Page 1

INTEL® FALCON™ 8+

USER MANUAL

UNMANNED AIRCRAFT SYSTEM

ENGLISH

AUGUST 2017

Page 2

COPYRIGHT

This publication is protected by copyright. No part of the publication may be used, reproduced, or translated, in any

form, without the prior written consent of Intel Corporation.

AscTec, Ascending Technologies, the Ascending Technologies and Falcon logos are trademarks of Intel Corporation.

© 2017 Intel Corporation. All rights reserved.

Intel and the Intel logo are trademarks of Intel Corporation.

Other names and brands may be claimed as the property of others.

DISCLAIMER

The information contained herein is subject to change without notice. All statements, information and

recommendations contained herein do not constitute a warranty of any kind, express or implied. All images are for

illustration purposes only; actual items shown in the images may vary as to, without limitation, size, color, and

labeling. Please review this product guide thoroughly, paying particular attention to any safety sections, to make sure

that you use your unmanned aircraft system safely.

Intel Corporation reserves the right to change, amend or update all available documents, including this Aircraft Flight

Manual, at any time and without notice regarding the Intel® Falcon 8+ Unmanned Aircraft System. Contact your Intel

Corporation representative or go to http://intel.com/FalconManual to obtain the latest documentation for this

product.

The features and benefits of the unmanned aircraft system depend on system configuration and may require enabled

hardware, software, or service activation. Technical results may have been estimated or simulated using internal

analysis or architecture simulation or modeling of any one or more of the following companies, and are provided to

you for informational purposes: Intel Corporation, Ascending Technologies GmbH, which became an Intel

Corporation subsidiary after acquisition by Intel Corporation, or Intel Deutschland GmbH, the Intel Corporation

subsidiary into which Ascending Technologies GmbH merged after Intel Corporation acquired it. Any differences in

your system hardware, software or configuration may affect actual performance.

Learn more at http://intel.com/FalconManual.

Intel Corporation (Intel), and its subsidiaries, disclaim all other warranties, of any kind, express, implied, statutory, or

otherwise, published specifications, including, without limitation, warranties of merchantability, fitness for a

particular purpose, and non-infringement, as well as any warranty arising from course of performance, course of

dealing, or usage in trade.

To the extent permitted by applicable law, Intel disclaims all liability for any damages, direct or indirect, arising from

the use of the unmanned aircraft system (UAS) outside of its intended use, in breach of Intel Corporation's Safety

Guidelines, Safety Precautions or any other documentation for this product, in violation of any applicable laws or

regulations, or in violation of any of the operating limitations of the aircraft, or from any error of the Operator.

© 2017 Intel Corporation. All rights reserved.

No license of any kind, whether express, implied, statutory, by estoppel or otherwise to any intellectual property

rights, technology, software, in each case whether in whole or part, is granted by Intel, or any of its subsidiaries, in this

User Manual.

Page 3

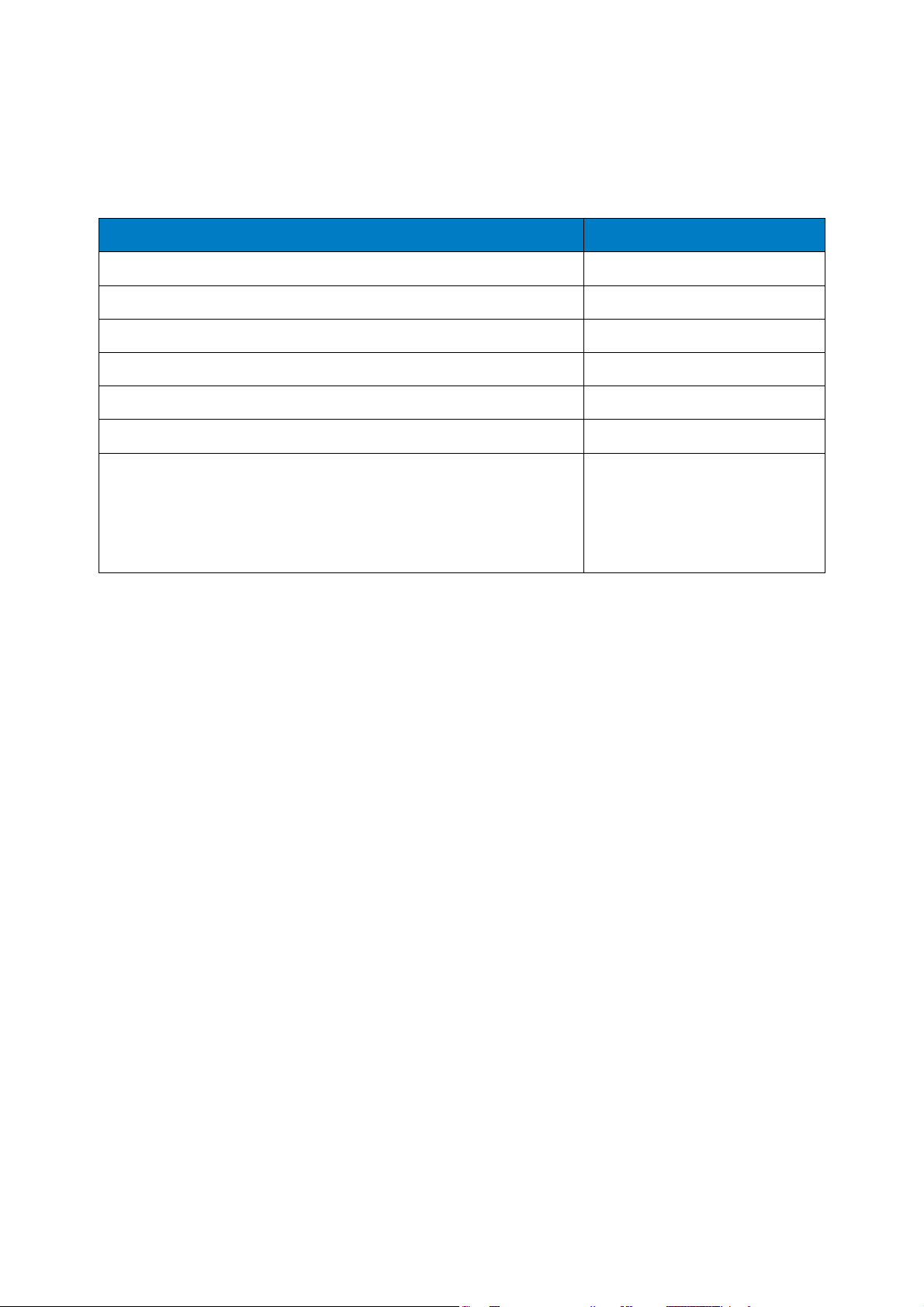

RECORD OF REVISION

REVISION NUMBER REVISION DATE

Version 1 April 2017

Version 1.0.1 May 2017

Version 2 July 2017

Version 2.1 July 2017

Version 2.2 August 2017

Version 2.2.1 August 2017

Described Firmware Versions:

NAV/PER: 0.95

Intel® Cockpit Controller (CTR): 0.95

Cockpit Control application (on tablet): 1.1.10

Page 4

USER MANUAL

INTEL® FALCON™ 8+ UAS

TABLE OF CONTENTS

1. INTEL® FALCON™ 8+ UAS ............................................................................................................. 7

1.1. SAFETY FIRST .........................................................................................................7

1.1.1. Intended Use ......................................................................................................................... 7

1.1.2. Safety Guidelines ................................................................................................................ 8

1.2. UAS AND SAFETY CHECK ...............................................................................11

1.3. PRE-FLIGHT CHECK ...........................................................................................13

1.4. POST-FLIGHT CHECK .......................................................................................16

2. DESCRIPTION OF THE SYSTEM .................................................................................................. 18

2.1. THE INTEL® FALCON™ 8+ UAV ......................................................................18

2.1.1. Central Unit ..........................................................................................................................20

2.1.2. Motor Rails Of The UAV .................................................................................................22

2.1.3. Actively Stabilized Camera Mount (Gimbal) ..........................................................23

2.2. THE INTEL® COCKPIT CONTROLLER (CTR) .............................................23

2.2.1. The Status Display ............................................................................................................27

2.2.2. The Touchscreen Tablet ................................................................................................27

2.3. THE INDEPENDENT CAMERA CONTROL (ICC) .......................................28

2.4. THE 2ND OPERATOR MONITOR ..................................................................29

2.5. PAYLOADS - CAMERA OPTIONS .................................................................30

2.5.1. Changing a Payload (Camera) ......................................................................................32

2.5.2. Payload and Compass Calibration .............................................................................34

2.5.3. Sony Alpha 7R Full Frame Camera ............................................................................37

2.5.4. Inspection Payload ...........................................................................................................41

2.6. THE INTEL® POWERPACK BATTERIES ......................................................46

2.6.1. Charging the Intel® Powerpack Batteries ................................................................49

2.6.2. Operating The BMS Menu .............................................................................................50

2.6.3. .Battery Update ..................................................................................................................53

2.6.4. Battery Information Safety Instructions And Warnings ...................................53

2.7. TRANSPORT CASES & INTEL® BACKPACK ..............................................57

2.7.1. Packing Instructions .........................................................................................................57

2.8. SOFTWARE FEATURE PACKAGES ...............................................................61

2.8.1. Activating Software Feature Packages .....................................................................62

2.8.2. Checking Activated Software Feature Packages .................................................63

2.9. INTEL® FALCON™ 8+ UAV FLIGHT LOGS ..................................................64

3. OPERATING THE SYSTEM .........................................................................................................68

3.1. PREPARING THE INTEL® FALCON™ 8+ UAV ............................................68

3.2. PREPARING THE INTEL® COCKPIT CONTROLLER (CTR) ...................70

3.3. THE TOUCHSCREEN TABLET ........................................................................72

© 2017 Intel Corporation. All rights reserved 4

Page 5

USER MANUAL

INTEL® FALCON™ 8+ UAS

3.3.1. PATH Projects .....................................................................................................................76

3.3.2. AscTec Navigator Software Projects .........................................................................84

3.4. AUTOMATED START-UP CHECKS ..............................................................88

3.4.1. Magnetic Field Warning ..................................................................................................88

3.5. LINK LOSS PROCEDURE ..................................................................................90

3.6. FLIGHT MODES ....................................................................................................93

3.6.1. GPS-Mode ............................................................................................................................95

3.6.2. Height-Mode .......................................................................................................................99

3.6.3. Manual-Mode ...................................................................................................................100

3.7. STARTING AND STOPPING THE MOTORS ........................................... 101

3.8. TAKING OFF ....................................................................................................... 101

3.8.1. Launching In GPS-Mode .............................................................................................102

3.8.2. Launching In Height-Mode ........................................................................................102

3.8.3. Launching In Manual-Mode .......................................................................................103

3.9. THE FLIGHT ........................................................................................................ 103

3.9.1. Controlling The Intel® Falcon™ 8+ UAV From The CTR .................................105

3.9.2. Mission Planning ............................................................................................................106

3.9.3. In-Flight ..............................................................................................................................107

3.9.4. General Operating Tips ...............................................................................................107

3.9.5. Battery Warnings ............................................................................................................108

3.10. IN-FLIGHT EMERGENCIES .........................................................................110

3.11. LANDING ........................................................................................................... 117

3.11.1. Landing In GPS-Mode ...............................................................................................117

3.11.2. Landing In Height-Mode ...........................................................................................117

3.11.3. Landing In Manual-Mode .........................................................................................118

3.11.4. Switching OFF The UAS ............................................................................................119

3.12. WARNINGS ....................................................................................................... 119

3.12.1. Magnetic Field Warning ............................................................................................121

3.12.2.Critical Battery Levels & Warnings Of The UAV And The CTR ..................123

3.12.3. Data Link Warnings .....................................................................................................125

3.12.4. GPS Warning .................................................................................................................126

3.12.5. Motor Failure Warning ..............................................................................................127

3.12.6. CTR Warnings ...............................................................................................................127

3.12.7. AscTec Trinity Control Unit System Warnings ...............................................129

3.13. OPERATIONAL LIMITATIONS .................................................................. 137

4. STATUS DISPLAY ................................................................................................................... 138

4.1. STATUS DISPLAY OVERVIEW .................................................................... 138

4.1.1. Status Display Menu Structure .................................................................................139

4.1.2. The Main Information Screens .................................................................................150

5. SPECIAL FUNCTIONS ...............................................................................................................155

5.1. CIRCLE OF INTEREST (COI) ..........................................................................155

© 2017 Intel Corporation. All rights reserved 5

Page 6

USER MANUAL

INTEL® FALCON™ 8+ UAS

5.2. PANORAMA ........................................................................................................ 156

5.3. QUICK SURVEYING ASSISTANT ................................................................ 160

5.4. WAYPOINT NAVIGATION Using AscTec Navigator Software ....... 164

6. MAINTENANCE, TROUBLESHOOTING, AND SUPPORT ...............................................................165

6.1. MAINTENANCE .................................................................................................165

6.1.1. Intel® Falcon™ 8+ UAS Firmware Updates ...........................................................165

6.1.2. Caring for the Intel® Falcon™ 8+ UAV ....................................................................170

6.1.3. Propeller Replacement ................................................................................................171

6.2. TROUBLESHOOTING ..................................................................................... 172

6.2.1. Establishing A Connection Between The CTR And The UAV ......................172

6.2.2. Analyzing Data Link Connection Issues ................................................................173

6.2.3. No Preview Video On The Touchscreen Tablet Of The CTR .......................174

6.2.4. Flight Logs .........................................................................................................................174

6.3. SUPPORT ............................................................................................................176

7. TECHNICAL SPECIFICATION .....................................................................................................178

LIST OF FIGURES ........................................................................................................................ 184

LIST OF TABLES .......................................................................................................................... 186

INDEX ........................................................................................................................................187

© 2017 Intel Corporation. All rights reserved 6

Page 7

USER MANUAL

INTEL® FALCON™ 8+ UAS

1. INTEL® FALCON™ 8+ UAS

Thank you very much for choosing the Intel® Falcon™ 8+ UAS!

