Page 1

User Guide

p

s

XB1 COM Express™ Module

Document No. 4162 • Edition 5

2007-05

COM

Ex

res

Page 2

User Guide XB1 COM Express Module

Contents

About this Manual ........................................................... 4

Edition History......................................................... 4

Related Documents ..................................................... 5

Nomenclature ......................................................... 5

Trade Marks .......................................................... 5

Legal Disclaimer - Liability Exclusion ......................................... 5

XB1 COM Express Module Features .............................................. 6

Feature Summary ...................................................... 6

Short Description XB1 COM Express Module .................................. 8

Block Diagram XB1 COM Express Module ................................... 10

Assembly Drawing XB1 COM Express Module ................................ 11

Strapping Headers ..................................................... 12

Connectors & Sockets .................................................. 12

Indicators ........................................................... 12

Microprocessor ....................................................... 13

Thermal Considerations ................................................. 14

Main Memory ........................................................ 15

LAN Subsystem ....................................................... 15

Serial ATA Interface (SATA) .............................................. 16

Enhanced IDE Interface (PATA) ........................................... 16

Graphics Subsystem ................................................... 17

Real-Time Clock ....................................................... 18

Universal Serial Bus (USB) ............................................... 18

LPC Super-I/O Interface ................................................. 18

Firmware Hub (Flash BIOS) .............................................. 18

Watchdog/Reset ...................................................... 19

PG (Power Good) LED .................................................. 19

GP (General Purpose) LED ............................................... 19

Installing and Replacing Components ............................................ 20

Before You Begin...................................................... 20

Installing the Board .................................................... 21

Removing the Board ................................................... 22

EMC Recommendations................................................. 23

Installing or Replacing the Memory Modules ................................. 24

Replacement of the Battery .............................................. 24

Technical Reference ......................................................... 25

Local PCI Devices ...................................................... 25

Local SMB Devices ..................................................... 26

Hardware Monitor LM87 ................................................ 26

GPIO Usage .......................................................... 27

GPIO Usage ICH6 ................................................ 27

GPIO Usage FWH ................................................ 28

GPIO Usage SIO ................................................. 29

Configuration Jumpers ................................................. 30

Reset Jumper BIOS CMOS RAM Values (J-GP) ........................... 30

Reset Jumper ICH6 RTC Core (J-RTC) .................................. 30

©EKF -2- ekf.com

Page 3

User Guide XB1 COM Express Module

Connectors .......................................................... 31

PLD Programming Header ISPCON ................................... 31

J-COM ........................................................ 32

Processor Debug Header PITP ....................................... 36

P-SIO ......................................................... 37

Board Dimensions ..................................................... 38

Top View, Bottom View................................................. 39

Literature ........................................................... 40

©EKF -3- ekf.com

Page 4

User Guide XB1 COM Express Module

About this Manual

This manual describes the technical aspects of the XB1 COM Express Module, required for installation

and system integration. It is intended for the experienced user only.

Edition History

Ed.

Contents/Changes

1 User Manual XB1 COM Express Module, English, initial edition (Text #4162,

File: xb1_uge.wpd)

2 Table J-COM modified (PCIe Lane #3) jj 1 August 2006

3 Illustration 'Assembly Drawing' jj 31 August

4 Added XB1 photographs jj 16 November

5 Added XB1-060 jj 2 May 2007

Author Date

jj 27 April 2006

2006

2006

©EKF -4- ekf.com

Page 5

User Guide XB1 COM Express Module

Related Documents

For ordering information refer to document XB1 COM Express Module Product Information, available

at http://www.ekf.com/x/xb1/xb1_pie.pdf.

Nomenclature

Signal names used herein with an attached '#' designate active low lines.

Trade Marks

Some terms used herein are property of their respective owners, e.g.

< Intel, Pentium, Celeron, SpeedStep: ® Intel

< PCI Express: ® PCI-SIG

< COM Express:™ PICMG

< CompactPCI, CompactPCI Express, PICMG: ® PICMG

< Windows (2000, XP, Vista etc): ® Microsoft

< EKF, ekf system: ® EKF

EKF does not claim this list to be complete.

Legal Disclaimer - Liability Exclusion

This manual has been edited as carefully as possible. We apologize for any potential mistake.

Information provided herein is designated exclusively to the proficient user (system integrator,

engineer). EKF can accept no responsibility for any damage caused by the use of this manual.

©EKF -5- ekf.com

Page 6

User Guide XB1 COM Express Module

XB1 COM Express Module Features

Feature Summary

Feature Summary XB1

Form Factor PICMG COM Express R1.0 (COM.0), Basic Module form factor (125x95mm2),

Pin-out Type 2

Processor Designed for Intel® Pentium® M Micro FC-BGA 479 processors (90nm

Dothan), maximum junction temperature 100°C

< XB1-060: 600MHz ULV Celeron® M (Banias 130nm), 400MHz FSB, 512KB

L2 cache, 7W

< XB1-100: 1.0GHz ULV Celeron® M (Dothan 373), 400MHz FSB,

512KB L2 cache, 5W

< XB1-140: 1.4GHz LV Pentium® M (Dothan 738), 400MHz FSB, 2MB

L2 cache, 10W

< XB1-200: 2.0GHz Pentium® M (Dothan 760), 533MHz FSB, 2MB L2

cache, 27W

Chipset Intel® i915 embedded systems chipset (Alviso) consisting of:

< 82915GM Graphics/Memory Controller Hub (GMCH) with Intel®

Graphics Media Accelerator (GMA) 900

< 82801FB I/O Controller Hub (ICH6)

< 82802 Compatible Firmware Hub (FWH)

Memory Dual 200-pin SO-DIMM socket, DDR2 533 SDRAM, 2 x 1GB maximum,

symmetric dual channel capable

Video Up to 2048x1536 pixel 16M colours @75Hz refresh rate (analog), up to

1600 x 1200 pixel 16M colours @60Hz (digital), dual screen support

< Dual SDVO

< Analog VGA

< Dual LVDS

< TV Out

< PEG PCI Express x 16 external graphics interface, multiplexed with

SDVO

USB 8 x USB2.0

Ethernet PCIe to Gigabit Ethernet controller 10/100/1000Mbps

PATA (IDE) ICH6 integrated Ultra ATA/100 I/F

SATA 4 x SATA-150

GPIO 8 GPIO lines

Sound System AC '97 or HD Audio Azalia (external Codec)

PCI ICH6 integrated 32-bit PCI bridge, 133MBps CPCI master

PCI Express 3-Lane PCIe if PCIe Gigabit Ethernet controller is stuffed

4-Lane PCIe (x 4 Link) w/o PCIe Gigabit Ethernet controller (stuffing option)

BIOS Phoenix BIOS

©EKF -6- ekf.com

Page 7

User Guide XB1 COM Express Module

Feature Summary XB1

Drivers < Intel graphics drivers

< Intel networking drivers

Power

Requirements

Environmental

Conditions

MTBF tbd

EC Regulations • EN55022, EN55024, EN60950-1 (UL60950-1/IEC60950-1)

Performance

Rating

Measured with

PCMark2005

+12V ±0.5V, tbd A max. @2.0GHz (tbd A WinXP idle mode)

< Operating temperature: 0°C ... +70°C (CPU dependent)

< Storage temperature: -40°C ... +85°C, max. gradient 5°C/min

< Humidity 5% ... 95% RH non condensing

< Altitude -300m ... +3000m

< Shock 15g 0.33ms, 6g 6ms

< Vibration 1g 5-2000Hz

• 2002/95/EC (RoHS)

