Page 1

Intel® Server Products and Solutions

Intel® Server System

S9200WK

Product Family

Setup and Service Guide

Initial system setup instructions and procedures for

the installation and replacement of system components

and available Intel accessories

Rev 1.0

July 2019

S9200WK

Page 2

<This page is intentionally left blank>

Page 3

Intel® Server System S9200WK Product Family Setup and Service Guide

3

Document Revision History

Date

Revision

Changes

July 2019

1.0

Initial release.

Page 4

Intel® Server System S9200WK Product Family Setup and Service Guide

4

Disclaimers

Intel technologies’ features and benefits depend on system configuration and may require enabled

hardware, software, or service activation. Learn more at Intel.com, or from the OEM or retailer.

You may not use or facilitate the use of this document in connection with any infringement or other legal

analysis concerning Intel products described herein. You agree to grant Intel a non-exclusive, royalty-free

license to any patent claim thereafter drafted which includes subject matter disclosed herein.

No license (express or implied, by estoppel or otherwise) to any intellectual property rights is granted by this

document.

The products described may contain design defects or errors known as errata which may cause the product

to deviate from published specifications. Current characterized errata are available on request.

Intel disclaims all express and implied warranties, including without limitation, the implied warranties of

merchantability, fitness for a purpose, and non-infringement, as well as any warranty arising from course of

performance, course of dealing, or usage in trade.

Copies of documents which have an order number and are referenced in this document may be obtained by

calling 1-800-548-4725 or by visiting www.intel.com/design/literature.htm.

Intel and the Intel logo are trademarks of Intel Corporation or its subsidiaries in the U.S. and/or other

countries.

*Other names and brands may be claimed as the property of others.

© Intel Corporation

Page 5

Intel® Server System S9200WK Product Family Setup and Service Guide

5

Warnings

Heed safety instructions: Before working with your server product, whether you are using this guide or any

other resource as a reference, pay close attention to the safety instructions. You must adhere to the

assembly instructions in this guide to ensure and maintain compliance with existing product certifications

and approvals. Use only the described, regulated components specified in this guide. Use of other

products/components will void the UL listing and other regulatory approvals of the product and will most

likely result in noncompliance with product regulations in the region(s) in which the product is sold.

System power on/off: The power buttons located on the front panel of each compute module DO NOT turn

off the server chassis AC power. To remove power from the server chassis, you must unplug the AC power

cord from the wall outlet. Make sure the AC power cord is unplugged before you open the server chassis.

To service a compute module it is not necessary to power down the entire system. Power off only the

compute module requiring servicing before attempting to remove it from the server chassis.

Hazardous conditions, devices and cables: Hazardous electrical conditions may be present on power,

telephone, and communication cables. Turn off the compute module and disconnect all telecommunications

systems, networks, and modems attached to it before removing it from the server chassis. Otherwise,

personal injury or equipment damage can result.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips over two jumper

pins. Some jumpers have a small tab on top that you can grip with your fingertips or with a pair of fine needle

nosed pliers. If your jumpers do not have such a tab, take care when using needle nosed pliers to remove or

install a jumper; grip the narrow sides of the jumper with the pliers, never the wide sides. Gripping the wide

sides can damage the contacts inside the jumper, causing intermittent problems with the function controlled

by that jumper. Take care to grip with, but not squeeze, the pliers or other tool you use to remove a jumper,

or you may bend or break the pins on the board.

Electrostatic Discharge (ESD)

Electrostatic discharge can cause damage to your computer or the components within it. ESD can occur

without the user feeling a shock while working inside the system chassis or while improperly handling

electronic devices like processors, memory or other storage devices, and add-in cards.

Intel recommends the following steps be taken when performing any procedures described within this

document or while performing service to any computer system.

• Where available, all system integration and/or service should be performed at a properly equipped ESD

workstation.

• Wear ESD protective gear like a grounded antistatic wrist strap, sole grounders, and/or conductive

shoes.

• Wear an anti-static smock or gown to cover any clothing that may generate an electrostatic charge.

• Remove all jewelry.

• Disconnect all power cables and cords before opening the Sever Chassis

• Power down the Compute Module and remove it from the Server Chassis, remove power feed from the

Server Board before performing any integration or service

• Touch any unpainted metal surface of the chassis before performing any integration or service.

Page 6

Intel® Server System S9200WK Product Family Setup and Service Guide

6

• Hold all circuit boards and other electronic components by their edges only.

• After removing electronic devices from the system or from their protective packaging, place them

component side up on to a grounded anti-static surface or conductive foam pad. Do not place electronic

devices on to the outside of any protective packaging.

Caution: Slide/rail mounted equipment is not to be used as a shelf or a work space.

Intel warranties that this product will perform to its published specifications. However, all computer systems

are inherently subject to unpredictable system behavior under various environmental and other conditions.

This product is not intended to be the sole source for any critical data and the user must maintain a

verified backup. Failure to do so or to comply with other user notices in the product user guide and

specification documents may result in loss of or access to data.

Liquid cooling safety guidelines:

• Make sure there are no leaks and/or damaged parts before operating the liquid cooling system.

• Do not to energize system or compute module if liquid cooling system is compromised.

• Do not attempt to perform any service before removing power to the liquid compute module, turn off

and disconnect power before disconnecting the liquid cooling quick disconnects tube connectors.

• To reduce the risk of damage to the cooling system, use care when installing or removing the liquid

compute modules.

• Avoid excessive force when connecting and disconnecting quick disconnect couplings.

• Keep liquid cooling tubing clear of pinch points when sliding server nodes.

Page 7

Intel® Server System S9200WK Product Family Setup and Service Guide

7

Important Safety Certification Standards and Transition Support Information

The IEC 60950-1 2nd Edition safety standard (Information Technology Equipment) is going through a

replacement phase due to the new IEC 62368-1 3rd Edition safety standard (Audio/Video, Information, and

Communication Technology Equipment).

Intel® server systems identified in this document are certified to:

• The new IEC 62368-1 3rd Edition standard for countries that have adopted this new standard.

• The outgoing IEC 60950-1 2nd Edition standard for countries that have not yet adopted the new

standard.

During the global adoption/certification transition phase between the outgoing and new standards, safety

requirement differences between the standards may temporarily dictate restricted usage of Intel® server

system products as follows:

• In countries that have adopted the new IEC 62368-1 3rd Edition standard, no location restrictions

apply beyond the standard intended application use requirements.

• In countries that have not yet adopted the new IEC 62368-1 3rd Edition standard, restricted access

locations are required. Access in these locations is permitted only by technically trained and qualified

personnel who are aware of potential safety hazards.

Note: This requirement applies only to Intel® server system products released in 2019 or later. Legacy Intel®

server system products (released in 2018 or earlier) provide safeguards that require no additional access

restrictions.

Explanation of temporary restricted access location measures

The new IEC 62368-1 3rd Edition standard does not consider 240 VA an energy hazard. The outgoing IEC

60950-1 2nd Edition standard does consider 240 VA an energy hazard, therefore Intel® server system

products released in 2019 or later certified to this standard require restricted access locations. Legacy Intel®

server system products (released in 2018 or earlier) were designed with additional safeguards to meet IEC

60950-1 2nd Edition standard 240 VA requirements, so no location restrictions apply beyond the standard

intended application use requirements. After the IEC 60950-1 standard is phased out globally and Intel

server system products are certified to the new IEC 62368-1 standard, the temporarily restricted access

locations will no longer be required.

Page 8

Intel® Server System S9200WK Product Family Setup and Service Guide

8

Table of Contents

1. Introduction ............................................................................................................................................................... 15

1.1 The Intel® Server System S9200WK Product Family .................................................................................. 15

1.2 About This Document ........................................................................................................................................... 15

1.3 System Overview and Feature Identification ................................................................................................. 15

2. System Setup............................................................................................................................................................. 18

2.1 Requirements for liquid cooled systems ........................................................................................................ 18

2.2 Installing the System Into a Rack ....................................................................................................................... 19

2.2.1 Installing the Fixed Rail Kit ................................................................................................................................... 19

2.2.2 Installing the Chassis Into a Rack ...................................................................................................................... 20

2.3 Connecting the System to a Liquid Coolant Supply .................................................................................... 21

2.4 Updating System Firmware ................................................................................................................................. 21

3. Optional Accessory Kit Integration and Service ................................................................................................ 22

3.1 Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key – IPC VROCSTANMOD ................................. 23

3.1.1 Installing the Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key ................................................... 23

3.1.2 Removing the Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key ................................................. 23

3.2 Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key – iPC AXXRMM4LITE2 ............ 24

3.2.1 Installing the Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key ............................. 24

3.2.2 Removing the Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key ............................ 24

3.3 PCIe* Add-In Card ................................................................................................................................................... 25

3.3.1 Installing a PCIe* Add-In Card ............................................................................................................................ 25

3.3.2 Removing a PCIe* Add-In Card ........................................................................................................................... 25

3.4 Ethernet Management Port Module (EMP Module) – iPC AXXFCEMP................................................... 26

3.4.1 Installing the EMP Module ................................................................................................................................... 26

3.4.2 Removing the EMP Module ................................................................................................................................. 27

4. System Service .......................................................................................................................................................... 28

4.1 System Component Identification .................................................................................................................... 29

4.2 Compute Module Replacement ......................................................................................................................... 33

4.2.1 Compute Module Removal .................................................................................................................................. 33

4.2.2 Compute Module Installation ............................................................................................................................. 34

4.3 Riser Assembly Replacement .............................................................................................................................. 35

4.3.1 Riser Assembly Removal ...................................................................................................................................... 35

4.3.2 Riser Assembly Installation ................................................................................................................................. 36

4.4 Drive Carrier Extraction, Assembly, and Installation ................................................................................... 36

4.4.1 Drive Carrier Extraction ......................................................................................................................................... 37

4.4.2 Drive Carrier Assembly .......................................................................................................................................... 37

4.4.3 Drive Carrier Installation ....................................................................................................................................... 39

4.5 M.2 SSD Replacement ........................................................................................................................................... 39

4.5.1 M.2 Heat Sink Removal ......................................................................................................................................... 40

4.5.2 M.2 SSD Removal .................................................................................................................................................... 40

4.5.3 M.2 SSD Installation ............................................................................................................................................... 41

Page 9

Intel® Server System S9200WK Product Family Setup and Service Guide

9

4.5.4 M.2 Heat Sink Installation .................................................................................................................................... 41

4.6 System Battery Replacement .............................................................................................................................. 42

4.7 Liquid Cooling Loop Replacement (Liquid Cooled Compute Modules Only) ..................................... 43

4.7.1 Liquid Cooling Loop Removal ............................................................................................................................. 43

4.7.2 Liquid Cooling Loop Installation ........................................................................................................................ 45

4.8 Air Duct Replacement (Air Cooled Compute Modules Only) .................................................................... 46

4.8.1 Air Duct Removal..................................................................................................................................................... 46

4.8.2 Air Duct Installation ................................................................................................................................................ 46

4.9 Processor Heat Sink Replacement (Air Cooled Compute Modules Only) ............................................ 47

4.9.1 Processor Heat Sink Removal ............................................................................................................................. 47

4.9.2 Processor Heat Sink Installation ........................................................................................................................ 48

4.10 Memory (DIMM) Replacement ............................................................................................................................ 49

4.10.1 Air Cooled Compute Module DIMM Replacement ....................................................................................... 49

4.10.2 Liquid Cooled Compute Module DIMM Replacement ................................................................................ 50