The Intel® Falcon™ 8+ UAV is the first-choice drone for the most challenging

professional UAV inspections and surveying operations. Small and portable with a

maximum take-off weight of only 2.8 kg, but with a payload weight of 0.8 kg, the Intel®

Falcon™ 8+ UAV can carry professional cameras like the Sony Alpha 7R, offering the full

quality of an airborne image studio. The in-house developed AscTec Trinity Control

Unit - the world's first triple redundant, fully adaptive control unit for multi-rotor

aircrafts - makes the Intel® Falcon™ 8+ UAV the most advanced and reliable unmanned

aerial vehicle. Thanks to the modular concept, you can spontaneously exchange the

payload at any time, and get the very best out of each project by using the most

suitable camera.

In the following text, Unmanned Aircraft System (UAS) is used if the whole system

(including Intel® Cockpit™ Controller, payload, etc.) is referenced; Unmanned Aerial

Vehicle (UAV) is used when only the aircraft itself is referenced.

1.1. SAFETY FIRST

The following sections contain important safety information. Any personnel operating

the UAS must read, understand and accept these warnings and guidelines before

operating the Intel® Falcon™ 8+ UAV.

1.1.1. Intended Use

This product is an Unmanned Aircraft System (UAS) that is intended for commercial

use only, such as for visual inspection of infrastructure, surveying and mapping. It is not

intended for any consumer or recreational use. Acrobatic flight is prohibited.

You must read, understand, and agree to all documentation before using the Intel®

Falcon™ 8+ UAS. By using the Intel® Falcon™ 8+ UAS, you certify that you have read and

understand all the material in this document, as well as all user documentation, and

agree to abide by said materials.

Use the Intel® Falcon™ 8+ UAS only as intended. Always operate in accordance with the

operating limitations stated in the later sections of this User Manual.

Operating the system while ignoring these guidelines and warnings may be illegal and

subject to fine.

© 2017 Intel Corporation. All rights reserved 7

Page 8

USER MANUAL

INTEL® FALCON™ 8+ UAS

1.1.2. Safety Guidelines

Failure to adhere to the following guidelines and warnings and to operate within the

limitations of the UAS could result in an accident and death, serious injury, property

damage, or damage to the UAS.

• You are responsible for knowing and complying with all laws and regulations

applicable to the airspace in which you operate. Jurisdictions have different

safety rules pertaining to authorization for flying UAVs; flying near airports,

manned aircrafts, or people; operation within visual line of sight; altitude limits;

operation at night or twilight; operation of multiple UAVs at the same time; and

airspace usage. Know and understand all applicable laws before you fly. Follow

applicable laws at all times.

• Some jurisdictions also have rules that may affect your operation of UAS, such

as laws relating to receipt of wireless signals, aerial photography, aerial

surveying, privacy, and trespassing. You must know and follow all laws and

regulations applicable to your region.

• In some jurisdictions, the operator may be required to have a pilot certification

from the aviation authority or advance approval from the aviation authority or

air traffic control. Check your local laws before operating the UAS. You are

always responsible for operating the UAS safely and responsibility, and in

compliance with all laws.

• Professional drone operators must comply with all applicable insurance and

aviation-specific liability requirements.

• Completion of a UAS safety check, pre-flight check, and post-flight check

according to the following sections before every operation is compulsory for

every flight.

• Rotating propellers can cause serious personal injury and property damage.

Keep a safe distance and/or wear appropriate safety equipment (e.g. safety

goggles, gloves).

• Our UAS, like all comparable aircraft systems, can in rare cases, suffer electrical,

mechanical, and/or other failures. This may lead to a partial or complete loss of

flying capability. Therefore, the pilot is responsible for conducting all flights at a

safe distance from people, moving vehicles, etc. such that in the event of loss of

flight control no personal injury or property damage will occur.

• Operating the UAV close to power lines, power transformers or other areas with

high electromagnetic disturbances, or in urban canyons, can have severe effects

on the GPS stability and/or the magnetic field sensor, which ultimately also

effects GPS stability. The Intel® Falcon™ 8+ UAV is designed to compensate for

these errors in most cases, but the function is not guaranteed in any scenario.

Therefore, a pilot must have the training and ability to fly the Intel® Falcon™ 8+

UAV in Height-Mode in any situation. Only operate in these environments if you

have sufficient training!

© 2017 Intel Corporation. All rights reserved 8

Page 9

USER MANUAL

INTEL® FALCON™ 8+ UAS

• Risk of fire or explosion: Do not operate the UAV in potentially explosive

environments such as fueling stations, fueling areas, fuel or chemical storage

facilities, or areas where the air may contain chemical or dust particles, such as

grain particles or metal powders.

If possible, and if you can do so safely, physically remove this product from any

such environment. Do not connect any accessory cables or press any of the

product's buttons until outside of these environments.

• GPS-Mode will limit your maximum speed. Flying the Intel® Falcon™ 8+ UAV at

wind speeds above 12 m/s is not recommended. Please note that wind

conditions on the ground and in the air can differ.

• Do not fly the UAV outside the specified temperature range, see “TECHNICAL

SPECIFICATION” on page 178 for further details.

• The UAS and payloads are not waterproof. Do not operate the UAS in adverse

weather (sand storm, rain, fog, snow, etc.) or at night.

• Only operate the UAV on clear days and during daylight hours. The UAV has LED

position lights, but not anti-collision lights.

• The UAV is not equipped with a sense-and-avoid system. The operator is

responsible for seeing and avoiding all other traffic, persons, structures, and

obstacles. We recommend two-person operations (pilot and observer). All sense

and avoid is done by the pilot and observer.

• Avoid placing the UAV or the Intel® Cockpit Controller (CTR) next to heat

sources, leaving it in the direct sunlight for extended periods, or leaving it in a

place where the temperature may exceed the specified range (such as a parked

car on a hot day).

• Do not disassemble the UAS.

• Do not transport the UAS in transport containers not approved by Intel.

• Do not modify the UAS. Any modifications may compromise safety features,

increasing risk of injury, death, or property damage. There are no user

serviceable parts inside this UAS. Refer all service to your local support.

• Using devices in combination with the UAS other than those approved by Intel

(e. g. batteries, battery chargers, cameras, etc.) is prohibited. Any unapproved

modification of the UAS is prohibited.

• The UAS is equipped with a 2.4 GHz radio link for remote control and a 5.8 GHz

radio link for video transmission. Please note that local laws may apply and

restrictions in using radio equipment may exist in your area. The UAV may only

be used for flight with the original accessories and under the defined

environmental conditions.

• The UAV is equipped with Global Positioning System (GPS) or Assisted GPS

(AGPS) technology, which may be used to determine the approximate location

of the UAV. Please check the settings of any installed applications to ensure that

© 2017 Intel Corporation. All rights reserved 9

Page 10

USER MANUAL

INTEL® FALCON™ 8+ UAS

you manage these location-based services in accordance with your privacy

preferences.

• The pilot of an Intel UAV should always act according to his or her best

judgment focusing on the safety of the populace and the environment within

which he or she is flying.

• Every pilot must undergo intensive training to operate the UAV in all flight

modes and to maintain the UAV in a safe and airworthy condition - this is

mandatory.

• Do not operate the UAS under the influence of alcohol or drugs.

CAUTION: HAZARDOUS MOVING PARTS; KEEP FINGERS AND OTHER

BODY PARTS AWAY. THIS PRODUCT USES REPLACEABLE

BATTERIES; THERE IS RISK OF EXPLOSION IF BATTERY IS REPLACED

WITH AN INCORRECT TYPE. DISPOSE OF USED BATTERIES

ACCORDING TO THE INSTRUCTIONS.

CAUTION: ALWAYS FLY SAFELY AND RESPONSIBLY.

THIS MEANS, FOR EXAMPLE:

• Always keep a safe distance between the UAV and people.

• Do not fly too close to obstacles (e.g. houses, trees, etc.). The UAV could damage

third party property and/or the GPS signal might suffer from shadowing and

worsen the positional accuracy.

• Do not fly beyond the line of sight.

• Never fly in closed or restricted areas.

• Always keep both hands on the control sticks. You must be able to react at any

time, to prevent critical situations.

• Be aware of dogs or birds as they might attack your UAV.

• Always give way to other aircrafts! Watch out for low flying helicopters!

• All control inputs are given to the UAV as if you were sitting in the UAV as a pilot.

• We strongly recommend attending the basic training and to frequently practice

Height-Mode.

• Never exceed a speed of 16 m/s (35 mph) in Height-Mode.

• Never descend faster than 10 m/s (22 mph) in Manual Mode.

• In case of any problems close to the ground, ascend to a safe height.

• Always keep the left control stick, controlling the altitude, completely down

when the UAV is on the ground and the motors are running.

© 2017 Intel Corporation. All rights reserved 10

Page 11

USER MANUAL

INTEL® FALCON™ 8+ UAS

These safety guidelines are subject to change without prior notice. Errors and

omissions excepted.

Privacy and Property Rights

As the operator of a UAS, you must comply with all applicable laws, especially privacy,

property, and copyright laws. This includes the below common types of rules that may

apply in the jurisdiction in which you operate. Always consult the laws of your

jurisdiction before operating the UAS, as jurisdictions have different laws.

• Monitoring and filming public areas where individuals are staying may be only

permitted under limited circumstances, e.g. for safety reasons and provided

sufficient notice is provided.

• Monitoring and filming private areas may require the consent of the owner and,

potentially, any residents or visitors.

• Filming individuals and using their pictures (such as sharing them) may infringe

an individual's rights of his/her own image.

• Under copyright laws, some pictures may only be used for private purposes. In

addition, taking pictures of buildings may breach copyrights.

• Take-offs and landings of the UAV may only be allowed with consent of the

owner of the property on which take-offs / landings occur.

Violations of the laws and regulations referred to above may lead to penalties, damage

claims from individuals, or even criminal prosecution.

This information is provided for informational purposes and is not an exhaustive

description of legal requirements. This information is not designed to provide any legal

advice or include any kind of warranty regarding the usability of the UAS. Please

contact legal counsel for any specific and binding advice on the use of the UAS in your

jurisdiction.

1.2. UAS AND SAFETY CHECK

The UAS and safety check must be performed once per day before the first flight or any

time it may be necessary (e.g. after any incident like a hard landing). If you notice

anything unusual (any loose part, strange noise from the motors, or any other unusual

occurrence), please contact support through your reseller, if you purchased through a

reseller, or support at Intel, if you purchased directly from Intel. Please include a

detailed description of your observation and photos if applicable.

© 2017 Intel Corporation. All rights reserved 11

Page 12

USER MANUAL

INTEL® FALCON™ 8+ UAS

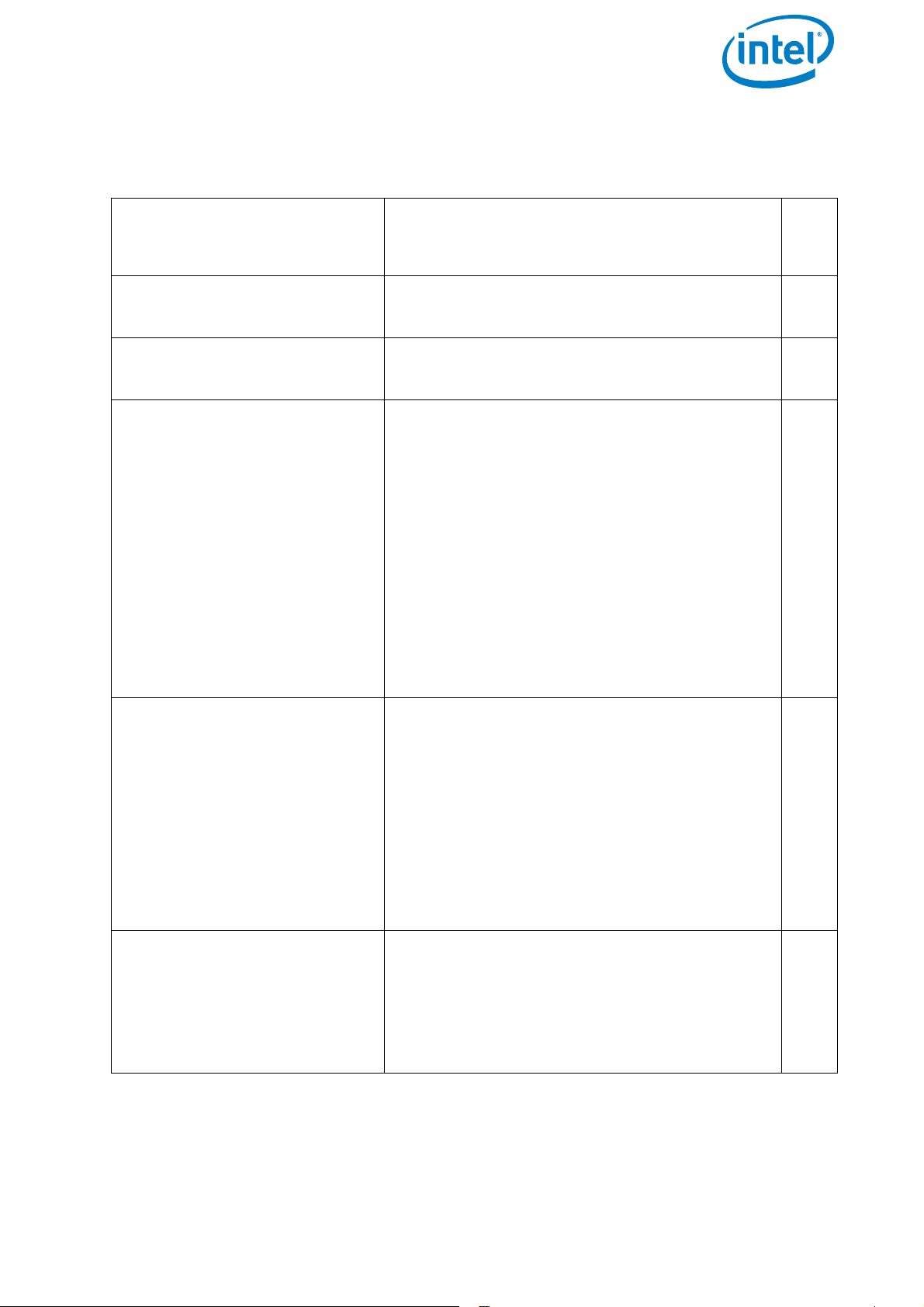

You must follow these steps to complete a close UAS and safety check:

Table 1.1: Safety Check List

1. Is the transport case free

of visible damage?

