DIMMs must be equal to or larger than the largest

in-service DIMM in that channel.

✏ NOTE

Memory mirroring and memory sparing are mutually exclusive. Only one can be active at a time.

Refer to the Intel

information regarding the memory sub-system.

®

Server Board SE7320VP2 Technical Product Specification for additional

Power Supply

A minimum of 450 Watts is required. Your supply must provide a minimum of 1.2 A of 5 V

standby current or the board will not boot. Use the power budget tool to determine the minimum

power supply for your system, based on all installed components. For a link to the power budget

utility, see “Additional Information and Software.”

Optional Hardware

Storage Devices

The Server Board SE7320VP2 provides two SATA connections and two ATA (IDE/ATAPI)

controllers. The two SATA connectors are on the powersupply side of the board marked “SATA 0”

and “SATA 1”. Each ATA connection supports one or two ATA/100 devices. IDE devices can be

connected to the standard ATA connector, next to the floppy connector, or to the 100-pin cable

connector.

A floppy drive connection is available through the standard floppy connector or through the 100pin front panel connector if you have installed the optional hot-swap backplane.

Drive power is supplied from the chassis power supply for conventional cable-attached drives.

Power is available from the IDE power header near the cutout in the center on the power supply

side of the board for ATA-compliant IDE flash drives (mini IDE, iDiskOnChip*, and others). For

multiple slimline devices a Y-cable for power can be used. For direct-plug IDE flash drives, use the

AXXFLASHPWR accessory cable.

See the documentation included with your server chassis for additional drive information and drive

installation instructions.

24

Page 25

2 Hardware Installations and Upgrades

Before You Begin

Before working with your server product, pay close attention to the Safety Information at the

beginning of this manual.

Tools and Supplies Needed

Phillips

Flat-head screwdriver if replacing the battery

Pen or pencil to write down BIOS settings

Antistatic wrist strap and conductive foam pad (recommended)

Installing and Removing Memory

The silkscreen on the board for the DIMMs displays DIMM1B, DIMM1A, DIMM2B, DIMM2A,

DIMM3B, and DIMM3A, starting from the edge of the board. DIMM3A is the socket closest to

the processor socket. See “Memory” for a discussion of the memory requirements and options. See

“Additional Information and Software” for a link to the list of tested DIMMs.

*

(cross head) screwdriver (#1 bit and #2 bit)

Installing DIMMs

To install DIMMs, follow these steps:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

Intel® Server Board SE7320VP2 User Guide 25

Page 26

Hardware Installations and Upgrades

4. Remove the server’s cover. See the documentation that accompanied your server chassis for

instructions on removing the server’s cover.

5. Locate the DIMM sockets (see Figure 7).

DIMM 2A

DIMM 3B

DIMM 3A

Figure 7. Installing Memory

DIMM 2B

DIMM 1A

DIMM 1B

TP00761

6. Make sure the clips at either end of the DIMM socket(s) are pushed outward to the open

position.

7. Holding the DIMM by the edges, remove it from its anti-static package.

8. Position the DIMM above the socket. Align the two small notches in the bottom edge of the

DIMM with the keys in the socket (see inset in Figure 7).

9. Insert the bottom edge of the DIMM into the socket.

10. When the DIMM is inserted, push down on the top edge of the DIMM until the retaining clips

snap into place. Make sure the clips are firmly in place.

11. Replace the server’s cover and reconnect the AC power cord. See the documentation that

accompanied your server chassis for instructions on installing the server’s cover.

26

Page 27

Hardware Installations and Upgrades

Removing DIMMs

To remove a DIMM, follow these steps:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Remove the AC power cord from the server.

4. Remove the server’s cover. See the documentation that accompanied your server chassis for

instructions on removing the server’s cover.

5. Gently spread the retaining clips at each end of the socket. The DIMM lifts from the socket.

6. Holding the DIMM by the edges, lift it from the socket, and store it in an anti-static package.

7. Reinstall and reconnect any parts you removed or disconnected to reach the DIMM sockets.

8. Replace the server’s cover and reconnect the AC power cord. See the documentation that

accompanied your server chassis for instructions on installing the server’s cover.

27

Page 28

Hardware Installations and Upgrades

Installing or Replacing the Processor

CAUTIONS

Processor must be appropriate: You may damage the server board if

you install a processor that is inappropriate for your server. See “Additional

Information and Software” for a link to the list of compatible processor(s).