4.11 Memory Heat Spreader Thermal Pad Replacement (Liquid Cooled Compute Modules only) ...... 53

4.11.1 Thermal Pad Removal ........................................................................................................................................... 53

4.11.2 Thermal Pad Installation ...................................................................................................................................... 54

4.12 Power Supply Replacement ................................................................................................................................ 54

4.12.1 Power Supply Removal ......................................................................................................................................... 54

4.12.2 Power Supply Installation .................................................................................................................................... 55

4.13 System Fan Replacement ..................................................................................................................................... 56

4.13.1 System Fan Removal ............................................................................................................................................. 57

4.13.2 System Fan Installation ......................................................................................................................................... 57

4.14 Chassis Plumbing Assembly Replacement (Liquid Cooled Systems Only).......................................... 58

4.14.1 Chassis Plumbing Assembly Removal ............................................................................................................. 58

4.14.2 Chassis Plumbing Assembly Installation ........................................................................................................ 61

4.15 Power Distribution Board (PDB) Assembly Replacement .......................................................................... 64

4.15.1 Power Distribution Board Assembly Removal .............................................................................................. 64

4.15.2 Power Distribution Board Assembly Installation .......................................................................................... 67

4.16 Internal Chassis Rail Replacement .................................................................................................................... 70

4.16.1 Internal Chassis Rail Removal ............................................................................................................................. 70

4.16.2 Internal Chassis Rail Installation ........................................................................................................................ 71

5. System Packaging Assembly Instructions .......................................................................................................... 72

Appendix A. Getting Help .......................................................................................................................................... 77

Appendix B. General Memory Population Rules .................................................................................................. 78

Appendix C. System Status LED State Definitions ............................................................................................... 81

Appendix D. POST Code Diagnostic LED Decoder ............................................................................................... 83

Appendix E. POST Code Errors ................................................................................................................................ 90

Appendix F. Safety Instructions ............................................................................................................................. 100

Appendix G. Additional References ...................................................................................................................... 110

Appendix H. Glossary ............................................................................................................................................... 111

Page 10

Intel® Server System S9200WK Product Family Setup and Service Guide

10

List of Figures

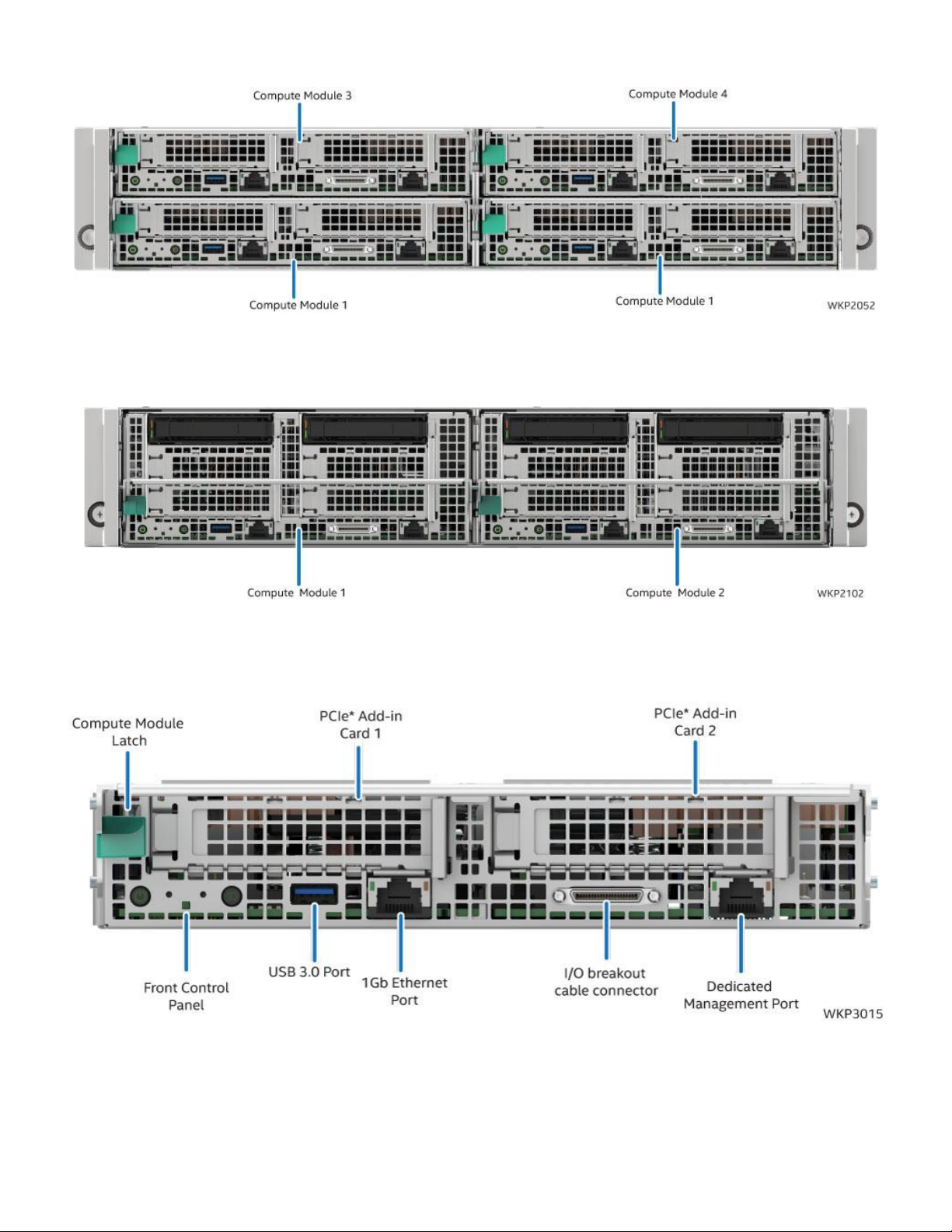

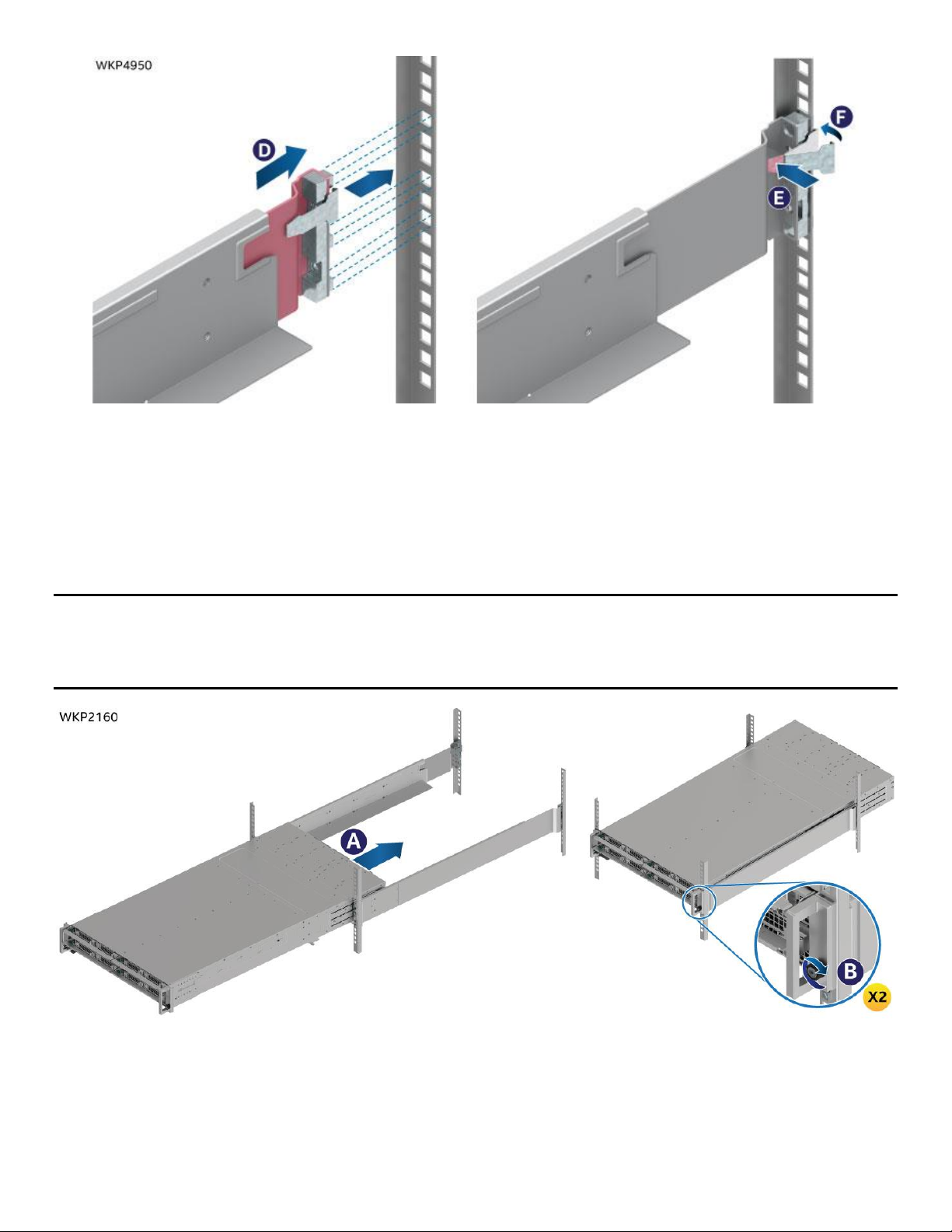

Figure 1. Liquid cooled system back view ................................................................................................................................ 15

Figure 2. Air cooled system back view ...................................................................................................................................... 15

Figure 3. Compute module identification – 4 node system with 1U compute modules ........................................... 16

Figure 4. Compute module identification – 2 node systems with 2U compute modules ......................................... 16

Figure 5. 1U compute module front panel feature identification ..................................................................................... 16

Figure 6. 2U compute module front panel feature identification ..................................................................................... 17

