Page 1

- EN -

DIRECT EXPANSION COMPRESSED AIR DRYERS

Operators Manual

For 60 Hz dryers

- FR -

SECHEUR D’AIR A EXPANSION DIRECTE

Manuel des Opérateurs

Pour des sécheurs à 60 Hz

D12IN D18IN D25IN

D42IN D54IN D72IN

D108IN D144IN D180IN

D300IN D360IN

Cod. 710.0138.39.00 Rev1A – 05.2008 1 - 27

Page 2

- EN -

CONTENTS

1. GENERAL INFORMATION

1.1 Functional Description 3

1.2 Safe Use of the Dryer 3

2. INSTALLATION

2.1 Acceptance and Transportation 4

2.2 Installation Site 4

2.3 Installation 4

3. START UP

3.1 Control Panel 5

3.1.1 Keys function 6

3.1.2 Condensate discharge Parameters

Programming 6

3.1.3 Anomaly Warning 7

3.1.4 Remote signalling Alarm 7

3.2 Before Start Up 8

3.3 Start Up 8

4. MAINTENANCE, TROUBLESHOOTING

AND DISMANTLING

4.1 Maintenance 8

4.2 Troubleshooting 8

4.3 Dismantling 10

ATTACHMENTS TO THIS MANUAL

A) Refrigerant Circuit 21

B) Electric Circuit Diagram 22

C) Technical Data Sheet 24

D) Correction Factors 25

E) Dryer Dimensions 26

F) Basic Spare Parts 28

- FR -

TABLE DES MATIERES

1. INFORMATIONS GENERALES

1.1 Description fonctionnelle 12

1.2 Utilisation du séchoir en toute sécurité

12

2. INSTALLATION

2.1 Réception et transport 13

2.2 Lieu d'installation 13

2.3 Installation

13

3. MISE EN SERVICE

3.1 Pupitre de commande 14

3.1.1 Fonction des touches 15

3.1.2 Programmation des paramètres 15

3.1.3 Signalisation des anomalies 16

3.1.4 Signalisation d’alarme a distance 16

3.2 Opérations préliminaires à la mise en marche 17

3.3 Mise en marche

17

4. ENTRETIEN, RECHERCHE DES PANNES ET

DEMANTELEMENT

4.1 Entretien 17

4.2 Recherche des pannes 17

4.3 Démantèlement 19

ANNEXES AU MANUEL

A) Circuit Frigorifique 21

B) Schéma électrique 22

C) Caractéristiques Techniques 24

D) Facteurs de Correction 25

E) Dimensions Du Sécheur 26

F) Pièces De Rechange Essentielles 28

Cod. 710.0138.39.00 Rev1A – 05.2008 1 - 28

Page 3

- EN -

INTRODUCTION

This manual is an integral part of the dryer you bought, and must remain with the machine even if this will be resold.

It is highly recommended that the qualified*personnel for installation maintenance and/or control will fully comply with the

contents of this manual and the prevention and safety rules in force in the country where the system will be used. In this way,

not only the usage of the machine will be rational, but also the service will result cost effective.

In case your dryer will present any kind of problem, please contact your local authorized Ingersoll Rand distributor.

Please note that, when necessary, the use of original spare parts will ensure efficiency and long duration to your dryer.

Due to the continuous technological evolution, Ingersoll Rand reserves the right to modify the specifications contained in this

manual without giving previous notice.

SYMBOLS AND LABELS USED IN THE MANUAL AND ON THE DRYER

or or or

Air inlet.

or or or

Air outlet.

Read the Operators manual before attempt to

start up the machine and to perform any

service operation on the dryer.

Pay particular attention to components or

systems under pressure.

Pay particular attention to the indications

preceded by these symbols.

Pay particular attention to hot surfaces.

Installation, maintenance, and/or control

operations preceded by these symbols must

be performed exclusively by qualified

personnel*.

Pay particular attention to the risk of electric

shock.

Condensate drain point.

Rotation direction of the fan.

Attention: Before performing any

maintenance operation on this

machine, do not forget to disconnect

the electric supply, to completely

discharge air pressure, and to refer to

the Operators manual

* Qualified personnel must be trained and certified in accordance with local laws and regulations.

WARRANTY

The Company warrants that the equipment manufactured by it and delivered hereunder will be free of defects in material and

workmanship for a period of twelve months from the date of placing the Equipment in operation or eighteen months from the

date of shipment from the factory, whichever shall first occur. The Purchaser shall be obligated to promptly report any failure to

conform to this warranty, in writing to the Company in said period, whereupon the Company shall, at its option, correct such

nonconformity, by suitable repair to such equipment or, furnish a replacement part F.O.B. point of shipment, provided the

Purchaser has stored, installed, maintained and operated such Equipment in accordance with good industry practices and has

complied with specific recommendations of the Company. Accessories or equipment furnished by the Company, but

manufactured by others, shall carry whatever warranty the manufacturers have conveyed to the Company and which can be

passed on to the Purchaser. The Company shall not be liable for any repairs, replacements, or adjustments to the Equipment or

any costs of labor performed by the Purchaser or others without Company's prior written approval.

The effects of corrosion, erosion and normal wear and tear are specifically excluded. Performance warranties are limited to

those specifically stated within the Company's proposal. Unless responsibility for meeting such performance warranties are

limited to specified tests, the Company's obligation shall be to correct in the manner and for the period of time provided above.

THE COMPANY MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER, EXPRESSED

OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, ARE HERBY DISCLAIMED.

Cod. 710.0138.39.00 Rev1A – 05.2008 2 - 28

Page 4

Correction by the Company of nonconformities whether patent or latent, in the manner and for the period of time provided

above, shall constitute fulfillment of all liabilities of the Company for such nonconformities whether based on contract, warranty

negligence, indemnity, strict liability or otherwise with respect to or arising out of such Equipment.

The Purchaser shall not operate Equipment which is considered to be defective, without first notifying the Company in writing

of its intention to do so. Any such use of Equipment will be at Purchaser's sole risk and liability.

Note that this is Ingersoll Rand standard warranty. Any warranty in force at the time of purchase of the equipment or

negotiated as part of the purchase order may take precedence over this warranty.

1. GENERAL INFORMATION

1.1 FUNCTIONAL DESCRIPTION

Ingersoll Rand refrigerated air dryers remove moisture from compressed air. Moisture is detrimental to pneumatically

operated appliances, controls, instruments, machinery and tools.

Compressed air enters the patented aluminum heat exchanger where it is cooled down to the dew point temperature in

two different stages: In the first air/air sector compressed inlet air is cooled thanks to the colder compressed air coming

out counterflow from the condensate separator. In the second refrigerant / air sector, compressed air temperature is

further lowered to the dew point temperature. During this two stages almost all the oil and water vapours contained in

compressed air are condensed to liquid and successively be separated from the compressed air in the condensate

separator and drained out by the automatic drain. At this point the obtained cold air re-enters counterflow the initial air / air

exchanger and it is reheated by the inlet hot air with the consequence of energy recovering and also reduction of the

relative humidity contained in the outflowing air.

This dryer can be easily installed into various pneumatic systems in which dry air is required or desired. Please refer to

Start up chapter for complete operating details.

The dryer comes provided with all the control, safety and adjustment devices, therefore no auxiliary devices

are needed.

A system overload not exceeding the maximum operative limits can worsen the operational performance of the

dryer (high dew point), but it will not affect its safety.

The electric diagram (attachment B) shows the minimum protection degree IP 42.

Improper grounding can result in electrical shock and can cause severe injury or death.

This product must be connected to a grounded, metallic, permanent wiring system or an equipment-grounding

terminal or lead on the product.

All grounding must be performed by a qualified electrician and comply with national and local electrical codes.

In the event of an electrical short circuit, grounding reduces the risk of electric shock by providing an escape

wire for the electric current.

Ground must be established with a bare grounding wire sized according to the voltage and minimum branch

circuit requirements.

Ensure good bare metal contact at all grounding connection points, and ensure all connections are clean and

tight.

Check grounding connections after initial installation and periodically thereafter to ensure good contact and

continuity has been maintained.

Check with a qualified electrician or service technician if the grounding instructions are not completely

understood, or if in doubt as to whether the product is properly grounded.

1.2 USE OF THE MACHINE IN SAFE CONDITIONS

This system has been designed and manufactured in compliance with the European safety directive in force and

UL/ULC, therefore any installation, use and maintenance operations must be performed respecting the instructions

contained in this manual.

Because an air dryer is pressurized and contains rotating parts, the same precautions should be observed as with any

piece of machinery of this type where carelessness in operation or maintenance could be hazardous to personnel. In

addition to obvious safety rules that should be followed with this type of machinery, safety precautions as listed below

must be observed.

1. Only qualified personnel shall be permitted to adjust, perform maintenance or repair this air dryer.

2. Read all instructions completely before operating unit.

3. Pull main electrical disconnect switch and disconnect any separate control lines, if used, before

attempting to work or perform maintenance on the unit.

4. Do not attempt to service any part while machine is in an operational mode.

5. Do not attempt to remove any parts without first relieving the entire air system of pressure.

6. Do not attempt to remove any part of the refrigeration system without removing and containing

refrigerant in accordance with the EPA and local regulations.

7. Do not operate the dryer at pressures in excess of its rating.

8. Do not operate the dryer without guards, shields and screen in place.

9. Inspect unit daily to observe and correct any unsafe operating conditions.

Cod. 710.0138.39.00 Rev1A – 05.2008 3 - 28

Page 5

2. INSTALLATION

2.1 ACCEPTANCE, UNPACKING AND HANDLING

Upon receiving your Ingersoll Rand air dryer, please inspect the unit closely. If rough handling is detected, please note

it on your delivery receipt, especially if the dryer will not be uncrated immediately. Obtaining the delivery person's signed

agreement to any noted damages will facilitate any insurance claims by the customer.

It is mandatory to keep the dryer always in vertical position, as indicated by the symbols present on the packaging. For

handling, use devices having sufficient capacity for the weight of the machine.

Remove the packaging after having positioned the dryer in the installation site. Dispose the various packaging

materials in compliance with the relevant rules locally in force.

If not in use, the dryer can be stored in its packaging in a dust free and protected site between 32°F (0°C) and 120 °F

(50 °C), and a specific humidity not exceeding 90 %. Should the stocking time exceed 12 months, please contact your

local Ingersoll Rand authorized distributor.

Under no circumstances should any person attempt to lift heavy objects without proper lifting equipment (i.e., crane,

hoist, slings or fork truck). Lifting any unit without proper lifting equipment, may cause serious injury. Use fork lift channels

where provided.

2.2 INSTALLATION SITE

While preparing a proper site for the installation of the dryer, please take into account the following

requirements

The machine must be protected from atmospheric agents and not directly exposed to sun light.

A seating base flat and capable to hold the weight of the machine.

Ambient temperature complying with the nominal data of the dryer.