ESD and handling processors: Reduce the risk of electrostatic

discharge (ESD) damage to the processor by doing the following: (1) Touch

the metal chassis before touching the processor or server board. Keep part of

your body in contact with the metal chassis to dissipate the static charge

while handling the processor. (2) Avoid moving around unnecessarily.

Installing the Processor

To install a processor, follow these instructions:

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the server’s cover. See the documentation that accompanied your server chassis for

instructions on removing the server’s cover

5. Locate the processor socket and raise the socket handle completely (see Figure 8).

TP00763

Figure 8. Opening Socket Lever

28

Page 29

Hardware Installations and Upgrades

6. Align the pins of the processor with the socket, and insert the processor into the socket.

NOTE

✏

Make sure the alignment triangle mark and the alignment triangle cutout

align correctly.

A

B

A

Figure 9. Inserting Processor

7. Lower the socket lever completely.

Figure 10. Closing Socket Lever

TP00764

TP00765

29

Page 30

Hardware Installations and Upgrades

Installing the Heat Sink(s)

1. The heat sink has Thermal Interface Material (TIM) located on the bottom of it. Use caution

when you unpack the heat sink so you do not damage the TIM.

2. Set the heat sink over the processor, lining up the four captive screws with the four posts

surrounding the processor.

3. Loosely screw in the captive screws on the heat sink corners in a diagonal manner (screw in

one screw, then the screw located diagonally to the first screw). Do not fully tighten one screw

before tightening another.

4. Gradually and equally tighten each captive screw until each is firmly tightened. Do not over-

tighten the screws.

TP00774

Figure 11. Installing Heat Sink

5. Reinstall and reconnect any parts you removed or disconnected to reach the processor sockets.

6. Replace the server’s cover and reconnect the AC power cord. See the documentation that

accompanied your server chassis for instructions on installing the server’s cover.

Removing a Processor

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Remove the AC power cord from the server.

4. Remove the server’s cover. See the documentation that accompanied your server chassis for

instructions on removing the server’s cover.

5. Unplug the processor fan cable from the server board.

6. Loosen the four captive screws on the corners of the heat sink.

7. Twist the heat sink slightly to break the seal between the heat sink and the processor.

30

Page 31

Hardware Installations and Upgrades

8. Lift the heat sink from the processor. If it does not pull up easily, twist the heat sink again. Do

not force the heat sink from the processor. Doing so could damage the processor.

9. Lift the processor lever.

10. Remove the processor.

11. If installing a replacement processor, see “Installing the Processor.” Otherwise, reinstall the

chassis cover.

RJ45 Serial Port Configuration

The RJ45 serial port connector can be configured to support either a DSR signal or a DCD signal.

As the server board is shipped, it is configured to support DSR signals. To change the configuration

to support DCD signals a jumper on the board must be changed. Use the following instructions to

configure your server board to support DCD signals.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the server’s cover. See the documentation that accompanied your server chassis for

instructions on removing the server’s cover.

5. Locate the jumper block for the serial port. See Figure 12.

6. Move the jumper from the default position covering pins 1 and 3 to cover pins 2 and 4.

J8A3

34

1-3: DCD to DTR (Default)

2-4: DSR to DTR

2

TP00944

Figure 12. Changing the Serial Port Configuration

31

Page 32

Hardware Installations and Upgrades

Installing a PCI, PCI-X, or PCI-Express* Add-in Card

Add-in cards are not included with your system and must be purchased separately. This server

board requires the use of a riser bracket assembly with one or more riser connectors installed on it

in order to use a PCI, PCI-X, or PCI-Express add-in card. The riser assembly is typically included

with your server chassis. You may need to order the riser connector(s) separately, depending on the

server chassis.

See your server chassis documentation for additional requirements and for instructions on installing

an add-in card into a riser connector and then installing the assembly into the chassis.