Board Processor CPU/MEM

XB1-060

XB1-100

XB1-140

600MHz ULV Celeron® M (Banias) tbd

1.0GHz ULV Celeron® M (Dothan 373) tbd

1.4GHz LV Pentium® M (Dothan 738) tbd

Score

XB1-201

2.0GHz Pentium® M (Dothan 760) tbd

Subject to technical changes

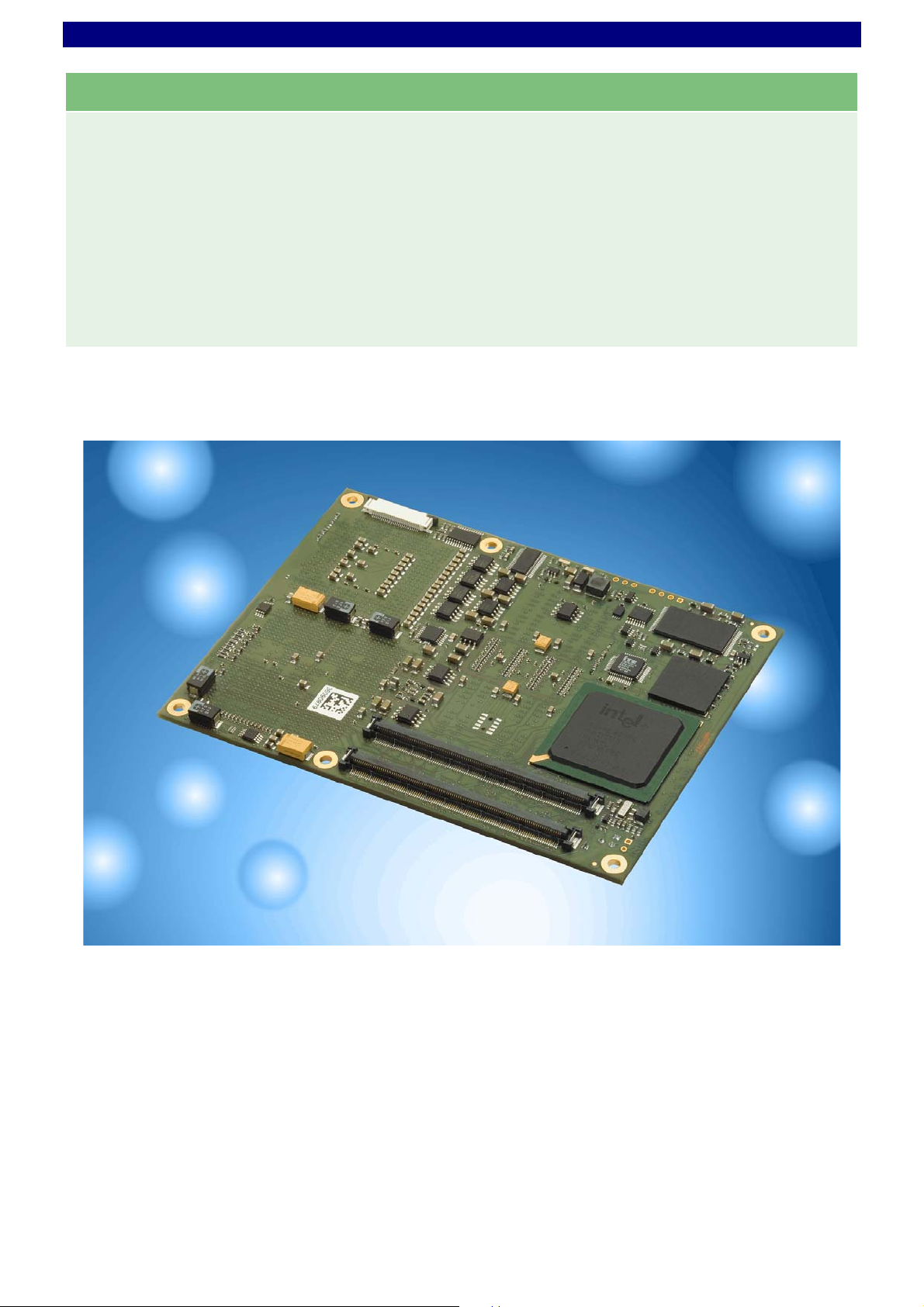

XB1 COM Express Module with Heatspreader

©EKF -7- ekf.com

Page 8

User Guide XB1 COM Express Module

Short Description XB1 COM Express Module

COM Express™ (also known as ETXexpress™) is

an open PICMG® standard for Computer-OnModules, comprising of latest technologies such

as PCI Express, Serial ATA, Gigabit Ethernet and

SDVO. While designing the carrier board only

once, users profit from upgrading or scaling

their application by simply changing the CPU

module.

Alternatively equipped with the Intel series of

(LV) Pentium® M and ULV Celeron® M

processors and up to 2GB RAM, the EKF

XB1 is

a versatile COM Express basic form factor

module, designed especially for systems which

require high performance at low power

consumption.

technology and has integrated a powerful dual

screen graphics accelerator. The SDVO and VGA

video interfaces allow for attachment of digital flat

panel displays and analog monitors.

The chipset is based on PCI Express

The XB1 is provided with a Gigabit Ethernet

controller, and eight USB 2.0 ports for high speed

communication. Four Serial ATA channels are

available in addition to the legacy PATA I/F. The dual

slot DIMM socket is suitable to address up to 2GB

interleaved (symmetric) dual channel memory.

Typically, the XB1 will be combined with a custom

specific carrier board. As a basic development tool,

EKF can supply a third party evaluation carrier board.

In addition, EKF offers their design services to create

a turn-key ready customer solution.

The XB1 COM Express module is the perfect choice

for embedded applications that require a low power

standard processor at the centre of their design.

OEMs can significantly improve their flexibility and

reduce their total cost by adopting the open

standards based architecture of COM Express.

XB1 COM Express Module

©EKF -8- ekf.com

Page 9

User Guide XB1 COM Express Module

Benefits of the XB1 COM Express Module

< PICMG COM.0 Compliant Module Type 2

< Pentium® M 2GHz (FSB 533MHz)

< PCI Express Chipset for Embedded Applications

< 2 x 1GB DDR2 Memory (Dual Channel Mode Capable)

< Dual-Screen Graphics Controller

< Video I/F SDVO, PEG, LVDS, VGA, TV

< Gigabit Ethernet Controller

< 4 x SATA I/F

< 8 x USB 2.0 Channels

< RoHS Compliant

XB1 from Bottom

©EKF -9- ekf.com

Page 10

User Guide XB1 COM Express Module

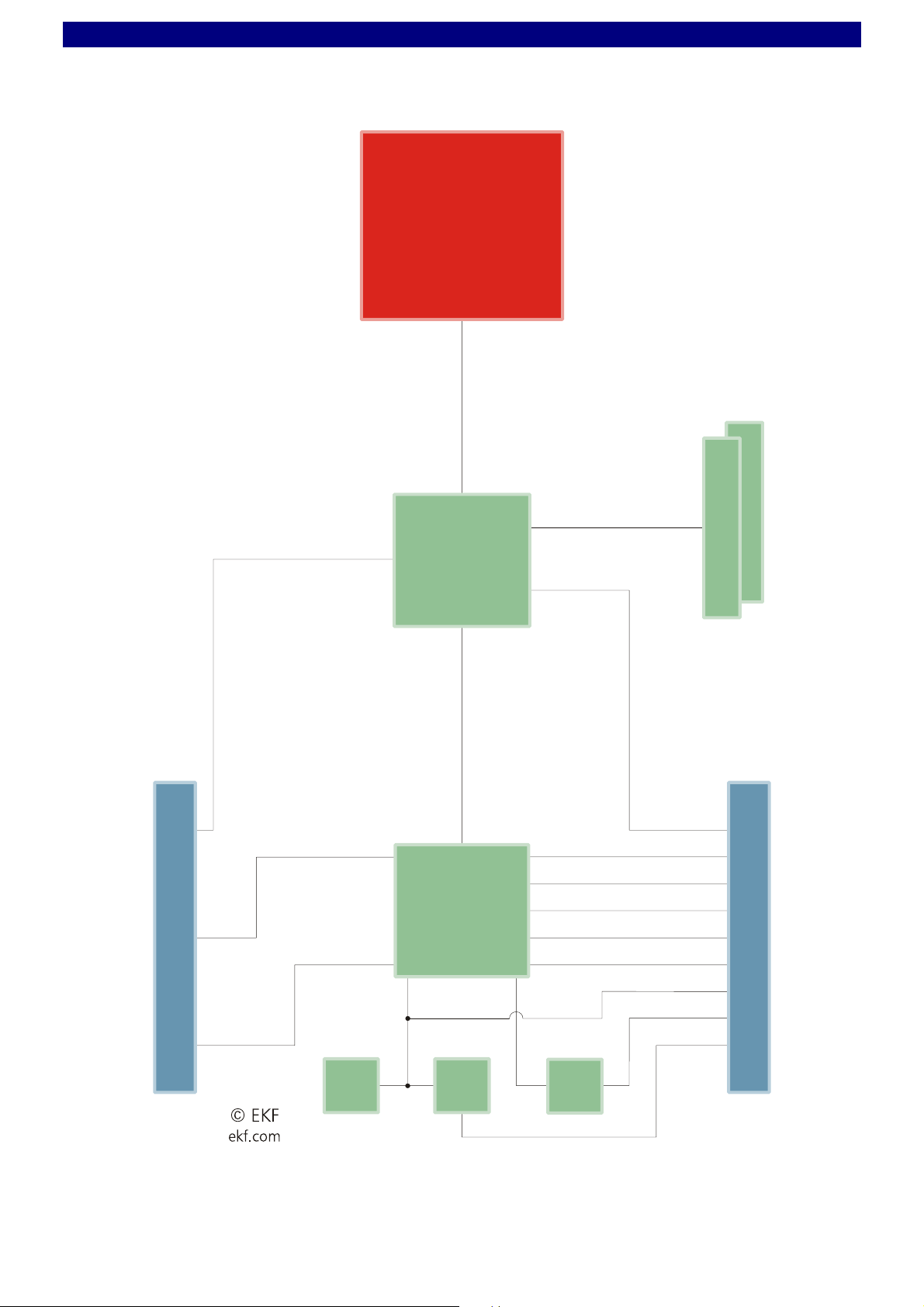

Block Diagram XB1 COM Express Module

Simplified

Block Diagram

X

B1

COM Express

Module

SDVO

PEG

Pentium® M

760

2.0GHz

FSB 533MHz

GMCH

82915

GM

VGA

LVDS/TV

Alternative CPU:

• Pentium® M 745 1.8GHz

• LV Pentium® M 738 1.4GHz

• Celeron® M 370 1.5GHz

• ULV Celeron® M 373 1.0GHz

DDR2 533

512MB-2GB

Dual

Channel

SO-DIMM 200

SO-DIMM 200

C-D

SDVO

PEG

IDE

PCI

BIOS

82

802

DMI x 4

ICH6

82801

SIO

87

61

VGA

8 x USB

4 x SATA

3 x PCIe

AC '97

SMB

PCIeLPC

G-ETH

LPC

GBE

GPIO

A-B

82

573

©EKF -10- ekf.com

Page 11

User Guide XB1 COM Express Module

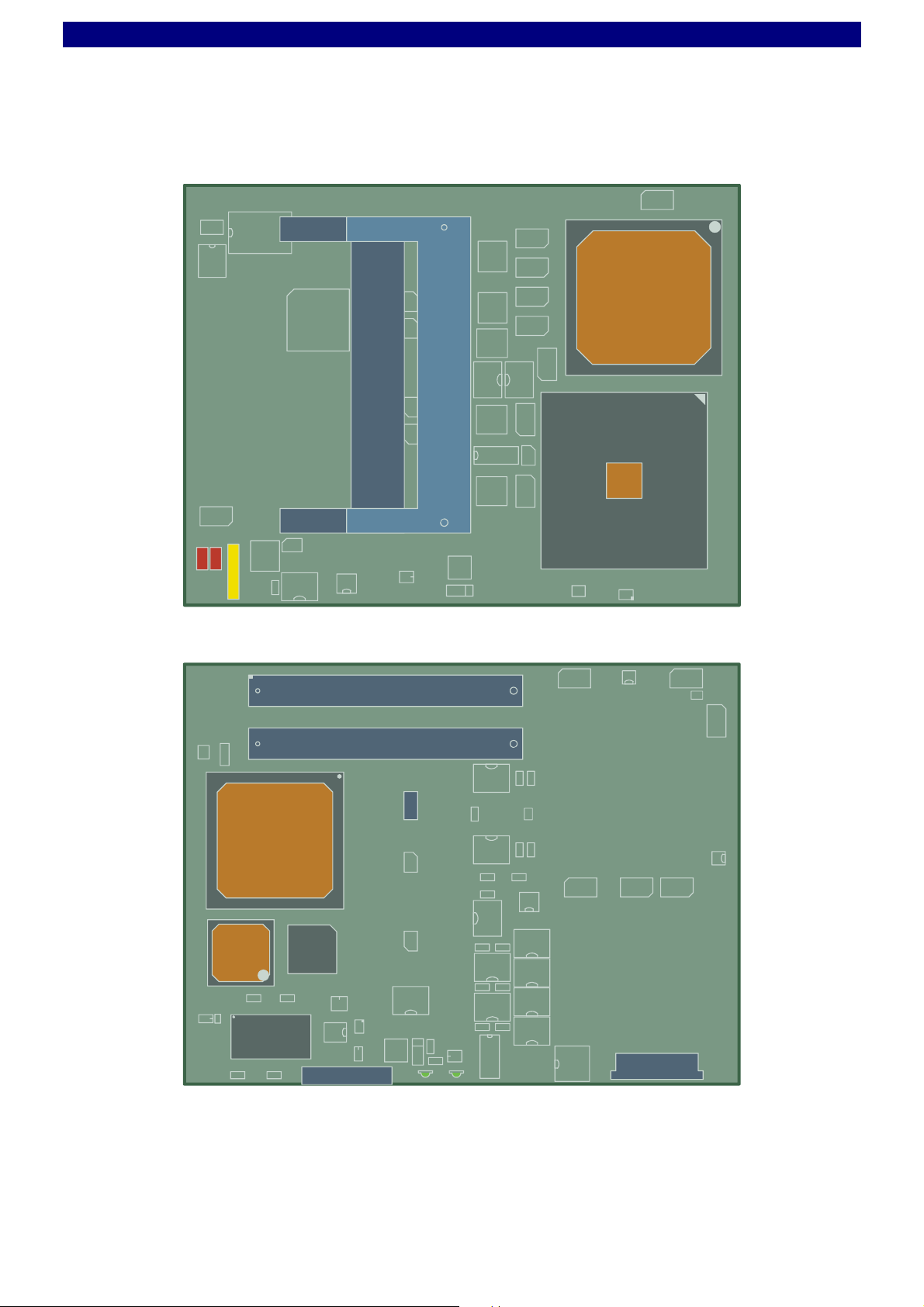

Assembly Drawing XB1 COM Express Module

DDR2 SODIMM

isp

DDR2 SODIMM

CPU

GAL

X

B1

Top

© EKF

ekf.com

BAT

+

J-GP

J-RTC

© EKF • B1 COM Express Module • ekf.com

A1

B1

COM Express Module Connector

C1

D1

X

J-COM A-B

J-COM C-D

1

P-SIO

GMCH

X

B1

Bottom

© EKF

ekf.com

ICH

NIC

SIO

FWH

1

1

ISPCON

©EKF -11- ekf.com

GP

LED

PG

P-ITP

Page 12

Strapping Headers

J-GP Jumper to reset BIOS CMOS RAM values

J-RTC Jumper to reset RTC core of ICH6, not stuffed

Connectors & Sockets

ISPCON PLD programming connector, not stuffed

J-COM A-B COM Express connector rows A and B (VGA, LVDS, TV, PCIe, SATA,

J-COM C-D COM Express connector rows C and D (Dual SDVO / PEG, IDE, PCI)

P-ITP CPU debug port

User Guide XB1 COM Express Module

Ethernet, USB, AC'97, SMB, LPC)

P-SIO I/O connector for debugging (not stuffed), comprises PS/2

SODIMM1

SODIMM2

Indicators

GP General Purpose LED

PG LED indicating Power Good / Board Healthy

mouse/keyboard signals, UART (TTL)

200-pin DDR2 SDRAM PC2-3200/4200 (DDR400/533) 1.8V memory

module sockets

©EKF -12- ekf.com

Page 13

User Guide XB1 COM Express Module

Microprocessor

The XB1 COM Express Module is designed for use with Pentium® M and Celeron® M processors

manufactured in 90nm technology (Dothan). These include also the Ultra Low-Voltage (ULV)

Celeron® M and the Low-Voltage (LV) Pentium® M processors as listed below. The processors are

housed in a Micro FC-BGA package for direct soldering to the PCB, i.e. the CPU chip cannot be

removed or changed by the user.

The processors supported by the XB1 COM Express Module are running at FSB clock speeds of

400MHz and 533MHz. The internal Pentium M processor speed is achieved by multiplying the host

bus frequency by a variable value. The multiplier is chosen by currently required performance and the

actual core temperature. This technology is called Enhanced Intel SpeedStep®.

Power is applied across the COM Express connectors J-COM (+12V). The processor core voltage is

generated by a switched voltage regulator. The processor signals its required core voltage by 6

dedicated pins according to Intels IMVP-IV voltage regulator specification.

90nm (Dothan) Processors Supported

Processor Speed

min/max

[GHz]

2)

2)

1) 2)

1.0/1.0 400 0.5 5 0-100 06D8h C-0 SL8LW

2)

0.6/1.4 400 2 10 0-100 06D6h

0.6/1.8 400 2 21 0-100 06D6h

0.8/2.0 533 2 27 0-100 06D8h C-0 SL869

ULV Celeron M 373

LV Pentium M 738

Pentium M 745

Pentium M 760

1)

This processor does not support SpeedStep® technology, instead it runs at a fixed core speed

2)

Following the Intel Embedded Roadmap, this processor is recommended for long time availability

Host Bus

[MHz]

L2 Cache

[MB]

TDP

[W]

Die Temp

[°C]

CPU ID Stepping sSpec

06D8h

06D8h

B-1

C-0

B-0

C-0

SL7P9

SL89N

SL7Q6

SL8U8

©EKF -13- ekf.com

Page 14

User Guide XB1 COM Express Module

Thermal Considerations

In order to avoid malfunctioning of the XB1 COM Express Module, take care of appropriate cooling

of the processor and system, e.g. by a cooling fan suitable to the maximum power consumption of

the CPU chip actually in use. Please note, that the processors temperature is steadily measured by a

special controller (LM87), attached to the onboard SMBus® (System Management Bus). A second

temperature sensor internal to the LM87 allows for acquisition of the boards surface temperature.