The dryer should be located in a clean area, without forced air draft that can affect the fan control

system.

Make sure to leave sufficient clearance (20 inches, 500 mm) around the dryer in order to allow an

adequate cooling of the machine and for maintenance and/or control operations.

The incoming air must be free from smoke or flammable vapours which could lead to explosion or fire risks.

2.3 INSTALLATION

Before attempting any installation operation, make sure that

No parts of the air system are under pressure.

No parts of the system are electrically powered.

Tubing to be connected to the dryer are free of impurities.

All interconnecting piping has been tightened.

After having verified the points listed above, you can proceed to the installation of the machine.

1. Connect the dryer to the compressed air lines. If not already existing, we suggest to install a by-pass

allowing to isolate the machine from the plant, thus to facilitate eventual maintenance operations.

2. Perform the electrical connection in accordance with any local laws and regulations after reviewing

the dryer electrical specifications and wiring diagram.

3. Check the condensate drainage assembly, and connect the drain flexible hose to the draining line,

keeping in mind that the condensate separated by the dryer may contain oil, therefore, in order

to dispose of it in compliance with the local rules in force, we suggest installing a water-oil

separator having adequate capacity.

4. Power the dryer after having checked that the nominal voltage and line frequency are constant and

matching the nominal values of the machine. The user must provide the installation with an

adequate line protection and a ground terminal complying with the electrical rules locally in

force.

In order to optimise the use of the dryer, we suggest to place it in such a way that all the control instruments

of the machine will result easily visible.

A suitably sized prefilter must be installed before the dryer. Failure to install and maintain a proper

prefilter will void the dryer warranty. The rating for this filter must be at least 10 micron.

Cod. 710.0138.39.00 Rev1A – 05.2008 4 - 28

Page 6

3. START UP

Ensure that the dryer is by−passed, or there is no load on the cooler.

Switch on the main electrical isolation switch (if present). The control panel will show the message OFF, indicating that the

line and control voltages are available.

Start sequence

The dryer will initially start by pressing the local ON/OFF button for 1 second. The start sequence will progress only if there

are no active alarms. The compressor motor will start AFTER 120 SECONDS. The fan motor will start simultaneously with

the compressor for D300-360IN models, after 30 seconds for smaller models.

Stop sequence

The dryer can be stopped locally from the control panel. After having pressed the ON/OFF switch for 1 second, the

compressor and the fan motor keep on running for further 10 seconds in order to re-balance the internal pressures. The

dryer can be also stopped due to an alarm or energy saving condition (ESA or ES2). Any alarm will de−energize the

compressor, fan motor can still running, it depends on the type of alarm (see Display indications chapter). If the shutdown is

due to an alarm, a message will blink on display indicating the reason for the shutdown. Energy saving condition (ESA or

ES2) occurs when the dew point stands below the set value for a long time in order to save energy and avoid heat

exchanger freezing. This situation can happen when ambient temperature is low and there is no compressed air load.

Variable speed fan control

A patented microprocessor allows to adjust dryer’s cooling capacity by changing the fan motor speed. If the dew point is

greater than the set value, the fan speed is increased, if the dew point is smaller than the set value, the fan velocity is

decreased. The range can be from 0 to 100% and the higher is the fan speed, the faster the fan LED blinks, you can read

the exact value by pressing the UP button. If the velocity is 100% you will read FL (Full Load). Under load standard

condition the fan speed is usually at 100%, if there is no load the fan velocity can oscillate between 0 and 20%.

In models D300-360IN, in order to adjust the greater dryer’s cooling capacity, a hot gas by-pass valve cooperates with the

variable speed system.

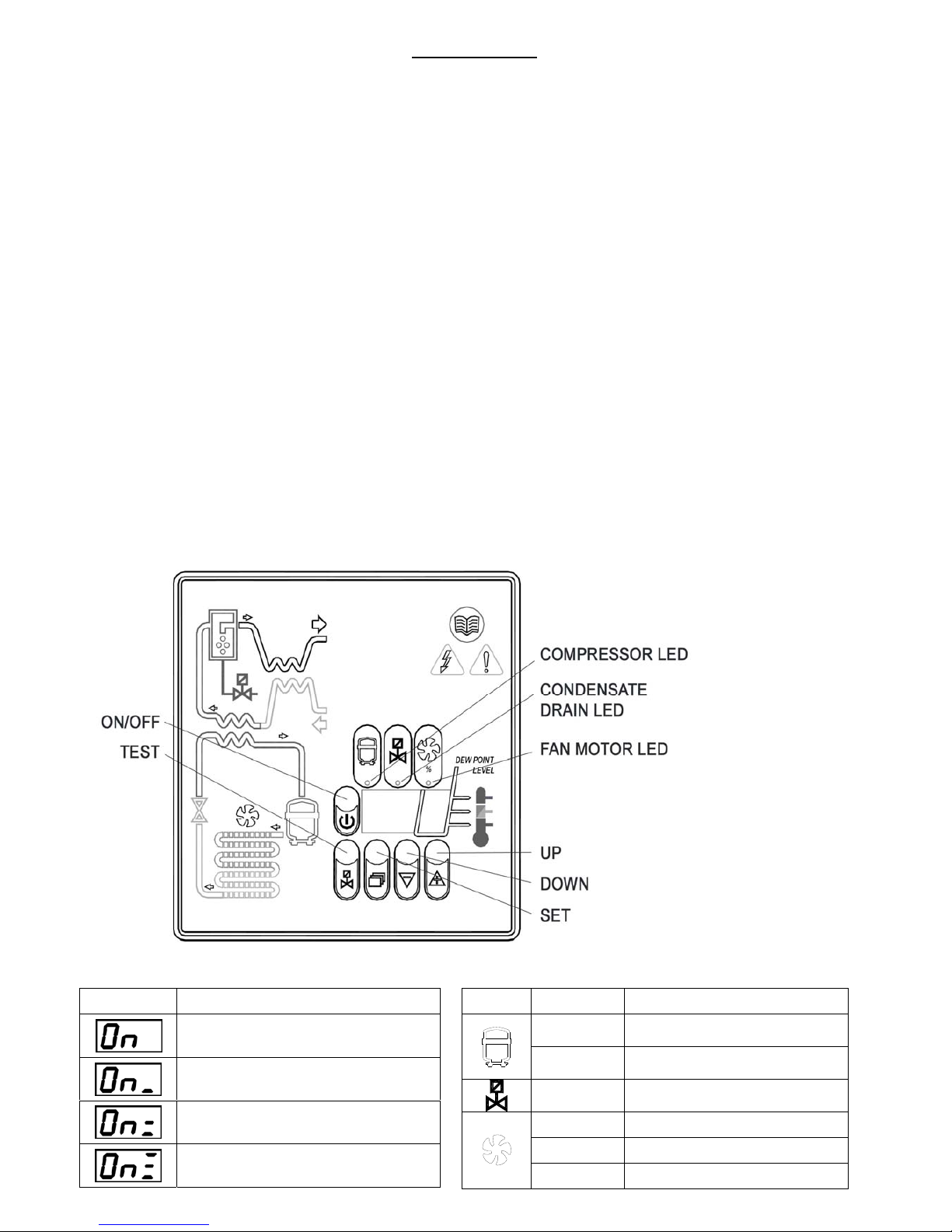

3.1 CONTROL PANEL

The dryers are provided with an electronic control system. All adjustments and resets can be performed by means of the

digital panel located on the front of the dryer.

The control panel is composed of 5 keys (ON/OFF, TEST, SET, DOWN and UP) and a 3 digit display, with three

signalling LEDs indicated by icons (PIC 1)

PIC. 1

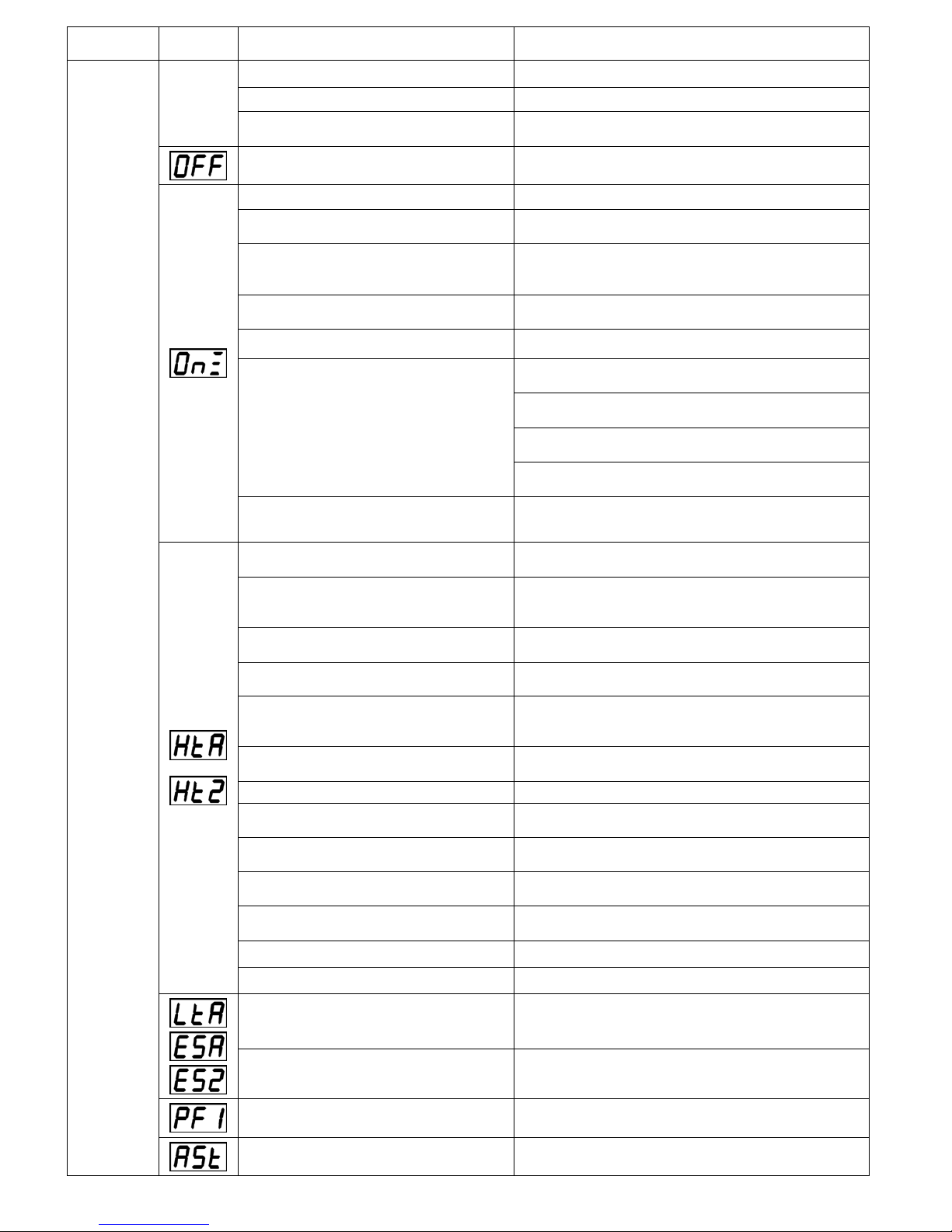

DISPLAY VISUALIZATION AND SIGNALLING LEDS

DISPLAY DESCRIPTION

the unit is ON with low load

the unit is ON with normal load

the unit is ON with normal-high load

the unit is ON with high load

LED STATUS DESCRIPTION

ON

Compressor energized

Blinking

Programming mode activated

ON

Condensate drain energized

ON

Speed of the fan = 100%

Blinking

Speed of the fan < 100%

OFF

Fan not running

Cod. 710.0138.39.00 Rev1A – 05.2008 5 - 28

Page 7

3.1.1 KEYS FUNCTION

TEST: When pushed for 3 sec. during normal operation, it activates the condensate drain.

