Page 1

OPERATOR’S MANUAL

INCLUDING: OPERATION, INSTALLATION & MAINTENANCE

6564X-X

6566X-X

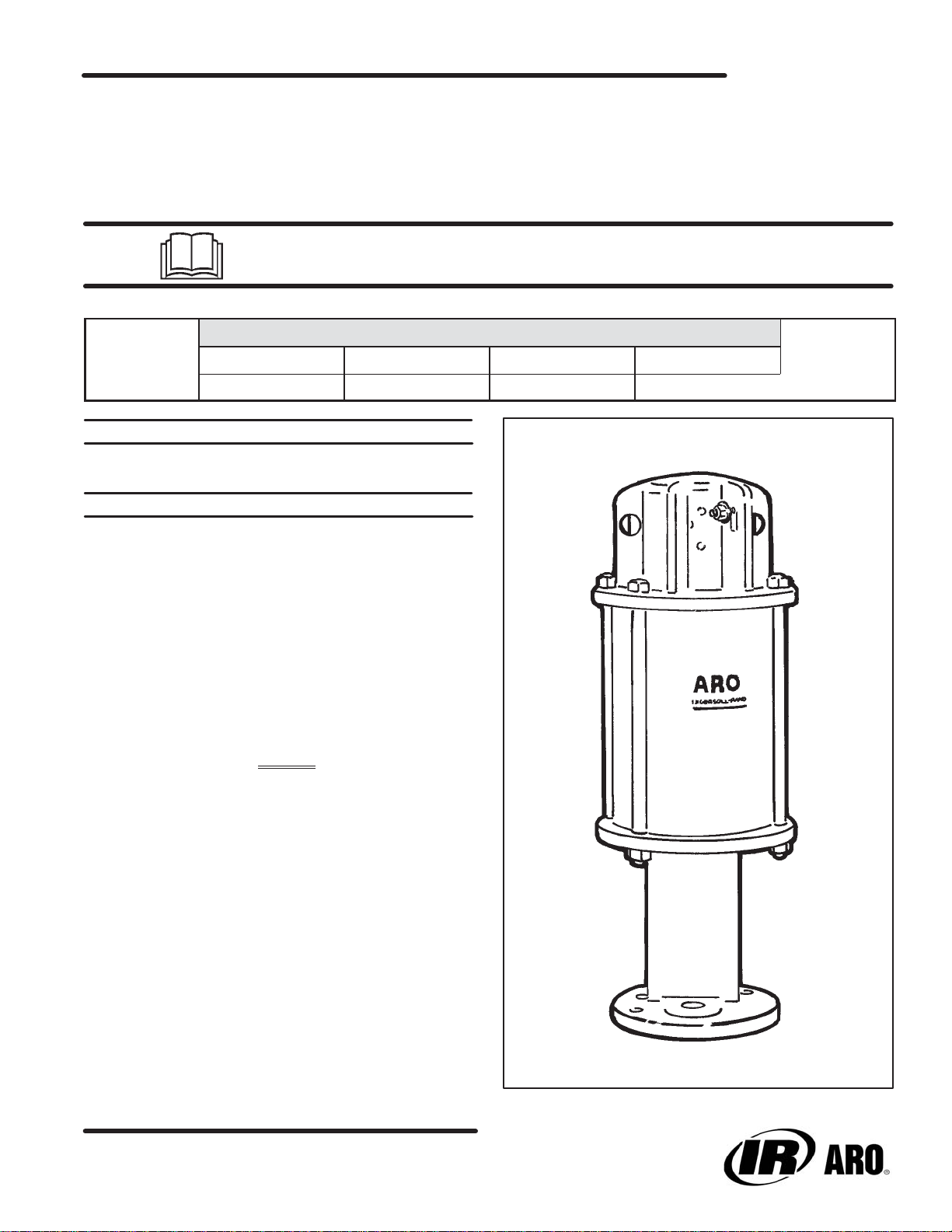

6” AIR MOTORS

6564X-X and 66620

4” STROKE

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

THIS MANUAL COVERS THE FOLLOWING MODELS

65643 65662 65665Ć2B 66620

65645 65665ĆB 65666

SERVICE KITS

61355 for general repair of all 6" air motors.