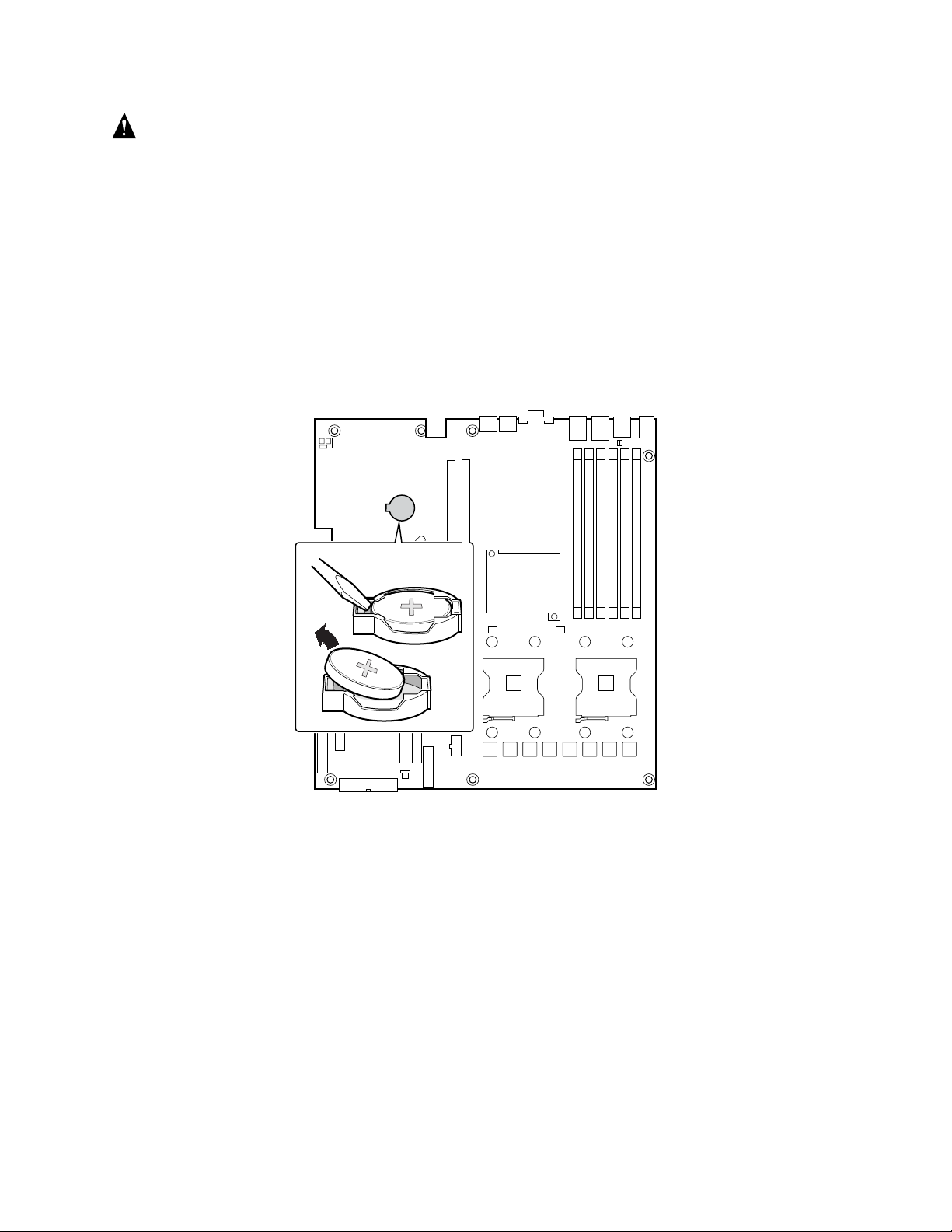

Replacing the Backup Battery

The lithium battery on the server board powers the RTC for up to four to five years in the absence

of power. When the battery starts to weaken, it loses voltage, and the server settings stored in

CMOS RAM in the RTC (for example, the date and time) may be wrong. Contact your customer

service representative or dealer for a list of approved devices.

WARNING

Danger of explosion if battery is incorrectly replaced. Replace only with

the same or equivalent type recommended by the equipment

manufacturer. Discard used batteries according to manufacturer’s

instructions.

ADVARSEL!

Lithiumbatteri - Eksplosionsfare ved fejlagtig håndtering. Udskiftning

må kun ske med batteri af samme fabrikat og type. Levér det brugte

batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare. Ved utskifting benyttes kun batteri

som anbefalt av apparatfabrikanten. Brukt batteri returneres

apparatleverandøren.

VARNING

Explosionsfara vid felaktigt batteribyte. Använd samma batterityp eller

en ekvivalent typ som rekommenderas av apparattillverkaren. Kassera

använt batteri enligt fabrikantens instruktion.

32

Page 33

Hardware Installations and Upgrades

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu. Vaihda paristo

ainoastaan laitevalmistajan suosittelemaan tyyppiin. Hävitä käytetty

paristo valmistajan ohjeiden mukaisesti.

1. Observe the safety and ESD precautions at the beginning of this book.

2. Turn off all peripheral devices connected to the server. Turn off the server.

3. Disconnect the AC power cord from the server.

4. Remove the server’s cover and locate the battery. See the documentation that accompanied

your server chassis for instructions on removing the server’s cover.