SET: When pushed and released during normal operation, it displays the dew point set value (decimal).

When pushed for 10 seconds, it allows to enter the C8 and C9 condensate drain parameters programming

menu (see relevant table).

When pushed after having set new configuration values, it stores the applied modifications.

DOWN: When pushed while setting the drain set point, it decreases the displayed value of one unit per

second, during the first 10 seconds, than of one unit every 0,1 sec.

When pushed for 10 seconds during normal operation, it starts an automatic test cycle of the controller.

UP: When pushed while setting the drain set point, it increases the displayed value of one unit per second,

during the first 10 seconds, than of one unit every 0,1 sec.

ON / OFF: Pushed for 1 second, it activates or deactivates the dryer. When the dryer is deactivated, the

display shows OFF.

NOTE: when the controller is in the OFF position, some parts of the dryer may still be energized. Therefore, for

safety purposes, disconnect the electrical power before performing any operation on the machine.

3.1.2 CONDENSATE DISCHARGE PARAMETERS PROGRAMMING

Push the SET key for 10 seconds to enter the parameters configuration menu: the display will show in

sequence the set point value, the code of the first modifiable parameter (C8) and its value).

Only if strictly necessary, use the UP and/or DOWN keys to change the displayed parameter value.

Press the SET key to store the previously changed parameter value or to browse the parameters without

changing them.

15 seconds after the last performed operation, the controller will return automatically to the normal

operation mode.

PARAMETER DESCRIPTION RANGE DEFAULT SET VALUE

C8

Delay between condensate

discharges

1 ÷ 999 (min)

1

D12-144IN D180IN D300-360IN

C9

Time required for condensate

discharge

1 ÷ 999 (sec)

1 2 3

NOTE: Changes entered for timing values will be effective only after exiting the programming, while changes to

other variables will be immediately effective.

Please remember that eventual changes to the configuration parameters of the machine could negatively affect

its efficiency. Thus, changes have to be performed by a person familiar with the operation of the dryer.

WARNING FOR USER:

IT’S FORBIDDEN TO ATTEMPT TO MODIFY THE OTHER CONFIGURATION PARAMETERS OF THE

ELECTRONIC CONTROLLER WITHOUT AUTHORIZATION AND COLLABORATION OF INGERSOLL RAND’S

AUTHORIZED DISTRIBUTOR.

Cod. 710.0138.39.00 Rev1A – 05.2008 6 - 28

Page 8

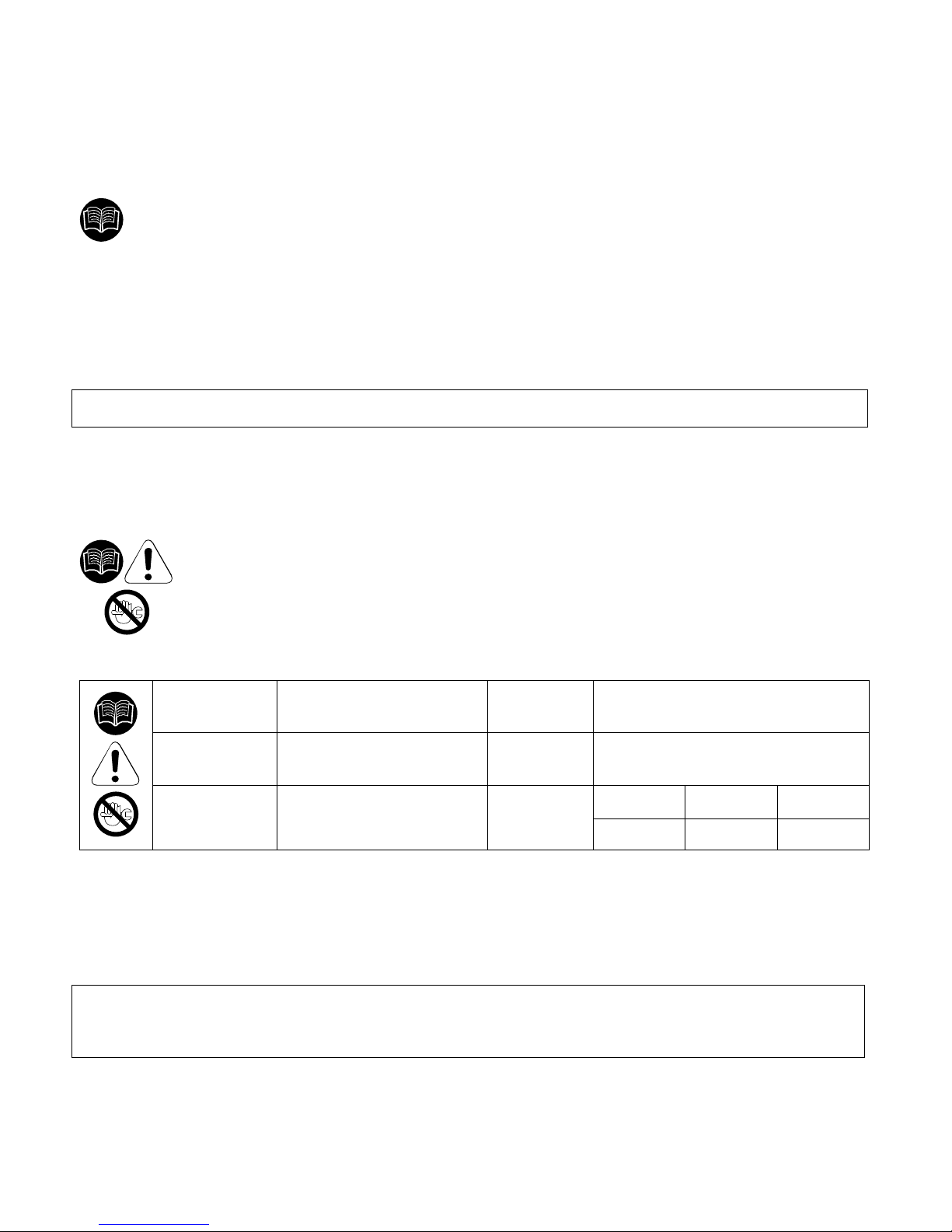

3.1.3 DISPLAY INDICATIONS

The controller is capable of recognizing certain types of anomalies in the drying circuit. In such cases, a message will

blink on the display, alternated to the current dew point value.

MESSAGE

(BLINKING)

CAUSE OUTPUTS ACTIONS

HtA

High dew point value

(delayed alarm)

Ht2

Very high dew point value

(immediate alarm)

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Resettable by switching off the

dryer.

If problem persists call your

local Ingersoll Rand distributor.

LtA

Low dew point value

Alarm output ON

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

Automatic reset when dew

point returns to preset range.

If problem persists call your

local Ingersoll Rand distributor.

PF1

Interruption or short circuit on

the PTC probe input line

Alarm output ON

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

Resettable by switching off the

dryer. May require replacing the

faulty probe.

If problem persists call your

local Ingersoll Rand distributor.

ESA

ES2

The automatic Energy saving

mode activated due to low

load

Alarm output OFF

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

No action necessary.

Automatic Reset

ASt

Activated after repeated

alarms

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Call your local Ingersoll Rand

distributor.

Note: PF1 has priority on all other messages.

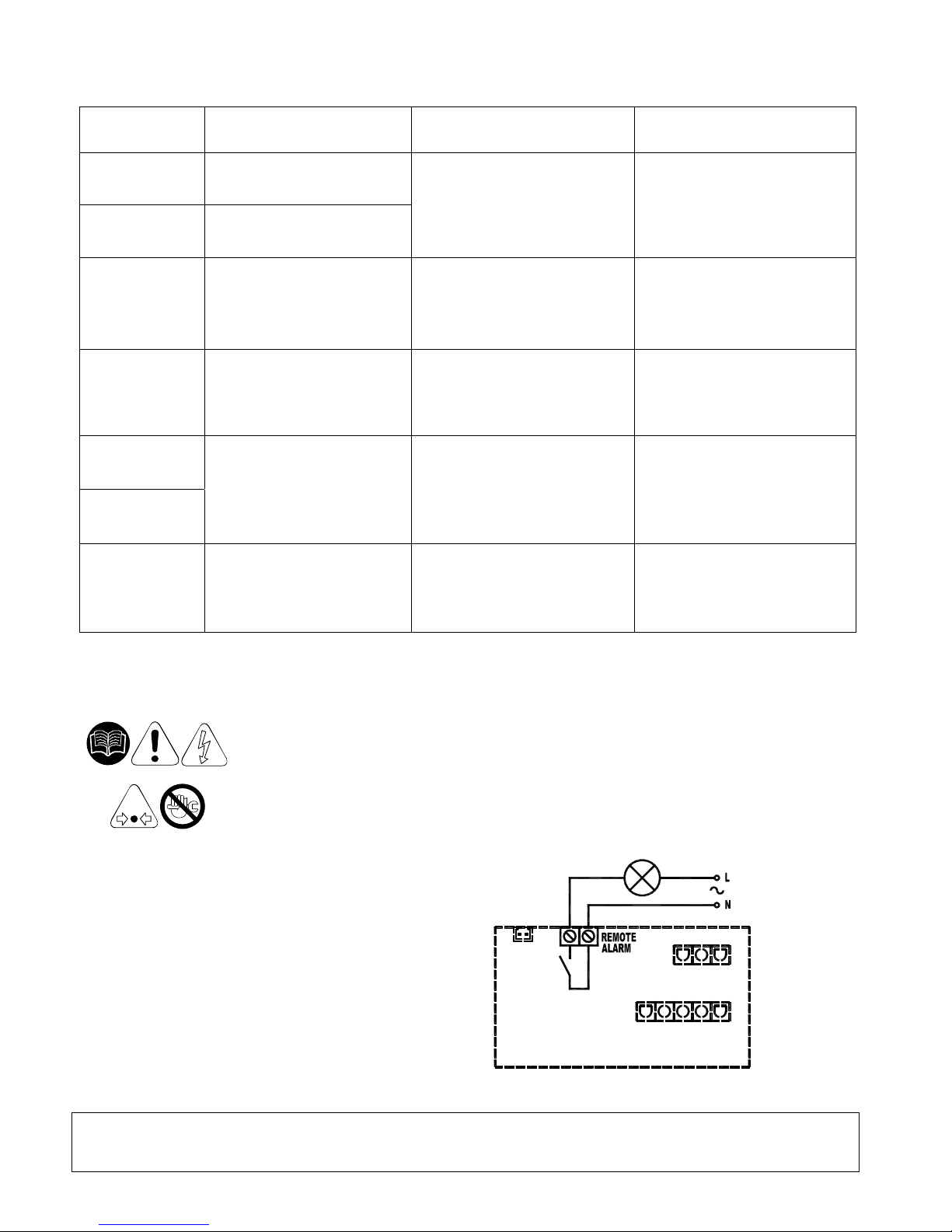

3.1.4 REMOTE SIGNALING ALARM

The dryer control board is equipped with a dry contact for a remote alarm signal. This is

normally open contact: when an alarm is detected, this contact is closed.

