Ingersoll-Rand CENTAC Technical Reference Manual

CENTAC

CMC Technical Reference Manual

INGERSOLL-RAND

AIR COMPRESSORS

CMC TECHNICAL REFERENCE MANUAL

Copyright Notice

Copyright 1996-1999 Ingersoll-Rand Company

THIS MANUAL IS SOLD "AS IS" AND WITHOUT ANY EXPRESSED OR IMPLIED

WARRANTIES WHATSOEVER.

Printing Date: 18 October, 1999

Ingersoll-Rand air compressors are not designed, intended, or approved for breathing air

applications. Ingersoll-Rand does not approve specialized equipment for breathing air

applications and assumes no responsibility or liability for compressors used for breathing air

service.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Table of Contents

What’s New In This Manual_____________________________________________1

References __________________________________________________________2

General - CMC Panel __________________________________________________3

Control Methodology__________________________________________________4

Performance Control ________________________________________________________4

Unload _____________________________________________________________________________ 4

Constant Pressure Control - Modulate____________________________________________________ 4

Energy Saving Control - Autodual________________________________________________________ 5

How does Constant Pressure Modulation Work? _________________________________________ 6

Measuring the Discharge Pressure __________________________________________________ 6

Proportional Band ________________________________________________________________ 7

Integral Time ____________________________________________________________________ 7

Motor Current, MinLoad and MaxLoad ________________________________________________ 8

Surge Control _____________________________________________________________10

Control Methodology _________________________________________________________________ 10

Surge Detection_____________________________________________________________________ 10

Insufficient Rise To Surge ___________________________________________________________ 10

Changes in System Discharge Pressure_______________________________________________ 11

Rapid System Demand Changes _____________________________________________________ 11

Incorrect Instrumentation Output _____________________________________________________ 12

How is Surge Detected? ____________________________________________________________ 12

Surge AbsorberTM___________________________________________________________________ 12

Surge Indexing______________________________________________________________________ 13

Oil System Control___________________________________________________14

Prelube Pump _____________________________________________________________14

Oil Heater_________________________________________________________________14

Protection and Monitoring_____________________________________________15

Analog Functions __________________________________________________________15

Analog Inputs_______________________________________________________________________ 15

Analog Outputs _____________________________________________________________________ 15

Digital Functions___________________________________________________________15

Digital Inputs _______________________________________________________________________ 16

Digital Outputs______________________________________________________________________ 16

Compressor Operating Methodology ____________________________________17

Stopped __________________________________________________________________17

Waiting____________________________________________________________________________ 17

Not Ready _________________________________________________________________________ 17

Ready _____________________________________________________________________________ 17

Rotating __________________________________________________________________17

Starting____________________________________________________________________________ 17

Unloaded __________________________________________________________________________ 18

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Loading____________________________________________________________________________ 18

MinLoad, Loaded, Full Load and MaxLoad________________________________________________ 18

Unloading __________________________________________________________________________ 18

Coasting___________________________________________________________________________ 18

Compressor Operating States _______________________________________________19

User Interface_______________________________________________________20

OUI (Operator User Interface) _______________________________________________20

Command Keys_____________________________________________________________________ 21

Enter Key - Display Operating Mode ____________________________________________________ 21

Navigation Keys_____________________________________________________________________ 21

Contrast Key _______________________________________________________________________ 22

Graphic Display _____________________________________________________________________ 22

Folder and Page __________________________________________________________________ 22

Status Bar _______________________________________________________________________ 22

Edit (Setpoint Changes) Mode _________________________________________________________ 23

Navigation Mode_____________________________________________________________________ 23

SYSTEM Folder _____________________________________________________________________ 25

INFO Folder ________________________________________________________________________ 26

SETTINGS Folder ___________________________________________________________________ 29

General Sequence of Operation _____________________________________________34

Indicator, Switch and Light Layout ____________________________________________35

Lights _____________________________________________________________________________ 35

Push Buttons _______________________________________________________________________ 35

Switches___________________________________________________________________________ 35

CMC Tuning Procedures______________________________________________35

Setting MaxLoad___________________________________________________________36

Setting MinLoad ___________________________________________________________36

Setting MinLoad Surge Index Increment_______________________________________37

Setting Surge Sensitivity____________________________________________________37

Tuning Stability____________________________________________________________38

Calibrating the Control Valves _______________________________________________39

Autodual Control Settings ___________________________________________________40

Unload Point (Bypass Valve % Open) ___________________________________________________ 40

Unload Delay Time (seconds) __________________________________________________________ 41

Reload Percent _____________________________________________________________________ 41

Setting the Start Time ______________________________________________________42

Setting the CT Ratio________________________________________________________42

Inlet Unload Position _______________________________________________________42

Setting Set Point Ramp Rate_________________________________________________43

Alarm and Trip Settings _____________________________________________________43

Troubleshooting_____________________________________________________44

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Troubleshooting Example ___________________________________________________45

Input/Output (I/O) System ___________________________________________________46

Vibration Monitoring System (VMS) _____________________________________________________ 46

Checking Vibration Transmitter Power _______________________________________________ 47

Checking Vibration Circuit ________________________________________________________ 47

Check the Vibration Probe, and Cable _______________________________________________ 48

Checking the Vibration Probe ______________________________________________________ 48

Check the BCM_________________________________________________________________ 49

Temperature Monitoring System (TMS) __________________________________________________ 50

Checking for Power to the Temperature Transmitter____________________________________ 51

Checking for a Faulty RTD ________________________________________________________ 52

Degrees Fahrenheit versus Ohms value chart for 100 OHM Platinum RTD __________________ 53

Degrees Celsius versus Ohms value chart for 100 OHM Platinum RTD ____________________ 54

Checking the RTD Transmitter _____________________________________________________ 55

Checking proper operation of the BCM and wiring______________________________________ 56

Valve Control System (VCS)___________________________________________________________ 57

Checking proper operation of the BCM and wiring______________________________________ 58

Checking proper operation of the I/P and positioner ____________________________________ 59

Pressure Monitoring System (PMS)_____________________________________________________ 60

Checking for Power to the Pressure Transmitter _______________________________________ 61

Checking proper operation of the BCM and wiring______________________________________ 62

Quick check of the PT ___________________________________________________________ 63

Functional PT test _______________________________________________________________ 63

Digital Input System (DIS)_____________________________________________________________ 64

Checking proper operation of the digital devices _______________________________________ 65

Control Power System (CPS) ________________________________________________66

No AC power ___________________________________________________________________ 67

No DC power ___________________________________________________________________ 68

No digital input power ____________________________________________________________ 68

No digital output power ___________________________________________________________ 68

No analog input power____________________________________________________________ 68

No analog output power __________________________________________________________ 68

No OUI power __________________________________________________________________ 68

No CPU power __________________________________________________________________ 69

Controller Problems ________________________________________________________70

BCM Problems______________________________________________________________________ 71

BCM is not controlling____________________________________________________________ 71

OUI Problems_______________________________________________________________________ 71

OUI is dim _____________________________________________________________________ 71

OUI is black ____________________________________________________________________ 71

OUI displays “INGERSOLL-RAND Centrifugal Compressor Division” _______________________ 71

UCM Problems______________________________________________________________________ 71

All UCM LED’s are not lit _________________________________________________________ 71

Options ____________________________________________________________72

Enclosures________________________________________________________________72

NEMA 12 (IP 64) ____________________________________________________________________ 72

Cooling Fan ________________________________________________________________________ 72

NEMA 4 (IP 65) _____________________________________________________________________ 72

NEMA 4X (IP 65) ____________________________________________________________________ 72

Space Heater_______________________________________________________________________ 73

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Vortex Tube Cooler __________________________________________________________________ 73

Type Z Purge _______________________________________________________________________ 73

Fused Control Power Disconnect _______________________________________________________ 73

Control Electrical Package __________________________________________________74

Stage Data Package ________________________________________________________74

Alarm Horn ________________________________________________________________74

Running Unloaded Shutdown Timer __________________________________________74

Water Solenoid Post Run Timer ______________________________________________74

Panel Mounted Wye-Delta Starter ____________________________________________74

N.O. Contact for Remote Indication of Common Alarm and Trip ___________________74

Power Regulating Constant Voltage Transformer_______________________________75

Automatic Starting__________________________________________________________75

Remote Start and Remote Stop – Hardwired______________________________________________ 75

Remote Start Digital Input___________________________________________________________ 75

Remote Stop Digital Input ___________________________________________________________ 75

Communications ____________________________________________________________________ 75

Auto-Hot Start ______________________________________________________________________ 76

Auto-Cold Start _____________________________________________________________________ 76

Remote 4-20 mA Pressure Setpoint ___________________________________________76

Steam and Gas Turbine Driven Compressors __________________________________76

Performance Control _________________________________________________________________ 76

Motor Current, MinLoad and MaxLoad_________________________________________________ 76

Surge Control_______________________________________________________________________ 77

How Surge is Detected _____________________________________________________________ 77

Compressor Operating Methodology ____________________________________________________ 77

Accelerate-1______________________________________________________________________ 77

Accelerate-2______________________________________________________________________ 78

Slow Rolling______________________________________________________________________ 78

Quick Start Turbines _______________________________________________________________ 78

Operator User Interface (OUI) __________________________________________________________ 78

Status Bar _______________________________________________________________________ 78

System Folder____________________________________________________________________ 78

Info Folder _______________________________________________________________________ 78

Settings Folder ___________________________________________________________________ 79

General Sequence of Operation ________________________________________________________ 80

Starting Methodology ______________________________________________________________ 80

Diesel Driven Compressors _________________________________________________83

Communication _____________________________________________________84

Centac Energy Master (CEM) ________________________________________________84

Direct CMC Communications with RS422/485___________________________________84

The CMC-MODBUS Interface ________________________________________________85

Introduction_________________________________________________________________________ 85

Serial Modes _______________________________________________________________________ 85

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

MODBUS Messages _________________________________________________________________ 86

Device Address ___________________________________________________________________ 86

Function Code ____________________________________________________________________ 86

Data Addresses___________________________________________________________________ 86

Single Module Addresses_________________________________________________________ 87

Multiple Module Addresses _______________________________________________________ 87

Data ____________________________________________________________________________ 87

Byte Count_______________________________________________________________________ 87

Cyclical Redundancy Check (CRC) ___________________________________________________ 87

Function Details _____________________________________________________________________ 87

Function 01 - Read Coil Status _______________________________________________________ 87

Example: Reading a Single Coil ___________________________________________________ 88

Example: Reading Multiple Coils __________________________________________________ 89

Function 02 - Read Input Status______________________________________________________ 89

Example: Read Single Discrete Input _______________________________________________ 90

Example: Read Multiple Discrete Inputs_____________________________________________ 90

Function 03 - Read Holding Registers _________________________________________________ 91

Example: See example for Function 04. _____________________________________________ 94

Function 04 - Read Input Registers ___________________________________________________ 94

Example: Read Single Channel 16-Bit Integer and Fraction _____________________________ 95

Example: Read Single Channel IEEE 32-Bit Floating Point Number ______________________ 96

Example: Read Multiple Channels _________________________________________________ 97

Function 05 - Force Single Coil ______________________________________________________ 97

Example: Forcing a Coil _________________________________________________________ 98

Function 06 - Preset Single Register __________________________________________________ 98

Example: Presetting a Single Register (16-bit) Integer _________________________________ 99

Function 15 (0F Hex) - Force Multiple Coils ____________________________________________ 99

Example: Forcing Multiple Coils __________________________________________________ 100

Function 16 (10 Hex) - Preset Multiple Registers _______________________________________ 100

Example: Presetting Holding Registers for 32-bit Values ______________________________ 101

Example: Presetting a 16-bit Integer and 16-bit Fraction Holding Register ________________ 103

Exception Responses _______________________________________________________________ 103

Function Code Field ______________________________________________________________ 104

Data Field_______________________________________________________________________ 104

Exception Codes Supported by the CMC Microcontroller _________________________________ 104

Maximum Query / Response Parameters _______________________________________________ 105

CMC Data_________________________________________________________________________ 105

Scaling and Units of Measure_________________________________________________________ 105

Communication Parameters __________________________________________________________ 105

The CMC-DF1 Interface ____________________________________________________106

Introduction________________________________________________________________________ 106

Full-Duplex Protocol ________________________________________________________________ 107

DF1 Full-Duplex Protocol Message Frames ___________________________________________ 107

DF1 Device Address ______________________________________________________________ 107

Destination (DST) Byte____________________________________________________________ 107

