Page 1

User’s Manual

ECB-865

Intel 815E Tualatin Pentium III / Celeron Full-size CPU Card

1st Ed. – 7 February 2002

Part No.2047865000

Page 2

ECB-865

FCC STATEMENT

THIS DEVICE COMPLIES WITH PART 15 FCC RULES. OPERATION IS SUBJECT TO

THE FOLLOWING TWO CONDITIONS:

(1) THIS DEVICE MAY NOT CAUSE HARMFUL INTERFERENCE.

(2) THIS DEVICE MUST ACCEPT ANY INTERFERENCE

RECEIVED INCLUDING INTERFERENCE THAT MAY CAUSE UNDESIRED

OPERATION.

THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS

FOR A CLASS "A" DIGITAL DEVICE, PURSUANT TO PART 15 OF THE FCC RULES.

THESE LIMITS ARE DESIGNED TO PROVIDE REASONABLE PROTECTION

AGAINTST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A

COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES, AND CAN

RADIATE RADIO FREQUENCY ENERGY AND, IF NOT INSTATLLED AND USED IN

ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL

INTERFERENCE TO RADIO COMMUNICATIONS.

OPERATION OF THIS EQUIPMENT IN A RESIDENTIAL AREA IS LIKELY TO CAUSE

HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO

CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

Evalue Technology Inc.

Page 3

User’s Manual

Copyright Notice

Copyright 2000, 2001, Evalue Technology Inc., ALL RIGHTS RESERVED.

No part of this document may be reproduced, copied, translated, or transmitted in any

form or by any means, electronic or mechanical, for any purpose, without the prior written

permission of the original manufacturer.

Trademark Acknowledgement

Brand and product names are trademarks or registered trademarks of their respective

owners.

Disclaimer

Evalue Technology Inc. reserves the right to make changes, without notice, to any product,

including circuits and/or software described or contained in this manual in order to improve

design and/or performance. Evalue Technology assumes no responsibility or liability for

the use of the described product(s), conveys no license or title under any patent, copyright,

or mask work rights to these products, and makes no representations or warranties that

these products are free from patent, copyright, or mask work right infringement, unless

otherwise specified. Applications that are described in this manual are for illustration

purposes only. Evalue Technology Inc. makes no representation or warranty that such

application will be suitable for the specified use without further testing or modification.

Life Support Policy

Evalue Technology’s PRODUCTS ARE NOT FOR USE AS CRITICAL COMPONENTS IN

LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE PRIOR WRITTEN APPROVAL

OF Evalue Technology Inc.

As used herein:

1. Life support devices or systems are devices or systems which, (a) are intended for

surgical implant into body, or (b) support or sustain life and whose failure to perform,

when properly used in accordance with instructions for use provided in the labelling,

can be reasonably expected to result in significant injury to the user.

2. A critical component is any component of a life support device or system whose failure

to perform can be reasonably expected to cause the failure of the life support device or

system, or to affect its safety or effectiveness.

Evalue Technology Inc.

Page 4

ECB-865

A Message to the Customer

Evalue Customer Services

Each and every Evalue’s product is built to the most exacting specifications to ensure

reliable performance in the harsh and demanding conditions typical of industrial

environments. Whether your new Evalue device is destined for the laboratory or the

factory floor, you can be assured that your product will provide the reliability and ease of

operation for which the name Evalue has come to be known.

Your satisfaction is our primary concern. Here is a guide to Evalue’s customer services.

To ensure you get the full benefit of our services, please follow the instructions below

carefully.

Technical Support

We want you to get the maximum performance from your products. So if you run into

technical difficulties, we are here to help. For the most frequently asked questions, you

can easily find answers in your product documentation. These answers are normally a lot

more detailed than the ones we can give over the phone. So please consult the user’s

manual first.

To receive the latest version of the user’s manual, please visit our Web site at:

http://www.evalue-tech.com/

If you still cannot find the answer, gather all the information or questions that apply to your

problem, and with the product close at hand, call your dealer. Our dealers are well trained

and ready to give you the support you need to get the most from your Evalue’s products.

In fact, most problems reported are minor and are able to be easily solved over the phone.

In addition, free technical support is available from Evalue’s engineers every business day.

We are always ready to give advice on application requirements or specific information on

the installation and operation of any of our products. Please do not hesitate to call or email us.

Headquarters

Evalue Technology Inc.

5F~7, No.130, Chien Kang Road,

Chung Ho City, Taipei,

Taiwan

Tel : +886-2-2228-6111

Fax : +886-2-2228-6228

http://www.evalue-tech.com

E-mail: service@evalue-tech.com

Europe Branch Office

Evalue Europe A/S

Nordre Strandvej 119C,

3150 Hellebaek,

Denmark

Tel : +45-7025-0310

Fax : +45-4975-5026

http://www.evalue-tech.com

E-mail: service.europe@evalue-tech.com

Evalue Technology Inc.

Page 5

User’s Manual

Product Warranty

Evalue warrants to you, the original purchaser, that each of its products will be free from

defects in materials and workmanship for two years from the date of purchase.

This warranty does not apply to any products which have been repaired or altered by

persons other than repair personnel authorized by Evalue, or which have been subject to

misuse, abuse, accident or improper installation. Evalue assumes no liability under the

terms of this warranty as a consequence of such events. Because of Evalue’s high qualitycontrol standards and rigorous testing, most of our customers never need to use our

repair service. If any of Evalue’s products is defective, it will be repaired or replaced at no

charge during the warranty period. For out-of-warranty repairs, you will be billed according

to the cost of replacement materials, service time, and freight. Please consult your dealer

for more details. If you think you have a defective product, follow these steps:

1. Collect all the information about the problem encountered. (For example, CPU type

and speed, Evalue’s products model name, hardware & BIOS revision number, other

hardware and software used, etc.) Note anything abnormal and list any on-screen

messages you get when the problem occurs.

2. Call your dealer and describe the problem. Please have your manual, product, and any

helpful information available.

3. If your product is diagnosed as defective, obtain an RMA (return material authorization)

number from your dealer. This allows us to process your good return more quickly.

4. Carefully pack the defective product, a complete Repair and Replacement Order Card

and a photocopy proof of purchase date (such as your sales receipt) in a shippable

container. A product returned without proof of the purchase date is not eligible for

warranty service.

5. Write the RMA number visibly on the outside of the package and ship it prepaid to your

dealer.

Evalue Technology Inc.

Page 6

ECB-865

Packing List

Before you begin installing your single board, please make sure that the following

materials have been shipped:

1 ECB-865 Full-size Celeron / Pentium III single board

1 Quick Installation Guide

1 CD-ROM contains the followings:

— User’s Manual (this manual in PDF file)

— Ethernet driver and utilities

— VGA drivers and utilities

— Latest BIOS (as of the CD-ROM was made)

Cable set includes the followings:

— 1 IDE HDD cable (40-pin, pitch 2.54mm)

— 1 FDD cable (34-pin, pitch 2.54mm)

— 1 bracket with one Printer port cable (26-pin, pitch 2.54mm) and one Serial port

cable (10-pin, pitch 2.0mm)

— 1 bracket with two Serial port cable (10-pin, pitch 2.54mm)

— 1 5-pin to 5-pin keyboard cable for passive backplane connection

— 1 4-pin ATX power control cable for backplane connection

If any of these items are missing or damaged, please contact your distributor or sales

representative immediately.

Evalue Technology Inc.

Page 7

User’s Manual

1. MANUAL OBJECTIVES.............................................................................................1

2. INTRODUCTION.........................................................................................................2

2.1 System Overview ...................................................................................................2

2.2 System Specifications...........................................................................................3

2.3 Architecture Overview...........................................................................................6

2.3.1 82815 GMCH and 82801BA ........................................................................................7

2.3.2 DRAM Interface ........................................................................................................... 8

2.3.3 Multiplexed AGP and Display Cache Interface.............................................................8

2.3.4 PCI Interface................................................................................................................9

2.3.5 IDE Interface (Bus Master Capability and Synchronous DMA Mode) ...........................9

2.3.6 USB .............................................................................................................................9

2.3.7 Ethernet....................................................................................................................... 9

2.3.8 ITE IT8712F-A ........................................................................................................... 10

2.3.9 M-Systems DiskOnChip............................................................................................. 10

3. HARDWARE CONFIGURATION..............................................................................11

3.1 Installation Procedure .........................................................................................11

3.2 Safety Precautions...............................................................................................11

3.2.1 Warning! .................................................................................................................... 11

3.2.2 Caution! ..................................................................................................................... 11

3.3 Socket 370 Processor..........................................................................................12

3.3.1 Installing Celeron / Pentium III (Coppermine/Tualatin) CPU....................................... 12

3.3.2 Removing CPU ..........................................................................................................12

3.4 Main Memory........................................................................................................12

3.5 M-Systems’ DiskOnChip Flash Disk...................................................................13

3.5.1 Installing DOC............................................................................................................ 13

3.6 Expansion Interface.............................................................................................13

3.7 Installing the Single Board Computer................................................................13

3.7.1 815E integrated Graphics Controller.......................................................................... 14

3.7.2 Intel 82559(or REALTEK RTL8139C) & 82801BA(ICH2) + 82562ET (PHY) Network

Controller 15

3.7.3 Drivers Support.......................................................................................................... 15

3.8 Watchdog Timer Programming...........................................................................16

3.9 Jumper & Connector............................................................................................17

3.9.1 Jumper & Connector Layout ...................................................................................... 17

3.9.2 Jumper & Connector List ...........................................................................................18

Evalue Technology Inc.