Proceed as follows to activate a remote alarm output:

1. The User must review the diagram below.

2. Disconnect the dryer from electrical power supply, remove cover and left side panel.

3. Connect the alarm circuit to the terminal blocks (See PIC.2).

4. Replace cover, left side panel and reconnect power.

Alarm Output relays electric

features:

Max. 250VAC / 3A – AC 15 (Amp. Inductive)

PIC.2

The activation of the above function is at the User’s discretion. The User will purchase all necessary

installation material. Any operation which needs access to the dryer must be carried out by qualified

personnel.

Cod. 710.0138.39.00 Rev1A – 05.2008 7 - 28

Page 9

3.2 BEFORE START UP

Before starting the machine, make sure that all operating parameters correspond to the nominal data.

The dryer is supplied already tested and preset for normal operation, and it doesn’t require any calibration.

Nevertheless, it’s necessary to check the operating performances during the first working hours.

3.3 START UP

The operations specified below must be performed after the first start up and at each start up after a

prolonged inactive period of time due to maintenance operations, or any other reason.

1. Make sure that all instructions contained in chapters INSTALLATION SITE and INSTALLATION

have been observed.

2. Ensure dryer by-pass is open and air inlet/outlet valves closed. (if existing).

3. Activate power supply and press the ON/OFF switch on the control panel for at least 1 second.

(note there is a 2 minute delay before the dryer will start after the dryer is turned on).

4. Wait 5 to 10 minutes until machine has achieved its standard operating parameters.

5. Slowly open the air outlet valve and successively open the air inlet valve.

6. If existent, close the air by-pass valve.

7. Check if the condensate drain is working properly.

8. Check if all connecting pipes are properly tightened and fixed.

Before disconnecting the dryer from electrical power supply, use ON/OFF switch to stop the

dryer. Otherwise wait 10 minutes before switching the dryer on again, in order to allow freon

pressure to rebalance.

4. MAINTENANCE, TROUBLESHOOTING AND DECOMMISSIONING

4.1 MAINTENANCE

Before attempting any maintenance operation, make sure that:

1. No parts of the system are under pressure.

2. No parts of the system are electrically powered.

Î WEEKLY OR EVERY 40 HOURS OF OPERATION

Verify the temperature on the control panel display is acceptable.

Visually check if the condensate is drained regularly.

Î MONTHLY OR EVERY 200 HOURS OF OPERATION

Clean the condenser with compressed air, taking care not to damage the condenser fins..

At the end of the above mentioned operations, check if the dryer is working properly.

Check the condition of any filters installed with the dryer. Replace elements as needed.

Î YEARLY OR EVERY 2000 HOURS OF OPERATION

Check if the flexible tube used for condensate drainage is damaged and replace it if necessary.

Check if all connecting pipes are properly tightened and fixed.

At the end of the above mentioned operations, check if the dryer is working properly.

4.2 TROUBLESHOOTING

NOTE: FOLLOWING BEHAVIORS ARE NORMAL CHARACTERISTIC OF OPERATION AND NOT TROUBLES

• Variable speed of the fan.

• Display of message ESA and ES2 in case of operation without load or low load.

• A 2 minute delay for dryer to start after pressing the on/off switch.

Troubleshooting and eventual control and/or maintenance operations must be performed

by qualified personnel.

For maintaining the refrigerating circuit of the machine, contact a refrigeration engineer.

Cod. 710.0138.39.00 Rev1A – 05.2008 8 - 28

Page 10

TROUBLE DISPLAY POSSIBLE CAUSE REMEDY

No power in the line. Restore the power in the line.

Problems with cabling. Check cabling; if the trouble persists, replace it.

Control

panel

display is

blank

Problems with the electronic control

board.

Check the electronic control board; if the trouble

persists, replace it.

The dryer is off.

Turn it on by pressing the ON/OFF switch for 1

second.

Dryer in stand-by. Wait 2 minutes after the dryer is switched on.

Compressed air inlet/outlet inverted.

Check if the compressed air inlet/outlet is connected

properly.

The flow rate and/or temperature of the

air entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than

the nominal values.

Restore the nominal conditions.

The condenser is dirty. Clean the condenser.

Clean the condensate drainage system pre-filter.

(Pic.3)

Replace the coil of the drainage solenoid valve if

burned.

Clean or replace the drainage solenoid valve if

clogged/jammed.

Condensate drain is not functioning.

Check the C8 and C9 parameters of the electronic

control board; if the trouble persists, replace it.

The temperature control probe is

positioned improperly or faulty.

Check the probe; if the trouble persists, replace it.

Problems with cabling or with the

electronic control board.

Check the cabling and the electronic control board, if

the trouble persists, replace them.

Activation of compressor’s internal

thermal protection.

Wait one hour and check again. If the fault persists:

stop dryer and call your local Ingersoll Rand

distributor.

Problems with the electrical components

of the compressor.

Check the electrical components of the compressor.

Defective compressor. Replace the compressor.

The flow rate and/or temperature of the

air entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than

the nominal values.

Restore the nominal conditions.

The condenser is dirty. Clean the condenser.

The temperature control probe is

positioned improperly or faulty.

Check the probe; if the trouble persists, replace it.

Fan pressure switch defective or burned

out (if present).

Turn off the dryer and call your local Ingersoll Rand

distributor.

High pressure switch defective or burned

out (if present).

Turn off the dryer and call your local Ingersoll Rand

distributor.

Gas leakage in the refrigerating circuit.

Turn off the dryer and call your local Ingersoll Rand

distributor.

Defective fan. Replace the fan.

Protection fuse burned out (if present). Replace the fuse.

The temperature control probe is

positioned improperly or faulty.

Check the probe; if the trouble persists, replace it.

Gas leakage in the refrigerating circuit

without load.

Turn off the dryer and call your local Ingersoll Rand

distributor.

The temperature control probe is

positioned improperly or faulty.

Check the probe; if the trouble persists, replace it.

WATER IN THE SYSTEM

Series of alarms very close to each

other.

Call your local Ingersoll Rand distributor.

Cod. 710.0138.39.00 Rev1A – 05.2008 9 - 28

Page 11

Check the probe; if the trouble persists, replace it.

Check the electronic control board; if the trouble

persists, replace it.

Ice formation in the evaporator.

Contact our Service Centre to check the gas charge.

Check if the compressed air inlet/outlet is connected

properly.

Check if the connecting tubing is clogged; in case

proceed accordingly.

Check if any valves are closed.

Clog.

Check the condition of any filter.

Drainage solenoid valve jammed, clean or replace it.

Verify the condensate drainage times set on the

electronic control board (C8 and C9).

LOW PRESSURE IN THE LINE

Air flows continuously through the

condensate drainage.

Check the signal from the control board: if it is

continuous, replace the control board.

TROUBLE DISPLAY POSSIBLE CAUSE REMEDY

IMPORTANT:

The temperature control probe is extremely delicate. Do not remove the probe from its position. In case

of any kind of problem, please contact your local Ingersoll Rand distributor

Pic.3

4.3 DECOMMISSIONING

In case of necessity, decommission the machine and the relevant packaging in compliance with the

rules locally in force.

Pay particular attention to the refrigerant, as it contains part of the refrigerating compressor lubricating

oil.

Always contact a waste disposal and recycling facility.

Cod. 710.0138.39.00 Rev1A – 05.2008 10 - 28

Page 12

- FR -

PREAMBULE

Le présent manuel fait partie intégrante du séchoir que vous venez d'acheter et doit toujours accompagner la machine,

même en cas de revente de cette dernière.

Il est indispensable que le personnel spécialisé* chargé des opérations d'installation, d'entretien et/ou de contrôle observe

scrupuleusement les consignes données dans ce manuel ainsi que les normes de prévention et de sécurité en vigueur dans le

pays d'utilisation. Telles sont les conditions pour un usage rationnel et une exploitation rentable de la machine.

En cas de problème avec votre séchoir, n'hésitez pas à consulter votre revendeur Ingersoll Rand local autorisé.

En cas de nécessité, à noter que l'utilisation de pièces détachées originales garantit l'efficacité et la longévité de votre

séchoir.

En raison de l'évolution constante sur le plan technique, Ingersoll Rand se réserve le droit de modifier sans préavis les

spécifications figurant dans le présent manuel.

SYMBOLES UTILISES DANS LE MANUEL ET SUR LE SECHOIR

ou ou ou

Point d'entrée

de l'air.

ou ou ou

Point de sortie

de l'air.

Lire le manuel des opérateurs avant la mise

en service et avant toute intervention sur la

machine.

Faire particulièrement attention: composant ou

installation sous pression.

Faire particulièrement attention aux

indications précédées par ce symbole.

Faire particulièrement attention: surface chaude.

Les opérations d’installation, d'entretien

et/ou de contrôle précédées par ce symbole

doivent être effectuées exclusivement par du

personnel spécialisé*.

Faire particulièrement attention: risque de

décharge électrique.

Point d'évacuation des condensants.

Sens de rotation du moteur du ventilateur.

Attention: n'effectuer aucune

opération d'entretien sur cette

machine sans avoir coupé

l'alimentation électrique, avoir purgé

complètement l'air sous pression et

consulté le manuel des opérateurs.

* Le personnel qualifié doit être formé et certifié conformément aux lois et aux règlements locaux.

