Ingersoll-Rand 66266-X User Manual

OPERATOR’S MANUAL

INCLUDING: SERVICE KITS, TROUBLESHOOTING, PARTS LIST, DISASSEMBLY & REASSEMBLY

LOWER PUMP END

CHOP--CHECK STYLE

ALSO COVERS 637074-XXX SERVICE KIT

IMPORTANT: READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

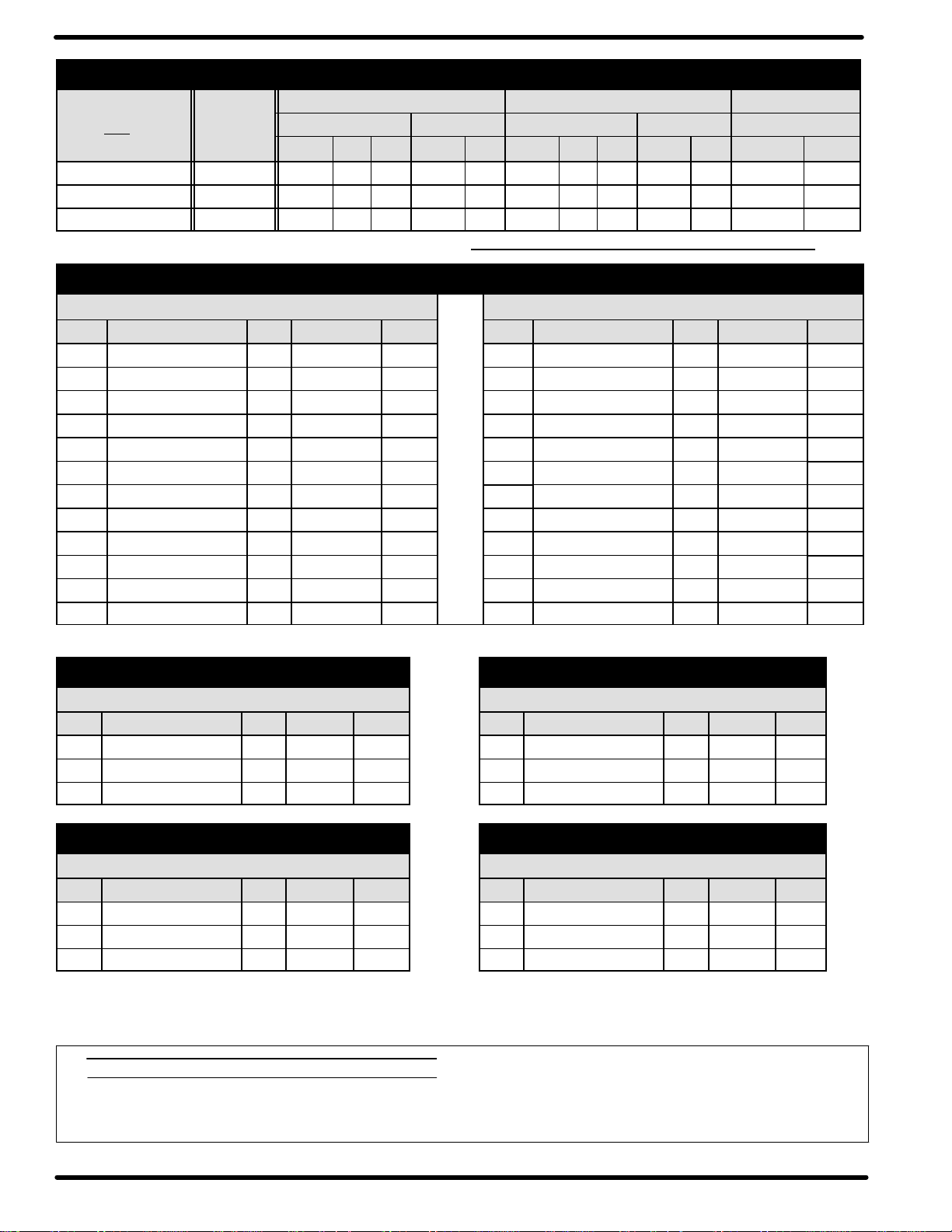

LOWER PUMP END OPTION

DESCRIPTION CHART*

66266--X

RELEASED: 7--7--90

REVISED: 6--4--10

(REV. G) IPP

66266--XXX

(PACKINGS ARE UPPER AND LOWER UNLESS NOTED)

