Page 1

Ingersoll Rand

System Automation

Before installing or starting this unit for the first

time, this manual should be studied carefully to

obtain a working knowledge of the unit and or the

duties to be performed while operating and

maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and

should be kept with the unit at all times.

Instruction Manual

VSD Box

More Than Air. Answers.

Online answers: http://www.air.irco.com

C.C.N. : 80444128

REV. : B

DATE : JULY 2008

Page 2

SECTION 1 TABLE OF CONTENTS

Section 1 - tABLe oF contentS .............................3

Section 2 - intRoDUction ......................................4

Section 3 - SAFety ......................................................4

INSTALLATION .............................................................................4

OPERATION

MAINTENANCE AND REPAIR

..................................................................................4

.................................................4

Section 4 - coMPReSSoR connection AnD

contRoL .........................................................................5

COMPRESSOR CONNECTION AND CONTROL ................5

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

VSD BOX OPERATION

.........................................................................5

...............................................................6

Section 5 - inStALLAtion .........................................7

UNIT LOCATION ..........................................................................7

POWER SUPPLY

RS485 NETWORK

...........................................................................7

........................................................................7

Section 12 - PARtS LiSt .......................................... 25

IR VSD BOX .................................................................................25

Section 13 - tecHnicAL DAtA ............................... 25

VSD BOX ...................................................................................... 25

Section 14 - WiRinG DiAGRAM ............................. 26

Section 15 - coMMiSSioninG FoRM .................. 28

Refer to Section Indicated

Note

Important or Caution, Safety

PRESSURE SENSOR CONNECTIONS

VSD AND IRPCB COMPRESSOR CONNECTIVITY ..........9

IRPCB COMPRESSOR CONTROL ..........................................9

IRPCB COMPRESSOR STATUS MONITORING .................9

.............................................................................................9

READY

RUNNING

LOADED

.................................................................................... 10

......................................................................................10

....................................8

Section 6 - VSD BoX HARDWARe

conFiGURAtion ........................................................ 12

Section 7 - inGeRSoLL RAnD to VSD BoX

inteRconnect ........................................................... 13

Section 8 - coMMiSSioninG ................................. 15

Section 9 - DiSPLAy AnD MenU oPeRAtion .... 17

MENU NAVIGATION ...............................................................17

Section 10 - DiAGnoSticS ..................................... 22

Section 11 - oPeRAtion ......................................... 23

KEYPAD ........................................................................................23

DISPLAY .......................................................................................23

INDICATORS ..............................................................................23

USER MENU ITEMS.................................................................. 24

POWER FAILURE AUTORESTART ......................................24

3

Page 3

SECTION 2 INTRODUCTION

The VSD Box is intended to provide a method of

system integration for a VSD (Variable Speed Drive) air

compressor that is not equipped with any accessible

means of remote connectivity (such as the Ingersoll

SECTION 3 SAFETY

WARNING : Risk of Danger

WARNING : Risk of Electric Shock

WARNING : Risk of High Pressure

WARNING : Consult Manual

Before installing or operating the VSD BOX, take time

•

to carefully read all the instructions contained in this

manual, all compressor manuals, and all manuals of

any other peripheral devices that may be installed or

connected to the unit.

Electricity and compressed air have the potential to

•

cause severe personal injury or property damage.

The operator should use common sense and good

•

working practices while operating and maintaining

this system. All applicable codes should be strictly

adhered to.

Maintenance must be performed by adequately

•

qualified personnel that are equipped with the

proper tools.

INSTALLATION

Installation work must only be carried out by a

•

competent person under qualified supervision.

A fused isolation switch must be fitted between the

•

main power supply and the VSD BOX.

The VSD BOX should be mounted in such a location

•

as to allow operational and maintenance access

without obstruction or hazard and to allow clear

visibility of indicators at all times.

If raised platforms are required to provide access to

•

the VSD BOX, they must not interfere with normal

operation or obstruct access. Platforms and stairs

should be of grid or plate construction with safety

rails on all open sides.

OPERATION

The VSD BOX must only be operated by competent

•

personnel under qualified supervision.

Never remove or tamper with safety devices, guards

•

or insulation materials fitted to the VSD BOX.

Rand Nirvana). The VSD Box will provide the required

functionality to enable system integration and efficient

control using the X8I Automation System.

The VSD BOX must only be operated at the supply

•

voltage and frequency for which it is designed.

When main power is switched on, lethal voltages are

•

present in the electrical circuits and extreme caution

must be exercised whenever it is necessary to carry

out any work on the unit.

Do not open access panels or touch electrical

•

components while voltage is applied unless it is

necessary for measurements, tests or adjustments.

Such work should be carried out only by a qualified

electrician equipped with the correct tools and

wearing appropriate protection against electrical

hazards.

All air compressors and/or other equipment

•

connected to the unit should have a warning sign

attached stating ‘THIS UNIT MAY START WITHOUT

WARNING’ next to the display panel.

If an air compressor and/or other equipment

•

connected to the unit is to be started remotely,

attach two warning signs to the equipment stating

‘THIS UNIT CAN BE STARTED REMOTELY’. Attach one

sign in a prominent location, one on the outside of

the equipment, and the other inside the equipment

control compartment.

MAINTENANCE AND REPAIR

Maintenance, repairs or modifications must only be

•

carried out by competent personnel under qualified

supervision.

If replacement parts are required use only genuine

•

parts from the original equipment manufacturer, or

an alternative approved source.

Carry out the following operations before opening or

•

removing any access panels or carrying out any work

on the VSD BOX:

Isolate the VSD BOX from the main electrical

i.

power supply. Lock the isolator in the ‘OFF’

position and remove the fuses.

Attach a label to the isolator switch and to the

ii.

unit stating ‘WORK IN PROGRESS - DO NOT

APPLY VOLTAGE’. Do not switch on electrical

power or attempt to start the VSD BOX if such

a warning label is attached.

Make sure that all instructions concerning operation

•

and maintenance are strictly followed and that

the complete unit, with all accessories and safety

devices, is kept in good working order.

4

Page 4

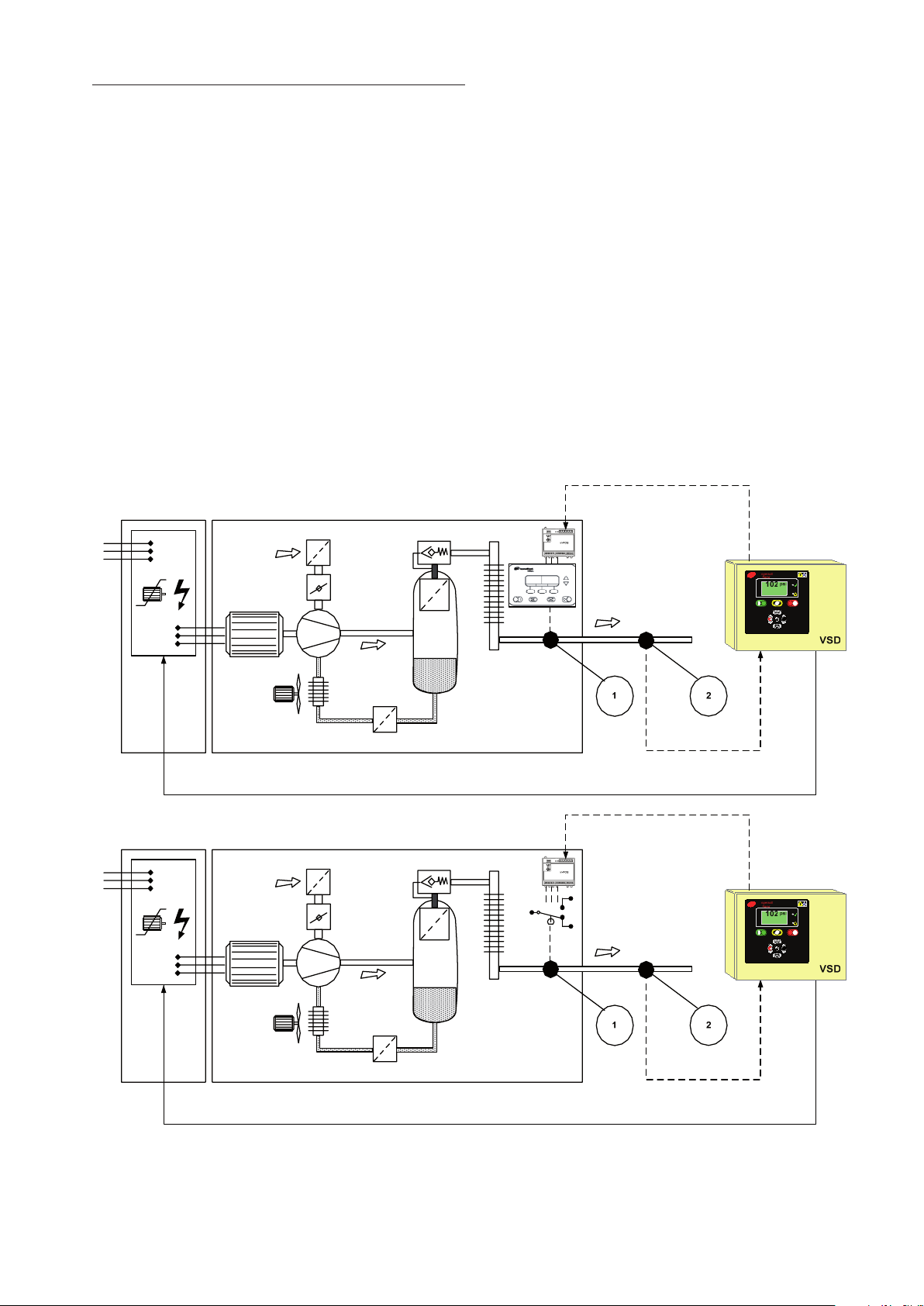

5

1

2

1

2

1

2

The accuracy of sensor devices must be checked

• The VSD BOX must only be cleaned with a damp

on a regular basis. They must be calibrated when

acceptable tolerances are exceeded. Always ensure

any pressure within the compressed air system is

safely vented to atmosphere before attempting to

remove or install a sensor device.

•

cloth, using mild detergents if necessary. Avoid the

use of any substances containing corrosive acids or

alkalis.

Do not paint the control faceplate or obscure any

•

indicators, controls, instructions or warnings.

SECTION 4 COMPRESSOR CONNECTION AND CONTROL

COMPRESSOR CONNECTION AND CONTROL

The VSD BOX is designed to connect to an X8I

Automation System unit, using a 2-wire RS485 data cable.

The VSD Box is intended to provide a method of system

integration for the Ingersoll Rand Bolt-On VSD’s as well

as other 3rd party air compressors that are not equipped

with any accessible means of remote connectivity.

Each air compressor in a system that requires VSD Box

integration must be equipped with an individual VSD

Box. Any number of VSD Boxes can be connected to the

Automation System unit as long as the total number

of compressors does not exceed the total number of

compressors for the Automation System model.

In conjunction with a ‘speed monitoring kit’ (available

separately) the VSD Box will provide all required

functionality to maximize the ENER, energy control mode,

in the X8I or X12I Automation System

3) 3rd party integrated VSD air compressors that are

equipped with a single package discharge pressure

sensor (1).

STANDARD CONTROL FEATURES AND

FUNCTIONALITY

The Bolt-On VSD or the VSD equipped air compressor

must be equipped with a 4-20mA pressure sensor or a

0.5V to 4.5VDC a pressure sensor that is used for variable

speed drive regulation or compressor pressure regulation

control. A VSD Box will accommodate a pressure sensor

range of 1.0bar to 600bar.

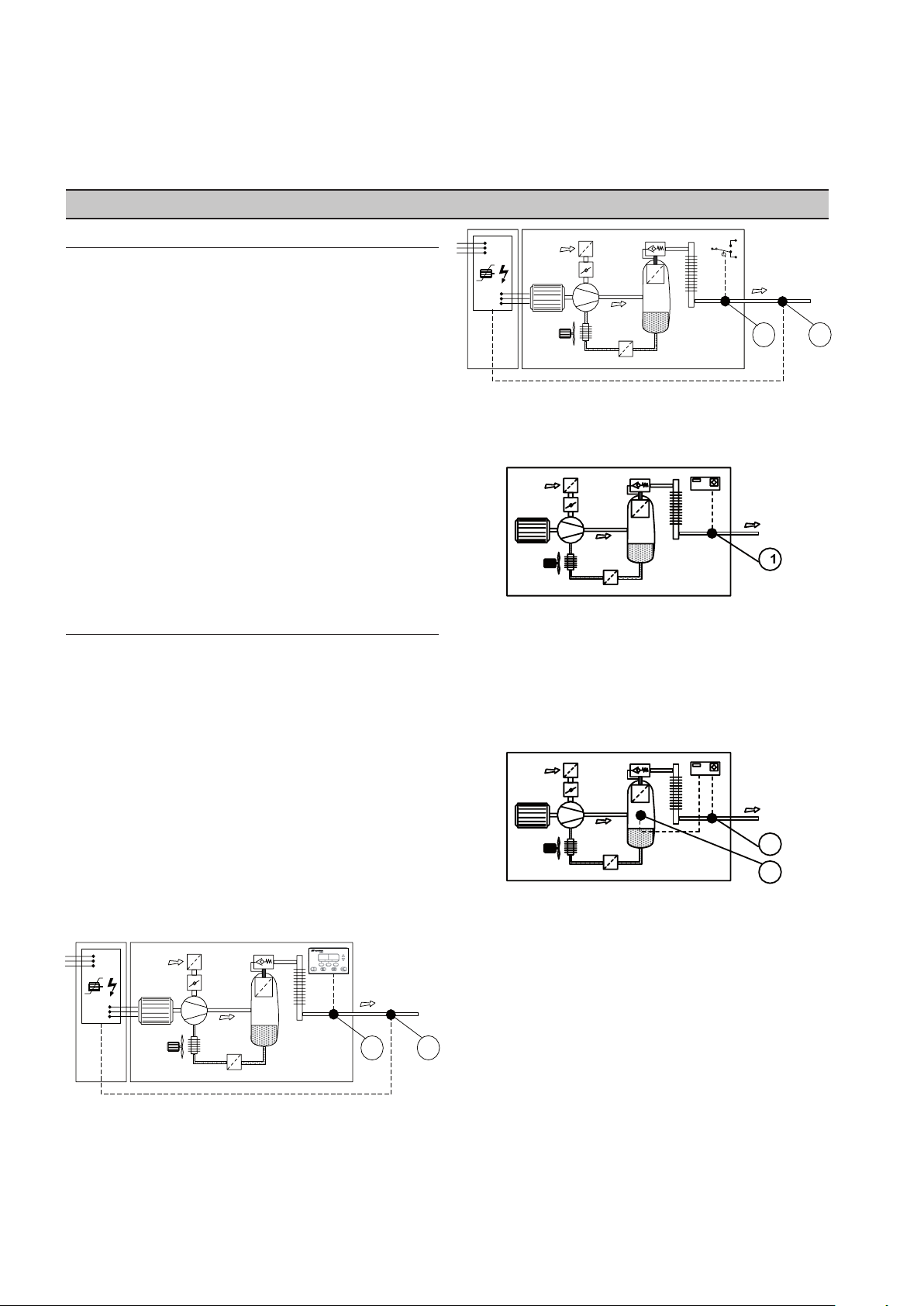

Various Compressor Configurations and Characteristics

Can Be Accommodated by the VSD Box. These include:

1) Bolt-On VSD air compressors that are equipped with

two pressure sensors (1 and 2) that both monitor

package discharge pressure. One sensor is dedicated

to the compressor control system for load/unload

regulation functions and the other pressure sensor

is dedicated to the VSD for variable speed drive

regulation.

2) Bolt-On VSD air compressors that are equipped with

a package discharge pressure switch (1) dedicated

to the compressor control system for load/unload

regulation and a pressure sensor (2) dedicated to the

VSD for variable speed drive regulation.

4) 3rd party integrated VSD air compressors that are

equipped with a package discharge pressure sensor

(1) and a second internal pressure sensor (2). The

internal pressure sensor is generally used for internal

air/oil filtration differential pressure monitoring and/

or internal pressure safety functions.

NOTE: There are VSD air compressors that are unable

to maintain maximum speed operation for a prolonged

period of time. In these instances, the compressor control

system may automatically reduce speed regardless

of demand. The VSD Box and Automation System will

recognize this, and if necessary, utilize an additional

compressor to meet demand.