GENERAL DESCRIPTION

The 6" air motor is a general purpose power unit and is used with many

2Ćball, 4Ćball and chop check pumps. It utilizes tie rod type construction

for easy breakdown and it connects to the various lower ends via tie rods

for easy operation. Consult pump model operator's manual for specific

instructions. It is recommended that a muffler be connected to the exĆ

haust port to reduce noise to acceptable OSHA standards.

MODEL

6566X-X

6” STROKE

66620

RELEASED: 8-28-91

REVISED: 10-11-01

(REV. K)

Filtered and oiled air will allow the air motor to operate more efficiently

and yield a longer life to operating parts and mechanisms. A filter capaĆ

ble of filtering particles larger than 50 microns should be used with an

oiler. Keep the oiler supplied with a good grade of S.A.E. no. 90W nonĆ

detergent gear oil, set at a rate not to exceed 1 or 2 drops per minute.

NOTICE

DO NOT OPERATE AIR MOTOR ABOVE RECOMMENDED

AIR PRESSURE OF 150 P.S.I. (10.3 BAR) OR 75 CYCLES PER

MINUTE.

Check model plate.

Air motor may be rated differently in the next assembly.

INGERSOLL-RAND COMPANY

P.O. BOX 151 ONE ARO CENTER BRYAN, OHIO 43506Ć0151

(419) 636-4242 FAX (419) 633-1674

2001 PRINTED IN U.S.A.

Page 2

AIR MOTOR PARTS LIST

PARTS SO MARKED ARE INCLUDED IN 61355 SERVICE KIT.

REF. DESCRIPTION (SIZE IN INCHES) QTY PART NO. REF. DESCRIPTION (SIZE IN INCHES) QTY PART NO.

1 Machine Screw (#8 Ć 32 x 7/8") 4 Y136Ć90ĆS

2 Deflector 1 90409

Deflector (model 65665Ć2B) 1 90409Ć1

3 Screw (#10 Ć 24 x 1/2") 6 95956827

4 Machine Screw (#8 Ć 32 x 3/4") 8 Y19Ć89ĆS

5 Washer 8 90084

6 Machine Screw (1/4" Ć 28 x 3/4") 2 Y119Ć49ĆC

7 Lock Washer (1/4" i.d.) 2 Y14Ć416

8 Air Motor Cap 1 90078

Air Motor Cap (model 65665Ć2B) 1 90078Ć5

9 Valve Guide 1 90488

10 Gasket 1 90083Ć1

11 Valve Plate and Pin Assembly 1 65756

12 Insert Spring Assembly 1 65807

13 Valve Insert 1 99202

14 Valve Plate Gasket 1 90479

15 O" Ring (1/16" x 1Ć3/8" o.d.) 2 Y325Ć26

16 Washer 1 91344

17 O" Ring (1/16" x 7/8" o.d.) 2 Y325Ć18

18 Head Assembly 1 65890

Head Assembly (model 65665Ć2B) 1 65890Ć3

19 U" Cup (3/16" x 1Ć3/8" o.d.) 1 Y186Ć51

20 O" Ring (1/8" x 6" o.d.) 2 Y325Ć256

21 Machine Screw (#8 Ć 32 x 3/8") 4 Y136Ć85ĆS

22 Adapter 1 90111

23 Piston Assembly 1 61419

24 O" Ring (1.191" o.d.) 1 90085

25 Nut 1 90112

26 Valve Rod See chart, page 4

27 Air Cylinder See chart, page 4

28 Tube See chart, page 4

29 O" Ring See chart, page 4

30 Air Motor Base Assembly See chart, page 4

31 Valve Piston 1 92395

32 Valve Plate Gasket 1 90482

33 Valve Plate 1 90480

34 Pilot Insert 1 90487

35 Valve Guide 2 90481

36 Washer 1 90105

37 Upper Gland 1 91006

38 Seal 1 91007

39 O" Ring (.103" x 1.255" o.d.) 1 91207

40 Extension Rod 1 90080

41 Ground Lug 1 93006

42 Piston Adapter 1 92393

43 Lower Gland 1 90114

44 Washer 1 91345

45 O" Ring (1/16" x 7/16" o.d.) 1 Y325Ć11

46 Bolt See chart, page 4

47 Retaining Ring See chart, page 4

48 Guide Washer See chart, page 4

49 U" Cup See chart, page 4

50 Nut See chart, page 4

51 Washer See chart, page 4

52 Piston Rod See chart, page 4

Smart Parts", Keep these items on hand in addition to the service kits for fast repair and reduction of downtime.