Page 8

ECB-865

3.10 Setting Jumpers...................................................................................................20

3.10.1 Clear CMOS (JP9)..................................................................................................... 21

3.10.2 Watchdog Timer ........................................................................................................21

3.10.3 COM2 RS-232/422/485 Select (JP1, JP2~JP5)......................................................... 22

3.10.4 M-Systems DiskOnChip Memory Address Select (JP11)........................................... 23

3.10.5 Proprietary PCI Bus Master Selection (JP13) ............................................................23

3.11 Connector Definitions..........................................................................................24

3.11.1 System Reset Connector (J1).................................................................................... 24

3.11.2 External Speaker Connector (J2)............................................................................... 24

3.11.3 Keyboard Lock & Power Indicator Connector (J3)......................................................24

3.11.4 Primary IDE / Secondary IDE Active Indicator Connector (J4) ...................................24

3.11.5 Primary IDE Connector (J5).......................................................................................25

3.11.6 Secondary IDE Connector (J10) ................................................................................ 26

3.11.7 Signal Description – Primary & Secondary IDE Connector (J5 & J10) ....................... 27

3.11.8 Floppy Connector (J6) ...............................................................................................31

3.11.9 Signal Description – Floppy Connector (J6) ............................................................... 32

3.11.10 ATX Power Button Connector (J8).............................................................................33

3.11.11 Parallel Port Connector (J11)..................................................................................... 33

3.11.12 DB25 Parallel Port Connector (J11)........................................................................... 34

3.11.13 Signal Description – Parallel Port Connector (J11) ....................................................35

3.11.14 Box Header Serial Port 1 / Serial Port 2 Connector in RS-232 (J9, J12).................... 35

3.11.15 Serial Port 1 / Serial Port 2 with External DB9 Connector (J9, J12) ........................... 36

3.11.16 Signal Description – Serial Port 1 / Serial Port 2 in RS-232 Mode (J9, J12)............... 36

3.11.17 Box Header Serial Port 1 / Serial Port 2 Connector in RS-422 (J9, J12).................... 37

3.11.18 Signal Description – Serial Port 1 / Serial Port 2 in RS-422 Mode (J9, J12)............... 37

3.11.19 Box Header Serial Port 1 / Serial Port 2 Connector in RS-485 (J9, J12).................... 37

3.11.20 Signal Description – Serial Port 1 / Serial Port 2 in RS-485 Mode (J9, J12)............... 38

3.11.21 USB Connector (J13, J19) ......................................................................................... 39

3.11.22 Signal Description – USB Connector (J13, J19).........................................................39

3.11.23 CPU Fan and System Fan Connector (J14, J25) .......................................................39

3.11.24 Fast & Standard IrDA Connector (J15) ......................................................................39

3.11.25 Signal Configuration – Fast & Standard IrDA Connector (J15)...................................40

3.11.26 ATX Power Controller (J16) .......................................................................................40

3.11.27 Smart Card Interface (J17) ........................................................................................ 40

3.11.28 10/100 BASE-Tx Ethernet Connector (J18, J20)........................................................ 41

3.11.29 Signal Description – 10/100Base-Tx Ethernet Connector (J18, J20)..........................41

3.11.30 CRT Connector (J22)................................................................................................. 42

3.11.31 Signal Description – CRT Connector (J22) ................................................................ 42

3.11.32 Internal Keyboard Connector (J24) ............................................................................ 43

3.11.33 PS/2 Keyboard Connector (J26) ................................................................................ 43

3.11.34 Signal Description – Int. & PS/2 Keyboard Connector (J24, J26)............................... 43

3.11.35 PS/2 Mouse Connector (J26)..................................................................................... 43

3.11.36 Signal Description – PS/2 Mouse Connector (J26) ....................................................43

3.11.37 Proprietary PCI Connector (J21)................................................................................44

3.11.38 Signal Description – Proprietary PCI Connector (J21) ...............................................45

4. AMI BIOS SETUP.....................................................................................................50

4.1 Entering Setup......................................................................................................50

Evalue Technology Inc.

Page 9

User’s Manual

4.2 AMI BIOS Setup Main Menu ................................................................................51

4.3 CMOS Setup Reference Table.............................................................................52

4.3.1 Standard CMOS Setup Menu.....................................................................................52

4.3.2 Advanced CMOS Setup Defaults............................................................................... 54

4.3.3 Advanced Chipset Setup Defaults..............................................................................57

4.3.4 Power Management Setup Defaults........................................................................... 59

4.3.5 PCI / Plug and Play Setup Defaults............................................................................62

4.3.6 Peripheral Setup Defaults.......................................................................................... 64

4.3.7 Hardware Monitor Setup Defaults ..............................................................................67

4.4 Flash BIOS Utility.................................................................................................68

5. DRIVER INSTALLATION..........................................................................................69

5.1 Driver Installation for Ethernet Adapter.............................................................69

5.1.1 Windows 9x ...............................................................................................................69

5.1.2 Windows NT 4.0 Ethernet Installation ........................................................................ 74

5.2 Driver Installation for Display Adapter...............................................................79

5.2.1 Windows 9x ...............................................................................................................79

5.2.2 Windows NT 4.0 Display Installation.......................................................................... 84

6. MEASUREMENT DRAWING....................................................................................88

APPENDIX A: BIOS REVISIONS......................................................................................89

APPENDIX B: SYSTEM RESOURCES.............................................................................90

Memory Map........................................................................................................................... 90

I/O – Map 91

Interrupt Usage.......................................................................................................................93

DMA-channel Usage...............................................................................................................94

APPENDIX C: AMIBIOS POWER-ON SELF TEST ..........................................................95

APPENDIX D: AMIBIOS POST CHECK POINT LIST.......................................................96

Evalue Technology Inc.

Page 10

ECB-865

Document Amendment History

Revision Date By Comment

1st Feb. 02. Harris Chen Initial Release

Evalue Technology Inc.

Page 11

ECB-865

1. Manual Objectives

This manual describes in detail the Evalue Technology ECB-865 Single Board.

We have tried to include as much information as possible but we have not duplicated

information that is provided in the standard IBM Technical References, unless it proved to

be necessary to aid in the understanding of this board. The manual is sectioned and

includes a User’s Guide that will help the non-technical user to get the unit up and running.

A Troubleshooting Guide is also included to help when things go wrong.

We strongly recommend that you study this manual carefully before attempting to

interface with ECB-865 or change the standard configurations. Whilst all the necessary

information is available in this manual we would recommend that unless you are confident,

you contact your supplier for guidance.

Please be aware that it is possible to create configurations within the CMOS RAM that

make booting impossible. If this should happen, clear the CMOS settings, (see the

description of the Jumper Settings for details).

If you have any suggestions or find any errors concerning this manual and want to inform

us of these, please contact our Customer Service department with the relevant details.

ECB-865 User’s Manual 1

Page 12

User’s Manual

2. Introduction

2.1 System Overview

The ECB-865 is an all-in-one Full-size Pentium III / Celeron Single Board Computer (SBC)

designed with Intel embedded chipset 815E-B which supports the latest Intel FC-PGA/FCPGA2 Pentium III / Celeron processor (CopperMine and Tualatin) up to 1.1GHz or above

and AGP 4X 3D Graphics Accelerator w/ shared display memory of 4MB SDRAM, dual

Intel PCI-bus Fast Ethernet controllers, and M-Systems DiskOnChip socket.

Targeting on the mission critical telecommunication or industrial applications, the ECB-865

comes designed with Intel EMD solutions. These include Intel 815E-B AGPset, 82562ET

PLC and 82559 10/100Base-Tx Fast Ethernet controller. Unlike regular commercial

solutions, Intel EMD solutions provide higher system stability and longer product supply

time (Intel EMD products' typical life cycle is 5 years). The long product life cycle

guarantee is particularly important for systems that are designed to last for many years.

This makes it a perfect solution for not only popular Networking Devices like Firewall,

Gateway, Router, and e-Server, but also CTI (Computer Telephony Integration)

equipments such as PBX, Digital Logger, etc.

Other onboard features include PC133 FSB, Address/Data buffer to enhance the ISA-bus

driving capacity up to 64mA, dual UDMA 100 IDE channels, two 16C550 compatible serial

ports (one RS-232, one RS-232/422/485), one multi-mode parallel port, three 168-pin

DIMM sockets allowing for up to 1.5GB of SDRAM to be installed, and on-board

proprietary PCI interface for optional PCI module expansion. The PCI modules currently

available are Adaptec 7892 Ultra 160 SCSI, and Intel 82559 10/100Base-Tx Ethernet

modules

2 ECB-865 User’s Manual

Page 13

ECB-865

2.2 System Specifications

General Functions

• Bus Interface: PICMG 2.0 Compliant

• ISA Driving Capacity: Built-in Address/Data buffer supports driving capacity up to

64mA

• CPU: Supports Intel FCPGA/FCPGA2 Pentium III / Celeron processor up to 1GHz

or above (with system bus frequencies of 66/100/133MHz)

• CPU Socket: Intel FC Socket 370

• BIOS: AMI 4Mb FWH BIOS

• Chipset: Intel 815E-B AGPset

• I/O Chipset: ITE IT8712F-A

• Memory: Onboard three 168-pin DIMM sockets support up to 1.5Gbytes SDRAM

• Enhanced IDE: Supports up to four IDE devices. Supports Ultra DMA 33/66/100

mode with data transfer rate up to 100MB/sec. (20 x 2 header x 2 onboard)

• FDD Interface: Supports up to two floppy disk drives, 5.25" (360KB and 1.2MB)

and/or 3.5" (720KB, 1.44MB, and 2.88MB)

• Parallel Port: One bi-directional parallel port. Supports SPP, ECP, and EPP

modes

• Serial Port: One RS-232 serial ports and one RS-232/422/485 serial port. Ports

can be configured as COM1, COM2, COM3, COM4, or disabled individually.