Source (SRC) Byte _______________________________________________________________ 108

Command (CMD) and Function (FNC) Bytes ___________________________________________ 108

Status (STS) Byte - Status Error Code _______________________________________________ 108

Transaction (TNS) Bytes___________________________________________________________ 108

BCC (Block Check Character) and CRC (Cyclic Redundancy Check)_______________________ 108

BCC (One Byte) _______________________________________________________________ 109

CRC (Two Bytes)_______________________________________________________________ 109

Data Addressing ___________________________________________________________________ 110

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

CMC as PLC5 ___________________________________________________________________ 110

CMC as SLC5/04_________________________________________________________________ 111

Data File Addressing for PLC5/SLC504_______________________________________________ 111

CMC Data Addressing_____________________________________________________________ 112

Supported Functions ________________________________________________________________ 116

Command 0F/Function 68 - PLC5 Typed Read_________________________________________ 116

Example: Reading an Analog Input________________________________________________ 116

As 16-Bit Integer and Fraction ____________________________________________________ 117

As IEEE 32-Bit Floating Point Number _____________________________________________ 118

Example: Read Multiple Analog Channels __________________________________________ 119

Example: Reading a Discrete Value_______________________________________________ 119

Example: Reading Multiple Discrete Values ________________________________________ 120

Example: Reading Bit-Packed Discrete Data________________________________________ 120

Command 0F/Function 67 - PLC5 Typed Write_________________________________________ 121

Example: Presetting Analog Setpoints for 32-bit Values_______________________________ 121

Example: Presetting a 16-bit Integer and 16-bit Fraction Analog Setpoint _________________ 123

Example: Forcing a Coil ________________________________________________________ 123

Example: Forcing Multiple Coils __________________________________________________ 124

Command 0F/Function A2 - SLC Typed Logical Read ___________________________________ 125

Example: Reading an Analog Value _______________________________________________ 125

Example: Reading Multiple Analog Values __________________________________________ 126

Example: Reading Single Discrete Data____________________________________________ 126

Example: Reading 16 Bit-Packed Discrete Data_____________________________________ 126

Command 0F/Function AA - SLC Typed Logical Write___________________________________ 127

Example: Presetting Analog Setpoint for 32-bit Value _________________________________ 127

Example: Presetting a 16-bit Integer and 16-bit Fraction Analog Setpoint _________________ 127

Example: Forcing a Coil ________________________________________________________ 127

Example: Forcing Multiple Coils __________________________________________________ 128

Allen-Bradley SLC 504 Example_______________________________________________________ 128

Data Files _______________________________________________________________________ 128

RSLogix 500 Ladder Diagram_______________________________________________________ 128

UCM STS Error Codes ______________________________________________________________ 129

Communication Parameters __________________________________________________________ 130

Network Setup _____________________________________________________________________ 130

1770-KF2 Setup ____________________________________________________________________ 132

SW-1 (Asynchronous Link Features) _________________________________________________ 132

SW-2, SW-3, SW-4 (Node Address) _________________________________________________ 132

SW-5 (Network Link Communication Rate) ____________________________________________ 133

SW-6 (Asynchronous Link Communication Rate and Diagnostic Commands)________________ 133

SW-7 (Network Link Selection)______________________________________________________ 134

SW-8 (RS-232C/RS-422A Selection)_________________________________________________ 134

Wiring Diagram for RS-422A________________________________________________________ 134

Documentation_____________________________________________________135

System Information _________________________________________________135

Status Codes_____________________________________________________________135

Base Control Module (BCM)________________________________________________137

Module Layout _____________________________________________________________________ 137

Connector Description_______________________________________________________________ 138

Connector Input and Output (I/O) ______________________________________________________ 139

Operator User Interface Module (OUI) _______________________________________140

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Module Layout _____________________________________________________________________ 140

Connector Description_______________________________________________________________ 140

Connector Input and Output (I/O) ______________________________________________________ 140

CMC User Interface/Bezel Cleaning Instructions __________________________________________ 141

Backlight Replacement Procedure _____________________________________________________ 141

Universal Communication Module (UCM) Optional_____________________________144

Module Layout _____________________________________________________________________ 144

Connector Description_______________________________________________________________ 145

Connector Input and Output (I/O) ______________________________________________________ 145

Setting UCM Switches ______________________________________________________________ 145

UCM Port Activity LEDs _____________________________________________________________ 145

UCM Communications Parameters ____________________________________________________ 146

UCM Timeout ______________________________________________________________________ 146

RS422/485 Network Wiring Diagram - Full Duplex ________________________________________ 147

RS422 Network Wiring Diagram - Half Duplex ____________________________________________ 148

Terminating Resistor ________________________________________________________________ 149

Typical System Layout ______________________________________________________________ 149

Network Diagram ___________________________________________________________________ 150

Technical Specification ______________________________________________151

Glossary ____________________________________________________________1

Service Tool Variable Names ___________________________________________7

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Table of Figures

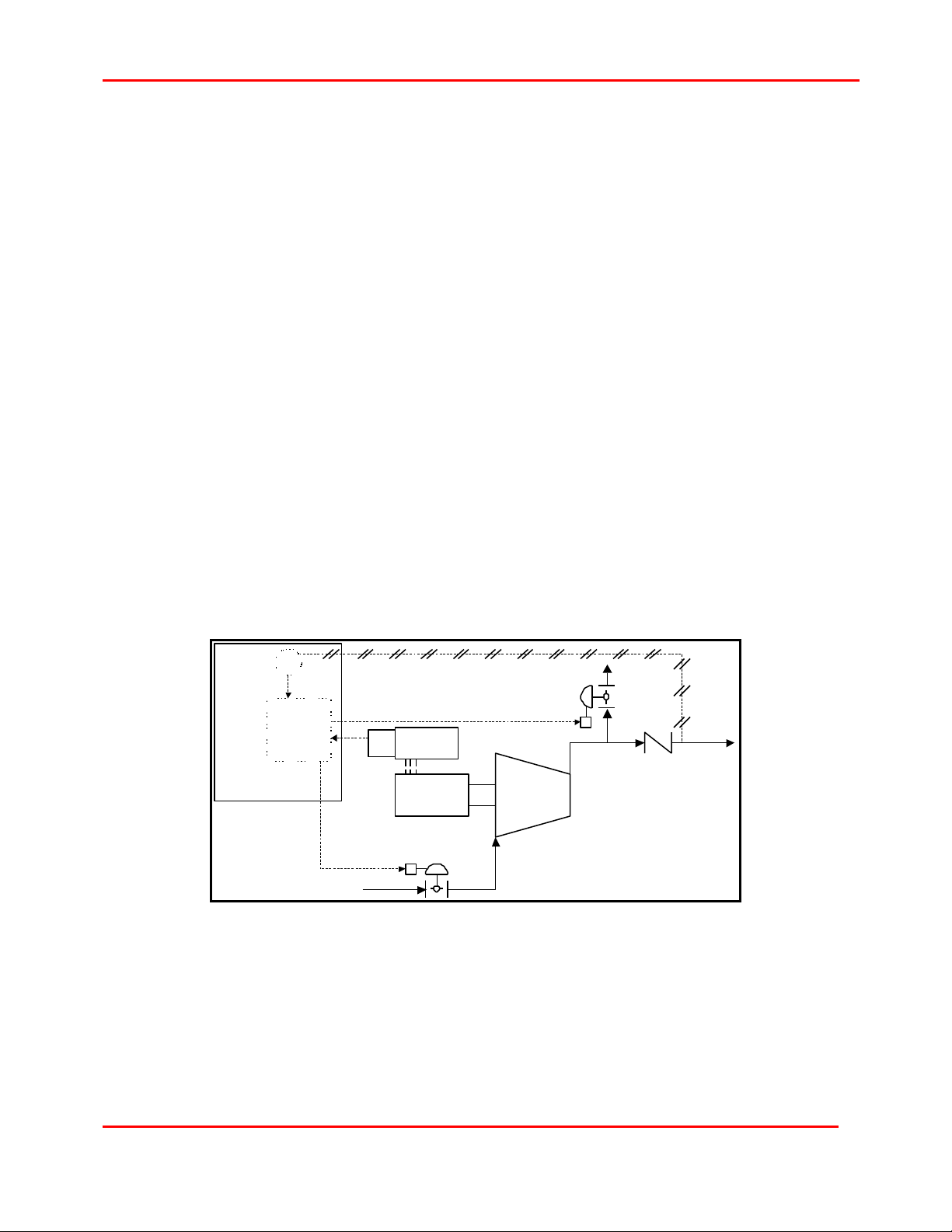

Figure 1: Compressed Air System ........................................................................................................ 4

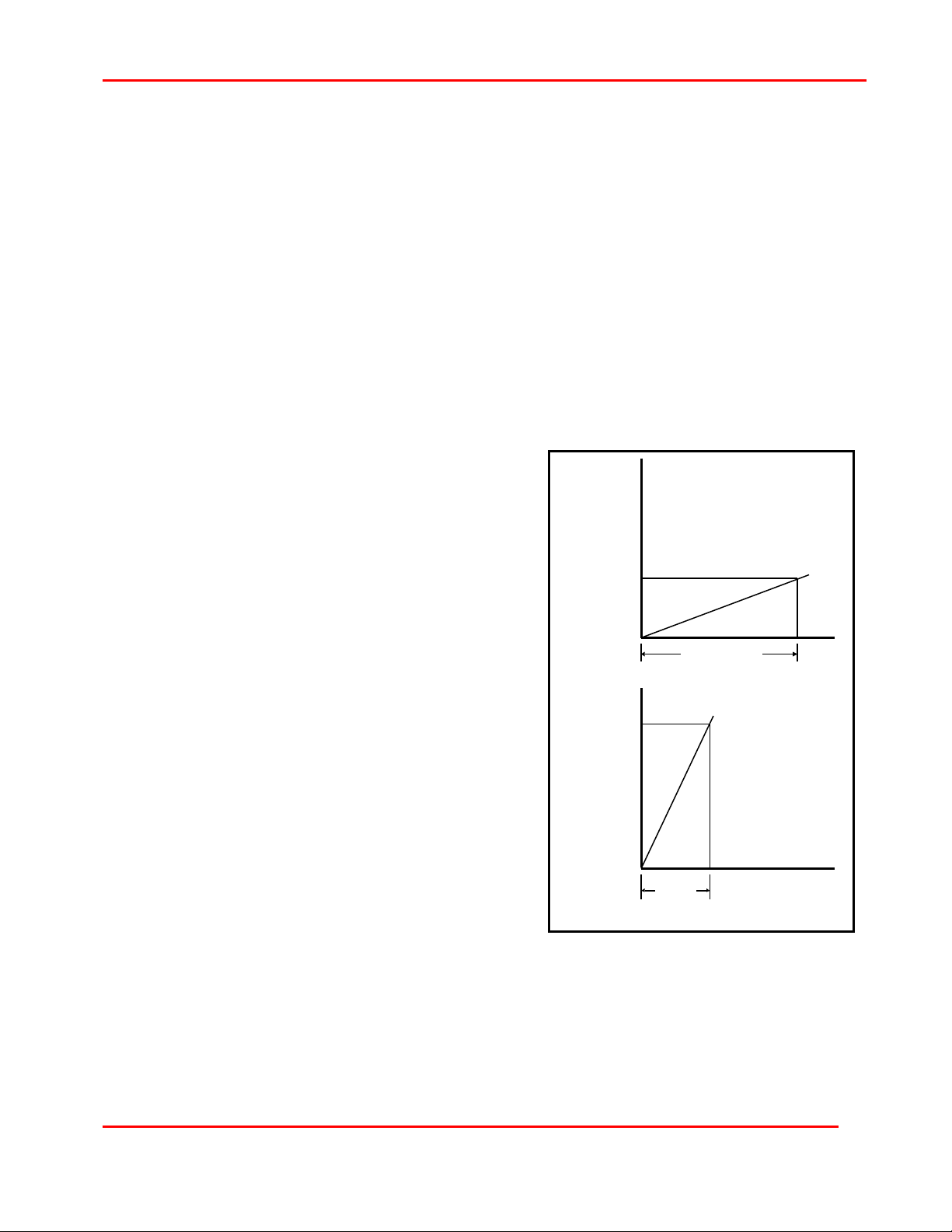

Figure 2: Autodual Control ....................................................................................................................5

Figure 3: Modulate Control ................................................................................................................... 5

Figure 4: Performance Control .............................................................................................................. 6

Figure 5: Proportional Band, Pb ............................................................................................................7