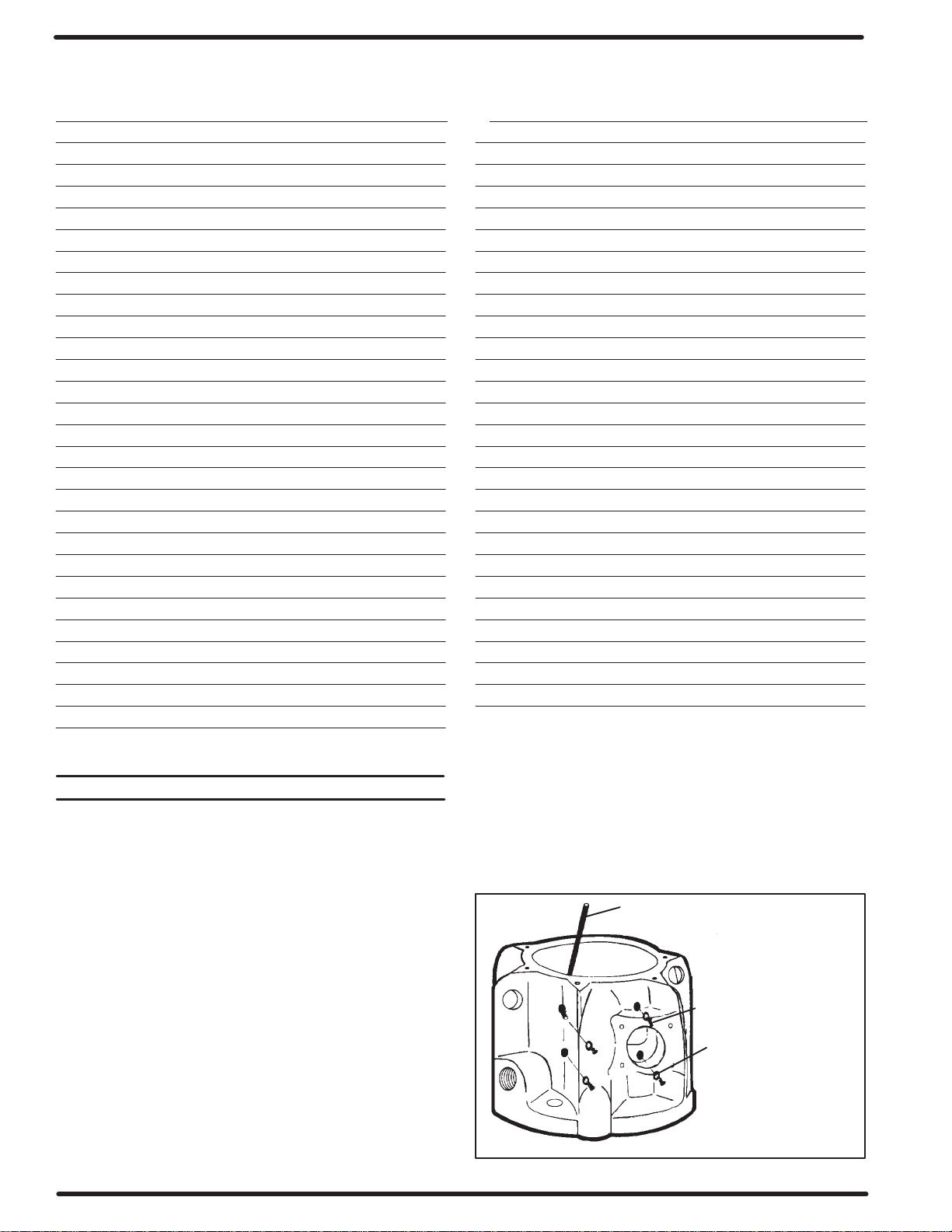

DISASSEMBLY OF AIR MOTOR

NOTE: ALL THREADS ARE RIGHT HAND.