2. Is the UAV free of visible

damage?

3. Are all the propellers in

good condition?

4. Are all the propellers

firmly mounted to the

motors?

If there is new visible damage from the last

transport, please take special care during the

check of the complete UAS.

If there is visible damage, please contact your

support as noted directly above this table.

Replace propellers if there are any cracks,

breaks or other damages.

Move each propeller gently while holding the

connected motor. The nut on top of the propellers is self-tightening. It only needs to be

finger tight (20 Ncm +- 5 Ncm). Never tighten

it with too much force, as it might damage

the motor.

To tighten the nut, use the supplied screwwrench. Put the screw wrench on the nut,

hold the motor head with thumb and index

finger of one hand, and use the index finger

of the other hand to turn the screw wrench.

As soon as the motor head starts turning as

well, sufficient force has been applied

□

□

□

□

5. Nudge every single

propeller so that it turns,

and check if any unusual

sound can be heard, or if a

propeller spins slower

than the others and stops

spinning abruptly.

6. Is the User SD card of the

“Black Box” (flight logger)

correctly inserted?

© 2017 Intel Corporation. All rights reserved 12

If there is a scratching sound or if a propeller

spins slower than the others without any

unusual sound, this might come from an

obstacle inside the motor. Please try canned

pressurized air to clean the motor. If there is

a rattling sound this might come from a propeller which is not attached tightly enough. In

this case, carefully check the self-tightening

nut on top of the propeller.

Tighten the nut as described in step 4.

Check the User SD card in the back of the

Intel® Falcon™ 8+ UAV. If on the Status Display of the CTR there is the message No user

SD card, please take out the card, make a

backup copy, format it and re-insert it into

the Intel® Falcon™ 8+ UAV

□

□

Page 13

USER MANUAL

INTEL® FALCON™ 8+ UAS

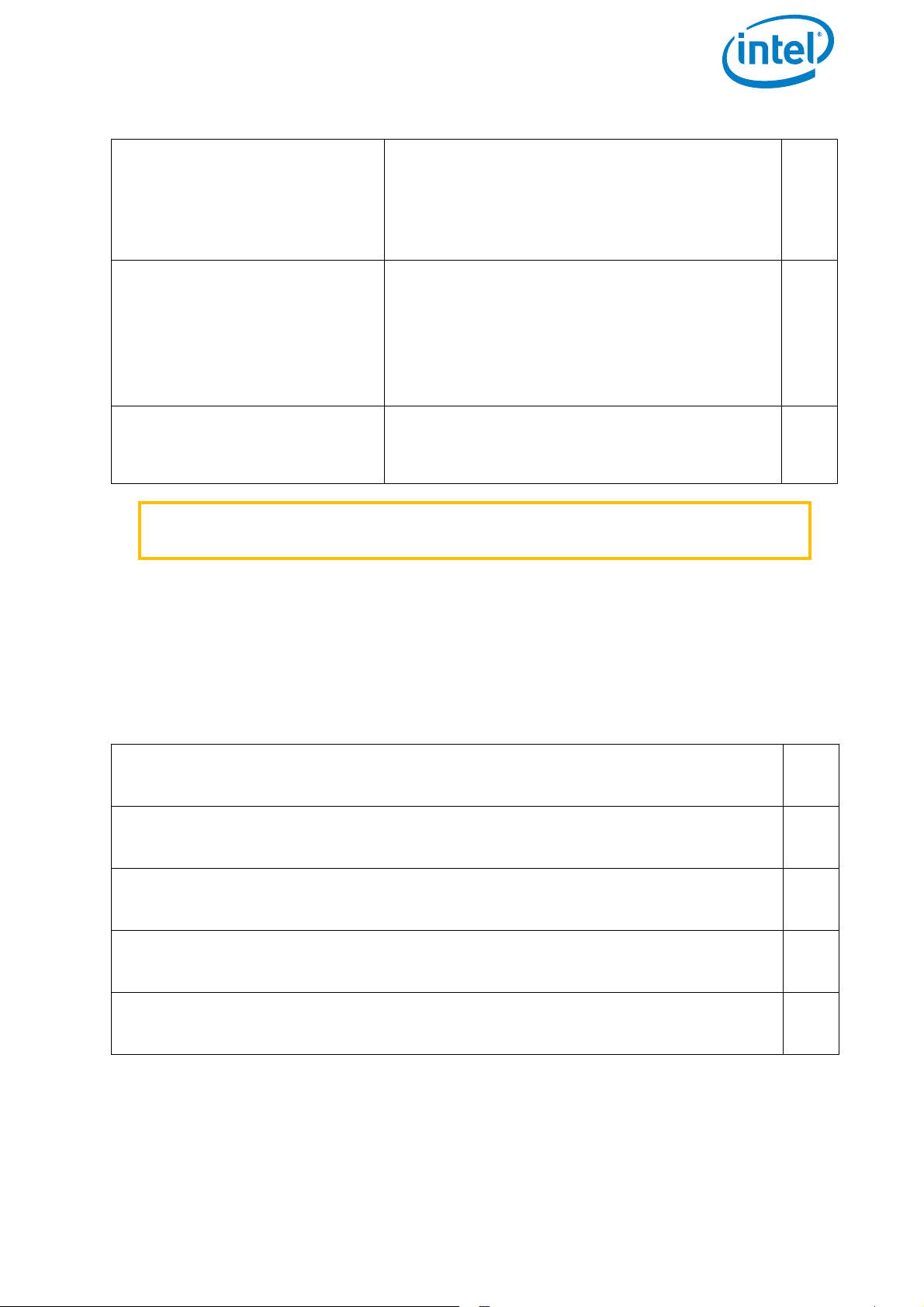

Table 1.1: Safety Check List (Continued)

7. Is the gimbal correctly

attached, and its

thumbscrew installed in

the back of the Intel®

Falcon™ 8+ UAV?

Make sure that the camera mount is pushed

all the way in and that the thumbscrew is

installed finger tight.

□

8. Is the payload adapter

firmly connected to the

central unit?

9. Are all the batteries fully

charged?

WARNING VIOLATION OF THESE SAFETY PRECAUTIONS RESULTS IN

THE LOSS OF WARRANTY!

Make sure that the connector plug of the

adapter is connected to the equivalent at the

front side of the UAV.

Make sure that the ball of the ball link connector of the roll servo is fixed in the respective slot in the payload adapter.

Voltage level can easily be checked using the

BMS of the batteries. It will be shown by the

LEDs on the front of the batteries.

1.3. PRE-FLIGHT CHECK

You must follow these steps for a close pre-flight check:

Table 1.2: Pre Flight Check List

□

□

1. Is the UAS in proper condition (according to the points listed in “UAS AND

SAFETY CHECK” on page 11)?

2. Make sure to have an empty and correctly formatted SD card inserted in

the camera.

3. Are there two batteries fully inserted into the Intel® Falcon™ 8+ UAV, with

the colored label facing upwards and secured by the retaining clips?

4. Is the battery of the Intel® Cockpit Controller (CTR) fully inserted, with the

colored Intel label facing downwards?

5. Is the Intel® Cockpit Controller in proper condition (no loose parts) and the

antenna panel folded out?

© 2017 Intel Corporation. All rights reserved 13

□

□

□

□

□

Page 14

USER MANUAL

INTEL® FALCON™ 8+ UAS

Table 1.2: Pre Flight Check List (Continued)

6. Place the UAV on the take-off location and verify the following:

• There is enough space to take-off and land (no people, animals or

obstacles within a radius of 10 m).

• There are no obstacles around that could shadow the GPS signal.

• The surface allows all propellers to spin freely.

• There are no small rocks, dust or sand which could be sucked into the

motors.

• There are no magnetic fields to be expected.

CAUTION: TO AVOID INTERFERENCES WITH THE UAS PLEASE SET

YOUR SMARTPHONE TO AIRPLANE (FLIGHT) MODE AS THEY USE

THE SAME 2.4 GHZ AND 5.8 GHZ FREQUENCIES.

Table 1.3: Pre Flight Checklist (Continued)

□

7. Always switch on the UAS in the following order:

1. Payload

2. Intel® Falcon™ 8+ UAV

3. Touchscreen tablet

4. Intel® Cockpit Controller (CTR)

Wait for the link to be established.

8. The end of the boot process is marked by a triple beep emitted by the

Intel® Falcon™ 8+ UAV. During boot up, the Intel® Falcon™ 8+ UAV does not

need to stand still. It can be moved - for example, it can be started from a

moving boat.

9. The start-up process is finished when camera mount stabilization starts

working. A gentle buzzing sound can be heard from the gimbal.

10. Make sure to comply with all points in the checklist presented on the

touchscreen tablet. Confirm the checklist on the tablet.

11. Confirm the preview video image is visible on the touchscreen tablet of

the Intel® Cockpit Controller.

12.Choose a Link Loss Procedure, which is suitable for the current flight

mission.

□

□

□

□

□

□

13.Confirm the displayed battery capacity of the CTR is sufficient for the

planned mission (displayed in minutes in the Status Display - see “STATUS

DISPLAY” on page 138).

© 2017 Intel Corporation. All rights reserved 14

□

Page 15

USER MANUAL

INTEL® FALCON™ 8+ UAS

Table 1.3: Pre Flight Checklist (Continued)

14.Confirm the battery capacity of the UAV is at least 80% (displayed in the

top line of the tablet).

15.The bottom line in the Status Display shows OK.

16.Is the GPS quality greater than or equal to 4 bars? This is mandatory if you

want to fly in GPS-Mode.

17.Confirm the wind speed is within the operational limits: 16 m/s in HeightMode or 12 m/s in GPS-Mode.

18.Choose the correct flight mode (usually GPS-Mode or Height-Mode).

19.Switch the motors on (with both hands, only in idle mode).

While the Intel® Falcon™ 8+ UAV is on the ground with running motors,

always keep the left control stick, which controls the height, in the fully

downward position.

□

□

□

□

□

□

20.Are all the motors running correctly?

21.Ready for take-off!

WARNING VIOLATION OF THE SAFETY PRECAUTIONS RESULTS IN THE

LOSS OF WARRANTY!

□

□

© 2017 Intel Corporation. All rights reserved 15

Page 16

USER MANUAL

INTEL® FALCON™ 8+ UAS

1.4. POST-FLIGHT CHECK

You must follow these steps closely for a post-flight check:

Table 1.4: Post-flight Check List

1. Before landing the Intel® Falcon™ 8+ UAV, adjust the camera to a horizontal

position.

2. Land the Intel® Falcon™ 8+ UAV.

Always keep the left control stick, which controls the height, in the fully

downward position when the system is on the ground with running

motors.

3. When the system is on the ground, switch off the motors.

Always switch off the system in the following order:

• Camera (depending on the payload, wait at least 10 seconds until the

camera has stored all data and is fully powered down).

□

□

• Intel® Falcon™ 8+ UAV

• Push and hold the power button.

The LED position lights will increase brightness.

The LED position lights will decrease brightness and

simultaneously there will be a short beep from the UAV.

• After the beep, let go of the button.

• Touchscreen tablet

• Push and hold the power button until “Slide to shut down your

PC” is shown.

• Let go of the button.

• Follow the instructions on the tablet to fully power down the

touchscreen tablet.

• Intel® Cockpit Controller (CTR)

• Push and hold the POWER button.

The CTR will vibrate a few seconds later.

• Let go of the button.

4. Remove all batteries of the Intel® Falcon™ 8+ UAV.

□

□

5. Store the UAV safely in the transport case or in the backpack.

□

© 2017 Intel Corporation. All rights reserved 16

Page 17

USER MANUAL

INTEL® FALCON™ 8+ UAS

Table 1.4: Post-flight Check List (Continued)

6. Remove the battery of the CTR.

7. Fold in the antenna panel of the CTR.

8. Remove the shoulder harness of the CTR.

9. Store the CTR and all accessories safely in the transport case or in the

backpack.