GARANTIE

La société garantit que l’équipement qu’elle fabrique et qui est fourni ici est exempt de défauts matériels et de maind’œuvre pour une durée de douze mois à compter de la date de mise en service de l’équipement ou de dix-huit mois à

compter de la date d’expédition de l’usine, selon le premier terme arrivé à échéance. L’acheteur doit être obligé à signaler

rapidement toute non-conformité à cette garantie, en écrivant à la société dans le délai susmentionné, sur quoi la société devra,

à sa discrétion, corriger cette non-conformité en effectuant une réparation appropriée de cet équipement ou fournir une pièce de

rechange F.A.B. au point d’expédition, à condition que l’acheteur ait stocké, installé, entretenu et utilisé cet équipement

conformément aux bonnes pratiques du secteur et qu’il ait respecté les recommandations spécifiques de la société. Les

accessoires ou l’équipement fourni par la société, mais fabriqué par des tiers, doit reporter toutes les garanties que les

fabricants ont transmises à la société et qui peuvent être transmises à l’acheteur. La société ne peut être tenue responsable des

réparations, remplacements ou ajustement de l’équipement ou de tout coût de main-d’œuvre soutenu par l’acheteur ou des tiers

pour sans l’accord écrit préalable de la société.

Les effets de corrosion, érosion et l’usure normale sont spécifiquement exclus. Les garanties de performance se limitent à

celles spécifiquement mentionnées dans la proposition de la société. Les obligations de la société doivent être de corriger de la

façon et durant la période indiquée ci-dessus sauf si la responsabilité d’obtention de ces garanties de performance est limitée

aux tests spécifiés.

Cod. 710.0138.39.00 Rev1A – 05.2008 11 - 28

Page 13

LA SOCIÉTÉ N’ACCORDE AUCUNE AUTRE GARANTIE OU REPRÉSENTATION D’AUCUNE SORTE, EXPLICITE OU

IMPLICITE, A L’EXCEPTION DE LA GARANTIE EN OBJET ET TOUTES LES GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D’APTITUDE A UNE UTILISATION SPÉCIFIQUE, SONT PAR CONSÉQUENT REFUSÉES.

La correction par la société des non-conformités évidentes ou cachées, de la façon et pour la période de temps indiquées cidessus, doit constituer l’accomplissement de toutes les responsabilités de la société pour ces non-conformités qu’elles soient

basées sur contrat, négligence de garantie, indemnité, responsabilité stricte ou en rapport avec ou provenant de cet

équipement.

L’acheteur ne doit pas utiliser l’équipement s’il est considéré comme défectueux sans avoir préalablement averti la société

par écrit de sont intention. Une telle utilisation de l’équipement s’effectue sous la seule responsabilité de l’acheteur.

Veuillez noter qu’il s’agit d’une garantie standard d’Ingersoll Rand. Toute garantie en vigueur au moment de l’achat de

l’équipement ou négociée en tant que partie de l'achat possède la priorité sur cette garantie.

1. INFORMATIONS GENERALES

1.1 DESCRIPTION FONCTIONNELLE

Les séchoirs à air Ingersoll Rand éliminent l’humidité de l’air comprimé. L’humidité nuit aux appareils, commandes, instruments,

machines et outils à actionnement pneumatique.

L'air comprimé entre dans l'échangeur de chaleur breveté en aluminium dans lequel il est refroidi en deux étapes jusqu'à ce que

la température de l'air atteigne son point de condensation: dans le premier secteur air-air, l'air comprimé entrant est refroidi

grâce au contre-courant d'air froid comprimé provenant du séparateur de condensat. Dans le deuxième secteur air-air

réfrigérant, la température de l'air comprimé est de nouveau abaissée jusqu'à l'obtention de la température de point de

condensation. Durant ces deux étapes, la quasi totalité de la vapeur d'eau et d'huile contenue dans l'air comprimé s'est

condensée en liquide et a été ensuite séparée de l'air comprimé dans le séparateur de condensat pour enfin être rejetée par

l'évacuation automatique. A ce stade, l'air refroidi obtenu entre de nouveau à contre courant dans l'échangeur air-air initial et est

réchauffé par l'air chaud entrant, provoquant ainsi une récupération d'énergie et une réduction de l'humidité ambiante contenue

dans l'air sortant.

Ce séchoir peut être facilement installé dans différents systèmes pneumatiques qui nécessitent de l’air sec. Veuillez vous référer

aux principes de fonctionnement pour obtenir tous les détails sur le fonctionnement.

Le séchoir est déjà équipé de tous les dispositifs de contrôle, de sécurité et de réglage. Il n'a donc pas besoin de

dispositifs auxiliaires.

Une surcharge de l'installation dans les limites d'utilisation maximum entraîne une diminution des prestations du

séchoir (point de rosée élevé) mais ne nuit pas à la sécurité.

Le circuit électrique (annexe B) a un degré de protection minimum IP 42.

Merci de noter que une mise à terre incorrecte peut provoquer des chocs électriques et causer pourtant décès et

blessures graves.

Les séchoirs doivent être raccordés à un système de câblage à terre, en métal et permanent, ou au équipement des

bornes à terre, ou au conducteur isolé du séchoir..

Toutes opérations de mise à terre doivent être remplies par électriciens compétents conformément aux lois

nationaux et locales. Dans le cas de court-circuit, la mise à terre réduit le risqué de choc électrique permettant

l’échappement du courant.

La mise à terre doit être effectuée par câble dénudé à terre conformément aux voltage et qualités requise minimes

du branche du circuit.

S’assurer que les éléments métalliques dénudés soient raccordés aux points de mise à terre, vérifier que les

connexions soient propres et fermes.

Vérifier les connexions à terre après la première installation et effectuer les vérifications périodiques à fin d’assurer

que le contact et la continuité soient gardés.

Si les indications de mise à terre ne sont pas claires ou s’il y a des doutes sur la propriété de la mise à terre du

produit, consulter un électricien compètent ou un technicien du service .

1.2 UTILISATION DU SECHOIR EN TOUTE SECURITE

Cette installation a été conçue et réalisée conformément aux directives européennes en vigueur. En conséquence de quoi,

toutes les opérations d'installation, d'utilisation et d'entretien doivent être effectuées conformément aux consignes données dans

le présent manuel.

Le séchoir d’air est sous pression et contient des pièces rotatives. Il faut donc prendre les mêmes précautions que pour une

machine du même genre pour laquelle une négligence lors de l’utilisation ou de l’entretien peut être dangereuse pour le

personnel. Les précautions de sécurité ci-dessous doivent être observées en plus des règles de sécurité évidentes qui doivent

être respectées avec ce type de machine.

1. Seul le personnel qualifié doit être autorisé à ajuster, effectuer l’entretien ou réparer ce séchoir d’air.

2. Lisez intégralement les instructions avant d’utiliser cet appareil.

3. Tirez l’interrupteur de déconnexion électrique et débranchez toutes les lignes de commande

séparées, le cas échéant, avant de travailler ou d’effectuer l’entretien sur l’appareil.

4. N’essayez jamais de réparer une pièce de la machine si cette dernière est en fonction.

5. N’essayez jamais de retirer une pièce sans avoir au préalable purgé l’air du système de pression.

6. N’essayez jamais de retirer une pièce du système de réfrigération sans avoir retiré et stocké le

frigorigène conformément aux règlements locaux et de l’APE.

7. N’utilisez pas le séchoir à une pression dépassant la pression nominale.

8. N’utilisez pas le séchoir si toutes les protections ne sont pas en place.

9. Inspectez l’appareil tous les jours afin de vérifier et de corriger toute condition de fonctionnement

dangereuse.

Cod. 710.0138.39.00 Rev1A – 05.2008 12 - 28

Page 14

2. INSTALLATION

2.1 RECEPTION ET TRANSPORT

Lors de la réception de votre séchoir d’air Ingersoll Rand, veuillez vérifier attentivement l’appareil. Si vous remarquez des

signes de manutention brusque, veuillez les noter sur le bordereau de livraison, en particulier si le séchoir n’est pas

déballé immédiatement. L’obtention de la signature du livreur pour convenir des dommages remarqués facilitera toute

demande d’assurance par le client.

Il est indispensable de maintenir le séchoir toujours en position verticale comme indiqué par les symboles sur l'emballage

et de le déplacer avec un dispositif ayant une portée suffisante pour le poids de la machine.

Déballer le séchoir après l'avoir déposé sur le lieu d'installation. Il est conseillé de conserver l'emballage original pendant

au moins toute la durée de la garantie de la machine ; A noter toutefois que l'élimination de chaque matériau d'emballage

doit être effectuée conformément à la réglementation en vigueur dans le pays d'utilisation.

Si le séchoir n'est utilisé pas dans l'immédiat, il peut être entreposé emballé dans un lieu fermé, non poussiéreux, à une

température entre 32°F et 120°F et une humidité inférieure à 90 %. Si le stockage doit durer pendant plus de 12 mois,

contacter votre revendeur Ingersoll Rand local autorisé.

Il ne faut en aucun cas tenter de soulever des objets lourds sans un équipement de levage approprié (grue, palan, élingue

ou chariot à fourches). Le levage de tout appareil sans un équipement de levage approprié peut entraîner de graves

blessures. Utilisez les glissières pour chariot à fourches le cas échéant.

2.2 LIEU D'INSTALLATION

Il est nécessaire de préparer le lieu d'installation du séchoir en tenant compte des critères suivants :

La machine devra être protégée contre les agents atmosphériques et contre la lumière directe du

soleil.

Base d'appui plat et en mesure de supporter le poids de la machine.

Température ambiante conforme aux données figurant sur la plaque du séchoir.

Le séchoir doit être placé dans un lieu propre, sans installation de ventilation forcée pouvant affecter

le système de commande du ventilateur.

Garantir suffisamment d'espace libre autour du séchoir (20 inches, 500 mm) pour permettre le

refroidissement correct de la machine et pour les opérations d'entretien et/ou de contrôle.

L’air aspiré doit être exempt de fumées ou de vapeurs inflammables susceptibles d'entraîner un risque

d'explosion ou d'incendie.

2.3 INSTALLATION

Avant toute opération d'installation, s'assurer que :

L’installation ne présente par de parties sous pression.

L’installation ne présente pas de parties sous tension.

Les conduites à raccorder le séchoir sont exemptes d'impuretés.

Toutes les tuyauteries raccordées ont été serrées.

Après avoir vérifié les points ci-dessus, il est possible de procéder à l'installation de la machine :

1. Raccorder le séchoir à la ligne d'air comprimé. L'installation d'un groupe by-pass est conseillée

(s'il est absent) car il permet d'isoler la machine de l'installation pour faciliter d'éventuelles

opérations d'entretien.

2. Effectuez les branchements électriques conformément aux lois et aux règlements locaux après

avoir consulté les spécifications électriques et le schéma de câblage du séchoir.

3. Vérifier le groupe de purge des condensants et raccorder le flexible d'évacuation à la ligne de

drainage en se rappelant du fait que les condensants séparés du séchoir contiennent des

particules d'huile ; Pour les éliminer conformément à la réglementation en vigueur dans le

pays d'utilisation, il est par conséquent conseillé d'installer un séparateur eau-huile d'une

capacité appropriée.