Beside this the LM87 also monitors most of the supply voltages. A suitable software to display both,

the temperatures as well as the supply voltages, is MBM (Motherboard Monitor), which can be

downloaded from the web. After installation, both temperatures and voltages can be observed

permanently from the Windows taskbar.

The XB1 COM Express Module is equipped with a passive heatsink (heat-spreader). In addition, a

forced airflow through the system enclosure by a suitable fan unit is highly recommended (>15m3/h

or 200LFM around the CPU module). As an exception, the XB1-100 (ULV Celeron M 1GHz) can be

operated with natural convection only. Be sure to thoroughly discuss your actual cooling needs with

EKF. Generally, the faster the CPU speed the higher its power consumption. For higher ambient

temperatures, consider increasing the forced airflow to 400 or 600LFM.

The table showing the supported processors above give also the maximum power consumption (TDP

= Thermal Design Power) of a particular processor. Fortunately, the power consumption is by far

lower when executing typical Windows or Linux tasks. The heat dissipation may increase considerably

when e.g. rendering software such as the Acrobat Distiller is executed.

The Pentium M processors support Intel's Enhanced SpeedStep® technology. This enables dynamic

switching between multiple core voltages and frequencies depending on core temperature and

currently required performance. The processors are able to reduce their core speed and core voltage

in up to 8 steps down to 600MHz. This leads to an obvious reduction of power consumption (max.

7.5W @600MHz) resulting in less heating. This mode of lowering the processor core temperature is

called TM2 (TM=Thermal Monitor). Note, that TM2 is not supported by Celeron M processors.

Another way to reduce power consumption is to modulate the processor clock. This mode (TM1) is

supported also by the Celeron M processors and is achieved by actuating the 'Stop Clock' input of the

CPU. A throttling of 50% e.g. means a duty cycle of 50% on the stop clock input. However, while

saving considerable power consumption, the data throughput of the processor is also reduced. The

processor works at full speed until the core temperature reaches a critical value. Then the processor

is throttled by 50%. As soon as the high temperature situation disappears the throttling will be

disabled and the processors runs at full speed again.

A similar feature is embedded within the Graphics and Memory Controller (GMCH) i915GM. An ondie temperature sensor is used to protect the GMCH from exceeding its maximum junction

temperature (T

=105°C) by reducing the memory bandwidth.

J,max

These features are controllable by BIOS menu entries. By default the BIOS of the XB1 COM Express

Module enables mode TM2 which is the most efficient.

©EKF -14- ekf.com

Page 15

User Guide XB1 COM Express Module

Main Memory

The XB1 COM Express Module is equipped with two sockets for installing 200-pin SO-DIMM modules

(module height = 1.25 inch). Supported are unbuffered DDR2 SO-DIMMs (VCC=1.8V) without ECC

featuring on-die termination (ODT), according the PC2-3200 or PC2-4200 specification. Minimum

memory size is 128MB; maximum memory size is 2GB. Due to the video requirements of the i915GM

chipset (some of the system memory is dedicated to the graphics controller), a minimum of 2x256MB

memory is recommended for the operating systems Windows NT 4.0, Windows 2000 or Windows XP.

The contents of the SPD EEPROM on the SO-DIMMs are read during POST (Power-on Self Test) to

program the memory controller within the chipset.

The i915GM chipset supports symmetric and asymmetric memory organization. The maximum

memory performance can be obtained by using the symmetric mode. To achieve this mode, two

SO-DIMMs of equal capacity must be installed in the memory sockets. In asymmetric mode different

memory modules may be used with the drawback of less bandwidth. A special case of asymmetric

mode is to populate only one memory module (i.e. one socket may be left empty).

LAN Subsystem

The Ethernet LAN subsystem is comprised of the Intel 82573 Gigabit Ethernet controller, which

provides also legacy 10Base-T and 100Base-TX connectivity.

< Single PCI Express lane linkage

< 1000Base-Tx (Gigabit Ethernet), 100Base-TX (Fast Ethernet) and 10Base-T (Classic Ethernet)

capability

< Half- or full-duplex operation

< IEEE 802.3u Auto-Negotiation for the fastest available connection

< Jumperless configuration (completely software-configurable)

The NIC (Networking Interface Controller) is connected by a single PCI Express lane to the chipset

southbridge (ICH6). Its MAC address (unique hardware number) is stored in a dedicated EEPROM. The

Intel Ethernet software and drivers for the 82573 is available from Intel's World Wide Web site for

download (link provided on the EKF website).

By specification, the XB1 COM Express Module does not provide any I/O connector. Instead, the

carrier board must provide the RJ45 receptacle with integrated magnetics for copper twisted pair

Ethernet. All MDI (Media Dependent Interface) signals of the Ethernet PHY are routed to the

connector J-COM A-B.

The 82573 controller is connected to the PCI Express lane #3. As an alternate stuffing option, this

lane is available across the J-COM connector instead, for carrier board applications which require 4

PCIe lanes (typically configured as PCIe x 4 link). If this stuffing option had been ordered, no Ethernet

connectivity is provided on the XB1 itself, but may be replicated on the carrier board.

©EKF -15- ekf.com

Page 16

User Guide XB1 COM Express Module

Serial ATA Interface (SATA)

The XB1 COM Express Module provides four serial ATA (SATA) ports, each capable of transferring

150MB/s. Integrated within the ICH6, the SATA controller features different modes to support also

legacy operating systems. The SATA channels are available to the carrier board across the J-COM A-B

connector.

Available for download from Intel are drivers for popular operating systems, e.g. Windows® 2000,

Windows® XP and Linux.

Enhanced IDE Interface (PATA)

The parallel ATA (PATA, also known as IDE) interface is provided for attachment of legacy peripheral

devices such as hard disks, ATA CompactFlash cards and CD-ROM drives. The interface supports:

C Up to two ATA devices

C PIO Mode 3/4, Ultra ATA/33, Ultra ATA/66, Ultra ATA/100

The PATA port is available to the carrier board across the J-COM C-D connector. The IDE controller is

integrated into the ICH6. Ultra ATA IDE drivers can be downloaded from the Intel website.

©EKF -16- ekf.com

Page 17

User Guide XB1 COM Express Module

Graphics Subsystem

The graphics subsystem is part of the versatile Intel i915GM Graphics/Memory Controller Hub

(GMCH), and is also known as Intel Graphics Media Accelerator (GMA) 900. As an alternative, PCI

Express based graphics is supported (requires discrete PEG controller present on the carrier board).

The main features of the GMA900 are:

< Dual Serial Digital Video Output (SDVO) - allows for two independent DVI connectors

< RGB output - suitable for a VGA style connector

< TV out (HDTV resolution)

< LVDS wide panel support

For legacy CRT style monitors, the XB1 COM Express Module is provided with RGB signals on the

J-COM A-B connector, suitable for a VGA D-Sub accommodated on the carrier board. Also the TV out

and the LCD panel signals (LVDS port) are routed to the J-COM A-B connector.

The GMCH multiplexes a PCI Express Graphics interface with two Intel SDVO ports. The SDVO ports

can each support a single-channel SDVO device. If both ports are active in single-channel mode, they

can have different display timing and data. Alternatively the SDVO ports can be combined to support

dual channel devices, enabling higher resolutions and refresh rates. On the XB1 COM Express Module,

the SDVO/PEG signals are routed to the connector J-COM C-D. Typically, one or two discrete display

transmitter chips located on the carrier board are used to convert Intels proprietary, PCI express based

SDVO interfaces to the differential DVI signals required for attachment of modern flat panel monitors.

E.g., the SiI1362 (Silicon Image) transmitter uses PanelLink® Digital technology to support displays

ranging from VGA to UXGA resolutions (25 - 165Mpps) in a single link interface. With two DVI

connectors on the carrier board, independent dual screen operation is available (this also applies for

one DVI and one D-Sub connector).

The GMCH supports several video resolutions and refresh rates. A partial list is contained in the table

below. Please note, that flat-panel displays should be operated with their native (maximum) resolution

at 60Hz refresh rate (some models also accept 75Hz). 16-bit high colour mode is recommended.

Partial List of i915GM GMCH Video Modes (analog / digital)

Resolution 60Hz 70Hz 72Hz 75Hz 85Hz

640x480 T / TT / TT / TT / TT / T

800x600 T / TT / TT / TT / TT / T

1024x768 T / T

1280x1024 T / T

1600x1200 T / T1)

1)

1)

2)

T / TT / TT / TT / T

T / TT / TT / TT / T

T / - T / - T / - T / -

2048x1536 T / - T / - T / - T / - - / -

1)

This video mode is suitable for popular flat-panel displays

2)

In dual screen mode 2 x 1600x1200, 32-bit true colours are not available for both outputs simultaneously

Graphics drivers for the i915GM can be downloaded from the Intel website.

©EKF -17- ekf.com

Page 18

User Guide XB1 COM Express Module

Real-Time Clock

The XB1 COM Express Module has a time-of-day clock and 100-year calendar, integrated into the

ICH6.