(16C550 equivalent)

• IR Interface: Supports one IrDA Tx/Rx header

• KB/Mouse Connector: One 6-pin mini-DIN connector supports PS/2 keyboard and

mouse

• USB Connectors: Two 5 x 2 header onboard support up to four USB ports

• Smart Card Reader Connector: One 7 x 2 header onboard support a Smart Card

Reader port

• Watchdog Timer: Can generate a system reset, or NMI. Jumper selectable time-

out interval (0.5, 1, 2, 4, 8, 16, 32, 64 sec.)

• DMA: 7 DMA channels (8237 equivalent)

ECB-865 User’s Manual 3

Page 14

User’s Manual

• Interrupt: 15 interrupt levels (8259 equivalent)

• Hardware Status Monitoring: Monitoring system temperature, voltage, and

cooling fan status. Auto throttling control when CPU overheats

• Power Management: Supports ATX power supply. Supports PC98, LAN wake up

and modem ring-in functions. I/O peripheral devices support power saving and

doze/standby/suspend modes. APM 1.2 compliant

VGA Interface

• Chipset: Intel 815E-B 3D Graphics Accelerator

• Display Memory: Up to 4MB shared display memory

• Interface: AGP 4X, Accelerator Graphics Ports 1.0 compliant

• Resolution: 1280 x 1024 @ 24bpp

Ultra 160 SCSI Interface (Optional)

• Chipset: Adaptec 7892

• SCSI Interface: Supports 32-bit PCI interface and Ultra 160 SCSI or legacy single-

ended devices; data transfer rates up to 160MB/sec

Ethernet Interface

• Chipset: Intel 82801BA ICH2 built-in and 82559 PCI-bus Ethernet controller

onboard support dual Ethernet function

• Ethernet Interface: PCI 100/10 Mbps, IEEE 802.3U compatible, dual RJ-45

interfaces

• Remote Boot-ROM: For diskless system

SSD Interface

One 32-pin DIP socket supports M-Systems DiskOnChip 2000 series,

memory capacity from 8MB to 576MB

Expansion Interface

One 80-pin proprietary PCI interface for PCI device expansion

4 ECB-865 User’s Manual

Page 15

Mechanical and Environmental

• Power Supply Voltage: +5V (4.75V to 5.25V), +12V (11.4V to 12.6V), and -12V (-

11.4V to -12.6V)

• Typical Power Requirement: +5V @ 6.5A, +12V @ 140mA, -12V @ 30mA w/

Intel Celeron 466MHz CPU and 128MB SDRAM

• Operating Temperature: 32 to 140 °F (0 to 60 °C)

• Board Size: 13.3"(L) x 4.8"(W) (338mm x 122mm)

• Weight: 0.5 Kg

ECB-865

ECB-865 User’s Manual 5

Page 16

User’s Manual

2.3 Architecture Overview

The following block diagram shows the architecture and main components of ECB-865.

Two major chipsets on board are the 82815E Graph Memory Control Hub and 82801BA

ICH2. These two devices provide interface to Socket370 processor, supports CRT display,

SDRAM with ECC, PCI bus interface, ACPI compliant power management , USB port,

SMBus communication, and Ultra DMA/33/66/100 IDE Bus Master. The onboard super I/O

chip, IT8712F-A, supports PS/2 Keyboard/Mouse, two 16C550 UARTs, FDC, Parallel and

Infrared interface. In addition, the onboard Intel 82559 10/100BASE-TX Ethernet

controller delivers high speed data transfers over the PCI bus.

The following sections provide detail information about the functions provided onboard.

6 ECB-865 User’s Manual

Page 17

ECB-865

2.3.1 82815 GMCH and 82801BA

The Intel® 815 chipset for use with the universal socket 370 is a high-flexibility chipset

designed to extend from the basic graphics/multimedia PC platform up to the mainstream

performance desktop platform. The chipset consists of the Intel_ 82815 Graphics and

Memory Controller Hub (GMCH) and an I/O Controller Hub (ICH or ICH2) for the I/O

subsystem. The GMCH integrates a system memory SDRAM controller that supports a

64-bit 100/133 MHz SDRAM array.

The Intel 82815 GMCH integrates a Display Cache SDRAM controller that supports a 32bit 133 MHz SDRAM array for enhanced integrated 2D and 3D graphics performance.

Multiplexed with the display cache interface is an AGP controller interface to enable

graphics configuration and upgrade flexibility with the Intel 815 chipset for use with the

universal socket 370. The AGP interface and the internal graphics device are mutually

exclusive. When the AGP port is populated with an AGP graphics card, the integrated

graphics is disabled; thus, the display cache interface is not needed.

The Intel 815 chipset for use with the universal socket 370 supports the following

processors:

Intel® Pentium® III processor based on 0.18 micron technology (CPUID = 068xh).

These processors support the AGTL+ bus interface

Intel® Celeron™ processor based on 0.18 micron technology (CPUID = 068xh). This

applies to Celeron 533A MHz and ≥ 566 MHz processors. These processors support

the AGTL+ bus interface.

Future 0.13 micron socket 370 processors. These processors support the AGTL bus

interface.

The 82815 GMCH along with the 82801BA ICH2 provide the basic functionality and buses

of the system:

Interface to SDRAM, 64-bit data bus. Up to 3 double sided DIMMs at 100 MHz

system memory bus. Up to 2 double sided or 3 single sided DIMMs at 133 MHz

system memory bus.

PCI Rev 2.2 compliant with support for 33 MHz PCI operations, Supports up to 6

Req/Gnt pairs

System Management Bus (SMBus) compatible with most I2C devices

Integrated IDE controller support Ultra ATA/100/66/33 with two 40-pin connectors

2 USB ports integrated in ICH2.

Integrated LAN controller

AC.97 2.1 compliant link for audio and telephony codecs up to 6 channels

Low Pin Count (LPC) interface

Firmware Hub (FWH) interface support

.

ECB-865 User’s Manual 7

Page 18

User’s Manual

2.3.2 DRAM Interface

The GMCH integrates a system memory controller that supports a 64-bit 100/133 MHz

SDRAM array. The only DRAM type supported is industry standard Synchronous DRAM

(SDRAM). The SDRAM controller interface is fully configurable through a set of control

registers. The DRAM controller supports the following features:

DRAM type: Support for x8 and x16 SDRAM device width, Unbuffered, and Non-ECC

SDRAM only

Memory Size: 32 MB to 512 MB using 16Mb/64Mb/128Mb/256Mb technology

Addressing Type: Asymmetrical addressing only

DRAM Speeds: 100/133 MHz for synchronous memory (SDRAM).

Memory Modules supported: Up to 3 double-sided DIMMs at 100 MHz system

memory bus; Up to 2 double sided or 3 single-sided DIMMs at 133 MHz system

memory bus.

Suspend to RAM support

2.3.3 Multiplexed AGP and Display Cache Interface

The Intel 82815 GMCH multiplexes an AGP interface with a display cache interface for

internal 3D graphics performance improvement. The display cache is used only in the

internal graphics.

When an AGP card is installed in the system, the GMCH internal graphics will be disabled

and the AGP controller will be enabled.

2.3.3.1 AGP Interface

A single AGP connector is supported by the GMCH AGP interface. The AGP buffers

operate in one of two selectable modes in order to support the AGP Universal Connector:

3.3 V drive, not 5 Volt safe: This mode is compliant to the AGP 1.0 and 2.0

specifications

1.5 V drive, not 3.3 Volt safe: This mode is compliant with the AGP 2.0 specification.

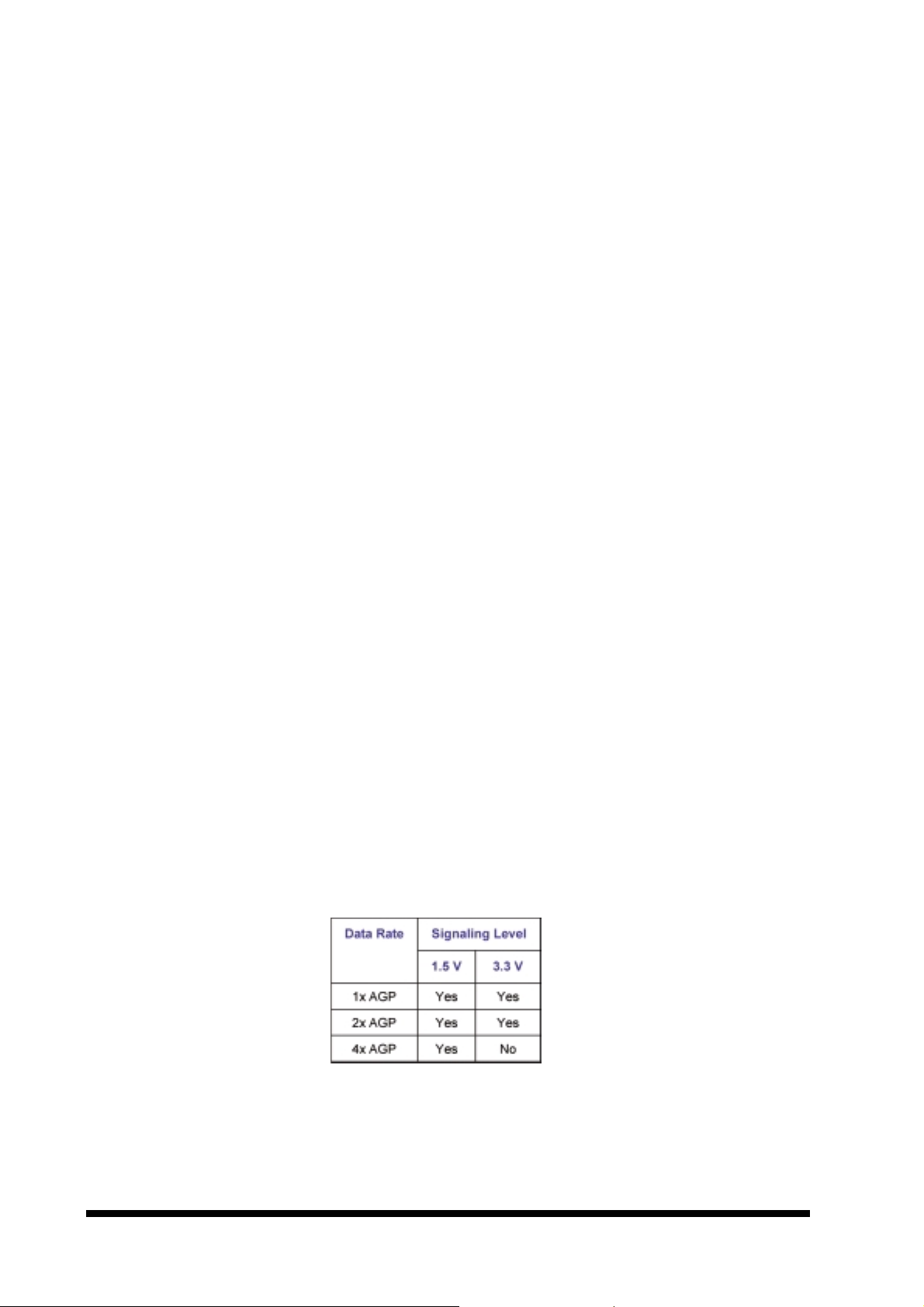

The following table shows the AGP Data Rate and the Signaling Levels supported by the

GMCH.

8 ECB-865 User’s Manual

Page 19

ECB-865

2.3.4 PCI Interface

The ICH2 PCI interface provides a 33 MHz, Rev. 2.2 compliant implementation. All PCI

signals are 5V tolerant, except PME#. The ICH2 integrates a PCI arbiter that supports up

to six external PCI bus masters in addition to the internal ICH2 requests.

2.3.5 IDE Interface (Bus Master Capability and Synchronous DMA Mode)

The fast IDE interface supports up to four IDE devices providing an interface for IDE hard

disks and CD ROMs. Each IDE device can have independent timings. The IDE interface

supports PIO IDE transfers up to 14 Mbytes/sec and Bus Master IDE transfers up 100

Mbytes/sec. It does not consume any ISA DMA resources. The IDE interface integrates

16x32-bit buffers for optimal transfers.

The ICH2’s IDE system contains two independent IDE signal channels. They can be

electrically isolated independently. They can be configured to the standard primary and

secondary channels (four devices). There are integrated series resistors on the data and

control lines.

Access to these controllers is provided by two standard IDC 40-pin connectors.

2.3.6 USB

The USB controller provides enhanced support for the Universal Host Controller Interface

(UHCI). This includes support that allows legacy software to use a USB-based keyboard

and mouse. The ICH2 is USB Revision 1.1 compliant. The ICH2 contains two USB Host

Controllers. Each Host Controller includes a root hub with two separate USB ports each,

for a total of 4 USB ports. The signals are provided by a 5 x 2 header or an optional USB

bracket adapter.

2.3.7 Ethernet

2.3.7.1 ICH2 LAN Controller

The ICH2’s integrated LAN Controller includes a 32-bit PCI controller that provides

enhanced scatter-gather bus mastering capabilities and enables the LAN Controller to

perform high speed data transfers over the PCI bus. Its bus master capabilities enable the

component to process high level commands and perform multiple operations; this lowers

processor utilization by off-loading communication tasks from the processor. Two large

transmit and receive FIFOs of 3 KB each help prevent data under runs and overruns while

waiting for bus accesses. This enables the integrated LAN Controller to transmit data with

minimum interframe spacing (IFS).

The LAN Controller can operate in either full duplex or half duplex mode. In full duplex

mode the LAN Controller adheres with the IEEE 802.3x Flow Control specification. Half

duplex performance is enhanced by a proprietary collision reduction mechanism.

ECB-865 User’s Manual 9

Page 20

User’s Manual

2.3.7.2 Intel 82559

The Ethernet interface is based on an Intel 82559 Ethernet controller that supports both

10BASE-T and 100BASE-TX. The 82559 consists of both the Media Access Controller

(MAC) and the physical layer (PHY) interface combined into a single component solution.

The 32-bit PCI controller provides enhanced scatter-gather bus mastering capabilities and

enables the 82559 to perform high speed data transfers over the PCI bus. Its bus master

capabilities enable the component to process high level commands and perform multiple

operations, which lowers CPU utilization by off-loading communication tasks from the CPU.

Two large transmit and receive FIFOs of 3 Kbyte each help prevent data under runs and

overruns while waiting for bus accesses. This enables the 82559 to transmit data with

minimum interframe spacing (IFS).

2.3.8 ITE IT8712F-A

The Winbond W83977TF-AW Super I/O chip provides most input / output interfaces of the

system as the following:

COM 1/2. RS-232/RS-422/RS-485 driver are used whereby RS-232, RS-422 and RS-

485 are provided. Mode can be selected by setting hardware jumper. Drivers use

charge pumps whereby only +5V is required

LPT. Support for SPP, EPP and ECP modes

Floppy interface

Keyboard interface

PS/2 Mouse interface

IrDA interface for infrared communication. This interface shares the controller of

COM2

Provision of buffered ISA databus for BIOS (denoted XDBus)

NVRam with battery backup for BIOS configuration and real time clock

2.3.9 M-Systems DiskOnChip

M-Systems’ DiskOnChip 2000 is a high performance single-chip flash disk in a standard

32-pin DIP package. This unique data storage solution offers cost effective data storage

beyond that of traditional hard disks. Perfect for applications with limited space and

varying capacity requirements. The DiskOnChip 2000 is simply inserted into a 32-pin DIP

socket on your platform board and you have a bootable flash disk.

10 ECB-865 User’s Manual

Page 21

ECB-865

3. Hardware Configuration

This chapter explains you the instructions of how to set up your system. The additional

information shows you how to install M-Systems’ DiskOnChip and program the Watchdog

Timer.

3.1 Installation Procedure

1. Turn off the power supply.

2. Insert the DIMM module (be careful with the orientation).

3. Insert all external cables for hard disk, floppy, keyboard, mouse, USB etc. except for flat

panel. A CRT monitor must be connected in order to change CMOS settings to support

flat panel.

4. Connect power supply to the board via the PWR1.

5. Turn on the power.

6. Enter the BIOS setup by pressing the delete key during boot up. Use the “Auto

Configuration with Optimal Settings” feature. The Peripheral Setup and the Standard

CMOS Setup Window must be entered and configured correctly to match the particular

system configuration.

7. If TFT panel display is to be utilised, make sure the panel voltage is correctly set

before connecting the display cable and turning on the power.

3.2 Safety Precautions

3.2.1 Warning!

Always completely disconnect the power cord from your chassis or power

cable from your board whenever you work with the hardware. Do not make

connections while the power is on. Sensitive electronic components can

be damaged by sudden power surges. Only experienced electronics

personnel should open the PC chassis.

3.2.2 Caution!

Always ground yourself to remove any static charge before touching the

board. Modern electronic devices are very sensitive to static electric

charges. As a safety precaution, use a grounding wrist strap at all times.

Place all electronic components in a static-dissipative surface or staticshielded bag when they are not in the chassis.

ECB-865 User’s Manual 11

Page 22

User’s Manual

3.3 Socket 370 Processor

3.3.1 Installing Celeron / Pentium III (Coppermine/Tualatin) CPU

Lift the handling lever of CPU socket outwards and upwards to the other end.

Align the processor pins with pin holes on the socket. Make sure that the notched

corner or dot mark (pin 1) of the CPU corresponds to the socket’s bevel end. Then

press the CPU gently until it fits into place. If this operation is not easy or smooth,

don’t do it forcibly. You need to check and rebuild the CPU pin uniformly.

Push down the lever to lock processor chip into the socket.

Follow the installation guide of cooling fan or heat sink to mount it on CPU surface

and lock it on the socket 370.

Be sure to follow particular CPU speed and voltage type to adjust the jumper settings

properly.