NOTE: There are VSD air compressors that are unable

to maintain minimum speed operation for a prolonged

period of time. In these instances, the compressor control

system may automatically stop the compressor regardless

of demand. The VSD Box will recognize and accommodate

this behavior. The Automation System will indicate and

record the compressor status correctly without fault

indication.

Page 5

VSD BOX OPERATION

From VSD Box

To ir-PCB

To Intellisys Controller

From VSD Box

To ir-PCB

To 1PS Pressure Switch

From Pressure Transducer

To VSD Box

From VSD Box

To IR-5000 Pressure Transducer Input

From Pressure Transducer

To VSD Box

From VSD Box

To IR-5000 Pressure Transducer Input

All air compressors are equipped with a method of

sensing pressure. An air compressor regulates using the

compressor package discharge pressure as the control

variable.

The VSD Box monitors the compressor pressure sensor

as an input and simulates the pressure sensor signal as

an output. The VSD Box uses this method to modify the

pressure signal and manipulate the behavior of the air

compressor. In other words, the VSD Box becomes the air

compressor pressure sensor. This functionality enables

the Automation System unit to utilize the compressor

effectively and optimize total system efficiency and

maintain air quality.

The VSD Box also monitors compressor status (Ready,

Run, and Load/Unload) and continuously reports this

information to the Automation System unit. This function

enables the VSD Box to simulate all features of a standard

X8I or X12I network compressor integration.

Actual System pressure and the Automation System

‘target’ pressure information is routinely transmitted

from the X8I or X12I to the VSD Box. The VSD Box uses

this information to calculate the difference between

the compressor discharge pressure and the system

‘target’ pressure. The VSD Box utilizes pressure signal

manipulation to continuously re-align compressor output

with system requirements.

This functionality also enables the VSD Box to

continuously compensate for any pressure differential

that may occur across local air treatment, along air pipe

work or between different locations in a compressed air

network.

6

Page 6

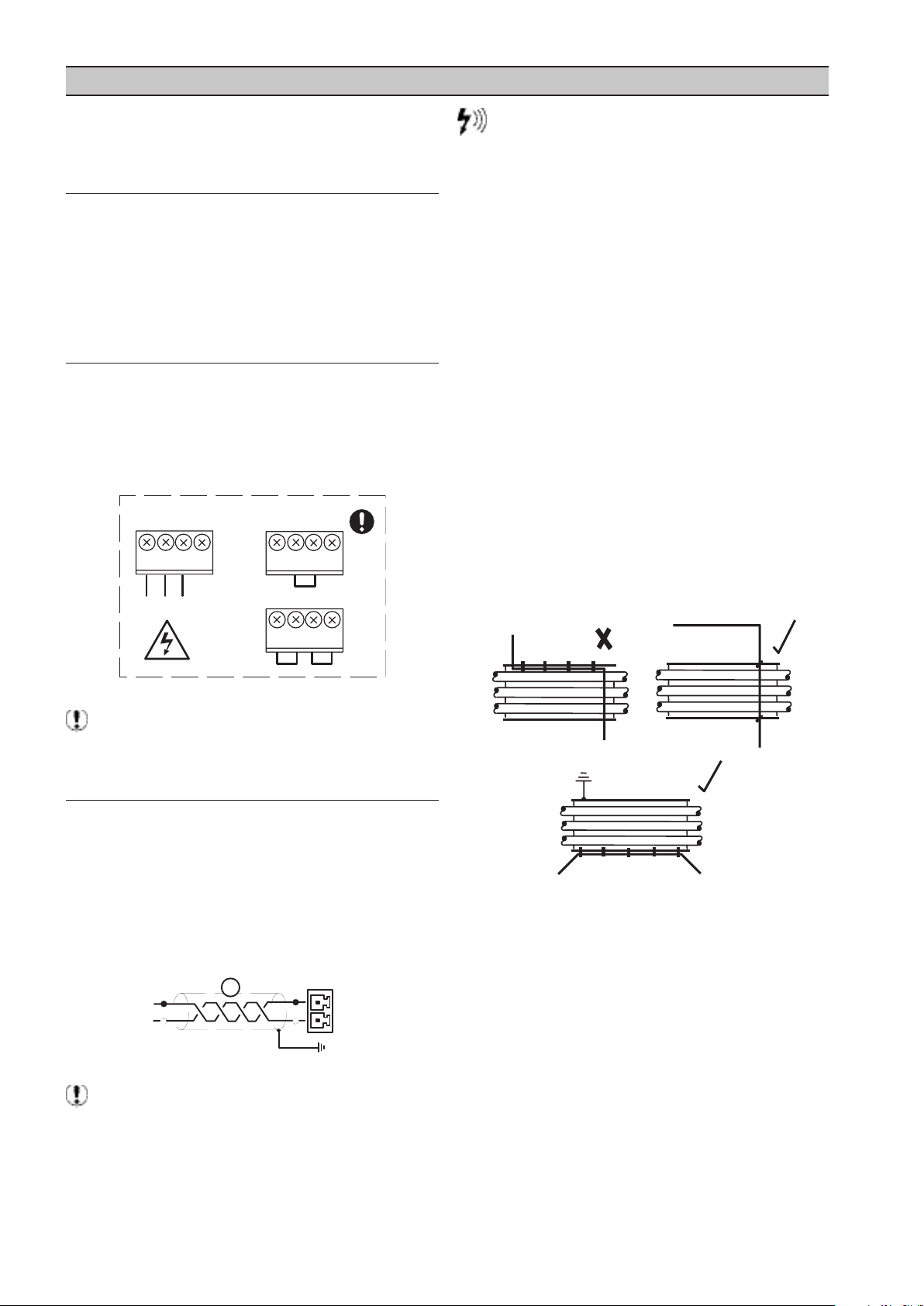

7

1

VOLTAGE SELECT

2 3 4

X04

1

VOLTAGE SELECT

2 3 4

X04

230Vac

115Vac

XPM-TAC24

L2

L1

X07

L2

L1

2

SECTION 5 INSTALLATION

It is recommended that installation and commissioning

be carried out by an authorized and trained product

supplier.

UNIT LOCATION

The VSD Box is wall mounted using conventional screws/

bolts. The maximum distance between the X8I or X12I

and the VSD Box is 4000ft (1219 meters) of cable length.

The maximum distance between the VSD Box and

each compressor is 330ft (100 meters) of cable length

and within 330ft (100 meters) of cable length from any

pressure sensor option (if applicable)..

POWER SUPPLY

A fused switching isolator must be installed to the

main incoming power supply, external to the VSD Box.

The isolator must be fitted with a properly sized fuse

to provide adequate protection to the power supply

cable used (in accordance with local electrical and safety

regulations).

1 2 3 4

L

N

N L E

EE

X01

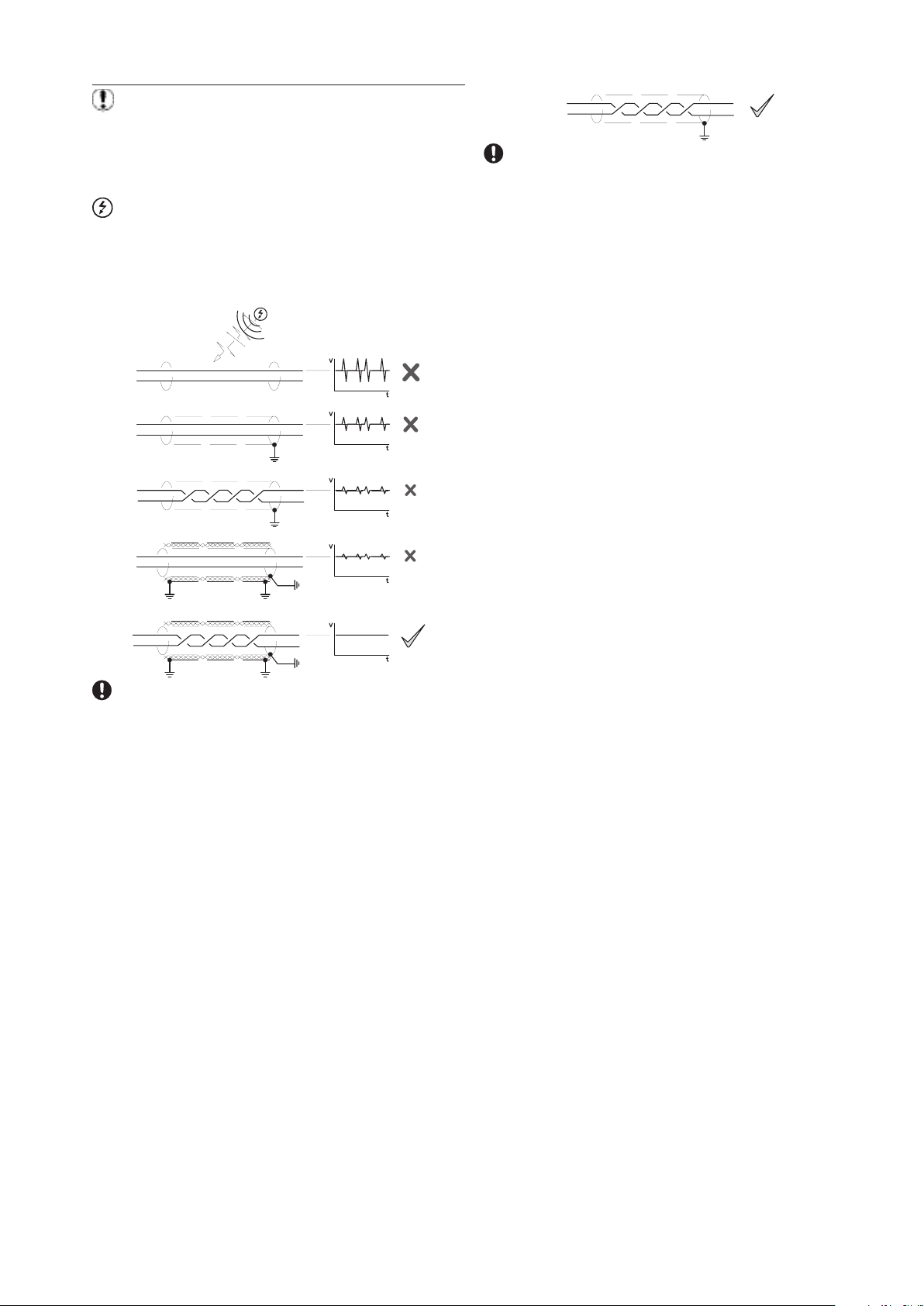

RS485 data communications and other low

voltage signals can be subject to electrical interference.

This potential can result in intermittent malfunction

or anomaly that is difficult to diagnose. To avoid this

possibility always use earth shielded cables, securely

bonded to a known good earth at one end. In addition,

give careful consideration to cable routing during

installation.

a.

Never route an RS485 data communications or low

voltage signal cable alongside a high voltage or 3phase power supply cable. If it is necessary to cross

the path of a power supply cable(s), always cross at a

right angle.

b.

If it is necessary to follow the route of power supply

cables for a short distance (for example: from a

compressor X8I to a wall along a suspended cable

tray) attach the RS485 or signal cable on the outside

of an earthed cable tray such that the cable tray

forms an earthed electrical interference shield.

c.

Where possible, never route an RS485 or signal cable

near to equipment or devices that may be a source

of electrical interference (for example: 3-phase

power supply transformer, high voltage switchgear

unit, frequency inverter drive module, radio

communications antenna).

Power Supply Terminals

Ensure that the voltage select input is properly

jumpered for the incoming power. Default voltage

configuration is 230Vac.

RS485 NETWORK

The VSD Box is equipped with an RS485 network

communications capability using the ir485 protocol.

The VSD Box is intended to operate as part of the X8I

or X12I Automation System. Connection to the system

management unit is two-wire, twisted pair, earth

shielded, RS485 data link. Connect the RS485 data

cable wires to terminal X07 located on the VSD Box ‘S1’

controller.

Note: Polarity is important.

The cable used between the X8I and the VSD Box is

Belden 9841 (or equivalent). It should be run in grounded

conduit and should not be greater than 4000 feet (1219

meters) in length.

Page 7

PRESSURE SENSOR CONNECTIONS

Consult the X8I Interconnect and Application Guide

prior to the installation of the VSD Box to the pressure

sensor on the VSD and the compressor.

Pressure sensor connectivity is dependant on compressor

and control system type.

Electrical Interference

0.5 to 4.5VDC Pressure Sensors

Voltage sensors and cables carrying low voltage analog

signals are highly susceptible to interference.

4 to 20mA Pressure Sensors

Always use shielded, 18 gauge, 2-conductor cable

no more than 330 feet (100 meters) in length. Ensure

the shield wire is securely connected to earth ground

at the VSD Box end only.

Always use shielded, braided, foil wrapped with a

drain wire, 18 AWG maximum, 2-conductor cable no

more than 330 feet (100 meters) in length. Ensure the

braided steel wire is securely connected to a known

good earth ground at both ends. Ensure the internal

drain wire is securely connected to a known good

earth ground at the VSD Box end only.

Failure to protect low voltage pressure signals between

the compressor and VSD Box will result in unstable and/or

erratic pressure readings; resulting in unstable and/or

erratic compressor regulation behavior.