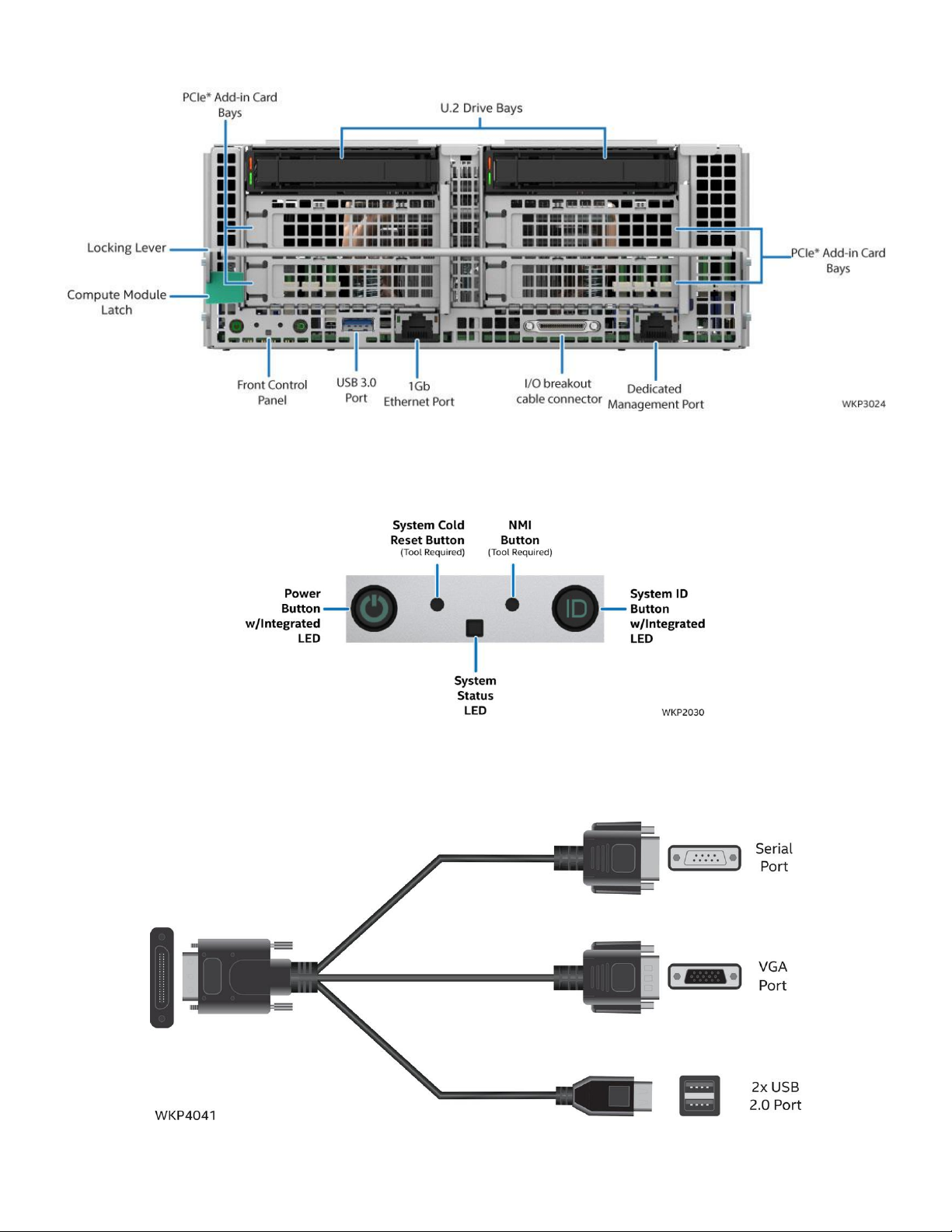

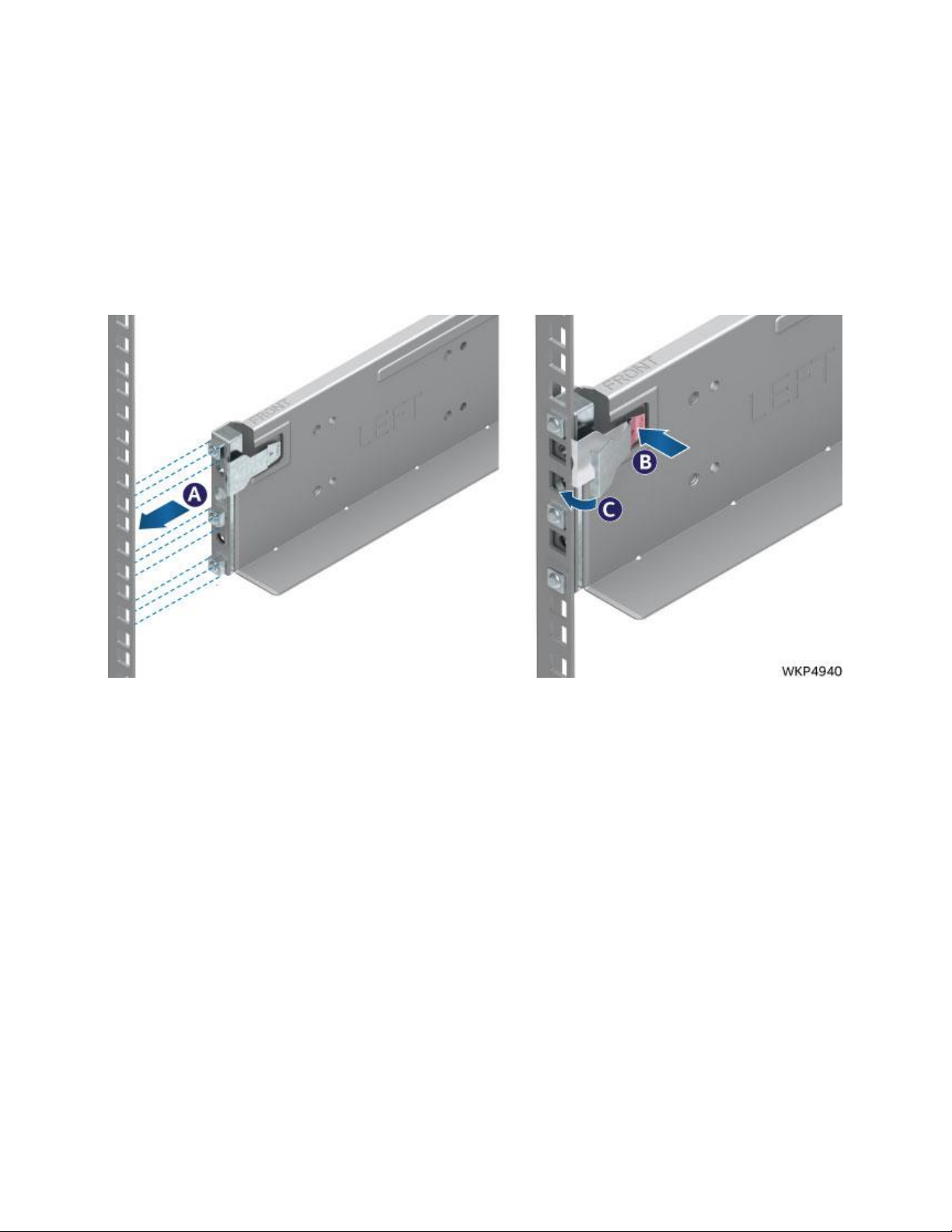

Figure 7. Front control panel features ....................................................................................................................................... 17

Figure 8. I/O breakout cable connector identification ......................................................................................................... 17

Figure 9. Securing the front of the rack rail ............................................................................................................................. 19

Figure 10. Securing the back of the rail ..................................................................................................................................... 20

Figure 11. Installing the chassis into the rack ......................................................................................................................... 20

Figure 12. Liquid cooling supply and return connections................................................................................................... 21

Figure 13. Installing the Intel® VROC Upgrade Key ............................................................................................................... 23

Figure 14. Removing the Intel® VROC Upgrade Key .............................................................................................................. 23

Figure 15. Installing the Intel® RMM4 Lite Key ........................................................................................................................ 24

Figure 16. Removing the Intel® RMM4 Lite Key ...................................................................................................................... 24

Figure 17. Installing an add-in card ............................................................................................................................................ 25

Figure 18. Removing an add-in card .......................................................................................................................................... 25

Figure 19. Removing the EMP Bay Filler Blank ....................................................................................................................... 26

Figure 20. Installing the EMP module/blank ........................................................................................................................... 26

Figure 21. Removing the EMP module/blank .......................................................................................................................... 27

Figure 22. Server chassis component identification ............................................................................................................. 29

Figure 23. 1U liquid cooled compute module component identification ...................................................................... 30

Figure 24. 2U liquid cooled compute module component identification ...................................................................... 31

Figure 25. 2U air cooled compute module component identification ............................................................................ 32

Figure 26. Removing a compute module .................................................................................................................................. 33

Figure 27. Installing a compute module ................................................................................................................................... 34

Figure 28. Removing a riser assembly ....................................................................................................................................... 35

Figure 29. Installing a riser assembly ......................................................................................................................................... 36

Figure 30. Drive carrier extraction from the chassis.............................................................................................................. 37

Figure 31. 2.5” drive carrier assembly – drive/drive blank removal ................................................................................ 37

Figure 32. 2.5” drive carrier assembly – drive installation into the carrier .................................................................... 38

Figure 33. 2.5” drive carrier assembly – alignment features .............................................................................................. 38

Figure 34. Drive carrier installation into the chassis ............................................................................................................. 39

Figure 35. Removing the M.2 heat sink ..................................................................................................................................... 40

Figure 36. Removing the M.2 SSD ............................................................................................................................................... 40

Figure 37. Installing the M.2 SSD................................................................................................................................................. 41

Figure 38. Removing the M.2 heat sink ..................................................................................................................................... 41

Figure 39. Removing the system battery .................................................................................................................................. 42

Figure 40. Installing the system battery .................................................................................................................................... 42

Page 11

Intel® Server System S9200WK Product Family Setup and Service Guide

11

Figure 41. Removing the cross head screws ............................................................................................................................ 43

Figure 42. Removing the T-20 screws ....................................................................................................................................... 43

Figure 43. Removing the liquid cooling loop ........................................................................................................................... 44

Figure 44. Securing the cross head screws .............................................................................................................................. 45

Figure 45. Securing the T-20 screws .......................................................................................................................................... 45

Figure 46. Removing the air duct................................................................................................................................................. 46

Figure 47. Installing the air duct .................................................................................................................................................. 46

Figure 48. Removing the processor heat sink ......................................................................................................................... 47

Figure 49. Installing the processor heat sink ........................................................................................................................... 48

Figure 50. Removing the DIMM in an air cooled system ...................................................................................................... 49

Figure 51. Installing the DIMM in an air cooled system ....................................................................................................... 49

Figure 52. Locating and retrieving the memory replacement tool .................................................................................. 50

Figure 53. Removing the DIMM retention clips....................................................................................................................... 51

Figure 54. Removing the DIMM in a liquid cooled system .................................................................................................. 51

Figure 55. Installing the DIMM in a liquid cooled system .................................................................................................... 52

Figure 56. Installing the DIMM retention clips ........................................................................................................................ 52

Figure 57. Removing a DIMM thermal pad ............................................................................................................................... 53

Figure 58. Installing a DIMM thermal pad ................................................................................................................................. 54

Figure 59. Removing the power supply ..................................................................................................................................... 54

Figure 60. Installing the power supply ...................................................................................................................................... 55

Figure 61. System Fan Configuration - Liquid cooled system ........................................................................................... 56

Figure 62. System Fan Configuration - Air cooled system ................................................................................................. 56

Figure 63. Removing the system fan .......................................................................................................................................... 57

Figure 64. Installing the system fan ............................................................................................................................................ 57

Figure 65. Removing the quick connect fillers ........................................................................................................................ 58

Figure 66. Removing the quick connect screws ..................................................................................................................... 59

Figure 67. Removing quick connect covers ............................................................................................................................. 59

Figure 68. Removing the back cover .......................................................................................................................................... 59

Figure 69. Removing the chassis plumbing assembly .......................................................................................................... 60

Figure 70. Installing the chassis plumbing assembly ........................................................................................................... 61

Figure 71. Installing quick connect covers ............................................................................................................................... 62

Figure 72. Securing the quick connect couplings to the covers ....................................................................................... 62

Figure 73. Installing the quick connect fillers ......................................................................................................................... 63

Figure 74. Securing the back cover............................................................................................................................................. 63

Figure 75. Removing the back cover .......................................................................................................................................... 64

Figure 76. Disconnecting the system fan power cables....................................................................................................... 65

Figure 77. Removing the power distribution board .............................................................................................................. 66

Figure 78. Installing the power distribution board ................................................................................................................ 67

Figure 79. Connecting system fan power cables.................................................................................................................... 68

Figure 80. Securing the back cover............................................................................................................................................. 69

Figure 81. Removing the internal chassis rail .......................................................................................................................... 70

Figure 82. Installing the internal chassis rail ........................................................................................................................... 71

Page 12

Intel® Server System S9200WK Product Family Setup and Service Guide

12

Figure 83. DIMM population for liquid cooled compute modules with 8 DIMMs of up to 32GB capacity .......... 78

Figure 84. DIMM population for liquid cooled compute modules with 8 DIMMs of 64GB capacity ..................... 79

Figure 85. DIMM population for air cooled compute modules with 8 DIMMs .............................................................. 79

Figure 86. DIMM population for liquid and air cooled compute modules with 16 DIMMs ...................................... 80

Figure 87. POST diagnostic LED identification ....................................................................................................................... 83

Page 13

Intel® Server System S9200WK Product Family Setup and Service Guide

13

List of Tables

Table 1. System status LED state definitions .......................................................................................................................... 81

Table 2. POST progress code LED example ............................................................................................................................ 83

Table 3. MRC progress codes ....................................................................................................................................................... 85

Table 4. MRC fatal error codes ..................................................................................................................................................... 86

Table 5. POST progress codes ..................................................................................................................................................... 87

Table 6. POST Error Codes and Messages ............................................................................................................................... 90

Table 7. Product family reference collaterals ...................................................................................................................... 110

Page 14

Intel® Server System S9200WK Product Family Setup and Service Guide

14

<This page is intentionally left blank>

Page 15

Intel® Server System S9200WK Product Family Setup and Service Guide

15

1. Introduction

1.1 The Intel® Server System S9200WK Product Family

The Intel® Server System S9200WK is a density-optimized, rack-mounted, 2U, multi-node product family

that is designed to support high-density, high-performance computing environments in both liquid and air

cooled configurations. Each system within the Intel Server System S9200WK product family includes

independent, pre-configured compute modules that allow for a power-on ready installation.