3.3.2 Removing CPU

Unlock the cooling fan first.

Lift the lever of CPU socket outwards and upwards to the other end.

Carefully lift up the existing CPU to remove it from the socket.

Follow the steps of installing a CPU to change to another one or place handling bar to

close the opened socket.

3.4 Main Memory

ECB-865 provides 3 DIMM sockets (168-pin Dual In-line Memory Module) to support 3.3V

SDRAM. The maximum memory size is 1.5GB (registered type of SDRAM). If 100MHz

FSB CPU is adopt, you have to use PC-100 SDRAM. For system compatibility and

stability, please do not use memory module without brand.

Both single and double-side DIMM module with ECC feature can be used on ECB-865.

And, it is not necessary to install the DIMM module in order. You can install different size

of SDRAM module on DIMM1, DIMM2, DIMM3, DIMM4 or all.

Watch out the contact and lock integrity of memory module with socket, it will influence the

system’s reliability. Follow the normal procedure to install your SDRAM module into the

DIMM socket. Before locking the DIMM module, make sure that the memory module has

been completely inserted into the DIMM socket.

Note:

Please do not change any SDRAM parameter in BIOS setup to increase your

system’s performance without acquiring technical information in advance.

12 ECB-865 User’s Manual

Page 23

ECB-865

3.5 M-Systems’ DiskOnChip Flash Disk

ECB-865 reserves a 32-pin DIP socket to support M-Systems’ DiskOnChip flash disk up to

288 MB. The DiskOnChip is based on pure ISA bus and without PnP (Plug and Play)

function. Before the installation, make sure that the DiskOnChip I/O address jumper is set

properly to prevent the I/O resource conflict.

3.5.1 Installing DOC

Align the DOC with the pinholes on the socket. Make sure that the notched corner or dot

mark (pin 1) of DOC corresponds to notched corner of the socket. Then press the DOC

gently until it fits into place. If installation procedure is correct, the flash disk can be viewed

as a normal hard disk to access read/write data now.

Note:

Please make sure that your DOC is properly inserted. Place the DOC in wrong

direction will damage the flash device.

If you system would like to boot from the flash disk, it is recommended to refer to the

application note provided by M-Systems first. You can easily obtain the application note

from M-Systems’ DiskOnChip user’s manual or from their web site as below.

http://www.m-sys.com

3.6 Expansion Interface

The ECB-865 reserves an 80-pin proprietary PCI interface, J22, for PCI device such as

LAN, Audio, SCSI, Video Capture expansion in the future. This installation of expansion

module is very simple and easy. Without any special tool, all you need to do is just make

the board-to-board connection and lock up the screw. For more information about the

expansion module, please refer to the instruction manual attached with each module.

3.7 Installing the Single Board Computer

To install your ECB-865 into chassis or proprietary environment, the following steps have

to be followed.

Make sure all jumpers are properly set.

Install and configure CPU and memory module correctly.

Place the ECB-865 into the dedicated position in your system.

Attach cables to peripherals.

Note:

Please ensure that your SBC is properly installed and fixed by mechanism.

Otherwise, the system might be unstable or do not work due to bad contact of

golden finger and slot.

ECB-865 User’s Manual 13

Page 24

User’s Manual

3.7.1 815E integrated Graphics Controller

The on-board graphics controller integrated in 815E(GMCH) chipset that integrates high

performance memory technology for the graphics frame buffer. 32 –bit data interface,133

Mhz SDRAM interface only.Flexible AGP in-line Memory Module (AIMM) implementation.

support for two1M X16,or one 2M X32,4MB maximum addressable, thus increasing the

available memory bandwidth for the graphics subsystem to support high color/high

resolution application. The ECB-865 is designed to support high performance graphics

and video acceleration for all supported display resolutions, display types, and color

modes on CRT monitor.

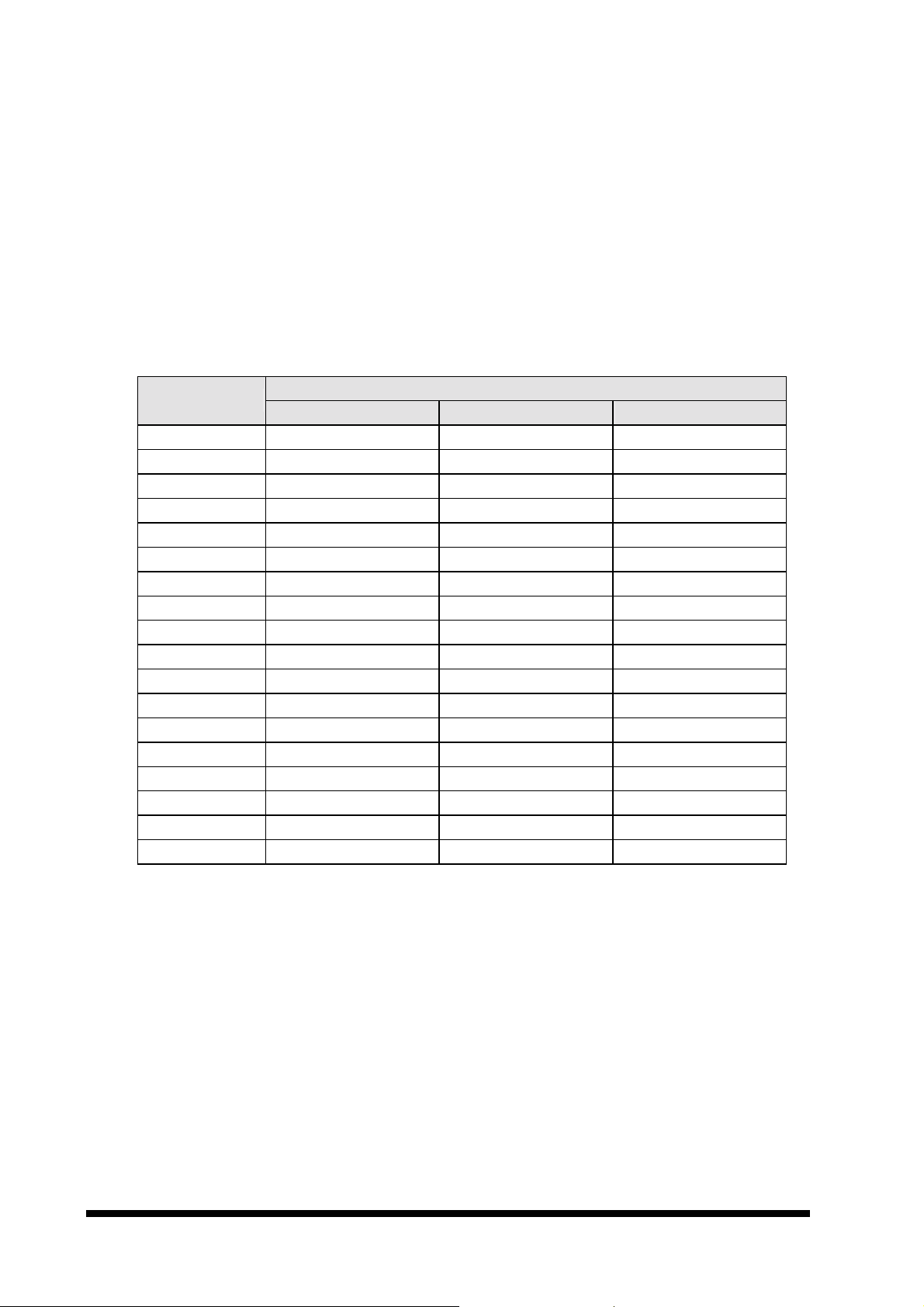

The 815E supports the modes which appear in the table below.

Resolution

8-bit Indexed 16-bit 24-bit

320x200 70 70 70

320x240 70 70 70

352x480 70 70 70

352x576 70 70 70

400x300 70 70 70

512x384 70 70 70

640x400 70 70 70

640x480 60,70,72,75,85 60,70,72,75,85 60,70,72,75,85

720x480 75,85 75,85 75,85

720x576 60,75,85 60,75,85 60,75,85

800x600 60,70,72,75,85 60,70,72,75,85 60,70,72,75,85

1024x768 60,70,72,75,85 60,70,72,75,85 60,70,72,75,85

1152x864 60,70,72,75,85 60,70,72,75,85 60,70,72,75,85

1280x720 60,75,85 60,75,85 60,75,85

1280x960 60,75,85 60,75,85 60,75,85

1280x1024 60,70,72,75,85 60,70,72,75,85 60,70,72,75,85

1600x900 60,75,85 60,75,85

1600x1200 60,70,72,75

Bits Per Pixel (frequency in Hz)

14 ECB-865 User’s Manual

Page 25

ECB-865

3.7.2 Intel 82559(or REALTEK RTL8139C) & 82801BA(ICH2) + 82562ET (PHY)

Network Controller

The 82559 (or RTL8139C) and ICH2+PHY is fully integrated 10BASE-T/100BASE-TX

LAN solution. The 32-bit PCI controller provides enhanced scatter-gather bus mastering

capabilities and enables the 8139C to perform high-speed data transfers over the PCI bus.

Its bus master capabilities enable the component to process high level commands and

perform multiple operations, which lower CPU utilization by off-loading communication

tasks from the CPU.

The ECB-865 equips two LED indicators on the RJ-45 connector to indicate the LAN

interface status. These messages will provide you a guide for troubleshooting.