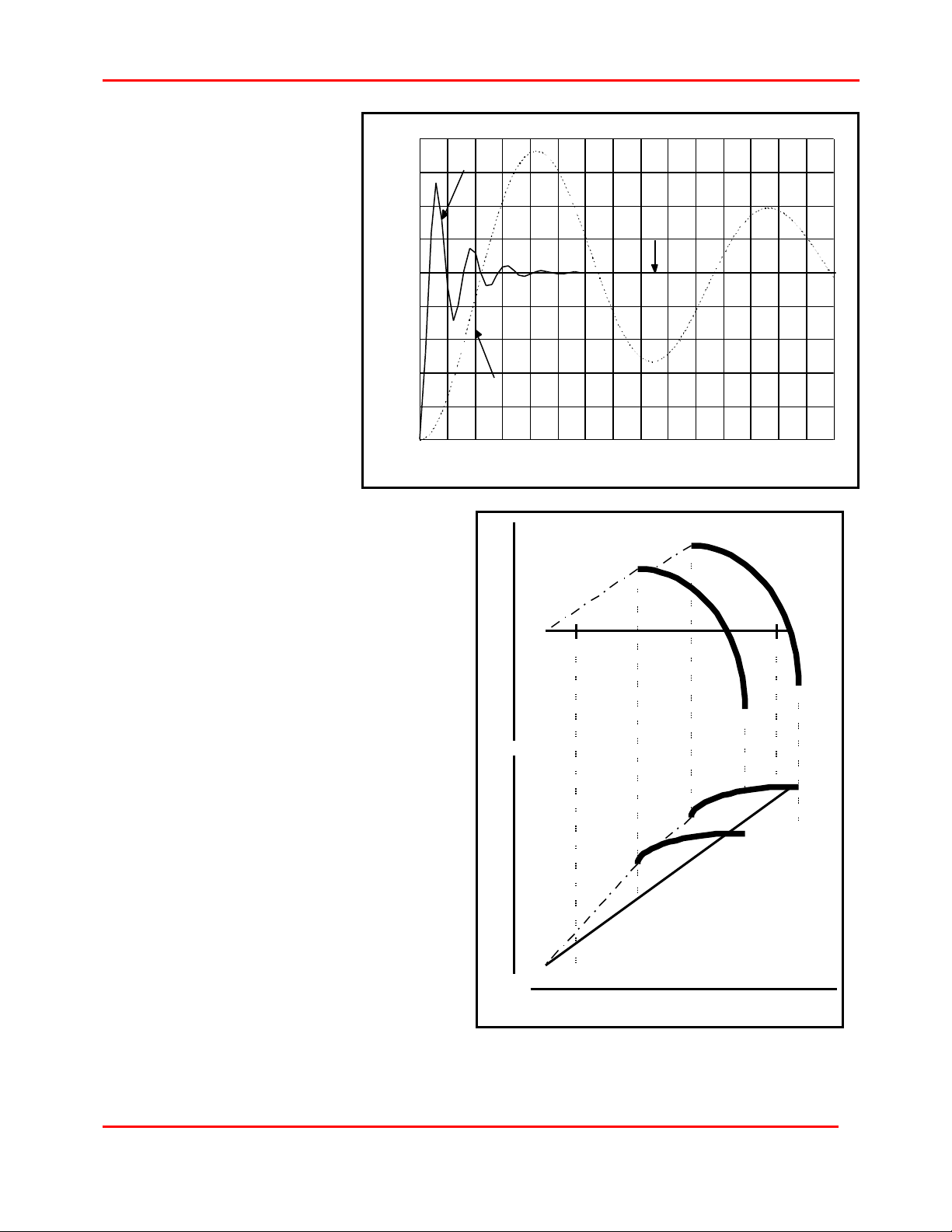

Figure 6: Proportional Plus Integral Control ............................................................................................ 8

Figure 7: MinLoad and MaxLoad........................................................................................................... 8

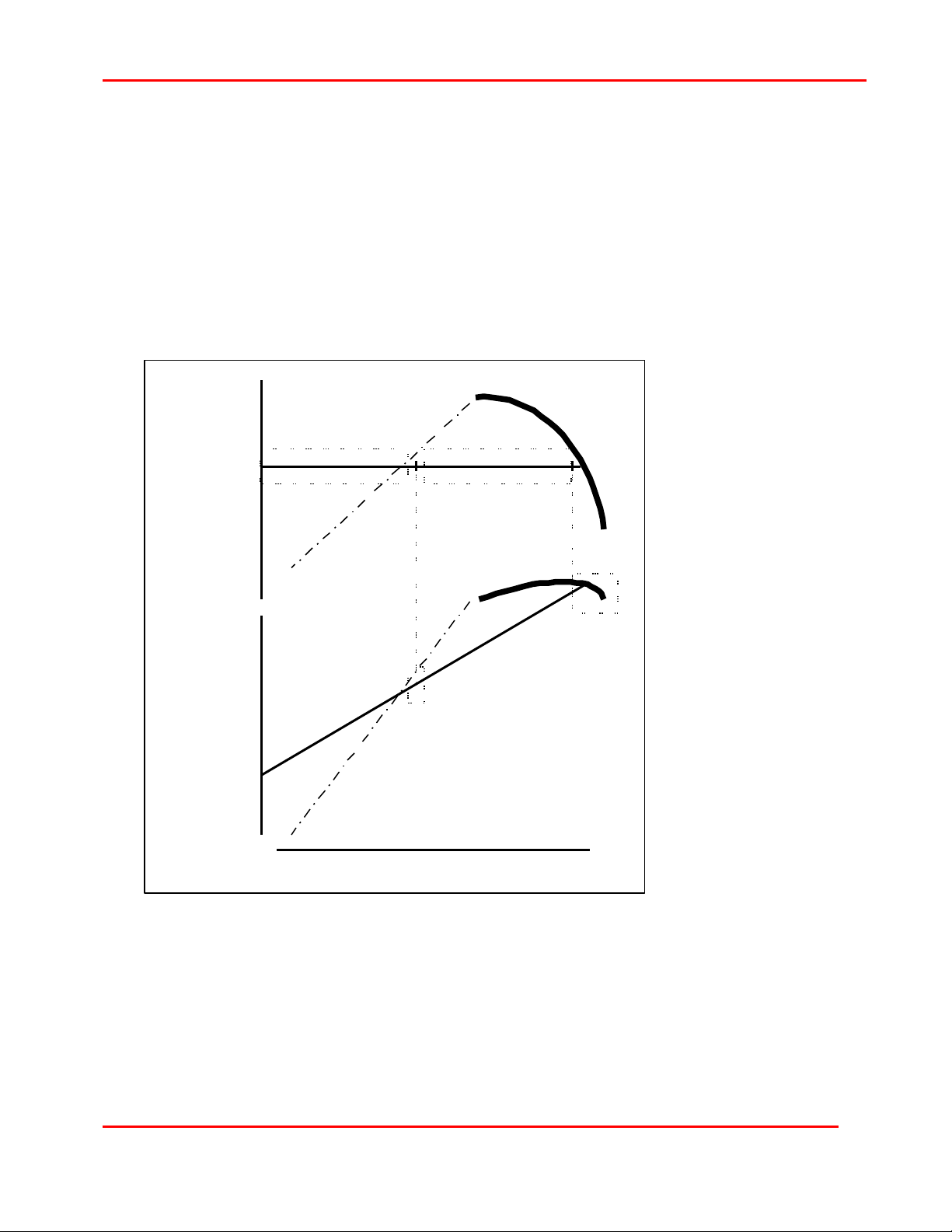

Figure 8: Rise To Surge .....................................................................................................................11

Figure 9: Changes in Discharge Pressure............................................................................................11

Figure 10: Changes in Discharge Pressure ..........................................................................................12

Figure 11: Plant Air System ...............................................................................................................35

Figure 12: Troubleshooting Tree..........................................................................................................44

Figure 13: MODBUS Messages.........................................................................................................85

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

What’s New In This Manual

This is the third version of the CMC Manual. This version was created to support new

features incorporated into the CMC Product, and provide additional information in general

compared with the first and second versions.

Specifically, new features are as follows:

1. The basic compressor control logic has been refined to give even better pressure

control than before.

2. Surge AbsorberTM. This feature replaces Surge Reload and reduces the magnitude and

duration of pressure variations for a surge cycle.

3. Gas and steam turbine driven compressor control with Adaptive StartingTM now

available as a standard option.

4. Diesel driven compressor control with Adaptive StartingTM now available as a standard

option.

5. Event log has been expanded to 224 events all scrollable from the OUI. New events

have been added for surge, turbine operation, multiple board failure and control

parameter edits from both local or remote control locations. This added information is

invaluable for troubleshooting.

1

6. Allen-Bradley DF1 communication protocol has been added for connection to Data

Highway Plus (DH+) networks.

7. More data available is available at a faster rate from a single communication read.

8. Three module support. This allows systems to contain as many as 69 analog inputs, 3

CT inputs, 3 speed inputs, 12 analog outputs, 48 discrete inputs and 48 discrete

outputs.

9. Added math capabilities allow for more options.

10. The OUI has been updated to enhance the overall look and feel and ease of use. The

Coasting Timer and BCM Version have been added.

11. New fonts have been added for Russian, Arabic and Greek.

12. New diagnostic feature for Motor Failure Trip. This helps in troubleshooting compressor

starting problems.

13. Derivative constants for the Inlet Valve Pressure, MinLoad and MaxLoad PID control

loops along with the Bypass Valve Pressure PID control loops have been added to the

OUI, this feature provides a higher level of tuning capabilities for the knowledgeable

User.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

2 CMC TECHNICAL REFERENCE MANUAL

References

The following references were used in creating this document. All of this documentation is

recommended for a more detailed understanding of specific control modes and control

panel functions.

NEMA STANDARDS PUBLICATION NO. 250, Enclosures for Electrical Equipment (1000 Volts

Maximum) , Revision 2, May 1988

NFPA 496 Standard for Purged and Pressurized Enclosures for Electrical Equipment, 1986

Edition

Nisenfeld, A. Eli, Centrifugal Compressors: Principles of Operation and Control, Instrument

Society of America, 1982

Moore, Ralph L., Control of Centrifugal Compressors, Instrument Society of America, 1989

Doebelin, Ernest O., Control System Principles and Design, John Wiley & Sons, 1985

Rowland, James R., Linear Control Systems Modeling, Analysis, and Design, John Wiley &

Sons, 1986

Deshpande, Pradeep B. and Ash, Raymond H., Computer Process Control With Advanced

Control Applications, 2nd Edition, Instrument Society of America, 1988

CENTAC ENERGY MASTER, Version CEM230, Ingersoll-Rand Company, March 1992

White, M.H., Surge Control for Centrifugal Compressors, Chemical Engineering, December 25,

1972

Hall, James W., THERMODYNAMICS OF COMPRESSION: A Review of Fundamentals,

Instrument Society of America, 1976

Gaston, John R., Centrifugal Compressor Operation & Control: Part II "Compressor Operation",

Instrument Society of America, 1976

Gaston, John R., Antisurge Control Schemes For Turbocompressors, Chemical Engineering,

April 1982

Warnock, J. D., Methods for Control of Centrifugal and Reciprocating Compressors, Moore

Products, 1984

Harrison, Howard L. and Bollinger, John G., Introduction to Automatic Controls, Second Edition,

Harper & Row, 1969

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

General - CMC Panel

The CMC panel is the microprocessor-based control and monitoring system for Centac and

X-FLO centrifugal compressors. The CMC handles all pressure control and monitoring

functions; as well as, control auxiliary equipment such as the main motor starter, oil heater,

and prelube pump.

The CMC panel has a custom designed computer board called the Base Control Module

(BCM). This board has a microcontroller and memory chips that tell the rest of the panel

what to do for the various input pressures, temperatures and vibrations. All hardware for

data analysis, number of input and output (I/O) points and system memory are optimally

selected for accurately controlling and protecting Centac and X -FLO compressors.

Features of the CMC system are:

• Ease of use ... only twelve buttons to push on the operator OUI!

• M ultiple function, 240 x 128 pixel graphic LCD display to display data and operating status

• Unload, Modulate and Auto-Dual operating modes.

• Advanced surge detection and control.

3

• High current limit for main drive electric motor protection.

• First-out indication and event log to help determine the root cause of a compressor trip.

• Pinion vibration alarm and trip for each compression stage.

• Optional port for communicating to the Centac Energy Master (CEM) or other Distributed

Control Systems (DCS) via MODBUS protocol.