CAUTION: ALWAYS REMOVE ALL BATTERIES FROM BOTH THE

INTEL® FALCON™ 8+ UAV AND CTR WHEN THE SYSTEM IS NO

LONGER IN USE.

□

□

□

□

WARNING VIOLATION OF THESE SAFETY PRECAUTIONS RESULTS IN

THE LOSS OF WARRANTY!

© 2017 Intel Corporation. All rights reserved 17

Page 18

USER MANUAL

1

2

2

3

4

4

4

4

1

2

2

3

4

4

5

5

INTEL® FALCON™ 8+ UAS

2. DESCRIPTION OF THE SYSTEM

In this chapter, you find a description of the whole system and its components:

• The Intel® Falcon™ 8+ UAV

• The Intel® Cockpit Controller (CTR)

• Payloads/Cameras

• The Intel® Powerpack Batteries

2.1. THE INTEL® FALCON™ 8+ UAV

The following section describes the single parts of the Intel® Falcon™ 8+ UAV.

Figure 2.1: The Intel® Falcon™ 8+ UAV Components

The Intel® Falcon™ 8+ UAV consists of

several components:

(1) Actively stabilized camera mount

(gimbal) with camera

(2) Motor rails

(3) Central unit

(4) Carbon cross

The Intel® Falcon™ 8+ UAV bottom view:

(1) Actively stabilized camera mount with

camera

(2) Motor rails

(3) Center cross piece with LEDs

(4) Carbon cross

(5) Landing feet

For orientation reasons, the UAV has

three LED position lights:

• white at the bottom

• green on the right side

• red on the left side

© 2017 Intel Corporation. All rights reserved 18

Page 19

USER MANUAL

Data

Data

Video

Video

INTEL® FALCON™ 8+ UAS

Figure 2.1: The Intel® Falcon™ 8+ UAV Components (Continued)

The Intel® Falcon™ 8+ UAV bottom view,

Carbon Cross with center cross piece,

antenna arrangement:

The data link antennas (2.4 GHz) as well

as the video link antennas (5.8 GHz) are

integrated into the landing feet.

They are diagonally arranged as shown

in the image to the left.

© 2017 Intel Corporation. All rights reserved 19

Page 20

USER MANUAL

1

2

3

4

4

5

6

7

7

8

INTEL® FALCON™ 8+ UAS

2.1.1. Central Unit

The following figures describe the single parts of the Central Unit.

Figure 2.2: Central Unit Back View without Gimbal (Camera Mount)

The Central Unit consists of:

(1) Carbon fiber chassis

(2) USB stick slot (supports up to 16 GB,

file system: FAT32, allocation unit

size: 32 kilobytes) for firmware

updates

(3) Hole for the camera mount’s carbon

rod, see “Units of the Gimbal” on

page 23

(4) Battery compartments with retaining

clips (7) for batteries

(5) Power button

(6) Micro SD-card slot (SD card: speed

class 10 minimum, supports up to 16

GB, file system: FAT32, allocation unit

size: 32 kilobytes), for flight logs

(“Black Box”), must be inserted

contacts upwards

(7) Retaining clips for the batteries

(8) Place for the label with the serial

number of the UAV

Built inside:

• The electronics for flight

stabilization and power supply

• Diversity Data Link modules

• Video Transmitter module

© 2017 Intel Corporation. All rights reserved 20

Page 21

USER MANUAL

4

5

1

2

6

6

6

6

3

1

2

3

2

INTEL® FALCON™ 8+ UAS

Figure 2.3: Central Unit Front View without Gimbal (Camera Mount)

Front view:

(1) Hole for the camera mount’s carbon

rod

(2) Connector slot for the plug of the

payload adapter, (see no. (1) in “Units

of the Gimbal” on page 23

(3) Retaining clip for the payload adapter

(4) Cable tube (contains the cabling of

the antennas)

(5) Fan for the internal cooling behind

the slots

(6) Vibration dampers

Figure 2.4: Central Unit Side View, Left Side without Gimbal (Camera Mount)

Side view (left):

(1) LED position light (red when UAV is

running), same on the right side

(green when UAV is running)

(2) Vibration dampers

(3) Cable tube (which contains, e.g., the

cabling of the antennas)

© 2017 Intel Corporation. All rights reserved 21

Page 22

USER MANUAL

1

1

2

2

3

3

4

5

6

INTEL® FALCON™ 8+ UAS

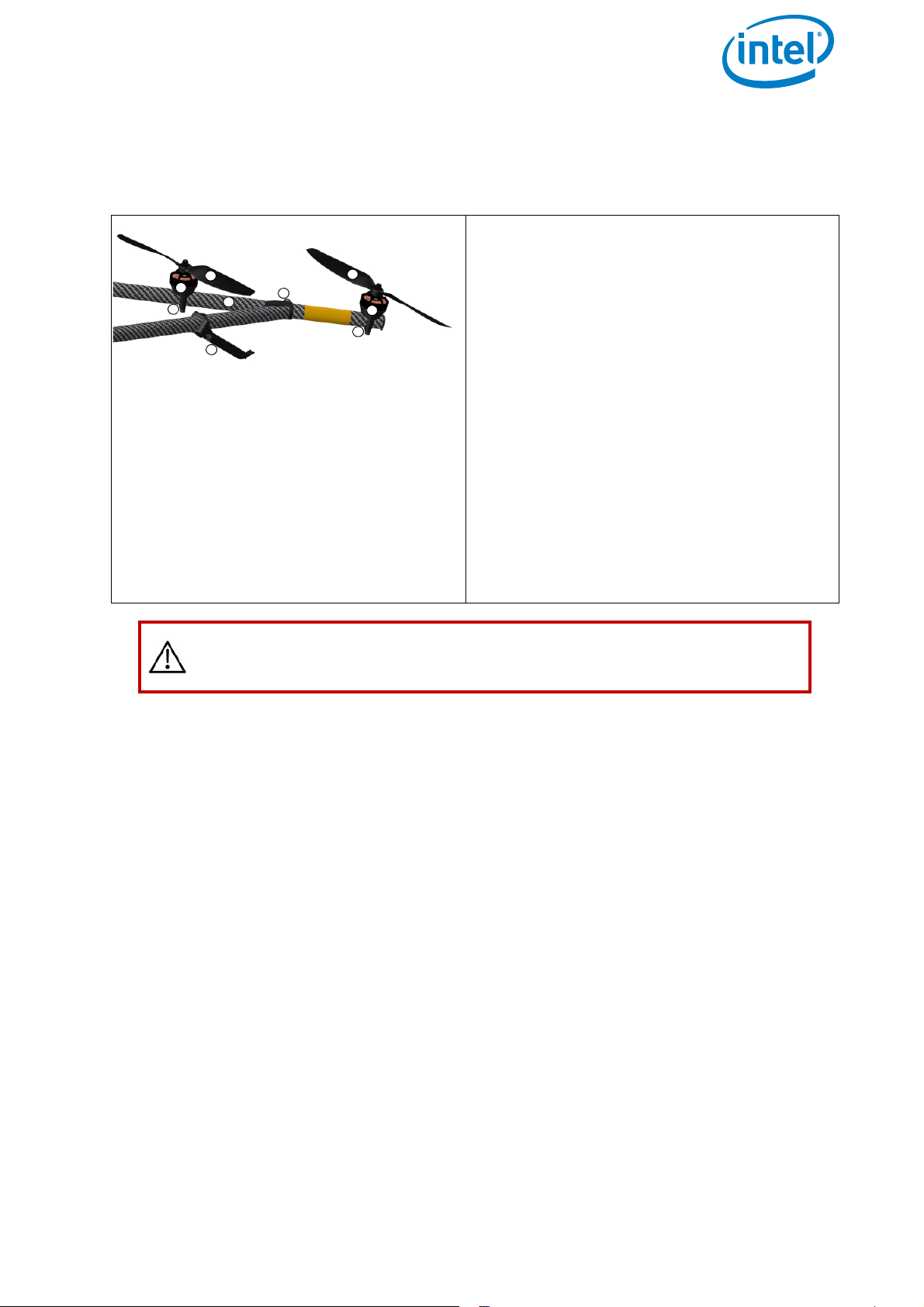

2.1.2. Motor Rails Of The UAV

The following figure shows the front part of the left motor rail.

Figure 2.5: Motor Rails and Equipment

The motor rails and the related elements

consist of:

(1) Propellers, mounted directly on the

motors

(2) Brushless motors, mounted directly

onto the motor mounts

(3) Motor mount

(4) Carbon fiber tube

(5) Connector between carbon cross and

motor rails

(6) Landing foot (front left shown): the

video link antenna (or data link

antenna as applicable) is integrated

(see “The Intel® Falcon™ 8+ UAV

Components” on page 18).

Each motor rail consists of four motor

controllers seated within the carbon tube.

CAUTION: HAZARDOUS MOVING PARTS, KEEP FINGERS AND OTHER

BODY PARTS AWAY.

The motor rails are connected by a carbon cross which consists of four carbon tubes

connected by a center cross piece.

The antenna cabling is found inside the tubes of the carbon cross.

© 2017 Intel Corporation. All rights reserved 22

Page 23

USER MANUAL

1

2

3

4

5

6

3

1

2

4

INTEL® FALCON™ 8+ UAS

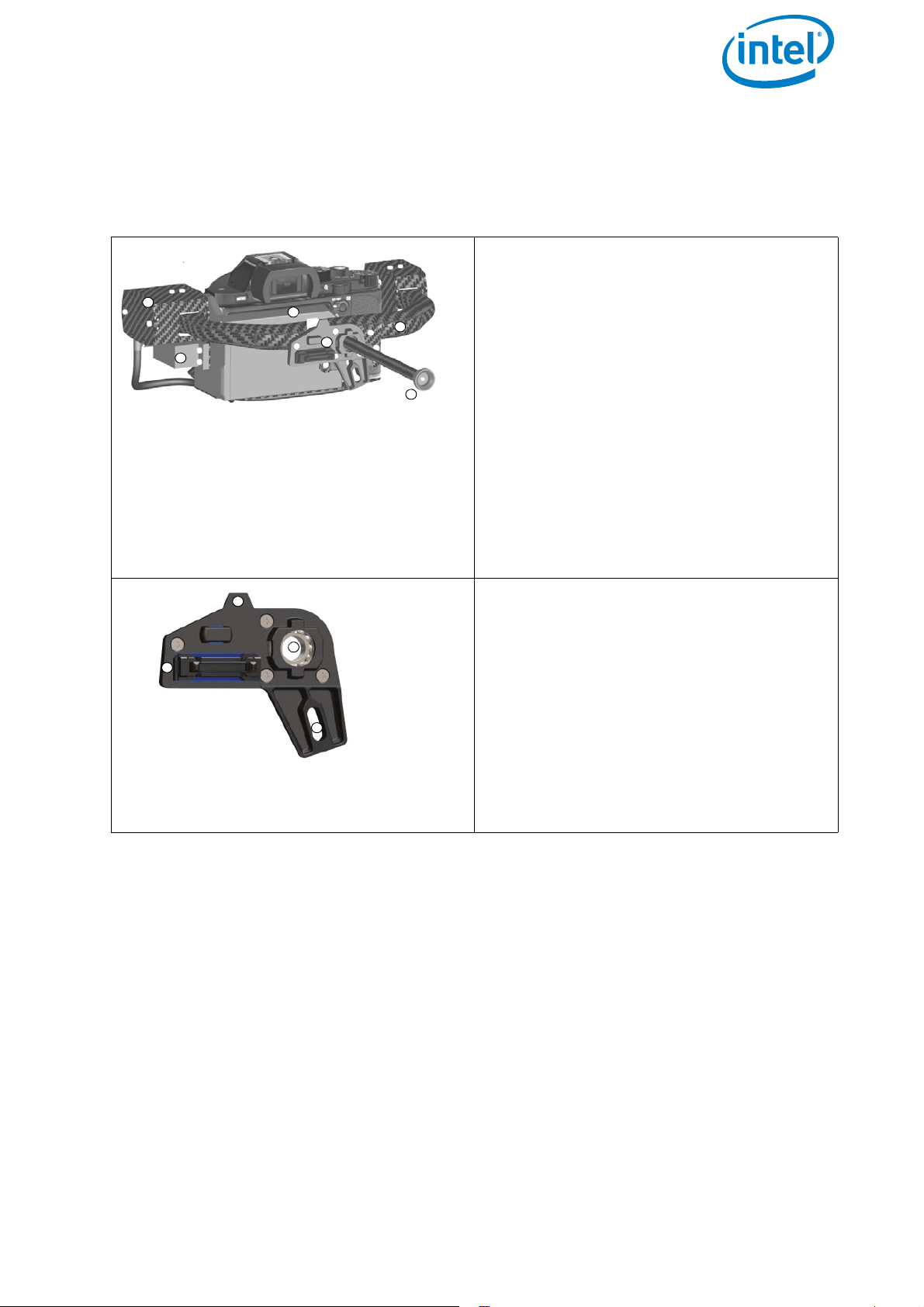

2.1.3. Actively Stabilized Camera Mount (Gimbal)

The following figure describes the parts (or sub-assemblies) of the gimbal.

Figure 2.6: Units of the Gimbal

The actively stabilized camera mount

consists of:

(1) Circuitry for controlling the camera

(2) Payload (e. g. Sony Alpha 7R)

(3) Pitch servo

(4) Carbon fiber structure

(5) Knurled securing nut for the actively

stabilized camera mount

(6) Payload adapter (see below for

details). The payload adapter is the

connection between the camera

mount and the central unit of the

UAV. It is movable when mounted on

the rod of the camera mount and

connected by a cable.

