Page 1

OPERATOR’S MANUAL

INCLUDING: SPECIFICATIONS, SERVICE KITS, PARTS, TROUBLESHOOTING

INCLUDE MANUAL: S--633 GENERAL INFORMATION (PN 97999--625)

4--1/4” AIR MOTOR

46:1 RATIO

0 -- 6900 PSI RANGE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

BASIC PUMP

CHOP--CHECK TYPE

65875--XC

RELEASED: 8--1--95

REVISED: 6--4--10

(REV. C)

SERVICE KITS

• Use only genuine AROR replacement parts to assure compatible

pressure rating and longest service life.

• 61268 for repair of Air Motor section.

Service Note: The Air Motor Service/Parts Manual is not shipped

with thepump butit is included with each Service Kit. If thisService/

PartsInformation is needed,request theAir MotorOperator’sManual from ARO. (Manual 6544X--X, PN 97999--64).

• 637056 for repair of Lower Pump section (Leather Packings).

• 637057 for repair of Lower Pump section (PTFE Packings).

• 637280 for repair of Lower Pump section (UHMW- PE Pack-

ings).

SPECIFICATIONS

Model Series 66875--XC..............

Type Air Operated, Basic Pump....................

Chop--Check

Ratio 46:1....................

Air Motor Diameter 4--1/4’’ (108 mm).........

Stroke 4’’ (102 mm)..................

Air Inlet 1/2” -- 14 NPTF -- 1 (f).................

Material Inlet Immersed or Follower Plate.............

Material Outlet 1/2” -- 14 NPTF -- 1 (f)...........

Pump Construction Carbon Steel.......

Dimensional Data See Fig.1..........

PERFORMANCE

Air Inlet Pressure Range 0 -- 150 PSI (0 -- 10.3 bar).....

Fluid Pressure Range 0 -- 6900 PSI (0 -- 475 bar).......

Displacement In

Cycles Per Gallon 92.8..........

Noise Level* -- 81.8 db(A) @ 60 psi, 40 cycles per minute

* The pump sound pressure level has been updated to an Equivalent Continuous Sound

Level (L

microphone locations.

) to meet the intent of ANSI S1. 13--1971, CAGI--PNEUROP S5.1 using four

Aeq

3

Per Cycle 2.5...