5. Insert the tip of a small flat bladed screwdriver, or an equivalent, under the tab in the plastic

retainer. Gently push down on the screwdriver to lift the battery.

6. Remove the battery from its socket.

TP00945

Figure 13. Replacing the Backup Battery

7. Dispose of the battery according to local ordinance.

8. Remove the new lithium battery from its package, and, being careful to observe the correct

polarity, insert it in the battery socket.

9. Close the chassis.

10. Run Setup to restore the configuration settings to the RTC.

33

Page 34

3 Server Utilities

Using the BIOS Setup Utility

This section describes the BIOS Setup Utility options, which is used to change server configuration

defaults. You can run BIOS Setup with or without an operating system being present. See

“Additional Information and Software” for a link to the Technical Product Specification where you

will find details about specific BIOS setup screens.

Starting Setup

You can enter and start BIOS Setup under several conditions:

When you turn on the server, after POST completes the memory test

When you have moved the CMOS jumper on the server board to the “Clear CMOS” position

(enabled)

In the two conditions listed above, after rebooting, you will see this prompt:

Press <F2> to enter SETUP

In a third condition, when CMOS/NVRAM has been corrupted, you will see other prompts but not

the <F2> prompt:

Warning: CMOS checksum invalid

Warning: CMOS time and date not set

In this condition, the BIOS will load default values for CMOS and attempt to boot.

If You Cannot Access Setup

If you are not able to access BIOS Setup, you might need to clear the CMOS memory. For

instructions on clearing the CMOS, see “Clearing the CMOS”.

Setup Menus

Each BIOS Setup menu page contains a number of features. Except for those features that are

provided only to display automatically configured information, each feature is associated with a

value field that contains user-selectable parameters. These parameters can be changed if the user

has adequate security rights. If a value cannot be changed for any reason, the feature’s value field is

inaccessible.

Table 8 describes the keyboard commands you can use in the BIOS Setup menus.