The payload adapter (backside)

(1) Connector plug, should be connected

to the equivalent at the front side of

the UAV (see no. (2) in “Central Unit

Front View without Gimbal (Camera

Mount)” on page 21).

(2) Adapter slot for the ball link

connector of the roll servo

(3) Releasing clip

(4) Hole for the camera mount’s carbon

rod

2.2. THE INTEL® COCKPIT CONTROLLER (CTR)

The CTR is the main control hub for the Intel® Falcon™ 8+ UAV and the attached

payloads/ cameras. It is designed to be carried and operated by one person and

displays all relevant flight information.

The communication between the CTR and the Intel® Falcon™ 8+ UAV is ensured by two

independent 2.4 GHz digital data links. The preview video is transmitted digitally on 5.8

GHz. The CTR uses the same battery type as the Intel® Falcon™ 8+ UAV. The battery is in

© 2017 Intel Corporation. All rights reserved 23

Page 24

USER MANUAL

1

2

3

1

2

3

INTEL® FALCON™ 8+ UAS

the battery compartment which can be accessed from the bottom of the CTR (see

“Preparing the CTR” on page 70).

The CTR serves as an interface device to the flight system. It is pre-programmed and

ready to use.

The Status Display is used for communication between the CTR and the Intel® Falcon™

8+ UAV.

The touchscreen tablet displays the live video preview from the attached camera.

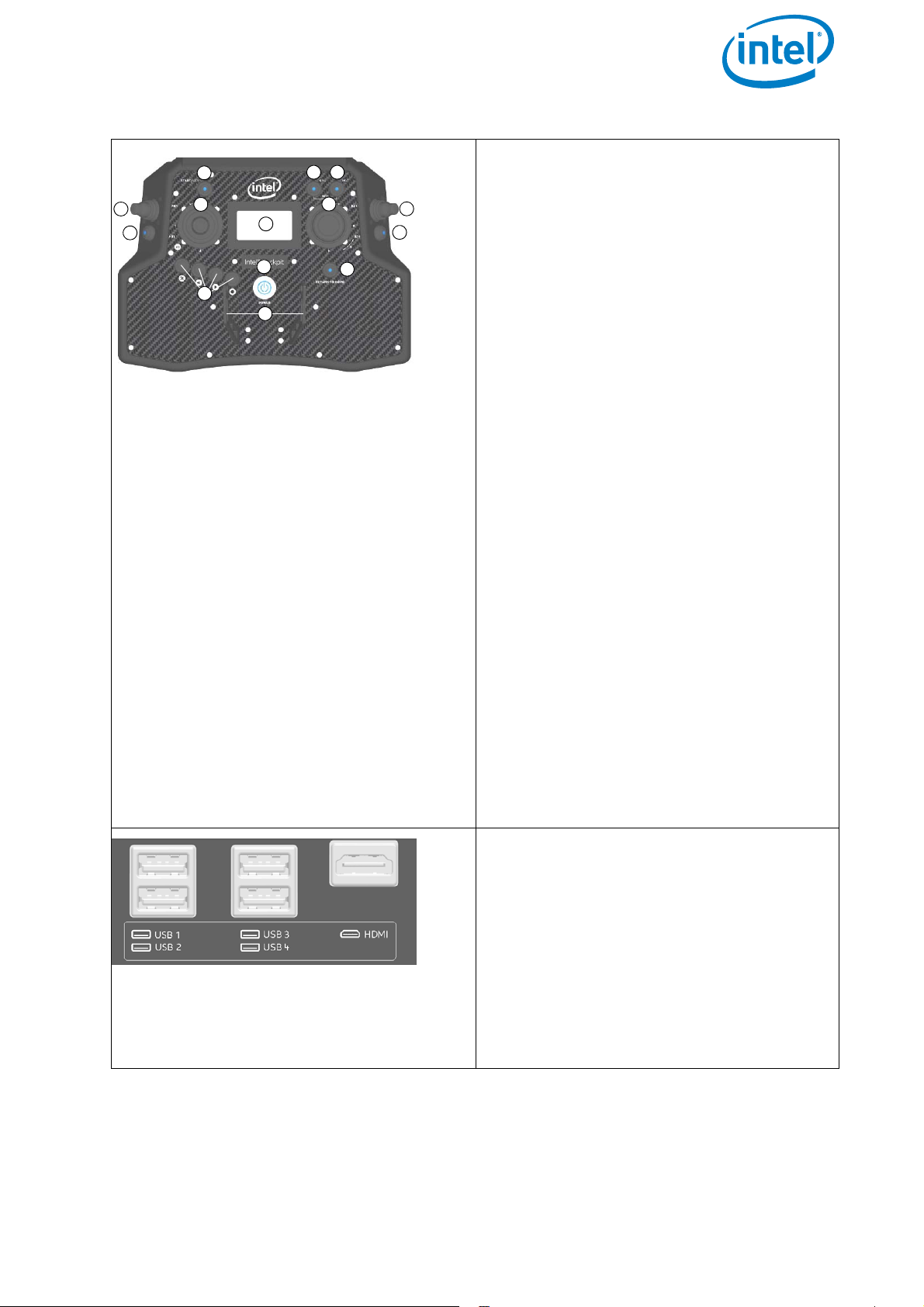

Figure 2.7: Intel® Cockpit Controller (CTR) Overview

Front view, with unfolded antenna panel.

The CTR can be divided into (from bot-

tom to top):

(1) Remote control unit

(2) Touchscreen tablet (for preview video

and more, see “THE TOUCHSCREEN

TABLET” on page 72), displayed

without sun shade

(3) Antenna panel (unfolded). All

communication between CTR and the

Intel® Falcon™ 8+ UAV is sent and

received by the antenna panel. It

features 2.4 GHz antennas for all

control and telemetry communication

and 5.8 GHz antennas to receive the

preview video.

Overview, side view right side.

(1) Remote control unit

(2) Touchscreen tablet, displayed

without sun shade

(3) Antenna panel (unfolded)

To avoid reflections, there is a sun shield

permanently attached to the touchscreen tablet. It folds away for storage

and transport.

© 2017 Intel Corporation. All rights reserved 24

Page 25

USER MANUAL

1

2 3

4

4

5

5

6

7

7

8

9

10

11

INTEL® FALCON™ 8+ UAS

Figure 2.7: Intel® Cockpit Controller (CTR) Overview (Continued)

The functional elements of the CTR

remote control unit are:

(1) START/STOP button: starts/stops the

motors when the left stick is

simultaneously held down (see

“STARTING AND STOPPING THE

MOTORS” on page 101).

(2) GPS button: GPS-Mode ON

(3) HGT button: Height-Mode ON. When

both buttons are switched ON/lit

Manual-Mode is activated

(4) Left rocker switch (R1) controls the

camera pitch angle, right rocker

switch (R2), controls different camera

functions depending on the attached

payload

(5) Left and right control sticks

(6) Status Display (see “STATUS

DISPLAY” on page 138).

(7) Left push button (B1) sets the camera

to predefined angles +/- 90°, +/- 45°

and 0° when the left rocker switch R1

(4) is pushed simultaneously, right

push button (B2) controls different

camera functions depending on the

attached payload

(8) Four function buttons for the Status

Display

(9) RETURN TO HOME button

(10)POWER button

(11)Integrated shoulder harness holders

There are different connectors on the

back of the CTR:

4 X USB

1 X HDMI

The USB port labeled USB 1 can only be

used to perform firmware updates from a

USB stick. The other USB ports can be

used to connect the Independent Camera Control (ICC) or USB sticks with preplanned flight missions.

© 2017 Intel Corporation. All rights reserved 25

Page 26

USER MANUAL

2

1

INTEL® FALCON™ 8+ UAS

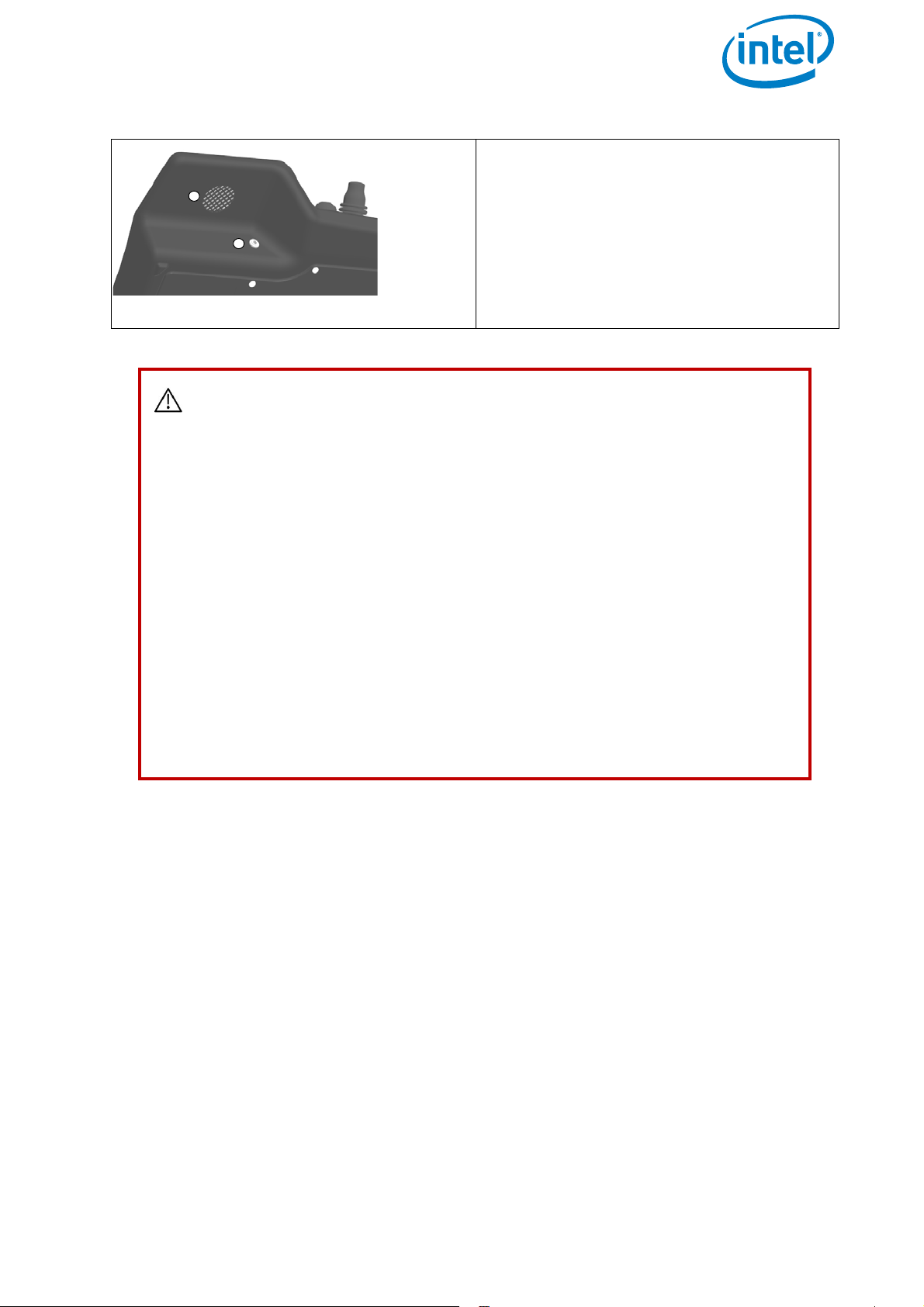

Figure 2.7: Intel® Cockpit Controller (CTR) Overview (Continued)

A headphone port (mini jack) is located

on the lower right-hand side of the CTR

remote control unit (1). It is possible to

connect headphones, which might be

helpful under noisy conditions.

Without headphones connected, acoustic warnings are played back through a

small loudspeaker (2) inside the CTR.

CAUTION: RISK OF PERMANENT HEARING LOSS FROM USING

EARPHONES OR HEADPHONES WITH THIS PRODUCT AT HIGH

VOLUME.

BEFORE PLACING HEADPHONES OR EARPHONES NEAR THE EAR, 1)

FIND A QUIET ENVIRONMENT, 2) TURN THE VOLUME DOWN ON

THIS PRODUCT TO THE MINIMUM SETTING, 3) CONNECT THE

EARPHONE OR HEADPHONE TO THE PRODUCT, 4) PLACE THE

EARPHONE OR HEADPHONE NEAR OR ON THE EAR AND 5) SLOWLY

INCREASE THE VOLUME ON THE PRODUCT TO A COMFORTABLE

LEVEL. AVOID INCREASING THE VOLUME ABOVE THIS LEVEL.

INCREASING THE VOLUME TO BE LOUDER THAN A NOISY

ENVIRONMENT, SUCH AS A CITY STREET, MAY EXCEED SAFE

LISTENING LEVELS. IF YOU EXPERIENCE DISCOMFORT OR BUZZING

IN YOUR EARS, REDUCE THE VOLUME OR DISCONTINUE USE OF

YOUR EARPHONES OR HEADPHONES.

RISK OF PERMANENT HEARING LOSS FROM USING THE

LOUDSPEAKER IN CLOSE PROXIMITY TO THE EAR.

© 2017 Intel Corporation. All rights reserved 26

Page 27

USER MANUAL

INTEL® FALCON™ 8+ UAS

2.2.1. The Status Display

The Status Display shows all relevant information for flying. It is built into the CTR

remote control unit. For further information about the handling of the Status Display

see “STATUS DISPLAY” on page 138).