A battery on the board keeps the clock current when the computer is turned off. The XB1 uses a

Vanadium-Pentoxide-Lithium rechargeable battery, giving an autonomy of more than 50 days when

fully loaded after 24 hours. The cell is free of memory effects and withstands deep discharging. Under

normal conditions, replacement should be superfluous during lifetime of the board. Custom specific

versions of the XB1 may not provide the accumulator.

In addition, VCC_RTC is also redundantly derived from the carrier board (if supported). The time

keeping autonomy period is then defined by the battery capacity accommodated on the carrier.

Universal Serial Bus (USB)

The XB1 COM Express Module is provided with eight USB ports, all of them are USB 2.0 capable. Four

active-low over-current sensing inputs are available in addition, suitable for attachment of electronic

switches such as the LM3526-L on the carrier board. The USB controllers are integrated into the ICH6.

LPC Super-I/O Interface

In a modern system, legacy ports as PS/2 keyboard/mouse, COM1/2 and LPT have been replaced by

USB and Ethernet connectivity. The 1.4MB floppy disk drive has been swapped against CD/DVD-RW

drives or USB memory sticks. Hence, the XB1 COM Express Module is virtually provided with all

necessary I/O functionality. However, for BIOS and OS software compatibility, the XB1 is additionally

equipped with a simple Super-I/O chip. The Super-I/O controller resides on the local LPC bus (LPC =

Low Pin Count interface standard), which is a serialized ISA bus replacement. For debug only, a

connector P-SIO may be stuffed on the XB1, with KB/MS signals derived from the SIO and also a

rudimentary serial I/F (TTL-level Tx/Rx RTS/CTS).

The SIO provides a rich set of GPIO lines. Four channels are used as GPI0..3, and another 4 channels

as GPO0..3, all routed to the connector J-COM A-B, for use on the carrier board.

Firmware Hub (Flash BIOS)

The BIOS is stored in an 8Mbit Firmware Hub attached to the LPC bus. The firmware hub contains a

nonvolatile memory core based on flash technology, allowing the BIOS to be upgraded. The XB1

firmware hub may be deselected by the carrier board from use as primary BIOS source, by activating

the signal BIOS_DISABLE# on J-COM A-B. This allows a potential secondary firmware hub residing on

the carrier board to be used as alternative BIOS source.

The FWH can be reprogrammed (if suitable) by a DOS based tool. This program and the latest XB1

COM Express Module BIOS are available from the EKF website. Read carefully the enclosed

instructions. If the programming procedure fails e.g. caused by a power interruption, the XB1 COM

Express Module may no more be operable. In this case you would have to send in the board, because

the BIOS is directly soldered to the PCB and cannot be changed by the user.

©EKF -18- ekf.com

Page 19

User Guide XB1 COM Express Module

Watchdog/Reset

The XB1 COM Express Module is provided with two supervisor circuits to monitor the supply voltages

1.8V, 3.3V, 5V, and to generate a clean power-on reset signal. The healthy state of the XB1 COM

Express Module immideately after a reset is signalled by the LED PG (Power Good), indicating that all

power voltages are within their specifications and the reset signal has been deasserted.

An important reliability feature is the watchdog function, which is programmable by software. The

behaviour of the watchdog is defined within the PLD, which activates/deactivates the watchdog and

controls its time-out period. The time-out delay is adjustable in the steps 2, 10, 50 and 255 seconds.

After alerting the WD and programming the time-out value, the related software (e.g. application

program) must trigger the watchdog periodically. All watchdog related functions are made available

by calling service requests within the BIOS.

The watchdog is in a passive state after a system reset. There is no need to trigger it at boot time. The

watchdog is activated on the first trigger request. If the duration between two trigger requests

exceeds the programmed period, the watchdog times out and a system reset will be generated. The

watchdog remains in its active state until the next system reset. There is no way to disable it once it

had been put on alert, whwereas it is possible to reprogram its time-out value at any time.

PG (Power Good) LED

The XB1 COM Express Module offers a software programmable LED located. After system reset, this

LED defaults to signal the board healthy respectively power good. By the first setting of the GPO20 of

the ICH6 this LED changes its function and is then controlled only by the level of the GPO20 pin.

Setting this pin to 1 will switch on the LED. The PG LED remains in the programmable state until the

next system reset.

GP (General Purpose) LED

A second, programmable LED can be also observed from the front panel. The status of the GP LED is

controlled by the GPO18 output of the ICH6. Setting this pin to 1 will switch on the LED. As of

current, the GP LED is not dedicated to any particular hardware or firmware function (this may change

in the future).

©EKF -19- ekf.com

Page 20

User Guide XB1 COM Express Module

Installing and Replacing Components

Before You Begin

Warnings

The procedures in this chapter assume familiarity with the general terminology associated with

industrial electronics and with safety practices and regulatory compliance required for using and

modifying electronic equipment. Disconnect the system from its power source and from

any telecommunication links, networks or modems before performing any of the

procedures described in this chapter. Failure to disconnect power, or telecommunication

links before you open the system or perform any procedures can result in personal injury

or equipment damage. Some parts of the system can continue to operate even though

the power switch is in its off state.

Caution

Electrostatic discharge (ESD) can damage components. Perform the procedures described in this

chapter only at an ESD workstation. If such a station is not available, you can provide

some ESD protection by wearing an antistatic wrist strap and attaching it to a

metal part of the system chassis or board front panel. Store the board only in its

original ESD protected packaging. Retain the original packaging (antistatic bag and

antistatic box) in case of returning the board to EKF for rapair.

©EKF -20- ekf.com

Page 21

User Guide XB1 COM Express Module

Installing the Board

Warning

This procedure should be done only by qualified technical personnel. Disconnect the system from its

power source before doing the procedures described here. Failure to disconnect power, or

telecommunication links before you open the system or perform any procedures can result in personal

injury or equipment damage.

Typically you will perform the following steps:

C Switch off the system, remove the AC power cord

C Attach your antistatic wrist strap to a metallic part of the system

C Remove the board packaging, be sure to touch the board only at the heat spreader

C Insert module carefully into the complementary J-COM connectors on the carrier board

C Fix mounting screws

C Retain original packaging in case of return

©EKF -21- ekf.com

Page 22

User Guide XB1 COM Express Module

Removing the Board

Warning

This procedure should be done only by qualified technical personnel. Disconnect the system from its

power source before doing the procedures described here. Failure to disconnect power, or

telecommunication links before you open the system or perform any procedures can result in personal

injury or equipment damage.

Typically you will perform the following steps:

C Switch off the system, remove the AC power cord

C Attach your antistatic wrist strap to a metallic part of the system

C Identify the board, be sure to touch the board only at the front panel

C Unfasten screws

C Remove the module carefully

C Store board in the original packaging, do not touch any components, hold the board at the

heat spreader only

Warning

Do not expose the card to fire. Battery cells and other components could explode

and cause personal injury.

©EKF -22- ekf.com

Page 23

User Guide XB1 COM Express Module

EMC Recommendations

In order to comply with the CE regulations for EMC, it is mandatory to observe the following rules:

C The chassis or rack including other boards in use must comply entirely with CE

C Close all board slots not in use with a blind front panel

C Front panels must be fastened by built-in screws

C Cover any unused front panel mounted connector with a shielding cap

C External communications cable assemblies must be shielded (shield connected only at one end

of the cable)

C Use ferrite beads for cabling wherever appropriate

C External I/O connectors may require additional isolating parts

Reccomended Accessories

Blind CPCI Front

Panels

Ferrit Bead Filters ARP Datacom,

Metal Shielding

Caps

EKF Elektronik Widths currently available

(1HP=5.08mm):

with handle 4HP/8HP

without handle

2HP/4HP/8HP/10HP/12HP

Ordering No.

63115 Dietzenbach

102 820 (cable diameter 6.5mm)

102 821 (cable diameter 10.0mm)

102 822 (cable diameter 13.0mm)

Conec-Polytronic,

59557 Lippstadt

Ordering No.

CDFA 09 165 X 13129 X (DB9)

CDSFA 15 165 X 12979 X (DB15)

CDSFA 25 165 X 12989 X (DB25)

©EKF -23- ekf.com

Page 24

User Guide XB1 COM Express Module

Installing or Replacing the Memory Modules

Note: If you decide to replace the memory, observe the precautions in 'Before You Begin'

By default, the XB1 COM Express Module comes fully equipped and tested with two DDR2 SDRAM

memory modules. So normally there should be no need to install the memory modules.

The XB1 COM Express Module requires at least one PC2-3200/4200 (400/533MHz) DDR2 SDRAM SODIMM module. For optimum performance two SO-DIMMs of equal capacity are recommended.

Further it is highly recommended that Serial Presence Detect (SPD) SO-DIMMs be used, since this

allows the chipset to accurately configure the memory settings for optimum performance.