Intel® Server Board SE7320VP2 User Guide 34

Page 35

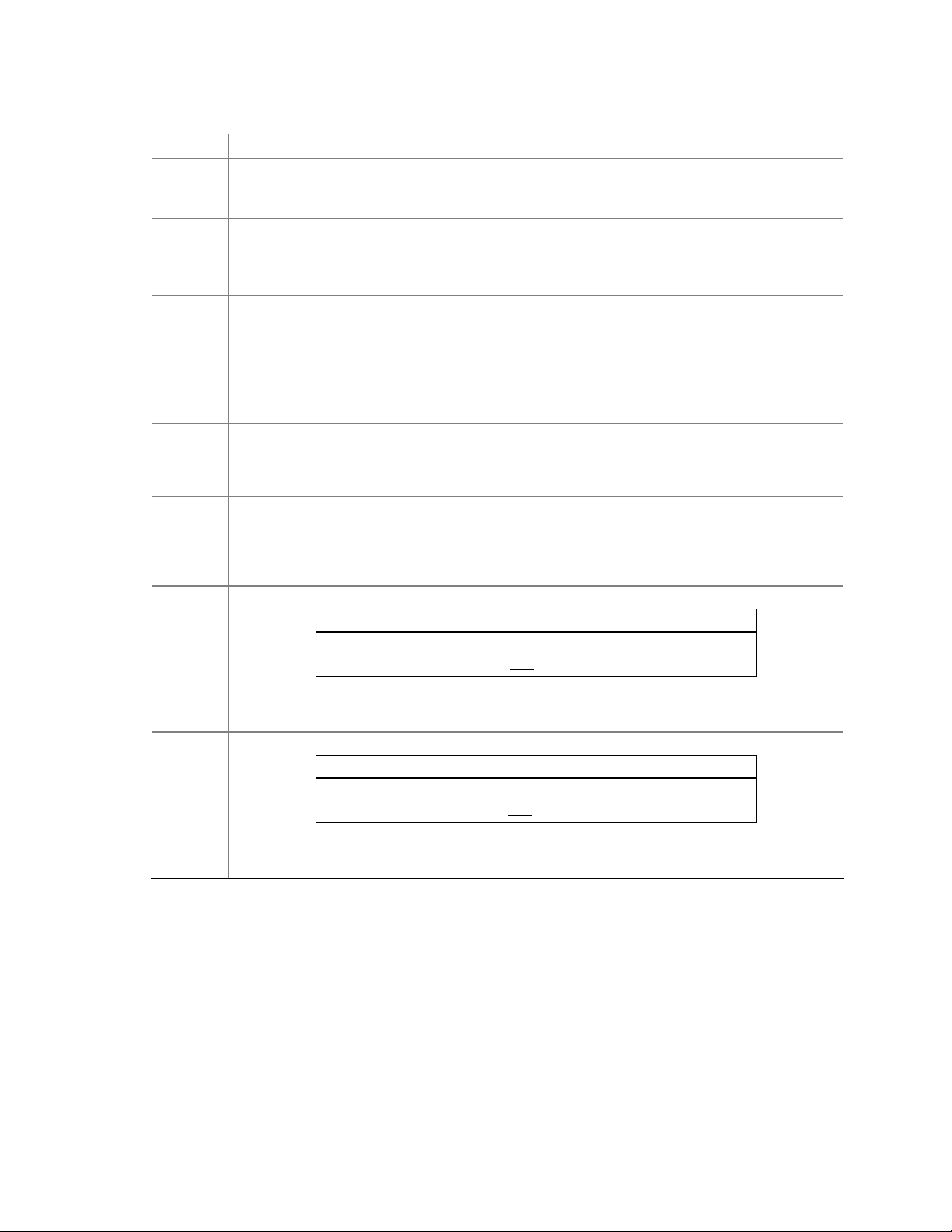

Table 8. Keyboard Commands

Press Description

<F1> Help - Pressing F1 on any menu invokes the general Help window.

F5/- Change Value - The minus key or the F5 function key is used to change the value of the current

F6/+ Change Value - The plus key or the F6 function key is used to change the value of the current

<Enter> Execute Command - The Enter key is used to activate submenus when the selected feature is a

<Esc> Exit - The ESC key provides a mechanism for backing out of any field. This key will undo the

<F9> Setup Defaults - Pressing F9 causes the following to appear:

<F10> Save and Exit - Pressing F10 causes the following message to appear:

The left and right arrow keys are used to move between the major menu pages. The keys have

no affect if a submenu or pick list is displayed.

Select Item up - The up arrow is used to select the previous value in a menu item’s option list, or

a value field pick list. Pressing the Enter key activates the selected item.

Select Item down - The down arrow is used to select the next value in a menu item’s option list,

or a value field pick list. Pressing the Enter key activates the selected item.

item to the previous value. This key scrolls through the values in the associated pick list without

displaying the full list.

menu item to the next value. This key scrolls through the values in the associated pick list

without displaying the full list. On 106-key Japanese keyboards, the plus key has a different

scan code than the plus key on the other keyboard, but it has the same effect.

submenu, or to display a pick list if a selected feature has a value field, or to select a sub-field for

multi-valued features like time and date. If a pick list is displayed, the Enter key will undo the

pick list, and allow another selection in the parent menu.

pressing of the Enter key. When the ESC key is pressed while editing any field or selecting

features of a menu, the parent menu is re-entered. When the ESC key is pressed in any

submenu, the parent menu is re-entered. When the ESC key is pressed in any major menu, the

exit confirmation window is displayed and the user is asked whether changes can be discarded.

If “Yes” is selected and the Enter key is pressed, all Setup fields are set to their default values. If

“No” is selected and the Enter key is pressed, or if the ESC key is pressed, the user is returned

to where they were before F9 was pressed without affecting any existing field values.

If “Yes” is selected and the Enter key is pressed, all changes are saved and Setup is exited. If

“No” is selected and the Enter key is pressed, or the ESC key is pressed, the user is returned to

where they were before F10 was pressed without affecting any existing values.

Server Utilities

Setup Confirmation

Load default configuration now?

[Yes] [No]

Setup Confirmation

Save Configuration changes and exit now?

[Yes] [NO]

35

Page 36

Server Utilities

Upgrading the BIOS

The upgrade utility allows you to upgrade the BIOS in flash memory. The code and data in the

upgrade file include the following:

On-board system BIOS, including the recovery code, BIOS Setup Utility, and strings.

On-board video BIOS and other option ROMs for devices embedded on the server board.

OEM binary area

Microcode

A means to change the BIOS Language

Preparing for the Upgrade

The steps below explain how to prepare to upgrade the BIOS, including how to record the current

BIOS settings and how to obtain the upgrade utility.

Recording the Current BIOS Settings

1. Boot the computer and press <F2> when you see the message:

Press <F2> Key if you want to run SETUP

2. Write down the current settings in the BIOS Setup program.

NOTE

✏

Do not skip step 2. You will need these settings to configure your computer

at the end of the procedure.