1. Force the (23) piston assembly up by pushing the (52) piston rod toĆ

ward the top of the air motor.

2. Remove the four (1) machine screws from the (2) deflector.

3. Remove the (2) deflector.

4. Remove the six (3) screws from the (8) air motor cap.

5. Remove the (8) air motor cap and (10) gasket.

6. Loosen the eight (4) machine screws (which hold the (11) valve plate

and pin assembly, (9) valve guide, two (35) valve guides and the (33)

valve plate) until the (9 and 35) valve guides can be removed by pullĆ

11. Remove the (13) valve insert and the (34) pilot insert.

12. Remove the (32 and 14) gaskets.

13. Remove the (12) insert spring assembly.

14. Remove the two (6) machine screws and the two (7) lock washers

from the (37) upper gland (see figure 9).

15. Pull the (31) valve piston upward until the (37) upper gland has

pulled out of its chamber.

ALLEN WRENCH

(USE AN ALLEN WRENCH

TO PUSH OUT SCREWS &

WASHERS AS SHOWN.)

ing upward (see figure 9).

7. Remove the eight (4) machine screws and eight (5) washers from

4 SCREWS (8)

the 6" air motor by pressing outward with a small allen wrench (see

figures 1 and 9).

5 WASHERS (8)

8. With a screwdriver, unhook the (12) insert spring assembly from the

bottom of the (11) valve plate and pin assembly.

9. Remove the (12) insert spring assembly from the pins in the top of

the (11) valve plate and pin assembly.

10. Remove the (11) valve plate and pin assembly and (33) valve plate

by pulling upward. If they are stuck, tap the top edge lightly with a soft

FIGURE 1

(THE REMAINING FOUR

WASHERS AND SCREWS

ARE ON THE OPPOSITE

SIDE.)

face hammer or screwdriver handle (do not tap with anything metalĆ

lic).