PACKING MATERIAL

1 THIOKOL LEATHER 3 GLASS FILLED PTFE

5 PTFE(GF)/LEATHER STAG’D (UPPER)

GLASS FILLED PTFE (LOWER)

C UHMW--PE

D

UHMW--PE/LEATHER STAG’D (UPPER)

LEATHER (LOWER)

- AS OF MAY 15, 1995 NO LONGER AVAILABLE

-

-

G UHMW--PE/LEATHER STAG’D

P UHMW--PE/PTFE STAG’D (UPPER)

UHMW--PE (LOWER)

R PTFE/UHMW--PE STAG’D (UPPER)

PTFE (LOWER)

* NOT ALL MODEL COMBINATIONS ARE AVAILABLE, REFER TO PUMP MODEL MANUAL (650XXX--XXX) FOR ‘‘ACTIVE” MODELS.

SERVICE KITS

• Use only genuine ARO replacement parts to assure compatible-

pressure rating and longest service life.

• 637074--XXX for general repair of 66266--XXX Lower Pump End

GENERAL DESCRIPTION

WARNING

SURE AS INDICATED ON PUMP MODEL PLATE

WARNING

FOR ADDITIONAL SAFETY PRECAUTlONS AND IMPORTANT

INFORMATION.(Seethe pump model manual for the proper Form

No.)

DO NOT EXCEED MAXIMUM OPERATING PRES-

REFER TO GENERAL INFORMATION SHEET

• This LOWER PUMP END MANUAL is one of four documentsneed-

ed to properly support an ARO pump model.

Part A. 650XXX--XXX--X MODEL (OPERATOR’S) MANUAL,

Part B. GENERAL INFORMATION,

Part C. MOTOR (OPERATOR’S) MANUAL,

Part D. LOWER PUMP END (OPERATOR’S) MANUAL.

Copies are available from the factory upon request.

• The Chop--Checkdesign provides far easy priming of thelower foot

valve. The double acting feature is standard in all ARO industrial

pumps, material is delivered to the pump discharge outlet on both

the up and down stroke.

PLUNGER TYPE

PACKING MATERIAL

SPRING ARRANGEMENT

1COILSPRING4 WAVE SPRING

5 COMPOSITE SPRING W/ADJ P’KG NUT -

PLUNGER TYPE

3 HD SS W/HD CHROME PLATING

SPRING ARRANGEMENT

• The pump ratio is an expression of the relationship between the air

motor area and the lower pump end area.

REGULATED INLET AIR PRESSURE X PUMP RATI0 =

MAXIMUM FLUID OUTLET PRESSURE PRESSURE

EXAMPLE: When 150 PSI (10.3 Bar) air pressure is supplied to the

pump motor on a 3:1 ratio pump, the lower pump end will develop a

maximum of 450 PSI (31 Bar) fluid pressure (at no flow).

As the fluid control is opened, the flow rate will increase as the motor

cycle rate increases to keep up with the demand.

• Operating at excessive pressures will shorten the life of the pump.

TROUBLE SHOOTING CHOP-CHECK PUMPS

Common Lower Pump End Problems

• No material at outlet. (Pump continually cycles.)

Check material supply, disconnect or shut off the air supply and re-

plenish the material, reconnect.

• Material on one stroke only. (fast downstroke.)

The lower check may not be seating in the foot valve. (See lower

pump disassembly) Remove the check from the foot valve, clean

and inspect the valve seat area. If check or foot valve are damaged,

replace.

• Material on one stroke only. (fast upstroke.)

Check for worn or damaged seals. Replace the seals as necessary.

• Material leakage out of the solvent cup or material appears on

the pump plunger rod.

For Models (--X5X Only). Increase the load on the packings by tightening the packing nut.

Check for worn upper packings and replace them as necessary.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

© 2010

PACKING OPTIONS AND SERVICE KITS

LOWER PUMP SERVICE UPPER PACKING MIDDLE PACKING LOWER PACKING

66266- XXX KIT

(Popular Models)

- G13, - - G43.- G53 -

- P13, - - P43, - P53 -

- R13, - - R43, - R53 -

(See Page 4 for more Options) - After May 15, 1995 these models are no longer available. EXAMPLE: 66266- G13 is replaced by 66266- G43 & Svce kit is 637074-G43.