8

Page 8

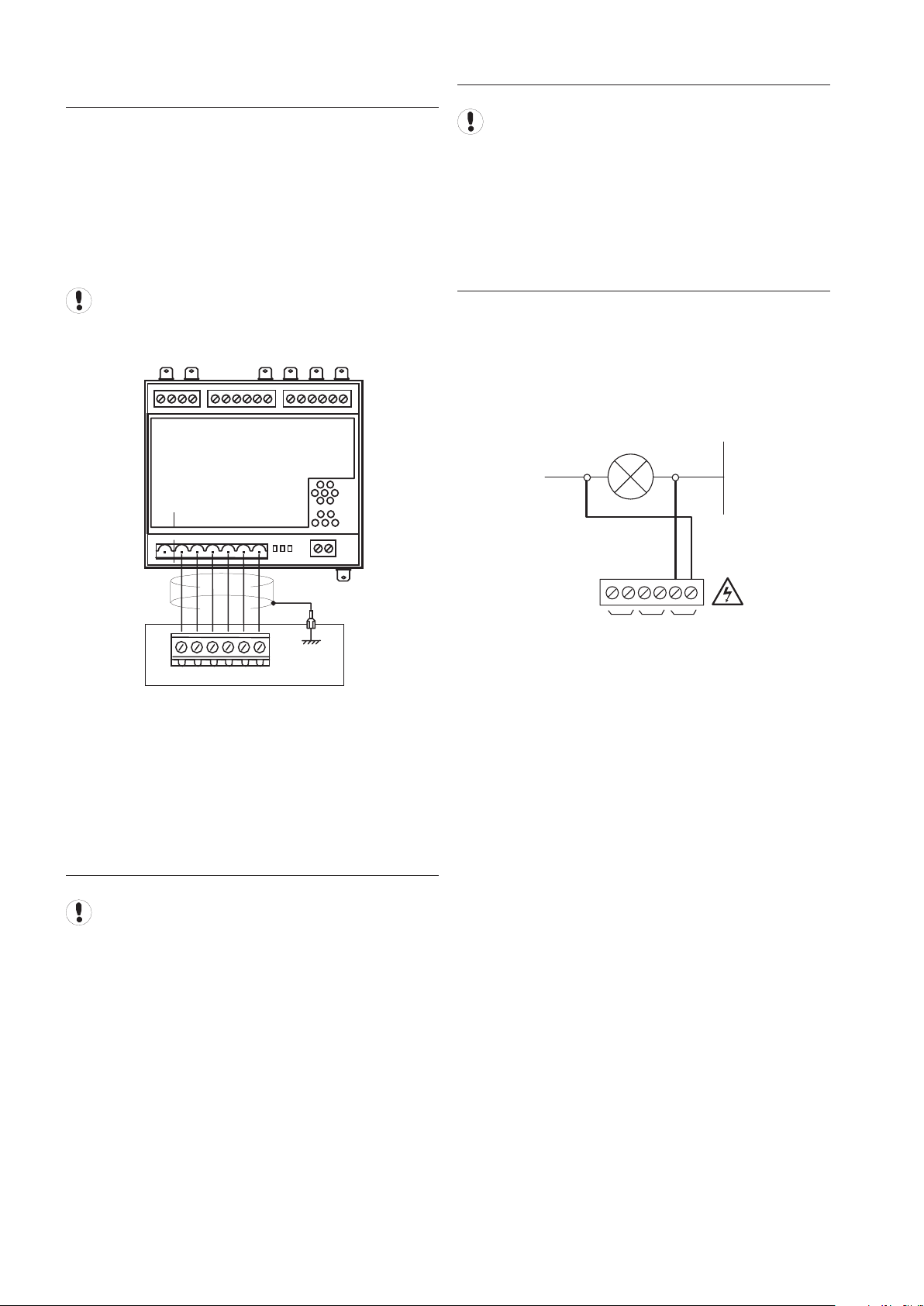

9

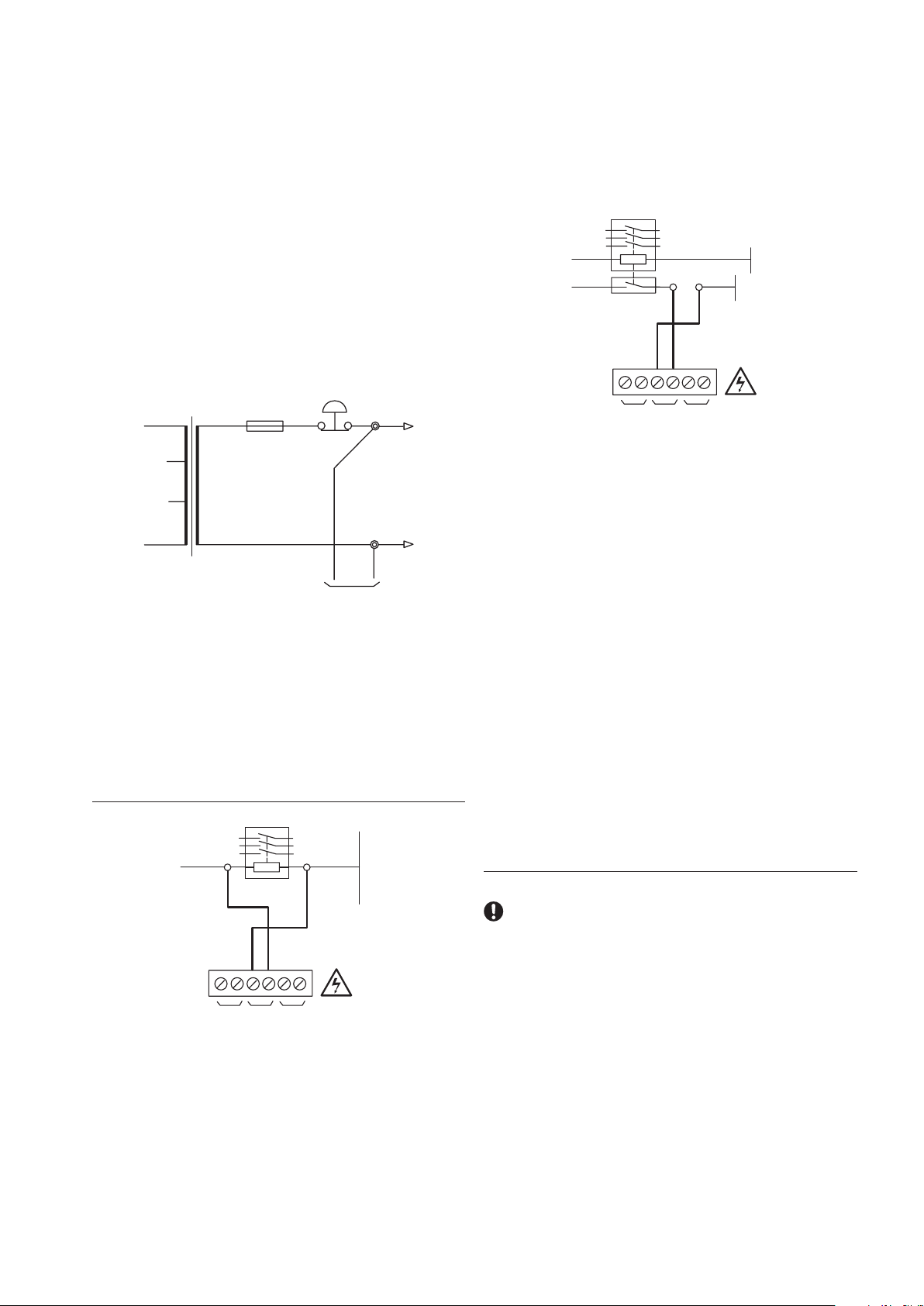

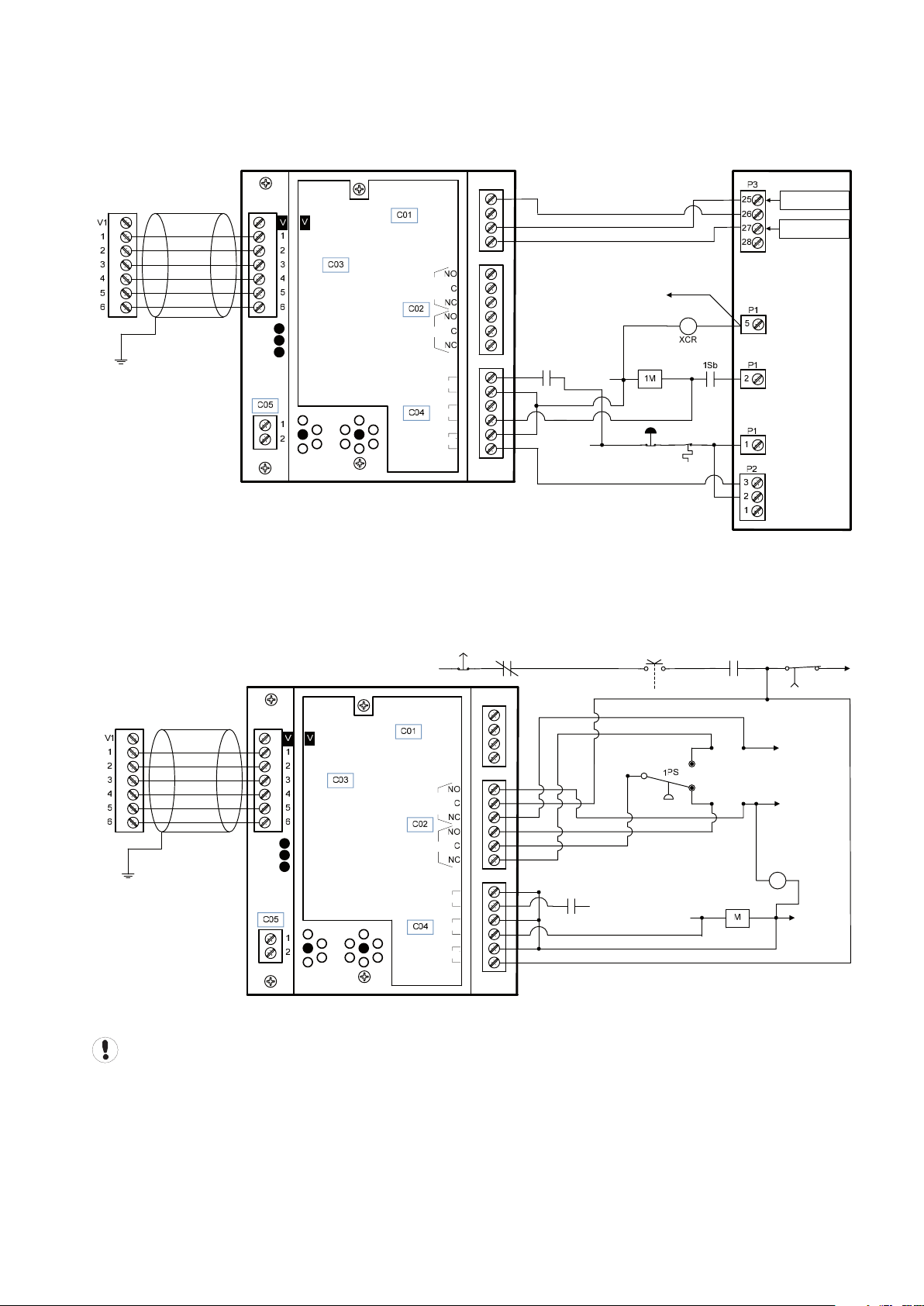

VSD AND IRPCB COMPRESSOR

ir-PCB

LED 1LED 2

C01 C02 C04

C03

2 4 61 3 5

X01

2 4 61 3 5

#1

V

C05

0V

+V

READY LAMP

RUN

READY

ALARM

C04

CONNECTIVITY

IRPCB COMPRESSOR STATUS MONITORING

An ir-PCB is a requirement for a VSD Box installation.

The ir-PCB is a DIN rail mountable unit designed to be

installed within the compressor control or switchgear

area and connected to the VSD Box using a six-wire cable.

The ir-PCB is used for compressor status monitoring and

in some installations, for remote load/unload or pressure

switch regulation control.

Consult the X8I Interconnect and Application Guide

prior to the installation of the VSD Box and the ir-PCB to

the air compressor.

Consult the X8I Interconnect and Application Guide

prior to the installation of the VSD Box and the ir-PCB to

the air compressor.

The ir-PCB is fitted with a six-pin terminal C04 for

compressor monitoring. The ir-PCB uses three inputs

(Ready, Run and Loaded) to determine compressor status.

All three status-monitoring input signals are required.

READY

The ‘Ready’ connection is intended to indicate that the

compressor is in a ‘started’ state, has no operational

inhibiting fault condition and is ready to respond to VSD

Box regulation without manual intervention.

Ready Input

The ir-PCB uses a 12V to 250V ac/dc input voltage

detection system and universal relay contact control

outputs (250Vac/dc @ 5A maximum). Integrated directly

into the circuits of an air compressor, the ir-PCB avoids

the need for additional relays or remote inputs. The ir-PCB

also acts as an electrical barrier between the compressor

and the VSD Box providing protection and voltage

isolation.

IRPCB COMPRESSOR CONTROL

Consult the X8I Interconnect and Application Guide

prior to the installation of the VSD Box and the ir-PCB to

the air compressor.

When connecting to an VSD, the VSD Box will control the

ir-PCB load/unload relay outputs (terminals C01 and C02)

in accordance with the VSD Box load and unload pressure

set points. The ir-PCB load/unload relay contacts can be

used for compressor that have pressure switch load/

unload regulation as well as those that have digital inputs

for load/unload regulation.

The READY input will accept 12V to 250V ac (50/60Hz) or

dc.

Caution: Do not connect a voltage greater than 250Vac/

dc to this input.

This input must be connected to the terminals of a ‘ready’

or ‘operational’ lamp, or other circuit of the compressor

control system, that will be energized when the

compressor is in started (standby or running) condition.

The voltage to this input must de-energize when the

compressor is stopped and unavailable to produce air

upon a load signal or the Emergency Stop button is

pressed or when the compressor experiences a fault that

prevents the compressor from running.

When the compressor ready lamp, or other control circuit,

is energized the ir-PCB will detect the voltage and signal

the VSD Box that the compressor is ready and available to

load and produce air when a load request signal is given

Note: The ir-PCB input common terminal must always

be connected to the neutral, common or 0V line of the

applied input.

Page 9

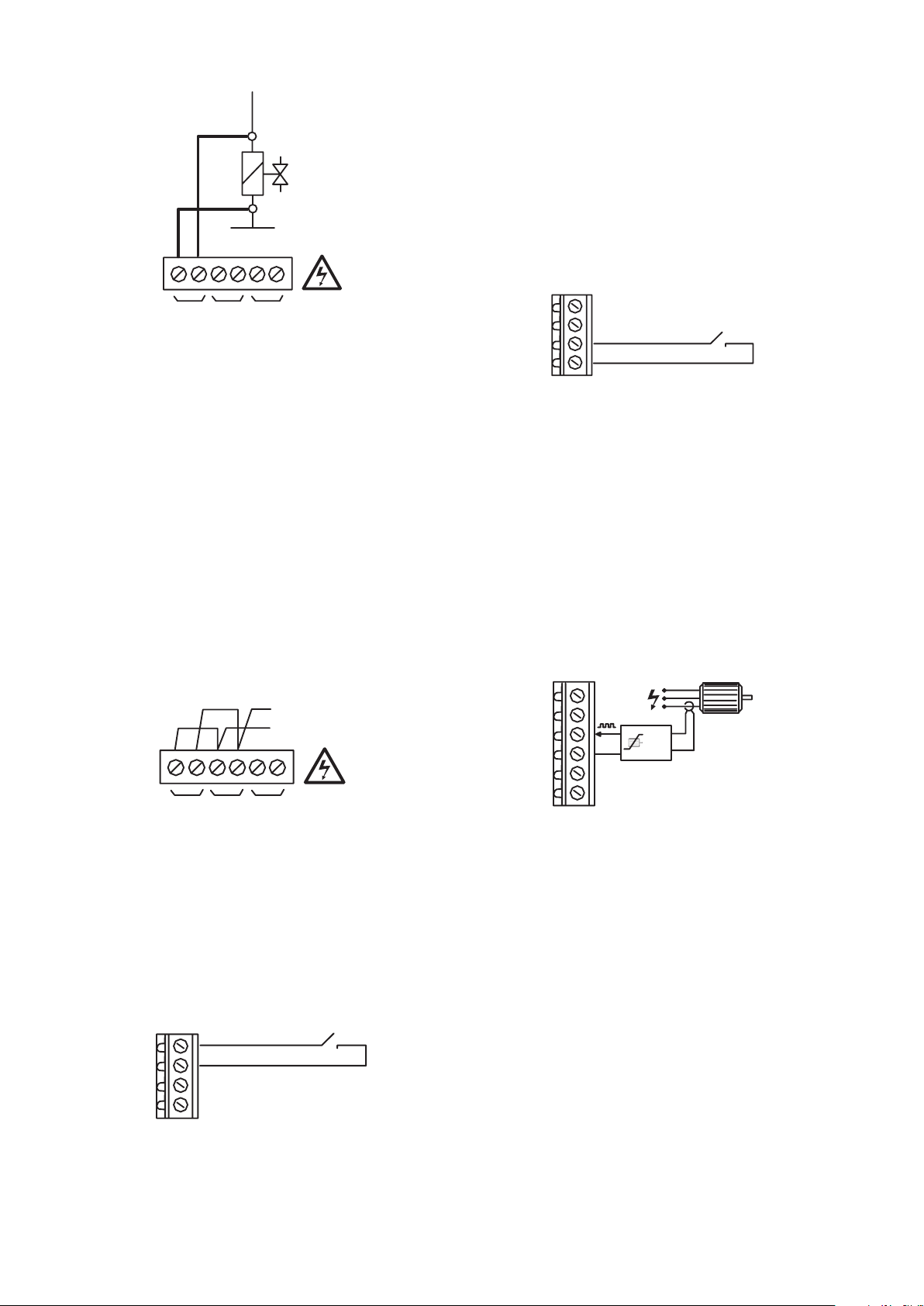

Ready Input, Alternative Connection Method:

F1

+Vac

0Vac

READY

0V

RUN

READY

ALARM

+V

MAIN (LINE) CONTACTOR

C04

0V

+V

MAIN (LINE) CONTACTOR

0V

+V

AUXILIARY SWITCH

RUN

READY

ALARM

C04

In instances where a convenient voltage signal for a

compressor ready condition is not available the ‘Ready’

input can be connected directly to a constant compressor

control system power supply voltage (12V to 250Vac or

dc). This will signal the VSD Box that the compressor is

ready and available at all times when power is applied

to the compressor. The VSD has a built-in function to

determine when a compressor is not responding, or is

in a shutdown condition, regardless of a constant ready

signal. If the VSD Box requests a compressor to run/load,

but fails to detect a RUN signal within 60 seconds, the

VSD Box will regard the compressor as ‘not ready’ and

indicate the compressor as not available. If a RUN signal is

detected at any time, the VSD Box will automatically reset

the compressor ‘not ready’ condition and re-establish

control.

For a fixed speed air compressor this input can be

connected to the control terminals A1 and A2 (coil) of

the main starter contactor of the compressor. When the

compressor control system energizes the main contactor,

the ir-PCB will detect the voltage across the contactor coil

terminals and signal the VSD Box that the compressor is

running

Alternatively, if the main contactor coil voltage is greater

than 250Vac, a contactor auxiliary relay can be used to

apply a suitable voltage to the ‘Run’ input terminals.

For a ‘Variable Speed’ air compressor alternative methods

of determining a running condition may have to be

established.

Safety: Never connect the READY input positive

connection directly to the output of a control system

transformer; always connect after a fuse or circuit breaker.

If a normally closed contact of an Emergency Stop button

is included in the compressor power supply circuit,

connect after the Emergency Stop button contacts. This

will instantly indicate a compressor ‘not ready’ condition if

the Emergency Stop button is activated

RUNNING

The majority of VSD compressors are fitted with a

single main motor contactor but in most instances this

contactor energizes at compressor initialization and

remains energized regardless of motor running. The

following alternative signals may be used to indicate

motor running in most cases:-

1) The ‘Fan’ contactor – in instances where the cooling

fan energizes and de-energizes in conjunction with

the main motor.

2) The compressor controller ‘run’ signal to the ‘Inverter

Drive Unit’; an interface relay may be required.

Note: The ir-PCB input common terminal must always

be connected to the neutral, common or 0V line of the

applied input voltage.

LOADED

ALARM = LOAD

The VSD Box uses the ir-PCB ALARM input to detect the

load condition of the compressor. There is no Alarm

input facility on the ir-PCB when used with a VSD Box.

An auxiliary ‘Alarm’ input terminal within the VSD Box is

available.

The RUN input will accept 12V to 250V ac (50/60Hz) only

(DC can not be used).

Caution: Do not connect a voltage greater than 250V to

this input.

12V to 250Vac must be applied to the ‘Run’ terminals

when the compressor motor is running.

Note: A fault that stops the compressor, and/or prevents

the compressor from running, is determined from the

‘Run’ and ‘Ready’ inputs; Alarm detection is optional and is

not a requirement.

10

Page 10

11

0V

+V

LOAD

SOLENOID

RUN

READY

ALARM

C04

The LOAD input will accept 12V to 250V ac (50/60Hz) or dc.

RUN

READY

ALARM

C04

Running

0v

1

4

1

6

X04

1

3

1

5

Aux Alarm

Aux Trip

1

4

1

6

X04

1

3

1

5

X05

1

8

2

0

2

2

1

7

1

9

2

1

+

rpm

Auxiliary Trip Input (Option)

The VSD Box is equipped with an auxiliary ‘Trip’ input. The

input can be used to detect a compressor shutdown trip

condition. The input can also be used to monitor other

auxiliary equipment associated with the compressor and

initiate a compressor trip condition.

The Automation System unit will regard the trip as

a compressor shutdown trip and will remove the

compressor from sequence; the compressor will run-on

for the compressor controller’s set run-on time and stop.

Caution: Do not connect a voltage greater than 250Vac/dc to

this input.

Note: The Alarm input can not be directly connected to a Triac

Output, as used on the IntelliSys controller. When connecting

to an IntelliSys controller, an auxiliary relay must be used to

apply a suitable voltage to the ‘Alarm’ input terminals.

The ‘Load’ input can be connected to the terminals of the

compressor’s load solenoid; or other accessible part of the

control circuit that is energized when the compressor is loaded.

Note: The ir-PCB input common terminal must always be

connected to the neutral, common or 0V line of the applied

input voltage.

For a compressor that is not equipped with a load solenoid (a

compressor that is loaded at all times while running) the ‘Load’

input can be connected to the ‘Run’ input.

Auxiliary Alarm Input (Option)

The VSD Box is equipped with an auxiliary ‘Alarm

(Warning)’ input. This input can be used to detect a

compressor ‘Warning’ or ‘Alarm’ condition. The input can

also be used to detect an ‘Alarm’ condition of auxiliary

equipment associated with the compressor.

The Automation System unit will regard the alarm as a

compressor alarm.

As default the auxiliary ‘Alarm’ input is normally open,

Alarm on closed circuit condition. If required this can

be reversed in the VSD Box setup menu to be normally

closed, alarm on open circuit.

As default the auxiliary ‘Trip’ input is normally open,

Trip on closed circuit condition. If required this can be

reversed in the VSD Box setup menu to be normally

closed, trip on open circuit.

Note: The maximum cable length for Auxiliary ‘Alarm’ or

‘Trip’ inputs is 330ft (100m).

Speed Monitoring Input (Option)

The VSD Box is equipped with a ‘speed detection’ input

designed to function with a ‘VSD Speed Monitoring Kit’

(available separately). This optional feature will provide

all required functionality to enable total synergy with the

energy control, VSD compressor aware, functions of an

X8I or X12I.

Remote Outputs

Compressor Running:

The VSD Box is equipped with a volt-free relay contact

output (R5) to indicate when the compressor is detected

as running. The output contacts will close when the

compressor is running.

Group Alarm:

The VSD Box is equipped with a volt-free relay contact

output (R6) to indicate Group Alarm. The Group Alarm

relay contacts are normally closed and will open in the

following conditions:-

1) VSD Box power failure

2) VSD Box internal fault condition

3) Input pressure sensor fault

4) Compressor ‘Not Ready’

Page 11

3

1

3

2

3

3

3

4

X08

X09

R5

R6

Compressor

Running

Group Alarm

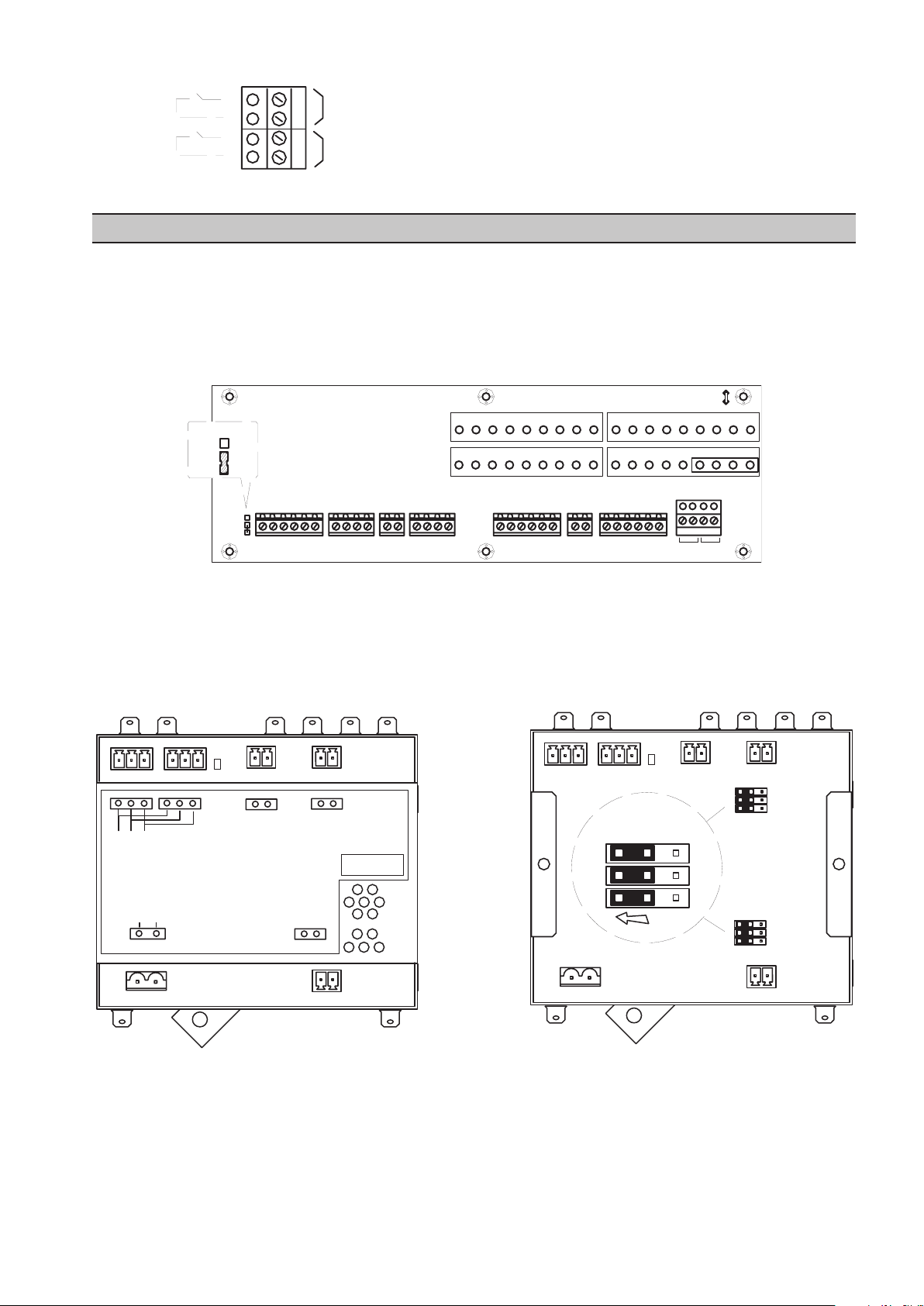

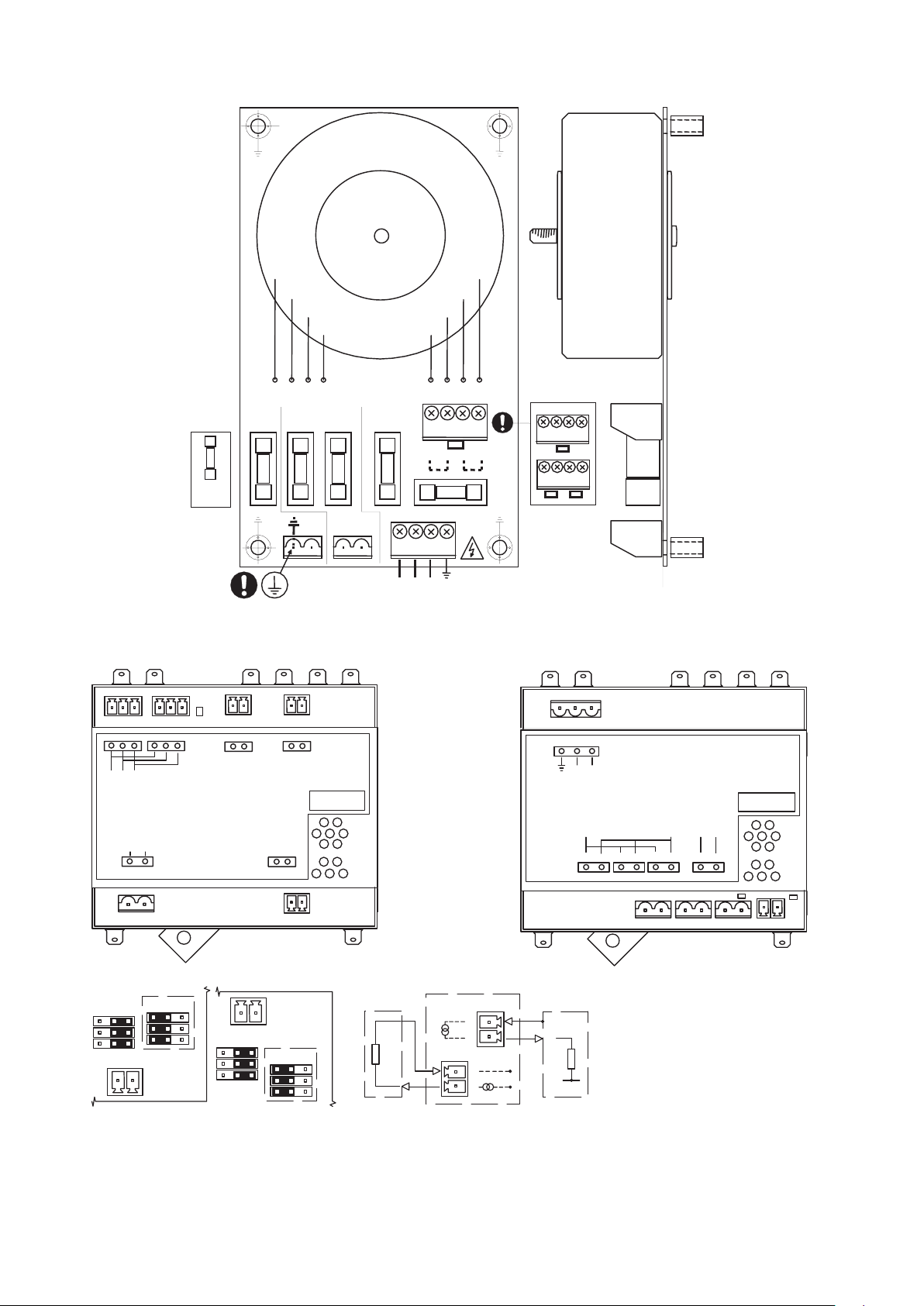

SECTION 6 VSD BOX HARDWARE CONFIGURATION

J1

2 4 6

281027 26 25 24 23 22 21

20 19

9 8 7 6 5

4 3

2 1

18 17 16 15 14 13 12

11

KC-

KC-

8 10 12 14 16 18 20 22 24 26 282930

2725

23

21

19171513

119

7

53

1

31 32 33 34

R06

R05

X07X06X05

X04

X03

X02

X01

X08

X09

VSD/EX

+

2

4

V

D

C

0

V

X01

2 1

RS485

L

1

L

2

X04X05

L

E

D

1

123 3

s

c

r

e

e

n

X02

X03X06

-

A

N

A

1

+

A

N

A

1

VDC

4-20mA(2)

4-20mA(1)

Ao2

2 1

A

N

A

3

+

A

N

A

3

-

2 1

A

N

A

2

+

A

N

A

2

-

#1

#2

C03

C010

PASSIVE MODE

4-20mA(2)

4-20mA(1)

X06 X03

X02

VSD Box Terminal PCB Type Selector

VSD Box Terminal PCB has a jumper on it that determines

the type of control box the PCB is being used in. Check to

determine if jumper (J1), as shown below, is placed in the

correct position for a VSD Box.

Relay contact rating:

CE: 250V @ 5A max

UL: 115V @ 5A max

XPM-Ao2 Module 4-20mA Output Mode Selectors

Remove the top cover of the XPM-Ao2 module and check

the 4-20mA output mode selectors are in the ‘PASSIVE’

mode position. (The default position as shipped from the

factory.)

12

Page 12

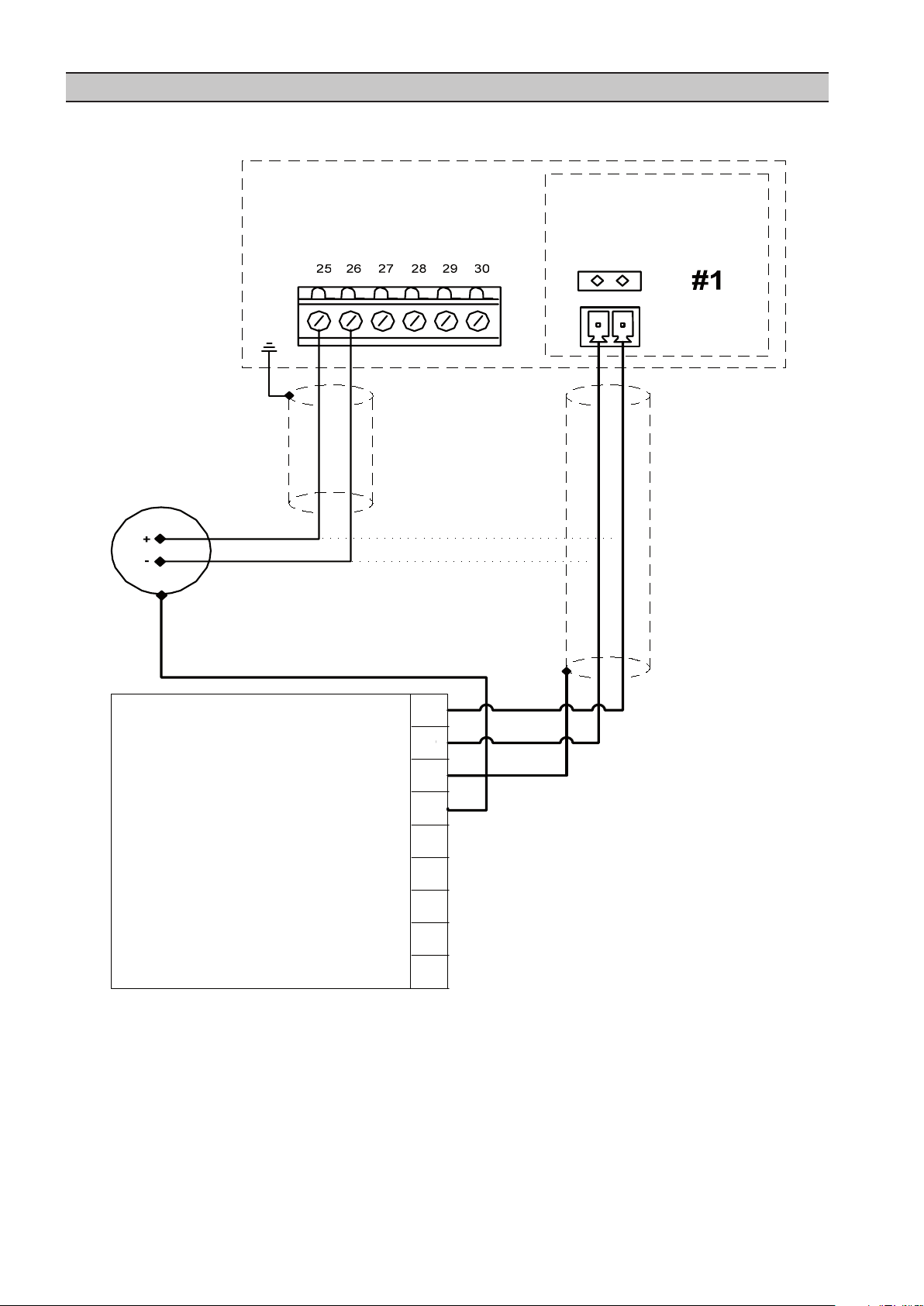

13

VSD Box

XPM-Ao2

Pressure

Transducer

Case Ground

IR-5000

Signal

Signal

+VDC

+VDC

COM

A1

13

60

55

39

+24

- ANA1

+ ANA1

X07

X02

SECTION 7 INGERSOLL RAND TO VSD BOX INTERCONNECT

The following drawing represents the correct method for wiring the VSD Box and Ingersoll Rand Bolt-On VSD’s.

Page 13

INGERSOLL RAND INTELLISYS CONTROLLED VSD COMPRESSORS TO VSD BOX INTERCONNECT

IN

OUT

LED 4

READY

LED 3

RUN

SEQ CONT

LOAD UNL

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

GND

D11

D12

+20V

ALARM

RUN

READY

IR-PCB

+VDC

COL

ON

HATR

Contact

Restart TD

Relay

Contact

To TR Relay

To M Contact

To 1SV

To 3SV

To 2CR

OFF

E-STOP

SSR UP6 20-30 FV

VFD/fixed

Load Enable

Load/Unload

XCR

XCR

110VAC

110VAC

0 VAC

VSD BOX

X01 TERMINAL

SG SSR

VSD BOX

X01 TERMINAL

SEQ CONT

LOAD UNL

GND

D11

D12

+20V

LED 5 VFD

LED 2 LOAD

LED 1 SEQ

LED 4

READY

LED 3

RUN

VFD/fixed

Load Enable

Load/Unload

IR-PCB

+VDC

OUT

IN

ALARM

RUN

READY

XCR

110VAC

0VAC

To Exixting

Blowdown

Solenoid

2CR Relay

E-STOP

1ATS

Remote Load Enable

Remote Load/Unload

Intellisys SG

INGERSOLL RAND PRESSURE SWITCH CONTROLLED VSD COMPRESSORS TO VSD INTERCONNECT

Consult the X8I Interconnect and Application Guide

prior to the installation of the VSD Box and the ir-PCB to

the air compressor.

14

Page 14

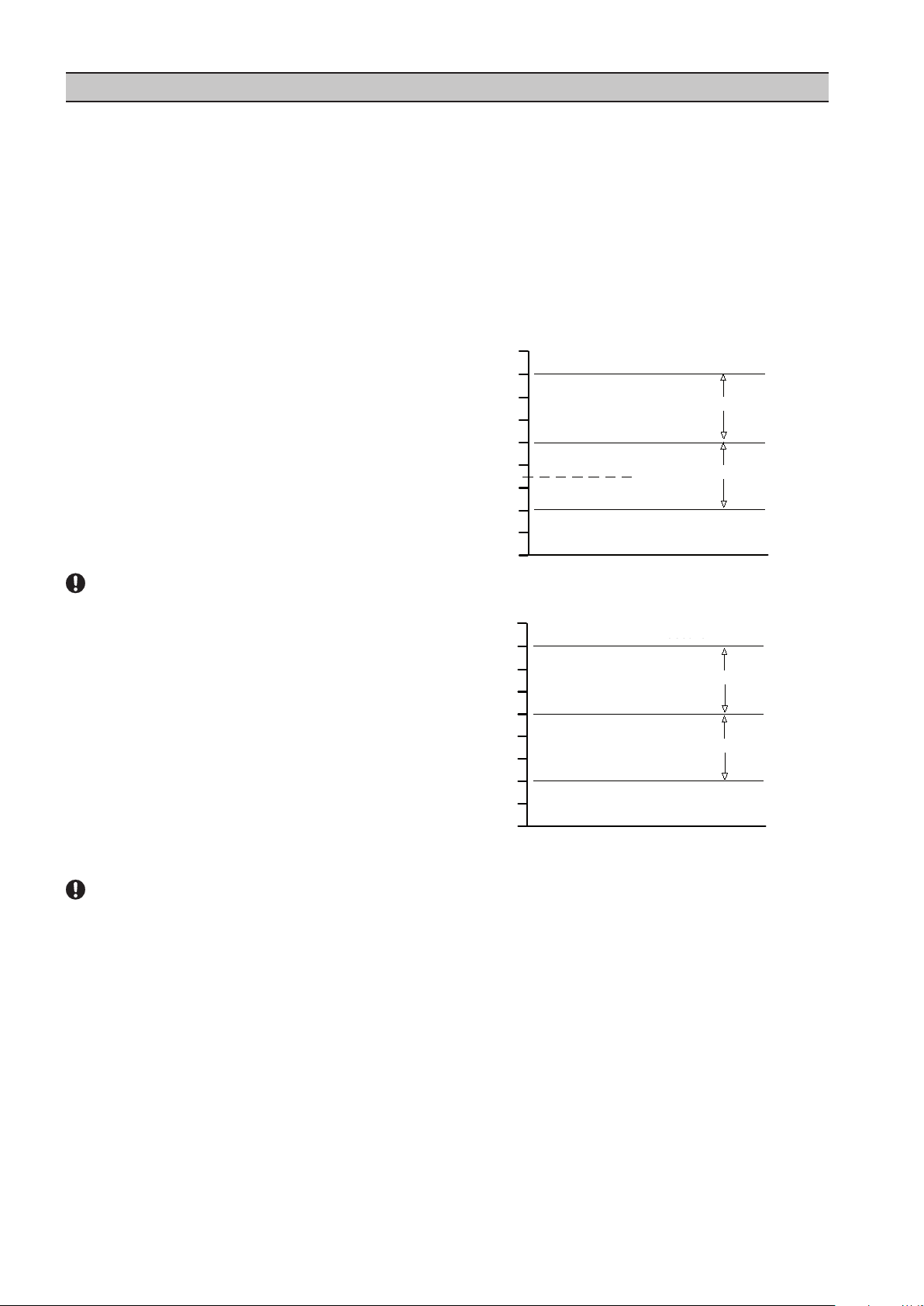

15

COMPRESSOR

Pressure Set Points

COMPRESSOR

Pressure Set Points

I

m

m

e

d

i

a

t

e

S

t

o

p

P

r

e

s

s

u

r

e

7psi (0.5bar) min

Controlled Stop Pressure

7psi (0.5bar) min

7psi (0.5bar) min

7psi (0.5bar) min

Target Pressure

Unload Pressure

Excess or Alarm Pressure

Target Pressure

Load Pressure

Pressure

Pressure

SECTION 8 COMMISSIONING

It is recommended that installation and commissioning

be carried out by an authorized and trained product

supplier.

Information regarding the compressor control system,

method of operation and regulation settings, is required.

Knowledge of VSD compressor regulation methods,

experience working with compressor control systems and

basic principle knowledge of compressed air systems,

is also required to be able to successfully install and

commission this product.

Physical Checks

Before applying power to the VSD Box ensure that the

power supply connections are correct and secure and

that the operating voltage selector is set correctly for the

power supply voltage in use; 115Vac or 230Vac (+-10%),

50/60Hz; see ‘Installation’.

Check and ensure all pressure sensor, output pressure

signal and ir-PCB connections are correctly installed and

secure.

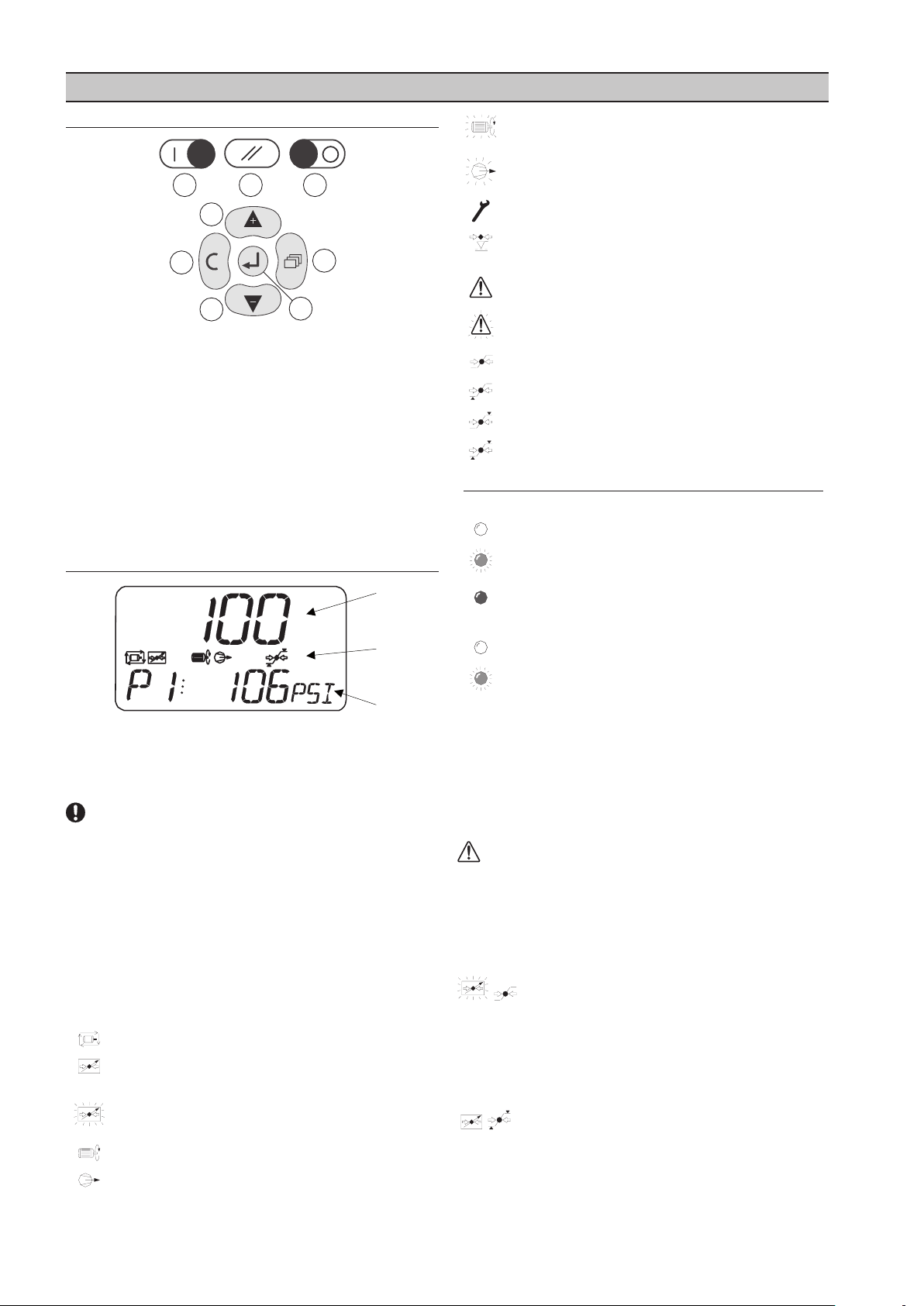

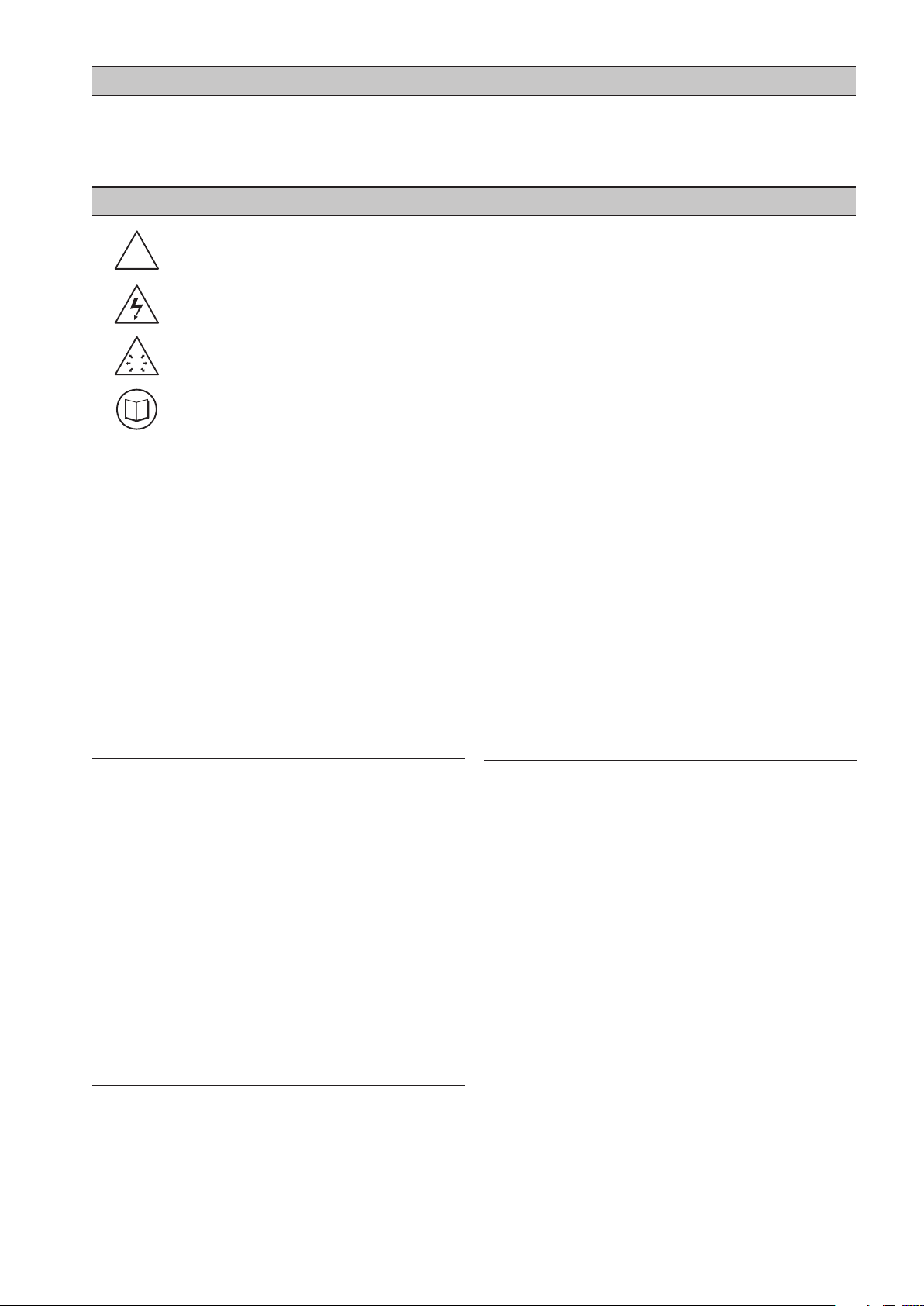

Compressor Pressure Set Points

Establish the following pressure set point values from the

compressor control system.

NOTE: For fixed speed compressors the ‘target’ pressure

can be set at the mid-point between the compressor

‘load’ and ‘unload’ pressure set points.

4) The maximum Discharge pressure level (and maximum

Internal pressure level if used) set in the compressor

controller. This value will be the Excess or High pressure

Alarm safety level. On fully integrated VSD compressor

controllers this value may be represented as the

‘Immediate Stop Pressure’ level.

Establishing the correct compressor pressure set

point values is critical to successful VSD Box operation.

1) Compressor ‘Load’ pressure set point: The pressure at

which the compressor will start/load.

On 3rd party fully integrated VSD compressor

controllers this value may be represented as the

‘Target Pressure’ level.

2) Compressor ‘Unload’ pressure set point. The pressure

at which the compressor will stop/unload.

On 3rd party fully integrated VSD compressor

controllers this value may be represented as the

‘Controlled Stop Pressure’ level.

3) Compressor ‘Target’ pressure set point.

For 3rd party integrated VSD type compressors this

is the pressure that the variable speed drive is set to

maintain.

This value will generally be the same as the

‘load’ pressure set point for 3rd party variable speed

compressors that have fully integrated VSD control

systems. For Ingersoll Rand Bolt-On VSD compressors,

this value will be the mid-point between the ‘load’ and

‘unload’ pressure set points.

NOTE: If the variable speed ‘target’ pressure is set

separately from the compressor controller (in the variable

speed drive controller menu or using a potentiometer

connected to the variable speed drive controller), then

the compressor controller is not a fully integrated type.

In this instance the ‘target’ pressure may have to be

determined by observation and/or experiment.

NOTE: If the compressor pressure set points have

been set with small differentials then the pressure set

points of the compressor will require adjustment before

proceeding.

NOTE: It is recommended that the pressure differential

between the ‘load’ and ‘unload’ (or ‘target’ and ‘controlled

stop’) pressures is a minimum of 7psi (0.5bar).

NOTE: It is recommended that the pressure differential

between the ‘unload’ and ‘excess’ (or ‘controlled stop’ and

‘immediate stop’) pressures is a minimum of 7psi (0.5bar).

Page 15

VSD Box Configuration

Output Pressure Signal Calibration

Apply power to the VSD Box.

If the VSD Box automatically starts (the green started

indicator illuminates or flashes) press the STOP button.

Using the VSD Box menu routines, set the ‘IC’ (I/O

Configuration - Type) in menu P03 to the correct setting

for the pressure sensor input/output configuration.

VSD Box Network Address

Each VSD compressor connected to the Automation

System unit must be assigned a unique compressor

identification number (1 to the maximum number of

compressors). This number will be the ‘network address’

number for the compressor. The number should be clearly

marked on the compressor for identification purposes.

When connecting a compressor(s) to the VSD Box, always

use the Automation System unit’s unique identification

number as the compressor ‘network address’ number.

Using the VSD Box menu routines, set the ‘Ad’ (Network

Address) in menu P03 to the Automation System unit’s

compressor identification number.

Input Pressure Sensor(s)

The offset and range of the pressure sensor(s) used on

the compressor must be established for VSD Box pressure

sensor calibration. Generally this information is indicated

on the pressure sensor label.

The correct ‘offset’ and ‘range’ values of each pressure

sensor are required for VSD Box ‘input’ pressure sensor

calibration.

Using the VSD Box menu navigation procedure, select

menu page P05 (Output Pressure Calibration). The ‘items’

of this menu enable calibration of the pressure signal(s)

transmitted to the compressor controller.

Pressure Set Points

Establishing and implementing the correct pressure

set points is critical for successful VSD Box operation.

Using VSD Box menu navigation, select menu page P03

(Configuration).

1) Set the ‘Dm’ (Discharge Pressure Maximum Limit) to

the compressor’s ‘Excess Discharge Pressure Alarm’ or

‘Immediate Stop’ pressure setting.

2) If an ‘Internal’ pressure sensor is in use set the

‘Im’ (Internal Pressure Maximum Limit) to the

compressor’s ‘Excess Internal Pressure Alarm’

pressure setting. Typically this value will be at least

12psi (0.8bar) above the excess or alarm ‘discharge’

pressure limit.

Using VSD Box menu navigation, select menu page P01

(Pressure Set Points).

1) Set the ‘Pu’ (Unload) pressure set point to the

compressor’s ‘Unload’ or ‘Controlled Stop’ pressure

set point value.

2) Set the ‘Pt’ (Target) pressure set point to the ‘target’

pressure setting established for the compressor.

3) Set the ‘PL’ (Load) pressure set point to the

compressor’s ‘Load’ or ‘Target’ pressure set point

value.

The main value display should show a pressure value; for

example 0.0 bar. If the display shows dashes (- - - -) check

the ‘Discharge‘ pressure sensor connections.

Note: Wire polarity is important.

If an ‘Internal’ pressure sensor is in use press DOWN to

view the ‘P2’ pressure value in the User menu ‘items’

display. The ‘P2’ value display should show a pressure

value; for example 0.0 bar. If the display shows dashes (- -

- -) check the ‘Internal‘ pressure sensor connections.

Note: Wire polarity is important.

At this stage the displayed pressure values will probably

be incorrect; this is normal.

Calibrate the input ‘Discharge’ pressure sensor, and input

‘Internal’ pressure sensor if used, following the input

‘Pressure Sensor Calibration’ procedure below:

Input and Output pressure calibration is critical for

successful VSD Box operation.

Input Pressure Sensor Calibration

Using the VSD Box menu navigation procedure, select

menu page P04 (Input Pressure Calibration). The ‘items’

of this menu enable calibration of the pressure sensor(s)

connected to the VSD Box.

16

Page 16

17

SECTION 9 DISPLAY AND MENU OPERATION

MENU NAVIGATION

Display Item Structure:

All value, parameter or option selection displays are

grouped into menu lists. Items are assigned to a list

according to type and classification. Items that can be

used to select options or modify functions are assigned to

‘menu mode’ lists. Items that a User may require to view

during routine operation, detected pressure for example,

are assigned to the normal operational mode list. Lists are

identified by page number; the normal User display list

is page ‘P00’. All parameters and options are assigned to

menu mode pages ‘P01’ or higher. All Page ‘P00’ items are

view only and cannot be adjusted.

Normal Operational Mode (Page P00):

At controller initialization, all display elements and LED

indicators are switched on for three seconds, the display

will then show the software version code for a further

3 seconds before initialization is complete and the

normal operating display (Page P0) is shown. In page

P00 ‘normal operational display mode’ the main display

will continuously show the detected delivery pressure

and the Item display will show the first item of the ‘User’

menu. User menu ‘Items’ can be selected using the Up or

Down buttons at any time. Pressing the Enter button will

lock any selected Item display and inhibit return to the

default display. When an Item display is locked the lock

key symbol will slow flash. To unlock an Item display press

Up or Down to view an alternative Item display or press

Reset or Escape. No Item values, options or parameters

can be adjusted in page ‘P00’. If a fault condition occurs

the fault code becomes the first list item and the display

will automatically jump to display the fault code. More

than one active fault code item can exist at any one time.

Access Code:

Access to page list displays higher than page ‘P00’ is

restricted by access code. To access menu mode pages

press MENU, an access code entry display is shown and

the first code character will flash. Use PLUS or MINUS to

adjust the value of the first code character then press

ENTER. The next code character will flash; use UP or

DOWN to adjust then press ENTER. Repeat for all four

code characters.

Access Code Timeouts:

When in menu mode, if no key activity is detected for a

period of time the display will automatically reset to the

normal operational display; Page ‘P00’.

Menu Mode Navigation:

In menu mode the main value display will flash and show

the Page number. To select a page press UP or DOWN. For

each page the display will show the first Item of the page

list. To view a page list press ENTER, the Page number

will stop flashing and the Item display will flash. Press UP

or DOWN to view the selected page list items. To select

an Item value for modification, press ENTER. The Item

display will stop flashing and the Value display will flash.

The value or option can now be modified by pressing

UP(Plus) or DOWN(Minus). To enter a modified value

or option in memory press, ENTER. Alternatively, the

modification can be abandoned and the original setting

maintained by pressing ESCAPE.

Press ESCAPE at any time in menu mode to step

backwards one stage in the navigation process. Pressing

ESCAPE when the page number is flashing will exit menu

mode and return the display to normal operational mode;

page ‘P00’.

Press and hold RESET for two seconds at any time

to immediately exit menu mode and return to the

normal operational mode display. Any value or option

adjustment that has not been confirmed and entered

into memory will be abandoned and the original setting

maintained

A flashing Key symbol displayed with any Item

indicates the Item is locked and cannot be modified. This will

occur if the Item is view only (non adjustable) or in instances

where the item cannot be adjusted while the EX Box is in

‘Remote Mode’.

If the code number is less than 1000 then the first code

character will be 0(zero). To return to a previous code

character press ESCAPE. When all four code characters

have been set to an authorized code number press

ENTER. An invalid code will return the display to normal

operational mode; page ‘P00’.

Page 17

Menu Items and Settings

MENU P00 - User

1 P1 Discharge Pressure - Output (view only)

2 P2 Internal Pressure - Output (view only)

3 SP Percent Speed (view only)

MENU P01 - Pressure Set Points

1 Pu Unload Pressure

2 Pt Target Pressure

3 PL Load Pressure

MENU P02 – Error Log

1 Hr VSD Box Operating Hours

2 01 Error Log #1

to

16 15 Error Log #15

MENU P10 – Unit Configuration

1 D7 Aux Alarm Input Configuration

2 D8 Aux Trip Input Configuration

3 SQ ir-PCB Sequence control hold

4 Ao Analog Output Function (4-20mA)

5

Er Error Log Reset

6 Hr VSD Box Operating Hours Adjust

MENU P16 – Analog Output Diagnostic

See ‘Diagnostics’

Note: Menus P07, 9 and 11 to 15 are not used.

Access Code = 0021

MENU P01 - Pressure Set Points

MENU P03 - Configuration

1 P> Pressure Units Select

2 Ad Network Address (Compressor No.)

3 PA Pressure Averaging Factor

4

IC I/O Configuration (Type)

5 DM Discharge Pressure Maximum Level

6 Im Internal Pressure Maximum Level

MENU P04 – Input Pressure Calibration

1 Do Discharge Pressure ‘Offset’

2 Dr Discharge Pressure ‘Range’

3

Io Internal Pressure ‘Offset’

4 Ir Internal Pressure ‘Range’

MENU P05 – Output Pressure Calibration

1 Do Discharge Pressure ‘Offset’

2 Dr Discharge Pressure ‘Range’

3

Io Internal Pressure ‘Offset’

4 Ir Internal Pressure ‘Range’

MENU P06 / Diagnostics

See ‘Diagnostics’

Pu: Unload Pressure

Compressor ‘Unload’ pressure set point: The pressure

at which the compressor will stop/unload. On fully

integrated VSD compressor controllers this value may be

represented as the ‘Controlled Stop Pressure’ level. Set

the ‘Pu’ (Unload) pressure set point to the compressor’s

‘Unload’ or ‘Controlled Stop’ pressure set point value.

Pt: Target Pressure

Compressor ‘Target’ pressure set point. For VSD type

compressors this is the pressure that the variable speed

drive is set to maintain. Set the ‘Pt’ (Target) pressure set

point to the ‘target’ pressure setting established for the

compressor.

PL: Load Pressure

Compressor ‘Load’ pressure set point: The pressure

at which the compressor will start/load. On fully

integrated VSD compressor controllers this value may

be represented as the ‘Target Pressure’ level. Set the ‘PL’

(Load) pressure set point to the compressor’s ‘Load’ or

‘Target’ pressure set point value.

Establishing and maintaining the correct pressure set

point values (Pu, Pt and PL ) is critical to the successful

operation of VSD Box control functions.

See ‘Commissioning - Pressure Set Points’

MENU P02 - Error Log

MENU P08 – Speed Monitoring

1 FL Frequency at Minimum Speed

2 FH Frequency at Maximum Speed

3

C< Control Percentage (view only)

The first item of the log error menu is the VSD Box

operational hours (Hr). This is an indication of the

accumulated hours the VSD Box has been operational

and is used to time-stamp fault codes in the error log. The

hours counter has no other function.

The VSD Box operating hours counter is NOT intended

as a measure of compressor operation or running

hours; the hours counter will differ from, and operate

independently from, the compressor hours counter.

18

Page 18

19

Each error log item will show the fault code alternating

with the VSD Box operational hours when the fault

occurred. The error log stores the last 15 faults in

chronological order; item ‘01’ is the most recent fault.

MENU P03 – Configuration

P>: Pressure Units Select

Selects the display pressure units (bar, psi or kPa)

Im: Internal Pressure Maximum Level

If the detected Internal pressure input exceeds this

setting ‘Pressure Control’ is disabled and the detected

Discharge and Internal pressure is transmitted directly

to the compressor controller without alteration. This is

intended as a safety feature that will allow the safety

functions of the compressor controller to respond to

excess pressure situations.

Ad: Network Address

Network address; must be set to the compressor

identification number used by the Automation System

unit for the compressor (1 to the maximum number of

compressors). Each compressor in a system must have a

unique identification number.

PA: Pressure Averaging Factor

Pressure corrections supplied by the Automation System

unit are averaged to prevent abrupt changes and

enable smooth and controlled pressure adjustments.

The Automation System updates pressure information

approximately every two seconds. The ‘Pressure

Averaging Factor’ is the number of previous pressure

corrections that are used for averaging. For example:

a factor of ‘2’ will average the most recent pressure

correction value received with the previous two values

received.

If system volume is large and/or pressure variations are

slow a higher ‘Pressure Averaging Factor’ can be used to

dampen response and smooth control pressure changes.

If system volume is small and/or pressure variations are

fast a lower ‘Pressure Averaging Factor’ should be used

to enable a faster response. In some instances pressure

differential across air treatment and/or small diameter

pipe work can result in sudden and abrupt changes in

detected pressure.

A higher ‘Pressure Averaging Factor’ can be used to

dampen this effect.

IC: I/O Configuration (Type)

Determines the pressure detection and pressure output

signal configuration.

‘1’ – Discharge pressure 4-20mA input with associating

discharge pressure 4-20mA output. Internal pressure is

ignored.

‘2’ – Discharge pressure 4-20mA input and Internal

pressure 4-20mA input with associating 4-20mA outputs.

‘3’ – 0.5V to 4.5V Discharge pressure input with

associating 0.5V to 4.5V output.

Internal pressure is ignored.

Dm: Discharge Pressure Maximum Level

If the detected Discharge pressure input exceeds this

setting ‘Pressure Control’ is disabled and the detected

Discharge pressure (and Internal pressure if in use) is

transmitted directly to the compressor controller without

alteration. This is intended as a safety feature that will

allow the safety functions of the compressor controller to

respond to excess pressure situations.

Note: Internal compressor pressure will increase over time

with an increase in air/oil separator element differential

and will generally be 0.8bar (12psi) above discharge

pressure.

MENU P04 – Input Pressure Calibration

Do: Discharge Pressure Offset

This parameter will be the minimum value of the pressure

transducer, 0 PSI, 0 BAR, or 0 kPA. It can also be used to

create an ‘Offset’ if there is a difference in the zero value

being displayed. The default setting for this parameter is

0 PSI. The values for this parameter are:

“0” when using the minimum value of the pressure

transducer range

A value greater than or less than 0 if the display

does not read 0 or when using an Offset pressure

transducer (an example of an Offset pressure

transducer would be one where the range was minus

PSI (-25) to a positive PSI (200).

The pressure transducer must be vented to

atmosphere when setting the 0 or offset.

Dr: Discharge Pressure Range

This parameter will be the maximum range of the

pressure transducer, 232 PSI, 16 BAR, or 1600 kPA. It can

also be used to create an ‘Offset’ if there is a difference in

the range value being displayed. The default setting for

this parameter is 232 PSI. The values for this parameter

are:

“232” when using the maximum value of the

pressure transducer range

A value greater than or less than 232 if the display

does not read 232.

The pressure transducer must have a known,

accurate pressure applied to it when changing

this value to a value other than 232.

Calibration Checks

When the ‘Discharge’ pressure sensor offset and range

menu items are selected the menu page display value will

change to show the actual detected ‘Discharge’ pressure

measurement. This value can be used to compare with

a ‘known’ pressure applied to the ‘Discharge’ pressure

sensor for accurate calibration purposes. An independent

and accurate means of measuring the applied pressure is

required.

Page 19

1) Subject the ‘Discharge’ pressure sensor to

atmosphere 0psi (0bar).

2) Adjust the ‘Do’ pressure ‘offset’ value until the

‘Discharge’ pressure displayed by the VSD Box shows

0psi ((0) bar.

3) Apply a known pressure to the ‘Discharge’ pressure

sensor. It is recommended that the applied pressure

is representative of normal working pressure levels.

It is not important if the applied pressure is static or

continuously fluctuating.

4) Adjust the ‘Dr’ pressure ‘range’ value until the

‘Discharge’ pressure displayed by the VSD Box shows

the same as the ‘known’ applied pressure.

The detected pressure is displayed with the

calibration menu item and will change to match the new

calibration setting as the setting is adjusted.

1) Subject the input ‘Discharge’ pressure sensor to

atmosphere 0psi (0bar).

2) Adjust the ‘Do’ pressure signal ‘offset’ value until the

compressor controller’s discharge pressure display

value shows 0psi (0) bar.

3) Apply a known pressure to the input ‘Discharge’

pressure sensor. It is recommended that the applied

pressure is representative of normal working

pressure levels. It is not important if the applied

pressure is static or continuously fluctuating.

4) Adjust the ‘Dr’ pressure signal ‘range’ value until the

compressor controller’s discharge pressure display

value shows the same as the VSD Box discharge

pressure.

Io: Internal Pressure Offset

Use the same procedure as described for Do: to set the

Offset for Io:

Ir: Internal Pressure Range

There is no need for the applied pressure to be static;

it can be dynamic and changing. This enables calibration

to be carried out on a fully operational system where

changing system pressure can be accurately verified from

another source.

Correct pressure sensor set-up and calibration

is critical for successful system operation. It is

recommended that pressure sensor calibration is

examined, and adjusted if necessary, annually or a predetermined routine periodic basis.

Io: Internal Pressure Offset

Use the same procedure as described for Do: to set the

Offset for Io:

Ir: Internal Pressure Range

Use the same procedure as described for Dr: to set the

Offset for Ir:

Follow the same procedure described above for Do: and

Dr: Calibration Checks for applying adjustments to the

‘Io’ (Internal offset) and ‘Ir’ (Internal range).

MENU P05 – Output Pressure Calibration

Do: Discharge Pressure Offset

Enter the ‘OFFSET’ value for the ‘Discharge’ pressure signal

in the ‘Do’ menu item. Set this value will to same as the

initial ‘Discharge’ pressure sensor input ‘offset’.

Dr: Discharge Pressure Range

Enter the ‘RANGE’ value for the ‘Discharge’ pressure signal

in the ‘Dr’ menu item. Set this value to the same as the

initial ‘Discharge’ pressure sensor input ‘range’.

Calibration Checks

When the output ‘Discharge’ pressure signal offset and

range menu items are selected the menu page display

value will change to show the actual detected input

‘Discharge’ pressure measurement. This value represents

the pressure the VSD Box is attempting to transmit to the

compressor controller and can be used to compare with

the compressor controller’s displayed pressure value.

Use the same procedure as described for Dr: to set the

Offset for Ir:

Follow the same procedure described above for Do: and

Dr: Calibration Checks for applying adjustments to the

‘Io’ (Internal offset) and ‘Ir’ (Internal range).

Input and Output pressure calibration is critical to

the successful operation of VSD Box functions and must

be examined, and adjusted if necessary, periodically on a

routine basis.

MENU P08 – Speed Monitoring

FL: Frequency at Minimum Speed

Used for optional ‘Speed Monitoring Kit’ if fitted. Must be

set to 0(zero) if speed detection is not in use.

Note: Intended for inverter drive variable speed type

compressors.

The inverter drive output frequency at the compressor’s

minimum operating speed.

When this menu item is selected the menu page

number display will change to show the actual detected

frequency. By restricting the output air from the

compressor the compressor inverter drive can be forced

to minimum speed. Set the value to the lowest frequency

detected.

The frequency setting must represent the lowest

inverter drive output frequency that will occur in normal

operation.

FH: Frequency at Maximum Speed

Used for optional ‘Speed Monitoring Kit’ if fitted. Must be

set to 0(zero) if speed detection is not in use. Intended for

inverter drive variable speed type compressors.

The inverter drive output frequency at the compressor’s

maximum operating speed.

20

Page 20

21

When this menu item is selected the menu page

number display will change to show the actual detected

frequency. By creating a demand for air the compressor

inverter drive can be forced to maximum speed. Set the

value to the highest frequency detected.

The frequency setting must represent the maximum

(100%) inverter drive output frequency that will occur in

normal operation.

C>: Control Percentage

This menu item value is view only and cannot be

adjusted. The value represents the variation in inverter

drive output frequency; where 0% is minimum speed and

100% is maximum speed.

Note: The ‘Control Percentage’ value represents the

percentage of speed variation from minimum speed to

maximum speed and differs from the ‘User’ menu percent

motor speed value. This value is used internally by the

VSD Box for Automation System unit functions and is

only active when an optional ‘Speed Monitoring Kit’ is

installed.

MENU P10 – Unit Configuration

D7: Auxiliary Alarm Input Configuration

‘0’ – Disabled

‘9’ – Detected Discharge pressure

‘10’ – Detected Internal pressure

Er: Error Log Reset

Adjust to ‘RST’ and press ENTER to clear and reset the

‘Error Log’ menu.

Hr: VSD Box Operating Hours Adjust

Allows adjustment of the VSD Box operating hours

counter. The accumulated hours counter is used for ‘Error

Log’ time-stamp only and has no other function.

Determines the input configuration for the auxiliary

Alarm input:

‘0’ – Normally open, Alarm when closed

‘1’ – Normally closed, Alarm when open

D8: Auxiliary Trip Input Configuration

Determines the input configuration for the auxiliary Trip

input:

‘0’ – Normally open, Trip when closed

‘1’ – Normally closed, Trip when open

SQ: ir-PCB Sequence Control Hold

If using the ir-PCB load relay output on a remote

digital input pressure control, or pressure switch, type

compressor controller, it may be desirable to maintain

VSD Box load/unload control of the compressor when the

VSD Box is stopped.

If this item is set to ‘1’ the VSD Box will continue to load

and unload the compressor, in accordance with the set

VSD Box ‘load’ and ‘unload’ pressure set points, at all times.

If set to ‘0’ (Default) the VSD Box will deactivate remote

pressure control (SEQ) and/or re-introduce the pressure

switch, when the VSD Box is stopped. The compressor will

operate in ‘local’ pressure control mode.

Ao: Analog Output Function

The VSD Box controller is equipped with a 4-20mA

auxiliary output. The output can be used to remotely

signal the selected analog value.

Page 21

SECTION 10 DIAGNOSTICS

The VSD Box controller is equipped with comprehensive

diagnostic functions. Each input can be examined

individually and each output can be manually activated

or manipulated individually.

Controller Diagnostics:

Menu P06 - Diagnostics

D1 Digital Input 1

D2 Digital Input 2 ON

D3 Digital Input 3

D4 Digital Input 4

D5 Digital Input 5

D6 Digital Input 6

D7 Digital Input 7

D8 Digital Input 8

---------------------------------------------------------------------------

R1 Relay Output 1

R3 Relay Output 3

R4 Relay Output 4

R6 Relay Output 6

---------------------------------------------------------------------------

A1 Analog Input 1 bar <> mA

A2 Analog Input 2 bar <> mA

A3 Analog Input 3 bar <> +VDC

---------------------------------------------------------------------------

Ao Analog Output 1 4.0 to 20.0mA

Digital Inputs:

D2 and D6 (connected to the ir-PCB) are the only digital

inputs that will detect a pulsing signal.

D2: ir-PCB Compressor Ready/Run Status

OFF Not Ready

OFF

Pulsing

OFFR2 Relay Output 2

ONR5 Relay Output 5

Relay Outputs:

Each relay output can be energised and de-energised

manually by selecting the item. Use PLUS and MINUS to

adjust and ENTER.

Analog Inputs:

The item will alternate between the detected value and

the electrical measurement on the input terminals. An

independent measuring device can be used to check the

displayed electrical measurement.

A1: Discharge Pressure 4-20mA

A2: Internal Pressure 4-20mA

A3: Discharge Pressure 0.5-4.5VDC

Analog Output:

The output can be manually adjusted by selecting the

item. Use PLUS and MINUS to adjust and ENTER. The

output will return to normal operational value upon

menu exit.

XPM-Ao2 Module Diagnostics:

MENU P16 / XPM-Ao2 Diagnostics

A1 Analog Output 1 4-20mA #1

A2 Analog Output 2 4-20mA #2

A3 Analog Output 3 0.5-4.5VDC

Analog Outputs:

Each output can be manually adjusted by selecting the

item. Use PLUS and MINUS to adjust and ENTER. The

output will return to normal operational value upon

menu exit.

A1: Discharge Pressure 4-20mA

A2: Internal Pressure 4-20mA

A3: Discharge Pressure 0.5-4.5VDC

ON Ready

Pulsing Running

D3: ir-PCB Compressor Load/Maintenance

OFF Alarm (unless reversed in menu)

ON OK (unless reversed in menu)

Pulsing Service Maintenance

The pulse signal is 24VDC at 50/60Hz. A DC voltage meter

will detect this as 12VDC +-4V.

22

Page 22

23

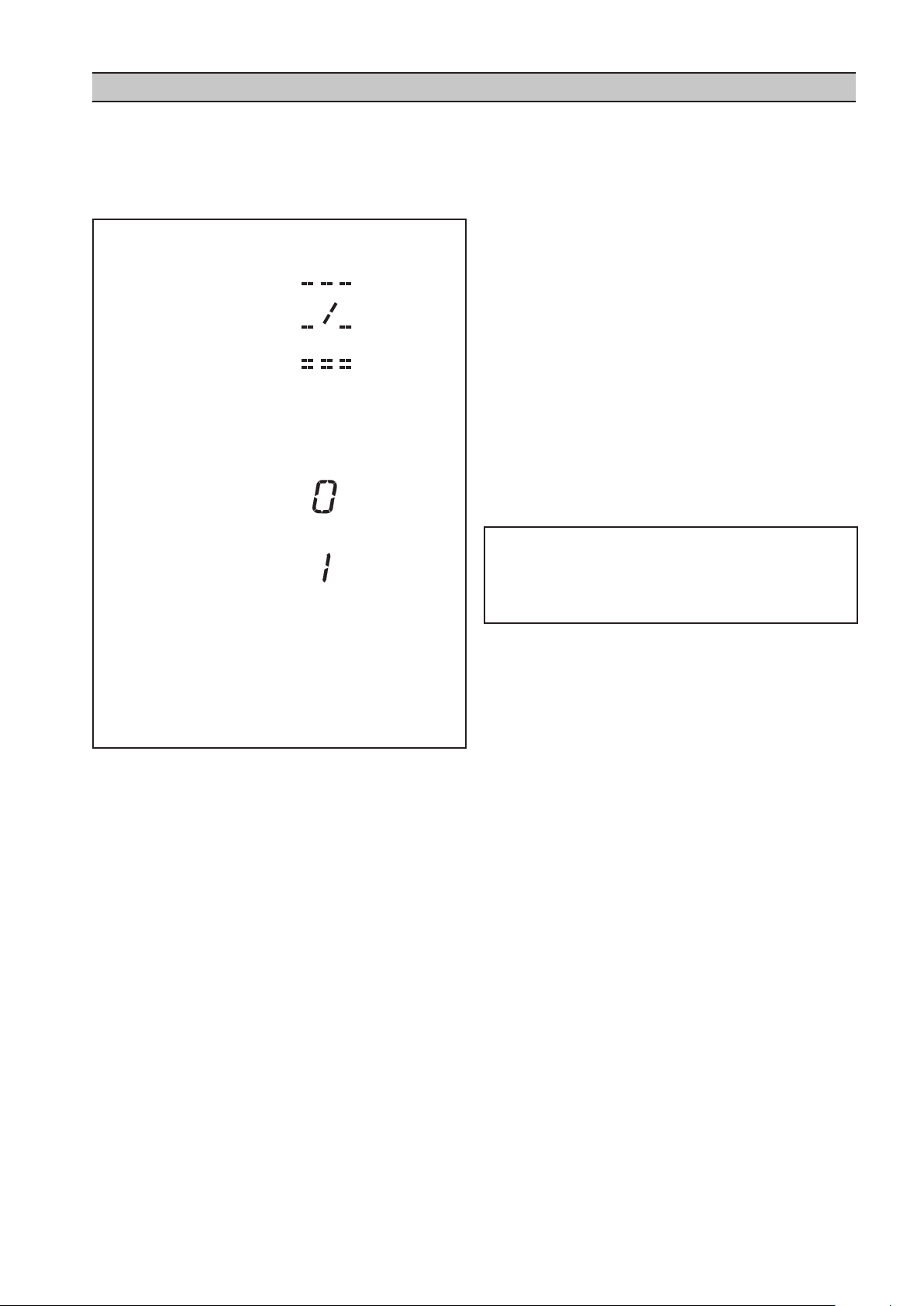

SECTION 11 OPERATION

a

b

c

d

f

g

h

e

psi

A

C

B

KEYPAD

Start

a.

Reset

b.

Stop

c.

Menu

d.

Enter

e.

Escape (Cancel)

f.

Up (Plus)

g.

Down (Minus)

h.

DISPLAY

Flashing - Not Responding, Compressor Not

Running When Required

Flashing - Not Responding, Compressor Not

Loading When Required

Service Maintenance function active

Discharge Pressure or Internal Pressure has

exceeded the maximum set limit

Compressor Not Ready

Fault, Auxiliary Input Alarm/Trip

Pressure Control OFF or inhibited

Load Request to compressor

Unload Request to compressor

Pressure Control Active

INDICATORS

Run Indicator (Green LED)

OFF - Pressure Control Off, Stopped

Flashing - Pressure Control ON, waiting for

compressor to respond

ON - Pressure Control On, Started

Fault Indicator (Red LED)

OFF – No fault

Flashing – VSD Box Fault Condition (see Fault

Codes)

The primary display value (A) will continuously show the

detected ‘Discharge’ pressure. The pressure is derived

from the compressor ‘Discharge’ pressure sensor and the

displayed value is not manipulated or adjusted.

The compressor controller ‘Pressure Display’ may

not represent the actual true local pressure(s) when VSD

Box ‘Pressure Control’ is active. Use the VSD Box ‘Input’

pressure display(s) for local pressure reference.

The ‘User Menu’ item display (B) will show the selected

user menu item. Press UP or DOWN to scroll through the

display ‘items’ list.

Status Symbols

The Status display will continuously show the current

state of the VSD Box (C) by using the following icons.

Power Failure Auto Restart (always on)

Communicating with System Management

Controller

Flashing - No Communications with System

Management Controller

Compressor Running

Compressor Loaded

The VSD Box will report that the compressor is ‘Not

Available’ to the Automation System controller when the

VSD Box is in a stopped or fault condition.

Start

Press START to activate VSD Box pressure control. The run

indicator (9) will illuminate or flash.

The compressor must be in a started state (running or

in standby) before VSD Box pressure control will function.

When started the VSD Box will begin to manipulate the

pressure signal(s) to the compressor controller – ‘Pressure

Control’ is active.

Pressure Control will de-activate automatically

if communications with the system management unit is

disrupted or not connected; the detected pressure from

the pressure sensor(s) is re-transmitted to the compressor

control directly

VSD Box will automatically re-activate ‘Pressure Control’.

When communications are re-established the

Page 23

Stop

Percentage Motor Speed:

Press STOP to de-activate VSD Box pressure control. The

run indicator (9) will extinguish.

When stopped the VSD Box will not manipulate or adjust

the pressure signal(s) to the compressor controller; the

detected pressure from the pressure sensor(s) is retransmitted to the compressor control directly.

The VSD Box will report that the compressor is ‘Not

Available’ to the system management unit when the VSD

Box is in a stopped condition.

Note: During compressor service or routine maintenance

the VSD Box can be stopped to return the compressor to

normal local pressure regulation.

Compressor Status

The detected status of the compressor is indicated by the

VSD Box display status symbols (see Status Symbols)

VSD Box Status

VSD Box operation is indicated by the ‘Run’ LED indicator

(see Indicators). Pressure Control status is indicated by the

‘pressure’ status symbols (see Status Symbols).

USER MENU ITEMS

To view the ‘User Menu Items’ press UP or DOWN. The

‘Item’ display value will scroll through the available items.

P1 ‘Discharge’ output pressure transmitted to the

compressor controller.

The percentage of detected motor speed compared

to maximum motor speed. This value provides a

direct indication of variable speed compressor output

regulation.

VSD Box Status:

The central ‘item’ display value (B) is the compressor

system identification number (network address number).