4. Alimenter le séchoir après s'être assuré que la tension de référence et la fréquence du réseau

électrique sont constantes et correspondent aux spécifications de référence de la machine. C'est

à l'utilisateur qu'il revient d'équiper l'installation d'un dispositif de protection de ligne et de

prise de terre conforme à la réglementation électrique en vigueur dans le pays d'utilisation.

Pour optimiser l'utilisation du séchoir, il est conseillé de l'orienter de façon à ce que tous les instruments

de contrôle de la machine soient facilement lisibles.

Un filtre correctement dimensionné doit être installé avant le séchoir. L’absence d’installation ou

d’entretien d’un filtre correct annule la garantie. Les mailles de ce filtre doivent être d’au moins 10 microns.

Cod. 710.0138.39.00 Rev1A – 05.2008 13 - 28

Page 15

3. MISE EN SERVICE

S'assurer que le sécheur est activé, et que le refroidisseur n'est pas en condition de travail.

Activer le commutateur sur la commande d'isolation électrique principale (si présent). Le panneau de commande affichera le message

OFF, indiquant que la tension de ligne et de contrôle est activée.

Séquence de démarrage

Le sécheur devra tout d'abord être mis en marche en pressant le bouton ON/OFF situé sur celui-ci pendant 1 seconde. La séquence de

démarrage ne continuera qu'en cas d'absence de toute alarme active. Le moteur du compresseur se mettra en marche APRES 120

SECONDES. Concernant les modèles D300-360IN, le moteur du ventilateur et le compresseur démarreront simultanément, alors qu'il

faudra compter 30 secondes entre les deux démarrages pour les plus petits modèles.

Séquence d'arrêt

Le sécheur peut être arrêté localement à partir du panneau de commande. Après avoir pressé le bouton ON/OFF pendant 1 seconde,

le compresseur et le moteur du ventilateur vont continuer à fonctionner pendant encore 10 secondes de façon à rééquilibrer la pression

interne. Le sécheur peut être également arrêté en raison d'une alarme ou d'une condition de conservation d'énergie (ESA ou ES2).

N'importe quelle alarme entraînera la coupure de l'alimentation électrique du compresseur, il est possible que le moteur du ventilateur

continue à fonctionner en fonction du type d'alarme (voir le Chapitre des indications de l'écran). Si l'interruption est due à une alarme, un

message clignotera sur l'écran en indiquant la raison de l'arrêt. Une condition de conservation d'énergie (ESA ou ES2) se produit lorsque

le point de condensation reste en dessous de la valeur de réglage pendant une longue période de façon à conserver l'énergie et à

éviter que l'échangeur de chaleur ne gèle. Cette situation peut survenir lorsque la température ambiante est basse et qu'il n'y a pas de

traitement d'air comprimé.

Commande de variation de vitesse du ventilateur

Un microprocesseur breveté permet d'ajuster la capacité de refroidissement du sécheur en variant la vitesse du moteur du ventilateur.

Si le point de condensation est plus élevé que la valeur de réglage, la vitesse de ventilation augmente, en revanche, si le point de

condensation est plus bas, la vitesse de ventilation diminue. Le niveau de vitesse peut aller de 0 à 100%, et la vitesse de clignotement

de la LED correspond à celle du ventilateur, il est possible de lire la valeur exacte en pressant le bouton HAUT. Si la vitesse est à

100%, le message FL ("Full Load", Pleine charge) s'affichera. En condition standard de travail, la vitesse de ventilation est

habituellement à 100%, en cas d'absence de travail, la vitesse de ventilation peut varier entre 0 et 20%. Dans les modèles D300-360IN,

une soupape de dérivation de gaz chaud fonctionne en collaboration avec le système de variation de vitesse.

3.1 PUPITRE DE COMMANDE

Les machines faisant partie de cette série sont équipées d'un système électronique de modification des paramètres ; Les éventuelles

opérations de réinitialisation peuvent en effet être effectuées à l'aide du pupitre numérique se trouvant sur la façade du séchoir.

Le pupitre de commande se compose de 5 touches (ON/OFF, TEST, SET, DOWN et UP) et par un afficheur à 3 chiffres avec trois

diodes électroluminescentes de signalisation indiquées par icônes (Fig. 1)

Le bon fonctionnement de la machine peut être contrôlé à l'aide du pupitre de commande illustré ci-dessous.

Fig. 1

ECRAN D AFFICHAGE ET DIODES ELECTROLUMINESCENTES DE SIGNALISATION

DISPLAY DESCRIPTION

Indique que le sécheur est en marche à

faible charge

Indique que le sécheur est en marche à

charge normale

Indique que l le sécheur est en marche à

charge moyenne;

Indique que le sécheur est en marche à

pleine charge

LED STATUS DESCRIPTION

Allumée

Compresseur active

Clignotant

Modalité programmation

Allumée

Purge de condesants active

Allumée

Vitesse ventilateur = 100%

Clignotant

Vitesse ventilateur < 100%

Eteint

Ventilateur ne pas courir

Cod. 710.0138.39.00 Rev1A – 05.2008 14 - 28

Page 16

3.1.1 FONCTION DES TOUCHES

TEST: Lorsqu'on appuie dessus pendant 3 secondes lors du fonctionnement normal, elle permet d'activer un

cycle de purge des condensants.

SET: Si l'on appuie dessus pendant le fonctionnement normal, elle affiche la valeur du point de consigne.

Maintenu sous pression pendant 10 secondes, elle permet l'accès au menu de programmation des paramètres

(Voir le tableau correspondant).

Si l'on appuie dessus après avoir programmé de nouvelles valeurs de configuration et du point de consigne, elle

mémorise les variations apportées.

DOWN: Si l'on appuie dessus pendant le paramétrage du point de consigne ou des paramètres de

configuration, elle diminue la valeur affichée sur l'afficheur d'une unité par seconde, pendant les 10 premières

secondes de pression, et ensuite d'une unité toutes les 0,1 secondes.

Si l'on appuie dessus pendant 10 secondes pendant le fonctionnement normal, elle fait démarrer le cycle de test

automatique du contrôleur.

UP: Si l'on appuie dessus pendant le paramétrage du point de consigne ou des paramètres de configuration,

elle augmente la valeur affichée sur l'afficheur d'une unité par seconde, pendant les 10 premières secondes de

pression, et ensuite d'une unité toutes les 0,1 secondes.

ON / OFF: Appuyer sur la touche pendant 1 seconde active ou désactive le processus. Lorsque le processus est

désactivé, l'afficheur affiche le message OFF.

ATTENTION: lorsque la carte électronique indique OFF, plusieurs composants du sécheur reste sous tension.

Donc, pour des raisons de sécurité, il est impératif de couper l'alimentation électrique du sécheur avant toute

opération sur celui-ci.

3.1.2 CONTROLE ET MODIFICATION DES PARAMETRES DE CONFIGURATION

Appuyer sur SET pendant 10 secondes pour l'entrée dans le menu de programmation des

paramètres : l'afficheur affiche dans l'ordre la valeur du point de consigne, le code du premier

paramètre modifiable E1 et sa valeur.

Utiliser les touches UP et/ou DOWN pour modifier, seulement si cela est strictement nécessaire, la

valeur du paramètre affiché.

Appuyer sur la touche SET pour mémoriser la valeur du paramètre préalablement modifié ou pour

faire défiler les paramètres sans les modifier.

Passé un laps de temps de 15 secondes après la dernière opération effectuée, le contrôleur se

remet automatiquement en mode de fonctionnement normal.

PARAMETRE DESCRIPTION PLAGE VALEUR REGLEE

C8

Retard entre les purges de

condensants

1 ÷ 999 (min)

1

D12-144IN D180IN D300-360IN

C9

Durée de purge des

condensants

1 ÷ 999 (sec)

1 2 3

AVERTISSEMENT POUR L’UTILISATEUR :

IL EST INTERDIT DE MODIFIER LES PARAMETRES DE CONFIGURATION RESTANTS DU CONTROLEUR

ELECTRONIQUE SANS L'AUTORISATION DU FOURNISSEUR.

Cod. 710.0138.39.00 Rev1A – 05.2008 15 - 28

Page 17

3.1.3 SIGNALISATION D'ANOMALIES

Le contrôleur est en mesure de reconnaître des types d’anomalies déterminés du circuit de séchage qui entraîne

l’affichage d’un message d’alarme clignotant sur l’écran alterné à la valeur courante du point de condensation.

MESSAGE

(CLIGNOTANT)

CAUSE SORTIES ACTIONS

HtA

Point de condensation élevé

(alarme retardée)

Ht2

Point de condensation très

élevé

(alarme immédiate)

Sortie alarme active

Sortie compresseur inactive

Sortie ventilateur active

Sortie évacuation standard

Réinitialisation par extinction de la

centrale lorsque le point de

condensation rentre dans la plage

préprogrammée.

Si le problème persiste, contacter

votre revendeur Ingersoll Rand local

autorisé.

LtA

Point de condensation bas

Sortie alarme active

Sortie compresseur inactive

Sortie ventilateur inactive

Sortie évacuation standard

Réinitialisation automatique si le point

de condensation rentre dans la plage

préprogrammée.

Si le problème persiste, contacter

votre revendeur Ingersoll Rand local

autorisé.

PF1

Interruption ou court-circuit

de la ligne d’entrée de la

sonde PTC

Sortie alarme active

Sortie compresseur inactive

Sortie ventilateur inactive

Sortie évacuation standard

Réinitialisation après remplacement

de la sonde et extinction de la

centrale.

Contacter le votre revendeur Ingersoll

Rand local autorisé.

ESA

ES2

Option d’économie d’énergie

active

Sortie alarme active

Sortie compresseur inactive

Sortie ventilateur inactive

Sortie évacuation standard

Aucune réinitialisation automatique.

ASt

Série d'alarme proche les

unes des autres

Sortie alarme active

Sortie compresseur inactive

Sortie ventilateur active

Sortie évacuation standard

Contacter le votre revendeur Ingersoll

Rand local autorisé.

REMARQUE : PF1 a la priorité sur tous les autres messages d’alarme.

3.1.4 SIGNALISATION D’ALARME Á DISTANCE

La centrale du séchoir est dotée d’une sortie numérique pour la signalisation à distance de

conditions d’alarme détectées. La sortie est commandée par un relais qui, en présence d’une

alarme, ferme le circuit.

Intervenir comme suit afin de prédisposer un avertisseur d’alarme à distance :

1. Se procurer un avertisseur conforme aux caractéristiques électriques de la sortie (bobine,

lampe, sirène, etc.).

2. Débrancher le séchoir de l’alimentation, relever le couvercle ainsi que le tableau latéral.

3. Brancher l’avertisseur aux bornes indiquées à la fig.2

4. Remettez le couvercle et le panneau latéral gauche en place et rebranchez l’alimentation.

Caractéristiques de la sortie de

l’alarme :

Max. 250VAC / 3A – c.a 15 (inductifs)

fig.2

L’activation de cette fonction est à discrétion de l’utilisateur qui devra fournir le matériel nécessaire de

façon autonome. Les opérations d’installation devront être effectuées par un personnel qualifié.