637074- XXX

637074- G43 93661- 4 (3) [UH] 93661-1 [L] 93662-4 (2) [UH] 93662- 1 [L] 90911 [T]

637074- P43 93661- 4 (3) [UH] 93661-2 [T] 93662-4 (4) [UH] ------- -- 90911 [T]

637074- R43 93661-2 (3) [T] 93661-4 [UH] 93662-2 (4) [T] ------- -- 90911 [T]

51 (X) ‘‘V” PACKING 52 (2) ‘‘V” PKG

PART NO (QTY)

PART NO [MT’L] PART NO (QTY) [MT’L] PART NO [MT’L] PART NO [MT’L]

[MT’L]

55 (X) ‘‘V” PACKING

56 (2) ‘‘V” PKG 65 (1) ‘‘U” CUP

COMMON WETTED PARTS

66266- XXX 66266- XXX

ITEM DESCRIPTION (QTY) PART NO [MTL]

1 Solvent Cup (1) 66866- 1 [CS] 26 Plunger Rod (1) 91552- 1 [SS]

6 Pump Body (1) 90848 [DI] 28 Seat (1) 90914 [SS]

7 Gasket (2) 90306 [Cu] 30 Rod (1) 91719 [SS]

9 Tube (1) 91844 [SS] 31 Plate (1) 93597- 1 [SS]

10 Tie Rod (3) 91725 [CS] 32 Button (1) 93596- 1 [SS]

11 Nut (3) Y11-110- N [CS] 33 Nut (1) Y171-7-C [SS]

15 Foot Valve Body (1) 91730 [CS] 34 Rod (1) 90847 [SS]

21 Body (1) 90916 [SS] 35

22 Seat (1) 91716 [Cu] 36 Nut (1) 90912 [CS]

23 Gasket (2) 91736 [SS] 37 Snap Ring (1) Y147- 102 [CS]

24 ‘‘O” Ring (1) Y325- 229 [B] 58

25 Adapter (1) 91842 [DI] 61

Y Use only on -1XX,- AXX,- DXX & - KXX P Use only on -1XX, - AXX & - DXX

ITEM DESCRIPTION (QTY) PART NO [MTL]

Wavy Washer Y

Washer, F Backup P

Washer, M Backup P

(1) 91745 [CS]

(1) 91743 [Br]

(1) 91744 [Br]

UPPER PACKING PARTS

COIL SPRING MODELS --X1X ONLY

ITEM DESCRIPTION (QTY) PART NO [MTL]

41 Spring (1) 90836 [CS]

50 Washer, F Backup (1) 90840 [Br]

53 Washer, M Backup (1) 90839 [Br]

UPPER PACKING PARTS

WAVE SPRING MODELS --X4X ONLY

ITEM DESCRIPTION (QTY) PART NO [MTL]

43 Wave Spring (1) 94131 [SS]

53 Washer, M Backup (1) 90839 [Br]

115 Washer, F Backup (1) 94132 [De]

- KXX PACKING OPTION CONSISTS OF: 75 Packing Assembly (93451-1), 76

Packing Assembly (93452-1) & 77 Packing Assembly (93453-1).

MATERIAL CODE

[B]=Buna ‘‘N’’

[Br]=Brass

[CS]=Carbon Steel

[Cu]=Copper

[De]=Delrin

[DI]=Ductile Iron

[L]=Leather

[SS]=Stainless Steel

[T]=PTFE

[UH]=UHMW--PE

UPPER PACKING PARTS

COMPOSITE SPRING MODELS --X5X ONLY

ITEM DESCRIPTION (QTY) PART NO [MTL]

42 Composite Spring (1) 66752-102 [SS]

50 Washer, F Backup (1) 90840 [Br]

MIDDLE PACKING PARTS

‘‘V” TYPE MODELS

ITEM DESCRIPTION (QTY) PART NO [MTL]

47 Wave Spring (1) 90915 [CS]

54 Washer, F Backup (1) 90910 [SS]

57 Washer, M Backup (1) 90909 [SS]

SERVICE KITS INCLUDE:

‘‘V” Type Models: 7, 23, 24, 37, 51, 52, 55, 56 & 59.

Cup Type Models: 7, 23, 24, 37, 51, 52, 55, 56 & 65.

- K3X Type Models: 7, 23, 24, 37, 75, 76 & 77.

Also in kit: Two Y15--47--C Cotter Pins to connect pump to Air Motor

PAGE 2 OF 4

66266- X

Loading...

Loading...