This is the same as the compressor system identification

number shown on the system management unit.

The ‘right hand’ display value indicates the VSD Box status

condition (see Status Block Diagram).

POWER FAILURE AUTORESTART

Power failure auto restart is always active and cannot be

de-activated.

The VSD Box will re-start if the VSD Box was in an

operational started status before the break or failure of

the main power supply occurred.

The VSD Box will not re-start if it was not in an operational

started status before the break or failure of the main

power supply occurred.

Fault Codes

If a VSD Box fault, or auxiliary input fault, occurs the ‘Item’

display will show a fault code:

0080E Auxiliary Input Shutdown Trip

P2* ‘Internal’ output pressure transmitted to the

compressor controller.

SP** Percent motor speed

C> VSD Box Status

(*) The ‘Internal’ output pressure item is only shown if the

‘Internal’ pressure control function is activated (IC = 2).

(**) The percentage motor speed item is only shown

if a ‘Speed Monitoring Kit’ is fitted and the function is

activated (Menu P08).

Discharge Output Pressure:

The discharge output pressure is manipulated during

‘Pressure Control’ and will differ from the actual ‘Input

Discharge’ pressure displayed as the main display value.

Pressure control function can be observed by comparing

the ‘Output’ discharge pressure with the actual detected

‘Input’ discharge pressure. The two pressures will be

identical when ‘Pressure Control’ is not active.

Internal Output Pressure:

The internal output pressure is manipulated during

‘Pressure Control’ to simulate and maintain the actual

detected differential between the ‘Input’ discharge

pressure and the ‘Input’ Internal pressure. This

functionality allows compressor controller differential

pressure monitoring functions to be maintained

regardless of VSD Box output pressure signal

manipulation.

0115E 4-20mA Discharge P. Sensor Fault

0125E 4-20mA Internal P. Sensor Fault

0135E 4.5VDC Discharge .P. Sensor Fault

0821E Short Circuit Condition Detected

Check all inputs and outputs.

0845E S1 Controller Communications with XPM-Ao2

unit disrupted

2070A Auxiliary Input Alarm

Press RESET to reset the fault code display when the fault

condition is resolved.

24

Page 24

25

SECTION 12 PARTS LIST

20mm

5mm

IEC

3

2

1

24mm

238mm

24mm

188mm

8mm Ø

236mm

286mm

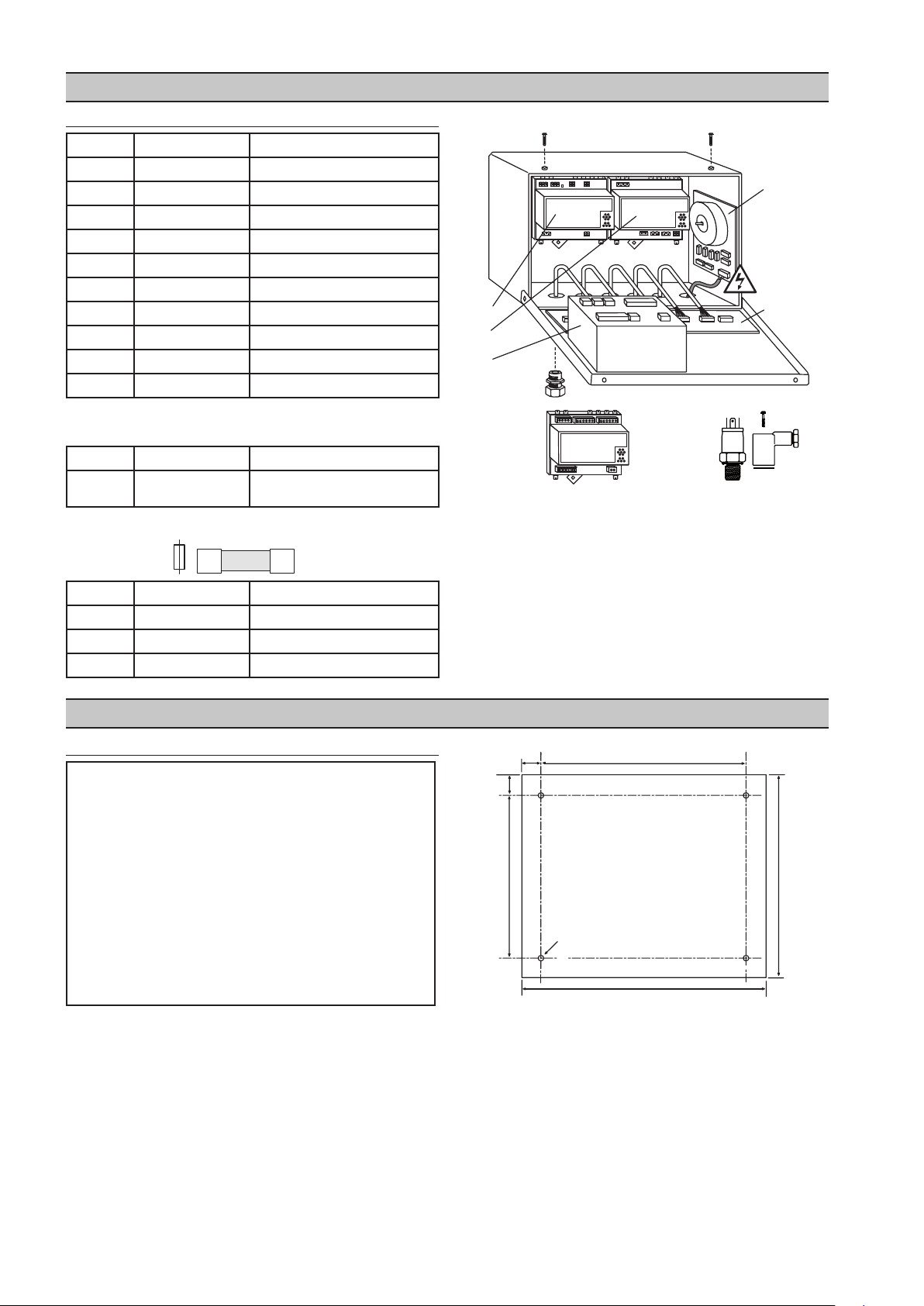

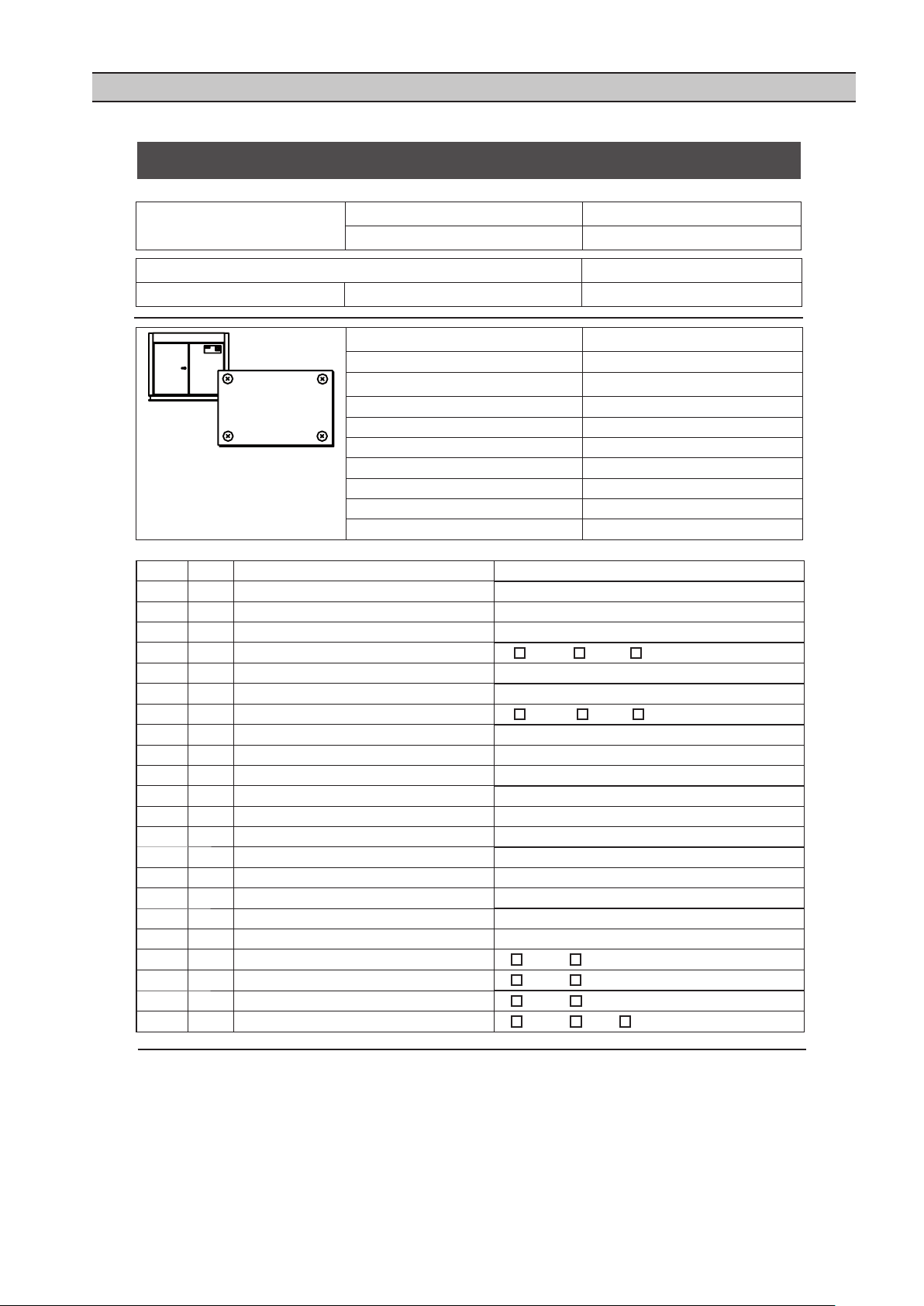

Item Part No. Description

- 42659417 Kit, VSD Box

- 23242225 Unit, VSD Box

- 80444086 Manual, User CD

1 42659490 Controller, VSD

2 42659284 Unit, XPM-PSU24

3 23242282 Unit, XPM-Ao2

4 39265913 Unit, XPM-TAC24

5 23242993 PCB, Terminal VSD

6 38036703 Gland, Set - Pg13.5

7 39265921 Unit, ir-PCB

6

XPM-Ao2

XPM-PSU24

4

5

Optional Accessories:

Item Part No. Description

8 39265939 Sensor, Pressure

4-20mA, 0-16.0bar

Qty Part No. Description

10 39265962 IEC Fuse T1.0A

10 39265970 IEC Fuse T1.6A

10 39265988 IEC Fuse T3.15A

SECTION 13 TECHNICAL DATA

Dimensions 11.45” x 9.45” x 6.0”

291mm x 241mm x 152mm

Weight 14Ib (6.5kg)

Mounting wall, 4 x screw fixings

Enclosure IP54, NEMA 12

Supply 230Vac +/- 10%

115Vac +/- 10%

Power 50VA

Temperature 0°C to 46°C (32°F to 115°F)

Humidity 95% RH non-condensing

7

ir-PCB

8

Page 25

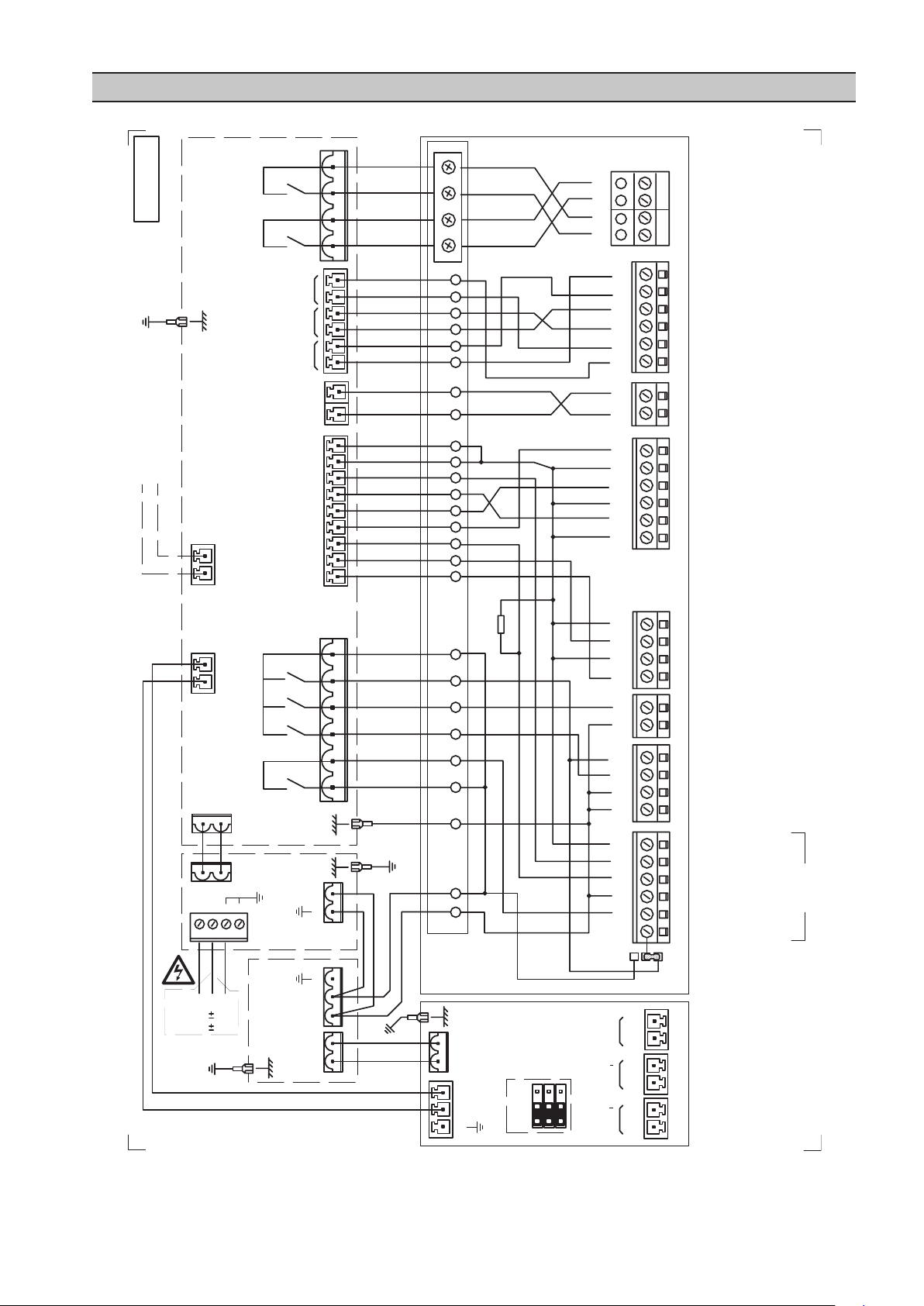

SECTION 14 WIRING DIAGRAM

x

o

B

D

S

V

r

lle

o

r

t

n

o

C

1

S

2

0

X

+VDC

5

R

6

R

Ai1

5

+VDC

0

X

Ai2

A-GND

Ai3

A-GND

6

o

0

A

k

r

m

o

e

t

tw

s

e

y

S

N

1

2

L

L

5

8

7

i4

0

lt

u

X

M

1

#

1

5

L

8

4

2

L

S

R

X

+

C

1

2

3

4

4

0

X

5

6

7

8

C023

C035

C036

C037

C038

C039

C040

C034

C033

C032

C031

C030

C029

C028

C027

C026

C025

C024

1

2

3

4

4

3

3

3

2

3

1

3

0

3

9

2

8

2

7

2

6

2

5

2

4

2

3

2

2

2

1

2

0

2

9

1

8

1

7

1

9

0

X

8

0

7

0

X

6

0

X

5

0

X

R6

R6

R5

R5

+

Ai3

-

-

Ai2

+

-

Ai1

+

+

Ao

-

A-GND

Di5

+C

Speed Signal

Di4

+C

Di3

+C

Group Alarm

Compressor

Running

0.5 to 4.5VDC

Delivery P. < IN

4-20mA

Internal P. < IN

4-20mA

Delivery P. < IN

8

0

X

5

8

4

M

P

X

1

0

X

1

1

N

L

N

L

230Vac 10%

115Vac 10%

+C

Di7

4

0

X

+C

Di8

R2

3

0

X

GND

R1

R3

2

0

X

GND

GND