Obtaining the Upgrade

Download the BIOS image file to a temporary folder on your hard drive. See “Additional

Information and Software” for a link to the update software.

✏

NOTE

Review the instructions and release notes that are provided in the readme file

distributed with the BIOS image file before attempting a BIOS upgrade. The

release notes contain critical information regarding jumper settings, specific

fixes, or other information to complete the upgrade.

36

Page 37

Upgrading the BIOS

Follow the instructions in the readme file that came with the BIOS upgrade. When the update

completes, remove the bootable media from which you performed the upgrade.

Server Utilities

✏

NOTES

Do not power down the system during the BIOS update process! The system

will reset automatically when the BIOS update process is completed.

You may encounter a CMOS Checksum error or other problem after reboot. If this

happens, shut down the system and boot it again. CMOS checksum errors require

that you enter Setup, check your settings, save your settings, and exit Setup.

Clearing the Password

If the user or administrator password(s) is lost or forgotten, moving the password clear jumper into

the “clear” position clears both passwords. The password clear jumper must be restored to its

original position before a new password(s) can be set. The password clear jumper is located on

jumper block J1H2.

1. Power down the system and disconnect the AC power.

2. Open the server chassis.

3. Move the jumper from the normal operation position, Password Clear Protect, at pins 2 and 3 to

the Password Clear Erase position, covering pins 1 and 2 as indicated in the following diagram.

Figure 14. Password Recovery Jumper

37

Page 38

Server Utilities

4. Reconnect the AC power, power up the system.

5. Power down the system and disconnect the AC power.

6. Return the Password Clear jumper to the Password Clear Protect position, covering pins

2 and 3.

7. Close the server chassis.

8. Reconnect the AC power and power up the server.

Clearing the CMOS

If you are not able to access the BIOS setup screens, the CMOS Clear jumper will need to be used

to reset the configuration RAM. The CMOS Clear jumper is located on jumper block J1H5.

1. Power down the system and disconnect the AC power.

2. Open the server.

3. Move the jumper from the normal operation position, CMOS Clear by BMC, at pins 2 and 3 to

the CMOS Clear Force Erase position, covering pins 1 and 2 as indicated in the following

diagram.

Figure 15. CMOS Recovery Jumper

4. Reconnect the AC power, power up the system.

5. When the system begins beeping, power it down and disconnect the AC power.

6. Return the CMOS Clear jumper to the CMOS Clear by BMC location, covering pins 2 and 3.

7. Close the server chassis.

8. Reconnect the AC power and power up the system.

38

Page 39

4 Troubleshooting

This chapter helps you identify and solve problems that might occur while you are using the

system.

For any issue, first ensure you are using the latest firmware and files. Firmware upgrades include

updates for BIOS, the baseboard management controller (BMC), and the hot-swap controller

(HSC). See “Additional Information and Software” for a link to the software updates. In addition to

the server firmware and files, also update any drivers used for components you have installed in

your system, such as video drivers, network drivers, and SCSI drivers.

Intel provides a package called the “Platform Confidence Test” that may help with your

diagnostics. See “Additional Information and Software” for a link to this software.

If you are unable to resolve your server problems on your own, see “Getting Help” for assistance.

Resetting the System

Before going through in-depth troubleshooting, attempt first to perform reset your system using one

of the methods below.

To do this: Press:

Soft boot reset to clear the system memory and reload the operating system. <Ctrl+Alt+Del>

Clear system memory, restart POST, and reload the operating system. Reset button

Cold boot reset. Turn the system power off and then on. This clears system memory,

restarts POST, reloads the operating system, and halts power to all peripherals.

Power off/on

Intel® Server Board SE7320VP2 User Guide 39

Page 40

Troubleshooting

Problems following Initial System Installation

Problems that occur at initial system startup are usually caused by an incorrect installation or

configuration. Hardware failure is a less frequent cause. If the problem you are experiencing is

with a specific software application, see “Problems with Newly Installed Application Software.”

First Steps Checklist

Is AC power available at the wall outlet?

Are the power supplies plugged in? Check the AC cable(s) on the back of the chassis and at the

AC source.

Are all cables correctly connected and secured?

Are the processors fully seated in their sockets on the server board?

Are all standoffs in the proper location and not touching any components, causing a potential

short?

Are all add-in PCI boards fully seated in their slots on the server board?

Are all jumper settings on the server board correct?

Are all jumper and switch settings on add-in boards and peripheral devices correct? To check

these settings, refer to the manufacturer’s documentation that comes with them. If applicable,

ensure that there are no conflicts—for example, two add-in boards sharing the same interrupt.

