Ingersoll-Rand 66266-XXX-B User Manual

OPERATOR’S MANUAL 66266-XXX-B

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST,

DISASSEMBLY & REASSEMBLY.

CHOP-CHECK STYLE

LOWER PUMP ENDS

Also covers 637074-X43-B service kits

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

RELEASED: 1-8-99

REVISED: 10-18-10

(REV. 0

4)

SERVICE KITS

Use only genuine ARO® replacement parts to assure com-

y

patible pressure rating and longest service life.

637074-X43-B for general repair of 66266-XXX-B lower

y

pump ends.

GENERAL DESCRIPTION

WARNING

PRESSURE AS INDICATED ON PUMP MODEL PLATE.

WARNING

FOR ADDITIONAL SAFETY PRECAUTIONS AND IMPORTANT INFORMATION.

This manual only covers the lower pump section. It is one

y

of four documents which support an ARO pump. Replacement copies of these forms are available upon request.

650XXX-X Pump Model Operator’s Manual.

General Information for Air Operated or Hydraulically

Lower Pump End Operator’s Manual.

:

Air or Hydraulic Motor Operator’s Manual.

The chop-check design provides for easy priming of the

y

lower foot valve. The double acting feature is standard

in all ARO industrial pumps. Material is delivered to the

pump discharge outlet on both the up and down stroke.

DO NOT EXCEED MAXIMUM OPERATING

REFER TO GENERAL INFORMATION SHEET

Operated Pumps.

MAINTENANCE

The air / hydraulic motor is completely separate from the

lower pump end. This helps to keep the motor from being

contaminated by the material being pumped. Periodically,

ush entire pump system with a solvent that is compatible

with the material being pumped.

Keep solvent cup lled with this compatible solvent. This will

keep material from drying on the piston rod, which would

drag thru the packings, ruin them and eventually scour the

piston rod.

Provide a clean work surface to protect sensitive internal

moving parts from contamination from dirt and foreign matter during disassembly and reassembly.

Before reassembling, lubricate parts as required. When assembling “O” rings, or parts adjacent to “O” rings, exercise

care to prevent damage to “O” rings and “O” ring groove surface.

LOWER PUMP END DESCRIPTION CHART

66266 - X 4 3 - B

Packing Material

3 - Glass lled PTFE (upper and lower)

C - UHMW-PE (upper and lower)

G - UHMW-PE / Leather staggered (upper and lower)

P - UHMW-PE / Glass lled PTFE staggered (upper)

- UHMW-PE (lower)

R - Glass lled PTFE / UHMW-PE staggered (upper)

- Glass lled PTFE (lower)

Spring Arrangement

4 - Multiple wave spring

Plunger Type

3 - Hardened stainless steel with hard chrome plating

Service Kit Selection

Example: Lower Pump End # 66266-C43-B

Service Kit # 637074-C43-B

66266 - X 4 3 - B

637074 - X 4 3 - B

Packing Plunger

TROUBLE SHOOTING

No material at outlet (pump continually cycles).

Check material supply. Disconnect or shut o the air sup-

y

ply and replenish the material, reconnect.

Material on one stroke only (fast downstroke).

The (21) check may not be seating in the (22) seat (see

y

lower pump disassembly). Remove the check from the

seat, clean and inspect the check and seat area. If the

check or seat is damaged, replace.

Material on one stroke only (fast upstroke).

The (34) valve rod may not be seating in the (28) seat (see

y

lower pump disassembly). Remove the valve rod from the

seat, clean and inspect the valve rod and seat area. If the

valve rod or seat is damaged, replace. Check for worn or

damaged packings. Replace the packings as necessary.

Material leakage out of the solvent cup or material appears on the pump plunger rod.