PAGE 2 OF 8 6564XĆX

Page 3

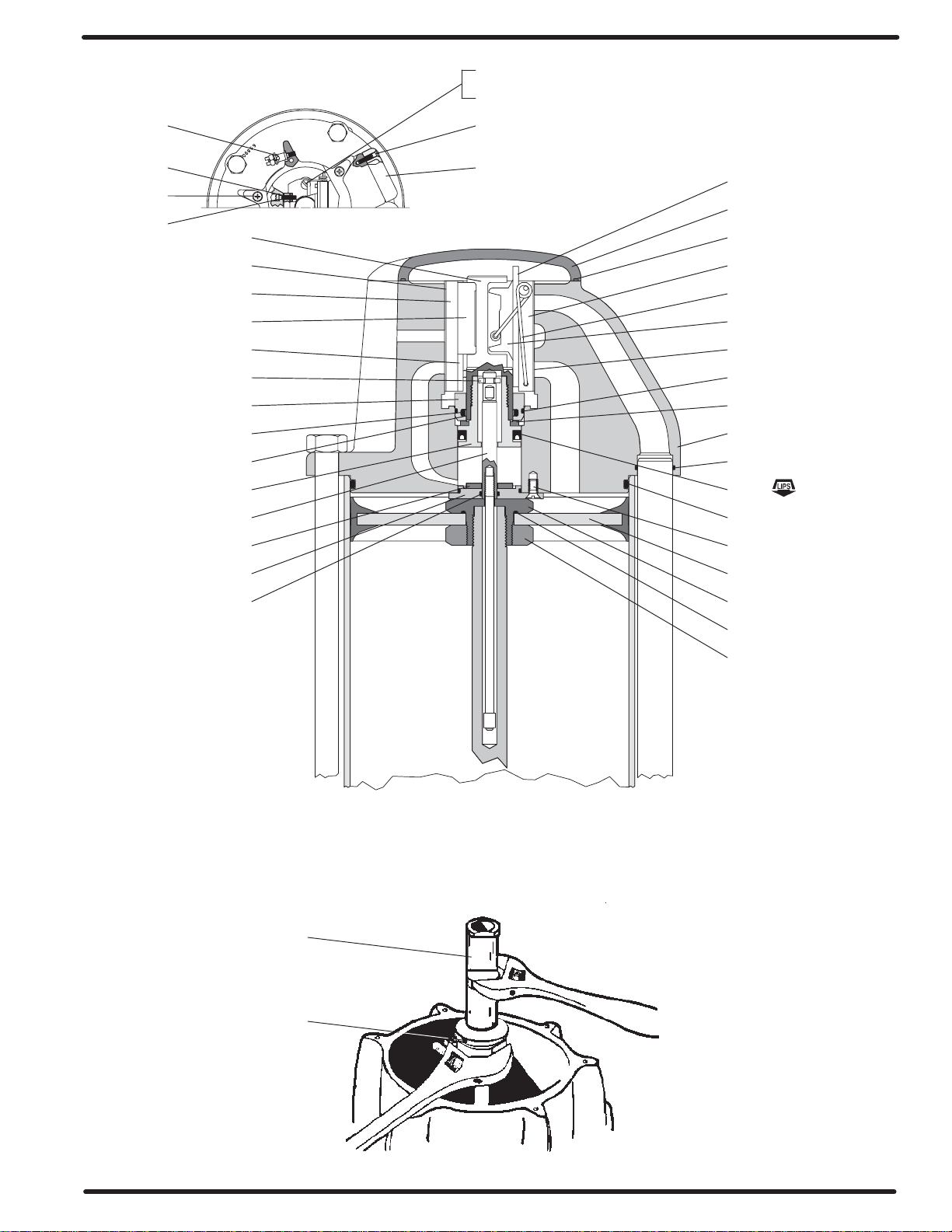

41

6

PART NUMBERS LISTED BELOW AND ON PARTS

7

1

AIR MOTOR HEAD

LIST (OPPOSITE PAGE) ARE TYPICAL.

4

3

5

31

32

33

34

35

36

37

39

38

42

40

44

43

45

2

9

8

10

11

12

13

14

15

16

18

17

19

20

21

23

22

NOTE: LUBRICATE WITH PARKER

‘‘O” RING LUBE (ARO P/N 36460).

31

42

24

25

FIGURE 2

FIGURE 3

PAGE 3 OF 86564XĆX

Page 4

AIR MOTOR PARTS LIST

INDICATES WHERE PARTS ARE USED.

MODELS NO LONGER ACTIVE, SHOWN

FOR REFERENCE ONLY.

ITEM DESCRIPTION PART # (QTY)

26

27

28 Tube 90485Ć1

29

30 Air Motor Base Assembly 65065

46 Bolt (1/2" Ć 20 x 10Ć1/4") 94046Ć1 (4)

47

48

49

50 Nut Y11Ć8ĆC (4)

51

52

Valve Rod 90107Ć1

Valve Rod 90107Ć2

Air Cylinder 90215Ć1

Air Cylinder 90215Ć2

Tube 90485Ć2

O" Ring Y325Ć210

Air Motor Base Assembly 65065Ć2

Air Motor Base Assembly 65067

Air Motor Base Assembly

Bolt (1/2" Ć 20 x 8Ć1/4") 94046Ć2 (4)

Retaining Ring Y147Ć131

Guide Washer 73986

U" Cup Y186Ć16

Washer 90103

Piston Rod 66628

Piston Rod 90082

Piston Rod 90108Ć1

Piston Rod 90108Ć2

65868

AIR MOTOR MODEL NO.

Smart Parts", Keep these items on hand in addition to the service kits for fast repair and reduction of downtime.

INDICATES WHERE

See model plate on (30) base for number.

NOTE: Base styles and lower packings may vary from that shown on

the cover. Refer to model number in the chart above.

PARTS ARE USED.

