Page 1

Before installing or starting this unit for the first time, this

manual should be studied carefully to obtain a working

knowledge of the unit and/or the duties to be performed while

operating and maintaining the unit.

RETAIN THIS MANUAL WITH UNIT. This Technical

manual contains IMPORTANT SAFETY DATA and should

be kept with the unit at all times.

More Than Air Answers.

Online answers: http://www.air.irco.com

Ingersoll Rand

System Automation

VSD B Box or VSD mA Box

MODBUS RTU

User’s Manual

C.C.N. : 80445000

REV. B

DATE: JUNE 2009

Page 2

2

Page 3

SECTION 1 – TABLE OF CONTENTS

SECTION 1 – TABLE OF CONTENTS .................................................................................................................... 3

SECTION 2 - INTRODUCTION ................................................................................................................................ 4

SECTION 3 - SAFETY PRECAUTIONS .................................................................................................................. 4

SECTION 4 - MODBUS RTU ................................................................................................................................... 6

MODBUS TABLE(S) ............................................................................................................................................. 6

MODBUS RTU ...................................................................................................................................................... 6 U

COMMUNICATION LINK ...................................................................................................................................... 6

RS485 SERIAL DATA FORMAT ........................................................................................................................... 6

MESSAGE DATA FORMAT ................................................................................................................................. 6

SLAVE RESPONSE TIMEOUT ............................................................................................................................ 8

MESSAGE ANSWER FROM SLAVE TO MASTER .............................................................................................. 8

EXCEPTION RESPONSE .................................................................................................................................... 9

TROUBLESHOOTING ......................................................................................................................................... 9

SECTION 5 - MODBUS TABLE DESCRIPTION ................................................................................................... 10

TABLE ITEM FORMAT ....................................................................................................................................... 10

NAME AND FUNCTION ..................................................................................................................................... 10

CODING ............................................................................................................................................................. 10

MENU REFERENCE .......................................................................................................................................... 11

‘ADV’ ADVISE FUNCTION ................................................................................................................................. 11

‘ADV’ ADVISE FUNCTION – SINGLE ITEM FORMAT OPTION ........................................................................ 11

‘CMD’ COMMAND FUNCTION ........................................................................................................................... 13

‘GET’ FUNCTION ............................................................................................................................................... 14

‘SET’ FUNCTION ................................................................................................................................................ 14

DATA CODING DEFINITIONS: .......................................................................................................................... 15

DATA TYPES ...................................................................................................................................................... 15

DATA UNITS ....................................................................................................................................................... 16

SECTION 6 - X-SERIES AIR SYSTEM .................................................................................................................. 18

SMG BOX ........................................................................................................................................................... 19

GENERAL X-SERIES SYSTEM COMPONENTS .............................................................................................. 19

X-SERIES NETWORK ADDRESSES................................................................................................................. 20

COMMUNICATION LINK .................................................................................................................................... 20

MODBUS TIMING............................................................................................................................................... 20

RS485 MODBUS SERIAL DATA FORMAT ........................................................................................................ 20

SECTION 7 – VSD B BOX OR VSD MA BOX MODBUS RTU DEFINITIONS ..................................................... 21

3

Page 4

SECTION 2 - INTRODUCTION

System MODBUS Gateway (SMG Box) communication is RS485, RTU, Master-Slave configuration. The SMG Box acts as

a transparent interface to enable a remote ‘master’ device to be able to communicate with the X-Series Units and th e

Intellisys Controllers via the ir485 network ‘slave’ device(s). The MODBUS RTU data construction and formatting for a

‘master’ device is the subject of this document. This information is intended for a systems integrator to facilitate set-up of a

‘master’ device in order to communicate successfully with the X-Series Units and the Intellisys Controllers through a SMG

Box.

SECTION 3 - SAFETY PRECAUTIONS

WARNING :

!

WARNING :

WARNING :

!

WARNING :

• Before installing or operating the

SYSTEM MODBUS GATEWAY (SMG)

BOX, take time to carefully read all the

instructions contained in this manual, all

compressor manuals, and all manuals

of any other peripheral devices that may

be installed or connected to the unit.

• Electricity and compressed air have the

potential to cause severe personal injury

or property damage.

• The operator should use common sense

and good working practices while

operating and maintaining this system.

All applicable codes should be strictly

adhered to.

• Maintenance must be performed by

adequately qualified personnel that are

equipped with the proper tools.

INSTALLATION

• Installation work must only be carried

out by a competent person under

qualified supervision.

• A fused isolation switch must be fitted

between the main power supply and the

SYSTEM MODBUS GATEWAY (SMG)

BOX.

• The SYSTEM MODBUS GATEWAY

(SMG) BOX should be mounted in such

a location as to allow operational and

maintenance access without obstruction

or hazard and to allow clear visibility of

indicators at all times.

• If raised platforms are required to

provide access to the SYSTEM

MODBUS GATEWAY (SMG) BOX,

they must not interfere with normal

operation or obstruct access. Platforms

and stairs should be of grid or plate

construction with safety rails on all open

sides.

Risk of Danger

Risk of Electric Shock

Risk of High Pressure

Consult Manual

OPERATION

• The SYSTEM MODBUS GATEWAY

(SMG) BOX must only be operated by

competent personnel under qualified

supervision.

• Never remove or tamper with safety

devices, guards or insulation materials

fitted to the SYSTEM MODBUS

GATEWAY (SMG) BOX.

• The SYSTEM MODBUS GATEWAY

(SMG) BOX must only be operated at

the supply voltage and frequency for

which it is designed.

• When main power is switched on,

lethal voltages are present in the

electrical circuits and extreme caution

must be exercised whenever it is

necessary to carry out any work on

the unit.

• Do not open access panels or touch

electrical components while voltage is

applied unless it is necessary for

measurements, tests or adjustments.

Such work should be carried out only

by a qualified electrician equipped

with the correct tools and wearing

appropriate protection against

electrical hazards.

• All air compressors and/or other

equipment connected to the unit

should have a warning sign attached

stating “THIS UNIT MAY START

WITHOUT WARNING” next to the

display panel.

• If an air compressor and/or other

equipment connected to the unit is to

be started remotely, attach two

warning signs to the equipment

stating “THIS UNIT CAN BE

STARTED REMOTELY”. Attach one

sign in a prominent location on the

outside of the equipment, and the

other sign inside the equipment

control compartment.

4

Page 5

MAINTENANCE AND REPAIR

• Maintenance, repairs or modifications

must only be carried out by competent

personnel under qualified supervision.

• If replacement parts are required, use

only genuine parts from the original

equipment manufacturer, or an

alternative approved source.

• Carry out the following operations

before opening or removing any access

panels or carrying out any work on the

SYSTEM MODBUS GATEWAY (SMG)

BOX:

i. Isolate the SYSTEM MODBUS

GATEWAY (SMG) BOX from

the main electrical power

supply. Lock the isolator in the

“OFF” position and remove the

fuses.

ii. Attach labels to the isolator

switch and to the unit stating

“WORK IN PROGRESS - DO

NOT APPLY VOLTAGE”. Do

not switch on electrical power

or attempt to start the SYSTEM

MODBUS GATEWAY (SMG)

BOX if such a warning label is

attached.

• Make sure that all instructions

concerning operation and maintenance

are strictly followed and that the

complete unit, with all accessories and

safety devices, is kept in good working

order.

• The accuracy of sensor devices must be

checked on a regular basis. They must

be calibrated when acceptable

tolerances are exceeded. Always

ensure any pressure within the

compressed air system is safely vented

to atmosphere before attempting to

remove or install a sensor device.

• The SYSTEM MODBUS GATEWAY

(SMG) BOX must only be cleaned with

a damp cloth, using mild detergents if

necessary. Avoid the use of any

substances containing corrosive acids

or alkalis.

• Do not paint the control faceplate or

obscure any indicators, controls,

instructions or warnings

5

Page 6

SECTION 4 - MODBUS RTU

MODBUS TABLE(S)

This document discusses generic MODBUS communications and how to implement the software specific ‘MODBUS Table’

information. MODBUS communication formatting may differ from controller to controller and you may require more than one

‘MODBUS Table’.

Always check the software variant identification and version number for a controller or unit with the variant and version of

the ‘MODBUS Table’ supplied. In some instances the information contained in a ‘MODBUS Table’ may not be ap plicable to

a controller or unit installed with the same software variant but a different version number.

MODBUS RTU

MODBUS RTU (Remote Terminal Unit) is a master-slave type protocol. An X-Series Automation System Controller or

Intellisys Controller functions as the slave device. Information requests or commands are communicated from master to

slave only through a System Modbus Gateway Box (SMG). The SMG Box will always respond to communications from a

remote master device in accordance with the MODBUS RTU protocol standard.

The MODBUS protocol is used to communicate with personal computers (PC), Programmable Logic Controllers

(PLC’s), or Distributed Control Systems (DCS) over the Network port. The SMG Box only responds to three MODBUS

commands, Read Holding Register 03 (03 Hex), Preset Single Register 06 (06 Hex), and Preset Multip le Registers

command 16 (10 Hex) (See Modicon MODBUS Protocol Reference Guide, PI-MBUS-300 Rev. J, for more details on

MODBUS).

COMMUNICATION LINK

MODBUS is implemented using a two-wire RS485 industry standard communications link operating in master-slave mode.

Polarity of the two RS485 wires (L1+ and L2-) is important; reversal will disrupt communications.

RS485 SERIAL DATA FORMAT

The RS485 MODBUS port is a 2-wire operating with an asynchronous serial data format:

8 data bits / no parity / 1 stop - (8,N, 1) - transmitted at 9600 baud.

MESSAGE DATA FORMAT

The bytes of the MODBUS RTU message must be sent in one message package. The RTU protocol allows for a maximum

pause of 1.5 byte-times between 2 consecutive bytes of a message.

A pause longer than 1.5 byte-times will render the message invalid and it will be ignored.

Message data format is dependant on function and will consist of a combination of the following elements:

1) Destination address (slave network address)

2) Function Code

3) Data start address (slave register start address)

4) Number of registers, number of bytes of data

5) Message data

6) CRC checksum

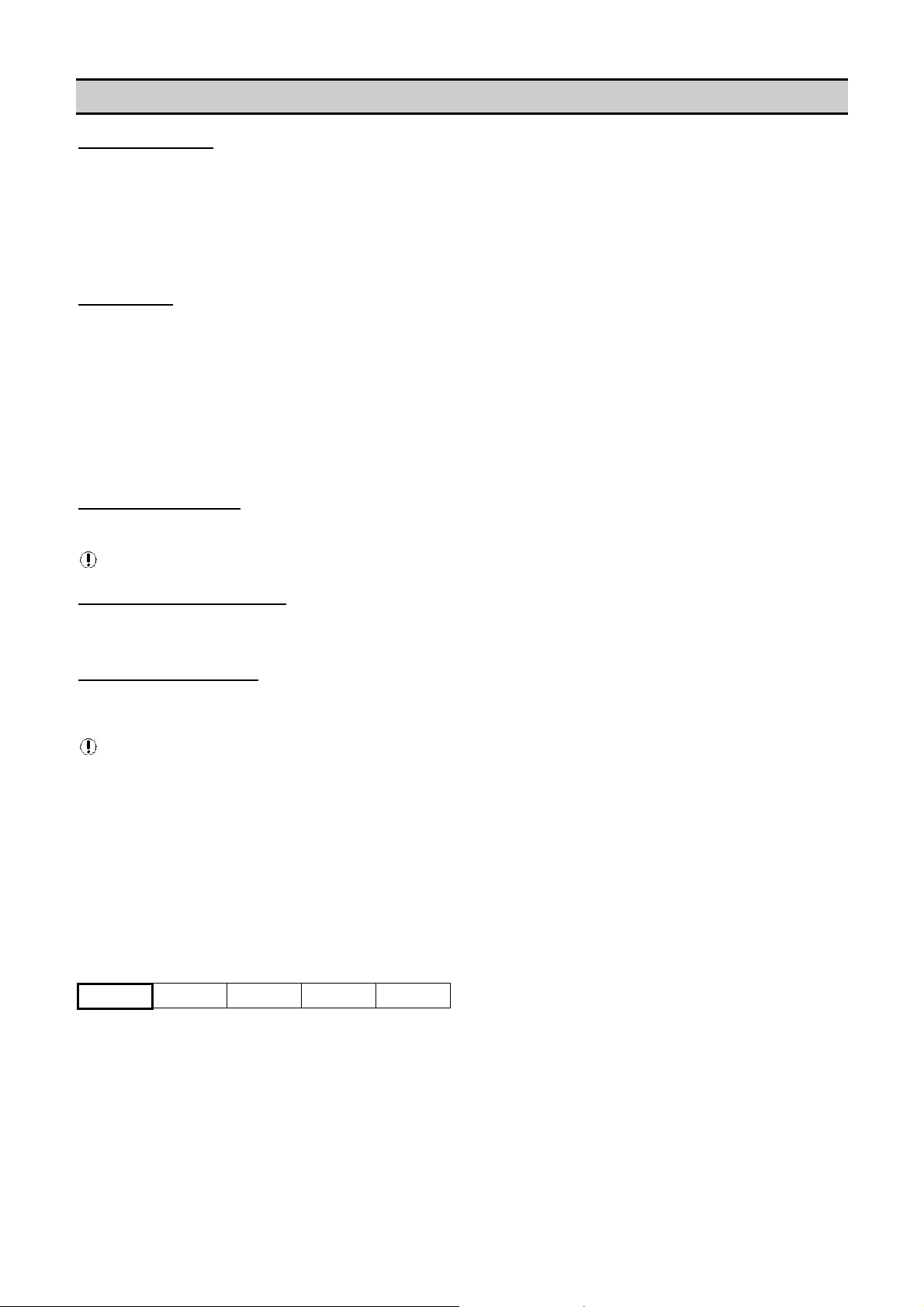

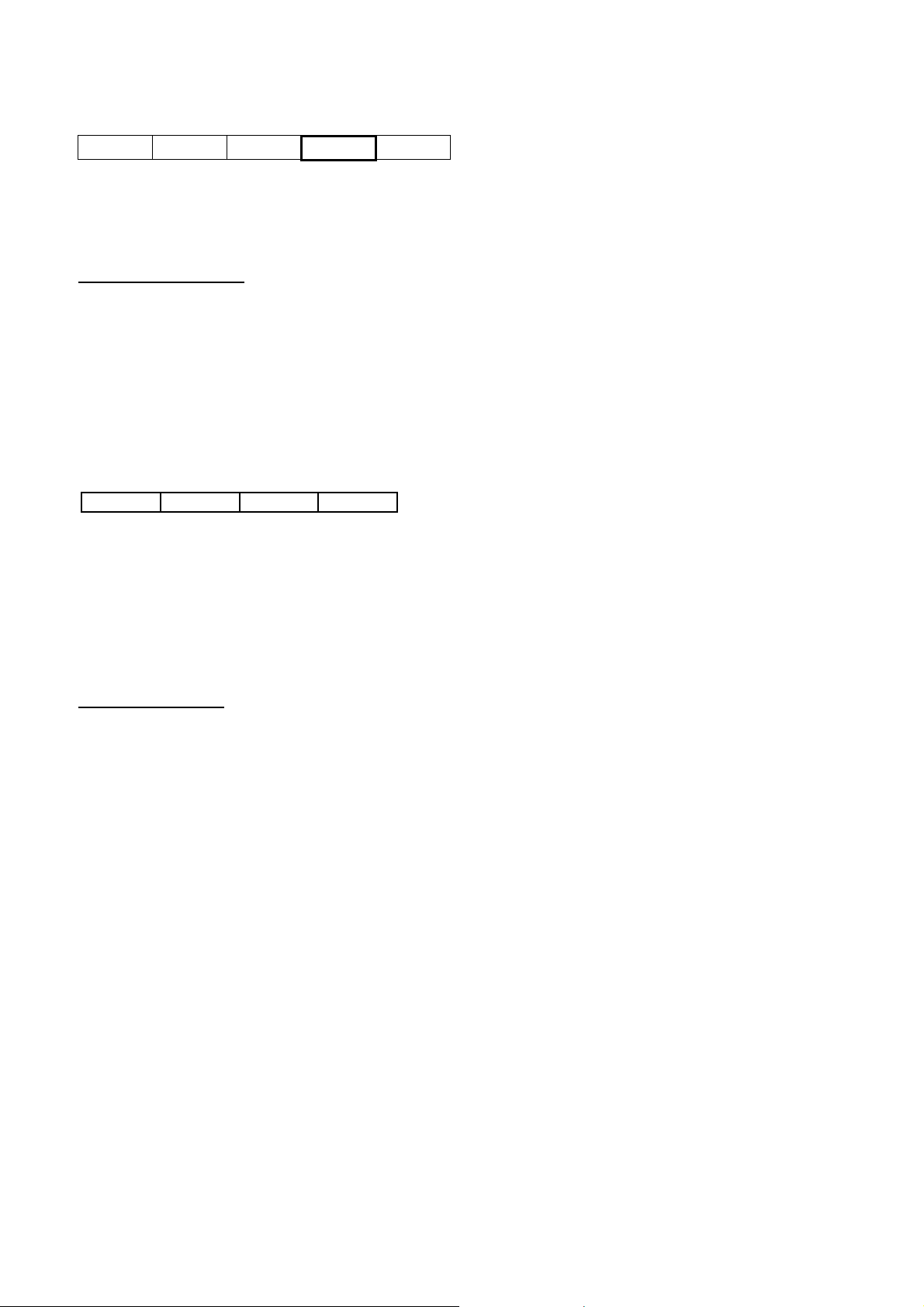

Message Destination Address

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 03 40 06 00 02 30 CA

The ‘destination address’ must be correct for the ‘slave’ controller device for which the message is inten ded. An address can

be from 01Hex to EFHex. The SMG Box is transparent and addresses must be for the destination ‘slave’ controller or unit.

Each controller or unit must be set with a unique address.

6

Page 7

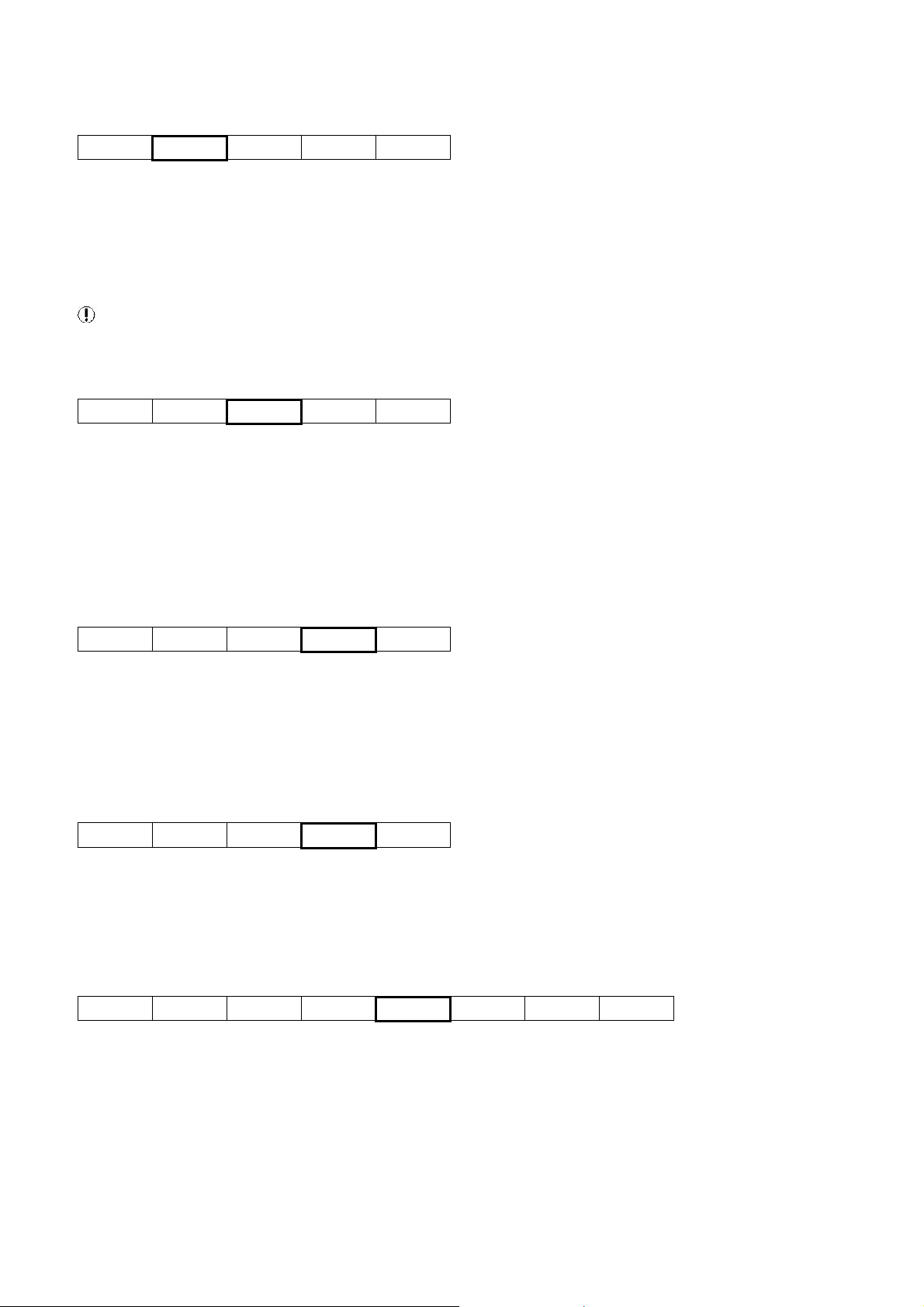

Message Function Codes

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 03 40 06 00 02 30 CA

The message function code defines the required data processing operation of the slave controller. Although several types of

message function codes are defined by the MODBUS standard, only the message function code types working directl y with

registers are implemented on controller units:

03H Read Holding Register(s) – Get (Get Data) or Adv (Advise Data) (X-Series) and Read (Intellisys)

06H Preset Single Register - Write (Intellisys Only)

10H Preset Multiple Registers – Set (Set Data) or Cmd (Command Instruction) (X-Series only)

Any other message function code type will result in an EXCEPTION response.

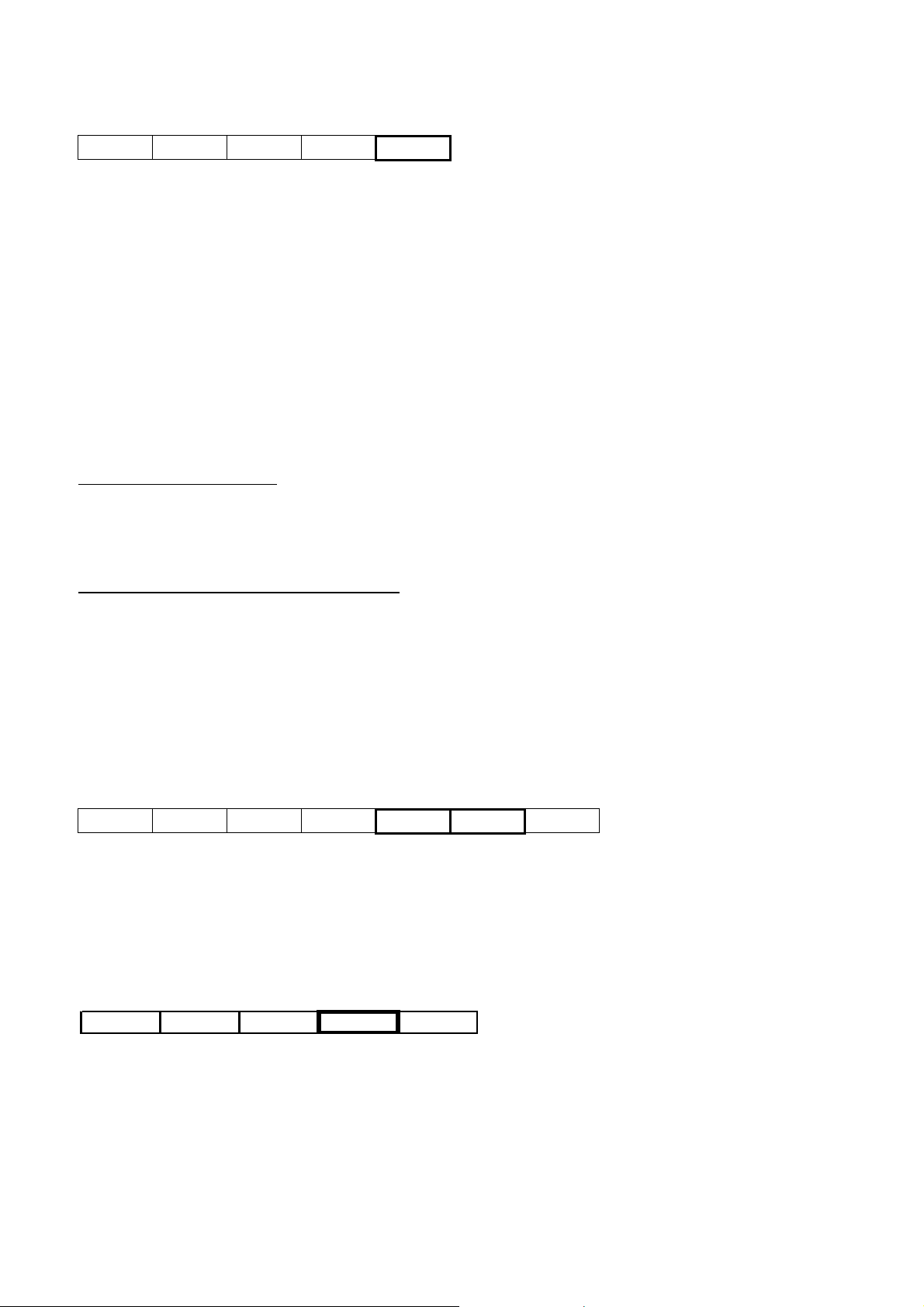

Message Data Start Address

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 03 40 06 00 02 30 CA

The message data start address (16bit word) designates the initial register address location in the contr oller from which the

data is processed. Start address information is contained in the ‘MODBUS Table’.

Note: high-byte transmitted first followed by low-byte.

Message Data

The message data content depends on the message function code type.

03H Read Holding Register(s) – Get (Get Data), Adv (Advise Data) (X-Series) or Read (Intellisys)

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 03 40 06 00 02 30 CA

Slave address + function code ’03 Hex’ + start address of registers in slave memory + 16bit integer value that determines

the size (in 16bit ‘word’ registers) of the message data being requested (00 02 = 2 registers of data). This is the number of

16bit registers to read. A maximum of 32 registers can be read at one time. This information is contained in the ‘MODBUS

Table’.

06H Preset Single Register - Write (Intellisys Only)

Slave

Address

Function

Code

Start

Address

DATA

byte 0 byte 1

CRC Check

Sum

01 06 00 6F 00 5F FE BC

Slave address + function code ’06 Hex’ + start address of register(s) in slave memory to be set then the ‘data’ itself. This

information is contained in the ‘MODBUS Table’.

10H Preset Multiple Registers – Set (Set Data) or Cmd (Command Instruction) (X-Series only)

Slave

Address

Function

Code

Start

Address

Number of

Registers To

Be Set

Number of

Bytes of

Data

DATA

1st Register

byte 0 byte 1

DATA

2nd Register

byte 2 byte 3

CRC Check

Sum

01 10 40 18 00 02 04 00 00 1B 5F 88 0E

Slave address + function code ’10 Hex’ + start address of register(s) in slave memory to be set + 16bit (integer valve of the

number of registers to be set) + 8bit ‘byte’ (integer value for the number of following data bytes) then the ‘data’ itself. This

information is contained in the ‘MODBUS Table’.

Note: A function ’10 Hex’ Set message also requires an additional byte defining the number of ‘data’ bytes in the data

message. This will always be the number of ‘registers’ multiplied by 2 as each ‘data’ register consists of 2 bytes (if number

of ‘data’ registers = 2 then number of ‘data’ bytes = 4).

7

Page 8

Message CRC Checksum

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 03 40 06 00 02 30 CA

The CRC (Cyclical Redundancy Check) is a check-sum generated by means of ‘A001H polynomial’.

The CRC is two bytes containing a 16-bit binary value (word). The CRC value is calculated by the transmitting device that

appends the CRC to the end of the message. The receiving device recalculates the CRC value prior to processing of a

received message and compares the result to the actual CRC value appended to the message. If the two values do n ot

match the message is regarded as invalid. The CRC is initiated by first preloading a 16bit register to all 1's (FFFF Hex).

Then a process begins of applying each consecutive 8bit byte of the message to the register contents us ing an exclusive

‘OR’ calculation. The result is shifted one bit in the direction of the least significant bit (LSB), with the most significant bit

(MSB) set at ‘0’. The LSB is then examined; if ‘1’ the register content is applied to the polynomial value ‘A001’ Hex (101 0

0000 0000 0001) using an exclusive ‘OR’ calculation - if ‘0’ no exclusive OR takes place. This process is repeated until eight

‘bit’ shifts have been performed. After the eighth bit shift, the next 8bit message byte is applied to the register contents using

an exclusive ‘OR’ calculation. The bit shift and re-calculation process is then repeated again. When all message bytes have

been processed the final content of the 16bit register is the message CRC value.

Only the 8bits of ‘data’ in each message character is used for generating the CRC; start, stop and parity bits are ignored.

Note: When the 16bit CRC value is appended to a message, the low order byte must be transmitted first followed by the

high order byte. An incorrect or byte reversed check sum will render the message invalid and it will be ignored.

SLAVE RESPONSE TIMEOUT

A slave controller may not answer immediately. Ensure the ‘slave timeout’ setting of the ‘master’ device is set to a value no

less than 500ms. If the ‘slave’ device fails to receive a valid message due to a communication disruption, parity error, CRC

error or other reasons, no response is given and the master must process a timeout condition in this instance. If the ‘slave’

receives a valid message that cannot be processed an exception response will be returned.

MESSAGE ANSWER FROM SLAVE TO MASTER

The format of the ‘slave’ controller answer is similar to the original master request format; the message data content

depends on the message function code type.

The ‘address’ and ‘code’ of the slave answer is identical to the original request message; the address is the ‘slave’ device

address and the ‘code’ is a repeat of received function code type from the master. The remainder of the message is

dependant on the requested function code type. The CRC checksum is re-calculated for the answer message character s

using the specified CRC process.

03Hex – Get: read from register (or ‘Adv’ Advise)

Slave

Address

Function

Code

Start

Address

Number of

Bytes of

Data

DATA

1st Register

byte 0 byte 1

DATA

2nd Register

byte 2 byte 3

CRC Check

Sum

01 03 40 18 04 00 00 1B 5F BE 61

1) slave address 1byte

2) function code 1byte

3) bytes of data 1byte (number of bytes in ‘data’ answer)

4) data (high byte of each register transmitted first)

5) CRC checksum 2bytes (low byte first followed by high byte)

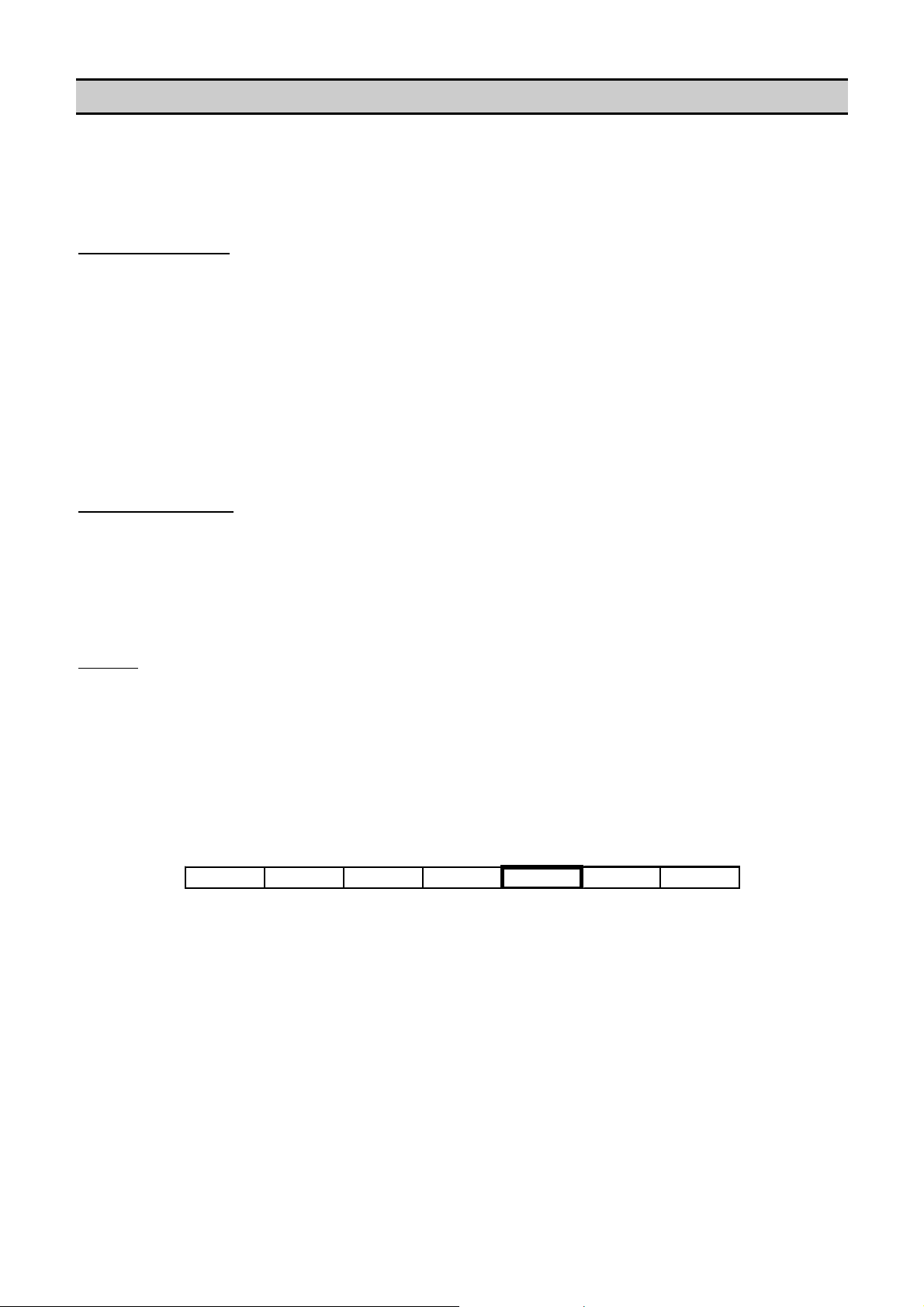

06Hex - Preset Single Register: write to single register

Slave Address Function Code Start Address

DATA

byte 0 byte 1

CRC Check Sum

01 06 00 6F 00 5F FE BC

1) slave address 1byte

2) function code 1byte

3) bytes of data 1byte (number of bytes in ‘data’ answer)

4) data (high byte of each register transmitted first)

5) CRC checksum 2bytes (low byte first followed by high byte)

8

Page 9

10H Preset Multiple Registers – Set (Set Data) or Cmd (Command Instruction) (X-Series only)

Slave

Address

Function

Code

Start

Address

Number of

Registers

CRC Check

Sum

01 10 40 18 00 02 D4 0F

1) slave address 1byte

2) function code 1byte

3) number of registers set 2 bytes

4) CRC checksum 2 Bytes (low byte first followed by high byte)

EXCEPTION RESPONSE

If the ‘slave’ device receives a request that cannot be processed an ‘exception response’ is given. An exception response

message consists of the following elements:

1) Slave Network Address (1 byte): Slave address identification

2) Function Code (1 byte): In a normal response, the slave repeats the function code of the original master request. All

function codes have an MSB (most significant bit) of 0 (values are all below 80 hexadecimal). In an exception response,

the slave sets the MSB of the function ‘code’ to 1. This makes the ‘code’ value 80 Hex greater than the received ‘code’

value from the master.

3) Data (1 byte): The ‘data’ response will contain a ‘1 byte’ value exception code.

4) CRC Checksum (2 byte).

CRC Check SumSlave Address Function Code Error Code

01 90 04 4D C3

Exception Codes:

01H Illegal Function Code

The requested ‘code’ function is not supported.

02H Illegal Data Address

The requested ‘data start address’ is not supported.

03H Illegal Data Value

The requested ‘data’ value is not supported.

04H Function Error

The slave cannot execute the request or the request type is inhibited.

TROUBLESHOOTING

Problem: No ‘slave’ response or corrupt MODBUS message

Solution: Check that the ‘slave’ controller is set for the anticipated slave address

Check that all ‘slave’ controllers are set with a unique system address

Check that the controller is set for MODBUS RTU mode (if applicable)

Check that the ‘master’ is operating in MODBUS RTU mode

Check that the ‘master’ baud rate, parity bit and number of s t op bits are correct

Check that the ‘master ‘response timeout is set for a minimum of 500ms

Check that the ‘master’ is implementing the specified CRC check sum process

Check RS485 wiring polarity and security of connections

Problem: Last character of MODBUS message is corrupted

Solution: Add a delay of 2ms after last character received before releasing RTS signal

Problem: The MODBUS master message is reflected in the slave answer

Solution: Inhibit RX/TX echo on ‘master’ device communications port

9

Page 10

SECTION 5 - MODBUS TABLE DESCRIPTION

A ‘MODBUS table’ describes the “items” used to access information in the memory registers of different types of controller,

or similar controllers using different application software variants or versions. The MODBUS Table will contain the valid

message items (“Name”) together with the Function Code (Function), Register Start Address (“Register Address”), Register

Size (“Register Length”) and a definition for coding and decoding the item data (“Coding”). A ‘MODBUS Table’ order form,

detailing the required order information, can be found on the last page of this document.

TABLE ITEM FORMAT

Each ‘item’ of a ‘MODBUS Table’ will define the massage format to read or set the information contained in the slave

controller register(s):-

Name

Descriptive ‘name’ or ‘item tag’ for the data item. The ‘Name’ is not used in code or message

formatting and serves only as a reference for the defined item.

Function

The Hex code required that instructs the slave (Intellisys controller) to perform a GET, ADV

(Advise), CMD (command) or SET function.

Register Address

Register Length

Coding

Menu

The slave controller register start address for the defined processing function.

The number of registers to be processed.

How to construct or interpret the data elements of a message.

Controller menu item reference.

Note: see “MODBUS RTU” for a detailed description of ‘Function’, ‘Register Address’ and ‘Register Length’ formats.

NAME AND FUNCTION

The ‘name’ for each table item will always start with 3 characters that describe the function type:

Adv Advise Function (03Hex) – same format as a Get function, see ‘Advise Function’.

Get Read from register (03Hex)

Set Write to registe r (10Hex)

Cmd Command (10Hex) – same format as a Set function; will instruct the slave to perform a defined action or

process

CODING

Item coding definitions specify the ‘number of data bytes’ and the ‘data conversion type’. In some instances a data message

may contain multiple sets of data items; an ‘Advise’ message for example. In this instance the ‘start location of data’ within

the message is also specified to enable extraction of the required data item from the entire message data.

Number of data bytes:

This specifies the length of the item data in bytes (6 = 6 bytes (3 registers) of data)

Start location of data bytes:

Number of Data

Bytes to Follow

DATA

1st Register byte

0 byte 1

DATA

2nd Register

byte 2 byte 3

DATA

3rd Register byte

4 byte 5

CRC Check SumSlave Address Function Code

01 03 06 09 00 00 65 00 A8 30 4D

If a data message consists of more than one set of data items (multiple item data message) the ‘start location’ specifies

where the first byte of the data associated with in item begins. If, for example, a 6 byte (3 register) answer is returned that

consists of three different ‘2 byte’ item data values, a ‘start location of data bytes’ = ‘2’ indicates that the item data starts with

the 3rd byte (byte 2) of the data message. The 1st byte of a data message is regarded as byte 0(zero). In this instance the

‘number of data bytes’ will be ‘2’ indicating that the data associated with the item is 2 bytes of data in length. A ‘start

location’ of byte ‘2’ and register length of ‘1’ (register = 2 bytes) means the data is contained in the 3rd and 4th bytes of the

data message. If no ‘start location’ is specified then data associated with the item will start with the first byte (byte 0) of the

message data.

Data Conversion Type:

This specifies how to interpret the data; refer to the ‘Data Conversion Type’ list in the Modbus Table.

For example: If the ‘Data Conversion Type’ = CODED, STATUS then the decimal integer value of the data has a defined

meaning; refer to the ‘STATUS’ Coded data list in the ‘MODBUS Table’ for definitions. If the ‘Data Conversion Type’ = PSI

then the decimal integer value of the data is ‘pressure’ in ‘psi’ units.

10

Page 11

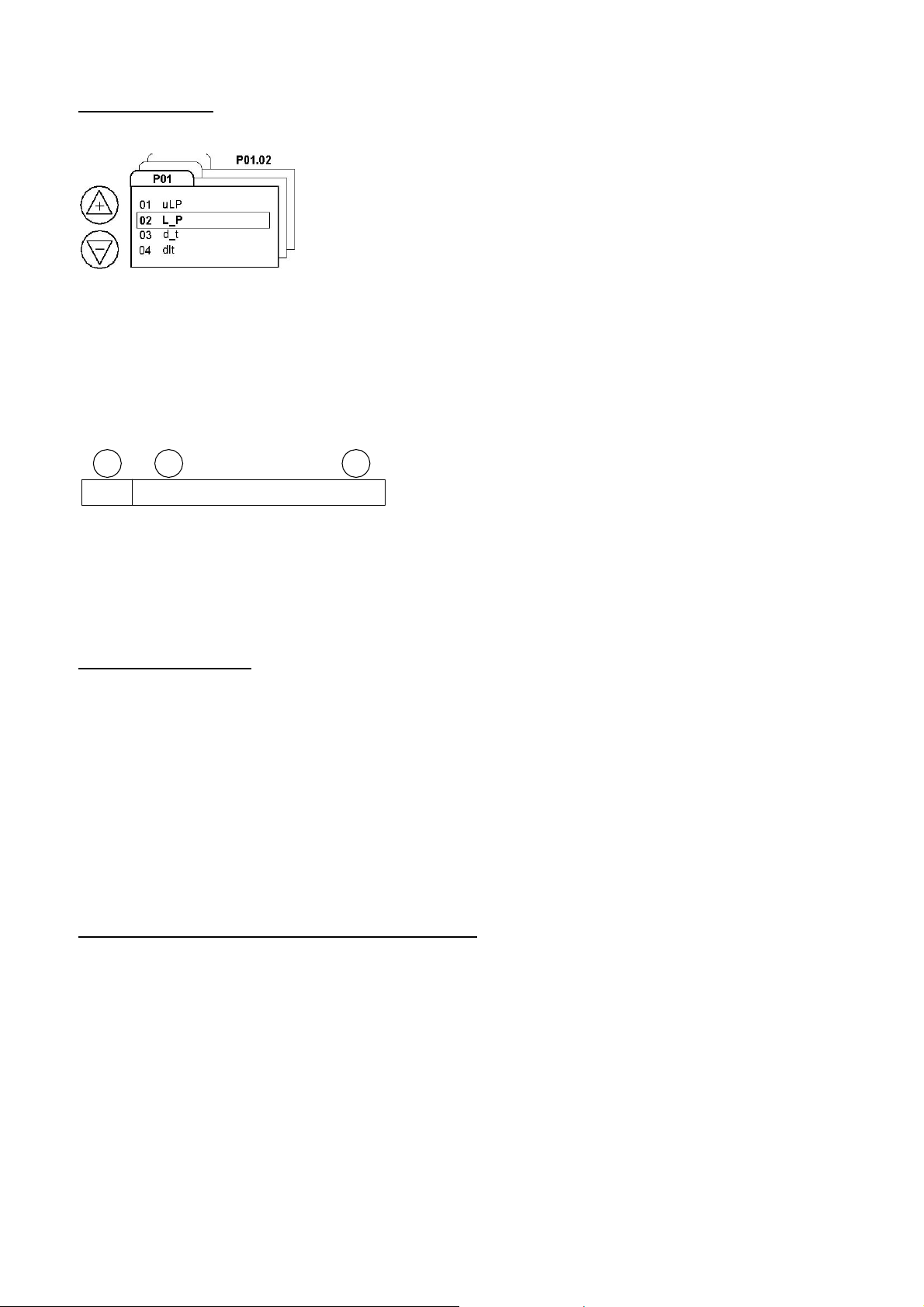

MENU REFERENCE

The menu structure of a controller has menu pages that contain a number of menu page ‘items’.

example menu and items

For example: menu pages P00, P01, P02 > P’n’.

Menu page P00 is the normal running list of display items that can be accessed and viewed on the controller displ ay without

access code. These items are ‘read only’ and consist of status, hours run and other general control or monitoring value (s).

Menu pages other than P00 are setup and configuration items that require an ‘access code’ when accessing the items on

the controller display.

Each menu page has a list of items that are referenced ‘1, 2, 3 > ‘n’.

a b c

P01

For example, a menu reference of P01.02 “AB” refers to menu item ‘2’ of menu page P01.

Each menu page item reference also has a two or three alphanumeric character item identification that is displayed by the

controller. With a menu reference the controller manual can be examined to determine the exact function, definition, scope

and limits for the specified item value.

Items that do not have a ‘Menu’ reference are general controller status or menu page P00 items.

‘ADV’ ADVISE FUNCTION

The ‘Advise’ function is a special type of ‘Get’ function. Each ‘Advise’ function item has an equivale nt ‘Get’ function; both

functions will provide a similar result.

Controllers on a Multi485 network will routinely broadcast key value and status specific data to all other controllers on the

network. This information is used, for example, by a system management unit for systems monitoring and control functions.

A SMG Box will automatically capture, store and continuously update these information items for each controller on the

network. Adv are Routine network broadcasts that occur every 2 seconds. Th transmission of this data consumes no

network bandwidth. (The maximum recommended request rate is 1 request every 2 seconds.)

This facility provides a method of retrieving ‘Adv’ data items directly from the SMG Box resulting in a faster response time

for information requests from a master. The method also has the advantage of reducing the amount of data traffic on the

Multi485 network enabling system management controllers to perform there functions without potential communication

delays. For this reason MODBUS ‘Adv’ functions are preferable to ‘Get’ functions when implemented on a Multi485 network

that consists of a system management controller with multiple machine controllers.

‘ADV’ ADVISE FUNCTION – SINGLE ITEM FORMAT OPTION

Controllers or units on a Multi485 network routinely broadcast general status and key per formance information. The SMG

Box will capture and store each ‘Broadcast’ detected. The Gateway ‘Broadcast’ registers will always contain the latest

‘broadcast’ information for each controller or unit on the Multi485 network. When a Modbus ‘Adv’ request is made the SMG

Box will respond immediately with information from it’s own ‘Broadcast’ registers for the unit addr ess specified. This function

reduces network activity and enables a faster Modbus response to commonly requested data.

A standard ‘Advise’ function defined in the ‘MODBUS Table’ will show the entire ‘broadcast’ being returned as a response.

The table will define for each ‘name’ item where in the returned data message the actual requ ested data can be found. The

‘master’ must then extract the required data from the returned data message. This method is very efficient as the master

can extract all ‘broadcast’ data from the single returned data message without the need to perform multiple requests for

each individual data item contained in a single slave controller ‘broadcast’ message.

01.02 AB

11

Page 12

Some ‘master’ devices may not be equipped with the necessary data message memory to handle a large message of many

bytes or have the ability to extract multiple data items from a single data message item. In this instance an alternativ e

‘Advise’ function request method can be implemented.If the ‘Advise’ items of a ‘MODBUS Table’ are examined it will be

seen that the ‘Register Address’ for each individual ‘Advise’ item contained in a single slave controller ‘broadcast’ message

will have the same start address (Register Address). If the entire ‘broadcast’ data message is 7 registers (14 bytes) in length

and only the 2nd register (2 bytes) of item data is required, it is possible to specify a ‘Register Address’ that is 2 bytes higher

(skip the first 2 bytes of the broadcast data message) with a ‘Register Length’ that is consistent with the required item data

length. This will instruct the MODBUS Gateway to extract the 2 bytes of required item data from the entire broadcast data

message and only return the required 2 bytes of data as a response. Using this method an ‘Advise’ fu nction can be handled

by a ‘master’ in exactly the same way as a ‘Get’ function.

For Example: (AdvDeliveryPressure):

The ‘broadcast’ of an example slave controller may be 6 bytes of data (3 registers) in length starting at register address

location ‘F000’ Hex. The 1st byte (byte 0) is 8bits coded status, the 2nd byte (byte 1) is 8bits status flags which together

form a single 16bit status register (1st register). The 3rd and 4th bytes (byte 2 and byte 3) are a single16bit register (2nd

register) containing a ‘delivery pressure’ value. The 5th and 6th b ytes (byte 4 and byte 5) are a single 16bit register (3rd

register) containing a ‘delivery temperature’ value. From an example ‘MODBUS Table’ it may be seen that the ‘Register

Address’ for all four of these separate ‘Adv’ items is ‘F000 Hex’ (the start address of the entire ‘Broadcast’ message that

contains the data specified).

An entire ‘Broadcast’ message may, for example, contain 3 registers (6 bytes) of data. For a particular item the ‘Modbus

Table’ may show the ‘start address’ for the entire broadcast to be ‘F000’ with a length of 3 registers (6 bytes). The Modbus

Table will indicate that the required data is 2 bytes long (number of data bytes) starting at the 2nd byte of data in the entire

broadcast (start location of data bytes).

Name AdvDeliveryPressure

Modbus Function 03

Modbus Register Address F000 (start address of entire Broadcast message)

Modbus Register Length 0003 (length of entire Broadcast message)

Coding Number of data bytes = 2 (length of AdvDeliveryPressure data)

Start location of data bytes = 2 (the 2 data bytes of the AdvDeliveryPressure data item

start at byte 2 in the Broadcast message = bytes 2 and 3 of the message)

Data Conversion Type = PSI

Master Request Message “01 03 F000 00 03 36CB” (36CB = CRC check sum)

Slave Answer Message “01 03 06 09 00 00 65 00 A8 304D” (304D = CRC)

Coding = PSI ‘00 65’Hex = 101 decimal = 101 psi

Register addresses shown are examples only

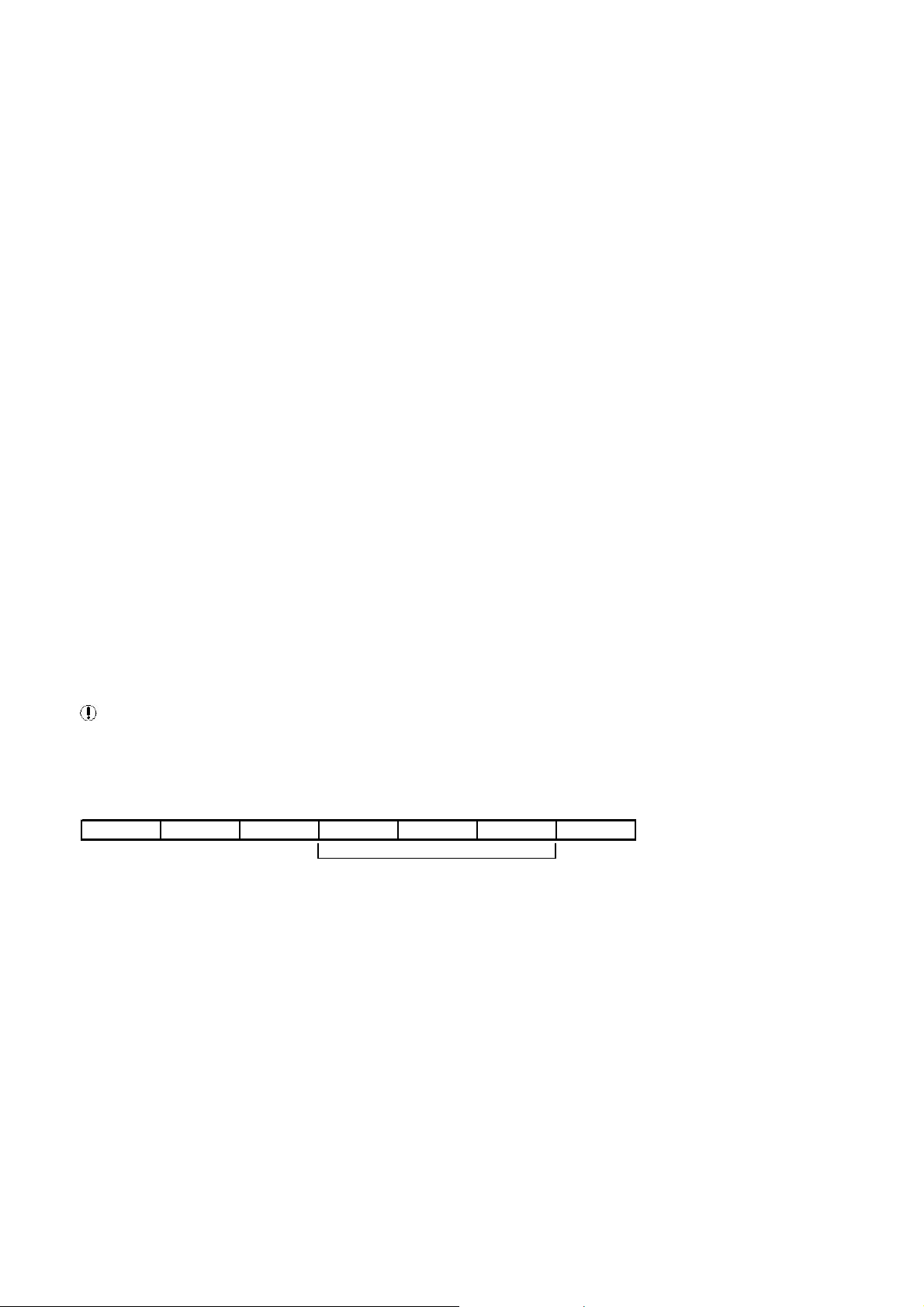

Status Register

Delivery

Pressure

Delivery

Temperature

Slave Address Function Code

Number of Data

Bytes to Follow

DATA

1st Register byte

0 byte 1

DATA

2nd Register

byte 2 byte 3

DATA

3rd Register byte

4 byte 5

CRC Check Sum

01 03 06 09 00 00 65 00 A8 30 4D

F000 F001 F002

Message Data

12

Page 13

If only the ‘delivery pressure’ (AdvDeliveryPressure) data value is required a new ‘Advise’ req uest message format can be

constructed from the Modbus Table definition:

Name AdvDeliveryPressure

Modbus Function 03

Modbus Register Address F001 (start at the second regi ster, byte 2, of the Broadcast)

Modbus Register Length 0001 (only return one register, 2 bytes, of data)

Using the new ‘Advise’ message format the SMG Box will return only the 2nd Broadcast message register (2 bytes)

containing the ‘delivery pressure’ data value.

Master Request Message “01 03 F001 0001 E6CA” (E6CA = CRC check sum)

Slave Answer Message “01 03 02 00 65 786F” (786F = CRC check sum)

Coding = PSI ’00 6 5’Hex = 101 decimal = 101 psi

Status Register

Delivery

Pressure

Delivery

Temperature

Modbus Register Address F000

Modbus Register Length 0003

Slave Address Function Code

Number of Data

Bytes to Follow

DATA

1st Register byte

0 byte 1

01 03 06 09 00 00 65 00 A8 30 4D

DATA

2nd Register

byte 2 byte 3

DATA

3rd Register byte

4 byte 5

CRC Check Sum

F000 F001 F002

Number of Data

Bytes to Follow

Modbus Register Address F001

Modbus Register Length 0001

Slave Address Function Code

01 03 02 00 65 78 6F

It is only possible to manipulate a Modbus message format using ‘registers’ (1 register = 2 bytes = 1 word = 16bits); it is

not possible to manipulate addresses or register lengths to a single byte of data. At least one register (2 bytes) of data must

be specified even if only one byte of information is required. The ‘master’ must extract the required byte of data from the

returned message.

The data type (the definition of the returned data) may be different when using an ‘Advise’ function than it is when using

a ‘Get’ function for the same information. The ‘delivery pressure’ returned by an ‘Advise’ function will be 2 bytes in length

and will represent pressure as an integer value in ‘psi’ units (PSI). The ‘delivery pressure’ returned by a ‘Get’ function may,

for example, be 4 bytes (2 registers) in length and represent a 32bit signed integer value in miliBar units (mBAR). Always

check the item ‘Coding’ definition to establish the data definition type.

Register addresses shown are examples only

‘CMD’ COMMAND FUNCTION

A ‘Command’ function will instruct the ‘slave’ controller or unit to execute a pre-defined action or process. With a command

type message the content of the ‘message data’ from the ‘master’ must always be the same value as the ‘lower byte’ of the

command register address. For example: if the command item ‘Register Address’ = 3302 then the ‘data’ value must be ’00

02’ Hex.

Slave Address Function Code Start Address

Number of

Registers To Be

Set

Number of Bytes

of Data

DATA

DATA

2nd Register

byte 2 byte 3

CRC Check Sum

CRC Check Sum

01 10 33 02 00 01 02 00 02 25 70

It is the act of setting the specified register in the ‘slave’ controller with the defined ‘data’ value that initiates the action or

process. An incorrect ‘data’ value will result in an exception response. If the ‘command’ is accepted the ‘slave’ will answer

with a normal ‘Set’ register response. If the slave is unable to execute the command it will give a code ‘04’ exception

response.

13

Page 14

Example:

Using a command function item to set the specified item register to the correct value, the ‘slave’ controller is instructed to

perform the defined action or process. In the case of a ‘CmdStart’ item, for example, the ‘slave’ controller is instructed to

start the machine. The implementation of a ‘Cmd’ function message by the ‘master’ is identical to a ‘Set’ function message;

both operations use function code ‘10 Hex’ to write data to a slave controller register.

Name CmdStart

Modbus Function 10

Modbus Register Address 3300

Modbus Register Length 0001

Coding Number of data bytes = 1

CmdStart (to slave at address ‘01’ Hex)

Master Command Message “01 10 3300 0001 02 0000 A553” (A553 = CRC check sum)

Slave Answer Message “01 10 3300 0001 0E8D” if start command executed or “01 90 04 4D C3” exception

response if not executed, ‘90’ = repeat of ‘10’ function code with MSB set to ‘1’ and ‘04’

= exception error code.

Register addresses shown are examples only

Names that begin with CMD are Non-routine. This data must be written to the device. (The maximum recommended

request rate is 2 requests per second up to 32 words per request.)

‘GET’ FUNCTION

Using the MODBUS Table a read data (Get) function message can be constructed:

Name GetDeliveryPressure Modbus

Function 03

Modbus Register Address 4006

Modbus Register Length 0002

Coding Number of data bytes = 4

Data Conversion Type = mBAR

GetDeliveryPressure (request to slave at address ‘01’ Hex)

Master Request Message “01 03 400 6 0002 31CA” (31CA = CRC check sum)

Slave Answer Message “01 03 04 00 00 1B 58 F139” (F139 = CRC check sum)

Coding = mBAR 1B 58Hex = 7000 decimal = 7000 miliBar (7.0 bar)

Register addresses shown are examples only

Note: Names that begin with Get are Non-routine. This data must be requested from the device. (The maximum

recommended request rate is 2 requests per second up to 32 words per request.)

‘SET’ FUNCTION

Using the MODBUS Table a write data (Set) function message can be constructed:

Name SetLoadPressure Modbus

Function 10

Modbus Register Address 4018

Modbus Register Length 0002

Coding Number of data bytes = 4

SetLoadPressure (to slave at address ‘01’ Hex)

Master Write Message “01 10 4018 0002 04 0000 1B58 C9CC” (C9CC = CRC)

Slave Answer Message “01 10 4018 0002 D40F” (D40F = CRC check sum)

Coding = mBAR 0000 1B58Hex = 7000 decimal = 7000 miliBar (7.0 bar)

Register addresses shown are examples only

Names that begin with Set are Non-routine. This data must be written to the device. (The maximum recommended

request rate is 2 requests per second up to 32 words per request.)

Data Conversion Type = mBAR

14

Page 15

DATA CODING DEFINITIONS:

Definitions for ‘data units’ and ‘data conversion types’ are listed for each ‘item’ in the “MODBUS Table” document.

All ‘data’ values are ‘whole’ numbers (integers); decimal places are not permitted in MODBUS data messages.

All ‘data’ values are unsigned (always positive) unless otherwise stated. Values specified as ‘SIGNED’ in the MODBUS

Table can be negative in accordance to the standard data conventio n for ‘sign ed’ number values.

DATA TYPES

Each standard definition will start with a “key” word that defines the data type:-

The following are selected examples; data types not included below are detaile d in individual ‘Modbus Tables’

Type Description

Coded a decimal value that has a defined definition; see the ‘Coded’ lists in

the ‘MODBUS Table’ for value definitions

Value a ‘whole’ number or value in the specified units

Pressure a ‘whole’ number defining a pressure in the specified units

Temperature a ‘whole’ number defining a temperature in the specified units

Time a ‘whole’ number defining a time period in the specified units

Electrical a ‘whole’ number defining a volt, amp, power, or speed value in the

specified units

Clock Clock values are relevant to real time clock functions; for example

pressure schedules. These ‘whole number’ unsigned values are

‘packaged’ multiple values and must be interpreted as follows.

Clock Data Type Coding

HH_MM 1) Divide the value by 60 = Hours (0 to 23)

2) The remainder (modulus) = Minutes (0 to 59)

Example for a value of ‘1050’

Hours = 1050 / 60 = 17.5 = 17 Hours

Minutes = remainder = 30 = 30 Minutes

Time = 17:30 (5:30pm)

D_HH_MM 1) Divide the value by 10000 = Day (1 = Monday, 7 = Sunday)

2) Divide the remainder (modulus) by 60 = Hours (0 to 23)

3) The remainder (modulus) = Minutes

Example for a value of ‘31050’

Day = 31050 / 10000 = 3.105 = 3 = Wednesday

Hours = = remainder / 60 = 17.5 = 17 Hours

Minutes = remainder = 30 = 30 Minutes

Day/Time = Wednesday 17:30 (5:30pm)

YYYY_DD_MO 1) Divide the value by 10000 = Year

2) Divide the remainder (modulus) by 100 = Day (1 to 31)

3) The remainder (modulus) = Month (1 to 12)

Example for a value of ‘20051605’

Year = 20051605 / 10000 = 2005.1605 = Year 2005

Day = remainder / 100 = 16.05 = Day 16

Month = remainder = 5 = Month 5

Date = 16th May 2005

15

Page 16

DATA UNITS

The ‘MODBUS Table’ will define the ‘data units’ for each item. Data unit definitions are specified in the ‘M ODBUS Table’ as

a separate list; for example:

The following are selected examples; data types not included below are detailed in the ‘Modbus Tables’

Value

The engineering units will differ dependant on unit set-up or item definition.

PSI

BAR

FAH

CEL

HRS

%

BOOLEAN

BINARY

The value must be interpreted in terms of each ‘bit’ as a set of sixteen Boolean (0 or 1) flags. These values

are compressor related or I/O Box Input related. For compressor related items the least significant bit (Bit 0)

represents compressor 1. For unit inputs the least significant bit (Bit 0) generally represents input 1.

The number is the value in the specified engineering units

Pressure in ‘psi’

Pressure in ‘Bar’

Temperature in oF

Temperature in oC

Hours

Percentage 0 to 100

The number will be 0 or greater than 0, (Boolean: 0 = False, 1 = True)

The number represents a 16bit (two byte) binary value of 16bit flags.

16 bit Register

1st Byte (byte 0) 2nd Byte (byte 1)

15141312111098 76543210

Bit

MSB

The example illustrates the bit pattern for a value of ’00 81 Hex’. This value is interpr eted as a ‘true’ condition with respect to

the item definition for compressors 1 and 8. If the ‘item’ definition is ‘Compressors Running’ then com pressors 1 and 8 are in

a ‘running’ condition.

00000000 10000001

Compressor 8 Compressor 1

LSB

16

Page 17

The example illustrates the bit pattern for a value of "1A 04 C2 01" Hex. A reference to ‘Bit 18’ equates to bit ‘2’ of byte ‘1’ in

the answer data message. If the ‘bit’ is ‘1’ then the condition is ‘TRUE’.

2nd Register1st Register

1st Byte (byte 0) 2nd Byte (byte 1) 3rd Byte (byte 2) 4th Byte (byte 3)

3130292827262524 2322212019181716 15141312111098 76543210

Bit

00011010 00000100 11000010 00000000

MSB

BIT ‘n’

Note: The LSB (least significant bit) of a register or byte is regarded as Bit 0(zero)

A Boolean (true/false) can be established from examining the specified ‘bit’ of the

16bit register. If the item specifies ‘Bit 4’ then the 4th bit should be examined:

LSB

16 bit Register

1st Byte (byte 0) 2nd Byte (by te 1)

15141312111098 76543210

Bit

MSB

00011010 10010001

LSB

AND

00000000 00010000

EQUALS

00000000 00010000

= 16 Decimal (Condition is TRUE)

The 4th bit of a register can be extracted by ‘masking’ the register content with “10 Hex”; if the resulting value is greater than

0(zero) then the condition is ‘True’, if the result is 0(zero) then the condition is ‘False’.

Decimal Places:

Numbers with decimal places (eg 20.55) are not permissible in MODBUS data transfer – all numbers must be integer

‘whole’ numbers. To provide ‘decimal place’ accuracy some data values are multiplied by 10, 100 or 1000 and transmitted

as a ‘whole’ number (integer). In this instance the ‘Data Units’ will specify that the number represe nts a value to one or more

decimal places.

For example: PERCENT_DP2 = Percent to 2 decimal places

“2055” divided by 100 = 20.55%

If the ‘Data Units’ specifies “to 1 decimal place”, divide the number by 10 to convert to the correct engineering units. If the

‘Data Units’ specifies “to 2 decimal places”, divide the number by 100; if 3 decimal places divide by 1000.

17

Page 18

SECTION 6 - X-SERIES AIR SYSTEM

Note: example only; systems will differ from installation to installation

18

Page 19

SMG BOX

For Remote Monitoring/Control of X-Series Units and Boxes. The SMG Box provides a RS485 Modbus connection to the

X8I Automation System. A system will only contain one SMG Box.

GENERAL X-SERIES SYSTEM COMPONENTS

The following Components can be monitored by the SMG Box.

X8I Series Controller or X12I Series Controller: Automation System Unit

Monitors and controls the air compressors, all general system and air compressor related information is governed and

available from this unit. A system will only contain one X-Series Automation System controller.

EX Box: Extension to the X-Series Unit

For connection to remote compressor(s) or other specialized compressor integration. All common air compressor status

information is sent to, and available from, the X-Series system management unit. A system may contain multiple EX Boxes.

I/O Box: Monitoring/Control of Auxiliary Equipment and/or Sensors

For monitoring and/or control of auxiliary compressed air equipment (for exam ple: dryer, auto drain, filtration differential,

isolation valves, cooling water towers/pumps, ventilation) or sensors (for example: pressure, pressure differential, dewpoint,

air flow, temperature). A system may contain multiple IO Boxes.

VSD Box: Extension to the X-Series Unit

For connection to variable speed compressor(s) or other specialized compressor integration. All common air compressor

status information is sent to, and available from, the X-Series system management unit. A system may contain multiple VSD

Boxes.

CX Box: Extension to the X-Series Unit

For connection to non-Ingersoll Rand air compressors that are not equipped with any accessible means of remote

connectivity. All common air compressor status information is sent to, and available from, the X-Series system management

unit. A system may contain multiple CX Boxes.

DX Box: Extension to the X-Series Unit

For connection to two fixed speed online/offline air compressors to be seen as one compressor by the X8I or X12I. All

common air compressor status information is sent to, and available from, the X-Series system management unit. A system

may contain multiple DX Boxes.

ir-485 Gateway / irV-485 Gateway

For connection to all Ingersoll Rand Intellisys based compressors. All common air compressor status information is sent to,

and available from, the X-Series system management unit. A system may contain multiple Gateways.

ir-485 Direct

For connection to all Ingersoll Rand R Series (S3) based compressors. All common air compressor status information is

sent to, and available from, the X-Series system management unit. A system may contain multiple R series compressors.

19

Page 20

X-SERIES NETWORK ADDRESSES

UNIT

X8I or X12I

EX, VSD B / mA / V, CX, DX, ir485 / irV485, S3

(As It Relates To The Compressor Number Assigned)

Compressor 1 1 (01)

Compressor 2 2 (02)

Compressor 3 3 (03)

Compressor 4 4 (04)

Compressor 5 5 (05)

Compressor 6 6 (06)

Compressor 7 7 (07)

Compressor 8 8 (08)

Compressor 9 9 (09) X12I ONLY

Compressor 10 10 (0A) X12I ONLY

Compressor 11 11 (0B) X12I ONLY

Compressor 12 12 (0C) X12I ONLY

I/O

I/O Box 1 105(69)

I/O Box 2 112(70)

I/O Box 3 106(6A) X12I ONLY

I/O Box 4 107(6B) X12I ONLY

I/O Box 5 108(6C) X12I ONLY

I/O Box 6 109(6D) X12I ONLY

I/O Box 7 110(6E) X12I ONLY

I/O Box 8 111(6F) X12I ONLY

I/O Box 9 113(71) X12I ONLY

I/O Box 10 114(72) X12I ONLY

I/O Box 11 115(73) X12I ONLY

I/O Box 12 116(74) X12I ONLY

Note: I/O Unit 2 address (70Hex) is intentionally out of sequence; this is not a print error.

DECIMAL (HEX) ADDRESS NOTES

101(65)

COMMUNICATION LINK

To Interface with a X-Series product that is equipped with a Multi485 enabled network port, or to interface with multiple XSeries products operating on a single Multi485 system network, a SMG Box unit is required. The SMG Box forms the

interface between the Multi485 protocol and MODBUS RTU master/slave communications link.

SMG Box connectivity is implemented using a two-wire RS485 industry standard commun ications link operating in point-topoint, master-slave mode. In use the SMG Box is transparent and each X-Series system unit is accessible using individual

system device addresses.

Polarity of the two MODBUS RS485 wires (L1+ or ‘A’ and L2- or ‘B’) is important; reversal will inhibit communications

and result in error.

MODBUS TIMING

The SMG will handle ONE (1) MODBUS request at a time from the customer’s port. The maximum recommended request

rate is 2 requests per second. When a MODBUS request is received for any device connected to the XI Automation System,

that request will be forwarded to the device between sequencer broadcasts and the response from the device will then be

relayed back to the customer’s port. If a second MODBUS command is sent before the first command has been responded

to, the second command will be ignored.

RS485 MODBUS SERIAL DATA FORMAT

The SMG supports only the RTU transmission mode. The user must configure their serial port communication parameters

(baud rate, parity mode, etc.) during configuration to match those of the SMG Box. The SMG Box port operates with an

asynchronous serial data format:

SMG Communication Parameters:

Data Bits: 8

Parity: None

Stop Bit: 1

Baud Rate: 9600

8-N-1-9600

20

Page 21

SECTION 7 – VSD B BOX OR VSD MA BOX MODBUS RTU

DEFINITIONS

Name : AdvStatusRegister

Modbus Function : 03

Modbus Register Address : F000

Modbus Register Length : 0003

Coding : Number of data bytes = 1

Data Conversion Type = CODED,STATUS

Conversion table for CODED,STATUS can be found at the end of

this document

Name : AdvStatusFlags

Modbus Function : 03

Modbus Register Address : F000

Modbus Register Length : 0003

Coding : Number of data bytes = 1

: Start location of data bytes = 1

Name : AdvDeliveryPressure

Modbus Function : 03

Modbus Register Address : F000

Modbus Register Length : 0003

Coding : Number of data bytes = 2

: Start location of data bytes = 2

Data Units = PSI

Name : AdvDeliveryAirTemperature

Modbus Function : 03

Modbus Register Address : F000

Modbus Register Length : 0003

Coding : Number of data bytes = 2

: Start location of data bytes = 4

Data Units = FAH

21

Page 22

Name : GetSoftwareVersionIdString

Modbus Function : 03

Modbus Register Address : 3400

Modbus Register Length : 0003

Coding : Number of data bytes = 6

Data Conversion Type = STRING

Name : GetSoftwareVersionRevString

Modbus Function : 03

Modbus Register Address : 3403

Modbus Register Length : 0003

Coding : Number of data bytes = 6

Data Conversion Type = STRING

Name : CmdStart

Modbus Function : 10

Modbus Register Address : 3300

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : CmdStop

Modbus Function : 10

Modbus Register Address : 3301

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : CmdLoad

Modbus Function : 10

Modbus Register Address : 3304

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : CmdUnload

Modbus Function : 10

Modbus Register Address : 3305

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : CmdReset

Modbus Function : 10

Modbus Register Address : 3306

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : CmdClearLog

Modbus Function : 10

Modbus Register Address : 3307

Modbus Register Length : 0001

Coding : Number of data bytes = 1

Name : GetStatus

Modbus Function : 03

Modbus Register Address : 3406

Modbus Register Length : 0003

Coding : Number of data bytes = 6

Data Conversion Type = CODED,STATUS

Conversion table for CODED,STATUS can be found at the end of

this document

22

Page 23

Name : GetAnalogInput1

Modbus Function : 03

Modbus Register Address : 3100

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = ADSTEPS

Name : GetAnalogInput2

Modbus Function : 03

Modbus Register Address : 3101

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = ADSTEPS

Name : GetAnalogInput3

Modbus Function : 03

Modbus Register Address : 3102

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = ADSTEPS

Name : GetAnalogOutput1

Modbus Function : 03

Modbus Register Address : 310C

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = ADSTEPS

Name : GetDigitalInputs

Modbus Function : 03

Modbus Register Address : 310E

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = BINARY

bitvalue = 0 = digital input INACTIVE

bitvalue = 1 = digital input ACTIVE

bit = Name (Config, Delay in ms)

0 = EMERGENCY_STOP (Normal Closed, 0)

1 = READY_RUN (Pulsed, 0)

2 = SPARE_1 (Normal Open, 0)

3 = SPEED_DETECT (Normal Open, 100)

4 = SPARE_2 (Normal Open, 200)

5 = LOAD_MAINTENANCE (Pulsed, 0)

6 = AUXILIARY_ALARM (Pulsed, 0)

7 = AUXILIARY_TRIP (Normal Closed, 100)

Name : GetDigitalInputsConfiguration

Modbus Function : 03

Modbus Register Address : 310F

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = BINARY

bitvalue = 0 = digital input NO

bitvalue = 1 = digital input NC

bit = Name

0 = EMERGENCY_STOP

1 = READY_RUN

2 = SPARE_1

3 = SPEED_DETECT

4 = SPARE_2

5 = LOAD_MAINTENANCE

6 = AUXILIARY_ALARM

7 = AUXILIARY_TRIP

23

Page 24

Name : GetDigitalOutputs

Modbus Function : 03

Modbus Register Address : 3110

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Units = BINARY

bitvalue = 0 = digital output OFF

bitvalue = 1 = digital output ON

bit = Name

0 = RELAY_SEQUENCE

1 = RELAY_SPARE1

2 = RELAY_SPARE2

3 = RELAY_LOAD

4 = RELAY_FUNCTION_1

5 = RELAY_FUNCTION_2

Name : GetDeliveryPressure

Modbus Function : 03

Modbus Register Address : 4004

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Name : GetInternalPressure

Modbus Function : 03

Modbus Register Address : 4006

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Name : GetDiffPressure

Modbus Function : 03

Modbus Register Address : 4008

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = SIGNED,NUMERIC

Data Units = mBAR

Name : GetRunningHours

Modbus Function : 03

Modbus Register Address : 400A

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.01 'H1'

Menu = P10.06 'H1'

Name : GetLoadUnloadPressMinDiff

Modbus Function : 03

Modbus Register Address : 400E

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Name : SetLoadUnloadPressMinDiff

Modbus Function : 10

Modbus Register Address : 400E

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

24

Page 25

Name : GetParUnloadPressure

Modbus Function : 03

Modbus Register Address : 4010

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P01.01 'Pu'

Name : SetParUnloadPressure

Modbus Function : 10

Modbus Register Address : 4010

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P01.01 'Pu'

Name : GetParLoadPressure

Modbus Function : 03

Modbus Register Address : 4012

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P01.03 'PL'

Name : SetParLoadPressure

Modbus Function : 10

Modbus Register Address : 4012

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P01.03 'PL'

Name : GetPressureUnitsSel

Modbus Function : 03

Modbus Register Address : 4014

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = CODED,P_UNIT

Conversion table for CODED,P_UNIT can be found at the end of this

document

Data Units = LONG_VAL

Menu = P03.01 'P>'

Name : SetPressureUnitsSel

Modbus Function : 10

Modbus Register Address : 4014

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = CODED,P_UNIT

Conversion table for CODED,P_UNIT can be found at the end of this

document

Data Units = LONG_VAL

Menu = P03.01 'P>'

Name : GetFaultErrorLog1Fault

Modbus Function : 03

Modbus Register Address : 4017

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.02 '01'

25

Page 26

Name : GetFaultErrorLog1RunningHours

Modbus Function : 03

Modbus Register Address : 4018

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.02 '01'

Name : GetFaultErrorLog2Fault

Modbus Function : 03

Modbus Register Address : 401B

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.03 '02'

Name : GetFaultErrorLog2RunningHours

Modbus Function : 03

Modbus Register Address : 401C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.03 '02'

Name : GetFaultErrorLog3Fault

Modbus Function : 03

Modbus Register Address : 401F

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.04 '03'

Name : GetFaultErrorLog3RunningHours

Modbus Function : 03

Modbus Register Address : 4020

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.04 '03'

Name : GetFaultErrorLog4Fault

Modbus Function : 03

Modbus Register Address : 4023

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.05 '04'

Name : GetFaultErrorLog4RunningHours

Modbus Function : 03

Modbus Register Address : 4024

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.05 '04'

26

Page 27

Name : GetFaultErrorLog5Fault

Modbus Function : 03

Modbus Register Address : 4027

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.06 '05'

Name : GetFaultErrorLog5RunningHours

Modbus Function : 03

Modbus Register Address : 4028

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.06 '05'

Name : GetFaultErrorLog6Fault

Modbus Function : 03

Modbus Register Address : 402B

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.07 '06'

Name : GetFaultErrorLog6RunningHours

Modbus Function : 03

Modbus Register Address : 402C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.07 '06'

Name : GetFaultErrorLog7Fault

Modbus Function : 03

Modbus Register Address : 402F

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.08 '07'

Name : GetFaultErrorLog7RunningHours

Modbus Function : 03

Modbus Register Address : 4030

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.08 '07'

Name : GetFaultErrorLog8Fault

Modbus Function : 03

Modbus Register Address : 4033

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.09 '08'

27

Page 28

Name : GetFaultErrorLog8RunningHours

Modbus Function : 03

Modbus Register Address : 4034

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.09 '08'

Name : GetFaultErrorLog9Fault

Modbus Function : 03

Modbus Register Address : 4037

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.10 '09'

Name : GetFaultErrorLog9RunningHours

Modbus Function : 03

Modbus Register Address : 4038

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.10 '09'

Name : GetFaultErrorLog10Fault

Modbus Function : 03

Modbus Register Address : 403B

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.11 '10'

Name : GetFaultErrorLog10RunningHours

Modbus Function : 03

Modbus Register Address : 403C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.11 '10'

Name : GetFaultErrorLog11Fault

Modbus Function : 03

Modbus Register Address : 403F

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.12 '11'

Name : GetFaultErrorLog11RunningHours

Modbus Function : 03

Modbus Register Address : 4040

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.12 '11'

28

Page 29

Name : GetFaultErrorLog12Fault

Modbus Function : 03

Modbus Register Address : 4043

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.13 '12'

Name : GetFaultErrorLog12RunningHours

Modbus Function : 03

Modbus Register Address : 4044

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.13 '12'

Name : GetFaultErrorLog13Fault

Modbus Function : 03

Modbus Register Address : 4047

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.14 '13'

Name : GetFaultErrorLog13RunningHours

Modbus Function : 03

Modbus Register Address : 4048

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.14 '13'

Name : GetFaultErrorLog14Fault

Modbus Function : 03

Modbus Register Address : 404B

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.15 '14'

Name : GetFaultErrorLog14RunningHours

Modbus Function : 03

Modbus Register Address : 404C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.15 '14'

Name : GetFaultErrorLog15Fault

Modbus Function : 03

Modbus Register Address : 404F

Modbus Register Length : 0001

Coding : Number of data bytes = 2

Data Conversion Type = CODED,ERROR

Conversion table for CODED,ERROR can be found at the end of this

document

Menu = P02.16 '15'

29

Page 30

Name : GetFaultErrorLog15RunningHours

Modbus Function : 03

Modbus Register Address : 4050

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HRS

Menu = P02.16 '15'

Name : GetDeliveryPressureMaxLevel

Modbus Function : 03

Modbus Register Address : 4052

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P03.05 'Dm'

Name : SetDeliveryPressureMaxLevel

Modbus Function : 10

Modbus Register Address : 4052

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P03.05 'Dm'

Name : GetInternalPressureMaxLevel

Modbus Function : 03

Modbus Register Address : 4054

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P03.06 'Im'

Name : SetInternalPressureMaxLevel

Modbus Function : 10

Modbus Register Address : 4054

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P03.06 'Im'

Name : GetSelectedLoadEnable

Modbus Function : 03

Modbus Register Address : 407A

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : SetSelectedLoadEnable

Modbus Function : 10

Modbus Register Address : 407A

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : GetSelectedStartEnable

Modbus Function : 03

Modbus Register Address : 407C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

30

Page 31

Name : SetSelectedStartEnable

Modbus Function : 10

Modbus Register Address : 407C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : GetConfigDigOut5

Modbus Function : 03

Modbus Register Address : 4080

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : SetConfigDigOut5

Modbus Function : 10

Modbus Register Address : 4080

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : GetConfigDigOut6

Modbus Function : 03

Modbus Register Address : 4082

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : SetConfigDigOut6

Modbus Function : 10

Modbus Register Address : 4082

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : GetIndicationFieldFunction

Modbus Function : 03

Modbus Register Address : 4084

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : SetIndicationFieldFunction

Modbus Function : 10

Modbus Register Address : 4084

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Name : GetAnalogOutputFunction

Modbus Function : 03

Modbus Register Address : 4086

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Menu = P10.04 'Ao'

Name : SetAnalogOutputFunction

Modbus Function : 10

Modbus Register Address : 4086

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = UCHAR_VAL

Menu = P10.04 'Ao'

31

Page 32

Name : GetFrequencyHighLimit

Modbus Function : 03

Modbus Register Address : 4088

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HZ

Menu = P08.02 'FH'

Name : SetFrequencyHighLimit

Modbus Function : 10

Modbus Register Address : 4088

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HZ

Menu = P08.02 'FH'

Name : GetFrequencyLowLimit

Modbus Function : 03

Modbus Register Address : 408A

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HZ

Menu = P08.01 'FL'

Name : SetFrequencyLowLimit

Modbus Function : 10

Modbus Register Address : 408A

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = HZ

Menu = P08.01 'FL'

Name : GetVsdSpeedPercentActual

Modbus Function : 03

Modbus Register Address : 408C

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = PERCENT_DP2

Name : GetVsdControlPercentActual

Modbus Function : 03

Modbus Register Address : 408E

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = PERCENT_DP2

Menu = P08.03 'C>'

Name : GetDeliveryPressureOffset

Modbus Function : 03

Modbus Register Address : 4090

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = SIGNED,NUMERIC

Data Units = mBAR

Menu = P04.01 'do'

Name : SetDeliveryPressureOffset

Modbus Function : 10

Modbus Register Address : 4090

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = SIGNED,NUMERIC

Data Units = mBAR

Menu = P04.01 'do'

32

Page 33

Name : GetDeliveryPressureRange

Modbus Function : 03

Modbus Register Address : 4092

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P04.02 'dr'

Name : SetDeliveryPressureRange

Modbus Function : 10

Modbus Register Address : 4092

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Units = mBAR

Menu = P04.02 'dr'

Name : GetInternalPressureOffset

Modbus Function : 03

Modbus Register Address : 4094

Modbus Register Length : 0002

Coding : Number of data bytes = 4

Data Conversion Type = SIGNED,NUMERIC

Data Units = mBAR

Menu = P04.03 'Io'

Name : SetInternalPressureOffset

Modbus Function : 10

Modbus Register Address : 4094

Modbus Register Length : 0002

Coding : Number of data bytes = 4