Relieve the pressure in the pump and tighten the solvent

y

cup until leakage discontinues. If this procedure does not

aid in stopping the leakage problem, the upper packings

may be worn (see lower pump disassembly). Replace the

packings as necessary.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

www.ingersollrandproducts.com

FAX (800) 892-6276

y

© 2010

CCN 99768657

C

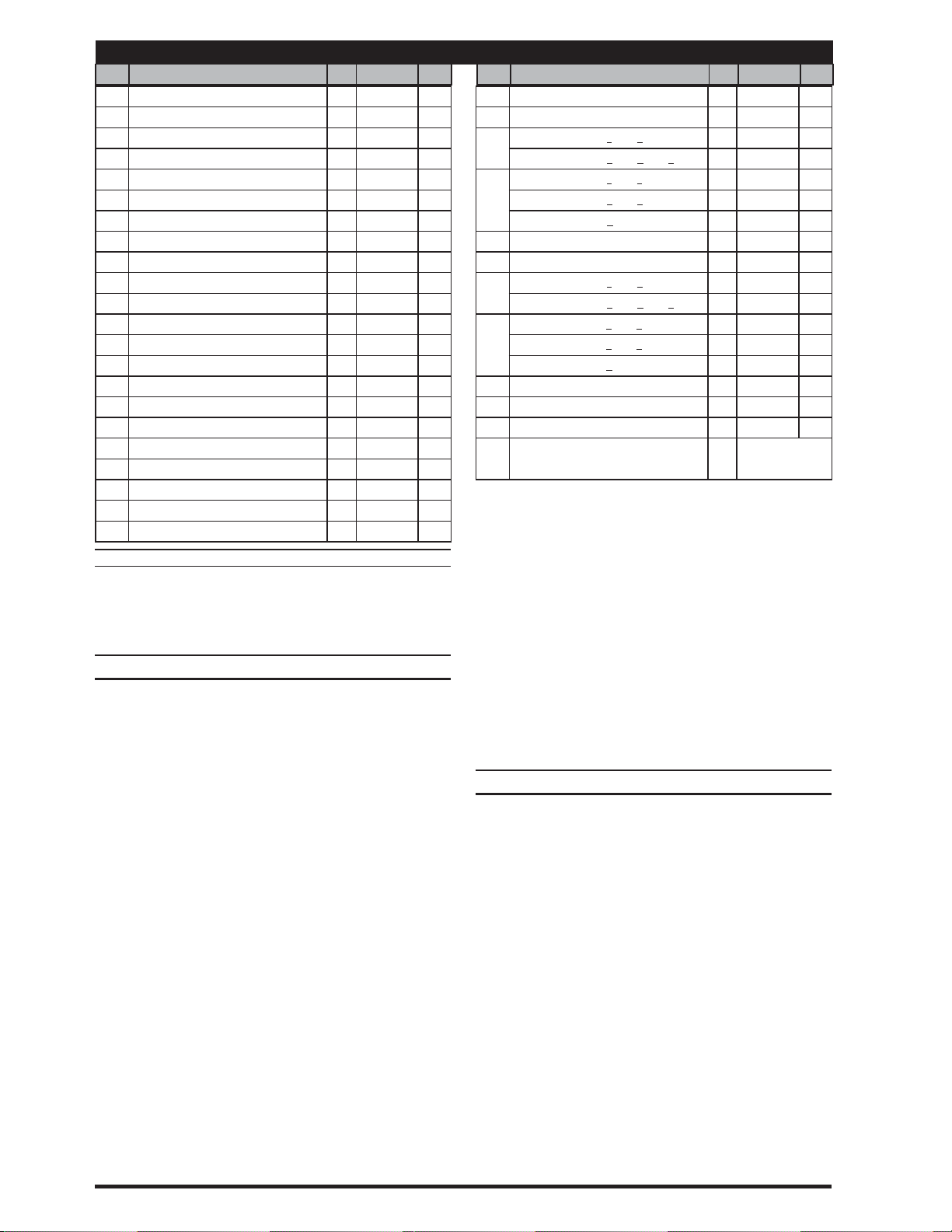

PARTS LIST / 66266-XXX-B

Item Description

1 Solvent Cup Assembly (1) 66866-1 [C]

4Rod

6 Pump Body (1) 90848 [DI]

7 Gasket (2) 90306 [Co]

9

9 Suction Tube (1) 91844 [C]

10 Tie Rod (3) 91725 [C]

11 Nut

15 Pressure Chamber Body (1) 91730 [DI]

21 Check (1) 90916 [SH]

22 Seat (1) 94791 [SH]

23 “O” Ring

9

24 “O” Ring

9

25 Check Stop (1) 94793 [DI]

26 Plunger Rod (1) 91552-1 [SH]

28 Seat (1) 90914 [SH]

30 Primer Rod (1) 91719 [SH]

31 Primer Plate (1) 93597-1 [SS]

32 Primer Button (1) 93596-1 [SS]

33 Lock Nut

34 Valve Rod (1) 90847 [SH]

36 Valve Seat Nut (1) 90912 [C]

37 Retaining Ring (1) Y147-102 [C]

9

[B] = Nitrile [GFT] = Glass lled PTFE

[Br] = Brass [L] = Leather

[C] = Carbon Steel [SH] = Hard Stainless Steel

[Co] = Copper [SS] = Stainless Steel

[D] = Acetal [T] = PTFE

[DI] = Ductile Iron [UH] = UHMW-PE

NOTE: All threads are right hand.

1.

Remove the (6) pump body from the (9) suction tube by

sliding it o of the three (10) tie rods.

2.

Remove the (7) gasket from the top of the (9) suction

(size)

(not shown, used to adjust item 1)

(5/8” - 18)

(3/32” x 2-5/8” o.d.)