1.2 About This Document

This setup and service guide provides system integrators and service technicians guidance for the setup,

configuration, upgrade, and future maintenance of the Intel Server System S9200WK product family.

Refer to Appendix G for the complete list of documentation available. For the latest revision of this

document go to http://www.intel.com/support.

1.3 System Overview and Feature Identification

The illustrations on the following pages provide a quick reference identifying the key features of this server

product family.

Figure 1. Liquid cooled system back view

Figure 2. Air cooled system back view

Page 16

Intel® Server System S9200WK Product Family Setup and Service Guide

16

Figure 3. Compute module identification – 4 node system with 1U compute modules

Figure 4. Compute module identification – 2 node systems with 2U compute modules

Figure 5. 1U compute module front panel feature identification

Page 17

Intel® Server System S9200WK Product Family Setup and Service Guide

17

Figure 6. 2U compute module front panel feature identification

Figure 7. Front control panel features

Figure 8. I/O breakout cable connector identification

Page 18

Intel® Server System S9200WK Product Family Setup and Service Guide

18

2. System Setup

Each server system within the Intel® Server System S9200WK product family includes power supplies,

cooling components, rack mounting accessories, and configurable compute modules that include memory,

storage, and network components. Refer to the Intel® Server System S9200WK Product Family Configuration

Guide for a complete list of available options.

This chapter provides service personnel the information necessary to set up the Intel Server System

S9200WK product family. Illustrations identify the system features and procedures to install the system in a

rack environment and prepare it for use. The system comes fully assembled containing all components

necessary to be fully functional, so that once the system is physically set up in the operating environment

and updated to the latest available firmware version, it is ready for use.

Before Setting Up or Servicing the Intel® Server System S9200WK

Before working with this server product, observe the safety and ESD precautions found in the beginning of

this guide.

System Directional Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the chassis and

front of a compute module.

2.1 Requirements for liquid cooled systems

The liquid cooled systems within the Intel® Server System S9200WK product family are designed to operate

while being connected to a non-Intel coolant distribution unit that supports Staubli* SCG 06 quick connect

couplings.

Server Chassis

Compute Module

Page 19

Intel® Server System S9200WK Product Family Setup and Service Guide

19

2.2 Installing the System Into a Rack

Before following the instructions in this section, remove all compute modules from the server chassis (see

Section 4.2.1). If the rail kit is already installed, proceed to Section 2.2.2.

2.2.1 Installing the Fixed Rail Kit

The Intel® Server System S9200WK product family includes a fixed rail kit that serves as a shelf for the

system upon installation into the rack. When a system is installed onto the fixed rails, it can be secured to

both the rail and the rack through a pair of thumbscrews on the front of the system.

Figure 9. Securing the front of the rack rail

1. Remove the chassis rail kit from the packaging. Locate the rail, either left or right, and align the rail

guides with the slots in the front of the rack (see Letter A).

2. Insert the rail guides into their respective rack slots while pressing on the clip (see Letter B).

3. Release the clip once the guides are fully inserted into the rack (see Letter C).

Page 20

Intel® Server System S9200WK Product Family Setup and Service Guide

20

Figure 10. Securing the back of the rail

4. Extend and align the rear guides with their slots in the back of the rack (see Letter D).

5. Insert the rail guides into their respective rack slots while pressing on the clip (see Letter E).

6. Release the clip once the guides are fully inserted into the rack (see Letter F).

7. Repeat this process with the opposite rail.

2.2.2 Installing the Chassis Into a Rack

Important Safety Note: Due to the weight of a fully configured system, Intel® recommends using a

mechanical lift to aid with the installation of the system into the rack, and/or to use at least two people to

install the system into the rack, or remove all installed compute modules from the system before attempting

to install the system into the rack.

Figure 11. Installing the chassis into the rack

1. Insert the chassis onto the rails and slide it back to the rear of the rack (see Letter A).

2. Tighten the thumbscrews located on the chassis handles to secure the chassis to the rack (see Letter

B).

3. If removed, install the compute modules into the chassis (see Section 4.2).

Page 21

Intel® Server System S9200WK Product Family Setup and Service Guide

21

2.3 Connecting the System to a Liquid Coolant Supply

The liquid cooled systems within the Intel® Server System S9200WK product family include Staubli* SCG O6

quick connect couplings on the back of the chassis. When integrating a liquid cooled system into an

operating environment, it must be connected to the facility’s liquid coolant supply.

Figure 12. Liquid cooling supply and return connections

1. Locate the two quick connect couplings in the rear of the chassis as shown in Figure 12.

2. Attach the liquid supply to the quick connect coupling marked with a blue ring.

3. Attach the liquid return to the quick connect coupling marked with a red ring.

2.4 Updating System Firmware

Each compute module within the Intel® Server System S9200WK product family includes a software stack

that includes a BIOS, BMC firmware, Intel® Management Engine (Intel® ME) firmware, and both FRU and SDR

data. A full software stack is installed during the system manufacturing process, but may not be the latest

available version. Intel highly recommends updating the full system software stack on each installed

compute module to the latest available version for optimal performance and system reliability. A System

Update Package (SUP) containing the latest available system software stack can be downloaded from the

following Intel web site: http://downloadcenter.intel.com.

To ensure that the embedded platform management subsystem is configured properly, the latest FRU and

SDR data for each compute module must be installed after updating the full system software stack. Updated

FRU and SDR data allows the platform management subsystem to monitor the specific system sensors used

to determine appropriate system cooling, optimal performance, and accurate error reporting. FRU and SDR

data is loaded by using the FRUSDR utility which is included with the System Update Package (SUP).

Page 22

Intel® Server System S9200WK Product Family Setup and Service Guide

22

3. Optional Accessory Kit Integration and Service

This chapter provides installation and removal instructions for supported optional accessory kits.

Before Beginning

Before working with the server product, observe the safety and ESD precautions found in the Warnings

section at the beginning of this guide.

Ensure the compute module is powered off before removing it from the system chassis

Required Tools and Supplies

1. Anti-static wrist strap and conductive foam pad (recommended)

System Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the server chassis

or compute module.

Server Chassis

Compute Module

Page 23

Intel® Server System S9200WK Product Family Setup and Service Guide

23

3.1 Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key – IPC VROCSTANMOD

3.1.1 Installing the Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key

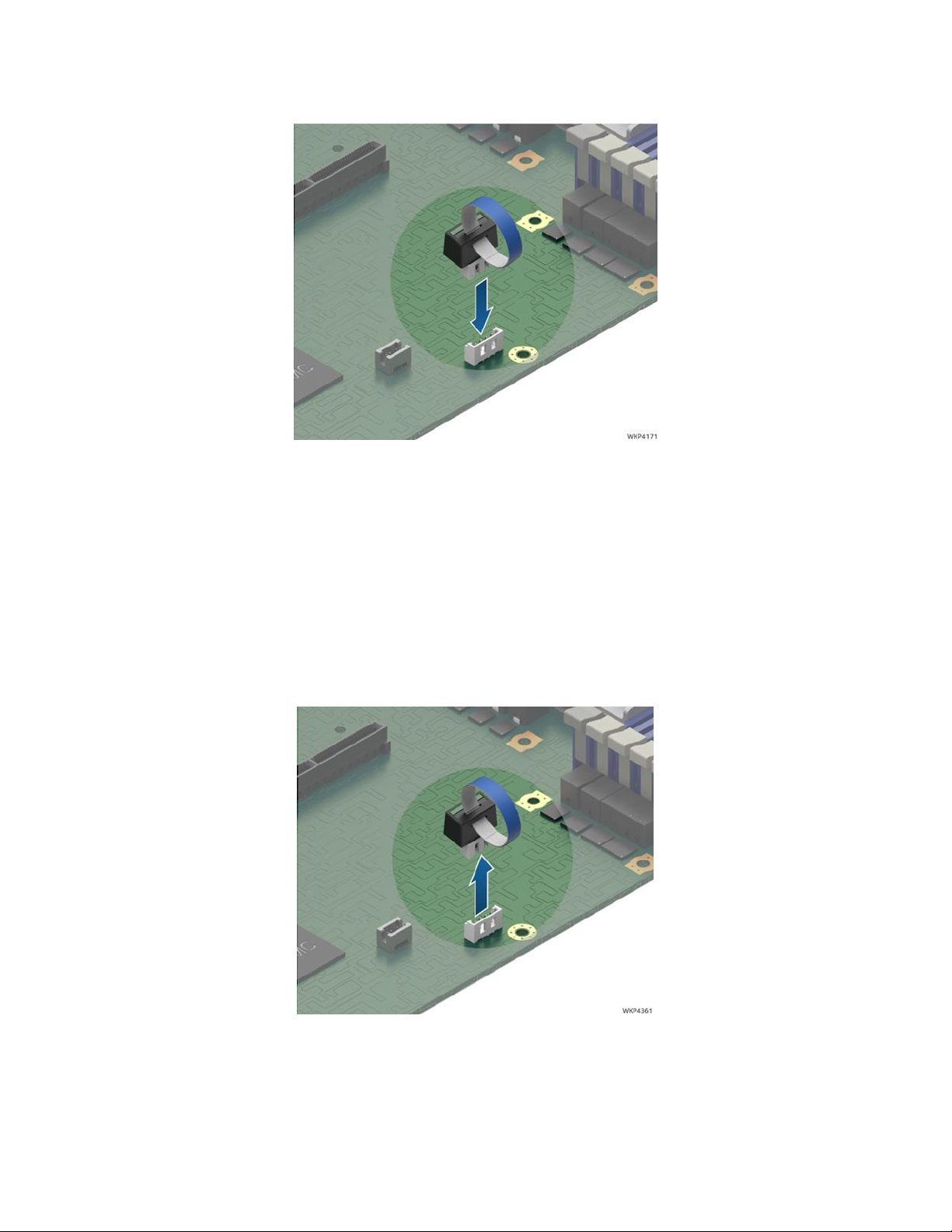

Figure 13. Installing the Intel® VROC Upgrade Key

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface (see Section 4.2.1)

2. Remove the right riser assembly from Riser Slot 2. (see Section 0)

3. Remove the Intel® VROC Upgrade Key from its packaging.

4. Locate the white 4-pin key connector near the right edge of the server board

5. Place the key over the connector and confirm that the orientation of the key matches that of the

connector.