• Optional reduced voltage motor starter included in panel for some sizes.

NOTE

For the purpose of consistency and clarity, all of the descriptions and examples that

follow refer to "air" for the more generic "gas". Any gas compressed by a Centac or XFLO compressor would also apply.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

4 CMC TECHNICAL REFERENCE MANUAL

Control Methodology

The CMC utilizes performance and surge control methodologies to meet varying

compressed air system needs. The term "performance control" is used for grouping the

control modes that affect compressor power consumption through movement of the intake

and discharge valves.

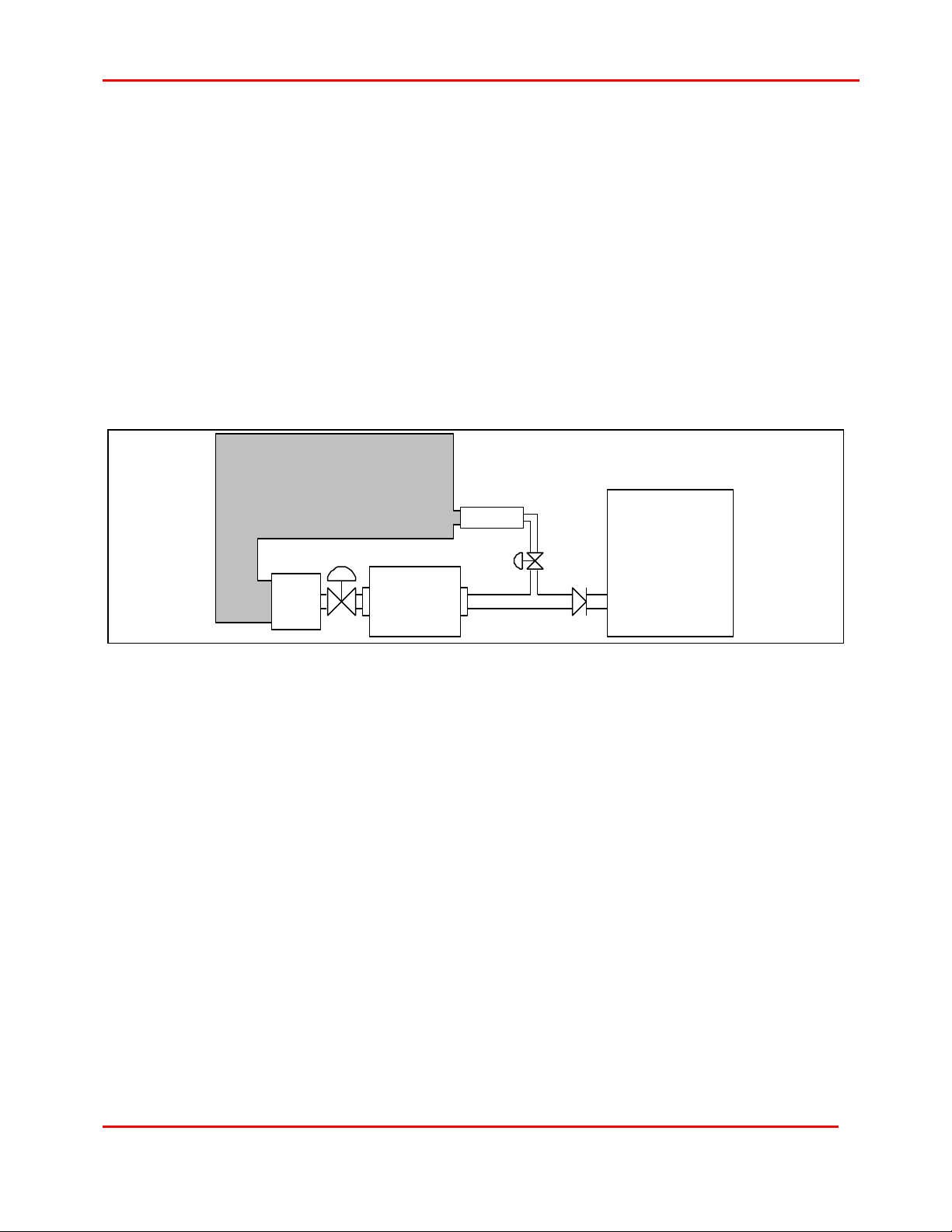

Performance Control

The CMC has three standard performance control modes or methods of operation. These

modes are Unload, Modulate and Autodual for typical plant air compressors operating in

constant pressure applications. For the discussions that follow, Figure 1 depicts a

compressed air system and the relationship between the compressor and the plant air

system.

Atmosphere

Silencer

Inlet

Filter

Inlet

Valve

Compressor

Figure 1: Compressed Air System

Bypass

Valve

Check

Valve

Plant Air System

Unload

The compressor is unloaded, when no air is being supplied to the Plant Air System, and all

of the air produced by the compressor is being vented to the atmosphere. In this mode, the

inlet valve is slightly open to allow enough air to pass through the compressor for internal

cooling, prevention of rotor instability and surge avoidance. This air is then discharged

through the fully open bypass valve to the atmosphere. Typically, the compressor is set to

make a positive pressure across the first compression stage, which produces a discharge

pressure something greater than the atmospheric pressure.

The inlet valve opening required to create this positive pressure is directly related to the

horsepower consumed; therefore, careful consideration should be given to this inlet valve

position for minimizing overall power consumption.

Constant Pressure Control - Modulate

Constant pressure control is a frequently required performance control method for Centac

air compressors. If left uncontrolled, the compressor's discharge pressure would rise and

fall along the natural performance curve as system demand changed. Modulate control

satisfies the constant pressure requirement.

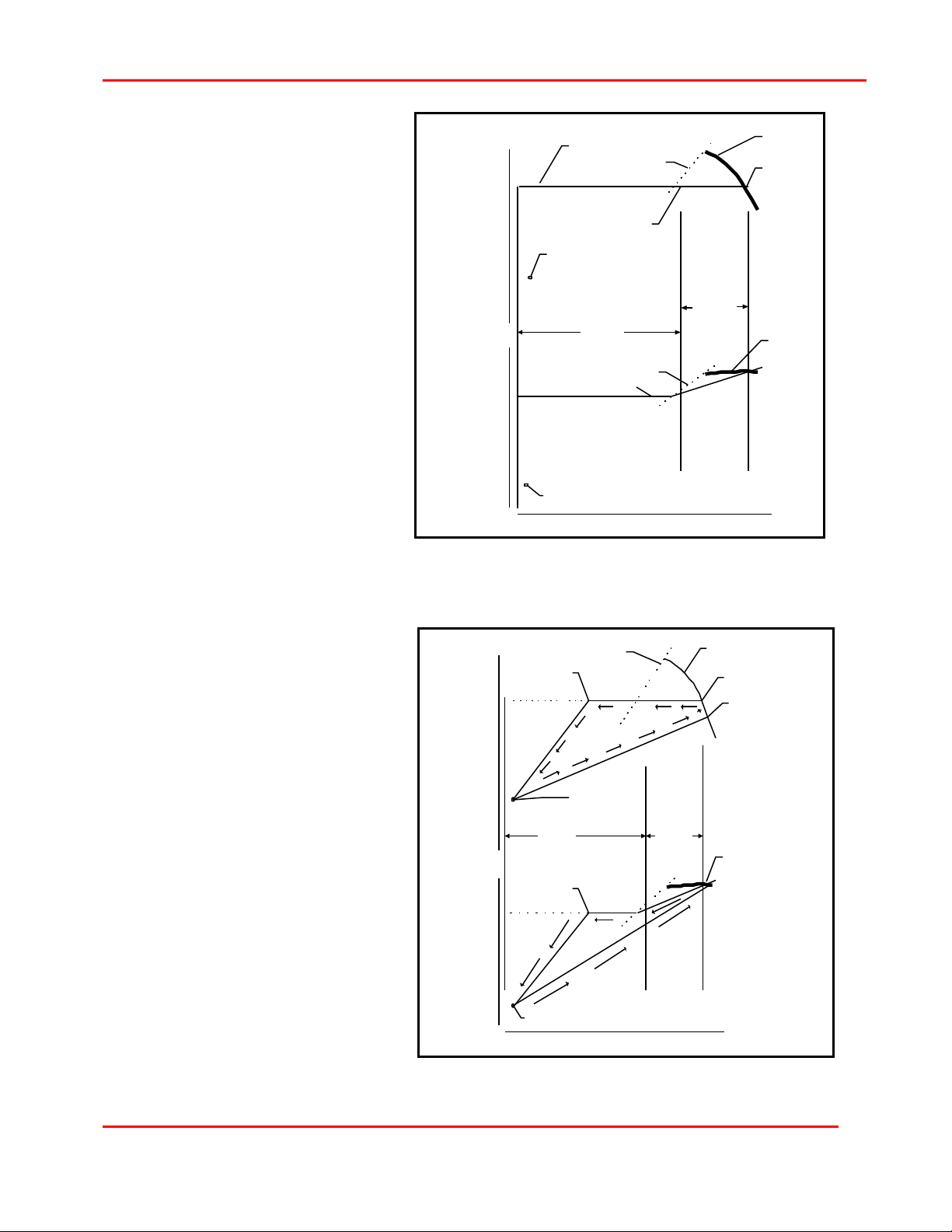

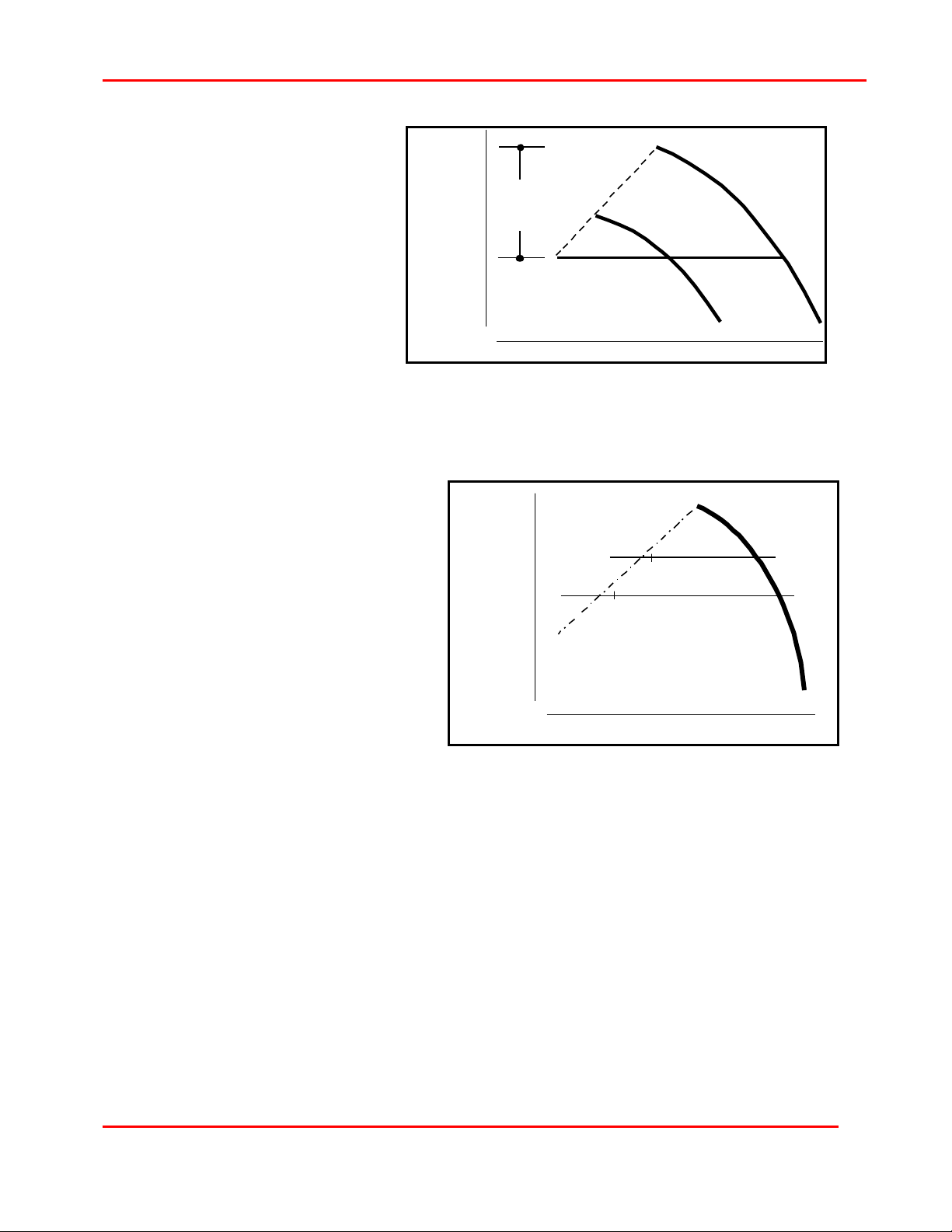

The performance map in Figure 2 shows Modulate control. Modulate maintains the system

discharge pressure at the system pressure set point as entered into the CMC by the user.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

5

Once loaded, the compressor

will operate along the constant

pressure line until the user

switches to Unload or presses

the stop button.