Are all peripheral devices installed correctly?

If the system has a hard disk drive, is it properly formatted or configured?

Are all device drivers properly installed?

Are the configuration settings made in Setup correct?

Is the operating system properly loaded? Refer to the operating system documentation.

Did you press the system power on/off switch on the front panel to turn the server on (power on

light should be lit)?

Is the system power cord properly connected to the system and plugged into a

NEMA 5-15R outlet for 100-120 V or a NEMA 6-15R outlet for 200-240 V ?

Are all integrated components from the tested components lists? Check the tested memory, and

chassis lists, as well as the supported hardware and operating system list. See “Additional

Information and Software” for links to the tested component lists.

40

Page 41

Troubleshooting

Hardware Diagnostic Testing

This section provides a more detailed approach to identifying a hardware problem and locating its

source.

CAUTION

Turn off devices before disconnecting cables: Before disconnecting any

peripheral cables from the system, turn off the system and any external

peripheral devices. Failure to do so can cause permanent damage to the

system and/or the peripheral devices.

1. Turn off the system and all external peripheral devices. Disconnect each of device from the

system, except for the keyboard and the video monitor.

2. Make sure the system power cord is plugged into a properly grounded AC outlet.

3. Make sure your video display monitor and keyboard are correctly connected to the system.

Turn on the video monitor. Set its brightness and contrast controls to at least two thirds of their

maximum ranges (see the documentation supplied with your video display monitor).

4. If the operating system normally loads from the hard disk drive, make sure there is no diskette

in drive A and no CD-ROM disk in the CD-ROM drive.

5. If the power LED does light, attempt to boot from a floppy diskette or from a CD-ROM disk.

6. Turn on the system. If the power LED does not light, see “Power Light Does Not Light.”

Verifying Proper Operation of Key System Lights

As POST determines the system configuration, it tests for the presence of each mass storage device

installed in the system. As each device is checked, its activity light should turn on briefly. Check

for the following:

Does the diskette drive activity light turn on briefly? If not, see “Diskette Drive Activity Light

Does Not Light.”

If system LEDs are illuminated, see “LED Information” for a description of the light and steps

to take to correct the problem.

Confirming Loading of the Operating System

Once the system boots up, the operating system prompt appears on the screen. The prompt varies

according to the operating system. If the operating system prompt does not appear, see “No

Characters Appear on Screen.”

41

Page 42

Troubleshooting

Specific Problems and Corrective Actions

This section provides possible solutions for these specific problems:

Power light does not light.

No characters appear on screen.

Characters on the screen appear distorted or incorrect.

System cooling fans do not rotate.

Diskette drive activity light does not light.

Hard disk drive activity light does not light.

CD-ROM drive activity light does not light.

There are problems with application software.

The bootable CD-ROM is not detected.

Try the solutions below in the order given. If you cannot correct the problem, contact your service

representative or authorized dealer for help.

Power Light Does Not Light

Check the following:

Did you press the power-on button?

Is the system operating normally? If so, the power LED might be defective or the cable from

the front panel to the server board might be loose.

Have you securely plugged the server AC power cord into the power supply?

Will other items plugged into the same power outlet function correctly?

Some ATX power supplies have a power switch on the back of the power supply, next to the

fan. If your system as one, is it turned on?

Remove all add-in cares and see if the system boots. If successful, add the cards back in one at

a time with a reboot between each addition.

Make sure the memory DIMMs comply with the system requirements.

Make sure the memory DIMMs have been populated according to the system requirements.

Remove the memory DIMMs and re-seat them.

Make sure the processor(s) comply with the system requirements.

Make sure the processor(s) have been populated according to the system requirements.

Remove the processor(s) and re-seat them.

Make sure the chassis standoffs are installed only below mounting holes. Misplaced standoffs

can contact the pins on the bottom of the server board and cause a short.

42

Page 43

Troubleshooting

No Characters Appear on Screen

Check the following:

Is the keyboard functioning? Test it by turning the “Num Lock” function on and off to make

sure the Num Lock light is functioning.

Is the video monitor plugged in and turned on? If you are using a switch box, is it switched to

the correct system?

Are the brightness and contrast controls on the video monitor properly adjusted?

Is the video monitor signal cable properly installed?

Does this video monitor work correctly if plugged into a different system?

Is the onboard video controller enabled in the BIOS?

Remove all add-in cares and see if the video returns. If successful, add the cards back in one at

a time with a reboot between each addition.