6. Press the key down onto the connector.

3.1.2 Removing the Intel® Virtual RAID on CPU (Intel® VROC) Upgrade Key

Figure 14. Removing the Intel® VROC Upgrade Key

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface (see Section 4.2.1)

2. Remove the right riser assembly from Riser Slot 2. (see Section 0)

3. Using the key pull tab, carefully pull the key up until it disengages from the connector.

Page 24

Intel® Server System S9200WK Product Family Setup and Service Guide

24

3.2 Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key – iPC

AXXRMM4LITE2

3.2.1 Installing the Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key

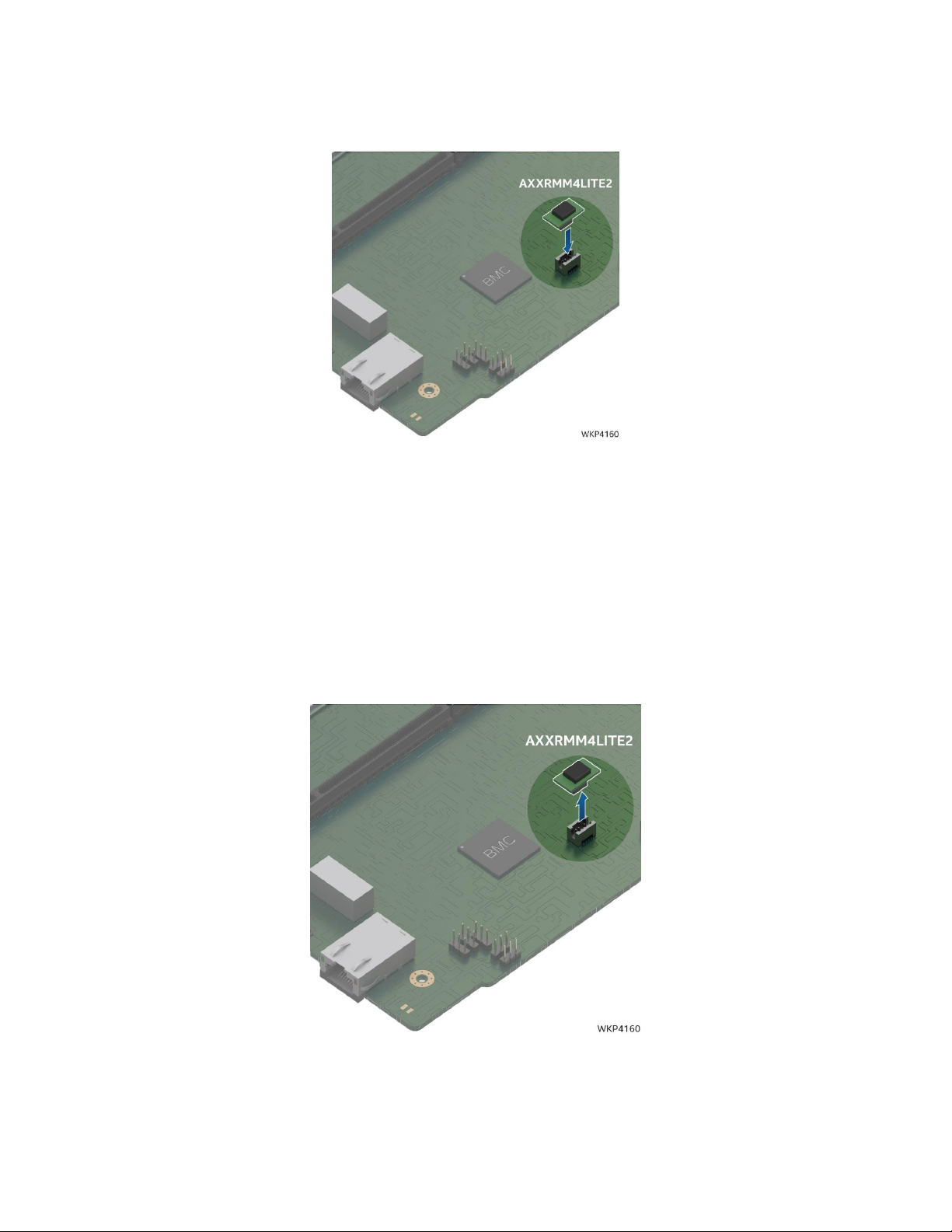

Figure 15. Installing the Intel® RMM4 Lite Key

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface (see Section 4.2.1)

2. Remove the right riser assembly from Riser Slot 2. (see Section 0)

3. Remove the Intel RMM4 Lite Key from its packaging.

4. Locate the Intel RMM4 Lite key connector near the right edge of the server board behind the RJ45

Management Port connector.

5. Match the orientation of the Intel RMM4 Lite key to the onboard connector.

6. Press the Intel RMM4 Lite key down into the connector until fully engaged.

3.2.2 Removing the Intel® Remote Management Module 4 Lite (Intel® RMM4 Lite) Key

Figure 16. Removing the Intel® RMM4 Lite Key

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface(see Section 4.2.1)

2. Remove the right riser assembly from Riser Slot 2. (see Section 0)

3. Carefully grasp the Intel® RMM4 Lite key and pull it up until disengaged from the connector.

Page 25

Intel® Server System S9200WK Product Family Setup and Service Guide

25

3.3 PCIe* Add-In Card

The following procedures are identical for both 1U and 2U riser card assemblies

3.3.1 Installing a PCIe* Add-In Card

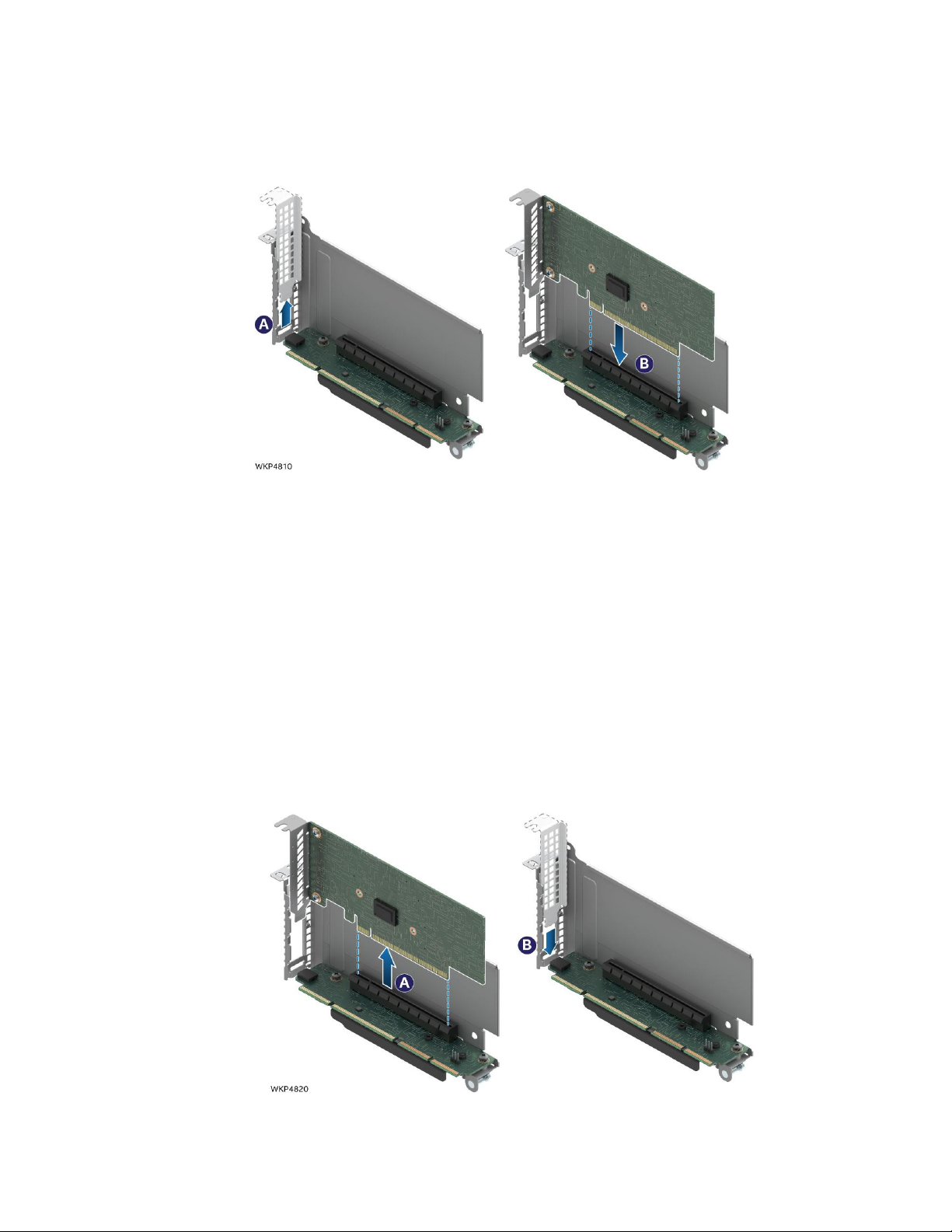

Figure 17. Installing an add-in card

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface (see Section 4.2.1)

2. Remove the selected riser assembly from the compute module (see Section 0)

3. If present, carefully remove the rear metal filler plate from the metal frame of the riser assembly (see

Letter A).

4. Align the rear bracket of the add-in card to the rear opening of the riser assembly

5. Carefully push the add-in card down into the PCIe slot (see Letter B).

6. Ensure the add-in card is fully seated

7. Re-install the riser card assembly into the compute module (see Section 4.3)

3.3.2 Removing a PCIe* Add-In Card

Figure 18. Removing an add-in card

1U riser card assembly shown**

1U Riser assembly shown **

Page 26

Intel® Server System S9200WK Product Family Setup and Service Guide

26

1. Remove the compute module to be serviced from the server chassis and place it on to an anti-static

work surface (see Section 4.2.1)

2. Remove the selected riser assembly from the compute module (see Section 0)

3. Carefully remove the add-in card from the PCIe slot (see Letter A).

4. Carefully install the metal filler plate over the opening on the metal frame of the riser assembly (see

Letter B).

5. Re-install the riser card assembly into the compute module (see Section 4.3)

3.4 Ethernet Management Port Module (EMP Module) – iPC AXXFCEMP

Your system may or may not come preconfigured with an Ethernet Management Port Module. This section

provides instruction for the installation and removal of this accessory option. The EMP module is hot-swap

capable. It can be installed or removed without powering down the system or any of its compute modules.