A replacement memory module must match the 200-pin SO-DIMM form factor (known from

Notebook PCs), DDR2, VCC=1.8V, PC2-3200/PC2-4200 (400/533MHz), on-die termination (ODT),

unbuffered, non-ECC style. Suitable modules are available up to 1GB each. The i915GM supports

modules of up to a maximum of 14 address lines (A0...A13). Memory modules organized by more

than14 address lines are not suitable.

Replacement of the Battery

When the XB1 is removed from the carrier board, an optional on-board battery maintains the voltage

to run the time-of-day clock and to keep the values in the CMOS RAM over ~30 days. The battery is

rechargeable und should last during the lifetime of the XB1 COM Express Module. For replacement,

the old battery must be desoldered, and the new one soldered. We suggest that you send back the

board to EKF for battery replacement.

Warning

Danger of explosion if the battery is incorrectly replaced. Replace only with the same or

equivalent type. Do not expose a battery to fire.

©EKF -24- ekf.com

Page 25

User Guide XB1 COM Express Module

Technical Reference

Local PCI Devices

The following table shows the on-board PCI devices and their location within the PCI configuration

space. These devices reside mainly within the i915GM chipset.

Bus

Number

0 0 0 0x8086 0x2590 Host Bridge

0 2 0 0x8086 0x2592 Internal Graphics Device

0 2 1 0x8086 0x2792 Int. Graphics Config. Regs.

0 27 0 0x8086 0x2668 Intel High Definition Audio

0 28 0 0x8086 0x2660 PCI Express Port 1

0 28 1 0x8086 0x2662 PCI Express Port 2

0 28 2 0x8086 0x2664 PCI Express Port 3

0 28 3 0x8086 0x2666 PCI Express Port 4

0 29 0 0x8086 0x2658 USB UHCI Controller #1

0 29 1 0x8086 0x2659 USB UHCI Controller #2

0 29 2 0x8086 0x265A USB UHCI Controller #3

0 29 3 0x8086 0x265B USB UHCI Controller #4

0 29 7 0x8086 0x265C USB 2.0 EHCI Controller

Device

Number

Function

Number

Vendor ID Device ID Description

0 30 0 0x8086 0x244E PCI-to-PCI Bridge

0 30 2 0x8086 0x266E AC'97 Audio Controller

0 30 3 0x8086 0x266D AC'97 Modem Controller

0 31 0 0x8086 0x2640 LPC Bridge

0 31 1 0x8086 0x266F IDE Controller

0 31 2 0x8086 0x2651 SATA Controller

0 31 3 0x8086 0x266A SMB Controller

1)

3

1)

2)

This bus number can vary depending on the PCI enumeration schema implemented in BIOS.

The XB1 COM Express Module is available with a 82573L or 82573E/V Ethernet controller.

0 0 0x8086 0x108B

0x108C

2)

2)

Ethernet Controller NC1

©EKF -25- ekf.com

Page 26

User Guide XB1 COM Express Module

Local SMB Devices

The XB1 COM Express Module contains a few devices that are attached to the System Management

Bus (SMBus). These are the clock generation chip, the SPD EEPROMs on the SO-DIMM memory

modules, a general purpose serial EEPROM and a supply voltage and CPU temperature controlling

device in particular. Other devices could be connected to the SMB on the carrier board across J-COM

A-B.

Address Description

0x58 Hardware Monitor/CPU Temperature Sensor (LM87)

0xA0 SPD of SODIMM1

0xA2 SPD of SODIMM2

0xAE General Purpose EEPROM

0xD2 Main Clock Generation (CK-410M)

Hardware Monitor LM87

The XB1 COM Express Module is provided with a LM87 hardware monitor attached to the SMB. This

device is capable to observe board and CPU temperatures as well as several supply voltages generated

on the board with a resolution of 8 bit. The following table shows the mapping of the voltage inputs

of the LM87 to the corresponding supply voltages of the XB1 COM Express Module:

Input Source Resolution

Register

[mV]

AIN1 CPU Core Voltage 9.8 0x28

AIN2 +1.05V 9.8 0x29

VCCP1 +1.5V 14.1 0x21

VCCP2/D2- +1.8V 14.1 0x25

+2.5V/D2+ +2.5V 13 0x20

+3.3V +3.3V 17.2 0x22

+5V +5V 26 0x23

+12V +12V 62.5 0x24

Besides the continuous measuring of temperatures and voltages the LM87 may compare these values

against programmable upper and lower boundaries. As soon as a measurement violates the allowed

value range, the LM87 may request an interrupt via the GPI[7] of the ICH6.

©EKF -26- ekf.com

Page 27

User Guide XB1 COM Express Module

GPIO Usage

GPIO Usage ICH6

XB1 COM Express Module GPIO Usage ICH6

GPIO Type Tol. Function Description

GPI 0 I 5V EXCD1_CPPE# PCI ExpressCard PCI Express capable card 1 request

GPI 1 I 5V EXCD0_CPPE# PCI ExpressCard PCI Express capable card 0 request

GPI 2 I 5V PG_VR33 Power Good signal from 3.3V voltage regulator

GPI 3 I 5V WAKE1# General purpose wake up signal from carrier board

GPI 4 I 5V PWR_OK Power OK from main power supply

GPI 5 I 5V BATLOW# Indicates that external battery is low

GPI 6 I 3.3V GP_JUMP# BIOS CMOS Values Reset Jumper JGP

GPI 7 I 3.3V HM_INT# Hardware Monitor LM87 Interrupt Line

2

GPI 8 I 3.3V I2C_DAT I

C emulated data signal (input only, see also GPIO 28)

GPI 9 I 3.3V USB_OC45# USB Ports 4 & 5 Overcurrent Detect Line (GPI9/10 joined)

GPI 10 I 3.3V USB_OC45# USB Ports 4 & 5 Overcurrent Detect Line (GPI9/10 joined)

GPI 11 I 3.3V SMB_ALERT# System Management Bus Alert

GPI 12 I 3.3V PEG_ENABLE# If pulled low externally, enables the PCI Express x 16 external

graphics interface and disables internal graphics (internally

pulled up 10k/3.3V)

2

GPI 13 I 3.3V I2C_CK I

C emulated clock signal (input only, see also GPIO 27)

GPI 14 I 3.3V USB_OC67# USB Ports 6 & 7 Overcurrent Detect Line (GPI14/15 joined)

GPI 15 I 3.3V USB_OC67# USB Ports 6 & 7 Overcurrent Detect Line (GPI14/15 joined)

GPO 16 O 3.3V EXCD1_RST# PCI ExpressCard reset card 1

GPO 17 O 3.3V EXCD0_RST# PCI ExpressCard reset card 0

GPO 18 O 3.3V ICH_GPO18 Control output to PLD

GPO 19 O 3.3V ICH_GPO19 Control output to PLD

GPO 20 O 3.3V ICH_GPO20 Control output to PLD

GPO 21 O 3.3V ICH_GPO21 Control output to PLD

GPO 23 O 3.3V not used - open

GPIO 24 I/O 3.3V ICH_GPIO24 for future use as PLD control signal (either input or output)

GPIO 25 O 3.3V not used - open (configured as output by BIOS)

GPI 26 I 3.3V CLK_64HZ 64Hz clock from 4040 binary counter

2

GPIO 27 O 3.3V I2C_CK I

GPIO 28 O 3.3V I2C_DAT I

C emulated clock signal (output only, see also GPI 13)

2

C emulated data signal (output only, see also GPI 8)

GPI 29 I 3.3V BOARD_CFG1 Board configuration options line 1

©EKF -27- ekf.com

Page 28

User Guide XB1 COM Express Module

XB1 COM Express Module GPIO Usage ICH6

GPIO Type Tol. Function Description

GPI 30 I 3.3V BOARD_CFG2 Board configuration options line 2

GPI 31 I 3.3V BOARD_CFG3 Board configuration options line 3

GPIO 32 O 3.3V not used - open (configured as output by BIOS)

GPIO 33 O 3.3V NC1_OFF# Enable Ethernet Controller NC1

GPIO 34 I/O 3.3V ICH_GPIO34 for future use as PLD control signal (either input or output)

GPI 40 I 5V PG_VR18 Power Good signal from 1.8V voltage regulator

GPI 41 I 3.3V LPC_DRQCOM# LPC Port DMA request from COM Express carrier board

GPO 48 O 3.3V not used - open

GPO 49 OD 1.05V CPU_PWRGD CPU Power Good signal

italic blue –> signal available on J-COM

GPIO Usage FWH

XB1 COM Express Module GPIO Usage FWH

GPIO Type Tol. Function Description

GPI 0 I 3.3V FWH_ID FWH Identity: Fixed to GND (indicates FWH #1)

GPI 1 I 3.3V IDE_CLBID# IDE 80-pos. Cable Detection Line

GPI 2 I 3.3V WDOGRST Last Hardware Reset caused by watchdog

GPI 3 I 3.3V LSB PCB REV GPI 4 GPI 3 Rev.