Control is accomplished by

modulating the inlet valve within

the compressor's throttle range.

When system demand is less

than the minimum throttled

capacity, the discharge

pressure is maintained by

modulating the bypass valve and

venting some or all of the air to

atmosphere. This valve is

opened just prior to reaching the

surge line. Whenever the

bypass valve is open, the inlet

valve maintains its position at

the minimum throttled capacity

setting. Modulate provides a

constant discharge pressure

with variable capacity from

Discharge

Pressure

Power at

Coupling

Constant Pressure Line

Surge Line

Maximum

Throttle Point

(MinLoad)

Unloaded

Bypass

Valve

Throttle

Range

Constant Power Line

Unloaded

Surge Line

Capacity

Figure 3: Modulate Control

Inlet

Valve

Throttle

Range

Natural

Pressure

Curve

Design

Point

Natural

Power

Curve

design to zero.

This control method is used

when reliable control of the

discharge pressure is required.

Modulate is the most commonly

used control method for Centac

and X-FLO compressors.

Energy Saving Control - Autodual

Autodual automatically loads the

machine when demand is high

and unloads the machine when

demand is low.

When the compressor is

controlling to pressure setpoint

and demand is within the inlet

valve throttle range, constant

pressure is maintained in the

same manner as Modulate.

When the machine is controlling

to the pressure setpoint and

system demand is low, the

compressor is operated in the

bypass valve throttle range.

Discharge

Pressure

Power at

Coupling

Surge Line

Unload

Point

Unloaded

Bypass

Valve

Throttle

Range

Unload

Point

Unloaded

Capacity

Inlet

Valve

Throttle

Range

Figure 2: Autodual Control

Natural

Curve

Design

Point

Reload Point

(Reload Percent)

Natural

Curve

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

6 CMC TECHNICAL REFERENCE MANUAL

Autodual automatically unloads the machine when the bypass valve is opened beyond the

Unload Point for a programmed time period called the Unload Delay Time. The Bypass

Valve Unload Point is selected to correspond with the check valve closing since at this point

the machine is not supplying the system (Figure 1). The Unload Delay Timer should be set

to prevent unloading during short excursions through the Unload Point. The Reload Percent

determines the System Pressure at which the machine will automatically load into the

system.

How does Constant Pressure Modulation Work?

The goal of constant pressure modulation is to maintain a specified discharge pressure in

the compressed air system while the capacity requirements change. Modulate control

provides constant pressure from 100 percent of the compressor's capacity to zero capacity.

Autodual control provides constant pressure from the 100 percent of the compressor's

capacity to the Unload Point.

If all plant air systems were identical in capacity usage requirements, the CMC could be

preprogrammed to respond to those changes; however, all plant air systems are not alike.

The frequency and variability of the capacity changes means that the control logic must be

flexible, so the CMC utilizes proportional plus integral control algorithms to determine the

magnitude of the signal that is sent to the inlet and bypass valves. These algorithms, or

programming logic, allow the CMC control system to be "tuned" to a specific plant air

system.

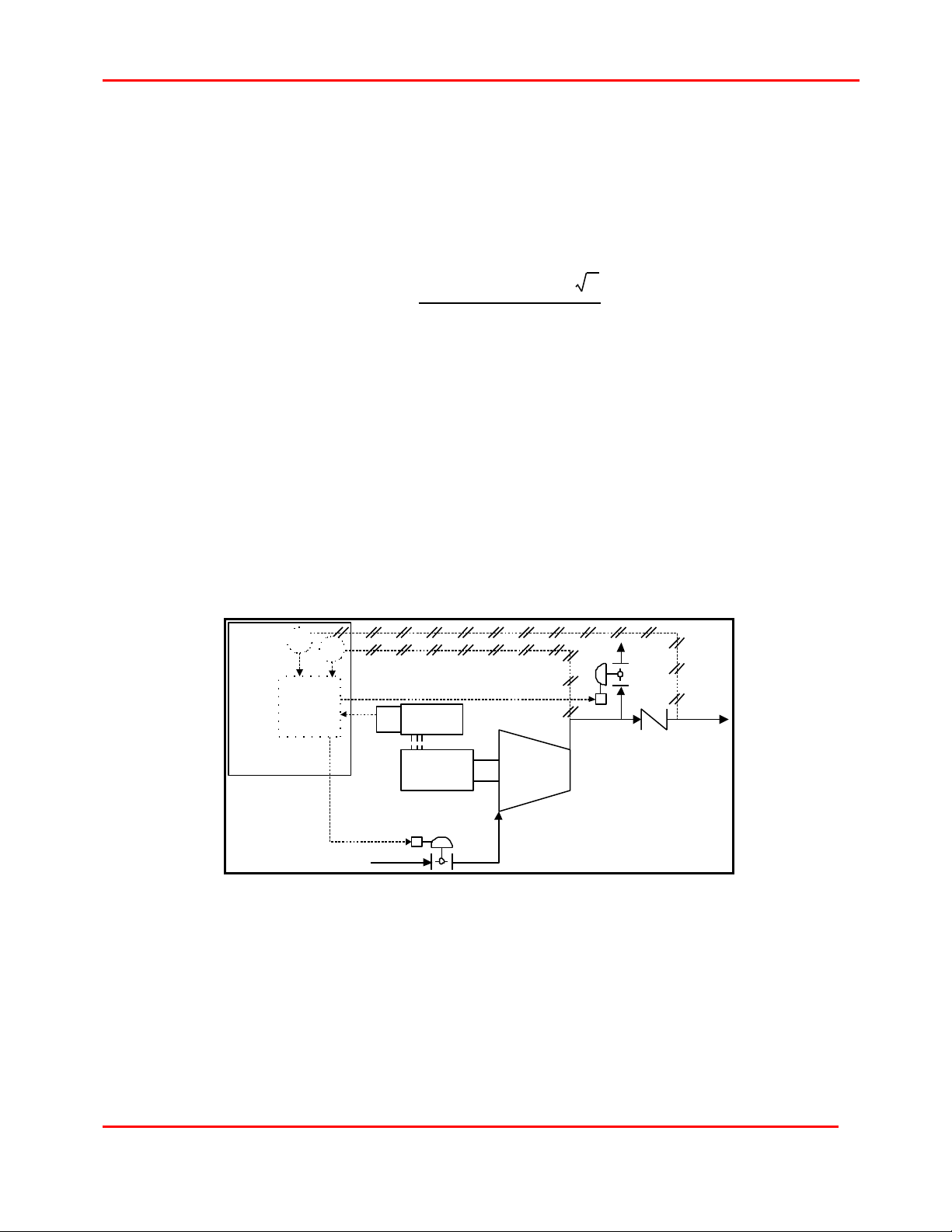

Measuring the Discharge Pressure

In order to maintain constant pressure, the system discharge air pressure must be

measured. A pressure transducer is mounted in the control panel and tubed to the

compressor discharge downstream of the check valve as shown in Figure 4.

CMC

PT

Base

Control

Module

Pneumatic Tubing

4-20 mA

StarterCT

Inlet

4-20 mA

Valve

Figure 4: Performance Control

Bypass

Valve

CompressorMotor

Check

Valve

This transducer sends a 4-20 mA signal to the CMC board. The CMC compares the

measured discharge pressure to the system pressure set point entered into the CMC by the

user through the Operator User Interface (OUI). Depending upon the difference between

these two values the CMC will send a 4-20 mA signal to "Modulate", open or close, the inlet

and/or bypass valve to maintain the specified system pressure set point.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Proportional Band

Proportional control varies the signal sent to the valves as a linear response to the

difference between the actual system pressure and the system pressure set point. Valve

responsiveness can be adjusted through the CMC with the proportional band, Pb, set point.

This scaling factor, graphically depicted in Figure 5, is the amount of change in the input

variable (actual minus set point pressures) to cause a full scale change in the output

variable (valve position).

In other words, if the pressure in the air system fluctuates frequently, it would be prudent to

set Pb to a low value to keep up with those system changes. Otherwise, if the system is

very stable, a larger value can be used. Pb is directly related to valve life and indirectly

related to valve cycling; so, as Pb decreases, valve life decreases and cycling increases.

As stated earlier, the CMC uses a proportional plus integral control algorithm. The result of

proportional only control is offset from the controlled variable, discharge pressure. This

means that if the set point pressure is 100, the actual pressure may only be 95. The value of

this offset depends upon the proportional band

value.

What is the valve response when the difference

between actual and set point pressures is zero?

There is no response. Proportional control only

functions when a difference or error exists. Design

discharge pressure could not be attained in a

proportional only control system. Therefore, an

integral control algorithm is added to achieve the

desired discharge pressure.

Output

Variable

(Valve Position)

Full Scale

Slow

Response

Pb

7

high

Integral Time

The offset produced by the proportional control

0

Large Change

algorithm could be eliminated by manually

readjusting the system pressure set point. Using

the example above, the set point could be reset to

Full Scale

Fast

Response

Pb

low

105 to obtain the 100 desired. Manually resetting

the set point would be required as the system

demand fluctuated. Integral control, also known as

Output

Variable

(Valve Position)

reset control, automatically resets the desired

system pressure set point. For the CMC, the rate

at which the controller resets the system pressure

setting is known as Integral Time, It, and is

expressed in units of repeats per second.

If precise control of the specified discharge

pressure is required, the It set point should be set

0

Small

Change

(Actual - Set Point Pressures)

Input Variable

for a fast value. It is inversely related to valve life

and directly related to valve cycling, therefore, as It

Figure 5: Proportional Band, Pb

decreases, valve life increases and cycling

decreases. For the CMC controlling Centac and X-FLO compressors, It values are typically

less than 1.00.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

8 CMC TECHNICAL REFERENCE MANUAL

Time

Activity

Proportional Band - Low

Proportional Band - High

Opened

Set Point

Figure 6 shows the

relative valve response

over time for two

combinations of Pb and It.

As shown, when Pb is low

and It is fast, valve activity

is significant in both

magnitude and frequency

to obtain the desired set

point. The other scenario,

Pb is high and It is slow,

has relatively little valve

activity, and may never

reach the set point

position.

Valve

Integral Time - Fast

Integral Time - Slow

Proportional Band and

Integral Time are

Closed

variables used internally

by the control system to

determine valve response

and direction for a given

compressed air system. Each has an

optimum value based upon the

system's characteristics. Determining

these optimum values is a trial and

error exercise. These set points should

be re-evaluated any time there is a

major change in the compressed air

system.

Up to this point, constant pressure

control has been accomplished with an

analog input (system pressure) and two

analog outputs (inlet valve and bypass

valve position). How is motor current,

the other analog input, used for

constant pressure control? When does

the bypass valve modulate as opposed

to the inlet valve?

Figure 6: Proportional Plus Integral Control

T

cold

T

hot

Discharge PressurePower at Coupling

MinLoad

MaxLoad

Motor Current, MinLoad and MaxLoad

Motor current, in units of power

(normally amps), has two functions in

the CMC. The first is over current

protection for the main motor, and is

referred to as MaxLoad or High Load

Limit (HLL). The second function

determines the point at which the

bypass valve begins to modulate for

Capacity - Mass Flow

Figure 7: MinLoad and MaxLoad

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

controlling pressure. This point is called MinLoad or Throttle Limit (TL). The location of these

two points is graphically depicted on the pressure and power versus capacity curves as

shown in Figure 7.

MaxLoad or High Load Limit (HLL) setpoint, in units of amps, is a parameter entered into

the CMC that prevents the main drive motor from overloading. Once this value is reached,

the CMC logic limits the inlet valve from opening any further. This action constrains the

motor by limiting the amp draw to the maximum allowable service factor amps by using the

inlet valve MaxLoad PID loop to maintain the MaxLoad current setpoint.

When the motor is sized for cold conditions, there are circumstances when MaxLoad will

never be reached. For example, the value of MaxLoad as shown in Figure 7, cannot be

attained for the T=hot curve because it is beyond the maximum compressor capability; that

is, the inlet valve is fully

open. This scenario

never limits the inlet

valve.