3.4.1 Installing the EMP Module

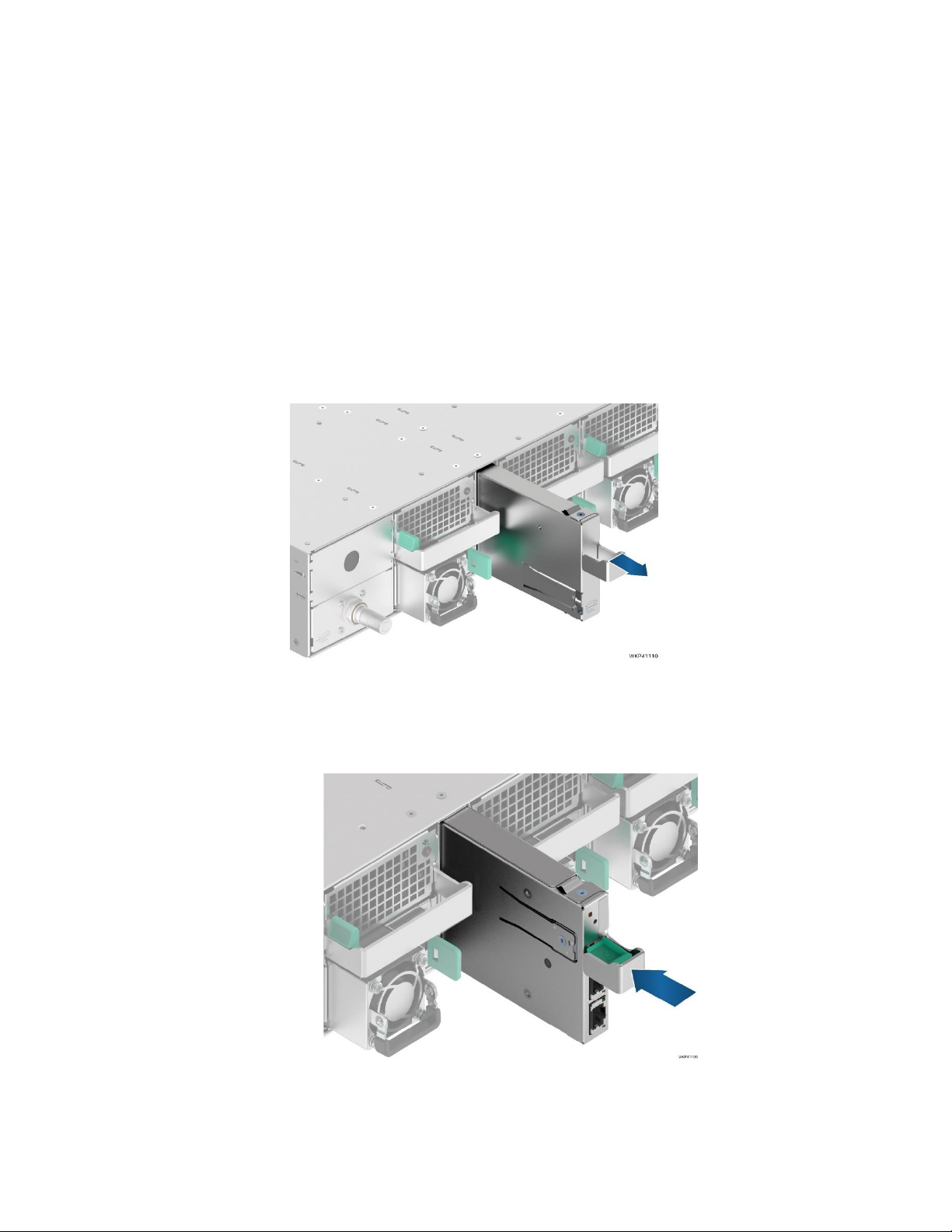

Figure 19. Removing the EMP Bay Filler Blank

1. If present, remove the EMP Bay Filler blank from the back of the server chassis by pulling it out from

the chassis as shown in Figure 19.

Figure 20. Installing the EMP module/blank

2. Install the EMP module, by sliding it into the open EMP bay until it locks into place (see Letter A).

A

Page 27

Intel® Server System S9200WK Product Family Setup and Service Guide

27

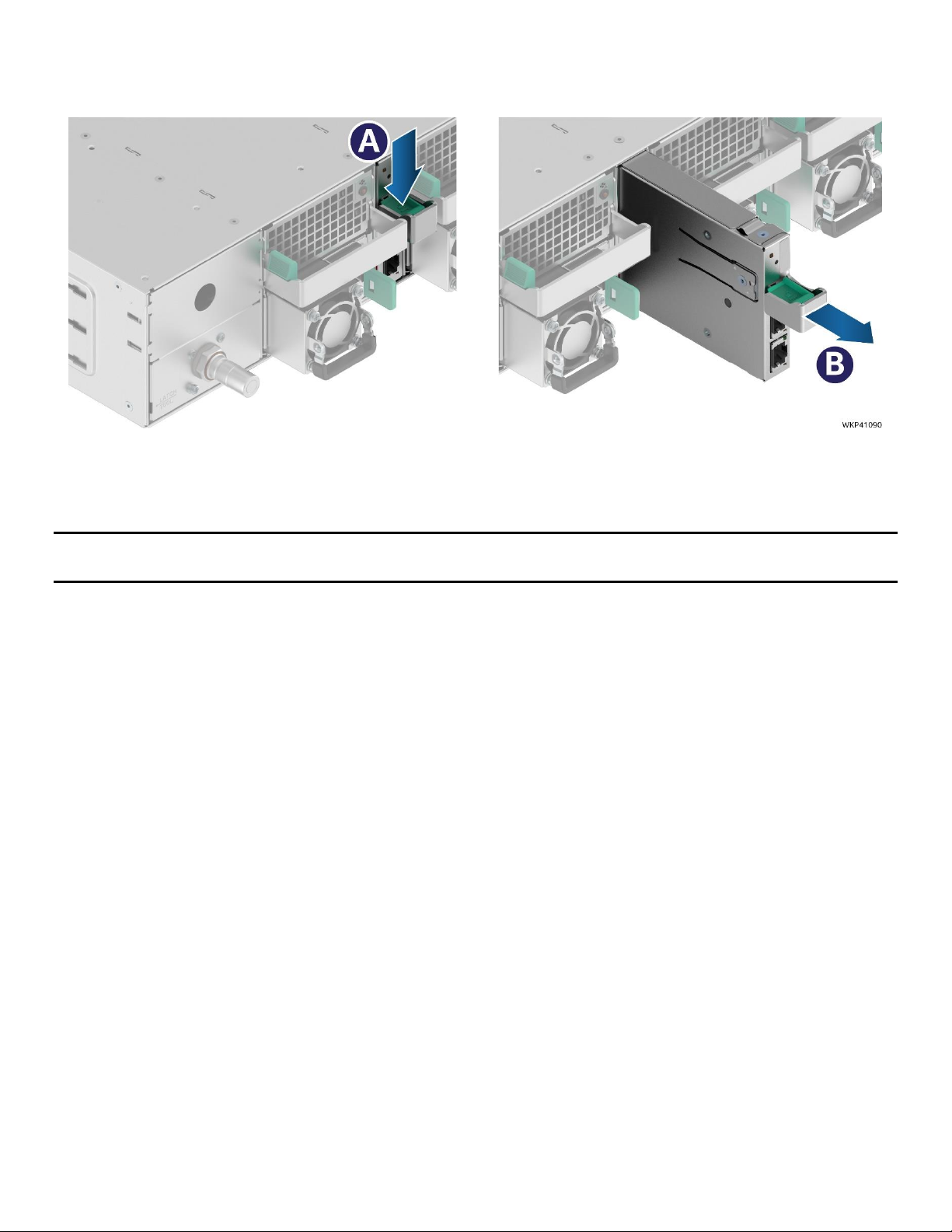

3.4.2 Removing the EMP Module

1. Locate the EMP module on the back of the chassis.

Figure 21. Removing the EMP module/blank

2. Remove the EMP module by pushing down on the Green latch (see Letter A) and then pulling it out

from the chassis (see Letter B).

Note: To keep the system operating within its thermal limits, the EMP module bay must be populated with

either an EMP module or EMP blank when any of the installed compute modules are operational.

Page 28

Intel® Server System S9200WK Product Family Setup and Service Guide

28

4. System Service

This chapter provides instructions for removing and installing system components considered field

replaceable (field-replaceable units, or FRUs). The Intel® Server System S9200WK product family features a

modular design, allowing for servicing of system fans, power supply modules, compute modules and

Ethernet Management Port module (EMP module) without having to power off the entire system.

System components that do require that the full system be powered off and AC power cords disconnected

from the system include the following:

For air cooled configurations:

• Power distribution board

For liquid cooled configurations:

• Power distribution board

• Chassis plumbing assembly

When service is necessary for any of the individual compute modules within the server system, it is

necessary to power off the selected compute module before removing it from the server chassis.

Before Setting Up or Servicing the Intel® Server System S9200WK

Before working with this server product, observe the safety and ESD precautions found at the beginning of

this guide.

System Directional Reference

All references to left, right, front, top, and bottom assume the reader is facing the front of the server chassis

or the front of the compute module.

Server Chassis

Compute Module

Page 29

Intel® Server System S9200WK Product Family Setup and Service Guide

29

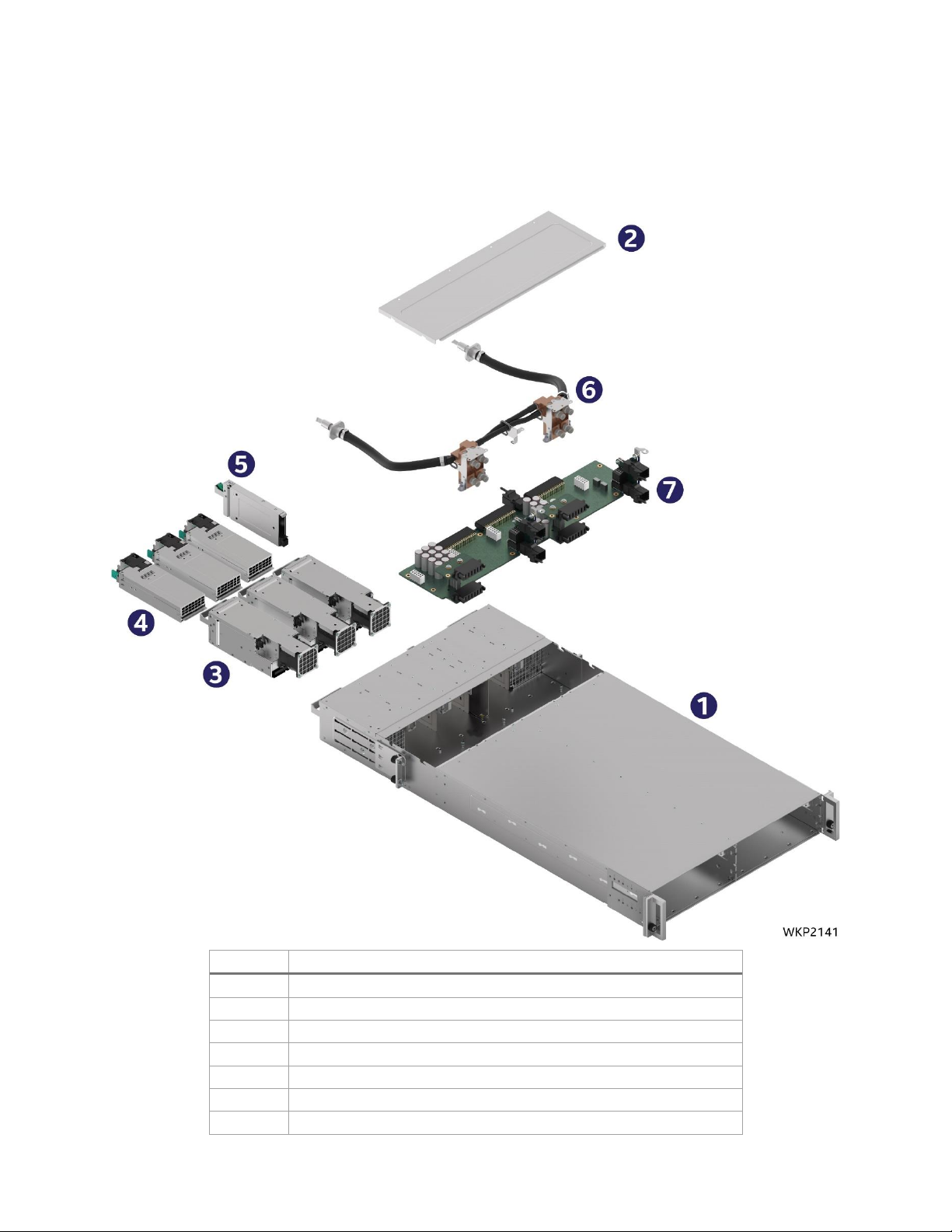

4.1 System Component Identification

The following illustrations provide a quick reference to identify system components that are considered field

serviceable. Refer to the Intel® Server System S9200WK product family Configuration Guide for a complete

list of available spares.