(1/8” x 2-5/8” o.d.)

(7/16” - 20)

MATERIAL CODE

(Qty) Part No. [Mtl] Item Description

(1) 93456-1 [C]

(3) Y11-110-N [C]

(2) Y328-143 [T]

(1) Y325-229 [B]

(1) Y171-7-C [C]

LOWER PUMP DISASSEMBLY

43 Wave Spring (1) 94131 [SH]

47 Wave Spring (1) 90915 [SH]

9

51

9

“V” Packing

52

9

“V” Packing

53 Male Packing Washer (1) 90839 [Br]

54 Female Packing Washer (1) 90910 [SS]

55

9

“V” Packing

56

9

“V” Packing

57 Male Packing Washer (1) 90909 [SS]

65 “U” Cup (1) 90911 [GFT]

9

115 Backup (1) 94132 [D]

Items included in Service Kit

9

below)

NOTE: The service kit includes (2) 91736 copper gaskets which are used on

models 66266-X43 (these models are prior to models 66266-X43-B). These

gaskets are used in place of the (2) Y328-143 “O” rings.

the (30) primer rod from the (34) valve rod and unthread

and remove the (34) valve rod from the (26) plunger rod.

CAUTION: Be careful not to mar or damage the surfaces

of these rods.

13.

Slide the middle packing assembly o of the (34) valve

rod.

14.

Clamp the (28) seat in a vise and remove the (36) valve

seat nut, allowing removal of the middle packing components.

15.

Remove the (1) solvent cup assembly from the (6) pump

body, allowing removal of the upper packing components.

tube.

3.

Remove the three (10) tie rods.

4.

Pull the (9) suction tube off of the middle packing and

valve section and out of (25) check stop.

5.

Push the (26) plunger rod down to expose the primer

components.

6.

Remove the (33) lock nut, (32) primer button and (31)

primer plate from the (30) primer rod.

7.

Pull up on the (26) rod and remove the middle packing,

valve section and (30) primer rod from the (15) pressure

chamber body.

8.

Remove the (7) gasket from the (25) check stop.

9.

Using a at bladed screwdriver to pry on the slot in the

(25) check stop, remove the (25) check stop, (21) check,

(22) seat and two (23) “O” rings from the (15) pressure

chamber body.

10.

Remove the (24) “O” ring from the (25) check stop.

11.

Using a retaining ring pliers, remove the (37) retaining

ring from the (21) check, allowing removal of the (65) “U”

cup packing.

.

12

Using the wrench ats provided, unthread and remove

ARO® is a registered trademark of Ingersoll Rand Company

y

Loctite® and 242® are registered trademarks of Henkel Loctite Corporation

y

Page 2 of 4 66266-XXX-B (en)

y

y

NOTE: Inspect and replace old parts with new parts as necessary. Look for deep scratches on metallic surfaces. Replace all

“O” rings upon reassembly. Lubricate all threads upon reassembly. Refer to sealant and torque notes on page 3.

Assemble the (65) “U” cup packing into the (21) check,

1.

securing with the (37) retaining ring.

Assemble the (54) female packing washer, (55 and 56) “V”

2.

packings, (57) male packing washer and (47) wave spring

to the (28) seat, securing with the (36) valve seat nut (refer to page 3).

Slide the (21) check (beveled end rst) onto the end of

3.

the (30) primer rod opposite the wrench flats (refer to

page 3).

Thread the (30) primer rod into the (34) valve rod and

4.

tighten.

Assemble the (24) “O” ring to the groove in the (25) check

5.

stop.

Slide the (25) check stop onto the (34) valve rod and (30)

6.

primer rod assembly and t over the (21) check.

.

Slide the (28) seat and middle packing assembly over the

7

(size)

(66266-343-B, -R43-B)

(66266-C43-B, -G43-B, -P43-B)

(66266-343-B, -P43-B)

(66266-C43-B, -R43-B)

(66266-G43-B)

(66266-343-B, -R43-B)

(66266-C43-B, -G43-B, -P43-B)

(66266-343-B, -R43-B)

(66266-C43-B, -P43-B)

(66266-G43-B)

(see note

(Qty) Part No. [Mtl]

(3) 93661-2 [GFT]

(3) 93661-4 [UH]

(2) 93661-2 [GFT]

(2) 93661-4 [UH]

(2) 93661-1 [L]

(2) 93662-2 [GFT]

(2) 93662-4 [UH]

(2) 93662-2 [GFT]

(2) 93662-4 [UH]

(2) 93662-1 [L]

637074-X43-B

LOWER PUMP REASSEMBLY

(continued on page 4)

Loading...

Loading...