When ambient

conditions produce the

T=cold curve, the

compressor will not be

able to achieve the

maximum capacity

because it is beyond

the MaxLoad value.

Since MaxLoad is less

than or equal to the

motor nameplate FLA

times the adjusted

service factor, the

maximum compressor

capacity at T=cold

could only be reached

if the motor were sized

for the T=cold

condition.

Discharge

Pressure

Power at

Coupling

Amps

Bypass Valve

Pressure PID

Control Zone

TL

Inlet Valve

MinLoad PID

Control Zone

Inlet Valve

Pressure PID

Control Zone

HLL

Inlet Valve

MaxLoad PID

Control Zone

9

MinLoad Control

Capacity - Mass Flow

Setpoint in units of

amps is the power

value at which the

CMC transfers modulation control from the inlet to the bypass valve. The reason for this

transfer is to prevent the compressor from entering into a surge condition. The bypass valve

vents air to the atmosphere and maintains the pressure setpoint by using the bypass valve

pressure PID loop. At the same time, the inlet valve maintains the MinLoad setpoint by

using the inlet valve MinLoad PID loop; therefore, once the MinLoad setpoint is reached,

the compressor continues to produce a constant amount of air. Part of this air goes to the

Plant Air System, and the remainder is blown off. Even though the Plant Air System receives

only a portion of the air produced, the amount of power remains constant.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

10 CMC TECHNICAL REFERENCE MANUAL

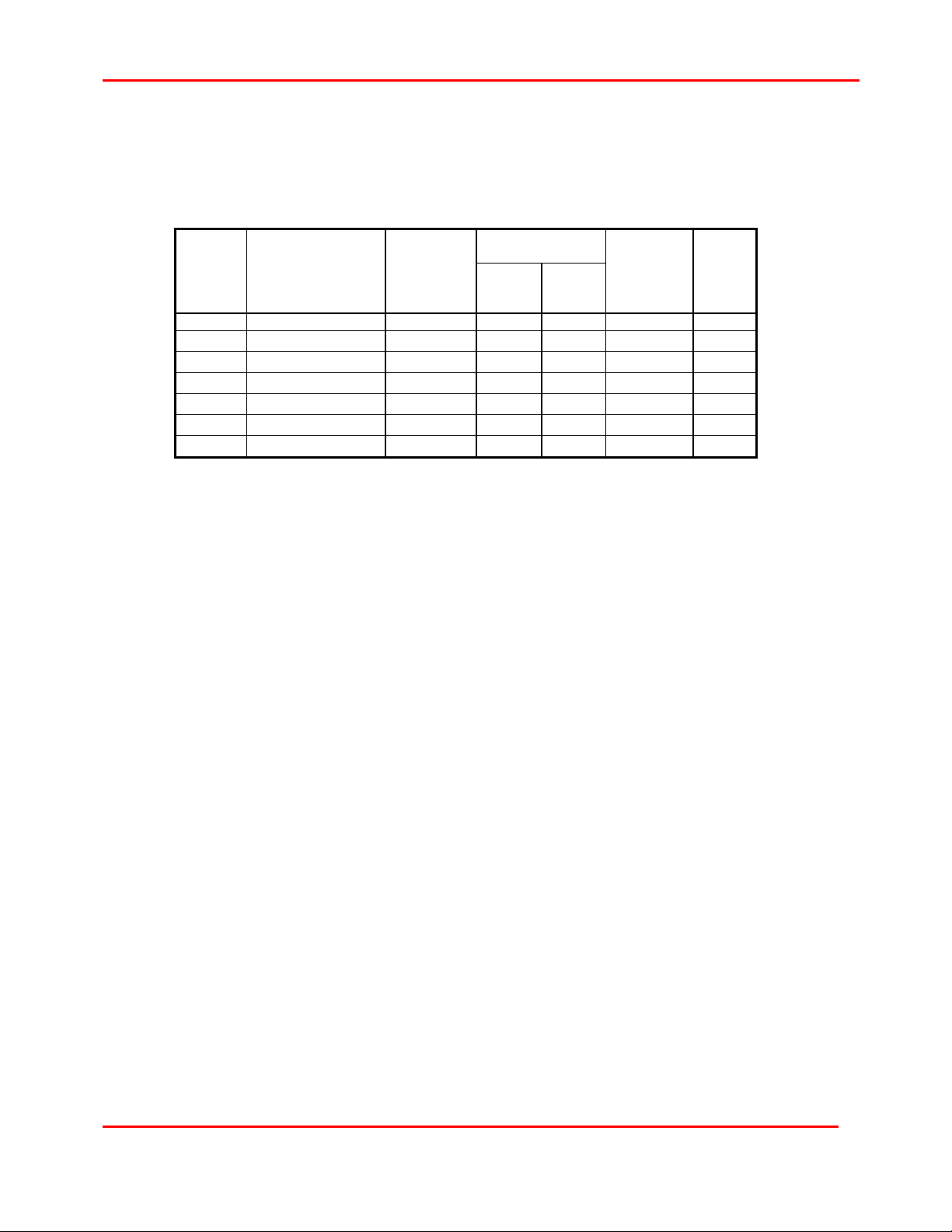

The following table presents seven capacity requirements for a plant air system. At each of

the capacities, the table shows the compressor output, valve position, discharge pressure

and power. Each of these values represents a percentage and is only an example. P2 is the

specified discharge pressure and P0 is the barometric pressure.

System Compressor Compress

or

Require

d

Capacity

0 Off 0 0 100 0 0

0 Unloaded 10 10 100 >P

100 Full Load 100 100 0 P

75 MinLoad 75 70 0 P

50 MinLoad 75 70 25 P

25 MinLoad 75 70 50 P

0 MinLoad 75 70 100 P

Operating

State

Output

Capacity

Open Position

Inlet

Valve

Bypass

Valve

Discharge

Pressure Power

0

2

2

2

2

2

20

100

80

80

80

80

From the table above, once the system required capacity moves below 75 percent, the

compressor still produces 75 percent capacity with 80 percent of the power. If the system

needs only 25 percent capacity, it will still have to pay for 80 percent of the power. This is

why it is important to open the bypass valve at the last possible moment; therefore, setting

MinLoad properly is critical for efficient energy management.

Surge Control

Surge is the reversal of flow within a dynamic compressor that takes place when the

capacity being handled is reduced to a point where insufficient pressure is being generated

to maintain flow. This condition can potentially damage the compressor if it is severe and is

allowed to remain in that state for a prolonged period; therefore, control and prevention is

required.

Control Methodology

Surge prevention is accomplished by opening the bypass valve prior to reaching the surge

point. The point at which the bypass valve opens is MinLoad. By blowing a portion of the air

to the atmosphere, the compressed air system gets the air that it demands. The

compressor avoids surge because it is still producing a constant air capacity.

Surge Detection

Even though the CMC controls to prevent surge, it can still occur. Insufficient rise to surge,

rapid changes in system discharge pressure, and various other reasons exist for a

compressor to surge.

Insufficient Rise To Surge

Rise to surge is the percentage of the compressor's surge pressure to discharge pressure

(see Figure 8). When an insufficient rise to surge situation exists, small fluctuations in the

air system demand and ambient temperature can cause the compressor to surge.

From Figure 8, when T=cold, there is sufficient rise to surge. As the ambient temperature

increases to T=hot, the amount of rise to surge decreases because the discharge pressure

is remaining constant and the natural curve is changing with temperature.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Capacity

Typically sufficient rise to surge

exists when a ten- percent rise

to surge can be achieved for the

hottest ambients that are

expected for the site. If this

design criterion is followed, the

control system should be able

to prevent surge for variations in

air demand and inlet

temperature. The same design

methodology applies for

changes in cooling water

temperature for multi-stage

compressors.

Changes in System Discharge Pressure

MinLoad corresponds to a specific

constant discharge pressure;

therefore, if the discharge pressure

changes, MinLoad must be reset to

properly control surge. As shown in

Figure 9, when the discharge

pressure is changed from point 1 to

2, a surge can occur at point 2 if

MinLoad is not reset.

Discharge

Pressure

Discharge

Pressure

Rise

To

Surge

T=hot

Figure 8: Rise To Surge

TL

T=cold

1

TL

11

2

Changes in system discharge

pressure also apply, but more subtly,

when the compressor begins to age.

Dirty inlet filter elements and fouled

Capacity - Mass Flow

coolers can change the

compressor's natural curve; so

MinLoad should be checked

Figure 9: Changes in Discharge Pressure

periodically to prevent surge from an

incorrect setting.

Rapid System Demand Changes

When the system demand varies rapidly over a wide range of capacity, the controller may

not react fast enough to open the bypass valve to prevent surge. The CMC reads discharge

pressure, motor amps, and approximately twenty other pressure and temperature inputs;

plus controls the inlet and bypass valve position. The time required to do all of this

approximately 100 milliseconds. When the controller is too slow to react, it is referred to as

"driving through MinLoad". The only prevention for a situation like this is to set MinLoad at a

more conservative value. The only negative implication to this is reduced energy savings,

because the bypass valve is opened early.

Incorrect Instrumentation Output

If the instrumentation, defined in Figure 4, is improperly calibrated or gives inaccurate

readings, the compressor could surge even though the CMC thinks it should not. Areas of

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

12 CMC TECHNICAL REFERENCE MANUAL

746

concern are insufficient power air, incorrect valve transducer calibration, and repeatability of

both inlet and bypass valves. If the valves are being sent signals for specific movements

and they do not respond by moving to the new positions, then the CMC has very little

chance of correctly controlling surge, or even the discharge pressure.

As discussed earlier, the CMC uses motor current as the standard method for determining

when to open the bypass valve. The time to begin opening the bypass valve is near

MinLoad amps. The equation,

I V PF

GHP

× × × ×η3

=

motor

indicates that horsepower is directly related to current; it is, but it is also related to voltage.

This is not normally a concern because voltage is primarily constant. However, there are

some locations where extreme voltage variations do exist. In these circumstances, the CMC

cannot correctly determine when it reaches MinLoad and a surge can occur. For these

applications, an optional watt transducer can be used to avoid this situation.

How is Surge Detected?

Note that it has been shown that even though the CMC has surge prevention logic, a surge

can still occur. The CMC has a surge detection system comprised of a surge pressure

transducer and motor current transformer (see Figure 10). The CMC senses surge when

the rate of change in last stage discharge pressure and the rate of change in motor current

are greater than the surge sensitivity setpoint value. When this occurs, the CMC will alarm

and unload the compressor.

CMC

PT

Base

Control

Module

PT

4-20 mA

Pneumatic Tubing

4-20 mA

StarterCT

Inlet

Valve

CompressorMotor

Bypass

Valve

Check

Valve

Figure 10: Changes in Discharge Pressure

Surge AbsorberTM

When the controller recognizes that a surge occurred, the compressor will unload. With the

Surge AbsorberTM feature enabled, the controller will increment the bypass valve position by

a fixed percentage, send the inlet valve to the MinLoad point (if it is not already there) and

then let normal system demand reload to the operating pressure. This process will repeat

up to three times within a ten-minute period. If the compressor surges four times in ten

minutes, the compressor will remain unloaded until an operator presses the reset button.