Number

Name

1

Server Chassis

2

Chassis back cover

3

System fan assemblies

4

Power supplies

5

EMP module

6

Chassis plumbing assembly (Liquid cooled systems only)

7

Power distribution board

Figure 22. Server chassis component identification

Page 30

Intel® Server System S9200WK Product Family Setup and Service Guide

30

Number

Name

1

Compute module tray with server board

2

Liquid cooling loop

3

DIMM retention clips

4

Riser assemblies

Figure 23. 1U liquid cooled compute module component identification

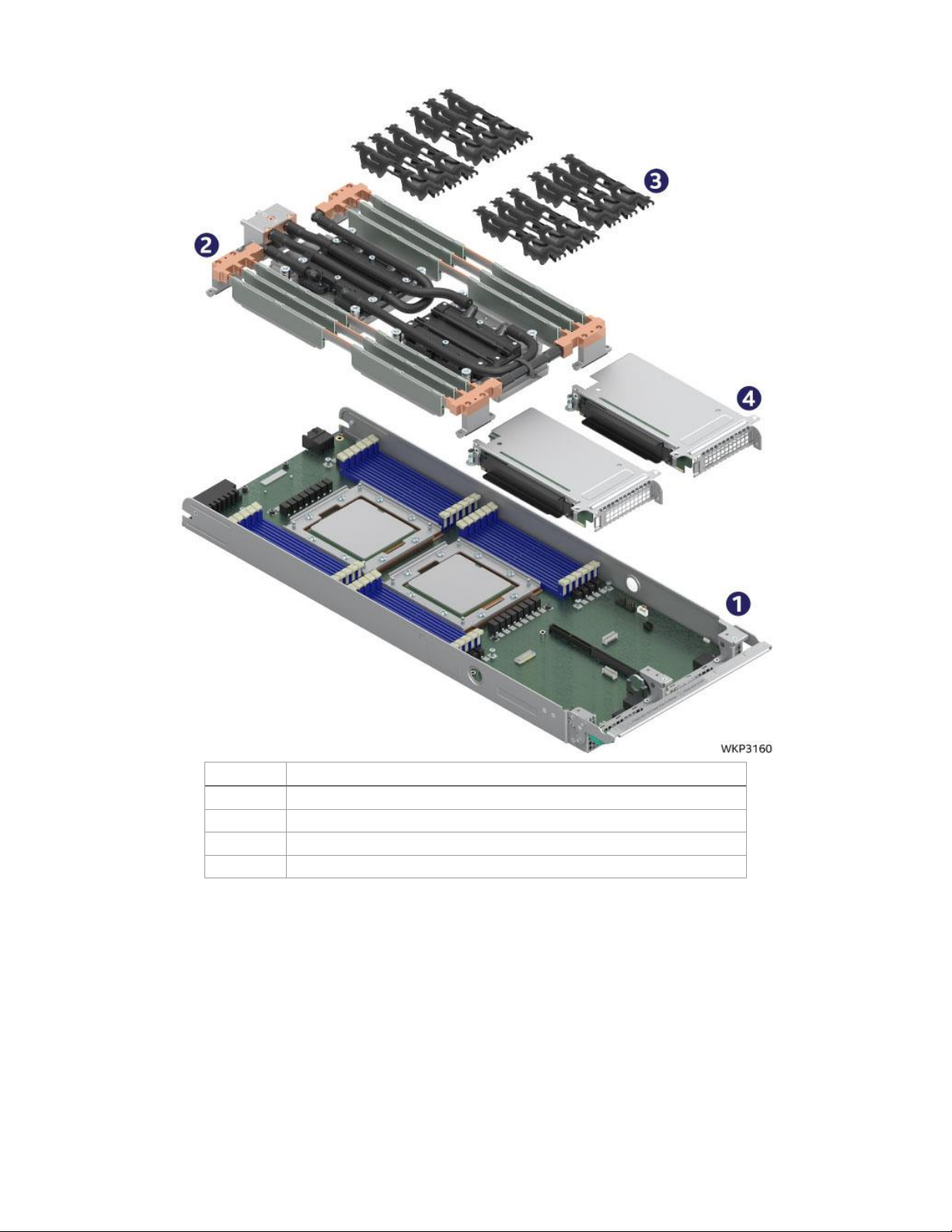

Page 31

Intel® Server System S9200WK Product Family Setup and Service Guide

31

Number

Name

1

Compute module tray with server board

2

Liquid cooling loop

3

DIMM retention clips

4

Riser assemblies

Figure 24. 2U liquid cooled compute module component identification

Page 32

Intel® Server System S9200WK Product Family Setup and Service Guide

32

Number

Name

1

Compute module tray with server board

2

CPU Heat sinks

3

Air duct

4

Riser assemblies

Figure 25. 2U air cooled compute module component identification

Page 33

Intel® Server System S9200WK Product Family Setup and Service Guide

33

4.2 Compute Module Replacement

All installed compute modules within an Intel® Server System S9200WK are independent from each other.

Servicing a compute module does not require having to power down the full server system. Only the

compute module to be serviced must be powered down before being removed from the server chassis.

Replacement of compute modules (spare or warranty replacement) will include the following:

• Compute Module Tray

• Server Board with processors

• Riser Card Assemblies

• Liquid Cooling Loop (liquid cooled compute modules only)

• Processor Heat Sinks (air cooled compute modules only)

• Air Duct (2U air cooled compute modules only)

When returning a compute module for warranty replacement, the following components must be removed

before shipment (if present) :

• Memory (DIMMs)

• DIMM retention clips

• PCIe* add-in cards

• Add-on storage devices (M.2 SSD, U.2 SSD)

• Intel® RMM4 Lite key

• Intel® VROC upgrade key

Note: Processors are soldered to the server board, they are not removable. Processors are included when

ordering a spare or warranty replacement compute module. Refer to the Intel® Server System S9200WK

Product Family Configuration Guide for available spares.

The following procedures are identical for both 1U and 2U compute modules.

4.2.1 Compute Module Removal

1. Power down the compute module using the Power Button located on the front panel of the

compute module to be serviced.

Figure 26. Removing a compute module

Page 34

Intel® Server System S9200WK Product Family Setup and Service Guide

34

2. Press the green latch inward (see Letter A) and lower the lever in front of the compute module (see

Letter B).

3. Grasp the lever and pull out the compute module from the chassis (see Letter C).

Note: To keep the system operating within its thermal limits, compute module bays must be populated

with either a compute module or blank when any of the installed compute modules are operational.

4.2.2 Compute Module Installation

Replacement compute modules can be re-installed into a server chassis without impacting the operation or

functionality of other operational compute modules.

•

Figure 27. Installing a compute module

1. Ensure the lever in front of the compute module is lowered. If not, press the green latch inward and

lower the lever.

2. Align the compute module to its corresponding bay and push it into the chassis until the key pins in

the lever are inside the chassis inner wall key hole.

3. Raise the lever to secure the compute module. (see Letter B)

2U Compute Module shown **

Page 35

Intel® Server System S9200WK Product Family Setup and Service Guide

35

4.3 Riser Assembly Replacement

Before following the instructions in this section, remove the Intel® compute module (see Section 4.2.1)

needing service. This procedure applies to both 1U and 2U compute modules.

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

• Phillips head screwdriver

4.3.1 Riser Assembly Removal

Figure 28. Removing a riser assembly

1. Remove the three screws that secure the riser assembly to the compute module (see Letter A).

2. Carefully remove the riser assembly by lifting it up away from the compute module (see Letter B).

If the riser assembly is going to be shipped as part of a warranty replacement, remove all installed add-in

cards and/or storage SSDs.

Page 36

Intel® Server System S9200WK Product Family Setup and Service Guide

36

4.3.2 Riser Assembly Installation

Figure 29. Installing a riser assembly

1. Align the riser card edge connector to the riser slot on the server board (see Letter A).

2. Carefully push down on the riser assembly until the riser card is securely seated into the riser slot.

3. Ensure the three screw holes of the riser assembly are aligned and flush with the mounting holes of

the compute module.

4. With three screws, secure the riser assembly to the compute module using 8 lbs. of torque on each

(see Letter B).

4.4 Drive Carrier Extraction, Assembly, and Installation

The 2U compute modules of the Intel® Server System S9200WK product family have support for up to two

hot-swap 2.5” form factor U.2 Solid State Drives (SSDs). Each drive installed to a tool-less drive carrier. This

section provides instructions for drive extraction from the chassis, drive assembly, and drive installation into

the chassis.

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

Page 37

Intel® Server System S9200WK Product Family Setup and Service Guide

37

4.4.1 Drive Carrier Extraction

Figure 30. Drive carrier extraction from the chassis

1. Press the button on the carrier face plate to release the lever (see Letter A).

2. Using the lever, pull the carrier from the drive bay (see Letter B).

4.4.2 Drive Carrier Assembly

Important: The S9200WK server product family is designed and tested to support 2.5” U.2 NVMe* Solid

State Drives only.

Figure 31. 2.5” drive carrier assembly – drive/blank removal

1. Remove the drive (or drive blank) from the carrier by gently rotating the top edge of a carrier rail

outwards while simultaneously pushing the drive up from the bottom as shown in .

Page 38

Intel® Server System S9200WK Product Family Setup and Service Guide

38

Figure 32. 2.5” drive carrier assembly – drive installation into the carrier

2. Carefully unpack the new drive, taking care not to touch any of the connector pins located on the

back side of the drive.

3. With the rear drive connector positioned toward the back of the drive carrier, align and position the

mounting holes on one side of the drive over the mounting tabs located on the drive carrier side rail

(see Letter A).

4. Lower the other side of the drive into the carrier (see Letter B) and press down on the drive until all

mounting tabs are locked in place.

Figure 33. 2.5” drive carrier assembly – alignment features

Note: The 2.5” drive blank and drive carrier each have alignment features (shown in ) ensuring proper

assembly. When re-installing a drive blank into the drive carrier ensure the features are aligned prior to

installation, as failure to properly install a drive blank may result in the carrier assembly not fitting properly

into the drive bay.

Page 39

Intel® Server System S9200WK Product Family Setup and Service Guide

39

4.4.3 Drive Carrier Installation

Figure 34. Drive carrier installation into the chassis

1. Align the drive assembly with the open drive bay.

2. With the lever in the open position, insert the drive assembly into the drive bay (see Letter A) and

push forward until the drive makes contact with the internal backplane.

3. Complete the drive installation by closing the drive assembly lever until it locks into place (see Letter

B).

4.5 M.2 SSD Replacement

Before following the instructions in this section, remove the selected compute module (see Section 4.2.1)

from the server chassis and then remove the selected riser assembly from the compute module (see Section

0).