GENERAL DESCRIPTION

PUMP DATA

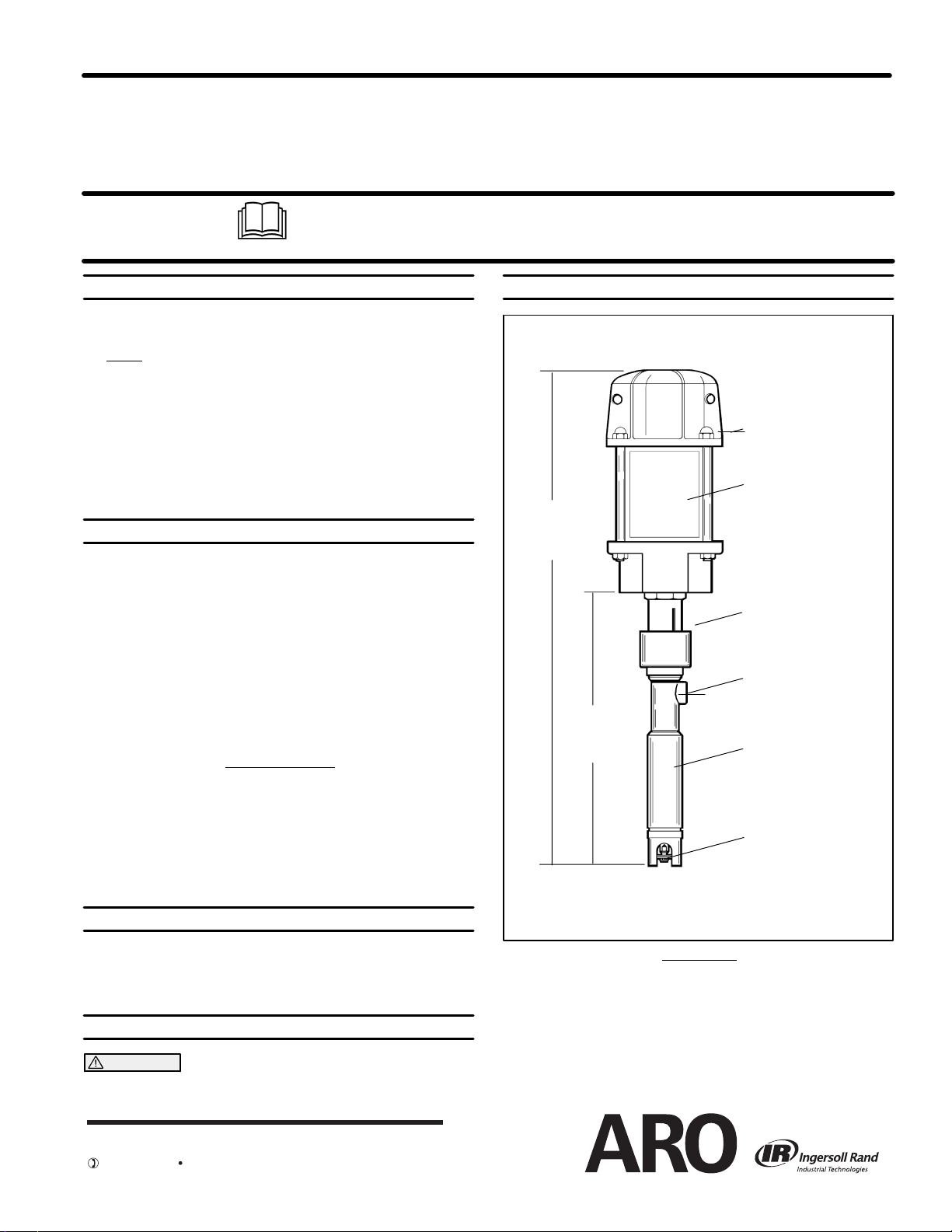

65875- XC BASIC PUMP

Air Inlet (female)

1/2” -- 14 NPTF

65445--B

Air Motor

35 11/32”

(897.7 mm)

65874 Adapter Kit

See Fig. 2

Material Outlet (female)

1/2” -- 14 NPTF

21 15/32”

(545.3 mm)

NOTE: Dimensions are shown in inches and (mm), supplied for reference only

and are typically rounded up to the nearest 1/16 inch.

65873--X

Lower Pump

Mat’l Inlet

(Immersed)

FIGURE 1

This model is designed for delivery of heavy viscosity fluids such as

grease. Material dispensing accessories and supply lines and fittings

must be capable of withstanding pressures developed by pump.

OPERATING AND SAFETY PRECAUTIONS

WARNING

ing and safety precautions and important information.

INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276 FAX(800) 892-6276

www.ingersollrandproducts.com

Read the General Information Manual for operat-

© 2010

IMPORTANT

This is one of two documents which support the pump.

Replacement copies of these forms are available upon request.

= 65875- XC MODEL OPERATOR’S MANUAL

- S- 633 GENERAL INFORMATION LUBRICATION PISTON PUMPS

Page 2

INSTALLATION

MAINTENANCE

FLUSH PUMP

1. Connect fluid hose to pump outlet and be sure all fittings are tight.

2. Turn air regulator knob counter--clockwise until it turns freely.

3. Pump has been tested in oil and a small amountremains forprotection against rusting.Immerselower pump endincompatible solvent.

4. Connect air hose coupler to connector on FRL.

5. Turn air regulator knob clockwise until air motor starts operating.

6. Flush pump with oil.

7. Disconnect air supply from air motor.

PUMP MODEL CHART

BASIC PUMP PUMP SPACER SECTION

*65875--C 65873 65874

*65875--1C 65873--1 65874

65875--2C 65873 65874--1 *

65875--3C 65873--1 65874--1 *

*65875--4C 65873--4 65874

65875--5C 65873--4 65874--1 *

(* OBSOLETE PUMP MODELS, SHOWN FOR REFERENCE ONLY)

* 65874- 1 uses a 92483- 1 Tube in place of a 92483 Tube and a

90742- 1 Rod Adapter in place of a 90742 Rod Adapter.