Each detected surge drives a Surge Event to the Event Log. If the compressor unloads do

to repeated surges, a Surge Unload Alarm Event is driven to the Event Log.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

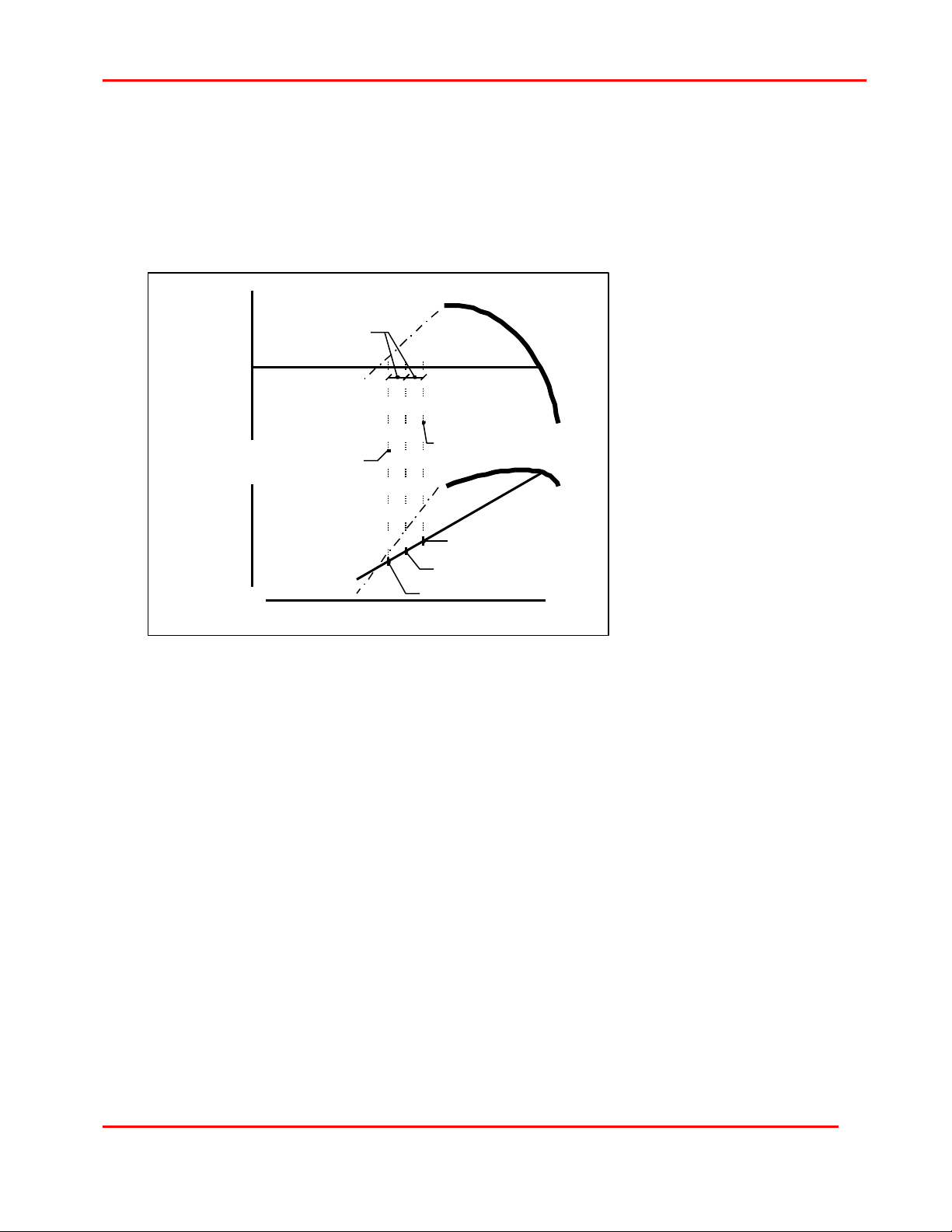

Surge Indexing

Since the setting of MinLoad Control Setpoint is sensitive to many variables in a

compressed gas system, there is potential for the setting to require adjustment throughout

the operation of the compressor. When MinLoad is set incorrectly, one of two things can

happen. When MinLoad is set too high, the compressor will consume excessive power at

MinLoad. When MinLoad is set too low, the compressor is allowed to go past the surge line

and surge occurs.

When Surge Indexing is

MinLoad

Surge

Index

Increment

Discharge

Pressure

MinLoad Control Setpoint

MinLoad Control Setpoint #3

(currently active)

MinLoad Control Setpoint #1

MinLoad Control Setpoint #1

Power at

Coupling

Amps

MinLoad User Setpoint

(reset returns control here)

Capacity - Mass Flow

match the new setting and when reset the MinLoad Control Setpoint is reset to the original

MinLoad.

enabled, it corrects the

situation when MinLoad is

set too low by automatically

adjusting MinLoad to a

higher value upon a surge.

The indexed setting,

MinLoad Control Setpoint

will remain in effect until

MinLoad User Setpoint is

manually changed on the

Operator User Interface, or

the Reset button is held for

more than five seconds.

When MinLoad User

Setpoint is manually

changed, the MinLoad

Control Setpoint is

automatically changed to

13

Entering a non-zero number into the MinLoad Surge Index Increment variable enables surge

Indexing.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

14 CMC TECHNICAL REFERENCE MANUAL

Oil System Control

The CMC panel provides control of the prelube pump and lube oil heater in the starting

sequence, during normal operation and after compressor stops or trips.

Prelube Pump

The prelube pump is started when the panel power is on and Seal Air is present. The

prelube pump stops after the compressor start button is pushed and the programmable

timer “Start Time” has expired. The pump does not come on again until the Stop key is

pressed, and will remain on until the panel power is turned off or Seal Air is lost.

Oil Heater

The oil heater is thermostatically controlled. When the oil temperature is below the set point

temperature, the oil heater is energized, above the set point temperature it is de-energized.

The oil heater control does not have any interaction with the microprocessor board and is

designed to operate with the control panel de-energized as long as three-phase power is

available.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Protection and Monitoring

Each CMC base module has twenty-three analog inputs, sixteen digital inputs, four analog

outputs and sixteen digital outputs for control, protection and monitoring. These input

functions provide the CMC with information about the compressor. The CMC board uses the

output functions to communicate to the user and perform actions like starting the

compressor and turning on the prelube pump. All of these inputs and outputs are required to

interface physical actions to and from the electronics.

Analog Functions

An analog function is one in which an electrical signal represents a specific pressure,

temperature, vibration and current input; or valve position output. As these inputs and

outputs fluctuate, the electrical signal to and from the microprocessor board also fluctuates

proportionally to the amount of change.

Analog Inputs

Twenty-one grounded and two floating analog inputs are used for protection, monitoring and

control. Each input used for protecting the compressor is programmed for alarm and trip

indication. Each of these functions is pre-programmed with the function title, engineering

units, range, alarm and trip values, so no configuration is required upon receipt by the

customer.

15

The CMC uses pressure transmitters to measure pressure, resistance temperature

detectors (RTD) and transmitters to measure temperature, eddy current based vibration

transmitters to measure shaft vibration and a current transformer to measure the motor

current.

The CMC logic used for the protective alarm and trip functions is as follows: if the actual

value of the input is greater than or equal to the alarm or trip value, indicate the condition.

This logic is used for all inputs except, low oil pressure and temperature where the logic is

reversed. To prevent nuisance alarms and trips, all standard analog inputs use an alternate

alarm and trip value during the stopped, starting, and coasting states. The alternate

setpoints cannot be edited through the Operator User Interface.

Analog Outputs

Two of the available four analog output functions are for inlet and bypass valve positioning.

These are only output functions. The standard configuration for a CMC has no input

information as to the valve location. The CMC calculates the position based upon where the

valves are supposed to be and sends those signals to the valves.

Digital Functions

A digital function is one in which the presence of an electrical signal indicates ON or YES,

and the lack of that signal represents OFF or NO. This is analogous to a light switch that

has only two states, ON or OFF. The term "discrete" is also used instead of digital in many

instances. The term that will be used throughout this documentation shall be digital.

Digital Inputs

The sixteen digital inputs provide status of field switches. Emergency Stop and Low Seal Air

Pressure trip are standard. Any of these inputs can be configured as an alarm or trip. All

inputs operate on 24 VDC power.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

16 CMC TECHNICAL REFERENCE MANUAL

Digital Outputs

The sixteen digital outputs are used by the CMC to start the prelube pump, energize the

main starter contacts, indicate that an alarm or trip condition exists, indicate that the

compressor is unloaded, activate the running unloaded shutdown timer and to sound the

horn. Outputs can operate on 120 VAC, 60 Hz, single-phase power or 24 VDC power.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

Compressor Operating Methodology

In the following description of compressor operation, the term “state” is used to indicate

what the compressor is doing, or mode of operation, at any given time. These operating

states exist in a hierarchy. For example, the two highest level states are “Stopped” and

“Rotating”. All other states exist at a level below these two states.

17

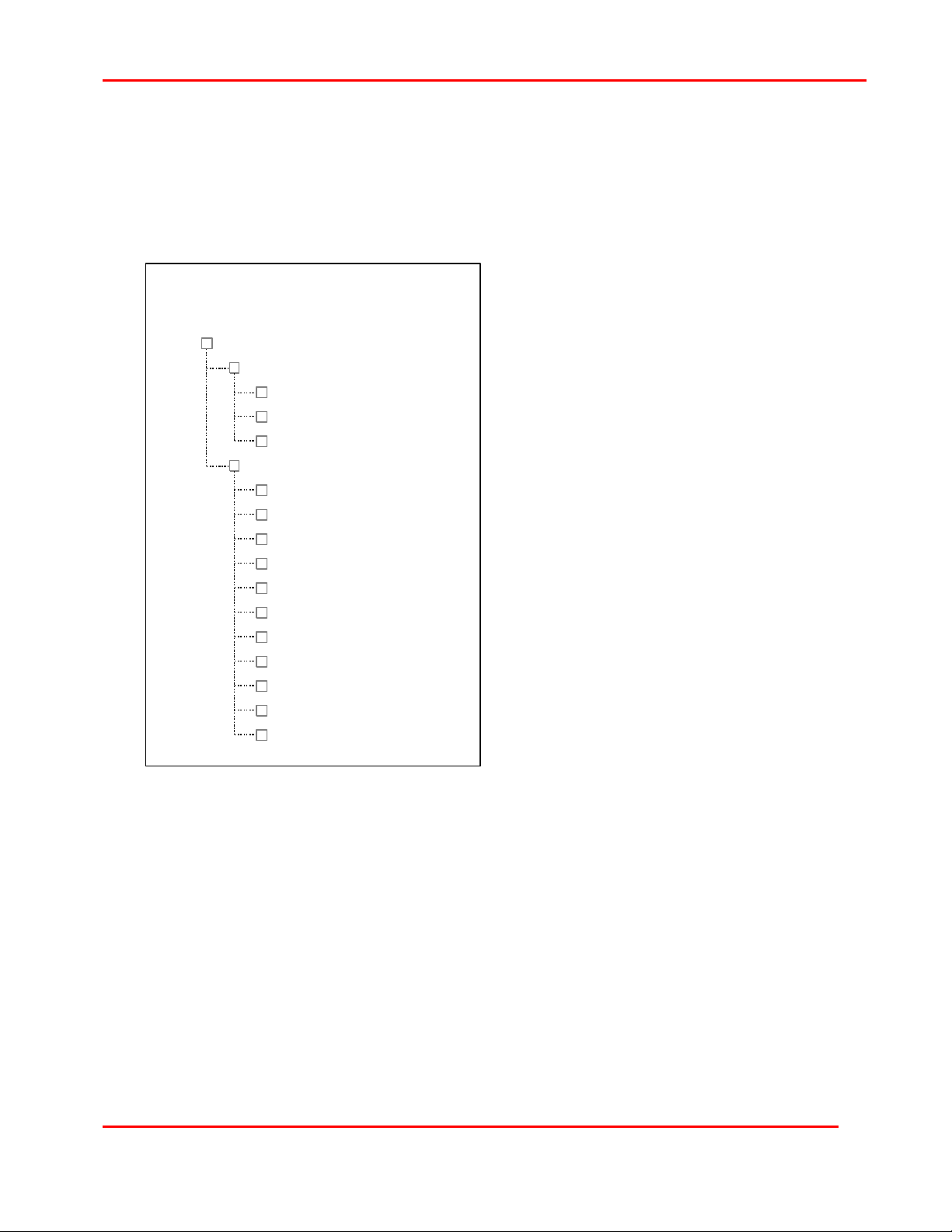

Compressor Operating States

Motor Driven Packages

+

Compressor

+

Stopped

Waiting

Not Ready

Ready

+

Rotating

Starting

Unloaded

A-D Unloaded

Surge Unload

Loading

MinLoad

Loaded

Full Load

MaxLoad

Unloading

Coasting

common and quite often overlooked reason for the compressor being “Not Ready” is when

the Emergency Stop push button has been engaged. This state can exist indefinitely.

This state implies that the compressor is or

NOT rotating. It is important to note that this

is an implication only. If the instrumentation is

not working properly or the system is setup

improperly, the compressor could be rotating.

Waiting

After the panel power is energized, the

controller starts the Waiting Timer and does

not allow further User operation until after the

timer expires. This timer is set at the factory

for two minutes (120 seconds) and is not

adjustable. This period allows the

compressor prelube pump to circulate oil

throughout the casing and prevents restarting

while the compressor is coasting down

during an electrical interruption.

Not Ready

When in this state, the compressor is “Not

Ready To Start”. This state is entered when

the Waiting Timer has expired and any time

that a compressor trip has been identified or

a stop command has been issued. A very

Stopped

Ready

Similar to the previous state, this state could be redefined as “Ready to Start”. This state is

entered when all compressor permissive functions have been satisfied. This state can exist

indefinitely.