This procedure applies to both 1U and 2U riser assemblies with illustrations showing differences where

applicable.

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

• Phillips head screwdriver

Page 40

Intel® Server System S9200WK Product Family Setup and Service Guide

40

4.5.1 M.2 Heat Sink Removal

The riser assembly includes an M.2 heat sink that must be removed prior to servicing any M.2 SSD.

Figure 35. Removing the M.2 heat sink

1. Locate the heat sink on the left side of the riser assembly and remove the screw (see Letter A).

2. Slide the heat sink in the direction shown to remove it (see Letter B).

4.5.2 M.2 SSD Removal

Figure 36. Removing the M.2 SSD

1. Remove the screw from the M.2 mounting stand-off on the left side of the riser assembly (see Letter

A).

2. Carefully rotate outward the free end of the M.2 SSD away from the riser assembly (see Letter B).

3. Grasp the M.2 SSD by its edges and gently remove it from the connector in the direction shown (see

Letter C).

If no SSD is being installed:

4. Return the previously removed screw to the M.2 mounting stand-off.

5. Re-Install the M.2 heat sink on to the riser assembly (see Section 4.5.4).

1U Riser Assembly

2U Riser Assembly

1U Riser Assembly

2U Riser Assembly

Page 41

Intel® Server System S9200WK Product Family Setup and Service Guide

41

4.5.3 M.2 SSD Installation

Figure 37. Installing the M.2 SSD

1. If present, remove the screw from the M.2 mounting stand-off on the left side of the riser assembly.

2. Align the notch within the SSD edge connector with the key in the M.2 connector and insert the SSD

into the connector (see Letter A).

3. Push the free edge of the SSD towards the riser assembly (see Letter B) and secure the SSD to the M.2

mounting stand-off with the previously removed screw (see Letter C).

4. Install the M.2 Heat Sink (see Section 4.5.4)

4.5.4 M.2 Heat Sink Installation

Figure 38. Removing the M.2 heat sink

1. If installing a new heatsink, peel off the protective film from the thermal interface material.

2. Align the heat sink to the riser assembly and slide into place in the direction shown (see Letter A).

3. Ensure the screw holes are properly aligned then secure the heat sink to the riser assembly with a

screw (see Letter B).

1U Riser Assembly

2U Riser Assembly

1U Riser Assembly

2U Riser Assembly

Page 42

Intel® Server System S9200WK Product Family Setup and Service Guide

42

4.6 System Battery Replacement

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

Before following the instructions in this section, remove the select compute module from the server chassis

(see Section 4.2.1), and then remove the riser assemblies from the compute module (see Section 4.3.1).

Figure 39. Removing the system battery

1. Locate the battery on the server board. See Figure 39.

2. Gently pull the metal clip to release the battery (see Letter A).

3. Remove the old battery from the plastic socket (see Letter B).

4. Dispose of the battery according to local laws.

5. Remove the new lithium battery from its package.

6. Orient the battery so the positive pole is facing towards the left side of the compute module.

Figure 40. Installing the system battery

7. Insert the battery into the battery socket. See Figure 40.

8. Use the <F2> BIOS Setup Utility to restore BIOS Settings and reset the system time and date.

Page 43

Intel® Server System S9200WK Product Family Setup and Service Guide

43

4.7 Liquid Cooling Loop Replacement (Liquid Cooled Compute Modules Only)

Before following the instructions in this section, remove the selected compute module from the server

chassis (see Section 4.2.1).

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

• Phillips head screwdriver

• Torx* T-20 screwdriver

4.7.1 Liquid Cooling Loop Removal

Figure 41. Removing the cross head screws

1. Remove the ten screws indicated in Figure 41 with a phillips head screwdriver.

Figure 42. Removing the T-20 screws

2. Remove the eight screws indicated in Figure 42 with a Torx* T-20 screwdriver.

Page 44

Intel® Server System S9200WK Product Family Setup and Service Guide

44

Figure 43. Removing the liquid cooling loop

3. Carefully lift the liquid cooling loop assembly up and away from the compute module. See Figure 43.

Page 45

Intel® Server System S9200WK Product Family Setup and Service Guide

45

4.7.2 Liquid Cooling Loop Installation

1. Carefully unpack the new liquid cooling loop.

2. Carefully place the liquid cooling loop assembly into the compute module, ensuring that both the

DIMM cooling assembly and processor cold plates are properly aligned with the mounting screw

holes.

Figure 44. Securing the cross head screws

3. Place and secure the ten phillips head screws indicated in Figure 44 with a phillips head screwdriver

using 8 lbs. of torque.

Figure 45. Securing the T-20 screws

4. Using a cross pattern for each cooling plate, place and secure the eight Torx* head screws as

indicated in Figure 45 with a Torx* T-20 screwdriver using 8 lbs. of torque

2 3 4

3

2 4 1

Page 46

Intel® Server System S9200WK Product Family Setup and Service Guide

46

4.8 Air Duct Replacement (Air Cooled Compute Modules Only)

4.8.1 Air Duct Removal

Figure 46. Removing the air duct

1. Remove the compute module to be serviced from the server chassis (see Section 4.2.1).

2. Press the latches located on both sides of the compute module inwards (see Letter A).

3. Carefully lift the front edge of the air duct away from the compute module (see Letter B).

4. Pull the air duct away from the compute module (see Letter C).

4.8.2 Air Duct Installation

Figure 47. Installing the air duct

1. Align and attach the hinge slots located on the back end of the air duct with the hinge posts located

on both sides of the compute module (see Letter A).

2. Lower the air duct down until both the left and right side latches snap into place (see Letter B).

Page 47

Intel® Server System S9200WK Product Family Setup and Service Guide

47

4.9 Processor Heat Sink Replacement (Air Cooled Compute Modules Only)

Due to possible damage to the server board while attempting to remove/install the processor heat sink, Intel

does NOT recommend removing the processor heat sink outside of the following:

• The processor heat sink is damaged and needs to be replaced

• The processor heat sink is faulty and needs to be replaced

Before following the instructions in this section, remove the compute module to be serviced from the server

chassis (see Section 4.2.1) and remove the air duct (see Section 4.8.1).

Required Tools and Supplies:

• Anti-static wrist strap and conductive foam pad (recommended)

• Torx* T-20 screwdriver

4.9.1 Processor Heat Sink Removal

Figure 48. Removing the processor heat sink

Note: Extreme care should be taken when removing the heat sink from a fixed mounted processor.

• Care should be taken not to accidentally bend or knock off any components mounted on the server

board while attempting to remove the heat sink or clean the top side of the processor.

1. Using a Torx* T-20 screwdriver, loosen all captive (non-removable) processor heat sink screws until

each is free from the server board (see Letter A). No specific order is required.

2. It will be necessary to break the thermal interface bond that has formed between the processor and

the heat sink. To break the bond and remove the heat sink, carefully rotate the heat sink in a short

back and forth pattern while at the same time carefully lifting the heat sink away from the processor

(see Letter B).

3. Using a commercially available isopropyl alcohol cleaning pad or other similar cleaning tool, carefully

clean away all Thermal Interface Material (TIM) residue from both the bottom of the heatsink and the

top of the processor.

Page 48

Intel® Server System S9200WK Product Family Setup and Service Guide

48

• No excess cleaning agent should flow from the top side of the processor onto any part of the server

board

4.9.2 Processor Heat Sink Installation

Figure 49. Installing the processor heat sink

Note: Replacement processor heat sinks will include thermal interface material (TIM) on the bottom side of

the heat sink. If present, remove the protective film from the TIM before installing the heat sink onto the

processor.

1. Align and place the heat sink on top of the processor. No specific heat sink fin orientation is required.

2. Secure the screws indicated in Figure 49 with a Torx* T-20 screwdriver using 8 lbs. of torque, in an X

pattern, alternating between screws until all are tight.

Page 49

Intel® Server System S9200WK Product Family Setup and Service Guide

49

4.10 Memory (DIMM) Replacement

This section documents the procedure to follow when replacement of a faulty DIMM is necessary. The DIMM

replacement procedure for a liquid cooled compute module and an air cooled cooled compute module is

different. Refer to the appropriate sub-section for your specific compute module configuration.

For memory population rules, refer to Appendix B.

4.10.1 Air Cooled Compute Module DIMM Replacement

1. Remove the select compute module from the server chassis (see Section 4.2.1)

2. Remove the air duct from the computer module (see Section 4.8.1).

4.10.1.1 DIMM Removal

Figure 50. Removing the DIMM in an air cooled system

3. Identify and locate the faulty DIMM. Ensure that the ejection tabs of adjacent DIMM slots are closed.

4. Open the DIMM ejection tabs at both ends of the selected DIMM slot (see Letter A). The DIMM will

slightly lift up from the slot.

5. Holding the DIMM by its edges, lift it away from the slot (see Letter B).

4.10.1.2 DIMM Installation

Figure 51. Installing the DIMM in an air cooled system

1. Locate the DIMM slot for installation. Ensure that the DIMM ejection tabs at both ends of the DIMM

slot are pushed outward to the open position (see Letter A).

2. Carefully unpack the replacement DIMM, taking care to only handle the device by its outer edges.

3. Align the notch at the bottom edge of the DIMM with the key in the DIMM slot (see Letter B).

Page 50

Intel® Server System S9200WK Product Family Setup and Service Guide

50

4. Insert the DIMM into the slot (see Letter C) pushing down on the DIMM, until the ejection tabs snap

into place (see Letter D). Ensure that the ejection tabs are firmly in place (see Letter E).

4.10.2 Liquid Cooled Compute Module DIMM Replacement

The DIMM replacement procedure for a liquid cooled compute module requires removal, replacement, and

re-installation of several components. The documented procedure should be followed in the order specified

with little or no deviation.

1. Remove the select compute module from the server chassis (see Section 4.2.1)

2. Remove the air duct from the computer module (see Section 4.8.1).

4.10.2.1 DIMM Removal

The liquid cooled compute modules within the Intel® Server System S9200WK product family include a

memory replacement tool located on top of the cold plates of the liquid cooling loop. This tool can be used

to remove the DIMM retainer clips in memory configurations that require them, and to open the DIMM

ejection tabs.

Figure 52. Locating and retrieving the memory replacement tool

1. Locate the memory replacement tool on top of the CPU0 cold plate.

2. Remove the tool from one of its sides first (see Letter A) and then lift it away (see Letter B).

Page 51

Intel® Server System S9200WK Product Family Setup and Service Guide

51

If the compute module does not have DIMM retention clips installed, skip to step 6.

Figure 53. Removing the DIMM retention clips

3. Identify and locate the faulty DIMM

4. Use the memory removal tool as a lever and position one end between the DIMM retention clip and

the liquid cooling loop (see Letter A).

5. Lift the DIMM retention clip from the liquid cooling loop (see Letter B).

Figure 54. Removing the DIMM in a liquid cooled system

6. Using the memory replacement tool, open the DIMM ejection tabs at both ends of the DIMM slot (see

Letter A and Letter B). The DIMM will slightly lift up from the slot.

7. Hold the DIMM by its edges and lift it away from the slot (see Letter C).

Page 52

Intel® Server System S9200WK Product Family Setup and Service Guide

52

4.10.2.2 DIMM Installation

Figure 55. Installing the DIMM in a liquid cooled system

1. Locate the DIMM slot for installation. Ensuring that the DIMM ejection tabs at both ends of the DIMM

slot are pushed outward to the open position (see Letter A). Use the provided tool if the DIMM

ejection tabs are in the closed position (see Section 4.10.2.1).