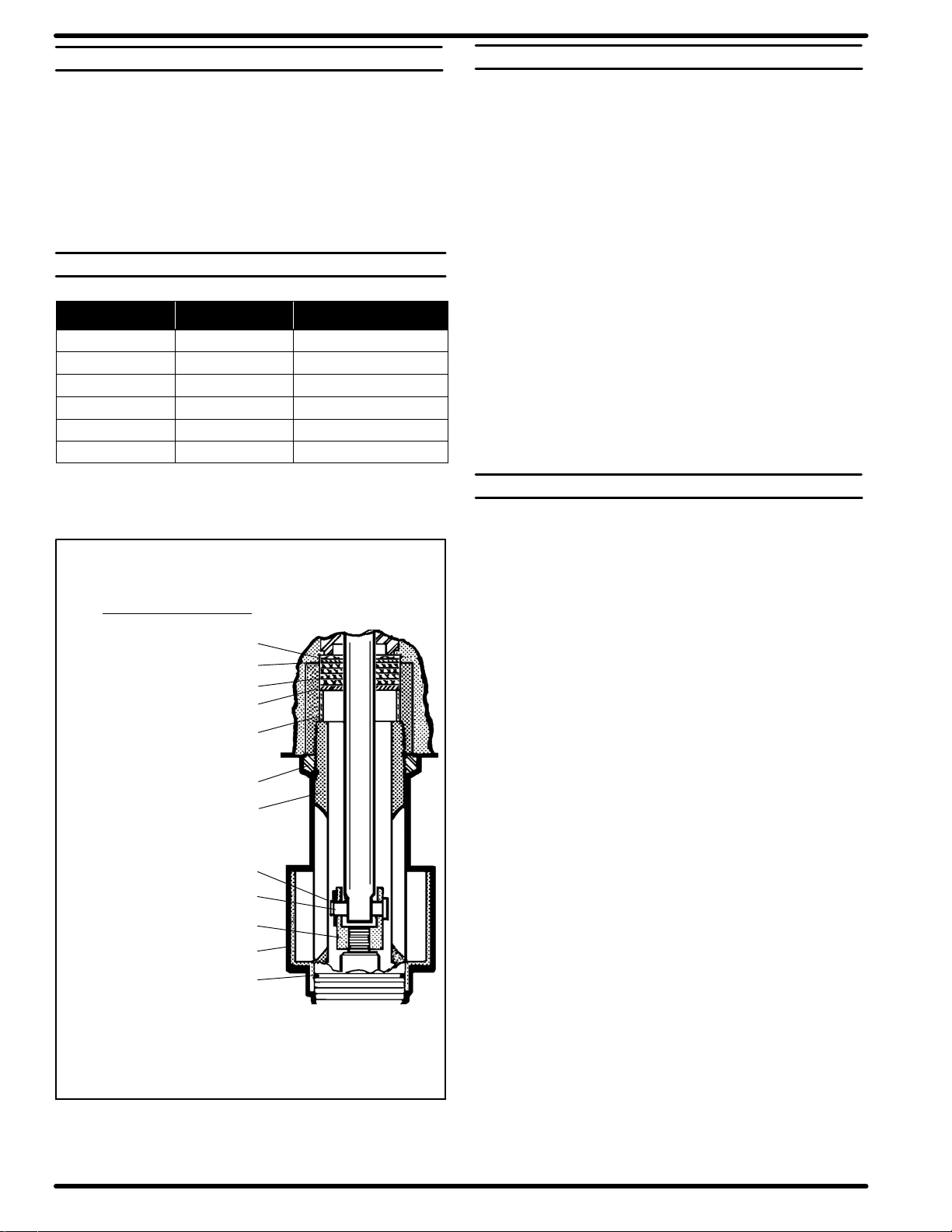

ADAPTER KIT 65874

90251 WAVY WASHER

90568 WASHER

90567 (4) PACKING

90568 WASHER

90570 SPACER

90571 LOCKNUT

92483 SPACER TUBE

Y145- 2 RETAINING RING

90746 CONNECTING PIN

The basic pumpconsists oftwo major components: 1. AirMotor, 2. Lower Pump. The motorisconnected to thelower pumpendby a spacersection. Thisallows for lubrication of the upper packing glandand prevents

motor contamination because of normal wear and eventual leakage

through the material packing gland. The air motor isremovable andis to

be serviced separately. Refer to air motor manual for service and parts.

It is recommendedthat anoiler be installedin theairline as closeas possible to thepump. This increasestheservice lifeofthe pump byreducing

wear of the air motor’s internal parts.

• Periodically flush entire pump systemwith a solvent that is compat-

ible with the material being pumped.

• Pump disassembly should be done on a clean work bench with

clean cloths to keep parts clean.

• If replacement parts are necessary, consult drawing containing

parts for identification, include the part name and number when ordering.

• Before assembling, lubricate parts where required. When assem-

bling ‘‘O” ringsorparts adjacent to‘‘O” rings, caremust be exercised

to prevent damage to ‘‘O” rings and ‘‘O” ring groove surfaces.