Cod. 710.0138.39.00 Rev1A – 05.2008 16 - 28

Page 18

3.2 OPERATIONS PRELIMINAIRES A LA MISE EN MARCHE

Avant de mettre la machine en service, s'assurer que tous les paramètres de fonctionnement sont

conformes aux spécifications de référence.

Le séchoir est fourni déjà testé et préréglé pour un fonctionnement normal et n'a besoin, par conséquent,

d'aucun étalonnage ; il convient toutefois de vérifier son bon fonctionnement pendant les premières heures

de travail.

3.3 MISE EN MARCHE

Les opérations ci-dessous doivent être effectuées lors de la première mise en marche et à chaque remise en

marche après un arrêt prolongé de la machine.

1. Vérifier que toutes les consignes des chapitres LIEU D'INSTALLATION et INSTALLATION ont bien

été observées.

2. Vérifier que le by-pass (si présent) n'est pas ouvert.

3. Pour enclencher l’alimentation électrique, appuyer le bouton lumineux ON/OFF pendant 1 seconde

au moins sur le système de commande (veuillez noter qu’il y a un délai de 2 minutes avant le

démarrage du séchoir une fois qu’il est mis en marche).

4. Attendre 5 à 10 minutes, jusqu’à ce que la machine ait atteint ses paramètres de fonctionnement

standard.

5. Ouvrir lentement la soupape de sortie de l'air et ensuite, toujours lentement, celle d'entrée de l'air.

6. Fermer le by-pass (si présent).

7. Vérifier le bon fonctionnement du système de purge des condensants.

8. Vérifier le bon serrage et la fixation de toutes les conduites de raccordement.

Avant de couper l’alimentation électrique, arrêter le sécheur à l’aide de la touche ON/OFF

(MARCHE/ARRET) sinon, attendre 10 minutes avant de rallumer le sécheur pour permettre un

rééquilibrage des pressions.

4. ENTRETIEN, RECHERCHE DES PANNES ET DEMANTELEMENT

4.1 ENTRETIEN

Avant d'effectuer toute opération d'entretien, s'assurer que :

1. L’installation n'a pas de parties sous pression.

2. L’installation n'a pas de parties sous tension.

Î UNE FOIS PAR SEMAINE OU TOUTES LES 40 HEURES DE FONCTIONNEMENT

Vérifiez la température sur l'affichage du panneau de commande est acceptable.

S'assurer visuellement que les condensants sont bien évacués.

Î UNE FOIS PAR MOIS OU TOUTES LES 200 HEURES DE FONCTIONNEMENT

Nettoyer le condenseur avec un jet d'air comprimé en faisant attention à ne pas détériorer les

ailettes en aluminium de la batterie de refroidissement.

Nettoyer le préfiltre du système de purge des condensants de façon à éliminer les éventuelles

impuretés s'étant déposées sur la grille interne. Faire particulièrement attention lors du remontage.

Vérifiez les conditions de tous les filtres installés avec le séchoir. Remplacez les éléments au besoin

Î UNE FOIS PAR AN ET TOUTES LES 2000 HEURES DE FONCTIONNEMENT

S'assurer du bon état du flexible d'évacuation des condensants et le remplacer éventuellement.

Vérifier le bon serrage et la bonne fixation de toutes les conduites de raccordement.

Vérifier le bon fonctionnement du séchoir après avoir terminé les opérations précitées.

4.2 RECHERCHE DES PANNES

NOTE: LES AFFICHAGES SUIVANTS SONT LIES AU BON FONCTIONNEMENT DU SECHEUR. IL NE S'AGIT PAS

DE DEFAUTS.

• Clignotement de la sortie ventilateur, le ventilateur fonctionne à vitesse variable.

• Affichage de ESA et ES2 si le sécheur n'est pas sollicité.

• Le démarrage du séchoir s’effectue au bout de 2 minutes après l’appui sur l’interrupteur marche/arrêt.

A recherche des pannes et les éventuelles interventions de contrôle et/ou d'entretien doivent

être effectuées par du personnel spécialisé.

Contacter un technicien frigoriste pour toute intervention sur le circuit frigorifique de la machine.

Cod. 710.0138.39.00 Rev1A – 05.2008

17 - 28

Page 19

PROBLÈME AFFICHAGE CAUSE POSSIBLE REMÈDE

Pas d’alimentation sur la ligne. Rétablissez l’alimentation de la ligne.

Problème de câblage.

Vérifiez le câblage et remplacez-le si le problème

persiste.

L’afficheur

du panneau

de

commande

est vide

Problème avec la carte de commande

électronique.

Vérifiez la carte de commande électronique et

remplacez-la si le problème persiste.

Le séchoir est arrêté.

Mettez-le en marche en appuyant sur l’interrupteur

MARCHE/ARRÊT pendant 1 seconde.

Le séchoir est en veille.

Attendez 2 minutes après avoir mis en marche le

séchoir.

L’entrée et la sortie de l’air comprimé sont

inversées.

Vérifiez que l’entrée et la sortie de l’air comprimé

sont branchées correctement.

Le débit ou la température de l’air entrant

dans le séchoir sont supérieurs aux valeurs

nominales.

Rétablissez les conditions nominales.

La température ambiante est supérieure à la

valeur nominale.

Rétablissez les conditions nominales.

Le condenseur est sale. Nettoyez le condenseur.

Nettoyez le filtre du système d’évacuation de la

condensation (Fig.3)

Remplacez la bobine de l’électrovanne de

l’évacuation si elle est grillée.

Nettoyez ou remplacez l’électrovanne de

l’évacuation si elle est engorgée/bloquée.

L’évacuation de la condensation ne

fonctionne pas.

Vérifiez les paramètres C8 et C9 de la carte de

commande électronique et remplacez la carte de

commande si le problème persiste.

La sonde de contrôle de température est mal

positionnée ou défectueuse.

Vérifiez la sonde et remplacez-la si le problème

persiste.

Problème de câblage ou avec la carte de

commande électronique.

Vérifiez le câblage et la carte de commande

électronique, remplacez-les si le problème persiste.

Activation de la protection thermique interne

du compresseur.

Attendez une heure, puis vérifiez à nouveau. Si la

panne persiste, arrêtez le séchoir et contactez votre

revendeur Ingersoll Rand local.

Problème avec les composants électriques du

compresseur.

Vérifiez les composants électriques du compresseur

.

Compresseur défectueux. Remplacez le compresseur.

Le débit ou la température de l’air entrant

dans le séchoir sont supérieurs aux valeurs

nominales.

Rétablissez les conditions nominales.

La température ambiante est supérieure à la

valeur nominale.

Rétablissez les conditions nominales.

Le condenseur est sale. Nettoyez le condenseur.

La sonde de contrôle de température est mal

positionnée ou défectueuse.

Vérifiez la sonde et remplacez-la si le problème

persiste.

Pressostat du ventilateur défectueux ou grillé

(si présent).

Arrêtez le séchoir et contactez votre revendeur

Ingersoll Rand local.

Pressostat de haute pression défectueux ou

grillé (si présent).

Arrêtez le séchoir et contactez votre revendeur

Ingersoll Rand local.

Fuite de gaz dans le circuit réfrigérant.

Arrêtez le séchoir et contactez votre revendeur

Ingersoll Rand local.

Ventilateur défectueux. Remplacez le ventilateur.

Fusible de protection grillé (si présent). Remplacez le fusible.

La sonde de contrôle de température est mal

positionnée ou défectueuse.

Vérifiez la sonde et remplacez-la si le problème

persiste.

Fuite de gaz dans le circuit réfrigérant sans

charge.

Arrêtez le séchoir et contactez votre revendeur

Ingersoll Rand local.

La sonde de contrôle de température est mal

positionnée ou défectueuse.

Vérifiez la sonde et remplacez-la si le problème

persiste.

EAU DANS LE SYSTÈME

Série d’alarmes très proche les unes des

autres.

Contactez votre revendeur Ingersoll Rand local.

Cod. 710.0138.39.00 Rev1A – 05.2008 18 - 28

Page 20

PROBLÈME AFFICHAGE CAUSE POSSIBLE REMÈDE

Vérifiez la sonde et remplacez-la si le problème

persiste.

Vérifiez la carte de commande électronique et

remplacez-la si le problème persiste.

Formation de givre dans l’évaporateur.

Contactez notre service après-vente pour vérifier la

charge de gaz.

Vérifiez que l’entrée et la sortie de l’air comprimé

sont branchées correctement.

Contrôlez si le tuyau de raccordement est engorgé

et agissez en conséquence si c’est le cas.

Vérifiez l’ouverture des robinets.

Engorgement.

Vérifiez les conditions des filtres.

Électrovanne d’évacuation bloquée. Nettoyez-la ou

remplacez-la.

Vérifiez les temps d’évacuation de la condensation

réglés sur la carte de commande électronique (C8 et

C9).

PRESSION FAIBLE DANS LA LIGNE

L’air s’écoule en permanence à travers

l’évacuation de la condensation.

Vérifiez le signal provenant de la carte de

commande : s’il est continu, remplacez la carte de

commande.

IMPORTANT :

La sonde de température est extrêmement fragile. Ne pas détacher ou enlever la sonde de son siège. Pour tout

problème, contacter de toute urgence le votre revendeur Ingersoll Rand local autorisé.

fig.3

4.3 DEMANTELEMENT

En cas de nécessité, éliminer la machine et son emballage conformément aux réglementations

en vigueur dans le pays d'utilisation.

Faire particulièrement attention au réfrigérant car il contient de l'huile lubrifiante du compresseur

frigorifique.

Dans tous les cas, toujours d’adresser aux organismes chargés de l’élimination et du recyclage des

déchets.