Make sure the memory DIMMs comply with the system requirements.

Make sure the memory DIMMs have been populated according to the system requirements.

Remove the memory DIMMs and re-seat them.

Make sure the processor(s) comply with the system requirements.

Make sure the processor(s) have been populated according to the system requirements.

Remove the processor(s) and re-seat them.

If you are using an add-in video controller board, do the following:

1. Verify that the video works using the onboard video controller.

2. Verify that the video controller board is fully seated in the server board connector.

3. Reboot the system for changes to take effect.

4. If there are still no characters on the screen after you reboot the system and POST emits a beep

code, write down the beep code you hear. This information is useful for your service

representative.

5. If you do not receive a beep code and characters do not appear, the video display monitor or

video controller may have failed. Contact your service representative or authorized dealer

for help.

Characters Are Distorted or Incorrect

Check the following:

Are the brightness and contrast controls properly adjusted on the video monitor? See the

manufacturer’s documentation.

Are the video monitor’s signal and power cables properly installed?

Does this video monitor work correctly if plugged into a different system?

43

Page 44

Troubleshooting

System Cooling Fans Do Not Rotate Properly

If the system cooling fans are not operating properly, it is an indication of possible system

component failure.

Check the following:

Is the power-on light lit? If not, see “Power Light Does Not Light”

If your system has LED lights for the fans, is one or more of these LEDs lit?

Are any other front panel LEDs lit?

Have any of the fan motors stopped? Use the server management subsystem to check the fan

status.

Have your fans speeded up in response to an overheating situation?

Have your fans speeded up in response to a fan that has failed?

Are the fan power connectors properly connected to the server board?

Is the cable from the front panel board connected to the both the front panel board and to the

server board?

Are the power supply cables properly connected to the server board?

Are there any shorted wires caused by pinched-cables or have power connector plugs been

forced into power connector sockets the wrong way?

Diskette Drive Activity Light Does Not Light

Check the following:

Are the diskette drive’s power and signal cables properly installed?

Are all relevant switches and jumpers on the diskette drive set correctly?

Is the diskette drive properly configured?

Is the diskette drive activity light always on? If so, the signal cable may be plugged in

incorrectly.

If you are using the onboard diskette controller, use the BIOS setup to make sure that “Onboard

Floppy” is set to “Enabled.” If you are using an add-in diskette controller, make sure that

“Onboard Floppy” is set to “Disabled.”

44

Page 45

Troubleshooting

CD-ROM Drive or DVD-ROM Drive Activity Light Does Not Light

Check the following:

Are the CD-ROM/DVD-ROM drive’s power and signal cables properly installed?

Are all relevant switches and jumpers on the drive set correctly?

Is the drive properly configured?

Cannot Connect to a Server

Make sure the network cable is securely attached to the correct connector at the system back

panel.

Try a different network cable.

Make sure you are using the correct and the current drivers. See “Additional Information and

Software” for a link to the current drivers.

Make sure the driver is loaded and the protocols are bound.

Make sure the hub port is configured for the same duplex mode as the network controller.

Make sure the correct networking software is installed.

If you are directly connecting two servers (without a hub), you will need a crossover cable.

Check the network controller LEDs next to the NIC connectors.

Problems with Network

The server hangs when the drivers are loaded.

Certain drivers may require interrupts that are not shared with other PCI drivers. For these

drivers, it may be necessary to alter settings so that interrupts are not shared. See the

documentation that came with your PCI card(s) for information on changing interrupts.

Diagnostics pass but the connection fails.

Make sure the network cable is securely attached.

Make sure you specify the correct frame type in your NET.CFG file.

The controller stopped working when an add-in adapter was installed.

Make sure the cable is connected to the port from the onboard network controller.

Make sure your BIOS is current. See “Additional Information and Software” for a link to the

current version.

Make sure the other adapter supports shared interrupts. Make sure your operating system

supports shared interrupts.

Try reseating the add-in adapter.

45

Page 46

Troubleshooting

The add-in adapter stopped working without apparent cause.

Try reseating the adapter first; then try a different slot if necessary.

The network driver files may be corrupt or deleted. Delete and then reinstall the drivers.

Run the diagnostics.

System Boots when Installing PCI Card

System Server Management features require full-time “standby” power. This means some parts of

the system have power going to them whenever the power cord is plugged in, even if you have

turned the system power off with the power button on the front panel. If you install a PCI card with

the AC power cord plugged in, a signal may be sent to the command the system to boot. Before

installing a PCI card, you should always: