Page 1

04662995

Edition 4

December 2006

Turbine Powered Starter

ST600 Series

Installation and

Maintenance Information

Save These Instructions

Page 2

WARNING

General Product Safety Information

• Read and understand this manual before operating this starter.

• It is your responsibility to make this safety information available to others that will operate this starter.

• Failure to observe the following warnings could result in injury.

WARNING

• For safety, maximum performance and maximum durability of parts, do not operate ST600 Starters at air pressures

over the pressure rating stamped on the nameplate. Use supply lines of adequate size as directed in the installation

instructions in this manual.

• Do not use damaged, frayed or deteriorated air hoses & fittings.

• Always turn off the air supply and disconnect the air supply hose before installing, removing or adjusting any

accessory on this starter, or before performing any maintenance on this starter.

• Operate Model ST600 Starters on compressed air only. They are not designed or sealed for operation on

compressed gas.

• Do not lubricate starters with flammable or volatile liquids such as kerosene or jet fuel.

• For personal protection, do not remove any labels. Replace any damaged labels.

• Use only recommended Ingersoll Rand accessories.

• Operate this starter only when properly installed on the engine.

• Always wear eye protection when operating or performing maintenance on this Starter.

• Always wear hearing protection when operating this Starter.

• This product is not designed for working in explosive environments, including those caused by fumes & dust, or

near flammable materials.

• This product is not insulated against electric shock.

• Keep hands, loose clothing, long hair and jewelry away from working end of product.

• Shaft and/or accessories may briefly continue their motion after throttle is released.

• Never use a damaged or malfunctioning product or accessory.

• Do not modify this product, safety devices, or accessories.

• Do not use this product for purposes other than those recommended.

NOTICE

• The use of other than genuine Ingersoll Rand Replacement parts may result in safety hazards, decreased starter

performance, increased maintenance, and may invalidate all warranties.

• Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll Rand Authorized

Service Center.

• Ingersoll Rand is not responsible for customer modifications of starters for applications on which Ingersoll Rand

was not consulted.

• It is the responsibility of the employer to place the information in this manual into the hands of the operator.

Safety Information - Explanation of Safety Signal Words

DANGER

WARNING

CAUTION

NOTICE

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or property damage.

Indicates information or a company policy that relates directly or indirectly to the safety of

personnel or protection of property.

Safety Symbol Identification

Wear Respiratory

Protection

(Dwg. MHP2598)

2 04662995_ed4

Wear Eye

Protection

Wear Hearing

Protection

Read Manuals Before

Operating Product

Page 3

Placing Starter in Service

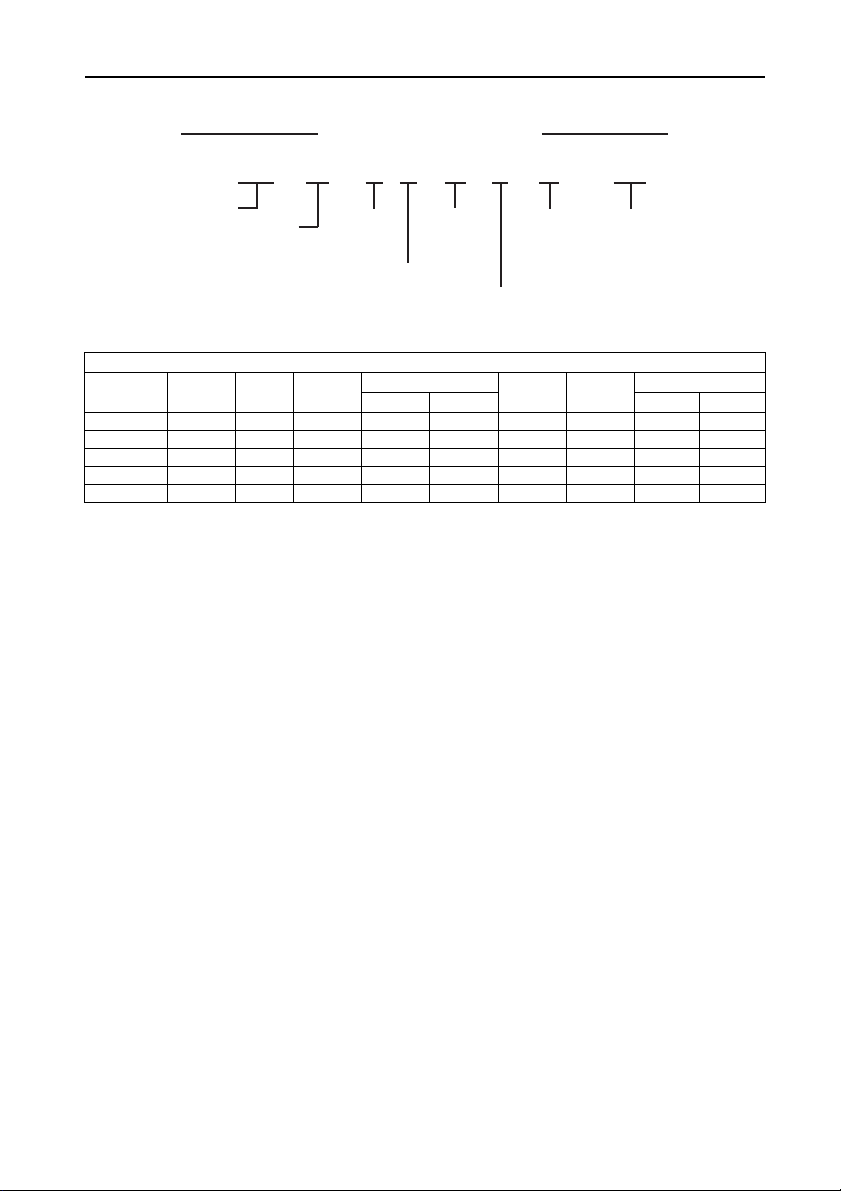

ST6 50 B P 03 R 31 045

HOW TO ORDER A STARTER

STARTER

ARC

HALF 50

FULL 99

GEAR

RATIO

P = PRE-ENGAGED

FLANGE

03 = SAE03

PINION

CODE

PINION ROTATION

R = RIGHT

L = LEFT

ORIENTATION

045

090

135

180

225

270

315

Pinion Data

Part

Number

ST600-13-31 12 12 6/8 2.000 50.80 20.0 R/L 2.250 57.15

ST600-13-51 15 15 6/8 2.500 63.50 20.0 R/L 2.750 69.85

ST600-13-83 12 12 3.5 Module 1.515 38.50 20.0 R/L 1.882 47.80

ST600-13-91 14 16 3.5 Module 1.929 49.00 20.0 R/L 2.441 62.00

ST600-13-942 14 15 3.5 Module 1.929 49.00 15.0 R/L 2.301 58.45

* Pinion Code must be specified when ordering.

Number

of Teeth

Blank DP/MOD

PD

inches mm inches mm

PA Ro tati on

OD

04662995_ed4 3

Page 4

Installation

NOTICE

For maximum performance, read this manual prior to

installation or operation of Series ST600 Starters.

General Information

1. This starter is designed for flange mounting at the inlet.

The Flange Mounting Kit is required for installation. All

Piping, hoses and valving must be clean prior to

installation. Make sure that the starter inlet is free of dirt

and foreign material during installation.

2. Engine design often requires mounting the starter

underneath in extremely close quarters, and even though

two of the mounting bolt holes are easy to reach, the third

one is less accessible. To install a starter, the following

tools are required: regular ratchet wrench, sockets,

universal joint, socket extension and single or double-end

box wrench.

3. Improper hook-up impairs the efficiency of a Starter.

Pressure Lines smaller than those recommended will

reduce the volume of air to the motor and the use of

reducers for piped-away applications in the exhaust port

will restrict the exhaust causing back pressure to the

motor resulting in reduced perfor mance. Keep the

number of tees and elbows, and the length of the supply

line upto a minimum. Use 1-1/2” hose or pipe for supply

lines up to 15 feet long: use 2” hose or pipe if the supply

line is over 15 feet long.

4. Install a 300 mesh strainer in the inlet line for each starter.

These 300 mesh strainers provide 50 micron filtration and

offer significant protection against supply line

contaminants which could damage the turbine

components. Ingersoll Rand offers 3 sizes:

ST900-267-24 for 1-1/2 inch lines, ST900-267-32 for 2

inch lines and ST900-267-64 for 4 inch lines.

Replacement elements are: ST900-266-24 for 1-1/2 inch,

ST900-266-32 for 2 inch and ST900-266-64 for 4 inch

lines.

5. Make your connections bubble tight to avoid unnecessary

costs and delays. On all threaded connections

throughout the system, use Ingersoll Rand No.SMB-441

Sealant, non-hardening No.2 Permatex or always run the

air supply line for the side or top of the receiver, never at

or near the bottom. Moisture in the air collects at the

bottom of the receiver resulting in damage which could

cause the valves to become inoperative. Periodically,

open the petcock at the bottom of the tank to drain the

water.

6. We recommend installation of a “glad hand” in vehicular

applications for emergency re-pressurizing of the system.

To keep the “glad hand” clean and free of dirt and to

protect it from damage, a second “glad hand” closed by a

pipe plug can be mated to it, or a “glad hand” protector

bracket can be used.

Orientation of the Starter

If the factory orientation will not fit your engine due to radial

location of the Drive Housing or location of the inlet and/or

exhaust ports, re-orient the starter as follows:

1. Refer to the dimension illustration and note that the drive

housing can be located in anyone of eight radial positions

relative to the air inlet (motor housing).

2. Study the engine mounting requirements, and determine

the required orientation of the Drive Housing relative to

the Gear Case. If the Drive Housing has to be reoriented,

remove the eight Drive Housing Cap Screws and rotate

the Drive Housing to its required positi on.

Mounting the Air Starter

1. Study the Piping diagram on Page 5.

2. The air receiver tank for a starter installation must meet

SAE J10B specifications. It must have a working

pressure capability equal to or grea ter than the maximum

pressure at which the starter will be operated.

3. When connecting the starter to a receiver tank that is

already in service, bleed off the air pressure by opening

the drain valve.

WARNING

Bleed off the air pressure through a valve or petcock. Do

not remove a plug from the tank while the tank is still

pressurized. Drain off any water that has accumulated in

the bottom of the tank.

4. Using a 1-1/2” short nipple, install the SRV150 Starter

Relay Valve on the end of the receiver tank as shown in

the piping diagram.

NOTICE

Make certain the connection is made to the inlet side of

the Relay valve indicated by the word “IN” cast on the

valve body.

5. Install the No.SMB-G618 Starter Control Valve on the

dash panel (for vehicular installations) or some other

appropriate panel (for stationary installations.)

6. Mount the No.150BMP-1064 Air Pressure Gauge on or

adjacent to the control panel. It should be located where it

is readily visible to the operator of the Control Valve.

7. Connect the Starter Control Valve to the Relay Valve with

1/4” hose. Install a Tee in this line with a short feeder

hose to the Pressure Gauge.

NOTICE

Make certain the hose is connected to the “SUPPLY”

side of the Starter Control Valve.

8. To determine the exact length of 1-1/2” air hose required,

run a piece of heavy-duty hose or some other flexible

tubing of the same diameter from the Relay Valve on the

receiver to the starter location on the engine.

9. Attach the 1-1/2” air hose to the outlet side of the Relay

Valve, and run the hose through the frame to its final

position at the starter location.

10. At this point, determine if it is feasible or practical to

attach the hose to the starter before or after the starter is

actually mounted. In many cases, it may be necessary to

attach the hose to the starter before mounting.

11. If possible, libe rally grease the teeth on t he ring gear with

a good, sticky gear grease or motorcycle chain lube. This

will help promote the life of the ring gear and the Starter

Pinion.

12. Place the starter into position, and mount it on the

flywheel bell housing. Tighten the mounting bolts to

100-ft-lb (136 Nm) of torque.

13. Pressurize the complete starting system and check every

connection with a soap bubble test. There must be no

leaks.

4 04662995_ed4

Page 5

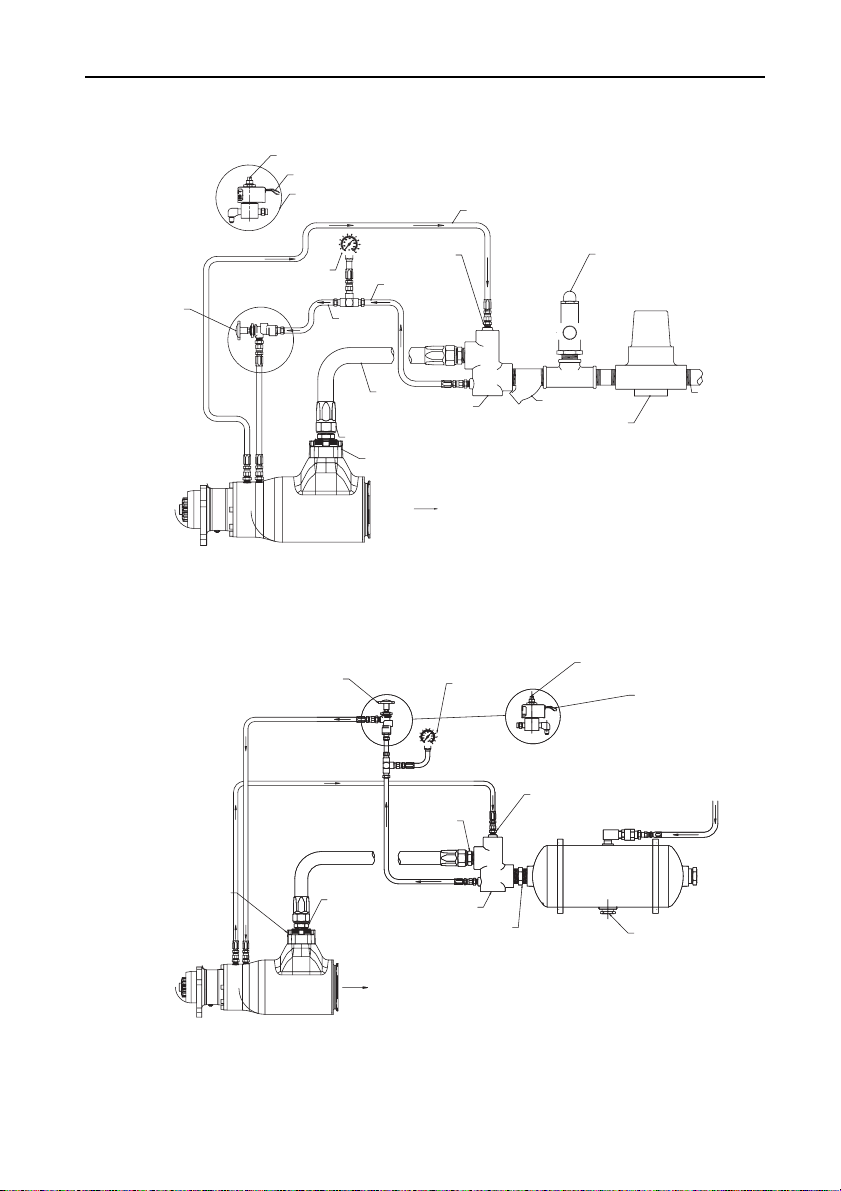

Piping Diagram

PIPING DIAGRAM FOR A TYPICAL STATIONARY INSTALLATION: PRE-ENGAGED

SOLENOID VALVE - 120 VOLT

*150BMP-2450

(2) LEADS TO OPERATORS

STARTING SWITCH.

OPTIONAL CONTROL CIRCUIT UTILIZING

ELECTRIC SOLENOID CONTROL VALVE AND

PANEL MOUNTED SWITCH.

#4 HOSE (1/4)

STARTER CONTROL VALVE

* SMB-618 (BRASS / AIR)

INLET FLANGE KIT

*ST700-K166

(Dwg. TPE_1028_01)

AIR PRESSURE GAGE

* 150BMP-1064L

(AIR ONLY)

JIC 37° ADAPTOR 1/4 NPT

* SS350-MC4

#4 HOSE (1/4)

#4 HOSE (1/4)

1 1/2 HOSE

RELAY VALVE 1 1/2

*SRV150

JIC 37° ADAPTOR 1 1/2 NPT

INLET FLANGE KIT

*ST700-K166

EXHAUST

NOTE:

FOR ALL APPLICATIONS USE SEALANT * SMB-441 OR EQUIVALENT

ON ALL PIPE CONNECTIONS.

* INDICATES INGERSOLL RAND PART NUMBER

RELIEF VALVE SET AT 15 PSI

ABOVE REGULATOR SETTING.

STRAINER

* ST900-267-24

PRESSURE REGULATOR

(MAXIMUM SETTING NOT TO EXCEED

PRESSURE RATING SHOWN ON

STARTER NAMEPLATE)

PIPING DIAGRAM FOR A TYPICAL VEHICULAR INSTALLATION: PRE-ENGAGED

SOLENOID VALVE - 12 VOLT

STARTER CONTROL VALVE

*SMB-618 (BRASS/AIR)

#4 HOSE (1/4”)

1 1/2” HOSE

1 1/2” INLET SIZE

EXHAUST

# HOSE (1/4”)

JIC 37° ADAPTER

1 1/2” NPT

RELAY VALVE 1 1/4”

*SRV150

AIR PRESSURE GAGE

*150BMP-1064L

“OPTIONAL CONTROL CIRCUIT UTILIZING

ELECTRIC SOLENOID CONTROL VALVE AND

PANEL MOUNTED SWITCH.” (AIR ONLY)

1 1/2” PIPE ADAPTER

NOTE:

USE SEALANT ON ALL PIPE

CONNECTIONS. *SMB-441

* INDICATES INGERSOLL RAND PART NUMBER

*150BMP-1051B

JIC 37° ADAPTOR 1/4” NPT

*SS350-MC4

CHECK VALVE

*150BMP-1056

AIR RECEIVER TANK

(2) LEADS TO OPERATORS

STARTING SWITCH.

DRAIN VALVE 1/2” NPT

*150BMP-1067

HIGH PRESSURE

AIR SUPPLY.

AIR SUPPLY FROM

DRY AIR BRAKE TANK

04662995_ed4 5

Page 6

Mounting Dimensions

(0.50)

[(12.70)]

(0.50)

[(12.70)]

(1.75)

[(44.57)]

SECTION A-A

(2.00)

[(50.92)]

ø (3.62)

[(91.90)]

3X (120°)

ø (5.75)

[(146.05)]

PINION

PINION ROTATION

“R” = RIGHT

ARC

STARTER

ORIENTATION OPTIONS

“L” = LEFT

FLANGE

- AIR

STD 00

HALF 55

FULL 99

DUAL INCH

DIMENSIONS MM

8 @ 45°

DRIVE HOUSING

03 SAE 03

- STD

I INERTIA

P PRE-ENGAGED

RATIO

A

(.60)

[(15.24)]

ø (5.28)

[(134.24)]

NOTES:

1. Please read instructions before attempting to reorient.

2. Starter weight is 39 Lbs.

3. Not to be used with natural gas.

1/4” NPT

CONTROL PORT

OUTLET

(4.48)

[(113.74)]

(5.64)

[(143.31)]

1/4” NPT

CONTROL PORTINLET

ST600 PRE-ENGAGED MOUNTING DIMENSIONS

(12.023)

(1.41)

[(35.71)]

(2.75)

[(69.85)]

[(305.384)]

STANDARD INLET FLANGE KIT

ST700-K166

A

(INCLUDES MOUNTING HARDWARE

(4.23)

(3.49)

[(107.46)]

[(88.54)]

(4.96)

[(125.93)]

ø (6.25)

[(158.75)]

(Dwg. TPE_1027)

6 04662995_ed4

Page 7

ST600 Turbine Powered Starter - Section View

2

3

4

5

6

11

12

7

8

1

A

9

10

14

15

13

20

16

18

17

19

21

22

23

24

SECTION A-A

A

(Dwg.TPE_1029)

04662995_ed4 7

Page 8

ST600 Turbine Powered Starter - Exploded Diagram

(Dwg.TPE_1030)

8 04662995_ed4

Page 9

ST600 Turbine Powered Starter - Parts List

Item Description Part Number Item Description Part Number

1 Screw ST700-737 18 Spring ST600-700

2 Spring D10-275 19 Spring Seat SS350-191

3 Deflector ST700-735 20 Screw (8) Y99-52

4 Exhaust Cap ST600-562 21 Drive Housing Assembly ST600-K300

5 O-Ring ST700-67 22 Pinion Collar ST600-175

6 Motor Assembly 23 Drive Pinion

for LH rotation models ST650L-A53B for ST650BP03L31, ST699BP03L31,

for RH rotation models ST650R-A53B ST650BP03R31 and ST699BP03R31 ST600-13-31

7 Deflector ST600-111 for ST650BP03L51, ST699BP03L51,

8 O-Ring Y325-253 ST650BP03R51 and ST699BP03R51 ST600-13-51

9 Wave Spring ST600-244 for ST650BP03L83 and ST650BP03R83 ST600-13-83

10 Gear Package Assembly ST600C-APGR for ST650BP03L91, ST699BP03L91,

11 Flange Kit ST700-K166 ST650BP03R91 and ST699BP03R91 ST600-13-91

12 Motor Housing Assembly ST600-A40 for ST650BP03L942, ST699BP03L942,

13 O-Ring SS350-151 ST650BP03R942 and ST699BP03R942 ST600-13-942

14 O-Ring SS800-337 24 Screw

15 Piston ST600-703 for LH rotation models ST600L-394

16 Retaining Ring SS350-107 for RH rotation models ST600R-394

17 Drive Package Assembly

for LH rotation models ST600L-APDR

for RH rotation models ST600R-APDR

04662995_ed4 9

Page 10

Maintenance

WARNING

Always wear eye protection when operating or

performing any maintenance on this starter. Always turn

off the air supply and disconnect the air supply hose

before installing, removing or adjusting any accessory

on this starter or before performing any maintenance on

this starter.

Disassembly

General Information

1. Do not disassemble the Starter any further than

necessary to replace worn or damaged parts.

2. When grasping a part in a vise, always use leathercovered or copper-covered vise jaws to protect the

surface of the part and help prevent distortion. This is

particularly true of threaded members.

3. Do not remove any part which is a press fit in or on a

subassembly unless the removal of that part is necessary

for replacement or repairs.

4. Always have a complete set of seals and O-Rings on

hand before starting any overhaul of a Series ST600

Turbine Starter. Never reuse old seals or O-Rings.

5. Do not press any needle bearing from a part unless you

have a new needle bearing on hand for installation.

Needle bearings are always damaged during the removal

process.

Disassembly of the Starter

1. Place the Starter on a workbench with Exhaust end

down.

2. Remove the Drive Pinion Retainin g Screw (24).

NOTICE

Models ending in R31, R51, R83, R91 and R942 have a

left-hand thread. Models ending in L31, L51, L83, L91 and

L942 have a right-hand thread.

Assembly

General Instructions

1. Always press on the inner ring of a ball-type bearing

when installing the bearing on a shaft.

2. Always press on the outer ring of a ball-type bearing

when pressing the bearing into a bearing recess.

3. Whenever grasping a starter or part in a vise, always use

leather-covered or copper-covered vise jaws. Take extra

care with threaded parts or housings.

4. Except for bearings, always clean every part and wipe

every part with a thin film of oil or stated type of grease

before installation.

5. Check every bearing for ro ughness. If an open bearing

must be cleaned, wash it thoroughly in a suitable

cleaning solution and dry with a clean cloth. Sealed or

shielded bearings should neve r be cleaned. Work grease

thoroughly into every open bea ring before installation.

6. Apply a film of O-ring lubricant to all O-rings before final

Assembly.

7. Unless otherwise noted, alw ays press on the stamped

end of a needle bearing when installing the needle

bearing in a recess. Use a bearing inserting tool similar to

the one shown in Dwg.TPD786.

Lubrication

Each time a Series ST600 Starter is disassembled for

maintenance or repair, lubricate the starter as follows:

1. Lubricate the inside diameter of the Drive Shaft (17) with

Ingersoll Rand No.130 Grease.

2. Lubricate the Pinion end of the Drive Shaft with

Ingersoll Rand No.11 Grease.

3. Wipe a thin film of Ingersoll Rand No.130 Grease in the

bore of the Drive Housing (12).

4. Roll the Piston Return Spring (18) in Ingersoll Rand

No.130 Grease.

5. Coat the outside of the Piston (15) with Ingersoll Rand

No.130 Grease.

6. Lubricate all O-Rings with O-Ring lubricant.

3. Remove the Drive Pinion (23) with Pinion Collar attached

off the Drive Shaft.

4. Unscrew and remove the eight Drive Housing Cap

Screws (20).

5. Remove Drive Housing (21).

6. Remove Spring (18) and seat (19).

7. Slide the Drive Package Assembly (17) from the Drive

Housing.

8. Place Motor Housing (12) in a copper faced vise

clamping on the flats of the Exhaust Cap (4).

9. Insert a rod in the inlet and turn counterclockwise to

remove exhaust cover (4).

NOTICE

Transmission Fluid will drain and build-up on the

Exhaust Cover. Handle Exhaust Cover with care.

10. Remove Motor Housing from vise and place on

workbench with Exhaust end upward.

11. Grasp the rear of the Motor Assembly (6) and pull it from

the rear of the Motor Housing.

12. Place Motor Housing in drip pan with Exhaust end down

to allow transmission fluid to drain.

13. Press on clutch Shaft through the front end to release

Gear Package (10) and Front Deflector (7).

SHOULDER TO

REGULATE DEPTH

(Dwg.TPD786)

NEEDLE BEARING INSERTING TOOL

15°

PILOT TO FIT I.D. OF BEARING.

LENGTH OF PILOT TO BE

APPROXIMATELY 1/8” LESS THAN

LENGTH OF BEARING

10 04662995_ed4

Page 11

Assembly of the Starter

1. Place Motor Housing on a workbench, exhaust end up.

2. Grasp Gear Package Assembly (10) and insert into Motor

Housing. Rotate Gear Package to align Planet Gear

Teeth with Ring Gear Teeth.

3. Place Wave Spring (9) onto Front Deflector (7).

4. Insert Front Deflector (7) into Motor Housing applying

force until it seats against Ring Gear.

5. Add 275 ml of Dextron®** II Automatic Transmission fluid

through the hole in the Front Deflector.

6. Before installing the Motor Assembly, coat the O-Rings

on the Motor Assembly and the inside of the Cylinder wit h

O-Ring lubricant. Install the Motor Assembly through the

rear of the Motor Housing with geared end of the rotor

toward the front.