Green LED LAN Activity LED that indicates the data transfer activity.

Blinking: indicates transmission/receiving activity

On: indicates no activity but link is valid

Off: link is invalid

Yellow LED LAN Link Integrity LED that indicates link speed

On: link speed at 100Mbps

Off: link speed at 10Mbps

3.7.3 Drivers Support

ECB-865 provides on CD-Title to support on-board VGA and Ethernet device drivers in

various operating systems. Before installing the device drivers, please see the reference

files in each sub-directory. You cannot install drivers from CD-Title directly.

815E CHIPSET INTEGRATED GRAPHY: Support NT4.0, Windows9x, Win2000, …

environment

INTEL 815E & ICH2 CHIPSET DRIVER: Support NT4.0, Windows9x, Win2000, …

environment

Intel 82559 (or REALTEK 8139C): Support Dos, Windows3.1, Windows9x, NT3.5,

NT4.0, Novell, OS/2 …

ECB-865 User’s Manual 15

Page 26

User’s Manual

3.8 Watchdog Timer Programming

When the Watch-Dog Timer (WDT) function is enabled, a system reset will be generated

unless an application triggers the timer periodically within time-out period. This allows the

system to restart in an orderly way in case of any abnormal condition is found.

An optional two-port WDT is provided on ECB-865. This WDT comes with 8 possible

ranges of time intervals from 500ms to 64sec., which can be adjusted by setting jumper

positions. It could be enabled and programmed by reading I/O port 0533H or 0543H to

issue trigger continuously, and disabled by reading I/O port 0033H or 0343H. A tolerance

of 30% timer limit must be considered. For instance, if the time-out interval is set to 1

second, the WDT trigger command must be issued within 700ms at least.

The below example gives you a reference algorithm for WDT programming via I/O port

0533H and 0033H in your application programs:

Enable WDT

MOV DX, 0533H

IN AL, DX

Re-trigger WDT

MOV DX, 0533H

IN AL, DX

Disable WDT

MOV DX, 0033H

IN AL, DX

16 ECB-865 User’s Manual

Page 27

3.9 Jumper & Connector

3.9.1 Jumper & Connector Layout

ECB-865

ECB-865 User’s Manual 17

Page 28

User’s Manual

3.9.2 Jumper & Connector List

Connectors on the board are linked to external devices such as hard disk drives, keyboard,

mouse, or floppy drives. In addition, the board has a number of jumpers that allow you to

configure your system to suit your application.

The following tables list the function of each of the board's jumpers and connectors.

Jumpers

Label Function Note

JP1 Serial port RS-232/422/485 select 3 x 2 header, pitch 2.54mm

JP2~JP5 Serial port RS-232/422/485 select 3 x 1 header, pitch 2.54mm

JP6 Watchdog timer select 2 x 1 header, pitch 2.54mm

JP9 Clear CMOS 3 x 1 header, pitch 2.54mm

JP10 Watchdog timer select 3 x 2 header, pitch 2.54mm

JP11 M-Systems DiskOnChip memory address

JP12 Watchdog timer select 2 x 1 header, pitch 2.54mm

JP13 Proprietary PCI Bus Master Selection 4 x 2 header, pitch 2.54mm

4 x 2 header, pitch 2.54mm

select

18 ECB-865 User’s Manual

Page 29

ECB-865

Connectors

Label Function Note

J1

J2

J3

J4

J5

J6 Floppy connector 17 x 2 header, pitch 2.54mm

J7 AT power button connector

J8 ATX power button interface to backplane 2 x 1 header, pitch 2.54mm

J9 Serial port 1 connector 5 x 2 header, pitch 2.54mm

J10 Secondary IDE connector 20 x 2 header, pitch 2.54mm

J11 Parallel port connector 5 x 2 header, pitch 2.54mm

J12 Serial port 2 connector 5 x 2 header, pitch 2.54mm

J13 USB connector 5 x 2 header, pitch 2.54mm

System reset connector 2 x 1 header, pitch 2.54mm

External speaker connector 4 x 1 header, pitch 2.54mm

Keyboard lock and power indicator

connector

Primary IDE / Secondary IDE active

indicator connector

Primary IDE connector 20 x 2 header, pitch 2.54mm

4 x 1 header, pitch 2.54mm

2 x 1 header, pitch 2.54mm

J14 CPU fan connector 3 x 1 wafer, pitch 2.54mm

J15 Fast and standard IrDA (Infrared)

connector

J16 ATX power control connector 4 x 1 wafer, pitch 2.54mm

J17 Smart card reader connector 7 x 2 header, pitch 2.54mm

J18 10/100Base-Tx Ethernet connector 1 RJ-45 6-pin mini DIN

J19 USB connector 5 x 2 header, pitch 2.54mm

J20 10/100Base-Tx Ethernet connector 2 RJ-45

J21 Proprietary PCI connector

J22 CRT connector DB-15 female connector

J23 M-Systems DiskOnChip socket 16 x 2 DIP socket

J24 Internal keyboard connector 5 x 1 wafer, pitch 2.54mm

J25 System fan connector 3 x 1 wafer, pitch 2.54mm

J26 PS/2 keyboard connector 6-pin mini DIN

6 x 1 header, pitch 2.54mm

ECB-865 User’s Manual 19

Page 30

User’s Manual

3.10 Setting Jumpers

You can configure your board to match the needs of your application by setting jumpers. A

jumper is the simplest kind of electric switch.

It consists of two metal pins and a small metal clip (often protected by a plastic cover) that

slides over the pins to connect them. To “close” a jumper you connect the pins with the

clip. To “open” a jumper you remove the clip. Sometimes a jumper will have three pins,

labeled 1, 2, and 3. In this case, you would connect either two pins.

The jumper settings are schematically depicted in this manual as follows:

A pair of needle-nose pliers may be helpful when working with jumpers.

If you have any doubts about the best hardware configuration for your application, contact

your local distributor or sales representative before you make any changes.

20 ECB-865 User’s Manual

Page 31

ECB-865

3.10.1 Clear CMOS (JP9)

You can use JP9 to clear the CMOS data if necessary. To reset the CMOS data, short

JP1 for just a few seconds, and then remove the jumper back to open.

Clear CMOS (JP1)

Protect* Clear CMOS

JP1

1 2 1 2

* default

3.10.2 Watchdog Timer

3.10.2.1 Enable / Disable Onboard Watchdog Timer (JP12)

You can use JP12 to enable / disable the onboard Watchdog timer function if necessary.

To disable the onboard Watchdog timer function, short JP12, to enable the function of

Watchdog timer, set JP12 to open.

Enable / Disable Onboard Watchdog Timer (JP12)

Enable Disable*

JP12

1 2 1 2

* default

3.10.2.2 Watchdog Timer Programming I/O Address Select (JP6)

You can set JP6 to select the Watchdog timer programming I/O address. The choice is

0553H / 0033H and 0543H / 0343H.

Watchdog Timer Programming I/O Address Select (JP6)

0553H / 0033H* 0543H / 0343H

JP6

1 2 1 2

* default

ECB-865 User’s Manual 21

Page 32

User’s Manual

3.10.2.3 Watchdog Timer Time-Out Interval Select (JP10)

You can set JP10 to select the Watchdog timer time-out interval to be 0.5, 1, 2, 4, 8, 16,

32, or 64 Sec.

Watchdog Timer Tim-Out Interval Select (JP10)

0.5 Sec. 1 Sec. * 2 Sec. 4 Sec.

1 3 5

1 3 5

1 3 5

1 3 5

2 4 6

2 4 6

2 4 6

2 4 6

JP10

8 Sec. 16 Sec. 32 Sec. 64 Sec.

1 3 5

1 3 5

1 3 5

1 3 5

2 4 6

2 4 6

2 4 6

2 4 6

* default

3.10.3 COM2 RS-232/422/485 Select (JP1, JP2~JP5)

The ECB-865 COM2 serial port can be selected as RS-232, RS-422, or RS-485 by setting

JP1 & JP2~JP5.

COM2 RS-232/422/485 Select (JP1, JP2~JP5)

RS-232* RS-422 RS-485

2 4 6

2 4 6

2 4 6

JP1

JP2

JP3

JP4

JP5

1 3 5

1

1

1

1

3

3

3

3

1 3 5

1

1

1

1

1 3 5

3

3

3

3

1

1

1

1

3

3

3

3

* default

22 ECB-865 User’s Manual

Page 33

ECB-865

3.10.4 M-Systems DiskOnChip Memory Address Select (JP11)

The M-systems DiskOnChip memory address can be selected by JP11. The choice is

D0000~D1FFF, D2000~D3FFF, D4000~D5FFF, D6000~D7FFF.