On model 65662 air motors, a plate is mounted on the bottom of the

(30) base. Therefore, the following parts are different and illustrated on

page 8.

For simplification of ordering and stocking, a Y325Ć210 O" ring and a

Y186Ć16 U" cup will be included in 61355 service kit. When repairing

the motor, use only the one that is needed.

93310 Bushing

93311 Retainer

93312 Guide

All of the service parts are the same for all motors except the lower pisĆ

ton rod packing.

93313 Plate (note the orientation of the plate with the air inlet)

Y6Ć66ĆC Screw (4 req'd)

Y14Ć616ĆC Lock Washer (4 req'd)

NOTE: It is highly recommended that a 90350 installation tool be used.

This will greatly ease installation of (42) piston adapter and piston

valve and will reduce the chances of damage to the (19) U" cup. A

90350 INSTALLATION TOOL

damaged (19) U" cup can usually lead to air motor failure.

PARTS SO MARKED ARE ALSO INĆ

CLUDED IN 61355 SERVICE KIT.

PAGE 4 OF 8 6564XĆX

Page 5

NOTE: LUBRICATE WITH PARKER

‘‘O” RING LUBE (ARO P/N 36460).

AIR MOTOR PISTON ROD AND BASE

SEE CHART ON OPPOSITE PAGE FOR EACH MODEL.

46

20

47

50

51

52

26

27

28

29

17

48 49

30

FIGURE 4

DISASSEMBLY OF AIR MOTOR (CONTINUED)

16. Remove the (37) upper gland.

17. Remove the (38) seal and (39 and 15) O" rings from the (37) upper

gland (see figure 7).

18. Disassemble the (31) valve piston from the (42) piston adapter (see

figure 3).

19. Remove the (31) valve piston.

20. Pull the (42) piston adapter upward and grasp the (40) extension rod

below the (42) piston adapter. Push the (42) piston adapter down on

the (40) extension rod. Remove the (36) washer and (42) piston

adapter.

21. Remove the (16) washer and the (19) U" cup from the (42) piston

adapter.

22. Remove the four (50) nuts from the four (46) bolts.

23. Remove the four (46) bolts.

24. Remove the (18) head assembly and place it on the workbench with

the end that the (28) tube fits in upward".

25. Remove the (20) O" ring from the (18) head assembly.

26. Remove the four (21) machine screws from the (43) lower gland.

27. Remove the (43) lower gland.

28. Remove the (44) washer and (15 and 45) O" rings from the (43) lowĆ

er gland.

29. Remove the (28) tube.

30. Remove the (17) O" ring from the (30) air motor base assembly and

(18) head assembly.

31. Pull upward on the (27) air cylinder until the (52) piston rod is sepaĆ

rated from the (30) air motor base assembly. If the (52) piston rod

does not separate from the (30) air motor base assembly, remove

the (52) piston rod after removal of the (27) air cylinder.

32. Remove the (20) O" ring from the (30) air motor base assembly.

33. Remove the (47) retaining ring, (48) guide washer, (49) U" cup and

(51) washer from the (30) air motor base assembly.

34. Unscrew the (40) extension rod from the (26) valve rod by holding

the (26) valve rod with adjustable type pliers and placing a wrench

on the provided wrench flat at the top of (40) extension rod.

35. Unscrew the (52) piston rod from (22) adapter, using wrench flats on

(52) piston rod. Remove (26) valve rod from (52) piston rod.

NOTE: Caution should be exercised so as not to mar or damage the finĆ

ish on (40) extension rod or (52) piston rod.

36. Remove (25) nut, (23) piston assembly and (24) O" ring from (22)

adapter.

PAGE 5 OF 86564XĆX

Page 6

REASSEMBLY OF AIR MOTOR

NOTE: ALL THREADS ARE RIGHT HAND.

Apply grease to all O" rings, U" cups and other rubber goods when

installing.

1. Slip the (24) O" ring on the (22) adapter, clean with solvent and apĆ

ply Loctite 271 to the external threads of the (22) adapter. Assemble

the (22) adapter and (25) nut to the (23) piston assembly and tighten

to 160 Ć 180 ft lbs.