0 0 0

0 1 1

GPI 4 I 3.3V MSB PCB REV

1 0 2

1 1 3+

©EKF -28- ekf.com

Page 29

User Guide XB1 COM Express Module

GPIO Usage SIO

XB1 COM Express Module GPIO Usage SIO

GPIO Type Tol. Function Description

GPIO 10 I/O 5V/16mA

GPIO 11 I/O 5V/16mA

1)

1)

GPIO 12 O LPC_DRQSIO# LPC Port DMA request from SIO

GPIO 13 I/O 5V/8mA

GPIO 14 I/O 5V/8mA

GPIO 15 I/O 5V/8mA

GPIO 16 I/O 5V/24mA

GPIO 17 I/O 5V/24mA

GPIO 20 I 5V

GPIO 21 I 5V

GPIO 22 I 5V

GPIO 23 I 5V

1)

1)

1)

1)

1)

1)

1)

1)

1)

MSDAT PS/2 mouse data or custom GPIO

MSCLK PS/2 mouse clock or custom GPIO

not used

not used

not used

not used

not used

GPI0 GPI signal from COM Express module carrier board

GPI1 GPI signal from COM Express module carrier board

GPI2 GPI signal from COM Express module carrier board

GPI3 GPI signal from COM Express module carrier board

GPIO 24 OC 10k/3.3V 24mA GPO0 GPO signal to COM Express module carrier board

GPIO 25 OC 10k/3.3V 24mA GPO1 GPO signal to COM Express module carrier board

GPIO 26 OC 10k/3.3V 24mA GPO2 GPO signal to COM Express module carrier board

GPIO 27 OC 10k/3.3V 24mA GPO3 GPO signal to COM Express module carrier board

1)

These GPIOs have pullup resistors of approx. 50kΩ within the SIO

italic blue –> signal available on J-COM

italic green –> signal available on P-SIO

©EKF -29- ekf.com

Page 30

User Guide XB1 COM Express Module

Configuration Jumpers

Reset Jumper BIOS CMOS RAM Values (J-GP)

The jumper J-GP is used to reset the contents of the battery backed CMOS RAM to their default state.

The BIOS uses the CMOS to store configuration values, e.g. the order of boot devices. Using this

jumper is appropriate only, if it is not possible to enter the setup screen of the BIOS. To restore the

CMOS RAM, install a short circuit jumper on JGP and perform a system reset. As long as the jumper

is stuffed, the BIOS will use the default CMOS values after any system reset. To get normal operation

again, the jumper has to be removed.

JGP

1

1=GPI6 2=GND

© EKF 240.1.02 ekf.com

JGP Function

Jumper removed

1)

No CMOS reset performed

Jumper set CMOS reset performed

1)

This setting is the factory default

Reset Jumper ICH6 RTC Core (J-RTC)

The jumper J-RTC can be used to reset the battery backed core of the ICH6. This effects some registers

within the ICH6 RTC core that are important before the CPU starts its work after a system reset. Note

that JRTC will neither perform the clearing of the CMOS RAM values nor resets the real time clock.

Normally JRTC is not stuffed on the XB1 COM Express Module. To reset the RTC core, the XB1 COM

Express Module must be removed from the carrier board. It is important to accomplish the RTC reset

while the module has no power applied to it. Short-circuit the JRTC pads for about 1s. After that,

reinstall the module to the carrier and switch on the power.

JRTC

1

1=RTCRST# 2=GND

© EKF 240.1.02 ekf.com

JRTC Function

Jumper OFF

1)

No RTC reset performed

Jumper ON RTC reset performed

1)

This setting is the factory default

©EKF -30- ekf.com

Page 31

User Guide XB1 COM Express Module

Connectors

Caution

Some of the internal connectors provide operating voltage (3.3V and 5V) to devices inside the system

chassis, such as internal peripherals. Not all of these connectors are overcurrent protected. Do not use

these internal connectors for powering devices external to the computer chassis. A fault in the load

presented by the external devices could cause damage to the board, the interconnecting cable and

the external devices themselves.

PLD Programming Header ISPCON

This pin header is the programming port for the on-board ispLSI2064 programmable glue logic chip.

The ISPCON is normally not stuffed.

ISPCON

1

1=3.3V 2=Serial Out 3=Serial In 4=ispGAL Enable

5=NC 6=Mode 7=GND 8=Clock

240.1.08.I

© EKF

ekf.com

©EKF -31- ekf.com

Page 32

User Guide XB1 COM Express Module

J-COM

J-COM is the pair of connectors which serves as interface between the XB1 COM Express Module and

the carrier board. The assembly is composed of two double-row, high speed, 0.5mm pitch plugs.

Each row has 110 leads, i.e. J-COM provides 440 contact positions in total. The COM.0 specification

assigns each row a letter A, B and C, D. For Type 1 COM Express modules, rows A and B are sufficient

(single connector, 220 leads). In addition, rows C and D (dual connector, 440 positions) are required

for extended functionality incorporated into Type 2 modules such as the XB1.

AB#CD

GND GND 1 GND GND

ETH_MX3- 1) ETH_LKACT# 1) 2 IDE_D7 IDE_D5

ETH_MX3+ 1) LPC_FRAME# 3 IDE_D6 IDE_D10

ETH_LK100# 1) LPC_AD0 4 IDE_D3 IDE_D11

ETH_LK1000# 1) LPC_AD1 5 IDE_D15 IDE_D12

ETH_MX2- 1) LPC_AD2 6 IDE_D8 IDE_D4

ETH_MX2+ 1) LPC_AD3 7 IDE_D9 IDE_D0

ETH_LKACT# 1) LPC_DRQCOM# (LPC_DRQ0#) 8 IDE_D2 IDE_DREQ

ETH_MX1- 1) LPC_DRQ1# 9 IDE_D13 IDE_IOW#

ETH_MX1+ 1) CLK_33LPC (LPC_CLK) 10 IDE_D1 IDE_DACK#

GND GND 11 GND GND

ETH_MX0- PWRBTN# 12 IDE_D14 IDE_IRQ

ETH_MX0+ SMB_CLK 13 IDE_IORDY IDE_A0

+2.5V (ETH_CTREF) SMB_DATA 14 IDE_IOR# IDE_A1

ICH_SLP_S3# (SUS_S3#) SMB_ALERT# 15 PCI_PME# IDE_A2

SATA_0TP SATA_1TP 16 PCI_GNT2# IDE_CS1#

SATA_0TN SATA_1TN 17 PCI_REQ2# IDE_CS3#

ICH_SLP_S4# (SUS_S4#) SUS_STAT# 18 PCI_GNT1# IDE_RST#

SATA_0RP SATA_1RP 19 PCI_REQ1# PCI_GNT3#

SATA_0RN SATA_1RN 20 PCI_GNT0# PCI_REQ3#

GND GND 21 GND GND

SATA_2TP SATA_3TP 22 PCI_REQ0# PCI_AD1

SATA_2TN SATA_3TN 23 PCI_RST# PCI_AD3

ICH_SLP_S5# (SUS_S5#) PWR_OK 24 PCI_AD0 PCI_AD5

SATA_2RP SATA_3RP 25 PCI_AD2 PCI_AD7

SATA_2RN SATA_3RN 26 PCI_AD4 PCI_CBE0#

BATLOW# WDOGRST (WDT) 27 PCI_AD6 PCI_AD9

SATA_ACT# AC_SDIN2 28 PCI_AD8 PCI_AD11

AC_SYNC AC_SDIN1 29 PCI_AD10 PCI_AD13

AC_RST# AC_SDIN0 30 PCI_AD12 PCI_AD15

©EKF -32- ekf.com

Page 33

User Guide XB1 COM Express Module

AB#CD

GND GND 31 GND GND

AC_BITCLK SPKR 32 PCI_AD14 PCI_PAR

AC_SDOUT I2C_CK 33 PCI_CBE1# PCI_SERR#

BIOS_DISABLE# I2C_DAT 34 PCI_PERR# PCI_STOP#

THRMTRIP# THRM# 35 PCI_LOCK# PCI_TRDY#

USB_6N USB_7N 36 PCI_DEVSEL# PCI_FRAME#

USB_6P USB_7P 37 PCI_IRDY# PCI_AD16

USB_OC67# USB_OC45# 38 PCI_CBE2# PCI_AD18

USB_4N USB_5N 39 PCI_AD17 PCI_AD20

USB_4P USB_5P 40 PCI_AD19 PCI_AD22

GND GND 41 GND GND

USB_2N USB_3N 42 PCI_AD21 PCI_AD24

USB_2P USB_3P 43 PCI_AD23 PCI_AD26

USB_OC23# USB_OC01# 44 PCI_CBE3# PCI_AD28

USB_0N USB_1N 45 PCI_AD25 PCI_AD30

USB_0P USB_1P 46 PCI_AD27 PCI_IRQC#

+VCCRTC EXCD1_RST# 47 PCI_AD29 PCI_IRQD#

EXCD0_RST# EXCD1_CPPE# 48 PCI_AD31 PCI_CLKRUN#

EXCD0_CPPE# SYS_RESET# 49 PCI_IRQA# PCI_M66EN

SERIRQ (LPC_SERIRQ) CB_RESET# 50 PCI_IRQB# CLK_33PCI (PCI_CLK)