Figure 2.8: Status Display

Via the Status Display you can view the

current settings and adjust specific functions of the UAV. In order to do so, use

the four buttons under the lower left corner of the Status Display.

Escape (left side) is used to leave

menus / sub-menus and to clear

functions. In the following text, it is

displayed as ESC.

With the arrow LEFT button (middle,

left side)

and the arrow RIGHT button (middle,

right side) you can scroll through

menus or alter parameters.

Enter (right side) is used to enter

menus and activate functions. In the

following text, it is displayed as ENT.

2.2.2. The Touchscreen Tablet

The Intel® based Windows® touchscreen tablet has an 8.3-inch screen with a resolution

of 1920 X 1200 pixels. It is directly mounted on the remote control unit of the Intel®

Cockpit Controller (CTR) and cannot be removed.

The tablet is powered by the battery of the CTR and must be switched ON before the

CTR is powered ON.

The touchscreen tablet serves as a video monitor, displays flight information and gives

access to extended functionality (see “THE TOUCHSCREEN TABLET” on page 72).

© 2017 Intel Corporation. All rights reserved 27

Page 28

USER MANUAL

1

INTEL® FALCON™ 8+ UAS

Figure 2.9: The Touchscreen Tablet

Power button on the top edge, right side

(1)

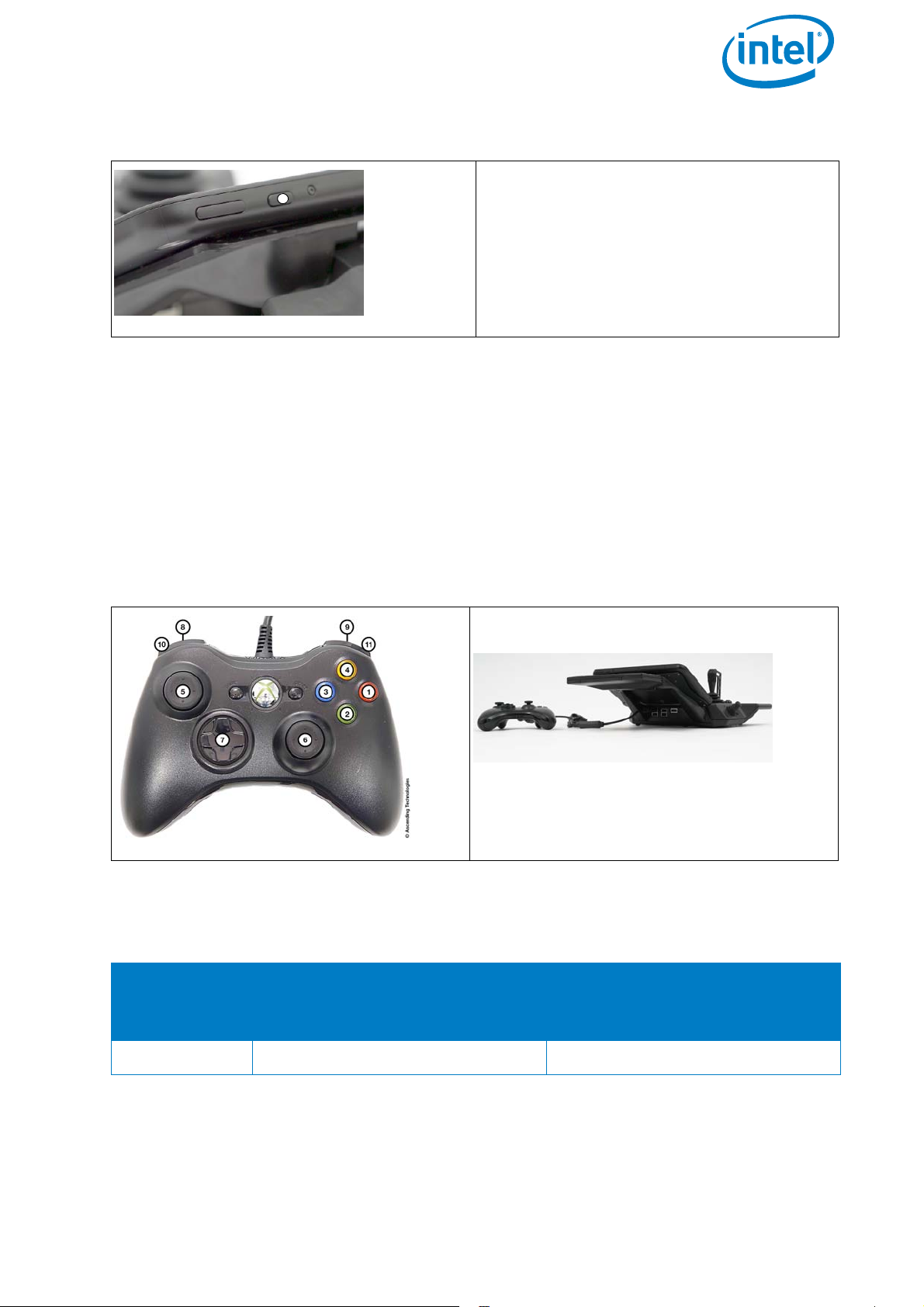

2.3. THE INDEPENDENT CAMERA CONTROL (ICC)

The Independent Camera Control (ICC) is an optional part of the Inspection Package

(see “SOFTWARE FEATURE PACKAGES” on page 61). Thanks to the ICC, a camera

operator can control the main camera functions from a gamepad, which is connected

to the CTR via a USB port (USB port 2 – 4). The USB ports are in the back of the CTR in

the upper left corner (see “Intel® Cockpit Controller (CTR) Overview” on page 24).

Figure 2.10: Independent Camera Control (ICC)

The following table presents an overview of the function assignment:

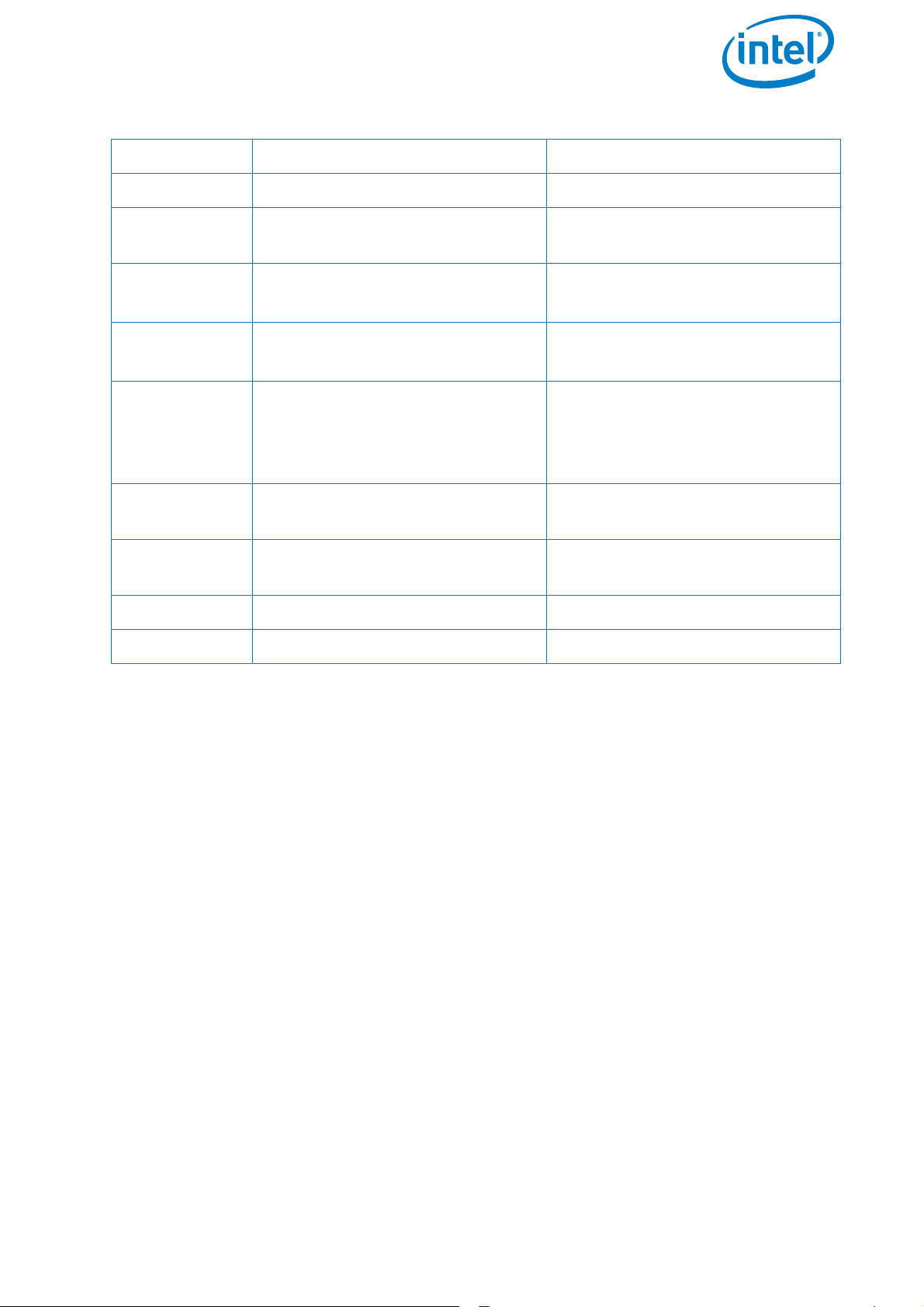

Table 2.1: Operating a Camera By ICC

BUTTON

REFERENCED

ON ICC

SONY ALPHA 7R INSPECTION-PAYLOAD TZ71

CAMERA

(1) Start/Stop video /

© 2017 Intel Corporation. All rights reserved 28

Page 29

USER MANUAL

INTEL® FALCON™ 8+ UAS

Table 2.1: Operating a Camera By ICC (Continued)

(2) Trigger photo Trigger photo (both cameras)

(3) View last image /

(4) /

(5)

(6)

(7)

(8) Shutter speed -

(9) Shutter speed +

(10) Camera tilt velocity - Camera tilt velocity -

(11) Camera tilt velocity + Camera tilt velocity +

Camera tilt (up/down)

Yaw (left/right)

Camera tilt (up/down)

Yaw (left /right)

Horizontal tilt (adjust camera

horizon) (left/right)

Exposure compensation +/- (up/

down)

Change color palette (when FLIR

is active)

Camera tilt (up/down)

Yaw (left/right)

Camera tilt (up/down)

Yaw (left/right)

Horizontal tilt (adjust camera

horizon) (left/right)

Switch camera (up/down)

Zoom - (when RGB camera is

active)

Zoom + (when RGB camera is

active)

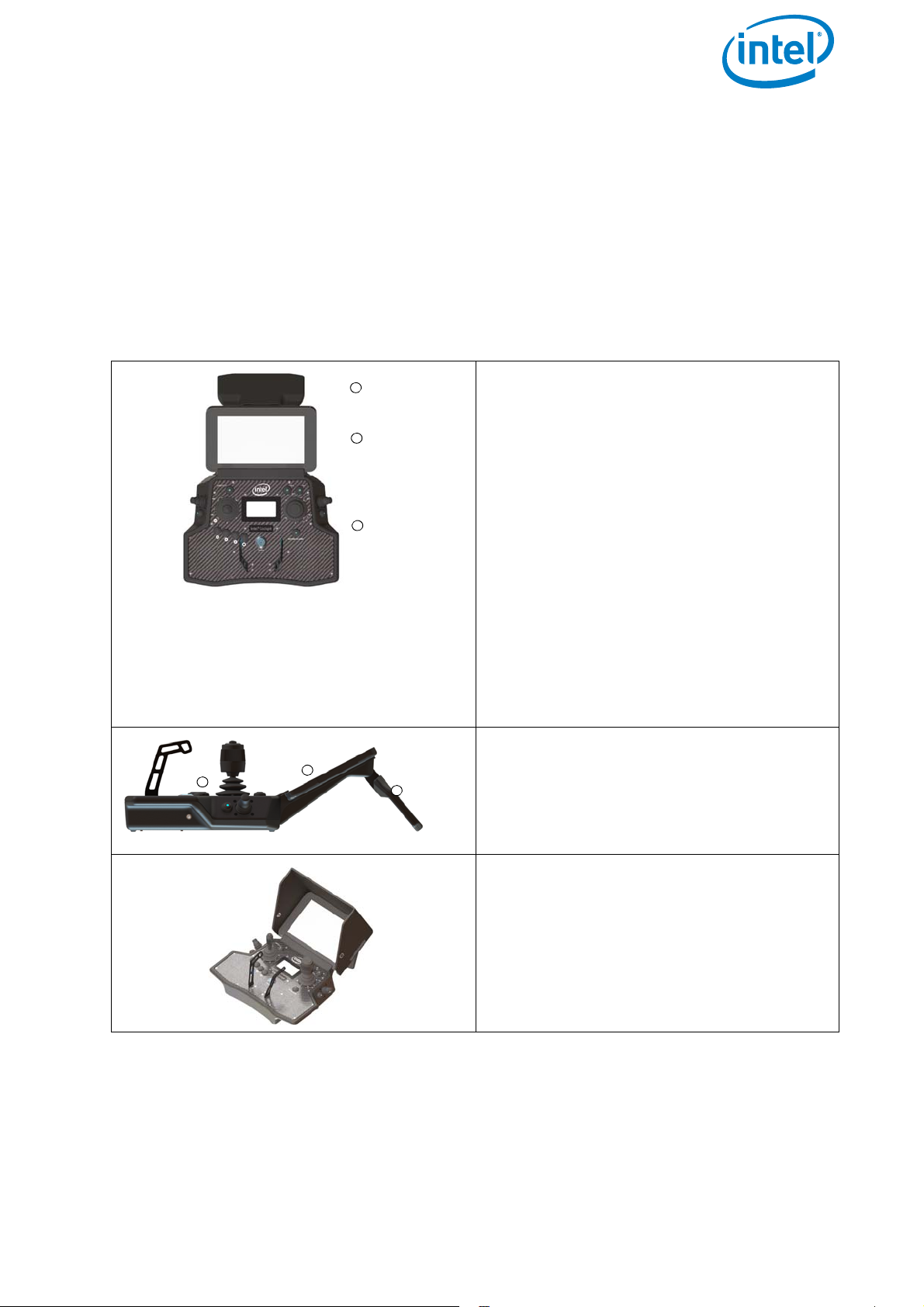

2.4. THE 2ND OPERATOR MONITOR

The 2nd operator monitor is an optional part of the UAS and can be delivered as an

additional accessory.