Rotating

This mode does not necessarily mean that the compressor is actually rotating. It means that

it is rotating or rotation is pending and expected.

Starting

Any time after the compressor is ready and a start command is given, this state is entered.

The goal for this period is to get the compressor to rated speed and running unloaded.

“Starting” is allowed for only the Start Timer period and is adjustable. This time period is

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

18 CMC TECHNICAL REFERENCE MANUAL

limited to a maximum of one minute, or 60 seconds. The reason for the limit is to prevent

the compressor from operating in the critical speed for an extended period. Stage vibration

alarm and trip setpoints are increased during this period to get the compressor through the

critical speed region. After the compressor has “Started”, the alarm and trip setpoints are

adjusted back to their original values. The same procedure occurs for stage air temperature

also.

This state exits only after the Starting Timer has expired. THE COMPRESSOR IS ALWAYS

STARTED UNLOADED. On exit of “Starting”, the compressor will return to the mode that it

was in the last time it ran. For example, typical operation implies that prior to stopping the

compressor, the Unload key is pressed. If this occurred, then the compressor will remain in

“Unload” after starting. If the compressor is was running and tripped, the compressor will

automatically return to the “Loaded” mode on exit of the Starting state. The User may also

press the Load or Unload key prior to pressing the Start key to force the compressor to into

either post-Starting state.

Unloaded

The compressor is in this state after a start (and Load Selected is not in effect) or when the

User issues an unload command. A-D Unloaded and Surge Unload are also considered

states. However, these two states are really just reasons for being in the Unloaded state. AD Unloaded means “AutoDual Unloaded” which occurs when AutoDual is enabled and the

system pressure has been high enough for a long enough time to drive an unload

command. “Surge Unload” is similar in that a surge event drives the unload command

instead of AutoDual. These states can exist indefinitely.

Loading

When a valid load command is issued, the compressor will enter this state. This state

exists until the MinLoad state is satisfied. The duration of this state depends upon PID

settings for the inlet valve at the MinLoad state and the demand for air.

MinLoad, Loaded, Full Load and MaxLoad

These states transition among themselves as demand for air changes. “MinLoad” means

that the bypass valve is controlling pressure and the inlet valve is maintaining the MinLoad

Control Setpoint. “Loaded” means that the inlet valve is controlling pressure and the bypass

valve is closed. “Full Load” occurs when the inlet valve has reached the full open or 100%

position. “MaxLoad” means that the inlet valve is maintaining the MaxLoad Setpoint to

prevent motor damage. In both the “Full Load” and “MaxLoad” states, system pressure will

be lower than setpoint pressure.

Unloading

This state occurs when a valid Unload command is issued and will persist until the

compressor reaches the Unloaded state.

Coasting

When a trip or any stop command is issued and the compressor is running, the motor will

be de-energized and the compressor will begin to coast to a Stopped state. This state will

remain as long as the adjustable Coast Timer is in effect. At the end of the timer, the

compressor will enter either the Ready or Not Ready state.

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

CMC TECHNICAL REFERENCE MANUAL

WARNING

Failure to set the Coast Timer for a period greater than or equal to the actual

coasting time can result in compressor damage.

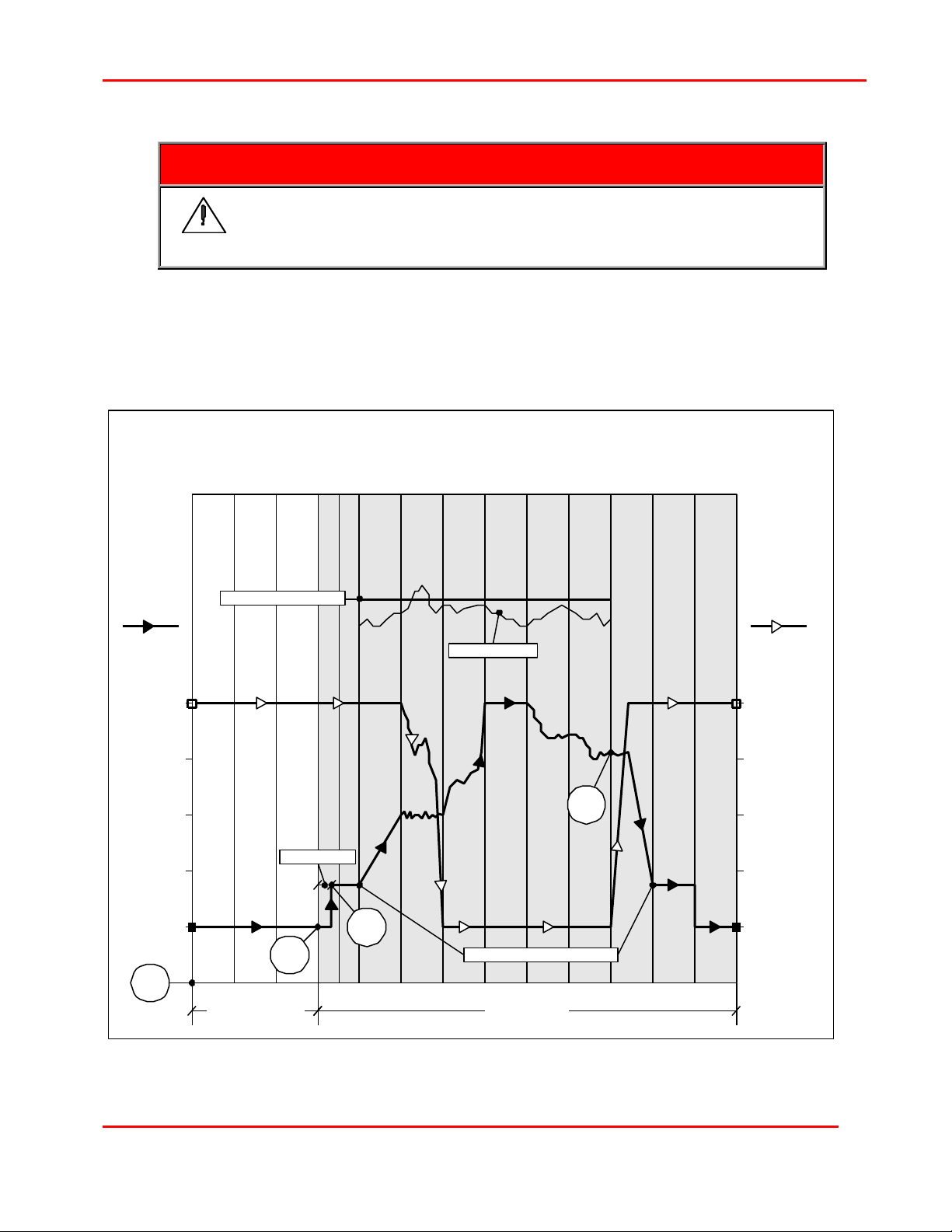

Compressor Operating States

The following diagrams graphically depict the states relative to valve position. This diagrams

is provided to assist in the understanding of overall compressor operation.

Compressor Operating States

with Valve Position

19

Inlet

Valve

%

100

75

50

25

0

Power

On

milli

amps

20

16

12

Waiting

System Pressure Setpoint

8

4

Ready

Not Ready

Tight Closure

Start

Starting

Unloaded

Load

Loading

MinLoad

System Pressure

Loaded

Full Load

Inlet Valve Unload Position

Loaded

Unload

MaxLoad

Unloading

Coasting

Unloaded

Bypass

Valve

milli

%

amps

100

4

75

8

50

12

25

16

0

20

RotatingStopped

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

20 CMC TECHNICAL REFERENCE MANUAL

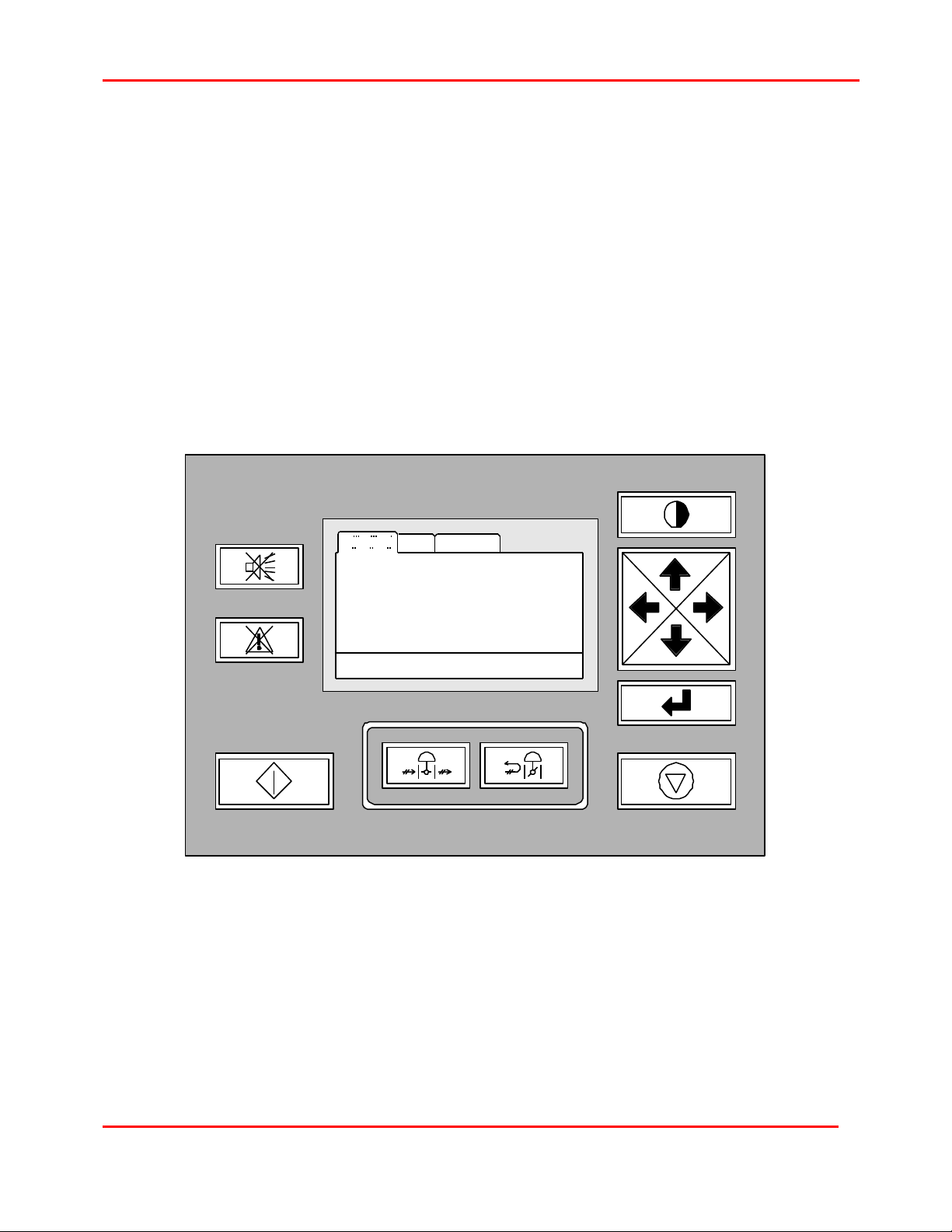

User Interface

OUI (Operator User Interface)

User interface is defined as the means by which people interact with the compressor control

system. The standard configuration of the CMC has two components of the user interface.

They are the OUI and the device plate. The key component of "easy to use" is that there are

only twelve buttons to press on the OUI and four buttons, lights, and switches on the device

plate.

The CMC OUI consists of six command buttons (Start, Stop, Load, Unload, Acknowledge

and Reset), four navigation keys (Up, Right, Left and Down), an Edit mode selection key

(Enter) and a Contrast key. These keys in conjunction with the 240x128-pixel graphics

display make up the user interface to the compressor. The bezel that surrounds the OUI

ensures that the NEMA 4 rating is maintained for the OUI.

CENTAC

Microcontroller

SYSTEM

System

Pressure

Pressure

Setpoint

Motor

Current

Running Hours 11445

Loaded

INFO

SETTINGS

105.3

105.0

173.4

Inlet

Valve

Bypass

Valve

22JUL96 12:00:00

95

0

Load Selected

Remote

1/2

1X36003 Version 2.52

1996-1999 Ingersoll-Rand Company

Date of Issue: 18-Oct-1999

Loading...

Loading...