GND GND 51 GND GND

PCIE_TX5+ PCIE_RX5+ 52 SDVO_TVCLKIN+ PEG_RX0+ SDVOB_RED0+ PEG_TX0+

PCIE_TX5- PCIE_RX5- 53 SDVO_TVCLKIN- PEG_RX0- SDVOB_RED- PEG_TX0-

GPI0 GPO1 54 TYPE0# (NC) PEG_LANE_RV#

PCIE_TX4+ PCIE_RX4+ 55 SDVOB_INT+ PEG_RX1+ SDVOB_GRN+ PEG_TX1+

PCIE_TX4- PCIE_RX4- 56 SDVOB_INT- PEG_RX1- SDVOB_GRN- PEG_TX1-

GND GPO2 57 TYPE1# (NC) TYPE2# (NC)

PCIE_TX3+ 1) PCIE_RX3+ 1) 58 SDVO_FLDSTALL+ PEG_RX2+ SDVOB_BLU+ PEG_TX2+

PCIE_TX3- 1) PCIE_RX3- 1) 59 SDVO_FLDSTALL- PEG_RX2- SDVOB_BLU- PEG_TX2-

©EKF -33- ekf.com

Page 34

User Guide XB1 COM Express Module

AB#CD

GND GND 60 GND GND

PCIE_TX2+ PCIE_RX2+ 61 PEG_RX3+ SDVOB_CLK+ PEG_TX3+

PCIE_TX2- PCIE_RX2- 62 PEG_RX3- SDVOB_CLK- PEG_TX3-

GPI1 GPO3 63 RSVD RSVD

PCIE_TX1+ PCIE_RX1+ 64 RSVD RSVD

PCIE_TX1- PCIE_RX1- 65 PEG_RX4+ SDVOC_RED+ PEG_TX4+

GND PE_WAKE# (WAKE0#) 66 PEG_RX4- SDVOC_RED- PEG_TX4-

GPI2 WAKE1# 67 RSVD GND

PCIE_TX0+ PCIE_RX0+ 68 SDVOC_INT+ PEG_RX5+ SDVOC_GRN+ PEG_TX5+

PCIE_TX0- PCIE_RX0- 69 SDVOC_INT- PEG_RX5- SDVOC_GRN- PEG_TX5-

GND GND 70 GND GND

LVDS_A0+ LVDS_B0+ 71 PEG_RX6+ SDVOC_BLU+ PEG_TX6+

LVDS_A0- LVDS_B0- 72 PEG_RX6- SDVOC_BLU- PEG_TX6-

LVDS_A1+ LVDS_B1+ 73 SDVO_I2C_DATA SDVO_I2C_CLK

LVDS_A1- LVDS_B1- 74 PEG_RX7+ SDVOC_CLK+ PEG_TX7+

LVDS_A2+ LVDS_B2+ 75 PEG_RX7- SDVOC_CLK- PEG_TX7-

LVDS_A2- LVDS_B2- 76 GND GND

LVDS_VDD_EN LVDS_B3+ 77 RSVD IDE_CBLID#

LVDS_A3+ LVDS_B3- 78 PEG_RX8+ PEG_TX8+

LVDS_A3- LVDS_BKLT_EN 79 PEG_RX8- PEG_TX8-

GND GND 80 GND GND

LVDS_A_CK+ LVDS_B_CK+ 81 PEG_RX9+ PEG_TX9+

LVDS_A_CK- LVDS_B_CK- 82 PEG_RX9- PEG_TX9-

LVDS_I2C_CK LVDS_BKLT_CTRL 83 RSVD RSVD

LVDS_I2C_DAT VCC_5V_SBY 84 GND GND

GPI3 VCC_5V_SBY 85 PEG_RX10+ PEG_TX10+

ICH_RCIN# (KBD_RST#) VCC_5V_SBY 86 PEG_RX10- PEG_TX10-

ICH_A20GATE (KBD_A20GATE) VCC_5V_SBY 87 GND GND

CLK_PE_COMP RSVD 88 PEG_RX11+ PEG_TX11+

CLK_PE_COMN VGA_RED 89 PEG_RX11- PEG_TX11-

©EKF -34- ekf.com

Page 35

User Guide XB1 COM Express Module

AB#CD

GND GND 90 GND GND

RSVD VGA_GREEN 91 PEG_RX12+ PEG_TX12+

RSVD VGA_BLUE 92 PEG_RX12- PEG_TX12-

GPO0 VGA_HSYNC 93 GND GND

RSVD VGA_VSYNC 94 PEG_RX13+ PEG_TX13+

RSVD VGA_DDCCL (VGA_I2C_CK) 95 PEG_RX13- PEG_TX13-

GND VGA_DDCDAT (VGA_I2C_DAT) 96 GND GND

+12V TV_DAC_A 97 RSVD PEG_ENABLE#

+12V TV_DAC_B 98 PEG_RX14+ PEG_TX14+

+12V TV_DAC_C 99 PEG_RX14- PEG_TX14-

GND GND 100 GND GND

+12V +12V 101 PEG_RX15+ PEG_TX15+

+12V +12V 102 PEG_RX15- PEG_TX15-

+12V +12V 103 GND GND

+12V +12V 104 +12V +12V

+12V +12V 105 +12V +12V

+12V +12V 106 +12V +12V

+12V +12V 107 +12V +12V

+12V +12V 108 +12V +12V

+12V +12V 109 +12V +12V

GND GND 110 GND GND

marked light gray italic - signal not available

marked light green italic - pin position reserved by specification

1) stuffing option: GB Ethernet provided by factory default, PCIe lane #3 via J-COM on request

A1

© EKF 275.50.00.440.00 ekf.com

D1

J-COM (View on Bottom Side of Board)

©EKF -35- ekf.com

Page 36

User Guide XB1 COM Express Module

Processor Debug Header PITP

This FFC style connector (Molex 52435-2872) can be used to attach an emulator probe to the board.

This is a valuable tool when debugging hardware or tracing software. The connector PITP is situated

at the bottom side of the board.

PITP

1TDI

2TMS

3TRST#

4NC

5TCK

6NC

7TDO

8BCLKN

9BCLKP

10 GND

11 FBO

12 RST#

13 BPM5#

14 GND

15 BPM4#

16 GND

17 BPM3#

18 GND

19 BPM2#

20 GND

21 BPM1#

22 GND

23 BPM0#

24 DBA#

25 DBR#

26 VTAP

27 V

28 V

©EKF -36- ekf.com

TT

TT

Page 37

User Guide XB1 COM Express Module

P-SIO

The connector P-SIO is normally not stuffed. The mature PS/2 and UART ports have been overcome by

USB in most applications. For low level debugging however, these interfaces can be very useful (e.g.

the BIOS can communicate across the serial I/O). Please contact EKF before ordering the XB1 COM

Express Module, if the P_SIO connector is required by the user.

P-SIO

21

MS_CLK 1 2 MS_DAT

KB_CLK 3 4 KB_DAT

10

276.53.010.01

1.27mm Socket

267.03.010.01

Mating Stacker

© EKF ekf.com

COM_CTS# (TTL) 5 6 COM_RTS# (TTL)

COM_RXD (TTL) 7 8 COM_TXD (TTL)

GND 9 10 +5V

The UART port does not include RS-232 transceivers (TTL level signals only). If necessary, the user must

provide RS-232 or RS-485 transceivers externally.

©EKF -37- ekf.com

Page 38

Board Dimensions

User Guide XB1 COM Express Module

D1

Top View ( seen through board)connectors

COM Express

Basic Module

© EKF

ekf.com

95.00

18.00 91.00

4.00

A1

16.50

74.20

80.00

121.00

125.00

6.00

4.00

©EKF -38- ekf.com

Page 39

Top View, Bottom View

User Guide XB1 COM Express Module

XB1 Top View

XB1 Bottom View

©EKF -39- ekf.com

Page 40

User Guide XB1 COM Express Module

Literature

Theme Document Title Origin

COM Express

Ethernet IEEE Std 802.3, 2000 Edition standards.ieee.org

PCI Express PCI Express Base Specification 1.1 www.pcisig.com

Serial ATA Serial ATA Revision 2.5 www.serialata.org

USB Universal Serial Bus Specification www.usb.org

PICMG® COM.0

COM Express™ Module Base Specification

Revision 1.0 2005-07

www.picmg.org

EKF Elektronik GmbH

Philipp-Reis-Str. 4

59065 HAMM

Germany

Fax. +49 (0)2381/6890-90

Tel. +49 (0)2381/6890-0

Internet www.ekf.com

E-Mail info@ekf.com

Loading...

Loading...