2. Put the threaded end of the (26) valve rod thru the hole in the (22)

adapter, with the machined shoulder" end of the (26) valve rod on

the threaded side of the (22) adapter.

3. While holding the (26) valve rod below the threads with locking pliĆ

ers, clean with solvent and apply Loctite 271 to the threads and atĆ

tach the (40) extension rod, using the provided wrench flats.

4. Place the machined shoulder" end of the (26) valve rod into the hole

in the end of the (52) piston rod and assemble (52) piston rod to (22)

adapter, tightening using a wrench on flats provided.

5. Thoroughly grease and install the (20) O" ring in the (30) air motor

base assembly.

6. Grease and place the (51) washer and (49) U" cup into the (30) air

motor base assembly. Place the (48) guide washer and (47) retainĆ

ing ring in the (30) air motor base assembly.

7. Grease and install (15) O" ring on the (43) lower gland.

8. Grease the bore in the (18) head assembly and insert the (43) lower

gland into the bore of the (18) head assembly, using a twisting moĆ

tion.

9. Align the screw holes in the (43) lower gland and (18) head assembly.

10. Secure the (43) lower gland to the (18) head assembly using four

(21) machine screws.

11. Put the (52) piston rod thru the (49) U" cup in the (30) air motor base

assembly, being careful not to damage the U" cup.

12. Thoroughly grease the inside of the (27) air cylinder.

27 CYLINDER (APPLY

GREASE THROUGHOUT

INSIDE)

13. Fill the area between the lips of (23) piston assembly with grease,

then insert into the bottom of the (27) air cylinder (see figure 3).

14. Push the (23) piston assembly to the top of the (27) air cylinder.

15. Thoroughly grease and install the (45 and 20) O" rings into the (18)

head assembly.

16. Thoroughly grease the two (17) O" rings and install one in the (30)

air motor base assembly. Install the other in the (18) head assembly.

17. Press the (28) tube into the counterbored hole in the (30) air motor

base assembly.

18. Push the (40) extension rod thru the (45) O" ring in the base of the

(18) head assembly.

19. Press the (18) head assembly down until the (27) air cylinder and

(28) tube are seated in the (18) head assembly.

20. Insert the four (46) bolts down thru the holes in the flanges of the (18)

head assembly and the (30) air motor base assembly.

21. Screw the four (50) nuts on the four (46) bolts. Alternately and evenly

tighten the nuts.

22. Thoroughly grease and install the (19) U" cup in the (42) piston

adapter, with the lips of the (19) U" cup down toward the thick flange

on the (42) piston adapter.

23. Thoroughly grease and install the (39 and 15) O" rings in the (37)

upper gland.

24. Bend the (38) seal in a heart shape and install in the (37) upper gland

inside the (39) O" ring (see figure 6).

SEAL FREE FORM SEAL COLLAPSED FORM

PUSH SIDES IN, AS SHOWN, THEN SLIDE INTO BORE AND POSIĆ

TION SEAL IN GROOVE.

FIGURE 6

25. Grease and carefully push the (31) valve piston into the (37) upper

gland to size the (38) seal, then remove (see figure 7 below).

15 ``O" RING

23 PISTON

(APPLY GREASE

AROUND EDGE)

52 PISTON ROD

39 ``O" RING

38 SEAL

DIRECTION FOR SIZING

31 VALVE PISTON

37 UPPER GLAND

FIGURE 7

26. Place the (44) washer over the (40) extension rod.

27. Pull the (40) extension rod up and grasp with two fingers (see figure 8).

28. Place the 90350 installation tool over the (40) extension rod, with the

turned diameter down and the chamfer up.

29. Fit the turned diameter of the 90350 installation tool into the bore in

the bottom of the (18) head assembly.

30. Place the (42) piston adapter down over the (40) extension rod, with

the threads up.

31. Insert the (36) washer into the groove in the top of the (40) extension

rod.

FIGURE 5

PAGE 6 OF 8 6564XĆX

Page 7

36 WASHER GROOVE

40 EXTENSION ROD

FIGURE 8

32. Pull the (42) piston adapter up around the (36) washer.

33. Place the (16) washer over the (40) extension rod and into the (42)

piston adapter.