Cod. 710.0138.39.00 Rev1A – 05.2008 19 - 28

Page 21

Cod. 710.0138.39.00 Rev1A – 05.2008 20 - 28

ATTACHMENTS TO THIS MANUAL - ANNEXES AU MANUEL

Legend - Légende:

Pos. - GB - DESCRIPTION - F - DESCRIPTION

1A1

Electronic Controller Contrôleur électronique

1B1

Drain solenoid valve coil Bobine électrovalve de décharge

1M1

Refrigerant compressor Compresseur réfrigérant

1M2

Fan Motor Ventilateur

1P1

High pressure Switch Pressostat haute pression

1P2

Fan pressure Switch Pressostat de ventilation

1Q1

Compressor circuit breaker Interrupteur automatique de compresseur

1Q2

Fan circuit breaker Interrupteur automatique de ventilation

1S1

Main power switch Interrupteur général

1S2

Plug Fiche

1T1

Transformer Transformateur

1V1

Solenoid drain Valve Purge de condensants

CB

Compressor box Boîte de compresseur

CBL

Cables câbles

CND

Condenser Condenseur

CNV

Fan capacitor Condenseur de ventilation

CPL

Capillary tube Tubo capillaire

EB

Electrical box Boîte électrique

ED

10 micron filter element Cartouche 10 micron

EH

0.01 micron filter element Cartouche 0.01 micron

EP

1 micron filter element Cartouche 1 micron

EQ

5 micron filter element Cartouche 5 micron

EVA

Evaporator Evaporateur

F1 – F2

Fuses Fusibles

FD

Air filter 10 micron Filtre à air 10 micron

FF

Filter dryer Filtre déshydrateur

FH

Air filter 0.01 micron Filtre à air 0.01 micron

FP

Air filter 1 micron Filtre à air 1 micron

FQ

Air filter 5 micron Filtre à air 5 micron

FR

Drain screen Filtro a red

FV

Fan motor fuse Fusible de ventilateur

G

Grid Grille

IM

Moisture indicator Indicateur d'humidité

K1

Contactor switch Commutat. de conjoncteur

K2

Fan contactor switch Commutat. de conjoncteur de ventilateur

PCP

Thermal protection Protection thermique

PR

Air-air heat exchanger Echangeur air-air

PSC

Air-air heat exchanger (D__IT) Echangeur air-air (D__IT)

RBF

Tap with strainer Valve à bille avec le tamis

RR

Rotalock cock Robinet rotalock

RT1 - RT4

Temperature probes Sondes de température

SC

Heat exchanger base Base de l’échangeur de chaleur

SCO

Condensate separator Séparateur de condensants

SLI

Liquid separator Liquide séparateur

SSC

Condensate drain Purge de condensants

TEMP

Time setter Temporisateur

TH

Thermostat Thermostat

TLT

Remote cont. Thermostat Tele Thermostat digital

VB

By-pass hot gas valve Vanne de fréon

VE

Expansion valve Soupape d’ expansion

VNR

One way valves with strainer Soupape unidirection. / filtre

VT

Fan blade Ventilateur

X1-X2

X3-XM

Terminal blocks Boîte terminale électrique

Page 22

A) REFRIGERANT CIRCUIT - CIRCUIT FRIGORIFÉRIQUE

Cod. 713.0048.04.00 – Rev. 00

Models D12IN to D180IN

Cod. 713.0057.06.00 – Rev. 00

Models D300IN to D360IN

Condensate drain Purge de condensant

Air inlet Entrée de l'air

Air outlet Sortie de l'air

Refrigerant line Ligne réfrigérant

Compressed air line Ligne de l'air comprimé

Condensate drain line Ligne de drainage

Equalization line Ligne de égalization

Cod. 710.0138.39.00 Rev1A – 05.2008 21 - 28

Page 23

B) WIRING DIAGRAM - SCHEMA ÉLECTRIQUE

Cod. 714.0164.01.00 – Rev. 00

Models D12IN to D72IN (115V/1Ph/60Hz)

Cod. 714.0165.01.00 – Rev. 00

Models D108IN to D180IN (115V/1Ph/60Hz)

Cod. 710.0138.39.00 Rev1A – 05.2008 22 - 28

Page 24

Cod. 714.0168.01.00 – Rev. 00

Models D300IN to D360IN (230V/1Ph/60Hz)

Cod. 710.0138.39.00 Rev1A – 05.2008 23 - 28

Page 25

Cod. 710.0138.39.00 Rev1A – 05.2008 24 - 28

C) DATA SHEET - CARACTERISTIQUES TECHNIQUES

MODEL

D12IN D18IN D25IN D42IN D54IN D72IN D108IN D144IN D180IN D300IN D360IN

CFM

7 11 15 25 32 42 64 85 106 176 212

AR

AIR FLOW

RATE*

M3/h

12 18 25 42 54 72 108 144 180 300 360

POW SUPPLY

VOLT/

PH/HZ

115/1/60 230/1/60

HP

1/10 1/10 1/10 1/6 1/4 1/4 1/2 1/2 2/3 1 1

kW

0.16 0.16 0.16 0.21 0.37 0.37 0.48 0.57 0.71 1.25 1.25

Max kW

0.22 0.22 0.22 0.27 0.49 0.49 0.66 0.75 1.14 1.56 1.56

RLA

1.89 1.89 1.89 2.51 4.23 4.23 5.63 6.56 8.16 5.79 5.79

FLA

2.21 2.21 2.21 2.95 5.24 5.24 6.96 7.97 11.6 7.22 7.22

1M1

COMPRESSOR

LRA

18 18 18 23 35 35 34 37 46 44 44

QTY

1 1 1 1 1 1 1 1 1 1 1

HP

1/80 1/80 1/80 1/80 1/80 1/80 1/46 1/46 1/46 2/5 2/5

RLA

0.58 0.58 0.58 0.58 0.58 0.58 1.00 1.00 1.00 1.04 1.04

1M2

FAN MOTOR

LRA

0.76 0.76 0.76 0.76 0.76 0.76 1.36 1.36 1.36 1.35 1.35

TOTAL A A

2.8 2.8 2.8 3.6 6 6 8 9 12.6 8.3 8.3

CONNECTION NPT

½" ½" ½" ½" ½" ½" ¾" ¾" 1" 1½" 1½"

°F

100

AIR T

°C

38

°F

140

AIR T MAX

°C

60

°F

100

AMB T

°C

38

°F

36 - 122

AMB T MIN-MAX

°C

2 - 50

psi

100

AIR W PRESS

bar

7

psi

203 174

AIR PRESS MAX

bar

14 12

°F

< 50 (ISO CLASS 6)

DEW POINT*

°C

< 10 (ISO CLASS 6)

TYPE

R134a

LB

0.31 0.31 0.44 0.62 0.57 0.57 0.77 0.84 0.99 1.87 2.20

OZ

4.94 4.94 7.05 9.88 9.17 9.17 12.35 13.40 15.87 29.98 35.27

REF.

REFRIGERANT

KG

0.14 0.14 0.20 0.28 0.26 0.26 0.35 0.38 0.45 0.85 1.00

MAX FUSE A Not present – Pas présent

15 15

MIN CIRCUIT

AMPACITY

A Not present – Pas présent

10 10

LB

39.7 39.7 39.7 77.2 61.7 61.7 77.2 81.6 103.6 191.8 191.8

W

WEIGHT

KG

18 18 18 27 28 28 35 37 47 87 87

°F

37 - 41

EVAP. TEMP.*

°C

3 – 5

°F

39 - 43

SUCTION

TEMP.*

°C

4 - 6

psig

170 - 230

DISCH. PRESS.*

Bar

12 – 16

psig

435

HP SWITCH

SETTING

Bar

30

*Rating conditions of: 38°C (100°F) and 100 psig Air Inlet, 38°C (100°F) Ambient

*Conditions de fonctionnement de: 38°C (100°F) et 100 psig air en entrée, 38°C (100°F) température ambient

Performance and specifications - Performances et caractéristiques techniques

+ / - 5%

Page 26

Cod. 710.0138.39.00 Rev1A – 05.2008 25 - 28

Legend - Légende:

Pos. - GB - DESCRIPTION - F - DESCRIPTION Pos. - GB - DESCRIPTION - F - DESCRIPTION

AR

Air flow rate Performances

AMB T MIN-

MAX

Min-Max. ambient

temperature

Temp. Ambiante min-

max.

POW SUPPLY

Power supply Alimentation

AIR W PRESS

Air working pressure Pression travail d’air

HP

Nominal power Puissance nom.

AIR PRESS

MAX

Max. air pressure Pression max. d’air

kW

Nominal consumption Consommation nom.

DEWP

Pressure dew point Pression pt de rosée

Max kW

Full load consumption Cons. pleine charge

REF

Refrigerant Réfrigérant

RLA

Nominal Current Ampère nominale

MAX FUSE

max fuse size

Maximum fusibles

FLA

Full load current Ampère pl. charge

MIN CIRCUIT

AMPACITY

minimum circuit

ampacity

Minimum courant

électrique

LRA

Locked rotor current Ampère max.

W

Weight Poids

TOTAL A

Total current Ampère total

EVAP. TEMP

Evaporation

Temperature

Température

d'évaporation

CONNECTION

Air connections Connexion aircomp.

SUCTION TEMP

Suction Temperature

Température

d'aspiration

AIR T

Air inlet temperature Temp. entrée d’air

DISCH. PRESS.

Discharge Pressure Pression de décharge

AIR T MAX

Max. air inlet temperature

Temp. entrée d’air

max.

HP SWITCH

SETTING

High pressure switch

setting

Réglage du pressostat

de haute pression

AMB T

Ambient temperature Temp. ambiante

D) CORRECTION FACTORS - FACTEURS DE CORRECTION

Correction factor for working pressure - Facteur de correction pour la pression du travail

bar

5 6 7 8 9 10 11 12 13 14

psi 73 87 102 116 131 145 160 174 188,5 203

FC1

0,85 0,93 1 1,06 1,11 1,15 1,18 1,2 1,22 1,24

Correction factor for inlet air temperature - Facteur de correction pour la température de l'air d'entrée

°C

26,5 32 37,8 43,5 49 54,5 60

°F 80 90 100 110 120 130 140

FC3

1,3 1,18 1 0,8 0,6 0,42 0,25

Correction factor for ambient temperature- Facteur de correction pour la température ambiante

°C

26,5 32 37,8 40,5 43,5 50

°F 80 90 100 105 110 122

FC2

1,1 1,05 1 0,93 0,83 0,65

Calculation of the dryer REAL FLOW RATE = nominal dryer flow rate x FC1 x FC2 x FC3

Calcul du DÉBIT RÉEL du séchoir = débit nominal du séchoir x FC1 x FC2 x FC3

Calculation of the GIVEN FLOW RATE to select a suitable dryer = given flow rate ÷ FC1 ÷ FC2 ÷ FC3

Calcul du DÉBIT DONNÉ pour sélectionner un séchoir approprié = débit donné ÷ FC1 ÷ FC2 ÷ FC3

Page 27

E) DRYER DIMENSIONS - DIMENSIONS DU SECHEUR

Models D12IN to D18IN

A B C D E F G H I

mm 305 360 408 51 40 50 332 24 30

inches

12"

14"

3/16

16"

1/16

2"

1"

9/16

2"

13"

1/16

15/16"

1"

3/16

1/2"

NPT

1/2"

NPT Ø 6mm

115/1/60

V/ph/Hz

Power supply Alimentation

Air flow Circulation de l'air

Models D25IN to D180IN

A B C D E F G H I L

mm 390 432 441 100 85 65 45 65 20 12

D25IN

to

D72IN

inches

15"

3/8

17" 17"

3/8

3"

15/16

3"

3/8

2"

9/16

1"

3/4

2"

9/16

13/16" 7/16"

1/2"

NPT