It can be used as a video preview monitor for the 2nd pilot, especially when used with

the ICC (see “THE INDEPENDENT CAMERA CONTROL (ICC)” on page 28). There is no

further (flight) information shown on this monitor.

Thanks to the 2nd monitor, a camera operator can control the video preview of the

camera used. It is connected to the CTR via the HDMI port by a cable. The HDMI port is

in the back of the CTR in the upper left corner (see “Intel® Cockpit Controller (CTR)

Overview” on page 24).

© 2017 Intel Corporation. All rights reserved 29

Page 30

USER MANUAL

1

2

3

4

5

6

7

8

INTEL® FALCON™ 8+ UAS

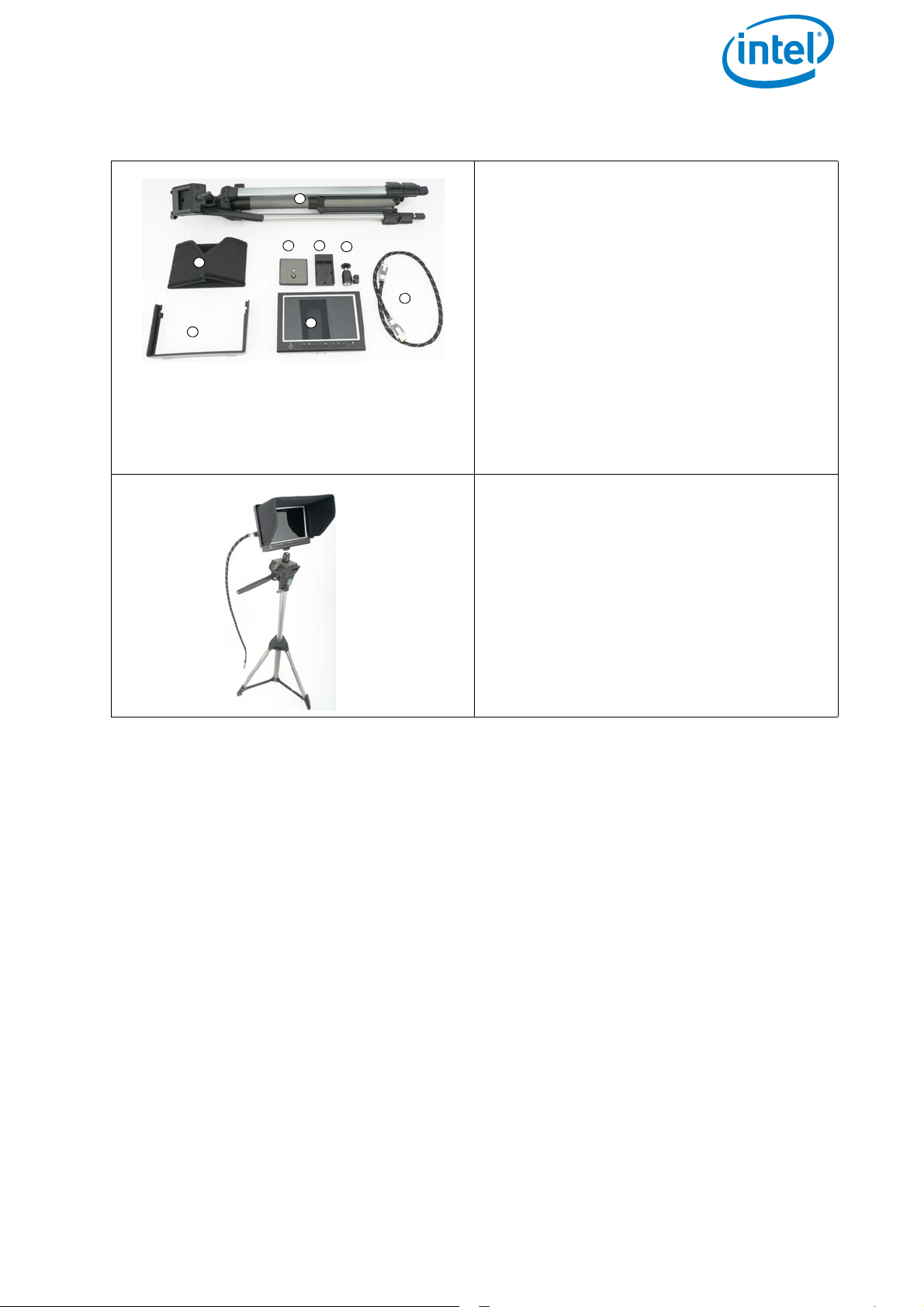

Figure 2.11: 2nd Operator Monitor Package

The elements of the 2nd operator monitor package are:

(1) Tripod

(2) Sunshield

(3) Adapter plate for tripod

(4) Battery adapter

(5) Monitor adapter

(6) Frame for sunshield

(7) Monitor

(8) HDMI cable

Not shown:

• Battery

•Charger

The 2nd operator monitor fully assembled.

2.5. PAYLOADS - CAMERA OPTIONS

Because of the deep integration of cameras, it is possible to change settings like

aperture, shutter speed or zoom (depending on the camera) directly from the Intel®

Cockpit Controller (CTR), while the system is airborne. To ensure complete integration

into the Intel® Falcon™ 8+ UAV, every payload must undergo mechanical and electrical

modifications. Therefore, only payloads approved by Intel are allowed. Payloads which

have not been integrated might affect the compass calibration due to magnetic

emissions by the camera and could have detrimental effects on the flight performance.

If you require assistance with determining which payload to choose for your

application, please contact our support team: support@intel.com.

© 2017 Intel Corporation. All rights reserved 30

Page 31

USER MANUAL

1

2

3

4

5

6

7

8

INTEL® FALCON™ 8+ UAS

Figure 2.12: Camera Control Via the Intel® Cockpit Controller (CTR)

All cameras integrated on the Intel® Falcon™ 8+ UAV can be controlled via the

CTR. Several switches on the CTR are

assigned to camera controls.

(1) Push Button B1: sets the camera to

predefined angles +/- 90°, +/- 45°

and 0° when R1 (4) is pushed

simultaneously (see below for details)

(2) Push Button B2: changes the function

depending on the connected payload

(3) Push Button B3: trigger button on top

of the left control stick (S1)

(4) Rocker Switch R1: camera tilt

(5) Rocker-Switch R2: changes its

function depending on the camera

used

(6) Control Stick S2: turning the right

control stick (S2) controls the yaw

axis of the UAV.

(7) Status Display and related control

buttons

(8) ESC, LEFT, RIGHT, ENT: depending

on the payload, additional options

can be accessed via the Status

Display. Pushing ENT and selecting

Camera Options opens the respective

menu (see “Status Display” on

page 27 and see “STATUS DISPLAY”

on page 138).

For exact details regarding accessible

functions see the individual payload

descriptions.

© 2017 Intel Corporation. All rights reserved 31

Page 32

USER MANUAL

INTEL® FALCON™ 8+ UAS

Figure 2.12: Camera Control Via the Intel® Cockpit Controller (CTR) (Continued)

Setting the Camera Angle

The Main Screen of the Status Display shows the camera angle. 0° means the camera

is looking straight forward and is leveled horizontally. -90° means the camera is

looking down, 90° means it is looking up.

Push the Rocker-Switch R1 away from you to tilt the camera downwards. Pull the

Rocker-Switch R1 towards you to tilt the camera upwards. The further R1 is pulled or

pushed the quicker the tilt movement.

When the camera is not at 0°, a single push of button B1 will set it back to 0°. When

the camera is at 0°, pushing and holding B1 and simultaneously pushing R1 shortly,

will set the camera to -45°, another short push of R1 while holding B1 will set it to 90°. When pulling R1 while holding B1 the camera can be tilted upwards accordingly

in 45° increments.

2.5.1. Changing a Payload (Camera)

Cameras are designed to remain within their gimbal (camera mount). The complete

gimbal with camera can be exchanged without tools. The Intel® Falcon™ 8+ UAV

automatically identifies the attached camera and the menus of the Status Display on

the CTR are changed accordingly.

© 2017 Intel Corporation. All rights reserved 32

Page 33

USER MANUAL

1

2

3

4

2

1

3

INTEL® FALCON™ 8+ UAS

Figure 2.13: Installing the Camera Mount

To install the camera mount:

1. Feed the camera mount carbon rod

into the front side of the central unit

(1). The Thumbscrew (2) is not

attached at this time. Make sure the

carbon rod is not at an angle when it

is inserted.

2. Fix the payload adapter (3).

Take care that the connector plug of

the adapter fits to the equivalent at

the front side of the UAV. See detail

#1 below.

3. On the roll servo, make sure the ball

link connector ball is fixed in the

respective slot in the adapter when

you fix the camera mount onto the

UAV. See detail # 2 below.

4. Press the releasing clip of the payload

adapter into the respective

counterpart opening at the front side

of the UAV. See detail # 3 below.

5. Install the thumbscrew nut (2) on the

back side of the central unit (Finger

tight. See detail # 4 below.

The payload adapter is the connection

between the camera mount and the central unit of the UAV. The payload adapter

is movable when mounted on the rod of

the camera mount and is connected by a

cable.

(1) Connector plug

(2) Adapter slot for the roll servo with

ball link connector inserted

(3) Releasing clip

(4) Knurled securing nut of the actively

stabilized camera mount

© 2017 Intel Corporation. All rights reserved 33

Page 34

USER MANUAL

1

2

INTEL® FALCON™ 8+ UAS

Figure 2.14: Removing the Camera Mount

To remove the camera mount:

1. Remove the knurled securing nut (1)

of the camera mount at the back side

of the central unit.

2. Carefully disconnect the payload

adapter with pressure against the

release clip of the adapter (2).

3. Disconnect the ball of the ball link

connector of the roll servo out of the

adapter slot.

4. Pull out the camera mount gently.

Make sure it comes out straight (not

at an angle)

2.5.2. Payload and Compass Calibration

CAUTION: WHEN INSTALLING A NEW PAYLOAD ONTO AN INTEL®

FALCON™ 8+ UAV, IT IS NECESSARY TO PERFORM A PAYLOAD

CALIBRATION AND A COMPASS CALIBRATION (STRICTLY IN THAT

ORDER).

THE INTEL® FALCON™ 8+ UAV WILL SAVE THE CALIBRATIONS FOR

THAT EXACT PAYLOAD AND REMEMBER IT THE NEXT TIME THE

PAYLOAD IS USED.

IF YOU FAIL TO CALIBRATE, THE SYSTEM WILL USE DEFAULT

PARAMETERS WHICH WILL LEAD TO DECREASED HEADING

ACCURACIES.

TO PERFORM THE CALIBRATIONS, PLEASE FOLLOW THE STEPS

BELOW.

The payload calibration is stored in the payload itself, and the compass calibration is

stored in the UAV.

© 2017 Intel Corporation. All rights reserved 34

Page 35

USER MANUAL

INTEL® FALCON™ 8+ UAS

2.5.2.1. Payload Calibration

The payload calibration can be done indoors with the motors switched off.

1. Attach the payload you are performing the calibration on.

2. Switch the payload ON, then the Intel® Falcon™ 8+ UAV, then the touchscreen tablet

and the finally the CTR.

3. On the CTR push the ENT button of the Status Display and navigate to Settings >

Payload calib (see “STATUS DISPLAY” on page 138).

4. Make sure the camera can turn freely from the full down position to the full up

position (with the Inspection Payload, you will need to raise the Intel® Falcon™ 8+

UAV to make sure the payload does not hit the ground and cause damage when it

tilts downwards).

5. Push ENT to start the calibration. The camera will first rotate fully downwards and

then progressively move to the fully upwards position. Do not touch the Intel®

Falcon™ 8+ UAV during the process.

6. When the payload does not move anymore, switch off the payload, then the Intel®

Falcon™ 8+ UAV, then the touchscreen tablet and finally, the CTR.

7. Restart the system in the specific sequence (see step #2 above).

CAUTION: IT IS IMPORTANT TO RESTART THE SYSTEM

IMMEDIATELY AFTER EACH CALIBRATION. THE NEW CALIBRATION

PARAMETERS WILL ONLY BECOME ACTIVE AFTER RESTARTING THE

SYSTEM.

8. Repeat the above steps for each new payload to be used with the Intel® Falcon™ 8+

UAV. Once a payload has been calibrated, the Intel® Falcon™ 8+ UAV will recall the

settings.

2.5.2.2. Compass Calibration

The compass calibration needs to be done outdoor in flight.