• If pump isto be inoperativefor anunspecified period oftime, discon-

nect air and relieve all pressure.

PUMP DISASSEMBLY

NOTE: All threads are right hand.

1. Clamp pump assembly in a vise on the air motor base assembly.

2. Unscrew 90571 Lock Nut. (See Figure 2)

3. Place a strap wrench around 92483 tube and loosen by turning

counterclockwise. If the wrench slips on the tube, wrap a piece of

400 grit sand paper around tube and under strap wrench.

Note: Pipe wrench will damage the finish of the tube.

4. After the tube hasbeenpulled down toexposethe air motorrod, hold

air motor piston rod and remove the Y145--2 retaining ring and

90746 pin from the air motor piston rod.

5. Remove the air motor assembly from the vise.

6. Vise the lower pump and push (6) piston rod untilflats on(16) rodar

exposed at other end of pump.

7. Unscrew (20) stop nut and remove (19) washer and (18) washer

from (16) rod.

8. Unscrew (17) primer tube from (7) tube and sleeve and remove (9)

washer,(10) retainingring, (11) ‘‘U” cup, (12)body,(13) sleeve,(14)

gasket and (15) valve seat.

9. Hold (6) piston rod and unscrew (16) rod from assembly.

10. Push (6) rod until (8) connector is exposed on other end of (7)tube.

11. Unscrew and remove (8) connector from (6) rod.

90742 ROD ADAPTER

91182 SOLVENT CUP

Y325- 32 ‘‘O” RING

FIGURE 2

-‘‘Smart Parts”Keep these items on hand in addition to the ServiceKitsforfast repair and reduction ofdown time.

PAGE 2 OF 4

Page 3

21

PARTS LIST / LOWER PUMP SECTION

ITEM Description Qty Part No.

1

2

3

4

5

6

:

7

8

:

9

10

11

12

13

14

1 Washer 1 90747

2 Female Washer 1 90748

n3 Packing (65873) Leather 5 93714- 1

Packing (65873- 1) PTFE 5 93714- 2

Packing (65873- 4) UHMW- PE 5 93714- 4

4 Male Washer 1 90749

n5 Bowed Washer 1 90744

-6 Piston Rod 1 90753

7 Tube & Sleeve 1 65871

8 Connector 1 90738

9 Washer 1 90136

n10 Retaining Ring 1 Y147- 77

n11 ‘‘U” Cup 1 90757

12 Body 1 90756

13 Sleeve 1 4170

n14 Gasket 1 92845

15 Valve Seat 1 4169

16 Rod 1 90739

17 Primer Tube 1 92485

18 Washer 1 90133

19 Washer 1 90686

20 Stop Nut 1 Y109- 428

21 Washer 1 90741

nP ARTS INDICATED ARE INCLUDED IN 637056, 637057 &

637280 SERVICE KITS

PUMP REASSEMBLY

:

APPLY LOCTITE 271 TO THREADS

FIGURE 3

15

16

17

18

19

20

1. Place (21) washer,(5) bowedwasher,(4)male washer,(3) packings

and (2) female washer into (7) tube and sleeve. Slide piston rod

through upperpackings andscrew (8) connector into (6) piston rod.

2. Screw (16) rodinto (8) connector.Place (15) valveseat, (14) gasket,

and (13) sleeve into (17) primer tube.

3. Place (9)washer over (16) rod and into position next to(7) tubeand

sleeve.

4. Place (12) body, (11) ‘‘U” cup and (10) retaining ring onto (16) rod.

5. Install (1) gasket in throat of air motor base.

6. Thread rod assembly into piston rod of air motor.

PAGE 3 OF 4

Page 4

TROUBLE SHOOTING

No Material. (Stalled Pump.)

• Obstructed Material Line. Disconnect air supply. Relieve all fluid

pressure in pump. Remove Obstruction in system.

No Material (Pump Continually Cycles.)

• Empty materialsupply. Shut down system.Replenish material sup-

ply.

Material on one stroke only. (Fast Downstroke.)

• Item (11) ‘‘U” Cup is worn. Remove the ‘‘U” Cup. Replace ‘‘U” Cup.

Material on one stroke only. (Fast Upstroke.)

• Item (12) body seat is not properly seating on (15) valve seat. Re-

move the seat. Clean and inspect body and seat. If either is damaged. replace with new parts.

PAGE 4 OF 4

PN 97999- 661

Loading...

Loading...