M-systems DiskOnChip Memory Address Select (JP11)

D0000* D2000 D4000 D6000

2 4 6 8

2 4 6 8

2 4 6 8

2 4 6 8

JP11

* default

1 3 5 7

1 3 5 7

1 3 5 7

1 3 5 7

3.10.5 Proprietary PCI Bus Master Selection (JP13)

The Proprietary PCI Bus Master is selected by JP13. The choice is Bus Master0 and Bus

Master3

Proprietary PCI Bus Master Select (JP13)

Bus Master 0* Bus Master 3

2 4 6 8

2 4 6 8

JP13

* default

1 3 5 7

1 3 5 7

ECB-865 User’s Manual 23

Page 34

User’s Manual

3.11 Connector Definitions

3.11.1 System Reset Connector (J1)

Signal PIN

Reset 1

GND 2

3.11.2 External Speaker Connector (J2)

Signal PIN

SPK 1

NC 2

GND 3

VCC 4

3.11.3 Keyboard Lock & Power Indicator Connector (J3)

Signal PIN

VCC 1

NC 2

GND 3

Keyboard Inhibit 4

GND 5

3.11.4 Primary IDE / Secondary IDE Active Indicator Connector (J4)

Signal PIN

VCC 1

HDD Active# 2

24 ECB-865 User’s Manual

Page 35

3.11.5 Primary IDE Connector (J5)

Signal PIN Signal

RESET# 1 2 GND

PDD7 3 4 PDD8

PDD6 5 6 PDD9

PDD5 7 8 PDD10

PDD4 9 10 PDD11

PDD3 11 12 PDD12

PDD2 13 14 PDD13

PDD1 15 16 PDD14

PDD0 17 18 PDD15

GND 19 20 NC

PDDREQ 21 22 GND

PDIOW# 23 24 GND

PDIOR# 25 26 GND

PDIORDY 27 28 GND

PDDACK# 29 30 GND

IRQ14 31 32 NC

PDA1 33 34 NC

PDA0 35 36 PDA2

PDCS1# 37 38 PDCS3#

PDDACT# 39 40 GND

ECB-865

ECB-865 User’s Manual 25

Page 36

User’s Manual

3.11.6 Secondary IDE Connector (J10)

Signal PIN Signal

RESET# 1 2 GND

SDD7 3 4 SDD8

SDD6 5 6 SDD9

SDD5 7 8 SDD10

SDD4 9 10 SDD11

SDD3 11 12 SDD12

SDD2 13 14 SDD13

SDD1 15 16 SDD14

SDD0 17 18 SDD15

GND 19 20 NC

SDDREQ 21 22 GND

SDIOW# 23 24 GND

SDIOR# 25 26 GND

SDIORDY 27 28 GND

SDDACK# 29 30 GND

IRQ15 31 32 NC

SDA1 33 34 NC

SDA0 35 36 SDA2

SDCS1# 37 38 SDCS3#

SDDACT# 39 40 GND

26 ECB-865 User’s Manual

Page 37

ECB-865

3.11.7 Signal Description – Primary & Secondary IDE Connector (J5 & J10)

PDA [2:0] Primary Disk Address [2:0]. These signals indicate which byte in either the ATA command

block or control block is being addressed. If the IDE signals are configured for Primary and

Secondary, these signals are connected to the corresponding signals on the Primary IDE

connector. If the IDE signals are configured for Primary 0 and Primary 1, these signals are

used for the Primary 0 connector.

SDA [2:0] Secondary Disk Address [2:0]. These signals indicate which byte in either the ATA

command block or control block is being addressed. If the IDE signals are configured for

Primary and Secondary, these signals are connected to the corresponding signals on the

Secondary IDE connector. If the IDE signals are configured for Primary Master and Primary

Slave, these signals are used for the Primary Slave connector.

PDCS1# Primary Disk Chip Select for 1F0H~1F7H Range. For ATA command register block. If the

IDE signals are configured for Primary and Secondary, this output signal is connected to the

corresponding signal on the Primary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, this signal is used for the Primary Master connector.

PDCS3# Primary Disk Chip Select for 3F0H~3F7H Range. For ATA control register block. If the IDE

signals are configured for Primary and Secondary, this output signal is connected to the

corresponding signal on the Primary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, this signal is used for the Primary Master connector.

SDCS1# Secondary Chip Select for 170H~177H Range. For ATA command register block. If the IDE

signals are configured for Primary and Secondary, this output signal is connected to the

corresponding signal on the Secondary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, these signals are used for the Primary Slave connector.

SDCS3# Secondary Chip Select for 370H~377H Range. For ATA control register block. If the IDE

signals are configured for Primary and Secondary, this output signal is connected to the

corresponding signal on the Secondary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, these signals are used for the Primary Slave connector.

PDD [15:0] Primary Disk Data [15:0]. These signals are used to transfer data to or from the IDE device.

If the IDE signals are configured for Primary and Secondary, these signals are connected to

the corresponding signals on the Primary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, this signal is used for the Primary Master connector.

SDD [15:0] Secondary Disk Data [15:0]. These signals are used to transfer data to or from the IDE

device. If the IDE signals are configured for Primary and Secondary, these signals are

connected to the corresponding signals on the Secondary IDE connector. If the IDE signals

are configured for Primary Master and Primary Slave, these signals are used for the Primary

Slave connector.

ECB-865 User’s Manual 27

Page 38

User’s Manual

PDIOR# Primary Disk IO Read. In normal IDE this is the command to the IDE device that it may drive

data onto the PDD [15:0] lines. Data is latched by PIIX4 on the negation edge of PDIOR#. The

IDE device is selected either by the ATA register file chip selects (PDCS1#, PDCS3#) and the

PDA [2:0] lines, or the IDE DMA slave arbitration signals (PDDACK#).

In an Ultra DMA/33 read cycle, this signal is used as DMARDY# which is negated by the PIIX4

to pause Ultra DMA/33 transfers. In an Ultra DMA/33 write cycle, this signal is used as the

STROBE signal, with the drive latching data on rising and falling edges of STROBE.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Primary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, this signal is used for the Primary Master connector.

SDIOR# Secondary Disk IO Read. In normal IDE mode, this is the command to the IDE device that it

may drive data onto the SDD [15:0] lines. Data is latched by the PIIX4 on the negation edge of

SDIOR#. The IDE device is selected either by the ATA register file chip selects (SDCS1#,

SDCS3#) and the SDA [2:0] lines, or the IDE DMA slave arbitration signals (SDDACK#).

In an Ultra DMA/33 read cycle, this signal is used as DMARDY# which is negated by the PIIX4

to pause Ultra DMA/33 transfers. In an Ultra DMA/33 write cycle, this signal is used as the

STROBE signal, with the drive latching data on rising and falling edges of STROBE.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Secondary IDE connector. If the IDE signals are configured for

Primary Master and Primary Slave, these signals are used for the Primary Slave connector.

PDIOW# Primary Disk IO Write. In normal IDE mode, this is the command to the IDE device that it

may latch data from the PDD [15:0] lines. Data is latched by the IDE device on the negation

edge of PDIOW#. The IDE device is selected either by the ATA register file chip selects

(PDCS1#, PDCS3#) and the PDA [2:0] lines, or the IDE DMA slave arbitration signals

(PDDACK#).

For Ultra DMA/33 mode, this signal is used as the STOP signal, which is used to terminate an

Ultra DMA/33 transaction. If the IDE signals are configured for Primary and Secondary, this

signal is connected to the corresponding signal on the Primary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, this signal is used for

the Primary Master connector.

SDIOW# Secondary Disk IO Write. In normal IDE mode, this is the command to the IDE device that it

may latch data from the SDD [15:0] lines. Data is latched by the IDE device on the negation

edge of SDIOW#. The IDE device is selected either by the ATA register file chip selects

(SDCS1#, SDCS3#) and the SDA [2:0] lines, or the IDE DMA slave arbitration signals

(SDDACK#).

In read and write cycles this signal is used as the STOP signal, which is used to terminate an

Ultra DMA/33 transaction.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Secondary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, these signals are used

for the Primary Slave connector.

28 ECB-865 User’s Manual

Page 39

ECB-865

PDIORDY Primary IO Channel Ready. In normal IDE mode, this input signal is directly driven by the

corresponding IDE device IORDY signal. In an Ultra DMA/33 read cycle, this signal is used as

STROBE, with the PIIX4 latching

data on rising and falling edges of STROBE. In an Ultra DMA/33 write cycle, this signal is used

as the DMARDY# signal which is negated by the drive to pause Ultra DMA/33 transfers.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Primary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, this signal is used for

the Primary Master connector.

This is a Schmitt triggered input.

SDIORDY Secondary IO Channel Ready. In normal IDE mode, this input signal is directly driven by the

corresponding IDE device IORDY signal. In an Ultra DMA/33 read cycle, this signal is used as

STROBE, with the PIIX4 latching

data on rising and falling edges of STROBE. In an Ultra DMA write cycle, this signal is used as

the DMARDY# signal which is negated by the drive to pause Ultra DMA/33 transfers.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Secondary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, these signals are used

for the Primary Slave connector.

This is a Schmitt triggered input.

PDDREQ Primary Disk DMA Request. This input signal is directly driven from the IDE device DMARQ

signal. It is asserted by the IDE device to request a data transfer, and used in conjunction with

the PCI bus master IDE function. It is not associated with any AT compatible DMA channel.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Primary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, this signal is used for

the Primary Master connector.

SDDREQ Secondary Disk DMA Request. This input signal is directly driven from the IDE device

DMARQ signal. It is asserted by the IDE device to request a data transfer, and used in

conjunction with the PCI bus master IDE function. It is not associated with any AT compatible

DMA channel.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Secondary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, these signals are used

for the Primary Slave connector.