NOTICE

Be careful not to damage O-Rings during assembly. If

necessary a .010” thick sleeve may be inserted to cover

inlet hole. Remove once Motor Assembly has been

installed.

7. Coat the Exhaust O-Ring (5) with O-Ring lubricant and

install in the groove on the Exhaust Cap (4).

8. Align the Exhaust Cap in the rear of the Motor Housing

and rotate until it seats. Tighten the Exhaust Cap to a

final torque of 50 ft.-lb.

9. Install the Deflector (3), Spring (2) and Screw (1) in the

rear of the Housing Exhaust Cover.

NOTICE

Coat the threads of the Deflector Retaining Screw with

Ingersoll Rand SMB-441 Sealant.

10. Place Starter in vise with exhaust end down clamping on

flats of Exhaust Cap.

11. Grasp Drive Package Assembly and align the spline teeth

of Drive Package Assembly with spline teeth of the Gear

Package Assembly. Apply pressure until Piston is seated.

12. Install Spring (18) and Seat (19).

13. Carefully position the Drive Housing (12) onto the Motor

Housing.

14. Install the Drive Housing Cap Screws (20) and torque to

20-25 ft-lbs.

15. Refer to TPE_1027 for prope r orientation.

16. Install Pinion (23) with Collar (22) attached. Align the

notches of the Pinion with notche s in the Drive Shaft.

17. Install the Drive Pinion Retaining Screw (24) into the end

of the Drive Shaft and torque to 18 0-220 ft-lb.

NOTICE

Models ending in R31, R51, R83, R91 and R942 have a

left-hand thread. Models ending in L31, L51, L83, L91 and

L942 have a right-hand thread.

NOTICE

After assembling the exhaust cover to the starter, add

20 ml of Dextron® **II Automatic Transmission Fluid

through the screw hole in the Exhaust Cover.

** Registered Trademark of Exxon Corp.

Troubleshooting Guide

Trouble Probable Cause Solution

Motor will not run No air supply Check for blockage or damage to air supply lines or tank.

Damaged motor assembly Inspect Motor Assembly and power train and repair or

Foreign material in motor and/or piping Remove Motor Assembly and/or piping and remove

Blocked exhaust system Remove Housing Exhaust Cover (1) and check for

Defective Control Valve or Relay Valve Replace Control Valve or Relay Valve.

Low air pressure to Starter Check air supply.

Restricted air supply line. Check for blockage or damage to air lines.

Relay Valve malfunctioning Clean or replace lines or Relay Valve. Lube relay Valve.

Loss of Power Exhaust flow restricted Check for blocked or damaged piping. Clean or replace

Worn motor parts Remove the motor from the Motor Housing (17) and

Lack of air to starter Check for clogged or damaged air line between relay valve

replace if necessary.

blockage.

blockage.

piping. Check for dirt or foreign material and clean or

remove. Check for ice build-up. Melt ice and reduce

moisture build-up to Starter.

disassemble the motor. Examine all parts and replace any

that are worn or damaged.

and starter. Check relay valve to determine if it is

functioning properly. Check air tank.

04662995_ed4 11

Page 12

Parts and Maintenance

NOTICE

The use of other than genuine Ingersoll Rand replacement parts may result in safety hazards, decreased motor

performance, and increased maintenance, and may invalidate all warranties.

Ingersoll Rand is not responsible for customer modification of motors for applications on which Ingersoll Rand was not

consulted.

Repairs should be made only by authorized trained personnel. Consult your nearest Ingersoll Rand Authorized Service

center.

When the life of the motor has expired, it is recommended that the motor be disassembled, degreased and parts be separated by

material so that they can be recycled.

Manuals can be downloaded from www.irtools.com.

Refer all communications to the nearest Ingers oll Rand Office or Distributor.

12 04662995_ed4

Page 13

Notes

Page 14

Notes

Page 15

Notes

Page 16

www.irtools.com

© 2006 Ingersoll Rand Company

Loading...

Loading...