34. Clean with solvent and put Loctite 271 on the threads of the (31)

valve piston. Screw the (31) valve piston into the (42) piston adapter

and tighten (see figure 3).

35. Push the assembled (42) piston adapter and (31) valve piston down

thru the 90350 installation tool until they bottom.

36. Remove the 90350 installation tool.

37. Install the (37) upper gland over the (31) valve piston and push

down, being careful to retain the (38) seal in the O" ring groove.

38. Align the two bolt holes and secure the (37) upper gland to the (18)

head assembly with the two (6) machine screws and two (7) lock

washers (see figure 9).

39. Insert the (12) insert spring assembly in the (18) head assembly,

with the hooks down and the nylon roller toward the (31) valve piston

(see figures 2 and 9).

40. Thoroughly grease and insert the (34) pilot insert, two (35) valve

guides, (33) valve plate and (32) gasket into the (18) head assembly

(see figure 9).

41. Thoroughly grease and insert the (13) valve insert into the (18) head

assembly (see figure 2).

42. Thoroughly grease and insert the (14) gasket and the (11) valve

plate and pin assembly between the (13) valve insert and the (18)

head assembly, with the two pins in the (11) valve plate and pin asĆ

sembly up (see figures 2 and 9).

43. Hook the round coils in the (12) insert spring assembly over the pins

in the (11) valve plate and pin assembly (see figure 9).

44. Hook the bottoms of the (12) insert spring assembly into the holes on

the side of the (11) valve plate and pin assembly.

45. Insert the (9) valve guide against the face of the (11) valve plate and

pin assembly. The legs of the (9) valve guide should be down, with

the leg having the threaded hole the farthest from the bottom toward

the air inlet in the (18) head assembly.

46. Insert and tighten across corners of eight (4) machine screws and

eight (5) washers (see figures 1 and 9).

47. Thoroughly grease and install the (10) gasket in the (8) air motor

cap.

48. Place the (8) air motor cap on the (18) head assembly and secure

with the six (3) screws (see figure 2).

49. Place the (2) deflector on exhaust port of the (18) head assembly,

with the opening down, and secure with four (1) machine screws

(see figure 2).

4 SCREW (8)

5 WASHER (8)

32 GASKET

33 VALVE PLATE

35 VALVE GUIDE (2)

37 UPPER GLAND

6 SCREW (2)

7 LOCK WASHER (2)

12 SPRING ASS'Y

9 VALVE GUIDE

11 VALVE PLATE

14 GASKET

18 HEAD ASSEMBLY

FIGURE 9

PROBLEM

Air leakage out of main exhaust.

CAUSE

Worn (13) valve insert.

REMEDY

Replace (13) valve insert.

CAUSE

Worn (11) valve plate and pin assembly.

REMEDY

Replace (11) valve plate and pin assembly.

CAUSE

Damaged (23) piston assembly.

REMEDY

Replace (23) piston assembly.

TROUBLE SHOOTING

PROBLEM

Continual air leakage out of bleeder hole in (18) head assembly.

CAUSE

Worn (15) O" ring or (38) seal.

REMEDY

Replace (15) O" ring and (38) seal.

PROBLEM

Air leakage around (52) piston rod.

CAUSE

Worn (49) U" cup.

REMEDY

Replace (49) U" cup.

PAGE 7 OF 86564XĆX

Page 8

65662 AIR MOTOR PISTON ROD & BASE

90108-1 Piston Rod

65868 Air Motor Base

Ass’y. (Stub)

93312 Guide

93313 Plate

ITEM 52 PISTON ROD END VARIETY

Y325-210 “O” Ring

93310 Bushing

93311 Retainer

Y6-66-C

Screw (4 req’d)

Y14-616-C

Lock Washer (4 req’d)

66628 Piston Rod 90082 Piston Rod90108-1 Piston Rod

90108-2 Piston Rod

P/N 97999Ć174

PAGE 8 OF 8 6564XĆX

Loading...

Loading...