1. Attach the payload you are performing the calibration on.

2. Take the Intel® Falcon™ 8+ UAV out to a spot with good GPS reception and no

magnetic disturbances.

3. Switch the payload ON, then the Intel® Falcon™ 8+ UAV, then the touchscreen

tablet, and finally, the CTR; take off.

4. Have the Intel® Falcon™ 8+ UAV hover in GPS mode at about 30 m above ground

level where no magnetic disturbances are to be expected.

5. On the CTR push the ENT button of the Status Display to navigate to

Compass Calib (see “STATUS DISPLAY” on page 138).

Settings >

6. Push ENT to confirm. The Intel® Falcon™ 8+ UAV will make a 400° turn.

© 2017 Intel Corporation. All rights reserved 35

Page 36

USER MANUAL

INTEL® FALCON™ 8+ UAS

7. Once the Intel® Falcon™ 8+ UAV has finished the turn, land, switch off the camera,

then the Intel® Falcon™ 8+ UAV, then the touchscreen tablet, and finally, the CTR.

Restart the complete system in the specific sequence (see step #2 above).

CAUTION: IT IS IMPORTANT TO LAND AND RESTART THE SYSTEM

IMMEDIATELY AFTER EACH CALIBRATION PROCESS. THE NEW

CALIBRATION PARAMETERS WILL ONLY BECOME ACTIVE AFTER

RESTARTING THE SYSTEM.

8. Repeat the above steps for each new payload to be used with the Intel® Falcon™ 8+

UAV. Once a payload has been calibrated, the Intel® Falcon™ 8+ UAV will recall the

settings.

2.5.2.3. Adjusting The Camera Horizon

The zero position of the camera horizon and/or tilt angle might occasionally need

adjustment, as it might change due to temperature variations. The adjustment of the

camera horizon can be done indoors with the motors switched off.

To re-adjust the zero position, follow these steps:

1. Switch the Intel® Falcon™ 8+ UAV and the CTR ON as usual.

2. Select the Link Loss Procedure.

3. Push the left control stick of the CTR fully upwards and hold it.

4. While holding the left control stick fully upwards, use the right control stick to

adjust the camera. It now directly controls the camera angles.

5. When the position is set correctly, release both control sticks. This position will

automatically be saved as the new zero position.

It is also possible to adjust the camera horizon in flight, but not the tilt angle.

To adjust the horizon in flight:

1. Enter the menu of the Status Display by pushing ENT.

2. Navigate to

3. Push ENT.

4. Use the arrow LEFT/RIGHT keys of the Status Display to change the horizon.

5. Push ENT to confirm.

Camera Options > Adjust Horizon.

© 2017 Intel Corporation. All rights reserved 36

Page 37

USER MANUAL

INTEL® FALCON™ 8+ UAS

2.5.3. Sony Alpha 7R Full Frame Camera

The Sony Alpha 7R has two main function dials that can be controlled through the CTR

(see “Camera Control By The CTR” on page 38).

Figure 2.15: Sony Alpha 7R and SD Card Slot

Specifications:

• Sensor size: 35.90 mm x 24.00 mm

• Resolution: 36.4 Mpx (7360 x 4912

pixels)

• Lens: Sonnar® T* FE 35 mm F2.8 ZA

(SEL35F28Z)

• Weight incl. lens and gimbal: ~ 790 g.

• Approximate max. flight time: 16 min

• Suggested applications: Aerial photography, inspection and surveying

Approved lenses:

• Sonnar® T* FE 35 mm F2.8 ZA

(SEL35F28Z)

Please note that all other available full frame

lenses are too heavy and cannot be approved

Images are stored on an SD card, which is

inserted underneath a lid on the right back side

of the camera. To transfer images to the computer, please use an SD card reader which is

connected to the computer.

For further information: https://esupport.sony.com/US/p/modelhome.pl?mdl=ILCE7R&LOC=3#/manalsTab

2.5.3.1. General Care

• Always handle the gimbal with care. If you need to tilt the camera manually

(when not connected or while the Intel® Falcon™ 8+ UAV is switched off), please

do so very cautiously. If too much force is applied, the gear wheels of the servo

motors might break.

• The camera is powered by the Intel® Falcon™ 8+ UAV battery to save weight.

When you switch off the system, switch off the camera first and wait for 10

seconds to allow the camera to fully power down and store all images and

settings. Only then should you switch off the Intel® Falcon™ 8+ UAV. If you switch

© 2017 Intel Corporation. All rights reserved 37

Page 38

USER MANUAL

1

2

3

4

5

6

8

7

INTEL® FALCON™ 8+ UAS

off the Intel® Falcon™ 8+ UAV too early, you will cut the power supply of the

camera and risk losing data.

• Keep the airplane mode of the camera switched on, to avoid radio interference

from the camera (MENU > > Airplane Mode > ON).

2.5.3.2. Camera Control By The CTR

This section describes how the Sony Alpha 7R can be operated by using the functional

elements of the CTR.

Figure 2.16: Sony Alpha 7R CTR Control Layout

Push Button B1 (1): sets the camera to

predefined angles +/-90°, +/-45° and 0°

when Rocker Switch R1 (4) is pushed

Push Button B2 (2): changes the function

depending on the connected payload

Push Button B3 (3): trigger button

Rocker Switch R1 (4): camera tilt; Dial 1

or Dial 2, depending on B2

Rocker Switch R2 (5): camera tilt; Dial 1

or Dial 2, depending on B2

Control Stick S2 (6): turning the right

control stick (S2) controls the yaw axis of

the UAV

Status Display (7): see “Camera Options

By The Status Display” on page 39

ESC, LEFT, RIGHT, ENT (8): Status Display control buttons (see “Status Display” on page 27).

© 2017 Intel Corporation. All rights reserved 38

Page 39

USER MANUAL

INTEL® FALCON™ 8+ UAS

Figure 2.16: Sony Alpha 7R CTR Control Layout (Continued)

The Sony Alpha 7R has two main function dials that can be controlled by the

CTR.

The function of Dial 1 on the Sony A7R

can be controlled by R2, when B2 is in

position 1 (LED off). The function of Dial

2 can be controlled by R2, when B2 is in

position 2 (LED on/blue) or via the Status

Display by pushing ENT > Camera

Options > Dial 2

The default functions of Dial 1 and 2

depend on the selected shooting mode

on the camera. The table below shows

the dependencies.

2.5.3.3. Camera Options By The Status Display

.

Table 2.1: Sony Alpha 7R Camera Control By Camera Functions

B2

POSITION

1 (LED off) Dial 1 Shutter speed Aperture Aperture

2 (LED on/

blue)

Push the ENT button of the Status Display to enter the menu. Navigate to Camera

Options

Table 2.2: Sony Alpha 7R Camera Control By Status Display

. The following options are available for the Sony Alpha 7R.

THE FOLLOWING OPTIONS ARE AVAILABLE FOR THE SONY ALPHA 7R.

Dial 2

Record/Stop

R2

FUNCTION

Starts and stops a video recording

CAMERA SET

TO

S MODE

(SHUTTER

PRIORITY)

Exposure compensation

CAMERA SET

TO

A MODE

(APERTURE

PRIORITY)

Exposure

compensation

CAMERA SET TO

M MODE

(MANUAL)

Shutter speed

Dial 2

Review

© 2017 Intel Corporation. All rights reserved 39

See previous table for details.

Reviews images already stored on the SD card of the camera.

Use Rocker Switch R2 (no. 5 in figure above) to navigate.

Page 40

USER MANUAL

INTEL® FALCON™ 8+ UAS

Table 2.2: Sony Alpha 7R Camera Control By Status Display (Continued)

THE FOLLOWING OPTIONS ARE AVAILABLE FOR THE SONY ALPHA 7R.

Occasionally the neutral position of the Gimbal's Servo Motors

might need to be re-adjusted. Use this command to adjust the

Adjust

Horizon

Roll Comp.

On/Off

2.5.3.4. Camera Settings

The following section describes the most important settings of the camera when used

with the Intel® Falcon™ 8+ UAV.

horizon (roll angle) while flying. If the system is still on the

ground and the motors are not running this can also be done in

both axes (roll and tilt) with the control sticks. see “Adjusting The

Camera Horizon” on page 36.

Default = ON.

When Roll Comp. = Off the gimbal will no longer compensate

roll movements of the Intel® Falcon™ 8+ UAV.

This can be useful when doing dynamic video flights.

Figure 2.17: Camera Settings By Camera Sony Alpha 7R

The most important settings can be

quickly accessed via the buttons:

(1) Fn: see below

(2) MENU: see below

(3) C2: provides quick access to the

Focus Mode

(4) WB: provides quick access to White

Balance.

ISO can be quickly accessed by turning

the control wheel in the back of the camera.

© 2017 Intel Corporation. All rights reserved 40

Page 41

USER MANUAL

INTEL® FALCON™ 8+ UAS

Figure 2.17: Camera Settings By Camera Sony Alpha 7R (Continued)

After pushing the Fn button (number (1)

above) by default the following parameters can be accessed:

Top row:

Drive Mode / Flash Mode / Flash Comp. /

Focus Mode / Focus Area / Exposure

Comp.

Bottom row:

ISO / Metering Mode / White Balance /

DRO/Auto HDR / Creative Style / Shoot

Mode

The camera menu can be accessed by

pushing the MENU button (number (2)

above). On the first page of the menu, the

Image Size and Quality can be set. Refer

to the camera manual for further details.

2.5.4. Inspection Payload

The Inspection Payload consists of two cameras: Panasonic RGB camera and infrared

(IR) camera FLIR TAU 2 640.

• Weight of the complete payload including gimbal: 550 g

• Approximate maximum flight time: approximately 18 minutes

© 2017 Intel Corporation. All rights reserved 41

Page 42

USER MANUAL

INTEL® FALCON™ 8+ UAS

.

Figure 2.18: Inspection Payload

Specifications of the Panasonic RGB camera:

• Sensor size: CMOS Sensor 1/2.3”, 6.2 x

4.6 mm

• Resolution: 12.1 Mpx (4000 x 3000 pixel)

• Lens: LEICA DC VARIO-ELMAR F3,3 - 6,4

/ Multistage Iris Diaphragma (F3,3 - 8,0

(W), F6,4 - 8,0 (T))

• Focal length: 4.3 - 129 mm (24 - 720 mm,

35 mm equiv.)

• Optical zoom: 30x

• Suggested applications: Inspection

Specifications of the IR camera FLIR Tau 2 640:

• Thermal Imager: Uncooled VOx

Microbolometer

• Resolution: 640 × 512 pixel

• Pixel pitch: 17 μm

• Spectral band: 7.5 - 13.5 μm

• Focal length: 19 mm (~ 59 mm, 35 mm

eqiv.)

Further details: http://www.flir.com/cores/display/?id=54717

The Panasonic camera needs its own fully

charged battery to work. The battery slot can be

accessed from the bottom of the payload.

The SD card of the camera is inserted next to

the battery.

A separate charger for the Panasonic batteries

is supplied with the payload.

© 2017 Intel Corporation. All rights reserved 42

Page 43

USER MANUAL

INTEL® FALCON™ 8+ UAS

Figure 2.18: Inspection Payload (Continued)

The FLIR Tau 2 640 camera is powered by the

Intel® Falcon™ 8+ UAV battery to save weight,

and does not need to be switched ON or OFF.

The micro SD card of the FLIR Tau is inserted at

the side of the camera, with the contacts of the

micro SD facing towards the camera lens.

Each time the Intel® Falcon™ 8+ UAV is switched

on, a new, subsequently numbered sub-folder

(FLIR0000, FLIR0001, FLIR0002...) is created on

the micro SD card. Up to 128 image files are

stored in one folder. If more than 128 images

are taken during one flight, a new sub-folder

will be created where the additional images are

stored. Before the camera can be used, the

black cap must be removed from the lens.

The images are stored in a proprietary file format .ARA. The 14-bit RAW output from the

camera is captured, which allows the displayed

temperature range to be set during post processing. Using Thermal Editor (part of AscTec

Navigator), the RAW images can be displayed

and converted into a FLIR Tools-compatible

Radiometric JPEG file.

AscTec Navigator Software can be downloaded

from the download area: http://intel.com/FalconDownloads

A detailed manual of the software is available

here: http://intel.com/FalconManual

When an Inspection Payload is attached, the

number 999 will appear underneath the flight

mode icon of the menu on the Status Display.

This number signifies the number of images

which can be stored onto the Micro SD card of

the FLIR Tau 2 640. The maximum number that

can be displayed on the screen is 999, however,

the actual number of images the SD card can

store is higher than 999. Therefore, the displayed number will not count down until the SD

Card has a capacity of less then 999 images.

© 2017 Intel Corporation. All rights reserved 43

Page 44

USER MANUAL

INTEL® FALCON™ 8+ UAS

Figure 2.18: Inspection Payload (Continued)

When the FLIR Tau 2 640 IR Raw Data Logger

cannot access the SD card, an error message

ERR will be displayed instead of the number of

remaining images.

In case this happens, please take out the SD

card and troubleshoot.

If after reinserting, if the error message remains,

reformat the SD card.

Format settings are:

• File system: FAT32

• Allocation unit size: 64 kilobytes

• Volume label: FLIRSD

The FLIR and the Panasonic RGB camera can record video. When a video

actively recording on the Panasonic RGB camera, the camera will not output any

Note

preview video. This means that the preview video on the touchscreen tablet of

the CTR must be switched to show the FLIR image (see “Inspection Payload

Control By The CTR” on page 44).