PDDACK# Primary DMA Acknowledge. This signal directly drives the IDE device DMACK# signal. It is

asserted by PIIX4 to indicate to IDE DMA slave devices that a given data transfer cycle

(assertion of PDIOR# or PDIOW #) is a DMA data transfer cycle. This signal is used in

conjunction with the PCI bus master IDE function. It is not associated with any AT compatible

DMA channel. If the IDE signals are configured for Primary and Secondary, this signal is

connected to the corresponding signal on the Primary IDE connector. If the IDE signals are

configured for Primary Master and Primary Slave, this signal is used for the Primary Master

connector.

ECB-865 User’s Manual 29

Page 40

User’s Manual

SDDACK# Secondary DMA Acknowledge. This signal directly drives the IDE device DMACK# signal. It

is asserted by PIIX4 to indicate to IDE DMA slave devices that a given data transfer cycle

(assertion of SDIOR# or SDIOW #) is a DMA data transfer cycle. This signal is used in

conjunction with the PCI bus master IDE function. It is not associated with any AT compatible

DMA channel.

If the IDE signals are configured for Primary and Secondary, this signal is connected to the

corresponding signal on the Secondary IDE connector.

If the IDE signals are configured for Primary Master and Primary Slave, these signals are used

for the Primary Slave connector.

PDDACT# Primary Disk Act. Signal from Primary IDE device indicating Primary IDE device activity. The

signal level depends on the hard disk type, normally active low.

SDDACT# Secondary Disk Act. Signal from Secondary IDE device indicating Secondary IDE device

activity. The signal level depends on the hard disk type, normally active low.

RESET# IDE Reset. This signal resets all the devices that are attached to the IDE interface.

IRQ14/15 Interrupt line from hard disk. Connected directly to PC-AT bus.

30 ECB-865 User’s Manual

Page 41

3.11.8 Floppy Connector (J6)

Signal PIN Signal

GND 1 2 DRVDEN0#

GND 3 4 NC

GND 5 6 DRVDEN1#

GND 7 8 INDEX#

GND 9 10 MOA#

GND 11 12 DSB#

GND 13 14 DSA#

GND 15 16 MOB#

GND 17 18 DIR#

GND 19 20 STEP#

GND 21 22 WD#

GND 23 24 WE#

GND 25 26 TRAK0#

GND 27 28 WPT#

GND 29 30 RDATA#

GND 31 32 SIDE1#

GND 33 34 DSKCHG#

ECB-865

ECB-865 User’s Manual 31

Page 42

User’s Manual

3.11.9 Signal Description – Floppy Connector (J6)

RDATA# The read data input signal from the FDD.

WD# W rite data. This logic low open drain writes pre-compensation serial data to the selected FDD.

An open drain output.

WE# Write enable. An open drain output.

MOA# Motor A On. When set to 0, this pin enables disk drive 0. This is an open drain output.

MOB# Motor B On. When set to 0, this pin enables disk drive 1. This is an open drain output.

DSA# Drive Select A. When set to 0, this pin enables disk drive A. This is an open drain output.

DSB# Drive Select B. When set to 0, this pin enables disk drive B. This is an open drain output.

SIDE1# This output signal selects side of the disk in the selected drive.

DIR# Direction of the head step motor. An open drain output

Logic 1 = outward motion

Logic 0 = inward motion

STEP# Step output pulses. This active low open drain output produces a pulse to move the head to

another track.

DRVDEN0/1# This output indicates whether a low drive density (250/300kbps at low level) or a high drive

density (500/1000kbps at high level) has been selected.

TRAK0# Track 0. This Schmitt-triggered input from the disk drive is active low when the head is

positioned over the outermost track.

INDEX# This Schmitt-triggered input from the disk drive is active low when the head is positioned over

the beginning of a track marked by an index hole.

WP# Write protected. This active low Schmitt input from the disk drive indicates that the diskette is

write-protected.

DSKCHG# Diskette change. This signal is active low at power on and whenever the diskette is removed.

32 ECB-865 User’s Manual

Page 43

3.11.10 ATX Power Button Connector (J8)

Signal PIN

ECB-865

Power Button

Control Signal

GND 2

3.11.11 Parallel Port Connector (J11)

Signal PIN Signal

STB# 1 2 AFD#

PD0 3 4 ERR#

PD1 5 6 INIT#

PD2 7 8 SLIN#

PD3 9 10 GND

PD4 11 12 GND

PD5 13 14 GND

PD6 15 16 GND

PD7 17 18 GND

ACK# 19 20 GND

BUSY 21 22 GND

PE 23 24 GND

SLCT 25 26 GND

1

ECB-865 User’s Manual 33

Page 44

User’s Manual

3.11.12 DB25 Parallel Port Connector (J11)

Signal PIN Signal

STB# 1

14 AFD#

PD0 2

15 ERR#

PD1 3

16 INIT#

PD2 4

17 SLIN#

PD3 5

18 GND

PD4 6

19 GND

PD5 7

20 GND

PD6 8

21 GND

PD7 9

22 GND

ACK# 10

23 GND

BUSY 11

24 GND

PE 12

25 GND

34 ECB-865 User’s Manual

SLCT 13

Page 45

ECB-865

3.11.13 Signal Description – Parallel Port Connector (J11)

The following signal description covers the signal definitions, when the parallel port is

operated in standard centronic mode. The parallel port controller also supports the fast

EPP and ECP modes. Please refer to reference 2 for further information.

PD7..0 Parallel data bus from PC board to printer. The data lines are able to operate in PS/2

compatible bi-directional mode.

SLIN# Output line for detection of printer selection. This pin is pulled high internally.

SLCT An active high input on this pin indicates that the printer is selected. This pin is pulled high

internally.

STB# An active low output is used to latch the parallel data into the printer. This pin is pulled high

internally.

BUSY An active high input indicates that the printer is not ready to receive data. This pin is pulled

high internally.

ACK# An active low input on this pin indicates that the printer has received data and is ready to

accept more data. This pin is pulled high internally.

INIT# Output line for the printer initialization. This pin is pulled high internally.

AFD# An active low output from this pin causes the printer to auto feed a line after a line is printed.

This pin is pulled high internally.

ERR# An active low input on this pin indicates that the printer has encountered an error condition.

This pin is pulled high internally.

PE An active high input on this pin indicates that the printer has detected the end of the paper.

This pin is pulled high internally.

3.11.14 Box Header Serial Port 1 / Serial Port 2 Connector in RS-232 (J9, J12)

Signal PIN Signal

DCD 1 2 RxD

TxD 3 4 DTR

GND 5 6 DSR

RTS 7 8 CTS

RI 9 10 NC

ECB-865 User’s Manual 35

Page 46

User’s Manual

3.11.15 Serial Port 1 / Serial Port 2 with External DB9 Connector (J9, J12)

Signal PIN Signal

GND 5

9 RI

DTR 4

8 CTS

TxD 3

7 RTS

RxD 2

6 DSR

DCD 1

3.11.16 Signal Description – Serial Port 1 / Serial Port 2 in RS-232 Mode (J9, J12)

TxD Serial output. This signal sends serial data to the communication link. The signal is set to a

marking state on hardware reset when the transmitter is empty or when loop mode operation

is initiated.

RxD Serial input. This signal receives serial data from the communication link.

DTR Data Terminal Ready. This signal indicates to the modem or data set that the on-board UART

is ready to establish a communication link.

DSR Data Set Ready. This signal indicates that the modem or data set is ready to establish a

communication link.

RTS Request To Send. This signal indicates to the modem or data set that the on-board UART is

ready to exchange data.

CTS Clear To Send. This signal indicates that the modem or data set is ready to exchange data.

DCD Data Carrier Detect. This signal indicates that the modem or data set has detected the data

carrier.

RI Ring Indicator. This signal indicates that the modem has received a telephone ringing signal.

36 ECB-865 User’s Manual

Page 47

ECB-865

3.11.17 Box Header Serial Port 1 / Serial Port 2 Connector in RS-422 (J9, J12)

Signal PIN Signal

NC 10 9 RI

CTS 8 7 RTS

DSR 6 5 GND

TxD+ 4 3 TxD-

RxD- 2 1 RxD+

3.11.18 Signal Description – Serial Port 1 / Serial Port 2 in RS-422 Mode (J9, J12)

TxD +/- Serial output. This differential signal pair sends serial data to the communication link. Data is

transferred from Serial Port 2 Transmit Buffer Register to the communication link, if the TxD

line driver is enabled through the Serial Port 2’s DTR signal. (Modem control register)

RxD +/- Serial input. This differential signal pair receives serial data from the communication link.

Received data is available in Serial Port 2 Receiver Buffer Register.

RTS +/- Request To Send. The level of this differential signal pair output is controlled through

the Serial Port 2’s RTS signal (Modem control register).

CTS +/- Clear To Send. The level of this differential signal pair input could be read from the Serial Port

2’s CTS signal. (Modem control register)

3.11.19 Box Header Serial Port 1 / Serial Port 2 Connector in RS-485 (J9, J12)

Signal PIN Signal

NC 10 9 CTS/RTS +

NC 8 7 CTS/RTS -

NC 6 5 GND

RxD/TxD + 4 3 RxD/TxD -

NC 2 1 NC

ECB-865 User’s Manual 37

Page 48

User’s Manual

3.11.20 Signal Description – Serial Port 1 / Serial Port 2 in RS-485 Mode (J9, J12)

RxD/TxD +/- Bi-directional data signal pair.

Received data is available in Serial Port 2 Receiver Buffer Register.

Data is transferred from Serial Port 2 Transmit Buffer Register to the communication line, if